Page 1

1201 •

Form No. 0284710A

EnglishFrançaisEspañol

The Painting People

PAINTMATE®PLUS

OWNER’S MANUAL • Read this manual for complete instructions

MANUEL DE L’UTILISATEUR • Ce manuel contient les instructions directives

MANUAL DEL PROPIETARIO

• Lea este manual para obtener instrucciones completas

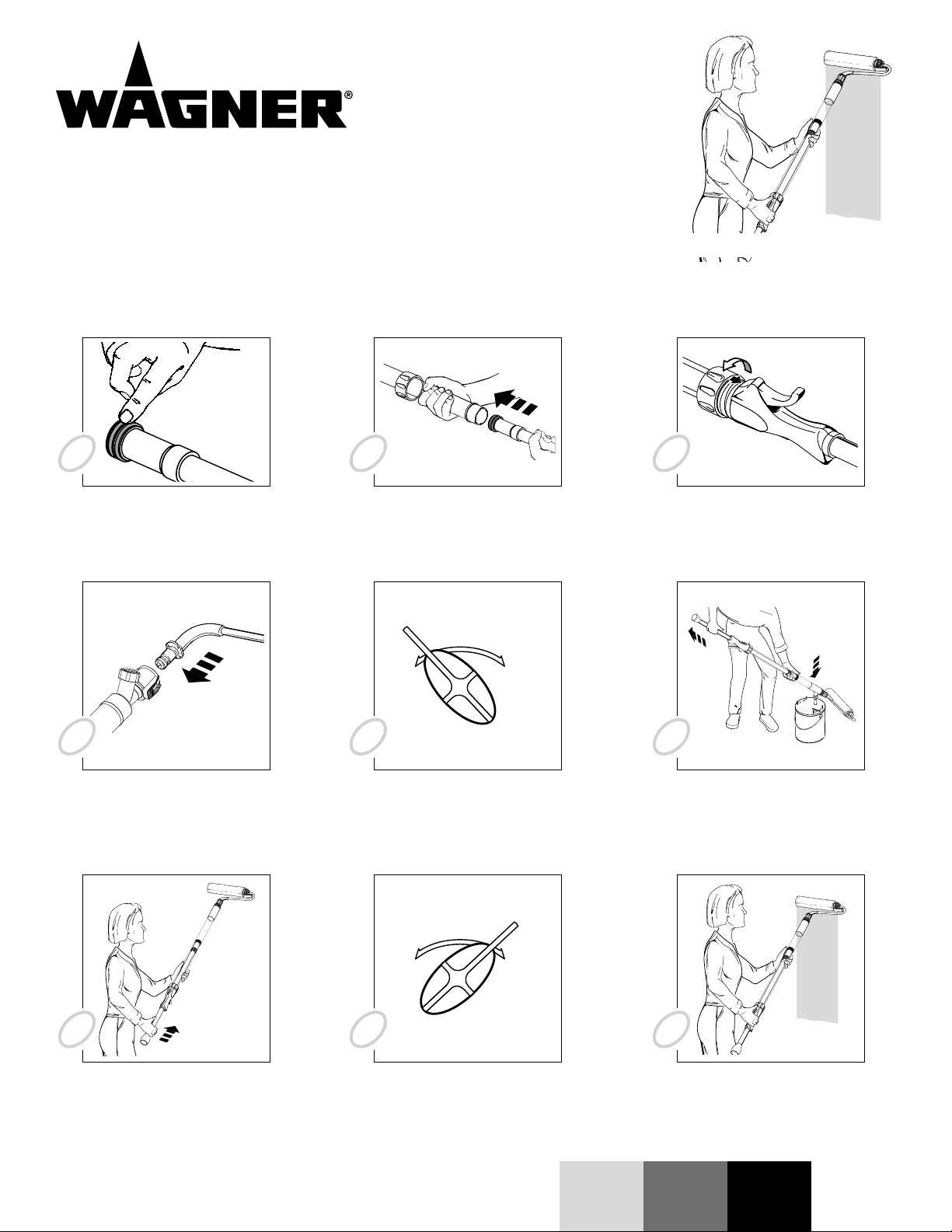

S

ETUP/USE

• MONTAGE/UTILISATION • DISPOSICIÓN/USO :

FILL

APPLY

Push plunger until paint appears in

roller cover

Pousser le piston jusqu’à ce que le

produit commence à suinter du manchon

Empuje el émbolo hasta que aparezca

pintura en el rodillo

Set the switch to APPLY

Mettre le commutateur à la position APPLY

Coloque el interruptor en APPLY

Squeeze Power Trigger

®

and apply

paint

Serrer la détente Power Trigger

MD

et

appliquer le produit

Presione el gatillo Power Trigger

®

y

pinte

FILL

APPLY

Assemble the PaintMate™ Plus

Assembler le PaintMateMCPlus

Arme el PaintMate™ Plus

Set the switch to FILL

Mettre le commutateur à la position FILL

Coloque el interruptor en FILL

Attach cover, press fill valve onto fill

tube, and pull plunger

Installer le couvercle, appuyer la soupape

sure le tube de remplissage et tirer le piston

Coloque el rodillo, acople la válvula de

llenado al tubo de llenado y jale el émbolo

Insert the plunger into the main tube

Introduire le piston dans le tube principal

Introduzca el émbolo en el tubo principal

Tighten the locking collar securely

Serrer le collier solidement

Apriete bien el collar inmovilizador

Lubricate plunger O-rings

Lubrifier les joints toriques de la piston

Lubrique los anillos en O del émbolo

PLUNGER TUBE ASSEMBLY INSTRUCTIONS • INSTRUCTIONS D’ASSEMBLAGE

POUR LE PISTON • INSTRUCCIONES DE ENSAMBLAJE PARA EL ÉMBOLO

™

1

1

2

2

3

3

4

5

6

Page 2

The Painting People

™

2 © 2001 Wagner Spray Tech. All rights reserved.

English

BEFORE YOU BEGIN

It is a good idea to have drop cloths protecting your floors and

anything else in the room that you do not want accidentally

splattered with paint.

Some oil-based paints require a stronger cleaning solution

than mineral spirits and should not be used with the

PaintMate

®

Plus. Using a cleaning solution stronger than

mineral spirits may cause damage to the PaintMate® Plus.

Check with your paint supplier to be sure the oil-based

paint you have can be cleaned with mineral spirits.

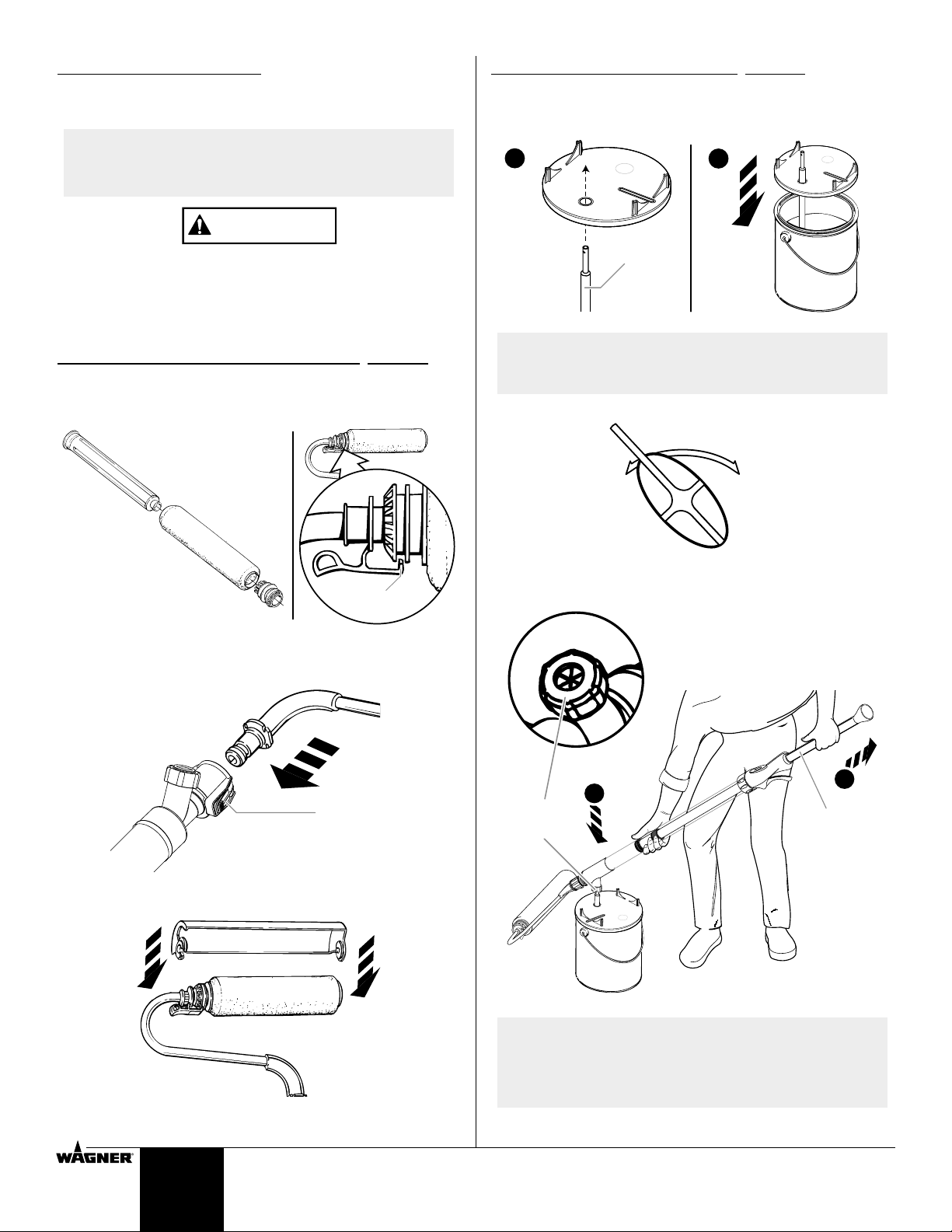

ASSEMBLING THE PAINTMATE® PLUS

1. Assemble core, roller cover and cap. Then attach

assembly to the arm, making sure the roller assembly

snaps into the locking tab.

2. Press the quick-release tabs on the unit and attach the arm

to the handle.

3. If painting a ceiling, attach the spatter shield.

Quick-release

tabs

Core

Roller cover

Cap

Locking tab

CAUTION

NOTE: Make sure the type of paint you use can be

cleaned with either mineral spirits (for oilbased paints) or a warm water and soap

solution (for latex paints).

FILLING THE PAINTMATE® PLUS

1. Slide the small end of the fill tube through the hole in the

can lid.

2. Attach the can lid securely to the paint can.

3. Turn the switch on the main handle to FILL.

4. Press down and firmly hold the fill valve of the main tube

onto the fill tube.

5. Pull the plunger to draw the paint into the main tube.

NOTE: If the plunger does not move easily, twist it

slightly to free it from sticking.

NOTE: Make sure to press down firmly on the main

tube to make sure the PaintMate® Plus fills

properly.

FILL

APPLY

NOTE: Applying a thin coat of petroleum jelly to the

end of the fill tube will help the PaintMate

®

Plus slide easily off the fill tube.

Fill tube

1

2

5

4

Fill

valve

Plunger

Page 3

The Painting People

™

© 2001 Wagner Spray Tech. All rights reserved. 3

English

PRIMING THE ROLLER

QUICK PRIMING METHOD

1. Leave switch on FILL and push plunger tube forward until

you see paint coming through the roller cover.

2. Once paint appears, flip switch to APPLY and begin rolling.

Squeeze Power Trigger

®

for additional paint as needed.

OPTIONAL

PRIMING METHOD

1. Move switch to APPLY, then squeeze the trigger on the

main tube. It will take several squeezes of the trigger to

fully saturate the roller cover.

APPLYING PAINT

Because priming the roller may use a lot of the paint in the main

tube, you may need to refill the main tube after priming. Once

paint appears through the roller cover, begin rolling. Keep paint

flowing to the roller by squeezing the trigger as necessary.

Refill as necessary to complete project.

NOTE: When painting, make sure your floors and

furnishings are sufficiently protected against

drips or spatters.

NOTE: When using either method, do not oversaturate

the roller. An oversaturated roller will slide,

drip, and spatter excessively.

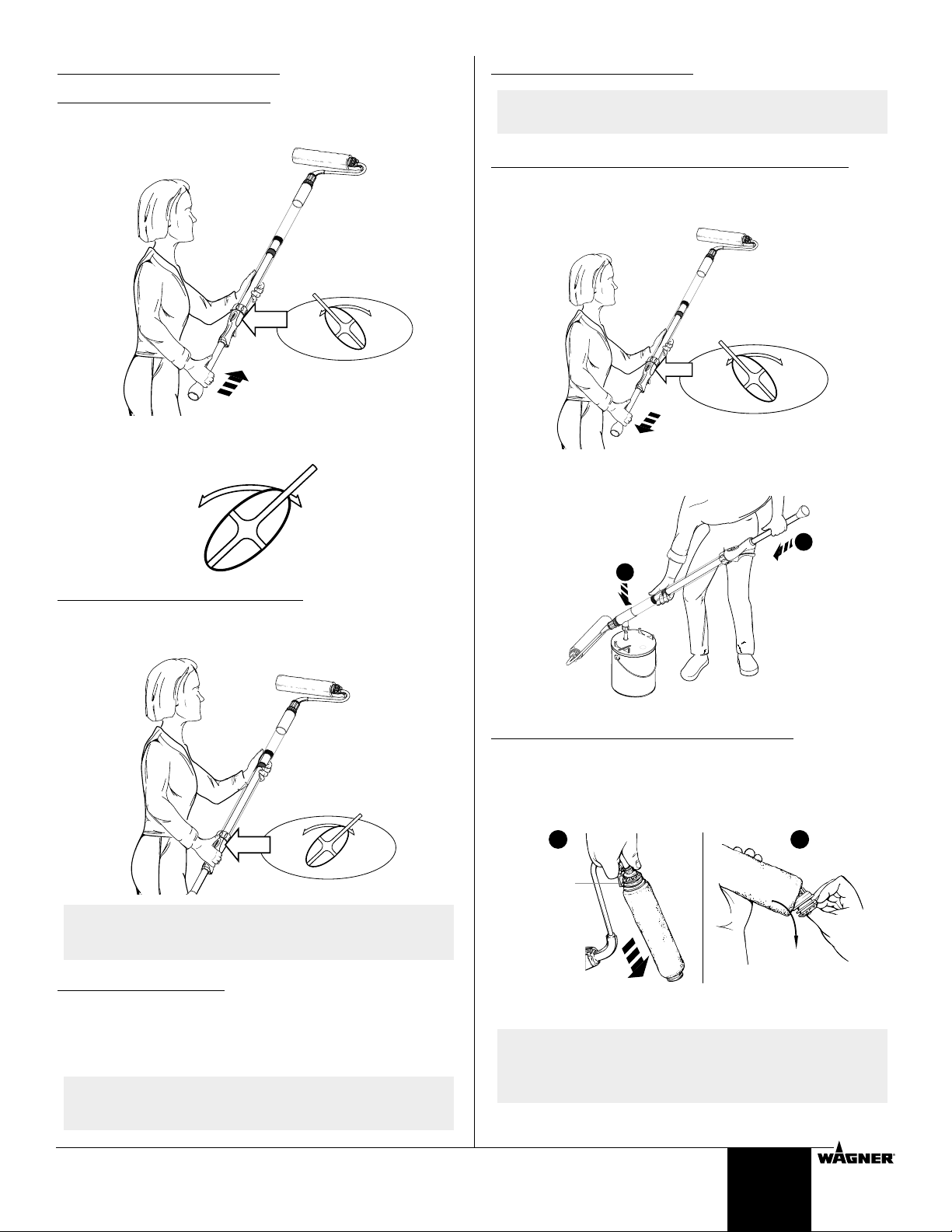

GENERAL CLEANUP

RETURNING EXCESS PAINT TO PAINT CAN

1. Turn the switch on the main tube handle to FILL.

2. Pull plunger back to draw remaining paint from roller arm

into tube.

3. Press fill valve of main tube onto fill tube.

4. Push plunger forward to return excess paint to can.

CLEANING THE ROLLER ASSEMBLY

1. Remove spatter shield. Press locking tab and remove roller

cover assembly from arm.

2. Insert thumb to first knuckle, PRY and PULL the cap from

the roller cover. Once the cap is removed, PUSH the roller

cover out the other end.

3. Place spatter shield, roller cover, cap and core in a bucket

with the appropriate cleaning solution.

NOTE: Make sure your floors and furnishings are

protected from dripping paint when removing

or disassembling the roller assembly.

Locking

tab

1 2

3

4

NOTE: These steps can be followed when using oil-

based and latex paints.

FILL

FILL

APPLY

APPLY

FILL

APPLY

FILL

APPLY

Page 4

The Painting People

™

4 © 2001 Wagner Spray Tech. All rights reserved.

English

CLEANUP FOR LATEX PAINTS

1. Remove fill tube from lid and install it into the fill valve

housing. Submerge the fill tube into warm, soapy water

and pull the plunger in and out a minimum of 5 times.

2. Remove the fill tube, then submerge the fill valve and the

roller arm and pull the plunger in and out a minimum of 5

times.

3. Submerge the connecting area and the fill valve under

warm, soapy water and pull the plunger in and out a

minimum of 5 times.

4. Rinse remaining parts under a faucet and drain all excess fluid.

CLEANUP

FOR OIL-BASED PAINTS

1. Remove fill tube from lid and

install it into the fill valve

housing. Submerge fill tube into

a gallon can of mineral spirits

and pull plunger in and out a

minimum of 5 times.

2. Remove fill tube, then submerge

roller arm into the same one

gallon bucket of mineral spirits,

making sure that ALL of the

holes in the roller arm are

submerged. Pull plunger in and out a minimum of 5 times.

NOTE: These steps should be followed for cleanup of

oil-based paints ONLY.

NOTE: These steps should be followed for cleanup of

latex paints ONLY.

3. Submerge the connecting area and valve

housing under the solvent and pull the

plunger in and out five a minimum of 5

times.

5. Drain all excess fluid and clean remaining

parts by hand.

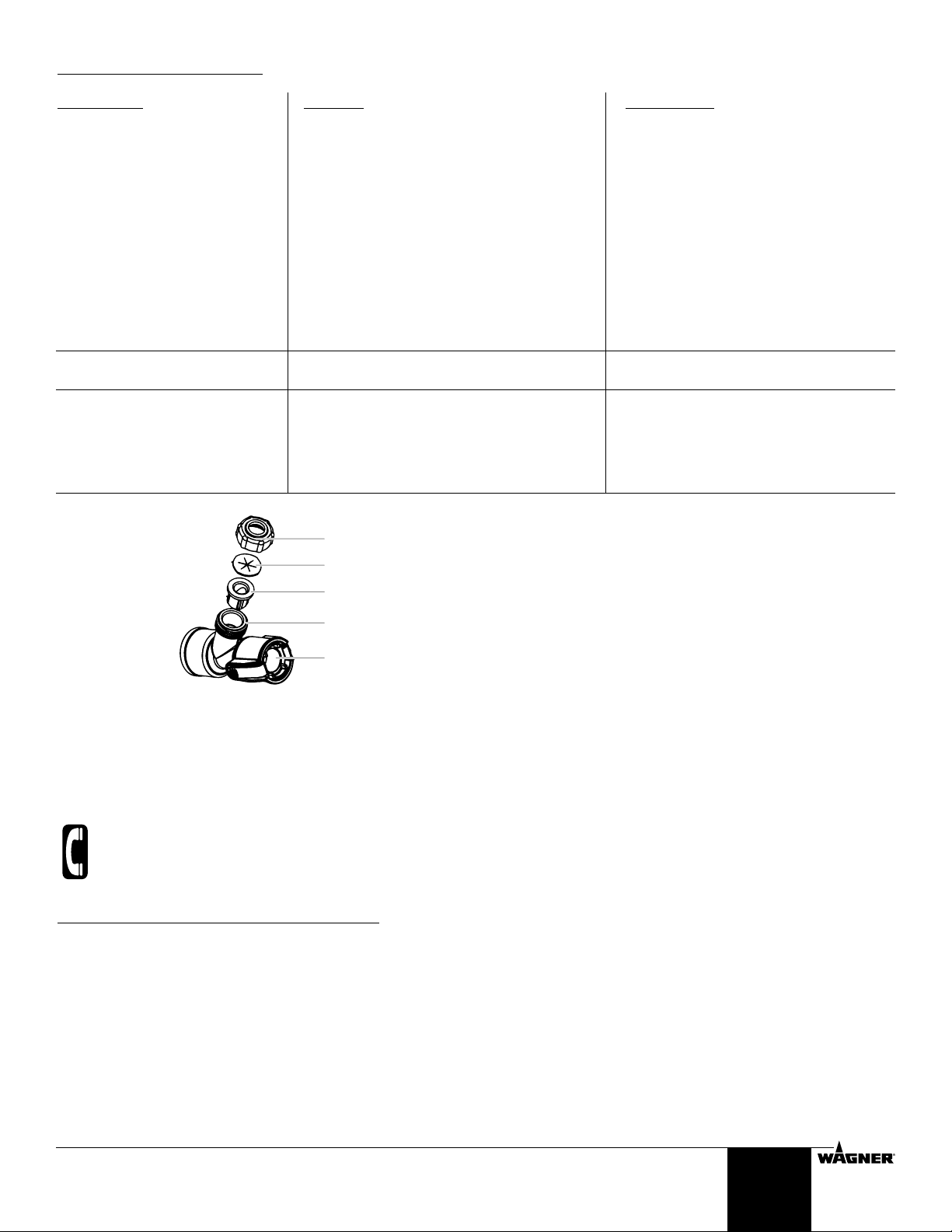

EXTENDED STORAGE

1. Turn the locking collar next to the trigger counterclockwise

until the main tube easily slides off the plunger.

2. Thoroughly pack a generous amount of petroleum jelly

around and in between the O-rings on the plunger.

3. Reassemble the main tube and plunger.

4. Apply a thin layer of petroleum jelly to the valve housing on

the main tube.

5. CLEAN and LUBRICATE the areas on the arm indicated

below. Use a thin layer of petroleum jelly to lubricate the

indicated areas.

6. Assemble the roller arm, core, and cover.

Seal

Bearing areas

O-Ring

NOTE: When putting the plunger back into the main

tube, make sure the O-rings do not twist or cut.

Locking collar

NOTE: When storing your PaintMate®Plus, make sure

the fill valve is pointing downward, and never

store your unit with the fill tube inserted into

the fill valve.

Page 5

The Painting People

™

© 2001 Wagner Spray Tech. All rights reserved. 5

English

TROUBLESHOOTING

PROBLEM

There is paint leakage on the

roller arm assembly

Plunger is difficult to pull/push

The fill tube will not fill with paint

or paint leaks from fill valve

CAUSE

The seal on the arm is backwards

The seal and cap were not properly cleaned

The O-ring and the connecting area were not

cleaned properly

Paint residue on connecting areas

The O-rings are damaged or missing

The roller cover is worn or damaged

The core or cap is worn or damaged

The bearing areas are worn

O-rings are not lubricated

Paint residue on fill valve components

SOLUTION

Turn the seal around

Clean and properly lubricate

Clean and properly lubricate

Clean connecting areas

Replace the O-rings*

Replace the roller cover*

Replace the core or cap*

Call Customer Service

Lubricate the O-rings on the plunger

A) Insert fill tube firmly into fill valve and

twist fill tube several times to break up

paint residue

B) If the problem persists, refer to the

steps below to clean the fill valve

components

Have you tried the recommendations above and are still having problems? In the United States, to speak to a

customer service representative, call our Customer Service at 1-763-519-3555 Monday through Friday between 8:00

AM and 4:30 PM Central time. An automated Self-Help option is also available at 1-800-328-8251, seven days a week,

twenty-four hours a day.

PRODUCT REGISTRATION CARD

Send in your product registration card or register online at www.wagnerspraytech.com. Proper registration will serve as proof of

purchase in the event your original receipt becomes misplaced or lost. Returning this card will expedite the processing of your

warranty. Be sure you write your unit’s date code on the card before sending it. The date code is located on the Power Trigger®of

your unit (for example, T087A). The additional information will also help us to develop new products that best meet your needs and

desires. If you have any questions or concerns regarding your registration card, please call our registration card center at 1-303-394-

9077.

* Replacement parts available by calling customer service

Retaining disk

Locking cap

Duckbill valve

Valve housing

Connecting

area

1. Unscrew the locking cap on the valve housing by turning it

counterclockwise.

2. Remove the retaining disk and the duckbill from the valve

housing.

3. Clean these parts thoroughly using the appropriate cleaning

solution.

4. Replace the duckbill valve and retainer disk.

5. Screw the locking cap on the valve housing by turning it

clockwise.

Page 6

6 © 2001 Wagner Spray Tech. Tous droits réservés.

The Painting People

™

Français

REMPLISSAGE DU PAINTMATEMC PLUS

1. Insérer la petite extrémité du tube de remplissage dans

l’orifice du couvercle.

2. Fixer solidement le couvercle au pot de produit.

3. Mettre le commutateur du manche principal à la position de

FILL.

4. Appuyer et maintenir fermement la soupape du manche sur

le tube de remplissage.

5. Tirer le piston de manière à aspirer le produit dans le

manche.

NOTA: Si le piston ne glisse pas aisément, le tourner

légèrement pour en décoller.

NOTA: Pour que le PaintMate

MC

Plus se remplisse

correctement, la soupape doit rester fermement

enfoncée sur le tube de remplissage.

FILL

APPLY

NOTA: Il suffit d’enduire l’extremité du tube de

remplissage d’une mince couche de gelée de

pétrole pour pouvoir le dégager plus

facilement du PaintMateMCPlus.

Tube de

remplissage

1

2

AVANT DE COMMENCER

On recommande d’utiliser des toiles pour protéger les planchers

ou tout autre objet qu’on veut éviter d’éclabousser

accidentellement.

Les peintures à l’huile qui requièrent une solution

nettoyante plus forte que l’essence minérale ne devraient

pas être utilisées dans le PaintMate

MC

Plus; de telles

solutions pourraient endommager l’outil. S’assurer auprès

du fournisseur que le produit utilisé peut être nettoyé au

moyen d’essence minérale.

ASSEMBLAGE DU PAINTMATEMC PLUS

1. Assembler l’armature, le manchon et l’embout, puis fixer le

tout au bras en s’assurant que le rouleau est bien retenu

par la languette de blocage.

2. Appuyer sur les pattes de dégagement rapide du manche

et insérer le bras dans ce dernier.

3. Si le produit doit être appliqué au plafond, fixer le pareéclaboussures au rouleau.

NOTA: S’assurer que le produit utilisé peut être

éliminé au moyen d’essence minérale (ex. :

peintures à huile) ou d’eau tiède savonneuse

(ex. : peintures au latex).

AVERTISSEMENT

Armature

Manchon

Embout

Languette de

blocage

Pattes de

dégagement

rapide

5

4

Soupape de

remplissage

Piston

Page 7

© 2001 Wagner Spray Tech. Tous droits réservés. 7

The Painting People

™

Français

AMORÇAGE DU ROULEAU

MÉTHODE RAPIDE

1. Laisser le commutateur à la position FILL et pousser le

piston jusqu’à ce que le produit se mettre du manche

principal.

2. Dès que le produit commence à suinter, mettre le

commutateur à la position APPLY et serrer la détente du

manche principal.

AUTRE MÉTHODE

1. Mettre le commutateur à la position APPLY et serrer la

détente du manche principal. On doit serrer plusieurs fois

pour bien saturer le manchon.

APPLICATION DU PRODUIT

Étant donné que l’amorçage peut prendre tout le produit aspiré

dans le manche, il pourrait s’avérer nécessaire de le remplir de

nouveau après cette opération On peut commencer à appliquer

le produit dès qu’il réapparaît à la surface du manchon. Il suffit

de serrer la détente au besoin pour maintenir le débit jusqu’au

rouleau. Remplir le manche autant de fois que le projet l’exige.

NOTA: S’assurer de bien protéger les planchers et

autres éléments du décor contre les

éclaboussures.

NOTA: Quelle que soit la méthode employée, il faut

éviter de trop saturer le manchon, puisqu’il

tend alors à trop glisser, couler ou

éclabousser.

NETTOYAGE GÉNÉRALE

PURGE DU PRODUIT RESTANT

1. Mettre le commutateur du manche principal à la position FILL.

2. Tirer le piston de manière à aspirer dans le manche le

produit restant dans le bras du rouleau.

3. Appuyer la soupape du manche sur le tube de remplissage.

4. Pousser le piston pour évacuer le produit restant dans le

pot.

NETT

OYAGE DU ROULEAU

1. Le cas échéant, retirer le pare-éclaboussures. Appuyer sur

la languette de blocage et retirer le rouleau du bras.

2. Insérer le pouce jusqu’à la première jointure dans l’embout

du rouleau; le DÉGAGER du manchon en TIRANT. Une

fois l’embout enlevé, POUSSER le manchon pour le retirer

à l’autre extrémité.

3. Mettre le pare-éclaboussures, le manchon, l’embout et

l’armature du rouleau dans la solution de nettoyage

appropriée.

NOTA: S’assurer de bien protéger les planchers et autres

éléments du décor contre les éclaboussures

avant de monter ou de démonter le rouleau.

Languette

de blocage

1 2

3

4

NOTA: Les étapes suivantes conviennent aux

produits à base d’huile ou de latex.

FILL

FILL

APPLY

APPLY

FILL

APPLY

FILL

APPLY

Page 8

8 © 2001 Wagner Spray Tech. Tous droits réservés.

The Painting People

™

Français

3. Submerger ensuite le raccord et le

logement de la soupape dans l’essence en

actionnant encore le piston au moins cinqu

fois.

4. Nettoyer les autres pièces à la main et

vien les égoutter.

RANGEMENT À LONG TERME

1. Tourner le bague de verrouillage située près de la détente

dans le sens antihoraire jusqu’à ce que le manche

principal glisse aisément hors du piston.

2. Appliquer une généreuse quantité de gelée de pétrole

autour des joints toriques du piston et entre ces derniers.

3. Réassembler le manche principal et le piston.

4. Enduire d’une mince couche de gelée de pétrole le

logement de la soupape situé sur le manche principal.

5. NETTOYER et LUBRIFIER au moyen d’une mince couche

de gelée de pétrole les éléments de bras indiqués cidessous.

6. Assembler le bras, l’armature et le manchon.

Joint d'étanchéité

Points de contact

Joint torique

NOTA: Lorsqu’on insère le piston dans le manche

principal, on doit s’assurer que les joints

toriques ne sont ni tordus, ni coupés.

Bague de

verrouillage

NOTA: Lorsqu’on range le PaintMateMCPlus, on doit

s’assurer que la soupape de remplissage

pointe vers le bas et que le tube de

remplissage n’y est pas inséré

NETTOYAGE - PRODUITS AU LATEX

1. Retirer le tube de remplissage du couvercle et le fixer au

logement de la soupape de remplissage. Submerger le

tube dans de l’eau tiède savonneuse en actionnant le

piston au moins cinq fois.

2. Retirer le tube, puis submerger la soupape et le bras de rouleau

en actionnant de nouveau le piston au moins cinqu fois.

3. Submerger ensuite la soupape et le raccord dans de l’eau

tiède savonneuse en actionnant encore le piston au moins

cinq fois.

4. Rincer les autres pièces sous l’eau courante et bien les égoutter.

NETTOYAGE - PRODUITS À BASE D’HUILE

1. Retirer le tube de remplissage du

couvercle et le fixer au logement

de la soupape de remplissage.

Submerger le tube dans un

contenant de 4 litres d’essence

minérale en actionnant le piston

au moins cinq fois.

2. Retirer le tube, puis submerger

le bras de rouleau dans le

même contenant en s’assurant

que TOUS les orifices du bras

sont bien couverts par l’essence minérale. Actionner de

nouveau le piston au moins cinq fois.

NOTA: Les étapes suivantes conviennent aux produits

à base d’huile SEULEMENT.

NOTA: Les étapes suivantes conviennent aux produits

à base de latex SEULEMENT.

Page 9

© 2001 Wagner Spray Tech. Tous droits réservés. 9

The Painting People

™

Français

DÉPANNAGE

PROBLÈME

Le bras de rouleau fuit

Le piston glisse difficilement

Le tube de remplissage ne se

remplit pas ou la soupape de

remplissage fuit

CAUSE

Le joint d’étanchéité du bras est placé à

l’envers

Le joint d’étanchéité et l’embout ne sont pas

bien nettoyés

Le joint torique et les raccords ne sont pas

bien nettoyés

Des résidus de produit se sont accumulés sur

les raccords

Les joints torique sont endommagés ou manquants

Le manchon est usé ou endommagé

L’armature ou l’embout sont usés ou

endommagés

Les points de contact sont usés

Les joints ne sont pas lubrifiés

Des résidues se sont accumulés sur les

pièces de la soupape de remplissage

SOLUTION

Inverser le joint d’étanchéité

Nettoyer et lubrifier correctement

Nettoyer et lubrifier correctement

Nettoyer les raccords

Remplacer les joints torique*

Remplacer le manchon*

Remplacer l’armature ou l’embout*

Téléphoner au service à la clientèle

Lubrifier les joints du piston

A) Insérer fermement le tube dans la

soupape de remplissage et tourner le

tube plusieurs fois pour dégager les

résidus.

B) Si le problème persiste, se reporter

aux étapes ci-dessous pour nettoyer

les composants de la soupape de

remplissage.

Si le problème persiste après avoir suivi les recommandations c-dessus, communiquer avec un représentant du

Service à la clientèle en composant le (763) 519-3555, du lundi au vendredi entre 8 h et 16 h 30 HNC (aux États-Unis

seulement), ou utiliser le Service d’auto-assistance sans frais au 1 800 328-8251, sept jours par semaine, 24 heurs par

jour.

* On peut obtenir des pièces de rechange en appelant le Service à la clientèle.

CARTE D'ENREGISTREMENT DE L

’APPAREIL

Prière de poster la carte d’enregistrement de l’appareil ou de la remplir en ligne au site www.wagnerspraytech.com. Cette carte

constitue une preuve d’achat dans l’éventualité où le reçu original serait égaré ou perdu; elle sert également à accélérer le traitement

de la garantie. On doit s’assurer d’y indiquer le code dateur avant de l’envoyer; le code dateur est inscrit sur la détente Power Trigger

de l’outil (T087A, par exemple). Les renseignements additionnels obtenus par le biais de ces cartes contribueront en outre au

développement de nouveaux produits mieux adaptés aux besoins et aux exigences des utilisateurs. Pour toute question ou

commentaire concernant les cartes d’enregistrement, prière de téléphoner au centre de traitement de ces dernières en composant le

(303) 394-9077.

Disque de retenue

Capuchon de

verrouillage

Soupape bec-de-canard

Logement de soupape

de remplissage

Points de

raccordement

1. Dévisser le capuchon de verrouillage du logement de la

soupape en le tournant dans le sens antihoraire.

2. Retirer l’anneau de retenue et la soupape bec-de canard du

logement.

3. Nettoyer ces pièces à fond au moyen de la solution

appropriée.

4. Remettre la soupape et l’anneau en place.

5. Visser le capuchon du logement en le tournant dans le sens

horaire.

Page 10

The Painting People

™

10 © 2001 Wagner Spray Tech. Reservados todos los derechos.

Español

ANTES DE COMENZAR

Es conveniente proteger con mantas los pisos y cualquier cosa

de la habitación que no quiera salpicar inadvertidamente con la

pintura.

Algunas pinturas de aceite requieren soluciones de

limpieza más fuertes que los alcoholes minerales y no se

deben usar con el PaintMate

®

Plus. El uso de soluciones

de limpieza más fuertes que los alcoholes minerales puede

dañar el PaintMate®Plus. Pregunte a su proveedor de

pinturas para asegurarse de que la pintura de aceite que

tiene se puede eliminar con alcoholes minerales.

INSTRUCCIONES PARA

ARMAR EL

PAINTMATE® PLUS

1. Ensamble el carrete central, la funda del rodillo y tapa.

Luego instale el ensamblaje en el brazo, asegurándose que

el ensamblaje del rodillo encaje en la lengüeta de bloqueo.

2. Presione las lengüetas de liberación rápida en el mango y

inserte el brazo en el mango.

3. Si la superficie que va a pintar es un techo, coloque la

salpicadera.

NOTA: Asegúrese de que el tipo de pintura que use se

pueda limpiar con alcoholes minerales

(pinturas de aceite) o con una solución de

agua y jabón (pinturas de látex).

INSTRUCCIONES PARA LLENAR EL

PAINTMATE® PLUS

1. Pase el extremo corto del tubo de llenado por el orificio de

la tapa del bote.

2. Fije la tapa en el bote de pintura.

3. Coloque el interruptor del mango principal en FILL.

4. Presione firmemente la válvula de llenado y coloque el tubo

principal en el tubo de llenado.

5. Jale el émbolo para hacer llegar la pintura al tubo principal.

NOTA: Si el émbolo no se mueve fácilemente, gírelo

ligeramente para desatascarlo.

NOTA: Presione firmemente el tubo principal para que

el PaintMate®Plus se llene correctamente.

FILL

APPLY

NOTA: La aplicación de una capa delgada de vaselina al

extremo del tubo de llenado facilitará la extracción

del PaintMate®Plus del tubo de llenado.

Tubo de

llemado

1

2

PRECAUCION

Centro

Forro

Tapa

Lengüetas de

liberación rapida

Pestaña

candado

5

4

Válvula de

llenado

Émbolo

Page 11

The Painting People

™

© 2001 Wagner Spray Tech. Reservados todos los derechos. 11

Español

LIMPIEZA GENERAL

REGRESAR EL EXCESO DE PINTURA AL BOTE

1. Coloque el interruptor del mango del tubo principal en la

posición de FILL.

2. Jale el émbolo hacia atrás para extraer la pintura restante

del rodillo hacia el tubo principal.

3. Presione la válvula de llenado del tubo principal para llenar

el tubo.

4. Empuje el émbolo hacia delante para regresar el exceso de

pintura al bote.

LIMPIEZA DE LA UNIDAD DEL RODILLO

1. Retire la salpicadera. Presione la lengüeta de bloqueo y

retire el rodillo del brazo.

2. Introduzca el dedo pulgar, hasta el primer nudillo, en la

tapa del rodillo, APALANQUE y JALE la tapa. Después de

retirar el tapón, EMPUJE el rodillo hacia el otro extremo

para sacarlo.

3. Coloque la salpicadera, el rodillo, el tapa y el carrete en

una cubeta con la solución de limpieza apropiadá.

NOTA: Asegúrese de que sus pisos y muebles estén

protegidos de las gotas de pintura cuando

retire o desmonte el ensamblaje del rodillo.

Lengüeta

de bloqueo

1 2

3

4

NOTA: Siga estos pasos cuando utilice pinturas de

aceite y de látex.

INSTRUCCIONES PAR CEBAR EL RODILLO

MÉTODO DE CEBADO RÁPIDO

1. Deje el interruptor en la posición de FILL y empuje el tubo

del émbolo hacia delante hasta que vea salir la pintura por

el rodillo.

2. Una vez que aparezca la pintura en el rodillo, coloque el

interruptor en la posición de APPLY y comience a pintar.

Presione el gatillo Power Trigger

®

según sea necesario

para obtener más pintura.

MÉT

ODO DE CABADO OPCIONAL

1. Coloque el interruptor en la posición de APPLY y después

oprima el gatillo del tubo principal. Presione el gatillo

varias veces para saturar el rodillo completamente.

APLICACIÓN DE LA

PINTURA

Es posible que tenga que rellenar el tubo principal después de

cebar el rodillo, ya que en el cebado se puede utilizar una gran

cantidad de pintura del tubo principal. Cuando aparezca la

pintura en el rodillo, comience a pintar. Mantenga un flujo

continuo de pintura al rodillo oprimiendo el gatillo cuando sea

necesario. Rellene con pintura según sea necesario hasta

completar el proyecto.

NOTA: Cuando pinte, asegúrese de que los pisos y

muebles estén bien protegidos contra goteos y

salpicaduras.

NOTA: Con ninguno de los dos métodos sature

excesivamente el rodillo, pues podría

deslizarse, chorrear y salpicar excesivamente.

FILL

FILL

APPLY

APPLY

FILL

APPLY

FILL

APPLY

Page 12

The Painting People

™

12 © 2001 Wagner Spray Tech. Reservados todos los derechos.

Español

LIMPIEZA PARA PINTURAS DE LÁTEX

1. Retire el tubo de llenado de la tapa e instálelo en el

alojamiento de la válvula de llenado. Sumerja el tubo de

llenado en agua tibia jabonosa y accione el émbolo un

mínimo de 5 veces.

2. Retire el tube de llenado, luego sumerja la válvula de llenado y

el brazo del rodillo y accione el émbolo un mínimo de 5 veces.

3. Sumerja las átreas de conexión y la válvula de llenado bajo

agua tibia jabonosa y accione el émbolo un mínimo de 5 veces.

4. Enjuague las otras piezas bajo la llave de agua y drene el

exceso de líquido de las mismas.

LIMPIEZA

PARA PINTURAS A BASE DE ACEITE

1. Retire el tubo de llenado de la

tapa e instálelo en el alojamiento

de la válvula de llenado.

Sumerja el tubo de llenado en

un bote de alcoholes minerales

de cuatro litros y accione el

émbolo un mímimo de 5 veces.

2. Retire el tubo de llenado, luego

sumerja el brazo del rodillo en el

mismo bote de cuatro litros de

alcoholes minerales,

asegurándose de que TODOS los orificios del brazo del rodillo

estén sumergidos. Accione el émbolo un mínimo de 5 veces.

NOTA: Estos pasos se deben seguir ÚNICAMENTE

para la limpieza de pinturas de aceite.

NOTA: Estos pasos se deben suguir ÚNICAMENTE

para la limpieza de pinturas de látex.

3. Sumerja el área de conexión y el

alojamiento de la válvula en el solvente y

accione el émbolo un mínimo de 5 veces.

4. Drene todo el exceso de líquido y limpie

las demás piezas a mano.

ALMACENAMIENTRO

PROLONGADO

1. Gire el collarín de seguridad ubicado junto al gatillo en

dirección opuesta a las manecillas del reloj hasta que

pueda retirar fácilemente el tubo principal del émbolo.

2. Unte una cantidad suficiente de vaselina alrededor y entre

las juntas tóricas del émbolo.

3. Vuelva a acoplar el tubo principal al émbolo.

4. Aplique una capa delgada de vaselina en el alojamiento de

la válvula, en el tubo principal.

5. LIMPIE y LUBRIQUE las áreas del brazo indicadas a

continuación. Lubrique los sitios indicados con una capa

delgada de vaselina.

6. Arme el brazo del rodillo, el carrete y el rodillo.

Sello

Àrea de rodamientos

Junto tórica

NOTA: Cuando vuelva a colocar el émbolo en el tubo

principal, asegúrese de que las juntas tóricas

no se tuerzan ni rompan.

Collarín de

seguridad

NOTA: Cuando guarde el PaintMate®Plus, asegúrese de

que la válvula de llenado esté apuntando hacia

abajo y nunca guarde la unidad con el tubo de

llenado acoplado a la válvula de llenado.

Page 13

The Painting People

™

© 2001 Wagner Spray Tech. Reservados todos los derechos. 13

Español

PROBLEMA

La unidad del brazo del rodillo

tiene una fuga de pintura

Cuesta trabajo acionar el émbolo

El tubo de llenado no se llena

de pintura o se chorrea

pintura de la válvula de

llenado

SOLUCIÓN

Invierta el sello

Limpie y lubrique el sello y la tapa

Limpie y lubrique

Limpie las áreas de conexión

Cambie las juntas tóricas*

Cambie el rodillo*

Cambie el carrete o la tapa*

Llame a Servicio al cliente

Lubrique las juntas tóricas del émbolo

A) Introduzca el tubo de llenado

firmemente en la válvula de llenado y

gírelo varias veces para aflojar los

residuos de pintura

B) Si el problema persiste, consulte los

siguientes pasos para limpiar los

componentes de la válvula de llenado

CAUSA

Está invertido el sello en el brazo

El sello y la tapa no tueron limpiados correctamente

Las juntas tóricas están dañadas áreas de conexión

no fueron limpiadas correctamente

Hay residuos de pintura en las áreas de conexión

Las juntas tóricas están dañadas o faltan

El rodillo está desgastado o dañado

El carrete central o la tapa está desgastado o

dañado

Las áreas de rodamientos están desgastadas

Las juntas tóricas no están lubricadas

Hay residuos de pintura en las piezas de la válvula

Si usted ha seguido las recomendaciones anteriores y aún tiene problemas, en los Estados Unidos, para hablar con

un representante de Servicio al cliente, llame al 1-763-519-3555 de lunes a viernes entre 8:00 AM y 4: 30 pm horario

central. También se encuentra disponible un sistema de autoayuda automatizado llamando al 1-800-328-8251, siete

días a la semana, veinticuatro horas al día.

* Los repuestos están disponibles llamando a Servicio al cliente

TARJETA DE REGISTRO DEL PRODUCTO

Envíe su tarjeta de registro del producto o regístrelo en línea en www.wagnerspraytech.com. El registro apropiado servirá como

comprobante de compra en caso de que se extravíe el recibo de compra original. El enviar esta tarjeta acelerará el proceso de su

garantía. Siempre escriba el código de la fecha de la unidad en la tarjeta antes de enviarla. El código de la fecha se encuentra en el

gatillo Power Trigger®de la unidad (por ejemplo, S087R). La información adicional nos ayudará también a desarrollar nuevos

productos que respondan mejor a sus necesidades o deseos. Si tiene preguntas referentes a su tarjeta de registro, llame a nuestro

centro de tarjetas de registro al 1-303-394-9077.

SOLUCIÓN DE PROBLEMAS

Disco de retención

Tapa de seguridad

Válvula de boca plana

Caja la válvula de

llenado

Àrea de conexión

1. Destornille la tapa de seguridad del alojamiento de la

válvula girándolo en sentido contrario a las manecillas

del reloj.

2. Retire el disco de retención y la válvula de boca plana del

alojamiento de la válvula.

3. Limpie las piezas completamente con la solución de

limpieza adecuada.

4. Vuelva a instalar la válvula de boca plana y el disco de

retención.

5. Atornille la tapa de seguridad en el alojamiento de la

válvula girándolo en el sentido de las manecillas del

reloj.

Page 14

The Painting People

™

14 © 2001 Wagner Spray Tech. All rights reserved.

Item Part No. Description Qty

1,3 0514118 Roller core and cap* . . . . . . . . . . . . . .1

2 0155206 Roller cover . . . . . . . . . . . . . . . . . . . . .1

4,5,6 0514150 Seal, roller arm, and O-ring* . . . . . . . . .1

4,6 0514112 Seal and O-ring . . . . . . . . . . . . . . . . . .1

7 0514230 Spatter shield . . . . . . . . . . . . . . . . . . . .1

8 9871022 O-ring . . . . . . . . . . . . . . . . . . . . . . . . .2

9 ----------- Main tube . . . . . . . . . . . . . . . . . . . . . . .1

10 ----------- Plunger . . . . . . . . . . . . . . . . . . . . . . . .1

11 0284398 Locking cap . . . . . . . . . . . . . . . . . . . . .1

12 0284395 Retainer disk . . . . . . . . . . . . . . . . . . . .1

13 0284435 Duckbill valve . . . . . . . . . . . . . . . . . . . .1

14 0284432 Fill tube . . . . . . . . . . . . . . . . . . . . . . . .1

15 0284320 Can cover . . . . . . . . . . . . . . . . . . . . . .1

* Denotes parts that can only be purchased together and not

individually.

Article N° de pièce Description Qté

1,3 0514118 Ensemble armature/embout* . . . . . . . .1

2 0155206 Manchon de rouleau . . . . . . . . . . . . . .1

4,5,6 0514150 Bras, joints d’étanchéité et torique* . . .1

4,6 0514112 Joints d’étanchéité et torique* . . . . . . .1

7 0514230 Pare-éclaboussures . . . . . . . . . . . . . . .1

8 9871022 Joint torique . . . . . . . . . . . . . . . . . . . . .2

9 ----------- Tube principal . . . . . . . . . . . . . . . . . . .1

10 ----------- Piston . . . . . . . . . . . . . . . . . . . . . . . . .1

11 0284398 Capuchon de verrouillage . . . . . . . . . .1

12 0284395 Disque de retenue . . . . . . . . . . . . . . . .1

13 0284435 Soupape bec-de-canard . . . . . . . . . . . .1

14 0284432 Tube de remplissage . . . . . . . . . . . . . .1

15 0284320 Couvercle de pot de produit . . . . . . . . .1

* Indique qu’il s’agit de pièces qui ne peuvent être achetées

qu’ensemble.

Articulo # de Parte Descripción Qty

1,3 0514118 Carrete y tapa* . . . . . . . . . . . . . . . . . .1

2 0155206 Rodillo . . . . . . . . . . . . . . . . . . . . . . . . .1

4,5,6 0514150 Sello, brazo del rodillo, y junta tórica* . .1

4,6 0514112 Sello y junta tórica* . . . . . . . . . . . . . . .1

7 0514230 Salpicadera . . . . . . . . . . . . . . . . . . . . .1

8 9871022 Junta tórica . . . . . . . . . . . . . . . . . . . . .2

9 ----------- Tubo principal . . . . . . . . . . . . . . . . . . .1

10 ----------- Émbolo . . . . . . . . . . . . . . . . . . . . . . . .1

11 0284398 Tapa de seguridad . . . . . . . . . . . . . . . .1

12 0284395 Disco de retención . . . . . . . . . . . . . . . .1

13 0284435 Válvula de boca plana . . . . . . . . . . . . .1

14 0284432 Tubo de llenado . . . . . . . . . . . . . . . . . .1

15 0284320 Tapa de la lata de pintura . . . . . . . . . . .1

* Indica las piezas que solamente se pueden adquirir como

unidad y no individualmente.

Español

Français

English

1

2

3

4

5

6

7

8

9

10

11

12

13

14 15

PARTS LIST • LISTE DES PIÈCES • LISTA DE PIEZAS

Page 15

Description Part Number

3/8” nap roller cover . . . . . . . . . . . . . . . . . . . . . . . . .0155206

3/4” nap roller cover . . . . . . . . . . . . . . . . . . . . . . . . .0155208

GlassMask™ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0284001

Paint Trimmer™ . . . . . . . . . . . . . . . . . . . . . . . . . . .0156130A

Roller Washer™ . . . . . . . . . . . . . . . . . . . . . . . . . . .0156118A

Swivel stain pad . . . . . . . . . . . . . . . . . . . . . . . . . . .0284055A

Replacement stain pad . . . . . . . . . . . . . . . . . . . . . .0284058A

5-gallon adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . .0284051

Accessories can be purchased by calling customer service.

Description Pièce N° #

Manchon de rouleau grain de 3/8 po . . . . . . . . . . . . .0155206

Manchon de rouleau grain de 3/4 po . . . . . . . . . . . . .0155208

GlassMask™ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0284001

Paint Trimmer™ . . . . . . . . . . . . . . . . . . . . . . . . . . .0156130A

Roller Washer™ . . . . . . . . . . . . . . . . . . . . . . . . . . .0156118A

Tampon à teinture pivotant . . . . . . . . . . . . . . . . . . .0284055A

Tampon à teinture de rechange . . . . . . . . . . . . . . . .0284058A

Adapteur pour pots de 19 litres . . . . . . . . . . . . . . . . .0284051

On peut acheter des accessoires en communiquant avec le

service à la clientèle.

Descripción

N° de Parte

Rodillo de 3/8 pulg . . . . . . . . . . . . . . . . . . . . . . . . . .0155206

Rodillo de 3/4 pulg . . . . . . . . . . . . . . . . . . . . . . . . . .0155208

GlassMask™ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0284001

Paint Trimmer™ . . . . . . . . . . . . . . . . . . . . . . . . . . .0156130A

Roller Washer™ . . . . . . . . . . . . . . . . . . . . . . . . . . .0156118A

Almohadilla giratoria para tinte . . . . . . . . . . . . . . . .0284055A

Almohadilla de repuesto para tinte . . . . . . . . . . . . .0284058A

Adaptator para envase de 5 gal (19 l) . . . . . . . . . . . .0284051

Los accesorios se puede adquirir llamando al departamento de

Servicio al cliente.

Español

Français

English

The Painting People

™

© 2001 Wagner Spray Tech. All rights reserved. 15

ACCESSORIES • ACCESSOIRES • ACCESORIOS

Page 16

WAGNER TWO YEAR LIMITED WARRANTY--KEEP ON FILE

This product, manufactured by Wagner Spray Tech Corporation (Wagner) is warranted against defects in material and workmanship

for two years following date of purchase if operated in accordance with Wagner’s printed recommendations and instructions. This

warranty does not cover damage resulting from improper use, accidents, user’s negligence or normal wear. This warranty does not

cover any defects or damages caused by service or repair performed by anyone other than a Wagner Authorized Service Center.

ANY IMPLIED WARRANTY OF MERCHANTABlLITY OR FITNESS FOR A PARTICULAR PURPOSE IS LIMITED TO TWO YEARS

FOLLOWING DATE OF PURCHASE. THIS PRODUCT IS DESIGNED FOR HOME USAGE ONLY. IF USED FOR COMMERCIAL OR

RENTAL PURPOSES, THIS WARRANTY APPLIES ONLY FOR 30 DAYS FROM DATE OF PURCHASE. WAGNER SHALL NOT IN

ANY EVENT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES OF ANY KIND, WHETHER FOR BREACH OF

THIS WARRANTY OR ANY OTHER REASON. THIS WARRANTY DOES NOT APPLY TO ACCESSORIES.

If any product is defective in material and/or workmanship during the applicable warranty period, return it with proof of purchase,

transportation prepaid, to any Wagner Authorized Service Center. Call the Wagner Technical Service at 1-763-519-3555 Monday

through Friday between 8:00 AM and 4:30 PM Central time. An automated Self-Help option is also available at 1-800-328-8251 and

www.wagnerspraytech.com, seven days a week, twenty-four hours a day.

GARANTIE LIMITÉE DE DEUX ANNÉES DE WAGNER--À CONSERVER

Cet appareil est fabriqué par Wagner Spray Tech Corporation (Wagner). Il est garanti pendant les deux années qui suivent son achat

contre les défauts de matériau ou de fabrication à condition qu'il soit utilisé conformément aux préconisations et notices d'utilisation

imprimées de Wagner. La présente garantie ne vise pas les dégâts causés par la mauvaise utilisation, les accidents, la négligence de

l'utilisateur ou l'usure normale. La présente garantie de vise pas les défauts ou dommages causés par l'entretien ou les réparations

effectués par toute personne, sauf par un centre d'entretien autorisé de Wagner.

TOUTE GARANTIE IMPLICITE DE QUALITE MARCHANDE OU D'ADAPTATION A UNE UTILISATION DONNEE EST LIMITEE AU

DEUX ANNEES SUIVANT LA DATE D'ACHAT. CE PRODUIT EST CONÇU POUR USAGE DOMESTIQUE SEULEMENT. LORSQU'IL

EST UTILISÉ À DES FINS COMMERCIALES OU DE LOCATION, LA PRÉSENTE GARANTIE NE S'APPLIQUE QUE POUR LES 30

JOURS QUI SUIVENT LA DATE D'ACHAT. EN TOUT ÉTAT DE CAUSE, WAGNER NE SAURAIT ÊTRE TENUE RESPONSABLE DE

TOUT DOMMAGE INDIRECT OU CONSÉCUTIF, QUELLE QU'EN SOIT LA NATURE, QUE CE SOIT POUR VIOLATION DE LA

PRÉSENTE GARANTIE OU POUR TOUT AUTRE MOTIF. LA PRÉSENTE GARANTIE NE S'APPLIQUE PAS AUX ACCESSOIRES.

Si un produit démontre un vice de matières ou une malfaçon durant la période de garantie pertinente, retournez-le avec la preuve

d'achat, port payé, à tout centre d'entretien autorisé Wagner. Communiquer avec les techniciens de Wagner en composant le (763)

519-3555, du lundi au vendredi entre 8 h 00 et 16 h 30, hueure du centre. On peut aussi se prévaloir d’un service d’autodépannage

en composant le 1 800 328-8251 ou en se rendant au www.wagnerspraytech.com, sept jours par semaine, 24 heures par jour.

GARANTÍA LIMITADA DE DOS AÑOS DE WAGNER--CONSERVAR EN ARCHIVO

Este aparato, fabricado por Wagner Spray Tech Corporation (Wagner) está garantizado contra defectos en materiales y mano de obra

por dos años a partir de la fecha de compra si es operado de acuerdo con las recomendaciones e instrucciones impresas de Wagner

Esta garantía no cubre ningún defecto o daño que resulte de usos indebidos, accidentes, negligencia del usuario o desgaste normal.

Esta garantía no cubre ningún defecto o daño ocasionado por mantenimiento o reparación efectuado por cualquiera persona o

entidad que no sea un centro de servicios autorizados de Wagner.

CUALESQUIERA GARANTIA IMPLICITA DE MERCANTIBILIDAD O ADECUACION PARA UN PROPOSITO PARTICULAR QUEDA

LIMITADO A DOS AÑOS DESPUES DE LA FECHA DE COMPRA. ESTE PRODUCTO HA SIDO DISEÑADO EXCLUSIVAMENTE

PARA USOS DOMESTICOS. SI SE USA CON MOTIVOS COMERCIALES O PARA ALQUILER, LA GARANTIA TENDRA UNA

DURACION DE 30 DIAS A PARTIR DE LA FECHA DE COMPRA. WAGNER NO SERA RESPONSABLE EN NINGUN CASO POR

DAÑOS INCIDENTALES O CONSECUENCIALES DE CUALQUIER TIPO, YA SEAN POR INCUMPLIMIENTO DE LA GARANTIA O

POR CUALQUIER OTRA RAZON. ESTA GARANTIA NO SE EXTIENDE A LOS ACCESORIOS.

Si cualquier producto presenta defectos de materiales o de mano de obra durante el período de garantía, devuélvalo junto con la

factura de compra y transporte prepagado a cualquier centro de servicios autorizado por Wagner. Llame a Servicio técnico de

Wagner al 1-763-519-3555, de lunes a viernes, entre las 8:00 a.m. y las 4:30 p.m., hora central. También existe una opción de

autoayuda automatizada, llamando al 1-800-328-8251 y en www.wagnerspraytech.com, todos los días y a toda hora.

The Painting People

™

16 © 2001 Wagner Spray Tech. All rights reserved.

Loading...

Loading...