Page 1

MAINTENANCE MANU AL

Model 29

10 MHz DDS

Function Generator

© 1997 Wavetek Ltd

This document contains information proprietary to

Wavetek and is provided solely for instrument

operation and maintenance. The information in this

document may not be duplicated in any manner

without the prior approval in writing from Wavetek.

Wavetek Ltd

Test and Measurement Division

Hurricane Way

Norwich Airport Industrial Estate

Norwich, Norfolk NR6 6JB, U.K.

Tel: 44 1603 256 600

Fax: 44 1603 483 670

Manual Issue: 1.1

Manual Part Number:

Page 2

Table of Contents

Specifications 2

Safety 6

EMC 7

Installation 7

General 9

Circuit Descriptions 10

Calibration 15

Parts List 18

Circuit Diagrams 25

1

Page 3

Specifications

Specifications apply at 18°-28°C after one hour warm-up, at maximum output into 50Ω

WAVEFORMS

STANDARD

Sine, square, positive pulse, negative pulse, multi-level squarewave, triangle, ramp up, ramp

down, DC and pseudo-random noise.

ARBITRARY

Sampling Frequency:

Waveform Length:: 1024 points maximum

Vertical Resolution: 10 bits

FREQUENCY

Frequency ranges for standard waveform are listed below. In Arbitrary mode all waveform points

are output up to approximately 27 kHz beyond which they are sampled.

Sine: 100 µHz to 10 MHz

Square: 100 µHz to 10 MHz

Positive/Negative Pulse: 100 µHz to 10 MHz

Triangle: 100 µHz to 100 kHz

Positive/Negative Ramp: 100 µHz to 100 kHz

Multi-level square: 100 µHz to 100 kHz

Pseudo-random noise: 30 mHz to 700 kHz

Resolution: 7 digits (limited by 100 µHz)

Accuracy: Typically 10 ppm for 1 year, 18°C to 28°C

Stability: Typically 1ppm per °C outside 18°C to 28°C

27.48MHz

WAVEFORM CHARACTERISTICS

Sine Distortion: <0.3% to 500 kHz

<-50 dBc to 1 MHz

<-35 dB to 10 MHz

Non-harmonic spurs: typically -50 dBc to 10 MHz

Square Rise/Fall Time: <25 ns

Square Aberrations: <5% + 2 mV

Square Symmetry Control: 1 to 99% (0.1% resolution) 100 µHz to 30 kHz

20 to 80% (0.1% resolution) 30 kHz to 10 MHz

Triangle Linearity Error: <0.5% to 30 kHz

Triangle Symmetry Control: 1 to 99% (0.1% resolution) 100 µHz to 100 kHz

Pulse Rise/Fall Time: <25 ns

Pulse Aberrations: <5% + 2 mV

Pulse Symmetry Control: 1 to 99% (0.1% resolution) 100 µHz to 30 kHz

20 to 80% (0.1% resolution) 30 kHz to 10 MHz

Multi-level Square: Maximum of 16 steps of discrete amplitude and duration (1 to 1,024

points). Allows generating 3 level square, staircase, multiplexed

LCD driver signals, etc.

2

Page 4

OUTPUT CHARACTERISTICS

Output Impedance:

Amplitude:

DC Offset:

Resolution: 3 digits (limited by 1 mV)

Accuracy:

Flatness: ±0.2 dB to 500 kHz, ±1 dB to 5 MHz, ±2.5 dB to 10 MHz

50Ω or 600Ω switchable

2.5 mVpp to 10 Vpp into 50Ω/600Ω

5 mVpp to 20 Vpp into open circuit

±5V (limited by offset plus signal peak) into 50Ω/600Ω

±10V (limited by offset plus signal peak) into open circuit

3% + 1 mV at 1 kHz into 50Ω/600Ω

OPERATING MODES

CONTINUOUS

Continuous cycles of the selected waveform are output at the programmed frequency.

TRIGGER/BURST

Phase coherent triggering of the programmed number of cycles of the selected waveform.

Waveforms start and stop at the phase angle specified in the Start/Stop phase parameter.

Trigger Sources: External signal, manual (front panel key), internal trigger generator or

remote command.

Burst Count: 1 to 1023 cycles

Trigger Repetition Rate: dc to 50 kHz (internal trigger generator)

dc to 1 MHz (external trigger signal)

GATE

Cycles of the selected waveform are continuously output while the trigger signal is present.

Trigger Sources: External signal, manual (front panel key), internal trigger generator or

remote command

Trigger Repetition Rate: dc to 50 kHz (internal trigger generator)

dc to 1 MHz (external trigger signal)

SWEEP

Sweep Mode: Linear or logarithmic, single triggered cycle or continuous

Frequency Range: 100 µHz to the maximum frequency for selected waveform

Markers: Two variable markers during sweep

Trigger Sources: External signal, manual (front panel key), or remote command

FREQUENCY HOP

Up to 16 different hop waveforms, each with independently setable frequency, amplitude, offset,

waveform (except noise), and duration for each waveform. Phase continuous switching between

frequencies can be executed via software or manually (front panel key). Waveform duration can

be set from 2 ms to 65 s in 1 ms increments. HOP can be externally triggered from the EXT TRIG

input.

3

Page 5

AMPLITUDE MODULATION

Carrier Frequency Range 100 µHz to the maximum frequency for selected waveform.

Carrier Waveforms: All

Depth: Typically variable from 0% to 100% in 1% increments

Internal Source: 1 kHz fixed sinewave or 5 mHz to 50 kHz squarewave

External Source: DC to 100 kHz (4 quadrant)

External Sensitivity: Approximately 2 Vpp for 50% modulation

FREQUENCY SHIFT KEYING (FSK)

Phase coherent switching between two selected frequencies at a rate defined by the switching

signal source.

Carrier Frequency: 100 µHz to the maximum frequency for selected waveform

Carrier Waveforms: All

Switch Repetition Rate: dc to 50 kHz (internal trigger generator)

dc to 1 MHz (external trigger signal)

Switching Signal Source: Internal from front panel key or internal trigger generator

External from Trig/Gate input or remote interface

START/STOP PHASE

Phase relationship between MAIN OUT and AUX OUT is determined by the START/STOP

PHASE setting.

Carrier Frequency: 100 µHz to 1 MHz

Carrier Waveforms: All

Range: 0 to 360 degrees

Resolution: 1 degree

TRIGGER GENERATOR

Internal source 5 mHz to 50 kHz squarewave adjustable in 20 µs steps with 3 digit resolution.

Available for output at the sweep/marker connector (except during sweep or HOP operation).

OUTPUTS/INPUTS

FRONT PANEL CONNECTIONS

MAIN OUT

AUX OUT: CMOS/TTL level signal at the frequency and symmetry of main output.

EXT TRIG: External trigger input for Trigger, Gate, Sweep and FSK operating

Waveform output at 50Ω or 600Ω (selectable) impedance.

Short circuit protection for up to 60 seconds is provided.

Phase relationship between MAIN OUT and AUX OUT is determined

by the START/STOP PHASE setting.

modes. It is also used to synchronize one Model 29 (as a slave) to

another Model 29 (as a master).

Maximum input voltage is ±10V.

4

Page 6

REAR PANEL CONNECTIONS

CLOCK IN/OUT The function of the CLOCK IN/OUT connector is set from the front

panel SYS (system) menu as follows:

CLOCK IN The connector serves as an input for an external clock

CLOCK OUT This is the default setting. The internal clock is made available as an

output. When two or more Model 29s are synchronized the CLOCK

OUT is used as a master to drive the CLOCK IN of the slave units.

PHASE LOCK For use as a slave unit phase locked to the master unit.

VCA IN Input connector for externally controlled Amplitude Modulation (AM).

Impedance is nominally 6 kΩ.

SYNC OUT When two or more generators are syncronized the SYNC OUT

connector on the master generator is connected to the EXT TRIG

inputs of the slave generators. SYNC OUT logic levels are nominally

0V and 5V with 50Ω output impedance.

TRIG/SWEEP OUT The function of this output is automatically determined by the generator

operating mode. Except in sweep and HOP modes the output is that of

the internal trigger generator, a fixed amplitude squarewave whose

frequency is set in the TRIG of GATE menus. The rising edge of the

trigger generator initiate trigger, gate and burst modes. In sweep mode

the output is a 3-level waveform, changing from high (4V) to low (0V) at

the start of the sweep, with narrow 1V pulses at marker points. In HOP

mode the output goes low on entry to each waveform step and high

after the new frequency and waveshape of that step have been set.

Output impedance is 1kΩ.

INTERFACES

Full remote control facilities are provided through RS232 and IEEE-488 (GPIB) interfaces.

RS232: Variable baud rate, 9600 baud max;, 9-pin D connector.

IEEE-488: Conforms with IEEE-488.1 and IEEE.488.2

STORED SETTINGS

Up to 9 complete instrument set-ups may be stored and recalled from battery backed memory.

GENERAL

Display: 20 character by 4 row alphanumeric display.

Size: 130 mm (height), 212 mm (width), 330 mm (depth)

Weight: 9 pounds (4.1 kg)

Power 115 V or 230 V nominal 50/60 Hz, adjustable internally,

operating range ±14% of nominal, 30 VA maximum.

Operating Range: 5°C to 40°C, 20-80%RH

Storage Range: -20°C to 60°C

Options: 19” Rack Mount Kit

Safety: Complies with EN61010-1

EMC: Complies with EN55011 and EN50082-1.

5

Page 7

Safety

This function generator is a Safety Class I instrument according to IEC classification and has

been designed to meet the requirements of EN61010-1 (Safety Requirements for Electrical

Equipment for Measurement, Control and Laboratory Use). It is an Installation Category II

instrument intended for operation from a normal single phase supply.

This instrument has been tested in accordance with EN61010-1 and has been supplied in a safe

condition. This service manual contains some information and warnings which have to be

followed by the user to ensure safe operation and to retain the instrument in a safe condition.

This instrument has been designed for indoor use in a Pollution Degree 1 environment (no

pollution, or only dry non-conductive pollution) in the temperature range 5°C to 40°C, 20% - 80%

RH (non-condensing). It may occasionally be subjected to temperatures between +5° and -10°C

without degradation of its safety.

Use of this instrument in a manner not specified by these instructions may impair the safety

protection provided. Do not operate the instrument outside its rated supply voltages or

environmental range. In particular excessive moisture may impair safety.

WARNING! THIS INSTRUMENT MUST BE EARTHED

Any interruption of the mains earth conductor inside or outside the instrument will make the

instrument dangerous. Intentional interruption is prohibited. The protective action must not be

negated by the use of an extension cord without a protective conductor.

When the instrument is connected to its supply, terminals may be live and opening the covers or

removal of parts (except those to which access can be gained by hand) is likely to expose live

parts. The apparatus shall be disconnected from all voltage sources before it is opened for any

adjustment, replacement, maintenance or repair.

Any adjustment, maintenance and repair of the opened instrument under voltage shall be avoided

as far as possible and, if inevitable, shall be carried out only by a skilled person who is aware of

the hazard involved.

If the instrument is clearly defective, has been subject to mechanical damage, excessive moisture

or chemical corrosion the safety protection may be impaired and the apparatus should be

withdrawn from use and returned for checking and repair.

Make sure that only fuses with the required rated current and of the specified type are used for

replacement. The use of makeshift fuses and the short-circuiting of fuse holders is prohibited.

This instrument uses a Lithium button cell for non-volatile memory battery back-up; typical life is 5

years. In the event of replacement becoming necessary, replace only with a cell of the correct

type, i.e. 3V Li/Mn0

in accordance with local regulations; do not cut open, incinerate, expose to temperatures above

60°C or attempt to recharge.

Do not wet the instrument when cleaning it and in particular use only a soft dry cloth to clean the

LCD window. The following symbols are used on the instrument and in this manual:-

l

20mm button cell type 2032. Exhausted cells must be disposed of carefully

2

Caution - refer to the accompanying documentation, incorrect

operation may damage the instrument.

terminal connected to chassis ground.

mains supply OFF.

mains supply ON.

6

alternating current.

Page 8

This function generator has been designed to meet the requirements of the EMC Directive

89/336/EEC.

Compliance was demonstrated by meeting the test limits of the following standards:

Emissions

Immunity

Cautions

To ensure continued compliance with the EMC directive the following precautions should be

observed:

EMC

EN55011 (1991) for industrial, scientific and medical (ISM) radio-frequency equipment;

Group 1 Class B limits were applied.

EN50082-1 (1992) Generic immunity standard for residential, commercial and light

industry. Test methods and limits used were:

a) EN60801-2 (1993) Electrostatic Discharge, 8 kV air discharge.

b) IEC801-3 (1984) RF Field, 3 V/m.

c) IEC801-4 (1988) Fast Transient, 1 kV peak.

a) connect the generator to other equipment using only high quality, double-screened cables.

b) after opening the case for any reason ensure that all signal and ground connections are

remade correctly before replacing the cover. Always ensure all case screws are correctly

refitted and tightened.

c) In the event of part replacement becoming necessary, only use components of an identical

type, see the Parts List.

Installation

Check that the instrument operating voltage marked on the rear panel is suitable for the local

supply. Should it be necessary to change the operating voltage, proceed as follows:

1) Disconnect the instrument from all voltage sources.

2) Remove the screws which retain the top cover and lift off the cover.

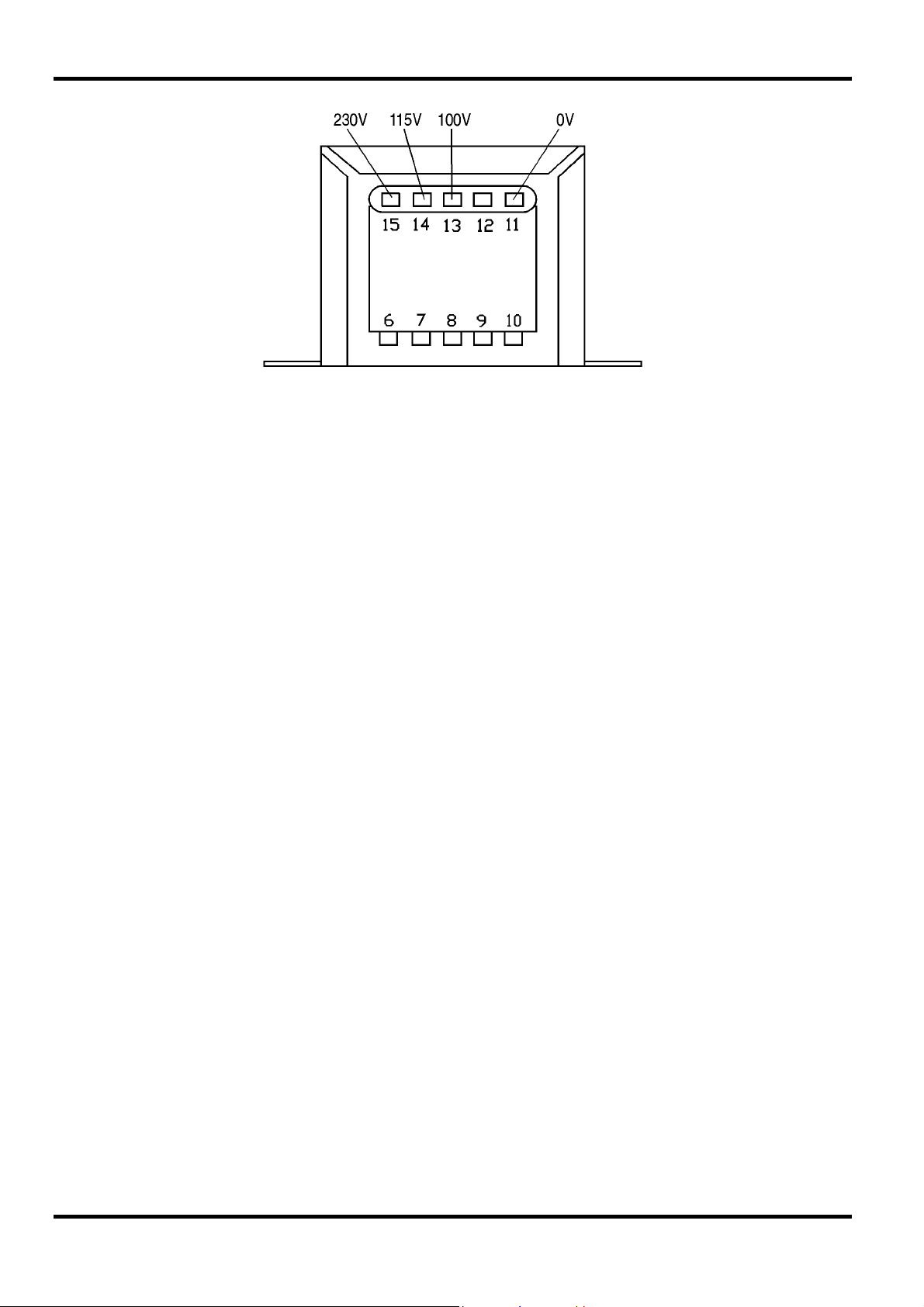

3) Change the transformer connections as follows:

for 230V operation connect the live (brown) wire to pin 15

for 115V operation connect the live (brown) wire to pin 14

for 100V operation connect the live (brown) wire to pin 13.

4) Refit the cover and the secure with the same screws.

5) To comply with safety standard requirements the operating voltage marked on the rear panel

must be changed to clearly show the new voltage setting.

6) Change the fuse to one of the correct rating, see below.

7

Page 9

Fuse

Ensure that the correct mains fuse is fitted for the set operating voltage. The correct mains fuse

types are:

for 230V operation: 250 mA (T) 250 V HRC

for 110V/115V operation: 500 mA (T) 250 V HRC

To replace the fuse, disconnect the mains lead from the inlet socket and release the fuse drawer

below the socket pins by depressing both clips together, with miniature screwdrivers, so that the

drawer can be eased open. Change the fuse and replace the drawer.

The use of makeshift fuses or the short-circuiting of the fuse holder is prohibited.

Mains Lead

When a three core mains lead with bare ends is provided it should be connected as follows:-

Any interruption of the mains earth conductor inside or outside the instrument will make the

instrument dangerous. Intentional interruption is prohibited. The protective action must not be

negated by the use of an extension cord without a protective conductor.

Mounting

This instrument is suitable both for bench use and rack mounting. It is delivered with feet for

bench mounting. The front feet include a tilt mechanism for optimal panel angle.

A rack kit for mounting one or two of these Half-width 3U high units in a 19” rack is available from

the Manufacturers or their overseas agents.

Brown - Mains Live

Blue - Mains Neutral

Green / Yellow - Mains Earth

WARNING! THIS INSTRUMENT MUST BE EARTHED

8

Page 10

Service Handling Precautions

Service work or calibration should only be carried out by skilled engineers. Please note the

following points before commencing work.

Most of the integrated circuits are CMOS devices and care should be taken when handling to

avoid damage by static discharge.

Many of the devices are miniature surface mount components with very fine leads on small

pitches; these components must be removed and replaced with great care to avoid damage to

the pcb. It is essential that only tools and soldering equipment specifically designed for surface

mount components are used.

The decoupling capacitors associated with the integrated circuits are surface mounted on the

solder side of the pcb.

Dismantling the Instrument

Disconnect the instrument from all voltage sources before it is opened for adjustment or repair. If

any adjustment or repair of the opened instrument is inevitable it shall be carried out only by a

skilled person who is aware of the hazards involved.

General

WARNING

1. Remove the six screws retaining the top cover.

2. The rear panel may be removed as follows. Disconnect the gray ribbon cable from PJ4

on the GPIB pcb and remove the 2 screwjacks which secure the RS232 connector to the

rear panel. Invert the instrument and remove the three screws securing the rear panel;

the panel may now be tilted back to allow access. If the panel is to be completely

removed unplug connectors from PJ4, PJ7 & PJ8 and the blue and brown wires from the

mains inlet filter; desolder the blue and brown wires from the mains transformer. The

panel can now be lifted free of the instrument.

3. The front panel assembly may be removed as follows. Unplug the connectors from PJ2,

PJ3, PJ5 & PJ6 and desolder the screened cable from PJ10. Remove the nut securing

the front panel earthing strap and the four nuts securing the front panel assembly. The

panel may now be drawn clear of the instrument.

4. Main pcb removal. Remove all connectors from the pcb and desolder the screened cable

from PJ10. Tilt the rear panel back as described in 2 above. Remove the pcb fixing screw

nearest PJ10; invert the instrument and remove the 5 screws retaining the pcb fixing

pillars to the case lower. The main pcb can now be lifted free, complete with its fixing

pillars.

5. When re-assembling the instrument ensure that the correct fastenings are used.

9

Page 11

General

The following sections should be read with reference to the block diagram and the circuit

diagrams.

Circuit Descriptions

DDS Principles

In this instrument waveforms are generated by Direct Digital Synthesis (DDS). One complete

cycle of the waveform is stored in RAM as 1024 10-bit amplitude values. As the RAM address is

incremented, the waveform values are output to a Digital-to-Analog Converter (DAC) which

reconstructs the waveform. Sinewaves and triangles are subsequently filtered to smooth the

steps in the DAC output. The frequency of the waveform is determined by the rate at which the

RAM addresses are changed. Further details of how this rate is varied, i.e. how the frequency is

changed, are given later in the DDS Operation section; it is sufficient to know that at low

frequencies the addresses are output sequentially but at higher frequencies the addresses are

sampled. The major advantages of DDS over conventional analog generation are:

• Frequency accuracy and stability is that of the crystal oscillator.

• Frequencies can be set with high resolution from mHz to MHz.

• Low phase noise and distortion.

• Very wide frequency sweeps are possible.

• Fast phase continuous frequency switching.

• Non-standard waveforms such as multi-level squarewaves are easily generated.

Simplified Block Diagram

10

• Basic arbitrary waveform capability in the same instrument.

In addition, being a digital technique, it is easier to make every parameter programmable from the

keyboard, or remotely via RS232 or GPIB interfaces.

The fundamental limitation of the DDS technique is that, as the generator frequency is increased,

each waveform cycle is constituted from fewer samples. This is not a problem with sinewaves

which, because they are filtered, can be produced with low distortion up to the frequency limit of

the generator. With DDS squarewaves and pulse waveforms the 1 clock edge uncertainty sets a

practical limit to the upper frequency. However, on this instrument the generation technique

changes at 30kHz (but is overridable by the user) to use a comparator driven by the DDS

Page 12

sinewave; this ensures jitter-free squarewaves and pulses up to the frequency limit of the

generator. Ramp and staircase waveforms are by default, unfiltered (although filtering can be

selected) and therefore become degraded above the frequencies indicated in the Specification;

all waveforms are, however, available up to the maximum frequency of the generator.

DDS Operation

One complete cycle of the selected waveform is stored in RAM as 1024 10-bit amplitude values.

As the RAM address is incremented the waveform values are output sequentially to a Digital-toAnalog Converter (DAC) which reconstructs the waveform as a series of voltage steps.

Sinewaves and triangles are subsequently filtered to smooth the steps in the DAC output.

The frequency of the output waveform is determined by the rate at which the RAM addresses are

changed; in a DDS system the address changes are generated as follows.

The RAM contains the amplitude values of all the individual points of 1 cycle (360°) of the

waveform; each sequential address change corresponds to a phase increment of the waveform of

360°/1024. Instead of using a counter to generate sequential RAM addresses, a phase

accumulator is used to increment the phase.

On each clock cycle the phase increment, which has been loaded into the phase increment

register by the CPU, is added to the current result in the phase accumulator; the 10 most

significant bits of the phase accumulator drive the RAM address lines. The output waveform

frequency is now determined by the size of the phase increment at each clock. If each increment

is the same size then the output frequency is constant; if it changes, the output frequency

changes but with phase continuity.

The generator uses a 38-bit accumulator and a clock frequency which is 2

(~27.487MHz); this yields a frequency resolution (corresponding to the smallest phase increment)

of f

CLK

38

= 0.1mHz.

/2

38

x 10

-4

Only the 10 most significant bits of the phase accumulator are used to address the RAM. At a

waveform frequency of fCLK

/1024 (~26.84kHz), the ‘natural’ frequency, the RAM address

increments on every clock. At all frequencies below this (i.e. at smaller phase increments) one or

more addresses are output for more than one clock period because the phase increment is not

big enough to step the address at every clock. Similarly at waveform frequencies above the

natural frequency the larger phase increment causes some addresses to be skipped, giving the

effect of the stored waveform being ‘sampled’; different points will be sampled on successive

cycles of the waveform. The minimum number of points required to accurately reproduce a

waveshape will determine the maximum useful output frequency:

fmax = f

CLK

/No. of points

For sinewaves the filter permits the waveform to be reproduced accurately up to the Nyquist limit

(fCLK

/2), although in this generator a practical limit of 10MHz is set.

11

Page 13

MPU and Memory

The majority of the digital hardware in the instrument is contained in 3 LSI devices, these being a

MicroProcessor Unit, IC36, and 2 Field Programmable Gate Arrays, IC41 and IC44.

The Z80180 MPU contains an 8 bit Z80 core, 2x16 bit counter-timers, 2x8 bit serial interfaces and

a memory management unit. The MPU is clocked at 12MHz by XTL1.

The MPU provides up to 20 memory address lines but only the lower 18 are used to provide

access to 256k bytes of memory This comprising a 256k byte EPROM, IC38, with the top 32k

bytes overlaid by SRAM, IC39. The MPU selects between the memory devices via a decoder

located in the FPGA at IC44.

The RS232 interface is provided directly by the MPU and is buffered to the rear panel connector,

PJ1, by IC34 and IC35.

One of the counter-timers provides a constant 125us 'tick' to the MPU which is used to time all

the housekeeping functions, e.g. keyboard scan, knob control, as well as some generator

functions, e.g. frequency sweep. The second counter-timer is used by the Trigger generator.

Keyboard, LCD and Leds

The keyboard is interrogated every 10ms. This is done by reading the registers in IC19 and IC45.

If a key is down then one of the transistors Q15-Q20 will be on and the corresponding bits read

from IC19/IC45 will be high. The MPU decodes this to produce a key code which is passed to the

software. Multiple keys down are ignored. IC44 provides the port decode signals for access to

IC19 and IC45.

The knob is connected directly to the FPGA, IC44. This decodes the 4 states of the switches and

increments/decrements a counter. The counter is read and cleared every 10ms and the value and

sign passed to the software.

The 16 leds are driven directly from the latches in the shift registers IC14 and IC15. These

latches are updated as required via the FPGA, IC44.

The LCD is accessed via a bi-directional 4 bit port in IC44

GPIB

The FPGA, IC44, provides the port select signals to the GPIB board if fitted. The software

automatically detects the presence of the GPIB board at power up and allows the user to select it

on the REMOTE menu.

DDS FPGA

The FPGA, IC41, provides the complete DDS system including 38-bit phase accumulator, two 38bit registers to hold the frequency values for FSK, trigger/gate control logic, 10-bit re-loadable

burst counter, multi-instrument phase synchronization logic and an 8-bit 16-port bi-directional

MPU interface. Access is provided to the waveform RAM to allow the patterns to be written and

the AUX output signal is generated or selected.

All internal operations of the FPGA are clocked by the signal DDSCLK. Note that if this signal is

interrupted it is possible for the FPGA to become non-functional requiring that the FPGA be

completely reset. The clock could be interrupted by a fault condition or by setting the CLOCK

BNC to INPUT and then providing an unacceptable clock. An unacceptable clock is any signal

which overrides the internal clock but produces a replacement which is less than 5MHz or greater

than 27.5MHz; one way to accidentally accomplish this is to connect a 50Ω pad across the clock

input.

12

Pseudo random noise may also be generated by the FPGA. Each time the user turns noise ON or

OFF the FPGA is re-programmed to the required function. Note that this also has the effect of

completely resetting the FPGA.

Page 14

Trigger Generator

This is created from the second counter-timer in the MPU and a programmable divide by

1/10/100/1000 counter in the FPGA, IC44. The counter-timer produces a squarewave in the

range 50kHz to 5Hz and the divider extends this to 0.005Hz.

Waveform DAC and filter

IC1 is a high speed 10-bit DAC whose data is latched on the rising edge of the clock. The DAC

output is 1Vp-p and is referred to the +5VA rail. IC1 has an internal 2V reference at pin 16

referred to +5VA.

L3, L4, L5 and associated components form a 7-stage elliptic filter with sinx/x correction. The

inductors L3,L4 and L5 are factory preset before manufacture and must not be adjusted. Relay

RL1 allows the filter to be switched in and out.

Amplifier and Level Shift

IC7 is a current feedback amplifier. The output of IC7 is approximately 4Vp-p and is centered

around 0VA. IC11C selects the waveform source and IC11A selects low pass filter R3/C17 when

in noise mode.

High Frequency Squarewaves

Low frequency squarewaves are generated via the RAM and DAC, high frequency squarewaves

are generated by converting the sinewave to square with comparator IC6. Adjusting the

comparator threshold varies high frequency symmetry. The comparator output drives IC4 which

gives squarewaves above, below or about 0VA.

Amplitude Control and Modulation

IC2 is a 4-quadrant multiplier. Amplitude is voltage controlled via IC8A. AM is selected by IC11B

and IC25C. The internal squarewave modulation source is generated by IC25B; the amplitude is

adjusted by varying the levels that IC25B switches between. The internal sinewave modulation

source is fixed at 1kHz and is achieved by passing the output of IC25B through a Sallen and Key

low pass filter. The current output of IC2 is converted to a voltage by R44 giving approximately

900mVp-p at maximum output. IC46 amplifies this to give approximately 3.6Vp-p.

Output Amplifier and Attenuators

IC3 is an intermediate switched attenuator giving 0dB, -12dB and -20dB. IC10 is a current

feedback amplifier with a gain of approximately 5.5 and gives 20Vp-p at maximum output. DC

offset control is via R33 and IC8B. Relays RL2 and RL3 select -20dB 50Ω attenuators. Relay RL4

selects 50 or 600 Ω output impedance and RL5 output on/off.

DAC and Sample and Holds

IC18 is a 12-bit serial DAC with internal 2V reference. IC31 provides a bipolar output. IC20

multiplexes the DAC output voltage onto the appropriate hold capacitor. FET input amplifiers IC12

and IC24 buffer the voltages on the hold capacitors. The voltage at each sample and hold is

controlled by the MCU which calculates each value from a combination of the instrument set up

and the calibration constants stored in EEPROM.

13

Page 15

Power Supply

The transformer has two separate secondaries, one for the digital supply the other for the analog

supplies. The digital 5V is supplied by low drop-out regulator IC27. The display backlight current

is sourced from the unregulated side of IC27. The backlight current is controlled by a 200mA

current source Q8/IC26A. IC28 and IC29 provide the analog +/-15V rails and IC30 the -5V. IC5

provides local regulation for the waveform DAC IC1. Digital and analog grounds join at the

waveform DAC IC1. PJ11 is a test point for the supply rails. Three PCB mounted fuses protect

the transformer secondaries under fault conditions.

Required values measured at PJ11:

pin 1: +15V +/-0.6V

pin 5: -15V +/-0.6V

pin 2: +5VA +/-0.2V

pin 6: +5VCPU +/-0.2V

pin 4: -5VA +/-0.2V

14

Page 16

All parameters can be calibrated without opening the case, i.e. the generator offers ‘closed-box’

calibration. All adjustments are made digitally with calibration constants stored in EEPROM. The

calibration routine requires only a DVM and a frequency counter and takes no more than a few

minutes.

The crystal in the timebase is pre-aged but a further aging of up to ± 5ppm can occur in the first

year. Since the aging rate decreases exponentially with time it is an advantage to recalibrate after

the first 6 month’s use. Apart from this it is unlikely that any other parameters will need

adjustment.

Calibration should be carried out only after the generator has been operating for at least an hour

in normal ambient conditions.

Equipment Required

• 3½ digit DVM with 0.25% DC accuracy and 0.5% AC accuracy at 1kHz.

• Frequency counter capable of measuring 10.00000MHz and 50µs ±0.1µs pulsewidths.

The DVM is connected to the MAIN OUT and the counter to the AUX OUT.

Frequency meter accuracy will determine the accuracy of the generator’s clock setting and

should ideally be ±1ppm.

Calibration

It may be quicker to use an oscilloscope for steps 05 and 15 (see next section).

Calibration Procedure

The CALibration procedure is accessed by pressing the blue EDIT key followed by CAL, the

shifted function of 6. At each step the display changes to prompt the user to adjust the rotary

control or FIELD/DIGIT keys, until the reading on the specified instrument is at the value given.

The FIELD keys provide very coarse adjustment, the DIGIT keys coarse adjustment and the

rotary control fine adjustment. Pressing ENTER increments the procedure to the next step;

pressing CE decrements back to the previous step. Alternatively, pressing ESCAPE exits to the

last CAL display at which the user can choose to either keep the new calibration values (ENTER),

return to the old values (ESCAPE) or restart the calibration procedure (CE).

The first two displays (CAL 00 and CAL 01) specify the connections and adjustment method. The

subsequent displays, CAL 02 to CAL 20, permit all adjustable parameters to be calibrated.

The full procedure is listed below; the name of the control signal being adjusted at each step and

the default DAC value are shown in brackets. The display itself shows a summary of the step

adjustment procedure and the actual DAC value.

CAL 02

CAL 03 Output DC offset +ve full scale; adjust for 10V ± 20mV (DCOFFSET, 4000).

CAL 04 Output DC offset -ve full scale; check for -10V ± 20mV (DCOFFSET, 0120).

CAL 05

Output DC offset zero; adjust for 0V ± 5mV (DCOFFSET, 2060).

Multiplier control zero offset; adjust for minimum output (AMPL, 2060).

CAL 06 HF squarewave, IC4 grounded; note offset.

CAL 07

Waveform DAC at mid-scale; adjust for CAL06 value ± 10mV (WAVOFST, 1820).

CAL 08 Waveform DC offset; adjust for 0V ± 5mV (DCOFFSET, 2058).

CAL 09 Waveform DAC at full scale; adjust for 10V ± 10mV (AMPL, 0300).

CAL 10

HF squarewave full scale; adjust for 10V ± 10mV (SQLEVEL, 1100).

CAL 11 –20dB output attenuator; adjust for 1V ± 1mV (AMPL, 4000).

15

Page 17

CAL 12

CAL 13

–40dB output attenuator; adjust for 0.1V ± 0.1mV (AMPL, 4000).

–12dB intermediate attenuator; adjust for 1.768VAC ± 5mV (AMPL, 0300).

CAL 14 –20dB intermediate attenuator; adjust for 0.707VAC ± 1mV (AMPL, 0300).

CAL 15

AM squarewave zero; adjust for minimum output, (+AMSQ, 2050).

CAL 16 AM squarewave full scale; adjust for 10V ± 10mV (+AMSQ, 1000).

CAL 17

AM sinewave full scale; adjust for 3.54VAC ± 10mV (+AMSQ, 0650).

Check for a good sinewave on the scope.

CAL 18 HF squarewave symmetry (50%); adjust for 50us ± 0.1us (SYM, 2060).

CAL 19

CAL 20

HF squarewave symmetry (75%); adjust for 75us ± 0.1us (SYM, 2741).

Clock calibrate. 10MHz at main and aux outputs or 27.48779MHz at clock in/out

when set as an output; adjust to ±1ppm. Fail if outside these limits. 300-3700

shown on the display (2000).

Press ENTER twice to store new values and exit calibration mode.

Each adjustment step allows the MCU to calculate a calibration constant which is stored in

EEPROM. Because each step allows a very wide adjustment range it is possible to stop the

instrument functioning completely; if this is suspected the default values listed above should be

set and a complete recalibration should then be performed.

When CAL is first entered and the confirmation screen is displayed, pressing the CE key will

invoke a set of hardware tests. Follow the on-screen prompts to execute these tests. Note: The

RAM test will not function correctly if SWEEP is active when CAL is entered.

CALIBRATION PASSWORD

V1.6 and later firmware provides for a 4-digit password in the range 0000 to 9999 to be used to

access the calibration procedure. If the password is left at the factory default of 0000 no

messages are shown and calibration is accessed exactly as described in the Calibration section;

only if a non-zero password has been set will the user be prompted to enter the password.

Setting the Password

Press the blue EDIT key followed by CAL (the shifted function of 6) to show the opening screen of

the calibration routine. With this screen displayed press EDIT again to show the password

screen:

Enter a 4-digit password from the keyboard; the display will show the message NEW

PASSWORD STORED! for two seconds and then revert to the Main menu. If any keys other than

0-9 are pressed while entering the password the message INCORRECT PASSWORD! will be

shown.

ENTER NEW PASSWORD

----

16

Page 18

Using the Password to Access Calibration or Change the Password

With the password set, pressing EDIT following by CAL will now change the screen to:

ENTER PASSWORD

----

When the correct password has been entered from the keyboard the display changes to the

opening screen of the calibration routine and calibration can proceed as described in the

Calibration section. If an incorrect password is entered the message INCORRECT PASSWORD!

is shown for two seconds before the display reverts to the Main menu.

With the opening screen of the calibration routine displayed after correctly entering the password,

the password can be changed by pressing the EDIT key and following the procedure described in

Setting the Password. If the password is set to 0000 again, password protection is removed.

The password is held in EEPROM and will not be lost when the memory battery back-up is lost.

In the event of the password being forgotten, contact the manufacturer for help in resetting the

instrument.

17

Page 19

PCB ASSY MAIN - (44912-0270)

Part Number Description Position

20234-0011 SCREW M3 X 10 PNHDPZ NPST FOR PJ1

20613-9401 WASHER TO220 ADHESIVE FOR SK1-4

20670-0130 HEATSINK PCB MTG 25MM HIGH SK1

20670-0135 CLIP GP02 FOR PCB MTG H/SINKS FOR SK1-4

20670-0200 HEATSINK PCB MTG 50MM HIGH SK2,3,4

20670-0340 T0220 CLIP ON HEATSINK 29DEG/W FOR Q8

22010-0610 BATTERY 3V LITH 20MM BUTTON BATT

22040-0920 BEAD FERRITE LEADED FB1-6

22042-0181 INDUCTOR 4.3UH L5

22042-0182 INDUCTOR 4.8UH L4

22042-0183 INDUCTOR 5.0UH L3

Parts List

22160-0002 CHOKE 1 AMP VHF SUPP L1

22240-0020 RELAY TYPE 53/5 (24V) RL1,2,3

22240-0050 RELAY TYPE 47 (24V) RL4,5

22315-0450 FUSE 500Mat SUBMIN PCB MNT FS1,3

22315-0453 FUSE 1.5AT SUBMIN PCB MNT FS2

22469-0203 VERO PIN 18-0223K FOR PJ10

22573-0041 HEADER 2 WAY STRAIGHT LK1,2

22573-0202 HEADER 2 WAY STRAIGHT .156P PJ5,8,9

22573-0205 HEADER 5 WAY STRAIGHT .156P PJ7

22573-0206 HEADER 6 WAY STRAIGHT .156P PJ4

22574-0400 SKT 9W R/A D-TYPE (RS232) PJ1

22575-0009 SHORTING BLOCK RED FOR BATTERY

22575-0038 HEADER 6 WAY STR 0.1P PJ11

22575-0065 HEADER 20 WAY (2X10) STR SKELN PJ6

22575-0066 HEADER 40 WAY (2X20) STR SKELN PJ2

22575-0100 HEADER 34 WAY (2X17) STR SKELN PJ3

23185-0000 RES ZERO OHM R58

23202-0100 RES 10R0F W25 MF 50PPM R121,147

23202-0102 RES 10R2F W25 MF 50PPM R53,56

23202-0360 RES 36R0F W25 MF 50PPM R37,40,185

23202-0470 RES 47R0F W25 MF 50PPM R23,32

23202-0560 RES 56R0F W25 MF 50PPM R39

23202-0680 RES 68R0F W25 MF 50PPM R36

18

Page 20

PCB ASSY MAIN – (44912-0270) continued/…

Part Number Description Position

23202-1100 RES 100RF W25 MF 50PPM R2,22,24,45,46,81,82,103,165,167,186

23202-1120 RES 120RF W25 MF 50PPM R85,86,87,88,90,91,97,98,99,159

23202-1150 RES 150RF W25 MF 50PPM R67

23202-1191 RES 191RF W25 MF 50PPM R176

23202-1220 RES 220RF W25 MF 50PPM R3,113

23202-1270 RES 270RF W25 MF 50PPM R38,168,169,170

23202-1330 RES 330RF W25 MF 50PPM R16,62

23202-1360 RES 360RF W25 MF 50PPM R149

23202-1470 RES 470RF W25 MF 50PPM R44,63,65

23202-1510 RES 510RF W25 MF 50PPM R31,33

23202-1549 RES 549RF W25 MF 50PPM R57

23202-1680 RES 680RF W25 MF 50PPM R21,71,77,89,93,134-140,175

23202-1750 RES 750RF W25 MF 50PPM R15

23202-2100 RES 1K00F W25 MF 50PPM R4-13,61,83,120,152,153,156-158,

163,173,174

23202-2137 RES 1K37F W25 MF 50PPM R142

23202-2150 RES 1K50F W25 MF 50PPM R66

23202-2200 RES 2K00F W25 MF 50PPM R68,164

23202-2270 RES 2K70F W25 MF 50PPM R184

23202-2330 RES 3K30F W25 MF 50PPM R35,116,179

23202-2470 RES 4K70F W25 MF 50PPM R34,70,72,73,74,75,154,155,162, 166,172,

177,178

23202-2820 RES 8K20F W25 MF 50PPM R60

23202-2910 RES 9K10F W25 MF 50PPM R59, 130

23202-3100 RES 10K0F W25 MF 50PPM R80,84,101,102,106-109,111,112,

114,115,123,124,127,129,143,180,181

23202-3120 RES 12K0F W25 MF 50PPM R17,20,25,27,28

23202-3180 RES 18K0F W25 MF 50PPM R148

23202-3200 RES 20K0F W25 MF 50PPM R132,160,161,171

23202-3270 RES 27K0F W25 MF 50PPM R144,150

23202-3330 RES 33K0F W25 MF 50PPM R151

23202-3430 RES 43K0F W25 MF 50PPM R133

23202-3470 RES 47K0F W25 MF 50PPM R117,118,146

23202-4100 RES 100KF W25 MF 50PPM R14,92,104,110,125

23202-5100 RES 1M00F W25 MF 50PPM R105

23206-0033 RES 3R3F W60 MF 100PPM MRS25 R141

23206-0412 RES 41R2F W60 MF 50PPM MRS25 R51,52,54,55

23206-1200 RES 200RF W60 MF 50PPM MRS25 R47,48,49,50

19

Page 21

PCB ASSY MAIN - (44912-0270) continued/...

Part Number Description Position

23206-6100 RES 10M0F W60 MF 50PPM MRS25 R126,128

23222-0047 RES 4R7J W33 MF FUSIBLE NFR25 R29,30,76,95,96,145

23301-0435 RES NETWK SIL 1K0 X 5 RP1,2

23301-0443 RES NETWK SIL 22K X 8 RP3,4,5

23427-0268 CAP 22PG 100V CER NPO P2.5 C10,39,45-48,64,103,104

23427-0325 CAP 10NZ 63V CER HI K P5 C73-75,81-84,92-95,99,121,136,138

23427-0357 CAP 33PG 63V CER N150 P2.5 C21,32,101

23427-0374 CAP 100PG 100V CER N150 P2.5 C16,20,62

23427-0385 CAP 39PG 100V CER N150 P2.5 C22,90

23427-9205 CAP 47PG 100V CER NPO P2.5 C14,98,149

23427-9206 CAP 15PG 100V CER NPO P2.5 C63,91

23427-9210 CAP 3P3C 100V CER NPO P2.5 C38

23427-9218 CAP 330PK 100V CER MED K P2.5 C61

23427-9221 CAP 12PG 100V CER NPO P2.5 C15,18

23461-0020 CAP SM0805 100NZ 50V CER Y5V SC1-37

23557-0530 CAP 100U 16V ELEC RC2 P2.5 C87

23557-0550 CAP 10U 16V ELEC BIPOLAR P2 C29,56,57,58,148

23557-0612 CAP 1U0 50V ELEC RE2 P2 C105

23557-0647 CAP 10U 35V ELEC RE2 P2 C1-9,33,34,78,79,80,89,119,120,135

23557-0664 CAP 1000U 35V ELEC RE2 P5 C76,77

23557-0673 CAP 22U 35V ELEC RE2 P2 C102

23557-9122 CAP 4700U 16V ELEC RE2 P7.5 C85

23620-0236 CAP 1N0K 100V P/E 435/1 P5 C17

23620-0242 CAP 22NJ 100V 5% P/E P5 C59

23620-0246 CAP 100NK 63V P/E P5 C11-13,24-28,35-37,41-44,49,52-54,60,

72,88,96,97,117,118,124,127,131,132,

134,137

23620-0249 CAP 330NK 63V P/E P5 C65-71,147

25021-0901 DIO 1N4148 B/R D3,5,6,8-13,24-26

25061-0200 LED - T1 ROUND (3mm) - RED LED1

25115-0907 DIO 1N4002 B/R D14-21

25130-0903 DIO ZEN 5V1 W4 D1,2

25131-0224 DIO ZEN 18V 1W3 D22,23

25131-0226 DIO ZEN 6V2 1W3 D27

25174-0222 DIO VARICAP BB909B D4

25336-5590 TRAN PNP BC559C Q10,15-20

25341-0214 TRAN PNP ZTX214L/BC559 Q12

PCB Assy Main - (44912-0270) continued/...

20

Page 22

Part Number Description Position

25380-0229 TRAN NPN BC549 Q3-7,11,13,14

25380-0230 TRAN NPN MPS2369 Q9

25386-9300 TRAN TIP31A Q8

27103-0040 IC NE529N14 PIN IC6

27106-0513 IC LM358N 8 PIN IC26

27106-0517 IC NE5532N8 PIN IC8

27106-0606 IC TL072CP8 PIN IC31

27106-0628 IC TL074 14 PIN IC9,12,24

27106-0633 IC EL2099CT 5 PIN TO-220 IC10

27106-0634 IC 2020 8 PIN IC7,46

27151-1000 IC SM HA9P2557-9 IC2

27153-0080 IC LTC1257CN88 PIN IC18

27153-0180 IC DAC MB4076020 PIN IC1

27160-0009 IC V/REG 7805 TO220 IC5

27160-0012 IC V/REG 79L05 TO92 IC30

27160-0013 IC V/REG 7815 TO220 IC28

27160-0020 IC V/REG 7915 TO220 IC29

27160-0440 IC V/REG LM2940CT5 TO220 IC27

27239-0000 IC SM 74HC00 IC23

27239-0140 IC SM 74HC14 IC37

27239-0320 IC SM 74HC32 IC40

27239-0510 IC SM 74HC4051 IC3,20

27239-0530 IC SM 74HC4053 IC11,25

27239-1000 IC SM 74HCT244 IC21

27239-1010 IC SM 74HCT4051 IC4

27239-2440 IC SM 74HC244 IC22

27239-3730 IC SM 74HC373 IC19,45

27253-0020 IC SM 64180 IC36

27253-0050 IC SM 14C88 IC34

27253-0060 IC SM 14C89 IC35

27256-0020 IC SM CD4094 IC14,15,16,17

27400-0130 IC 27C2001 256Kx8 EPROM IC38

27403-0010 IC SM 93C46 1K(64x16) EEPROM IC13

27412-0030 IC SM XC4002A-6 IC41

27412-0040 IC SM XC2064-50 IC44

27413-0080 IC SM 8Kx8 CMOS RAM 15ns IC42,43

21

Page 23

PCB ASSY MAIN - (44912-0270) continued/...

Part Number Description Position

27413-0420 IC SM 32Kx8 CMOS RAM 70-120ns IC39

28151-0010 BUZZER BUZZ

28500-1030 XTAL - 27.48779MHZ XTL2

28502-0020 RESONATOR CERAMIC 12MHZ XTL1

31331-9030 SCREEN S2

35555-2320 PCB - MAIN

PCB ASSY KEYBOARD - (44912-0260)

Part Number Description Position

22224-0010 ENCODER ROTARY 36 POSITION SW1

22226-0130 KEYSWITCH DARK BLUE K15

22226-0140 KEYSWITCH DARK GRAY K1-14,16-43

23185-0000 RES ZERO OHM LK1-5,8,9,R187,188

23202-1680 RES 680RF W25 MF 50PPM R76,78,79,94,131

23382-2470 RES PS/H 5K0 CERMET MIN VR3

25061-0200 LED - T1 ROUND (3mm) - RED LED1-16

35515-1410 PCB - KEYBOARD

43171-1380 CONN ASSY 40W MAIN/KEYBOARD PJ8 TO PJ2 MAIN

PCB ASSY GPIB - (44912-0250)

Part No. Description Position

20234-0011 SCREW M3 X 10 PNHDPZ NPST J5/PCB

22574-0430 SKT 24W R/A IEEE J5

22575-0065 HEADER 20W (2X10) STRAIGHT J4

23620-0246 CAP 100NK 63V P/E P5 52-54,122,123

27163-1600 IC 75160 C32

27163-1620 IC 75162 C31

27250-0410 IC UPD7210C C33

35555-2310 PCB - GPIB

FRONT PANEL ASSY - (46912-0610)

Part Number Description Position

20030-0264 WASHER M2.5 ZPST LCD

20038-9501 WASHER M3 SPRING KEYBOARD PCB/F.PANEL

20210-0104 NUT M2.5 ZPST LCD

20234-0027 SCREW M3 X 6 PNHDPZ ZPST KEYBOARD PCB/F.PANEL

20234-0040 SCREW M2.5 X 12MML PNHDPZ ZPST LCD

20612-0011 WASHER FIBER M3

22

Page 24

FRONT PANEL ASSY - (46912-0610) continued/...

Part Number Description Position

20620-0010 CLIP - ENCODER KNOB KNOB

22573-0056 HEADER 16 WAY STR SIL (6.8MM)

22219-0050 SWITCH ROCKER DPST SOLDER LUGS

22588-0004 BNC SKT BKHD 50R STANDARD

26100-0160 LCD 20 X 4 BACKLIT

33331-3550 FRONT PANEL

33331-3580 OVERLAY FRONT PANEL- MODEL 29

35358-0520 EARTHING STRIP

37151-0320 KNOB - ENCODER

REAR PANEL ASSY - (46912-0600)

Part Number Description Position

20030-0263 WASHER M3 ZPST MAINS INLET

20030-0266 WASHER M4 ZPST TRANSFORMER, EARTH

20037-0401 SOLDER TAG SHAKEPROOF - 4BA EARTH

20038-9501 WASHER M3 SPRING MAINS INLET

20038-9502 WASHER M4 SPRING TRANSFORMER, EARTH

20210-0101 NUT M3 ZPST MAINS INLET

20210-0102 NUT M4 ZPST TRANSFORMER, EARTH

20213-0010 CAPTIVE NUT SNU-1219-17-00

20223-9001 SCREW M3 X 8 RAISED CKHDPZ MAINS INLET

20234-0032 SCREW M4 X 25 PNHDPZ ZPST TRANSFORMER

20236-0010 SCREW M4 X 12 TAMPERPROOF EARTH

20661-0272 SPACER RND 21mmIDx15.8mmL NYL TRANSFORMER

22115-0280 TRANSFORMER

22520-0170 FILTER - IEC INLET + FUSE

22588-0004 BNC SKT BKHD 50R STANDARD

33331-3570 REAR PANEL PRINTED

CASED PARTS - (59120-0801)

Part Number Description Position

20030-0263 WASHER M3 ZPST CHASSIS/EARTH STRIP

20030-0266 WASHER M4 ZPST FEET

20037-0301 WASHER M3 SHK/PROOF I/T ZPST CHASSIS/FRONT PANEL

20038-9501 WASHER M3 SPRING CHASSIS/SPACERS,

PCB/SPACERS,

CHASSIS/EARTH STRIP

20062-0700 SCREW NO 6 X 3/8 RFLNGPZ ST/AB CHASSIS/REAR PANEL

23

Page 25

CASED PARTS - (59120-0801) continued/...

Part No. Description Position

20063-0010 SCREW NO6 X 3/8 NIB HDPZ ST/AB CASE UPPER

20210-0101 NUT M3 ZPST FRONT PANEL, EARTH STRIP

20213-0010 CAPTIVE NUT SNU-1219-17-00 CHASSIS

20234-0012 SCREW M3 X 8 PNHDPZ ZPST EARTH STRIP/CHASSIS

20234-0027 SCREW M3 X 6 PNHDPZ ZPST CHASSIS/SPACERS,

PCB/SPACERS

20234-0029 SCREW M4 X 12 PNHDPZ ZPST FEET

20612-0011 WASHER FIBER M3 PCB/SPACERS

20661-0219 SPACER Hex M3 x 15 NPBR

20662-0201 BRACKET PLAS FOOT 3786-7001

20662-0520 FOOT PVC PV2629 BLACK

22315-0232 FUSE 250MA TL HRC S/F UK/EURO

22315-0233 FUSE 500MA TL HRC S/F USA

22491-0010 MAINS LEAD UK

22491-0020 MAINS LEAD EUROPE

22491-0040 MAINS LEAD USA

22575-0202 SKT 2W .156 20AWG (YELLOW)IDT PJ5,8,9 ON MAIN

22575-0205 SKT 5W .156 20AWG (YELLOW)IDT PJ7 ON MAIN

22575-0206 SKT 6W .156 20AWG (YELLOW)IDT PJ4 ON MAIN

31711-0080 BEZEL HALF RACK - 3U CASE

33171-0130 SPRING FOOT

33537-0720 CASE UPPER

33537-0730 CASE LOWER

43171-1390 CONN ASSY 34W MAIN/DISPLAY

43171-1400 CONN ASSY 2W 270MM

48591-0450 INSTRUCTION BOOK - MODEL 29

MANUFACTURING CHANGES

August 2000: Main PCB becomes issue 4 to accommodate IC2 (Multiplier HA2557) in a DIP

package on a sub-board mounted on a pin-header; the original, surface-mount,

HA2557 is obsolete.

24

Details of the change are as follows:

Add: 22575-0038 Header 6-way straight (PJ12)

35555-3280 PCB-Multiplier

27151-0150 IC HA2557 (IC2)

Delete: 27151-1000 IC SM HA9P2557-9 (IC2)

Note that the following components move to the multiplier PCB:

FB1, FB5, R45, R46, R165, R167, C30, C31, C117, C118, IC2.

Page 26

Component Layouts

M odel 29 Main Pcb

25

Page 27

Model 29 Keyboard Pcb

26

Page 28

Circuit Diagrams

27

Page 29

Model 29 GPIB Interface Pcb

Page 30

Model 29 Main Pcb - Sheet 1 of 3

- Digital Section and GPIB

Page 31

Model 29 Main PCB - Sheet 2 of 3

Analogue Section

Page 32

Model 29 Main Pcb - Sheet 3 of 3

- Power Supplies and Clock

Page 33

Model 29 Keyboard Pcb

Loading...

Loading...