Page 1

This area cut out

to form a window

Page 2

Page 3

USER’S HANDBOOK

Model 395

100 MHz Synthesized

Arbitrary Waveform Generator

Page 4

USER'S HANDBOOK

for

THE MODEL 395

100MHz Synthesized

Arbitrary Waveform Generator

Part no. 850325 Issue 1.0 (April 2000)

ISO 9002

CERTIFICATE

No. FM 29700

For any assistance contact your nearest Wavetek-Datron Sales and Service Center.

Addresses can be found at the back of this handbook.

© 2000 Fluke Precision Measurement Ltd.

is a registered trademark of Fluke Precision Measurement Ltd.

Page 5

WARRANTY

Wavetek-Datron warrants that all products manufactured by Wavetek-Datron conform to published Wavetek-Datron

specifications and are free from defects in materials and workmanship for a period of one (1) year from the date of

delivery when used under normal operating conditions and within the service conditions for which they were furnished.

The obligation of Wavetek-Datron arising from a Warranty claim shall be limited to repairing, or at its option, replacing

without charge, any product which in Wavetek-Datron’s sole opinion proves to be defective within the scope of the

Warranty. In the event Wavetek-Datron is not able to modify, repair or replace non-conforming defective parts or

components to a condition as warranted within a reasonable time after receipt thereof, Buyers shall be credited for their

value at the original purchase price.

Wavetek-Datron must be notified in writing of the defect or nonconformity within the Warranty period and the affected

product returned to Wavetek-Datron’s factory or to an authorized service center within thirty (30) days after discovery

of such defect or nonconformity.

For product warranties requiring return to Wavetek-Datron, products must be returned to a service facility designated

by Wavetek-Datron. Buyer shall prepay shipping charges, taxes, duties and insurance for products returned to WavetekDatron for warranty service. Except for products returned to Buyer from another country, Wavetek-Datron shall pay

for return of products to Buyer.

Wavetek-Datron shall have no responsibility hereunder for any defect or damage caused by improper storage, improper

installation, unauthorized modification, misuse, neglect, inadequate maintenance, accident or for any product which

has been repaired or altered by anyone other than Wavetek-Datron or its authorized representative and not in accordance

with instructions furnished by Wavetek-Datron.

Exclusion of Other Warranties

The Warranty described above is Buyer’s sole and exclusive remedy and no other warranty, whether written

or oral, is expressed or implied. Wavetek-Datron specifically disclaims the implied warranties of merchantability

and fitness for a particular purpose. No statement, representation, agreement, or understanding, oral or written, made

by an agent, distributor, representative, or employee of Wavetek-Datron, which is not contained in the foregoing

Warranty will be binding upon Wavetek-Datron, unless made in writing and executed by an authorized WavetekDatron employee. Under no circumstances shall Wavetek-Datron be liable for any direct, indirect, special,

incidental, or consequential damages, expenses, losses or delays (including loss of profits) based on contact, tort,

or any other legal theory.

Page 6

EC Declaration of Conformity

WE:

Wavetek-Datron

Hurricane Way

Norwich, NR6 6JB

United Kingdom

Declare under sole responsibility that the

Model 395 100MHz Synthesized Arbitary Waveform Generator

meets the intent of Directive 89/336/EEC for Electromagnetic Compatibility and Low

Voltage Directive 72/23/EEC for Product Safety. Compliance was demonstrated to the

following specifications as listed in the Official Journal of the European Communities:

EMC Directive 89/336/EEC (rev 91/263/EEC. 92/31/EEC. 93/68/EEC):

EN 50081 - 1 Emissions:

EN 55011/22 Class A radiated and conducted emissions

EN 50082 - 1 Immunity:

IEC 801 - 2 Electrostatic discharge immunity

IEC 801 - 3 RF electromagnetic field immunity

IEC 801 - 4 Electrical fast transient / burst immunity

IEC 801 - 5 Power line surge immunity

Low Voltage Directive 73/23/EEC (rev 93/68/EEC):

EN 61010 - I Safety requirements for electrical equipment for measurement,

control and laboratory use.

Page 7

Contents

SAFETY ISSUES

READ THIS ENTIRE SECTION THOROUGHLY BEFORE ATTEMPTING TO INSTALL, OPERATE OR

SERVICE THE MODEL 395 100MHz SYNTHESIZED ARBITRARY WAVEFORM GENERATOR ix

Section 1 Introduction

1.1 THE MODEL 395...................................................................................1-1

1.2 ORGANIZATION OF THIS MANUAL.................................................... 1-2

Section 2 Initial Preparation

2.1 THIS SECTION......................................................................................2-1

2.2 RECEIVING AND INSPECTING SHIPMENTS..................................... 2-1

2.3 RETURNING EQUIPMENT FOR REPAIR............................................ 2-1

2.4 PREPARATION FOR STORAGE OR SHIPMENT ............................... 2-2

2.5 LINE VOLTAGES AND FUSES ............................................................ 2-2

2.6 INITIAL TURN–ON ................................................................................2-4

2.7 ERROR MESSAGES ............................................................................2-5

2.8 FUNCTIONAL CHECKOUT .................................................................. 2-5

Continuous Mode Check........................................................................ 2-5

Sweep Mode Check ...............................................................................2-5

Gated Mode Check ................................................................................2-5

Triggered Mode Check...........................................................................2-6

2.9 OPERATOR MAINTENANCE ............................................................... 2-6

2.9.1 Routine Maintenance ...................................................................2-6

2.9.2 Battery Replacement ...................................................................2-7

2.10 RACK MOUNTING EARS ................................................................... 2-7

2.11 REMOTE SETUP ................................................................................2-7

2.11.1 RS-232 .......................................................................................2-7

2.11.2 IEEE-488 (Option 001).............................................................. 2-10

Section 3 Introduction To The Model 395

3.1 OVERVIEW OF THE MODEL 395 ........................................................ 3-1

Using the Model 395 ..............................................................................3-1

3.2 NAVIGATING THE SCREENS.............................................................. 3-1

3.2.1 Front Panel Keys and Screens ..................................................... 3-1

3.2.2 Softkeys .......................................................................................3-2

3.2.3 Extended Screens........................................................................3-2

3.2.4 Changing Numeric Values ........................................................... 3-3

3.2.5 Correcting Mistakes ..................................................................... 3-4

3.3 ON-SCREEN HELP................................................................................3-4

3.4 ERROR MESSAGES ............................................................................3-5

3.5 INITIAL SETUP......................................................................................3-5

3.6 MODEL 395 AS A FUNCTION GENERATOR...................................... 3-6

Example 1. Setting Up the Function Generator ............................. 3-6

3.7 MODEL 395 AS AN ARBITRARY WAVEFORM GENERATOR............3-10

Example 2 Creating an Arbitrary Waveform Using Line Draw ........3-11

Example 3 Generating the Arb Waveform....................................... 3-14

Example 4. Creating an Arb Waveform Using Waveform Insert .....3-17

Example 5. Creating an Arbitrary Waveform Using Point Edit ........3-19

3.8 THE MODEL 395 AS A WAVEFORM SEQUENCE GENERATOR.......3-22

Example 6 Creating a Waveform Sequence .................................. 3-22

3.9 STORING AND RECALLING SETUPS................................................. 3-24

Example 7. Storing and Recalling an Instrument Setup .................3-24

3.10 THE MODEL 395 AS A SWEEP GENERATOR ................................. 3-25

Example 8. Setting up the Sweep Generator................................. 3-25

Contents v

Page 8

3.11 THE MODEL 395 AS A TRIGGER GENERATOR.............................. 3-27

Example 9 Setting up the Triggered Generator............................... 3-27

3.12 THE MODEL 395 AS A PULSE GENERATOR .................................. 3-31

Example 10 Setting up the Pulse Waveform.................................. 3-31

Example 11 Setting up the Pulse Train Waveform ......................... 3-34

3.13 THE MODEL 395 AS A NOISE GENERATOR ................................... 3-43

Example 12 Setting Up the Signal To Noise Waveform ................. 3-43

3.14 THE MODEL 395 AS AN AMPLITUDE MODULATION SIGNAL

SOURCE .......................................................................................3-46

Example 13 Setting Up Amplitude Modulation............................... 3-46

3.15 THE MODEL 395 SUMMING INPUT ................................................. 3-48

Example 14. Setting Up Summing Input ........................................ 3-48

Section 4 Front Panel Operation Reference

4.1 INTRODUCTION ....................................................................................4-1

4.2 FRONT PANEL.......................................................................................4-1

4.3 REAR PANEL ........................................................................................4-9

4.4 REFERENCE..........................................................................................4-11

4.4.1 Amplitude ......................................................................................4-11

4.4.2 AM In (amplitude modulation And SCM) ..................................... 4-14

4.4.3 Arbitrary Waveforms .................................................................... 4-16

4.4.3.1 Introduction..........................................................................4-16

4.4.3.2 Creating Waveforms............................................................ 4-17

4.4.3.3 Create From Copy .............................................................. 4-18

4.4.3.4 Modifying Waveforms......................................................... 4-19

4.4.4 Filter ..............................................................................................4-29

4.4.4.1 Introduction..........................................................................4-29

4.4.4.2 Mode...................................................................................4-29

4.4.4.3 Filter....................................................................................4-30

4.4.5 Frequency ....................................................................................4-30

4.4.5.1 Standard Waveform Frequency ......................................... 4-30

4.4.5.2 Standard Waveform Period ................................................ 4-30

4.4.5.3 Arbitrary Waveforms - Frequency / Period ......................... 4-31

4.4.5.4 Sequence - Frequency/Period............................................ 4-31

4.4.5.5 Pulse / Pulse Train Period................................................... 4-31

4.4.5.6 Noise Clock ........................................................................ 4-31

4.4.6 MODE .................................................................................................4-32

4.4.7 OFFSET..............................................................................................4-34

4.4.8 REMOTE ............................................................................................4-35

4.4.9 RESET................................................................................................4-36

4.4.10 SEQUENCE......................................................................................4-37

4.4.11 SETUPS ............................................................................................4-40

4.4.12 STANDARD WAVEFORMS ............................................................. 4-41

4.4.12.1 Introduction........................................................................ 4-41

4.4.12.2 Sine...................................................................................4-42

4.4.12.3 Square .............................................................................. 4-42

4.4.12.4 Triangle............................................................................. 4-42

4.4.12.5 DC.....................................................................................4-42

4.4.12.6 Positive Ramp .................................................................. 4-43

4.4.12. 7 Negative Ramp................................................................ 4-43

4.4.12.8 Sin(x)/x.............................................................................. 4-43

4.4.12.9 Positive Haversine............................................................ 4-43

4.4.12.10 Negative Haversine ........................................................ 4-43

4.4.12.11 Pulse............................................................................... 4-43

4.4.12.12 Pulse Train...................................................................... 4-46

4.4.12.13 Digital Noise ................................................................... 4-51

4.4.12.14 Analog Noise (White Analog Noise) ............................... 4-52

vi Contents

Page 9

4.4.12.15 Comb .............................................................................. 4-55

4.4.12.16 Signal Plus Noise ........................................................... 4-57

4.4.12.17 Signal Plus Comb............................................................ 4-60

4.4.12.18 AM / SCM ....................................................................... 4-63

4.4.12.19 FM...................................................................................4-65

4.4.12.20 Arb Waveforms ............................................................... 4-66

4.4.12.21 Sequence ....................................................................... 4-66

4.4.13 Status .........................................................................................4-67

4.4.14 Sum in ........................................................................................4-68

4.4.15 Sweep ........................................................................................4-69

4.4.16 Sync Out ....................................................................................4-74

4.4.17 Trigger ........................................................................................4-76

4.4.18 Utility...........................................................................................4-77

4.4.19 Ref In / Ref Out .......................................................................... 4-79

Section 5 Remote Operation

5.1 INTRODUCTION ...................................................................................5-1

5.2 SCPI PRIMER .......................................................................................5-2

5.2.1 Parameters...................................................................................5-3

5.2.2 Queries.........................................................................................5-4

5.2.3 SCPI Punctuation and Syntax...................................................... 5-4

5.2.4 Condensed Rules:........................................................................ 5-4

5.2.5 Text Symbols ...............................................................................5-5

5.2.6 Example Command Tree .............................................................5-6

5.2.7 Example Command Table ...........................................................5-8

5.2.8 Example Command Syntax Diagrams......................................... 5-8

5.3 REMOTE RS-232 SETUP ..................................................................... 5-11

5.3.1 Hardware Setup ...........................................................................5-11

5.3.2 Instrument Setup..........................................................................5-11

5.4 IEEE-488.1 (GPIB) SETUP ................................................................... 5-12

5.4.1 Hardware Setup ...........................................................................5-12

5.4.2 Instrument Setup..........................................................................5-12

5.5 SCPI PROGRAMMING EXAMPLES..................................................... 5-13

5.5.1 Model 395 As a Function Generator............................................ 5-14

Example 1. Setting Up the Function Generator ............................. 5-14

5.5.2 Model 395 as an Arbitrary Waveform Generator......................... 5-15

Example 2 Creating an Arbitrary Waveform Using Line Draw ........5-15

Example 3 Running the Arb Waveform .......................................... 5-16

Example 4. Creating an Arb Waveform Using Waveform Insert .....5-17

Example 5. Creating an Arbitrary Waveform Using Point Edit ........5-17

5.5.3 The Model 395 as a Waveform Sequence Generator ................. 5-19

Example 6 Creating a Waveform Sequence .................................. 5-19

5.5.4 Storing and Recalling Setups....................................................... 5-20

Example 7. Storing and Recalling an Instrument Setup .................5-20

5.5.5 The Model 395 As a Sweep Generator ....................................... 5-20

Example 8. Setting up the Sweep Generator................................. 5-20

5.5.6 The Model 395 as a Trigger Generator ....................................... 5-21

Example 9 Setting up the Triggered Generator............................... 5-21

5.5.7 The Model 395 as a Pulse Generator.......................................... 5-22

Example 10 Setting up the Pulse Waveform.................................. 5-22

Example 11 Setting up the Pulse Train Waveform ......................... 5-22

5.5.8 The Model 395 as a Noise Generator.......................................... 5-24

Example 12 Setting Up the Signal To Noise Waveform ................. 5-24

5.5.9 The Model 395 as an Amplitude Modulation Signal Source.........5-24

Example 13 Setting Up Amplitude Modulation............................... 5-24

5.5.10 The Model 395 and its Summing Input ...................................... 5-25

Example 14. Setting Up Summing Input ........................................ 5-25

Contents vii

Page 10

5.6 SCPI COMMANDS................................................................................5-27

5.6.1 ABORT ...............................................................................................5-27

5.6.2 CALibration ..................................................................................5-27

5.6.3 DISPlaY........................................................................................5-28

5.6.4 INITiate.........................................................................................5-29

5.6.5 MMEMory.....................................................................................5-29

5.6.6 OUTPut ........................................................................................5-31

5.6.7 RESet...........................................................................................5-32

5.6.8 [SOURce] .....................................................................................5-33

5.6.9 STATus ........................................................................................5-44

5.6.10 SYSTem.....................................................................................5-45

5.6.11 TEST ..........................................................................................5-45

5.6.12 TRACe .......................................................................................5-46

5.5.12 TRIGger .....................................................................................5-48

5.7 IEEE 488.2 COMMON COMMANDS .................................................... 5-50

5.8 HIGH SPEED BINARY WAVEFORM TRANSFER ............................... 5-51

5.9 RS-232-C PROGRAMMING.................................................................. 5-53

5.10 GPIB ERROR HANDLING AND STATUS REPORTING.................... 5-53

5.11 RESUMING LOCAL OPERATION ...................................................... 5-58

Appendix A Specifications

Appendix B Menu - Quick Reference

Appendix C SCPI Command - Quick Reference

Appendix D Rack Ears Kit Installation

Appendix E Information/Error Messages

Appendix F DSO Upload

Appendix G Performance Verification and Alignment Procedures

viii Contents

Page 11

SAFETY ISSUES

READ THIS ENTIRE SECTION THOROUGHLY BEFORE ATTEMPTING TO INSTALL, OPERATE OR SERVICE THE MODEL 395

General Safety Summary

This instrument has been designed and tested in accordance with the British and European standard publication

EN61010: 1993/A2: 1995, and has been supplied in a safe condition.

This manual contains information and warnings that must be observed to keep the instrument in a safe condition and

ensure safe operation. Operation or service in conditions, or in a manner other than specified could compromise safety.

For the correct and safe use of this instrument it is essential that both operating and service personnel follow generally

accepted safety procedures in addition to the safety precautions specified.

To avoid injury or fire hazard the instrument should not be switched on if it is damaged or suspected faulty, and it should

not be used under damp, wet, condensing, dusty or explosive gas conditions.

Whenever it is likely that safety-protection has been impaired, the instrument must be made inoperative and be secured

against any unintended operation. Qualified maintenance or repair personnel should be informed. Safety-protection is

likely to be impaired if, for, example the instrument shows visible damage or fails to operate normally.

Explanation of safety related symbols and terms

DANGER

Risk of Electric Shock The product is marked with this symbol to indicate that

hazardous voltage (> 30V dc or ac pk) may be present.

CAUTION

Refer to accompanying documents The product is marked with this symbol when it is necessary

for the user to refer to the instruction manual.

Earth (Ground) Terminal Functional Earth (Ground) only, must not be used as a

Protective Earth.

WARNING Warning statements identify conditions or practices that could result in injury or loss of life

CAUTION Caution statements identify conditions or practices that could result in damage to this or other

property.

WARNING

THIS INSTRUMENT CAN DELIVER A LETHAL ELECTRIC SHOCK. NEVER TOUCH ANY LEAD OR

TERMINAL UNLESS YOU ARE ABSOLUTELY CERTAIN THAT NO DANGEROUS VOLTAGE IS PRESENT.

ix

Page 12

Protective Earth (or Grounding)

Protection Class 1 - The instrument must be operated with a Protective Earth /Ground connected via the Protective

Earth/Grounding conductor of the supply cable.

This is connected to the instrument before the line and neutral connections when the supply plug is inserted into the

socket on the back of the instrument. If the final connection to the supply is made elsewhere, ensure that the ground

connection is made before line and neutral.

WARNING Any interruption of the protective ground conductor inside or outside the instrument is

likely to make the instrument dangerous. Intentional interruption is prohibited.

To avoid electric shock the signal connections to the instrument should be connected after the ground connection is

made and disconnected before the ground connection is removed, i.e. the supply lead must be connected whenever

signal leads are connected.

Do Not Operate without Covers

To avoid electric shock or fire hazard, the instrument must not be operated with covers removed. The covers protect

the user from live parts and unless otherwise stated they should be removed only by suitably qualified personnel for

maintenance and repair purposes.

WARNING Removing the covers may expose voltages in excess of l.5 kV pk; these may be present for

up to one minute after the instrument has been disconnected from the power source; longer

under fault conditions.

Safe Operating Conditions

The unit must be operated only within the manufacturers specified operating conditions. Examples of specification that

must be considered are:

Ambient temperature

Ambient humidity

Power supply voltage and frequency

Maximum terminal voltages or currents

Altitude

Ambient pollution level

Exposure to shock and vibration

To avoid electric shock or fire hazard, do not apply to or subject the instrument to any condition that is outside specified

range. Please refer to Appendix A of this manual for detailed Specification of the instrument and its operating

conditions.

CAUTION

Direct sunlight, radiators and other heat sources should be taken into account when

assessing the ambient temperature.

CAUTION

Before connecting the instrument to the supply, ensure that the rear panel AC supply voltage

selector is set to the appropriate voltage, either 115V or 230V and that correctly rated fuses

are fitted (see below)

Fuse Requirements

To avoid fire hazard the fuse arrangement shown in the table below must be followed. Additionally the supply network

must be fused at a maximum of 16 A and in the UK, a 5 A fuse should be fitted in the power cord plug.

x

Page 13

Power Input Fuse

Supply (Line)

Voltage

115 VAC

Fuse Action

T

Time delay

T

Time delay

Fuse Rating

UL/CSA

1 A

500 mA230 VAC

Wavetek-Datron

Part No.

2400-05-0029

2400-05-0010

Manufacturer

& Type No.

BUSSMAN MDL 1

BUSSMAN MDL 1/2

The Power Cord and Power Supply Disconnection

The power supply disconnect device is the ON / OFF switch on the rear panel of the instrument. The ON / OFF switch

should be readily accessible whilst the instrument is in operation. If this operating condition cannot be satisfied, it is

essential that either the power cord plug or a separate power disconnecting device be readily reached and accessible

to the operator.

To avoid electric shock and fire hazard, ensure that the power cord is not damaged and is adequately rated against power

supply network fusing. If the power plug is to be the accessible disconnecting device, the cord must not be longer than

3 metres.

Connection to Instrument Terminals

Ensure that the instrument is correctly Earthed (Grounded) via its power cord before and whilst any other connection

is made.

Installation Category I

Measurement and/or guard terminals are designed for connection at Installation (Over voltage) Category I. To avoid

electric shock or fire hazard the instrument terminals must not be connected directly to the mains power supply or any

other source of voltage or current that might temporarily exceed the peak ratings of the instrument

WARNING To avoid injury or loss of life, do not connect or disconnect signal leads while they are

connected, or suspected of being, connected to a hazardous voltage or current source

(internal or external to the instrument).

Maintenance and Repair

Local or national safety regulations and rules for the prevention of accidents and hazard must be observed in all work

performed. The unit must be disconnected from all signal sources and then the power supply before the removal of

covers. Any adjustment, parts replacement, maintenance or repair should be carried out only by authorised WavetekDatron technical personnel.

WARNING For continued protection against injury and fire hazard it is essential that only manufacturer

supplied parts be used to replace parts relevant to safety. Safety tests must be performed

after the replacement of parts relevant to safety.

Ventilation and Dust

The instrument relies on forced air cooling via a fan and ventilation slots. Adequate ventilation can usually be achieved

by positioning on a level surface and by leaving a 75 mm (3" gap) around the instrument. Care should be taken to avoid

restricting the airflow to or from the fan at the rear/sides of the instrument as damage may result from overheating.

Cleaning

Ensure the instrument signal and then power leads are disconnected prior to cleaning. Use only a damp, lint free cloth

to clean facia and case parts.

Observe any additional safety instructions or warnings given in this manual.

xi

Page 14

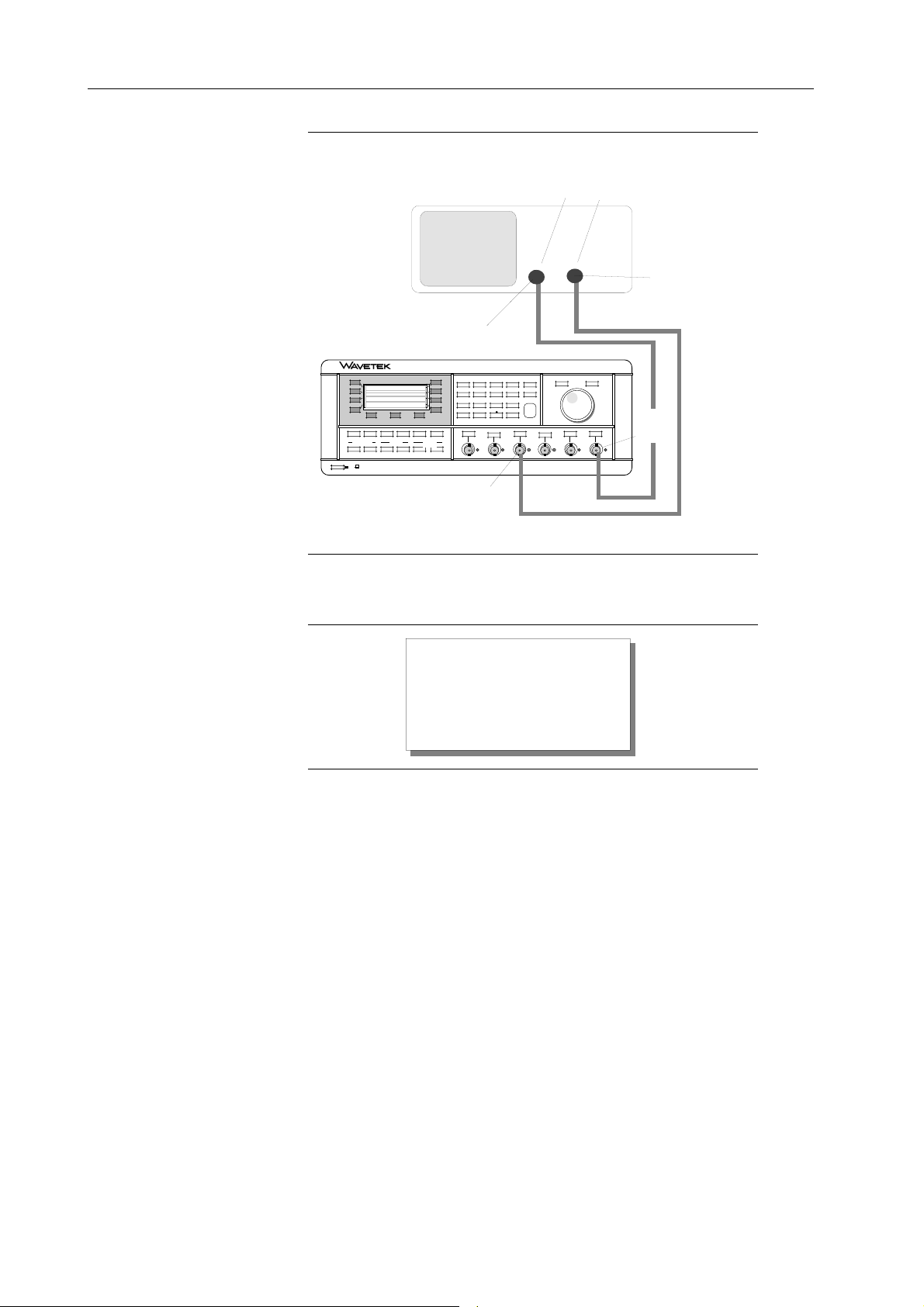

100 MHz Synthesized Arbitrary Waveform Generator model 395

987

4 5 6

1

0 • + /-

3

2

Model 395, 100 MHz Synthesized Arbitrary Waveform Generator

Page 15

Introduction

1.1 THE MODEL 395

Section 1

Wavetek-Datron’s Model 395 100-MHz synthesized arbitrary waveform

generator delivers high-speed performance in both bench-top

and ATE applications. The Model 395 combines the capabilities of a synthesized

arbitrary waveform generator, synthesized function generator, pulse generator, noise

generator, sweep generator, and trigger generator. As a modulation source, the Model

395 provides real-time AM and SCM, and synthesized AM, SCM and FM.

The Model 395’s 1mHz to 100 MHz clock generates arbitrary (user-defined) waveforms

with 12 bits of vertical resolution (4096 points: -2048 to +2047) and up to 256K points

of horizontal memory for simulating “real-world” non-standard signals. At clock rates

of 50 MHz or below, Model 395 uses direct digital synthesis (DDS) that provides highfrequency resolution (up to 10 digits). Model 395 is an excellent signal source for a wide

range of applications, including in-circuit testing of semiconductors, communication

testing requiring complex pulse patterns, and performance characterization testing of

electrical devices.

Create arbitrary waveforms using the Model 395’s front panel by using point-by-point,

copy, or line edit modes. Also, use the RS-232 interface or optional GPIB (IEEE-488.2,

SCPI compatible) interface to upload waveforms. Wavetek-Datron’s WaveForm DSP

software tool makes waveform creation, modification, and uploading easy over the

GPIB interface. The Direct DSO Upload, part of Option 001 IEEE-488 Interface, allows

transfer of waveforms captured with a digital storage oscilloscope directly into the

Model 395.

Another capability, Sequence, allows up to four waveforms to be linked in a sequence

with advancement from one waveform to the next conditional upon waveform repeat

(loop) counts and trigger signals.

In addition to complex arbitrary waveforms, Model 395 provides a number of synthesized

standard waveforms including sine waves to 40 MHz, square waves to 50 MHz, and

triangle waves to 10 MHz.

The built-in pulse generator generates pulses with programmable parameters that

include rate, width, delay, and rise/fall times. Pulse train allows you to create a series of

up to 10 independently programmable pulses each with their own level, width, delay,

rise/fall times.

Noise functions provide analog noise, digital noise, signal-plus-noise, comb, and combplus-noise.

Sweep allows frequency sweeps from 1mHz to 20 MHz in one continuous band and

include seven sweep modes, as well as linear or logarithmic spacing.

The Model 395 allows real-time AM and SCM modulation of both standard and arbitrary

waveforms.

For non-continuous operation, the Model 395 provides triggered and gated modes.

Triggered mode includes programmable burst counts from 1 to 1,048,575 counts.

Trigger sources include an internal trigger rate generator, manual trigger key, trigger

input BNC, and remote trigger command.

Model 395 is designed to provide an MTBF in excess of 10,000 hours, thus the Model

395 is extremely reliable. The easy-to-use calibration procedure can be performed

entirely from the front panel in less than fifteen minutes without removing the instrument

cover.

Introduction 1-1

Page 16

1.2 ORGANIZATION OF THIS MANUAL

Installation and Preparation For Use

Section 2 tells you how to set up and check out the Model 395 before you use it. It also

familiarizes you with the physical setup of the unit.

Introduction To The Model 395

Section 3 describes the fundamentals of front panel operation using a series of examples.

Operation Reference

Section 4 provides detailed explanations for every function and feature of the Model 395.

Remote Operation

Section 5 provides an introduction to the set up and operation of the Model 395 from

remote sources using the standard RS-232 or optional IEEE–488.2 interfaces. It also

contains the Model 395’s SCPI remote command set and IEEE-488.2 Common

Commands.

Specifications

Appendix A, located at the rear of this manual, contains the detailed specifications for

the Model 395.

Menu Quick Reference

Appendix B contains quick reference diagrams of the Model 395’s menu structure.

SCPI Quick Reference

Appendix C contains quick reference diagrams of the Model 395’s SCPI command tree.

The SCPI information is presented as a “Primer”. This appendix also contains the SCPI

required Conformance Information.

Rack Adapter Instructions

Appendix D contains instructions for mounting the Model 395 in an instrument rack.

DSO Upload

Appendix F contains instructions on DSO uploading to the Model 395. Plus, appendix

F describes how to create and load DSO driver files for DSOs not included in the unit’s

firmware.

Verification and Alignment Procedures

Appendix G contains both the verification test procedure and alignment procedure for

the Model 395.

1-2 Introduction

Page 17

Initial Preparation

2.1 THIS SECTION

This section contains:

Receiving and Inspecting Shipments;

Returning Equipment For Repair;

Preparation For Storage or Shipment;

Preparation For Use;

Initial Turn on;

Functional Checkout;

Routine Maintenance.

2.2 RECEIVING AND INSPECTING SHIPMENTS

Use the following steps to inspect a shipment of Wavetek-Datron equipment.

1. Inspect the shipment. If the shipment is damaged have the driver describe the box

damage and list shortages on the delivery bill.

If you find unreported shortages or damage, notify the shipper before further

unpacking.

2. After unpacking the boxes. Save all of the packing material.

Section 2

3. Inspect the equipment for damage. Inspect it carefully, regardless of the

condition of the shipping boxes.

4. If necessary, file a damage claim. If any damage is found, call the shipper within

10 days and start the claim process.

5. Call Wavetek-Datron. Call Wavetek-Datron’s Customer Service department

and tell them that the equipment arrived damaged.

2.3 RETURNING EQUIPMENT FOR REPAIR

Use the following steps if you should ever need to return the Model 395 to WavetekDatron for repair.

1. Save the packing material. Always return the equipment to Wavetek-Datron in

its original packing material and boxes. If you use inadequate packing material,

you will have to pay to repair any shipping damage. Carriers will not pay claims

on incorrectly packed equipment.

2. Call Wavetek-Datron for a Return Authorization. Wavetek-Datron’s customer

service representative will ask for the name of the person returning the equipment.

Plus, the representative will ask for your telephone number, company name,

equipment type and serial number, and a description of the problem.

Initial Preparation 2-1

Page 18

2.4 PREPARATION FOR STORAGE, SHIPMENT OR OPERATION

Packaging

If possible, always use the original shipping container. However, when using packing

materials other than the original, use the following guidelines:

Wrap the Model 395 in plastic packing material.

Use a double-walled cardboard shipping container.

Protect all sides with shock absorbing material (minimum of 2 inch thick

material) to prevent movement of the Model 395 within the container.

Seal the shipping container with approved sealing tape.

Mark “FRAGILE” on all sides, top, and bottom of the shipping container.

Storage

The Model 395 should be stored in a clean, dry environment. In high humidity

environments, protect the Model 395 from temperature variations that could cause

internal condensation. The following environmental conditions apply to both shipping

and storage;

Temperature –20°C to +70°C

Relative Humidity (sea level) Less than 95% at 11°C to +30°C.

Altitude Less 15,000 feet (4570 meters).

Vibration Less than 2g.

Shock Less than 40g.

Operation

The Model 395 should be operated on a flat surface or in an equipment rack within its

envoronmental specifications. All air vents should be clear of obstructions.

Signal connections should not be made to external hazardous voltages.

WARNING

THIS INSTRUMENT CAN DELIVER A LETHAL ELECTRIC SHOCK. NEVER

TOUCH ANY LEAD OR TERMINAL UNLESS YOU ARE FIRST

ABSOLUTELY CERTAIN THAT NO DANGEROUS VOLTAGE IS PRESENT.

SEE THE SAFETY ISSUES SECTION AT THE FRONT OF THIS MANUAL.

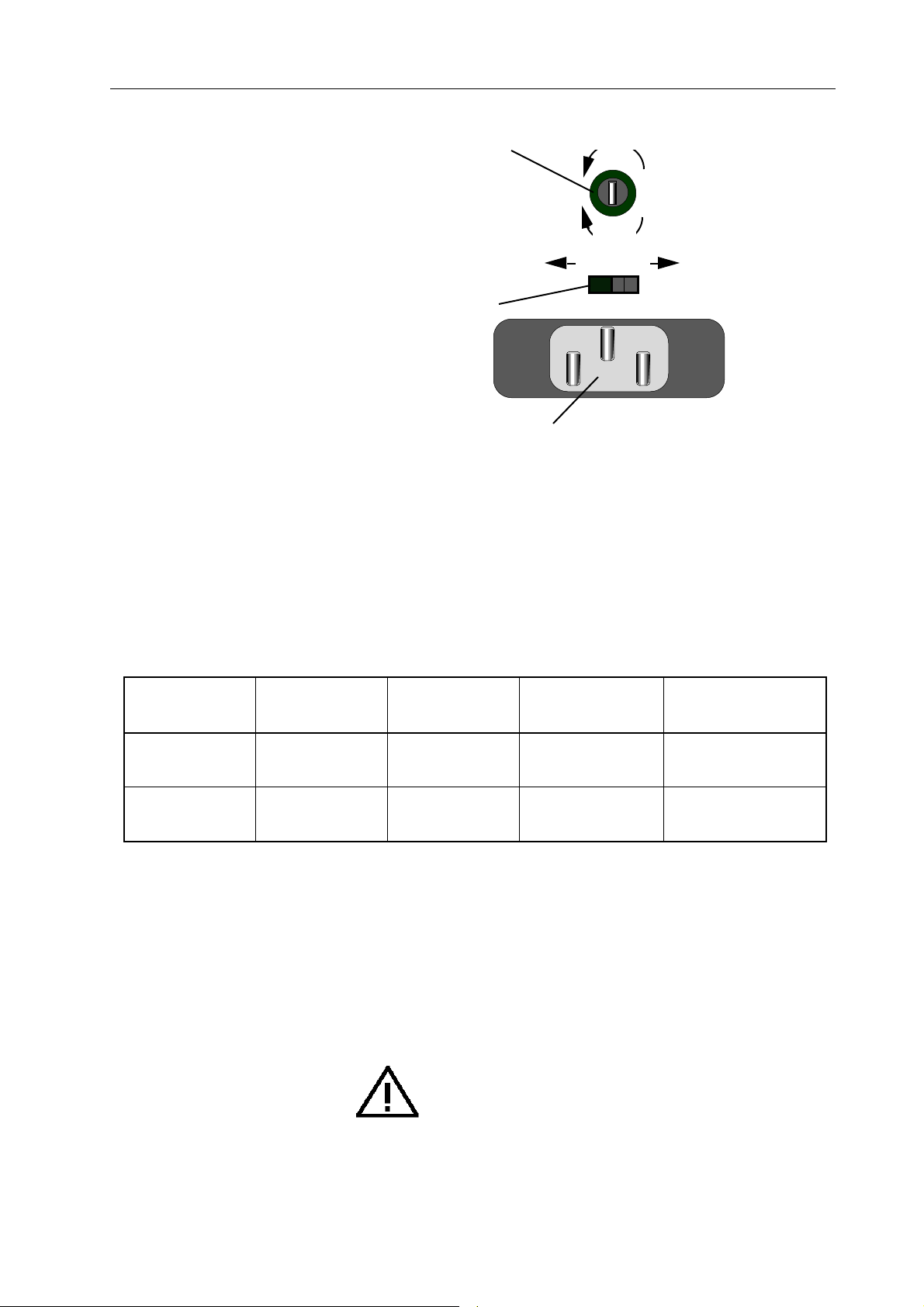

2.5 LINE VOLTAGES AND FUSES

The Model 395 accepts a primary input voltage of either 90 to 132 Vac or 198 to 252

Vac, 50/60 Hz. Wavetek-Datron ships the Model 395 set for the line voltage and with

the proper fuse for the destination country. Figure 2-1 illustrates the location of the line

voltage switch and fuse holder.

2-2 Initial Preparation

Page 19

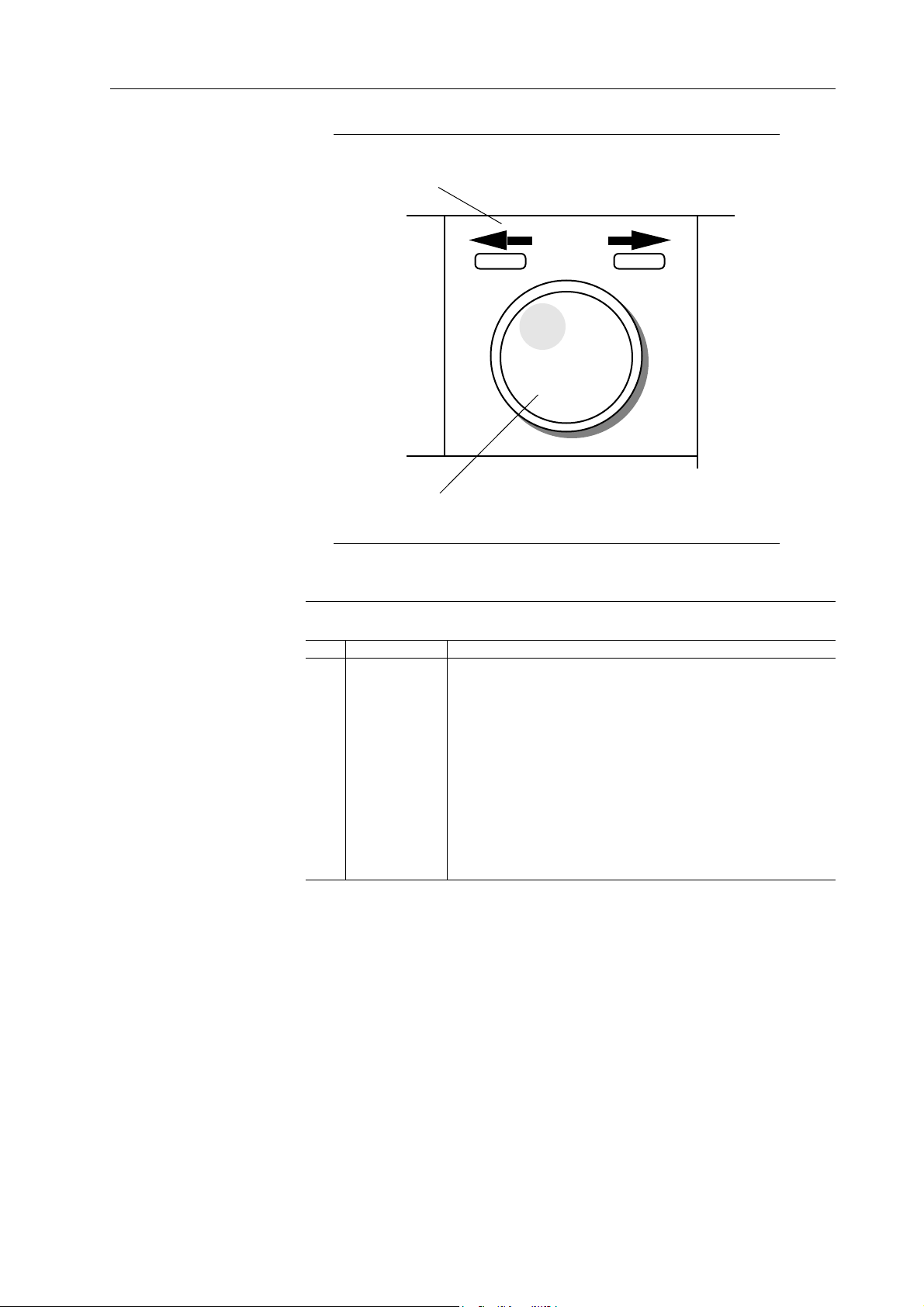

Fuse Holder

Remove

Install

230 115

Line Voltage

Selector

Power Connector

Figure 2-1. Line Voltage Switch and Fuse Holder

To change the line voltage, disconnect the power cord from the Model 395. Slide the

Line Voltage Selector (figure 2-1) to the desired line voltage: left for 230VAC, and right

for 115VAC. Refer to table 2-1 for voltage ranges for each voltage position. Also check

that the fuse is the correct rating; see the following procedure.

To change the fuse, perform the following steps:

1. Disconnect the power cord from the instrument. Remove the fuse from the fuse

holder.

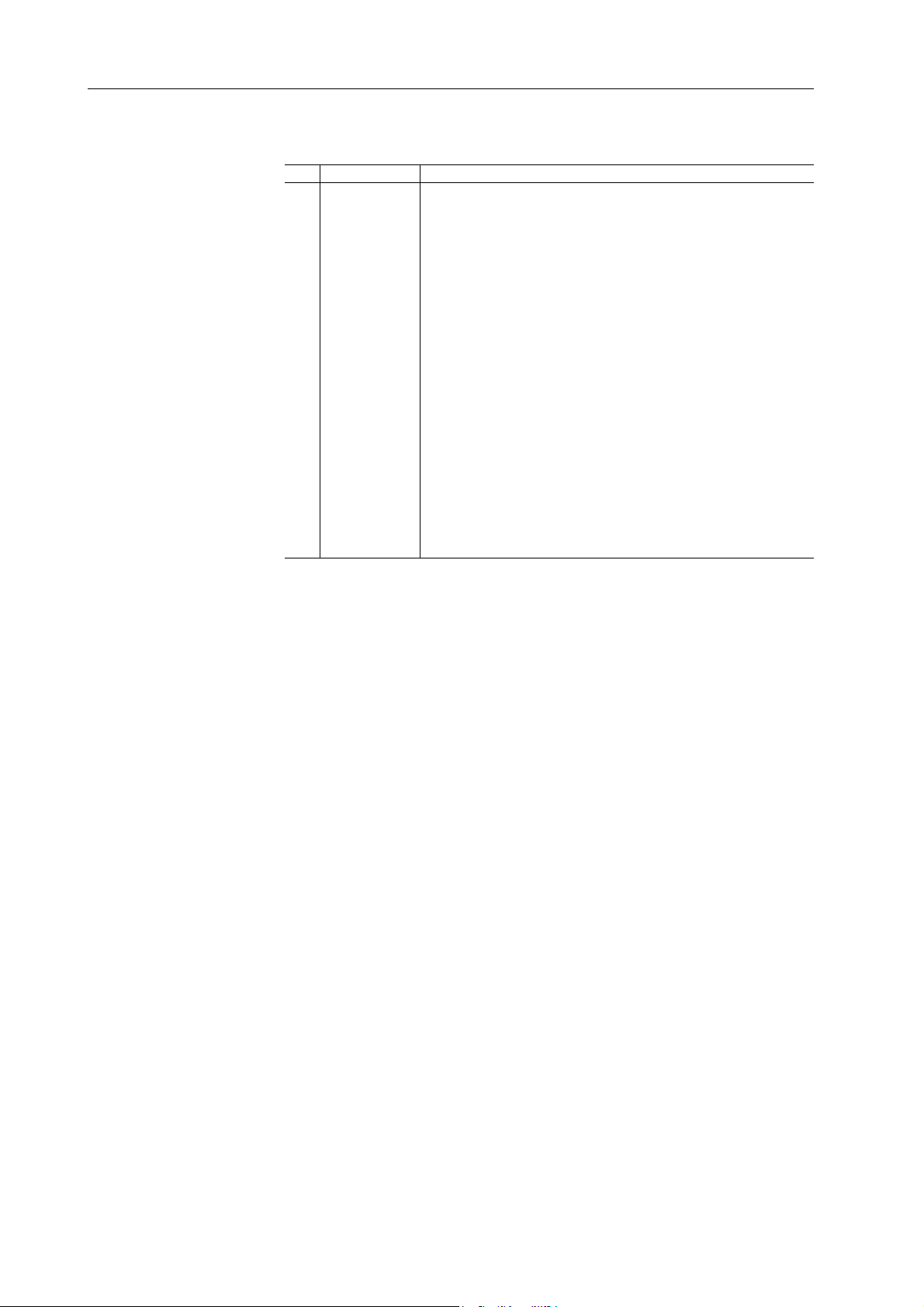

Table 2-1. Line Voltage and Fuse Selection

Supply (Line)

Voltage

115 VAC

230 VAC

Fuse Action

T

Time delay

Fuse Rating

UL/CSA

1 A

Wavetek-Datron

Part No.

2400-05-0029

Manufacturer

& Type No.

BUSSMAN MDL 1

T

Time delay

2. Compare the ampere rating on the fuse to the ampere ratings given in table 2-1.

If the fuse is blown, replace it by sliding the new fuse back into the fuse holder.

If the fuse is not blown and has the right rating, keep it. If the fuse has the wrong

rating, place the new fuse into the fuse holder.

3. Connect the ac line cord supplied to the power connector at the rear of the unit

and power source.

CAUTION IN THE EVENT OF FAILURE OF ANY FUSE, CONTACT

500 mA

THE SERVICE CENTER IMMEDIATELY. SEE THE SAFETY

ISSUES SECTION AT THE FRONT OF THIS MANUAL.

2400-05-0010

BUSSMAN MDL 1/2

Initial Preparation 2-3

Page 20

2.6 INITIAL TURN–ON

WARNING

The Model 395 is equipped with a three-wire power cable. When

connected to a grounded AC power receptacle, this cable grounds the

instrument. Do not use extension cords or AC adapters without a

ground.

1. Connect the power cable supplied to the power connector on the Model 395 rear

panel; see figure 2-2.

Power Connector

Figure 2-2. Power Connector

WARNING

ANY INTERRUPTION OF THE PROTECTIVE EARTH/GROUND

CONDUCTOR INSIDE OR OUTSIDE THE INSTRUMENT IS LIKELY

TO MAKE THE INSTRUMENT DANGEROUS. SEE THE SAFETY

ISSUES SECTION AT THE FRONT OF THIS MANUAL.

2. Press the “POWER” On/Off switch in to turn the unit on (figure 2-3).

2-4 Initial Preparation

Figure 2-3. Power Switch

Page 21

2.7 ERROR MESSAGES

Some front panel entries may cause error or information messages to appear on the

display.

2.8 FUNCTIONAL CHECKOUT

The functional checkout provides a quick method of verifying the Model 395 operation.

The only test equipment required is an oscilloscope (Tektronix 2445 - dual channel or

equivalent), and the appropriate cables and loads.

Continuous Mode Check

1. Connect the Model 395 to the primary power source. Leave all cables

disconnected. See Initial Turn-On in this section.

2. Turn on the Model 395 by pushing in the POWER switch.

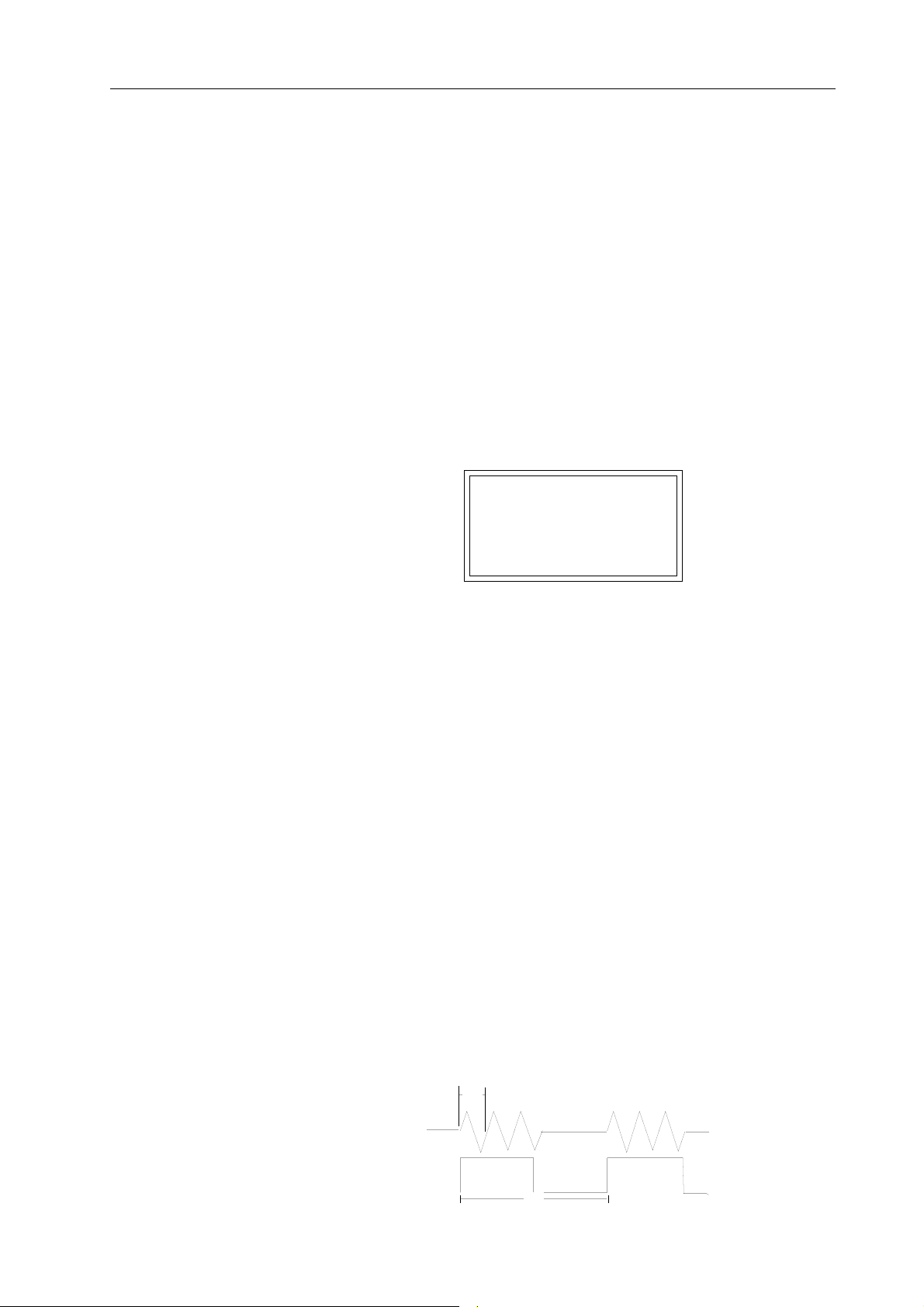

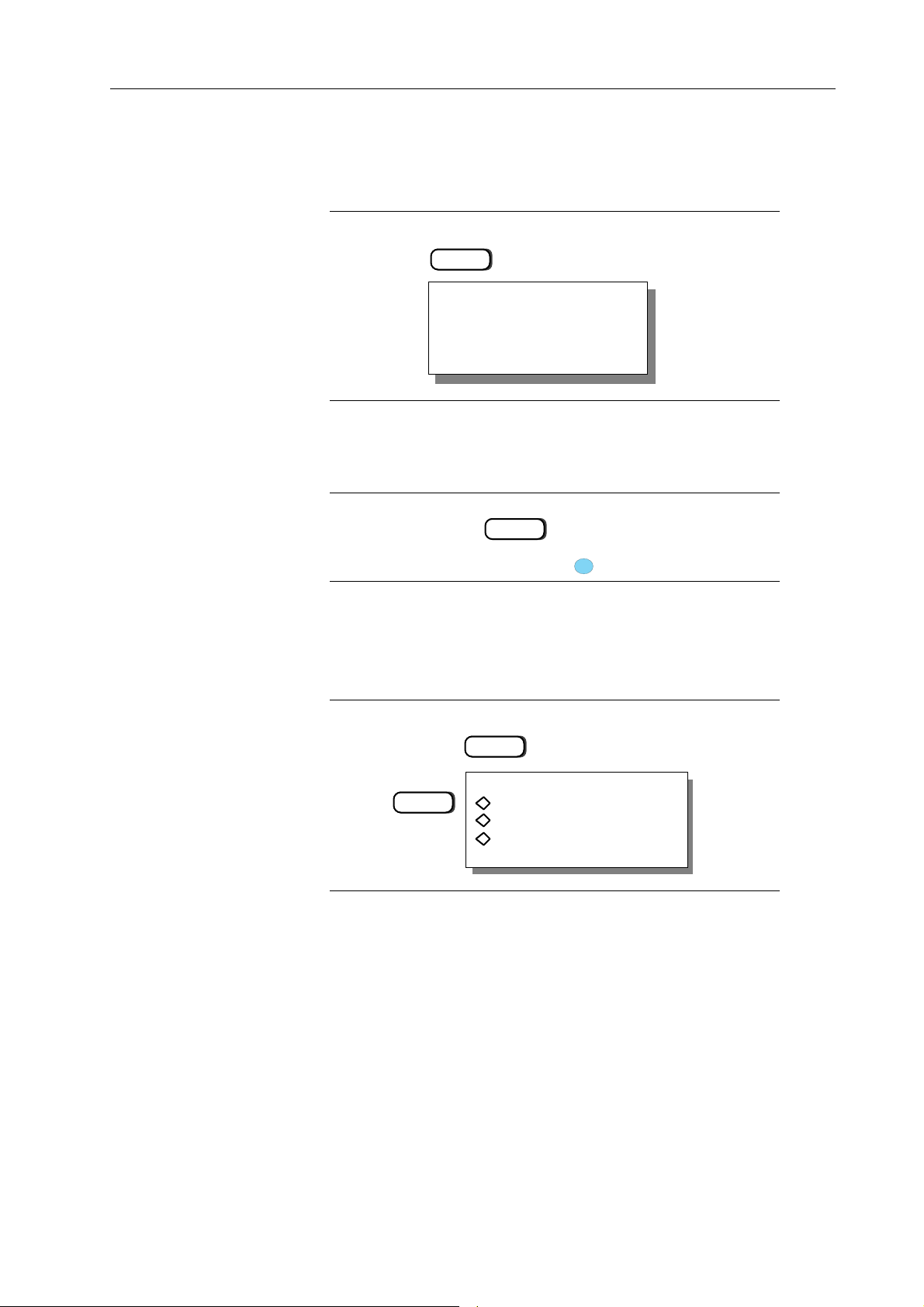

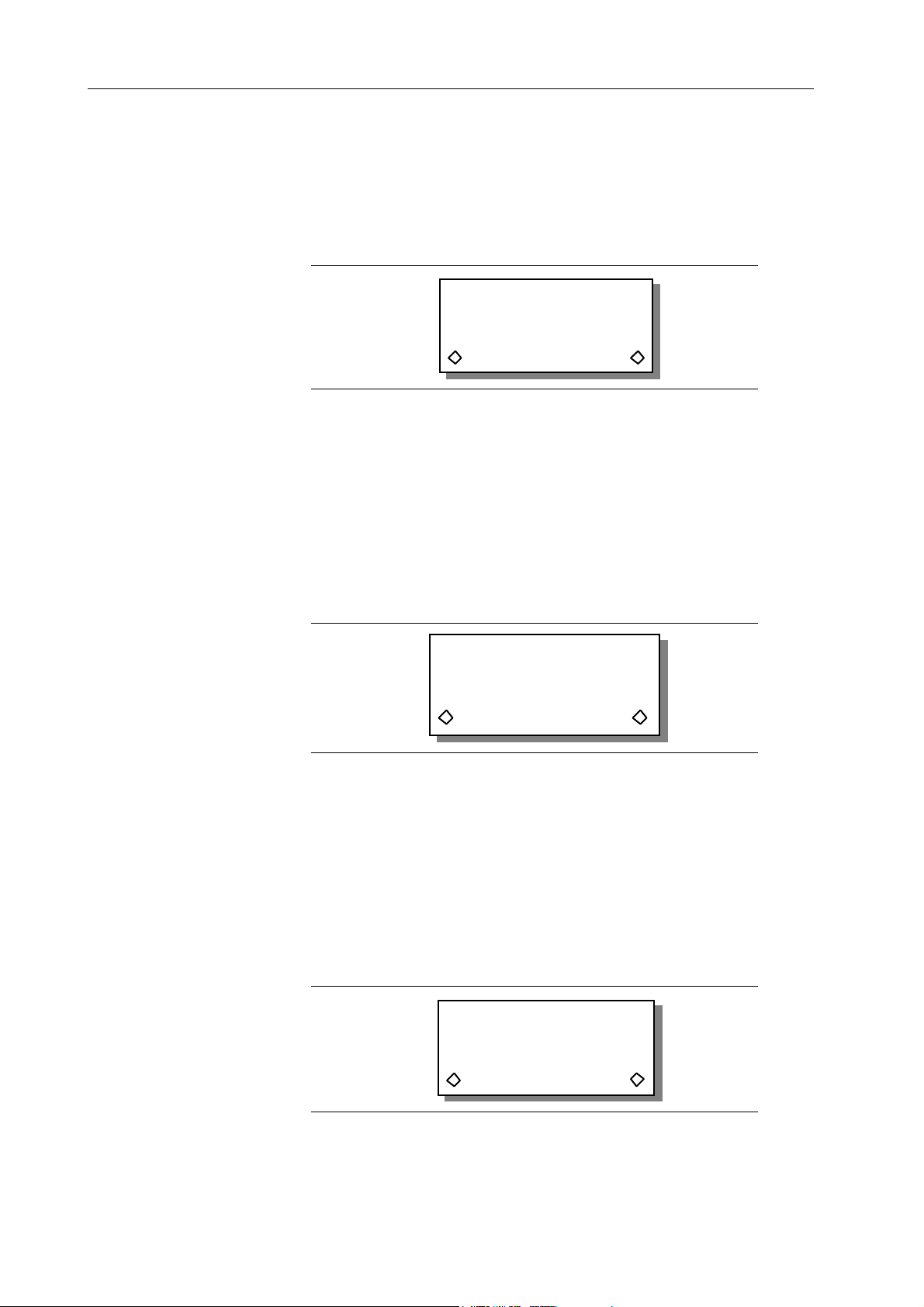

At power on, the Model 395 displays its start up screen (figure 2-4).

Wavetek

Model 395

(for assistance,

press HELP)

3. Press the RESET key, and from the Instrument Reset screen press F3 to reset all

parameters. Then press F8 to confirm reset.

4. Press the MAIN OUT key to turn on the Main Output. Main Out indicator

remains on.

5. Press the SYNC OUT key. From the Sync Output Setup screen, press F2 twice

to turn the Sync Output on (“output: on”).

Observe: Scope displays a 1Vp sine wave at 1kHz (Main Out must be terminated

into 50Ω).

Sweep Mode Check

Press the MODE key. From the Mode screen, press F2 “sweep.”

Observe: Scope displays a sweep of the frequency from 1kHz to 10 kHz.

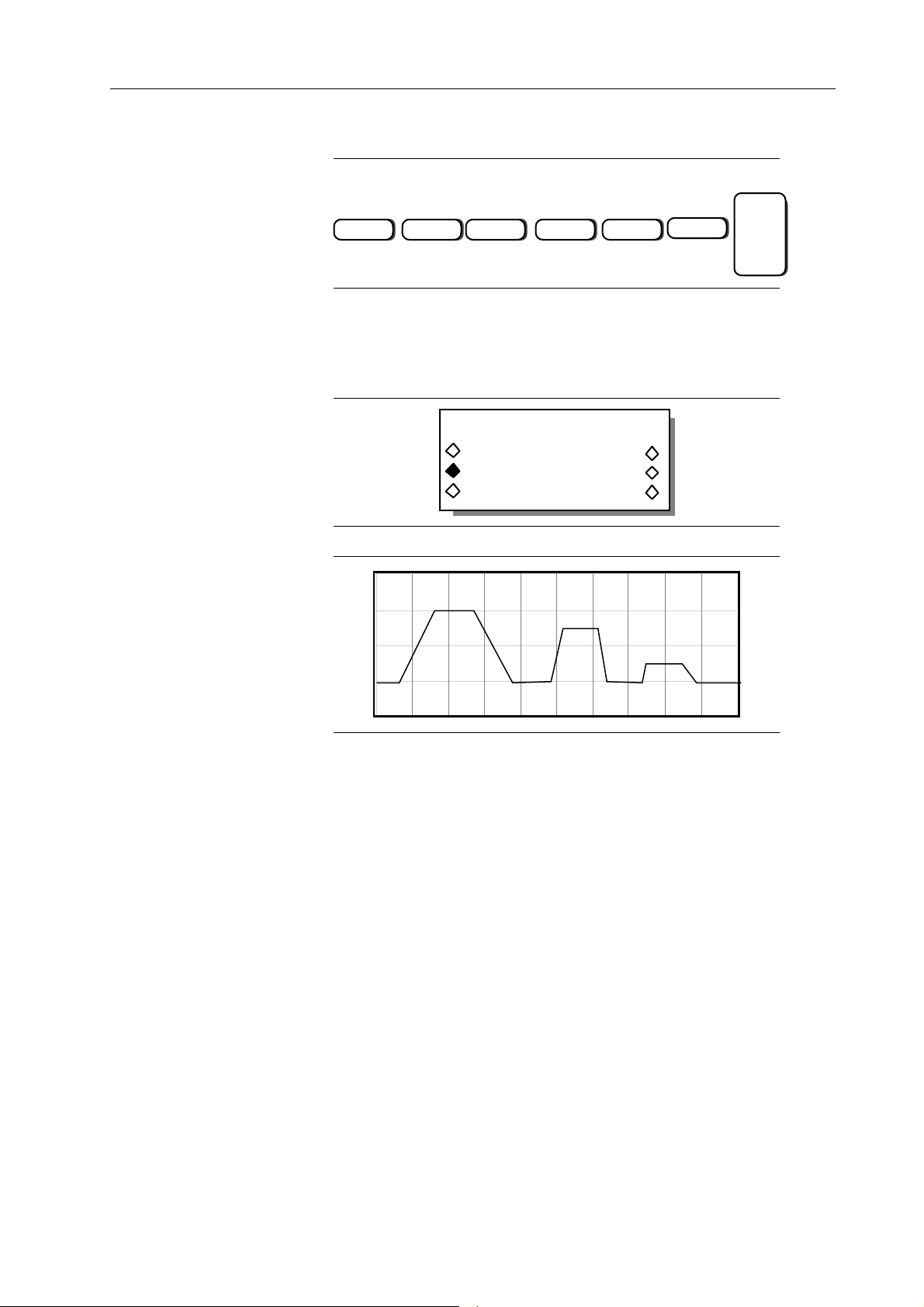

Gated Mode Check

Press the MODE key. From the Mode screen, press F3 “gated.” Press the

STANDARD key, and then rotate the knob; select the softkey to select

“triangle.”

This check uses the Model 395’s internal trigger source which is programmed

to 5 ms.

Observe: Scope displays a gated waveform; see below:

Figure 2-4. Model 395 Start Up Screen

1ms

5ms

Initial Preparation 2-5

Page 22

Triggered Mode Check

Press the MODE key. From the Mode screen, press F4 “trig’d.”

This check uses the Model 395’s internal trigger source which is programmed to

5 ms.

Observe: Scope displays a triggered waveform with a count of 1; see below:

This completes the functional test. Remove all cables and test equipment.

2.9 OPERATOR MAINTENANCE

2.9.1 Routine Maintenance

No tools or equipment are required for routine maintenance. Cleaning materials

required are listed below:

Description National Stock Number

Cotton Cheesecloth 8305-00-267-3015

Mild Liquid Detergent None

Routine maintenance for the Model 395 is limited to routine tasks such as listed below;

Cleaning, using cloth moistened with detergent

Dusting,

Wiping,

Checking for frayed cables,

Storing items not in use,

Covering unused receptacle,

Checking for loose screws.

Perform these routine tasks as required.

5ms

CCC-C-440, Type II,

Class 2 (81349)

2-6 Initial Preparation

Page 23

2.9.2 Battery Replacement

The Model 395 contains an internal battery for the unit’s internal memory. Its replacement

should only be carried out by a suitably qualified technician. Measure the battery voltage

when performing calibration of the unit (approximately every 12 months); refer to

paragraph 4.3, figure 4-7 and table 4-6 item 6. The battery should measure between +3.2

Vdc and +2.7 Vdc. Replace the battery when it measures +2.7 Vdc or below to avoid

loosing Arb waveforms, stored settings, “last setup,” and all remote setup parameters.

This instrument uses an internal battery containing more than 0.2

grams of Lithium. Do not charge or short this battery. A hazard of

explosion and or contamination exists.

CAUTION Always replace the battery with one of the same type: Panasonic BR-

2/3A

To replace the battery. This task should only be undertaken by a suitably qualified

technician.

1. Turn off the Power and disconnect the power cable.

2. Remove the two screws; one on each side of the cover.

3. Slide the cover back.

4. Remove the battery.

5. Remember, removing the battery will loose Arb waveforms, stored settings,

“last setup," and all remote setup parameters.

6. Install the new battery. Be sure to match the polarity on the battery with the

polarity indicator on the battery holder.

WARNING

2.10 RACK MOUNTING EARS

The Model 395 can be rack mounted using the optional mounting ears (Option 004).

Installation instructions are in appendix D of this manual.

2.11 REMOTE SETUP

2.11.1 RS-232

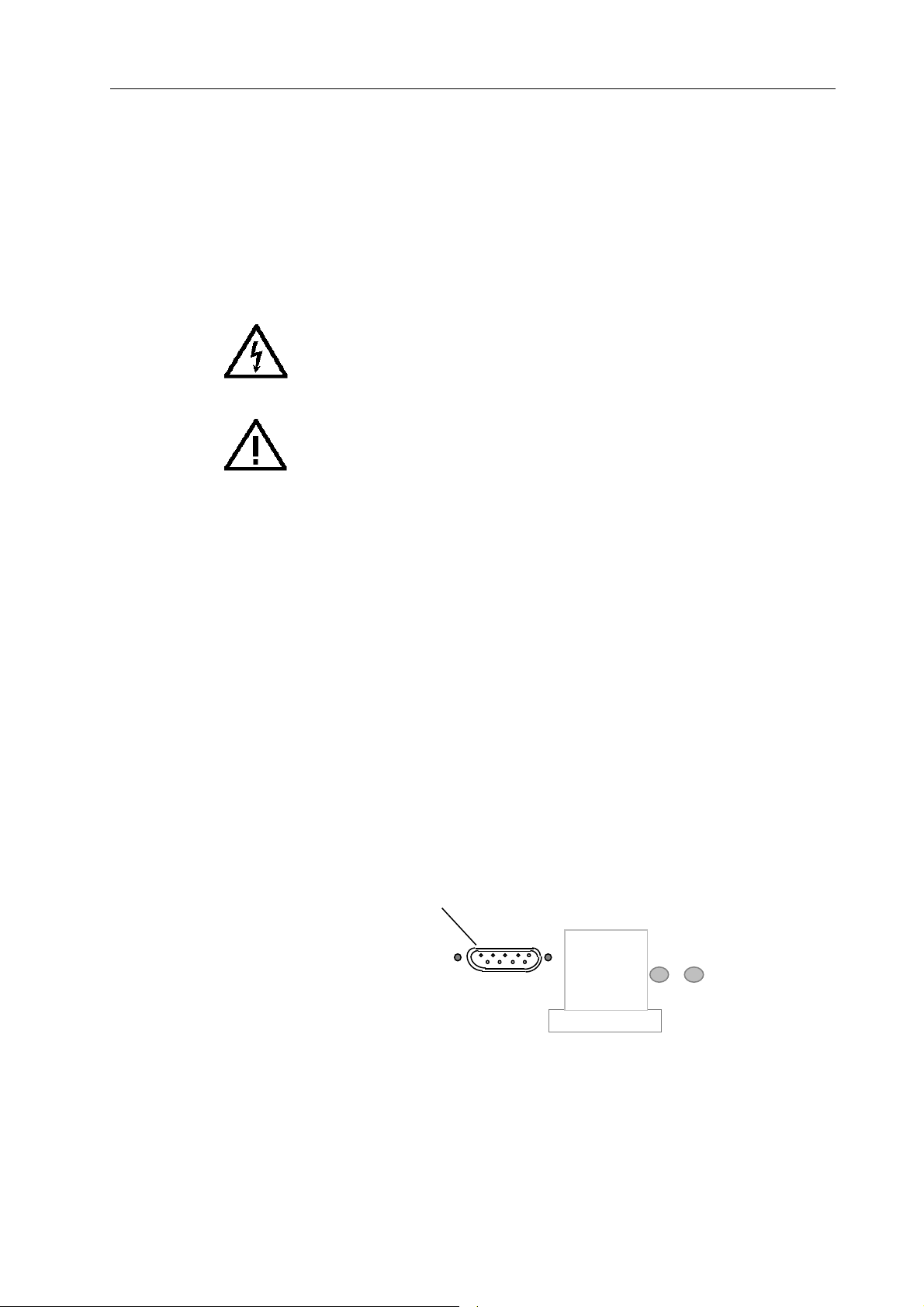

To connect the Model 395 to a computer via RS-232, use the provided RS-232 cable. For

information on RS-232 remote programming, refer to section 5 of this manual. Note that

the 0 V connection on the RS–232 connector is internally connected to the floating

analog common and not ground.

RS-232

Connector

CAL ENABLE

RS-232

NORM - CAL

Cal Sticker

Figure 2-5. RS-232-C Connector

BATTERY

TEST

BAT GND

Initial Preparation 2-7

Page 24

Standard RS-232 Connection

The Model 395 is configured as a DCE , and uses a 9-pin female connector (DB-9). The

standard connection will be to a DTE ( generally a computer) with a standard 9-pin male

connector (DB-9). This connection can be made using the 9-pin female to 9-pin male

cable (P/N 6001-00-0061) included with the Model 395. If the DTE uses a male DB-25,

the connection can be made using the 25-pin female to 9-pin male adapter (P/N 210002-0328 ) included with the Model 395. After connections are made, both the Model 395

and the DTE must be configured to have the same baud rate and data format. The data

format for the model 395 is 8-bits, no parity, one stop bit. Refer to section 5.3 for the

Model 395 RS-232 setup.

Non-Standard RS-232 Connection

Because the Model 395 is configured as a DCE, connection to a device configured other

than a standard DTE may require a special cable. Some knowledge of the RS-232 is

beneficial to insuring a proper connection. The pin assignments for the model 395 and

for a standard DTE (an AT comm port), are given in Table 2-2 .

EIA STANDARD RS-232-C specifies the electrical characteristics and pinouts of a

serial communication standard for connecting “Data Terminal Equipment” (DTE) to

“Data Communication Equipment” (DCE). A DTE is usually a device such as a

terminal, computer, or printer, that is the final destination of data. A DCE is usually a

device that converts data to another form and passes it through such as a modem.

Because RS-232 signal lines defined as outputs on a DTE are inputs on a DCE and vise

versa, connection of a DTE to a DTE or a DCE to a DCE requires a special cable with

many of the lines interchanged. Generally a “Null Modem” cable will have the correct

lines interchanged.

With RS-232-C, data is transferred serially between two devices using a voltage of +3

to +25 Vdc to represent a zero ( space ), and a voltage of -3 to -25 Vdc to represent a one

( mark ). Only two lines are required to transfer data, transmit and receive. When no data

is being transferred, these lines will be at a mark state. To transmit a byte, the

transmitting device first sends a start bit , a space, to synchronize the receiver. Then, the

data bits are sent LSB first (eight bits for 395). Some devices follow the data bits with

a parity bit (not 395). At the end there is up to 2 stop bits (395 uses one stop bit) that are

at the mark state.

The rate at which the bits are transferred is called baud rate and is in bits per second. The

baud rate must be set the same for both devices. The 395 has seven different baud rates

ranging from 1200 to 57.6K.

Handshaking is a communication between the two devices to control the transfer of data

to insure no data is lost when the data is transferring faster than a device can process it.

Handshaking can be accomplished in two ways, software or hardware. Software

handshaking is done using XON / XOFF protocol (not supported by 395), which sends

control characters over the data lines to control the flow.

2-8 Initial Preparation

Page 25

Hardware handshaking uses additional lines ( DSR, DTR, RTS, CTS) to signal when the

device is ready to receive data. These handshake lines use +3 to +25 Vdc to indicate a

true, and -3 to -25 to indicate a false condition. When a DTE is ready to communicate,

it drives the DTR line true. The DCE (395) will respond by driving the DSR line true.

Then the DTE will drive RTS true when it is ready to receive data and the DCE will drive

CTS true when it is ready to receive data.

Table 2-2a. Model 395 RS-232 Connections (DB-9)

Pin Name Direction Description

1 DCD OUT Carrier Detect

2 RxD IN Receive Data

3 TxD OUT Transmit Data

4 DTR IN Data Terminal Ready

5 GND COMMON Signal Ground

6 DSR OUT Data Set Ready

7 RTS IN Request To Send

8 CTS OUT Clear To Send

9 NC - - - No Connection

Table 2-2b. Standard DTE RS-232 Connections

Pin Name Direction Description

DB-9 DB-25

1 8 DCD IN Carrier Detect

2 3 RxD IN Receive Data

3 2 TxD OUT Transmit Data

4 20 DTR OUT Data Terminal Ready

5 7 GND COMMON Signal Ground

6 6 DSR IN Data Set Ready

7 4 RTS OUT Request To Send

8 5 CTS IN Clear To Send

9 22 RI IN Ring Indicator

The Model 395 RS-232 signal names are defined below. A positive voltage above

+3Vdc is defined as a logic ‘0’ or ‘ON’. A negative voltage below -3 Vdc is defined as

a logic ‘1’ or ‘OFF’.

DCD Internally connected to pins 4 (DTR) and 6 (DSR) in the model 395. A logic ‘0’

signifies that the 395 is ready for communication. See notes for DTR.

TxD Serial data output from Model 395.

RxD Serial data input to Model 395.

DTR Signal from a DTE that indicates it is ready for communication. This signal is

internally connected to pins 1 (DCD) and 6 (DSR). Upon receipt of a logic ‘0’,

the DCD and DSR are driven to logic ‘0’ thus signaling that the 395 is ready for

communication.

GND Connected to internal signal ground. This should be connected to a ground point

on the device that the 395 is going to communicate with for proper error free

operation.

Initial Preparation 2-9

Page 26

DSR Internally connected to pins 1 (DCD) and 4 (DTR) in the model 395. A logic ‘0’

signifies that the 395 is ready for communication. See notes for DTR.

RTS A logic ‘0’ on this pin indicates that the device that is connected to the 395 is ready

to receive data. When handshaking is disabled, this line is ignored by the 395.

The length of time that the 395 will wait before aborting transmission can be set

in the RS-232 setup screen (see section 5). The Model 395 will respond to a logic

‘1’ with a transmission latency of one character.

CTS A logic ‘0’ indicates that the Model 395 is ready to receive data. When

handshaking is enabled, this line is driven to logic ‘1’ when the 395 receive buffer

is about 2/3 full. Data will continue to be stored in the buffer until it is full. This

line will be driven to a logic ‘0’ when the buffer drops below 2/3 full. To prevent

data loss, this line should be connected and recognized by the other device.

NOTES:

Although communication can be accomplished using only the Transmit

and Receive lines, it is recommended that the ground and handshake

lines are connected so no data is lost due to the high transfer rates

possible with the Model 395.

Software handshaking ( XON / XOFF ) is not supported by the Model

395.

The Model 395 data format is 8 data bits, no parity, 1 stop bit.

2.11.2 IEEE-488 (Option 001)

To connect the Model 395 via the IEEE-488 interface to a computer or digital storage

oscilloscope, DSO, (figure 2-6), use a standard IEEE-488 bus cable [Wavetek-Datron

part number 630364 (1 metre) or 630366 (2 metres)]. For more information on remote

programming using IEEE-488, refer to section 5 of this manual.

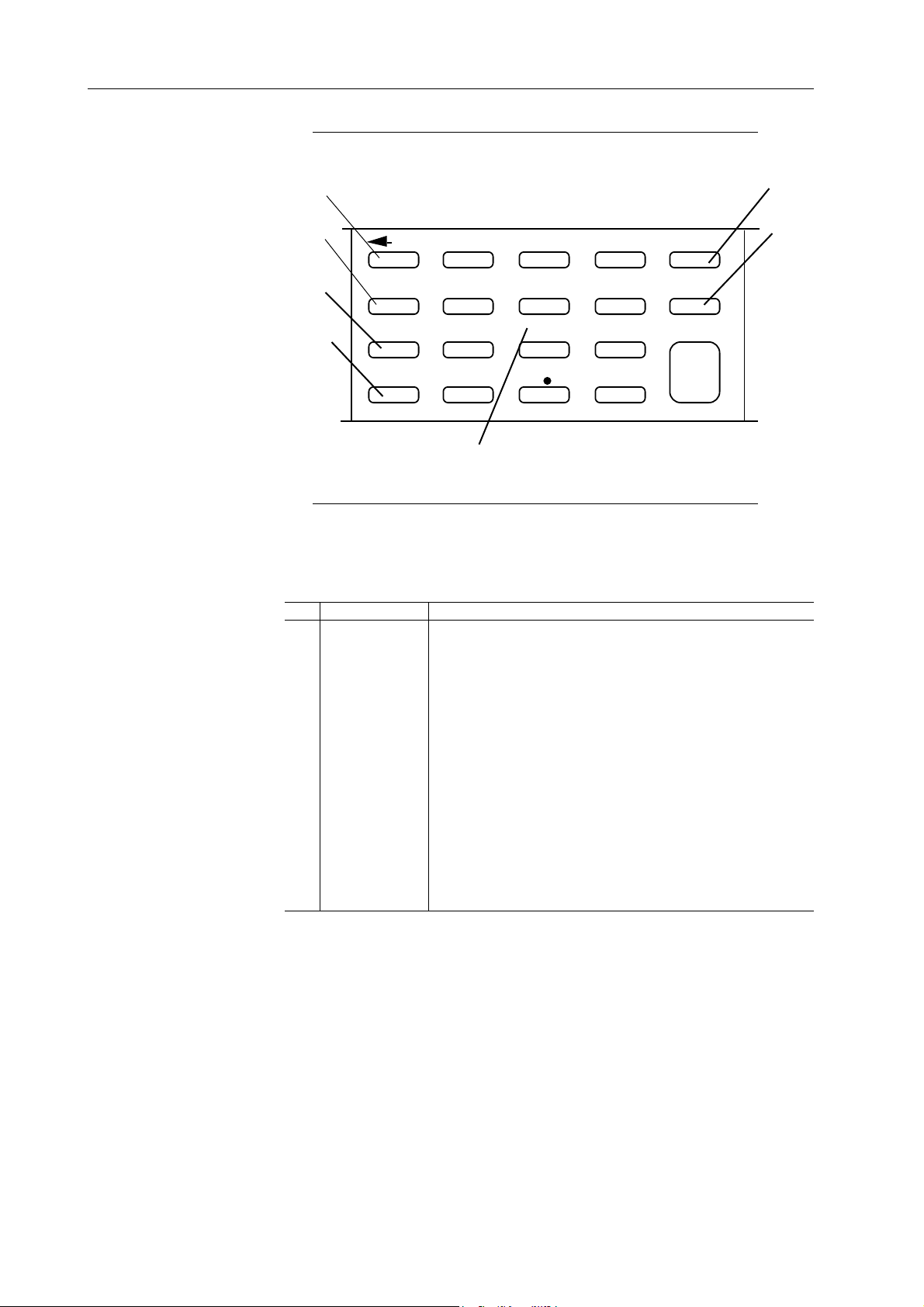

IEEE-488

CAL ENABLE

BATTERY

NORM - CAL

Cal Sticker

TEST

BAT GND

Figure 2-6. IEEE-488 Connector

Note that the 0 V connection on the IEEE-488 connector is internally connected to the

floating analog common and not ground.

Connector

2-10 Initial Preparation

Page 27

3.1 OVERVIEW OF THE MODEL 395

The Model 395, 100 MHz Synthesized Arbitrary Waveform Generator, produces

a variety of standard, pulse, noise, and user-defined (Arbitrary) waveforms. In

addition, the Model 395 allows linking of up to four arbitrary waveforms to form

a Sequence. Plus, the Model 395 triggers, sweeps, and modulates all waveforms.

Also, sum an external signal with the generator’s internal signal.

The Model 395 stores up to 100 Arbitrary waveforms in battery-backed memory.

Complete instrument setups can be stored and recalled.

Using the Model 395

Section 3Introduction To The Model 395

This section introduces front panel operation of the Model 395. Included in this

section are a series of examples demonstrating the features of the unit. Section 4

contains reference information about Model 395 operation. Section 5 describes the

SCPI remote programming commands, RS-232 operation, and optional IEEE 488

operation. Section 5 also contains a series of SCPI language remote programming

examples demonstrating the unit’s features; these examples are the remote

programming equivalent of the examples in this section.

Appendix B of this manual contains a front panel screens quick reference, while

appendix C contains SCPI commands quick reference.

3.2 NAVIGATING THE SCREENS

3.2.1 Front Panel Keys and Screens

Pressing front panel keys display screens with program parameters relative to the

key pressed. Change program parameters by using softkeys (F1 through F8), or

change numeric values using the keypad or knob. For example, press the

FREQUENCY key to display the Frequency screen; see figure 3-1.

Introduction To The Model 395 3-1

Page 28

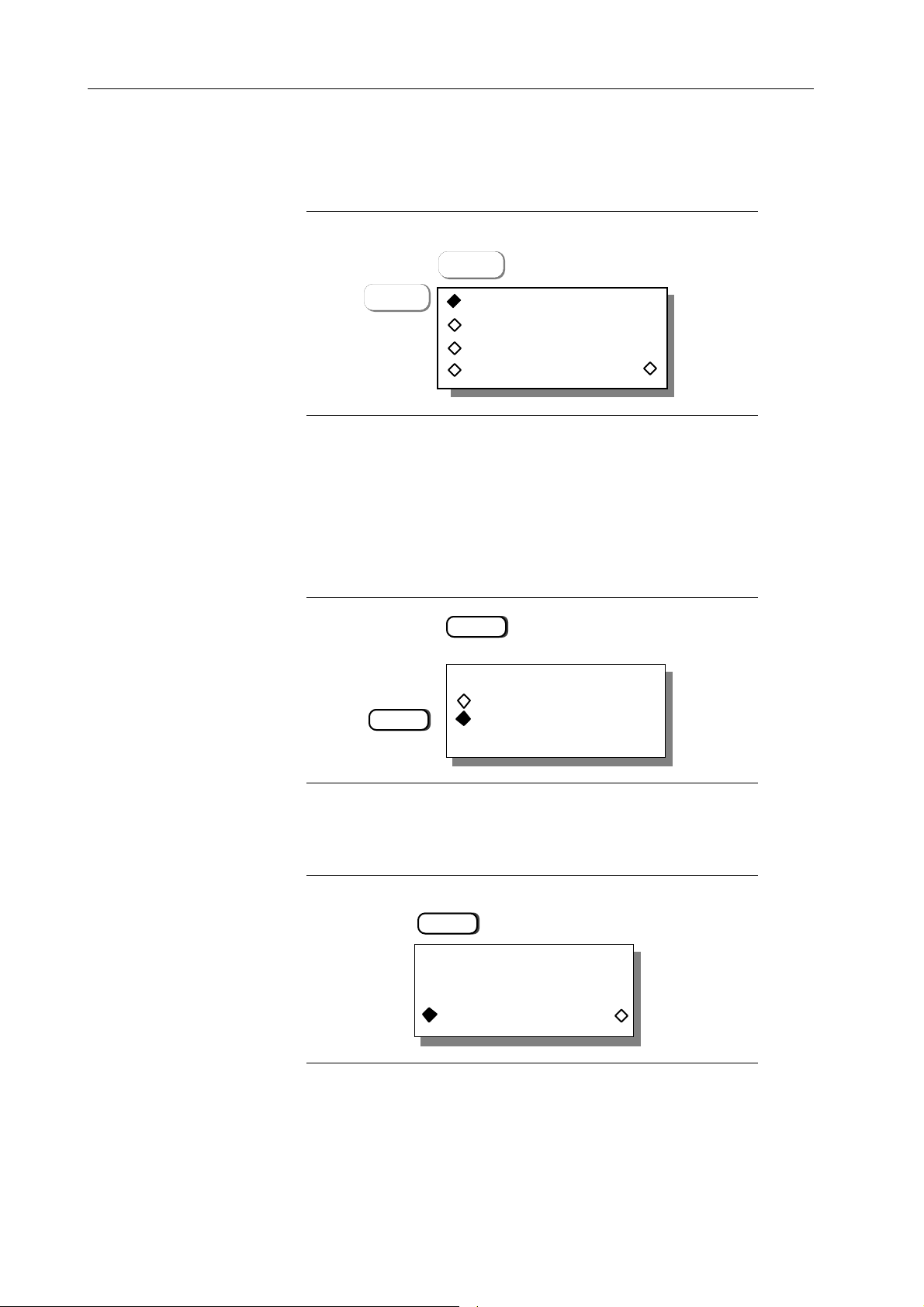

Try pressing the TRIG IN key or MODE key to display their screens.

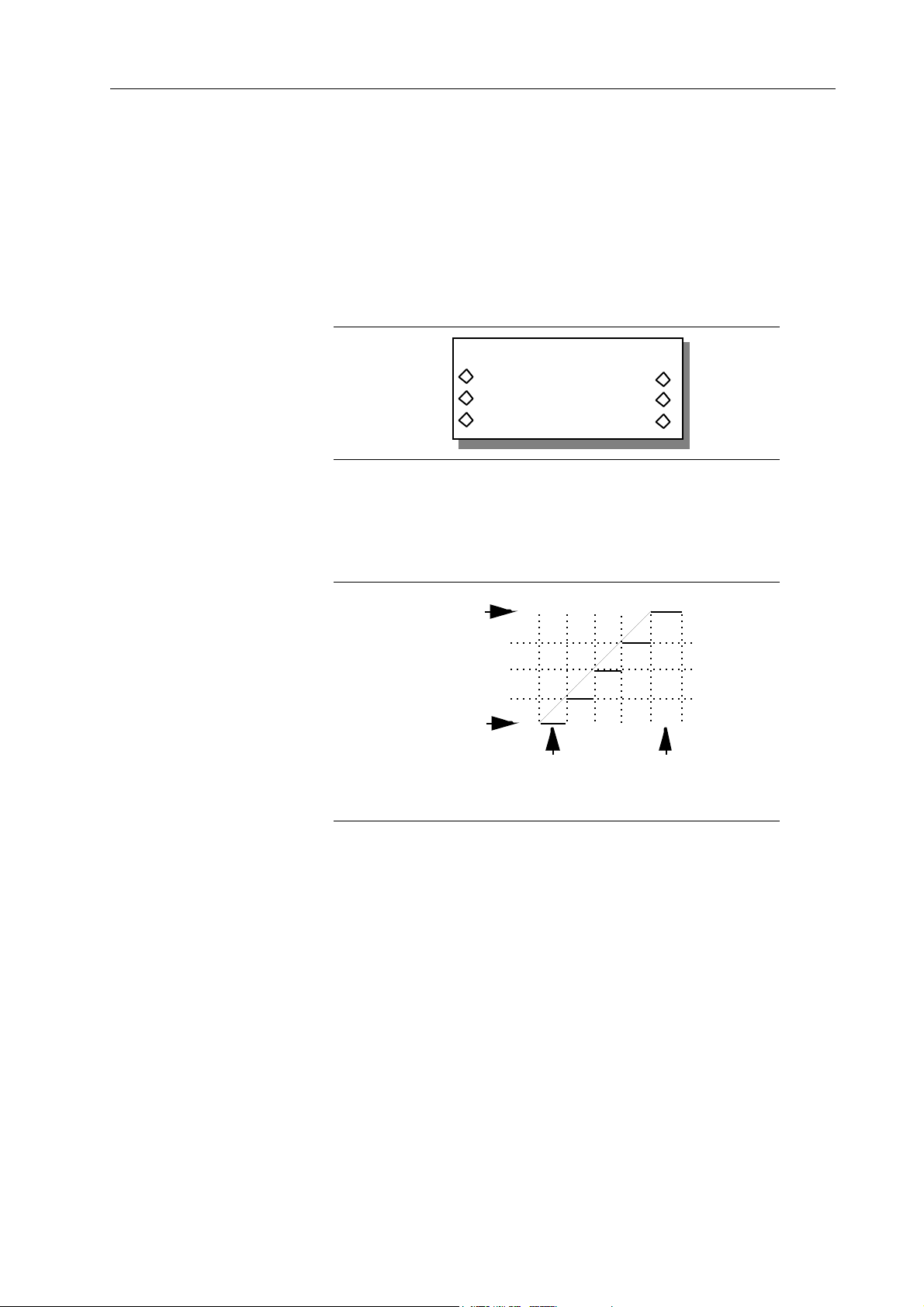

3.2.2 Softkeys

The Model 395 front panel softkeys (F1 through F8) allow you to select items from the

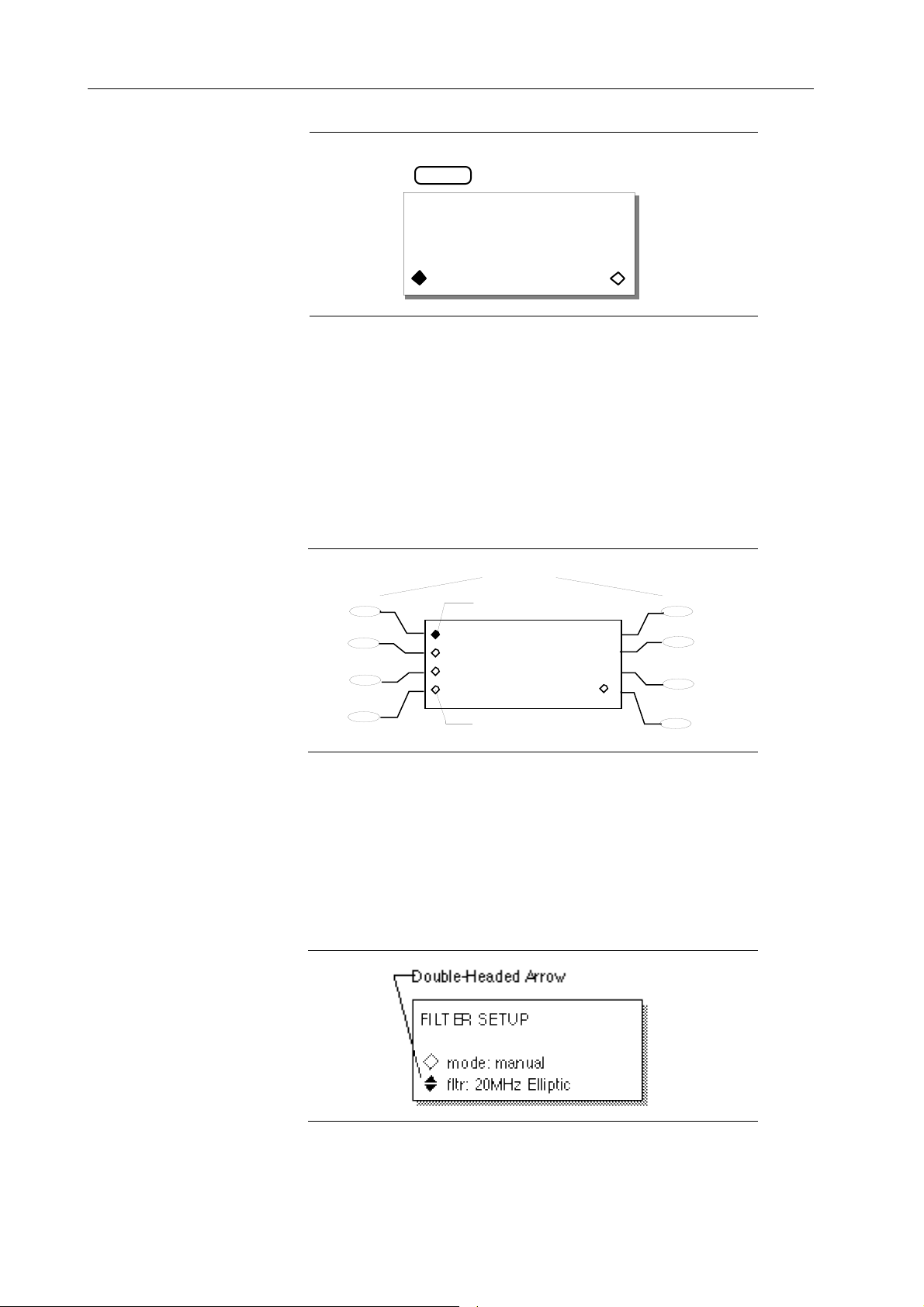

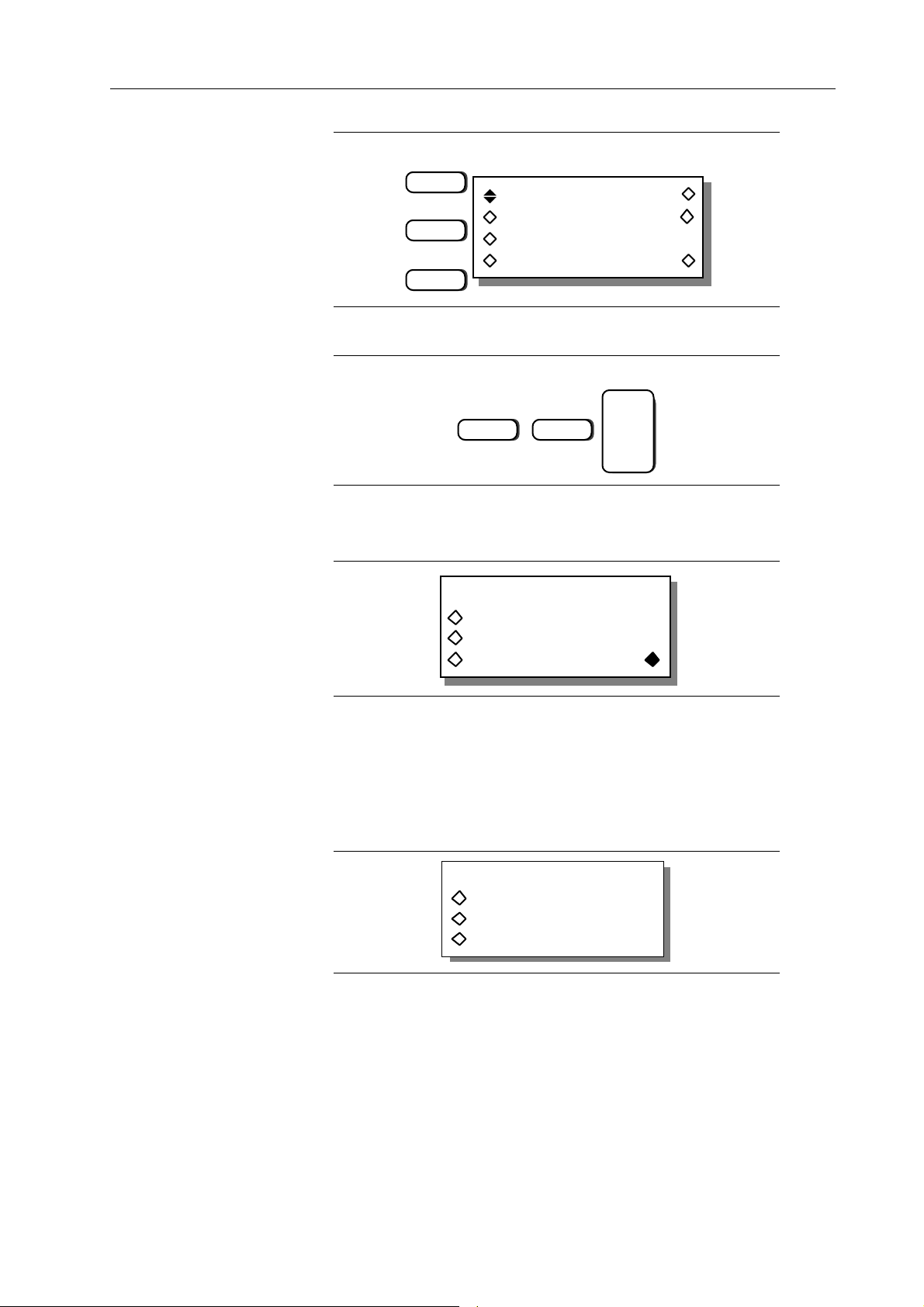

screen (figure 3-2).

Diamonds on the screen identify selectable screen items. Hollow diamonds identify

deselected items. Filled diamonds denote selected items. For example, press MODE

and then press F3 to select the “gated” mode (figure 3-2). Default items are initially

displayed with filled-in diamonds (like continuous in figure 3-2).

F1

F2

F3

F4

FREQUENCY

STANDARD FREQUENCY

1.000000000 kHz

freq period

Figure 3-1. Frequency Screen

Softkeys

Selected Item

continuous

sweep

gated

trig'd, cnt:0000001

Unselected Item

F5

F6

F7

F8

3.2.3 Extended Screens

Double-Headed Arrows

Double-headed arrows on the screen indicate additional screen items can be accessed by

using the knob or the cursor keys. See figure 3-3. Also, items next to double-headed

arrows also can be selected by using the softkey.

Figure 3-3. Double-Headed Arrow (Filter Screen)

Figure 3-2. Softkeys (Mode Screen)

3-2 Introduction To The Model 395

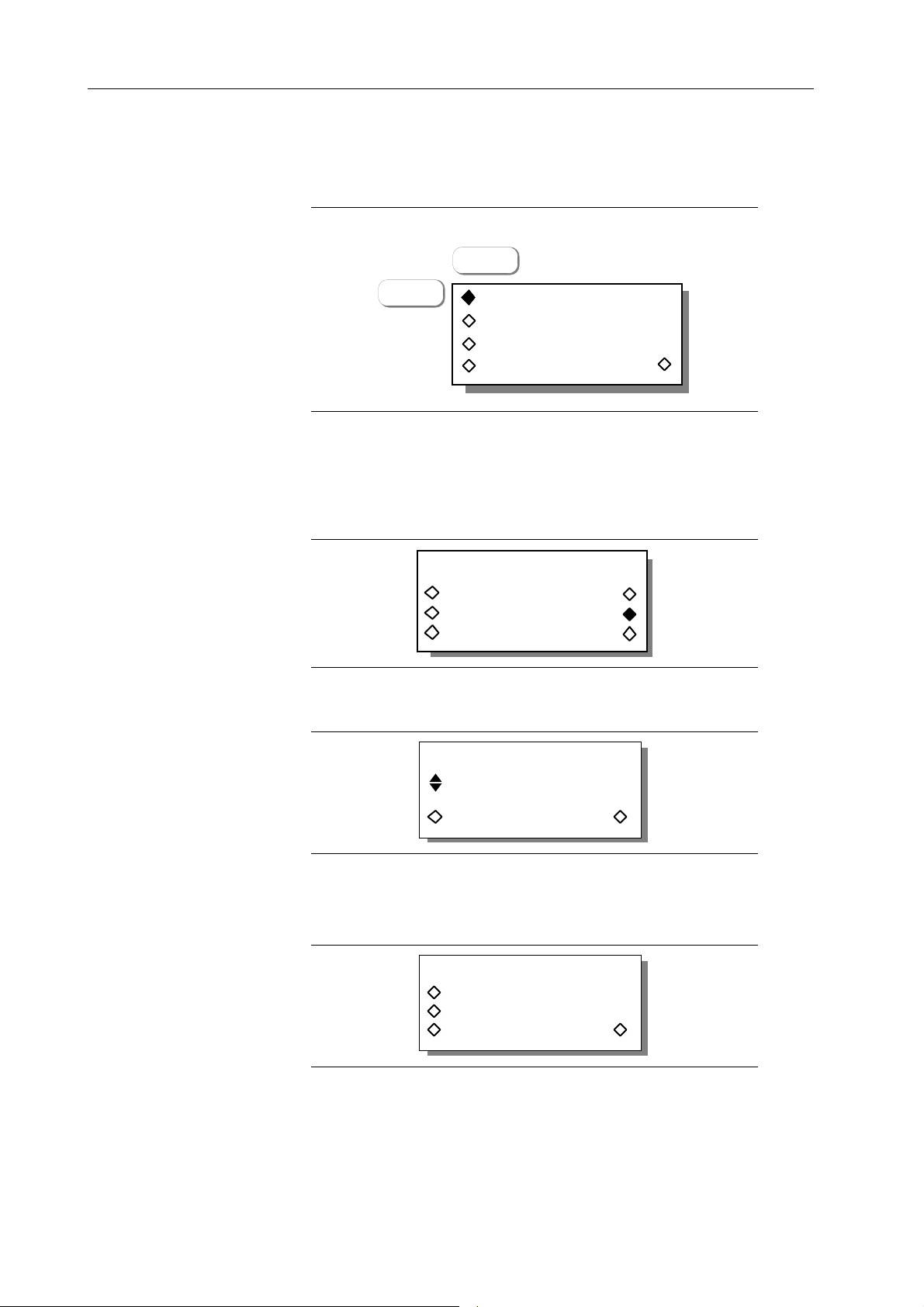

Page 29

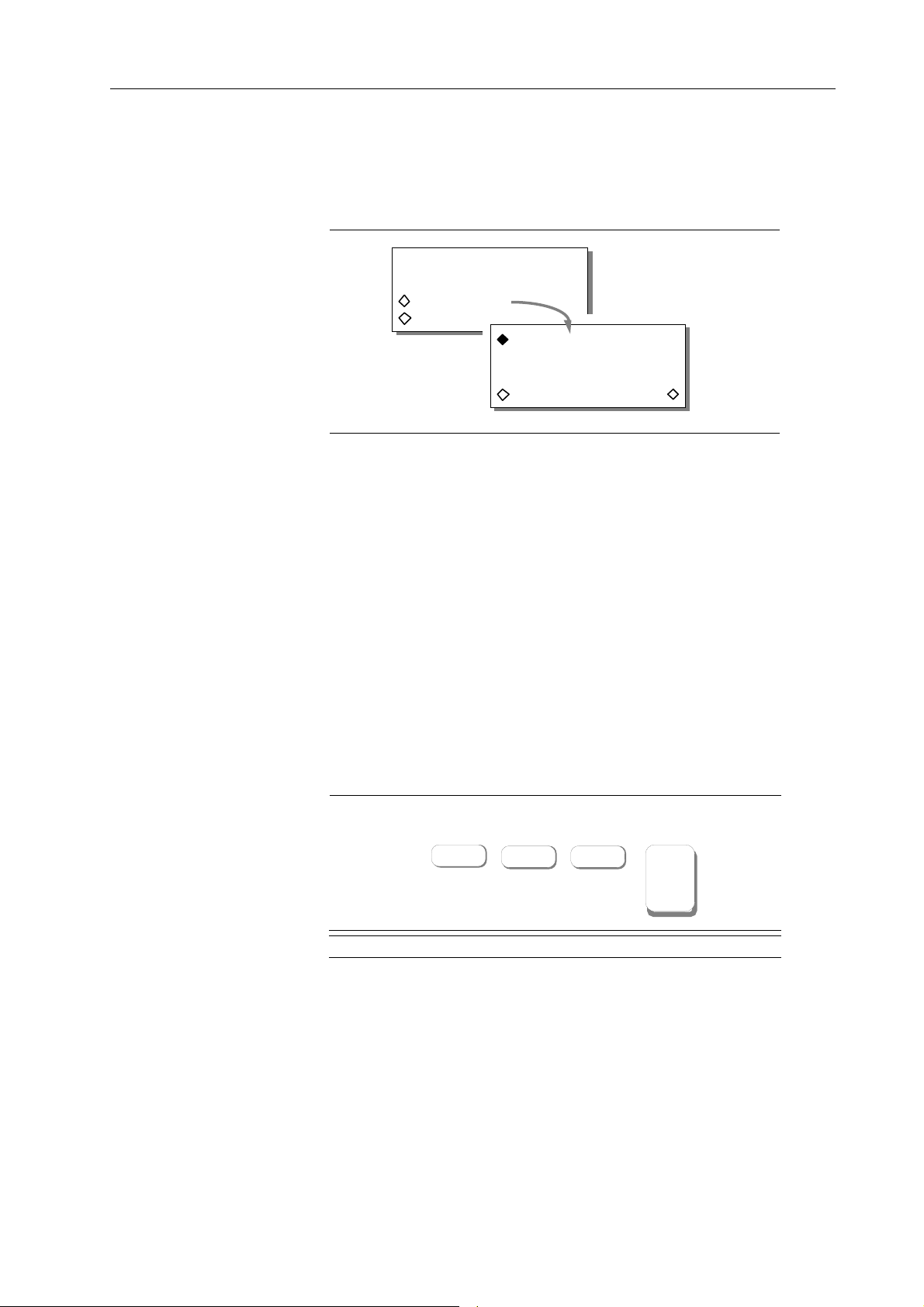

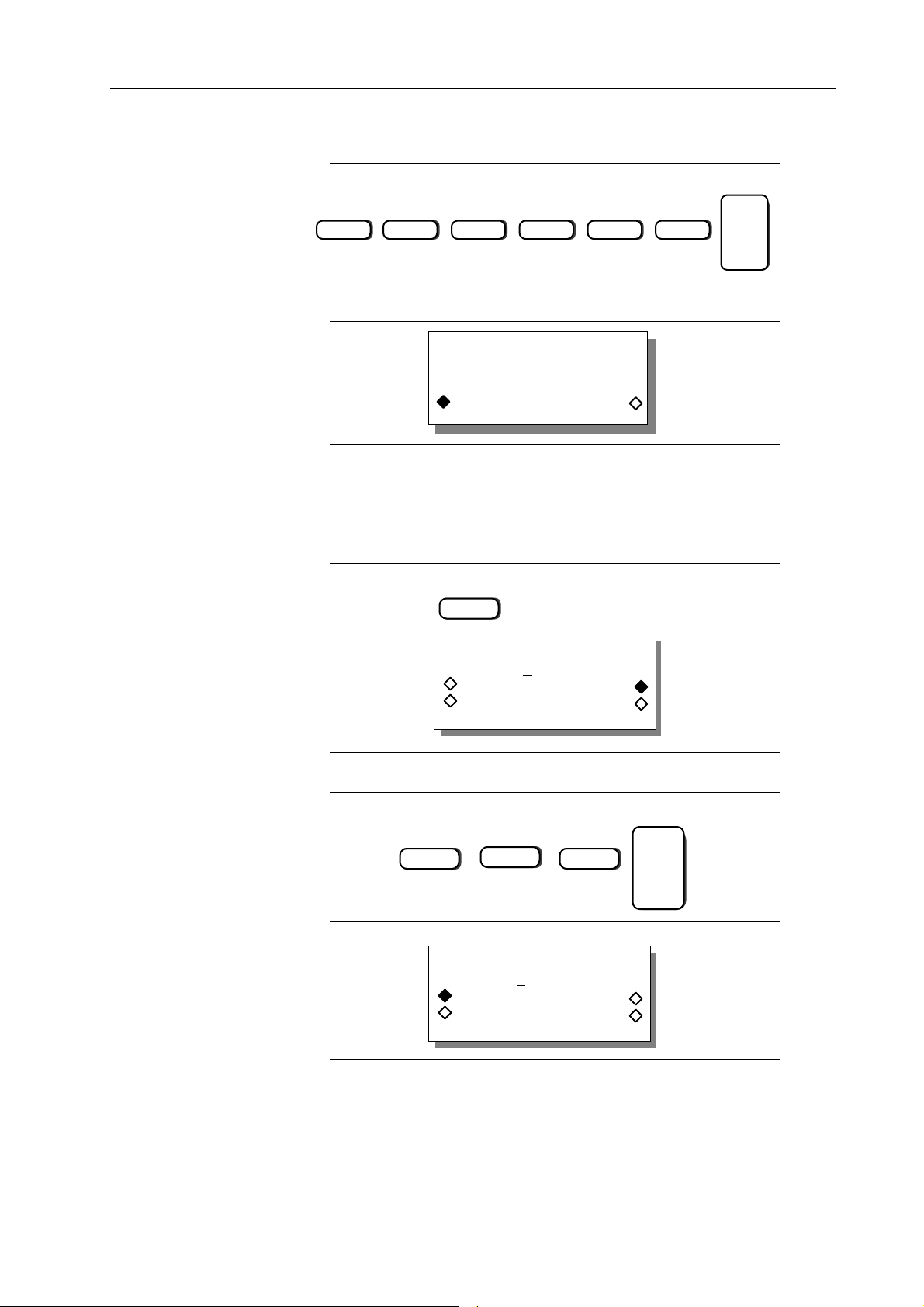

… Ellipsis

CREATE NEW WAVEFORM

(avail mem: 64512)

create blank …

create from copy …

An ellipsis (three dots following screen text) indicates additional screens will follow

when selected. For example, press the Waveform Edit’s CREATE key and check out

“create blank …,” see figure 3-4.

Figure 3-4. “Ellipsis” (Create Screen)

3.2.4 Changing Numeric Values

The Model 395 allows you to change numeric values using the numeric keypad or knob.

The screen displays modifiable values with the “cursor” starting under the most

significant digit. For example, try pressing the OFFSET key.

With the Keypad

CREATE: "wv2_____"

size: 1024

(max: 64512)

cancel create

To enter values using the keypad, press the numeric key. The Model 395 accepts the

value when the Enter key is pressed.

The Model 395 accepts values in three basic formats: Integer (10), floating point (10.0),

and exponential (1 exp 1).

For example, to change the frequency to 50 kHz using the exponential format, enter the

value by pressing these keys:

5

EXP

4

ENTER

50.00000000 kHz

Using the Knob

The front panel knob also can be used to change numeric values. When using the knob,

values are always changed starting from the digit over the cursor. To modify a value

using the knob, place the cursor under the desired digit, and rotate the knob to change

the value. Clockwise rotation increases the value; and counterclockwise rotation

decrease the values.

For example, to use the knob to set the frequency to 50.35 kHz, press the FREQUENCY

key to display the Standard Frequency screen; see figure 3-5. Note: the number of digits

shown on the frequency screen depends on the selected waveform.

Introduction To The Model 395 3-3

Page 30

STANDARD FREQUENCY

50.00000000 kHz

freq period

Figure 3-5. Knob Example

Use the right “cursor” key to move the cursor over three digits.

3X

50.00000000 kHz

Rotate the knob clockwise until the frequency reads 50.35000000 kHz.

50.35000000 kHz

3.2.5 Correcting Mistakes

3.3 ON-SCREEN HELP

If you make a mistake while entering a value from the front panel, you can make

corrections by using the CLEAR key or the BSP (Backspace) key.

Use the CLEAR key to erase the entire value. Pressing ENTER, rotating the knob, or

pressing a cursor key, restores the original value providing a value has not been entered

via the keypad.

When using the keypad to enter values, press the ¨ BSP (backspace) key to erase the digits

to the left of the cursor. Then use the keypad to enter the correct value.

The Model 395 includes on-screen help for the current screen. To access a Help screen,

press the HELP “button;” see figure 3- 6. Rotate the knob or use the cursor keys to display

additional help lines. Press the HELP key a second time to return to the operation screen.

3-4 Introduction To The Model 395

Page 31

STATUS

For example, press the AMPLITUDE key and then press the HELP key; see below figure

3-7 .

3.4 ERROR MESSAGES

When the Model 395 detects an operational error, it displays a message describing the

problem. Press any key to remove the error message and return to the operation screen,

.

ERROR messages occur if you attempt an illegal operation, such as setting the amplitude outside

the range supported by the instrument. For example if you try to program an amplitude of

6 Vp, you will see the message shown in figure 3-8.

HELP

Figure 3-6 . Help Key

--AMPLITUDE HELP-use knob to scroll

help message

------------------------------------

Figure 3-7 . Amplitude Help Screen

3.5 Initial Setup

Before operating the Model 395, connect the Model 395 to the correct AC power source;

see section 2 - Initial Turn-On.

Make sure the fuse in the instrument matches the fuse required for your primary power

source voltage. See Section 2, Preparation for Use, Fuse Replacement. Also, be sure

the specified line voltage of the unit matches the primary power source. Use the power

cord supplied with the unit to connect the Model 395 to the primary power source.

Use the correct cables and terminations to connect the Model 395 to an oscilloscope.

Figure 3-9 illustrates a typical setup that connects the Model 395 Main Out to channel

1 on the oscilloscope, and the Sync Out to the scope trigger input. Cables from both

outputs must be terminated with 50Ω. Some scopes contain built-in 50Ω terminations.

DATA OUT OF RANGE:

min value 0

max value 5

<press ENTER>

Figure 3-8 . Error Message Sample

Introduction To The Model 395 3-5

Page 32

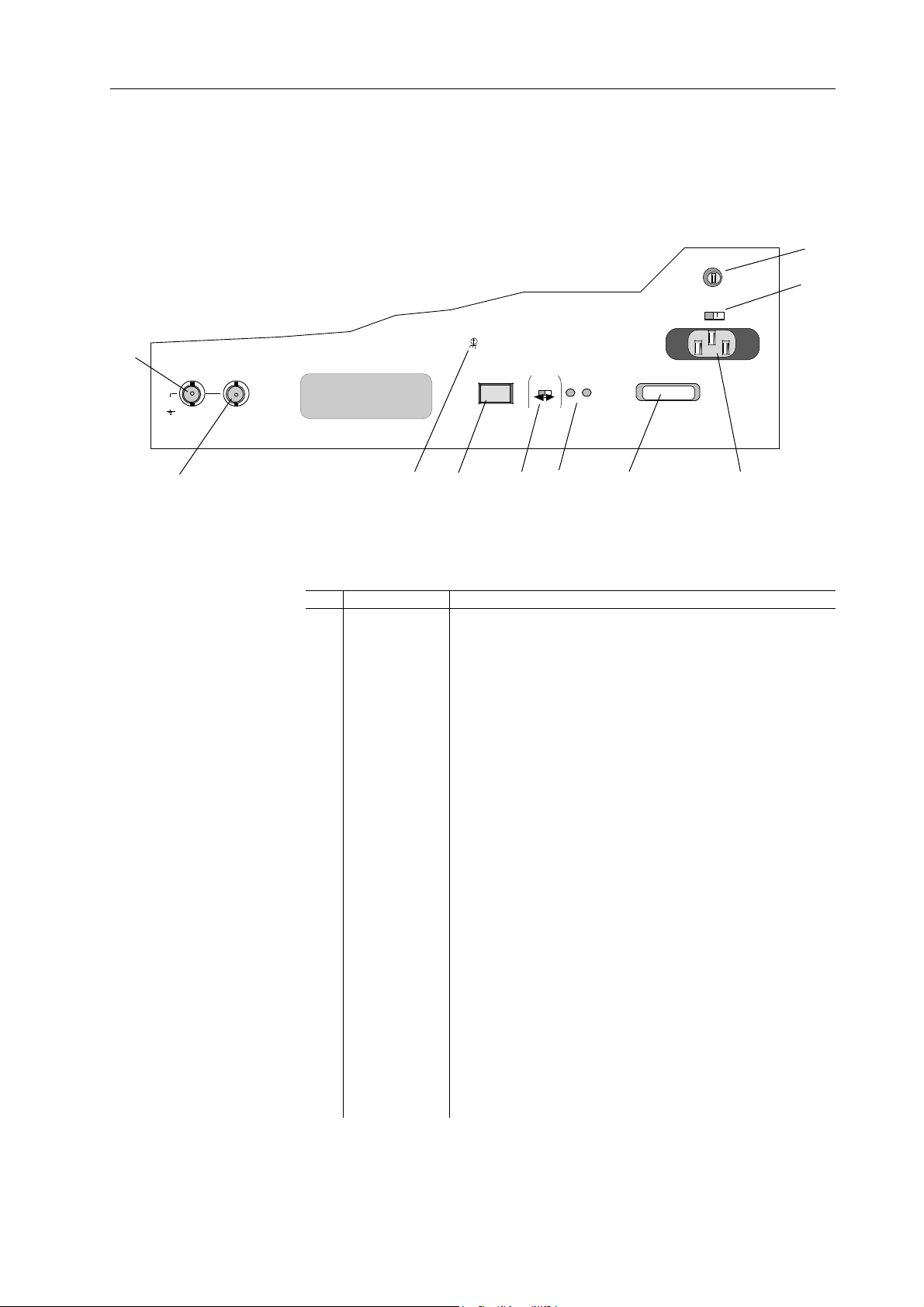

Oscilloscope

Channel 1

Input

Trigger

Input

50Ω

Termination

50Ω

Model 395

F1

F2

F3

F4

DISPLAY

FREQUENCY

WAVEFORM SELECT

POWER

ON OFF

OFFSET SEQUENCEMODE

AMPL

CREATE MODIFY

Termination

100 MHz Arbitrary Waveform Synthesizer Model 395

F5

F6

F7

F8

STATUSHELP

FILTER

WAVEFORM

INSTRUMENTS

EDIT

UTILITYSTANDARD ARBITRARY

SETUPS

RESET

REMOTE

MAN TRIG

BSP

7 8 9

4 5 6

1 2 3

0

TRIG IN

2kΩ

(0-10V)

CLEAR

EXP

ENTER

+/-

SYNC OUT

2kΩ

(±10V)

SUM IN MAIN OUT

AM INSWEEP OUT

50Ω

2.5kΩ

(TTL)

600Ω

(5Vpp)

(10Vpp)

Main

Out

50Ω

(10Vpp)

Sync

Out

Figure 3-9. Model 395 to Scope Interconnection

When the Power is turned on, the Model 395 displays its start-up screen (figure 3-10).

Wavetek

Model 395

(for assistance,

press HELP)

Figure 3-10. Model 395 Start-up Screen

3.6 MODEL 395 AS A FUNCTION GENERATOR

As a function generator, the Model 395 generates sine, square, triangle, positive ramp,

negative ramp, positive haversine, negative haversine, sin(x)/x, and dc waveforms.

Example 1. Setting Up the Function Generator

This example illustrates how to set up the Model 395 to produce a continuous, 4.58 MHz,

5.4 Vp-p square wave with a -1.2 Vdc offset. Paragraph 5.5.1, example 1 contains the

remote SCPI programming equivalent of this example. To view the signal on an

oscilloscope, connect the Model 395 to the scope as described in paragraph 3.5. This

example is the front panel equivalent of example 1, paragraph 5.5.1.

3-6 Introduction To The Model 395

Page 33

Step 1 Initial Setup and Power On

Connect the Model 395 to a power source - see paragraph 2.6 Initial Turn-On. Push the

POWER switch in. The Model 395 displays its start-up screen.

STEP 2. ENABLING THE MAIN OUT

To output the signal generated by the Model 395, you must enable the output by pressing

the MAIN OUT key. A lit indicator lights indicates the output is on.

POWER

Wavetek

Model 395

(for assistance,

press HELP)

MAIN OUT

ON

If a scope is connected to the Main Out, you will see a waveform on the scope screen.

Step 3 Synchronizing the Scope and Model 395

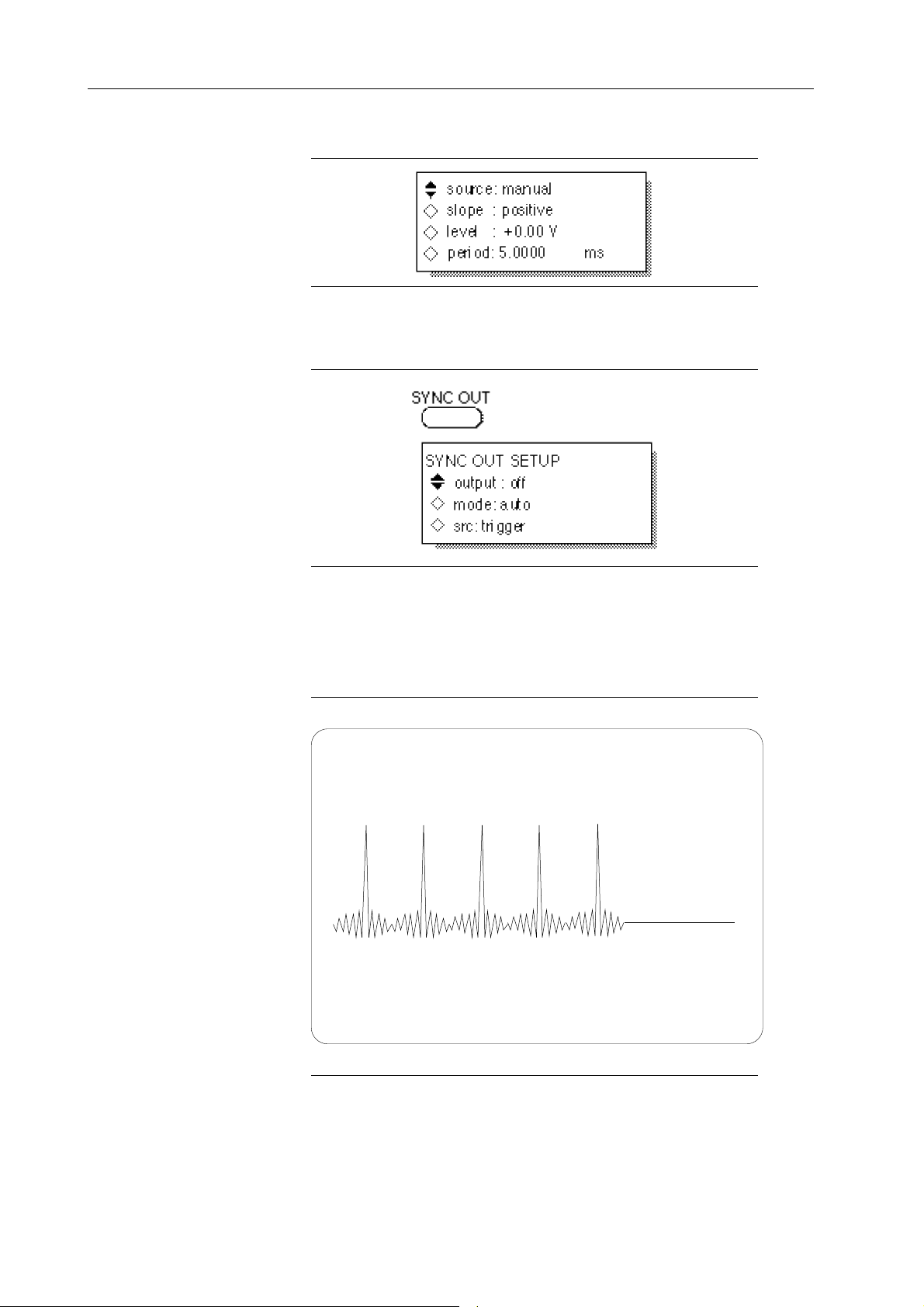

To synchronize the scope signal with the Model 395, press the SYNC OUT key to

display the Sync Output Setup screen:

SYNC OUT

F2

Enable the Sync Out signal by pressing F2 “output” until “output: on” appears. The Sync

Out indicator lights.

SYNC OUT SETUP

output: off

mode: auto

src: waveform sync

Introduction To The Model 395 3-7

Page 34

Step 4 Selecting Continuous Mode

Mode defines the operating state (continuous, triggered, etc.) of the Model 395. To set

the operating mode to continuous, press the MODE key to display the mode screen:

MODE

F1

continuous

sweep

gated

trig'd , cnt: 0000001

Press F1 “continuous” to selected this mode. Continuous is the default mode.

Step 5 Selecting Square Wave

Select a waveform by pressing the STANDARD key under Waveform Select to display

the Waveform screen. Select the square wave by pressing the softkey (initially F3) to

the left of “square.”

If square is not shown on the screen, rotate the knob until “square” is shown on the screen

of the Model 395.

STANDARD

F3

STANDARD WAVEFORMS

sine

square

(use knob to scroll)

Step 6 Setting the Frequency to 4.58 MHz

Program the frequency of the square wave by pressing the FREQUENCY key to display

the Standard Frequency screen:

FREQUENCY

STANDARD FREQUENCY

1.000 kHz

freq period

3-8 Introduction To The Model 395

Page 35

To change the frequency, press these keys:

ENTER

4 •

5

8 6

EXP

The screen reads:

STANDARD FREQUENCY

4.580 MHz

freq period

Pressing the softkey F8 will display the period of the square wave.

Step 7 Setting the Amplitude to 5.4 Vp-p

To change the amplitude (waveform level) of the square wave, press the AMPLITUDE

key to display the Amplitude screen.

AMPLITUDE

AMPLITUDE:

+1.00 Vp

Vpp Vp

Vrms dBm

Change the Amplitude units to “Vpp” by pressing F3. Then using the keypad, press:

ENTER

4•5

AMPLITUDE:

+5.40 Vpp

Vpp Vp

Vrms dBm

Amplitude units also can be displayed in Vrms (press F4), Vp (press F7), or dBm (press F8).

Introduction To The Model 395 3-9

Page 36

Step 8 Offsetting the Square Wave -1.2 Vdc

To offset (baseline value) the square wave, press the OFFSET key to display the Offset

screen:

OFFSET

OFFSET:

+0.00 Vdc

Using the keypad, press:

ENTER

+/-

1

•

2

OFFSET:

-1.20 Vdc

Summary

If you followed these steps, the scope displays a 4.58 MHz, 5.4 Vp-p square wave offset

-1.2 Vdc.

+1.5

0V

4.58 MHz

-3.9

3.7 MODEL 395 AS AN ARBITRARY WAVEFORM GENERATOR

Arbitrary waveform generators allow you to create and generate custom waveforms. In

addition to using the front panel controls, which will be used in these examples, you can

use the Model 395’s optional GPIB interface to upload waveforms from DSOs. Also,

waveforms can be created using waveform generation software like Waveform DSP.

3-10 Introduction To The Model 395

Page 37

These examples guides you through the creation of three Arbitrary waveforms. One

waveform, “gray,” demonstrates how to create and output an Arb waveform. The other

two Arb waveforms, “sync1” and “sync2” will demonstrate waveform sequencing

(paragraph 3.8).

Example 2 Creating an Arbitrary Waveform Using Line Draw

This example creates waveform that simulates a nine-step gray scale video signal.

Paragraph 5.5.2, example 2 contains the remote SCPI programming equivalent of this

example. You will use this waveform with example 3.

If you want to view the signal on an oscilloscope, connect the Model 395 to the scope

as described in paragraph 3.5. First setup the Model 395 as described in example 1, steps

1, 2, and 3.

Step 1 Naming and Sizing the Waveform

The first step in creating the waveform is to name it and define its size. Start by pressing

the CREATE key under WAVEFORM EDIT which displays the Create New Waveform

screen.

WAVEFORM EDIT

CREATE

CREATE NEW WAVEFORM

F3

(avail mem: 61972)

create blank …

create from copy …

Press F3 to select “create blank … .” Note: the Model 395 uses ellipsis, …, to tell you

there are additional screens. If you pressed F4, “create from copy … ,” you could copy

an existing waveform and modify the copy.

Give the waveform a name using the knob and right cursor key. Rotate the knob until

the first character displays “g” and press the right cursor. Again rotate the knob until the

second character displays “r” and press the right cursor. Continue until you have entered

“a” and “y.” Both letters and numbers can be used in names, but the first character must

always be a letter.

CREATE: "gray_____"

size: 1024

(max: 61972)

cancel create

Size defines the number of points in the waveform. Select “size” by pressing the F2 key.

Use the keypad to enter 2540 points.

2 5 4 0

Introduction To The Model 395 3-11

Page 38

CREATE: "gray_____"

size: 2540

(max: 61972)

cancel create

F8

Step 2. Creating the Waveform

Press F8 “create” to accept the name and size and advance to the Modify screen.

MODIFY: sync1

resize … rename …

F4

From the Modify screen press F4 “edit waveform” which displays the editing screen.

Then from the edit screen, press F3 to select “line draw.”

F3

delete … limits …

edit waveform …

EDIT FUNCTIONS

point edit …

line draw … exit

(use knob to scroll)

Line draw consists of defining points and drawing lines between the points (address and

data value). The range of addresses in this example are 0 to 2539, and the range of data

values for each address is -2048 to +2047.

To enter the first point, press F2 “fm … adrs.”

LINE (adrs ,data)

fm: (000000 ,+0000)

to: (002539 ,+0000)

exit draw line

Then using the keypad enter 0. Next press F6 “fm … data.”

LINE (adrs ,data)

fm: (000000 ,+0000)

to: (002539 ,+0000)

exit draw line

3-12 Introduction To The Model 395

Page 39

Then using the keypad, enter 0000. Next press F3 “to … adrs.”

LINE (adrs ,data)

fm: (000000 ,+0000)

to: (002539 ,+0000)

exit draw line

Next use the keypad to enter 59. Then press F7 “to … data.”

LINE (adrs ,data)

fm: (000000 ,+0000)

to: (000059 ,+0000)

exit draw line

Use the keypad to enter 2048. Finally, press F8 “line draw” to draw the line.

LINE (adrs ,data)

fm: (000000 ,+0000)

to: (000059 ,+2048)

exit draw line

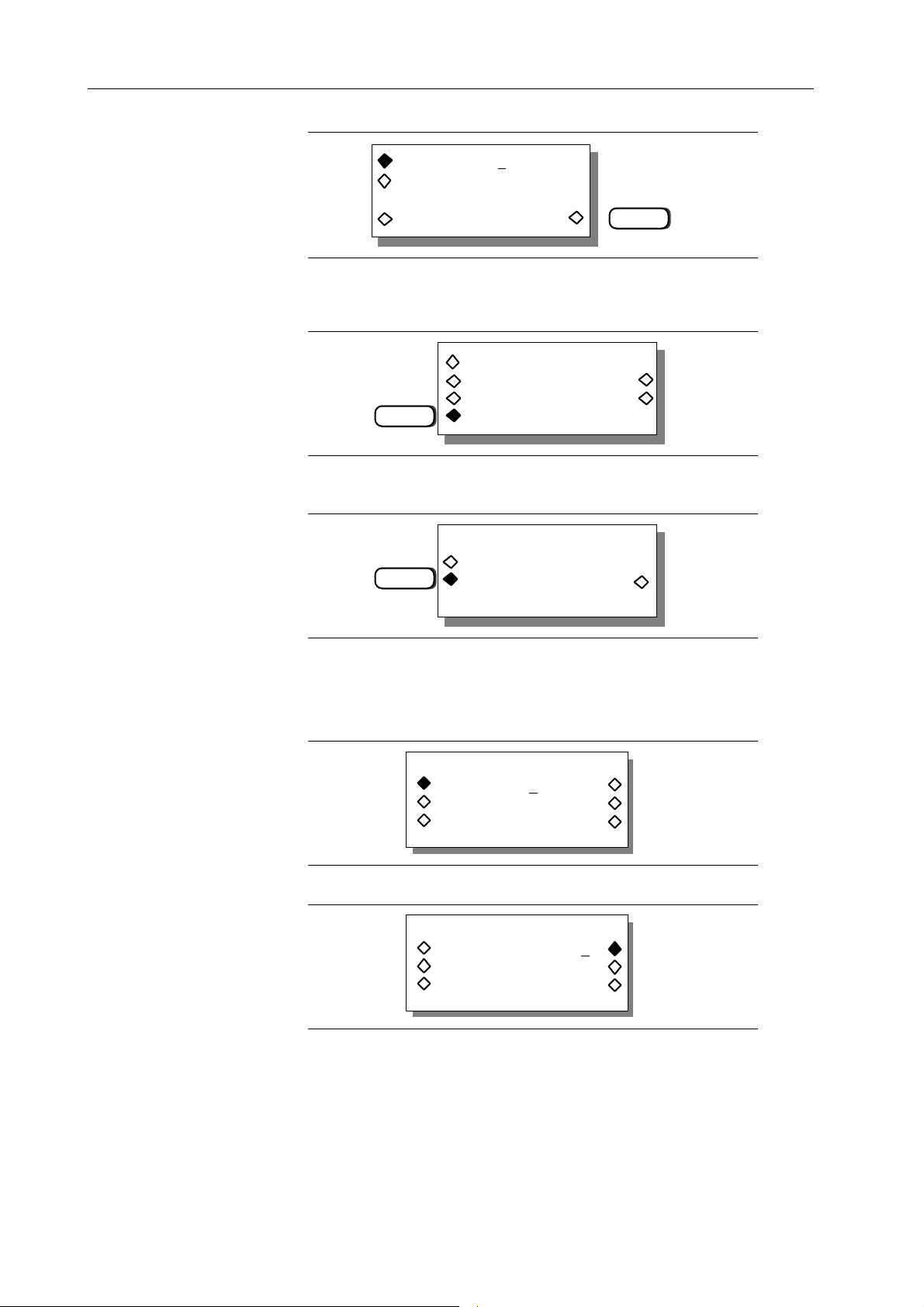

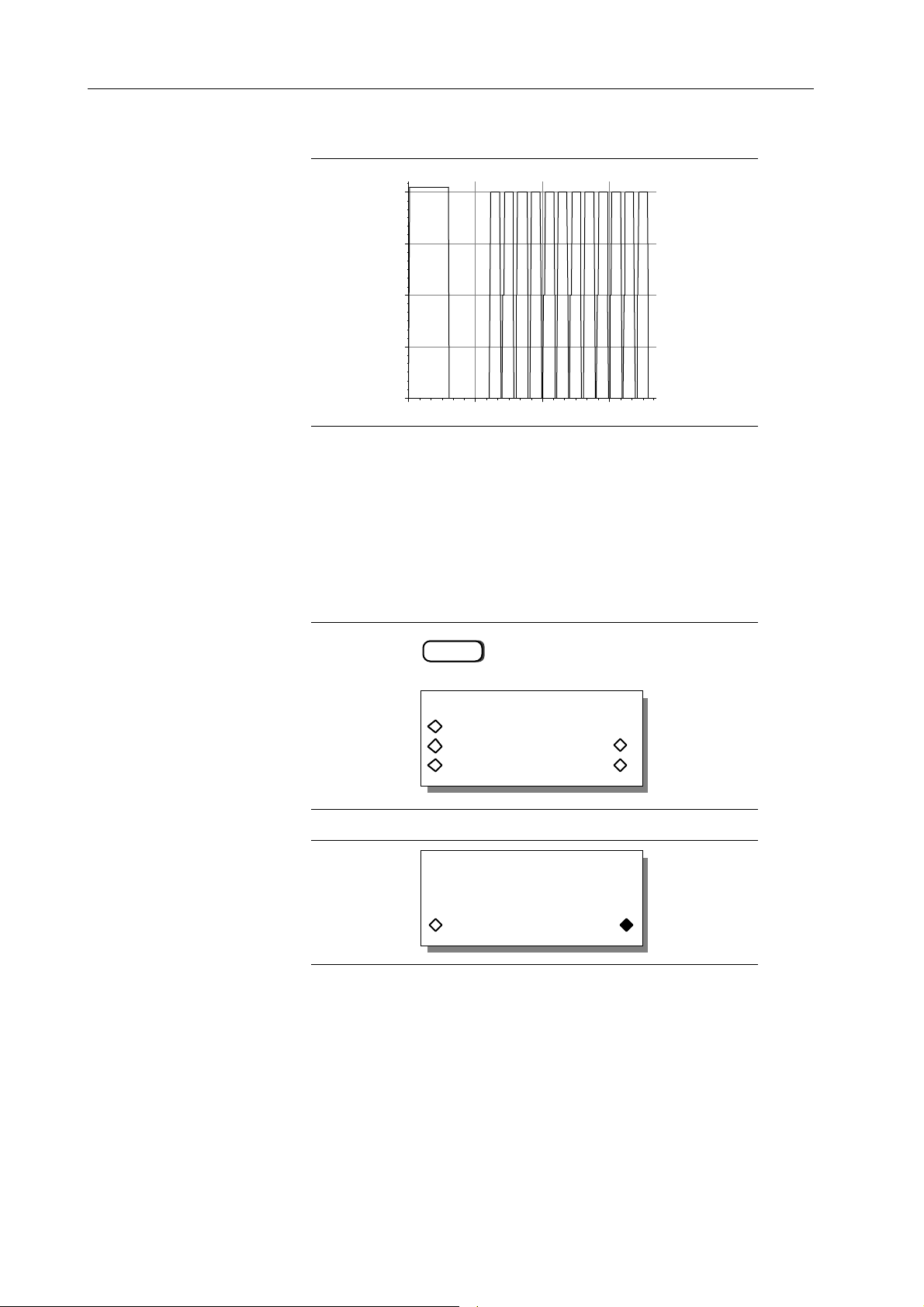

Use the following table to enter the rest of the waveform data. Figure 3-11 illustrates the

waveform plotted by the data.

From Adrs From Data To Adrs To Data Press

60 -577 280 -577 “draw line”

281 +0000 461 +0000 “draw line”

462 +154 981 +154 “draw line”

982 +308 1102 +308 “draw line”

1103 +462 1223 +462 “draw line”

1224 +616 1344 +616 “draw line”

1345 +770 1465 +770 “draw line”

1466 +924 1586 +924 “draw line”

1587 +1078 1707 +1078 “draw line”

1708 +1232 1827 +1232 “draw line”

1828 +1386 1949 +1386 “draw line”

1950 +1540 2539 +1540 “draw line”

Introduction To The Model 395 3-13

Page 40

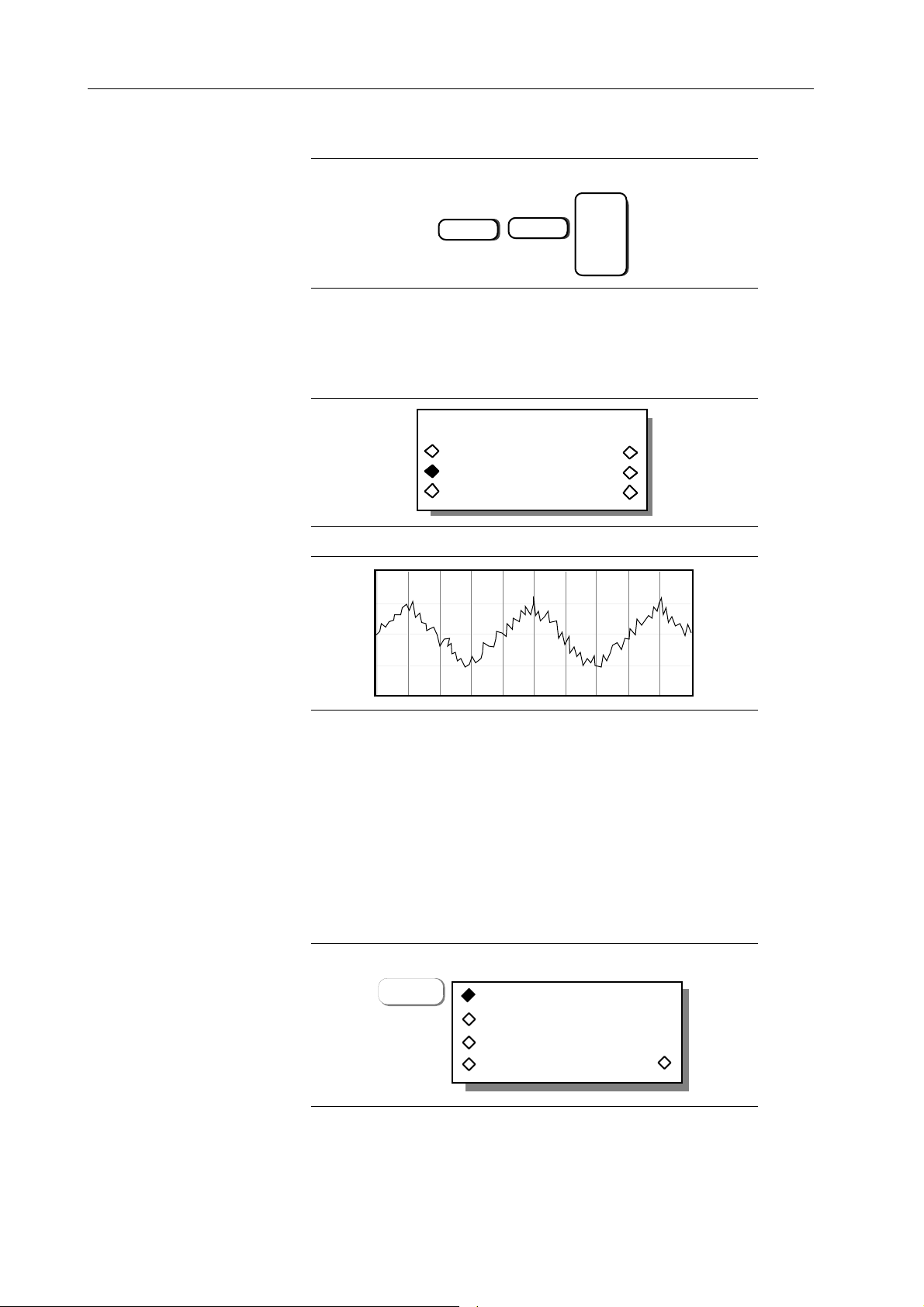

ADDRESS

+2047

+1536

+1024

+512

+0000

DATA

-512

-1024

-1536

-2048

Figure 3-11. Waveform: “gray”

Press F4 “exit” when finished.

300025002000150010005000

ADDRESS

LINE (adrs ,data)

fm: (001950 ,+1540)

to: (002539 ,+1540)

exit draw line

Example 3 Generating the Arb Waveform

Now that the Arbitrary waveform “gray” has been created, you can output it like a

standard waveform. Paragraph 5.5.2, example 3 contains the remote SCPI programming

equivalent of this example. First setup the Model 395 as described in example 1, steps

1, 2, and 3.

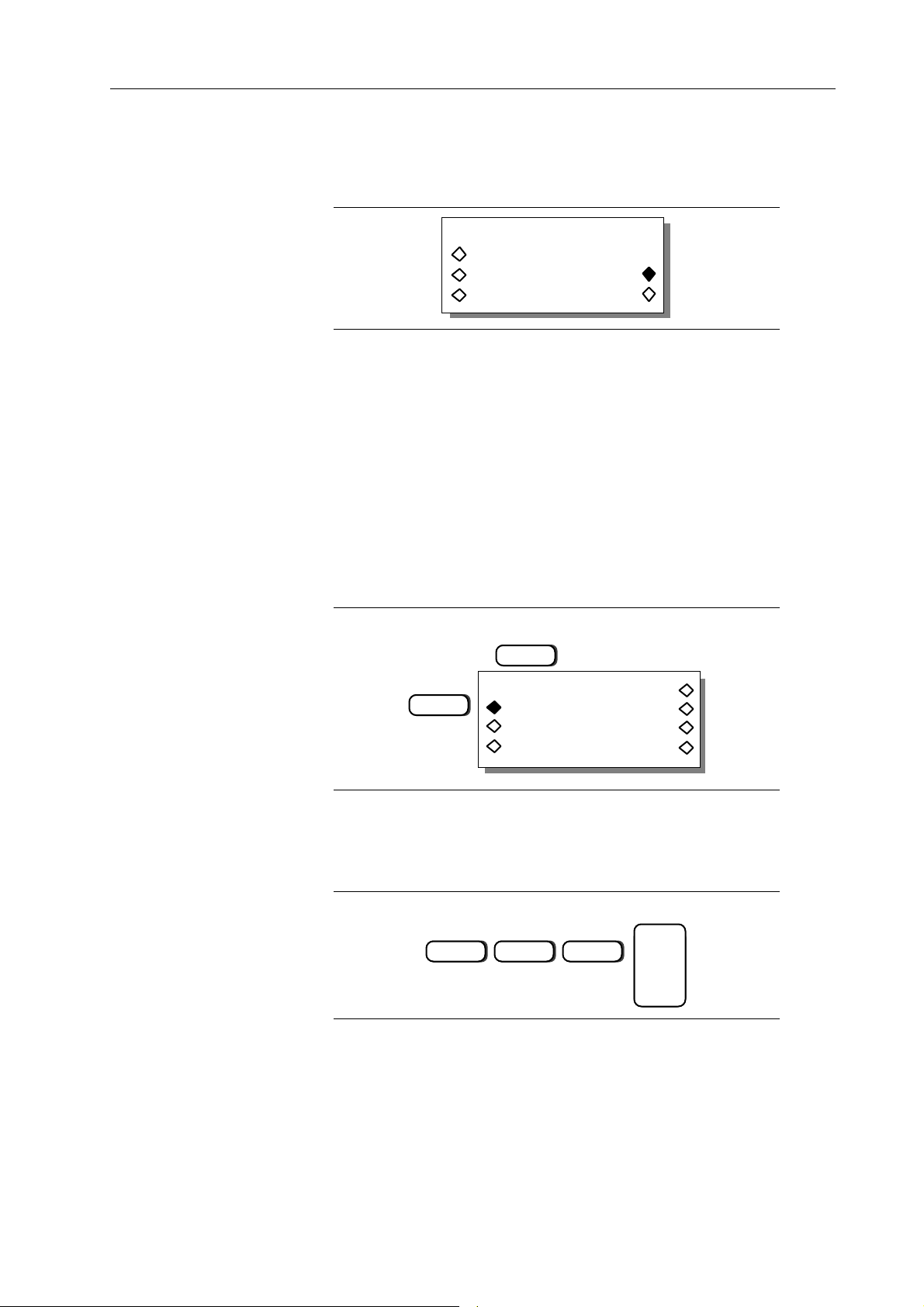

Step 1 Selecting Arb Waveform “gray”

Press the ARBITRARY key to display the Arbitrary Waveforms screen. The display

lists all Arbitrary waveforms stored in memory.

3-14 Introduction To The Model 395

Page 41

ARBITRARY

ARBITRARY WAVEFORMS

gray 002540

wv1 001024

(use knob to scroll)

Find “gray” and press the softkey next to it; for example, F2.

Step 2 Selecting Continuous Mode

Select the unit’s operating mode by pressing the MODE key which displays the Mode

screen.

F1

continuous

sweep

gated

trig'd , cnt: 0000001

Press F1 to select the continuous mode.

Step 3 Setting Waveform Period

To set the waveform period, press the FREQUENCY key to bring up the Arbitrary

Frequency screen. Press F7, “waveform,” and then press F8 “period.” Waveform

frequency, sample frequency, and sample period can also be displayed.

FREQUENCY

ARBITRARY FREQUENCY

50.80 µSec

sample waveform

freq peroid

Enter the waveform period by pressing:

6 4 +/-

EXP

F7

F8

ENTER

6

Introduction To The Model 395 3-15

Page 42

Step 4 Setting the Amplitude

Set the amplitude to 5.4 Vp-p by first pressing the AMPLITUDE key. From the

Amplitude screen, press F3, “Vpp”, to display the amplitude units in Volts peak-to-peak.

AMPLITUDE

AMPLITUDE

F3

Enter the amplitude level by pressing:

5

+2.00 Vpp

Vpp Vp

Vrms dBm

ENTER

•

4

Step 5 Offsetting the Waveform

Offset the waveform’s baseline -0.5 Vdc by pressing the OFFSET key.

OFFSET

OFFSET

+0.00 Vdc

From the Offset screen press:

ENTER

+/-

•

5

3-16 Introduction To The Model 395

Page 43

The scope now displays the Gray Scale waveform similar to the one shown below:

DATA

Example 4. Creating an Arb Waveform Using Waveform Insert

The waveform, sync1, is a 120 point square wave that illustrates wave insert editing.

Paragraph 5.5.2, example 4 contains the remote SCPI programming equivalent of

this example. The waveform, sync1, will be used with example 6, creating a

sequence.

First set up the Model 395 as described in example 1, steps 1, 2, and 3.

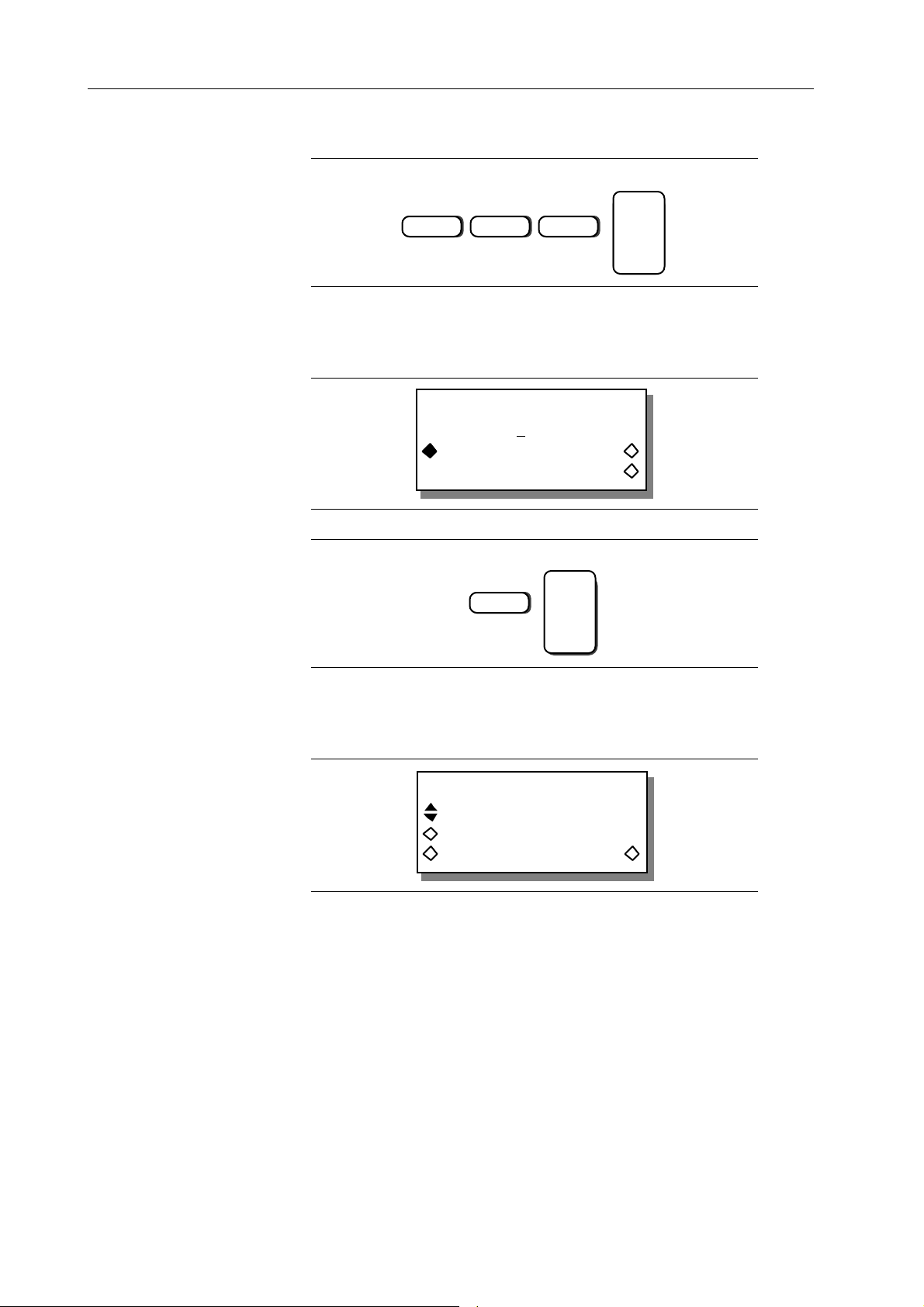

Step 1. Naming and Sizing the Waveform

The first step in creating the waveform is to name it and to define its size. Start by

pressing the CREATE key under WAVEFORM EDIT which displays the Create

New Waveform screen.

WAVEFORM EDIT

CREATE

CREATE NEW WAVEFORM

F3

(avail mem: 61972)

create blank …

create from copy …

Press F3 to select “create blank … .”

Using the knob and right cursor key name the waveform. Rotate the knob until the

first character displays “s” and press the right cursor. Repeat the process until you

spell sync1. Both letters and numbers can be used when creating a name, but the

first character must always be a letter.

CREATE: "sync1_____"

size: 1024

(max: 61972)

cancel create

Introduction To The Model 395 3-17

Page 44

Size defines the number of points in the waveform. Select “size” by pressing the F2 key.

Use the keypad to enter 120 points:

ENTER

1 2 0

Press F8, “create,” to accept the name and the size and advance to the Modify screen.

CREATE: "sync1_____"

size: 120

(max: 61972)

cancel create

F8

MODIFY: sync1

resize … rename …

F4

delete … limits …

edit waveform …

From the Modify screen press F4 “edit waveform” which displays the Edit screen.

EDIT FUNCTIONS

point edit …

line draw … exit

(use knob to scroll)

Rotate the knob until Wave Insert appears. Then press the soft key to select Wave Insert

….”

F1

square --> sync1

________ start 000000

________stop 000119

F8

exit insert

Press F1 until “square“ appears. Then press F8 to insert the square wave between

address 000000 and address 000119. Select “exit,” F4 to return to the waveform edit

screen.