Page 1

Warn Industries, Inc.

12900 S.E. Capps Road

Clackamas, OR USA 97015-8903

1-503-722-1200 FAX: 1-503-722-3000

www.warn.com

Customer Service / Service Clients: 1-800-543-9276

International Sales Support / Les Ventes internationales

Soutiennent: 1-503-722-3005

© 2012 Warn Industries, Inc.

WARN®, the WARN logo are registered trademarks of Warn Industries, Inc.

WARN® et le logo WARN sont des marques

déposées de Warn Industries, Inc.

(31”) ZEON CONTROL PACK

89969A0

RELOCATION KIT

INSTALLATION GUIDE

GUIDE D’INSTALLATION

Page 2

English .......................................................................... 1

Page 3

ORIGINAL INSTRUCTIONS

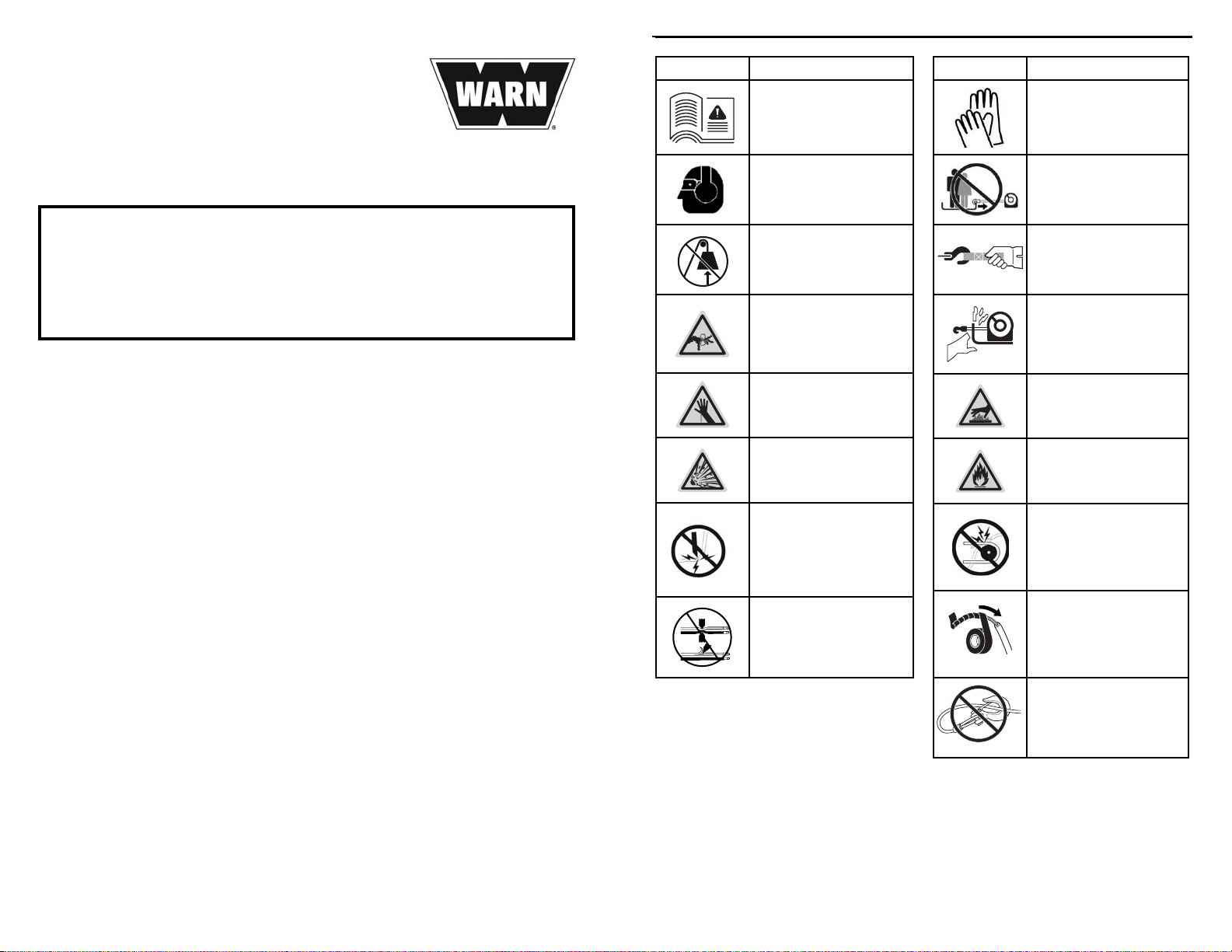

SYMBOL INDEX

Zeon Control Pack Relocation Kit

31” Cable Length

Every winching situation has the potential for personal injury. In order to minimize that risk, it is important to read

this guide and The Basic Guide to Winching Techniques carefully. Please familiarize yourself with the operation of your

winch before using it and be constantly safety oriented. In this guide we provide important safety information and

instructions on how to install your Control Pack Relocation Kit. Please read the Basic Guide to Winching Techniques for

information on how to properly use your winch and proper rigging techniques.

Please keep this manual and other product literature found in this kit for future reference. Should you be missing any of

the necessary instructions, please visit www.warn.com or contact us at the number below.

TABLE OF CONTENTS:

SAFETY

Symbol Index .............................................................................................................................................................................2

General Safety Precautions ................................................................................................................................................... 3

INSTRUCTIONS

Before you Begin ......................................................................................................................................................................4

Parts List ...........................................................................................................................................................................4

Tools Required ...............................................................................................................................................................5

Torque Specifications ..................................................................................................................................................5

Installation Instructions ......................................................................................................................................................6-9

Remove Control Pack From Winch .....................................................................................................................6-7

Installing Relocation Cables ......................................................................................................................................7

Relocating the Control Pack .....................................................................................................................................8

Connecting the Contactor .........................................................................................................................................9

Mounting Hole Drill Template .......................................................................................................................................... 10

SYMBOL EXPLANATION

Read All Product

Literature

Always Wear Hearing and

Eye Protection

Never Use Winch as a

Hoist

Finger/Fairlead Crushing

Hazard

Hand Piercing/Cutting

Hazard

Explosion/Bursting

Hazard

Never Route Electrical

Cables through Sharp

Edges Hazard

Avoid Installing Electrical

Cables around Pinch and

Wear/Abrasion Points

SYMBOL EXPLANATION

Always Wear Leather

Gloves

Do Not Move People

Always Use Supplied

Hook Strap

Fairlead Pinch Point

Hot Surface Hazard

Fire and Burn Hazard

Never Route Electrical

Cables through or near

Moving Parts Hazard

Exposed Wiring Hazard,

Insulate Exposed Wiring

and Terminals

Never Hook Back on

Rope

WARN® and th e WARN logo are reg istered tr ademark s of Warn Indus tries, Inc.

© 2012 Warn Industries, Inc.

WARN INDUSTRIES

1

Warn Industries Inc.

12900 SE Capps Road

Clackamas, OR 97015

USA

Customer Service: (800) 543-9276

International Fax: (503) 722-3005

Fax: (503) 722-3000

www.warn.com

WARN INDUSTRIES

89969A0 2

Page 4

GENERAL SAFETY PRECAUTIONS

BEFORE YOU BEGIN

Warnings and Cautions

As you read these instructions, you will see WARNINGS,

CAUTIONS, NOTICES and NOTES. Each message has a specifi c

purpose. WARNINGS are safety messages that indicate

a potentially hazardous situation, which, if not avoided

could result in serious injury or death. CAUTIONS are safety

messages that indicate a potentially hazardous situation

which, if not avoided, could result in minor or moderate injury.

A CAUTION may also be used to alert against unsafe practice.

CAUTIONS and WARNINGS identify the hazard, indicate how

to avoid the hazard, and advise of the probable consequence

of not avoiding the hazard. NOTICES are messages to avoid

property damage. NOTES are additional information to help

you complete a procedure. PLEASE WORK SAFELY!

WARNING

MOVING PARTS ENTANGLEMENT HAZARD

Failure to observe these instructions could lead to

serious injury or death.

General Safety:

• Always Know Your Winch. Take time to fully read the

Instructions and/or Operations Guide, and/or Basic

Guide to Winching Techniques, in order to understand

your winch and its operations.

• Always keep wired remote control lead and power cord

clear of the drum, rope, and rigging. Inspect for cracks,

pinches, frayed wires or loose connections. Damaged

components must be replaced before operation.

WARNING

CHEMICAL AND FIRE HAZARD

Failure to observe these instructions could lead to

serious injury or death.

• Always remove jewelry and wear eye protection.

• Never route electrical cables across sharp edges.

• Never route electrical cables near parts that get hot.

• Never route electrical cables through or near moving

parts.

• Always place the supplied terminal boots on

wires and terminals as directed by the installation

instructions.

• Never lean over battery while making connections.

• Never route electrical cables over battery terminals.

• Never short battery terminals with metal objects.

• Always verify area is clear of fuel lines, fuel tank,

brake lines, electrical wires, etc., when drilling.

• Always consult operator’s manual for proper wiring

details.

• Always insulate and protect all exposed wiring and

electrical terminals.

• Never mount contactor with electrical terminals

touching metal objects.

CAUTION

Please familiarize yourself with the components.

• Mounting Kit PN89970: Includes a mounting bracket and all needed hardware to mount your kit.

• Mounting Kit PN89965: Does not include a mounting bracket and you will need to purchase some

additional hardware to complete mounting*.

• Bracket Kit PN89770 is available for purchase if you later decide to use a bracket for mounting.

Contact a Warn Industries customer service representative at 1.800.543.9276.

Parts List

Description Qty Part Number Description Qty Part Number

31” Wire Assembly Kit with

Mounting Bracket

31” Cable Assembly 1 89663 31” Wire Assembly 1 89663

Wire housing top 1 89372 Wire housing top 1 89372

M4 screw 2 64503 M4 screw 2 64503

Butt splice 1 85978 Butt splice (18 AWG) 1 85978

31” ground extension 1 89963 31” ground extension 1 89963

Bracket 1 89729 *M6 bolt needed 4

M6 bolt 4 86346 *M6 lock washer needed 4

M6 lock washer 4 77009

5/16” bolt 4 21331

5/16” washer 8 1324

5/16” lock nut 4 2002

31” Cable Assembly

89970

31” Wire Assembly Kit without

Mounting Bracket*

OPTIONAL BRACKET KIT - - SOLD SEPARATELY

Bracket Kit 89770

Bracket 1 89729

M6 Bolt 4 86346

M6 Lock Washer 4 77009

5/16” Bolt 4 21331

5/6” Washer 8 1324

5/16” Lock Nut 4 2002

89965

NOT INCLUDED IN KIT

NOT INCLUDED IN KIT

Bracket

WARNING

FALLING OR CRUSHING HAZARD

Failure to observe these instructions could lead to

serious injury or death.

•

Always stand clear, keep hands clear, keep others away.

WARN INDUSTRIES

3 89969A0

MOVING PARTS ENTANGLEMENT HAZARD

Failure to observe these instructions could lead to

minor or moderate injury.

To avoid injury to hands or fi ngers:

• Never leave remote control where it can be activated

during free spooling, rigging, or when the winch is not

being used.

• Never leave the winch remote control plugged in

when installing, freespooling, rigging, servicing or

when the winch is not being used.

Wire Housing Top

M4 Screws (2)

Butt Splice

M6 Bolt (4)

5/16” Washer (8)

* NOTE: Four (4) M6 bolts and four (4) M6 lock washers must be purchased separately in order to complete installation without

use of bracket.

WARN INDUSTRIES

89969A0 4

5/16” Bolt (4)

5/16” Lock Nut (4)

31” Ground Extension

M6 Lock Washer (4)

Page 5

BEFORE YOU BEGIN

INSTALLATION INSTRUCTION

Tools Required

• Torx Driver Set

• Ratchet/Wrench Set (Standard/Metric)

• Drill and Drill Bit Set

• Wire Cutters

• Wire Strippers/Wire Crimps

• Torque Wrench (30 lb. ft. capacity)

• Zip Ties

• Cable Protection (i.e., flexible electrical conduit or electrical tape)

Torque Specifi cations

Please use the recommended torque specifi cations when assembling this product unless otherwise

specifi ed in the instructions.

FASTENER SIZE

(Grade 5)

FASTENER TORQUE FASTENER SIZE

(Class 8.8)

FASTENER TORQUE

lb-ft (N.m) lb-ft (N.m)

1/4" 8 (11) M4 (2) 3

5/16" 17 (23) M5 (4.5) 6

3/8" 30 (40) M6 (7.5) 10

7/16” 48 (66) M8 (18) 25

1/2" 74 (100) M10 (37) 50

9/16” 106 (144)

5/8" 148 (200)

3/4” 269 (364)

Inspect all nuts and bolts on all related hardware periodically. Tighten all nuts that appear to be loose. Stripped, fractured, or bent bolts

or nuts need to be replaced.

REMOVE CONTROL PACK FROM WINCH

To prevent serious injury or death. Always

WARNING

place the supplied terminal boots on wires and terminals as

directed by the installation instructions.

To prevent serious injury or death from

WARNING

electrical fi re:

Never route electrical cables across sharp edges.

Never route electrical cables near parts that get

hot.

Never route electrical cables through or near

moving parts.

Avoid pinch and wear/abrasion points when

installing all electrical cables.

Always insulate and protect all exposed wiring

WARNING

and electrical terminals.

1. Disconnect the vehicle battery cables, negative

terminal first. All work with electrical wires

and cables must be completed with the battery

completely disconnected from the vehicle

wiring.

2. Disconnect the ground cable on the under side

of the winch (see Figure 1). Make sure the small

black wire that connects to the control pack is

disconnected and hanging freely.

3. Remove the top buss bar cover by unscrewing the

fastener holding it in place. Retain fastener for

later use.

4. Remove the three motor terminal nuts and lock

washers that secure the buss bars to the motor.

Retain the terminal nuts and lock washers for

future step.

Remove

Screw

Terminal

Nuts

Small Black

Wire

Disconnect Ground Wire

Figure 1

Buss Bar Cover

Control Pack

Buss Bars

Figure 2

WARN INDUSTRIES

5 89969A0

5. Remove the four (4) flat head torx drive screws

located on the underside of the tie plate. NOTE:

Rope may need to be spooled out to complete

this step.

WARN INDUSTRIES

89969A0 6

Control Pack

Remove

(4 total)

Figure 3

Page 6

INSTALLATION INSTRUCTION

INSTALLATION INSTRUCTION

6. Once all four (4) control pack screws have been

removed, gently lift the control pack off of the tie

plate and set aside to be further disassembled.

7. Remove the motor terminal buss bar insulator

after control pack has been removed.

Motor Terminal Buss Bar

Insulator

Figure 4

INSTALLING RELOCATION CABLES

1. Disassemble the control pack by removing the

four (4) flat head torx drive screws.

2. Gently lift the control pack cover off of the

contactor plate assembly. The cover should

remain wired to the contactor during this

assembly process. Simply move the cover to

one side or out of the way while working on the

contactor. This cover will be reinstalled.

Remove

Figure 5

3. Remove terminal nuts and lock washers securing

the three buss bars to the contactor (see Figure 6).

Set aside terminal nuts and lock washers, as they

will be used later on. Buss bars will not be used

for new installation.

4. Loosen the two flat head torx drive screws

securing the contactor to the contactor plate.

Only loosen. Do not remove.

5. Using the terminal nuts and lock washers

removed in previous step, connect the

labeled cables (A, F1 and F2) to corresponding

contactor terminal. Torque nuts to 8.5 - 9 N-m

(75-80 in. lb.). Refer to Figure 7.

6. Tighten the two flat head torx drive screws

and nuts used to secure the contactor to the

contactor plate. Secure fasteners to specified

torque requirements in torque specification chart

found in these instructions.

7. Once the cables have been installed, reinstall

the cover using the four (4) flat head torx drive

screws previously removed. Refer to the torque

section of this document.

WARN INDUSTRIES

7 89969A0

Buss Bars

Loosen

Screws (2x)

Figure 6

A

F2

Tighten

screws (2x)

F1

F2

A

F1

Figure 7

RELOCATING THE CONTROL PACK

To prevent serious injury or death from

WARNING

electrical fi re:

Never route electrical cables across sharp edges.

Never route electrical cables near parts that get

hot.

Never route electrical cables through or near

moving parts.

Avoid pinch and wear/abrasion points when

installing all electrical cables.

1. (Optional) Depending on your specific

relocation kit, you can attach the shown

bracket, for easier mounting, using the supplied

hex head bolts and lock washers. If you would

like to purchase the bracket shown please

contact: WARN Industries at 1-800-543-9276 or

visit www.warn.com.

2. Find an appropriate mounting location to

mount the control pack. Make sure to check

that the cables and ground wire can be routed

to the winch and that the control pack is easily

accessible and on a solid mounting surface.

Always verify area is clear of fuel lines, fuel

WARNING

tank, brake lines, electrical wires, etc., when drilling.

Never mount contactor with electrical

WARNING

terminals touching metal objects.

3. If using the mounting bracket, match drill the

5/16” holes in the bracket to the mounting

surface you choose to mount your control pack

to. Be sure to check the area before you drill to

avoid hitting any electrical cables or gas lines.

If opting not to use the mounting bracket,

you can use the attached template as a guide

for drilling mounting holes. Holes should be

drilled to 6.5mm diameter.

4. Mount the bracket using the supplied 5/16”

bolts with two (2) flat washers and nylock nuts

as shown. If opting not to use the mounting

bracket, M6 screws and lock washers must

be purchased separately to complete this

installation.

WARN INDUSTRIES

89969A0 8

Bracket

[Kit (89770)]

[Bracket only (89729)]

M6 Hex Head Screws

(included in kit)

[89970]

Figure 8

5/16” Bolts

2x Flat

Washers

Nylock Nuts

Figure 9

Page 7

INSTALLATION INSTRUCTION

INSTALLATION INSTRUCTION

CONNECTING THE CONTROL PACK

Loose or unsecured power cables can cause

WARNING

serious injury or death.

1. Attach the wire terminal housing to the motor

terminals on the winch using terminal nuts and

lock washer previously removed.

2. Install the cover plate and fasten with the two

supplied machine screws. Do not over tighten

screws, over tightening could damage the

plastic components.

3. Use the supplied butt splice connector and the

black extension wire to lengthen the contactor

ground wire (see Figure 11).

4. Reconnect the ground cable and small black

wire to winch motor ground. Ensure the

ground wire is securely fastened. Secure

fasteners to specified torque requirements

in torque specification chart found in these

instructions.

5. Carefully inspect electrical cable routing. Is

it neat and tidy? Zip tie and secure electrical

cables. Zip ties should be snug, but not cutting

into wire insulation. Use electrical tape, pieces

of rubber hose or electrical conduit to protect

electrical cables and wire harness where

needed to avoid electrical cable insulation wear

or abrasion.

6. Attach battery cables, red (positive) cable

FIRST, black (negative) second. Install boots

as appropriate to protect connections. Torque

battery terminal fasteners as directed by vehicle

service manual.

7. Make sure to plug in the winch remote and

ensure that drum is turning in the proper

direction when spooling in/out before using in

the field.

OUT

Cover Plate

Figure 10

Ground Wire

Figure 11

Figure 12

Wire Terminal Housing

Butt Connector

Mounting Hole Drill Template

4.41

(112)

Template NOT to scale

3.70

(94)

IN

8. Installation complete.

WARN INDUSTRIES

9 89969A0

WARN INDUSTRIES

89969A0 10

Page 8

Loading...

Loading...