Page 1

Service Manual

Aneroid Sphygmomanometers

Welch Allyn, Inc.

4341 State Street Road

P.O. Box 220

Skaneateles Falls, NY 13153-0220

95P504 Rev. D Copyright 2001

Page 2

-

Page 3

Revision Information

Date ECN#/

ECO#

8/31/00 A Introduction of Aneroid

5/15/01 B Corrected tolerance levels in

8/18/03 5-46368 C Correction of tooling part

5/27/04 1000873 D Corrected BOM, tooling and

Revision Description Author Approved

JDB

Service Manual

JDB

the gauge tests sections.

Corrected m inor gramm atical

errors.

WWR DLK

numbers. Arden document

release to SKF.

BSW RJS

procedures.

Drawings and/or illustrations and/or part numbers in this document are for

reference only. For the most current revision call the Welch Allyn Customer

Service phone number listed in Section 1.

Service Manual 95P504 Rev. D Welch Allyn Aneroid Sphygmomanometers i

Page 4

ii

Welch Allyn Aneroid Sphygmomanometers 95P504 Rev. D

Page 5

Table of Contents

Section 1 General Information

To Service Personnel .....................................................................................................................1

Intent of Manual and Product Scope .............................................................................................1

Limited Warranty .........................................................................................................................2

Warranty, Service, and Spare Parts ...............................................................................................2

Warranty Service ...........................................................................................................................2

Assistance and Parts ......................................................................................................................2

Repairs ..........................................................................................................................................3

Packing Instructions ......................................................................................................................3

Periodic Calibration Requirements ................................................................................................3

New S&K Movement ...................................................................................................................5

Old Style Movements ....................................................................................................................6

Section 2 Service

Tools Required for Service ............................................................................................................9

Test Specifications .........................................................................................................................11

Test Equipment Bench Layout ......................................................................................................11

Section 3 Repair and Calibration

Classic Pocket Aneroid Gauges

(Date stamp of September 2003 or earlier)

..............................................13

Initial Gauge Check 13

Opening/Removing and Replacing Parts of the Classic Pocket Gauge ...........................................13

Calibration of the Classic Pocket Gauge .......................................................................................13

Aligning Sector Gear on the Classic Pocket Gauge ........................................................................13

Setting the Classic Pocket Gauge Tension .....................................................................................14

Setting the Classic Pocket Gauge Span ..........................................................................................14

Check and finish the calibration of the Classic Pocket Gauge .......................................................14

Classic Pocket Aneroid Gauges

(Date stamp of October 2003 or later)

...................................................16

Initial Gauge Check ......................................................................................................................16

Opening/Removing and Replacing Parts of the Classic Pocket Gauge ...........................................16

Calibration of the Classic Pocket Gauge .......................................................................................16

Checking the Classic Pocket Gauge Span ......................................................................................16

Average Zero Starting Position .....................................................................................................17

Span Adjustment of the Classic Pocket Aneroid ............................................................................17

Linearity Adjustment of the Classic Pocket Aneroid (As required) ................................................18

High Readings of the Classic Pocket Aneroid:

(Predominantly at 250 and 200)

....................................18

Check and finish the calibration of the Classic Pocket Gauge .......................................................19

Testing the Classic Pocket Gauge ..................................................................................................19

Classic Wall and Mobile Aneroid Gauge

(Date stamp of July 2003 or earlier)

....................................... 21

7670 series Wall and Mobile Aneroid Disassembly .......................................................................21

Classic Wall and Mobile Aneroid Disassembly .............................................................................21

Calibration of the Wall and Mobile Gauge ...................................................................................21

Sector Gear Alignment for the Wall and Mobile Aneroid ..............................................................21

Setting the Tension of the Wall and Mobile Aneroid .....................................................................22

Service Manual 95P504 Rev. D Welch Allyn Aneroid Sphygmomanometers iii

Page 6

Table of Contents

Setting the span of the Wall and Mobile Aneroid ..........................................................................22

Check and finish calibration of the Wall and Mobile Aneroid ......................................................22

Classic Wall and Mobile Aneroid Gauge

(Date stamp of October 2003 and later.)

.................................24

7670 series Wall and Mobile Aneroid Disassembly .......................................................................24

Classic Wall and Mobile Aneroid Disassembly .............................................................................24

Calibration of the Wall and Mobile Gauge ...................................................................................24

Checking the Wall/Mobile Gauge Span .........................................................................................24

Average Zero Starting Position .....................................................................................................25

Span Adjustment of the Wall Aneroid ...........................................................................................25

Check and finish calibration of the Wall and Mobile Aneroid ......................................................27

Classic Hand Aneroid Gauge

(Date stamp of September 2003 or earlier)

................................................29

Replacing Parts of the Hand Gauge ..............................................................................................29

Calibration of the Classic Hand Gauge .........................................................................................29

Aligning the Sector Gear on the Classic Hand Gauge ....................................................................30

To set the tension of the Classic Hand Gauge ...............................................................................30

Setting the span of the Classic Hand Gauge ..................................................................................30

Check and finish calibration of the Classic Hand Gauge ...............................................................31

Testing of the Classic Hand Gauge ...............................................................................................31

Test Specifications .........................................................................................................................31

Classic Hand Aneroid Gauge

(Date stamp of October 2003 or later)

......................................................32

Replacing Parts of the Classic Hand Gauge ...................................................................................32

Calibration of the Classic Hand Gauge .........................................................................................32

Checking the Classic Hand Gauge Span ........................................................................................32

Average Zero Starting Position .....................................................................................................33

Span Adjustment of the Classic Hand Aneroid ..............................................................................33

Linearity Adjustment of the Classic Hand Aneroid: (As required) .................................................34

Check and finish the calibration of the Classic Hand Gauge .........................................................35

Economy Aneroid Gauge

(Stopped production on 7/15/03)

..................................................................37

Replacing Parts of the Economy Gauge .........................................................................................37

Calibration of the Economy Gauge ...............................................................................................37

Aligning the Sector Gear of the Economy Gauge ...........................................................................37

Setting the tension of the Economy Gauge ....................................................................................37

Setting the span of the Economy Gauge ........................................................................................38

Check and finish calibration of the Economy Gauge .....................................................................38

Testing of the Economy Gauge 39

TR-1 Silver Ring Hand Aneroid ....................................................................................................40

Replacing Parts of the Silver Ring .................................................................................................40

Calibration of the Silver Ring Hand Aneroid ................................................................................40

Checking the Silver Ring Gauge Span ...........................................................................................40

Average Zero Starting Position .....................................................................................................41

Span Adjustment of the Silver Ring Aneroid .................................................................................41

iv

Welch Allyn Aneroid Sphygmomanometers 95P504 Rev. D

Page 7

Table of Contents

Linearity Adjustment of the Silver Ring Aneroid: (As required) ....................................................41

Check and finish the calibration of the Silver Ring Gauge .............................................................43

TR-2 Pro Check Hand Aneroid ....................................................................................................44

Replacing Parts on Pro Check Hand Aneroid ................................................................................44

Calibration of the Pro Check Hand Aneroid .................................................................................44

Checking the Pro Check Hand Gauge Span ..................................................................................44

Average Zero Starting Position .....................................................................................................44

Span Adjustment of the Pro Check Hand Aneroid ........................................................................45

Linearity Adjustment of the Pro Check Hand Aneroid: (As required) ...........................................45

High Readings of the Pro Check Aneroid: (Predominantly at 250 and 200) ..................................45

Check and finish the calibration of the Pro Check Hand Gauge ....................................................47

Section 4 Repair Parts

Old Style Classic Pocket Repair Parts ............................................................................................49

Old Style Classic Hand Repair Parts .............................................................................................50

Old Style 767 Wall Repair Parts ...................................................................................................51

Old Style Classic Wall/Mobile Repair Parts ..................................................................................52

Economy Aneroid Repair Parts .....................................................................................................53

TR1 Silver Ring Repair Parts ........................................................................................................54

TR2 Pro Check Repair Parts .........................................................................................................55

S&K Classic Pocket Repair Parts .................................................................................................56

S&K Classic Hand Repair Parts ....................................................................................................57

S&K Wall/Mobile Series 509 Repair Parts ....................................................................................58

S&K WalL 767 Series Repair Parts ...............................................................................................59

Service Manual 95P504 Rev. D Welch Allyn Aneroid Sphygmomanometers v

Page 8

General Information Section 1

To Service Personnel

The information contained in this publication is subject to change without notice and

should not be construed as a commitment by Welch Allyn, Inc.

Welch Allyn assumes no responsibility for any errors that may appear in this manual. If the

product and/or its operation varies significantly from any description herein, please contact

the following:

Welch Allyn, Inc.

1-800-535-6663

315-685-4100

Fax (315)-685-3361

Welch Allyn, Inc.

4341 State Street Road

Skaneateles Falls, NY 13153-0220

USA

This product has been designed to provide a high degree of safety and reliability. However,

we can not guarantee against: deterioration of components due to aging, normal wear,

tampering, and abuse.

Only Authorized Welch Allyn personnel or agents must perform all service and repairs,

using approved Welch Allyn replacement parts and approved process materials. Failure to

follow these guidelines will invalidate the product warranty. Please refer to the product

warranty for specific coverage.

Intent of Manual and Product Scope

This manual provides technical service and re-calibration information to technicians

authorized to repair and re-calibrate Welch Allyn, Inc. products. When used in conjunction

with the required test equipment and tools, technicians will be able to diagnose, repair, recalibrate, and test the Aneroid Sphygmomanometer.

The manual includes: re-calibration instructions, fault/cause analysis, step-by-step

disassembly and re-assembly procedures, repair, adjustment, and re-test procedures.

Service Manual 95P504 Rev. D Welch Allyn Aneroid Sphygmomanometers 1

Page 9

Section 1 General Information

Limited Warranty

Welch Allyn, Inc. warrants the Aneroid Sphygmomanometers when new, to be free of

defects in material and workmanship and to perform in accordance with manufacturer's

specifications for a period of (see Table 1-1) from the date of purchase from Welch Allyn,

Inc. or its authorized distributors or agents. Welch Allyn, Inc. will either repair or replace

any components found to be defective or at variance from manufacturer's specifications

within this time at no cost to the customer. It shall be the purchaser's responsibility to

return the instrument to Welch Allyn, Inc. or an authorized distributor, agent or service

representative. This warranty does not include breakage or failure due to tampering,

misuse, neglect, accidents, modification or shipping. This warranty is also void if the

instrument is not used in accordance with manufacturer's recommendations or if repaired

by other than Welch Allyn, Inc. or an authorized agent. Purchase date determines warranty

requirements. No other express warranty is given.

To receive service assistance or to ask questions regarding this warranty, please call your

nearest Welch Allyn Technical Support Center.

Warranty, Service, and Spare Parts

Warranty Service

All repairs on products under warranty must be performed or approved by Welch Allyn.

Unauthorized repairs will void the warranty. In addition, whether or not covered under

warranty, any product repair shall exclusively be performed by Welch Allyn trained and

certified service personnel.

Assistance and Parts

If the product fails to function properly or if assistance, service, or spare parts are required,

contact the nearest Welch Allyn Technical Support Center.

USA 1-800-535-6663 Latin America (+1) 305-669-9591

European Call Center (+353) 469-067-790 United Kingdom 0-207-365-6780

France (+33) 1-60-09-33-66 Germany (+49) 7477-927-173

Canada 1-800-561-8797 South Africa (+27) 11-777-7509

Australia (+61) 2-9638-3000 Singapore (+65) 6291-0882

Japan (+81) 3-5212-7391 China (+86) 21-6327-9631

Before contacting Welch Allyn it is helpful to attempt to duplicate the problem and to

check all accessories to ensure that they are not the cause of the problem.

2 Welch Allyn Aneroid Sphygmomanometers Service Manual 95P504 Rev. D

Page 10

General Information Section 1

When calling, please be prepared to provide:

• The product name, model number and complete description of the problem

• The serial number of your product (if applicable)

• The complete name, address and phone number of your facility

• For out-of-warranty repairs or spare parts orders, a purchase order (or credit card)

number

• The required spare or replacement part number(s), for parts order

Repairs

If your product requires warranty, extended warranty, or non-warranty repair service, first

call the nearest Welch Allyn Technical Support Center. A representative will assist you in

troubleshooting the problem and will make every effort to solve the problem over the

phone, avoiding a potential unnecessary return.

In case the return cannot be avoided, the representative will record all necessary

information and will provide a Return Material Authorization (RMA) number, as well as

the appropriate return address.

A Return Material Authorization (RMA) number must be obtained prior to any return. Be

sure to note this number on the outside of your shipping box.

Packing Instructions

If you have to return goods for service, follow these recommended packing instructions:

• Remove all hoses, and ancillary products (as appropriate) before packing, unless you

suspect they are associated with the problem.

• Wherever possible use the original shipping carton and packing materials.

• Include a packing list and the Welch Allyn Return Material Authorization (RMA)

number.

• Be sure to note the (RMA) number on the outside of your shipping box.

It is recommended that all returned goods be insured. Claims for loss or damage to the

product must be initiated by the sender.

Periodic Calibration Requirements

Welch Allyn sphygmomanometers are manufactured to high standards for quality and

accuracy. The instruments are manufactured using calibrated pressure standards traceable

to the National Institute of Standards and Technology.

During normal operation, the location of the pointer within the oval/square indicates that

the instrument is most likely in calibration. Should the pointer rest outside the oval/box

with zero pressure applied, the instrument should be re-calibrated.

Welch Allyn recommends that the calibration of mechanical sphygmomanometers be

checked using the following procedures on an annual basis even if the pointer rests inside

the oval/box.

Service Manual 95P504 Rev. D Welch Allyn Aneroid Sphygmomanometers 3

Page 11

Section 1 General Information

1. Connect the instrument under test to a high-quality, known pressure standard (traceable

to the National Institute of Standards and Technology) and a 500 cc test volume.

2. Pressurize the gauge to slightly above 300 mmHg and bleed down the pressure no faster

than 10 mmHg per second, stopping to check the pressure at 300, 250, 200, 150, 100, 60,

and 0 mmHg.

3. Record the readings of the instrument under test and the applied pressure. The

difference is the error of the instrument. The error of the reference pressure should be

added to the specified accuracy of the instrument under test (±3 mmHg) to determine the

working accuracy of your calibration set-up.

NOTE: Your ability to measure the accuracy of a sphygmomanometer depends upon the

sensitivity of the pressure standard you use for the calibration procedure.

Example: If using a device (e.g., digital pressure standard) rated at ±0.1 mmHg, you will

be able to determine the accuracy of the gauge being tested to within ±3.1 mmHg.

Welch Allyn recommends using a pressure standard that is as sensitive as possible when

performing calibration checks. A Setra Pressure Meter (part no. 2270-01), which is

calibrated for ±0.1 mmHg, or Netech Pressure Meter (part no. 200-2000IN), which is

calibrated for ±1.0 mmHg, work well for this application.

4 Welch Allyn Aneroid Sphygmomanometers Service Manual 95P504 Rev. D

Page 12

General Information Section 1

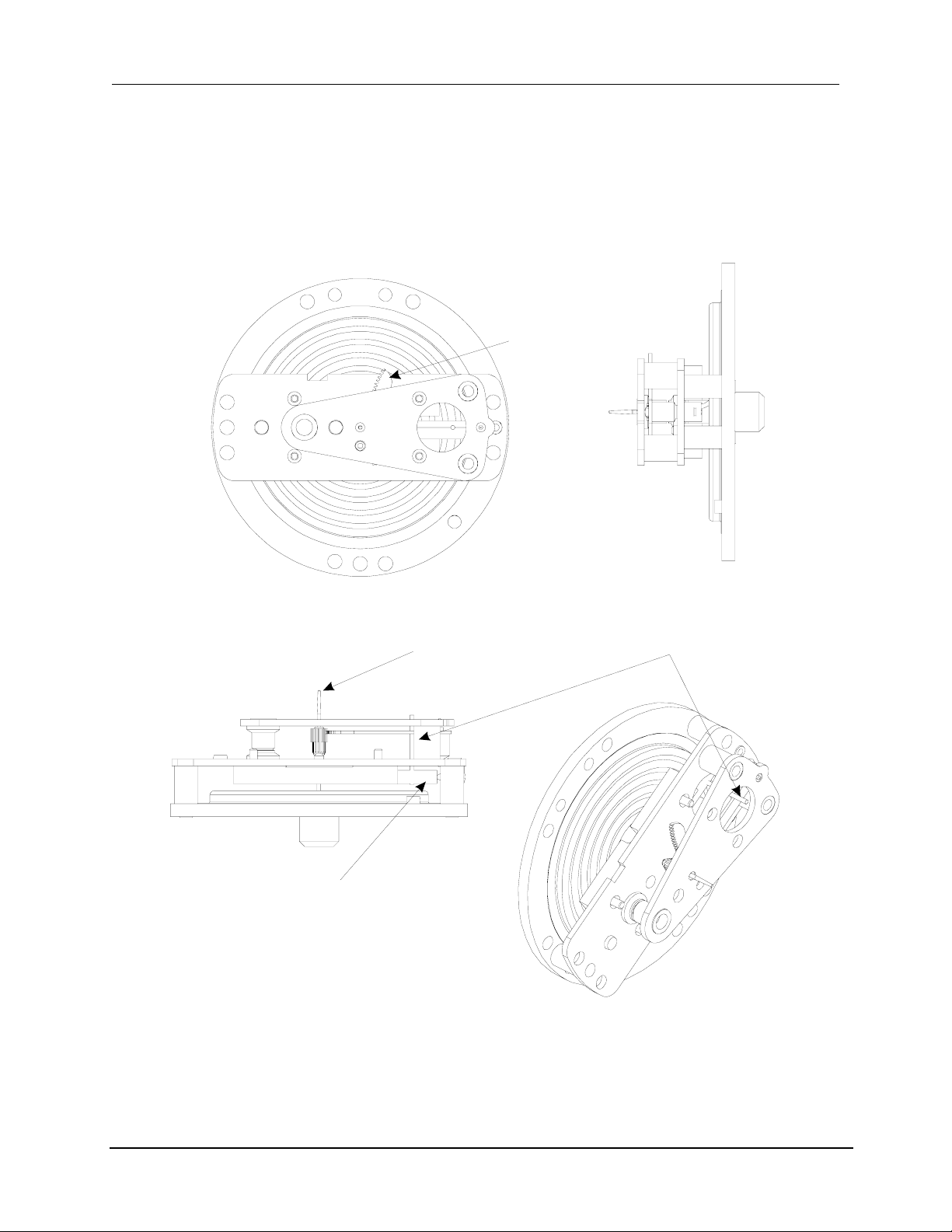

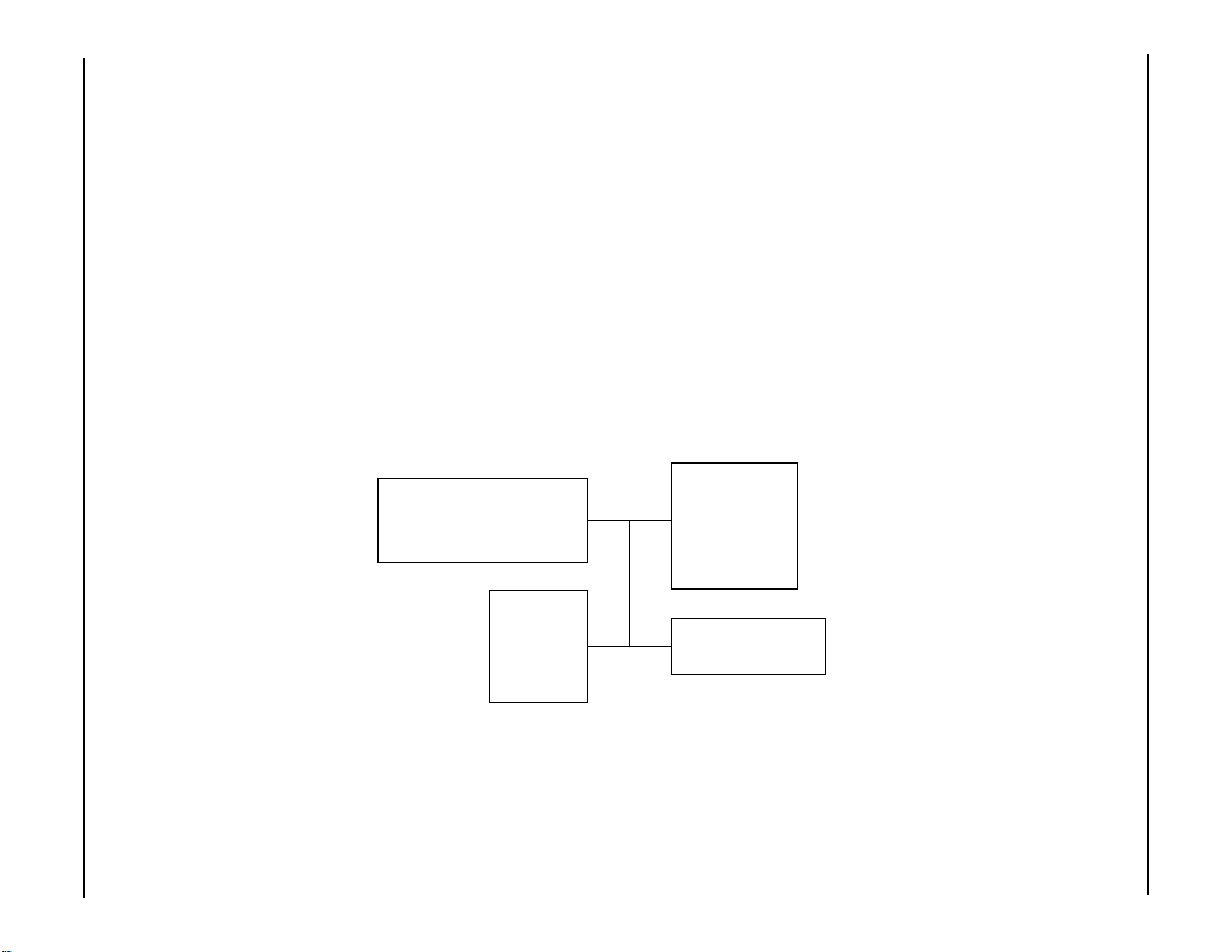

New S&K Movement

The S&K movement is now being used in all Classic Hand Aneroid, Classic Pocket

Aneroid, Wall Aneroid Series 509, Wall Aneroid Series 767, TR1 Silver Ring and TR2

ProCheck aneroids. The S&K movement looks similar to Figure 1-1. Please familiarize

yourself with the different parts of the S&K movement.

Sector Gear

Cross Shaft

Figure 1-1. New style S&K Movement.

Adjustment PinPinion

Service Manual 95P504 Rev. D Welch Allyn Aneroid Sphygmomanometers 5

Page 13

Section 1 General Information

A

A

Old Style Movements

Welch Allyn still supports the Older Style Classic Hand Aneroid, Classic Pocket Aneroid,

Wall Aneroid Series 509 and Wall Aneroid Series 767. The Older movements look similar

to Figure 1-2.

BOTTOM PLATE

ND BEARING PLATE

TapTite

Screw

TOP PLATE

AND JEWELS

ASSEMBLY

(JEWEL VERSION)

Pinion

Hair

Spring

ASSEMBLY

ARBOR AND GEAR

SECTOR ASSY

Radius Plate

nd Push Rod

Assembly

Screw &

Washer

Top

Plate

Sector Alignment

Mark

Stop Lug

Leaf Spring

Figure 1-2. Old style aneroid movement.

Bottom

Plate

6 Welch Allyn Aneroid Sphygmomanometers Service Manual 95P504 Rev. D

Page 14

General Information Section 1

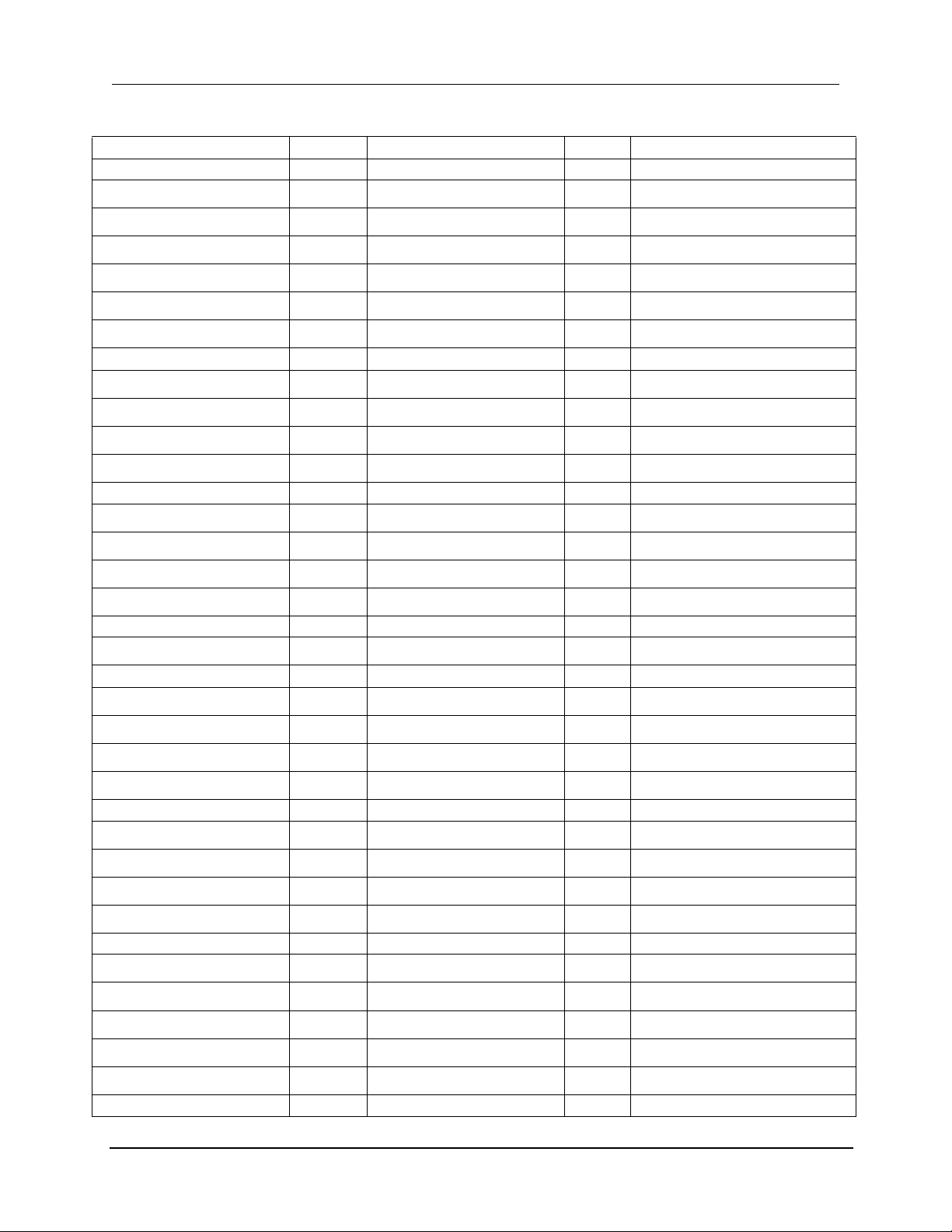

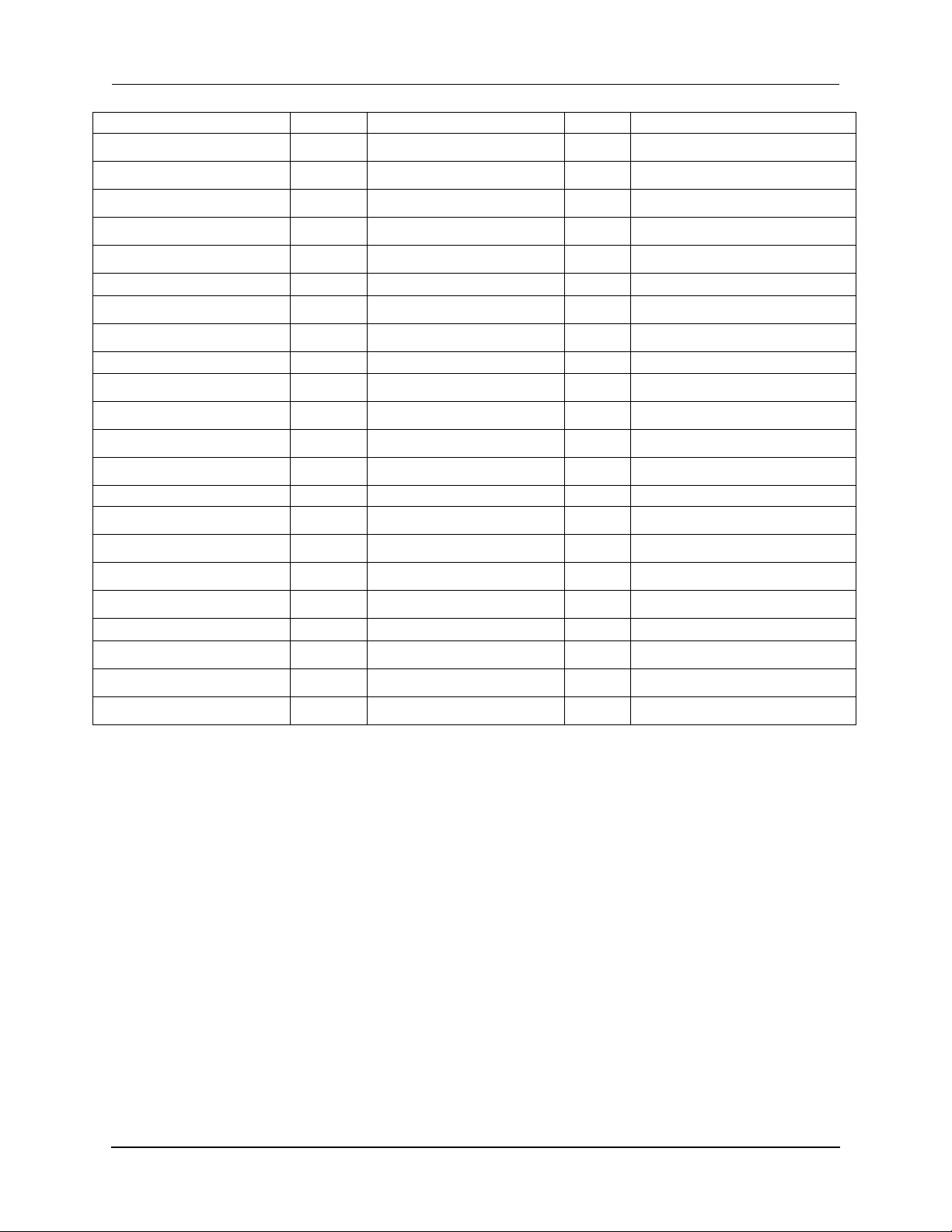

Table 1-1. Aneroid warranty table.

Model Model No. Description Warranty Comments

Classic Hand Aneroid 5098-06 w/Infant Cuff Lifetime Replace w/S&K Assy.

5098-05 w/Adult Cuff Lifetime Replace w/S&K Assy.

5098-02 w/Child Cuff Lifetime Replace w/S&K Assy.

5098-20 w/Various Size Cuffs Lifetime Replace w/S&K Assy.

5098-23 w/Various Size Printed Cuffs Lifetime Replace w/S&K Assy.

5098-18 w/Various Printed Ped Cuffs Lifetime Replace w/S&K Assy.

Classic Pocket Aneroid 5090-06 w/Child Cuff Lifetime Replace w/S&K Assy.

5090-02 w/Adult Cuff Lifetime Replace w/S&K Assy.

5090-41 w/Lg. Adult Cuff Lifetime Replace w/S&K Assy.

5090-37 w/Thigh Cuff Lifetime Replace w/S&K Assy.

Wall Aneroid Series 509 5091-38 w/Adult Cuff Lifetime Replace w/S&K Assy.

5091-22 w/Adult Cuff & Orange Scale Lifetime Replace w/S&K Assy.

5091-60 w/5 legged stand Lifetime Replace w/S&K Assy.

5091-41 w/4 legged stand

Wall Aneroid 767 Series 7670-01 w/Adult Cuff Lifetime Replace w/S&K Assy.

TR1 (Siler Ring) Hand Aneroid 5098-29 w/Child Cuff 10 year No Change

5098-27 w/Adult Cuff 10 year No Change

5098-28 w/Lg. Adult Cuff 10 year No Change

5098-30 w/Various Size Printed Cuffs 10 year No Change

TR2 (Procheck) Hand Aneroid 5098-72 w/Child Cuff 5 year No Change

5098-70 w/Adult Cuff 5 year No Change

5098-71 w/Lg. Adult Cuff 5 year No Change

5098-73 w//Various Size Printed Cuffs 5 year No Change

Durashock DS45-09 w/Child Cuff 10 year No Change

DS45-09P w/Printed Child Cuff 10 year No Change

DS45-10 w/Sm. Adult Cuff 10 year No Change

DS45-11 w/Adult Cuff 10 year No Change

DS45-12 w/Lg. Adult Cuff 10 year No Change

Durashock DS44-09 w/Child Cuff 5 year No Change

Service Manual 95P504 Rev. D Welch Allyn Aneroid Sphygmomanometers 7

Page 15

Section 1 General Information

Model Model No. Description Warranty Comments

DS44-09P w/Printed Child Cuff 5 year No Change

DS44-10 w/Sm. Adult Cuff 5 year No Change

DS44-11 w/Adult Cuff 5 year No Change

DS44-12 w/Lg. Adult Cuff 5 year No Change

Arden Wall Aneroid Arden-W01 Gage & Cuff 5 year No Change

Arden-W02 Gage Only 5 year No Change

Arden Pocket Aneroid Arden-G01 w/Adult Cuff 5 year No Change

Arden-G02 w/Lg. Adult Cuff 5 year No Change

Arden-G03 w/Child Cuff 5 year No Change

Arden-G04 Gage Only 5 year No Change

Economy Pocket Aneroid 7050-23 w/Child Cuff 10 year Discontinue selling after 7/15/2003

7050-14 w/Adult Cuff 10 year Discontinue selling after 7/15/2003

7050-24 w/Lg. Adult Cuff 10 year Discontinue selling after 7/15/2003

7050-43 w/Thigh Cuff 10 year Discontinue selling after 7/15/2003

Mercurial 5097-30 Desk 10 year Discontinued selling after 3/15/2003

5097-29 w/Mobile Stand 10 year Discontinued selling after 3/15/2003

5097-26 w/Wall Mount 10 year Discontinued selling after 3/15/2003

5097-11 w/Wall Mount & Orange Scale 10 year Discontinued selling after 3/15/2003

8 Welch Allyn Aneroid Sphygmomanometers Service Manual 95P504 Rev. D

Page 16

Service Manual 95P504 Rev. D Welch Allyn Aneroid Sphygmomanometers 9

Tools Required for Service

Service Section 2

Tool Number Description Old Style

Economy

Local Tool Store Tweezers X

Local Tool Store Jewelers Screwdriver X X X

Local Tool Store 3/8" Open End Wrench X

Local Tool Store Pliers to Grip Luer X

Local Tool Store 5/16" Open End Wrench X

T112854 500cc Volume X X X X X X X X X X X

T106763 509/7670 Fixture X X X X

T18891 Adapter for Torque wrench X X X X X X

T110657 Calibration Dial X

T112663 Calibration Dial X

T112949 Calibration Dial X

T18781 Calibration Dial X X

T18833 Calibration Dial X X

T19036 Calibration Dial X

T105721 Calibration Dial X X

T106845A Calibration Tool X X X X X

T18816 Calibration Tool (S+K) X X X X X X

T105644 Collet X

T108212 Economy Gauge Fixture X

T107569 Hand Gauge Fixture X X

T108897 Movement Removal Wrench X X X

T74555 Pocket Gauge Fixture X X

T55804-1 Pocket Screw Cap Assy. X

T19034 Pointer Assembly Tool X X X X X X

T34935 Pointer Block X X X X

T18814 Pointer Removal Tool X X X X X X X X X X X

T19035 S&K removal Wrench X X X X X X

T113249 Screw Cap Removal Tool X

T107345 Span Wrench X

T119628 Tension Setting Tool X X X X X

T113265 Thumbscrew Wrench X X

T112655 Top Plate Wrench X X X X

T112459 Torque Screwdriver X X X X

Old Style

Pocket

Old Style

Hand

Old Style

509

Old Style

7670

TR-2 TR-1 S&K

Hand

S&K

Pocket

S&K

509

S&K

7670

Page 17

10 Welch Allyn Aneroid Sphygmomanometers Service Manual 95P504 Rev. D

Tool Number Description Old Style

Economy

T18904 Torque Wrench (S & K) X X X X X X

T112584 TR-1 & TR-2 Fixture X X

T105258 Wrench X X X

Local Tool Store Red Loctite #266 X X X X X X X X X X X

Local Tool Store 3M Plastic Adhesive #1099 X

Tool Number Description Old Style

Economy

5088-01 Bulb and Valve X X X X X X X

Gomco 300 or

equivlant∗∗∗∗

9585TPK4∗∗∗ "T" Fitting X X X X X X X X X X X

9586TPK4∗∗∗ "Y" Fitting X X X X X X X X X X X

97P24 Pneumatic Tubing (4ft.) X X X X X X X X X X X

200-2000in∗ Netech Digital Pressure Meter X X X X X X X X X X X

2270-01∗∗ Setra Digital Pressure Meter X X X X X X X X X X X

Local Tool Store Torque Bit size T5 X X X X

NOTE: Only one of the pressure meters are needed. The user can choose which will work best for them.

∗ Order from Netech (800-547-6557)

∗ ∗ Order from Setra (800-257-3872)

∗ ∗ ∗ Order from Festo (704-527-1427)

∗ ∗ ∗ ∗ Order from PMED (303-393-7800)

Suction Pump (Must be able to

pull a suction of -20 mmHg)

Old Style

Pocket

Old Style

Pocket

Old Style

Hand

Test equipment

Old Style

Hand

Old Style

509

Old Style

509

Old Style

7670

Old Style

7670

TR-2 TR-1 S&K

Hand

TR-2 TR-1 S&K

Hand

X X X X X X

S&K

Pocket

S&K

Pocket

S&K

509

S&K

509

S&K

7670

S&K

7670

Section 2 Service

Page 18

Service Manual 95P504 Rev. D Welch Allyn Aneroid Sphygmomanometers 11

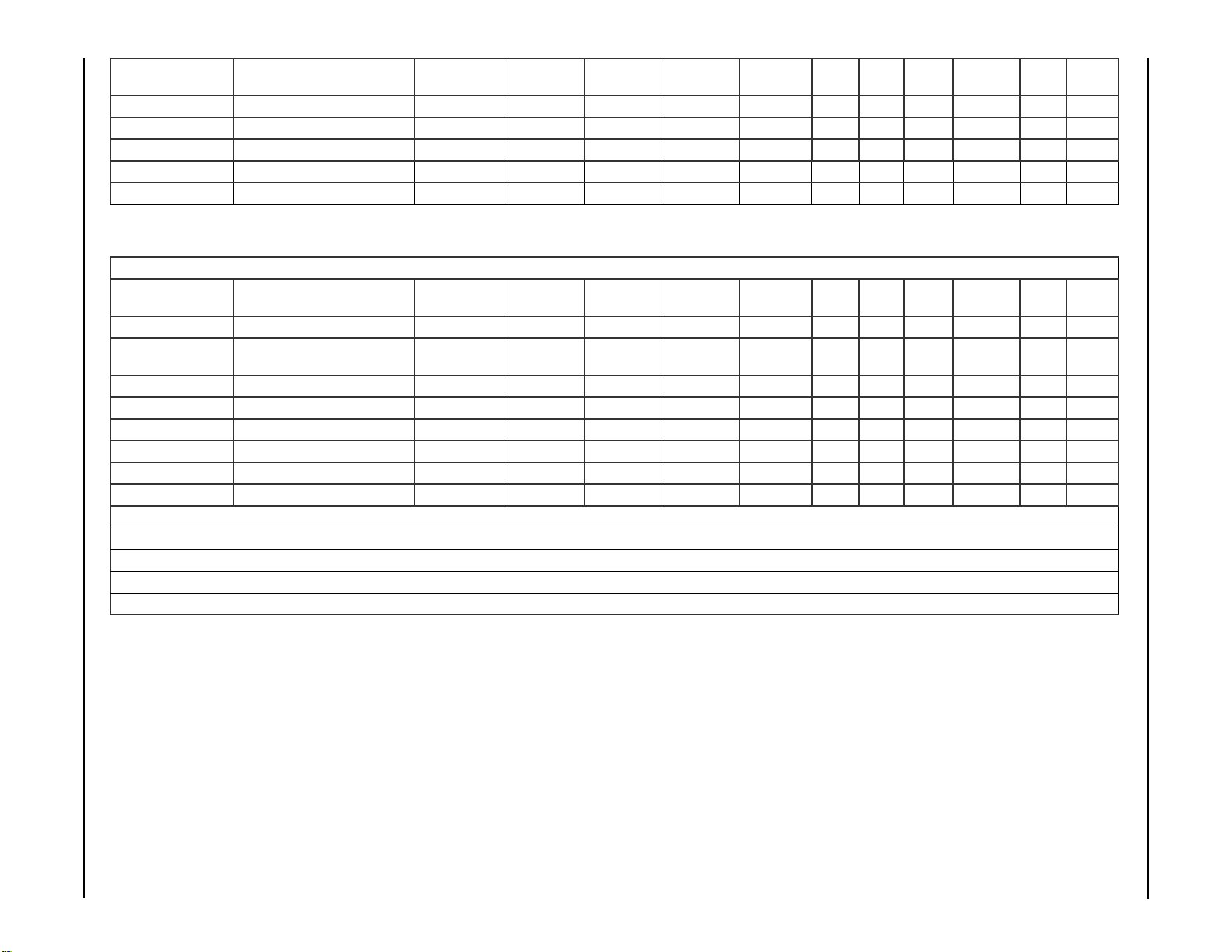

Test Specifications

The following are the pressure test points that each gauge must be tested to after any repair is made.

1. The gauge must be accurate to within ±3 mmHg at the following test pressures:

a) 0 mmHg (pointer inside the oval/rectangle)

b) 60 mmHg

c)100 mmHg

d)150 mmHg

e)200 mmHg

f)250 mmHg

g)300 mmHg

Note: Calibration of all gauges must be performed using a Calibrated Digital Pressure Meter, traceable to NIST standards, as

the pressure standard, to ensure complete accuracy.

Test Equipment Bench Layout

Service Section 2

500 cc Volume

Figure 2-1. Test Equipment Bench layout.

Gauge

Under

Test

Digital

Pressure

Meter

Bulb and Valve

Page 19

12 Welch Allyn Aneroid Sphygmomanometers Service Manual 95P504 Rev. D

Section 2 Service

Page 20

Repair and Calibration Section 3

Classic Pocket Aneroid Gauges

Initial Gauge Check

1. Before performing calibration:

a) Check the clip for correct tension. Replace before calibration.

b) Ensure the lock nut is tight.

c) Check the hair spring. Ensure that the hair spring is uniform and not distorted.

d) Check the pinion. Ensure that it rotates correctly and is not bent.

(Date stamp of September 2003 or earlier)

Opening/Removing and Replacing Parts of the Classic Pocket Gauge

2. Place the pocket gauge into the Pocket Gauge Fixture (T74555).

3. Remove the bezel by unscrewing it from the case. Remove the crystal.

4. Remove the pointer, using the pointer removal tool (T18814).

5. Pry out the dial, using a small flat head screwdriver.

6. Remove the capsule locking nut using span wrench (T107345).

7. Remove the screw cap, using (T113249). Remove the capsule.

Note: The arm of the movement fits into the top of the capsule.

8. Remove the 2 screws that are holding down the gauge movement using (T108897).

Note: Some units will use phillip head screws to secure the movement.

9. Remove the movement.

Note: Reassemble in reverse order.

Calibration of the Classic Pocket Gauge

10. Connect the gauge to test equipment.

11. Place the gauge in to the pocket fixture (T74555).

12. Remove the bezel, crystal, pointer and dial.

Aligning Sector Gear on the Classic Pocket Gauge

13. View the sector gear and ensure that it is in the proper position. The right edge of the

sector gear should align with the mark on the base of the movement.

14. If the sector gear is not aligned properly, loosen the capsule nut using (T107345). Adjust

the sector gear by turning the capsule until the sector gear is in the correct position per step

#13. Tighten the capsule nut.

Service Manual 95P504 Rev. D Welch Allyn Aneroid Sphygmomanometers 13

Page 21

Section 3

Repair and Calibration

Setting the Classic Pocket Gauge Tension

15. Loosen the sector stop lug and pull it towards the bottom of the gauge.

16. Using your left index finger, push the sector gear all the way to the post and hold in

that position.

17. Place the tension setting tool (T119628) onto the pinion at the 9 o’clock position.

18. Rotate the tension setting tool clockwise to the 5 o’clock position.

19. Release the sector gear and continue rotating the tension setting tool to the 9 o’clock

position. The sector gear should be moving during this step.

20. Bring the sector stop lug back to correct position and lock it into place.

Setting the Classic Pocket Gauge Span

21. Place the test dial (T105721) onto the gauge. Place the test pointer onto the pinion.

Rotate the test dial until the pointer is at "0".

22. Apply 320 mmHg to the gauge.

23. Release the pressure to 300 mmHg.

24. If the pointer is pointing to less than "300", place the calibration tool (T106845A) into

the radius plate slot above the screw. Rotate the calibration tool counter clockwise towards

the bottom of the gauge until the test pointer reaches "300". Release the pressure to 0

mmHg and check at the "0" point.

25. If the test pointer is pointing to greater than "300", position the calibration tool

(T106845A) between the sector gear and the radius plate. Rotate the tool clockwise until

the pointer is at "300" (this brings the radius plate down). Release the pressure to 0 mmHg

and check the "0" point.

26. If the pointer is not at "0" upon full release of pressure, rotate the test dial until the test

pointer is on the "0" mark of test dial. Repeat steps 22-25 until span is set.

27. Check for leaks by pinching off the tubing from the test equipment while pressure is

applied to the gauge. There should be no leakage or movement of the pointer.

Check and finish the calibration of the Classic Pocket Gauge

28. Remove the test pointer and test dial. Replace the gauge’s dial.

29. Apply a small amount of red Loctite #266 to the hub of the pointer. Place the gauge’s

pointer onto the pinion. Ensure that it is resting in the center of the oval/square. Gently tap

the pointer with a small hammer to secure.

14 Welch Allyn Aneroid Sphygmomanometers Service Manual 95P504 Rev. D

Page 22

Repair and Calibration Section 3

30. If the pointer is to the left of the oval/square’s center, rotate the pointer counter

clockwise until you feel a slight resistance. Release the pointer. Ensure that the pointer

returns to the center of the oval/square "0". Repeat until correct.

31. If the pointer is to the right of the oval/square’s center, rotate the pointer clockwise

until a slight resistance is felt. Release the pointer. Ensure that the pointer returns to the

center of the oval/square "0" each time. Repeat until correct.

32. Place the crystal and bezel back onto the gauge. Test the gauge.

33. Connect the gauge to the test equipment.

34. Apply 320 mmHg to the gauge.

35. Release the pressure to 300 mmHg.

Note: The aneroid gauge must be accurate to "3 mmHg at the stated target pressures. Use

a calibrated digital pressure meter.

36. Compare the reading of the calibrated digital pressure meter to that of the gauge under

test.

37. The following are the pressure test points that each gauge must be tested to after any

repair is made. The gauge must be accurate to within "3 mmHg at the following test

pressures:

a) 0 mmHg (pointer inside the oval/rectangle)

b) 60 mmHg

c) 100 mmHg

d) 150 mmHg

e) 200 mmHg

f) 250 mmHg

g) 300 mmHg

Note: Calibration of all gauges must be performed using a Calibrated Digital Pressure

Meter as the pressure standard for complete accuracy.

Service Manual 95P504 Rev. D Welch Allyn Aneroid Sphygmomanometers 15

Page 23

Section 3

Repair and Calibration

Classic Pocket Aneroid Gauges

(With S&K movement)

(Date stamp of October 2003 or later)

Initial Gauge Check

1. Before performing calibration:

a) Check the gauge for a sticky or jumpy pointer movement.

b) Attach gauge to test equipment and test for leaks.

c) Check the clip for correct tension. Replace before calibration.

Opening/Removing and Replacing Parts of the Classic Pocket Gauge

2. Place the pocket gauge into the Pocket Gauge Fixture (T74555).

3. Remove the bezel by unscrewing it from the case. Remove the crystal.

4. Remove the pointer by using the pointer removal tool (T18814).

5. Pry out the dial by using a small flat head screwdriver.

6. The pocket end cap cannot be removed.

7. Remove the movement using (T18904).

Note: Reassemble in reverse order. Ensure you tighten the movement down with torque

wrench (T18904) using adapter (T18891)

Calibration of the Classic Pocket Gauge

8. Connect the gauge to the test equipment.

9. Place the gauge in to the pocket fixture (T74555).

10. Remove the bezel, crystal, pointer and dial.

Checking the Classic Pocket Gauge Span:

11. Place the test dial (T18781) onto the gauge. Place the test pointer onto the pinion.

Rotate the test dial until the pointer is at "0".

12. Apply 320 mmHg to the gauge.

13. Release the pressure to 300 mmHg.

14. Observe the position of the pointer. If the pointer does not align with the "300", go to

Average Zero Starting Position

16 Welch Allyn Aneroid Sphygmomanometers Service Manual 95P504 Rev. D

Page 24

Repair and Calibration Section 3

15. If the pointer does align with "300", go to Linearity Adjustment of the Classic Pocket

Aneroid.

Average Zero Starting Position

16. Apply 60 mmHg of pressure to the gauge. Release the pressure to zero. Mentally note

where the test pointer is pointing on the test dial.

17. Apply a -20 mmHg of vacuum to the gauge. Release the pressure to zero. Mentally

note where the test pointer is pointing on the test dial.

18. Take the average of where the pointer was between step 16 and step 17. Rotate the test

dial’s zero mark to that averaged position.

Span Adjustment of the Classic Pocket Aneroid

19. Apply 320 mmHg of pressure to the gauge. Bleed down to 300 mmHg. Note the

pointer’s position and maintain pressure.

20. If the span is too low, using calibration tool (T18816), bend the adjustment pin away

from pinion parallel to gear sector arm. See Figure 3-1. Release the pressure to 0. Make

sure to re-adjust the test dial so that the pointer will be slightly left of the graduation line.

Re-pressurize to 320 mmHg then to 300 mmHg to evaluate the effects of the adjustment.

21. If the span is too high, using calibration tool (T18816), bend the adjustment pin

towards the pinion parallel to the gear sector arm. See Figure 3-1. Release the pressure to

0. Make sure to re-adjust the test dial so that the pointer will be slightly left of the

graduation line. Re-pressurize to 320 mmHg then to 300 mmHg to evaluate effects of

adjustment.

22. Repeat the above steps as required to obtain correct span adjustment.

Pinion

Figure 3-1. S&K span adjustment.

Service Manual 95P504 Rev. D Welch Allyn Aneroid Sphygmomanometers 17

Page 25

Section 3

Repair and Calibration

Linearity Adjustment of the Classic Pocket Aneroid: (

As required

)

Note: If the 0 mmHg and 300 mmHg position are correct, and the other points at 250

mmHg or 60 mmHg are either too high or too low, perform the following adjustments.

High Readings of the Classic Pocket Aneroid:

(Predominantly at 250 and 200)

23. Remove the test pointer and test dial. Position the calibration tool (T18816) over the

adjusting pin and push it down to the cross shaft. Note:You may have to move the gear

sector with your finger of other hand to allow the calibration tool to slide down to the

cross shaft.

24. Move the hook away from the diaphragm (approximately 15 degrees), by pushing on

the sector gear. While maintaining this position, lift the tool up from cross shaft

approximately 1/16 inch and bend the pin back approximately 15 degrees. See Figure 3-2.

Lift the calibration tool up to the point where the pin makes contact with the gear sector

and bend the pin up, approximately 30 degrees.

Approximately 15 degrees

Approximately 30 degrees

Cross Shaft

Hook

Figure 3-2. S&K pin adjustment if reading is high at 250 mmHg.

25. Remove the tool and release the gear sector. The resultant bend should result in the

gear sector starting position being a maximum of 2 teeth extending beyond the top plate

when viewed from a top position and a minimum of 2 teeth within the edge of the top

plate. (This must be checked by pushing the gear sector 2 teeth from the other side of the

top plate). Adjust the secondary bend if the gear sector is out of these limits. Re-assemble

the test dial and test pointer. Recheck span and adjust as necessary prior to inspecting the

intermediate points.

Low Readings of the Classic Pocket Aneroid at 60 or 100:

26. Remove the test pointer and test dial. Position the calibration tool over the adjusting

pin and push it down to the cross shaft. Lift the tool approximately 1/16 inch and bend the

pin approximately 15 degrees. See Figure 3-3. While maintaining this position, lift the tool

18 Welch Allyn Aneroid Sphygmomanometers Service Manual 95P504 Rev. D

Page 26

Repair and Calibration Section 3

to point where the pin makes contact with the gear sector. Bend the pin down 30 degrees.

Remove the tool and release the gear sector. Check for gear sector starting position as

defined previously. Adjust if necessary. Re-assemble the test dial and test pointer. Recheck

the span and adjust as necessary prior to inspection at the intermediate points.

Approximately 15 degrees

Figure 3-3. S&K pin adjustment if reading is low at 60 mmHg.

Approximately 30 degrees

Note: In all adjustments during calibration, the gear sector starting position will affect

accuracy. Sometimes, this alone can be used as an individual adjustment to achieve

conformance. Higher readings will be realized when the gear sector is extending beyond

the edge of the top plate and lower readings will be realized when it is within the edge of

the top plate.

27. Check for leaks by pinching off the tubing from the test equipment while pressure is

applied to the gauge. There should be no leakage or movement of the pointer.

Check and finish the calibration of the Classic Pocket Gauge

28. Remove the test pointer and test dial. Replace the gauge’s dial.

29. Apply a small amount of red Loctite #266 to the hub of the pointer. Place the gauge’s

pointer onto the pinion. Ensure that it is resting in the center of the oval. Gently tap the

pointer with small hammer to secure or use (T19034) pointer assembly tool.

30. Place the crystal and bezel back onto the gauge and test the gauge.

Testing the Classic Pocket Gauge

31. Connect the Pocket Gauge to the test equipment.

32. Apply 320 mmHg to the gauges.

33. Release the pressure to 300 mmHg.

Service Manual 95P504 Rev. D Welch Allyn Aneroid Sphygmomanometers 19

Page 27

Section 3

Repair and Calibration

Note: The aneroid or mercury gauge must be accurate to "3 mmHg at the stated target

pressures. Use a calibrated digital pressure meter.

34. Compare the reading of the calibrated digital pressure meter to that of the Pocket

Gauge under test.

35. The following are the pressure test points that each gauge must be tested to after any

repair is made. The gauge must be accurate to within "3 mmHg at the following test

pressures:

a) 0 mmHg (pointer inside the oval/rectangle)

b) 60 mmHg

c) 100 mmHg

d) 150 mmHg

e) 200 mmHg

f) 250 mmHg

g) 300 mmHg

Note: Calibration of all gauges must be performed using a Calibrated Digital Pressure

Meter as the pressure standard for complete accuracy.

20 Welch Allyn Aneroid Sphygmomanometers Service Manual 95P504 Rev. D

Page 28

Repair and Calibration Section 3

Classic Wall and Mobile Aneroid Gauge

7670 series Wall and Mobile Aneroid Disassembly

1. Remove the bezel from the case by prying the 4 tabs up. Pull out on the bezel.

2. Remove the crystal.

3. Remove the pointer by using the pointer removal tool (T18814). Visually inspect and

straighten if needed.

4. Remove the screws of the dial by using the torque driver (T112459). Remove the dial.

5. Remove the screws that are holding down the mount to the case of the gauge by using a

Phillips head screwdriver.

Note: Reassemble in reverse order.

Classic Wall and Mobile Aneroid Disassembly

6. Remove the crystal by pushing down and out at the top. Remove the crystal.

(Date stamp of July 2003 or earlier)

7. Remove the pointer by using the pointer removal tool (T18814). Inspect and straighten

if needed.

8. Remove the dial by removing the screws with the torque driver (T112459).

9. Remove the movement and the mount by unscrewing the standoffs. Remove them from

the case.

Note: Reassemble in reverse order.

Calibration of the Wall and Mobile Gauge

Note: Before performing calibration:

a) Check the hair spring. Ensure it is uniform and not distorted.

b) The movement should be slow when released.

c) Check the pinion. Ensure that it rotates correctly and is not bent.

10. Connect the gauge to the test equipment.

11. Remove the bezel, crystal, pointer and dial.

Sector Gear Alignment for the Wall and Mobile Aneroid

13. View the sector gear and ensure proper position. The right edge of the sector gear

should align with the mark on the base of the movement.

Service Manual 95P504 Rev. D Welch Allyn Aneroid Sphygmomanometers 21

Page 29

Section 3

Repair and Calibration

14. If the sector gear is not aligned properly, loosen the capsule nut using (T105258).

Adjust the sector gear by turning the capsule until the sector gear is in the correct position

per step 13. Tighten the capsule nut.

Setting the Tension of the Wall and Mobile Aneroid

15. Loosen the sector stop lug and pull it towards the bottom of the gauge.

16. Using your left index finger, push the sector gear all the way to the post and hold that

in position.

17. Place the tension setting tool (T119628) onto the pinion at the 9 o’clock position.

18. Rotate the tension setting tool clock wise to the 5 o’clock position.

19. Release the sector gear and continue rotation to the 9 o’clock position. The sector gear

should be moving during this step.

20. Bring the lug back to the correct position and lock it into place.

Setting the span of the Wall and Mobile Aneroid

21. Place the test dial (T112641 for 767 Series) or (T112663 for 509 Series) onto the

gauge. Place the test pointer onto the pinion. Rotate the test dial until the pointer is at "0".

22. Apply 320 mmHg of pressure to the gauge.

23. Release the pressure to 300 mmHg.

24. If the pointer is pointing to less than "300", place the calibration tool (T106845A) into

the radius plate slot above the screw. Rotate the calibration tool counter clockwise towards

the bottom of the gauge until the sector gear pointer reaches "300". Release the pressure

to 0 mmHg and check at the "0" point.

25. If the pointer is pointing to greater than "300", using the calibration tool (T106845A)

positioned between the sector gear and the radius plate. Rotate the tool clockwise until the

pointer is at "300" (this brings the radius plate down). Release the pressure to 0 mmHg

and check the "0" point.

26. If the pointer is not pointing at "0" upon the release of pressure, rotate the test dial

until the pointer is on the "0" mark of test dial. Repeat steps 22-25 until the span is set.

27. Check for leaks by pinching off the tubing from the test equipment while pressure is on

the gauge. There should be no visible leak.

Check and finish calibration of the Wall and Mobile Aneroid

28. Remove the test pointer and test dial. Replace the gauge’s dial.

22 Welch Allyn Aneroid Sphygmomanometers Service Manual 95P504 Rev. D

Page 30

Repair and Calibration Section 3

29. Apply a small amount of red Loctite #266 to the hub of the pointer. Place the gauge’s

pointer onto the pinion. Ensure the pointer is resting in center of oval "0". Tap the pointer

with small hammer slightly to secure.

30. If the pointer is to the left of the oval/square’s center, rotate the pointer counter

clockwise until you feel a slight resistance. Release the pointer. Ensure the pointer returns

to the center of the oval/square "0". Repeat until correct.

31. If the pointer is to the right of the oval/square’s center, rotate the pointer clockwise

until a slight resistance is felt. Release the pointer. Ensure the pointer returns to the center

of the oval/square "0" each time. Repeat until correct.

32. Place the crystal and perform a full test.

Testing of the Wall and Mobile Aneroid

33. Connect the Wall or Mobile Gauge to the test equipment.

34. Apply 320 mmHg of pressure to the gauge.

35. Release the pressure to 300 mmHg.

36. Compare the reading of wall or mobile gauge under test to a calibrated digital pressure

meter.

Test Specifications

37. The following are the pressure test points that each gauge must be tested to after any

repair is made. The gauge must be accurate to within "3 mmHg at the following test

pressures:

a) 0 mmHg (pointer inside the oval/rectangle)

b) 60 mmHg

c) 100 mmHg

d) 150 mmHg

e) 200 mmHg

f) 250 mmHg

g) 300 mmHg

Note: Calibration of all gauges must be performed using a Calibrated Digital Pressure

Meter as the pressure standard for complete accuracy.

Service Manual 95P504 Rev. D Welch Allyn Aneroid Sphygmomanometers 23

Page 31

Section 3

Repair and Calibration

Classic Wall and Mobile Aneroid Gauge

(With S&K movement.)

(Date stamp of October 2003 and later.)

7670 series Wall and Mobile Aneroid Disassembly

1. Remove the bezel from the case by prying the 4 tabs up. Pull out on the bezel.

2. Remove the crystal.

3. Remove the pointer by using the pointer removal tool (T18814). Visually inspect and

straighten if needed.

4. Remove the screws of the dial by using the torque driver (T112594A). Remove the dial.

5. Remove the screws that are holding down the mount to the case of the gauge by using a

Phillips head screwdriver.

6. Remove the movement using (T19035).

Note: Reassemble in reverse order. Ensure you tighten the movement down with torque

wrench (T18904) using adapter (T18891).

Classic Wall and Mobile Aneroid Disassembly

7. Remove the crystal by pushing down and out at the top. Remove the crystal.

8. Remove the pointer by using the pointer removal tool (T18814). Inspect and straighten

if needed.

9. Remove the dial by removing the screws with the torque driver (T112459A).

10. Remove the movement and the mount by unscrewing the standoffs. Remove them

from the case.

Note: Reassemble in reverse order. Ensure you tighten the movement down with torque

wrench (T18904) using adapter (T18891).

Calibration of the Wall and Mobile Gauge

11. Connect the gauge to the test equipment.

12. Remove the bezel, crystal, pointer and dial.

Checking the Wall/Mobile Gauge Span

13. Place the test dial (T18833) onto the gauge. Place the test pointer onto the pinion.

Rotate the test dial until the pointer is at "0".

24 Welch Allyn Aneroid Sphygmomanometers Service Manual 95P504 Rev. D

Page 32

Repair and Calibration Section 3

14. Apply 320 mmHg to the Gauge.

15. Release the pressure to 300 mmHg.

16. Observe the position of the pointer. If the pointer does not align with the "300", go to

Average Zero Starting Position.

17. If the pointer does align with "300", go to Linearity Adjustment of the Wall/Mobile

Aneroid.

Average Zero Starting Position

18. Apply 60 mmHg of pressure to the gauge. Release the pressure to zero. Mentally note

where the test pointer is pointing on the test dial.

19. Apply a -20 mmHg of vacuum to the gauge. Release the pressure to zero. Mentally

note where the test pointer is pointing on the test dial.

20. Take the average of where the pointer was between step 18 and step 19. Rotate the test

dial’s zero mark to that averaged position.

Span Adjustment of the Wall Aneroid

21. Apply 320 mmHg of pressure to the gage to then bleed down to 300 mmHg. Mentally

note position and maintain pressure.

22. If the span is too low, using calibration tool (T18816), bend the adjustment pin away

from pinion parallel to gear sector arm. Change pressure to 0 mmHg. Make sure to readjust the test dial so that the pointer will be slightly left of the graduation line. Repressurize to 320 mmHg then to 300 mmHg to evaluate the effects of the adjustment. See

Figure 3-4.

23. If the span is too high, using calibration tool (T18816), bend the adjustment pin

towards the pinion parallel to the gear sector when pressurized at 300 mmHg. Change the

pressure to 0 mmHg. Make sure to re-adjust the test dial so that the pointer will be slightly

left of the graduation line. Re-pressurize to 320 mmHg then to 300 mmHg to evaluate

effects of adjustment. See Figure 3-4.

24. Repeat the above steps as required to obtain correct span adjustment.

Service Manual 95P504 Rev. D Welch Allyn Aneroid Sphygmomanometers 25

Page 33

Section 3

Figure 3-4. S&K span adjustment.

Repair and Calibration

Linearity Adjustment of the Wall/Mobile Aneroid: (As required)

Note: If the 0 mmHg and 300 mmHg position are correct, and the other points at 250

mmHg or 60 mmHg are either too high or too low, then perform the following

adjustments.

High Readings of the Wall/Mobile Aneroid:

(Predominantly at 250 and 200)

25. Remove the test pointer and test dial. Position the calibration tool (T18816) over the

adjusting pin and push it down to the cross shaft. Move the gear sector with your finger of

other hand to allow access. Rotate the pin by pushing the sector gear, to move the hook

away from the diaphragm (approximately 15 degrees). While maintaining this position, lift

the tool up from cross shaft approximately 1/16 inch and bend the pin back approximately

15 degrees. See Figure 3-5. Lift the calibration tool up to the point where the pin makes

contact with the gear sector and bend the pin up, approximately 30 degrees.

Approximately 15 degrees

Approximately 30 degrees

Cross Shaft

Hook

Figure 3-5. S&K pin adjustment if reading is high at 250 mmHg.

26 Welch Allyn Aneroid Sphygmomanometers Service Manual 95P504 Rev. D

Page 34

Repair and Calibration Section 3

26. Remove the tool and release the gear sector. The resultant bend should result in the

gear sector starting position being a max. of 2 teeth extending beyond the top plate when

viewed from a top position and a minimum of 2 teeth within the edge of the top plate.

(This must be checked by pushing the gear sector 2 teeth from the other side of the top

plate). Adjust the secondary bend if the gear sector is out of these limits. Re-assemble the

test dial and test pointer. Recheck span and adjust as necessary prior to inspecting the

intermediate points.

Low Readings of the Wall/Mobile Aneroid at 60 or 100

27. Remove the test pointer and test dial. Position the calibration tool over the adjusting

pin and push it down to the cross shaft. Lift the tool approximately 1/16 inch and bend the

pin approximately 15 degrees. See Figure 3-6. While maintaining this position, lift the tool

to point where the pin makes contact with the gear sector. Bend the pin down 30 degrees.

Remove the tool and release the gear sector. Check for gear sector starting position as

defined previously. Adjust if necessary. Re-assemble the test dial and test pointer. Recheck

the span and adjust as necessary prior to inspection at the intermediate points.

Approximately 15 degrees

Figure 3-6. S&K pin adjustment if reading is low at 60 mmHg.

Approximately 30 degrees

Note: In all adjustments during calibration, the gear sector starting position will affect

accuracy. Sometimes, this alone can be used as an individual adjustment to achieve

conformance. Higher readings will be realized when the gear sector is extending beyond

the edge of the top plate and lower readings will be realized when it is within the edge of

the top plate.

28. Check for leaks by pinching off the tubing from the test equipment while pressure is

applied to the gauge. There should be no leakage or movement of the pointer.

Check and finish calibration of the Wall and Mobile Aneroid

29. Remove the test pointer and test dial. Replace the gauge’s dial.

Service Manual 95P504 Rev. D Welch Allyn Aneroid Sphygmomanometers 27

Page 35

Section 3

Repair and Calibration

30. Apply a small amount of red Loctite #266 to the pointer’s hub. Place the gauge’s

pointer onto the pinion. Ensure the pointer is resting in center of oval "0". Gently tap the

pointer with small hammer to secure or use (T112697) pointer assembly tool.

31. Place the crystal and perform a full test.

Testing of the Wall and Mobile Aneroid

32. Connect the Wall or Mobile Gauge to the test equipment.

33. Apply 320 mmHg of pressure to the gauge.

34. Release the pressure to 300 mmHg.

35. Compare the reading of wall or mobile gauge under test to a calibrated digital pressure

meter.

36. The following are the pressure test points that each gauge must be tested to after any

repair is made. The gauge must be accurate to within "3 mmHg at the following test

pressures:

a) 0 mmHg (pointer inside the oval/rectangle)

b) 60 mmHg

c) 100 mmHg

d) 150 mmHg

e) 200 mmHg

f) 250 mmHg

g) 300 mmHg

Note: Calibration of all gauges must be performed using a Calibrated Digital Pressure

Meter as the pressure standard for complete accuracy.

28 Welch Allyn Aneroid Sphygmomanometers Service Manual 95P504 Rev. D

Page 36

Repair and Calibration Section 3

Classic Hand Aneroid Gauge

Note: Before calibrating the Classic Hand Gauge:

a) Check the connector fitting for damage

b) Inspect o-ring

c) Check spring and ball

d) Move thumb screw and check for uniform movement

e) Check movement for damage.

(Date stamp of September 2003 or earlier)

Replacing Parts of the Hand Gauge

1. Pull the bulb off of the valve body.

2. Place the hand gauge into the hand gauge fixture (T107569).

3. Remove the bezel by unscrewing it counter clockwise from the case. Remove the crystal.

4. Remove the pointer by using the pointer removal tool (T18814).

5. Pry out the dial by using a small flat head screwdriver.

6. Remove the cover of the hand gauge by unscrewing the two cover screws with a phillips

head screwdriver.

7. Loosen the locking nut from the capsule. Remove both from the case.

8. Remove the movement screws from the case. Remove the movement from the case.

9. Remove the thumbscrew using tool (T113265 thumbscrew wrench). Turn the

thumbscrew counter clockwise to remove.

10. Remove the thumbscrew valve body using a 5/8" socket.

Note: Reassemble in reverse order.

Calibration of the Classic Hand Gauge

11. Connect the gauge to the test equipment.

12. Ensure that the valve of the gauge is closed. Place the gauge in to fixture (T107569).

13. Increase the pressure to 250 mmHg. Allow the pressure to stabilize for 15 seconds.

Check for a leak.

14. Remove the bezel, crystal, pointer and dial.

Service Manual 95P504 Rev. D Welch Allyn Aneroid Sphygmomanometers 29

Page 37

Section 3

Repair and Calibration

Aligning the Sector Gear on the Classic Hand Gauge

15. Tighten all screws.

16. View the sector gear and ensure proper position. The sector gear is in the proper

position when the right edge of the sector gear is aligned with the mark on the base of the

movement.

17. If the sector gear not aligned properly, remove the two cover screws. Loosen the

capsule nut using a 3/8" wrench. Adjust the sector gear using a 5/16 wrench. Turn the

capsule sector gear until is in the correct position per step 16. Tighten capsule nut.

To set the tension of the Classic Hand Gauge

18. Loosen the sector stop lug and pull it towards the bottom of gauge.

19. Using your left index finger, push the sector gear all the way to the post and hold it in

that position.

20. Place the tension setting tool (T119628) onto pinion at the 9 o’clock position.

21. Rotate the tool clock wise to the 5 o’clock position.

22. Release the sector gear and continue rotation to the 9 o’clock position. The sector gear

should be moving during this step.

23. Bring the lug back to the correct position and lock it into place.

Setting the span of the Classic Hand Gauge

24. Place the test dial (T105721) onto the gauge. Place the test pointer onto the pinion.

Rotate the dial until the pointer is at pointing at "0".

25. Apply 320 mmHg of pressure to the gauge.

26. Bleed the pressure down to 300 mmHg.

27. If the pointer is pointing to less than "300", place the calibration tool (T106845A) into

the radius plate slot above screw. Rotate the calibration tool counter clockwise towards the

bottom of the gauge until the sector gear pointer reaches "300". Release the pressure to 0

mmHg and check at the "0" point.

28. If the pointer is pointing to greater than "300", using the calibration tool (T106845A)

positioned between the sector gear and the radius plate. Rotate the tool clockwise until the

pointer is at "300" (this brings the radius plate down). Release the pressure to 0 mmHg

and check the "0" point.

30 Welch Allyn Aneroid Sphygmomanometers Service Manual 95P504 Rev. D

Page 38

Repair and Calibration Section 3

29. If the pointer is not at "0" upon the release of pressure, rotate the test dial until the

pointer is on the "0" mark of test dial. Repeat steps 25-28 until the span is set.

Check and finish calibration of the Classic Hand Gauge

30. Remove the test pointer and test dial. Replace the gauge’s dial.

31. Apply a small amount of red Loctite #266 to the hub of the pointer. Place the pointer

onto the pinion and ensure it is resting in center of oval "0". Gently tap the pointer with a

small hammer to secure.

32. If the pointer is to the left of the oval/square’s center, rotate the pointer counter

clockwise until you feel a slight resistance. Release the pointer. Ensure the pointer returns

to the center of the oval/square "0". Repeat until correct.

33. If the pointer is to the right of the oval/square’s center, rotate the pointer clockwise

until a slight resistance is felt. Release the pointer. Ensure the pointer returns to the center

of the oval/square "0" each time. Repeat until correct.

34. Place the crystal and bezel back onto the gauge and check.

Testing of the Classic Hand Gauge

35. Connect the hand gauge to the test equipment.

36. Apply 320 mmHg of pressure to the gauge.

37. Release the pressure to 300 mmHg.

38. Compare the reading of the gauge to that of the calibrated digital pressure meter.

Test Specifications

39. The following are the pressure test points that each gauge must be tested to after any

repair is made. The gauge must be accurate to within "3 mmHg at the following test

pressures:

a) 0 mmHg (pointer inside the oval/rectangle)

b) 60 mmHg

c) 100 mmHg

d) 150 mmHg

e) 200 mmHg

f) 250 mmHg

g) 300 mmHg

Note: Calibration of all gauges must be performed using a Calibrated Digital Pressure

Meter as the pressure standard for complete accuracy.

Service Manual 95P504 Rev. D Welch Allyn Aneroid Sphygmomanometers 31

Page 39

Section 3

Repair and Calibration

Classic Hand Aneroid Gauge

Note: Before calibrating the Classic Hand Gauge:

a) Check pointer movement for sticky or jumpy movement

b) Check for bent pinion.

c) On gages with air release valve, check air release valve function.

d) Connect to test equipment and check for a leak.

e) Pump bulb to indicate between 250-300 mmHg. Actuate air release valve by

partially depressing button and observe for controllable deflation rate.

f) Fully depress button and observe for rapid dump rate (should be immediate).

g) On gages with button, check button function.

(Date stamp of October 2003 or later)

Replacing Parts of the Classic Hand Gauge

1. Pull the bulb off of the valve body.

2. Place the hand gauge into the hand gauge fixture (T107569).

3. Remove the bezel by unscrewing it counter clockwise from the case. Remove the crystal.

4. Remove the pointer by using the pointer removal tool (T18814).

5. Pry out the dial by using a small flat head screwdriver.

6. Remove the thumbscrew using tool (T113265 thumbscrew wrench). Turn the

thumbscrew counter clockwise to remove.

7. Remove the thumbscrew valve body using a 5/8" socket.

Note: Reassemble in reverse order. Ensure you tighten the movement down with torque

wrench (T18904) using adapter (T18891)

Calibration of the Classic Hand Gauge

8. Connect the gauge to the test equipment.

9. Ensure that the valve of the gauge is closed.

10. Increase the pressure to 250 mmHg. Allow the pressure to stabilize for 15 seconds.

Check for a leak.

11. Remove the bezel, crystal, pointer and dial.

Checking the Classic Hand Gauge Span

12. Place the test dial (T18781) onto the gauge. Place the test pointer onto the pinion.

Rotate the test dial until the pointer is at "0".

32 Welch Allyn Aneroid Sphygmomanometers Service Manual 95P504 Rev. D

Page 40

Repair and Calibration Section 3

13. Apply 320 mmHg to the Gauge.

14. Release the pressure to 300 mmHg.

15. Observe the position of the pointer. If the pointer does not align with the "300", go to

Average Zero Starting Position.

16. If the pointer does align with "300", go to Linearity Adjustment of the Classic Hand

Aneroid.

Average Zero Starting Position

17. Apply 60 mmHg of pressure to the gauge. Release the pressure to zero. Mentally note

where the test pointer is pointing on the test dial.

18. Apply a -20 mmHg of vacuum to the gauge. Release the pressure to zero. Mentally

note where the test pointer is pointing on the test dial.

19. Take the average of where the pointer was between step 17 and step 18. Rotate the test

dial’s zero mark to that averaged position.

Span Adjustment of the Classic Hand Aneroid

20. Apply 320 mmHg of pressure to the gage to then bleed down to 300 mmHg. Note

position and maintain pressure.

21. If the span is too low, using calibration tool (T18816), bend the adjustment pin away

from pinion parallel to gear sector arm. Change pressure to 0. Make sure to re-adjust the

test dial so that the pointer will be slightly left of the graduation line. Re-pressurize to

320 mmHg then to 300 mmHg to evaluate the effects of the adjustment.

22. If the span is too high, using calibration tool (T18816), bend the adjustment pin

towards the pinion parallel to the gear sector when pressurized at 300 mmHg. Change the

pressure to 0. Make sure to re-adjust the test dial so that the pointer will be slightly left of

the graduation line. Re-pressurize to 320 mmHg then to 300 mmHg to evaluate effects of

adjustment. See Figure 3-7.

23. Repeat the above steps as required to obtain correct span adjustment.

Service Manual 95P504 Rev. D Welch Allyn Aneroid Sphygmomanometers 33

Page 41

Section 3

Figure 3-7. S&K span adjustment.

Repair and Calibration

Linearity Adjustment of the Classic Hand Aneroid: (

As required

)

Note: If the 0 mmHg and 300 mmHg position are correct, and the other points at 250

mmHg or 60 mmHg are either too high or too low, then perform the following

adjustments.

High Readings of the Wall/Mobile Aneroid:

(Predominantly at 250 and 200)

24. Remove the test pointer and test dial. Position the calibration tool (T18816) over the

adjusting pin and push it down to the cross shaft. Move the gear sector with your finger of

other hand to allow access. Rotate the pin by pushing the sector gear, to move the hook

away from the diaphragm (approximately 15 degrees). While maintaining this position, lift

the tool up from cross shaft approximately 1/16 inch and bend the pin back approximately

15 degrees. See Figure 3-8. Lift the calibration tool up to the point where the pin makes

contact with the gear sector and bend the pin up, approximately 30 degrees.

Approximately 15 degrees

Approximately 30 degrees

Cross Shaft

Hook

Figure 3-8. S&K pin adjustment if reading is high at 250 mmHg.

34 Welch Allyn Aneroid Sphygmomanometers Service Manual 95P504 Rev. D

Page 42

Repair and Calibration Section 3

25. Remove the tool and release the gear sector. The resultant bend should result in the

gear sector starting position being a max. of 2 teeth extending beyond the top plate when

viewed from a top position and a minimum of 2 teeth within the edge of the top plate.

(This must be checked by pushing the gear sector 2 teeth from the other side of the top

plate). Adjust the secondary bend if the gear sector is out of these limits. Re-assemble the

test dial and test pointer. Recheck span and adjust as necessary prior to inspecting the

intermediate points.

Low Readings of the Classic Hand Aneroid at 60 or 100

26. Remove the test pointer and test dial. Position the calibration tool over the adjusting

pin and push it down to the cross shaft. Lift the tool approximately 1/16 inch and bend the

pin approximately 15 degrees. See Figure 3-9. While maintaining this position, lift the tool

to point where the pin makes contact with the gear sector. Bend the pin down 30 degrees.

Remove the tool and release the gear sector. Check for gear sector starting position as

defined previously. Adjust if necessary. Re-assemble the test dial and test pointer. Recheck

the span and adjust as necessary prior to inspection at the intermediate points.

Approximately 15 degrees

Figure 3-9. S&K pin adjustment if reading is low at 60 mmHg.

Approximately 30 degrees

Note: In all adjustments during calibration, the gear sector starting position will affect

accuracy. Sometimes, this alone can be used as an individual adjustment to achieve

conformance. Higher readings will be realized when the gear sector is extending beyond

the edge of the top plate and lower readings will be realized when it is within the edge of

the top plate.

27. Check for leaks by pinching off the tubing from the test equipment while pressure is

applied to the gauge. There should be no leakage or movement of the pointer.

Check and finish the calibration of the Classic Hand Gauge

28. Remove the test pointer and test dial. Replace the gauge’s dial.

Service Manual 95P504 Rev. D Welch Allyn Aneroid Sphygmomanometers 35

Page 43

Section 3

Repair and Calibration

29. Apply a small amount of red Loctite #266 to the hub of the pointer. Place the gauge’s

pointer onto the pinion. Ensure that it is resting in the center of the oval. Gently tap the

pointer with small hammer to secure or use (T112697) pointer assembly tool.

30. Place the crystal and bezel back onto the gauge and test the gauge.

31. The following are the pressure test points that each gauge must be tested to after any

repair is made. The gauge must be accurate to within "3 mmHg at the following test

pressures:

a) 0 mmHg (pointer inside the oval/rectangle)

b) 60 mmHg

c) 100 mmHg

d) 150 mmHg

e) 200 mmHg

f) 250 mmHg

g) 300 mmHg

Note: Calibration of all gauges must be performed using a Calibrated Digital Pressure

Meter as the pressure standard for complete accuracy.

36 Welch Allyn Aneroid Sphygmomanometers Service Manual 95P504 Rev. D

Page 44

Repair and Calibration Section 3

Economy Aneroid Gauge

Note: Before performing calibration:

a) Check the clip for correct tension. Replace before calibration.

b) Ensure the lock nut is tight.

c) Check the hair spring. Ensure that the hair spring is uniform and not distorted.

d) Check the pinion. Ensure that it rotates correctly and is not bent.

(Stopped production on 7/15/03)

Replacing Parts of the Economy Gauge

1. Remove the two screws from the back of the case using a phillips head screwdriver.

2. Remove the Economy cover and the crystal.

3. Remove the pointer using the pointer removal tool (T18814).

4. Pry the dial from the case using a small flat head screwdriver.

5. Remove the movement from the case using (T108897).

6. Loosen the screw from the case using (T105258) and remove the capsule.

Note: Reassemble in reverse order. Use 3M Plastic Adhesive #1099 to secure the dial onto

the case.

Calibration of the Economy Gauge

7. Connect the gauge to the test equipment.

8. Place the gauge in to fixture (T108212)

9. Remove the bezel, crystal, pointer and dial.

Aligning the Sector Gear of the Economy Gauge

10. Tighten all screws.

11. View the sector gear and ensure it is in the proper position. The right edge of sector

gear should align with the mark on base of the movement.

12. If the sector gear not aligned properly, loosen the capsule nut using wrench (T105258).

Adjust the sector gear by turning the capsule until sector gear is in correct position per step

#11. Tighten the capsule nut.

Setting the tension of the Economy Gauge

13. Loosen the sector stop lug with (T112772) and pull it towards the bottom of the

gauge.

Service Manual 95P504 Rev. D Welch Allyn Aneroid Sphygmomanometers 37

Page 45

Section 3

Repair and Calibration

14. Using your left index finger, push the sector gear all the way to the post and hold it in

that position.

15. Place the tension setting tool (T119628) onto the pinion at the 9 o’clock position.

16. Rotate the tool clock wise to the 5 o’clock position.

17. Release the sector gear and continue rotation to the 9 o’clock position. The sector gear

should be moving during this step.

18. Bring the lug back to the correct position and lock it into place.