Page 1

MEDUMAT Standard a

Ventilator

Description and instructions for use

Page 2

EN

Contents

1. Overview . . . . . . . . . . . . . . . . . . . . 4

1.1 Device . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Symbols used on the ventilator . . . . 7

2. Description of ventilator . . . . . . 10

2.1 Uses . . . . . . . . . . . . . . . . . . . . . . . 10

2.2 Owner/operator and user

qualification . . . . . . . . . . . . . . . . . 11

2.3 Ventilation function . . . . . . . . . . . 11

2.4 Controlled ventilation. . . . . . . . . . 13

2.5 Assisted ventilation. . . . . . . . . . . . 13

2.6 Check ventilation curve . . . . . . . . 14

2.7 Patient valve. . . . . . . . . . . . . . . . . 14

2.8 Modules. . . . . . . . . . . . . . . . . . . . 15

3. Safety instructions . . . . . . . . . . . 16

3.1 Safety regulations. . . . . . . . . . . . . 16

4. Installation . . . . . . . . . . . . . . . . . . 20

4.1 Wall mounting for STATION

MEDUMAT. . . . . . . . . . . . . . . . . . 20

4.2 Installation kit for the wall

mounting . . . . . . . . . . . . . . . . . . . 21

4.3 Connecting up the oxygen

cylinder . . . . . . . . . . . . . . . . . . . . 21

4.4 Ventilation hose . . . . . . . . . . . . . . 22

5. Using the ventilator . . . . . . . . . . 25

5.1 Switching on/self test . . . . . . . . . . 25

5.2 Selecting the ventilation settings. . 26

5.3 Select ventilation method . . . . . . . 28

5.4 Performing ventilation . . . . . . . . . 30

5.5 Monitoring ventilation . . . . . . . . . 30

5.6 Ventilation with PEEP Valve . . . . . 31

5.7 Ventilation with HME filter . . . . . . 32

5.8 Ventilating with bacteria filter. . . . 32

5.9 Terminating ventilation. . . . . . . . . 33

5.10 Alarm signals . . . . . . . . . . . . . . . . 33

5.11 Calculation of oxygen content/

remaining operating time . . . . . . . 37

5.12 Alternative ventilation

procedures . . . . . . . . . . . . . . . . . . 38

6. Hygienic preparation . . . . . . . . . 39

6.1 MEDUMAT Standard a. . . . . . . . . 39

6.2 Patient valve . . . . . . . . . . . . . . . . 40

6.3 Hose system . . . . . . . . . . . . . . . . 41

6.4 Components and accessories . . . . 42

6.5 Fittings . . . . . . . . . . . . . . . . . . . . 43

6.6 Cleaning, disinfecting and

sterilizing . . . . . . . . . . . . . . . . . . . 44

7. Functional checks . . . . . . . . . . . . 45

7.1 Preparation for functional check . 45

7.2 Obligatory checks . . . . . . . . . . . . 46

7.3 Check for leaks in the system. . . . 47

7.4 Check of patient valve . . . . . . . . . 48

7.5 Checking the minute volume . . . . 49

7.6 Check of maximal ventilation

pressure. . . . . . . . . . . . . . . . . . . . 51

7.7 Check assisted ventilation . . . . . . 52

7.8 Check of alarm systems . . . . . . . . 54

8. Troubleshooting . . . . . . . . . . . . . 57

8.1 Batteries . . . . . . . . . . . . . . . . . . . 59

8.2 Cut-out system . . . . . . . . . . . . . . 60

8.3 Adjustment of manometer. . . . . . 61

8.4 Change valve membrane in

patient valve . . . . . . . . . . . . . . . . 61

9. Servicing . . . . . . . . . . . . . . . . . . . . 63

9.1 Intervals. . . . . . . . . . . . . . . . . . . . 63

9.2 Sending in device. . . . . . . . . . . . . 64

9.3 Storage . . . . . . . . . . . . . . . . . . . . 64

9.4 Disposal. . . . . . . . . . . . . . . . . . . . 65

10. Supply schedule . . . . . . . . . . . . . . 66

10.1 Standard supply schedule . . . . . . 66

10.2 Accessories . . . . . . . . . . . . . . . . . 66

10.3 Spare parts . . . . . . . . . . . . . . . . . 67

11. Technical data . . . . . . . . . . . . . . . 68

11.1 Device . . . . . . . . . . . . . . . . . . . . . 68

11.2 Patient’s hose system. . . . . . . . . . 70

11.3 Pneumatics . . . . . . . . . . . . . . . . . 71

11.4 Resistance to interference . . . . . . 72

11.5 O

content when using Air Mix . . 72

2

2 Contents

Page 3

EN

11.6 Switching from Air Mix to

No Air Mix . . . . . . . . . . . . . . . . . . 73

12. Warranty . . . . . . . . . . . . . . . . . . . . 74

13. Declaration of conformity . . . . . 74

Contents 3

Page 4

EN

1. Overview

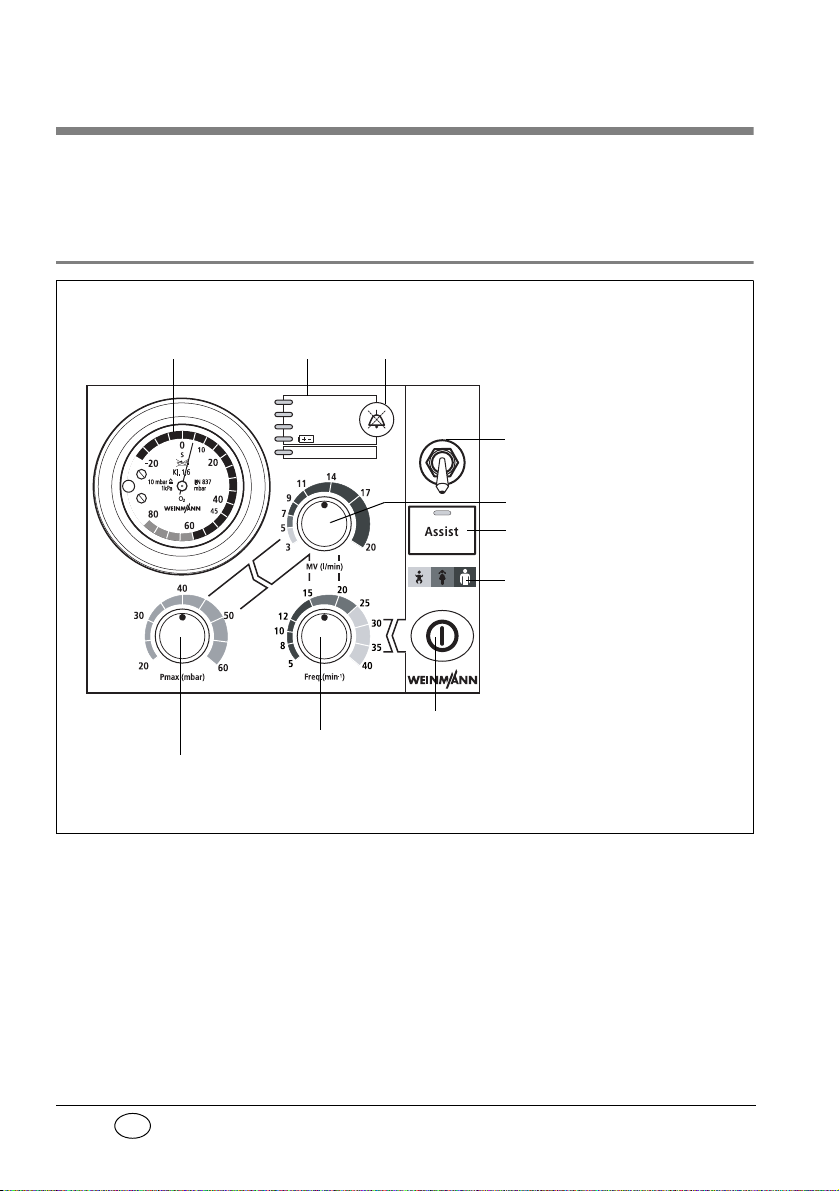

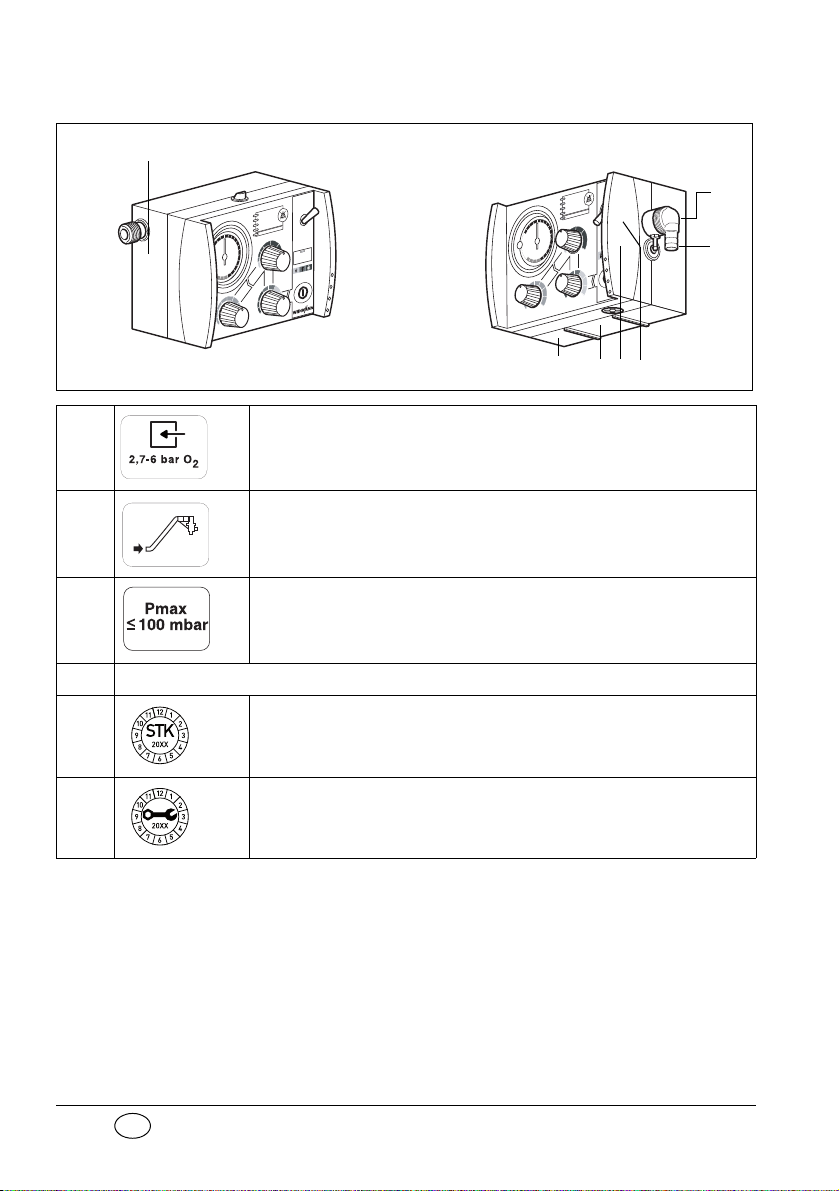

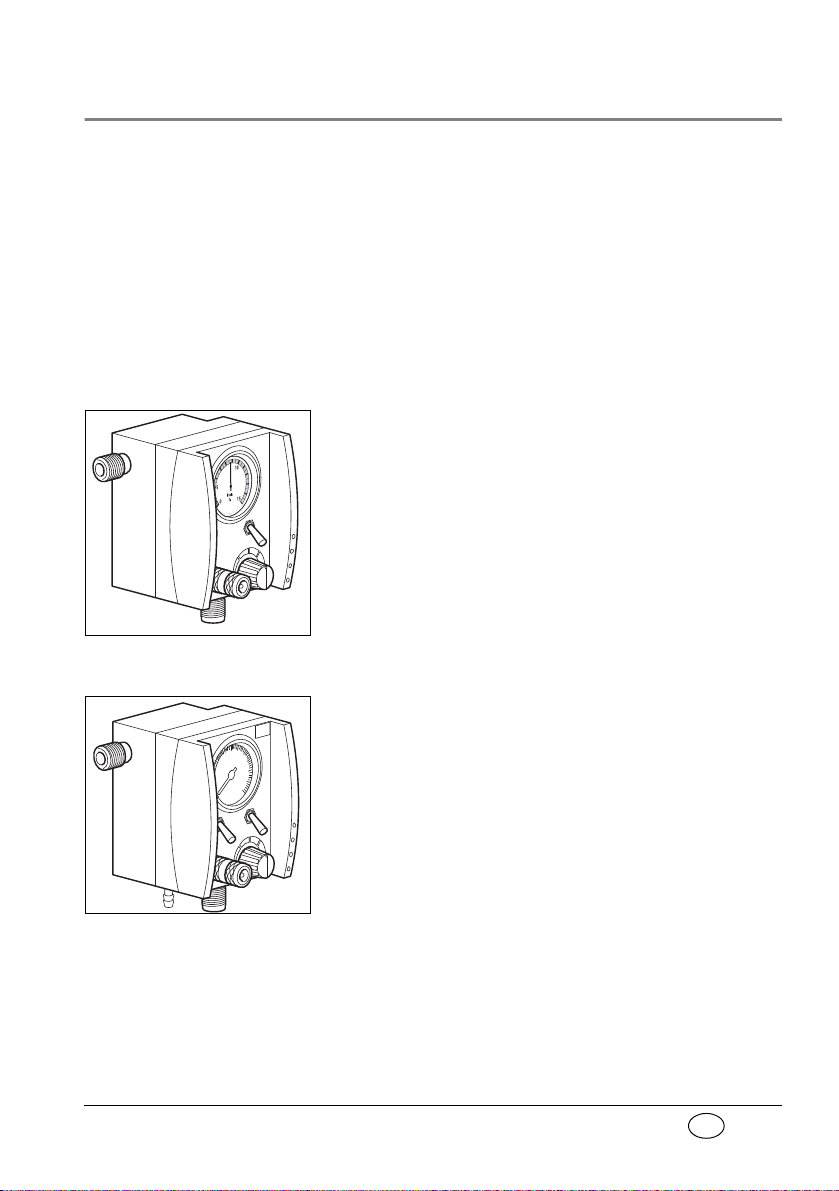

Control panel MEDUMAT Standard a

1 Ventilation pressure gauge

7 Colour code

Toddler (yellow, 10 kg to 30 kg)

Child (orange, 30 kg to 60 kg)

Adult (brown, 60 kg to 110 kg)

4 Air Mix/No Air Mix switch

3 Alarm acknowledgement2 Alarm panel

8 ON/OFF switch

9 Ventilation frequency regulator

5 Minute volume regulator

10 Max. ventilation pressure

regulator

6 On/Off switch,

assisted ventilation

1.1 Device

Stenosis

Disconnection

< 2,7 bar O

2

No assist

MEDUMAT

Standard a

Air Mix

No Air Mix

4 Overview

Page 5

EN

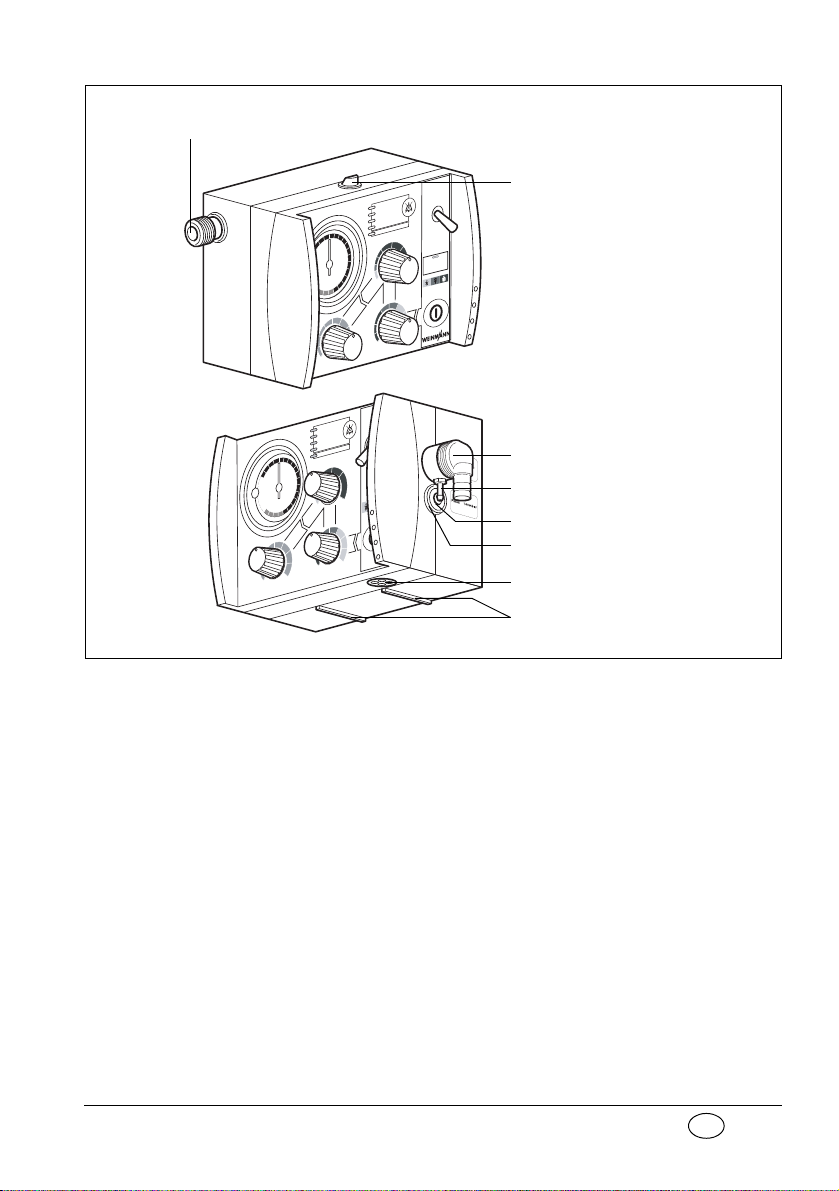

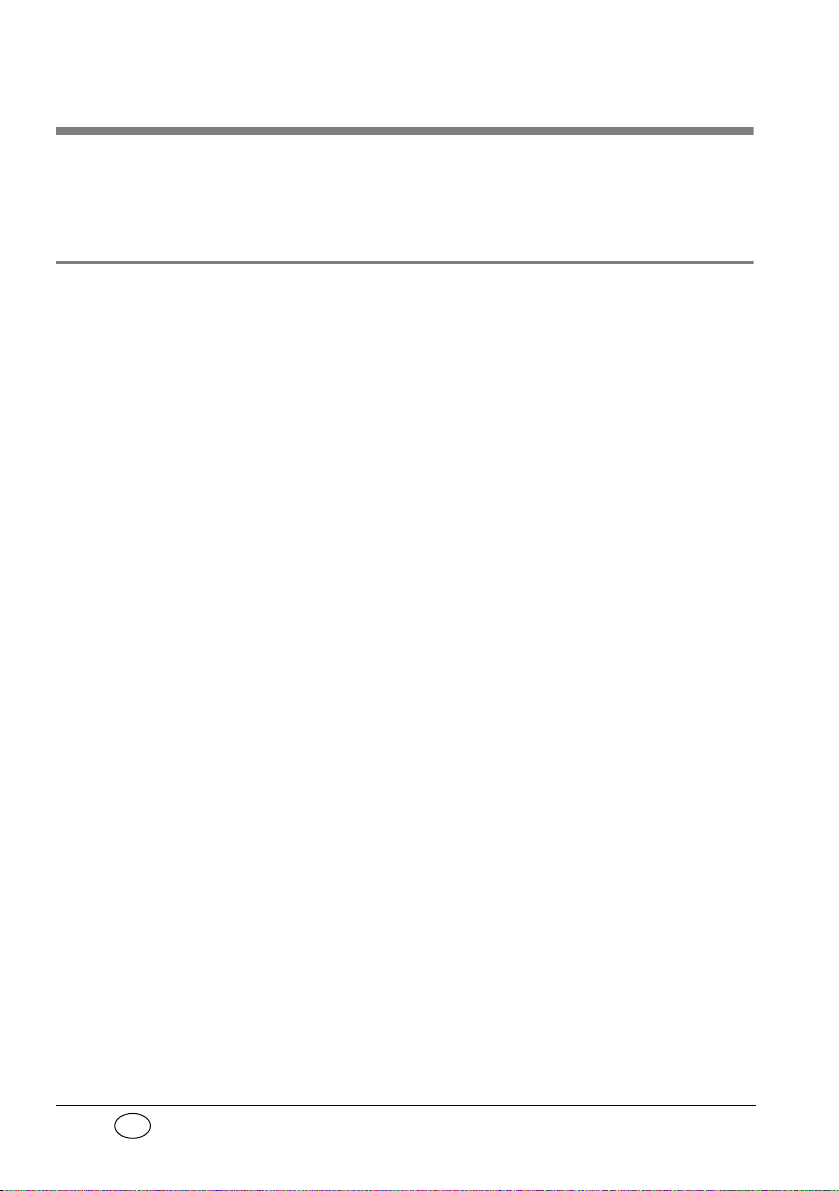

MEDUMAT Standard a connections

12 Catch for STATION MEDUMAT

wall mounting

11 Pressure gas connection

13 Connection for ventilation tube

14 Pressure gauge hose connection

15 Relief valve

16 Dust cover

17 Mixed air filter

12 Catch for STATION MEDUMAT

wall mounting

I

Overview 5

Page 6

EN

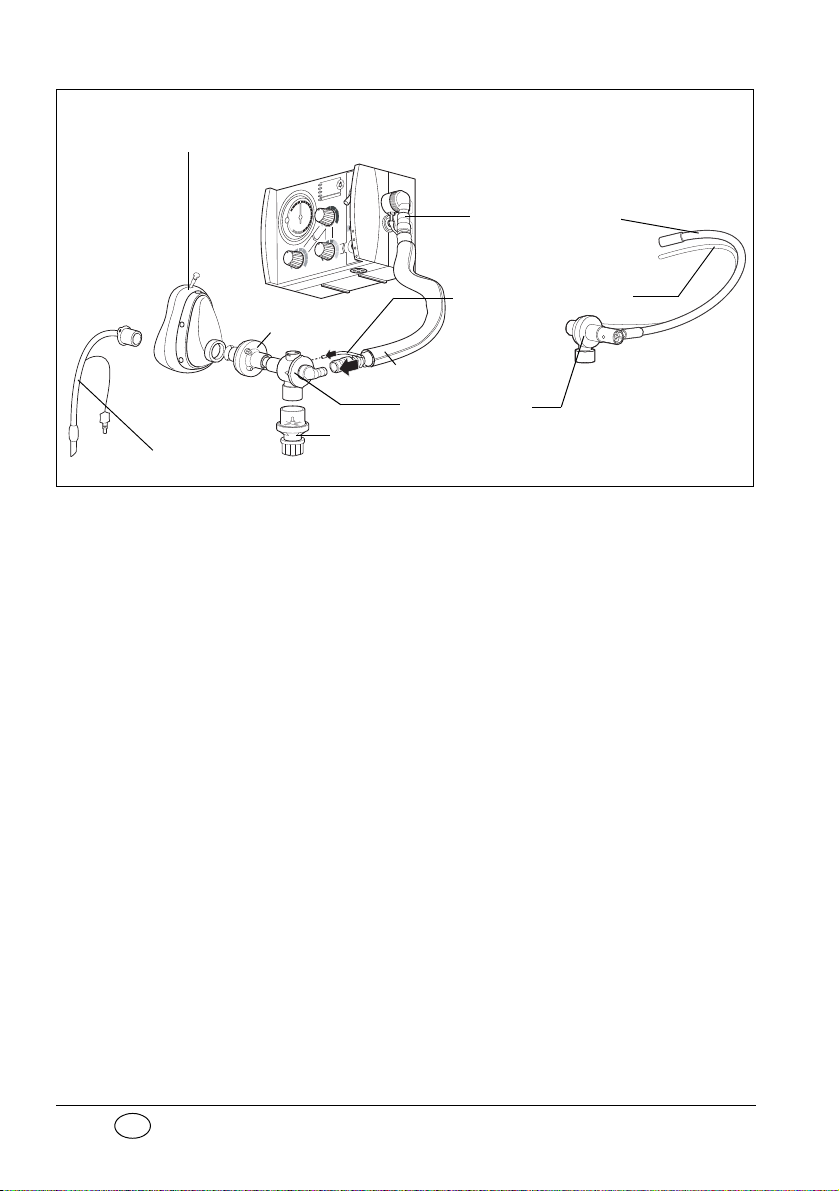

MEDUMAT Standard a device combinations

19 Ventilation hose

18 Ventilation mask

21 Filter

23 Patient valve

24 PEEP valve

22 Hose casing

25 Tube

or

20 Pressure gauge hose

Disposable hose system

6 Overview

Page 7

EN

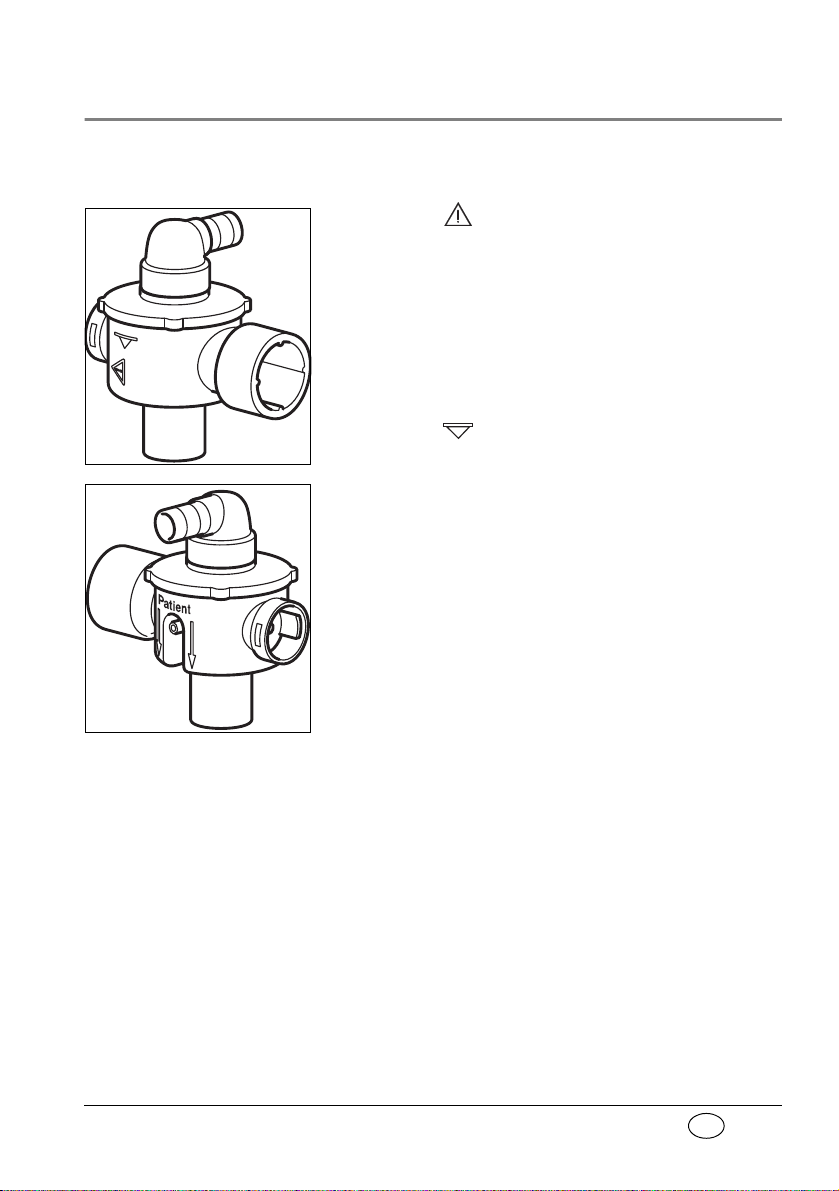

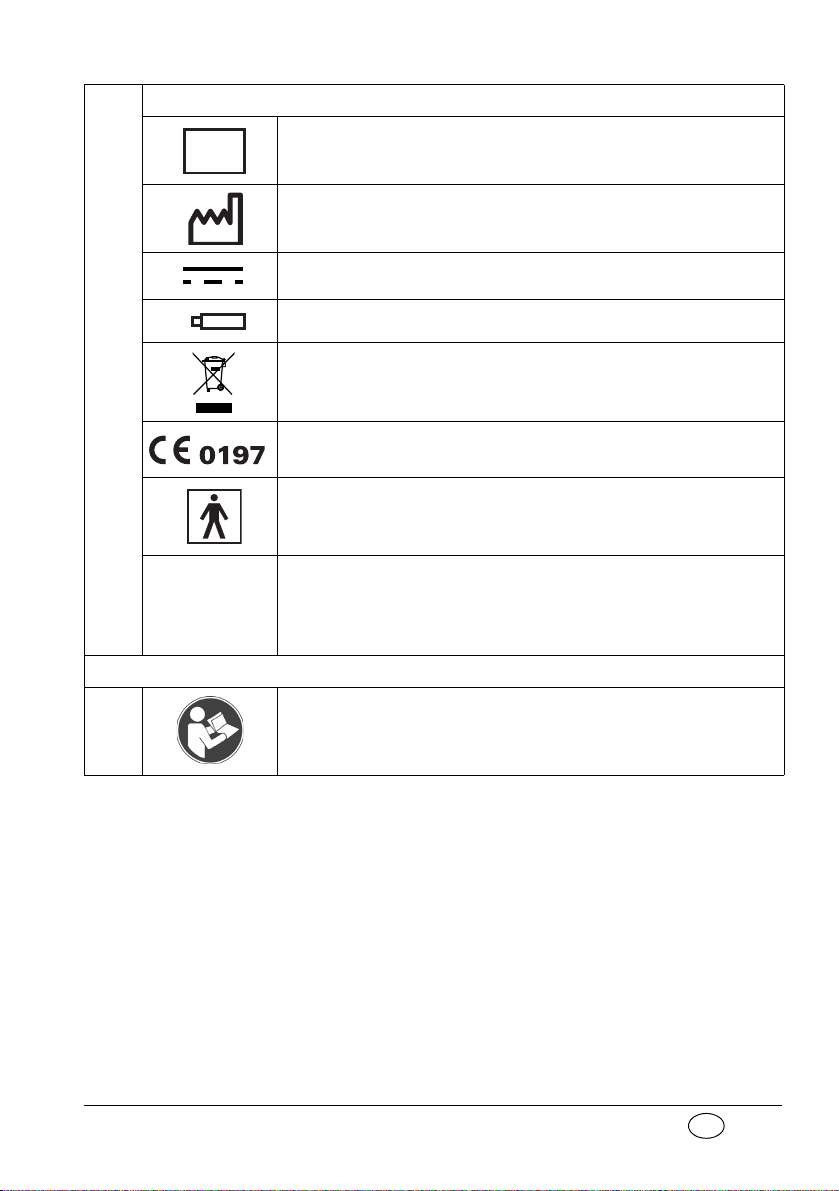

1.2 Symbols used on the ventilator

Position

> PSU< 134°

Patient valve

The symbol on the patient valve indicates that

the lip and valve membranes in the expiration and

spontaneous breathing arms must be changed immediately if they are crinkled, sticky or misshapen.

Under no circumstances continue to use the patient

valve for ventilation in this case, as malfunctions are

likely (note “7.4 Check of patient valve“ on

page 48).

The symbol indicates the correct position for

insertion of the lip membrane.

When connecting the patient valve, take care to

ensure that the direction of respiratory gas flow is

correct.

Overview 7

Page 8

EN

MEDUMAT Standard a

1

2

3

4567

1 Inlet 2,7 - 6 bar O2.

2 Tube system connection

3 Maximum pressure ≤100mbar

I

4

5 Servicing label: indicates when the next service is due.

8 Overview

Safety check and servicing label

Safety check label: (in Germany only) marks when the next safety

check as per §6 of the German law relating to users of medical

devices is required.

Page 9

EN

MEDUMAT Standard a device information plate

SN

6

IP24

Serial number of device

Date of manufacture

Direct voltage

3,6 V lithium battery

Do not dispose of device in domestic waste

CE symbol (confirms that the product conforms to the applicable

European directives)

Type BF application part

Degree of protection

– against the ingress of solid particles

– against access to hazardous parts

– against the ingress of water with a harmful effect

Other markings

7 Follow instructions for use

Overview 9

Page 10

EN

2. Description of ventilator

2.1 Uses

The MEDUMAT Standard a is an automatic (shortterm) ventilator with the option of assisted ventilation.

You can use MEDUMAT Standard a:

• to revive patients at the site of the emergency

• on a longer term basis in more protracted emergencies, e.g. fires.

You can use MEDUMAT Standard a while transporting patients:

• between the various rooms and departments of

a hospital;

• between the hospital and other premises;

• in emergencies;

• when transport over a considerable distance is

planned.

10 Description of ventilator

MEDUMAT Standard a:

• is designed to provide controlled ventilation to

persons of approx. 10 kg body weight or more,

or in the case of assisted ventilation, of approx.

15 kg body weight or more.

• is used to treat respiratory arrest;

• can be preset to parameters that ensure evenly

balanced ventilation provided that the selected maximum ventilation pressure P

• can be supplied with additional modules for

aspiration and oxygen inhalation. (N.B.

is not exceeded.

max

Page 11

EN

MEDUMAT Standard a cannot be used as a ventilator simultaneously with these modules.)

2.2 Owner/operator and user qualification

As an owner/operator or user, you must be familiar

with the operation of this medical device. Observe

the legal requirements for operation and use (in Germany, the regulations governing owner/operators of

medical devices apply in particular). Basic recommendation: get a person authorized by Weinmann

to provide you with proper instruction about the

handling, use and operation of this medical device.

2.3 Ventilation function

MEDUMAT Standard a operates within a pressure

range of 2.7 to 6 bar and at a flow rate of not less

than 70 l/min O

It uses high-pressure, medicinal-grade oxygen. An

external pressure reducer brings this down to the required operating pressure. The oxygen supply is fed

in at input valve.

Both the infinitely variable ventilation frequency and

the inspiration/expiration ratio of 1:1.67 in the case

of controlled ventilation are regulated by internal

electronic control mechanisms.

. It has an in-built power pack.

2

The gas for inspiration is routed to the patient

through the ventilation tube via the patient valve

and the ventilation mask or hose. A lip membrane

Description of ventilator 11

Page 12

EN

Air Mix

No Air Mix

Air Mix

No Air Mix

in the patient valve ensures that the expiration gas

can be exhaled through the expiration arm.

Regardless of the ventilation mode selected, the patient has the option of breathing spontaneously between ventilation strokes via the patient valve. In

this case, the patient draws air for breathing from

the ambient air.

With the Air Mix setting, in the case of mechanical

ventilation, atmospheric air is admixed to give an O

concentration generally of between 55 % and 85 %

at 10 mbar ventilation pressure (note “11.5 O

con-

2

tent when using Air Mix“ on page 72).

In certain indications and in cases where the surrounding atmosphere is contaminated, you can switch to

No Air Mix and ventilate with pure oxygen.

The injector unit is switched off when switching

from

Air Mix to No Air Mix. This increases minute vol-

ume which can result in the set pressure limit being

exceeded and a stenosis alarm (Stenosis) being trig-

gered. In this case, set minute volume correspondingly

lower.

In the opposite instance, in other words when

switching from

No Air Mix to Air Mix, the injector

unit is switched on. This reduces minute volume

which can lead to the set pressure limit being

. In this case, set minute volume correspondingly

shot

higher.

under-

2

12 Description of ventilator

Page 13

EN

2.4 Controlled ventilation

Mandatory ventilation

stroke: the device, not the

patient, determines the

time of the next breathing

stroke.

After being switched on, the MEDUMAT Standard a

is automatically in Controlled Ventilation mode. This

administers mandatory ventilation strokes to the intubated patient according to the ventilation values

set on the device.

2.5 Assisted ventilation

In addition to Controlled Ventilation mode, the

MEDUMAT Standard a also has an Assisted Ventilation mode.

After you have switched on Assisted Ventilation

mode by pressing the

LED indicates this mode.

Triggered ventilation

stroke: the patient can trigger a ventilation stroke by

his own breathing efforts.

IPPV: intermittent positive

pressure ventilation (= controlled ventilation).

The patient now has the option of triggering a triggered ventilation stroke within a time window of 40

% of expiration. To do so, the patient must generate

a flow of over 6 l/min. by his own breathing efforts.

If the breathing efforts of the patient are not sufficient to trigger, the patient automatically receives a

mandatory ventilation stroke at the end of the time

window, so that the set minute volume is guaranteed.

With this function, the ventilation strokes of the device can be synchronised with the breathing efforts

of the patient.

Between the mandatory ventilation strokes of the

device, the patient has the option of breathing in air

from the surrounding atmosphere via the patient

valve.

Assist key, a flashing green

Description of ventilator 13

Page 14

EN

If the patient does not trigger the device, an alarm is

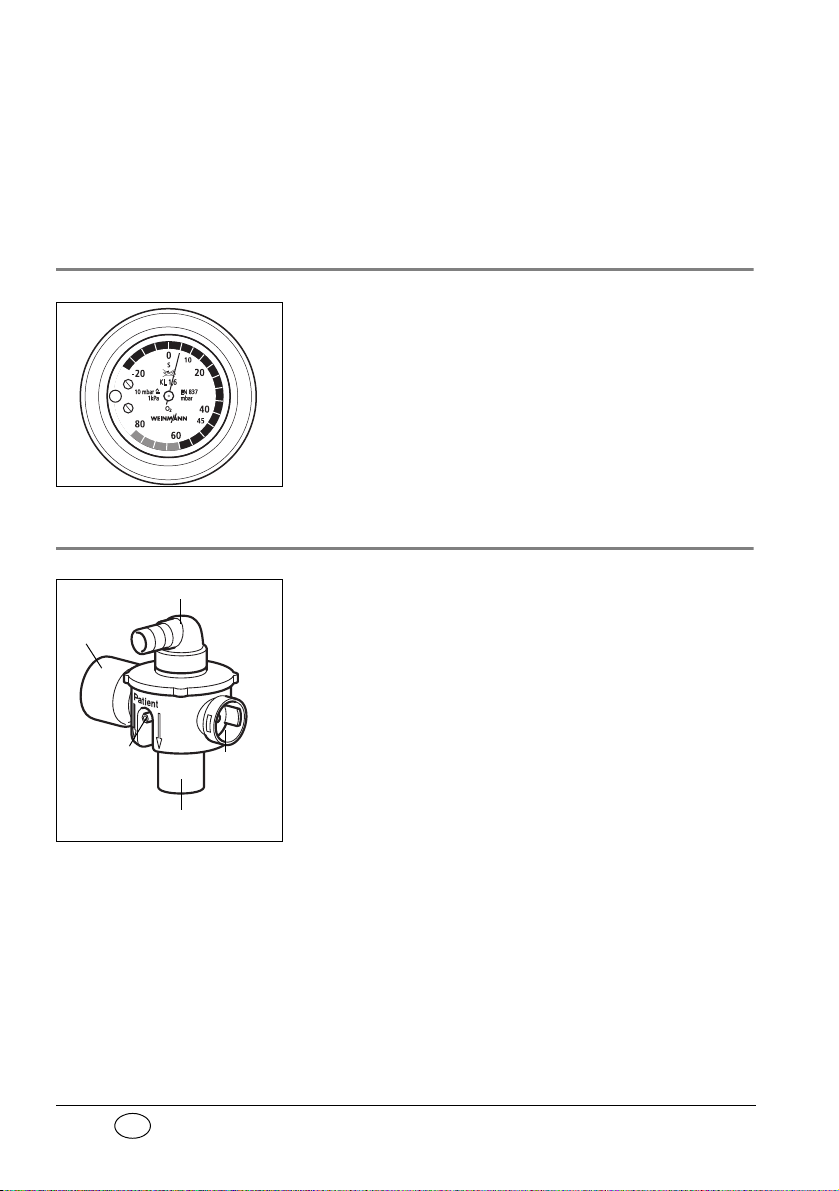

Respiration hose connection

Expiration

tube

Connection

for pressure

gauge tube

Mask/tube connection

Spontaneous

breathing tube

triggered. The patient continues to receive controlled ventilation.

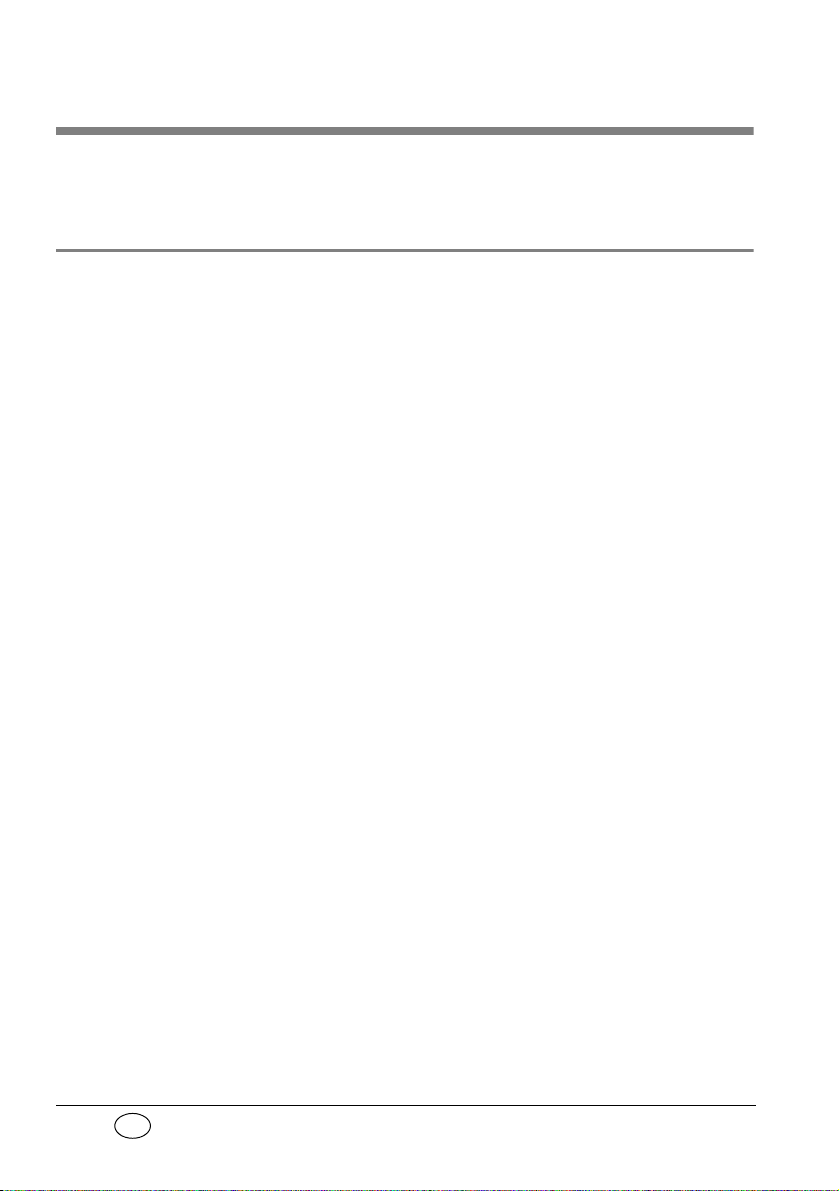

2.6 Check ventilation curve

The ventilation curve is checked at ventilation

pressure gauge.

2.7 Patient valve

The gas for inspiration is channelled into the

patient’s airways through the patient valve.

It is designed so that spontaneous breathing is possible, even if the MEDUMAT Standard a fails, regardless of which ventilation mode you have selected.

14 Description of ventilator

Page 15

EN

2.8 Modules

M

OD

UL

O

x

y

g

e

n

O

2

0

5

1

0

1

5

l/min

O

2

MODUL

Combi

O

2

Modules with additional functions can be attached

to MEDUMAT Standard a.

Please refer to the directions for use enclosed with

the modules for exact details of how to fit and operate these. It is essential to read these directions carefully before using the modules. The most important

points are listed below:

Oxygen MODULE

The Oxygen MODULE enables you to apply oxygen

inhalation.

Put the switch marked

O

into the “I“ position. Se-

2

lect the desired oxygen volume by turning the knob

marked

l/min to a setting between 0 and 15 l/min.

You can check this setting on the volume manometer.

Combi MODULE

The Combi MODULE enables you to apply both

oxygen inhalation and suction.

For inhalation put the switch marked

position. Select the desired oxygen volume by turning

the knob marked

l/min to a setting between 0 and

15 l/min. You can check this setting on the volume

manometer.

For suction switch the tumbler marked

position. The suction pressure is locked at -0.5 bar.

O2 into the “I“

Vac to the “I“

Description of ventilator 15

Page 16

EN

3. Safety instructions

3.1 Safety regulations

For your own safety, the safety of your patients, and

to comply with the requirements of EU Directive 93/

42/EEC, please observe the following points:

General

• Please read the directions for use carefully. They

are an integral part of the ventilator and should

be available for reference at all times.

• Before starting to work with

MEDUMAT Standard a, you must understand

how to operate it.

• Please comply with section “6. Hygienic preparation“ on page 39 to prevent infection or bacterial contamination.

• MEDUMAT Standard a should be used only by

medically qualified personnel who have had

training in ventilation techniques. Incorrect use

can cause severe physical injury.

16 Safety instructions

• It is advisable for you to have servicing and repairs carried out only by the manufacturer,

Weinmann, or by qualified technicians expressly

authorized by Weinmann.

• If third-party items are used, functional failures

may occur and fitness for use may be restricted.

Biocompatibility requirements may also not be

met. Please note that in such cases, any claim

under warranty and liability will be voided if neither the accessories nor genuine replacement

Page 17

EN

parts recommended in the instructions for use

are used.

• MEDUMAT Standard a should be used only for

the purposes for which it is designed (note “2.1

Uses“ on page 10).

• MEDUMAT Standard a is not designed for use

under hyperbaric conditions (pressure chamber).

• MEDUMAT Standard a should never be used

with flammable anaesthetics.

• In the case of use in poisoned or low-oxygen

atmospheres, do not operate the

MEDUMAT Standard a with the „Air Mix“

setting or in Assist mode.

• A back-up ventilator should always be available

in case of technical failure.

Warning: • Modifications may not be made to the device.

Have modifications to the device carried out only

by the manufacturer, Weinmann, or by specialist

staff expressly authorized by the manufacturer.

Oxygen

Highly-compressed oxygen can lead to spontaneous

explosive reactions in combination with flammable

substances (fat, oil, alcohol, disinfectants, etc.):

• All screw connections and other components of

the ventilator must be kept absolutely free of oil

and grease.

• Always wash your hands before starting to work

on the oxygen supply.

• Smoking and open flames are strictly prohibited

in the vicinity of all fittings containing or transporting oxygen.

• During assembly and when changing the oxygen

cylinder, only hand pressure should be used

Safety instructions 17

Page 18

EN

when tightening the screw connections to the

cylinder and to the pressure reducer. Never use

tools for this purpose. Excessive tightening damages the screw threads and seals and can cause

leaks.

• Protect oxygen cylinders from accidental falls. If

a cylinder falls, the pressure reducer or the valve

may break off and cause a violent explosion.

Important note • Always open the valve of the oxygen cylinder

slowly to prevent pressure damage to the other

fittings.

• The oxygen cylinder should never be completely

emptied as this may allow moisture-containing

air to enter the cylinder and cause corrosion.

Operation

• Both the patient and the ventilator must be kept

under constant observation during ventilation.

• Make sure that neither the expiration tube nor

the spontaneous breathing tube on the patient

valve is blocked or impeded in any other way,

e.g. by the patient’s position.

18 Safety instructions

• MEDUMAT Standard a must never be used simultaneously with a module as this would make

it impossible to work to the selected parameters.

Note • Disposable hose systems WM 28110 (2 m) and

WM 28188 (3 m) are only intended to be used

once.

Software

• Extensive validation tests have been performed

to minimize risks arising from software errors.

Page 19

EN

Accessories

• Please protect the silicone and rubber components against UV radiation and prolonged exposure to direct sunlight, as this can make them

brittle and friable.

Safety instructions 19

Page 20

EN

4. Installation

A permanent mounting is usually necessary only

when MEDUMAT Standard a is installed as a fixture

in rescue vehicles, helicopters or aircraft. In these

cases either the STATION MEDUMAT or installation

kits are available as accessories.

If MEDUMAT Standard a is supplied complete with

carrying platform, it is ready for use and requires no

further installation. Separate directions for use are

supplied with the carrying platform.

Functional tests must be carried out after installation

(note “7. Functional checks“ on page 45).

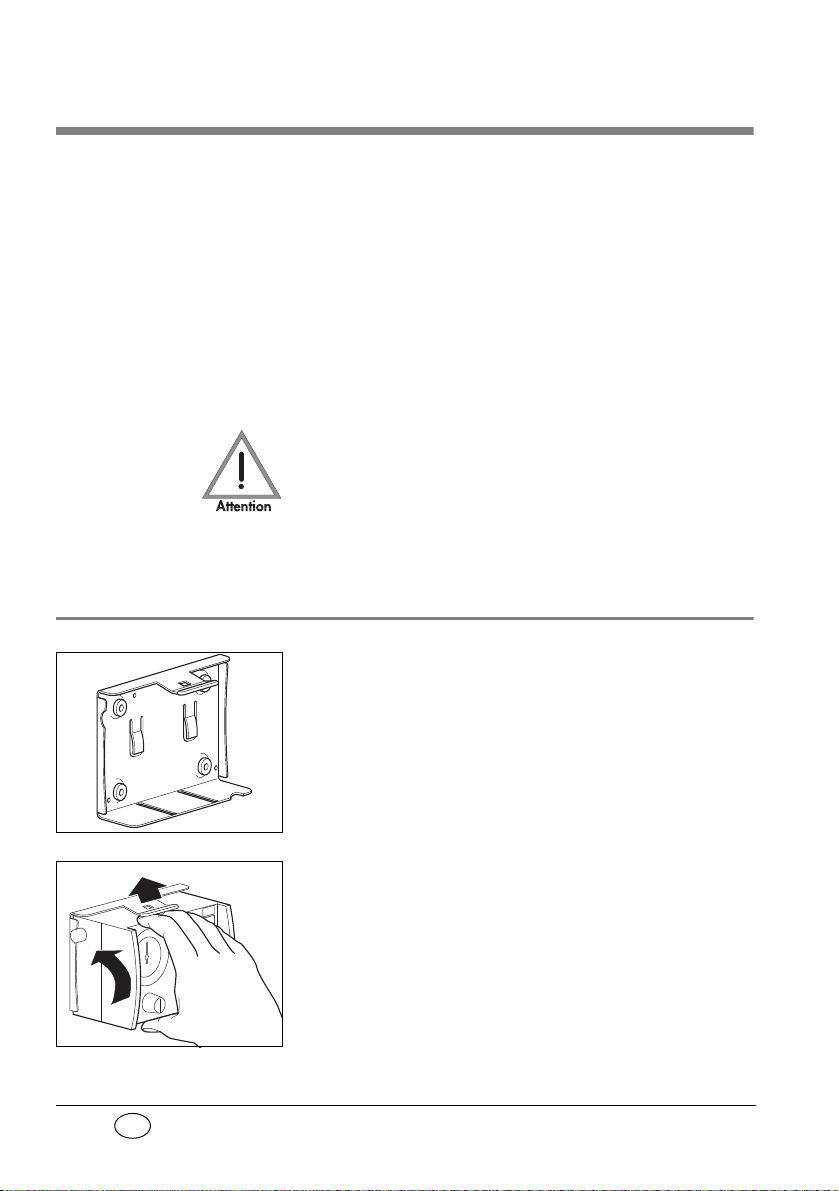

4.1 Wall mounting for STATION MEDUMAT

The wall mounting for the STATION MEDUMAT

should be installed at an appropriate place, e.g., on

a side panel inside the vehicle. Please refer to the

sheet enclosed with the STATION MEDUMAT for

details of dimensions and the installation procedure.

20 Installation

To place MEDUMAT Standard a in the wall mounting,

first insert the slides on the underside of the ventilator

into the matching grooves in the STATION MEDUMAT

and then press the MEDUMAT Standard a inwards

until the catch snaps into the fastening at the top of

the STATION MEDUMAT.

Page 21

EN

4.2 Installation kit for the wall mounting

A number of kits are available for installing a wall

mounting, e.g. on a panel inside a vehicle. The kit

size varies according to the number of modules attached to the MEDUMAT Standard a.

Please refer to the sheet enclosed with each installation kit for details of dimensions and installation

procedure.

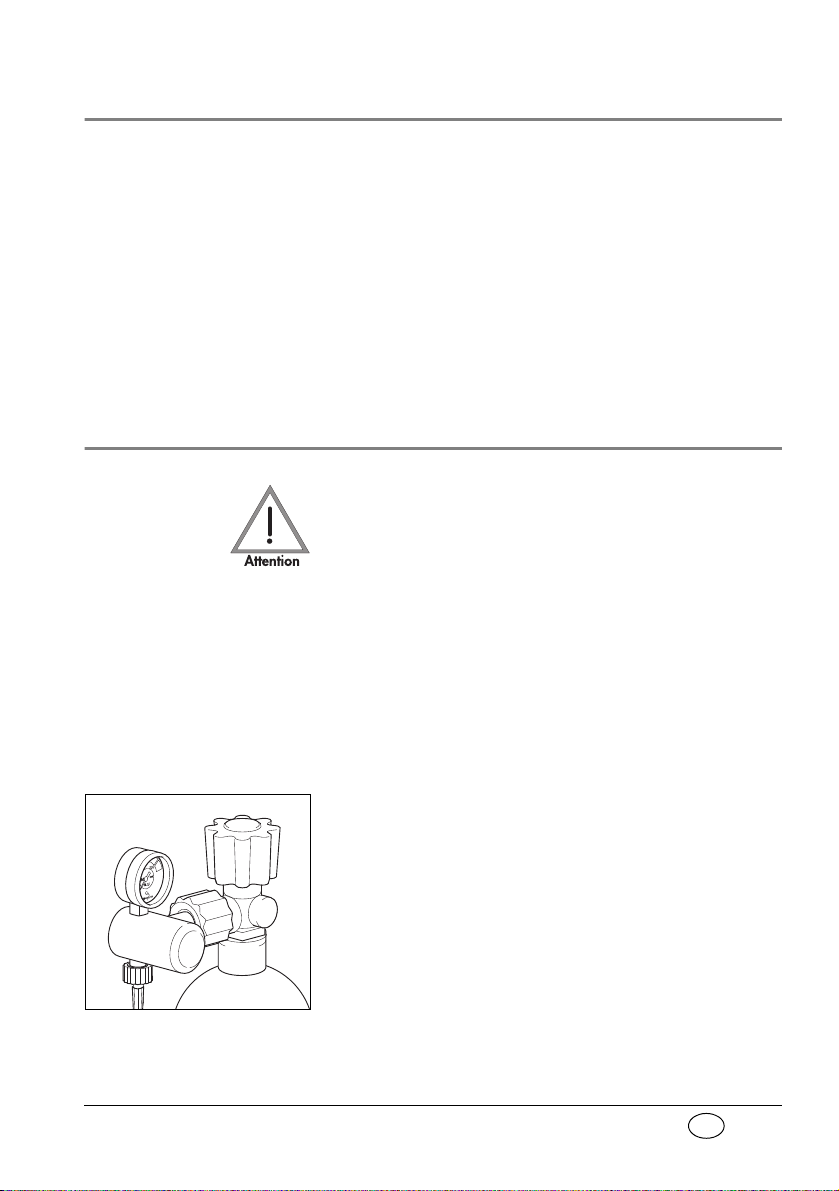

4.3 Connecting up the oxygen cylinder

Wash your hands thoroughly before any work on the

oxygen supply. Hydrocarbon compounds (e.g. oils,

greases, alcohol for cleaning, disinfectants, hand

cream or sticking plaster) can lead to explosive reactions if they come into contact with highly-compressed oxygen.

Never use wrenches or similar tools to tighten or

loosen the screw connections.

Removal of empty cylinder

1. Close the valve of the oxygen cylinder.

Switch on MEDUMAT Standard a with ON/OFF

switch. This exhausts any residual oxygen and

depressurizes the ventilator. Wait until the pressure gauge on the pressure reducer shows

oxygen content before uncoupling the screw

connection by hand.

2. First switch off MEDUMAT Standard a again.

3. Then loosen the screw connection to the

cylinder.

Installation 21

0 bar

Page 22

EN

Connecting up new cylinder

I

1. First open the valve of the new oxygen cylinder

and close it again quickly. This will blow out any

particulate matter.

Keep the valve opening away from the body,

making sure that neither yourself or other persons can be injured by escaping particles!

2. Next couple the pressure reducer to the valve on

the oxygen cylinder with the fluted connecting

nut. Tighten up the nut by hand.

3. If the pressure hose is not already connected to

the exit valve of the pressure reducer, make this

connection with the G 3/8 connecting nut.

4. Screw the other end of the pressure hose on to

pressure gas connection on the

MEDUMAT Standard a if this has not yet been

done.

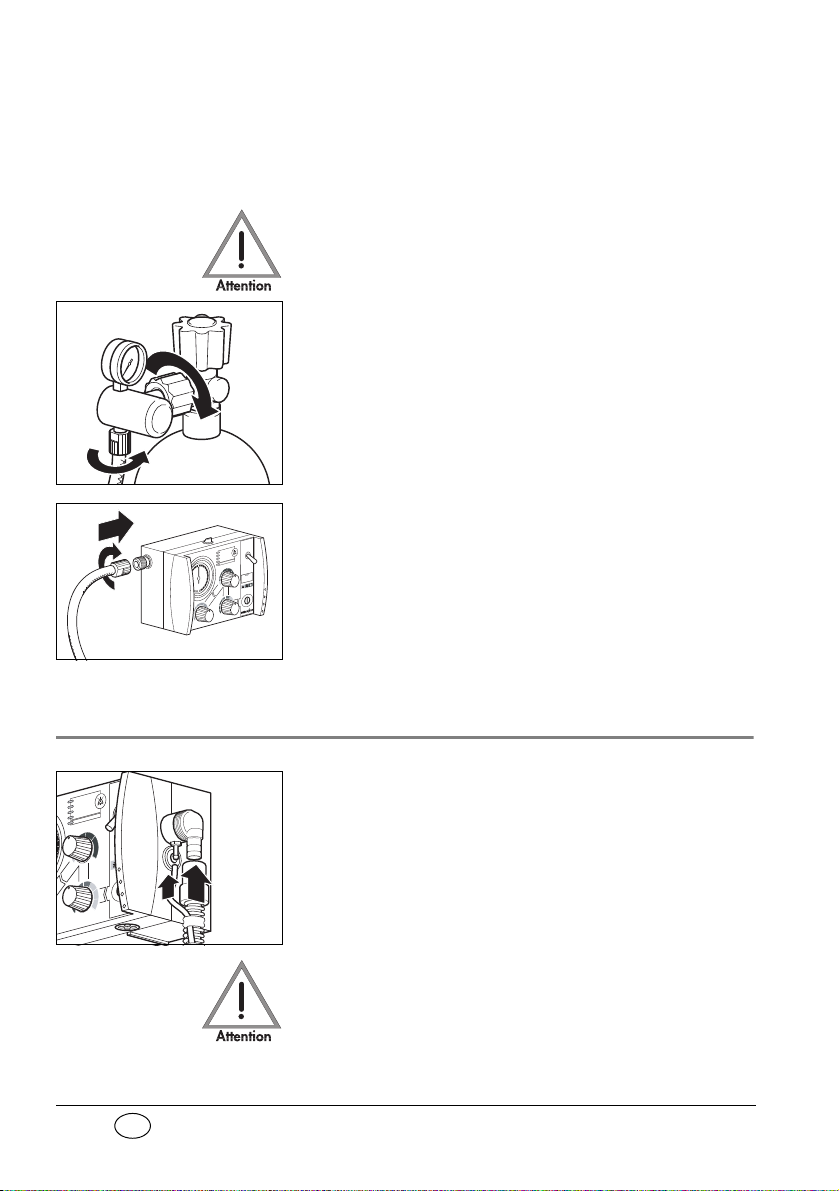

4.4 Ventilation hose

22 Installation

1. Slide the pressure gauge hose onto the

connection.

2. Slide the ventilation tube onto the connection.

Make sure that the pressure gauge hose already

connected is not kinked. If necessary, turn the

ventilation tube while sliding on as appropriate.

Do solely grasp the ventilation tube by its end (position of arrow in adjacent drawing). Otherwise the

hose may become damaged or tear.

Page 23

EN

3. Plug the other end of the ventilation tube and the

Po

s

it

i

o

n

>

PS

U

<

1

3

4

°

P

o

s

i

t

io

n

>

P

S

U

<

1

34°

pressure measurement tube onto the patient

valve.

4. If the patient is intubated, insert the patient

valve into the tube,

or

if a mask is being used for ventilation, insert the

patient valve into the connector on the mask.

(This is identical with the connector on the tube.)

HME-Filter

If a heat and moisture exchanger (HME) filter is

required, this should be installed between the patient-side connector on the patient valve and the

tube or mask.

Always follow the manufacturer’s directions for use.

Installation 23

Page 24

EN

PEEP Valve

If a PEEP valve is needed, this should be inserted into

the expiration tube on the patient valve.

Always follow the manufacturer’s directions for use.

Bacteria filter

If a bacteria filter is used, fit it between the device

outlet port and the ventilation tube.

Always follow the manufacturer’s directions for use.

24 Installation

Page 25

EN

5. Using the ventilator

Stenosis

Disconnection

< 2,7 bar O

2

No assist

5.1 Switching on/self test

1. Open the valve of the oxygen cylinder slowly.

The pressure gauge will now show the pressure

in the cylinder.

2. Where appropriate, calculate how long the remaining oxygen will last (note “5.11 Calculation

of oxygen content/remaining operating time“

on page 37). Always change the cylinder in good

time, e.g., when the pressure is lower than

50 bar, to ensure that oxygen is available for an

adequate period.

3. Select the desired settings for the ventilation

(note “5.2 Selecting the ventilation settings“ on

page 26).

4. Switch on the MEDUMAT Standard a with ON/

OFF switch. The ventilator will then run a self test

lasting approx. 2 seconds.

If no fault is detected, the five LEDs in alarm field

come on and a brief alarm sounds. After that, the

MEDUMAT Standard a starts working with the

set ventilation values in „Controlled Ventilation“

mode.

If an error is found, the LED’s in alarm panel will

start to flash. If this happens,

MEDUMAT Standard a must not be used for

ventilation.

Using the ventilator 25

Page 26

EN

5.2 Selecting the ventilation settings

MEDUMAT

Standard a must

never be used

simultaneously

with a module as this

would make it impossible

to work to the selected

parameters.

Air Mix

No Air Mix

The settings can be selected either before or after the

MEDUMAT Standard a is switched on. We recommend selection before switching on to prevent

unnecessary waste of oxygen.

Air Mix/No Air Mix

In the case of a given indication, it is possible to

ventilate using pure oxygen or using mixed air.

1. For mixed air, set switch to

The oxygen concentration administered will normally lie somewhere between 55% and 85% at

a ventilation pressure of 10 mbar. You can read

off the exact figure from relevant diagram (note

“11.5 O

content when using Air Mix“ on

2

page 72).

No Air Mix setting should be used when the

The

surrounding atmosphere is polluted or has a low

oxygen content or when the indication requires this.

Air Mix.

No Air Mix

26 Using the ventilator

Air Mix

2. Set Switch to

No Air Mix.

When the ventilator is switched from an air/oxygen mixture (

Air Mix) to pure oxygen (No Air Mix),

the minute volume will vary only within the set

tolerances (note “11. Technical data“ on

page 68).

Page 27

EN

Respiratory frequency

MV (l/min)

1. The respiratory frequency can be set with

regulator knob.

Minute volume

1. The minute volume can be set with regulator

knob.

Recommendation for breathing frequency and

minute volume in the case of controlled

ventilation:

Toddler

yellow

Body weight 10 - 30 kg 30 - 60 kg 60 - 110 kg

Respiratory

frequency

Minute volume 3 - 5 l/min 5 - 7 l/min 7 - 13 l/min

25 - 40 min-115 - 25 min-18 - 15 min

The values given in the table are recommendations.

Deviating values are possible for certain indications.

Child

orange

Adult

brown

-1

Maximal ventilation pressure

1. The ventilation pressure can be set with regulator knob max. ventilation pressure.

Recommendations for the Maximal ventilation

pressure:

Intubation Mask ventilation

45 mbar 20 mbar

The values given in the table are recommendations.

Deviating values are possible for certain indications.

Using the ventilator 27

Page 28

EN

If the set level is reached, e.g. in cases where compli-

Ventilation pressure

in mbar

Time in s

Expiration

Inspiration

Ventilation frequency

30

20

10

Example of a ventilation curve in Controlled

Ventilation mode:

ance is inadequate, MEDUMAT Standard a sets off a

stenosis alarm (note “ Stenosis alarm“ on page 34).

5.3 Select ventilation method

Ventilation in Controlled Ventilation

mode

The MEDUMAT Standard a is automatically in

Controlled Ventilation mode when switched on.

The LED in key

The patient is supplied with air for breathing at an inspiration/expiration ratio of 1: 1.67 according to the

set ventilation parameters (note “5.2 Selecting the

ventilation settings“ on page 26).

Assist does not come on.

Ventilation in Assisted Ventilation

mode

28 Using the ventilator

To switch on „Assisted Ventilation“ mode, please

press key

Assist.

„Assisted Ventilation“ mode is indicated by the

green LED in key

Assist flashing.

Page 29

EN

Triggered ventilation

Time in s

Inspiration

30

20

10

Trigger

window

Triggered

ventilation pulse

Expiration

Trigger

pulse

Spontaneous breath

Example of a ventilation curve in Assisted

Ventilation mode:

stroke: the patient triggers

a ventilation stroke

through his own breathing

effort.

During assisted ventilation, the patient likewise receives a controlled ventilation stroke in accordance

with the ventilation frequency set.

In addition, the patient is given the option of triggering the device himself before a controlled ventilation

stroke. This synchronises the controlled ventilation

strokes with the breathing efforts of the patient.

Note:

different trigger points in

consecutive phases can

lead to a change in the inspiration/expiration ratio.

The set values for breathing frequency and minute

volume are maintained.

The patient furthermore has the option of performing a spontaneous breath via the patient valve between triggered ventilation strokes. In this case, the

patient draws air for breathing from the ambient air.

If the patient fails to trigger the device within the

time window in two consecutive phases, i.e., is

making no more breathing effort, the No Assist

alarm is triggered (note “5.10 Alarm signals“ on

page 33).

You end „Assisted Ventilation“ mode by pressing key

Assist. The MEDUMAT Standard a then continues

working in “Controlled Ventilation” mode. The LED

in key

Assist goes out.

Using the ventilator 29

Page 30

EN

5.4 Performing ventilation

Intubation

The patient will normally be intubated before the

patient valve is connected to the tube.

1. Attach the patient valve to the connector of the

tracheal tube.

2. Monitor the respiratory parameters during ventilation, e.g., with Weinmann’s CAPNOCOUNT mini

WM 97144. This will indicate whether the tube

is correctly positioned and ventilation is adequate.

Ventilation mask

1. Attach the mask to the patient valve.

2. Place the mask over the patient’s mouth and

nose.

3. Stretch the mask over the head and use

Esmarch’s grip to seal it hermetically.

If necessary, insert a Guedel tube to keep the airways

open before putting on the mask.

5.5 Monitoring ventilation

The patient must be monitored constantly during

ventilation.

Ventilation pressure gauge shows the ventilation

sequence.

High airway resistance, e.g., caused by obstructions

or external cardiac massage, tend to affect minute

volume (exact details can be obtained from the

30 Using the ventilator

Page 31

EN

manufacturer Weinmann on request). If the preset

Example for the ventilation sequence before and

after the lung compliance diminishes

maximal ventilation pressure is exceeded in two successive inspiration phases (note “ Stenosis alarm“ on

page 34) you should use a respirometer to check the

ventilation volume actually being received by the patient. The respirometer can be attached to the expiration tube on the patient valve with an adapter.

Monitor the respiratory parameters during ventilation,

e.g., with Weinmann’s CAPNOCOUNT mini

WM 97144.

If lung compliance diminishes during ventilation in

the

No Air Mix setting, the ventilator will react with

an increase in ventilation pressure at constant volume. For details of how MEDUMAT Standard a reacts in the

“11.5 O

Air Mix setting, please refer to Section

content when using Air Mix” on page 72.

2

5.6 Ventilation with PEEP Valve

A PEEP valve can be fitted to the expiration tube on

the patient valve with an adapter.

This valve makes it possible to use positive endexpiratory pressure (PEEP). Please see the PEEP valve

instructions for details of settings.

Using the ventilator 31

Page 32

EN

5.7 Ventilation with HME filter

A conventional heat and moisture exchange (HME)

filter with standard 15/22 mm connectors can be

fitted on the inspiration tube of the patient valve for

hygienic purposes and to condition the inspired air.

This will increase both inspiratory and expiratory

resistance. You should therefore monitor ventilation

pressure and ventilation volume very carefully.

A close watch must be kept for any increase in dead

space, especially in children.

Always read and follow the manufacturer’s

directions for use.

5.8 Ventilating with bacteria filter

To protect the patient and the environment from infection, you can connect the upgrade set for the device outlet port filter between the device outlet port

and the ventilation tube. Always monitor the exchange of air at the device inlet carefully.

32 Using the ventilator

Follow the instructions for use for the device outlet

port filter upgrade set.

Page 33

EN

5.9 Terminating ventilation

Stenosis

Disconnection

< 2,7 bar O

2

No assist

Important note!

Never empty the oxygen

cylinder completely. Return

the cylinder for filling while

it still contains residual pressure. This prevents entry of

moist atmospheric air that

can cause corrosion.

5.10 Alarm signals

1. Check the oxygen supply on the gauge on the

pressure reducer gauge. If the pressure has

dropped to 50 bar or less, the cylinder should be

refilled or a reserve cylinder should be available in

order to ensure that the ventilator will be able to

function properly.

2. Close the valve of the oxygen cylinder.

3. Switch off MEDUMAT Standard a. ON/OFF

switch must be kept pressed down for at least

2 seconds until the LEDs in the alarm panel light

up. This is a safety device to prevent the ventilator from being switched off unintentionally.

Alarm panel signals the following alarms:

Stenosis: Stenosis or a rise to maximal ventila-

tion pressure P

in two successive

max

inspiration phases

Disconnection:Disconnection between

MEDUMAT Standard a and the

patient in two successive inspiration

phases

< 2,7 bar: Drop in oxygen pressure to below

2.7 bar

: Battery charge inadequate

Using the ventilator 33

Page 34

EN

No Assist: in „Assisted Ventilation“ mode,

patient fails to trigger within the time

window in two consecutive phases.

In addition to all the visual alarms, an acoustic alarm

is triggered. Only in the case of the No Assist alarm,

is the acoustic alarm triggered with a delay of 1 minute.

The patient valve is designed to enable spontaneous

breathing in case of equipment failure.

When is the alarm set off?

An alarm signal is given as soon as any one of the

aforementioned functional failures occurs. The relevant LED starts to flash and an acoustic signal

sounds.

Simultaneous disconnection and drop in oxygen

pressure will initially set off only the < 2,7 bar alarm.

Stenosis alarm

Actual ventilation pressure exceeds the level set with

regulator knob max. ventilation pressure.

Up to Serial No. 1799 MEDUMAT Standard a switches to expiration immedi-

From Serial No. 1800 MEDUMAT Standard a briefly switches to expiration

34 Using the ventilator

ately if the maximum ventilation pressure is exceeded.

This does not affect the set frequency. Old appliances

(up to serial no.1799) that have been given a new

board in the course of repairs or servicing behave in

the same way as appliances from serial no. 1800 onwards.

whenever the maximum ventilation pressure is exceeded but tries to continue inspiration in the same

inspiration phase.

Page 35

EN

If the maximum ventilation pressure is exceeded for

a second time during the same inspiration phase, the

device finally switches to expiration and vents the

patient tube system completely. The next inspiration

starts with the following ventilation stroke according

to the frequency selected. The frequency is not

affected.

The alarm is set off when airway resistance is exceeded in two successive inspiration phases. This is to

prevent false alarms, alarms caused by coughing for

example.

Disconnection alarm

The rise in pressure during the inspiration phase is

less than 5 mbar. This is generally due to an interruption in the breathing system.

The alarm is set off when the rise in pressure is less

than 5 mbar in two successive inspiration phases.

< 2,7 bar O2 alarm

Oxygen pressure at the pressure connection to

MEDUMAT Standard a has dropped to less than

2.7 bar. The reason is usually an almost empty

oxygen cylinder.

In this case MEDUMAT Standard a will no longer

function correctly because the operating parameters

will not lie within the permissible limits.

Alarm

The battery is failing. Failure of the automatic ventilation function must be expected. Immediate steps

must be taken to provide alternative ventilation

(note “5.12 Alternative ventilation procedures“ on

page 38).

Using the ventilator 35

Page 36

EN

No Assist Alarm

In “Assisted Ventilation” mode, patient fails to trigger within the time window in two consecutive

phases.

The LED in alarm field flashes and the acoustic alarm

is triggered after a 1-minute delay.

Cancelling acoustic alarm

The acoustic alarm can be temporarily cancelled by

pressing alarm acknowledgement:

Stenosis: 30 Seconds

Disconnection: 30 Seconds

< 2,7 bar: 30 Seconds

: 120 Seconds

No Assist: 120 Seconds

The optical alarm will continue to flash.

If the cause of the alarm is not eliminated, the acoustic alarm will start to sound again after a short interval.

Both the optical and the acoustic alarm are cancelled

automatically as soon as the cause is eliminated.

36 Using the ventilator

Page 37

EN

5.11 Calculation of oxygen content/remaining

Real ventilation time(min)

oxygen content (l)

MV (l/min)

----------------------------------------------

100

O

2

-concentration()

--------------------------------------------------¥=

x

Real ventilation time(min)

1000l

11l/min

---------------------

100

100%

----------------¥91min 1h31min===

x

operating time

Oxygen content of cylinder

Oxygen volume = Volume of cylinder x cylinder pressure.

Cylinder volume x cylinder pressure = oxygen content

Example 1

Example 2

Real ventilation time

Example 1:

O

-content = 1000 l; MV = 11 l/min; 100% O2 (No Air Mix).

2

This gives the following equation:

10 l x 200 bar = 2000 l

10 l x 100 bar = 1000 l

The real ventilation time is prolonged when MEDUMAT Standard a is switched to

Mix.

Using the ventilator 37

Air

Page 38

EN

5.12 Alternative ventilation procedures

If MEDUMAT Standard a ceases to function during a

ventilation procedure, the following alternatives can

be applied:

Ventilation bags

1. Remove the patient valve from the tube or the

mask.

2. Replace it with the ventilation bag, e.g. a Weinmann

COMBIBAG WM 11000, and perform manual

ventilation.

A ventilation aid

Alternatively, you can perform mouth/mask ventilation with a Weinmann LIFEWAY WM 10580.

Exhaustion of oxygen supply

In emergency situations when the oxygen supply

runs out, MEDUMAT Standard a can also function

with compressed air.

38 Using the ventilator

Page 39

EN

6. Hygienic preparation

Whenever MEDUMAT Standard a and accessories

have been used, they must undergo a hygienic

preparation. Observe the instructions regarding use

of disinfectant. We recommend gigasept

for disinfecting by immersion and terralin

for disinfecting by wiping.

Make sure you perform a functional check after

every hygienic preparation (note “7. Functional

checks“ on page 45).

This product may contain disposable items. Dispos-

able items are intended to be used only once. So use

these items only once and do

Reprocessing disposable items may impair the functionality and safety of the product and lead to unforeseeable reactions as a result of ageing,

embrittlement, wear, thermal load, the effects of

chemical processes, etc.

®

FF (new)

®

protect

not reprocess them.

6.1 MEDUMAT Standard a

MEDUMAT Standard a’s outer casing simply needs

to be wiped with a dry or damp cloth.

Never immerse MEDUMAT Standard a in disinfectant or other fluids. Just wipe over with disinfectant.

Otherwise damage may be caused to the device,

thus endangering users and patients (note “6.6

Cleaning, disinfecting and sterilizing“ on page 44).

Hygienic preparation 39

Page 40

EN

6.2 Patient valve

Lip

membrane

Disc

membrane

Expiration

tube

Disc

membrane

Spontaneous

breathing

tube

Always grasp the hoses by their ends. Otherwise you

might damage or tear them.

1. Disconnect the patient valve from the hoses.

2. Dismantle the patient valve as shown in the adjacent diagram. It is neither necessary nor permissible to remove the membrane in the

spontaneous breathing nozzle for cleaning and

disinfection.

3. Clean the components under running water.

4. Brush the parts of the patient valve inside and

outside thoroughly, using a normal soft laboratory bottle brush.

5. Carry out sterilization/disinfection.

6. Make sure all internal and external surfaces are

thoroughly wetted and free from bubbles. Wait

for the full disinfection time to elapse.

7. Then rinse the components thoroughly inside

and out with distilled water.

40 Hygienic preparation

8. Dry the components thoroughly.

9. Reassemble the patient valve.

When reassembling, make sure that the lip

membrane is correctly positioned. The patient

valve may not function properly if it contains residual water!

Crinkled, misshapen and sticky lip and valve

membranes must be replaced.

10. Always perform a functional check before reusing the valve (note “7.4 Check of patient valve“

on page 48).

Page 41

EN

6.3 Hose system

I

Caution! Only reusable hose system WM 22520 (scope of

supply) is suitable for the hygienic preparation described here. Do

WM 28110 (2 m) and WM 28188 (3 m) available as

accessories to hygiene preparation. Replace it with a

new one.

not subject disposable hose systems

Ventilation hose

1. Take the ventilation tube and the pressure

gauge hose off both connection ports.

Warning! Take hold of the hoses at the end as

shown in the drawing, otherwise the hoses may

be damaged or pulled off. Seal both ends of the

pressure gauge hose.

2. Carry out sterilization/disinfection.

3. Make sure all internal and external surfaces are

thoroughly wetted and free from bubbles. Wait

for the full disinfection time to elapse.

4. Rinse the ventilation tube thoroughly inside and

out with distilled water.

5. Dry the components thoroughly.

6. For reassembling see “4.4 Ventilation hose” on

page 22.

Pressure gauge tube

To disinfect the pressure gauge tube of the ventilation tube, proceed as follows:

1. Connect one end of the pressure gauge tube to

a sterile disposable 20-ml syringe.

Hygienic preparation 41

Page 42

EN

2. Immerse the other end in the dilute disinfectant

solution (for gigasept

residence time 15 minutes).

3. Draw the disinfectant solution through the

pressure gauge tube into the syringe until the

latter is full. Do not flush through the pressure

gauge tube in the opposite direction!

4. Detach the syringe from the pressure gauge

tube and empty it out completely.

5. Repeat the procedure 5 more times.

6. After disinfection, the pressure gauge tube must

be rinsed with distilled water at least 8 times

using the same principle.

You can support the subsequent drying process with

medical compressed air or medical oxygen.

Then allow the component to dry thoroughly. If any

water is left in the pressure gauge tube of the ventilation tube, the device may not function correctly!

6.4 Components and accessories

®

FF: 6% solution,

42 Hygienic preparation

Masks, hoses and all rubber components should be

cleaned in a disinfectant solution:

1. Make sure all internal and external surfaces are

thoroughly wetted and free from bubbles. Wait

for the full disinfection time to elapse.

2. After disinfection always rinse the components

thoroughly with distilled water to prevent any

adverse effects from disinfectant residues.

3. Always let the rubber components dry out in the

air.

Page 43

EN

4. Carry out a visual check of the masks and hoses

and replace any damaged components.

Silicone ventilation tubes, patient valves (see preceding section) and ventilation masks can also be

autoclaved.

6.5 Fittings

This does

WM 28110 (2 m) and WM 28188 (3 m).

In cases where external cleaning of fittings (e.g., pressure reducer, valve) becomes absolutely essential,

use only a clean cloth which should either be dry or

moistened with clean water.

Never immerse fittings in disinfectant or other fluids.

Just wipe over with disinfectant. Fluids must not get

into the pressure reducer. Otherwise explosions

might occur.

If in exceptional cases you have no alternative but to

disinfect by wiping, take particular care to prevent

any fluid getting into the pressure reducer.

In addition to the risk of explosion, there is also the

risk of disinfectant getting into the patient’s respiratory tract with the oxygen and leading to injury.

not apply to disposable hose systems

Hygienic preparation 43

Page 44

EN

6.6 Cleaning, disinfecting and sterilizing

The hygienic preparation should be performed on

MEDUMAT Standard a and the accessories used as

described in the following table.

Description of

component

MEDUMAT Standard a

Patient valve

Silicone ventilation

mask

Ventilation hose

Oxygen fittings

Device outlet port filter

upgrade set

Hose casing, reusable

Always follow the directions for use supplied with

the disinfectant. We recommend gigasept

for disinfecting by immersion and terralin

®

FF (new)

®

protect

for disinfecting by wiping. You are recommended to

wear suitable gloves (e.g. household or disposable

gloves) during disinfection procedures.

For further information on hygiene treatment and a

list of all cleaning agents and disinfectants which can

be used, please see our Internet brochure at

www.weinmann-emergency.com.

Cleaning Disinfection

With a dry or damp

cloth

In warm water with

a mild household

detergent

With a dry or damp

cloth

Follow the instructions for use for the device outlet port filter upgrade set

Wipe with a dry or

damp cloth

Wiping Not permissible

Immerse in a weak

(1)

solution

Wiping Not permissible

Rinse cycle 30°C,

no spin

Rinsing in

washing machine

Rinse program at

(2)

95 °C

Possible during

cycle

Sterilization

Not

permissible

Steam

sterilization at

up to 134 °C

(3)

Not

permissible

Not permitted

44 Hygienic preparation

(1) After disinfection rinse the components thoroughly with dis-

tilled water and allow them to dry.

(2) Thermal disinfection in automatic cleansing device.

(3) Steam sterilization at 134 °C with devices to EN 285, dwell

time 5 minutes (or 18 minutes at 121 °C).

Page 45

EN

7. Functional checks

MEDUMAT Standard a must not be used if the functional checks reveal defects or deviations from the

selected parameters.

First try to correct the error with the help of the information provided in section “8. Troubleshooting“

on page 57. If this is not possible, have the device repaired by the manufacturer Weinmann or by specialists explicitly authorised to do so by same.

7.1 Preparation for functional check

For the functional check, you require:

– patient’s hose system

– test bag

– oxygen cylinder

– soap-and-water solution made from non-

perfumed soap

– adapter from test set WM 15357

We recommend that you hold reserve stocks of the

following items:

• washers for the connections;

• dust filters;

• lip membranes for the patient valve;

• membrane for spontaneous breathing arm;

• membrane for expiration arm.

1. Connect the device to the oxygen cylinder.

2. Connect the patient’s hose system to the device.

Functional checks 45

Page 46

EN

Note Check the test bag before each functional

check. The balloon of the test bag must be undamaged and firmly connected to the connector. Have the test bag serviced at the same time

as the device.

7.2 Obligatory checks

Before each use:

• Carry out a functional check.

After each use or dismantling:

• Clean, disinfect or sterilize the ventilator and its

components (note “6. Hygienic preparation“ on

page 39);

•Check the:

– lip membrane in the patient valve

– valve membrane in the expiration arm

– valve membrane in the spontaneous breath-

• Carry out a functional check.

ing arm (note “7.4 Check of patient valve“

on page 48). They may be neither crinkled,

sticky or misshapen.

46 Functional checks

At least every 6 months, if the ventilator

has not been used in the intervening

period:

• Carry out a functional check.

Page 47

EN

7.3 Check for leaks in the system

1. Open the valve of the oxygen cylinder slowly.

You will now be able to read the pressure in the

cylinder from the gauge on the pressure reducer.

For example, a reading of 200 bar means that

the cylinder is full, 100 bar that it is half full.

Always change the cylinder in good time, e.g.,

when the pressure is lower than 50 bar, to ensure that oxygen is available for an adequate

period.

2. Close the cylinder valve again.

3. Watch the needle of the gauge on the pressure

reducer for approx. 1 Minute. If it stays in the

same place, the system is free of leaks. If the

needle drops steadily, there is a leak somewhere.

Repairing leaks

Always keep a stock of

washers for the connections available.

Important note!

The screw connections on

the oxygen supply system

must be tightened by hand

only.

1. Prepare a soap/water solution using non-perfumed soap.

2. Wet all the screw and hose connections with the

solution. Bubbles will form at the site of the leak.

3. Depressurise the system:

To do this, first close the oxygen cylinder. Switch

on MEDUMAT Standard a briefly until the

pressure gauge on the O

cylinder reads “0“.

2

Then switch MEDUMAT Standard a off again.

4. If leaks are discovered, the defective

components must be changed.

5. After changing, recheck the seal.

6. If it proves impossible to eliminate the leak, the

ventilator will have to be repaired.

Functional checks 47

Page 48

EN

7.4 Check of patient valve

Checking reusable hose system

1. Dismantle the patient valve.

2. Carry out a visual check of all the components

for cracks or other physical damage.

Crinkled, sticky or misshapen lip membranes

must be changed immediately. They must never

be used during ventilation as they can cause

serious functional disturbances.

Also perform a visual check of the valve membranes in the expiration and spontaneous

breathing arms. To do so, there is no need to

dismantle the valve membranes. Crinkled, misshapen or sticky valve membranes must be replaced, however, as they can lead to considerable malfunctions.

3. Reassemble the patient valve.

48 Functional checks

When reassembling, make sure that the lip

membrane is correctly positioned.

Page 49

EN

Checking disposable hose system

Visual inspection

Check the following items by inspecting the patient

hose system:

• the patient valve and the connectors may not

exhibit any external damage, cracks or dirt.

• the hose connections must be located firmly and

securely on the connecting pieces.

• the patient valve and emergency air membranes

may not exhibit any damage or deformation.

7.5 Checking the minute volume

Check the ventilation frequency

1. Open the valve of the oxygen cylinder slowly.

2. Switch on MEDUMAT Standard a.

3. Select the following settings.

– Frequency: 8 min

-1

–MV: 5 l/min

– Ventilation pressure (P

): 60 mbar

max

– Air Mix: switched on.

4. Count the number of inspiration phases over a

period of one minute exactly. The number

should lie between 7 and 9.

5. Turn up the frequency to 40 min

-1

(right limit).

6. Count the number of inspiration phases over a

period of one minute exactly. The number

should lie between 38 and 42.

7. Switch MEDUMAT Standard a off again.

Functional checks 49

Page 50

EN

Inspiration stroke =

MV/frequency = 8/8 = 1

Check the breath volume

1. MEDUMAT Standard a must be switched off

and the oxygen cylinder must be open.

2. Place the bag from test kit WM 15382 on to the

patient valve.

3. Select the following settings:

– Frequency: 8 min

–MV: 8 l/min

–P

: 60 mbar

max

–No Air Mix

Note For the test, place the test bag on a firm base.

During the expiration phase, press the test bag

with the flat of your hand until the volume is

completely expelled through the patient valve.

4. Switch on MEDUMAT Standard a. The test bag

must be completely inflated at the end of the inspiration phase. This ensures a breath volume of

1 litre per inspiration stroke. At all events the test

bag is not sufficiently inflated if a disconnection

alarm is set off. During the expiration phase you

must simulate the expiration stroke of the test

bag by hand.

5. Switch off MEDUMAT Standard a.

-1

50 Functional checks

Risk of injury if test bag removed

incorrectly!

If the test bag is removed incorrectly, the connector of the test bag may remain on the patient’s hose system. The increased airway resistance on inspiration which results may injure the

patient.

– When removing the test bag, always take it

off at the connector.

6. Detach the test bag from the patient valve.

7. Select the following setting:

Page 51

EN

– Frequency 30 min

-1

–MV 3 L/min

–P

max

60 mbar

–No Air mix

8. Switch on MEDUMAT Standard a and close the

patient connection to the patient valve. A stenosis alarm should be set off.

9. Switch MEDUMAT Standard a off again.

Note Instead of the test bag you can also use a respiro-

meter (see accessories) to check the breath volume.

7.6 Check of maximal ventilation pressure

Important note!

For this test, always set the

tumbler switch to “No Air

Mix”. For physical reasons,

losses occur at the injector

if the switch is set to “Air

Mix”.

Important note!

Use the test bag. If you try

to keep the tube connector

closed with your hand, the

needle will swing over and

it will be impossible to obtain an accurate reading.

1. MEDUMAT Standard a must be switched off

and the oxygen cylinder must be open.

2. Check that the needle of the manometer on

MEDUMAT Standard a is standing at “

0“ (note

“8.3 Adjustment of manometer“ on page 61).

3. Place the bag from test kit WM15382 on to the

patient valve.

4. Select the following settings:

– Frequency: 8 min

-1

–MV: 7 l/min

–P

: 20 mbar

max

–No Air Mix

5. Switch on MEDUMAT Standard a.

During this test you must not assist the expiration stroke. The oxygen must remain unpressurized in the test bag. In this way the pressure

gradually builds up. Between 15 and 25 mbar

MEDUMAT Standard a should set off the

Stenosis alarm.

6. Switch off MEDUMAT Standard a.

Functional checks 51

Page 52

EN

Risk of injury if test bag removed

incorrectly!

If the test bag is removed incorrectly, the connector of the test bag may remain on the patient’s hose system. The increased airway resistance on inspiration which results may injure the

patient.

– When removing the test bag, always take it

off at the connector.

7. Detach the test bag from the patient valve.

8. Repeat this test for a maximum ventilation

pressure of 60 mbar with the following setting:

– Frequency: 8 min

-1

–MV: 9 l/min

–P

: 60 mbar

max

–No Air Mix

During this test you must not assist the expiration stroke. The oxygen must remain unpressurized in the test bag. In this way the pressure

gradually builds up. Between 55 and 65 mbar

MEDUMAT Standard a should set off the

Stenosis alarm.

7.7 Check assisted ventilation

1. The MEDUMAT Standard a must be switched

off and the oxygen cylinder must be open.

2. Plug the test bag with adapter of test set

WM15382 onto the patient valve.

3. Select the following setting:

– frequency: 8 min

– MV: 8 l/min.

–P

–Air Mix

52 Functional checks

: 60 mbar

max

-1

Page 53

EN

4. Switch on the MEDUMAT Standard a.

Stenosis

Disconnection

< 2,7 bar O

2

No assist

5. Press the Assist key to switch on „Assisted

Ventilation“ mode.

„Assisted Ventilation“ mode is indicated by the

flashing green LED in the Assist key.

6. Wait 2 inspiration phases.

The No Assist alarm should then be triggered:

the yellow No Assist LED in alarm field flashes.

The acoustic alarm comes on only after 1 minute.

7. Simulate inspiration pulses with one hand by

pressing the test bag together several times.

– The pointer of ventilation pressure gauge

must go into the negative range during the

simulation. Negative pressure must be at

least – 0.8 mbar;

– As soon as the MEDUMAT Standard a

detects the pulse within the time window,

the yellow No Assist LED goes out. This ensures that the MEDUMAT Standard a recognizes trigger pulses.

8. Switch the MEDUMAT Standard a off again.

Risk of injury if test bag removed

incorrectly!

If the test bag is removed incorrectly, the connector of the test bag may remain on the patient’s hose system. The increased airway resistance on inspiration which results may injure the

patient.

– When removing the test bag, always take it

off at the connector.

9. Detach the test bag from the patient valve.

1

Functional checks 53

Page 54

EN

7.8 Check of alarm systems

Important note!

The stenosis and disconnection alarms are set off only

when the cause of the

alarm is repeated in two

successive inspiration

phases. This prevents triggering of the alarm by a

very short-lived

dysfunction.

Important note!

In this test the rise in pressure is strong enough to

make the manometer needle overswing considerably. There are technical

reasons for this and it does

not indicate any malfunction.

Important note!

In this test the rise in pressure is strong enough to

make the manometer needle overswing considerably. There are technical

reasons for this and it does

not indicate any malfunction.

Stenosis

1. Open the oxygen cylinder.

2. If necessary: Remove the tube or the ventilation

mask from the patient valve.

3. Switch on MEDUMAT Standard a

4. Set max. ventilation pressure regulator at

60 mbar.

5. Keep the ventilation connector on the patient

valve closed with the flat of your hand during

two successive inspiration phases. The

Stenosis

alarm should be set off.

6. Switch the MEDUMAT Standard a off again.

Interruption of breathing system

(Disconnection)

1. Open the oxygen cylinder.

2. If necessary: Remove the tube or the ventilation

mask from the patient valve.

3. Switch on MEDUMAT Standard a

4. Set max. ventilation pressure regulator at

60 mbar.

5. Keep the ventilation connector on the patient

valve closed with the flat of your hand during

two successive inspiration phases. The

alarm should be set off.

6. Then remove your hand. The

Stenosis alarm

should cease (LED stops flashing, acoustic alarm

stops sounding).

After two successive inspiration phases the

Disconnection alarm should be set off.

Stenosis

54 Functional checks

Page 55

EN

7. Switch the MEDUMAT Standard a off again.

Drop in O2 pressure (<2,7 bar O2)

1. Open the valve of the oxygen cylinder slowly.

2. Switch on MEDUMAT Standard a.

3. Close the valve on the oxygen cylinder. When

the oxygen pressure in the system has sunk below 2.7 bar, the

<2,7 bar O

alarm should be set

2

off.

4. Switch the MEDUMAT Standard a off again.

Energy supply ( )

The alarm signalling a failing battery is checked

automatically in the self test that runs when

MEDUMAT Standard a is switched on.

The energy supply is in order if no alarm is set off

when the valve on the oxygen cylinder is opened and

MEDUMAT Standard a is switched on and starts to

function correctly.

Failure to trigger (No Assist)

1. The oxygen cylinder must be open.

2. Switch on the MEDUMAT Standard a.

3. To switch on „Assisted Ventilation“ mode, press

Assist.

key

„Assisted Ventilation“ mode is indicated by the

flashing green LED in key

Assist.

Functional checks 55

Page 56

EN

4. After the second ventilation stroke, the yellow

Stenosis

Disconnection

< 2,7 bar O

2

No assist

alarm message „No Assist“ must flash in alarm

field. The acoustic alarm sounds after a delay of

1 minute if the fault has not been eliminated in

the meantime.

5. Switch the MEDUMAT Standard a off again.

56 Functional checks

Page 57

EN

8. Troubleshooting

Defect Cause of defect Elimination

MEDUMAT Standard a

cannot be switched on

Stenosis alarm

(excessive airway

resistance)

Disconnection alarm

(interruption of breathing

system)

< 2,7 bar alarm (oxygen

pressure too low)

Alarm

Alarm No Assist

MEDUMAT Standard a defective Arrange for repair

Battery failure Replace both batteries (8.1, page 59)

Obstruction of airways Remove obstruction.

Tube incorrectly positioned Correct tube position.

P

set too low Adapt P

max

Kink or obstruction in ventilation

hose/mask/tube

MEDUMAT Standard a defective Arrange for repair

Ventilation hose leaking/slipped

out

Pressure gauge hose leaking/

slipped out/not connected

MEDUMAT Standard a defective Arrange for repair

Oxygen cylinder nearly empty Change O2 cylinder (4.3, page 21)

Oxygen valve closed Open oxygen valve

Pressure reducer defective Replace pressure reducer

Kink or blockage in oxygen hose Take action to correct

Battery failing Replace both batteries (8.1, page 59)

Fuse defective Replace fuse (8.2, page 60)

Patient does not trigger device

within time window

Patient does not trigger device at all

Valve membrane in spontaneous

breathing arm defective or missing

max

Remove kink or obstruction; if

necessary replace parts.

Check connectionsTube/mask incorrectly positioned

Adapt ventilation frequency to suit

patient

Continue ventilating in Controlled

Ventilation mode

Insert new valve membrane (8.4,

page 61))

.

Troubleshooting 57

Page 58

EN

Defect Cause of defect Elimination

Visual alarms flashing but

no acoustic alarm.

Acoustic alarm but no

visual alarm

Acoustic alarm and all

visual alarms flashing

MEDUMAT Standard a is

functioning but without

any displays

MV too low

Unusually high oxygen

consumption

MEDUMAT Standard a

cannot be switched off

Manometer needle not

standing at “0“

Test bag is not sufficiently

inflated during functional

check, disconnection

alarm

No stenosis alarm when

patient valve is closed

during functional

check(see “7.5 Checking

the minute volume”, item

6–9)

Short-term electronic disruption

Pressure gauge hose on

MEDUMAT Standard a or on

patient valve slipped off

Kink in pressure gauge hose

Wrongly selected ventilation

parameter

MEDUMAT Standard a defective Arrange for repair

Leak in oxygen supply Seek and eliminate leak (7.3, page 47)

User error

Manometer needle needs

adjustment

Ventilation parameters wrongly

selected

Patient valve not working

properly

Pressure gauge hose not fitted Fit pressure gauge hose

Patient valve not working

properly

Switch off and on again. If error recurs,

arrange for repair.

Check pressure gauge hose

Check ventilation parameters

Keep switch depressed for at least

2 seconds.

Adjust (8.3, page 61)

Correct ventilation parameters

Check lip membrane

Check lip membrane

58 Troubleshooting

Page 59

EN

8.1 Batteries

18: Button cell for auxiliary power

19: Fuse protecting against internal

short circuit

20: 3.6 V lithium battery for main

power supply to

MEDUMAT Standard a

18

20

19

Caution!

Batteries and rechargeable

batteries do not belong in

domestic waste! Every

consumer is obliged by law

to hand in all batteries and

rechargeable batteries, regardless of whether they

contain harmful substances

or not, at a community/local collection point or at a

store so that they can be

disposed of in an environmentally-friendly way.

MEDUMAT Standard a is fitted with two batteries

which should always be replaced simultaneously.

A CR2430 button cell supplies auxiliary power to the

electronics if the main batteries fail. This makes it

possible to set off an alarm if the main batteries fail.

At the same time, the MEDUMAT Standard a

switches to expiration.

The battery capacity is calculated to be sufficient for

power requirements under normal operating conditions for the full period between servicing every two

years. All the batteries are replaced at every two

years during servicing.

We recommend having the batteries changed only

by Weinmann the manufacturer or by qualified persons expressly authorized by that company. Special

precautions need to be taken during the change in

order to prevent disruption of the electronics.

The following action should be taken in emergencies:

Troubleshooting 59

Page 60

EN

Important note!

In order to prevent damage

to the electronics, avoid all

contact with the printed

circuit board unless adequate protection against

electrostatic charge is

available.

Important note!

The 3.6 V lithium battery is

specially designed for this

ventilator. Only batteries

supplied by Weinmann

should be used.

8.2 Cut-out system

Battery replacement

1. Unscrew the back panel of MEDUMAT Standard a

(6 cross-slotted screws).

2. Tilt the CR2430 button cell slightly to remove it.

3. Insert a new button cell.

4. Remove the plug from the printed circuit board

and lift the 3.6 V lithium battery out of its holder.

5. Insert the new battery.

6. Replace the back panel of MEDUMAT Standard a.

MEDUMAT Standard a is fitted with a fusible cut-out

to protect it against internal short circuits.

Important note!

In order to prevent damage

to the electronics, avoid all

contact with the printed

circuit board.

60 Troubleshooting

Changing a fuse

1. Unscrew the back panel of MEDUMAT Standard a

(6 cross-slotted screws).

2. Remove the defective fuse.

3. Insert a new fuse. Use only officially approved

fuses (see “11. Technical data” on page 68).

Page 61

EN

4. Replace the back panel and carry out a function-

adjustment

screw

Spontaneous

breathing arm

Expirationarm

al check (see “7. Functional checks” on

page 45).

8.3 Adjustment of manometer

When MEDUMAT Standard a is switched off and the

valve of the oxygen cylinder is closed, the manometer needle should read exactly “

0“.

Proceed as follows to adjust the needle:

1. Carefully pry off the plastic cover of the adjustment screw.

2. Adjust the position of the needle by turning the

adjustment screw with a small screwdriver (e.g.

a watchmaker’s screwdriver).

3. Reinsert the plastic cover.

8.4 Change valve membrane in patient valve

If one of the valve membranes in the expiration or

spontaneous breathing arms of the patient valve is

crinkled, sticky or misshapen, it must be changed.

Spontaneous breathing arm

1. Take the spontaneous breathing insert out of

the patient valve. To do so, push the two locking lugs out of their seat, using a small screwdriver, for example.

2. Pull the defective valve membrane out of the

spontaneous breathing insert using pointed

tweezers.

Troubleshooting 61

Page 62

EN

3. Put in a new valve membrane.

4. Push the spontaneous breathing insert back into

the patient valve.

Expiration arm

1. Use pointed tweezers to pull the defective valve

membrane out of the expiration arm.

2. Insert a new valve membrane.

Note:

This applies only to the reusable system.

62 Troubleshooting

Page 63

EN

9. Servicing

9.1 Intervals

Have the cleaned and disinfected device serviced at

regular intervals. Servicing, safety checks ([sicherheitstechnische Kontrollen or STKs] in accordance with

§6 of the German law governing the owners/operators of medical devices - only applies to Germany)

and maintenance measures such as servicing and repairs may only be performed by the manufacturer or

by specialists expressly so authorized by the manufacturer.

Maintain the following intervals:

Interval Parts affected

– System components: e.g. carrying

systems, tube connections

Every 2 years (service and

safety check)

Every 4 years

Every 10 years Steel and aluminum oxygen cylinders

– Accessories

– Test bag

– Oxygen fittings

– Specified wear parts relevant to safety

– Oxygen fittings

– Specified wear parts relevant to safety

* Disposable hose systems WM 28110 (2 m) and

WM 28188 (3 m) do not require any maintenance.

Person to carry

out

Manufacturer or

specialists expressly

so authorized by the

manufacturer

Servicing 63

Page 64

EN

9.2 Sending in device

Warning!

Risk of infection from contaminated parts

during maintenance measures!

The device, components and accessories may be

contaminated and infect specialist staff with bacteria

or viruses when they are carrying out maintenance

measures.

• Clean and disinfect device, components and ac-

• Do not send in potentially contaminated parts.

1. Remove components and accessories.

2. Clean the device, components and accessories

3. Send device, and if necessary components and

Note If you send in obviously contaminated parts,

cessories.

(note “6. Hygienic preparation“ on page 39).

accessories, to WEINMANN Emergency or to

specialist staff expressly authorized by

WEINMANN Emergency.

these will be disposed of by WEINMANN Emergency or by specialist staff expressly authorized

by WEINMANN Emergency at your expense.

9.3 Storage

64 Servicing

If you do not intend to use MEDUMAT Standard a for

a long period, we recommend the following storage

precautions:

1. Clean and disinfect the ventilator (note “6.

Hygienic preparation“ on page 39).

Page 65

EN

Important note! Remember that the ventilator still requires servic-

9.4 Disposal

2. Store MEDUMAT Standard a in a dry place.

ing at the stipulated intervals even when in storage, otherwise it cannot be used when removed

from storage.

Note With disposable hose systems WM 28110 (2 m)

and WM 28188 (3 m), observe the storage temperature of -40 °C to 70 °C at a rel. humidity of

15 % to 95 %. These products can be stored for

a maximum of 2 years.

Do not dispose of the device with domestic waste.

For proper disposal of the device and its components, please contact a certified waste disposal site

for electronic goods. Ask your Environmental Officer