Volvo VN, VHD Service Manual

Service Manual

Trucks

Group 177–500

Preventive Maintenance

Basic Service

VN,VHD

PV776-TSP151476

Foreword

The descriptions and service procedures contained in this manual are based on designs and methods studies carried out up to December 2001.

The products are under continuous development. Vehicles and components produced

after the above date may therefore have different specifications and repair methods.

When this is believed to have a significant bearing on this manual, supplementary service bulletins will be issued to cover the changes.

The new edition of this manual will update the changes.

In service procedures where the title incorporates an operation number, this is a refer-

ence to an S.R.T. (Standard Repair Time).

Service procedures which do not include an operation number in the title are for gen-

eral information and no reference is made to an S.R.T.

The following levels of observations, cautions and warnings are used in this Service

Documentation:

Note: Indicates a procedure, practice, or condition that must be followed in order to

have the vehicle or component function in the manner intended.

Caution: Indicates an unsafe practice where damage to the product could occur.

Warning: Indicates an unsafe practice where personal injury or severe damage to the

product could occur.

Danger: Indicates an unsafe practice where serious personal injury or death could oc-

cur.

Volvo Trucks North America, Inc.

Greensboro, NC USA

Order number: PV776-TSP151476

© 2001 Volvo Trucks North America, Inc., Greensboro, NC USA

All rights reserved. No part of this publication may be reproduced, stored in

retrieval system, or transmitted in any forms by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior written

permission of Volvo Trucks North America, Inc..

Contents

General .................................................................................................... 3

Preventive Maintenance, General ........................................................... 3

Safety Advice ......................................................................................... 7

Specifications ......................................................................................... 9

Engine .................................................................................................... 9

Transmission ........................................................................................ 12

Rear Axle ............................................................................................. 13

Tools ...................................................................................................... 14

Special Tools and Special Equipment ................................................. 14

Preventive Maintenance Inspection Bay ............................................. 21

Design and Function ........................................................................... 23

Clutch ................................................................................................... 23

Power Take-off ..................................................................................... 25

Driveshaft ............................................................................................. 25

Brakes .................................................................................................. 26

Steering System .................................................................................. 27

Hubs .................................................................................................... 28

Chassis ................................................................................................ 29

Cab ...................................................................................................... 30

Preventive Maintenance ...................................................................... 31

Basic Service ....................................................................................... 31

............................................................................................................... 97

Additional Time Based Maintenance ..................................................... 97

............................................................................................................... 99

Additional Mileage Based Maintenance ................................................ 99

Feedback

1

2

Group 177 General

General

Preventive Maintenance, General

Introduction

This manual describes inspection and lubrication requirements during the Basic Service of Volvo VN/VHD

vehicles. The purpose for doing the preventive maintenance is to ensure that the vehicle is safe and

roadworthy over its full lifetime.

The driver is taking part in the continuous preventive

maintenance program by completing the required Daily

Pre-trip Inspection. This is a purely visual inspection that

is designed to detect any obvious problems that would

make the vehicle unsafe to take on the road. Added to

the Pre-trip Inspection is the Preventive Maintenance

Program that is typically carried out by trained personnel

using a systematic approach to cover all important components of the new vehicle.

Preventive Maintenance is a planned vehicle maintenance program that provides an orderly series of

servicing and inspecting procedures. A well applied

maintenance program realizes the investment made in

the vehicle. The difference between a poorly maintained

vehicle and a well maintained vehicle will not show up

until later mileage. Good maintenance is necessary to

assure the designed life expectancy of the vehicle and

its individual components.

Maintenance Coverage

There is no firm maintenance program that will apply to

all operations. A basic maintenance program is not difficult to set up; to make the program the most effective

takes time and effort, and is based around the needs

and experiences of each individual operation. The program in this service manual covers all types of Volvo

VN/VHD vehicles with medium to high mileage and

sometimes high loads.

Use this established maintenance program as a base to

tailor an individual maintenance program for customers

that have requirements that are outside of the scope of

this program.

To establish an individual program, look at information

sources that are usually available, such as:

Driver’s repair or complaint reports.

Unusual parts usage.

Repetitive failures or problems found in inspection.

Unscheduled maintenance or repairs.

Road failures.

3

Group 177 General

Program Structure

This maintenance program has been based on the

progress in vehicle technology and increases in oil quality to simplify the maintenance.

For simplified scheduling, the program has tied maintenance to logical time or mileage limits that make it easy

to anticipate needed servicing. For the majority of onhighway operators, the 24,000 km (15,000 miles) or 4

months schedule can be used with little change.

It is important that the scheduled intervals are followed

as limits. Maintenance can be done before either 24,000

km (15,000 miles) have been reached or before 4

months are up but must be made at or before either the

mileage or the time limit has been reached.

For further information concerning component specifications see service information in Group 1, “Oil and Filter

Change Intervals for Volvo Components, All Models”,

Publication Number 175–001, and any appropriate vendor literature.

Advantages

A well-planned preventive maintenance program offers

the following advantages:

There are many time — and/or mileage-based — service items that are not listed on the form. Look at the

end of this document for a listing of additional components that may need to be serviced, depending on the

mileage or time since last service.

Maintenance Records

It is important to use the inspection form together with

other reports to come up with the best maintenance program for a specific application. Use driver’s reports,

complaints, parts usage, repetitive failures, previous repair orders, road failures, etc. to build a maintenance

history.

Records should be collected over the lifetime of the vehicle to form a permanent vehicle record file. The vehicle

file should be used to customize the operational maintenance needs.

The “Driver Inspection Form” is also required by

Federal law. The use of this inspection report makes

the driver a part of the maintenance program and

places direct responsibility on the driver to report

problems that may come up during operation. When

properly used, there should be no excuse for a defective vehicle being in service.

The lowest attainable maintenance cost.

Maximum vehicle uptime.

Better fuel economy.

Reduced road failures; greater dependability.

Increased customer confidence, better public rela-

tions.

Less possibility of accidents due to defective equip-

ment.

Fewer driver complaints.

Regardless of the planning and the details of the maintenance program, the success of the program hinges on

the caliber of workmanship in performing the actual

inspection. A major cause of failure is a “pencil inspection;” that is, the mechanic checks off each operation as

being OK without making the actual inspection. A “pencil

inspection” defeats the purpose of the inspection, which

is to detect an impending failure.

Maintenance Form

A Service Manual is issued detailing the current inspection forms. Forms are created for different users but all

with the same references to this document. When the inspection point is carried out, check the box if the item is

OK. If further work, such as adjustment, repair, etc.,

needs to be performed, record this information and go

on with the next inspection point. Items noted as being

faulty or in need of adjustment need to be shown to the

customer and scheduled for repair.

4

Basic Inspection

Note: The included Basic Service checklist is an

original copy. The document can be updated without

notice.

The Basic inspection is carried out at a maximum of

24,000 km (15,000 miles) or 4 months, whichever comes

first.

All inspection points are to be carried out as verification

of function or condition. Any defects are noted on the inspection form for later correction, if so ordered by the

vehicle owner.

Note: The standard repair time for performing the

Basic Service Preventive Maintenance is based on

inspection and Oil and Filter Change, without repair

or adjustment.

Annual Inspection

The Annual inspection is carried out yearly in addition to

a Basic inspection. This inspection is designed to open

up components for inspection or using test equipment to

record performance.

The ideal time to carry out the Annual inspection is right

before the hardest season, which means just before winter in the cold weather climates and just before summer

in the hot weather climates.

For further information refer to “Annual Preventive Service Manual”, Publication Number 177–501.

Group 177 General

Other Inspection

There are additional service points that are carried out at

specific mileage or time intervals. These are not part of

the Preventive Maintenance Basic time. They should be

scheduled as an adjustment or repair job carried out at

the same time as the Preventive Maintenance, and are

listed in this document as reminders only.

5

Group 177 General

Noise Emissions

Volvo Trucks North America, Inc. warrants to the first

person who purchases this vehicle for purposes other

than resale and to each subsequent purchaser, that this

vehicle as manufactured by Volvo Trucks North America,

Inc. was designed, built and equipped to conform, to all

applicable U.S. EPA Noise Control Regulations, at the

time it left the control of Volvo Trucks North America, Inc.

This warranty covers this vehicle as designed, built and

equipped by Volvo Trucks North America, Inc., and is not

limited to any particular part, component or system of

the vehicle manufactured by Volvo Trucks North America, Inc. Defects in design, assembly or in any part,

component or system of the vehicle as manufactured by

Volvo Trucks North America, Inc., which, at the time it

left the control of Volvo Trucks North America, Inc.

caused noise emissions to exceed Federal standards,

are covered by this warranty for the life of the vehicle.

Tampering with Noise Control System

Noise Shields and Insulation

Removing or rendering inoperative the engine and/or

transmission noise deadening panels, shields or insulating materials.

Removing or rendering inoperative the cab tunnel or

hood noise insulating materials.

Removing or rendering inoperative any truck body

mounted sound insulation components and/or shields

(e.g., cab or fender shields, skirts, wheel housing splash

shields, etc.).

Engine Control and Fuel Systems

Removing or rendering inoperative, or modifying the engine control system (such a the ECU or the fuel system

components) in order to allow the engine to operate outside of the manufacturer’s specifications (e.g., exceeding

the manufacturer’s engine speed limits).

Federal law prohibits the following acts or the causing

thereof:

(1) The removal or rendering inoperative by any person,

other than for purposes of maintenance, repair, or

replacement, of any device or element of design incorporated into any new vehicle for the purpose of noise

control prior to its sale or delivery to the ultimate purchaser or while it is in use;

or

(2) the use of the vehicle after such device or element of

design has been removed or rendered inoperative by

any person.

Among those acts presumed to constitute tampering are

the acts listed below:

Cooling System

Removing or rendering inoperative cooling system components (e.g., temperature-controlled fan clutch, fan

shroud, fan ring, recirculation shields, etc.).

Exhaust System

Removing or rendering inoperative exhaust system components (e.g., muffler, pipes, clamps, etc.).

Air Intake System

Removing or rendering inoperative air intake/induction

system components (e.g., filter, filter housing, ducts,

etc.).

6

Group 177 General

Safety Advice

Never operate a diesel engine in an area where hydrocarbon vapors (gasoline for example) are present

or are suspected to be present. Hydrocarbon vapors

can enter the air intake and make the engine overspeed, causing severe damage and/or explosion or

fire. Serious personal injury or death can occur.

When entering and exiting the cab, use caution. Always have a firm hand hold and/or stable foot position

before transferring weight to that position. Do not

carry anything when entering or exiting. Make sure

the soles of your shoes and the cab steps are free

from dirt, grease, oil or moisture before using the

steps. Failure to do so can result in a fall, and serious

personal injury or death may occur.

Always chock the wheels before working under the

vehicle to prevent it from rolling. Failure to do so can

result in unexpected vehicle movement and serious

personal injury or death could occur.

If using a jack and/or jack stands, choose proper

fault-free equipment. Failure to do so can result in

equipment failures and personal injury or death may

occur.

Note: During the Preventive Maintenance inspection,

check the condition of warning labels on the vehicle. If a

label is damaged or defaced to the point where the message cannot be read, note on the inspection form to

have it replaced.

7

8

Group 177 Specifications

Specifications

Engine

General

For further information concerning component specifications see service information in Group 1, “Oil and Filter

Change Intervals for Volvo Components,” Publication

Number 175–001, and any appropriate vendor literature.

of the combustion by-products that contaminate the oil.

These contaminates will make the change intervals the

same as for regular oil. However, in extreme driving conditions, a synthetic oil may be the only choice for the

application.

In a modern diesel engine it is very important to have

regular oil changes. The demands of pulling high loads,

pulling at high elevations, extreme high or low temperatures and longer service intervals, make the choice of

correct oil a hard task. The Volvo dealer, the engine

manufacturer or the oil manufacturer has the expertise to

analyze driving conditions and to recommend what oil

gives the best protection and economy.

Oil

The engine oil has the task of lubricating, sealing, cooling and cleaning the engine. Filtering the intake air and

using a low sulfur fuel helps the oil protect the engine

parts. With better engine designs and improved oils, the

service intervals have steadily increased. The interval

choice depends on the engine manufacturer specifications. Make sure the correct oil type and also the correct

viscosity are chosen for the mileage interval driven.

Periodic oil testing is recommended. The test results

give a continuous picture of the health of the engine and

can warn well in advance of a problem developing.

The intervals will not cover all applications. In on/off

highway driving, severe off highway, continuous stopand-go city driving and extremely high mileage, the oil

change interval and preventive maintenance schedule

need to be customized for the best protection and economy. The intervals listed in these specifications are

guidelines that should be used in establishing a correct

maintenance program.

CAUTION

Note: It is not recommended to mix synthetic oils with

petroleum-based oils.

Coolant

The engine coolant protects the cooling system from

freezing or boil over problems. It also protects against

corrosion and cylinder liner pitting. Coolant requirements

are based on the additive levels present in the cooling

system. To be able to run the cooling system as long as

2 years between coolant changes, there must be a replenishment of additives as they are used up. Testing

should be done regularly to be sure the additive levels

are within recommended levels.

Never run the engine with only water in the cooling

system. Always use a mixture of clean water and a recommended antifreeze. The mixture should never be less

than 40% antifreeze and 60% clean water or more than

60% antifreeze and 40% clean water.

Note: For further information on Long life coolant refer to

Service Bulletin 260–002, “Texaco Extended Life

Coolant.”

CAUTION

Long life coolant is colored red for identification purposes, so as not to mistake it for conventional, green

coolant. Long life coolant will test as out of additives

(SCA), but SCA should not be added.

Adding unknown additives may put the engine at risk

of failure. There are many aftermarket oil additives

that claim improved performance if added to the engine oil. Each oil type recommended already contains

additives that have been tested by a collaboration with

engine and oil manufacturers.

Synthetic oil is offered as an alternative to the traditional

petroleum based oil for the engines. The ability of synthetic oil to protect the engine is better than regular oil

but its life is the same as for regular oil. This is because

Fuel

The sulfur content in low-sulfur fuel has been regulated

to a maximum of 0.05% per weight for No.2–D diesel

fuel. For fuels that have a sulfur content of 0.5% by

weight and above, most engine manufacturers are requiring that oil is changed at shorter intervals. Sulfur

creates highly acidic pollutants in the oil that break down

the additives at a higher rate. If fuel with a higher sulfur

content is used, the engine manufacturers recommend

that the oil change intervals be reduced.

9

Group 177 Specifications

VOLVO ENGINES

Note: It is not recommended to mix synthetic oils with

petroleum based oils.

For further information concerning component specifications see service information in Group 1, “Oil and Filter

Change Intervals for Volvo Components,” publication

number 175–001, and appropriate vendor literature.

Maximum change intervals are 40,000 km (25,000 miles)

if using oil that meets the Volvo Drain Specification

(VDS). If the oil does not meet the requirements according to VDS, change intervals should be 24,000 km

(15,000 miles). Contact Volvo or a Volvo authorized

dealer to obtain a list of approved VDS oils.

Shorter oil change intervals maybe required if the engine

is operating in a dusty environment or if frequent stops

and starts are made (see oil change interval below).

Supplemental coolant additives are recommended for all

Volvo cooling systems. Antifreeze alone does not provide

sufficient corrosion protection for heavy duty diesel engines.

If the fuel has a sulfur content exceeding 0.5% by

weight, halve the indicated maximum mileage intervals.

Oil filters should always be changed when changing oil.

CUMMINS ENGINES

For further information concerning component specifications see service information in Group 1, “Oil and Filter

Change Intervals for Volvo Components,” publication

number 175–001, and appropriate vendor literature.

If engine is operating in ambient temperatures consistently below - 20

perform maintenance at shorter intervals. Shorter intervals are also required if the engine is operating in a dusty

environment or if frequent stops and starts are made.

Oil filters should always be changed when changing oil.

Supplemental coolant additives are recommended for all

Cummins cooling systems. Antifreeze alone does not

provide sufficient corrosion protection for heavy duty

diesel engines.

C(0F) or above 40C (100F),

10

Group 177 Specifications

DETROIT DIESEL ENGINES

For further information concerning component specifications see service information in Group 1, “Oil and Filter

Change Intervals for Volvo Components,” publication

number 175–001, and appropriate vendor literature.

The use of fuels with a sulfur content above 0.5% by

weight will require more frequent oil changes. Refer to

Detroit Diesel Publications for details. More frequent oil

changes are also required if the engine is operating in a

dusty environment or if frequent stops and starts are

made (see oil change interval below).

Oil filters should always be changed when changing oil.

Supplemental coolant additives are recommended for all

Detroit Diesel cooling systems. Antifreeze alone does

not provide sufficient corrosion protection for heavy duty

diesel engines.

Note: The Detroit Diesel Engine is installed in earlier VN

vehicles (from 1996–2000) only.

CATERPILLAR ENGINES

For further information concerning component specifications see service information in Group 1, “Oil and Filter

Change Intervals for Volvo Components,” publication

number 175–001, and appropriate vendor literature.

Caterpillar does NOT recommend an automatic extension of oil drain intervals with high quality oil, low sulfur

fuel and non-severe duty driving. Oil drain intervals can

only be extended with an oil analysis program containing

the following elements: oil condition and wear metals,

trend analysis, fuel consumption and oil consumption.

In areas where fuel sulfur content exceeds 1.5%, choose

an oil with a total base number that is within the API

CF-4 or CG-4 categories and shorten the oil change period based on oil analysis.

Shorter oil change intervals are required if the engine is

operating in a dusty environment or if frequent stops and

starts are made (see oil change interval below).

Oil filters should always be changed when changing oil.

Supplemental coolant additives are recommended for all

Caterpillar cooling systems. Antifreeze alone does not

provide sufficient corrosion protection for heavy duty

diesel engines.

Note: Caterpillar Engines were installed in later model

VN vehicles (from 1996–1999) only.

11

Group 177 Specifications

Transmission

Includes Volvo, Eaton Fuller, Meritor, and Allison HD Transmissions

For further information concerning component specifications see service information in

Group 1, “Oil and Filter Change Intervals for Volvo Components,” publication number

175–001, and appropriate vendor literature.

12

Group 177 Specifications

Rear Axle

Includes Volvo, Arvin Meritor, and Eaton Dana Rear Axles

For further information concerning component specifications see service information in

Group 1, “Oil and Filter Change Intervals for Volvo Components,” publication number

175–001, and appropriate vendor literature.

13

Group 177 Tools

Tools

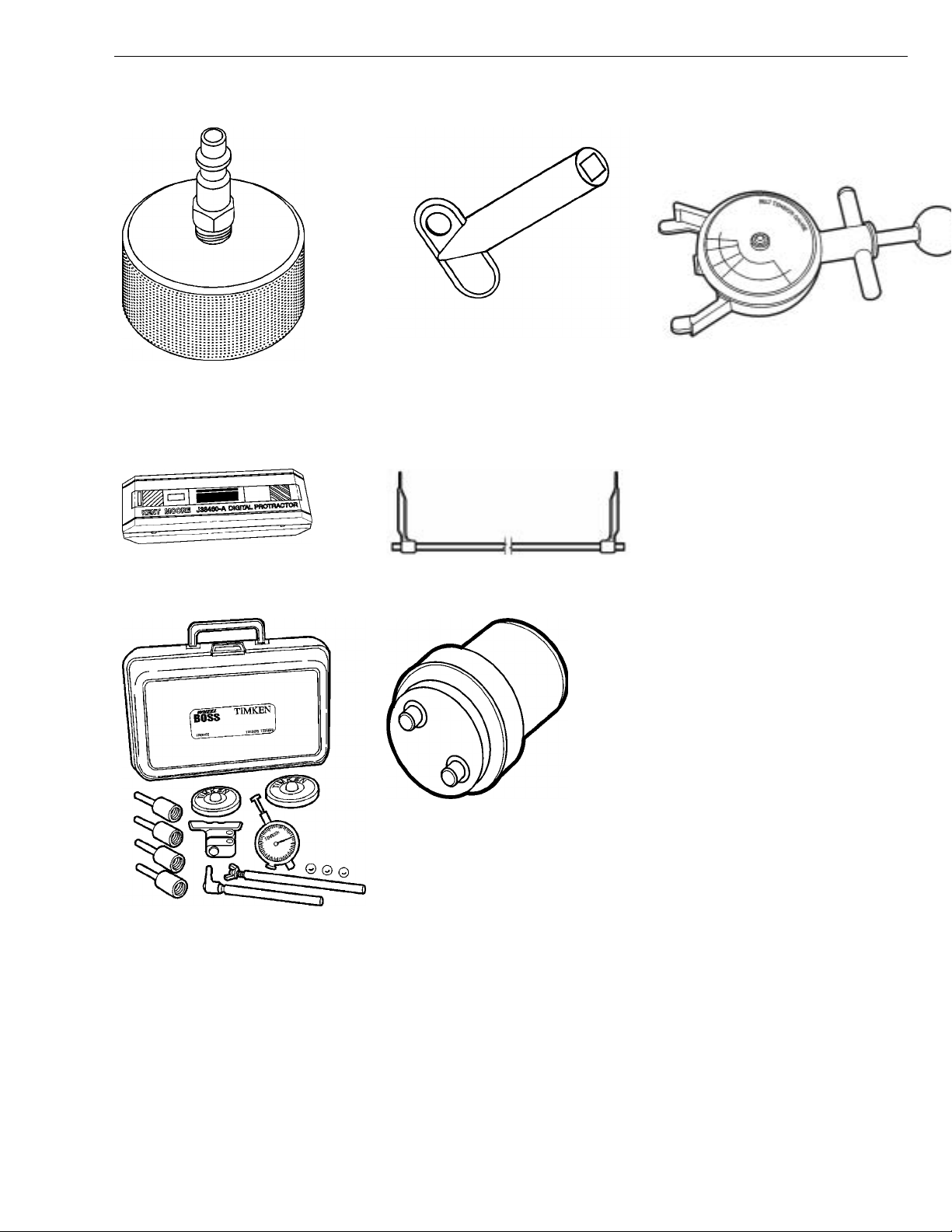

Special Tools and Special Equipment

The following special tools are recommended for use in the preventive maintenance inspection. Special tools can be ordered through Volvo Special Tools program in the parts

ordering system or already from Kent-Moore by calling (800) 328–6657. (Kent-Moore

tools are preceded by a J.) Please refer to the specific tool number when ordering.

Special Tools

J-42942

ABS Sensor Adjustment Tool

(Kent-Moore)

J-44399

Air System Tester

J-42189

Airline Release Tool

(Kent-Moore)

J-44773

Airline Release Tool

J-44769

Wheel Speed Sensor Extractor

14

J-44966

Wheel Speed Sensor Remover for Heavy Duty Steer Axle

and Aluminum Hub

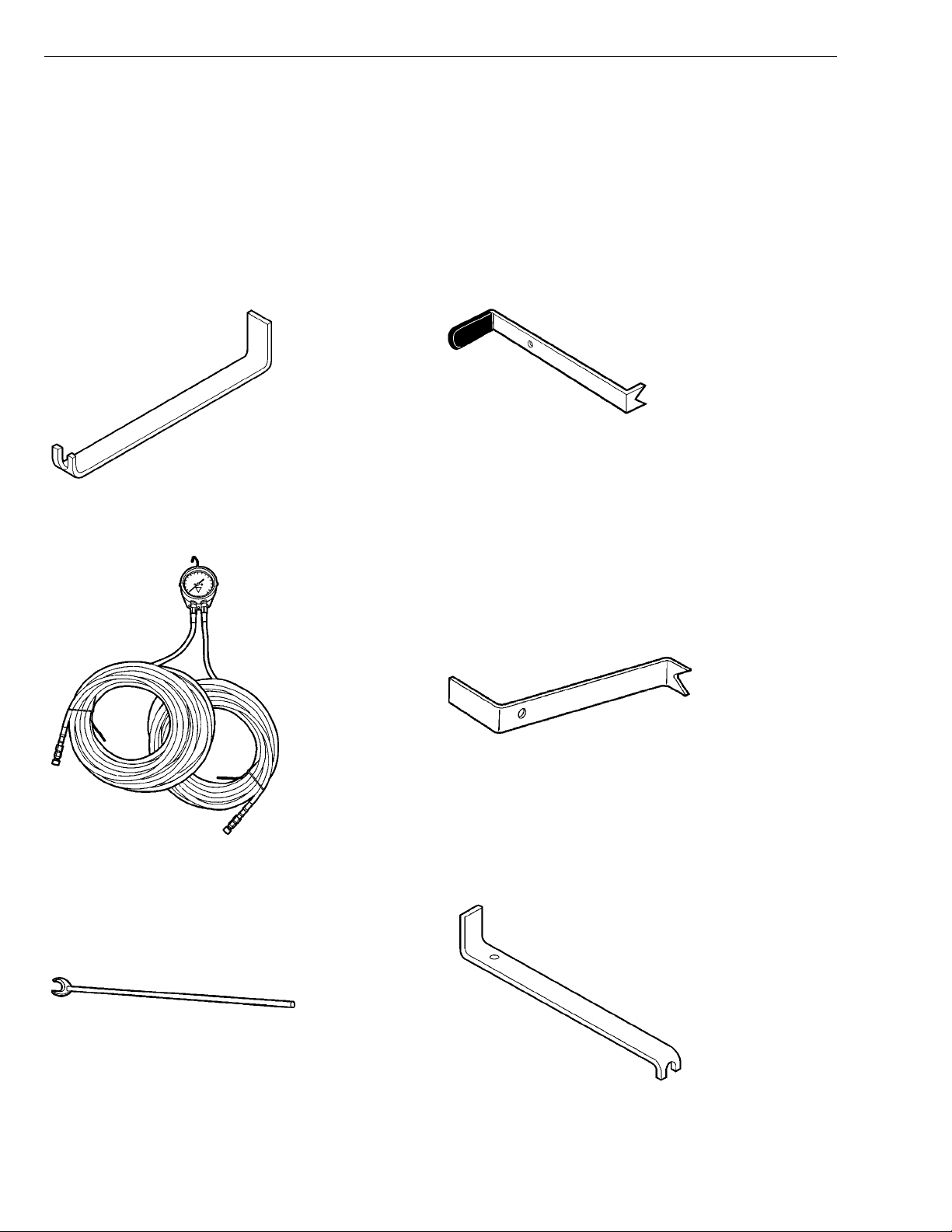

Group 177 Tools

Special Tools (Continued)

J-44302

A/C Schrader Valve Core Removal Tool

J-22610

Drive Shaft Boot Camp Pliers

J-443338

Oil Dipstick for A/C Compressor

J-43143

Tie Strap Tensioner

J-41610

Feeler Gauge Set

J-44392

Fan Belt Tensioner Tool

15

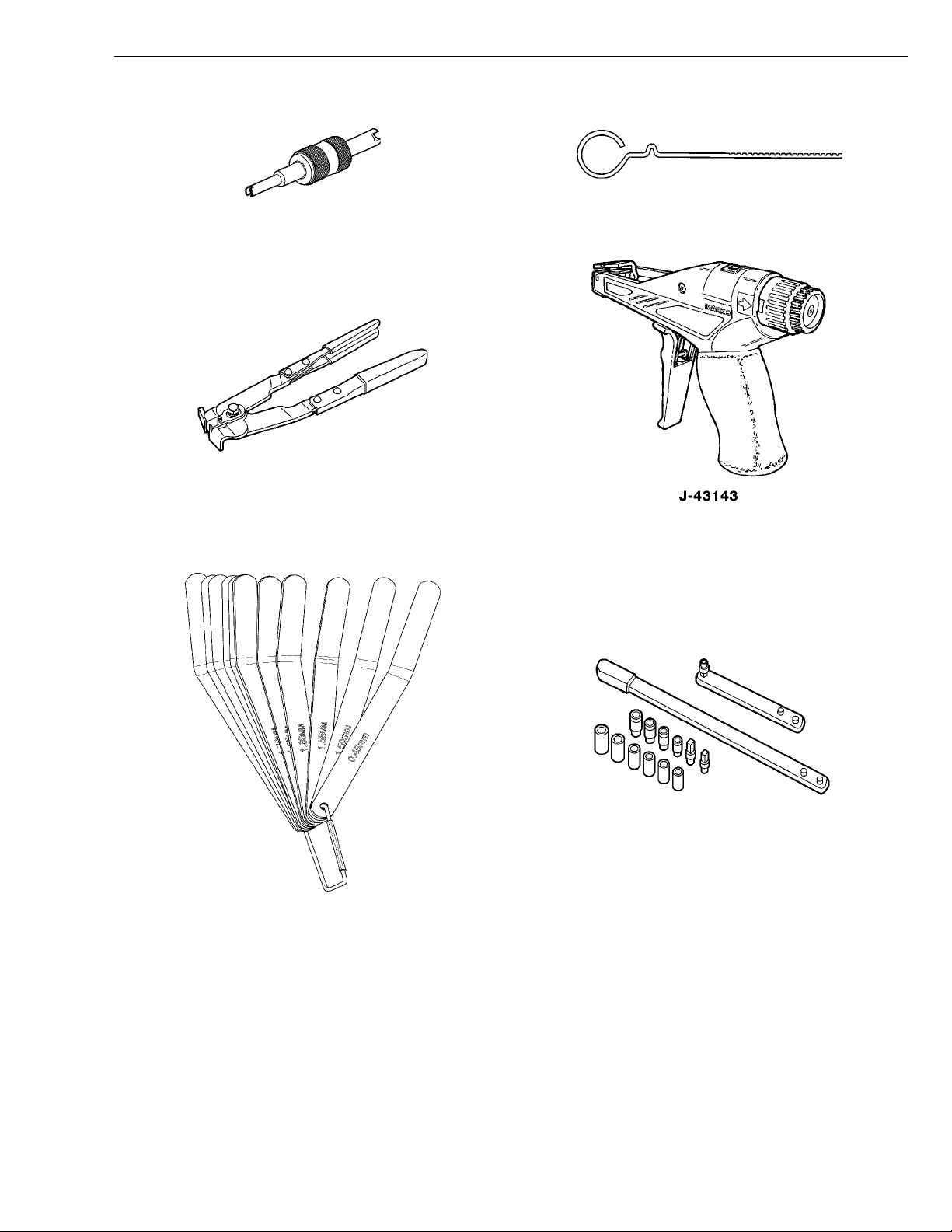

Group 177 Tools

Special Tools (Continued)

PT 5900

Chip Vacuum

J-38641-B

Diesel Fuel Hydrometer

9998142

Charge Air Cooler Pressure Tester

J-44544

Ride Height Gauge

16

000700

Rim Flange Wear Gauge

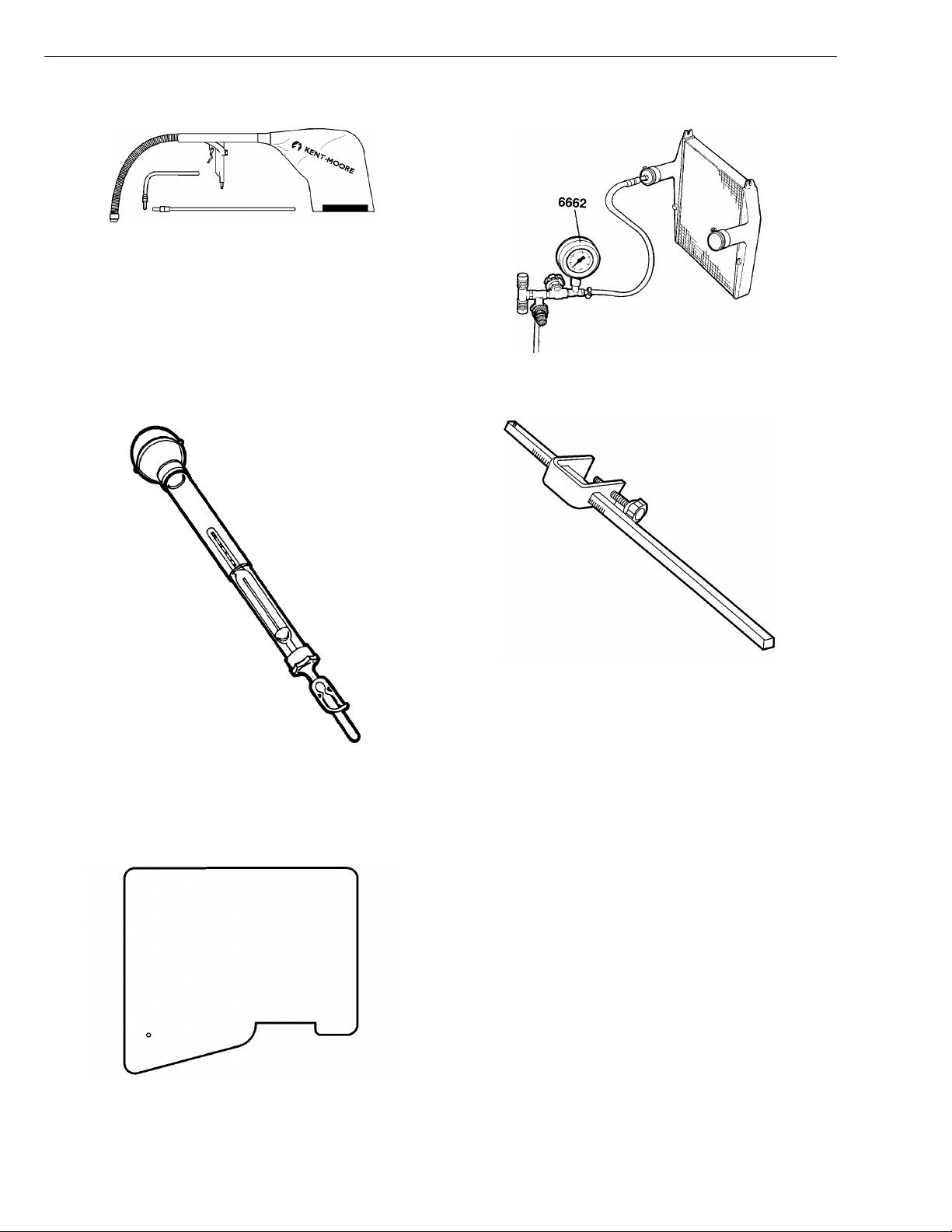

Group 177 Tools

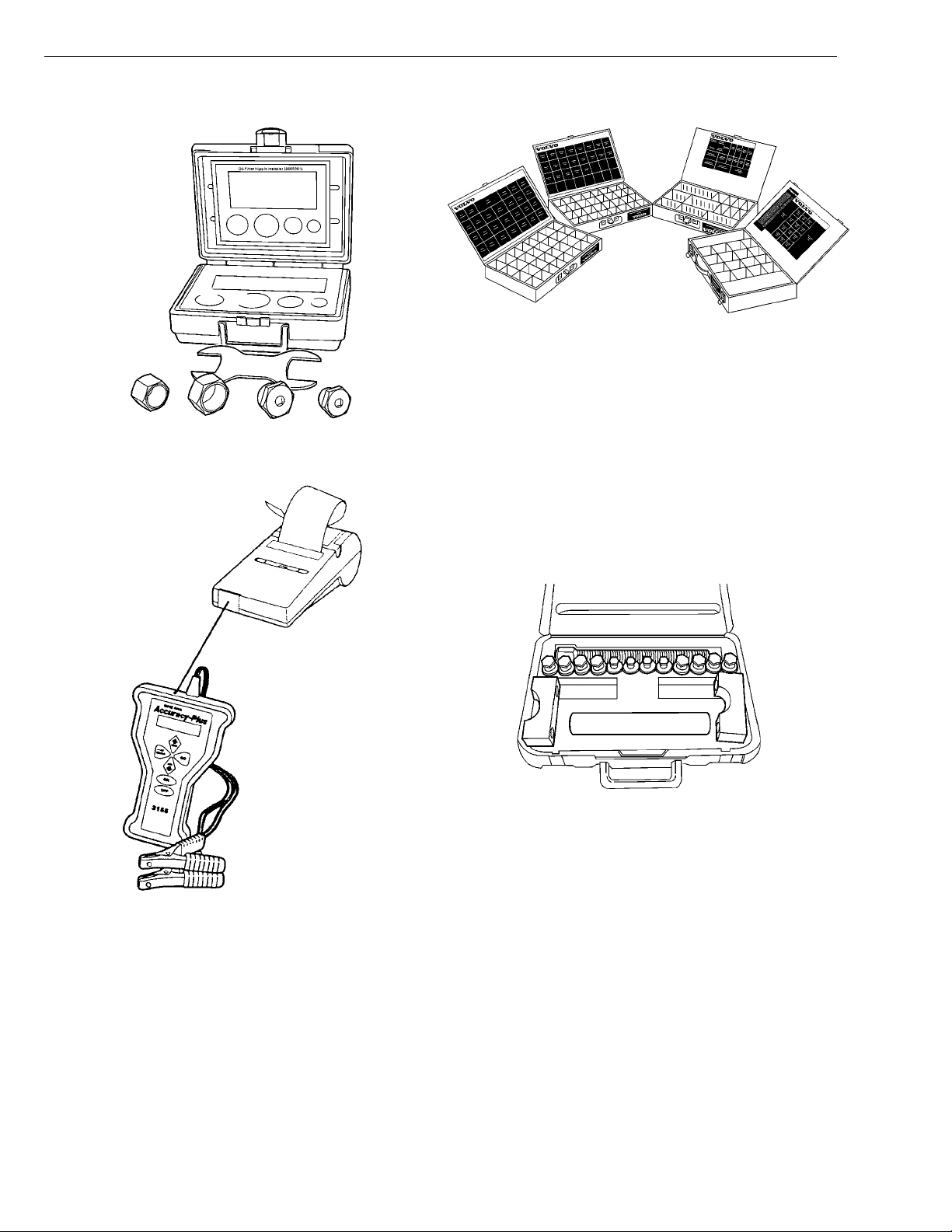

Other Special Equipment

J-42397-A

Coolant Pressure Test Adapter

J-38460-ADigital Inclinometer J-36795

1089953

Bulb Removal Tool

Tandem Axle Calipers

J-23600-B

Belt Tension Gauge

3093472

Timken Wheel End Play Gauge

9996791

Spring Pin Socket

17

Group 177 Tools

Other Special Equipment (Continued)

9998691

Oil Filter Nipple Installer Kit

3947553, 3949521, 3946522, 3949523

Terminal and Shim Kits

18

J-44701

Battery Tester Kit

J-44778, J-44779

Driveshaft U-Joint and Yoke Kits

Group 177 Tools

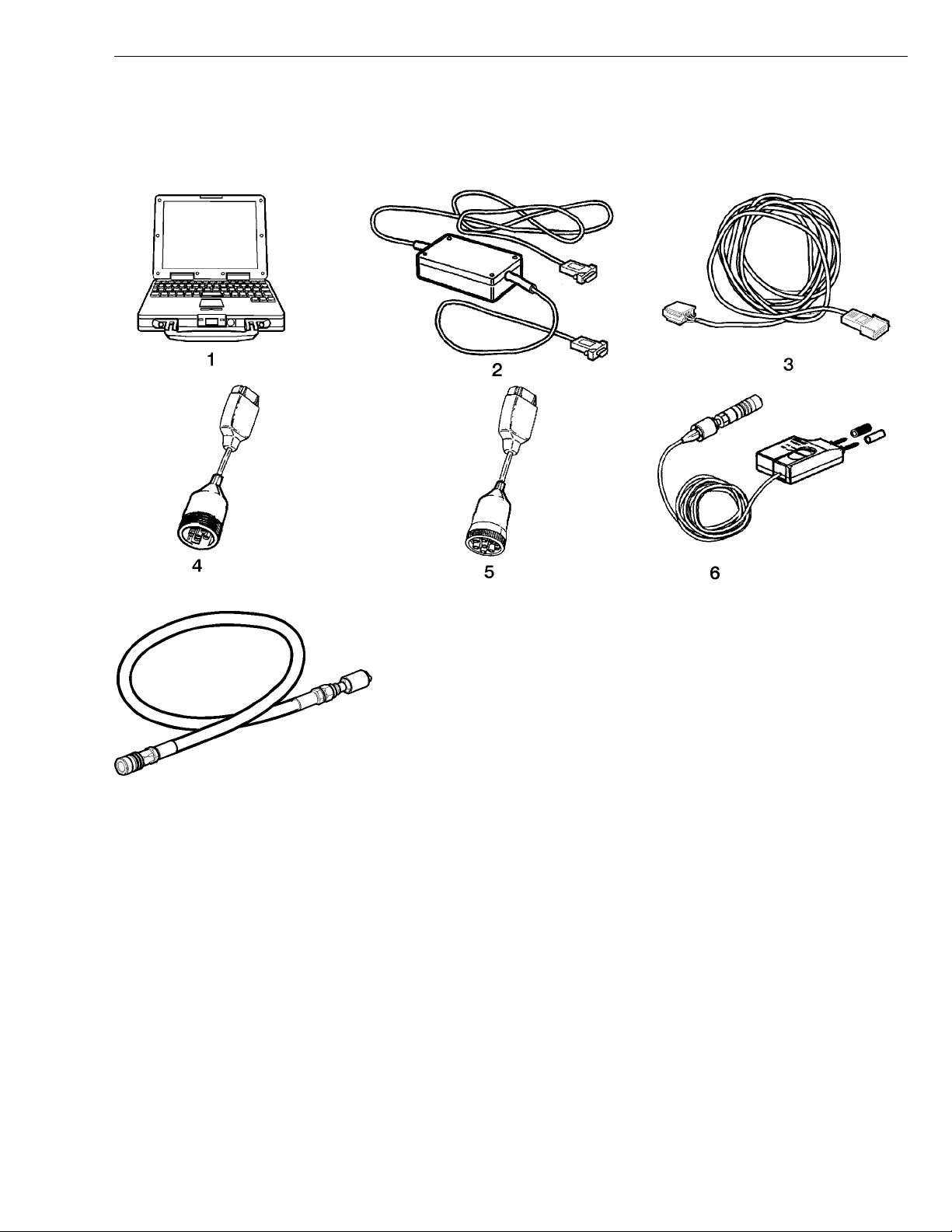

VCADS Pro Tools

The following hardware is used to operate VCADS Pro. The tools can be ordered from

Volvo Trucks North America; please refer to the specific tool number when ordering.

7

1 PC tool-package

2 9998555, Communication interface unit

3 9812331, Extension cable

4 J-43999, 6 pin Diagnostic adapter (for VN vehicles

prior to 1999)

5 J-43939, 9 pin Diagnostic adapter (for VN vehicles

built from January 1999)

6 9998496, Pressure gauge

7 9998495, Air Pressure Hose

19

Group 177 Tools

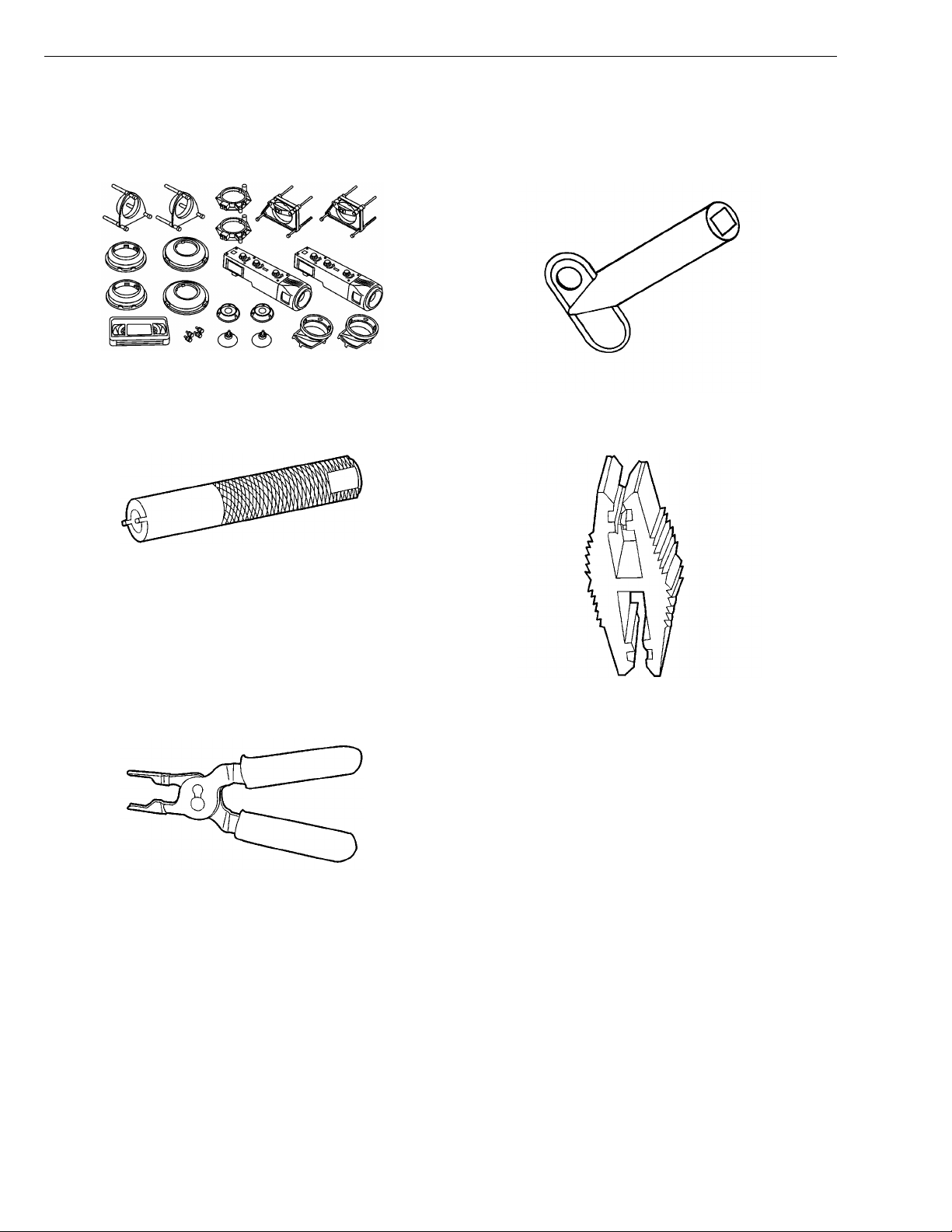

Lighting System, Special Tools

The tools listed below are used to complete maintenance on the Lighting System for

Volvo Trucks. They may be obtained from Volvo or, where indicated, from Kent Moore

at (800) 328-6657.

J-25300-D

Headlight Aiming Kit (Kent Moore)

J-42395

Rheostat Removal Tool (Kent Moore)

1089953

Lamp Removal Tool (Volvo)

20378326

Fuse Puller Tool (Volvo)

20

J-43244

Relay Puller Tool (Kent Moore)

Group 177 Tools

Preventive Maintenance Inspection Bay

Location

Preventive Maintenance is logically carried out at the

same time as lubrication of the vehicle. It is then natural

to use a bay with a grease pit to be assigned and

equipped for Preventive Maintenance. If a pit is not available, a regular workshop bay can be used, with jacks

added to the necessary equipment.

The bay needs to be well lit so inspection can be done

without having to use a flashlight (unless inspecting in

the frame).

Equipment

Inspection bay equipment should be specifically assigned to that bay and not be shared with the rest of the

shop. The floor equipment should have floor space for

storage in between using them and tools should be hung

on boards or stored in a cabinet for easy overview and

access.

Install mirrors in four corners of the bay so one person

can do a lighting function check without having to leave

the cab or rely on a spotter. Mirrors do not need to be

larger than truck door mirrors. Any type of equipment

that allows inspection by one person instead of having to

use a helper, makes inspection easier and faster.

21

22

Group 177 Design and Function

Design and Function

Clutch

General

For further information concerning component specifications see service information in Group 1, “Oil and Filter

Change Intervals for Volvo Components,” publication

number 175–001, and appropriate vendor literature.

Hydraulic fluid in the clutch system collects moisture

from the air and will eventually hold enough moisture to

affect the metal surfaces in the system unless removed.

Replace the fluid at the recommended intervals or more

frequently.

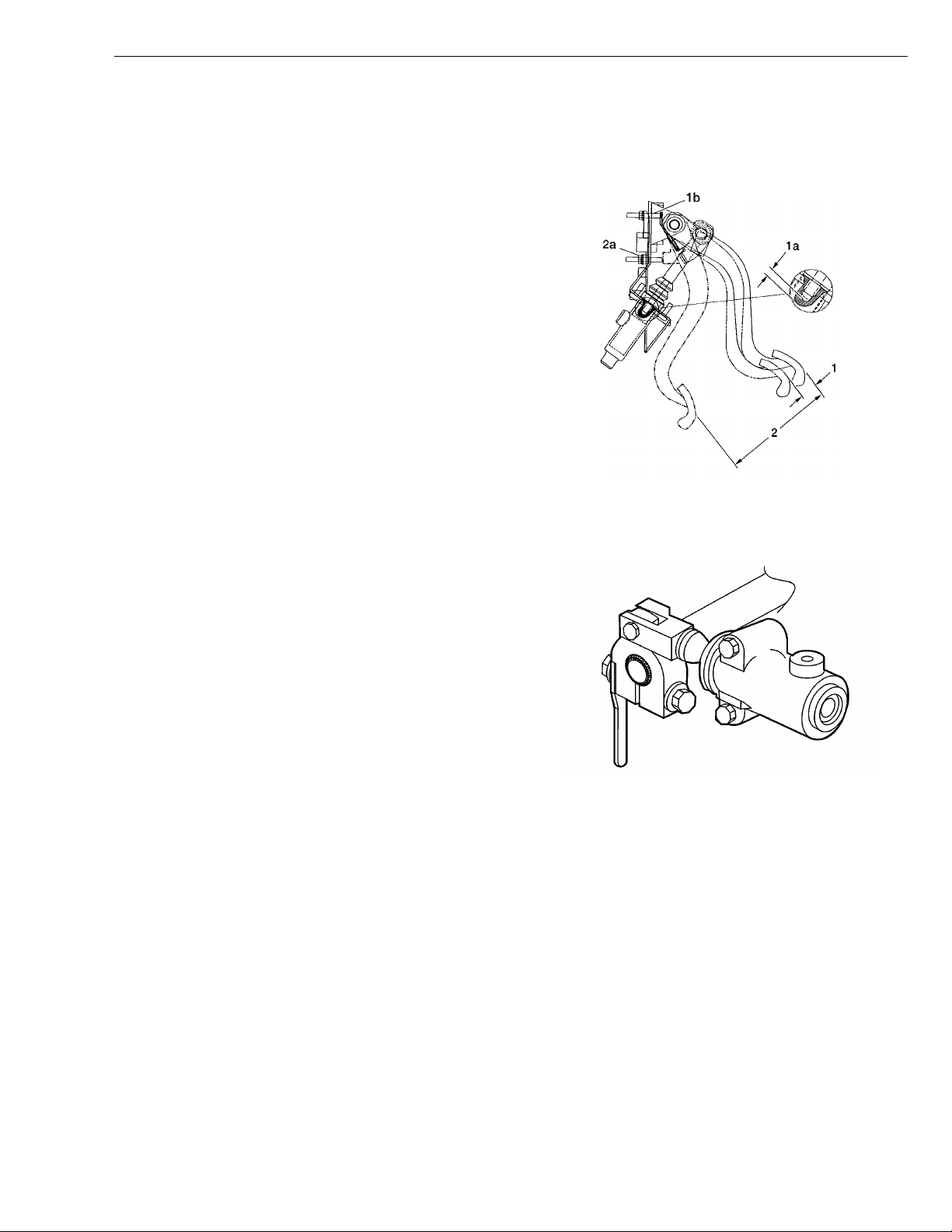

The clutch pedal play (1) is given by the clearance between the plunger and the piston (1a) in the master

cylinder. Thus the pedal will always have a play, regardless of the clutch adjustment. The correct play is adjusted

with the upper adjusting screw (1b) in the pedal carrier.

Volvo Clutch Slave Cylinder

Slave cylinder stroke (A) is 29 ± 1 mm (1.14 ± 0.04 in.).

The clutch pedal throw (2 - Figure 1) gives the stroke.

The lower adjusting screw (2a) limits the pedal throw

and thereby the clutch slave cylinder stroke.

Distance B should never be exceeded. The distance is

adjusted by removing the fork from the lever and reposition lever on the cross shaft.

Distance C is set when the clutch is new. During wear of

clutch, the distance will decrease. Readjustment should

not be needed before it is time to reface the clutch disc.

Fig. 1: Clutch

Fig. 2: Volvo Clutch Slave Cylinder

23

Group 177 Design and Function

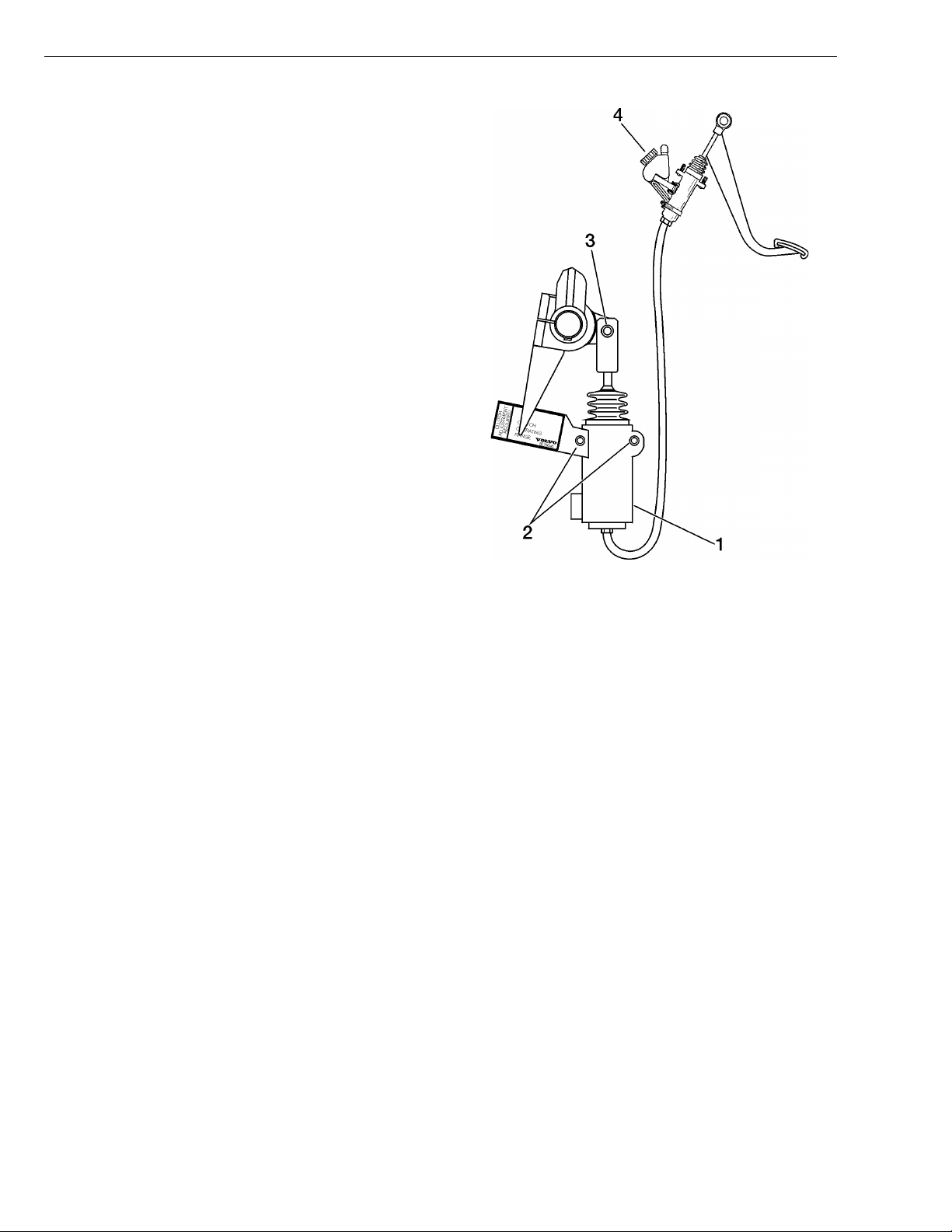

Other Clutch Slave Cylinder

A slave cylinder for any non-Volvo clutch has a wear indicator. When the indicator is out of the operating range,

it is time to adjust the clutch.

To get the slave cylinder throw into the accepted range,

adjust the clutch plate until the indicator is in the operating range again.

1 Slave Cylinder

2 Mounting Bolts

3 Clutch Clevis Pin

4 Clutch Master Cylinder and Reservoir (Found

on the Bulkhead in the Engine Coupling)

24

Group 177 Design and Function

Power Take-off

Volvo PTO

For further information concerning component specifications see service information in Group 1, “Oil and Filter

Change Intervals for Volvo Components,” publication

number 175–001, and appropriate vendor literature.

Volvo PTO’s mount directly to the transmission and do

not need separate oil fill and check. Make sure there is

extra oil filled in the transmission for the PTO volume.

CAUTION

Transmission oil heat exchanger should be installed

when using PTO continuously over 15 minutes at a

time or with a continuous power output over 55 kW

(75 hp). Without heat exchanger, the oil can overheat

and transmission damage may follow.

If the application has a remotely installed pump or blower

with a driveshaft connection, the driveshaft U-joints need

to be greased at every maintenance interval or more often, depending on usage. Use a lithium based grease

with EP additives and of the consistency of NLGI No. 2.

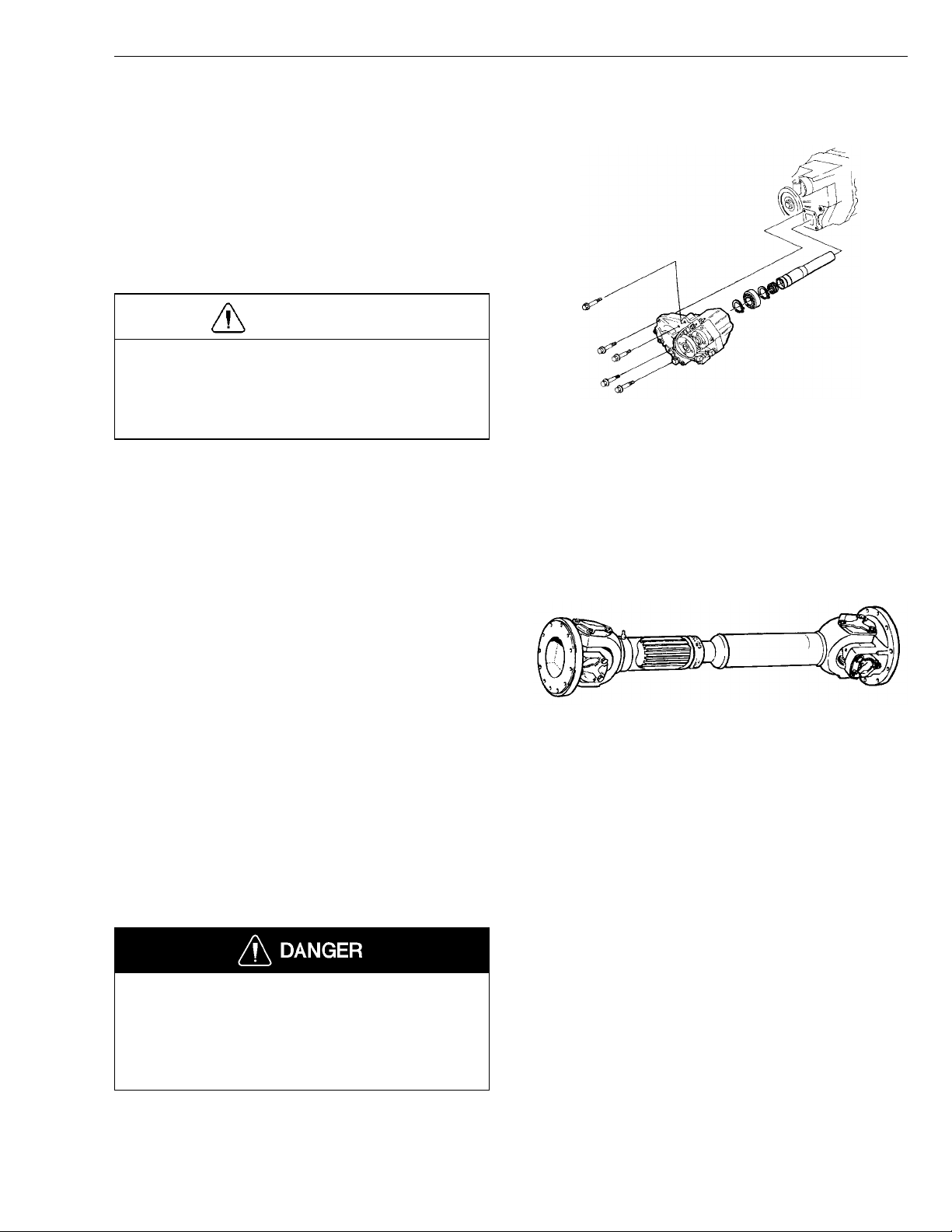

Driveshaft

For further information concerning component specifications see service information in Group 1, “Oil and Filter

Change Intervals for Volvo Components,” publication

number 175–001, and appropriate vendor literature.

Use a lithium-based grease with EP additives with a

consistency of NLGI No. 2. Do not use conventional

chassis grease.

The driveshaft U-joints must be lubricated correctly for

the bearings to receive grease. The most common case

of U-joint failure is incorrect greasing. Always make sure

that grease is coming out of all four seals. If one seal

fails to purge old grease, move the driveshaft from side

to side while applying gun pressure. This allows for

greater clearance on the thrust end of the bearing that is

not purging. New grease flushes abrasive contaminants

from each bearing and assures that the bearing is filled

properly.

Failure to correctly grease the driveshaft U-joints or

slip-joints can lead to component failure which can result in separation of the driveshaft from the vehicle. A

separated driveshaft can result in major component

damage and loss of vehicle control, and can cause

serious personal injury or death.

25

Group 177 Design and Function

Brakes

Brake Cams and Slack Adjusters

For further information concerning component specifications see service information in Group 1, “Oil and Filter

Change Intervals for Volvo Components,” publication

number 175–001, and appropriate vendor literature.

Lubricate the brake cam bushings using a lithium based

grease with EP additives and consistency NLGI No. 2.

Fill grease until old grease has been pushed out past

the seal and new grease can be seen flowing.

Lubricate the slack adjusters using a lithium based

grease with EP additives and consistency NLGI No. 2.

Fill grease until old grease has been pushed out past

the splined shaft area, and adjustment pawl and new

grease can be seen flowing.

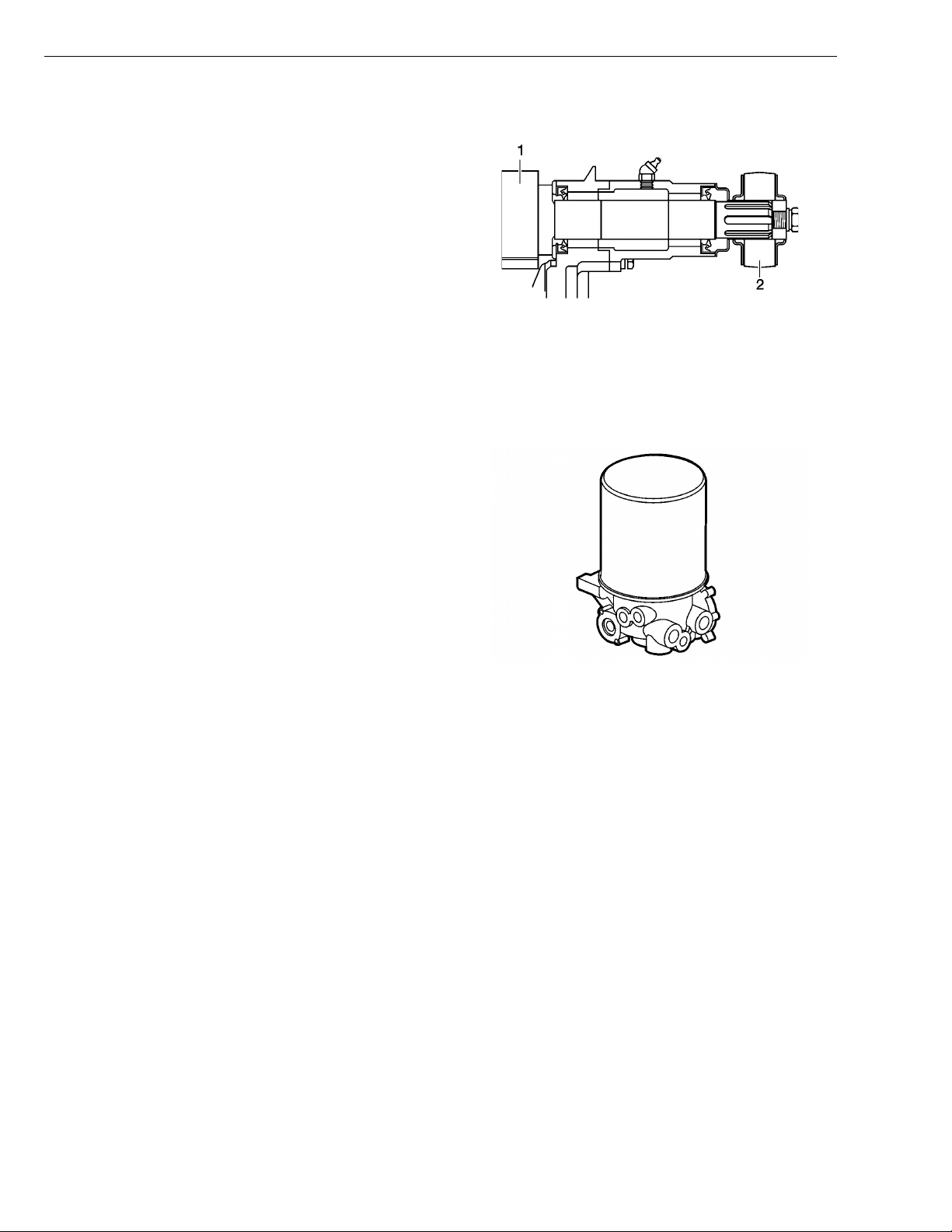

Air Dryers

Air dryers have internal maintenance systems that clean

out the accumulated moisture frequently and can therefore work with long maintenance intervals. Eventually the

drying medium will be filled up and the cartridge will

need to be changed. Change cartridge when there is

more water being drained in the daily emptying of the

tank than usual. This is a progressive development and

the time interval will be different from application to application.

Dryer manufacturers recommend changing cartridge every 2 to 3 years but intervals need to be adjusted for

application. The only dryer with regular maintenance is

the Midland, where the coalescent filter needs changing

every year.

26

Group 177 Design and Function

Steering System

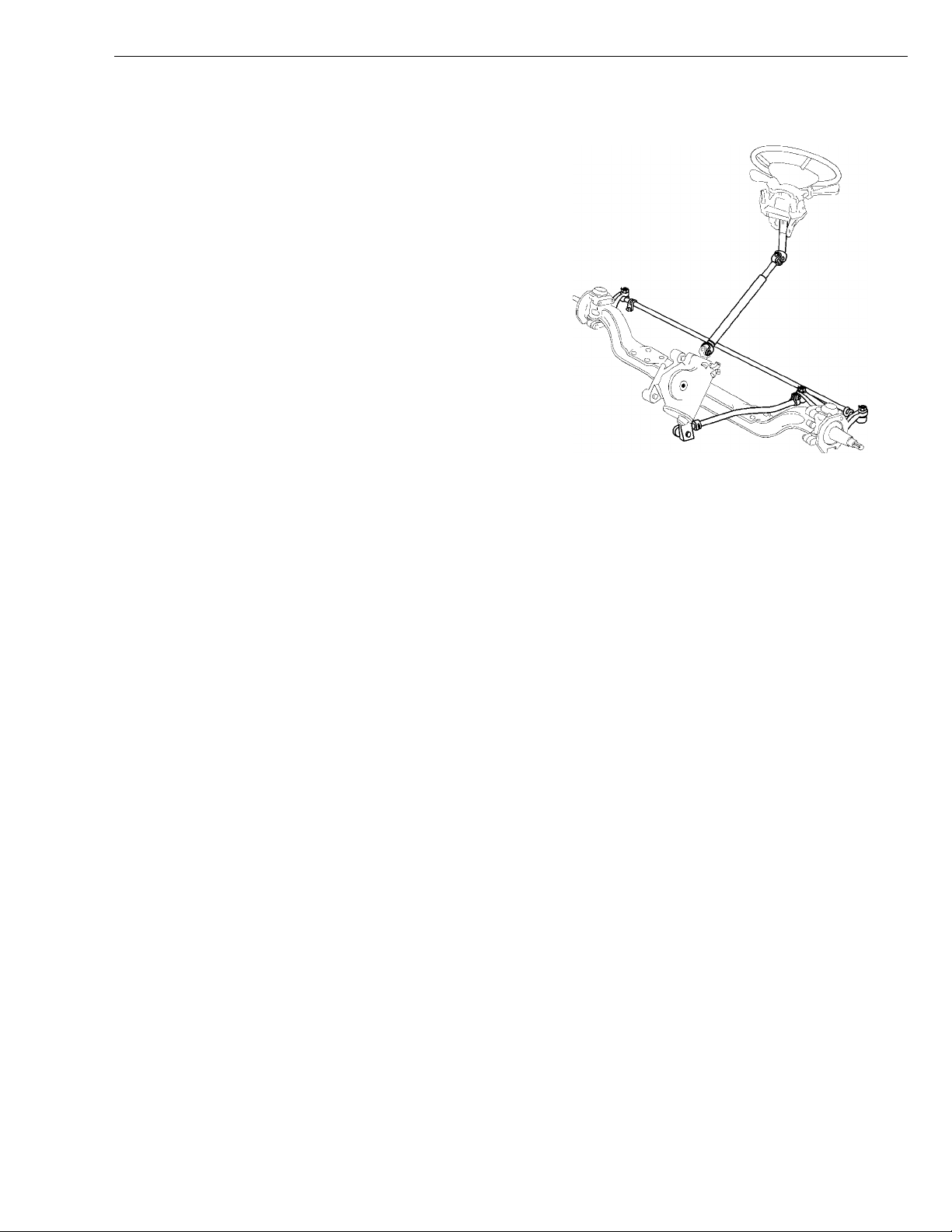

Steering Linkage and Knuckles

For further information concerning component specifications see service information in Group 1, “Oil and Filter

Change Intervals for Volvo Components,” publication

number 175–001, and appropriate vendor literature.

Lubricate the Steering shaft and drag link.

Lubricated the tie rod.

TRW steering gears have a seal at the sector shaft that

needs greasing with a hand gun every 4 months or

more often if the weather and road conditions are severe.

Sheppard steering gears have seals at input shaft and at

the sector shaft that need greasing with a hand gun every 4 months or more often if the weather and road

conditions are severe.

No axial movement is allowable when 100 lbs. of hand

pressure is applied. Use hand pressure only, do not

check using pliers, wrenches or any other tools.

For all VHD Axle Back models, the steering shaft Ujoints should be inspected to see that the plastic caps

are intact. Complete this inspection every 4 months. A

shorter inspection period interval may be required if the

vehicle is operated under severe driving conditions.

For VHD Axle Forward models, grease the steering shaft

U-joints every 4 months. A shorter maintenance interval

may be required if the vehicle is operated under severe

driving conditions.

27

Group 177 Design and Function

Steering System

For further information concerning component specifications see service information in Group 1, “Oil and Filter

Change Intervals for Volvo Components,” publication

number 175–001, and appropriate vendor literature.

A darkened fluid indicates a steering system that is running hotter than normal and the fluid is overheated.

Troubleshoot the reason for overheating and change

fluid.

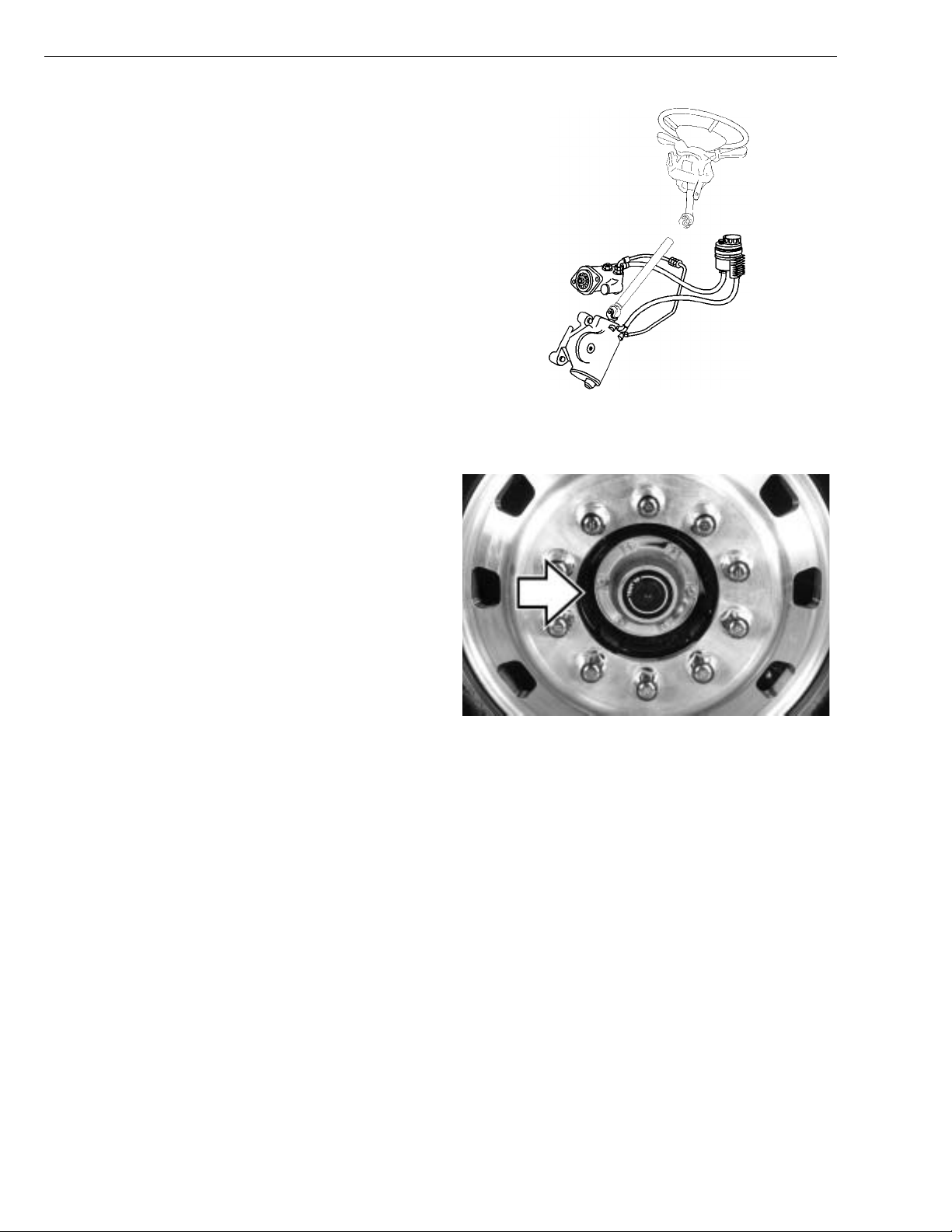

Hubs

Oil Lubricated Hubs

For further information concerning component specifications see service information in Group 1, “Oil and Filter

Change Intervals for Volvo Components,” publication

number 175–001, and appropriate vendor literature.

Hubs are generally oil lubricated and should be lubricated during maintenance. Change oil when the hub is

removed for repairs.

28

Loading...

Loading...