Page 1

Hose Pump Series

SP/10, SP/15, SP/20, SP/25, SP/32,

SP/40, SP/50, SP/65, SP/80 and SP/100

Manual

1

Page 2

2

Page 3

Contents

1 GENERAL.........................................................................................................................6

1.1 How to use this manual..............................................................................................6

1.2 Other supplied documentation ...................................................................................6

1.3 Service and support ...................................................................................................6

1.4 Used products and the environment ..........................................................................6

2 SAFETY ............................................................................................................................7

2.1 Pictograms .................................................................................................................7

2.2 Intended use ..............................................................................................................7

2.3 Responsibility.............................................................................................................7

2.4 Qualification of the user .............................................................................................8

2.5 Regulations and instructions......................................................................................8

3 WARRANTY CONDITIONS..............................................................................................9

4 DESCRIPTION................................................................................................................10

4.1 Identification of the product......................................................................................10

4.2 Construction of the pump.........................................................................................10

4.3 Operation of the pump .............................................................................................11

4.4 Pump hose...............................................................................................................12

4.4.1 General .............................................................................................................12

4.4.2 Hose compression force adjustment (shimming). (not applicable for series

SP/10, SP/15 and SP/20). ................................................................................12

4.4.3 Lubrication and cooling.....................................................................................12

4.4.4 Gearbox ............................................................................................................12

4.4.5 Electric motor....................................................................................................13

4.4.6 Available options...............................................................................................13

5 INSTALLATION..............................................................................................................14

5.1 Unpacking ................................................................................................................14

5.2 Inspections...............................................................................................................14

5.3 Installation conditions...............................................................................................14

5.3.1 Ambient conditions ...........................................................................................14

5.3.2 Set-up ...............................................................................................................14

5.3.3 Pipework ...........................................................................................................14

5.3.4 Pulsating flow....................................................................................................15

5.3.5 Pumping pressure (counter pressure) ..............................................................15

5.4 Lifting and moving the pump....................................................................................15

5.5 Placing the pump .....................................................................................................16

3

Page 4

6 COMMISSIONING ..........................................................................................................17

6.1 Preparations.............................................................................................................17

6.2 Commissioning ........................................................................................................ 17

7 MAINTENANCE..............................................................................................................18

7.1 Maintenance and periodic inspections.....................................................................18

7.2 Cleaning pump hose ................................................................................................19

7.3 Changing lubricant ...................................................................................................19

7.4 Changing oil in gearbox ...........................................................................................19

7.5 Replacing pump hose ..............................................................................................19

7.5.1 Hose removal....................................................................................................19

7.5.2 Removal of lubricant .........................................................................................19

7.5.3 Removal of piping .............................................................................................19

7.5.4 Loosening of hose clamps ................................................................................19

7.5.5 Removal of flanges and/or inserts ....................................................................19

7.5.6 Removal of flange brackets ..............................................................................20

7.5.7 Removal of the hose.........................................................................................20

7.5.8 Cleaning of pump casing ..................................................................................20

7.5.9 Tighten drain plug (not applicable for SP/10, SP/15 and SP/20)......................20

7.5.10 Preparation of pump hose ................................................................................20

7.5.11 Insertion of the hose .........................................................................................20

7.5.12 Place hose clamps............................................................................................20

7.6 Hose connection ......................................................................................................20

7.6.1 Mount flange brackets (SP/25 to SP/100) ........................................................21

7.6.2 Positioning of pump hose .................................................................................21

7.6.3 Tighten hose clamps.........................................................................................21

7.6.4 Tighten bolts of all flange brackets ...................................................................21

7.6.5 Filling with lubricant ..........................................................................................21

7.6.6 Finally ...............................................................................................................21

7.7 Exchanging replacement parts ................................................................................22

7.7.1 Replacing pressing shoes (not applicable for SP/10, SP/15 and SP/20) .........22

7.7.2 Replacing seal and bearings ............................................................................22

7.8 Hose compression force adjustment (shimming) (not applicable for SP/10, SP/15

and SP/20). ..............................................................................................................23

7.9 Fitting options...........................................................................................................24

7.9.1 Fitting a high-level float switch..........................................................................24

7.9.2 Fitting a low level float switch (not applicable for SP/10, SP/15 and SP/20) ....24

8 STORAGE ......................................................................................................................25

8.1 Hose pump...............................................................................................................25

8.2 Pump hose...............................................................................................................25

9 TROUBLESHOOTING....................................................................................................26

10 SPECIFICATIONS ......................................................................................................28

10.1 Pumphead................................................................................................................28

4

Page 5

10.1.1 Performance .....................................................................................................28

10.1.2 Materials ...........................................................................................................28

10.1.3 Lubricant ...........................................................................................................28

10.1.4 Surface treatment .............................................................................................29

10.1.5 Weights and dimensions...................................................................................29

10.1.6 Torques.............................................................................................................30

10.1.7 Shimming..........................................................................................................31

10.1.8 Parts list: SP/10-SP/15 .....................................................................................32

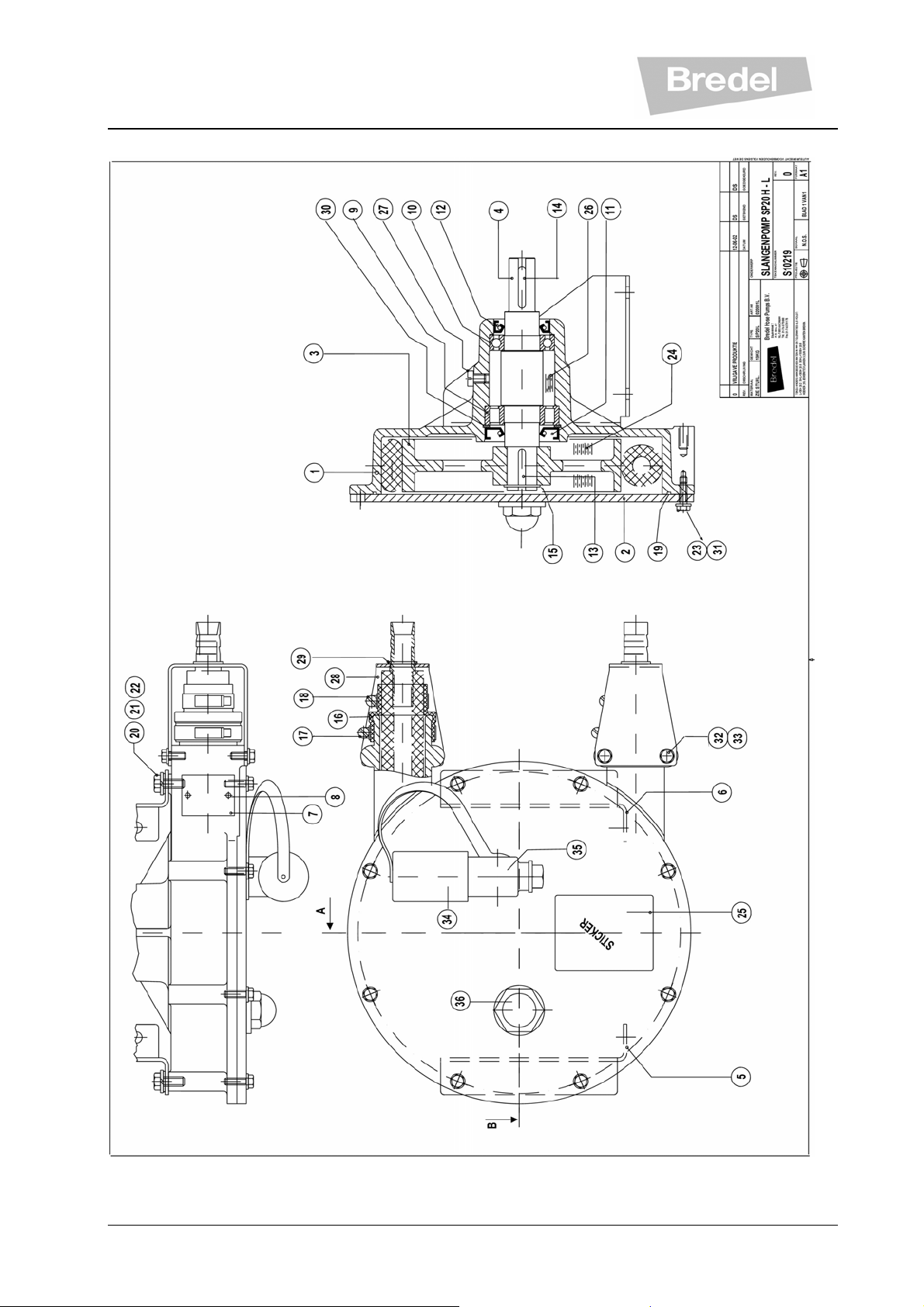

10.1.9 Parts list: SP/20 H-L .........................................................................................34

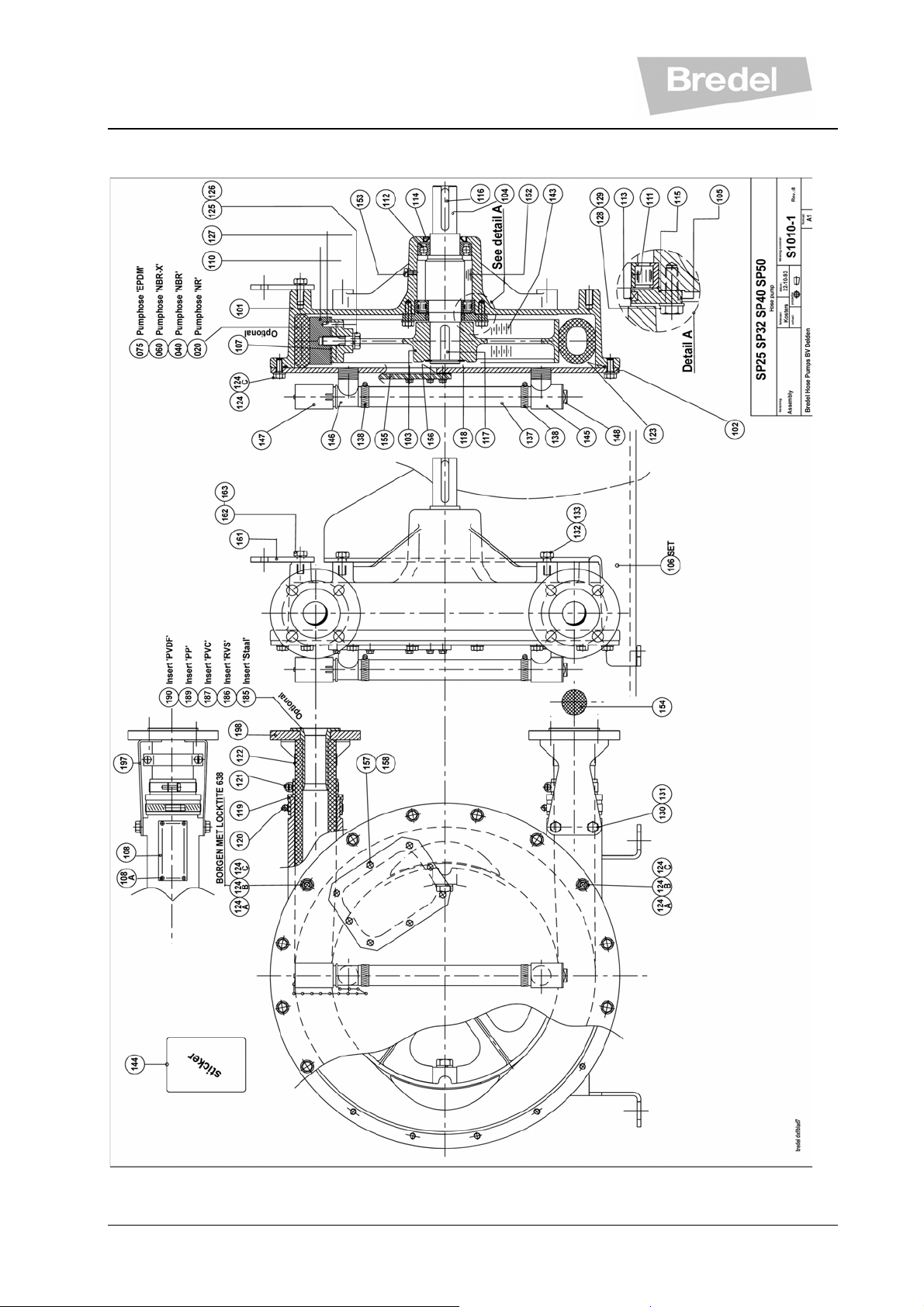

10.1.10 Parts list: SP/25, SP/32, SP/40 and SP/50 ...................................................36

10.1.11 Parts list: SP/65, SP/80 and SP/100 .............................................................39

10.1.12 Dimensional drawings...................................................................................43

10.1.13 EG-Declaration of Conformity .......................................................................46

10.1.14 Manufacturer’s Declaration ........................................................................... 47

10.1.15 Product Use and Decontamination Declaration ............................................48

5

Page 6

1 GENERAL

1.1 How to use this manual

This manual is intended as a reference book by means of which qualified users are able to

install, commission and maintain the hose pumps mentioned on the front cover.

1.2 Other supplied documentation

In this manual the documentation of pump components i.e. engines, etc. is not included. But

if the documentation of a certain component is part of this manual, you must respect and act

according the instructions as given in the supplied documentation.

1.3 Service and support

For information with respect to specific adjustments, installation, maintenance or repair jobs

which fall beyond the scope of this manual, contact your Bredel representative. Make sure

you have the following data at hand:

•

serial number hose pump

• article number pump hose

You will find these data on the identification plates or stickers of the pumphead and the pump hose. See “Description”:

“Identification of the product”, § 4.1.

1.4 Used products and the environment

ENVIRONMENT

Enquire with your local government about the possibilities for reuse or

environment friendly processing of packaging materials, (contaminated)

lubricant and oil.

Always observe the local rules and regulations with respect to processing

(non reusable) parts of the hose pump.

6

Page 7

2 SAFETY

2.1 Pictograms

In this manual the following symbols are used:

WARNING

Procedures which, if not carried out with the necessary care, may result

in serious damage to the hose pump or in serious bodily harm.

CAUTION

Procedures which, if not carried out with the necessary care, may result

in serious damage to the hose pump, the surrounding area or the

environment.

Remarks, suggestions and advice.

2.2 Intended use

The hose pump is exclusively designed for pumping suitable products. Every other or further

(1)

use is not in conformance with the intended use.

The manufacturer cannot be held responsible for damage or harm resulting from this. The

hose pump is designed in conformance with the valid standards and directives.

Only use the pump in conformance with the intended use described above. If you want to

change the application of your hose pump, contact your Bredel representative first.

c The “Intended use” as laid down in EN 292-1 is “… the use for which the technical product is intended in

accordance with the specifications of the manufacturer, inclusive of his indications in the sales brochure”. In

case of doubt it is the use which appears to be its intended use judging from the construction, execution and

function of the product. Observing the instructions in the user’s documentation also belongs to intended use.

2.3 Responsibility

The manufacturer does not accept any responsibility for damage or harm caused by not

(strictly) observing the safety regulations and instructions in this manual and the also

supplied documentation, or by negligence during installation, use, maintenance and repair of

the hose pumps mentioned on the front cover. Depending on the specific working conditions

or accessories used, additional safety instructions can be required.

Immediately contact your Bredel representative, if you noticed a potential danger while using

your hose pump.

WARNING

The user of the hose pump is always fully responsible for observing the local

valid safety regulations and directives. Observe these safety regulations and

directives when using the hose pump.

7

Page 8

2.4 Qualification of the user

The installation, use and maintenance of the hose pump is only reserved for well trained and

qualified users. Temporary staff and persons in training may only use the hose pump under

the supervision and responsibility of well trained and qualified users.

2.5 Regulations and instructions

• Everyone who will work with the hose pump must know the content of this manual and

observe the instructions with great care.

• Never change the order of the actions to be carried out.

• Always store the manual near the hose pump.

8

Page 9

3 WARRANTY CONDITIONS

The manufacturer offers a one–year warranty on proper workmanship of all parts of the hose

pump. Exclusion is made for normal wear and tear of consumables, such as pump hoses,

lubricant, hose clamps, pressing shoes, ball bearings, wear ring, an seals, or parts which

have been misused or damaged through negligence.

This manufacturer’s warranty is null and void for any user who has substituted the parts of an

alternate manufacturer into a Bredel hose pump.

Damaged parts which are covered by the applicable warranty conditions can be returned to

the manufacturer. The parts must be accompanied by a fully filled in and signed safety form,

as present in the back of this manual. The safety form must be applied to the outside of the

shipping carton. Parts which have been contaminated or which have been corroded by

chemicals or other substances which can pose a health risk, must be cleaned before they

are returned to the manufacturer.

Furthermore, it should be indicated on the safety form which specific cleaning procedure has

been followed, and it should be indicated that the equipment has been decontaminated. The

safety form is required at all items, even if the parts have not been used.

Warranties purporting to be on behalf of Bredel Hose Pumps B.V. made by any person,

including representatives of Bredel Hose Pumps B.V., its subsidiaries, or its distributors,

which do not accord with the terms of this warranty shall not be binding upon

Bredel Hose Pumps B.V. unless expressly approved in writing by a Director or Manager of

Bredel Hose Pumps B.V.

9

Page 10

4 DESCRIPTION

4.1 Identification of the product

The hose pump can be identified based on the identification plates or stickers on:

A. Pump hose

B. Pumphead

C. Gearbox

D. Electric motor

E. Pump hose

The identification plate on the pumphead contains the following data:

A. Type number

B. Serial number

If applicable: the identification plate on the gearbox contains (depending on the brand) the

following data:

A. Article number

B. Serial number

C. Type number

D. Reduction

E. Number of rounds per minute

F. Oil type upon delivery

If applicable: the identification plate on the electric motor contains (depending on the brand)

the following data:

A. Type number

B. Serial number

C. Article number

D. Mains

E. Frequency

F. Speed

G. Power

H. Power factor

I. Current

The identification sticker on the pump hose contains the following data:

A. Order number

B. Internal diameter

C. Type of material of inner liner

D. Maximum permissible working pressure

4.2 Construction of the pump

A. Pump hose

B. Pump housing

C. Rotor

D. Pressing shoes

E. Cover

F. Support

G. Gearbox

H. Electric motor

10

Page 11

4.3 Operation of the pump

The heart of the pumphead consists of a specially constructed pump hose which lies

contorted against the inside of the pump housing. Both ends of the hose are connected to

the suction and discharge lines by means of a flange construction. A bearing-mounted rotor

with two facing pressing shoes is in the center of the pumphead.

In phase 1 the lower pressing shoe compressed the pump hose by the rotational movement

of the rotor, forcing the fluid through the hose. As soon as the pressing shoe has passed, the

hose recovers to its original shape due to the mechanical properties of the material.

In phase 2 the product is drawn into the hose by the (continuous) turning motion of the rotor.

In phase 3, the second pressing shoe will subsequently compress the pump hose. Due to the

continuous rotating movement of the rotor not only new product is sucked in, but also the

already present product is pressed out by the pressing shoe. When the first pressing shoe

runs from the pump hose, the second pressing shoe has already closed the pump hose and

the product is prevented from flowing back. This method of liquid displacement is also known

as the “positive displacement principle”.

11

Page 12

4.4 Pump hose

4.4.1 General

The pump hose is made of special rubbers, reinforced with nylon cords and is constructed as

follows:

A. Outer extruded layer made of natural rubber

B. Nylon reinforcement layers

C. Inner extruded liner

The pump hose liner material should be chemically resistant with the product to be pumped.

Dependent on the specific requirements of your application a corresponding pump hose must

be selected. For each pump model various hose types are available.

The material of the inner liner of the pump hose determines the hose type. Each hose type is

marked by a unique colour code.

Hose type Material Colour code

NR Natural rubber Purple

NBR Perbunan Yellow

EPDM EPDM Red

CSM Hypalon© Blue

Consult your Bredel representative for more detailed information about the

chemical and temperature resistance of pump hoses.

The Bredel pump hoses have been carefully machined, therefore there are minimum

tolerances in wall thickness. It is very important to guarantee the correct compression of the

pump hose, because:

• When the compression is too high, it creates a too high load of the pump and pump

hose, which will result in a reduction of the life of the pump hose and bearings.

• When the compression is too low, this will result in loss of capacity and backflow.

Backflow results in a reduction of the life of the pump hose.

4.4.2 Hose compression force adjustment (shimming). (not applicable for series SP/10,

SP/15 and SP/20).

In order to achieve optimal life of the pump hose, the compression force of the pump hose

can be adjusted by placing a number of shims under the pressing shoes.

The shims are fitted between the rotor and the pressing shoe. The number of shims will vary

for each counter-pressure situation. See “Hose compression force adjustment” § 7.8 and

“Shimming table” §10.1.7. Caution: insufficient shimming reduces hose life.

4.4.3 Lubrication and cooling

The pumphead, in which the rotor and pump hose can be found are filled with a special

lubricant.The lubricant lubricates the movement between the hose and the pressing shoes

and transfers the generated heat from the hose to the pump housing and the cover.

4.4.4 Gearbox

The hose pump types described in this manual use various types of gearbox units. The

gearboxes are fitted with a foot rest.

12

Page 13

4.4.5 Electric motor

The hose pump type described in this manual use various types of motors. If the pump is to

be used in potentially explosive atmospheres, please contact your Bredel representative, as

these type of pumps are not

in compliance with ATEX.

4.4.6 Available options

The following options are available for the hose pump:

• High (lubricant) level float switch

• Low (lubricant) level float switch (not applicable for SP/10, SP/15 and SP/20)

• Epoxy pressing shoes (not applicable for SP/10, SP/15 and SP/20)

• Stainless steel 316 flanges, flange brackets, hose clamps, supporting and mounting

articles

13

Page 14

5 INSTALLATION

5.1 Unpacking

When unpacking carefully follow the instructions as given on the packaging or on the hose

pump.

5.2 Inspections

Check that your delivery is correct and check it for any transport damage, see “Description:

“Identification of the product”, § 4.1. Report any damage immediately to your Bredel

representative.

5.3 Installation conditions

5.3.1 Ambient conditions

Make sure that the hose pump is in an area where the ambient temperature during operation

is not lower than –20° and not higher than +45°C.

5.3.2 Set-up

• The pump materials and protective layers are suitable for indoor set-up and a

protected outdoor set-up. Under certain conditions the pump is suitable for limited

outdoor set-up or a salty or aggressive atmosphere. Consult your Bredel

representative for more information.

• Make sure that the floor surface is horizontal and has a maximum slope of 1 mm per

meter.

• Make sure that there is sufficient room around the pump to carry out the necessary

maintenance activities.

• Make sure that the room is sufficiently ventilated, so that the heat developed by the

pump and drive can be discharged. Keep some distance between the ventilation

cover of the electric motor and wall to enable the supply of necessary cooling air.

5.3.3 Pipework

When determining and connecting suction and discharge lines consider the following points:

• The bore size of the suction line must be larger than the bore size of the pump hose.

The bore size of the discharge line must be minimal or larger than the bore size of the

pump hose. For more information consult your Bredel representative.

• Limit the presence of sharp bends. Make sure that the radius of the bends are as

large as possible (preferably 5S). It is recommended to use Y-connections instead of

T-connections.

• It is recommended to use a minimum of three quarter (3/4) of the hose length as

flexible hose in the suction or discharge line. In this way you prevent that connection

lines must be removed when changing a pump hose.

• Keep the delivery and suction lines as short and direct as possible.

• Prevent any possibilities of exceeding the maximum working pressure of the hose

pump, see “Specifications”: “Performance”, § 10.1.1. If necessary fit an overpressure

valve.

14

Page 15

CAUTION

Consider the maximum permissible working pressure on the discharge side.

Exceeding the maximum working pressure may lead to serious damage to the pump.

• Make sure that the maximum forces on the flanges are not exceeded. The maximum

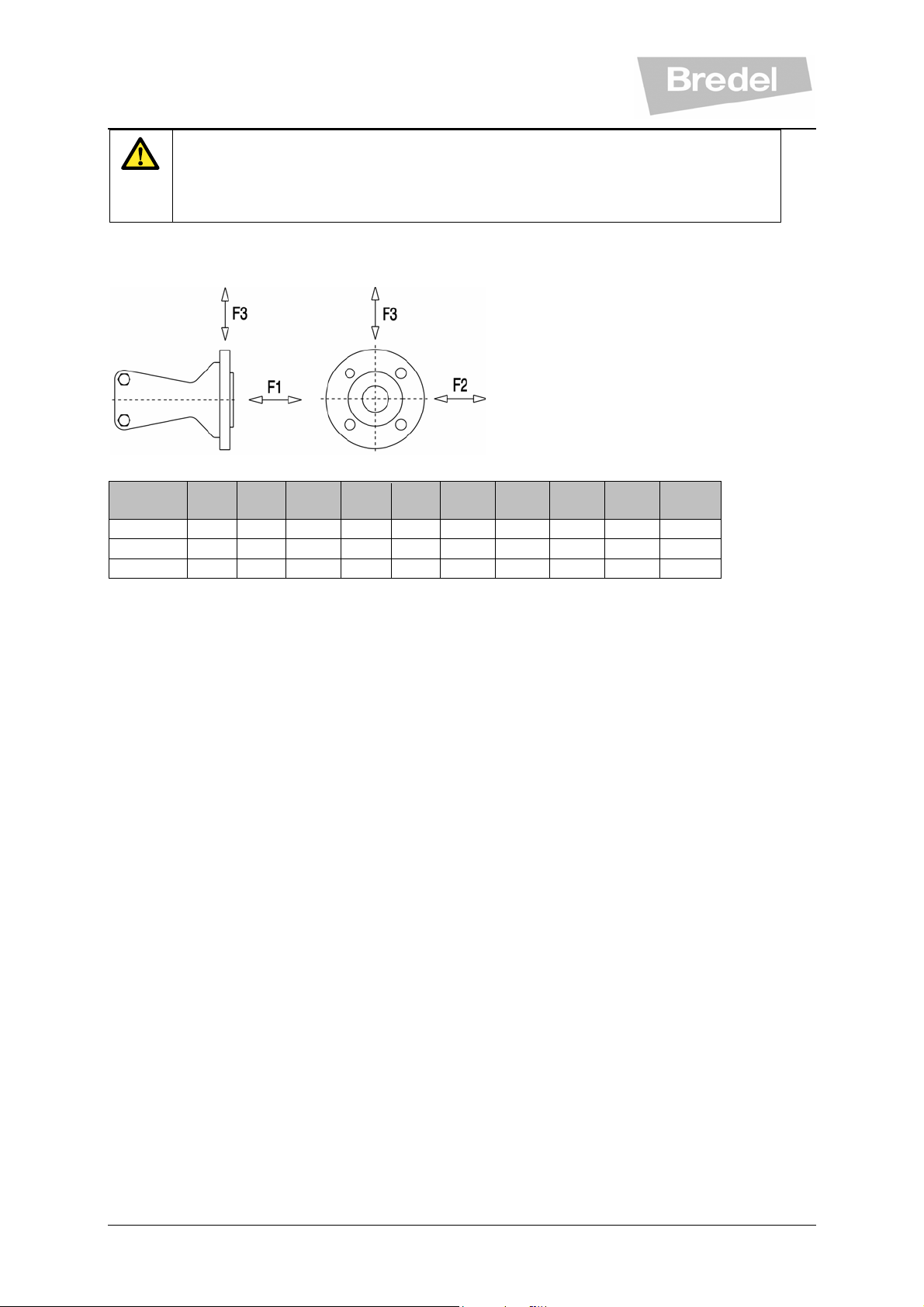

permissible loads on the pump flange are given in the table below:

Force

F1 [N] SP/10 SP/15 SP/20 SP25 SP/32 SP/40 SP/50 SP/65 SP/80 SP/100

F1 600 600 600 1000 1000 1000 1400 1400 2000 2000

F2 120 120 120 200 200 200 300 300 400 400

F3 300 300 300 500 500 500 700 700 1000 1000

5.3.4 Pulsating flow

Hose pumps have a pulsating flow that can result in vibrations of pump and lines under the

following circumstances:

• suction and discharge lines are not fixed correctly

• high pump speed in combination with long suction and discharge lines or high specific

gravity of the product

• diameter of suction and/or discharge line too small

In case of unacceptable pulsations, dampeners for suction and/or discharge line can be

supplied for the pump series SP/25 to SP/100. Please consult your Bredel representative for

literature on Inlet Pulsation Accumulators (IPA) or Pulsation Dampeners (PD). These

accumulators and dampeners are not available for SP/10, SP15 and SP/20.

5.3.5 Pumping pressure (counter pressure)

Should not go over maximum allowance (7,5 bar for SP/10, SP/15 and SP/20; 16 bar for

bigger models). If hose failure looks like explosion, check system for blocked lines, closed

valves or failing pressure relief valves.

5.4 Lifting and moving the pump

For lifting and moving the pumphead, it has been fitted with a lifting strip. This lifting strip is

fitted on the rear of the pumphead. For the weights of the pump, see “Specifications”:

“Weights”, § 10.1.5.

The complete hose pump, i.e. pumphead, gearbox and electric motor, must be lifted using

the lifting eyes in the pump support plus additional support on gearbox and motor using

suitably rated straps or slings, see “Specifications”: Weights, § 10.1.5.

15

Page 16

WARNING

If the pump is to be lifted ensure that all standard lifting practices are

adhered to and carried out by qualified personnel only.

5.5 Placing the pump

Position the pump on a horizontal surface. Use suitable anchor bolts to attach the pump to

the floor surface.

16

Page 17

6 COMMISSIONING

6.1 Preparations

• Connect the electric motor in conformance with the locally applicable rules and

regulations. Have the electrical installation work be carried out by qualified personnel.

• The pump casing is filled to half way level with a specially compounded hose

lubricant. If necessary refill Bredel lubricant via the breather/vent plug (also see:

“Maintenance”: “Changing lubricant”, § 7.3).

• Check the rotation of the rotor.

• Check that the correct number of shims (series SP/25 to SP/100) corresponds with

your application, see “Specifications”: “Shimming”, § 10.1.7.

• For adjusting the compression force of the hose, see “Maintenance”: “Hose

compression force adjustment (shimming)”, § 7.8.

6.2 Commissioning

• Connect the pipework. Make sure that there are no obstructions such as closed

valves.

• Switch on the hose pump.

• Check the rotation of the rotor.

• Check the capacity of the hose pump. If the capacity differs from your specification,

follow the instructions in chapter 9 “Troubleshooting” or consult your Bredel

representative.

• Check the hose pump in accordance with points 1 to 4 of the maintenance table from

section “Maintenance and periodic inspections”, § 7.1.

17

Page 18

7 MAINTENANCE

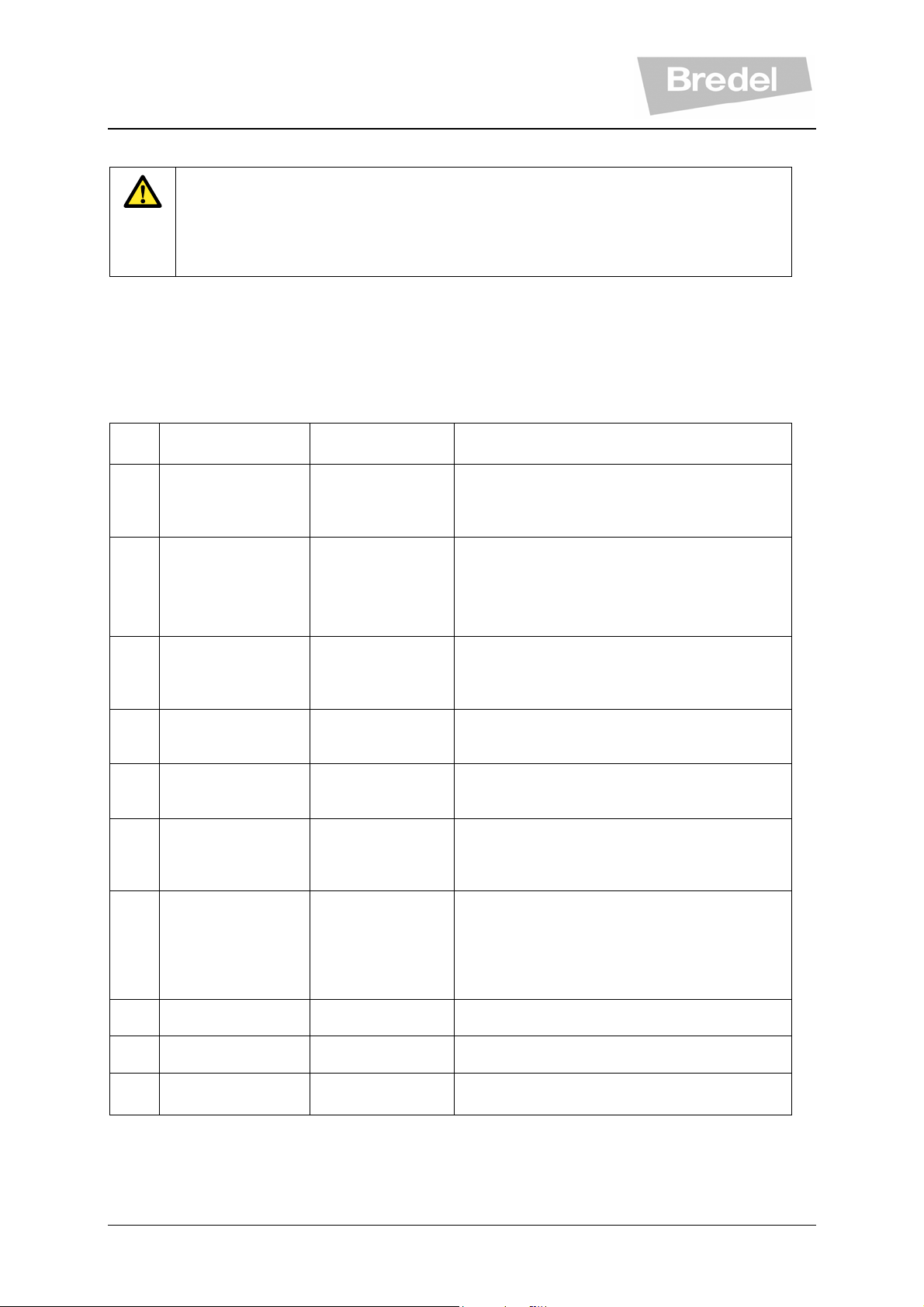

WARNING

Only use original Bredel parts when maintaining the hose pump. Bredel cannot

guarantee a correct functioning and any consequential damage that occurs

7.1 Maintenance and periodic inspections

In the diagram below it is indicated which maintenance and periodic inspections need to be

carried out on the hose pump to guarantee an optimal safety, operation and life of the pump.

Point Action To be carried out Remark

from the use of non-original Bredel components, also see: “Safety” and

“Warranties”.

1 Check the lubricant

level

2 Check the pumphead

for any leakage of

lubricant around the

cover and the

flanges.

3 Check pump for

deviating

temperature or

strange noises.

4 Check pressing

shoes for excessive

damage.

5 Internal cleaning of

the pump hose.

6 Replacing pump

hose.

7 Changing lubricant After every 2nd hose

8 Replacing pump

seal.

9 Replacing pressing

shoes.

10 Replacing bearings. If necessary. See “Replacing pressing shoes”.

Before start up of

the pump and on a

scheduled interval

during operation.

Before start up of

the pump and on a

scheduled interval

during operation.

On a scheduled

interval during

operation.

When replacing the

pump hose.

Cleaning of the

system or product

change.

Preventive, this

means after 75% of

the hose life of the

first hose.

change or after

5,000 service hours,

whichever comes

first or after hose

rupture.

If necessary. See “Replacing seal ring, bearings and wear

Wear on the running

surface.

Make sure that the pump casing is filled to half

way level with a specially compounded hose

lubricant. If necessary refill the lubricant (also

see “Maintenance”: “Changing lubricant”).

See “Troubleshooting”.

See “Troubleshooting”.

See “Replacing pump hose’.

See “Cleaning pump hose”.

See “Replacing pump hose”.

See “Changing lubricant”.

ring”.

See “Replacing pressing shoes”.

18

Page 19

Cleaning pump hose

7.2

With a lot of products it is necessary to have the pump hose cleaned immediately after

pumping to avoid hardening of the product inside. The inside of the pump hose can be easily

cleaned by rinsing the pump with clean water. If a cleaning fluid is added to the water, it must

be checked that the hose liner material is resistant to that. Also note that the pump hose can

resist the cleaning temperature. Special cleaning balls are also available; please consult your

Bredel representative).

7.3 Changing lubricant

• Place a tray under the drain plug (series SP/25 to SP/100) in the cover of the pump.

Remove the drain plug. Catch the lubricant from the pump housing in the tray.

Position the drain plug and tighten it firmly. In case of SP/10, SP/15 and SP/20

pumps: remove the hose and drain via the lower port.

• The pump housing can be filled with lubricant via the breather/vent on the cover. For

this purpose remove the breather cap and position a funnel in the breather. In order

to facilitate the filling with lubricant for the series SP/25 to SP/100 it is advised to

remove one or two bolts in the inspection window. Pour the lubricant in the pump

housing via the funnel.

• Keep on pouring until the lubricant level has risen at approx. half way of the pump

casing, or that the specified quantity has been filled. See “Lubricant” § 10.1.3.

7.4 Changing oil in gearbox

For information regarding the changing of oil in the gearbox and the type of oil to be used we

refer to the documentation of the manufacturer of this item.

7.5 Replacing pump hose

7.5.1 Hose removal

The pump hose can be changed without removing the pump cover. If applicable, close the

isolation valves on both the inlet and discharge of the pump to minimize fluid loss.

7.5.2 Removal of lubricant

Place a lubricant tray of sufficient capacity to contain the hose lubricant plus any process

fluid that might be contained within the pump housing. Remove the drain plug (not applicable

for SP/10, SP/15 and SP/20; lubricant will flow when hose is removed) . Ensure that the

breather vent in front is not blocked.

7.5.3 Removal of piping

Shut off the valves on both suction and discharge side and disconnect the piping of both the

ports.

7.5.4 Loosening of hose clamps

Loosen all hose clamps on both suction and discharge ports.

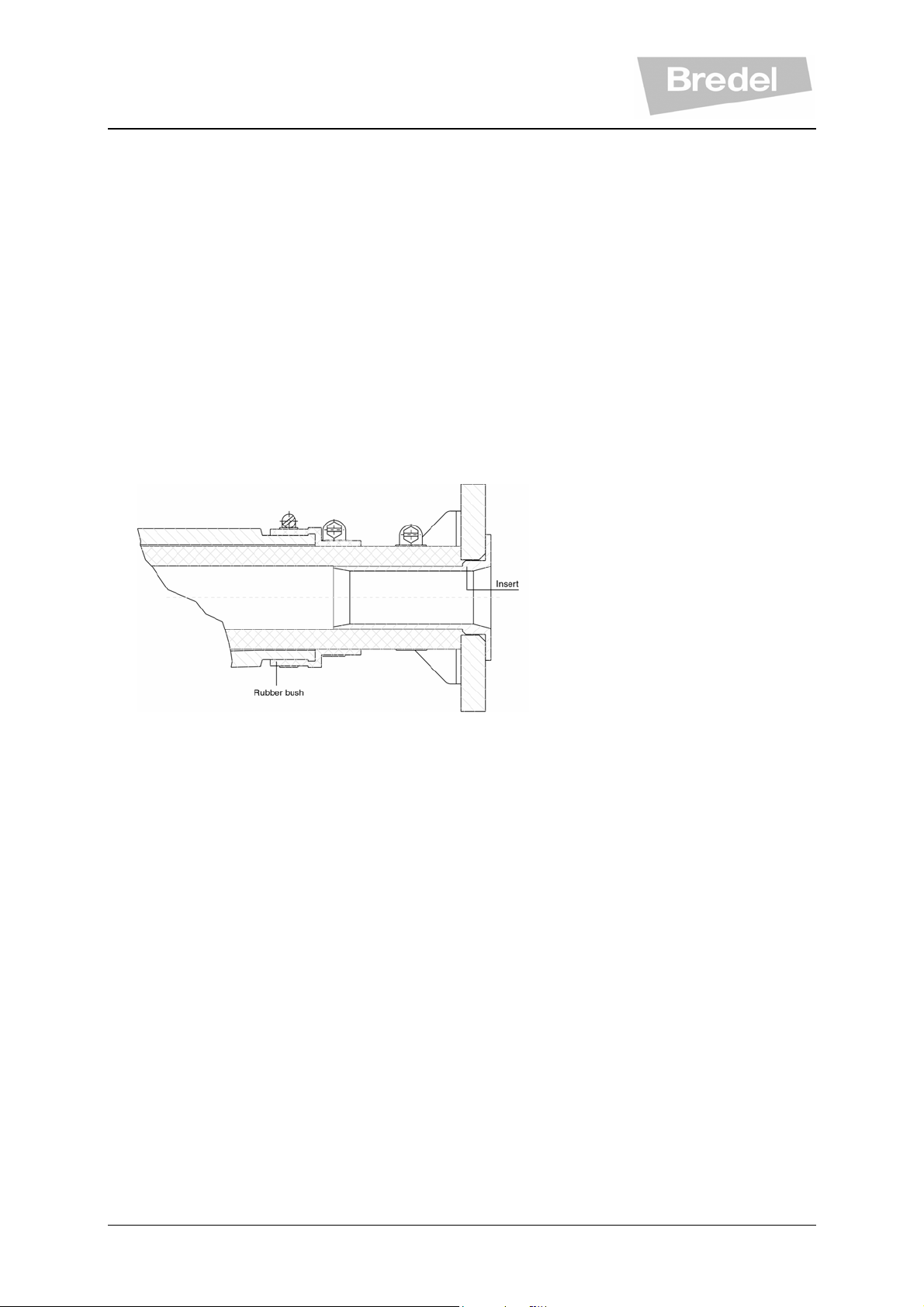

7.5.5 Removal of flanges and/or inserts

Pull the inserts from the hose (SP/10, SP/15 and SP/20) by removing the flanges (SP/25SP/100) on both the suction and discharge port.

19

Page 20

7.5.6 Removal of flange brackets

Remove the flange bracket (SP/25-SP/100) or flange bracket and insert (SP/10, SP/15 and

SP/20) on both suction and discharge port.

7.5.7 Removal of the hose

The hose can be removed without removing the pump cover.

Simply remove the hose by jogging the drive motor.

7.5.8 Cleaning of pump casing

Flush out casing cavity to remove any contaminants. If necessary remove the pump cover to

clean casing completely (but isolate the pump from the electrical supply first).

WARNING

Never remove the pump cover whilst the hose is in place.

The front covers of the series SP/25 to SP/100 should not be removed whilst

the hose is in place. This can cause a deformation of the pump casing and a

non straight tension of the bolts. After fitting the cover and starting up the

pump, the bolts can be extremely forced and break.

When the pump cover was removed for cleaning purposes, refit it before installing the

hose Check the cover O-ring for damage and replace if necessary. Make sure that the bolts

are refitted and that they are tightened in the correct order, diagonally opposite each other,

see “Specifications”: ‘’Torques’’, § 10.1.6.

7.5.9 Tighten drain plug (not applicable for SP/10, SP/15 and SP/20)

Before the hose can be loaded the drain plug has to be mounted. Make sure that the drain

plug is mounted in such a way that no leakage of lubricant can occur.

7.5.10 Preparation of pump hose

Clean the outside of the pump hose and thoroughly lubricate the external surface of the hose

with the Bredel hose lubricant.

7.5.11 Insertion of the hose

• Switch on the electrical supply again and insert the hose into the upper port.

• Jog the drive motor to feed the hose through the housing.

• If necessary, help by pressing the hose firmly into the port opening.

• Stop the drive when the hose is equally extended from the ports.

7.5.12 Place hose clamps

Place on both the suction and discharge port the bushes, all hose clamps (do not tighten

yet!), the brackets, the flanges and the inserts.

7.6 Hose connection

Note: Always start hose connection at one port and finalize these actions completely. Then

repeat these actions for the other port. In this instruction we start from the suction port.

20

Page 21

7.6.1 Mount flange brackets (SP/25 to SP/100)

• Mount the flange brackets on the suction port by replacing the bolts.

• Do not tighten the bolts at this stage!

• Mount the flange and the insert

• Mount the suction line

7.6.2 Positioning of pump hose

Jog the motor in the direction of the suction port to drive the hose against the flange face.

Ensure that the hose butts up against the flange face and that the insert is seated correctly.

7.6.3 Tighten hose clamps

• Tighten all the hose clamps.

• Make sure that hose clamp is mounted directly against the vertical part of the rubber

bush.

Now repeat step 7.6.1 to 7.6.3 for the discharge port

7.6.4 Tighten bolts of all flange brackets

Now tighten the bolts of all flange brackets.

7.6.5 Filling with lubricant

• Remove one screw from the inspection window (not applicable for SP/10, SP/15 and

SP/20) to vent the pump housing.

• Add lubricant until ½ of the pump housing is filled. See “Specifications”, “Lubricant”,

§ 10.1.3 for the required quantity of lubricant per pump type.

7.6.6 Finally

• Replace removed bolt(s) in inspection window (not applicable for SP/10, SP/15 and

SP/20).

• Open the suction and discharge valves.

•

Switch on the electrical supply.

21

Page 22

CAUTION

When the pressing shoes are worn the compression force of the hose could

decrease. If the compression force is too low, this results in a loss of capacity

by the backflow of the liquid to be pumped. Backflow results in a reduction of

the life of the pump hose.

7.7 Exchanging replacement parts

7.7.1 Replacing pressing shoes (not applicable for SP/10, SP/15 and SP/20)

• Remove the pump hose and cover. See paragraph 7.5.1 through 7.5.8

• Loosen the retaining bolt(s) of the pressing shoe a few turns. Remove the shims.

• Loosen the retaining bolt(s) of pressing shoe completely and remove the pressing

shoe.

• Fit the eventually removed shims again. Position the (new) pressing shoe, tighten

the retaining bolt(s), see “Specifications”: “Torques”, § 10.1.6.

• Repeat the procedure for removing and fitting the second pressing shoe by

repeating above mentioned steps.

WARNING

Never remove the pump cover whilst the hose is in place.

The front covers of the series SP/25 to SP/100 should not be removed whilst

the hose is in place. This can cause a deformation of the pump casing and a

non straight tension of the bolts. After fitting the cover and starting up the

pump, the bolts can be extremely forced and break.

• Check the cover O-ring for damage and replace if necessary. Refit the cover. Make

sure that the bolts are refitted and that they are tightened in the correct order,

diagonally opposite each other, see “Specifications”: ‘Torques”, § 10.1.6.

• Switch on the electrical supply.

• Replace hose and refill the lubricant, see paragraph 7.5.9 through 7.6.5

7.7.2 Replacing seal and bearings

• Remove the pump hose and cover, see paragraph 7.5.1 through 7.5.8

• Isolate the pump from the electrical supply.

• Loosen coupling on drive end of shaft.

• Remove rotor retaining ring and pull rotor off shaft.

• Remove bearing cover for SP/25 to SP/100, or joint ring and safety ring for SP/10,

SP/15 and SP/20.

• Pull shaft assembly out at rotor side.

• Use arbor press and V-block to remove both bearings from shaft. Use file to deburr

key ways.

• Remove lip seals from housing and bearing cover. It is recommended to replace

seals whenever shaft has been removed.

22

Page 23

• Pre-grease bearings with lithium grease.

• Use arbor press and press new bearings on shaft. Coat shaft areas with anti-seize

compound to facilitate assembly.

• Press oil seal into housing.

• Insert joint ring into bearing cover groove.

• Press shaft assembly into housing.

• Add grease through grease fitting and fill housing cavity until grease is forced through

the exposed front bearing. Then take away grease nipple and plug the hole.

• Assemble bearing cover to housing to secure shaft assembly for SP/25 to SP/100.

Assemble safety ring and press in joint ring for SP/10, SP/15 and SP/20.

• Place rotor key and assemble rotor. Secure with retainer ring.

• Check the cover O- ring for damage and replace if necessary. Refit the cover. Make

sure that the bolts are refitted and that they are tightened in the correct order,

diagonally opposite each other, see “Specifications”: ‘Torques”, § 10.1.6.

• Switch on the electrical supply to the pump.

• Fit the (new) pump hose, see 7.5.9 through 7.6.5

7.8 Hose compression force adjustment (shimming) (not applicable for SP/10, SP/15

and SP/20).

Fitting and removing shims is a simple action which can be carried out via the inspection

window on the front of the pump housing. The pump hose or the pump cover does not need

to be removed. In order to determine the correct number of shims for your specific

application see “Specifications”: “Shimming”, § 10.1.7.

CAUTION

Too many shims, this means a too high compression force on the pump hose,

will create a too high load of the pumphead and pump hose, which may result in

a reduction of the life of the pump hose. Too few shims, this means a to low

compression force on the pump hose, create a loss of capacity and backflow.

Backflow results in a reduction of the life of the pump hose.

• Jog the motor until the pressing shoe is positioned in view of the inspection window.

• Isolate the pump from the electrical supply.

• Loosen the retaining bolts of the inspection window and remove the bolts.

• Remove the inspection window. Care must be taken not to damage the gasket.

• Loosen the retaining bolt(s) of the pressing shoe a few turns.

• Fit the shims or remove them until the correct number of shims is present (see

“Specifications”: “Shimming”, § 10.1.7). To aid in assembly, preform shim around

rotor. Then insert with slot oriented around bolt.

• Fasten the retaining bolt(s) of the pressing shoe with the correct torque (see

“Specifications”: “Torques”, § 10.1.6).

CAUTION

When maximum suction capability is required, the pump shimming must be as

for minimum 5 bar counter pressure at corresponding speed.

23

Page 24

• Refit the inspection window. Check the gasket for damage and replace if necessary.

Make sure that all bolts are refitted and that they are tightened in the correct order,

diagonally opposite each other, see “Specifications”: “Torques”, § 10.1.6.

• Switch on the electrical supply.

7.9 Fitting options

7.9.1 Fitting a high-level float switch

• Note: in case of series SP/10, SP/15 and SP/20 another type of cover is required.

• Dismount the standard breather on the cover of the pump

• Slide the standard breather cap from breather.

• Replace the standard breather cap with the breather cap with high level float switch

and slide it over breather.

• Mount the breather on the cover of the pump.

• Connect the high-level float switch to the electrical supply. Bear in mind that the

electrical contact of the float switch is normally closed (NC). When the lubricant level

is (too) high the contact will open.

7.9.2 Fitting a low level float switch (not applicable for SP/10, SP/15 and SP/20)

• If the pump is filled with lubricant this must be removed first. Place a tray under the drain

plug in the desaeration pipe on the cover of the pump. Remove the drain plug. Catch

the lubricant from the pump housing in the tray.

• Replace the drain plug by a low level floater.

• Connect the low level float switch to the electrical supply. Bear in mind that the

electrical contact of the float switch is normally closed (NC). This means that: the

contact of the low level float switch opens at a (too) low lubricant level.

• Make sure the lubricant returns to the prescribed level, see: “Maintenance”:

“Changing lubricant”, § 7.3.

24

Page 25

8 STORAGE

8.1 Hose pump

Store the hose pump or pump parts in a dry area. Make sure that the hose pump or pump

parts are not exposed to temperatures lower than - 40 °C or higher than + 70 °C.

Cover the openings of the inlet and outlet ports.

Prevent corrosion of untreated parts. For this purpose use the correct protection or

packaging means.

After a long period of standstill or storage, the static load on the pump hose may have

caused permanent deformation, which will reduce the life of the pump hose.

8.2 Pump hose

Store the pump hose in a cool and dark room. Pump hoses have a limited storage life. After

2 years the hose material will age, which will reduce the life of the hose.

25

Page 26

9 TROUBLESHOOTING

If the hose pump does not function (correctly), consult the following checklist to see if you

can remedy the error yourself. If this is not the case, please contact your Bredel

representative.

Problem Possible Cause Correction

Failure to operate

High pump temperature.

Low capacity/pressure

Stalled rotor Check that the pump is stalled by

Lubricant level monitoring system

has been activated.

Non standard hose lubricant used. Consult the Bredel representative for the

Low lubricant level. Add Bredel lubricant, see for the required

Product temperature too high. Consult the Bredel representative about

Internal friction on the hose caused

by blocked or poor suction

characteristics.

Over-shimming of the pump rotor

shoes (not for SP/10, SP/15 and

SP/20)

High pump speed. Reduce pump speed to a minimum.

Shut-off valve in the suction line

(partly) closed.

Check that the supply power switch is on. No voltage

Check the electrical supply is available at

the pump.

incorrect fitting of the hose.

Check that the lubricant level monitoring

system has stalled the pump. Check the

functioning of the lubricant level

monitoring system, or check the lubricant

level.

correct lubricant.

amount of lubricant “Maintenance”:

“Changing lubricant”.

the maximum temperature range of the

product.

Check pipework/valves for blockages.

Ensure that the suction pipework is as

short as possible and that the diameter is

large enough.

Consult the diagram, see “Specifications”:

“Shims specifications”. Remove excess

shims.

Consult with your Bredel pump

representative for advice on optimum

pump speeds.

Fully open the valve.

Under shimming of the pressing

shoes.

Hose rupture or badly worn hose Replace hose, see “Maintenance”:

(Partial) blockage of the suction line

or too little product on the suction

side.

Consult the diagram (see “Specifications”:

“Shims specifications”. Fit the correct

number of shims.

“Replacing pump hose”.

Ensure that the suction line is clear of

blockages and that sufficient product is

available.

26

Page 27

The filling degree of the pump hose

is too low, because the speed is too

high in relation to the viscosity of the

product to be pumped and the inlet

pressure. The suction line can be too

long or too narrow or a combination

of these factors.

Consult your Bredel representative for a

recommendation.

Vibration of the pump and

pipework.

Broken front cover bolts Pump cover (dis)mounted with the

Short hose life.

Hose pulled into the pump.

Suction and discharge lines are not

secured correctly.

High pump speed with long suction

and discharge lines or high product

specific gravity or a combination of

these factors.

Too narrow diameter of suction

and/or discharge line

hose in the pump

Chemical attack of the hose. Check the compatibility of the hose

High pump speed. Reduce pump speed.

High discharge pressures. Maximum working pressure 16 bar.

High product temperature. Consult your Bredel representative for

High pulsations. Restructure the discharge and inlet

Insufficient or no hose lubricant in

the pumphead.

Check and secure pipework.

Reduce pump speed. Reduce the line

lengths on both suction and discharge

where possible. Consult your Bredel

representative for a recommendation.

Increase the diameter of the

suction/discharge lines.

Never (dis)mount the pump cover when

the hose is still in the pump

material with the product to be pumped.

Consult your Bredel representative for

correct hose selection.

Check that the discharge line is not

blocked, the shut-off valves are fully

opened and the pressure relief valve

functions properly (if present in the

discharge line).

correct hose selection.

conditions.

Add extra lubricant, see “Maintenance”:

“Changing lubricant”.

No original Bredel lubricant. Consult the Bredel representative for the

correct lubricant.

Extremely high inlet pressure - larger

than 300 Kpa.

Lubricant leakage at flange

bracket.

Hose blocked by an incompressible

object in the hose. The hose cannot

be compressed and will be pulled

into the pump housing.

Bolts of flange bracket loose. Tighten to the specified torque settings

Bolts of hose clamps loose. Tighten to the specified torque settings

Reduce the inlet pressure.

Remove hose, check for blockages and

replace if necessary.

(see ‘Torques’).settings, see

“Specifications”: “Torques”.

(see ‘Torques’).settings, see “Torques”.

27

Page 28

10 SPECIFICATIONS

10.1 Pumphead

10.1.1 Performance

Description SP/10 SP/15 SP/20 SP/25 SP/32 SP/40 SP/50 SP/65 SP/80 SP/100

Max. capacity, continuous

[m3/h]

Max. capacity,

intermittently [m3/h] ◊

Capacity per revolution

[l/rev]

Max. permissible

discharge pressure [kPa]

Permissible ambient

temperature [°C]

Permissible product

temperature [°C]

Sound level on 1m

[dB(A)]

◊ Intermitted duty: “Let the pump stand still to cool down for at least 1 hour after 2 hours of operation”.

10.1.2 Materials

0,11 0,38 0,62 1,80 3,25 6,0 10,5 20,0 28,0 36,0

0,16 0,60 1,09 2,88 5,25 9,6 17,5 32,0 42,0 60,0

0.022 0,083 0,152 0,30 0,625 1,33 2,9 6,7 11,7 20,0

750 750 750 1600 1600 1600 1600 1600 1600 1600

- 20 to + 45

- 10 to + 80

60 60 60 70 70 70 70 70 70 70

Description

Pump housing

Cover

Pump rotor

Pressing shoe

Pump support Mild steel, galvanized

Flange bracket Mild steel, galvanized

Mounting material of pump cover Mild steel, galvanized

Mounting material of pump

support

Seals Nitrile

Bush Neoprene

Cast-iron

SP/10, SP/15: synthetic

optional: mild steel

SP/20 to SP/100: steel

Cast-iron

Aluminum (not applicable for SP/10, SP/15 and

SP/20)

Mild steel, galvanized

Material

10.1.3 Lubricant

Required quantity of lubricant [Liters]

SP/10 SP/15 SP/20 SP/25 SP/32 SP/40 SP/50 SP/65 SP/80 SP100

0,25 0,50 0,50 2 3 5 10 20 40 60

28

Page 29

10.1.4 Surface treatment

The pumphead is provided with a two component epoxy base coat. After drying the layer

thickness must be at least 30 microns.

Subsequently these components are provided with a two component polyurethane top coat, in

the RAL 5017 colour blue and with a 100% gloss rate. After this coat of paint has dried the layer

thickness must be at least 30 microns.

All galvanized parts, exclusive of mounting articles, have been provided with an electrolytic zinc

layer of 15 –20 microns.

10.1.5 Weights and dimensions

Description Weights and dimensions per pump model

series

Net weight pump

(kg)

Gross weight pump

(kg)

Dimensions crate

(cm)

Cubage (m3)

Dimension pump

hose (mm)

Weight pump hose

(kg)

Quantity lubricant

required (litres)

Weight lubricant (kg)

Weight supports [set]

(kg)

Weight pump shaft

(kg)

Weight rotor (kg)

Weight pressing

shoes [set] (kg)

Weight pump cover

(kg)

Weight pump

housing (kg)

Flange connection,

without inserts [set]

(kg)

Insert [set] (kg)

SP/10 SP/15 SP/20 SP/25 SP/32 SP/40 SP/50 SP/65 SP/80 SP/100

10 19 19 59 85 139 195 395 600 955

10 19 19 80 125 175 265 450 680 1055

30x26x

10x31x

37x32x

27

- - - 0,222 0,35 0,42 0,65 1,12 1,71 2,64

15x36x

510

0,35 0,70 0,70 2 3 3,80 6,40 11,50 21 31

0,25 0,50 0,50 2 3 5 10 20 40 60

0,30 0,60 0,60 2,5 3,6 6 13 26 52 78

0,75 1,60 1,60 17 24 43 56 50 92 160

0,50 0,90 0,90 2 5 5 9,50 18 39 53

0,75 2,50 2,50 4 8 12 24 44 69 108

- - - 0,70 1,10 2 2,50 5 8 13

0,2 0,65 0,65 7 10 16 24 54 89 123

5,70 10,7 10,7 21 40 50,50 82 170 238 390

1,47 1,72 1,90 2,98 4,26 4,88 6,38 7,80 11,4 14,9

0,04 0,05 0,07 0,13 0,18 0,34 0,46 3,13 4,06 5,69

28

755

37x32x

28

19x36x

755

72x56x

55

25x53x

1005

87x62x

65

32x61x

1250

87x76x

63

40x66x

1490

106x

90x68

50x80x

1820

127x

105x

65x99x

2335

84

148x

124x

93

80x

120x

2780

170x

145x

107

100x

144x

3275

29

Page 30

10.1.6 Torques

Description Torques in [Nm] per pump type

SP/10 SP/15 SP/20 SP/25 SP/32 SP/40 SP/50 SP/65 SP/80 SP/100

Pressing

shoe

Cover 3,5 3,5 10 25 50 50 50 50 50 85

Inspection

window

Hose clamp 2 2 2 12 12 12 12 12 12 12

Rubber bush

clamp

Flange

bracket

Support 25 25 25 50 85 85 85 210 410 710

- - - 30 40 120 160 160 160 160

- - - 1,75 1,75 1,75 1,75 1,75 3,5 3,5

1,75 1,75 1,75 1,75 1,75 1,75 1,75 1,75 1,75 1,75

10 10 10 25 50 50 50 85 210 210

30

Page 31

10.1.7 Shimming

31

Page 32

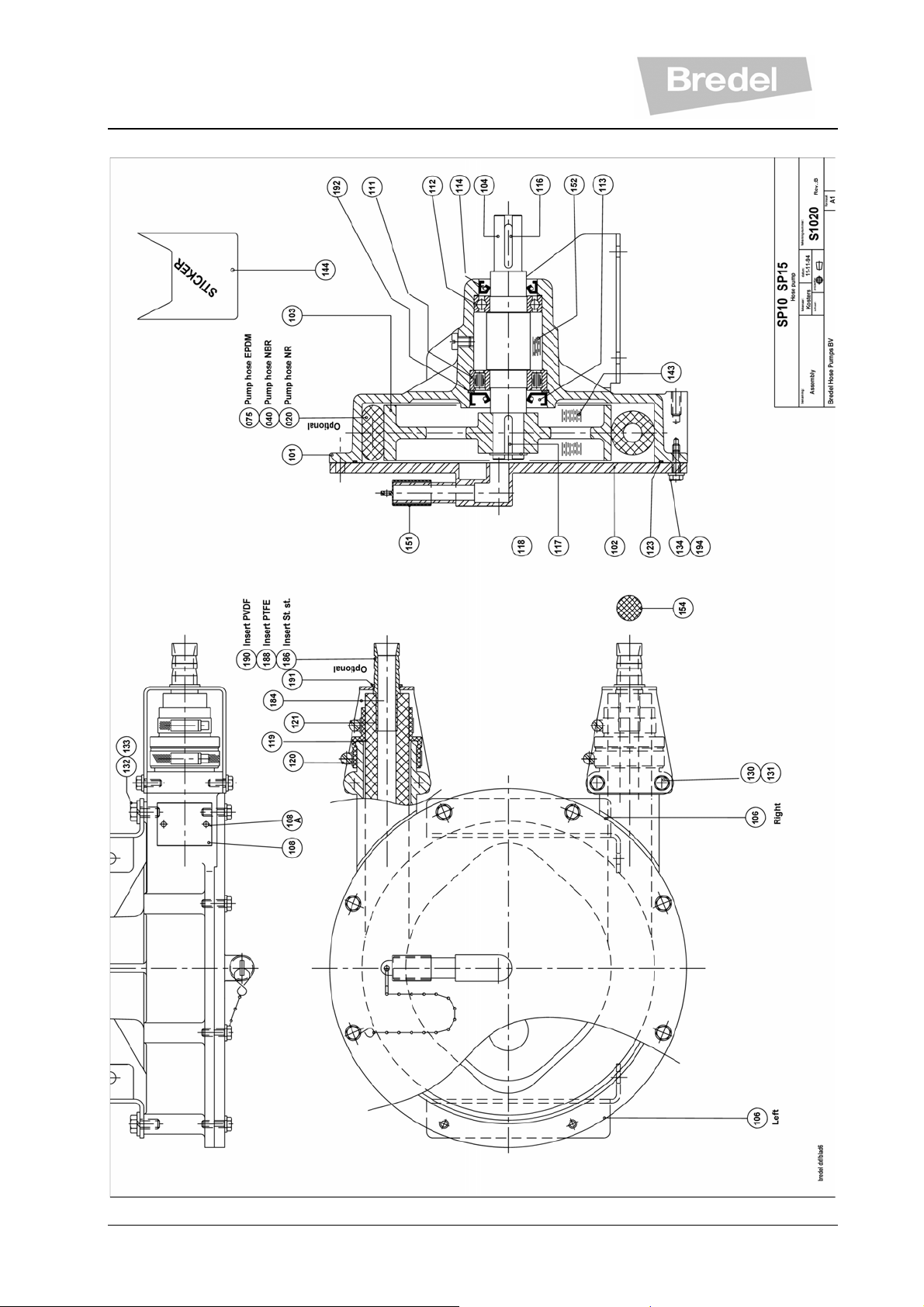

10.1.8 Parts list: SP/10-SP/15

32

Page 33

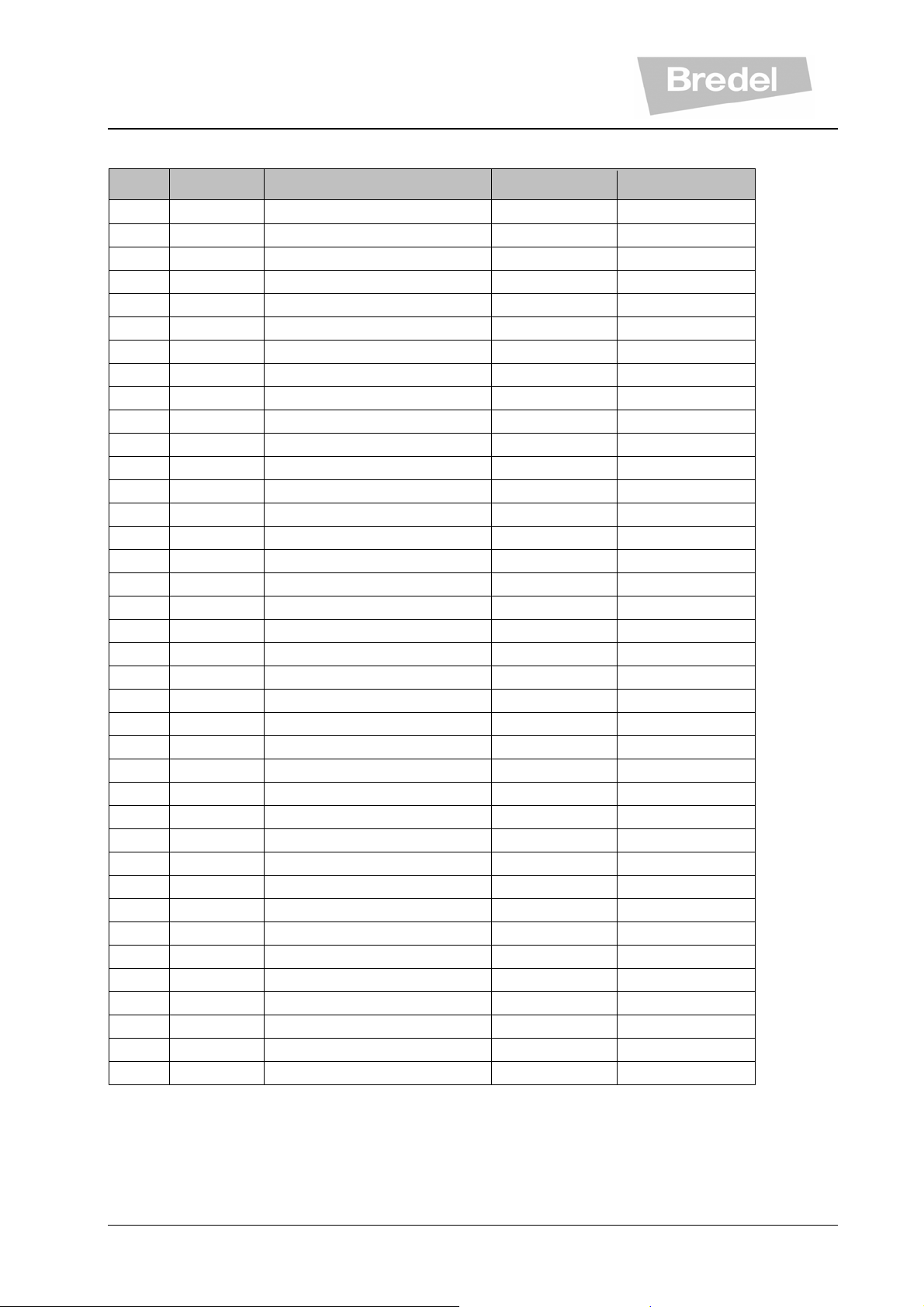

Parts list: SP/10-SP/15

Pos Pcs Description SP/10 SP/15

101 1 Pump housing 010101 015101

102 1 Pump cover 010102 015102

103 1 Rotor 010103 015103

104 1 Pump shaft 010104 015104

106R 1 Mounting support Right 010106R 015106R

106L 1 Mounting support Left 010106L 015106L

108 1 Name tag Z010108 Z015108

108A 2 Pin screw F419001 F419001

111 1 Cylinder roller bearing B220520 B220620

112 1 Deep groove ball bearing B140500 B140600

113 1 Joint ring S240240 S240290

114 1 Oil seal S210240 S210290

116 1 Drive key F436055 F436055

117 1 Rotor key F436052 F436076

118 1 Snap ring F343017 F343022

119 2 Rubber bush 010119 015119

120 2 Hose clip C111508 C111510

121 2 Hose clip C111506 C111508

123 1 O-ring S121641 S121771

130 8 Hexagon screw F111038 F111038

131 8 Spring washer F531008 F531008

132 4 Hexagon screw F111071 F111071

133 4 Spring washer F336011 F336011

134 8 Hexagon screw F111040 F111040

143 1 Lubricant 901143 901143

144 1 Sticker "Caution" 29082235 29082235

151 1 Air breather cap 29040223 29040223

152 0,04 Kg Grease Z010152

152 0,06 Kg Grease Z010152

153 1 Screw F401097 F401097

154 1 Cleaning sponge 010154 015154

184 2 Insert retaining flange 010184 015184

186 1 Insert stainless steel 010186 015186

188 1 Insert Teflon/PTFE 010188 015188

190 1 Insert PVDF 010190 015190

191 2 Circlips F543013 F543017

192 1 Circlips F344044 F344052

194 8 Washer F326005 F326005

33

Page 34

10.1.9 Parts list: SP/20 H-L

34

Page 35

Parts list: SP/20 H-L

Pos Pcs Description SP/20 H SP/20 L

1 1 Pump housing 15101 15101

2 1 Pump cover 015102STD 015102STD

3 1 Rotor 020103H 020103L

4 1 Pump shaft 15104 15104

5 1 Mounting support

015106R 015106R

Right

6 1 Mounting support Left 015106L 015106L

7 1 Name tag Z020108H Z020108L

8 2 Pin screw F419001 F419001

9 1 Cylinder roller bearing B220620 B220620

10 1 Deep groove ball

B140600 B140600

bearing

11 1 Joint ring S240290 S240290

12 1 Oil seal S210290 S210290

13 1 Drive key F436055 F436055

14 1 Rotor key F436076 F436076

15 1 Snap ring F343022 F343022

16 2 Rubber bush 15119 15119

17 2 Hose clip C111510 C111510

18 2 Hose clip C111508 C111508

19 1 O-ring S121771 S121771

20 4 Hexagon screw F111071 F111071

21 4 Spring washer F336011 F336011

22 4 Plain washer F322012 F322012

23 8 Hexagon screw F111040 F111040

24 0,5 L Lubricant 901143 901143

25 1 Sticker "Caution" 29082235 29082235

26 0,06 Kg

Grease

Z010152 Z010152

27 1 Hexagon screw F401097 F401097

28 2 Insert retaining flange W015184 W015184

29 2 Snap ring F543019 F543019

30 1 Snap ring F344052 F344052

31 8 Spring washer F336009 F336009

32 8 Hexagon screw F111038 F111038

33 8 Spring washer F336009 F336009

34 1 Air breather cap

29065223 29065223

35 1 Bend, 90 º 29011242 29011242

36 1 Cat eye 29036274 29036274

35

Page 36

10.1.10 Parts list: SP/25, SP/32, SP/40 and SP/50

36

Page 37

Parts list: SP/25, SP/32, SP/40 and SP/50

Pos Pcs Description SP/25 SP/32 SP/40 SP/50

101 1 Pump housing 025101 032101 040101 050101

102 1 Pump cover 025102 032102 040102 050102

103 1 Rotor 025103 032103 040103 050103

104 1 Pump shaft 025104 9298104 9298104 050104

105 1 Bearing cover 025105 9140105 9140105 050105

106R 1 Mounting support Right 025106R 032106R 040106R 050106R

106L 1 Mounting support Left 025106L 032106L 040106L 050106L

106B 1 Mounting support 025106B 032106B 040106B 050106B

106S 1 Mounting support - - 040106S 050106S

107 14 Shim 025107

107 10 Shim 032107

107 16 Shim 040107

107 20 Shim 050107

108 1 Name tag Z025108 Z032108 Z040108 Z050108

108A 4 Pin screw F419001 F419001 F419001 F419001

110 2 Pressing shoe 025110 032110 040110 050110

111 1 Cylinder roller bearing B220820 B221120 B221120 B221420

112 1 Deep groove ball bearing B150700 B151000 B151000 B151200

113 1 Joint ring S200400 S200550 S200550 S200700

114 1 Oil seal S210350 S210500 S210500 S210600

115 1 O-ring S120411 S120441 S120441 S121571

116 1 Drive key F436084 F436128 F436128 F436148

117 1 Rotor key F436101 F436901 F436901 F436902

118 1 Snap ring F343032 F343043 F343043 F343053

119 2 Rubber bush 025119 032119 040119 050119

120 2 Hoseclip C111512 C111513 C111513 C111515

121 2 Hoseclip C121006 C121008 C121010 C121014

122 2 Hoseclip C122005 C122005 C122007 C122009

123 1 Rubber cord for cover 025123 032123 040123 050123

124 10 Hexagon screw F111071 F111096

124 14 Hexagon screw F111096

124 16 Hexagon screw F111096

124A 2 Screw with cuppoint - F429014 F429014 F429014

124B 2 Hexagon nut - F301007 F301007 F301007

124C 10 Plain washer F322012 F322013 F322013 F322013

125 2 Hexagon bolt F111096 F111134 F111186 F101173

126 2 Spring washer F336012 F336013 F336015 F336017

127 2 Pin F415083 F415083 F415083 F415112

128 4 Hexagon screw F111073 F111098 F111098 F111098

129 4 Spring washer F336011 F336012 F336012 F336012

130 8 Hexagon screw F111069 F111093 F111093 F111093

131 8 Spring washer F336011 F336012 F336012 F336012

132 4 Hexagon screw F111096 F111130 F111130 F111130

37

Page 38

Pos Pcs Description SP/25 SP/32 SP/40 SP/50

133 4 Spring washer F336012 F336013 F336013 F336013

137 1 PVC Hose 025137 032137 040137 050137

138 2 Hose clip C111506 C111506 C111506 C111506

143 1 Lubricant 902143 908143 903143 904143

144 1 Sticker "Caution" 29082235 29082235 29082235 29082235

145 1 T with hose nipple 29010241 29010241 29010241 29010241

146 1 Desaeration pipe with

29010242 29010242 29010242 29010242

hose nipple

147 1 Air breather cap 29065223 29065223 29065223 29065223

148 1 Drain plug A131008 A131008 A131008 A131008

152 0,14 Kg Grease Z010152

152 0,29 Kg Grease Z010152 Z010152

152 0,59 Kg Grease Z010152

153 1 Screw F401097 F401097 F401097 F401097

154 1 Cleaning sponge 025154 032154 040154 050154

155 1 Inspection window 025155 032155 040155 050155

156 1 Gasket 025156 032156 040156 050156

157 8 Hexagon Screw F111038 F111040 F111040 F111040

158 8 Washer F322009 F322009 F322009 F322009

161 1 Eye bolt - 09100161 09100161 09100161

162 1 Hexagon screw - F111130 F111130 F111130

163 1 Spring washer - F336013 F336013 F336013

197 4 Flange bracket 025197 032197 040197 050197

198 2 Flange steel 025198 032198 040198 050198

Option 1 Floater in desaeration pipe 29104610 29104610 29104610 29104610

Option 1 Floater in drain plug 29104611 29104611 29104611 29104611

38

Page 39

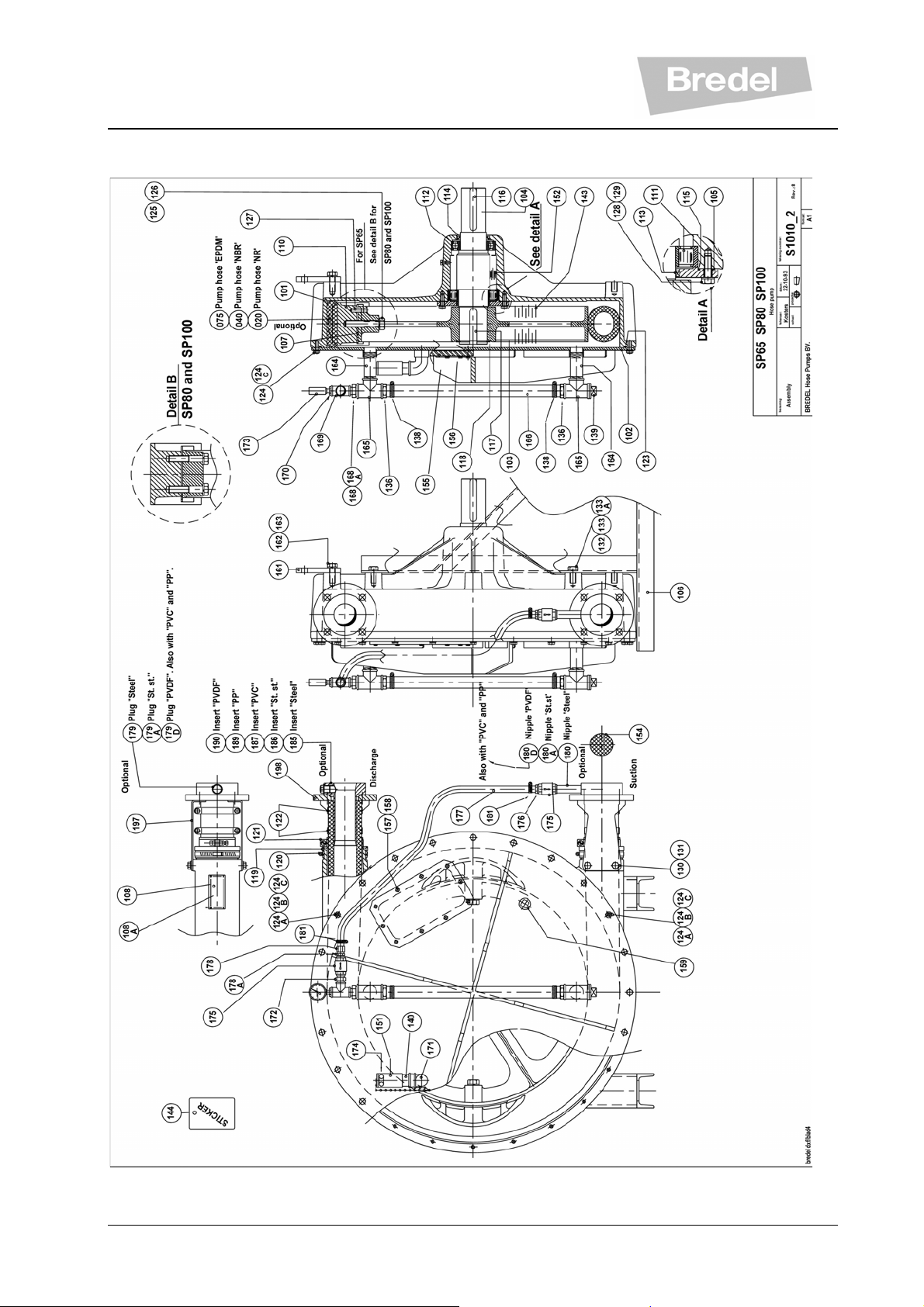

10.1.11 Parts list: SP/65, SP/80 and SP/100

39

Page 40

Parts list: SP/65, SP/80 and SP/100

Pos Pcs Description SP/65 SP/80 SP/100

101 1 Pump housing 065101 080101 100101

102 1 Pump cover 065102 080102 100102

103 1 Rotor 065103 080103 100103

104 1 Pump shaft 065104 080104 100104

105 1 Bearing cover 065105 080105 100105

106 2 Mounting support 065106

106

106

1 Mounting support - Right 080106R 100106R

1 Mounting support - Left - 080106L 100106L

107 24 Shim 065107 080107

107 28 Shim 100107

108 1 Name tag Z065108 Z080108 Z100108

108A 4 Pin screw F419001 F419001 F419001

110 2 Pressing shoe 065110 080110 100110

111 1 Cylinder roller bearing B221720 B222020 B222420

112 1 Deep groove ball bearing B151500 B151800 B152100

113 1 Joint ring S200850 S201000 S201200

114 1 Oil seal S210750 S210900 S211050

115 1 O-ring S121621 S121671 S121721

116 1 Drive key F436173 F436180 F436186

117 1 Rotor key F436903 F436904 F436905

118 1 Snap ring F343061 F343068 F343115

119 2 Rubber bush 065119 080119 100119

120 2 Hose clip C111516 C111517 C111518

121 2 Hose clip C121020 C121025 C121028

122 4 Hose clip C122014 C122019

122 6 Hose clip C122024

123 1 Rubber cord for cover 065123 080123 100123

124 22 Hexagon screw F111098

124 26 Hexagon screw F111098

124 28 Hexagon screw F111130

124A 2 Screw with cup point F429014 F429014 F429024

124B 2 Hexagon nut F301007 F301007 F301008

124C 24 Plain washer F322013

124C 28 Plain washer F322013

124C 32 Plain washer F322015

125 2 Hexagon bolt F101175

125 4 Hexagon bolt F101175 F101175

126 2 Spring washer F336017

126 4 Spring washer F336017 F336017

127 2 Pin F415112 - -

Pos Pcs Description SP/65 SP/80 SP/100

40

Page 41

128 6 Hexagon screw F111100

128 8 Hexagon screw F111100 F111132

129 6 Spring washer F336012

129 8 Spring washer F336012 F336013

130 8 Hexagon screw F111128 F111180 F111180

131 8 Spring washer F336013 F336015 F336015

132 4 Hexagon screw F111182 F111217 F111244

133 4 Spring washer F336015 F336017 F336019

133A 4 Square taper washer - F339005 F339007

136 2 Hose nipple A101018 A103019 A103019

138 2 Hose clip C111506 C111509 C111509

139 1 Drain plug A124006 A124008 A124008

140 1 Pipe nipple 09088140 09100140 09100140

143 1 Lubricant 905143 905143 905143

144 1 Sticker "Caution" 29082235 29082235 29082235

151 1 Air breather cap 09087151 09086151 09086151

152 1,00 Kg Grease Z010152

152 1,55 Kg Grease Z010152

152 3,36 Kg Grease Z010152

153 1 Screw F401097 F401097 F401097

154 1 Cleaning sponge 065154 080154 100154

155 1 Inspection window 065155 09325155 09325155

156 1 Gasket 065156 09325156 09325156

157 10 Hexagon Screw F111042

157 14 Hexagon Screw F111073 F111073

158 10 Washer F322009

158 14 Washer F322012 F322012

159 1 Plug A124006 A124008 A124008

161 1 Eye bolt 065161 080161 100161

162 1 Hexagon screw F111183 F111217 F111244

163 1 Spring washer F336015 F336017 F336019

164 2 Pipe nipple 065164 A127064 A127064

165 2 T 90º A126006 A126008 A126008

166 1 PVC Hose 065166 080166 100166

168 1 Reducing nipple A122013 A122013 A122013

168A 1 Reducing nipple - A122020 A122020

169 1 T 90º A126004 A126004 A126004

170 1 Reducing bush A122005 A122005 A122005

171 1 Bend 90º A128006 A128008 A128008

172 1 Hexagon nipple A121004 A121004 A121004

173 1 Vacuum gauge A220051 A220051 A220051

175 2 Check valve A107002 A107002 A107002

176 1 Hose nipple A101012 A101012 A101012

177 1 PVC Hose 065177 080177 100177

178 1 Hose nipple with nut A102012 A102012 A102012

Pos Pcs Description SP/65 SP/80 SP/100

41

Page 42

178A 1 Hexagon nipple A105004 A105004 A105004

179 1 Plug steel A124004 A124004 A124004

180 1 Pipe nipple steel A127024 A127024 A127024

181 2 Hose clip C111502 C111502 C111502

197 4 Flange bracket 065197 080197 100197

198 2 Flange steel 065198 080198 100198

Option

Option

1

Floater in desaeration pipe 29105610 29124610 29124610

1

Floater in drain plug 29106611 29105611 29105611

42

Page 43

10.1.12 Dimensional drawings

43

Page 44

Dimensional drawings SP/25, SP/32, SP/40 and SP/50

44

Page 45

Dimensional drawings SP/65, SP/80 and SP/100

45

Page 46

10.1.13 EG-Declaration of Conformity

The undersigned,

Company: Bredel Hose Pumps B.V.

Address: P.O. Box 47

City: NL-7490 AA Delden

Country: The Netherlands

Declares as the manufacturer for his own responsibility that the:

Description: Hose pump

Type/mode: SP series

to which this declaration applies, is in conformance with the conditions of the Machine directive

98/37/CE, annexe IIA : 98/37/EC EN60204-1.

If this hose pump is used as an independent pump then the Machine Directive applies.

Responsible person: Hanjo Kruisinga, Managing Director

Company: Bredel Hose Pumps B.V.

Address: P.O. Box 47

City: NL-7490 AA Delden

Country: The Netherlands

Tel.: +31 74 3770000

Fax: +31 74 3761175

Internet:

E-mail:

www.bredel.com

hosepumps@bredel.com

46

Page 47

10.1.14 Manufacturer’s Declaration

The undersigned,

Company: Bredel Hose Pumps B.V.

Address: P.O. Box 47

City: NL-7490 AA Delden

Country: The Netherlands

Declares as the manufacturer for his own responsibility that the:

Description : Hose pump

Type/mode : SP series

to which this declaration applies, is in conformance with the conditions of the Machine

directive 98/37/CE, annexe IIB ; 98/37/EC EN60204-1.

When this pump unit is to be installed into a machine or is to be assembled with other machines

for installations, it must not be put into service until the relevant machinery has been declared in

conformity with this Machinery Directive.

Responsible person: Hanjo Kruisinga, Managing Director

Company: Bredel Hose Pumps B.V.

Address: P.O. Box 47

City: NL-7490 AA Delden

Country: The Netherlands

Tel.: +31 74 3770000

Fax: +31 74 3761175

Internet:

E-mail:

www.bredel.com

hosepumps@bredel.com

47

Page 48

10.1.15 Product Use and Decontamination Declaration

48

Page 49

Bredel Hose Pumps B.V

P.O. Box 47

NL-7490 AA Delden

The Netherlands

Tel.: +31 74 3770000

Fax: +31 74 3761175

hosepumps@bredel.com

www.bredel.com

TS03-058-0

29210390

Member of the Spirax-Sarco Engineering Group

49

Loading...

Loading...