Page 1

English

Printed in China

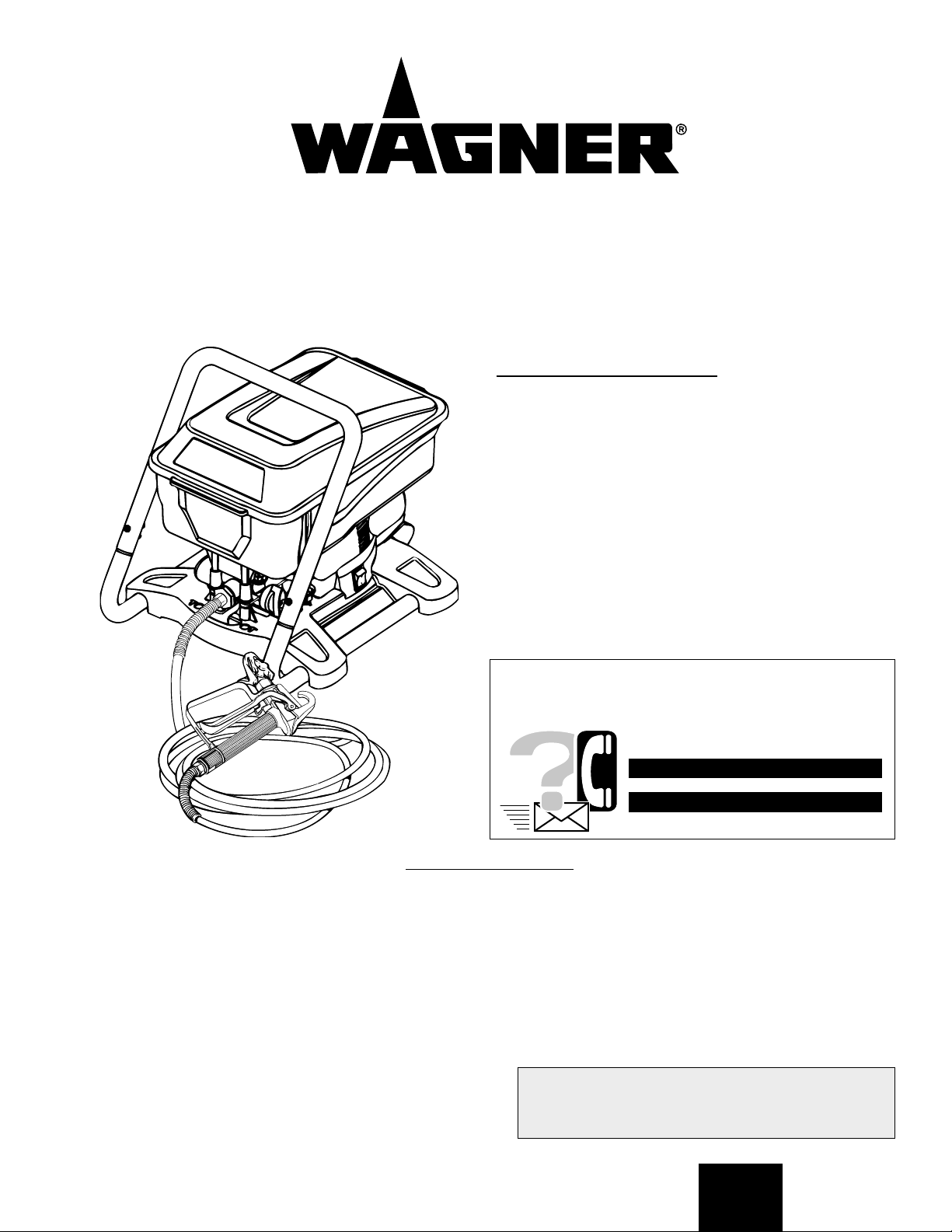

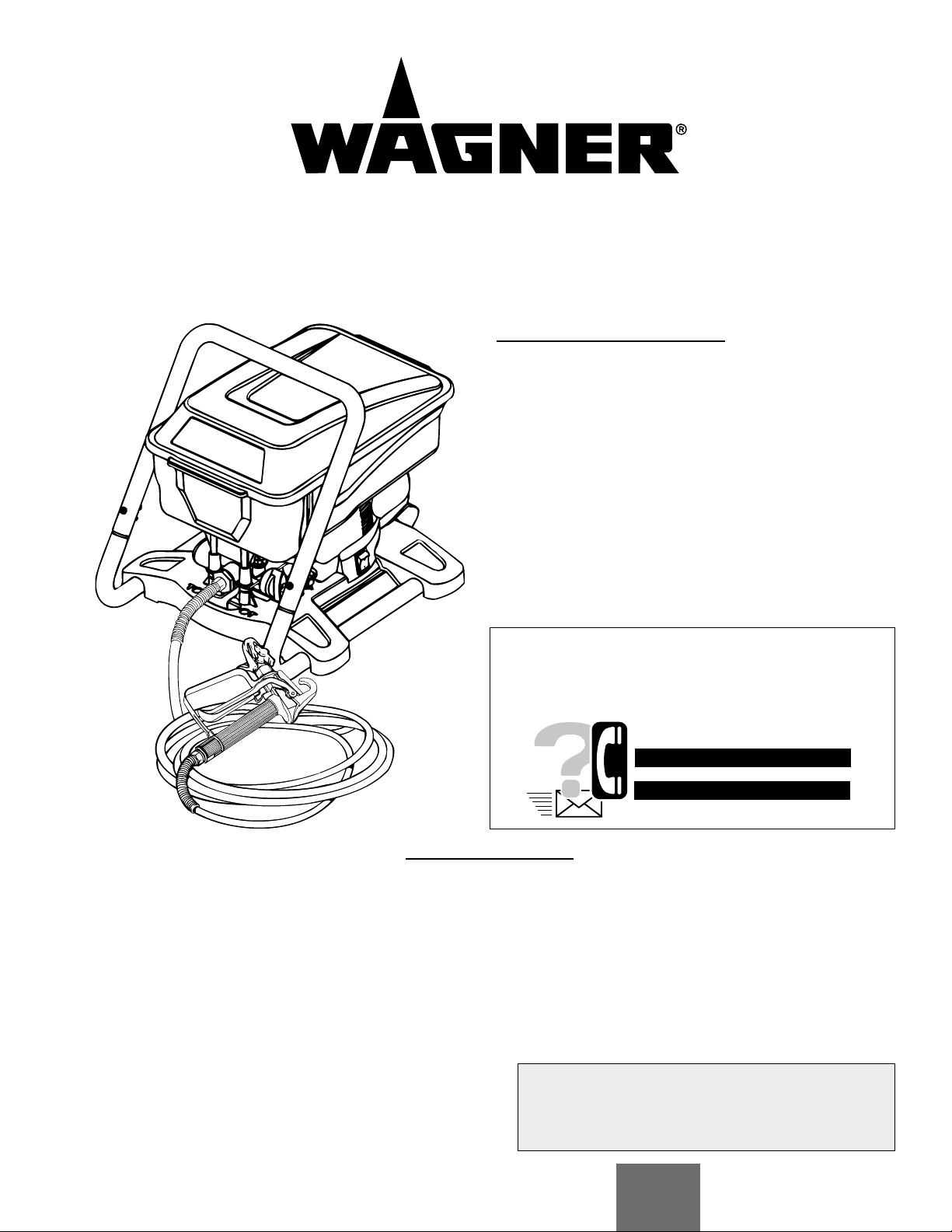

PAINT CREW

®

HIGH PERFORMANCE AIRLESS SPRAYER

TABLE OF CONTENTS:

SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

BEFORE YOU BEGIN SPRAYING . . . . . . . . . . . . . . . . . . . . 5

PURGING AND PRIMING. . . . . . . . . . . . . . . . . . . . . . . . . . . 6

SPRAYING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

SPRAYING TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . 8

CLEANUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

INLET/OUTLET VALVES. . . . . . . . . . . . . . . . . . . . . . . . . . . 10

STORAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37-38

SERVICE CENTER LIST . . . . . . . . . . . . . . . . . . . . . . . . 39-43

WARRANTY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

OWNER’S MANUAL • READ THIS MANUAL FOR COMPLETE INSTRUCTIONS

0503 • Form No. 0515801D

S

PECIFICATIONS:

Weight .............................. 25 lbs.

Capacity ........................... 2 gallon hopper

Power source ...................3/8 Hp universal motor

Power requirement...........15 amp minimum circuit on 120 VAC,

60 Hz current

Generator .........................8000 W

Spraying pressure............2800 PSI

Safety features.................Spray gun trigger lock and guard;

built-in tip safety guard; priming

knob for safe pressure release.

Conforms to UL STD 1450.

Certified to CAN/CSA C 22.2

NO 68-92.

Capability..........................Sprays a variety of paints, oil

base, latex, primers, stains,

preservatives and other

nonabrasive materials.

Do not use materials with flash

points below 70°F (21°C).

This pump should not be used with textured materials,

block filler, lacquers, industrial enamels, or asphalt

sealer or materials containing HHC. See coating

supplier if flash point is not listed on the container.

Need help? Call us first for answers fast.

Call Wagner Spray Tech toll-free if you have any

comments or problems with this product.

1-800-328-8251

Wagner Technical Service

Visit us on the world wide web!

http://www.wagnerspraytech.com

1770 Fernbrook Lane, Minneapolis, MN 55447

Page 2

HAZARD: INJECTION INJURY

A high pressure paint stream produced by this

equipment can pierce the skin and underlying

tissues, leading to serious injury and possible

amputation. SEE APHYSICIAN IMMEDIATELY.

DO NOT TREAT AN INJECTION INJURY AS A SIMPLE CUT!

Injection can lead to amputation. See a physician

immediately.

The maximum operating range of the gun is 2800

PSI/193BAR fluid pressure.

PREVENTION:

• NEVER aim the gun at any part of the body.

• NEVER allow any part of the body to touch the fluid stream.

DO NOT allow body to touch a leak in the fluid hose.

• NEVER put your hand in front of the gun. Gloves will not

provide protection against an injection injury.

• ALWAYS lock the gun trigger, shut the pump off, and release

all pressure before servicing, cleaning the tip or guard,

changing tip, or leaving unattended. Pressure will not be

released by turning off the motor. The PRIME/SPRAY knob

must be turned to PRIME to relieve the pressure. Refer to

the PRESSURE RELIEF PROCEDURE (page 5) described

in the pump manual.

• ALWAYS keep the tip guard in place while spraying. The tip

guard provides some protection but is mainly a warning

device.

• ALWAYS remove the spray tip before flushing or cleaning

the system.

• Paint hose can develop leaks from wear, kinking and abuse.

A leak can inject material into the skin. Inspect the hose

before each use.

• NEVER use a spray gun without a working trigger lock and

trigger guard in place.

• All accessories must be rated at or above 2800 PSI/193 BAR.

This includes spray tips, guns, extensions, and hose.

NOTE TO PHYSICIAN:

Injection into the skin is a traumatic injury. It is

important to treat the injury as soon as possible. DO

NOT delay treatment to research toxicity. Toxicity is a

concern with some coatings injected directly into the

blood stream. Consultation with a plastic surgeon or

reconstructive hand surgeon may be advisable.

2 1-800-328-8251 © 2003 Wagner Spray Tech - All rights reserved.

HAZARD: HAZARDOUS VAPORS

Paints, solvents, insecticides, and other

materials can be harmful if inhaled or come in

contact with the body. Vapors can cause

severe nausea, fainting, or poisoning.

PREVENTION:

• Use a respirator or mask if vapors can be

inhaled. Read all instructions supplied

with the mask to be sure it will provide the

necessary protection.

• Wear protective eyewear.

• Wear protective clothing as required by coating

manufacturer.

HAZARD: EXPLOSION OR FIRE

Solvent and paint fumes can explode or ignite.

Property damage and/or severe injury can occur.

PREVENTION:

• Provide extensive exhaust and fresh air

introduction to keep the air within the spray area free from

accumulation of flammable vapors.

• Avoid all ignition sources such as static

electric sparks, open flames, pilot lights,

electrical appliances, and hot objects.

Connecting or disconnecting power cords

or working light switches can make sparks.

• Do not smoke in spray area.

• Fire extinguisher must be present and in good working

order.

• Place paint pump at least 20 feet from the spray object in a

well ventilated area. Flammable vapors are often heavier

than air. Floor area must be extremely well ventilated. The

paint pump contains arcing parts that emit sparks and can

ignite vapors.

• The equipment and objects in and around the spray area

must be properly grounded to prevent static sparks.

• Use only conductive or grounded high pressure fluid hose.

Gun must be grounded through hose connections.

• Power cord must be connected to a grounded circuit.

• Always flush unit into a separate metal container, at low

pump pressure, with spray tip removed. Hold gun firmly

against side of container to ground container and prevent

static sparks.

• Follow the material and solvent manufacturer's warnings

and instructions.

• Do not use materials with a flashpoint below 70° F (21°

C). Flashpoint is the temperature that a fluid can produce

enough vapors to ignite.

• Plastic can cause static sparks. Never hang plastic to

enclose a spray area. Do not use plastic drop cloths

when spraying flammable materials.

• Use lowest possible pressure to flush equipment.

English

SAFETY INFORMATION • READ ALL SAFETY

INFORMATION BEFORE OPERATING THE EQUIPMENT

Page 3

HAZARD: EXPLOSION HAZARD DUE TO

INCOMPATIBLE MATERIALS

Will cause property damage or severe injury.

PREVENTION:

• Do not use materials containing bleach or

chlorine.

• Do not use halogenated hydrocarbon solvents such as

bleach, mildewcide, methylene chloride and 1,1,1 trichloroethane. They are not compatible with aluminum.

• Contact your coating supplier about the compatibility of

material with aluminum.

HAZARD: GENERAL

Can cause severe injury or property damage.

PREVENTION:

• Read all instructions and safety precautions before operating

equipment.

• Follow all appropriate local, state, and national codes

governing ventilation, fire prevention, and operation.

• The United States Government Safety Standards have been

adopted under the Occupational Safety and Health Act

(OSHA). These standards, particularly part 1910 of the

General Standards and part 1926 of the Construction

Standards should be consulted.

• Use only manufacturer authorized parts. User assumes all

risks and liabilities when using parts that do not meet the

minimum specifications and safety requirements of the pump

manufacturer.

• Before each use, check all hoses for cuts, leaks, abrasion

or bulging of cover. Check for damage or movement of

couplings. Immediately replace the hose if any of these

conditions exist. Never repair a paint hose. Replace it with

another grounded high-pressure hose.

• All hoses, swivels, guns, and accessories must be pressure

rated at or above 2800PSI/193 BAR.

• Do not spray outdoors on windy days.

• Wear clothing to keep paint off skin and hair.

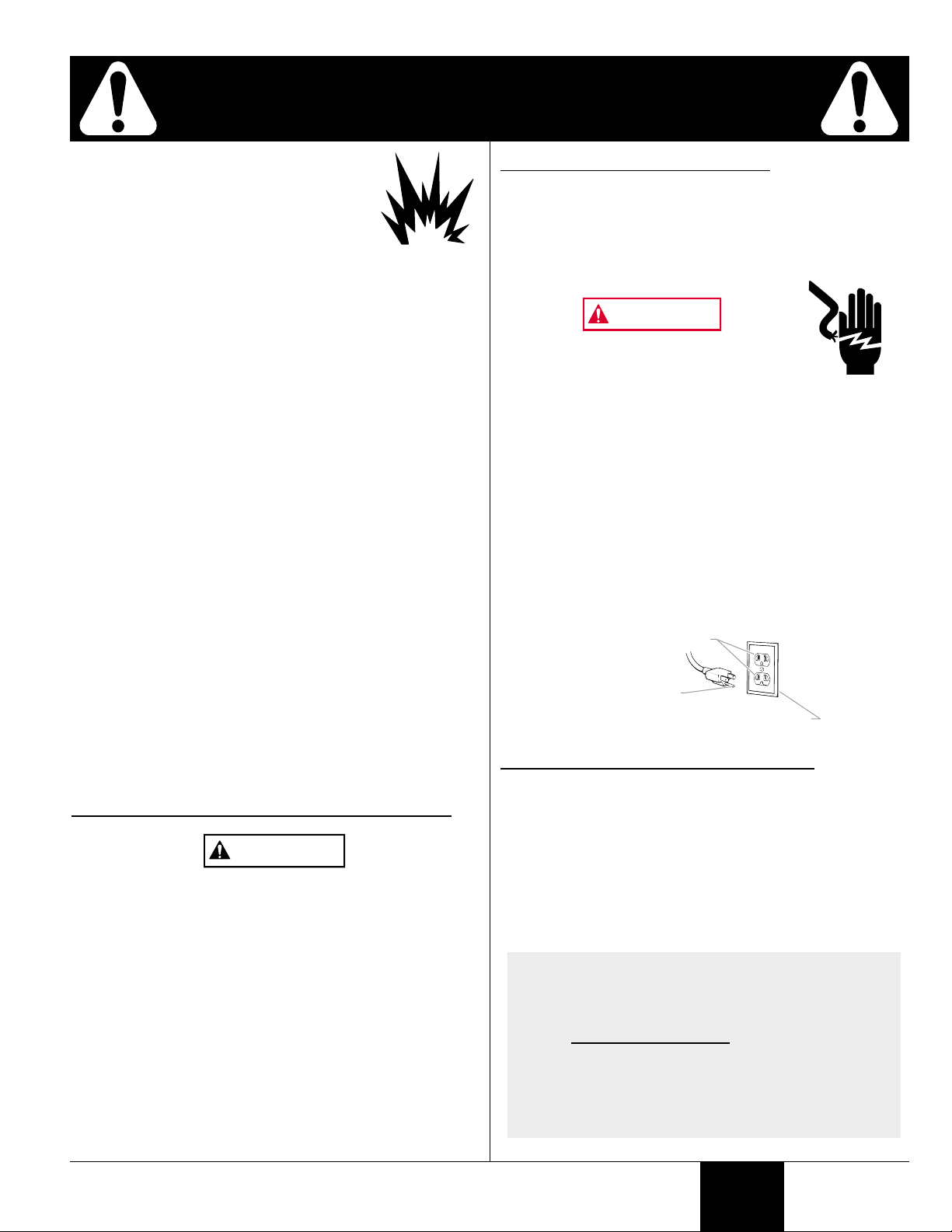

I

MPORTANT ELECTRICAL INFORMATION

Use only a 3-wire extension cord that has a 3-blade grounding plug

and a 3-slot receptacle that will accept the plug on the product.

Make sure your extension cord is in good condition. When using

an extension cord, be sure to use one heavy enough to carry the

current your product will draw. An undersized cord will cause a

drop in line voltage resulting in loss of power and overheating. A14

or 12 gauge cord is recommended. If an extension cord is to be

used outdoors, it must be marked with the suffix W-Aafter the cord

type designation. For example, a designation of SJTW-A would

indicate that the cord would be appropriate for outdoor use.

• Always disconnect the motor from the power supply and

relieve hose pressure before working on the equipment.

GROUNDING INSTRUCTIONS

This product must be grounded. In the event of an electrical

short circuit, grounding reduces the risk of electric shock by

providing an escape wire for the electric current. This product is

equipped with a cord having a grounding wire with an

appropriate grounding plug. The plug must be plugged into an

outlet that is properly installed and grounded in accordance with

all local codes and ordinances.

Improper installation of the grounding plug

can result in a risk of electric shock.

If repair or replacement of the cord or plug is

necessary, do not connect the green grounding wire to either flat

blade terminal. The wire with insulation having a green outer

surface with or without yellow stripes is the grounding wire and

must be connected to the grounding pin.

Check with a qualified electrician or serviceman if the grounding

instructions are not completely understood, or if you are in doubt

as to whether the product is properly grounded. Do not modify

the plug provided. If the plug will not fit the outlet, have the

proper outlet installed by a qualified electrician.

This product is for use on a nominal 120 volt circuit and has a

grounding plug that looks like the plug illustrated below. Make

sure that the product is connected to an outlet having the same

configuration as the plug. No adapter should be used with this

product.

PRODUCT REGISTRATION CARD

Send in your product registration card or register online at

www.wagnerspraytech.com. Proper registration will serve as

proof of purchase in the event your original receipt becomes

misplaced or lost. Returning this card will expedite the

processing of your warranty. Be sure you write your unit’s date

code on the card before sending it. The date code is located

underneath the base of your unit (for example, S087R). The

additional information will also help us to develop new products

that best meet your needs and desires. If you have any

questions or concerns regarding your registration card, please

call our registration card center at 1-303-394-9077.

IF YOU EXPERIENCE PROBLEMS WITH YOUR

SPRA YER AT ANY TIME DURING ASSEMBLY

,

OPERA TION OR CLEANUP, PLEASE REFER TO

THE TROUBLESHOOTING

SECTION OF THIS

MANUAL

(PAGE 12), OR CALL CUSTOMER

SERVICE A T

:

1-800-328-8251

WARNING

© 2003 Wagner Spray Tech - All rights reserved. 1-800-328-8251 3

English

SAFETY INFORMATION • READ ALL SAFETY

INFORMATION BEFORE OPERATING THE EQUIPMENT

CAUTION

Grounded Outlet

Grounding Pin

Cover for grounded outlet box

Page 4

Customer Service: 800-328-8251 4 © 2003 Wagner Spray Tech - All rights reserved.

English

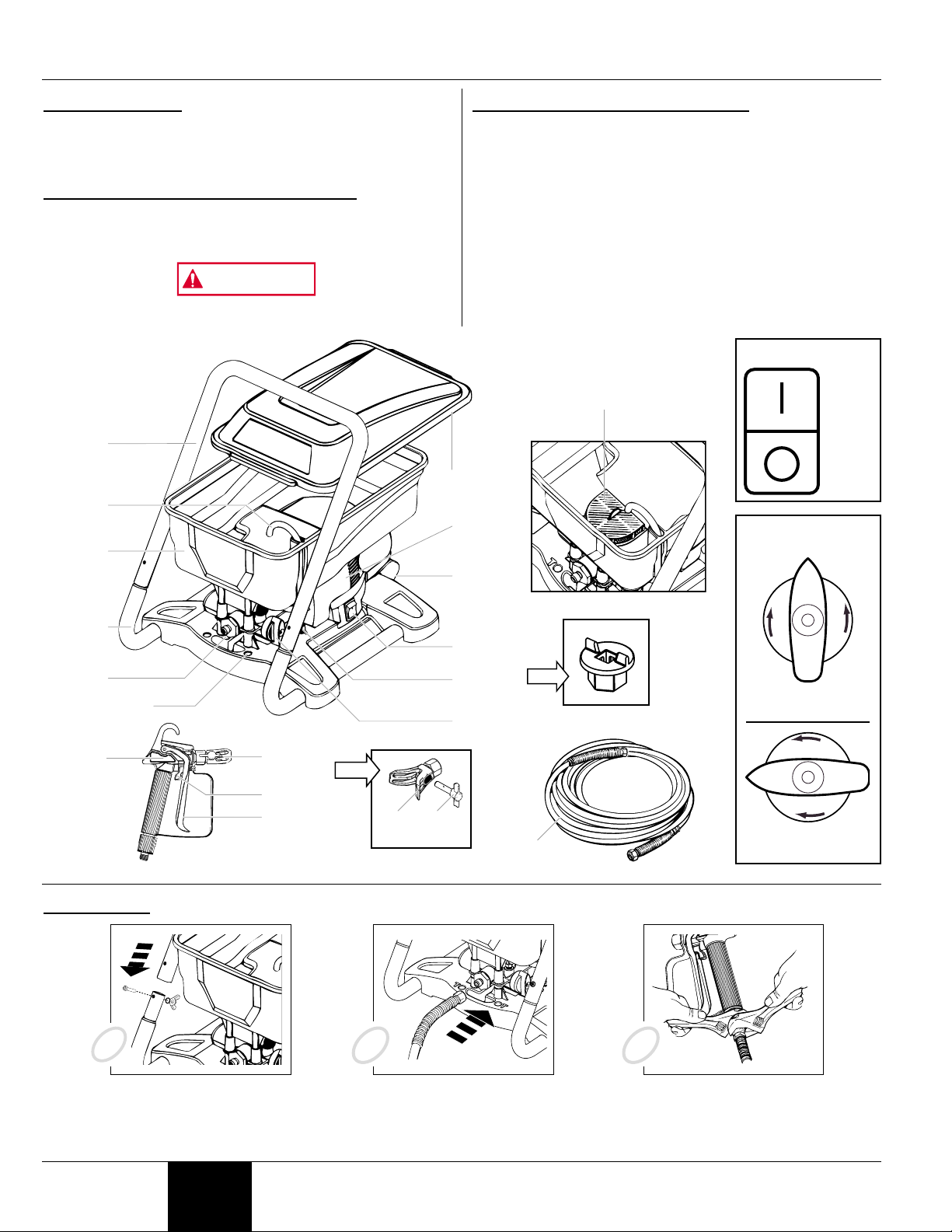

COMPONENTS AND ASSEMBLY

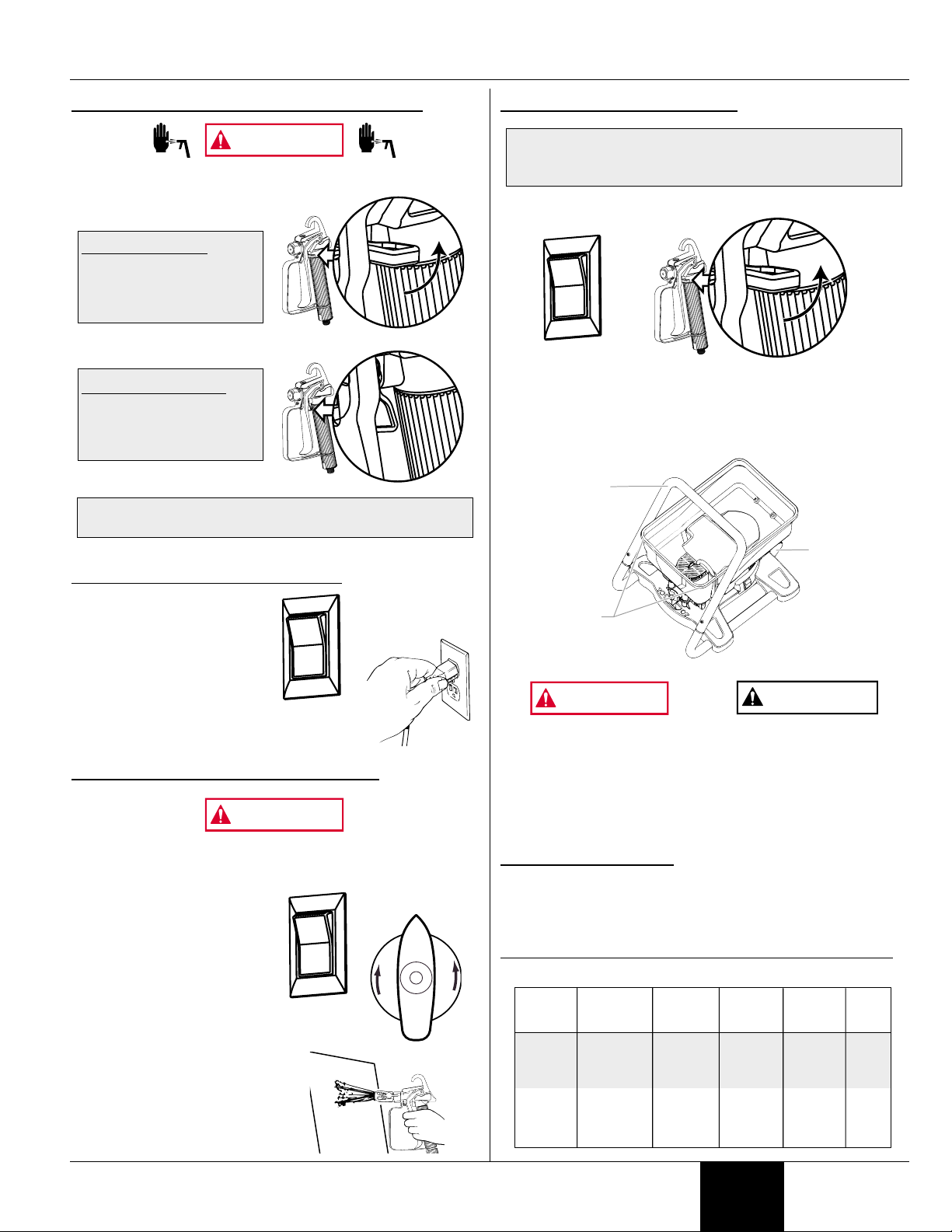

COMPONENTS

• Spray gun with filter

• Spray tip assembly

• 25 foot long, 1/4 inch diameter high pressure hose.

TOOLS NEEDED FOR ASSEMBLY

• Two adjustable wrenches.

• Extension cord (refer to Important Electrical Information

(page 3).

Do not plug in the unit until setup is complete.

WARNING

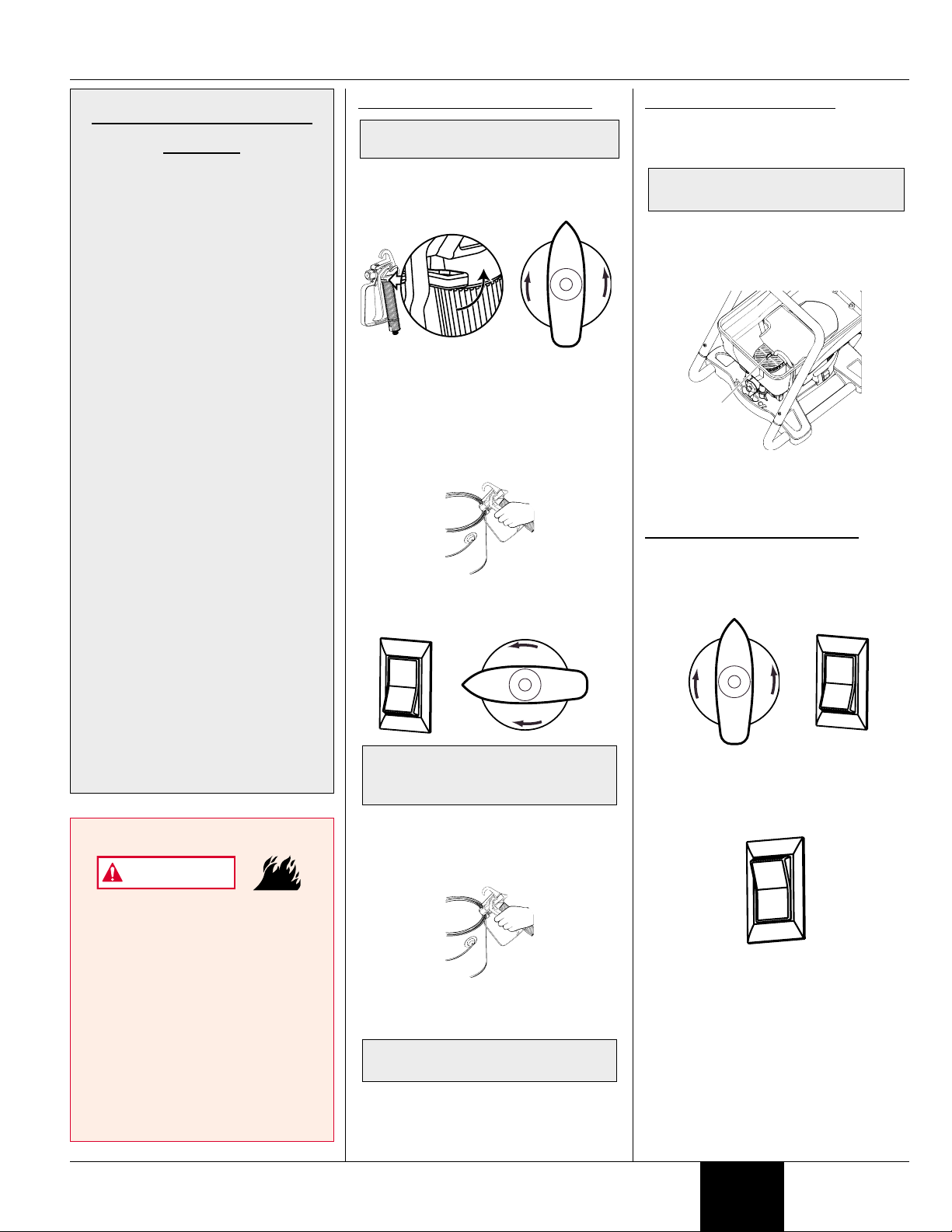

CONTROLS AND FUNCTIONS

ON/OFF switch .................The ON/OFF switch turns the unit on

and off (O = OFF, l = ON)

Spray Gun........................The spray gun controls the delivery of

the fluid being pumped.

Spray Hose.......................The spray hose connects the gun to

the pump.

Return Tube.......................Fluid is sent back out through the return

tube to the hopper when priming.

PRIME/SPRAY knob ........The PRIME/SPRAY knob directs fluid

to the spray hose when set to SPRAY,

or the return tube when set to PRIME.

ASSEMBLY

Place the handle over the unit

frame. Insert the bolts and tighten

the wing nuts over the lock washers.

Thread one end of the high pressure

spray hose to the outlet valve.

Tighten with an adjustable wrench.

Attach return tube to hopper.

Thread the other end of the hose to

the spray gun. Hold the gun with

one adjustable wrench, and tighten

the hose nut with the other.

Spray

hose

Rear

handle

Motor

housing

ON/OFF

switch

Inlet valve

tool

PRIME/SPRAY

knob

Hopper lid

Spray tip

assembly

Trigger lock

Trigger

Handle

Inlet filter

(inside of hopper)

Return

tube

Frame

Outlet

valve

Tip

storage

Spray

gun

Hopper

TipTip

guard

ON/OFF Switch

= ON

= OFF

PRIME/SPRAY

knob

1

2

SPRAY

PRIME

PRIME

position

SPRAY

PRIME

SPRAY

position

3

Page 5

© 2003 Wagner Spray Tech - All rights reserved. 5 Customer Service: 800-328-8251

English

LOCKING

AND UNLOCKING THE GUN

Always lock the trigger off when attaching the spray tip or

when the spray gun is not in use.

PLUGGING IN THE SPRAYER

1. Check that the ON/OFF

switch is in the OFF

postion.

2. Plug the sprayer into a

heavy duty grounded

extension cord (refer to

Important Electrical

Information, page 3).

PRESSURE RELIEF PROCEDURE

Be sure to follow the pressure relief procedure when

shutting the unit off FOR ANY PURPOSE. This procedure is

used to relieve pressure from the spray hose.

1. Lock the spray gun off and

flip the ON/OFF switch to

the OFF position.

2. Turn the PRIME/SPRAY

knob to PRIME.

3. Unlock the spray gun and

then trigger it onto a scrap

piece of wood or cardboard.

4. Lock the spray gun.

WARNING

The spray tip SHOULD NOT be attached until after the

sprayer and spray hose has been purged and primed.

UNLOCKING THE GUN

To unlock the gun, turn the

trigger lock to be in line with

the trigger.

LOCKING THE GUN

The gun is secured when

the trigger lock is at a 90°

angle (perpendicular) to the

trigger in either direction.

WARNING

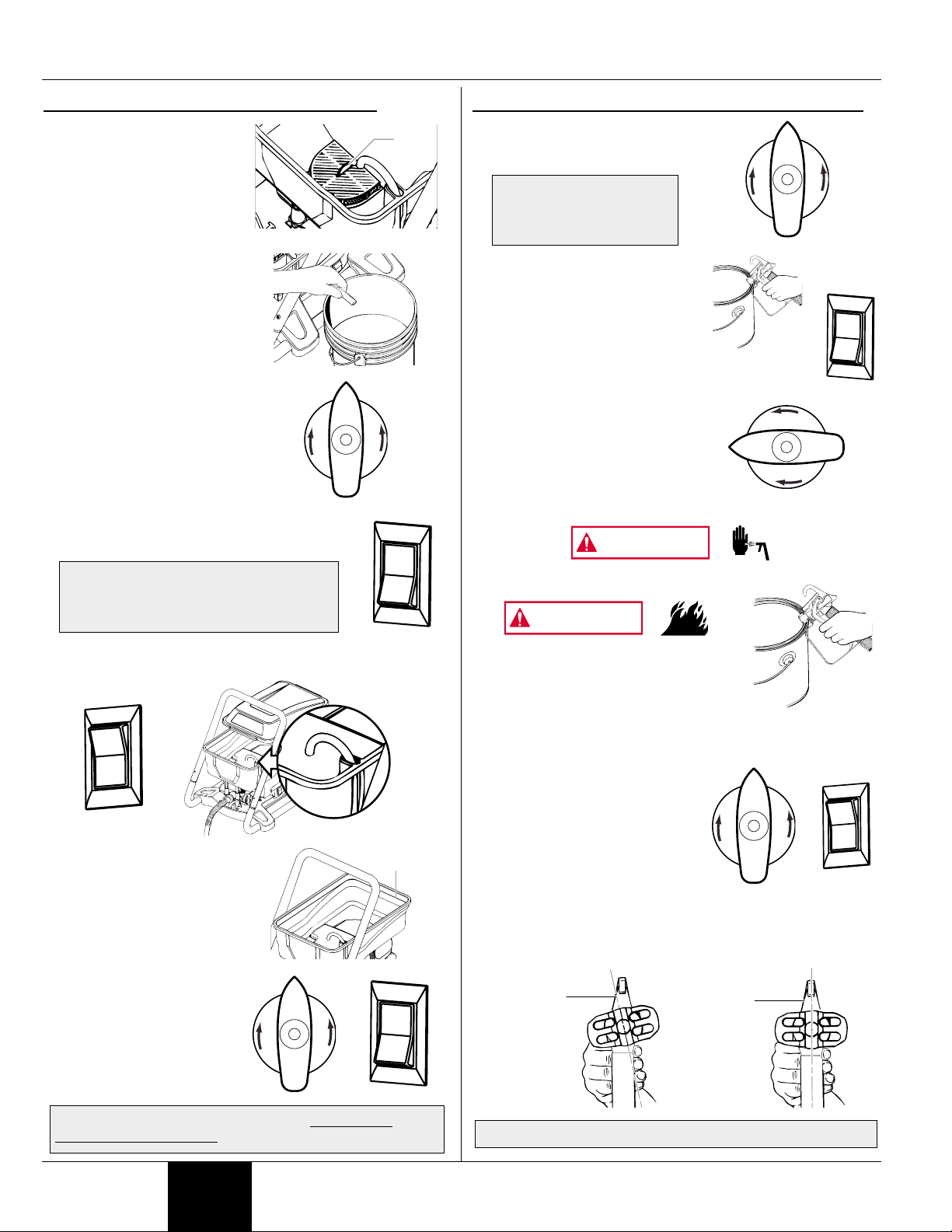

EMPTYING

THE HOPPER

1. Perform all the steps of the Pressure Relief Procedure (page 5).

2. Remove the lid from the hopper.

3. Grab top handle of the sprayer with one hand, grab rear

handle with the other.

4. Lift and tilt the sprayer so that material will pour from one of

the front corners of the hopper and into its original container.

PAINT STRAINING

It is recommended that in order to avoid premature tip and filter

clogging you should strain your paint before spraying. Follow

manufacturer’s recommendations.

C

HOOSING THE CORRECT SPRAY GUN FILTER

Use the proper gun filter based on the tip size being used.

Make sure your floors and

furnishings are protected

with drop cloths to avoid

property damage.

The unit, when filled with

spraying material, can be

heavy. Make sure to lift

with your legs and not your

back in order to reduce the

risk of injury.

WARNING

Follow these instructions if the hopper is filled with material

and 1) your sprayer malfunctions or 2) you finish your

spraying project without using all the material in the hopper.

BEFORE YOU BEGIN --

THIS PAGE CONTAINS INFORMATION THAT WILL BE

REPEATED THROUGHOUT THE MANUAL

.

O

Top

handle

Rear

handle

O

O

PRIME

SPRAY

Front

corners

CAUTION

Part No. Tip Size Filter

Type

0154918 .011 Extrafine

0154675 .013 - .015 Fine

Mesh

Number

180 mesh

0.084 mm

100 mesh

0.140 mm

Filter

Body

red

yellow

Qty.Color of

2 pack

2 pack

Page 6

PURGING

AND PRIMING THE PUMP

1. Make sure the inlet filter is in

place inside the hopper. If it

is not, snap in place as

shown.

2. Push the tab on top of the

filter down once. This will

ensure proper operation of

the inlet valve.

3. Pull the return tube from the

hopper and hold it over a

waste container.

4. Turn the PRIME/SPRAY

knob to PRIME.

5. Plug in the sprayer, and move the ON/OFF

switch to the ON position.

6. Switch the pump to OFF. Remove the return

tube from the waste container and secure it to the hopper.

7. Fill your hopper with the

material you plan to spray.

Do not exceed the fill line

as shown. Replace the

hopper lid.

8. Leave the PRIME/SPRAY

knob on PRIME and switch

your unit ON once more

and make sure that material

is flowing from the return

tube.

Your sprayer is now purged. Move to Purging and

Priming the Spray Hose.

Any fluids remaining in the pump and

the return tube will flow out of the

return tube. Let the pump run until no

fluid is coming from the return tube.

Customer Service: 800-328-8251 6 © 2003 Wagner Spray Tech - All rights reserved.

PURGING

AND PRIMING THE SPRA Y HOSE

1. Unlock the spray gun and turn

the PRIME/SPRAYknob to

PRIME.

2. Trigger and HOLD the spray

gun into a waste container

(see warnings below).

3. While holding the trigger,

switch the pump ON.

4. While holding the trigger, turn

the PRIME/SPRAYknob to

SPRAY. Hold the trigger until

all air, water, or solvent is

purged from the spray hose

and paint is flowing freely (read

warnings below).

Keep hands clear from fluid stream.

Using a metal container, ground the gun

by holding it against the edge of the

container while flushing. Failure to do

so may lead to a static electric

discharge which may cause a fire.

If the PRIME/SPRAY knob is still on SPRAY, there will be high

pressure in the hose and spray gun until the PRIME/SPRAY

knob is turned to PRIME.

5. Release trigger, turn the

PRIME/SPRAY knob to PRIME

and turn pump OFF .

6. Trigger the gun into the waste

container once more to be sure

that no pressure is left in the

hose.

7. Lock the spray gun off.

8. Thread the spray tip assembly onto the gun. Tighten by

hand.

Your hose is now purged and primed.

WARNING

WARNING

Your spray tip SHOULD

NOT be attached to your

spray gun when purging

your spray hose.

English

PURGING AND PRIMING

PRIME

Tab

SPRAY

SPRAY

PRIME

l

SPRAY

PRIME

l

O

Fill line

SPRAY

PRIME

l

Begin

tightening

the tip at

this angle

to achieve

the desired

spray angle

when tight.

PRIME

SPRAY

O

Page 7

© 2003 Wagner Spray Tech - All rights reserved. 7 Customer Service: 800-328-8251

English

PRACTICE

Be sure that the paint hose is free of kinks and clear of

objects with sharp cutting edges.

1. Switch the pump ON

and turn the

PRIME/SPRAY knob to

SPRAY.

2. When the motor shuts

off, unlock the spray gun

and spray a test area to

check the spray pattern.

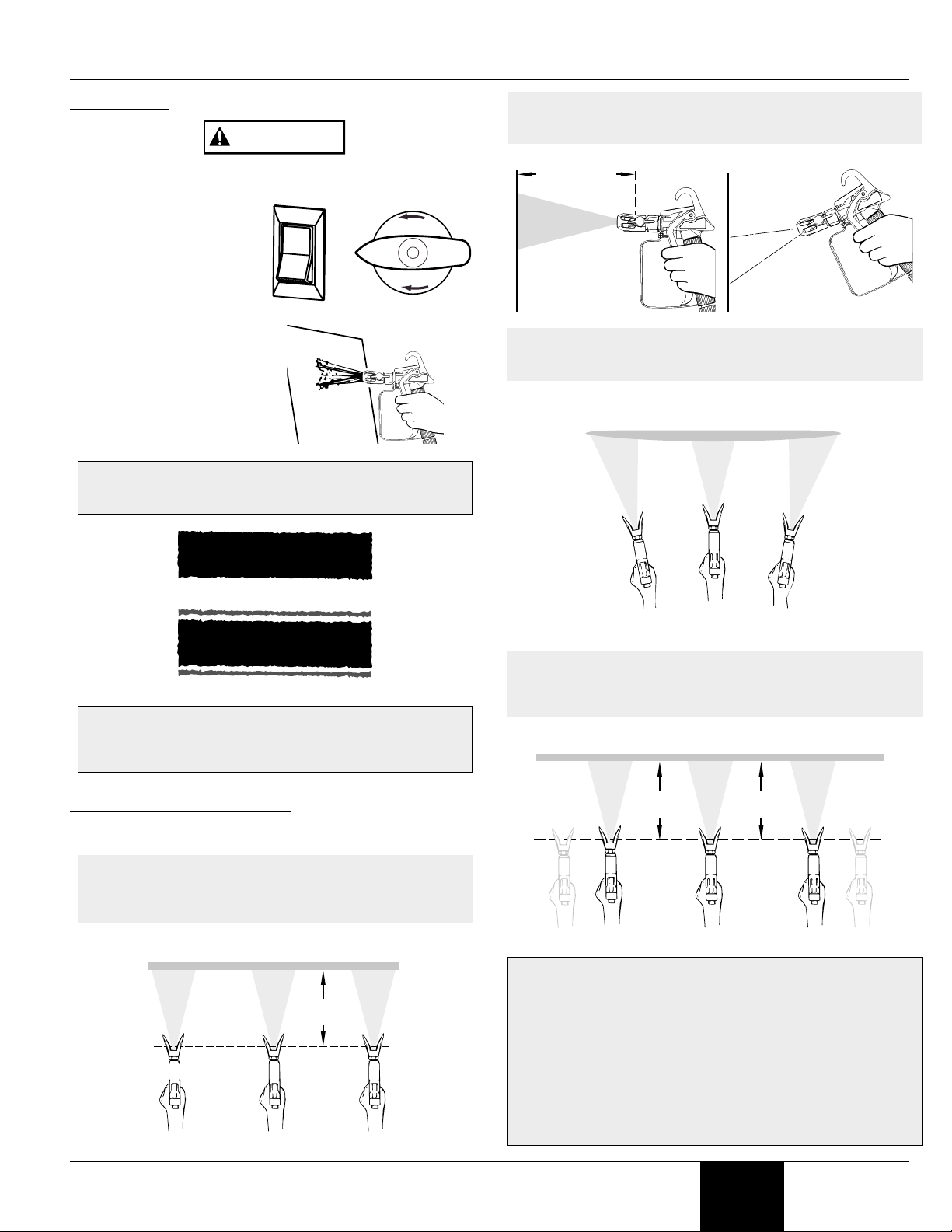

SPRAYING TECHNIQUE

The key to a good paint job is an even coating over the entire

surface. This is done by using even strokes. Follow the TIPS, below.

Keep stroke smooth and at an even speed.

Even coat throughout

Approximately

10 to 12 inches

TIP: Keep your arm moving at a constant speed and

keep the spray gun at a constant distance from the

surface. The best spraying distance is 10 to 12

inches between the spray tip and the surface.

If your pattern is tailing, your spray tip might have an

obstruction, your spray gun filter might be clogged or

your spray tip might be worn. Refer to Spraying

Troubleshooting on the next page.

Good spray pattern

Bad spray pattern (tailing)

When enough pressure has built up in the hose, the

motor will shut off automatically. The motor will cycle on

and off automatically as it needs pressure.

ADDITIONAL TIPS

Overlap each stroke by about 30%. This will ensure an even

coating.

When you stop painting, follow PRESSURE RELIEF

PROCEDURE and unplug electrical cord.

Keep the hopper lid placed on the hopper during spraying.

This will prevent debris from falling into your spray material.

IF YOU EXPECT TO BE AWAY FROM YOUR SPRAYER FOR

MORE THAN ONE HOUR, FOLLOW THE SHORT

-TERM

ST

ORAGE PROCEDURE DESCRIBED IN THE STORAGE

SECTION OF THIS MANUAL (page 11).

Proper way to trigger the spray gun

Approximately

10 to 12 inches

Keep stroke

even

Start stroke End strokePull trigger Release triggerKeep steady

TIP: The spray gun should be triggered by turning it on

and off with each stroke. Do not trigger the gun

during the middle of a stroke. This will result in an

uneven spray and splotchy coverage.

Heavy Coat

Do not flex wrist while spraying.

Light Coat Light Coat

TIP: Keep the spray gun at right angles to the surface.

This means moving your entire arm back and forth

rather than just flexing your wrist.

Right way

TIP: Keep the spray gun perpendicular to the surface,

otherwise one end of the pattern will be thicker

than the other.

SPRAYING

CAUTION

l

SPRAY

PRIME

Approximately

10 to 12 inches

Wrong way

Right way

Page 8

UNCLOGGING THE

SPRAY TIP

Do not attempt to unclog or clean the tip with your finger.

Do not use a needle or other sharp pointed instrument to

clean the tip. The hard tungsten carbide can chip.

If the spray pattern becomes distorted or stops completely while

the gun is triggered, follow these steps:

1. Turn the pump off, and release the trigger and lock the gun

off.

2. Rotate the reversible tip arrow 180° so that the point of the

arrow is toward the rear of the gun (CLEAN position).

3. Turn the PRIME/SPRAY knob

to SPRAY.

4. Unlock the gun and squeeze

the trigger, pointing the gun at

a scrap piece of wood or

cardboard. This allows

pressure in the spray hose to

blow out the obstruction. When

the nozzle is clean, paint will come out in a high pressure

stream.

5. Release the trigger and lock the gun off.

6. Reverse the tip so the arrow

points foward again (SPRAY

position).

7. Unlock the gun and resume

spraying.

If paint still will not spray from the spray tip, follow the

steps on the next column.

Under pressure, the spray tip

may be very difficult to turn.

Turn the PRIME/SPRAY knob

to PRIME and trigger the gun.

This will relieve pressure and

the tip will turn more easily.

WARNING

The following is a short list of minor difficulties you might

encounter while spraying. If any of these occur, it will reduce

the flow of material, making your spray pattern poor, or

material will fail to spray from the gun.

• Clogged spray tip

• Clogged gun filter

• Clogged inlet filter

Follow the guidelines on this page to correct any one of these

problems.

Customer Service: 800-328-8251 8 © 2003 Wagner Spray Tech - All rights reserved.

English

SPRAYING TROUBLESHOOTING

UNCLOGGING

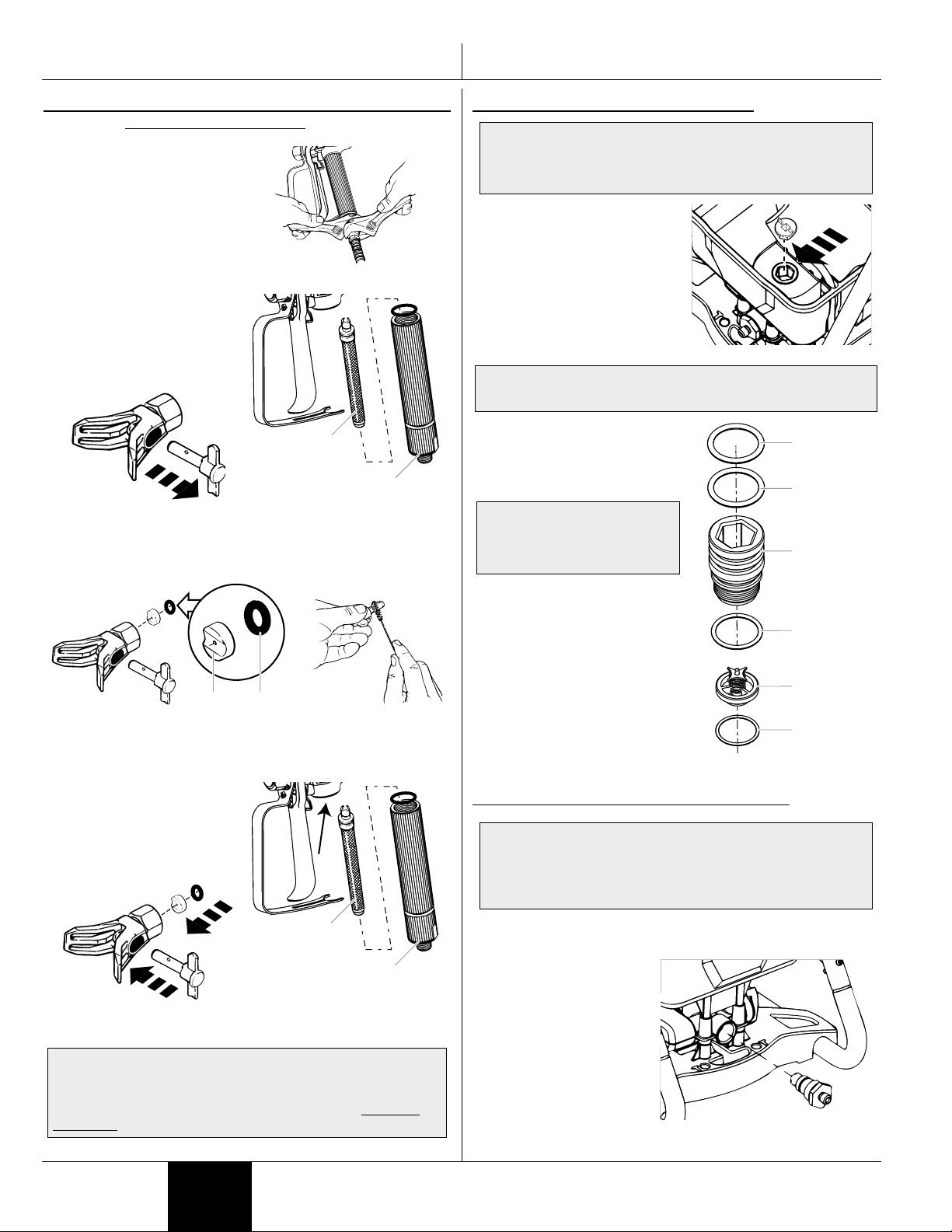

THE SPRAY GUN FILTER

1. Perform Pressure Relief Procedure (page 5).

2. Unclip the trigger guard from the filter housing by pulling

outward from the filter housing. Unscrew the housing.

3. Remove the filter from the spray gun housing and clean with

the appropriate cleaning solution (warm, soapy water for

latex paints, mineral spirits for oil-based materials).

4. Inspect the filter for holes (see Hole picture, above).

Replace if holes are found.

NEVER POKE THE FILTER WITH A SHARP INSTRUMENT!

5. Replace the cleaned filter, tapered end first, into the gun

housing.

6. Replace the housing and spring and snap the trigger guard

back into the housing.

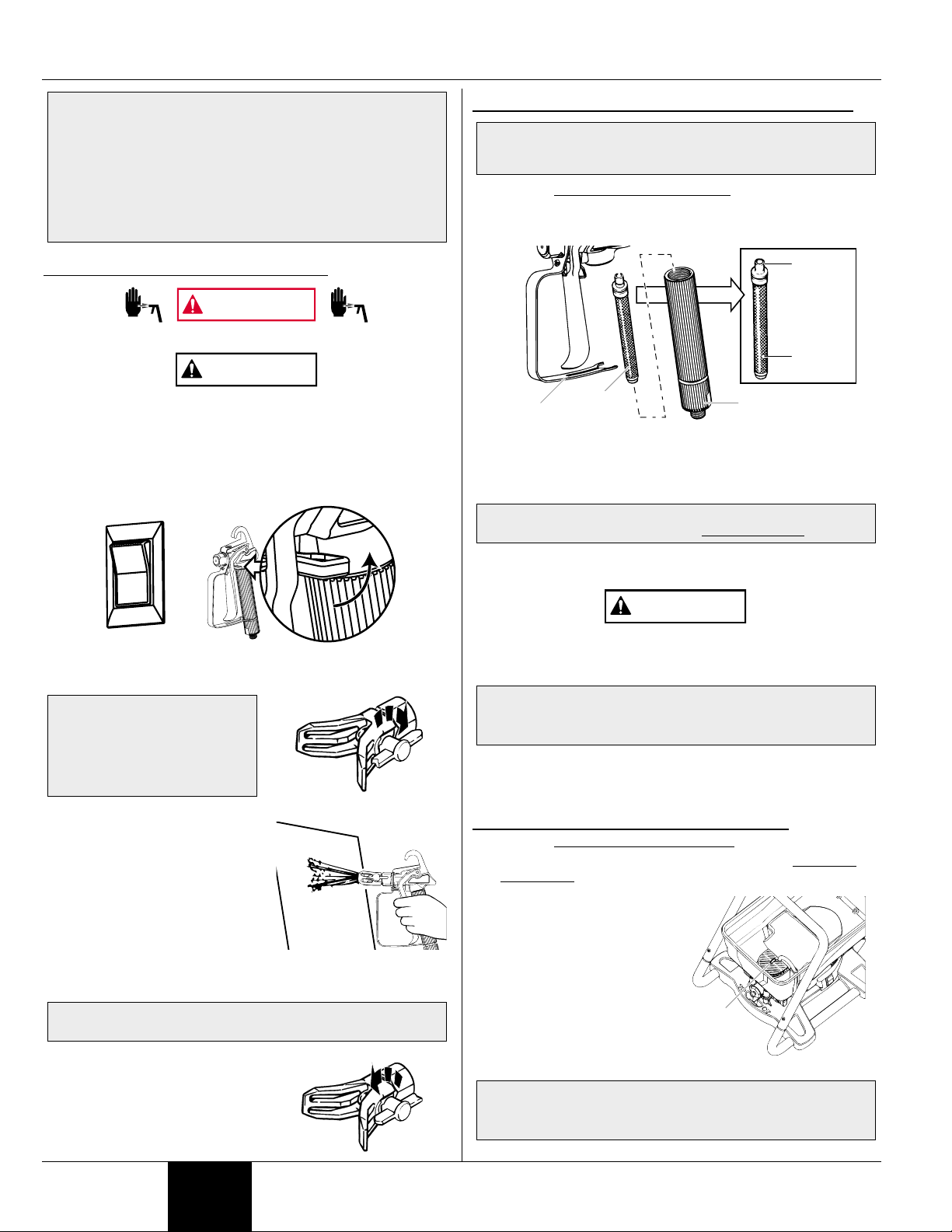

UNCLOGGING THE INLET FILTER

1. Perform Pressure Relief Procedure, (page 5).

2. Empty the hopper of all spraying material (see Emptying

the Hopper, page 5).

3. Remove the inlet filter from

the hopper. You may need

to use a screwdriver to pry

the filter loose.

4. Clean the inlet filter using

the appropriate cleaning

solution (warm, soapy water

with latex paints, mineral

spirits with oil-based paints

or stains).

5. Replace filter.

If after having completed all of the steps on this page you

are still experiencing problems spraying, refer to the

TROUBLESHOOTING page (page 12).

The tapered end of the filter must be loaded properly into

the gun. Improper assembly will result in a plugged tip

or no flow from the gun.

When cleaning filter, look for sediments in the spraying

material you are using. Refer to Paint Straining, (page 5).

T

This filter must be cleaned every time you use your

sprayer. When using thicker paints, the filter might need

to be cleaned more often.

CAUTION

rigger

guard

Filter

Housing

Filter top

(tapered

end)

Hole

O

CAUTION

Inlet

filter

Page 9

© 2003 Wagner Spray Tech - All rights reserved. 9 Customer Service: 800-328-8251

English

CLEANUP

IMPORTANT CLEANING

NOTES!

READ THESE NOTES AND

WARNINGS BEFORE YOU

START TO CLEAN YOUR

SPRAYER

!

• When using latex paints, clean

your sprayer and components

using warm, soapy water.

When using oil-based paints,

use mineral spirits.

• Do not use mineral spirits on

latex paint, or the mixture will

turn into a jelly-like substance

which is difficult to remove.

• No matter which cleaning

solution you use, make sure

to dispose of it properly when

finished cleaning your

sprayer.

• Thorough cleaning and

lubrication of the sprayer is

the most important step you

can take to ensure proper

operation after storage.

CALL 1-800-328-8251

IF YOU HAVE ANY QUESTIONS

REGARDING THE CLEANUP OF

YOUR SPRAYER

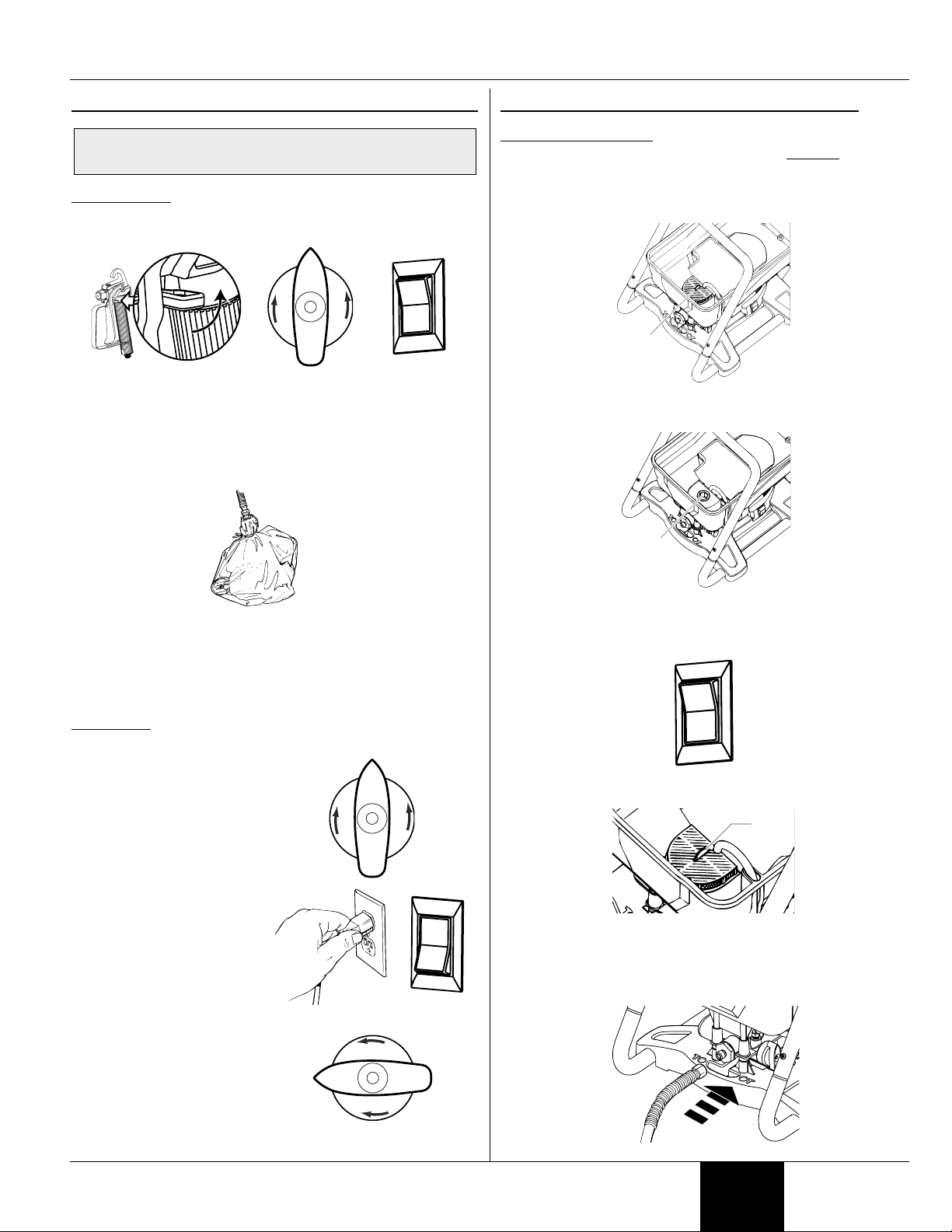

PURGING THE PAINT HOSE

1. Lock the gun, remove spray tip

assembly, and turn the

PRIME/SPRAY knob to PRIME.

2. Dump out any remaining spray material

from the hopper back into its container

(see Emptying the Hopper, page 5).

3. Fill the hopper with the appropriate

cleaning solution.

4. Hold the spray gun against the side of

the paint can and hold the trigger.

5. While holding the trigger, turn the

pump ON, and turn the

PRIME/SPRAYknob to SPRAY.

6. Release the trigger and turn the

PRIME/SPRAYknob to PRIME.

7. Hold the spray gun against the side of a

separate container and hold the trigger.

8. Turn the PRIME/SPRAY knob to

SPRAYand trigger the gun until the

fluid coming out of the gun is clear.

9. Turn the PRIME/SPRAY knob to

PRIME and trigger gun once more to

relieve pressure.

10. Move on to Rinsing the Hopper.

You might need to add more cleaning

solution to the hopper.

Let the pump run until all paint is

purged from the hose and cleaning

solution is coming out of the gun.

These steps will allow you to recover

excess paint left over in the paint hose.

RINSING THE HOPPER

1. Thoroughly rinse out the hopper

using the appropriate cleaning

solution.

2. Remove the inlet filter from the

bottom of the hopper and clean. You

may need to use a screwdriver to pry

the filter loose.

3. Replace the filter and properly

dispose of the cleaning solution.

FLUSHING THE SPRAYER

1. Fill the hopper with NEW cleaning

solution.

2. Turn the PRIME/SPRAY knob to

PRIME, turn the pump to ON .

3. Let the pump circulate the cleaning

solution out the return tube for 2-3

minutes.

4. Turn the pump OFF .

5. Properly dispose of cleaning solution

and move on to Cleaning the Spray

Gun Components, next page.

Make sure you do not drip any cleaning

solution into the motor housing.

Special cleanup instructions for use with

flammable solvents:

• ALWAYS FLUSH SPRAY GUN

ONE FULL HOSE LENGTH AWAY

FROM SPRAY PUMP.

• If collecting flushed solvents in

one gallon metal container, place

it into an empty five gallon

container, then flush.

• Area must be free from vapors.

• Follow all cleanup instructions.

WARNING

SPRAY

PRIME

l

SPRAY

Inlet

filter

SPRAY

l

PRIME

PRIME

O

Page 10

CLEANING

THE SPRAY GUN COMPONENTS

1. Perform Pressure Relief Procedure, page 5.

2. Remove spray gun from the

paint hose using adjustable

wrenches.

3. Remove filter from spray gun

(refer to Unclogging the

Spray Gun Filter, page 8).

4. Remove spray tip from

spray guard assembly.

5. Clean spray tip and filter with a soft-bristled brush and the

appropriate cleaning solution. Be sure to remove and clean

the washer and saddle seat located in the rear of the spray

tip assembly.

6. Pour a few drops of household oil inside the gun housing

(see area indicated below by arrow).

7. Reassemble spray gun:

• install gun filter tapered-end

first, and,

• install spray tip, saddle

seat and washer, and

replace spray guard

assembly.

8. Thread the paint hose back onto the spray gun. Tighten

with a wrench.

IMPORTANT!

If you cleaned your pump using mineral spirits, it is

recommended that you flush the pump again using warm,

soapy water to prepare it for storage. Repeat Flushing

the Pump

instructions.

r

Customer Service: 800-328-8251 10 © 2003 Wagner Spray Tech - All rights reserved.

English

CLEANUP (CONTINUED)

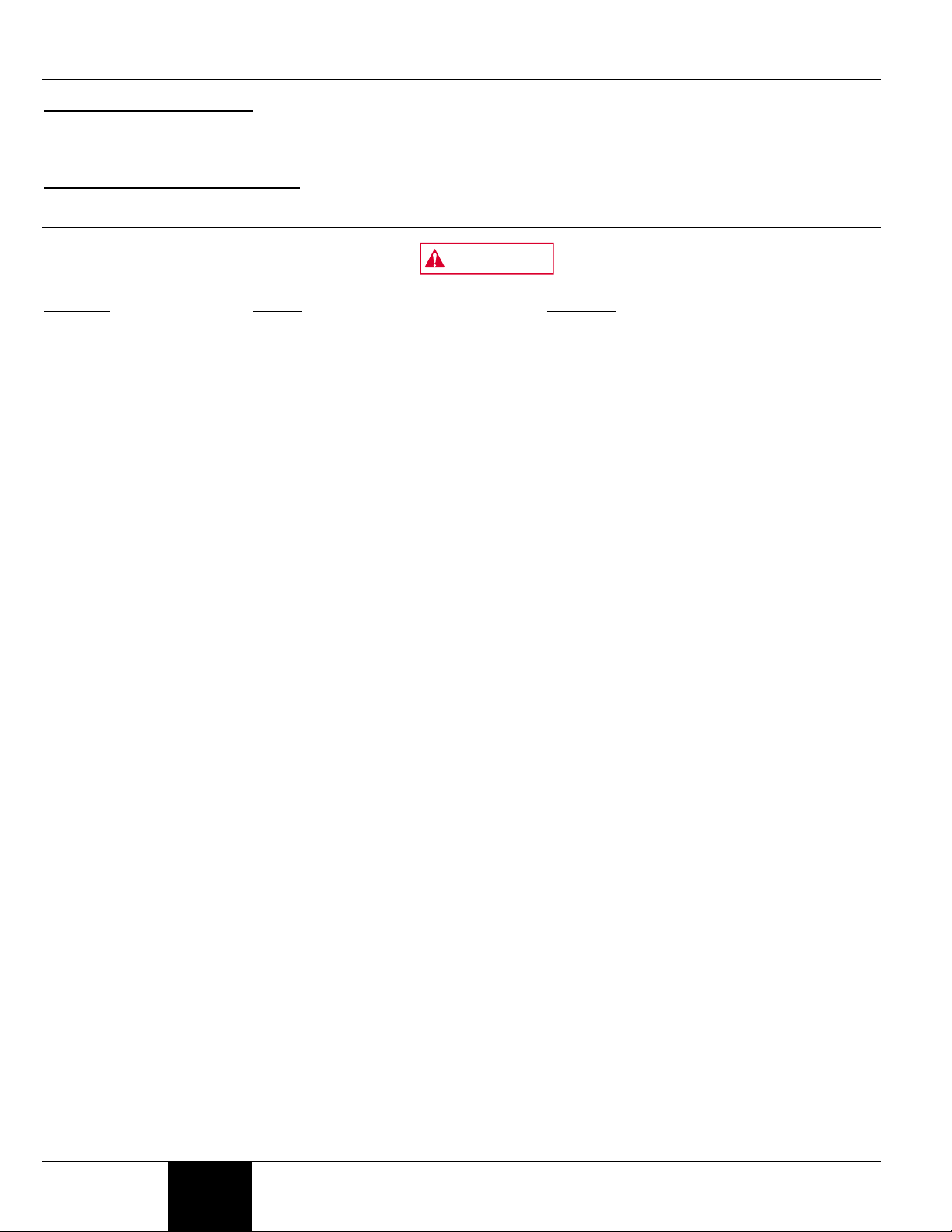

CLEANING

THE INLET VALVE

1. Remove the inlet filter from

the bottom of the hopper.

You may need to use a

screwdriver to pry the filter

loose.

2. Insert the inlet valve tool into

the inlet fitting. Twist

counter-clockwise and

remove from its housing.

3. Inspect the three inlet fitting

O-rings on the inlet fitting.

Clean or replace, and

lubricate with household oil.

4. Retrieve the inlet valve and

the inlet valve O-ring from

the inlet fitting housing.

Clean or replace and

lubricate the O-ring with a

light household oil.

5. Set the inlet valve O-ring

back into the housing, and

set the inlet valve on top of it.

6. Replace inlet fitting into the

housing. Tighten with the

inlet valve tool and ratchet.

REPLACING THE OUTLET VALVE

1. Unscrew the outlet valve from the outlet valve housing using

an adjustable wrench.

2. Inspect the inside of the

outlet valve housing.

Remove any

accumulated paint.

3. Replace with a new

outlet valve. Tighten

into outlet valve

housing with an

adjustable wrench.

Replacement of the outlet valve may be necessary if

your spray performance remains poor after having

performed all the steps contained in the Spraying

Troubleshooting section of this manual. Replacement

valves are available by calling customer service.

DO NOT remove the O-rings

on the inlet fitting to clean

them. Remove ONLY if you

plan to replace them.

You willl need to attach the inlet valve tool to a ratchet

wrench extension in order to remove it.

Cleaning or servicing the inlet valve may be required if

the unit has priming problems. This may be caused by

improper cleaning and/or storage. Replacement kits

may be ordered by calling customer service.

INLET/OUTLET VALVES

Filter

Housing

Saddle

seat

Washe

Inlet fitting

O-ring

Inlet fitting

O-ring

Inlet

fitting

Inlet fitting

O-ring

Inlet

valve

Inlet

valve

O-ring

Filter

Housing

Page 11

© 2003 Wagner Spray Tech - All rights reserved. 11 Customer Service: 800-328-8251

English

SHORT

-TERM STORAGE (UP TO 16 HOURS)

SHUTDOWN

1. Perform all the steps of the PRESSURE RELIEF

PROCEDURE (page 5).

2. Pour 1/2 cup water slowly on top of the paint to prevent it

from drying. Replace the hopper lid.

3. Wrap the spray gun assembly in a damp cloth and place it in

a plastic bag. Seal the bag shut.

4. Unplug the sprayer.

5. Place the sprayer in a safe place out of the sun for shortterm storage.

STARTUP

1. Remove the gun from the plastic bag and stir the water into

the paint.

2. Check to be sure the

PRIME/SPRAY knob is set

to PRIME.

3. Plug sprayer in and turn

the switch to ON.

4. Turn the PRIME/SPRAY

knob to SPRAY.

5. Test the sprayer on a

practice piece and begin

spraying.

Follow these steps when using LATEX PAINTS ONL Y. If using

materials that are oil-based, follow the long-term storage steps.

PREP

ARING THE SPRAYER FOR LONG-

TERM STORAGE

1. Make sure you have already completed the Cleanup steps on

pages 9-10.

2. Remove the inlet filter. You may need to use a screwdriver

to pry it loose.

3. Pour approximately two ounces of light household oil into

the inlet valve.

4. Remove hose from outlet valve, place a rag over the outlet

valve, and turn the switch ON. Let the unit run for five seconds.

5. Switch the pump OFF.

6. Replace the inlet filter and push the tab on the filter.

7. Wipe the entire unit, hose and gun with a damp cloth to

remove accumulated paint.

8. Replace the high pressure hose to the outlet valve and

replace the hopper lid.

STORAGE

SPRAY

PRIME

O

Inlet

filter

Inlet

valve

SPRAY

PRIME

l

SPRAY

O

Tab

PRIME

Page 12

DAIL

Y MAINTENANCE

The only daily maintenance necessary is thorough cleaning.

Follow the cleaning procedures in this manual.

EXTENDED MAINTENANCE

Some pump parts eventually wear out from use and must be

Customer Service: 800-328-8251 12 © 2003 Wagner Spray Tech - All rights reserved.

English

MAINTENANCE

replaced. The following is a list of available repair kits. Pump

performance is the only reliable indicator of when to replace

wear parts. Refer to the Troubleshooting section for more

information on when to use these kits.

Kit Part #

Description

0515221 Inlet valve seal kit

0515205 Outlet valve kit

TROUBLESHOOTING

PROBLEM

A. The sprayer does not start.

B. The sprayer starts but does

not draw in paint when the

PRIME/SPRAY knob is set to

PRIME.

C. The sprayer draws up paint

but the pressure drops when

the gun is triggered.

D. The PRIME/SPRAY valve is

on SPRAY and there is flow

through the return tube.

E. The spray gun leaks.

F. The tip assembly leaks.

G. The spray gun will not spray.

H. The paint pattern is tailing.

CAUSE

1. The sprayer is not plugged in.

2. The ON/OFF switch is set to OFF.

3. The sprayer shuts off while still under

pressure.

4. No voltage is coming from the wall plug.

5. The extension cord is damaged or has too

low a capacity.

6. There is a problem with the motor.

1. The unit will not prime properly or has lost prime.

2. The hopper is empty.

3. The unit is not on level ground.

4. The inlet filter is clogged.

5. The inlet or outlet valve is stuck.

6. The inlet valve is worn or damaged.

7. The PRIME/SPRAY valve is plugged.

1. The spray tip is worn.

2. The inlet filter is clogged.

3. The gun or spray tip filter is plugged.

4. The paint is too heavy or coarse.

5. The outlet valve assembly is dirty or worn.

6. The inlet valve assembly is damaged or worn.

1. The PRIME/SPRAY valve is dirty or worn.

1. Internal parts of the gun are worn

or dirty.

1. The tip was assembled incorrectly.

2. A seal is worn.

1. The spray tip or the gun filter is plugged.

2. The spray tip is in the CLEAN position.

3. PRIME/SPRAY knob not set on SPRAY.

1. The gun, the tip, or the inlet filter

is plugged.

2. The tip is worn.

3. The paint is too thick.

4. Pressure loss.

SOLUTION

1. Plug the sprayer in.

2. Turn the ON/OFF switch to ON.

3. Motor will cycle ON and OFF while spraying as it

needs pressure. This is normal. Resume painting.

4. Properly test the power supply voltage.

5. Replace the extension cord.

6. Take sprayer to Wagner Authorized Service Center.

1. Try to prime the unit again.

2. Refill the hopper.

3. Relocate unit to level ground.

4. Clean the inlet filter.

5. Clean the inlet and outlet valves and replace any worn

parts.* Inlet may be stuck from old paint. Push inlet

filter tab to release.

6. Replace the inlet valve.*

7. Take sprayer to Wagner Authorized Service Center.

1. Replace the spray tip with a new tip.**

2. Clean the inlet filter.

3. Clean or replace the proper filter. Always keep extra

filters on hand.

4. Thin or strain the paint.

5. Clean or replace the outlet valve assembly.*

6. Replace the inlet valve.*

1. Take sprayer to Wagner Authorized Service Center.

1. Take the sprayer to a Wagner Authorized Service

Center.

1. Check the tip assembly and assemble properly.

2. Replace the seal.*

1. Clean the spray tip or gun filter. Review Unclogging

the Spray Tip.

2. Put the tip in the SPRAY position.

3. Turn the PRIME/SPRAY knob to SPRAY.

1. Clean the filters and strain the paint.

2. Replace the spray tip.

3. Thin the paint.

4. Refer to Causes and Solutions for problem C.

* Special repair kits with instructions are available for these procedures. Refer to the Maintenance (page 12) section of this

manual for a list of the kits and their part numbers.

** Additional parts are available for this procedure. Refer to the Accessories (page 37) section of this manual for a list of the

parts and their part numbers.

Before servicing, always release system

pressure by following PRESSURE RELIEF

PROCEDURE (page 5).

WARNING

Page 13

Français

Impression aux Chine

PAINT CREW

®

PULVÉRISATEUR SANS AIR PERFORMANT

TABLE DES MATIÈRES :

SÉCURITÉ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-15

COMPOSANTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

ASSEMBLAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

AVANT DE COMMENCER . . . . . . . . . . . . . . . . . . . . . . . . . 17

PURGE ET AMORÇAGE . . . . . . . . . . . . . . . . . . . . . . . . . . 18

PULVÉRISATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

PROBLÈMES POTENTIELS. . . . . . . . . . . . . . . . . . . . . . . . 20

NETTOYAGE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21-22

SOUPAPES D’ENTRÉE/DE SORTIE . . . . . . . . . . . . . . . . . 22

RANGEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

DÉPANNAGE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

LISTE DE PIÈCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37-38

CENTRES DE SERVICE . . . . . . . . . . . . . . . . . . . . . . . . 39-43

GARANTIE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

MANUEL DE L’UTILISATEUR • LIRE CE MANUEL POUR OBTENIR DES DIRECTIVES COMPLÈTES

SPECIFICATIONS:

Poids ................................ 11,3 Kg

Capacité ........................... distributeur de 7,5 litres (2 gallons)

Source de puissance........Moteur universel de 3/8 ch

Exigences d’alimentation..Circuit d’au moins 15 A, à courant de

120 V c.a./60 Hz

Génératrice.......................8 000 W

Pression de pulvérisation. ..Jusqu’à 2800 PSI/193 bar

Caractéristiques de sécurité.Serrure et garde de déclenchement de

pistolet de pulvérisation; protège-embout

intégré; bouton d’amorçage

permettant la décompression en

toute sécurité.

Possibilitiés.......................Pulvérisation de divers types de

peintures (au latex ou à huile),

d’apprêts, de teintures, d’agent

d’imprégnation et d’autres

substances non abrasives.

Ne pas employer de matériaux

avec un point d’éclair au-dessous

de 70°F (21°C).

Cette pompe ne devrait pas être utilisée avec les

matériaux à grain, les blocs de remplissage, les

laques, les émaux industriels, l'asphalte scellant ou les

matériaux contenant du HHC. Vérifier le point d’éclair

énuméré par le fournisseur d’enduit sur le récipient.

Besoin d'aide?

rapidement conseil.

frais de Wagner Spray Tech si vous éprouvez

des difficultés ou avez des commentaires à

formuler (services en anglais seulement).

Appelez-nous d'abord pour obtenir

Composez le numéro sans

1-800-328-8251

Service technique de Wagner

Rendez-nous visite sur le Web!

www.wagnerspraytech.com

1770 Fernbrook Lane, Minneapolis, MN 55447 - USA

Page 14

DANGER : INJECTION CUTANÉE

Le jet de haute pression produit par cet appareil

peut transpercer la peau et les tissus sousjacents, causant des blessures graves pouvant

aller jusqu’à l’amputation.

NE PAS TRAITER CE TYPE DE BLESSURE COMME UNE

SIMPLE COUPURE! Une amputation peut en résulter. ON

DOIT CONSULTER UN MÉDICIN SUR-LE-CHAMP.

La pression maximale de ce pulvérisateur est d’environ

2800 PSI/193 bar

MESURES PRÉVENTIVES :

• NE JAMAIS pointer le pistolet vers une partie du corps.

• NE JAMAIS mettre une partie du corps devant le jet de produit.

NE JAMAIS toucher les fuites du flexible de pulvérisation.

• NE JAMAIS mettre la main, même gantée, devant le pistolet

(les gants n’offrent aucune protection contre les blessures par

injection).

• TOUJOURS verrouiller la détente, arrêter la pompe et relâcher

toute la pression avant d’effectuer la maintenance de l’appareil

ou de le laisser sans surveillance, d’en nettoyer le protègeembout ou l’embout, ou de remplacer ce dernier. La pression

ne sera pas relâchée par le simple arrêt du moteur; pour ce

faire, on doit se servir du bouton PRIME/SPRAY(se reporter à

la section DÉCOMPRESSION, page 17 du présent manuel).

• TOUJOURS s'assurer que le protège-embout est en place

avant de pulvériser. Il est cependant à noter que, s’il assure

une certaine protection, ce dispositif joue surtout un rôle

préventif.

• TOUJOURS retirer l’embout avant de vidanger ou de nettoyer

l’appareil.

• TOUJOURS inspecter le flexible avant de procéder; celui-ci

peut présenter des fuites attribuables à l’usure, à une flexion

excessive ou à un traitement abusif, lesquelles fuites

présentent des risques d’injection cutanée.

• NE JAMAIS utiliser de pistolet sans verrou de détente et

protège-doigts.

• Tous les accessoires (pistolets, embouts, rallonges, flexibles

etc.) doivent pouvoir subir une pression nominale de

2800 PSI/193 bar ou plus.

REMARQUE À L’INTENTION DES MÉDECINS :

Les injections cutanées sont des lésions traumatiques; il

importe donc de les traiter sans délai. On NE DOIT PAS

retarder ce traitement sous prétexte de vérifier la toxicité

du produit en cause, celle-ci n’étant conséquente que dans

le cas d’injection directe de certains produits dans le

système sanguin. Il pourrait s’avérer nécessaire de

consulter un plasticien ou un spécialiste en chirurgie

reconstructrice de la main.

14 1-800-328-8251 © 2003 Wagner Spray Tech - Tous droits réservés

DANGER : ÉMANATIONS DANGEREUSES

Certains produits (peintures, solvants,

insecticides ou autres) peuvent être nocifs s’ils

sont inhalés ou entrent en contact avec

l’organisme. Les émanations de ces produits

peuvent provoquer de graves nausées,

évanouissements ou empoisonnements.

MESURES PRÉVENTIVES :

• Se servir d’un masque ou d’un respirateur s’il y a risque

d’inhalation (lire toutes les directives concernant ces dispositifs

afin de s’assurer qu’ils offrent la protection requise).

• Porter des lunettes de protection.

• Porter les vêtements de protection prescrits

par le fabricant du produit utilisé.

DANGER : EXPLOSION OU INCENDIE

Les émanations de certains produits peuvent

exploser ou s’enflammer, et risquent d’entraîner

des dommages matériels ou de graves blessures.

MESURES PRÉVENTIVES :

• S’assurer que l’aire de travail est dotée de

moyens d’évacuation d’air vicié et

d’introduction d’air frais pour éviter l’accumulation de vapeurs

inflammables

• Ne pas travailler près de sources d’ignition

(décharges électrostatiques ou étincelles

provoquées par le branchement/débranchement

d’appareils ou la commutation d’interrupteurs,

appareils eléctriques, flammes nues,

veilleuses, objets chauds, etc.).

• Ne pas fumer dans l’aire de travail.

• L’aire de travail doit être munie d’un extincteur en bon état de marche.

• Prévoir un espace d’au moins 6 mètres entre le pompe et l’objet à

pulvériser s’ils sont dans la même pièce bien ventilée. Les vapeurs

inflammables étant souvent plus lourdes que l’air, l’espace audessus du plancher doit être particulièrement bien aéré. Cet

appareil est doté de composants susceptibles de former des arcs

électriques pouvant enflammer les émanations présentes.

• Les appareils et objets à l’intérieur ou à proximité de l’aire de

travail doivent être adéquatement mis à la terre pour éviter

les décharges électrostatiques.

• Les flexibles dont on se sert doivent être conçus pour subir

les pressions élevées et faits de matériaux conducteurs ou

mis à la terre adéquatement; le pistolet sera mis à la terre par

le biais de ses raccords aux flexibles.

• Le cordon d’alimentation doit être branché à un circuit trifilaire.

• L’appareil doit toujours être vidangé à basse pression,

embout retiré, dans un contenant métallique distinct. Tenir le

pistolet contre la paroi du contenant de manière à mettre ce

dernier à la terre et à prévenir les décharges électrostatiques.

• Toujours respecter les mises en garde et les directives du

fabricant des produits et solvants utilisés.

• Ne pas employer de matériaux avec un point d’éclair audessous de 70°F (21°C) (le point d’éclair correspond à la

température à laquelle un liquide peut produire suffisamment

d’émanations pour s’enflammer).

• Le plastique est générateur de décharges électrostatiques; ne

jamais en suspendre pour fermer une aire de travail ou en

utiliser en guise de toile de protection lorsqu’on pulvérise un

produit inflammable.

• Se servir de la pression la plus basse possible pour vidanger

l’appareil.

CONSIGNES DE SÉCURITE • LIRE TOUTES CES

CONSIGNES AVANT D

’UTILISER L’APPAREIL

Français

Page 15

DANGER : EXPLOSION CAUSÉE PAR DES

PRODUITS INCOMPATIBLES

Ce type d’explosion peut entraîner des

dommages matériels ou des blessures graves

• Ne pas utiliser de produits contenant du chlore

ou du javellisant.

• Ne pas utiliser de solvants à base de halons comme l’eau de

javel, les agents antimoisissure, le chlorure de méthylène et le

trichloroéthane-1-1-1, lesquels ne sont pas compatibles avec

l’aluminium.

• Communiquer avec le fournisseur du produit concerné pour en

connaître la compatibilité avec l’aluminium.

DANGER : GÉNÉRALITÉS

D’autres dangers peuvent entraîner des dommages matériels ou

des blessures graves.

MESURES PRÉVENTIVES :

• Lire toutes les directives et consignes de sécurité avant

d’utiliser l’appareil.

• Observer tous les codes locaux, provinciaux, d’état et

nationaux régissant la ventilation, la prévention des incendies

et le fonctionnement de l’appareil.

• Aux États-Unis, le gouvernement a adopté des normes de

sécurité en vertu de l’Occupational Safety and Health Act

(OSHA). Le cas échéant, on doit les consulter, notamment les

parties 1910 des normes générales et 1926 des normes de

construction.

• N’utiliser que les pièces autorisées par le fabricant; les

utilisateurs qui choisiront d’utiliser des composants dont les

caractéristiques techniques et les exigences en matière de

sécurité sont inférieures devront en assumer tous les risques

et responsabilités.

• Avant chaque usage, examiner tous les flexibles afin de

confirmer l’absence de coupures, de fuites, d’abrasions ou de

renflements. Vérifier également l’intégrité des raccords.

Remplacer sans délai les pièces qui semblent présenter des

défectuosités. Ne jamais tenter de réparer un flexible;

remplacer ceux qui font défaut par des modèles haute

pression, avec mise à la terre.

• Tous les flexibles, pistolets et autres accessoires doivent

pouvoir subir une pression nominale de 2800 PSI/193 bar ou

plus.

• Ne pas pulvériser à l’extérieur par grands vents.

• Porter des vêtements aptes à protéger la peau et les cheveux

du produit utilisé.

RENSEIGNEMENTS IMPORTANTS SUR

L’ÉLECTRICITÉ

Si l’application requiert l’utilisation d’une rallonge, celle-ci doit être

trifilaire et dotée d’une fiche à trois broches et d’un connecteur à

trois fentes pouvant accepter la fiche de l’appareil. Cette rallonge

doit être en bon état. On doit en outre s’assurer qu’elle est d’un

calibre suffisant pour éviter les baisses de tension susceptibles de

provoquer des pertes de puissance ou une surchauffe de

l’appareil. On recommande l’utilisation d’un cordon de calibre 14

ou 12. Si la rallonge doit servir à l’extérieur, on doit opter pour un

type de cordon dont la désignation arbore le suffixe « W-A » (ex.

SJTW-A).

• Toujours déconnecter le moteur de l'alimentation et soulager

la pression du flexible avant de travailler sur l'appareil.

DIRECTIVES DE MISE À LA TERRE

Cet appareil doit être mis à la terre. En cas de court-circuit, cette

précaution réduit les risques de choc en procurant un parcours au

courant électrique. Le cordon de l’appareil est doté d’un fil de terre

relié à la troisième broche de sa fiche. Cette dernière doit être

branchée dans une prise correctement câblée et mise à la terre

conformément aux codes et règlements locaux.

Le fait de ne pas brancher correctement la

fiche trifilaire de l’appareil peut entraîner des

risques de choc électrique.

Si on doit réparer ou remplacer le cordon ou la fiche, ne pas

raccorder le fil de terre à la borne des broches plates (lames) de

cette dernière. Ce fil, normalement vert (avec ou sans rayures

jaunes), doit être relié à la broche de terre.

Consulter un technicien ou un électricien qualifié à défaut de

comprendre l’ensemble des présentes directives ou en cas

d’incertitude quant à la mise à terre de l’appareil.

Ne pas modifier la fiche de l’appareil; si elle ne s’adapte pas dans

la prise voulue, faire remplacer cette dernière par un électricien

qualifié.

Conçu pour les circuits de 120 V, cet appareil est doté d’une fiche

ressemblant à celle illustrée ci-dessous. Veuillez-vous assurer que

le produit est connecté à une prise électrique ayant la même

configuration que la fiche mâle. Ne pas utiliser d’adaptateur avec

ce produit.

CARTE D'ENREGISTREMENT DU PRODUIT

Prière de poster la carte d’enregistrement du produit ou de la

remplir en ligne au site www.wagnerspraytech.com. La carte

d’enregistrement constitue une preuve d’achat dans l’éventualité

où le reçu original serait égaré ou perdu; elle sert également à

accélérer le traitement de la garantie. On doit s’assurer d’y

indiquer le code dateur avant de l’envoyer; ce code est situé sous

la base de l’appareil (p. ex., S087R). Les renseignements

additionnels obtenus par le biais de ces cartes contribueront en

outre au développement de nouveaux produits mieux adaptés aux

besoins et aux exigences des utilisateurs. Pour toute question ou

commentaire concernant la carte d’enregistrement, prière de

téléphoner au centre de traitement de ces dernières en composant

le (303) 394-9077.

EN CAS DE PROBLÈME D’ASSEMBLAGE,

D’UTILISATION OU DE NETTOYAGE DU

PULVÉRISATEUR

, SE REPORTER À LA

SECTION DÉP

ANNAGE DU PRÉSENT MANUEL

(PAGE 24) OU COMMUNIQUER AVEC LES

TECHNICIENS DU SERVICE A CLIENTÈLE EN

COMPOSANT LE

:

1-800-328-8251

(SERVICES EN ANGLAIS SEULEMENT)

© 2003 Wagner Spray Tech - Tous droits réservés 1-800-328-8251 15

CONSIGNES DE SÉCURITE • LIRE TOUTES CES

CONSIGNES AVANT D

’UTILISER L’APPAREIL

Français

AVERTISSEMENT

MISE EN GARDE

Prise trifilaire

Broche de mise à la terre

Plaque murale de la prise

Page 16

16 800-328-8251 © 2003 Wagner Spray Tech - Tous droits réservés.

Français

COMPOSANTS ET ASSEMBLAGE

COMPOSANTS

• un pistolet muni d’un filtre;

• un embout et ses composants;

• un flexible haute pression d’un diamètre de 0,6 centimètre, long

de 15,2 mètres.

OUTILS REQUIS

• Deux clés à molette.

• Une rallonge (se reporter à la section RENSEIGNEMENTS

IMPORTANTS SUR L’ÉLECTRICITE, page 15).

Ne pas brancher le pulvérisateur avant d’avoir terminé les

préparatifs.

COMMANDES ET FONCTIONS

Interrupteur .........................L’interrupteur permet de mettre l’appareil

sous et hors tension (O = hors tension, l

= sous tension).

Pistolet................................Le pistolet permet de réguler le débit du

produit aspiré par la pompe.

Flexible de pulvérisation.....Ce flexible relie le pistolet à la pompe.

Tube de retour....................Le fluide est envoyé par le tube de retour

au distributeur en amorçant.

Bouton PRIME/SPRAY .......Ce bouton permet de diriger le produit

vers le flexible quand il est réglé à

SPRAY et vers le tube de retour quand il

est réglé à PRIME. Les flèches

indiquent dans quelle direction le tourner.

ASSEMBLAGE

Placer la poignée au-dessus

del´armature. Insérer et serrer les

boulons.

Visser le flexible haute pression sur sa

soupape de sortie. Serrer au moyen

d’une clé à molette. Placer le tube de

retour le au distributeur

Visser le flexible haute pression sur

son pistolet. Tenir le pistolet dans une

clé à molette et serrer au moyen

d’une autre.

MISE EN GARDE

Manchon

Tube de

retour

Trémie

Châssis

Robinet

de décharge

Pistolet

Rangement

de embout

Embout et ses

composants

Verrou

de façon

Verrou

de bout

Filtre d'entrée

(à l'intérieur du distributeur)

Couvercle de

trémie

Carter du

moteur

Poignée

arrière

Interrupteur

Outil de

soupape

d'entrée

Bouton

PRIME/SPRAY

EmboutGarde

Flexible de

pulvérisateur

Interrupteur

Bouton

PRIME/SPRAY

PRIME

Position

PRIME

SPRAY

Position

SPRAY

= Sous

tension

= Hors

tension

SPRAY

PRIME

1

2

3

Page 17

© 2003 Wagner Spray Tech - Tous droits réservés. 800-328-8251 17

Français

VERROUILLAGE

ET DÉVERROUILLAGE DU

PISTOLET

La détente doit toujours être verrouillée quand on fixe l’embout

ou quand le pistolet n’est pas utilisé.

BRANCHEMENT DU PULVÉRISATEUR

1. Mettre l’interrupteur hors

tension (O).

2. Brancher le pulvérisateur dans

une rallonge trifilaire de

service robuste. Se reporter à

la section

RENSEIGNEMENTS

IMPORTANTS SUR

L’ÉLECTRICITÉ (page 15).

DÉCOMPRESSION

S’assurer de suivre cette procédure pour relâcher la pression à

l’intérieur du flexible de pulvérisation CHAQUE FOIS que

l’appareil est mis hors tension.

1. Verrouiller le pistolet et mettre

l’interrupteur hors tension (0).

2. Régler le bouton

PRIME/SPRAY à PRIME.

3. Ouvrir le pistolet de

pulvérisation et le déclencher

alors sur un morceau de bois

ou de carton.

4. Verrouiller le pistolet.

La buse NE DOIT PAS être attachée juste après que le

pulvérisateur et le flexible aient été purgé et amorcé.

DÉVERROUILLAGE DE

PISTOLET

Pour déverrouiller la gâchette,

tourner le verrou de façon à

ce qu’il s’aligne avec celle-ci.

VERROUILLAGE DE PISTOLET

Le pistolet est bloqué quand

le verrou forme un angle de

90° (perpendiculaire) avec la

détente dans l’une ou l’autre

des directions.

VIDANGE

DU DISTRIBUTEUR

1. Exécuter de la Décompression (page 17).

2. Enlever le couvercle du distributeur.

3. Saisir la poignée supérieure du pulvérisateur avec une main, et

la poignée arrière avec l'autre.

4. Soulever et incliner le pulvérisateur de sorte que le produit

s’écoule d'un des coins de devant du distributeur et dans son

récipient original.

FILTRAGE DU PRODUIT

Pour éviter l’obstruction prématurée de la buse et du filtre il est

recommandé de filtrer votre peinture avant la pulvérisation. Suivre

les recommandations du fabricant.

CHOIX DU FIL TRE DE PISTOLET APPROPRIÉ

On doit se servir du filtre qui convient à l’embout utilisé.

S'assurer que le plancher et

l'ameublement est recouvert

de toiles de protection pour

éviter tout dommages.

L'outil, une fois rempli de

produit de pulvérisation, peut

être lourd. Veiller à le soulever

avec l’aide de vos jambes et

non de votre dos pour réduire

le risque d’accident corporel.

Suivre ces instructions si le distributeur est rempli de produit

et 1) il y a un défaut de fonctionnement du pulvérisateur ou

2) vous avez fini la pulvérisation sans utiliser tout le produit.

AVANT DE COMMENCER --

LA PAGE CI-DESSOUS CONTIENT DES RENSEIGNEMENTS

QUI SERONT RÉPÉTÉS PLUS LOIN DANS LE MANUEL

MISE EN GARDE

O

Poignée

supérieure

Poignée

arrière

O

MISE EN GARDE

SPRAY

O

PRIME

Coins de

devant

MISE EN GARDE

AVERTISSEMENT

N° de

pièce

0154918 0,011 Extrafin

Numéro

d'embout

N° de

filtre

Maille Qté

180

0,084 mm

Couleur

du corps

rouge

Emb.

de 2

0154675

0,013 - 0,015

Fin

100

0,140 mm

jaune

Emb.

de 2

Page 18

PURGE

ET AMORÇAGE DE LA POMPE

1. S'assurer que le filtre d’entrée

est en place à l'intérieur du

distributeur. S'il n’y est pas,

encastrer le comme indiqué.

2. Pousser la languette sur le

filtre une fois vers le bas.

Ceci permettra le bon

fonctionnement de la valve

d’entrée.

3. Tirer le tube de retour du

distributeur et le tenir audessus d’un bac à vidange.

4. Régler le bouton

PRIME/SPRAYà PRIME.

5. Brancher le pulvérisateur et mettre l’interrupteur

sous tension (l).

6. Mettre l’interrupteur hors tension (O). Retirer le tube de retour du

bac à vidange et rattacher le au distributeur.

7. Remplir votre distributeur du

produit que vous voulez

pulvériser. Ne pas déborder

de la conduite d’emplissage

comme indiqué. Replacer le

couvercle du distributeur.

8. Laisser le bouton

PRIME/SPRAYsur PRIME et

allumer votre appareil sur ON

encore une fois pour vérifier

que la peinture s’écoule bien

du tube de retour.

Le pulvérisateur est amorcé; passer à la section PURGE ET

AMORÇAGE DU FLEXIBLE.

Tout fluide qui est resté dans la pompe et

dans le tube de retour sortira du tube.

Faire marcher la pompe jusqu'à ce qu'il

n’y ait plus rien qui sort.

18 800-328-8251 © 2003 Wagner Spray Tech - Tous droits réservés.

Français

PURGE

ET AMORÇAGE DU FLEXIBLE

1. Déverrouiller le pistolet et régler le

bouton PRIME/SPRAYà PRIME.

2. Pointer le pistolet vers le

contenant de vidage et serrer la

détente (voir les avertissements

ci-dessous)..

3. En gardant toujours le doigt sur la détenté, mettre

l’interrupteur sous tension (l).

4. Sans lâcher la détenté, régler le

bouton PRIME/SPRAY à

SPRAY. Serrer jusqu’à ce qu’il

n’y ait plus d’air, d’eau ou de

solvant dans le flexible et que le

produit s’échappe librement de

l’embout (lire les mises en garde

ce-dessous).

Garder les mains à l’écart du jet de produit.

Le contenant est en métal, appuyer le

pistolet sur le rebord pour en assurer la

mise à la terre pendant les opérations de

vidange. Sans mise à la terre, des

décharges électrostatiques pourraient

entraÎner des risques d’incendie.

Tant que le bouton PRIME/SPRAY est réglé à SPRAY, la pression

s’accumule dans le flexible et le pistolet; elle n’est relâchée que

lorsqu’on tourne bouton à PRIME.

5. Lâcher la détente; régler le bouton

PRIME/SPRAYà PRIME et mettre

l’interrupteur hors tension (O).

6. Serrer une dernière fois la

détente en pointant le pistolet

vers le contenant de vidange

pour s’assurer qu’il n’y a plus de

pression dans le flexible.

7. Verrouiller le pistolet.

8. Visser à la main l’embout et le protège-embout sur le pistolet.

Le flexible est amorcé; on peut maintenant procéder à

l’application du produit.

NE PAS fixer l’embout du

pistolet pendant la

procédure de purge du

flexible.

PURGING ET AMORÇAGE

Languette

SPRAY

PRIME

l

O

SPRAY

PRIME

l

SPRAY

PRIME

MISE EN GARDE

MISE EN GARDE

Conduite

d’emplissage

SPRAY

PRIME

l

Commencer

à visser à

cet angle. . .

. . . pour que

l'embout ait

l'inclinaison

voulue une

fois serré.

SPRAY

PRIME

O

Page 19

© 2003 Wagner Spray Tech - Tous droits réservés. 800-328-8251 19

Français

ESSAIS

S’assurer que le flexible n’est ni plié ni en contact avec des

arêtes coupantes.

1. Mettre l’interrupteur sous

tension (l) et régler le

bouton PRIME/SPRAY à

SPRAY.

2. Une fois le moteur arrêté,

déverrouiller le pistolet et

pulvériser le produit sur

une surface d’essai afin

de vérifier la forme du jet.

TECHNIQUES DE PULVÉRISATION

Le secret d’une bonne application est d’obtenir une couche uniforme

sur toute la surface. Pour ce faire, on doit procéder par mouvements

réguliers. Suivre les CONSEILS ci-dessous.

CONSEIL :

Le bras doit se déplacer à une vitesse constante et l’embout du

pistolet doit rester à une distance toujours égale de la surface,

soit entre 25 et 30 cm.

Si vous observez des bavures, votre buse est peut-être

obstruée, le filtre du pistolet est peut-être bouché ou la buse

peut être trop usée. Référez-vous à la section Dépannage de

pulvérisation à la page suivante.

Le moteur s’arrête automatiquement quand il y a

suffisamment de pression dans le flexible, et repart dès qu’il

n’y en a plus assez.

AUTRES CONSEILS

Pour obtenir une couverture égale, faire chevaucher chaque

passage d’environ 30 %.

Une fois l’application terminée, passer à la section

DÉCOMPRESSION et puis débrancher le pulvérisateur.

Garder le couvercle sur le distributeur pendant la pulvérisation.

Ceci empêchera tout débris de tomber dans votre produit de

pulvérisation.

SI ON PENSE NE PAS UTILISER LE PULVÉRISATEUR

PENDANT PLUS DE UNE HUERE, ON DOIT SUIVRE LA

PROCÉDURE DE RANGEMENT À COURT TERME

APPARAISANT À LA PAGE 23 DU PRÉSENT MANUEL.

t

CONSEIL :

On doit appuyer sur la détente au début de chaque mouvement

de pulvérisation, et ne la lâcher qu’à la fin. En actionnant le

pistolet en milieu de course, on obtient un jet irrégulier et une

couverture inégale.

CONSEIL :

Pour maintenir le pistolet perpendiculaire à la surface, on doit

déplacer le bras d’un côté à l’autre sans fléchir le poignet.

Bonne

manière

CONSEIL :

Le pistolet doit être perpendiculaire à la surface, sans quoi la

couche de produit sera plus épaisse d’un côté.

PULVÉRISATION

AVERTISSEMENT

l

SPRAY

PRIME

De 25 à 30 cm

(10 à 12 po)

Bonne

manière

Couche mince Couche mince

Couche épaisse

Mauvaise

manière

Bonne forme de jet

Formation de filaments

Appliquer une couche uniforme partout

De 25 à 30 cm

(10 à 12 po)

Mouvement régulier à vitesse constante

Ne pas fléchir le poignet

Bonne manière d'actionner la détente

De 25 à 30 cm

(10 à 12 po)

Progresser de

Lâcher

la détente

Terminer

le mouvemen

Commencer

le mouvement

Mantenir une

distance égale

Appuyer sur

la détente

manière uniforme

Page 20

NETTOY

AGE DE L’EMBOUT DE PUL VÉRISA TION

Ne pas tenter de débloquer ou de nettoyer l’embout avec le

doigt.

Ne pas utiliser une aiguille ou un instrument pointu pour

nettoyer l’embout; le carbure de tungstène pourrait s’écailler.

Si le jet se déforme ou s’arrête complètement alors qu’on serre la

détente, suivre les étapes suivantes :

1. Mettre l’interrupteur hors tension (O) et lâcher la détente et

verrouiller le pistolet.

2. Faire tourner la flèche de l’embout réversible de 180° de

manière à ce qu’elle pointe vers l’arrière du pistolet.

3. Régler le bouton

PRIME/SPRAY à SPRAY.

4. Déverrouiller le pistolet et

serrer la détente, en pointant

l’embout vers une retaille de

bois ou de carton. La

pression accumulée dans le

flexible dégagera

l’obstruction. Une fois

l’embout nettoyé, le produit

sortira en un jet droit, à haute pression.

5. Lâcher la détente et verrouiller le pistolet.

6. Réorienter l’embout de

manière à ce qu’il pointe de

nouveau vers l’avant.

7. Déverrouiller le pistolet et

reprendre le travail.

Si aucun produit ne sort de l’embout, suivre les étapes de

la colonne suivante.

Il se peut que l’embout soit

difficile à tourner s’il est sous

pression. Pour relâcher cette

dernière et faciliter l’opération,

régler le bouton PRIME/SPRAY

à PRIME et serrer la détente.

La liste qui suit énumère quelques-unes des difficultés qu’on peut

éprouver lorsqu’on utilise le pulvérisateur. Si l’une d’elles se

présente, le débit de produit pourrait s’arrêter ou ralentir, ce qui

aura pour effet de dégrader la forme de jet.

• Obstruction de l’embout de pulvérisation

• Obstruction du filtre de pistolet

• Obstruction de filtre d’entrée.

Il suffit de suivre les directives apparaissant sur cette page pour

résoudre ces problèmes.

20 800-328-8251 © 2003 Wagner Spray Tech - Tous droits réservés.

Français

PROBLÈMES POTENTIELS

NETT

OYAGE DU FILTRE DE PISTOLET

1. Exécuter de la Décompression (page 17).

2. Détacher le protège-doigts du logement de filtre en tirant dans

le sens opposé.Dévisser le logement

3. Retirer le filtre du corps de pistolet ou de son logement et

nettoyer le filtre au moyen de la solution nettoyante appropriée

(p. ex., eau tiède savonneuse pour les produits au latex,

essence minérale pour les produits à l’huile, etc.).

4. L’inspecter pour y déceler d’éventuels trous (image ci-contre).

Si les trous sont trouvés, remplace.

NE JAMAIS PIQUER LE FILTRE AU MOYEN D’UN INSTRUMENT

POINTU!

5. Remettre le filtre nettoyé, extrémité amincie en premier, dans

son logement ou le corps du pistolet.

6. Remettre le logement et ressort et ré-enclencher le protègedoigts sur le logement.

NETTOYAGE DU FILTRE D’ENTRÉE

1. Exécuter de la Décompression (page 17).

2. Vider le distributeur de tout produit de pulvérisation (voir

Vidange du Distributeur, page 17).

3. Enlever le filtre d’entrée du

distributeur. Vous aurez peutêtre besoin d’un tournevis

pour détacher le filtre.

4. Nettoyer la filtre d’entrée au

moyen de la solution

appropriée (p. ex., eau tiède

savonneuse pour les produits

au latex, essence minérale

pour les produits à l’huile, etc.).

5. Remettre le filtre d’entrée.

Si les problèmes persistent après qu’on ait procédé à toutes

les étapes de cette page, se reporter à la section

DÉPANNAGE (page 24).

L’extrémité amincie du filtre doit être correctement insérée, à

défaut de quoi l’embout pourrait s’obstruer et le produit,

cesser de s’écouler du pistolet.

En nettoyant le filtre, chercher les sédiments dans le produit

de pulvérisation utilisé. Se référer à la section Filtrage du

produit, (page 17).

On doit nettoyer ce filtre chaque fois qu’on utilise le

pulvérisateur (si le produit dont on se sert est plus épais, il

pourrait s’avérer nécessaire de le nettoyer plus souvent).

MISE EN GARDE

AVERTISSEMENT

Dessus

du filtre

(extrémité

amincie)

Trou

Protège

doigts

Filtre

Corps du

pistolet

O

AVERTISSEMENT

Filtre

d'entrée

Page 21

© 2003 Wagner Spray Tech - Tous droits réservés. 800-328-8251 21

Français

NETTOYAGE

REMARQUES

IMPORTANTES AU SUJET

DU NETTOYAGE

LIRE LES REMARQUES ET

MISES IN GARDE

SUIV ANTES A VANT DE

NETTOYER LE

PUL VÉRISATEUR

!

• En présence de produits au latex,

on doit se servir d’eau tiède

savonneuse pour nettoyer le

pulvérisateur et ses composants. Se

servir d’essence minérale en

présence de produits à l’huile.

• On ne doit pas utiliser d’essence

minérale pour ôter les produits au

latex, puisque ensemble, ils

produisent une substance

gélatineuse difficile à éliminer.

• Quelle que soit la solution de

nettoyage utilisée, il est important

de l’éliminer de la manière

appropriée une fois le travail

terminé.

• Le fait de bien nettoyer et lubrifier le

pulvérisateur constitue la meilleure

garantie de fonctionnement après le

rangement.

COMPOSER LE

1-800-328-8251

POUR TOUTE QUESTION

RELATIVE AU NETTOYAGE DU

PULVÉRISATEUR (SERVICES EN

ANGLAIS SEULEMENT)

PURGE DU FLEXIBLE

1. Verrouiller le pistolet, retirer l’embout et

ses composants, et régler le bouton

PRIME/SPRAY à PRIME.

2. Vider les restes de produit dans le

distributeur dans son récipient (voir la

section Vidange du distributeur, page 17).

3. Remplir le distributeur de solution de

nettoyage appropriée.

4. Tenir le pistolet contre la paroi du pot

produit et serrer la détente.

5. Sans lâcher la détente, mettre

l’interrupteur sous tension (l) et régler le

bouton PRIME/SPRAYà SPRAY.

6. Lâcher le détente et régler le bouton

PRIME/SPRAY à SPRAY.

7. Tenir le pistolet contre la paroi d’un autre

contenant et serrer la détente.

8. Régler le bouton PRIME/SPRAYà PRIME

et continuer de serrer la détente jusqu’à ce

que le liquide sortant soit translucide.

9. Régler le bouton PRIME/SPRAY à

PRIME et serrer de nouveau la détente

pour relâcher la pression accumulée.

10. Continuer par le Rinçage du distributeur.

Vous aurez peut-être besoin d’ajouter

un peu plus de solution de nettoyage.

Laisser la pompe fonctionner jusqu’à

ce qu’il n’y ait plus de produit dans le

flexible et que la solution nettoyante

s’échappe du pistolet.

Les étapes suivantes permettent de

récupérer le produit resté dans le flexible

de pulvérisation.

RINÇAGE DU DISTRIBUTEUR

1. Rincer complètement avec la solution

nettoyante appropriée.

2. Retirer le filtre d’entrée du fond du

distributeur pour le nettoyer. Vous

aurez peut-être besoin d’un tournevis

pour détacher le filtre.

3. Remplacer le filtre et disposer

correctement de la solution de

nettoyage.

PURGE

DE

PULVÉRISATEUR

1. Remplir le distributeur avec de la

solution de nettoyage NON UTILISÉE.

2. Régler le bouton PRIME/SPRAYà

PRIME et mettre l’interrupteur sous

tension.

3. Laisser la pompe faire circuler la

solution de nettoyage hors du tube de

retour pendant 2 ou 3 minutes.

4. Mettre l’interrupteur hors tension (O) .

5. Disposer correctement de la solution de

nettoyage et continuer par le

Nettoyage des pièces du

pulvérisateur, à la prochaine page.

Faire attention à ce qu’aucune solution de