Page 1

Präzision in Ihren Händen.

Aneroid Menu

Precision at your fingertips.

01

20

.

ov

N

:

nd

Sta

0

3

-1

4-01

9

Sercice Manual / Service Anleitung

+

Ersatzteilkatalog / Spare Part Catalogue

2001 / 2002

Speidel + Keller GmbH & Co. KG

Zollerstrasse 2-4

D - 72417 Jungingen

Tel.: (++49) 7477-9271-0

Fax.: (++49) 7477-9271-90

e-mail: info@speidel-keller.de

homepage: www.speidel-keller.de

Page 2

SERVICE MANUAL

WELCH ALLYN / SPEIDEL + KELLER

Preface

Dear S+K Servicepartner,

We are very happy to welcome you as a Service partner of Speidel + Keller.

The company Speidel + Keller is continually trying to offer optimal conditions and terms, so that,

a smooth servicing of our units is guaranteed.

The Speidel + Keller blood pressure units distinguish themselves through very high quality.

This is a warranty that S+K product possess a very long lifetime.

Even though the best units naturaly need regulary inspections so that a orderly run can be

accomplished. Further it is a neccessarity in reference to the requirements of the MPG

and the EC-medical product guidelings, service the medical products on a regular base as well

as carring out measurement inspections.

Because of the above mentioned reasons we have issued these repair instruction guides for all

our units.

These instructions shall escort you to carry out an orderly repair.

Mangement Service

Seite / Page 2

Page 3

Table of contents / Inhaltsverzeichnis: English Deutschsprachig

Page: Seite:

Preface / Vorwort 2 22

Table of contents / Inhaltsverzeichnis 3 Entfällt

Failure search mechanical blood pressure units 4 23

Failure search mechanical blood pressure units 5 24

Failure search mercury blood pressure units 6 25

Instruction of dismantling and re-assembling

Reparaturanweisung Demontage und Wiedermontage

Primus 50 Metal Art. No. 50-01-000 7 26

Primus 68 Metal Art. No. 50-04-000 7 26

Manuell 50 Metal Art. No. 50-16-000 7 26

Manuell 68 Metal Art. No. 50-17-000 7 26

Primus 50 KC Art.No. 50-81-000 8 27

Primus 68 KC Art. No. 50-84-000 8 27

Manuell 50 KC Art. No. 50-96-000 8 27

Manuell 68 KC Art.No. 50-97-000 8 27

Primus Stabil 3 Art.No. 50-25-000 9 28

Primus Stabil yellow Art.No. 50-49-000 9 28

Primus Stabil red Art.No. 50-59-000 9 28

Primus Stabil blue Art.No. 50-50-000 9 28

Primus Stabil green Art.No. 50-45-000 9 28

Manuell Stabil 3 Art.No. 50-63-000 9 28

ISO Stabil 5 Art.No. 50-71-000 10 29

Disytest Art.No. 52-09-000 11 30

Maxi Stabil 3 Art.No. 59-32-000 12 31

Fixomed Art. No. 50-91-000 13 32

Hand 2003 Art.No. 50-03-000 14 33

Oscillophon Art.No. 51-05-000 15 34

Instruction for end evaluation /measurements –

Anweisung für die Endprüfung 16 35

Tool list for blood pressure units - Werkzeugliste 17 36

Failure search for Stehoscopes - Fehlersuche Stehoskope

Stethoscope Art.No. 84-10-000 18 37

Planoscope 40 mm Art.No. 83-11-080 18 37

Planoscope 30 mm Art.No. 83-12-080 18 37

Duophon 40 mm Art.No. 82-11-080 18 37

Duophon 30 mm Art.No. 82-15-080 18 37

Professionell Art.No. 86-01-080 18 37

Harvey Elite Art.No. 87-01-080 18 37

Failure search for hand fans - Fehlersuche Handventile

Hand fan Art.No. 17-01-000 19 38

Hand fan Art.No.17-02-000 19 38

Hand fan Art.No. 17-08-000 19 38

Hand fan Art.No. 17-10-000 19 38

Failure search for special medical manometers Fehlersuche Spezial Manometer

Pressure inf. Cuff Art.No. 51-08-000 20 39

Sanipress unit Art.No. 50-09-000 20 39

Tournipress Art.No. 53-05-000 21 40

Seite / Page 3

Page 4

Repair instruction for Speidel + Keller blood pressure units

Failure search mechanical blood pressure units

------------------------------------------------------------------------------------------------------------------------------------- Units / Products concerned:

------------------------------------

- Primus 50/68 1 and 2 tube KC and Metal Art. No. 50-01-000/ 50-04-000/ 50-81-000/ 50-84-000

- Manuell 50/68 1 and 2 tube KC and Metal Art. No. 50-16-000/ 50-17-000/ 50-96-000/ 50-97-000

- Primus Stabil 3 and Primus Persona Art No. 50-25-000, 50-49-000 /50-59-000/ 50-50-000/

included the colour serie 50-45-000

- Manuell Stabil 3 Art.No. 50-63-000

- Disytest Art. No. 52-09-000

- ISO Stabil 5 Art. No. 50-71-000

- Fixomed Art. No. 50-91-000

- Hand 2001 und 2003 Art. No. 54-03-000, 54-07-000

- Oscillophon Art. No. 51-05-000

- Minimus Art. No. 51-02-000

- Maxi Stabil 3 Art. No. 59-32-000

1. Failure search - Locating missing parts

---------------------------------------------------------

- Cuff - Glass - Scale - Valve parts - Ball - Screws - Washer - other Accessories

2. Search on cause and reason for failure Neccessary repair

Possible causes/- reasons: Upcoming repair:

------------------------------------------------------ ----------------------------------------------------------------------

- Leaking membran/ base plate Replace complete base plate and movement +

measurement inspection

- Needle outside the tolerance on the zero- Replace needle + measurement inspection + eventually

point replace complete base plate and movement

- Hanging needle / jer ky movements Replace complete base plate with movement +

Propably bent movement axle carry out measurement inspection

movement spring tangled in the segment

- Glass / Scale fallen out, broken Insert glass and scale, carry out measurement inspection

bent, scratched etc.

(dropped unit)

- Leaking valve part, tube valve version Replace valve + leakage test

- Leak on the cuff Replace rubber bag + leakage test

- Leak on tube connector/other connector pieces/ Replace all defect parts + carry out leakage test

part valve

- Hart turning release screws Replace release screw + leakage test

- Defect trigger / bezel Replace trigger + test bezel on function

- Leak on valve part, trigger version Replace complete valve group + leakage test

- No air relase or air admittance possible Clean air inlet and outlet, possible replacement of the

release valve + test on fuction

Seite / Page 4

Page 5

2. Search on cause and reason for failure Neccessary repair

Possible causes/- reasons: Upcoming repair:

--------------------------------------------------------- ---------------------------------------------------------------------

- Not possible to inflate the ball / defect Assemble new ball + test on function

Possible damaged check valve /

or rip in material (also hand valve)

- Defect valve body / screw / trigger version Take out the complete body and re-assemble it with new

body + measurement inspection

- Missing washer Replace washer + leakage test

- Expired calibration time / Carry out measurement inspection + attach test label

Prepare documentation (see instruction on measurement

inspection

Instructions on measurement inspection on all blood pressure units - please see attachment

Measurement inspections.

Instructions on work procedures for dismantling and re-assembling (see attached description)

Seite / Page 5

Page 6

Repair instruction for Speidel + Keller blood pressure units

Mercury units

Units Products concerned:

- Miniatur 300 B Art. No. 65-11-000

- Miniatur 300 S Art. No. 65-13-000

- Mercuro 300 Art. No. 74-01-000

1. Failure search - Locating missing parts

- Cuffs - Glass tube - Filter caps - Washers - Cover - Ball valve - other accessories

2. Search on cause and reason for failure Neccessary repair

Possible causes/- reasons: Upcoming repair:

------------------------------------------------- --------------------------------------------

- Broken / dirty glass tube Replace or clean glass tube + measurement inspection

- Defect mercury container / ripped Assemble new mercury container + insert mercury + carry out

measurement inspection.

- Bezel does not shift, no mercury inlet Assemble bezel and container + pur in new mercury

possible + measurement inspection

- Mercury outflow Evaluate the leak place, replace defect parts + fill up

mercury + carry out measurement inspection

(Caution: Contact with mercury is

hazardous to your health)

- Defect /leak tube connector Insert new washer and assemble tube connector + refill

mercury + carry out measurement inspection

- Defect filter or filter cap/ leaking Insert new filter and filter cap + refill mercury + carry out

loosen, etc. + measurement inspection

- Defect housing parts / scale Replace parts + carry out function test.

- Expired calibration time Carry out measurement inspection + attach new test label with

information on the year.

If you need more information about the assembling combinations of the single parts please use the

exploding pictures from the following Spare Part Catalogue Page 28 –30.

Instructions on measurement inspection on all blood pressure units - please see attachment

Measurement inspections.

Instructions on work procedures for dismantling and re-assembling ( see attached description

Seite / Page 6

Page 7

Repair instruction for Speidel + Keller blood pressure units Rev./ Index: 001B

Unit type: Primus 50 metal Art.No. 50-01-000 / Manuell 50 metal Art.No. 50-16-000

------------- Primus 68 metal Art.Nr. 50-04-000 / Manuell 68 metal Art.No. 50-17-000

Instruction of complete dismantling and re-assembling of the unit

Dismantle: 1.1 unscrew glass holder 03/43-901/ 03-44-901.

---------------- 1.2 loosen glass 03-44-902 or glass remains with screwdriver (caution: adhered)

1.3 loosen pointer 18-50-923 / 18-87-906 with slip device resp. tweezers

1.4 remove scale 20-64-151 (caution: adhered)

1.5 unscrew the complete base plate with movement 01-21-000 on hand of the base plate tool.

1.6 unscrew cup screws 50-01-905 with screwdriver.

remove the seal 50-01-901 and cup 50-01-904 / 50-04-901 at 68mm

1.7 loosen the safety pin 19-40-905 with screwdriver and remove the release screw

19-40-901. Remove the single parts spring 19-40-904 and washer 19-40-903.

1.8 remove the ball 17-31-902 and span ring 17-31-911 from the body and loosen valve

screw 15-41-000 with special tool.

Point 1.8 not ablicaple for units manufactured since October 1999.

loosen span ring15-40-903 with a tweezers, remove seal 15-40-902 and

valve tube 15-40-907 with special tool

1.9 loosen spoon screws 50-01-902 with screwdriver

Re-assemble: 2.1 screw on the scoop 50-01-902 with screwdriver.

----------------- 2.2 screw on new cup with screwdriver onto the valve body 50-01-900

2.3 insert washer 19-40-903 and spring into valve body.

screw on the release screw and push the clip ring back in.

2.4 For units from October 99 assemble new valve 15-40-907, seal 15-40-902 and new circlip

15-40-903 with special tool.

2.5 Insert washer 50-01-901 and complete base plate with movement with spec. base plate

tool.

2.6 Put unit on calibration device and put on the special S+K test scale

2.7 Put on needle 18-50-923 / 18-87-906 and adjust with the 0-line

2.8 Go to pressure level 300mmHg and safe. Drive pressure level 50, 100, 150, 200, 250,

300, 350 mmHg up- and downwards, test tolerance +/- 3mmHg / and if neccessary recalibrate with a special calibration pen.

2.9 Set needle on the 0-position and impress with special trigger.

2.10 Insert new glass 03-44-904 and glue it on. (Glue Sicomet 9010)

2.11 screw on the glass ring 03-43-901/ 03-44-901.

End-evaluation / Carry out end-evaluation according to need of repair (see repair instruction

Function / screw valve version,)

Leakage test: If operating on the unit or the mechanism a complete end-evaluation has to be carried

out, including measurement inspection (see realization of mesurement technical

inspections after MPG.)

- If unsure, if the unit was dropped, we suggest to carry out a measurement technical

inspection.

Remarks: The neccessary repair expenditure has to be established and carried out. The needed

upcoming procedure can be taken out of the complete insctruction.

If you need more information about the assembling combinations of the single parts please use the

exploding pictures from the following Spare Part Catalogue Page 3, 5, 7, 9

Seite / Page 7

Page 8

Repair instruction for Speidel + Keller Blood pressure unit Rev./ Index: 001B

unit type: - Primus 50 KC Art.No. 50-81-000 / Manuell 50 KC Art.No. 50-96-000

------------- - Primus 68 KC Art.No. 50-84-000 / Manuell 68 KC Art.No. 50-97-000

Instruction of dismantling and re-assembling the unit

Dismantle: 1.1 clip out glass with a screwdriver on the bezel

--------------- 1.2 loosen glass 03-44-902 or glass remains with screwdriver (Caution: adhered)

1.3 loosen needle 18-50-923/ 18-87-906 with slip device resp. tweezers

1.4 remove scale 20-64-151 (caution: adhered)

1.5 unscrew the complete base plate with movement 01-21-000 on hand of the base plate tool.

1.6 unscrew cup screws 50-01-905 with screwdriver.

remove the seal 50-01-901 and cup 50-01-904 / 50-04-901 at 68mm

1.7 loosen the safety pin 19-40-905 with screwdriver and remove the release screw

19-40-901. Remove the single parts spring 19-40-904 and washer 19-40-903.

1.8 remove the ball 17-31-902 and span ring 17-31-911 from the body and loosen

valve screw 15-41-000 with special tool

Point 1.8 not ablicaple for units manufactured since October 1999.

loosen span ring15-40-903 with a tweezers, remove seal 15-40-902 and

valve tube 15-40-907 with special tool

1.9 loosen spoon screws 50-01-902 with screwdriver

Re-assemble: 2.1 screw on the scoop 50-01-902 with screwdriver.

----------------- 2.2 screw on new cup with screwdriver onto the valve body 50-01-900

2.3 insert washer 19-40-903 and spring into valve body.

screw on the release screw and push the clip ring back in.

2.4 For units from October 99 assemble new valve 15-40-907, seal 15-40-902 and new circlip

15-40-903 with special tool.

2.5 Insert washer 50-01-901 and complete base plate with movement with spec. base plate

tool.

2.6 Put unit on calibration device and put on the special S+K test scale

2.7 Put on needle 18-50-923 and adjust with the 0-line

2.8 Go to pressure level 300mmHg and safe. Drive pressure level 50, 100, 150, 200, 250,

300, 350 mmHg up- and downwards, test tolerance +/- 3mmHg / and if neccessary recalibrate with a special calibration pen.

2.9 Set needle on the 0-position and impress with special trigger.

2.10 Insert new glass 03-44-904 and glue it on. (Glue Sicomet 9010)

2.11 clip the glass back in to the bezels.

End-evaluation / Carry out end-evaluation according to need of repair (see repair instruction

Function / screw valve version, page 1)

Leakage test: If operating on the unit or the mechanism a complete end-evaluation has to be carried

out, including measurement inspection (see realization of mesurement technical

inspections after MPG.)

- If unsure, if the unit was dopped, we suggest to carry out a measurement technical

inspection.

Remarks: The neccessary repair expenditure has to be established and carried out. The needed

upcoming procedure can be taken out of the complete instructions.

If you need more information about the assembling combinations for single parts please use the exploding

pictures from the following Spare Part Catalogue Page 4, 6, 8, 10

Seite / Page 8

Page 9

Repair instruction for Speidel + Keller Blood pressure units Rev./ Index: 001B

Model: - Primus Stabil 3 Art.No. 50-25-000, 50-49-000, 50-59-000, 50-50-000, 50-45-000

---------- - Manuell Stabil 3 Art.No. 50-63-000

Instruction of dismantling and re-assembling the unit

Dismantle: 1.1 turn out the bezel 50-25-908 clock wise.

--------------- 1.2 clip out the glass 03-44-904 with a screwdriver on the bezel (Caution: adhered)

1.3 loosen needle 18-50-921 with slip device resp. tweezers

1.4 remove scale 20-64-161 (caution: adhered)

1.5 unscrew the complete base plate with movement 01-21-000 on hand of the base plate tool.

1.6 unscrew cup screws 50-01-905 with screwdriver.

remove the seal 50-01-901 and cup 50-01-907:

1.7 loosen the safety pin 19-40-905 with screwdriver and remove the release screw

19-40-901. Remove the single parts spring 19-40-904 and washer 19-40-903.

1.8 remove the ball 17-31-902 and span ring 17-31-911 from the body and loosen

valve screw 15-41-000 with special tool

Point 1.8 not ablicaple for units manufactured since October 1999.

loosen span ring15-40-903 with a tweezers, remove seal 15-40-902 and

valve tube 15-40-907 with special tool

1.9 loosen spoon screws 50-01-902 with screwdriver .

Re-assemble: 2.1 screw on the scoop 50-01-902 with screwdriver.

------------ 2.2 screw on new cup with screwdriver onto the valve body 50-01-900

2.3 insert washer 19-40-903 and spring into valve body.

screw on the release screw and push the clip ring back in.

2.4 For units from October 99 assemble new valve 15-40-907, seal 15-40-902 and new circlip

15-40-903 with special tool.

2.5 Insert washer 50-01-901 and complete base plate with movement with spec. base plate

tool.

2.6 Put unit on calibration device and put on the special S+K test scale

2.7 Put on needle 18-50-921 and adjust with the 0-line

2.8 Go to pressure level 300mmHg and safe. Drive pressure level 50, 100, 150, 200, 250,

300, 350 mmHg up- and downwards, test tolerance +/- 3mmHg / and if neccessary recalibrate with a special calibration pen.

2.9 Set needle on the 0-position and impress with special trigger.

2.10 Insert new glass 03-44-904 and glue it on. (Glue Sicomet 9010)

2.11 bring on the bezel 50-25-908 (double noses) and turn it glockwise until stop.

End-evaluation / Carry out end-evaluation according to need of repair (see repair instruction

Function / screw valve version, page 1)

Leakage test: If operating on the unit or the mechanism a complete end-evaluation has to be carried

out, including measurement inspection (see realization of mesurement technical

inspections after MPG.)

- If unsure, if the unit was dopped, we suggest to carry out a measurement technical

inspection.

Remarks: The neccessary repair expenditure has to be established and carried out. The needed

upcoming procedure can be taken out of the complete instructions.

If you need more information about the assembling combinations for single parts please use the exploding

pictures from the following Spare Part Catalogue Page 13 - 18.

Seite / Page 9

Page 10

Repair instruction for Speidel + Keller Blood pressure units Rev./ Index: 001B

Model: - ISO Stabil 5 Art. No. 50-71-000

------------- - Stabil 3 (predecessor. model Stabil 5)

Instruction of dismantling and re-assembling the unit

Dismantle: 1.1 turn out the bezel 50-25-908 clock wise.

--------------- 1.2 clip out the glass 03-44-904 with a screwdriver on the bezel (Caution: adhered)

1.3 loosen needle 18-50-921 with slip device resp. tweezers

1.4 remove scale 20-64-161 (caution: adhered)

1.5 unscrew the complete base plate with movement 01-21-000 on hand of the base plate tool.

1.6 unscrew cup screws 50-01-905 with screwdriver and then remove the cup 50-25-905

1.7 loosen the closing ring on the ball 17-31-000 and then take it off the va lve

1.8 release trigger 50-71-812 from valve body and take out pin 50-61-813

1.9 unscrew check valve 15-40-000 with special tool.

For units manufactured since October 1999.

loosen span ring15-40-903 with a tweezers, remove seal 15-40-902 and

valve tube 15-40-907 with special tool

Re-assemble: 2.1 Insert pin 50-61-813 though drilling o n the valve body.

------------ build in feather 54-31-904 on valve body and then insert trigger into valve body

push trigger pin with special pin forward and release trigger.

Carry out functional test (should run easy without creaking noise up to the stop)

2.2 Screw in new valve screw 15-41-000 and screw the ball 17-31-000 back on.

Turn on check valve as safety device.

2.3 Put the cup 50-25-905 onto the valve body and screw it in.

2.4 Insert washer 50-01-901, then complete ground plate with movement and screw

it in with the special base plate tool.

For units manufactured since October 1999.

loosen span ring15-40-903 with a tweezers, remove seal 15-40-902 and

valve tube 15-40-907 with special tool.

Assemble ball tube 17-31-911 and ball 17-31-902

2.5 Put unit into the calibration device and put on the special S+K test scale.

2.6 Bring on trigger 18-50-921 and adjust it to the zero-line.

2.7 Start pressure 300 mmHg and adjust.

Pressure levels 50, 100, 150, 200, 250, 300 , 350 mmHg drive up- and downwards

and test tolerance +/- 3mmHg / if necessary re-adjust with special calibration pin.

2.8 Set new trigger to zero-position and impress with a special printer.

2.9 Eventually assemble (engage) cub with a new spacer ring 50-25-912.

2.10 clip and clue in new glass 03-44-904 (Sicomet 9010).

2.11 Put on bezel 50-25-908 ( 2 nose whiskers left wing) and turn it clockwise until stop.

End-evaluation / Carry out end-evaluation according to need of repair

Function /

Leakage test: If operating on the unit or the mechanism a complete end-evaluation has to be carried

out, including measurement inspection (see realization of mesurement technical

inspections after MPG.)

- If unsure, if the unit was dopped, we suggest to carry out a measurement technical

inspection.

Remarks: The neccessary repair expenditure has to be established and carried out. The needed

upcoming procedure can be taken out of the complete instructions.

Seite / Page 10

Page 11

Repair instruction for Speidel + Keller Blood pressure units Rev./ Index: 001B

Model: - Disytest / Disytest HomeArt.No. 52-09-000

-------------

Instruction of dismantling and re-assembling the unit

Dismantle: 1.1 Enter with screwdriver and clip out glass 52-03-903.

--------------- 1.2 Loosen needle 18-50-924 / 18-50-923 (Persona) with the slip device resp. tweezers

1.3 Clip out the scale 20-51-106 / 20-51-103 (Persona) as you have down with the glass.

1.4 Unscrew the complete base plate with movement 01-21-000 on hand of the base plate

tool, take of the washer 50-01-901.

1.5 Remove ball 17-52-000 and span ring 17-01-902.

1.6 Turn off the check valve 15-40-000 with special tool.

For units manufactured since October 1999.

loosen span ring15-40-903 with tweezers, remove seal 15-40-902 and

valve tube 15-40-907 with special tool.

1.7 Release trigger 52-03-902 on the valve body, with special tool (inside, six-cant wrench)

turn off trigger release valve 12-12-900, take out spring 19-12-904.

Re-assemble: 2.1 Insert spring 19-12-904 in the valve body , insert trigger release valve 19-12-900

----------------- and tighten it with the special six-cant wrench, press in trigger 52-03-902

to the grid - Caution: test trigger function - should have easy play and easy handling

between the trigger release valves.

2.2 Screw in new check valve 15-41-000, push in span ring 17-01-902 and ball 17-52-000.

For units manufactured since October 1999.

Assemble new valve 15-40-907, seal 15-40-902 and circlip 15-40-903 with special tool.

Assemble ball tube 17-31-911 and Ball 17-31-902

2.3 Insert washer 50-01-901 and screw in the complete base plate including movement with

the special base plate tool.

2.4 Put the unit up onto the calibration device and insert the special S+K test scale „Disytest“.

2.5 Put on needle 18-50-924 and adjust to the zero-line.

2.6 Bring pressure to 300 mmHg and adjust Pressure levels 50, 100, 150, 200, 250, 300 ,

350 mmHg run up and downwards, test on tolerance +/- 3mmHg , if necessary adjust

with special calibration pin.

2.7 Set new pointer on zero-position and press on with special trigger.

2.8 Clip in new glass 52-03-903.

End-evaluation / Carry out end-evaluation according to need of repair

Function /

Leakage test: If operating on the unit or the mechanism a complete end-evaluation has to be carried

out, including measurement inspection (see realization of mesurement technical

inspections after MPG.)

- If unsure, if the unit was dropped, we suggest to carry out a measurement technical

inspection.

Remarks: The neccessary repair expenditure has to be established and carried out. The needed

upcoming procedure can be taken out of the complete instructions.

If you need more information about the assembling combinations for single parts please use the exploding

picture from the following Spare Part Catalogue Page 11.

Seite / Page 11

Page 12

Repair instruction for Speidel + Keller Blood pressure unit Rev./ Index: 001B

Model: - Maxi Stabil 3 Art.No. 59-30-000

------------

Instruction of dismantling and re-assembling the unit

Dismantle: 1.1 Turn bezel 59-30-901 anticlockwise and remove the housing

--------------- (Caution bezel may be adhered - dissolve).

1.1 Enter the groove with a scrwedriver and clip out the glass 59-30-902.

1.2 Loosen needle 18-87-908 with the slip device resp. tweezers

1.3 Clip out the scala 20-51-159 with a screwdriver (as done with the Glas).

1.4 Unscrew the complete base plate with movement 01-10-000 with the base plate

tool, take of the washer 50-01-915.

1.5 Unscrew the metal tube connector 16-40-000 and knurled nut 59-30-922

1.6 CAUTION: No further dismantling possible, because the air release connector is

clued. A dismantling of the connector could damage the housing. If this connector is

damaged the complete housing 59-30-750 has to be exchanged.

Re-assemble: 2.1 Screw in the metal tube connector 16-40-000 and knurled nut 59-30-922

----------------- 2.2 Insert washer 50-01-901 and screw the complete base plate inclusive movement back in

with the special base plate tool.

2.3 Put the unit on the calbration device and bring on the special S+K test scale „Maxi.

2.4 Put on the needle 18-87-908 and adjust on the 0-line.

2.5 Bring pressure to 300 mmHg and adjust Pressure levels 50, 100, 150, 200, 250, 300 ,

350 mmHg run up and downwards, test on tolerance +/- 3mmHg , if necessary adjust

with special calibration pin.

2.6 Impress new scala (prescribed groove).

2.7 Set the new pointer on zero-position and impress with special press.

2.8 Clip in new glass 59-30-902.

End-evaluation / Carry out end-evaluation according to need of repair

Function /

Leakage test: If operating on the unit or the mechanism a complete end-evaluation has to be

out, including measurement inspection (see realization of mesurement technical

inspections after MPG.)

- If unsure, if the unit was dopped, we suggest to carry out a measurement technical

inspection.

Remarks: The neccessary repair expenditure has to be established and carried out. The needed

upcoming procedure can be taken out of the complete instructions.

If you need more information about the assembling combinations for single parts please use the exploding

pictures from the following Spare Part Catalogue Page 19 and 20.

Seite / Page 12

Page 13

Repair instruction for Speidel + Keller Blood pressure units Rev./ Index: 001B

Model: - Fixomed Art. No. 50-91-000

-------------

Instruction of dismantling and re-assembling the unit

Dismantle: 1.1 Unscrew the safety ring 03-43-901.

--------------- 1.2 Loosen glass 03-42-902 or glass remains with screwdriver (Caution: adhered)

1.3 Loosen needle 18-87-905 with the slip device resp. tweezers.

1.4 Remove the scala 20-57-122 (Caution: adhered)

1.5 Unscrew the complete base plate and movement 01-21-000 with base plate tool.

1.6 Unscrew the flat head screws 50-01-905 with screwdriver.

Remove washer 50-01-901 and cup 50-04-901 (68mm).

1.7 Pull off the ball 17-31-902 and span ring 17-31-901 from the body and unscrew the

check valve 15-41-000 with special wrench

For units manufactured since October 1999.

Loosen span ring15-40-903 with tweezers, remove seal 15-40-902 and valve

tube 15-40-907 with special tool.

1.8 Loosen spoon 50-01-902 with screwdriver.

1.9 A dismantling of the release valve should not be carried out, because the re-assembling is

extremely difficult.

If the release valve is damanged, the complete valve body has to be replaced 50-85-000.

Re-assemble: 2.1 Screw on the spoon 50-01-902 with screwdriver.

------------ 2.2 Screw on the new cups with screwdriver on the valve body 50-85-900.

2.3 Screw in new check valve 15-41-000, and assemble new span ring 17-31-901 and Ball

17-31-902.

For units manufactured since October 1999.

Assemble new valve 15-40-907, seal 15-40-902 and circlip 15-40-903 with special tool.

Assemble ball tube 17-31-911 and Ball 17-31-902

2.4 Insert washer 50-01-901 and screw on the complete base plate with special base plate tool

2.5 Put unit into the calbration device and bring on the special test scale "Fixomed"

2.6 Put on needle 18-87-905 and adjust it to the zero-line.

2.7 Bring pressure to 300 mmHg and adjust Pressure levels 50, 100, 150, 200, 250, 300 ,

350 mmHg run up and downwards, test on tolerance +/- 3mmHg , if necessary adjust

with special calibration pin.

2.8 Insert scala 20-57-122 in cup.

2.9 Set needle on zero-position and impress with special press.

2.10 Insert new glass 03-42-902.

2.11 Screw on new safety glass 03-43-901 and tighten it.

End-evaluation / Carry out end-evaluation according to need of repair

Function /

Leakage test: If operating on the unit or the mechanism a complete end-evaluation has to be carried

out, including measurement inspection (see realization of mesurement technical

inspections after MPG.)

- If unsure, if the unit was dopped, we suggest to carry out a measurement technical

inspection.

Remarks: The neccessary repair expenditure has to be established and carried out. The needed

upcoming procedure can be taken out of the complete instructions.

Seite / Page 13

Page 14

Repair instruction for Speidel + Keller Blood pressure units Rev./ Index: 001B

Model: - Hand 2003 Art. No. 50-03-000

-------------

Instruction of dismantling and re-assembling the unit

Dismantle: 1.1 Unscrew safety glass 03-43-901.

--------------- 1.2 Loosen glass 03-42-902 or glass remains with screwdriver (Caution: adhered)

1.3 Loosen needle 18-87-906 with the slip device resp. tweezers.

1.4 Remove scala 20-57-940 (Caution: adhered)

1.5 Unscrew complete base plate incl. movement 01-21-000 with special base plate tool

and remove washer 50-01-901.

1.6 Loosen and unscrew the span ring ot the ball 17-31-000.

Unscrew check valve 15-40-000 with special tool.

1.7 Loosen spoons 50-01-902 with screwdriver.

1.8 A dismantling of the release valve should not be carried out, because the re-assembling is

extremely difficult.

If the release valve is damanged, the complete valve body has to be replaced 50-85-000.

Re-assemble: Goes the same for the unit Hand Version 2001 (50 mm)

----------------- 2.1 Screw the new check valve 15-40-000 in to the complete valve part 54-07-700

put up the new washer 54-31-910 and screw the Ball 17-31-000 on to the housing.

2.2 Insert washer 50-01-901 and screw on the complete base plate with special base plate tool

2.3 Put unit into the calbration device and bring on the special test scale 20-57-940

2.4 Put on needle 18-87-906 and adjust it to the zero-line.

2.7 Bring pressure to 300 mmHg and adjust Pressure levels 50, 100, 150, 200, 250, 300 ,

350 mmHg run up and downwards, test on tolerance +/- 3mmHg , if necessary adjust

with special calibration pin.

2.8 Insert scala 20-57-940 in cup.

2.9 Set needle on zero-position and impress with special press.

2.10 Insert new glass 03-42-902.

2.11 Screw on new safety glass 03-43-901 and tighten it.

End-evaluation / Carry out end-evaluation according to need of repair

Function /

Leakage test: If operating on the unit or the mechanism a complete end-evaluation has to be carried

out, including measurement inspection (see realization of mesurement technical

inspections after MPG.)

- If unsure, if the unit was dopped, we suggest to carry out a measurement technical

inspection.

Remarks: The neccessary repair expenditure has to be established and carried out. The needed

upcoming procedure can be taken out of the complete instructions.

If you need more information about the assembling combinations for single parts please use the exploding

picture from the following Spare Part Catalogue Page 23.

Seite / Page 14

Page 15

Repair instruction for Speidel + Keller Blood pressure units Rev./ Index: 001B

Model: - Oscillophon Art. No. 51-05-000

-------------

Instruction of complete dismantling and re-assembling of the unit

Dismantle: 1.1 Dismantle unit from the cuff with screwdriver

-------------- 1.2 Unscrew safety ring 03-44-901.

1.3 Loosen glass 03-44-902 or glass remains with screwdriver (Caution: adhered)

1.4 Loosen needle 18-50-923 with the slip device resp. tweezers.

1.5 Remove scala 20-57-940 (Caution: adhered)

1.6 Loosen three screws with screwdriver and complete base plate with movement 01-22-000

plus take out three washers 51-01-901.

Assemble:

------------- 2.1 Insert the three washer 51-01-901 and screw the three screws 01-21-901 back in with a

screwdriver and tighten the complete base plate with the movement

2.2 Put unit into the calbration device and bring on the special test scale 20-64-151

2.3 Put on needle 18-50-923 and adjust it to the zero-line.

2.4 Bring pressure to 300 mmHg and adjust Pressure levels 50, 100, 150, 200, 250, 300 ,

350 mmHg run up and downwards, test on tolerance +/- 3mmHg , if necessary adjust

with special calibration pin.

2.5 Insert scala 20-64-151 in cup. (note: inlay groove)

2.6 Set needle on zero-position and impress with special press.

2.7 Insert new glass 03-44-902.

2.8 Screw on new safety glass 03-44-901 and tighten it.

End-evaluation / Carry out end-evaluation according to need of repair

Function /

Leakage test: If operating on the unit or the mechanism a complete end-evaluation has to be carried

out, including measurement inspection (see realization of mesurement technic

inspections after MPG.)

- If unsure, if the unit was dopped, we suggest to carry out a measurement technical

inspection.

Remarks: The neccessary repair expenditure has to be established and carried out. The needed

upcoming procedure can be taken out of the complete instructions.

If you need more information about the assembling combinations for single parts please use the exploding

picture from the following Spare Part Catalogue Page 12.

Seite / Page 15

Page 16

Instruction for end evaluation including measurement inspections

1. Visual test:

- Check complete unit (chrome damages, etc).

- Check if pointer position is at zero range

2. Measurement test

- Connected unit to the certified pressure gauge class 0,1 (max. deviation 0,8 mmHg).

- Accuracy statistical pressure / Hysterisis on pressure values 50,100,150,200,250,300, mmHg test up-and

downwards Tolerance = < 3 mmHg on all test points / Hysterisis = < 4 mmHg on all test points. - start

pressure decrease 300 mmHg /seal unit system and test leakage. Pressure decrease should stay

at = < 4 mmHg/min.

3. Function test

- Connect unit with complete cuff onto the test tube, girth appox. 35 cm and pump up to 300 mmHg /test cuff

for leakage, then open air release valve / should turn easy / test pointer run and test speed outlet. During the

speed air release the time for pressure decrease from 260 mmHg to 15 mmHg should not exceed 10 Sec.

Run of the release screws / test printer - trigger grid (ie. Disytest)

4. Test Documentation

- Documentation as by S+K requested test report, entry of unit type, S/N, established deviations, leakage, test

date, tester, user, remarks.

These documentation has to be made available for S+K.

5. Following function

Fasten new test label with year when test was carried out.

6. Important remarks:

- Measurement technical controls with confirmation of a test label can only be carried out on CE - marked

blood pressure meters. Older units with PTB-Registration should be submitted to the notified body after

inspection for calibration as done in the past.

Seite / Page 16

Page 17

Tools: Description Article/ Order No.

Complete tool set 94-01-000

Base plate wrench metal for movement assembling (all types) 94-01-101

Test scale 50 mm metal for unit calibration 94-01-103

Test scale 68 mm metal for unit calibration 94-01-104

Test scale Disy for unit calibration 94-01-105

Calibration stick for unit calibration 94-01-106

Needle presser for needle assembling 94-01-107

Wrench SW3,5 for release assembling 94-01-108

Wrench SW6,5 for valve assembling 94-01-109

Wrench SW6 (inside) for valve part assembling 94-01-110

Square wrench for seal Seal dismantling (old units) 94-01-111

Test scale 50 mm KC for unit calibration 94-01-112

Test scale 68mm KC for unit calibration 94-01-113

Tweezcers size AA for various operations 94-01-115

Test scale for Stabil for unit calibration 94-01-116

Test scale Maxi for unit calibration 94-01-117

Calibration stand for unit calibration 94-01-118

Neddle disconnector for needle dismantling 94-01-119

Screw driver (fine) 1,5 assembling tool for various units 94-01-120

Screw driver(fine) 2,0 assembling tool for various units 94-01-121

Pinch pliers for ball sleve assemble / pinching 94-01-123

Spare part list + repair instructions for all blood pressure units 94-01-130

Ordering of single tools is possible. Please direct your orders to a S+K Sales department.

Other necessary tools:

----------------------------

Test gauge Measurement sector at least 0-300 mmHg self purchase nec. / on

+ Certificate with evidence Accuracy= < 0,8 mmHg request also from S+K

Spanblock for dismantling the seal self purchase nec.

Adjustment plate for adjusting defect parts self purchase nec.

Seite / Page 17

Page 18

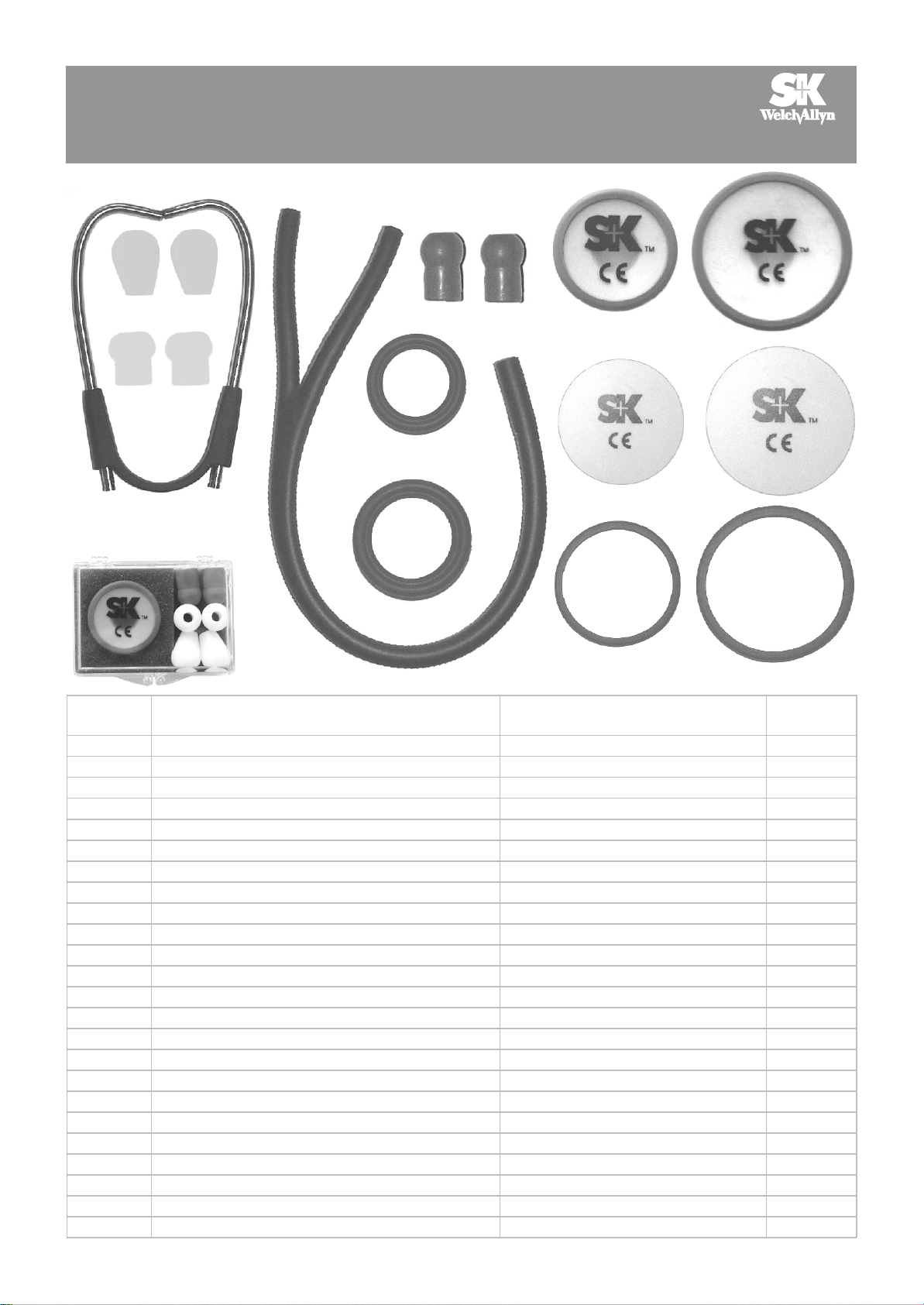

Repair instruction for Speidel + Keller blood pressure units

"Accessories for blood pressure units"

Failure search mechanical blood pressure units

Units / Products concerned:

- Membranstetoscope for self mesurement Art. No. 84-10-000 (integrated in cuff)

- Planoskop 40 mm Art. No. 83-11-080

- Planoskop 30 mm (child) Art. No. 83-12-080

- Duophon 40 mm Art. No. 82-11-080

- Duophon 30 mm (child) Art. No. 82-15-080

- Harvey Elite all models

- Professional all models

1. Failure search - Locating missing parts

-----------------------------------------------------

- Missing membran - Safety ring - Ear tips - Membran holder - Y-Tube

2. Search on cause and reason for failure Neccessary repair

----------------------------------------------------- -----------------------------------------

- Defect / broken membran Built in new membran + carry out functi on test

(can occur on all models)

- Bent / defect ear piece Fit new ear piece + funtion test

- Defect / plugged / missing Assemble new ear tips + function test

(can occur on all models)

- Defect / missing membran holder Assemble new membran holder + function test

- Y-tube porous / defect. Ripped material, etc. Assemble new Y-tube + function test

(all models)

- Tube connector turns / can not be Insert tube connector + function test

assembled (only on membran stethoscope

for self measurement)

- Not possible to switch over the Duophon shaft Dismantle and re-assemble (only Duophon) eventually

bent. assemble new shaft + function test

Instructions for function test / Membranstethoscope integrated in cuff "Self measuring"

1. Apply cuff on upper arm

2. Connect tube connector on S+K blood pressure unit.

3. Insert ear tips into the auditory canal

4. Inflate cuff (approx. 30 mmHg over expected blood pressure)

5. Release air and carry out the complete measurement.

6. Korotoff sounds should be well heared from the start of the Systole till the Diastole.

Planoskop / Professional

1. Apply cuff on upper arm

2. Push the Planoskop under the Cuff (Membran part skin contact)

3. Insert ear tips into the auditory canal

4. Inflate cuff (approx. 30 mmHg over expected blood pressure)

5. Release air and carry out the complete measurement.

6. Korotoff sounds should be well heared from the start of the Systole till the Diastole.

Duophon / Harvey Elite

1. Switch Duophon several times over - should be easy going and engage on half turn.

Duophon shaft hole visible - Duophon out of order

Duophon shaft hole not visible - turned to membran - Duo phon on stand by.

Seite / Page 18

Page 19

Repair instruction for Speidel + Keller blood pressure units

Failure search accessories hand fan

Units / Products concerned:

---------------------------------------

- Hand fan Art. No. 17-01-000

- Hand fan Art. No. 17-02-000

- Hand fan Art. No. 17-08-000

- Hand fan Art. No. 17-10-000

1. Failure search - Locating missing parts

----------------------------------------------------------------

- Trigger - Ball - Ring / Release screw - Valve part

2. Search on cause and reason for failure Neccessary repair

------------------------------------------------------ ----------------------------------------

- Not possible to orderly inflate Inspect ball valve - replace if necessary

( defect ball valve) + carry out function test

- Leakage in System Assemble new valve check screw / release screw

tube connector / release screw + carry out function test

- Worn out release screw Assemble new release screw + function test

- Defect / missing / broken trigger Assemble new trigger + function test

Instruction for function test:

All hand valves:

- Connect hand fan with connector tube onto a cuff

- Cuff around test tube (Girth approx. 35 cm)

- Interclose test gauge 0-600 mmHg

- Pump in pressure air till approx. 500 mmHg

- Wait for air balance

- Test leakage =< 4 mmHg / min

- Operate release screw and trigger, then carry out function test

(Should be easy to operate )

- Test speed air release (the air release with pressed valve should be 260 - 15 mmHg =< 10 seconds).

If you need more information about the assembling combinations for single parts please use the exploding

pictures from the following Spare Part Catalogue Page 24 - 27.

Seite / Page 19

Page 20

Repair instructions for Speidel + Keller

Medical Special units

----------------------------

Units / Products concerned:

- Pressure infusion cuff Art. No. 51-08-000

- Pressure unit Sanipress Art. No. 50-09-000

1. Failure Search - Locating missing parts

-Cuff - Glass - Scale - Valve parts - Ball valve - Screws - Washers - other Accessories

2. Search on cause and reason for failure Neccessary repair

Possible causes/- reasons: Upcoming repair:

- Leaking membran/ base plate Replace complete base plate and movement +

measurement inspection

- Needle outside the tolerance on the zero- Replace needle + measurement inspection + eventually

point replace complete base plate and movement

- Hanging needle / jerky movements Replace complete base plate with movement +

Probably bent movement axle carry out measurement inspection

movement spring tangled in the segment

- Glass / Scale fallen out, broken Insert glass and scale, carry out measurement inspection

bent, scratched etc.

(dropped unit)

- Leaking valve part, tube valve version Replace valve + leakage test

- Leak on the cuff Replace rubber bag + leakage test

- Leak on tube connector/other connector pieces/ Replace all defect parts + carry out leakage test

part valve

- Hart turning release screws Replace release screw + leakage test

- Defect trigger / bezel Replace trigger + test bezel on function

- Leak on valve part, trigger version Replace complete valve group + leakage test

- Defect air pump / not possible to inflate Replace air pump + leakage test

- No air inlet or release possible Clean in- and outlets. Replace release screw/ valve if

necessary + function test

- No speed air release possible Clean in- and outlets. Replace release screw/ valve if

necessary + function test

- Ball + valve not pumping / defect Assemble new ball + function test

possible defect check valve /

or rip in material

- Defect valve body Completely dismantle and reassemble new body +

measurement inspection.

- Missing washer Replace washer + leakage test

Seite / Page 20

Page 21

Repairs instruction for Speidel + Keller - Medical Special units.

Units / Products concerned:

- Pressure unit Tournipress Art.No. 53-05-000

1. Failure Search - Locating missing parts

-Cuff - Glass - Scale - Valve parts - Ball valve - Screws - Washers - other Accessories

2. Search on cause and reason for failure Neccessary repair

Possible causes/- reasons: Upcoming repair:

- Pressure not adjustable / Defect pressure Replace pressure regulator with regulator head ,

regulator / regulator head re-adjust pressure, carry out function + leakage test

- Aeration not possible, aeration -function Assemble new aeration valve + carry out function

valve hangs / defect + leakage test

- Pressure does not show on display Assemble new pressure dislay + carry out function +

at end pressure 600 and leakage test

Pressure display does not react if the main

operation gets cut off.

- Defect connector to supplier / defect Built in new shutter coupling + carry out function +

air coupling leakage test

- Not possible to switch over from distal Built in new switch valve + carry out function test

to proximal and reverse / defect switch valve

ventil defekt

- Timer does not function / no reaction Replace battery and solder new electric connectors

+ carry out function test.

- Leak membran/base plate from Manometer Replace complete base plate + movement

carry out measurement inspection.

- Needle outside the toleranc on the zero point Replace needle + measurement inspection - eventually

replace base plate including movement

- Needle hangs / jerky movements Replace complete base plate and movement +

Probably bent movement axle/ measurement inspection

movement spring tangled up in Segment

- Glass/ Scale fallen out, broken Insert new glass + scale + carry out measurement

bent, scratched, etc (dropped unit)

- Leak on cuff Replace rubber bag + leakage test

- Leakage on tube connector Replace all defect parts + carry out leakage test

connector pieces / valve bodies

- No air inlet / release possible Clean air inlets and outlets. Possibly replace release screw

/ valve + carry out function test.

- Accessory ball + valve not possible to Assemble new ball + function test

inflate / probably defect check valve or

rip in material

- Missing washers Replace washers + leakage test

Seite / Page 21

Page 22

SERVICE ANLEITUNG

WELCH ALLYN / SPEIDEL +KELLER

Vorwort

Sehr geehrter S+K Servicepartner,

wir freuen uns Sie als Reparaturpartner von Speidel + Keller begrüßen zu dürfen.

Die Fa. Speidel + Keller ist stets bemüht Ihren Servicepartnern optimale Bedingungen

zu schaffen, damit eine reibungsloser Service der Produkte gewährleistet ist.

Speidel +Keller Blutdruckmeßgeräte zeichnen sich durch eine qualitativ hochwertige

Verarbeitung aus. Dies ist ein Garant dafür, daß S+K Produkte eine sehr lange

Lebensdauer besitzen.

Natürlich bedarf auch das beste Gerät einer regelmäßígen Wartung damit stetig

ordnungsgemäß und reibungslos damit gearbeitet werden kann.

Zudem ist es eine Notwendigkeit, im Hinblick auf die Bestimmungen des MPG

und der EG- Medizinprodukterichtlinien, regelmäßige Wartungen und meßtechnische

Kontrollen an Medizinprodukten durchzuführen.

Aus den obengenannten Gründen haben wir Reparaturanweisungen für alle unsere

Geräte erstellt.

Diese Anweisungen sollen Ihnen bei der Durchführung einer ordnungsgemäßen

Reparatur begleitend helfen.

Seite / Page 22

Page 23

Reparaturanweisung für Speidel + Keller Blutdruckmeßgeräte

Fehlersuche Mechanische Blutdruckmeßgeräte

-------------------------------------------------------------------------------------------------------------------------------------Betroffene Geräte / Produkte:

-----------------------------------------

- Primus 50/68 1 u. 2 Schlauchv. KC und Metall Art. Nr. 50-01-000/ 50-04-000/ 50-81-000/ 50-84-000

- Manuell 50/68 1 u. 2 Schlauchv. KC und Metall Art. Nr. 50-16-000/ 50-17-000/ 50-96-000/ 50-97-000

- Primus Stabil 3 und Stabil 3 Home Art Nr. 50-25-000/ 50-49-000/ 50-59-000/ 50-50-000

und Farbserie gelb,blau,rot,blau 50-45-000

- Manuell Stabil 3 Art.Nr. 50-63-000

- Disytest / Disytest Home Art. Nr. 52-09-000

- ISO Stabil 5 Art. Nr. 50-71-000

- Fixomed Art. Nr. 50-91-000

- Hand 2003 Art. Nr. 54-03-000

- Oscillophon Art. N . 51-05-000

- Minimus Art. Nr. 51-02-000

- Maxi Stabil 3 Art. Nr. 59-32-000

1. Fehlersuche - Feststellung von fehlenden Teilen

-----------------------------------------------------------------

-Manschette -Glas -Skala -Ventilteile -Ball - Schrauben -Dichtungen -sonstiges Zubehör

2. Fehlersuche n. Fehlerart und Ursache Notwendiger Reparaturaufwand

Mögliche Fehlerarten- /ursachen: Durchzuführende Reparatur:

----------------------------------------------------- ------------------------------------------------------------

- Membrane/Grundplatte undicht Komplette Grundplatte m. Werk auswechseln +

meßt.Kontrolle

- Zeiger außerh. Toleranz am Nullpunkt Zeiger wechseln + meßtechnische Kontrolle - eventuell

komplette Grundplatte mit Werk wechseln

- Zeiger hängt / ruckartige Bewegungen Zeiger und komplette Grundplatte mit Werk wechseln +

Vermutlich Werkachse verbogen / meßtechnische Kontrolle

Werkfeder im Segment verwickelt.

- Glas/ Skala herausgefallen, gebrochen Neues Glas + Skala einsetzen + meßtechnische Kontrolle

verbogen , zerkratzt etc. durchführen

(Gerät gefallen)

- Ventilteil undicht Schraubventilversion Ventil auswechseln + Dichtheitsprüfung

- Undichtigkeiten an der Manschette Gummibeutel wechseln + Dichtheitsp rüfung

- Undichtigkeiten an Schlauchverbind. Komplettaustausch der defekten Teile + Dichtheitsprüfung

Anschlußstücken/ Ventilkörper vornehmen

- Auslaßschrauben schwergängig Auslaßschraube wecheln + Di chtheitsprüfung

- Drücker defekt / Rastung defekt Drücker wechseln + Funktionsprüfung der Rastung

- Ventilteil undicht Drückerversion Komplette Ventilbaugruppe auswechseln +

Dichtheitsprüfung

- Kein Lufteinlaß/ Auslaß möglich Lufteinlaß/ Ausgänge reinigen, Event. Auslaßschraube

Ventil wechseln + Funktionsprüfung

Seite / Page 23

Page 24

2. Fehlersuche n. Fehlerart und Ursache Notwendiger Reparaturaufwand

Mögliche Fehlerarten- /ursachen: Durchzuführende Reparatur:

------------------------------------------------------ --------------------------------------------

- Ball nicht pumpbar / defekt Neuer Ball montieren + Funktionsprüfung

Vermutlich Rückschlagventil defekt /

oder Materialriß (auch Handventile)

- Ventilkörper / Schraub/ Drückerversion Komplettausbau und Wiedereinbau neuer Körper

defekt + meßtechnischer Kontrolle

- Fehlende Dichtungen Dichtungen ersetzen + Dichtheitsprüfung

- Kalibrierzeitraum abgelaufen / Meßtechnische Kontr olle durchführen + P rüfmarke

überschritten anbringen , Dokumentation erstellen (siehe Anweisung

meßtechnische Kontrollen

Beschreibung zur Durchführung der meßtechnischen Kontrolle - siehe Blatt meßtechnische

Kontrollen.

Beschreibung der Arbeitsfolge bei Demontage und Wiedermontage siehe spezielle

Einzelbeschreibung

Seite / Page 24

Page 25

Reparaturanweisung für Speidel + Keller Blutdruckmeßgeräte

Quecksilbergeräte: Betroffene Geräte / Produkte:

- Miniatur 300 B Art. Nr. 65-11-000

- Miniatur 300 S Art. Nr. 65-13-000

- Mercuro 300 Art. Nr. 74-01-000

1. Fehlersuche - Feststellung von fehlenden Teilen

-------------------------------------------------------------------

- Manschette, - Glasrohr, - Filterkappen, - Dichtungen, - Deckel, - Ballventil, - sonstiges Zubehör

2. Fehlersuche n. Fehlerart und Ursache: Notwendiger Reparaturaufwand:

Mögliche Fehlerarten- / Ursachen: Durchzuführende Reparatur:

----------------------------------------------------- ----------------------------------------------

- Glasrohr gebrochen / verschmutzt Glasrohr wechseln bzw. reinigen + meßtechn. Kontrolle

- Quecksilberbehälter defekt / Riß Neuer Quecksilberbehälter montieren + Quecksilber

einfüllen + meßtechnischer Kontrolle durchführen.

- Rasthebel läßt sich nicht umlegen Neuer Rasthebel und Behälter montieren + Quecksilber

kein Quecksilbereinfließen möglich einfüllen + meßtechnische Kontrolle durchführen

- Quecksilberausfluß Untersuchung der undichten Stelle , Austausch des defekten

(Vorsicht Berührung mit Quecksilber Teiles + Quecksiber nachfüllen + meßtechn. Kontrolle

ist gesundheitsschädlich) durchf.

- Schlauchanschluß defekt/ undicht Neue Dichtung und Schlauchans chlußmontage +

Quecksilber nachfüllen + meßtechn. Kontrolle durchführen.

- Filter oder Filterkappe defekt / undicht Neuer Filter und Filterkappe einsetzen + Quecksilber

losgelöst etc. nachfüllen + meßtechn. Kontrolle durchführen

- Gehäuseteile / Skala etc. defekt Teile ersetzen + Funktionsprüfung durchführen.

- Kalibrierungszeitraum überschritten Meßtechnische Kontrolle durchführen + neuer Prüfkleber

mit Jahresangabe anbringen.

Beschreibung zur Durchführung der meßtechnischen Kontrolle - siehe Blatt meßtechnische

Kontrollen.

Beschreibung der Arbeitsfolge bei Demontage und Wiedermontage siehe spezielle

Einzelbeschreibung.

Weitere Details zur Demontage und Wiedermontage sind aus den Bildern im Anhang ersichtlich.

Hier kann die Zusammenbauansicht entnommen werden siehe Ersatzteilkatalog Seite 28 - 30.

Seite / Page 25

Page 26

Reparaturanweisung für Speidel + Keller Blutdruckmeßgerät Rev./ Index: 001B

Gerätetyp: Primus 50 Metall Art.Nr. 50-01-000 / Manuell 50 Metall Art.Nr. 50-16-000

Primus 68 Metall Art.Nr. 50-04-000 / Manuell 68 Metall Art.Nr. 50-17-000

Beschreibung einer kompletten Demontage und Wiedermontage des Gerätes

Demontage: 1.1 Glashaltering 03/43-901/ 03-44-901 abschrauben.

---------------- 1.2 Glas 03-44-902 oder Glasreste mit Schraubendreher lösen (Vorsicht verklebt)

1.3 Zeiger 18-50-923 / 18-87-906 mit Abhebevorrichtung bzw. Pinzette lösen.

1.4 Skala 20-64-151 abnehmen (Vorsicht verklebt)

1.5 Komplette Grundplatte mit Werk 01-21-000 mit Grundplattenschlüsse ausschrauben.

1.6 Becherschrauben 50-01-905 mit Schraubendreher ausschrauben.

Dichtung 50-01-901 und Becher 50-01-904 / 50-04-901 bei 68mm

entnehmen.

1.7 Sprengring 19-40-905 mit Schraubendreher lösen und Auslaßschraube

19-40-901 ausdrehen. Einzelteile Feder 19-40-904 und Unterlegscheiben

19-40-903 entnehmen.

1.8 Ball 17-31-902 und Klemmring 17-31-911vom Körper abziehen und

Ventilsitzschraube 15-41-000 mit Spezialschlüssel ausschrauben.

Für Geräte ab Oktober 1999 entfällt 1.8

Sprengring 15-40-903 mit Pinzette lösen, Dichtung 15-40-902 und Ventilschlauch 15-40-907 mit Spezialwerkzeug auslösen.

1.9 Löffelschrauben 50-01-902 mit Schraubendreher lösen

Montage: 2.1 Löffel 50-01-902 mit Schraubendreher anschrauben.

------------- 2.2 Neuer Becher mit Schraubendreher auf Ventilkörper 50-01-900

aufschrauben.

2.3 Unterlegscheiben 19-40-903 und Feder in Ventilkörper einlegen

Auslauslaßschraube einschrauben und Sprengring eindrücken.

2.4 Für Geräte ab Oktober 1999 Neues Ventil 15-40-907, Dichtung 15-40-902

und Sprengring 15-40-903 mit Spezialwerkzeug montieren.

Ballhülse 17-31-911 und Ball 17-31-902 montieren.

2.5 Dichtung 50-01-901 einlegen und komplette Grundplatte

mit Werk mit spez. Grundplattenschlüssel einschrauben

2.6 Gerät in Justiervorrichtung legen u. spezielle S+K Prüfskala aufsetzen

2.7 Zeiger 18-50-923 / 18-87-906 aufsetzen und mit 0 -Strich abgleichen

2.8 Druckstufe 300 mmHg anfahren und einstellen.

Druckstufen 50, 100, 150, 200, 250, 300 , 350 mmHg auf und abwärts

anfahren und Toleranz prüfen +/- 3mmHg / gegebenenfalls mit speziellem

Justierstift nachjustieren.

2.9 Zeiger auf 0- Stellung setzen und mit speziellem Aufdrücker aufdrücken

2.10 Neues Glas 03-44-904 einsetzen und einkleben (Kleber Sicomet 9010)

2.11 Glashaltering 03-43-901/ 03-44-901 aufschrauben.

Endprüfung / - Endprüfung je nach Reparaturaufwand durchführen (siehe

Funktion / Reparaturanweisung Schraub ventilversion S. 1)

Dichtprüfung: - Beim Eingriff ins Gerät oder ins Meßwerk ist auf alle Fälle

----------------- eine komplette Endpr üfung mit meßtechnischer Kontro lle

durchzuführen (siehe Durchführung meßtechn. Kontrolle

nach MPG ).

- Bei Unsicherheiten ob Gerät gefallen ist wird die Durchführung

einer meßtechnischen Kontrolle empfohlen.

Bemerkungen: Die jeweils notwendige Reparaturaufwand ist festzustellen und

------------------- durchzuführen. Die notwendig werdende Arbeitsfolge ist aus

dieser Gesamtbeschreibung zu entnehmen

Seite / Page 26

Page 27

Reparaturanweisung für Speidel + Keller Blutdruckmeßgerät Rev./ Index: 001B

Gerätetyp: Primus 50 KC Art.Nr. 50-81-000 / Manuell 50 KC Art.Nr. 50-96-000

------------- Primus 68 KC Art.Nr. 50-84-000 / Manuell 68 KC Art.Nr. 50-97-000

Beschreibung einer kompletten Demontage und Wiedermontage des Gerätes

Demontage: 1.1 Glas mit Schraubendreher an der Rastnase ausclipsen

--------------- 1.2 Glas 03-44-902 oder Glasreste mit Schraubendreher lösen (Vorsicht verklebt)

1.3 Zeiger 18-50-923/ 18-87-906 mit Abhebevorrichtung bzw. Pinzette lösen

1.4 Skala 20-64-151 abnehmen (Vorsicht verklebt)

1.5 Komplette Grundplatte mit Werk 01-21-000 mit Grundplattenschlüssel

ausschrauben.

1.6 Becherschrauben 50-01-905 mit Schraubendreher ausschrauben.

Dichtung 50-01-901 und Becher 50-85-910/ 50-87-903 bei 68 mm

entnehmen.

1.7 Sprengring 19-40-905 mit Schraubendreher lösen und Auslaßschraube

19-40-901 ausdrehen. Einzelteile Feder 19-40-904 und Unterlegscheiben

19-40-903 entnehmen.

1.8 Ball 17-31-902 und Klemmring 17-31-911 vom Körper abziehen und

Ventilsitzschraube 15-41-000 mit Spezialschlüssel ausschrauben.

Für Geräte ab Oktober 1999 entfällt 1.8.

Sprengring 15-40-903 mit Pinzette lösen, Dichtung 15-40-902 und Ventilschlauch 15-40-907 mit Spezialwerkzeug auslösen.

1.9 Löffelschrauben 50-01-902 mit Schraubendreher lösen

Montage: 2.1 Löffel 50-01-903 mit Schraubendreher anschrauben.

------------ 2.2 Neuer Becher mit Schraubendreher auf Ventilkörper 50-01-900 aufschrauben.

2.3 Unterlegscheiben 19-40-903 und Feder in Ventilkörper einlegen

Auslauslaßschraube einschr auben und Sprengring ei ndrücken.

2.4 Für Geräte ab Oktober 1999 Neues Ventil 15-40-907, Dichtung 15-40-902

und Sprengring 15-40-903 mit Spezialwerkzeug montieren.

Ballhülse 17-31-911 und Ball 17-31-902 montieren.

2.5 Dichtung 50-01-901 einlegen und komplette Grundplatte

mit Werk mit spez. Grundplattenschlüssel einschrauben

2.6 Gerät in Justiervorrichtung legen u. spezielle S+K Prüfskala aufsetzen

2.7 Zeiger 18-50-923 aufsetzen und mit 0 -Strich abgleichen

2.8 Druckstufe 300 mmHg anfahren und einstellen.

Druckstufen 50, 100, 150, 200, 250, 300 , 350 mmHg auf und abwärts

anfahren und Toleranz prüfen +/- 3mmHg / gegebenenfalls mit speziellem

Justierstift nachjustieren.

2.9 Zeiger auf 0- Stellung setzen und mit speziellem Aufdrücker aufdrücken

2.10 Neues Glas 03-44-902 einsetzen und einkleben (Kleber Sicomet 9010)

2.11 Glas in die Rastnasen einclipsen.

Endprüfung / - Endprüfung je nach Reparaturaufwand durchführen (siehe

Funktion / Reparaturanweisung Schraub ventilversion S. 1)

Dichtprüfung: - Beim Eingriff ins Gerät oder ins Meßwerk ist auf alle Fälle

------------------ eine komplette Endprüfung mit meßtechnischer Kontrolle

durchzuführen (siehe Durchführung meßtechn. Kontrolle

nach MPG ).

- Bei Unsicherheiten ob Gerät gefallen ist wird die Durchführung einer

meßtechnischen Kontrolle empfohlen.

Bemerkungen: Die jeweils notwendige Reparaturaufwand ist festzustellen und

------------------ durchzuführen. Die notwendig werdende Arbeitsfolge ist aus

dieser Gesamtbeschreibung zu entnehmen.

Seite / Page 27

Page 28

Reparaturanweisung für Speidel + Keller Blutdruckmeßgerät Rev./ Index: 001B

Gerätetyp: - Primus Stabil 3 Art.Nr. 50-25-000

-------------- - Primus Stabil 3 gelb Art.Nr. 50-49-000

- Primus Stabil 3 rot Art.Nr. 50-59-000

- Primus Stabil 3 blau Art. Nr. 50-50-000

- Primus Stabil 3 grün Art. Nr. 50-45-000

- Manuell Stabil 3 Art.Nr. 50-63-000

Beschreibung einer kompletten Demontage und Wiedermontage des Gerätes

Demontage: 1.1 Rastring 50-25-908 im Gegenuhrzeigersinn ausdrehen

--------------- 1.2 Glas 03-44-904 mit Schraubendreher an Rastnase ausclipsen (Vorsicht verklebt)

1.3 Zeiger mit Abhebevorrichtung bzw. Pinzette lösen

1.4 Skala abnehmen (Vorsicht verklebt)

1.5 Komplette Grundplatte mit Werk 01-21-000 mit Grundplattenschlüssel ausschrauben

1.6 Becherschrauben 50-01-905 mit Schraubendreher ausschrauben.

Dichtung 50-01-915 und Becher 50-25-907 entnehmen.

1.7 Sprengring 19-40-905 mit Schraubendreher lösen und Auslaßschraube

19-40-901 ausdrehen. Einzelteile Feder 19-40-904 und Unterlegscheiben

19-40-903 entnehmen.

1.8 Ball 17-31-902 und Klemmring 17-31-911 vom Körper abziehen und

Ventilsitzschraube 15-41-000 mit Spezialschlüssel ausschrauben.

Für Geräte ab Oktober 1999 entfällt 1.8.

Sprengring 15-40-903 mit Pinzette lösen, Dichtung 15-40-902 und Ventilschlauch 15-40-907 mit Spezialwerkzeug auslösen.

1.9 Löffelschrauben 50-01-902 mit Schraubendreher lösen

Montage: 2.1 Löffel 50-01-902 mit Schraubendreher anschrauben.

------------- 2.2 Neuer Becher mit Schraubendreher auf Ventilkörper 50-01-900 aufschrauben.

2.3 Unterlegscheiben 19-40-903 und Feder in Ventilkörper einlegen

Auslauslaßschraube einschrauben und Sprengring eindrücken

2.4 Für Geräte ab Oktober 1999 Neues Ventil 15-40-907, Dichtung 15-40-902

und Sprengring 15-40-903 mit Spezialwerkzeug montieren.

Ballhülse 17-31-911 und Ball 17-31-902 montieren.

2.5 Dichtung 50-01-901 einlegen und komplette Grundplatte

mit Werk mit spez. Grundplattenschlüssel einschrauben

2.6 Gerät in Justiervorrichtung legen u. spezielle S+K Prüfskala aufsetzen

2.7 Zeiger 18-50-921 aufsetzen und mit 0 -Strich abgleichen

2.8 Druckstufe 300 mmHg anfahren und einstellen.

Druckstufen 50, 100, 150, 200, 250, 300 , 350 mmHg auf und abwärts anfahren

und Toleranz prüfen +/- 3mmHg / gegebenenfalls mit speziellem Justierstift

nachjustieren.

2.9 Zeiger auf 0- Stellung setzen und mit speziellem Aufdrücker aufdrücken

2.10 Neues Glas 03-44-904 einclipsen und einkleben (Sicomet 9010)

2.11 Rastring 50-25-908 aufsetzen ( 2 Nasen l inksgerichtet) und im Uhrze igersinn

drehen bis Anschlag.

Endprüfung / - Endprüfung je nach Reparaturaufwand durchführen

Funktion / - Bei jedem Eingriff ins Gerät oder ins Meßwerk ist auf alle Fälle eine komplette

Dichtprüfung: Endprüfung mit meßtechnischer K ontrolle durchzuführen (siehe Durchführung

------------------ meßtechn. Kontrolle nach MPG ).

- Bei Unsicherheiten ob das Gerät gefallen ist wird die Durchführung einer

meßtechnischen Kontrolle empfohlen.

Bemerkungen: Die jeweils notwendige Reparaturaufwand ist festzustellen und durchzuführen.

------------------- Die notwendig werdende Arbeitsfolge ist aus dieser Gesamtbeschreibung zu entnehmen.

Seite / Page 28

Page 29

Reparaturanweisung für Speidel + Keller Blutdruckmeßgerät Rev./ Index: 001A

Gerätetyp: - ISO Stabil 5 Art. Nr. 50-71-000

------------- - Stabil 3 (Vorgänngermodell Stabil 5)

Beschreibung einer kompletten Demontage und Wiedermontage des Gerätes

Demontage: 1.1 Rastring 50-25-908 im Gegenuhrzeigersinn ausdrehen

--------------- 1.2 Glas 03-44-904 mit Schraubendreher an Rastnase ausclipsen (Vorsicht verklebt)

1.3 Zeiger 18-50-923 mit Abhebevorrichtung bzw. Pinzette lösen

1.4 Skala 20-64-155 ausclipsen (Vorsicht verklebt)

1.5 Komplette Grundplatte mit Werk 01-21-000 mit Grundplattenschlüssel ausschrauben.

1.6 Becherschrauben 20-64-972 mit Schraubendreher lösen und Becher 50-25-905 abnehmen

1.7 Feststellring am Ball 17-31-000 lösen und vom Ventilkörper a bdrehen

1.8 Drücker 50-71-812 vom Ventilkörper ausrasten und Stift 50-61-813 entnehmen

1.9 Ventilsitzschraube 15-40-000 mit Spezialschlüssel ausdrehen.

Für Geräte ab Oktober 1999

Sprengring 15-40-903 mit Pinzette lösen, Dichtung 15-40-902 und Ventilschlauch 15-40-907 mit Spezialwerkzeug auslösen.

Montage: 2.1 Druckstift 50-61-81 3 durch Bohrung am Ventil körper einführen.

Feder 54-31-904 in Ventilkörper e inbauen und Drücker in Ve ntilkörper einführen.

Druckstift mit Spezialstift nach vorne schieben und Drücker einrasten.

Gängigkeitsprüfung durchführen (muß leichtgängig ohne Knackgeräusch bis

zum Anschlag laufen).

2.2 Neue Ventilsitzschraube 15-41-000 einschrauben und Ball 17-31-000 aufschrauben.

Klemmring zur Sicherung andrehen.

2.3 Becher 50-25-905 auf Ventilkörper aufsetzen und einschrauben.

2.4 Dichtung 50-01-901 einlegen und komplette Grundplatte mit Werk mit spez.

Grundplattenschlüssel einschrauben.

Für Geräte ab Oktober 1999 Neues Ventil 15-40-907, Dichtung 15-40-902

und Sprengring 15-40-903 mit Spezialwerkzeug montieren.

Ballhülse 17-31-911 und Ball 17-31-902 montieren

2.5 Gerät in Justiervorrichtung legen u. spezielle S+K Prüfskala aufsetzen

2.6 Zeiger 18-50-921 aufsetzen und mit 0 -Strich abgleichen

2.7 Druckstufe 300 mmHg anfahren und einstellen.

Druckstufen 50, 100, 150, 200, 250, 300 , 350 mmHg auf und abwärts

anfahren und Toleranz prüfen +/- 3 mmHg / gegebenenfalls mit speziellem

Justierstift nachjustieren.

2.8 Neuer Zeiger auf 0- Stellung setzen und mit speziellem Aufdrücker aufdrücken.

2.9 Eventuell neuer Zierring 50-25-912 auf Becher montieren (einrasten).

2.10 Neues Glas 03-44-904 einclipsen und einkleben (Sicomet 9010).

2.11 Rastring 50-25-908 aufsetzen ( 2 Nasen linksgerichtet) und im Uhrzeigersinn

drehen bis Anschlag.

Endprüfung / - Endprüfung je nach Reparaturaufwand durchführen

Funktion /

Dichtprüfung: - Bei jedem Eingriff ins Gerät oder ins Meßwerk ist auf alle Fälle

------------------ eine komplette Endprüfung mit meßtechnischer Kontrolle

durchzuführen (siehe Durchführung meßtechn. Kontrolle

nach MPG ).

- Bei Unsicherheiten ob das Gerät gefallen ist wird die

Durchführung einer meßtechnischen Kontrolle empfohlen.

Bemerkungen: Die jeweils notwendige Reparaturaufwand ist festzustellen und

-------------------- durchzuführen. Die notwendig werdende Arbeitsfolge ist aus

dieser Gesamtbeschreibung zu entnehmen.

Seite / Page 29

Page 30

Reparaturanweisung für Speidel + Keller Blutdruckmeßgerät Rev./ Index: 001A

Gerätetyp: - Disytest Art.Nr. 52-09-000

-------------

Beschreibung einer kompletten Demontage und Wiedermontage des Gerätes

Demontage: 1.1 Mit Schraubendreher einfahren und Glas 52-03-903 herausausclipsen .

--------------- 1.2 Zeiger 18-50-924 / 18-50-923 (Persona) mit Abhebevorrichtung bzw.Pinzette lösen

1.3 Skala 20-51-106 / 20-51-103 (Persona) wie Glas ausclipsen.

1.4 Komplette Grundplatte mit Werk 01-21-000 mit Grundplattenschlüssel

ausschrauben / Dichtung 50-01-901 entnehmen.

1.5 Ball 17-52-000 und Ballhülse 17-01-902 abziehen

1.6 Ventilsitzschraube 15-40-000 mit Spezialschlüssel ausdrehen.

Für Geräte ab Oktober 1999

Sprengring 15-40-903 mit Pinzette lösen, Dichtung 15-40-902 und Ventilschlauch 15-40-907 mit Spezialwerkzeug auslösen

1.7 Drücker 52-03-902 am Ventilkörper ausrasten , mit Spezialschlüssel (Innensechskant)

Ventilbaugruppe 12-12-900 ausdrehen , Feder 19-12-904 entnehmen.

Montage: 2.1 Spannfeder 19-12-904 in Ventilkörper einführen ,Ventilbaugruppe 19-12-900

------------- einführen und mit Spezialsec hskantschlüssel anziehen , D rücker 52-03-90 2

in Rastungen eindrücken - Achtung: Drückerfunktion prüfen - muß leichtes

Spiel zwischen Ventilbaugruppe aufweisen und leichtgängig betätigbar sein.

2.2 Neue Ventilsitzschraube 15-41-000 einschrauben , Ballhülse 17-01-902 und

Ball 17-52-000 aufdrücken.

Für Geräte ab Oktober 1999 Neues Ventil 15-40-907, Dichtung 15-40-902

und Sprengring 15-40-903 mit Spezialwerkzeug montieren.

Ballhülse 17-31-911 und Ball 17-31-902 montieren

2.3. Dichtung 50-01-901 einlegen und komplette Grundplatte mit Werk mit spez.

Grundplattenschlüssel einschrauben

2.4 Gerät in Justiervorrichtung legen u. spezielle S+K Prüfskala „Disytest“ aufsetzen.

2.5 Zeiger 18-50-924 aufsetzen und mit 0 -Strich abgleichen

2.6 Druckstufe 300 mmHg anfahren und einstellen.

Druckstufen 50, 100, 150, 200, 250, 300 , 350 mmHg auf und abwärts anfahren und

Toleranz prüfen +/- 3mmHg / gegebenenfalls mit speziellem Justierstift nachjustieren.

2.7 Neuer Zeiger auf 0- Stellung setzen und mit speziellem Aufdrücker aufdrücken.

2.8 Neues Glas 52-03-903 einclipsen.

Endprüfung / - Endprüfung je nach Reparaturaufwand durchführen

Funktion /

Dichtprüfung: - Bei jedem Eingriff ins Gerät oder ins Meßwerk ist auf alle Fälle

------------------ eine komplette Endprüfung mit meßtechnischer Kontrolle

durchzuführen (siehe Durchführung meßtechn. Kontrolle

nach MPG ).

- Bei Unsicherheiten ob das Gerät gefallen ist wird die

Durchführung einer meßtechnischen Kontrolle empfohlen.

Bemerkungen: Die jeweils notwendige Reparaturaufwand ist festzustellen und

------------------- durchzuführen. Die notwendig werdende Arbeitsfolge ist aus

dieser Gesamtbeschreibung zu entnehmen.

Weitere Details zur Demontage und Wiedermontage sind aus den Bildern im

Anhang ersichtlich. Hier kann die Zusammenbauansicht entnommen werden

Siehe Ersatzteilkatalog Seite 11.

Seite / Page 30

Page 31

Reparaturanweisung für Speidel + Keller Blutdruckmeßgerät Rev./ Index: 001B

Gerätetyp: - Maxi Stabil 3 Art.Nr. 59-30-000

-------------

Beschreibung einer kompletten Demontage und Wiedermontage des Gerätes

Demontage: 1.1 Rastring 59-30-901 im Gegenuhrzeigersinn drehen und vom Gehäuse lösen

--------------- (Achtung Rastring verklebt - Verklebung lösen ).

1.2 Mit Schraubendreher in Aussparung einfahren und Glas 59-30-902 herausausclipsen.

1.3 Zeiger 18-87-908 mit Abhebevorrichtung bzw.Pinzette lösen

1.4 Skala 20-51-159 mit Schraubendrehen (wie Glas) ausclipsen.

1.5 Komplette Grundplatte mit Werk 01-10-000 mit Grundplattenschlüssel

ausschrauben / Dichtung 50-01-915 entnehmen.

1.6 Metallschlauchverbindung 16-40-000 und Rändelmutter 59-30-922 ausdrehen

1.7 Achtung: Weitere Demontage kann nicht durchgeführt werden da der Luftdurchlaßanschluß verklebt ist. Eine Demontage des Anschlußes würde das Gehäuse

beschädigen. Wenn dieser Anschluß defekt ist muß das komplette Gehäuse

59-30-750 ausgetauscht werden.

Montage: 2.1 Metallschlauchverbindung 16-40-000 und Rändelmutter 59-30-922 eindrehen

------------- 2.2 Dichtung 50-01-901 einlegen und komplette Grundplatte mit Werk mit spez.

Grundplattenschlüssel einschrauben

2.3 Gerät in Justiervorrichtung legen u. spezielle S+K Prüfskala „Maxi“ aufsetzen.

2.4 Zeiger 18-87-908 aufsetzen und mit 0 -Strich abgleichen

2.5 Druckstufe 300 mmHg anfahren und einstellen.

Druckstufen 50, 100, 150, 200, 250, 300 , 350 mmHg auf und abwärts

anfahren und Toleranz prüfen +/- 3 mmHg / gegebenenfalls mit speziellem

Justierstift nachjustieren.

2.6 Neue Skala eindrücken (vorgegebene Nut).

2.7 Neuer Zeiger auf 0- Stellung setzen und mit speziellem Aufdrücker aufdrücken.

2.8 Neues Glas 59-30-902 einclipsen.

Endprüfung / - Endprüfung je nach Reparaturaufwand durchführen

Funktion /

Dichtprüfung: - Bei jedem Eingriff ins Gerät oder ins Meßwerk ist auf alle Fälle

------------------ eine komplette Endprüfung mit meßtechnischer Kontrolle

durchzuführen (siehe Durchführung meßte chn. Kontrolle

nach MPG ).

- Bei Unsicherheiten ob das Gerät gefallen ist wird die

Durchführung einer meßtechnischen Kontrolle empfohlen.

Bemerkungen: Die jeweils notwendige Reparaturaufwand ist festzustellen und

------------------- durchzuführen. Die notwendig werdende Arbeitsfolge ist aus

dieser Gesamtbeschreibung zu entnehmen.

Weitere Details zur Demontage und Wiedermontage sind aus den Bildern im

Anhang ersichtlich. Hier kann die Zusammenbauansicht entnommen werden

siehe Ersatzteilkatalog Seite 19 und 20.

Seite / Page 31

Page 32

Reparaturanweisung für Speidel + Keller Blutdruckmeßgerät Rev./ Index: 001B

Gerätetyp: Fixomed Art. Nr. 50-91-000

-------------

Beschreibung einer kompletten Demontage und Wiedermontage des Gerätes

Demontage: 1.1 Glashaltering 03-43-901 abschrauben.

---------------- 1.2 Glas 03-42-902 oder Glasreste mit Schraubendreher lösen (Vorsicht verklebt)

1.3 Zeiger 18-87-905 mit Abhebevorrichtung bzw. Pinzette lösen.

1.4 Skala 20-57-122 abnehmen (Vorsicht verklebt)

1.5 Komplette Grundplatte mit Werk 01-21-000 mit Grundplattenschlüssel ausschrauben.

1.6 Becherschrauben 50-01-905 mit Schraubendreher ausschrauben.

Dichtung 50-01-901 und Becher 50-04-901 (68mm) entnehmen.

1.7 Ball 17-31-902 und Klemmring 17-31-901vom Körper abziehen und

Ventilsitzschraube 15-41-000 mit Spezialschlüssel ausschrauben.

Für Geräte ab Oktober 1999

Sprengring 15-40-903 mit Pinzette lösen, Dichtung 15-40-902 und Ventilschlauch 15-40-907 mit Spezialwerkzeug auslösen

1.8 Löffelschrauben 50-01-902 mit Schraubendreher lösen .

1.9 Eine Demontage der Auslaßschraube sollte nicht stattfinden da eine

Wiedermontage sehr kompliziert ist.

Bei defekter Auslaßschraube ist der komplette Ventilkörper 50-85-000

zu ersetzen.

Montage: 2.1 Löffel 50-01-902 mit Schraubendreher anschrauben.

------------ 2.2 Neuer Becher mit Schraubendreher auf Ventilkörper 50-85-900 aufschrauben

2.3 Neue Ventilsitzschraube 15-41-000 einschrauben, neuer Klemmring

17-31-901 und Ball 17-31-902 montieren.

Für Geräte ab Oktober 1999 Neues Ventil 15-40-907, Dichtung 15-40-902

und Sprengring 15-40-903 mit Spezialwerkzeug montieren.

Ballhülse 17-31-911 und Ball 17-31-902 montieren

2.4 Dichtung 50-01-901 einlegen und komplette Grundplatte mit Werk mit spez.

Grundplattenschlüssel einschrauben

2.5 Gerät in Justiervorrichtung legen u. spezielle S+K Prüfskala Fixomed aufsetzen.

2.6 Zeiger 18-87-905 aufsetzen und mit 0 -Strich abgleichen

2.7 Druckstufe 300 mmHg anfahren und einstellen.

Druckstufen 50, 100, 150, 200, 250, 300 , 350 mmHg auf und abwärts