Page 1

Audio Menu

Service Manual

Operating

Instructions

Page 2

Contents

Section 1 — Introduction

1.1 Description ...................................................................1

1.2 Unpacking and Inspection ............................................ 1

1.3 Connectors, Controls and Indicators............................ 2

1.3.1 The Front Panel Controls and Indicators (Fig. 1-1).... 3

1.3.2 Rear Panel Connectors and Indicators (Fig. 1-1)....... 3

1.3.3 Symbols .................................................................... 3

1.4 Installation..................................................................... 4

1.5 Pre-Test Procedure ...................................................... 4

1.5.1 Pre-Test Noise Recover Period ................................. 5

1.5.2 Elimination of Ambient Noise..................................... 5

Section 2 — Battery Option

2.1 Description ...................................................................6

2.2 NiCad Battery Operation .............................................. 6

2.3 Recharge NiCad Batteries ............................................ 7

2.4 To Replace NiCad Batteries ......................................... 8

2.5 Alkaline Battery Installation/Operation .......................... 9

Section 3 — Operation

3.1 Preliminary Check.......................................................10

3.2 Instructing the Subject................................................ 10

3.3 Placement of Earphones.............................................11

3.4 Response Handswitch................................................ 11

3.5 Audiogram Form......................................................... 11

3.6 Routine Calibration Check .......................................... 12

3.7 Routine Test Administration........................................ 12

3.7.1 HL Control (F3) ........................................................ 12

3.7.2 Range Extension Push-Button (F2) ......................... 12

3.7.3 Tone Type Selector (F9) .......................................... 13

3.8 Typical Testing Session .............................................. 13

3.8.1 Pre-Test Review ...................................................... 13

3.8.2 Familiarization.......................................................... 13

3.8.3 Threshold Determination (Pure Tone) ...................... 14

3.8.4 Testing Procedure ................................................... 14

Section 4 — Routine Maintenance

4.1 Calibration...................................................................15

4.2 Earphone Cords ......................................................... 15

4.3 Hum and Random Noise ............................................15

4.4 Distortion and Frequency Shift ................................... 15

4.5 Special Messages....................................................... 16

4.5.1 CAL .........................................................................16

4.5.2 Exx ..........................................................................16

Service and Warranty Information

Service and Repair................................................................ 17

Recalibration ......................................................................... 17

Warranty ...............................................................................17

Rechargeable Battery Warranty ............................................ 17

Specifications ................................................................18

Bibliography ................................................................... 20

Page 3

Section 1 — Introduction

1.1 DESCRIPTION

The Welch Allyn AM 232 Manual Audiometer is a single-channel, pure

tone, air conduction, portable instrument designed to provide basic

audiometric capability for physicians’ offices, schools and industry. The

lightweight design allows easy transport to a variety of testing locations

and the built-in storage cavity and case provide enough room to contain

all instrument accessories. The clearly labeled front panel controls and

full frequency range make accurate, reliable testing a simple matter for

any user.

The Welch Allyn AM 232 Manual Audiometer is a precisely designed

and calibrated instrument. With proper care it will deliver accurate

sound-pressure levels for years to come. The Welch Allyn AM 232

Manual Audiometer should be recalibrated yearly (or sooner if a problem develops). See Section 4.

1.2 UNPACKING AND INSPECTION

Although your Welch Allyn AM 232 Manual Audiometer was carefully

tested, inspected and packed for shipping, it is good practice after receiving the instrument to immediately examine the outside of the container for any signs of damage. Notify your distributor if any damage is

noted.

Carefully remove your Welch Allyn AM 232 Manual Audiometer from its

shipping container. If the instrument appears to have suffered mechanical damage, notify the carrier immediately so that a proper claim can be

made. Be certain to save all packing materials so that the claim adjuster

can inspect it as well. As soon as the carrier has completed the inspection, notify your Welch Allyn representative.

If the instrument must be returned to the factory, repack it carefully (in

the original container if possible) and return it prepaid to the factory for

necessary adjustments.

Check that all accessories itemized in Table 1-1 are received in good

condition. If any accessories are missing, contact your Welch Allyn representative immediately. See Specifications Section of this manual for

the catalog numbers of accessories and also for a listing of optional

accessories.

TABLE 1-1: Accessories Supplied

Test Headset Assembly (TDH39)

Audiogram Pad (1 Pad of 50)

Battery Pack Assembly (used with model #23210 and #23215 only)

AC Power Cord

1

Page 4

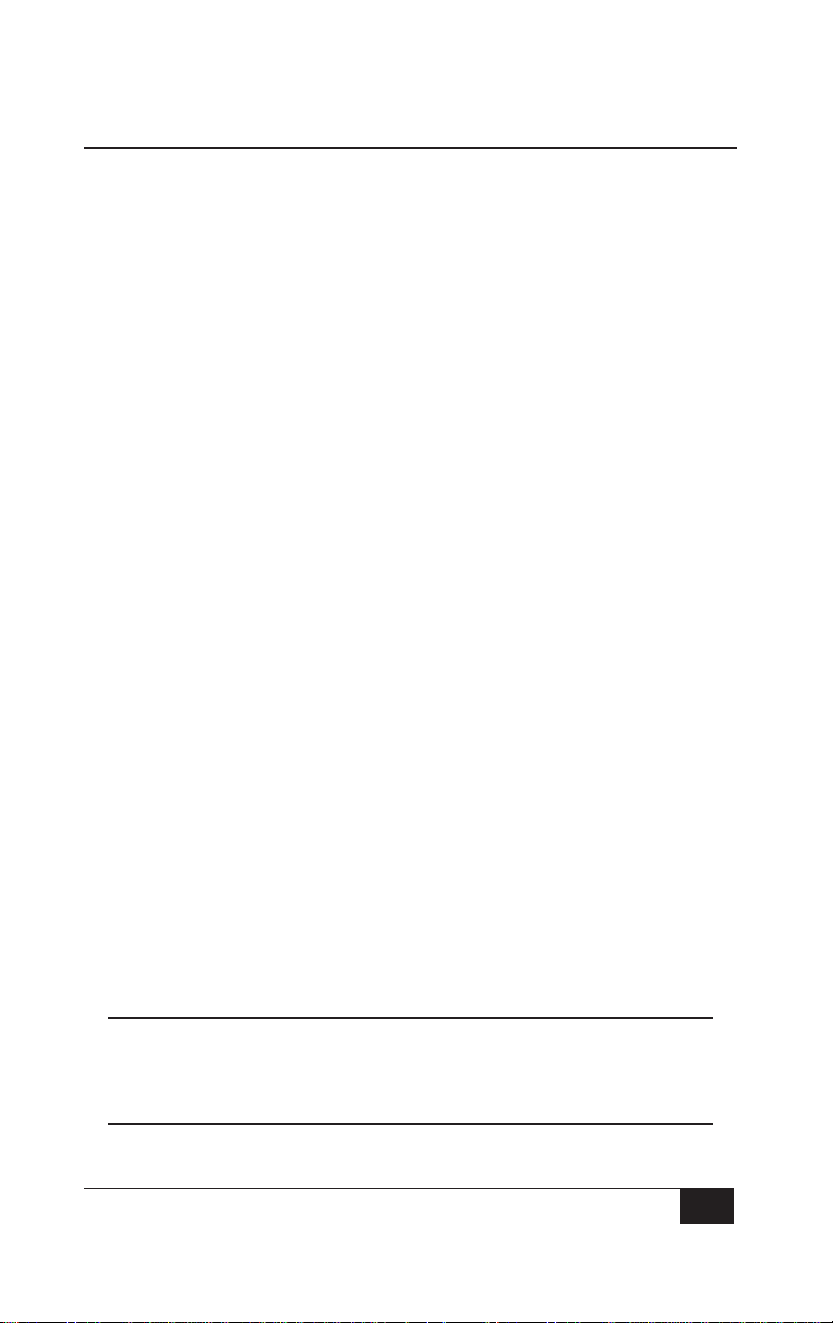

1.3 CONNECTORS, CONTROLS AND INDICATORS

FIGURE 1-1: Front and Rear Panel

F2

Front Panel

F1

F3

F10

LO BAT

F4

F3

90

F5

F8

F9

F6

F7

Rear Panel

2

R3 R2

12 VDC

200 MM

R1

Page 5

1.3.1 The Front Panel Controls and Indicators (Figure 1-1)

F1 Power switch and indicator for ON and OFF

F2 Range extension push-button allows operator to increase the

stimulus intensity 10 dB above the standard maximum HL at

any frequency. When in use, a “+” appears on the LCD.

F3 HL control for setting stimulus intensity level. Level is indicated

on LCD.

F4 Present bar for stimulus presentation.

F5 Stimulus being presented via earphone. Presentation indicated

by illuminated green LED.

F6 Subject response indicator shows the operator when the test

subject has pressed the handswitch button by an illuminated

green LED (with optional handswitch only).

F7 Control for setting stimulus frequency. Frequency is indicated

in window adjacent to control.

F8 Routing switch for stimulus presentation to the earphone. Left

or right indicated by illustration of subject.

F9 Switch for setting the stimulus tone type.

FM = warble tone

= steady tone

= pulsed tone

F10 Low battery indicator to alert the operator of a limited oper-

ating time. Recharge or replace batteries (dependent on

whether NiCad or Alkaline batteries are used).

1.3.2 Rear Panel Connectors and Indicators (Figure 1-1)

R1 Power input jack (5-pin DIN Connector) with front panel illus-

tration showing its location and a rear panel label giving the

input power specifications.

R2 Earphone output jacks (standard phone jacks). Front panel

illustration shows left and right phone.

R3 Response handswitch input jack (standard phone jack) with

front panel illustration showing location.

1.3.3 Symbols

Attention, consult accompanying document for instructions or

warnings pertaining to these parts.

Entry by qualified service personnel only.

This symbol is located inside the storage compartment.

It denotes a Type B, Class II product per IEC 878 as referenced in IEC 601 Standard.

3

Page 6

1.4 INSTALLATION

Warning

The AM 232 Manual Audiometer is designed to be used with a hospital grade

outlet. Injury to personnel or damage to equipment can result when a threeprong or two-prong adapter is connected between the AM 232 Manual Audiometer power plug and an AC outlet or extension cord. Additionally, the AM 232

Manual Audiometer is equipped with a specific power transformer which

should not be interchanged with any other transformer or supply.

The above symbol indicates the location of a service adjustment part and is

intended for service personnel use only. The AM 232 Manual Audiometer is

a specifically calibrated audiometer and the periodic service and adjustments

which the instrument may require should be done only by an authorized Welch

Allyn service technician.

Plug the power module into the appropriate jack (R1) on the back panel

of the instrument, then plug the other end into a line power (mains) outlet.

Plug the earphones into the earphone jacks (R3) on the rear panel. Note

the symbol along the top of the front panel which indicates which is

right and which is left. The right earphone is red, the left earphone

is blue. Turn the power switch to ON.

NOTE

For battery operation, please refer to Section 2.

1.5 PRE-TEST PROCEDURE

NOTE

The AM 232 Manual Audiometer is a versatile audiometer designed for use in

doctors’ offices, schools, industrial settings, the military, etc. This manual,

therefore employs the generic term “subject” to identify the person whose

hearing is being evaluated.

Although the AM 232 Manual Audiometer is simple enough to be operated by practically anyone, any program aimed at obtaining reliable records of hearing thresholds should be staffed and supervised by appropriately-trained individuals. Training courses leading to certification are

available for audiometric technicians in most urban areas.

Two prerequisites are of particular importance to the procurement of

reliable audiograms:

• Prior to testing, allow adequate time for the subject to recover

from the effects of previous exposure to high-level sound.

• Tests should be done in a quiet area.

4

Page 7

1.5.1 Pre-Test Noise Recover Period

Exposure to high levels of sound (unmuffled lawn mowers, many power

tools,

loud music, gunfire) tends to create a temporary threshold shift

(TTS) which diminishes with time after exposure. Any subject tested

soon after such exposure may manifest a hearing loss that does not reflect his or her normal hearing threshold. It is, therefore, important that

the testing procedure prescribe some time interval — usually at least 16

hours — between the last exposure to high-level sound and the administration of any hearing test.

1.5.2 Elimination of Ambient Noise

Excessive noise in the test environment such as that produced by conversation, typewriters, or other machines also reduces test validity because it tends to mask the test signals, particularly at the lower frequencies where earphone cushions provide less effective attenuation.

An acoustically-tested room may be required if ambient noise at the

subject’s ears reaches an objectionable level—i.e., sufficient to cause

apparent hearing loss at the low frequencies. Also, Audiocups are available from Welch Allyn as an optional accessory. If the test subject is in

the same room as the audiometer, it is recommended that the subject

be seated about one meter (3 ft) away from the instrument.

Maximum permissible test environment sound-pressure levels are specified by American National Standard Criteria for Permissible Background Noise during Audiometric Testing, S3.1-1991. Table 1-2 shows

the maximum background levels that can be present inside the room

while a valid hearing test is being conducted. For more comprehensive

information about hearing testing and hearing conservation, refer to the

Bibliography.

TABLE 1-2: Permissible Noise Levels

Test Tone

Frequency (Hz) 125 250 500 750 1000 1500 2000 3000 4000 6000 8000

Test Room

Ears covered 34.0 22.5 19.5 21.5 26.5 26.5 28.0 33.5 34.5 38.0 43.5

maximum

permissible octave

band levels

Ears covered

maximum

permissible one-third

octave band levels

29.0 17.5 14.5 16.5 21.5 21.5 23.0 28.5 29.5 33.0 38.5

5

Page 8

Section 2 — Battery Option

2.1 DESCRIPTION

This section describes the battery option of the AM 232 Manual Audiometer. It pertains only to those customers who purchased Models

#23210 or #23215 with the battery pack installed or to those who later

purchased the #72329 Battery Pack Assembly. In both cases, a rechargeable NiCad battery is included.

2.2 NiCad BATTERY OPERATION

The AM 232 Manual Audiometer battery option is supplied with an installed, rechargeable NiCad battery pack. It requires about 18 hours to

fully charge and will provide about 22 hours of continuous operation

when fully charged. The green LED on the pack itself will be lit when

charge is getting low so the operator will know when to recharge the

batteries. When LO BAT appears, the instrument will operate (continuously) for about two more hours before it shuts down completely.

NOTE

In no instance will loss of battery power affect instrument calibration.

To save battery life, the AM 232 Manual Audiometer has a special

“sleep mode” in which the audiometer will shut down after five minutes

of no operation. The operator will know the instrument is “asleep” because the LCD will show three dash lines (---). To “wake up” the instrument the operator only needs to press the present bar. There is no

danger of presenting a loud tone to the test subject when the instrument “wakes up” because no tone is presented until the audiometer

is awake. In addition, the instrument automatically resets its output to

0 dB HL.

If the AM 232 Manual Audiometer is operated until the battery charge

has dropped below an acceptable voltage level, the instrument will not

function at all. The display will be blank except for the LO BAT indica-

tion, and the controls will not function. To restore operation, the batteries must be recharged for some period of time up to 18 hours (full

charge), or line power (mains) may be used. If the audiometer is operated using line power (mains) with the rechargeable batteries in place,

some battery charging will occur.

6

Page 9

2.3 RECHARGE NiCad BATTERIES

A

B

FIGURE 2-1: NiCad Battery Recharge

Refer to Figure 2-1 when recharging NiCad batteries and proceed as

follows:

a. Be certain that the battery pack power cord is connected to the

power cord receptacle on the back panel of the audiometer (A).

b. Connect the instrument power cord to the receptacle on the

lower edge of the battery pack (B).

c. Plug the power cord into a wall outlet.

CAUTION

Although no damage to the rechargeable NiCad batteries will occur if the pack

is left charging for more than the 18 hours required for a full charge, the batteries

should not be left charging for extended periods (i.e., several days) because

the useful life of the rechargeable NiCad pack will be shortened. Welch Allyn

recommends unplugging the battery pack power input cord from the back of

the audiometer and plugging the main line power cord into the jack if main line

power is to be used most of the time.

7

Page 10

2.4 TO REPLACE NiCad BATTERIES

Please refer to Figures 2-2, 2-3, 2-4 and proceed as follows:

a. Unplug the AM 232 Manual Audiometer from the line power (mains).

b. Remove the two screws on the battery pack cover and lift off the

cover.

c. Pull the NiCad battery out of the pack. The battery is actually a set

of six batteries wrapped in plastic, but they will be removed as a

single unit.

FIGURE 2-2: FIGURE 2-3: FIGURE 2-4:

Battery Cover NiCad Battery Pack Internal View of

Removal Removal Battery Compartment

d. Carefully disconnect the lead wires of the NiCad battery from the

battery compartment by removing the small connector. Remove

NiCad pack.

e. Attach the lead wire connector on the new NiCad battery to the

mating connector within the battery pack base. Place the new

NiCad into the battery pack.

f. Replace the battery pack cover. There is only one way that the

cover can be replaced and the screws tightened. Note that the

screw housing is longer on one end. Orient the top cover so that

it will sit flat on the top of the battery compartments and replace

screws.

8

Page 11

2.5 ALKALINE BATTERY INSTALLATION/OPERATION

For longer continuous battery operation, such as periods when recharging on a regular basis is not possible, the rechargeable batteries can be

replaced with six size C alkaline batteries. These batteries will provide

about 45 hours of continuous operation.

The low voltage indicator works the same way for the alkaline batteries

as it does for the NiCad batteries. The words LO BAT will appear on

the LCD when about six hours of continuous battery operation remain.

In addition, the “sleep mode” also works with the alkaline batteries to

prolong their useful life.

To install the alkaline batteries, refer to Figures 2-2, 2-3, 2-4, and

proceed as follows:

a. Unplug the AM 232 Manual Audiometer from the line power (mains).

b. Remove the two screws on the battery pack cover and lift off the

cover.

c. Pull the NiCad battery out of the pack. The battery is actually a set

of six batteries wrapped in plastic, but they will be removed as a

single unit.

d. Carefully disconnect the lead wires of the NiCad battery from the

battery compartment by removing the small connector. Remove

NiCad pack.

e. There are six spring mounts on the top and bottom of the battery

compartment to hold the alkaline batteries. The label on the bottom surface of the compartment indicates the correct position for

each battery. Place each one of the six batteries into the pack

matching the polarity (+ or -) as shown on the label.

f. Replace the battery pack cover. Make certain that the cover is po-

sitioned with the spring mounts touching the batteries. There is

only one way that the cover can be replaced and the screws tightened. Note that the screw housing is longer on one end. Orient

the top so that it will sit flat on top of the battery compartment and

replace screws.

NOTE

If the alkaline batteries are not going to be used on a regular basis, they

should NOT be stored in the audiometer. They should be removed from the

battery pack and stored in a cool, dry place.

9

Page 12

Section 3 — Operation

Throughout this section there are references to front panel (F) and rear

panel (R) connectors, controls and indicators. Please refer to Section 1.3

and Figure 1-1 for specific descriptions and locations.

3.1 PRELIMINARY CHECK

Prior to testing, ensure that the power cord and earphone cords are

plugged in (R1 and R2 respectively). Turn the audiometer on, select the

desired tone type (F9—pulsed, steady or FM) and make whatever notations your procedure requires on the audiogram form.

CAUTION

Always handle earphones with care. Neither drop them nor permit them to be

squeezed together. Severe mechanical shock may change their operating

characteristics and require their replacement.

IMPORTANT

Always clean and maintain your earphone cushions, for hygiene purposes.

Check periodically for cracking or signs of wear. Cleanse cushions daily or

after each use (depending upon population being tested). Use a solution of

diluted alcohol or mild soap and water, taking care not to get any of the

cleaning solution into the earphone speaker. Use earphones only when

completely dry. Insert the earphone cords between the earphone cushions

during storage to prevent damage from mechanical shock.

3.2 INSTRUCTING THE SUBJECT

The operator should put the subject as much at ease as possible

before the test begins. In addition, he/she should try to make the

subject understand how the test is to be conducted and what the

subject will hear. For the sake of uniformity, an unvarying explanation

is advisable—something close to the following:

“I am going to place these earphones over your ears. You

will hear a variety of tones—some high, some low, some

loud, some very soft. Whenever you hear, or think you hear

one of those sounds, raise your hand. Lower your hand

when you no longer hear the sound.

“Remember that though some of the tones will be easy to

hear, others will be very faint. Therefore, you should listen

very carefully and raise your hand whenever you think you

hear the tone.”

Modify the instructions accordingly if the optional response

handswitch is to be used.

10

Page 13

3.3 PLACEMENT OF EARPHONES

The most important thing to remember is that a good seal is required

between the earphone cushion and the subject’s head and ear. To

increase the likelihood of a good seal:

a. Eliminate all obstruction between earphone and subject (hair,

eyeglasses, earrings, hearing aids, etc.).

b. Adjust the headband so that it rests solidly on the crown of the

subject’s head and exerts firm pressure on both ears.

c. Center earphones carefully over both ears—earphone with red

connector on right ear. Take care to eliminate any visible gaps

between earphone cushions and portions of the subject’s head

and the ear on which the cushion rests.

3.4 RESPONSE HANDSWITCH

If the optional Response Handswitch is to be used, insure that the

plugs and jacks are properly connected. The subject response indicator on the front panel will be illuminated when the subject presses the

response button.

3.5 AUDIOGRAM FORM

The AM 232 Audiogram Form (see Figure 3-1) consists of three distinct

parts:

• Space for entering information about the person to be tested.

• A convenient chart for manually plotting test data.

• Space for entering comments about the subject or the test.

Name

Age Sex Date Time

Job Description

-10

0

10

20

30

40

50

60

ISO 389-1985 ANSI S3.6-1989

HEARING LEVEL IN DECIBELS

70

80

90

100

110

120

Customer Reorder No. 52300

500

1000

750

250

1500 2000 3000 4000 6000 8000

TONE FREQUENCY (Hz)

FIGURE 3-1: Audiogram Form

AM 232 AUDIOGRAM

Audiometer Model No.

Serial No.

Examiner

Signature

COMMENTS

Right

SYMBOLS

Response

Ear

Left

Response

No

Printed in U.S.A.

Phone

Blue

Red

232002

11

Page 14

3.6 ROUTINE CALIBRATION CHECK

The microprocessor-controlled circuitry and quality construction of the

AM 232 Manual Audiometer will provide long and reliable service. It is

good practice, however, to make and file, at the start of each month’s

testing, the audiogram of a single subject or of a small group of subjects

who are likely to be routinely available for this purpose. Where physical

arrangements permit, the operator can serve as a subject.

This procedure should commence when the audiometer is installed,

and be performed each month thereafter. If the AM 232 Manual Audiometer is to be used to monitor employee thresholds as part of an industrial Hearing Conservation Program, this “biological listening check”

must be done at the beginning of each day the audiometer is to be

used (per CFR 1910.95 Occupational Noise Exposure, March 8, 1983).

Since individual thresholds can shift up or down as much as 5 dB from

one day to the next, variation within this range may be considered acceptable. Variations that exceed this range, however, are likely to reveal

problems that require attention. The routine maintenance checks described in Section 4 may suggest the source and solution to the problem. If they do not, the instrument should receive technical service by a

certified technician before further use.

3.7 ROUTINE TEST ADMINISTRATION

3.7.1 HL Control (F3)

The HL control will increase or decrease the presented intensity in

5 dB HL steps with the currently available intensity appearing on the

LCD. Rotating the control knob clockwise increases the intensity. Rotating the control knob counter-clockwise decreases intensity. When

the maximum or minimum available intensity is reached for any frequency, the display will flash to alert the operator he/she cannot exceed the available range.

3.7.2 Range Extension Push-Button (F2)

This control allows the operator to present tones of up to 10 dB above

the standard maximum HL at any frequency. It will only function when

the intensity is set within 10 dB below the maximum standard intensity

at any frequency. This feature requires an extra step to access or use

the highest available intensities, requiring the operator to make note of

those individuals requiring testing at these levels. It also prevents accidental presentation of the highest intensities to normal subjects, and it

alerts the operator to present the stimulus for only brief periods of time.

12

Page 15

To enable the range extension feature, simply push the button labeled

+10 dB. Note the appearance of the “+” sign on the LCD. To disable

the feature, either push the button a second time, reduce the intensity

(with the HL control knob) to 20 dB below the standard maximum HL,

or change any other parameter (frequency knob, routing switch).

3.7.3 Tone Type Selector (F9)

This control allows the operator to choose the type of tone presented

to the test subject. It can be set on steady, pulsed (2.5 pulses per

second) or FM (warble tone). Pulsed tones and warble tones are often

used with difficult-to-test subjects, such as children and hard-of-hearing

individuals, because they hold the subject’s attention better than the

steady tone.

3.8 TYPICAL TESTING SESSION

3.8.1 Pre-Test Review

a. Turn the instrument on.

b. Check that the earphones are operating properly.

c. Seat subject comfortably in the test area.

d. Explain the test procedure.

e. Assist subject with the earphones.

f. Select the desired tone type.

g. Make appropriate entry on the subject’s audiogram.

3.8.2 Familiarization

a. Set the routing selector to route the test tone to the selected ear.

Demonstrate the 1000 Hz tone at a 40 dB level. Duration of tone

should be between one and two seconds.

b. Set HL control to -10 dB.

c. Practice: Beginning with the tone continuously on (Present Bar held

down) gradually increase the intensity by turning the HL control

until a response occurs. Switch the tone off for at least two seconds

and present the tone again at the same level. If there is a second

positive response, proceed to threshold measurement. If a second

response does not occur, repeat this step. Practice is preliminary

to threshold measurement determination and is to be completed at

each new frequency setting.

13

Page 16

3.8.3 Threshold Determination (Pure Tone)

a. The level of the first presentation shall be 10 dB below the level at

which the subject responded during the familiarization procedure.

Present the tone for a period of one or two seconds. Time between

tones can be varied, but not shorter than the duration of the test

tone itself. After each failure to respond to a signal, the level is in-

creased by 5 dB until the first response occurs. After the response,

the intensity is decreased 10 dB and another ascending series

is begun.

NOTE

Descend in 10 dB steps and ascend in 5 dB steps.

b. The threshold is considered to be the minimum dial setting at

which a response has occurred two out of three times. Record

this setting on the audiogram form.

3.8.4 Testing Procedure

a. Repeat 3.8.2 and 3.8.3 for each tone-setting in the following order:

1000, 2000, 3000, 4000, 6000 and 8000 Hz. Retest 1000 followed

by 500 and 250. If there is a difference of 20 dB or more between

two successive octaves, test the inter-octave responses, i.e. 750,

1500, 3000 Hz. Record this information on the audiogram form.

b. Repeat process (3.8.2, 3.8.3, 3.8.4) for the other ear.

14

Page 17

Section 4 — Routine Maintenance

4.1 CALIBRATION

The biological listening check, or routine check, should be performed at

least monthly (see section 3.6 for description and explanation).

The following checks should be made at periodic intervals, even if routine

calibration checks do not reveal any problems. These procedures presuppose normal hearing on the part of the person doing the checking.

4.2 EARPHONE CORDS

With extended use, earphone cords tend to fray internally at the junctions of both earphone and audiometer connectors. This fraying will

ultimately either decrease the signal level in the associated earphone

or cause signals to be intermittent as the cord is flexed.

To check for either condition, set the audiometer frequency control (F7)

to 1000 or 2000 Hz, set HL control (F3) at a comfortable audible level,

press the Present Bar (F4) and flex earphone cord next to plug at both

ends, listening for intermittent signal, abrupt changes in signal level, or

a scratchy sound superimposed over the signal that coincides with the

flexing of the cord. The presence of any of these three conditions signifies

that the cord should be replaced.

Repeat the test for the other earphone.

4.3 HUM AND RANDOM NOISE

This test can be made during the check for attenuator noise. With the

instrument set on 1000 Hz, move the HL control (F3) from 0 to 60 dB

and listen for low-frequency hum (60 to 120 Hz) and random noise (hiss

or low rushing sound) at all attenuator levels. Some audible random noise

at levels above 60 dB is permissible. Below 60 dB, however, only the

signal should be audible. Any of these noises can be confused with the

signal by naive subjects and affect the accuracy of the audiogram. Schedule the audiometer for immediate service if any of the three is detected.

4.4 DISTORTION AND FREQUENCY SHIFT

This check can be best made by listening to the output of the AM 232

Manual Audiometer through the earphones while presenting all 11 frequencies at a loud, but not uncomfortable, level (70 to 80 dB HL for

normal ears).

Listen for rattling, rasping or distortion in the tones presented. Listen also

to ascertain that signal frequencies change plausibly when the frequency

selector (F7) is moved to a new position. If distortion is heard in one

earphone but not in the other, the chances are high that the earphones

are at fault and should be replaced. In any case, the audiometer should

be scheduled for immediate maintenance.

15

Page 18

4.5 SPECIAL MESSAGES

The AM 232 Manual Audiometer is a microprocessor-controlled instrument which performs a self-check each time the instrument is turned

on (the self-check does not occur when instrument operation resumes

from sleep mode). Certain messages will be displayed to the operator

on the front panel LCD if any error in the instrument operation is detected. These messages are described below.

4.5.1 CAL

When a transducer or frequency is selected which has a calibration

error (e.g., right earphone at 2000 Hz), the word “CAL” will be displayed to the operator. The audiometer will not function at this frequency

with this transducer, so that no invalid results can be recorded. The word

“CAL” will be displayed as long as the “problem” transducer and frequency are selected. If the calibration error is an isolated situation,

changing either the frequency or the transducer (e.g., left earphone at

3000 Hz) will restore normal instrument function.

As in the case with any instrument malfunction, a certified service technician should be contacted immediately. Remember to make note of

the combination of transducer and frequency which resulted in the

“CAL” message.

4.5.2 Exx

When an error code consisting of an “E” and a two-digit number

(xx = number) appears on the audiometer’s display, a system error has

been detected. The AM 232 Manual Audiometer will enter a “lock-out”

mode which will not permit the instrument to operate. The specific error

code will remain on the display for several seconds, then the instrument

will shut itself down completely. Should an Exx appear on the LCD, take

the following steps:

a. Power down, power up again. This could be only a temporary

failure and may never appear again. However, should the Exx

message appear again, proceed to steps b. and c.

b. Write down the numbers that appear on the display.

c. Contact your certified service representative and give them the

specific numbers you have recorded.

16

Page 19

Service and W arranty Information

SERVICE AND REPAIR

Repair must be performed by authorized personnel. Failure to do so

invalidates the AM 232 Manual Audiometer warranty.

For customers in the United States or Canada, please contact Welch

Allyn for information on where to return your AM 232 Manual Audiometer for service.

Technical Service Department Technical Service Department

Welch Allyn, Inc. Welch Allyn Canada Limited

1 Westchester Drive 160 Matheson Boulevard, East

Milford, NH 03055-3056 U.S.A. Mississauga, Ontario, Canada L4Z 1V4

Tel.: 1-800-535-6663 Tel.: 1-800-561-8797

(In U.S.A. only) (in Canada only)

RECALIBRATION

Welch Allyn recommends that the AM 232 Manual Audiometer be recalibrated annually. Arrangements may be made by returning the instrument

registration card or by contacting Welch Allyn’s Technical Service Department (as listed above). A moderate fee is charged for recalibration.

WARRANTY

NOTE

Return of the instrument registration card is required for proof of purchase and

warranty validation.

Welch Allyn, Inc. warrants the AM 232 Manual Audiometer to be free of original

defects in material and workmanship and to perform in accordance with manufacturer’s specifications for a period of one year from the date of purchase. If

this instrument or any component thereof is found to be defective or at variance from the manufacturer’s specifications during the warranty period, Welch

Allyn will repair, replace or recalibrate the instrument or component(s) at no

cost to the purchaser.

This warranty only applies to instruments purchased new from Welch Allyn or

its authorized distributors or representatives. The purchaser must return the instrument directly to Welch Allyn or an authorized distributor or representative

and bear the costs of shipping.

This warranty does not cover breakage or failure due to tampering, misuse,

neglect, accidents, modification or shipping and is void if the instrument is not

used in accordance with manufacturer’s recommendations or if repaired or

serviced by other than Welch Allyn or a Welch Allyn authorized representative.

No other express or implied warranty is given.

RECHARGEABLE BATTERY WARRANTY

Welch Allyn nickel-cadmium batteries are guaranteed by Welch Allyn for two

years from date of manufacture (when used in Welch Allyn instruments only).

Defective batteries will be replaced on a pro rata basis should failure occur

prior to expiration date on battery.

17

Page 20

Specifications

Standards

The AM 232 meets ANSI S3.6 and IEC 645 Type 4 Audiometer Standards,

and IEC 601-1, CSA C22.2 No. 601-1, and UL 544 electrical standards.

Frequency Range

Discrete Frequencies:

125, 250, 500, 750, 1000, 1500, 2000, 3000, 4000, 6000, 8000 Hz

Accuracy: ±3%

Total Harmonic Distortion: <2%

Intensity

Ranges:

125 Hz, _10 to 50 dB HL

500 to 6000 Hz, _10 to 90 dB HL

250 and 8000 Hz, _10 to 70 dB HL

(increments of 5 dB steps)

NOTE

A “+10” dB switch extends maximum at all frequencies by 10 dB.

Accuracy:

125 to 4000 Hz, ±3 dB

6000 to 8000 Hz, ±5 dB

Signal to Noise Ratio: >70 dB

Tone Type

Rise/Fall Time: 20 to 50 msec

Continuous: Steady when present bar depressed

Pulse: 2.5 pulse/Sec

FM: 5 Hz, ±5%

Headset

Telephonics TDH39 Earphones with MX41AR Cushions

(60 ohm impedance)

Power

Line Voltage: 100 to 120 V or 200 to 250 V (±10%)

Range: 50 to 60 Hz (±5%)

Consumption: 9 Watts

Battery

Types: Rechargeable (NiCad) or Non-Rechargeable (Alkaline)

Range: 7.0 V to 9.0 V

Capacity:

NiCad—22 hours continuous operations

Alkaline —45 hours continuous operations

18

Page 21

Environmental

Temperature:

Operating, 60° F to 105° F (15° C to 40° C)

Storage, Powerline _40° F to 140° F (_40° C to 60° C)

Storage, Battery _40° F to 105° F (_40° C to 40° C)

Humidity: 5% to 90%

Warm-up Time: 10 minutes for instruments stored at room temperature

Mechanical

Dimensions: 13.25" W x 14" D x 3.75" H

(33.66 cm x 35.56 cm x 9.53 cm)

Weight: 5.6 lb (2.53 kg) net

8 lb (3.64 kg) shipping

10 lb (4.55 kg) shipping with battery included

Accessories

Catalog

Numbers

23200 AM 232 Manual Audiometer, AC Power (USA)

23205 AM 232 Manual Audiometer, AC Power (Export,

23210 AM 232 Manual Audiometer, AC Power and Battery (USA)

23215 AM 232 Manual Audiometer, AC Power and Battery (Export,

23223 Test Headset (TDH39)

52300 Audiogram Forms (1 pad of 50)

232001 Instruction Manual

Catalog Listings

specify country and voltage)

specify country and voltage)

Supplied Accessories

Optional Accessories

23220 Response Handswitch

23221 Patch Cord, 2 Conductor

23222 Audiocups

72320 Replacement NiCad Battery Only

72329 Battery Pack Assembly

Includes NiCad batteries. May also be used with six (6),

Size C Alkaline batteries (not included)

19

Page 22

Bibliography

American National Standard Specifications for Audiometers

(ANSI S3.6—1989)

Criteria for Permissible Ambient Noise During Audiometric Testing

(ANSI S3.1—1977)

Methods for Manual Pure-Tone Threshold Audiometry

(ANSI S3.21—1978)

Michael P.L., and Bienvenue, G.R., “Noise Attenuation Characteristics

of Supra-Aural Audiometric Headsets Using the Models MX41/AR

and 51 Earphone Cushions,” J. Acoust. Soc. Am., 70(5), Nov. 1981,

1235-1238

Newby, H.A., Audiology (4th ed.), New Jersey: Prentice-Hall Inc. (1979)

U.S. Department of Labor, Occupational Noise Exposure, CFR 1910.95,

March 8, 1983

Welch Allyn, Inc.

4341 State Street Road

P.O. Box 220,

Skaneateles Falls, N.Y.

13153-0220 U.S.A.

Tel.: 800-535-6663

(in U.S.A. only) or

315-685-4560

Printed in U.S.A. Part No. 232001

Fax.: 315-685-3361

Loading...

Loading...