Volvo Trucks North America, Inc.

Greensboro, NC USA

This Service Bulletin replaces Service Bulletin 371–44,

“Data Links, Fault Tracing” (11.2002), publication number

PV776–TSP177224.

Data Links, Fault Tracing

Service Bulletin

Trucks

Date Group No. Page

12.2004 371 44 1(25)

Data links, fault tracing

VN, VHD VERSION2

From build date 11.2002

T3015830

Contents

“Data Links, Fault Tracing” page 3

“Terminating Resistor, Checking” page 13

“J1708 Information Link, Fault Tracing” page 14

“J1939 Control Link, Fault Tracing” page 16

PV776-20020644 USA16430

Volvo Trucks North America, Inc. Date Group No. Page

Service Bulletin 12.2004 371 44 2(25)

Tools

Special Tools

9990008

Set of Test Pins

9998699

Breakout Box 62 Pin

J-38125-8

Wire Crimpers

9990062

Cable Extension

J-39200

Digital Multimeter (DMM)

J-42449

JAE Terminal Probes

Volvo Trucks North America, Inc. Date Group No. Page

Service Bulletin 12.2004 371 44 3(25)

Troubleshooting

Data Links, Fault Tracing

General Troubleshooting Procedures

The control units share information via two different data links “information link SAE

J1587/1708” and “control link SAE J1939”

The messages on the SAE J1587/1708 information link are for example, fault codes and

warning messages. In some cases the SAE J1587/1708 link also acts as a reserve for

SAE J1939. VCADS Pro only communicates on SAE J1587/1708.

SAE J1939 is a faster link which means more data can be transmitted. SAE J1939

is used to transmit data that the system uses for control functions, for example,

engine speed (rpm).

Checks:

“J1708 Information Link, Fault Tracing” page 14

•

“J1939 Control Link, Fault Tracing” page 16

•

Use Multimeter J-39200 (or equivalent tool) to perform

•

tests.

When troubleshooting wiring and connectors use

•

breakout boxes/harnesses when available. A list

of various breakout boxes/harnesses is included in

“Special Tools” page 2.

Never pierce the wiring insulation with test probes.

•

Do not pierce through seals on water-resistant

•

connectors.

Never insert test probes into connectors. The probes

•

may spread the terminals and cause intermittent faults.

If breakout boxes/harnesses are not available, contact

•

the metal outer edges of connector terminals as

necessary to take readings.

Consult “VN or VHD Series Electrical Schematics” in

•

Group 37 for vehicle specific wiring and connector

information. These schematics include pin-out and

vehicle location drawings for connectors.

Volvo Trucks North America, Inc. Date Group No. Page

Service Bulletin 12.2004 371 44 4(25)

Visual Inspection

Before beginning electrical checks, visually inspect the

wiring and connectors.

Inspect for corrosion in wiring or connectors.

•

Check that terminal pins are not bent or damaged, and

•

are locked into their connectors and properly crimped.

Check that the terminal pins make good mechanical

•

contact with their mating pin.

To help locate intermittent faults, wiggle the wire and

•

connector while testing.

Wiring and Connectors

Troubleshooting data link wiring is no different than

troubleshooting any other wiring. A DMM is used to take

measurements for resistance or voltage at various points

in the circuit. Based on those readings and working with

wiring schematics, the technician can narrow the search

area until theexactcause of a wiring failure is determined.

For general information about how to troubleshoot the

wiring and connectors see "Troubleshooting Wiring and

Connectors" found in the "Electrical General, VN and

VHD" manual in group 30.

Volvo Trucks North America, Inc. Date Group No. Page

Service Bulletin 12.2004 371 44 5(25)

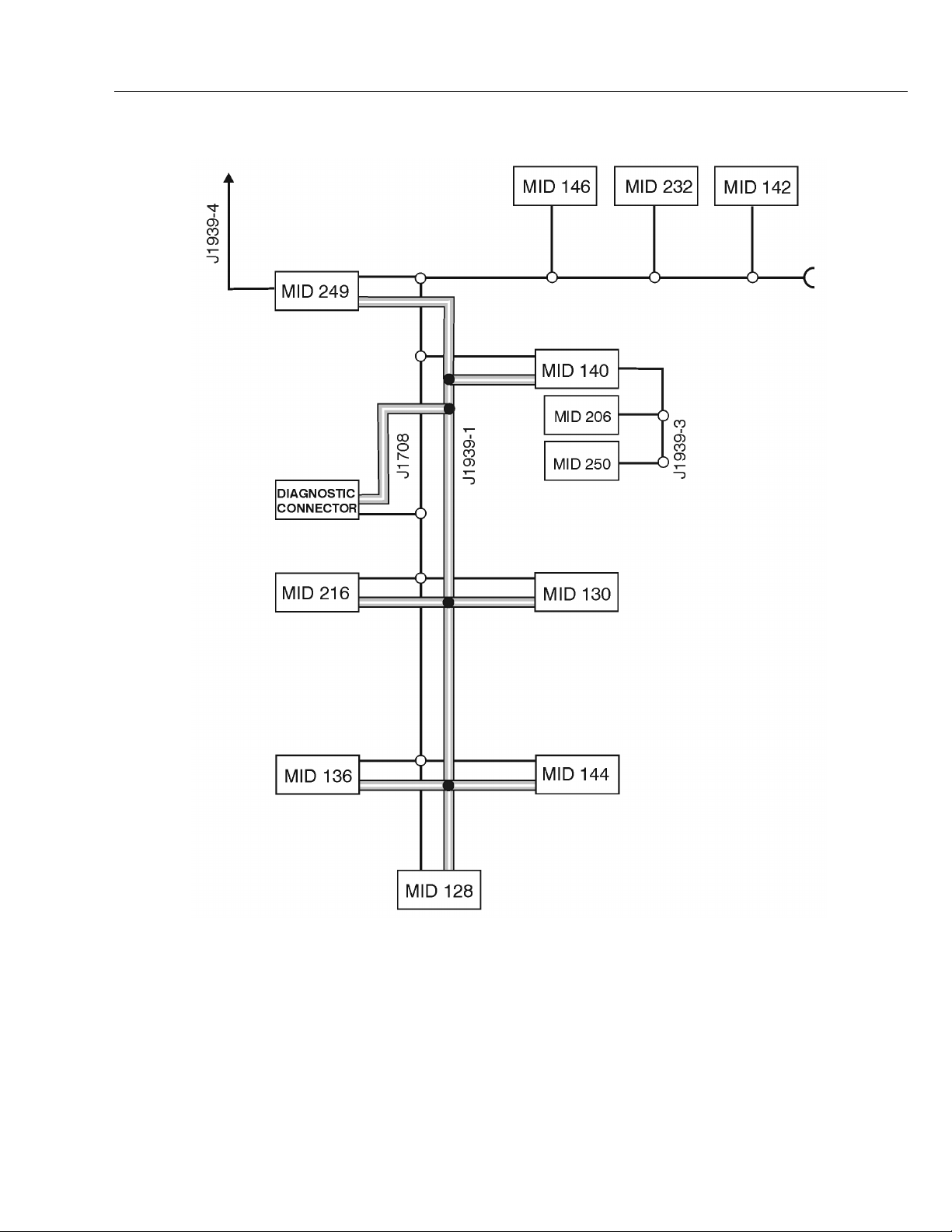

Data links

Note: Not all modules will be present

in every vehicle.

MID 128 Engine ECU

MID 136 Anti-lock Brake (ABS)

ECU

MID 140 Instrument Cluster

MID 142 Satellite

Communications

MID 144 Vehicle ECU

MID 146 Climate control ECU

MID 206 Radio

MID 216 Lighting Control

Module

MID 232 Airbag, control unit

MID 249 Body builder module

MID 250 Steering Wheel

Module

W3005654

J1939–1 Main network SAE

J1939

J1939–3 Section ofSAE J1939

under the instrument

cluster

J1939–4 Section ofSAE J1939

under the bodybuilder

control unit

Volvo Trucks North America, Inc. Date Group No. Page

Service Bulletin 12.2004 371 44 6(25)

SAE J1587/1708

For checking see “J1708 Information Link, Fault Tracing” page 14.

SAE J1587/1708 is used for, amongst other things, transmitting fault code information.

Faults which can affect the entire SAE J1587/1708 datalink can create problems when

fault tracing, since it can be difficult to communicate with the source in order to carry out

tests using VCADS pro. A simple way of checking if VCADS pro is in contact with all

control units on the SAE J1587/1708 link is “17034-2 Vehicle information, test”. An

indication that there is a problem with SAE J1587/1708 can be that fault codes from a

certain control unit can not be corrected.

There are various types of errors that store fault codes for the SAE J1587/1708 link

(SID 250). If a control unit is able to store a fault code then the faultmore than likely is

associated with faulty wiring, connectors or sensors. The fault could be an open-circuit

or short-circuit in the cable harness in one or more places. In order to determine an

open-circuit in the cable harness, check the voltage levels at each control unit. See

“J1708 Information Link, Fault Tracing” page 14.

Fault codes in the SAE J1587/1708 link (SID 250) can also be caused by another control

unit not transmitting information. The reason for this can be due to faults in components

connected to the other control unit. Therefore, all other fault codes must be corrected

before starting the datalink fault tracing process.

List of MID numbers

Note: Not all MIDs will be present on every vehicle.

MID 128 Engine ECU

MID 130 Transmission control unit

MID 136 Anti-lock Brake (ABS) ECU

MID 140 Instrument Cluster

MID 142 Satellite Communications

MID 144 Vehicle ECU

MID 146 Climate control ECU

MID 172 Test tool, ie. VCADS PRO

MID 206 Radio

MID 216 Lighting Control Module

MID 219 VORAD/ACC

MID 232 Airbag, control unit

MID 249 Body builder module (BBM)

MID 250 Steering Wheel Module

Volvo Trucks North America, Inc. Date Group No. Page

Service Bulletin 12.2004 371 44 7(25)

SAE J1939

For checking see “J1939 Control Link, Fault Tracing” page 16.

The information on the SAE J1939 control link is used for control functions. Therefore,

the diagnostics for SAE J1939 have been developed and supplemented with more fault

codes for a more precise reading. The fault codes that are transmitted on the SAE

J1587/1708 link are also transmitted, in the event of more serious faults, on the SAE

J1939 link.

If control unit A is missing the message from another control unit B, the fault codes

PSID 200 - 214 are used to determine from which control unit the message is missing.

If control unit B loses contact with the link, other control units can store fault codes

indicating control unit B has lost communications.

Example:

If there is an open - circuit on the SAE J1939 link at the vehicle ECU (MID 144), PC

connector, the message from the vehicleECU does not reach the other control units on

SAE J1939. The instrument cluster and ABS ECU use the messages from the vehicle

ECU. The instrument cluster and ABS ECU store fault codes when the message is not

received. The instrument cluster stores fault codes “MID 140 PSID 201 FMI 9” and the

ABS ECU stores “MID 136 PSID 201 FMI 9”.

PSID 201 is stored by both the instrument cluster and ABS ECU which indicates that the

vehicle control has an interruption in the SAE J-1939 data link. This can be useful in

order to find faults on the data link. If there is a fault in the cable harness the fact that

there is still contact between certain control units can be used to eliminate sections

of the cable harness. In the event of certain errors in the SAE J1939 link the fault

codes are stored as a SID 231 message.

Note: It is important to remember which control units the vehicle is equipped with and

which fault codes are stored in each control unit.

Explanation of PSID 200-214

Note: Not all controlunits will be presenton every vehicle.

PSID 200 Open-circuit, bad data, data link, engine

control unit (MID 128)

PSID 201 Open-circuit, bad data, data link, vehicle

ECU (MID 144)

PSID 202 Open-circuit, data link, instrument

cluster (MID 140)

PSID 204 Open-circuit, data link, ABS ECU (MID

136)

PSID 210 Open-circuit, data link, Lighting Control

Module(LCM) (MID 216)

PSID 214 Open-circuit, data link, body builder

module (MID 249)

Volvo Trucks North America, Inc. Date Group No. Page

Service Bulletin 12.2004 371 44 8(25)

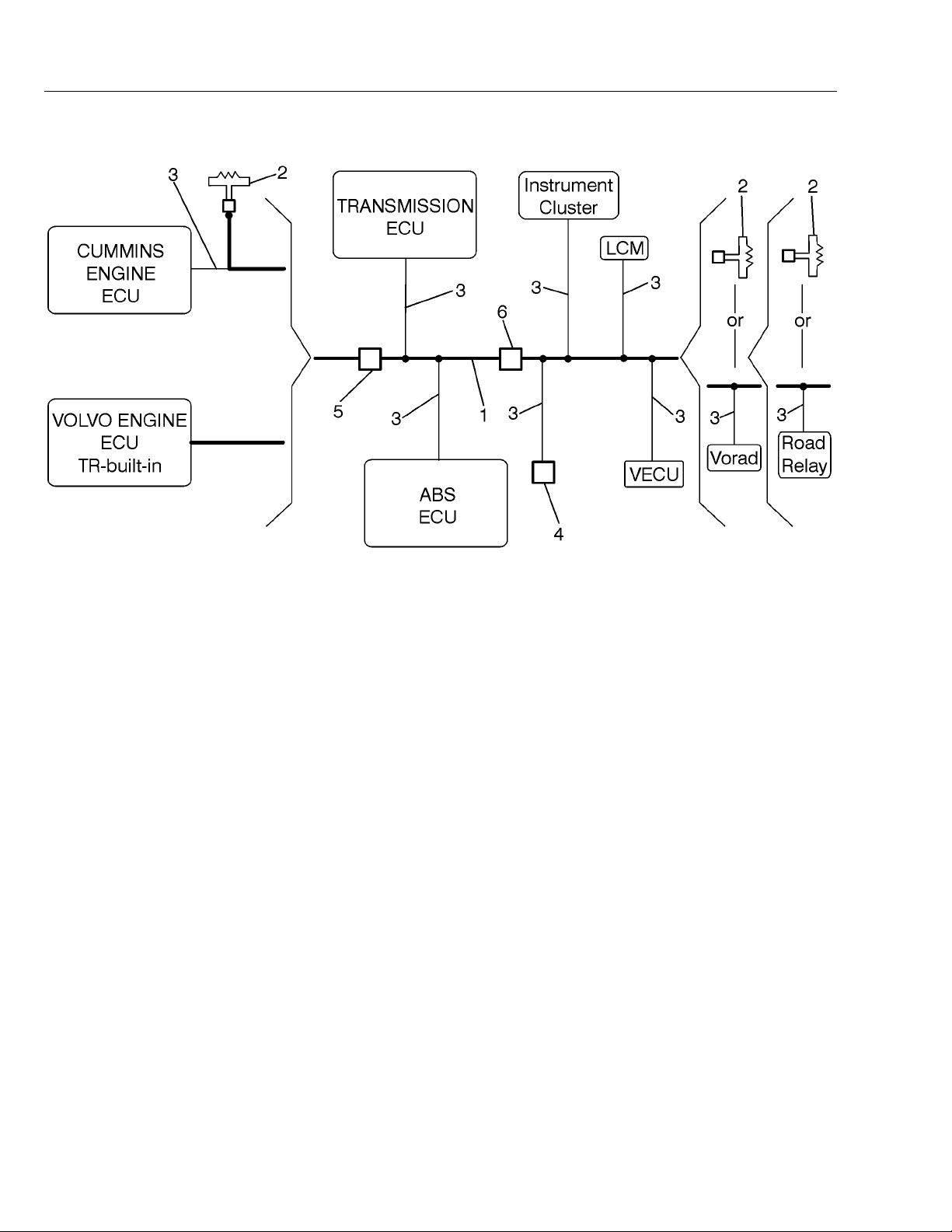

Data Link Construction

1 Data link backbone

2 Terminating resistors

3 Stub connections for ECUs

4 Diagnostic connector

The J1939 Control Data Link consistsof a backbone(1), terminating resistors(2) at each

end, and stubs spliced out (3) for each ECU on the data link. On vehicles with Volvo

engines, the terminating resistor at the engine end is located inside the Engine ECU.

The J1939 Control Data Link complies with SAE standards and consists of 2 twisted

wires:

Wire 406 is yellow in color and carries the Controller Area Network high (CAN_H)

•

digital signal of approximately 2–5 volts.

Wire 407 is green in color and carries the Controller Area Network low (CAN_L)

•

digital signal of approximately 0–3 volts.

5 Chassis harness — engine harness in-line connector

W3005333

6 Chassis harness — cab harness bulkhead pass-through

connector

Volvo Trucks North America, Inc. Date Group No. Page

Service Bulletin 12.2004 371 44 9(25)

Diagnostic Connector

9–pin Diagnostic Connector

Cavity

Position

A 0Z (B-)

B 402 (B+)

C 406C (CAN_H, yellow)

D 407C (CAN_L, green)

E not connected

F 400G (SAE A, 1708)

G 401G (SAE B, 1708)

H not connected

J 196DR (Ignition)

Note: The J1939 Data Link can be accessed at the 9–pin

diagnostic connector.

Circuit Description

W3005648

Volvo Trucks North America, Inc. Date Group No. Page

Service Bulletin 12.2004 371 44 10(25)

SID 231 J1939 Data Link Fault

W3005017

The following table lists Failure Mode Identifiers (FMI) that may be helpful in identifying

data link problems. Please note the following when troubleshooting data link failures

by fault codes.

The type of FMI that an individual ECU can monitor is dependent on the software in

•

the ECU. All FMIs cannot be recognized by all ECUs.

The ECU reporting the fault may not be the ECU that is involved at the site of the

•

specific failure. For example, The Engine ECU may report a data link fault that is

actually at the VECU. The VECU would not be able to report if the data link is broken

between the VECU and data link backbone.

FMI Description Note

0

1

2

3

4

5

6

7

8

9

10 Abnormal change rate

11

12

13

14

Data valid, but high

Date valid, but low

Data erratic A

Voltage shorted high

Voltage shorted low

Current low or open C

Current high or short C

Mech syst no response

Abnormal freq or PW

Abnormal update rate B

Failure unknown C

Loss of intelligent device D

Out of calibration

Special instruction

A. FMI 2, Data Erratic is given when the ECU does not see any J1939 messages

and is

not able

of a problem in the wiring, i.e., shorted high or low, or the ECU may be totally

disconnected from the J1939 data link. When an ECU detects this situation, it

should set the fault code FMI 2. Other ECUs will also set other fault codes for loss

of messages from this ECU.

B. FMI 9, Abnormal Update Rate is given when an ECU is seeing messages from

a specific ECU on the J1939 network, but needed data is not present. This is

typically where the J1939 data link is functioning, and the ECU is communicating, but

having a local problem with a sensor.

to communicate on the J1939 network. This is typically a result

Volvo Trucks North America, Inc. Date Group No. Page

Service Bulletin 12.2004 371 44 11(25)

C. FMI 11, Failure Unknown indicates an internal problem in the ECU.

D. FMI 12, Loss of Intelligent Device is given when an ECU is expecting to receive

messages from another ECU on the network, and the messages are not present. For

example, the Engine ECU expects certain messages from the ABS system; FMI 12 is

logged if those messages are not there. This fault is probably caused by a physical

break (open circuit) in the J1939 wiring, somewhere between the ECUs, or when an

ECU is off-line due to a blown fuse or bad component.

Note that the device that logs this fault is NOT the faulty ECU – it has instead

detected the fault.

J1939 Data Link Voltage Check

The J1939 Control Data Link operates at the following voltages:

Data Link Wires Key

Position

Wire 406 (CAN_H, yellow) On Pins for Wire 406 (yellow) - Ground Fluctuating

Wire 407 (CAN_L, green) On Pins for Wire 407 (green) - Ground Fluctuating

Between Wire 406 and Wire 407 On Pins for Wire 406 (yellow) - Pins for Wire

It is expected that the voltages quoted in the table above exist on Wire 406 (CAN_H,

yellow) and Wire 407 (CAN_L, green) at any point on the data link. Due to the fact that

multiple ECUs are both "talking" and "listening" any time the ignition key is on, the

voltage reading will have limited troubleshooting value.

Measuring Point Expected Value

between 2 - 5

Volts

between 0 - 3

Volts

Fluctuating

407 (green)

between 0 - 5

Volts

Volvo Trucks North America, Inc. Date Group No. Page

Service Bulletin 12.2004 371 44 12(25)

J1939 Data Link Resistance Check

When operating properly, the J1939 Control Data Link has a resistance of approximately

between Wire 406 (CAN_H, yellow) and Wire 407 (CAN_L, green) at any point on

60

the data link. Checks can be made at the diagnostic connector, terminating resistors, or

any ECU on the J1939 Control Data Link.

Use a DMM to check the resistance at suspected fault locations observing the following

points:

For detailed, vehicle specific schematics see "VN/VHD Electrical Schematics"

•

found in group 37.

Breakout boxes for some components may exist to aid in troubleshooting. See

•

"Tools" for more information.

Back probe connectors when possible to avoid pin or socket damage.

•

Terminating resistors must remain in the circuit for test.

•

Function Key

Position

Grounded Circuit

Check

Grounded Circuit

Check

J1939 Data Link

Resistance Check

Off Pins for Wire 406

Off Pins for Wire 407

Off Pins for Wire 406

Measuring Point Expected Value

OL (Infinite

(yellow) - Ground

(green) - Ground

(yellow) - Wire 407

(green)

Resistance)

OL (Infinite

Resistance)

60

If Expected ValueNot Correct Check:

Grounded Circuit

Grounded Circuit

1. Check terminating resistors. See

“Terminating Resistor, Checking” page

13.

2. Wiring/connector fault in backbone

or stubs. See “Wiring and Connectors”

page 4 and “J1939 Data Link

Troubleshooting Example” page 18.

Volvo Trucks North America, Inc. Date Group No. Page

Service Bulletin 12.2004 371 44 13(25)

Terminating Resistor, Checking

W3005518

Terminating Resistor, 2–pin

Terminating resistors are wired to each end of the J1939 data link to prevent signal

reflections. They must remain connected for the data link to function properly. The

resistance value of each terminating resistor is 120

data link, their combined resistance is 60

The terminating resistor at one end of the J1939 data link is located in the Fuse/Relay

Center near the VECU and the other near the engine ECU. On vehicles equipped

Volvo engines, the terminating resistor at the engine end is located inside the EECU.

On vehicles equipped with Cummins engine, the terminating resistor is located in the

harness area just outside of the Engine ECU.

since they are connected in parallel.

. When properly installed in the

A J1939 stub connection is located at the transmission area in the chassis harness.

On vehicles equipped with an electronically controlled transmission (Allison/Autoshift

II/Meritor Freedom Line), the connection to the transmission is located at the chassis

harness. On vehicles equipped with a manual non-electronically controlled transmission

- the connector stub will have an unterminated blanking plug installed.

Only two terminating resistors are used in a vehicle. Never install three in one truck.

If more than two terminating resistors exist in the J1939 circuit, damage to the ECU

electronics can occur over time. You can easily check to see if you have two resistors by

measuring the resistance between circuits 406 and 407, at the diagnostic connector,

with the ignition OFF. The correct resistance is 60

If by chance a vehicle has more terminating resistors installed in the link than required,

the resistance value between circuit 406 and 407 will be approx. 40 ohms. This would

give an indication to go and check the locations mentioned above and remove the plugs

one at a time until the correct resistance reading is obtained. You should then find that

you have more than one installed. To fix the problem order a blanking plug and install in

the appropriate location, depending on vehicle transmission type.

To check the terminating resistors, the J1939 data link can be accessed at the 9 pin

diagnostic connector.

Use a DMM to check the following:

9-pin Diagnostic Connector

Function Key Position Measuring Point Expected

Terminating

Resistor Check

Off Pin D - Pin C

.

Value

60

Note If Expected Value not met,

check

1. If 120 , one terminating

resistor missing or wiring fault.

2. If >1k

resistor missing or wiring fault.

3. If OL

4. If <1

wires.

, both terminating

(infinite), open circuit.

, short circuit in data link

Volvo Trucks North America, Inc. Date Group No. Page

Service Bulletin 12.2004 371 44 14(25)

3711-21-03-01

J1708 Information Link, Fault Tracing

Other special equipment: J-39200

NOTE!

During fault-tracing check the relevant connectors.

•

Check for loose connections, contact resistance

and oxidation. For a more detailed description of

fault-tracing cables and connectors, see separate

service information under group 37.

Do not use the chassis as a ground when taking

•

readings. Use the ground plate in the distribution box.

For measurement points and adapters see “Signal

•

Indication” for the relevant system.

Additional information

When checking the data link measurement and the

values are outside of the given ranges, there are several

possible explanations.

1

If the voltage is approx. greater than 5 V DC the data

link is possibly shorted to a higher voltage and must be

inspected to find the cause.

A wire of higher voltage could be cross connected

to the data link via chaffing or pin misalignment at

connectors or control units, etc.

A second, but least likely, possibility is that the internal

databus of an ecu has failed in some way causing

an interruption of messaging on the link. If this is

suspected, disconnect the suspect ecu temporarily or

either connect a spare ecu to check if the problem

goes away.

2

If the voltage is aprrox. less than 2 V DC the datalink

is possibly shorted to ground and must be inspected

to find the cause.

A wire of lower voltage or ground type could be

cross connected to the data link via chaffing or pin

misalignment at connectors or control units, etc.

Either one or both of the data link wires are shorted

to ground via a rub through (chaff). Inspect the

entire data link for possible signs of abrasion. Repair

according to guidelines outlined in this manual.

A third, but least likely, possibility is that the internal

databus of an ecu has failed in some way causing

an interruption of messaging on the link. If this is

suspected, disconnect the suspect ecu temporarily or

connect a spareecu to check if the problem goes away .

Volvo Trucks North America, Inc. Date Group No. Page

Service Bulletin 12.2004 371 44 15(25)

Checking sub-systems

1

Conditions:

Measurement box with adapter connected between

•

the relevant control unit and cable harness.

Measuring voltage using the multimeter with the

•

MAX

-function engaged.

Control unit connected.

•

The ignition key in the drive position.

•

Measuring points Desired value

SAE J1587/1708 A ground

SAE J1587/1708 B ground

SAE J1587/1708 A SAE J1587/1708 B

1

The voltage must vary within the interval.

Note: The voltage on the information link varies and

is dependent on the number of control units and traffic

on the information link.

J-39200

V ≈ 0-5VDC

V

≈ 5VDC

max

V

≈ 0VDC

min

V ≈ 0-5VDC

V

≈ 5VDC

max

V

≈ 0VDC

min

V ≈ 2-5VDC

1

1

MIN /

Volvo Trucks North America, Inc. Date Group No. Page

Service Bulletin 12.2004 371 44 16(25)

3711-21-03-02

J1939 Control Link, Fault Tracing

You must read and understand the precautions and

guidelines in Service Information, group 30, "General

Safety Practices", before performing this procedure.

If you are not properly trained and certified in this

procedure, ask your supervisor for training before

you perform it.

Other special equipment: J-39200

NOTE!

During fault-tracing check the relevant connectors.

•

Check for loose connections, contact resistance

and oxidation. For a more detailed description of

fault-tracing cables and connectors, see separate

service information under group 37.

Do not use the chassis as a ground when taking

•

readings. Use the ground plate in the distribution box.

For measurement points and adapters see “Signal

•

Indication” for the relevant system.

Checking sub-systems

1

Conditions:

Measurement box with adapter connected between

•

the relevant control unit and cable harness.

Control unit connected.

•

Measuring voltage using multi meter J-39200 with

•

the

MIN MAX

Ignition key in the drive position.

•

Note: The voltage of the control link varies and depends

on the number of control units and the traffic on the

control link.

Measuring points Desired value

SAE J1939A - ground V ≈ 2-5VDC

SAE J1939B - ground V ≈ 0-3VDC

SAE J1939A - SAE

J1939B

-function connected.

V ≈ 0-1VDC

J-39200

Volvo Trucks North America, Inc. Date Group No. Page

Service Bulletin 12.2004 371 44 17(25)

2

Conditions:

Measurement box with adapter connected between

•

the relevant control unit and cable harness.

Control unit connected.

•

Measuring resistance using a multimeter.

•

Ignition key in stop position.

•

Measuring points Desired value

SAE J1939A - SAE

J1939B

Two terminations

SAE J1939A - SAE

J1939B

One termination

Comments:

When the resistance R ≈ 60

probably fault free from the particular connector to

two terminating resistors.

If the resistance R ≈ 120

then measuring is only conducted to the terminating

resistor.

J-39200

R = 50 - 70

R = 100 - 140

the cable harness is

from the relevant connector

Volvo Trucks North America, Inc. Date Group No. Page

Service Bulletin 12.2004 371 44 18(25)

J1939 Data Link Troubleshooting Example

1 Data

W3005333

link

backbone

2 Terminating

resistors

3 Stub

connections

for

ECUs

4 Diagnostic

connector

5 Chassis

harness

—

Note: This example is intended as a guide for the

logic used to troubleshoot a data link wiring problem.

The illustration should be used to help clarify the

troubleshooting example. Always refer to vehicle-specific

wiring schematics found in Group 37 when performing

vehicle troubleshooting.

engine

harness

in-line

connector

6 Chassis

harness

—

cab

harness

bulkhead

passthrough

connector

Volvo Trucks North America, Inc. Date Group No. Page

Service Bulletin 12.2004 371 44 19(25)

1

Begin by visually verifying that the two terminating

resistors are in place:

1a. One at the engine ecu. Vehicle equipped with

the Volvo engine, the terminating resistor is built into

the EECU and is not visible. Vehicles with Cummins

engines the terminating resistor is located on the

engine harness.

1b. One inside the cab, forward of the fuse/relaypanel

(visible when the fuse/relay cover is removed).

2

Using an ohmmeter with the ignition key switch in the

OFF position, check the resistance between circuits 406

(CAN_H, J1939A, yellow) and 407 (CAN_L, J1939B,

green) at the diagnostic connector.

2a. If 60

that the backbone circuit is intact, since the 60

represents the two 120 terminating resistors in

parallel. If trouble is still present, it is most likely in

one of the ECU stub circuits or at the ECU terminal

themselves. Go to Step 6.

2b. If approximately 120

this indicates that one of the terminating resistors is

missing, poorly connected or else there is an open

circuit in the backbone at some point. Use the fault

codes (if present) to narrow down the likely location

based on which ECU’s are complaining about missing

data from other ECU’s. Go to Step 3.

2c. If approximately 40

there are more than 2 terminating resistors installed.

To fix the problem order a blanking plug and install

in the appropriate location, depending on vehicle

transmission type.

3

Disconnect the Cab-chassis/pass-through connector

(item 6) at the bulkhead and re-test the resistance of

circuit 406–407 at the diagnostic connector.

3a. If the resistance is the same as that measured in

Step 2b, then that means the trouble is likely on the

chassis side of the cab-chassis pass-through, since

the 120

located in the cab. Go to Step 4.

(±10 ) resistance is measured, it is likely

resistance is measured,

resistance is measured,

being measured must be teminating resistor

3b. If the resistance is greater than what was

measured in Step 2b, then the trouble is likely on the

cab side of the harness, since the different reading

means you can no longer ’see’ the engine side

terminating resistor. Go to Step 5.

Volvo Trucks North America, Inc. Date Group No. Page

Service Bulletin 12.2004 371 44 20(25)

4

With the pass-through (item 6) still disconnected, check

the resistance between circuit 406–407 on the chassis

harness side of the pass-through, ’looking’ towards the

engine (120

the harnesses to look for an intermittent connection,

check the following items:

Check for continuity between all circuit 406 points

•

— pass-though, EECU, terminating resistor, and

transmission (if automated/automatic transmission)

Check for continuity between all circuit 407 points

•

— pass-though, EECU, terminating resistor, and

transmission (if automated/automatic transmission)

The 406 and 407 backbone circuits can, also, be

disconnected at the engine-to-chassis harness in-line

connector (item 5 — located near the starter relay

breakout, near the bulkhead) to further isolatewhether the

problem exists on the ’engine’ side or the ’chassis’ side.

5

With the pass-through (item 6) still disconnected, check

the resistance between circuit 406–407 on the cab side of

the pass-through, ’looking’ into the cab (120

present). While shaking/moving the harnesses to look for

an intermittent connection, check the following items:

should be present). While shaking/moving

should be

Check for continuity between all circuit 406 points.

•

Check for continuity between all circuit 407 points.

•

6

Check for continuity between circuit 406 at the diagnostic

connector and all circuit 406 point at the ECU’s and

terminating resistors. All circuit 406 should have

continuity to all other ECU’s. Perform the same tests

for all circuit 407 points.

If continuity is not found at all points, the trouble

is most likely in the stub to that ECU, or the ECU

connector/terminal itself.

Volvo Trucks North America, Inc. Date Group No. Page

Service Bulletin 12.2004 371 44 21(25)

Service Procedures

3711-16-02-02

J1939 Data Link Wiring (Unshielded), Repair

You must read and understand the precautions and

guidelines in Service Information, group 30, "General

Safety Practices", before performing this procedure.

If you are not properly trained and certified in this

procedure, ask your supervisor for training before

you perform it.

Note: This procedure complies with TMC RP142

“High-Speed Data Link Repair Guidelines.”

Note: Stagger wire cuts and splices to minimize bulges in

data link cable.

W3004993

1 Cable bundle, existing

2 Cable bundle, new

3 Heat-shrinkable connector

1

Make certain the vehicles ignition is OFF before

beginning this procedure.

2

Remove the data link from the wiring harness as

necessary and cut out the damaged section of cable.

Note: The replacement section of cable (P

must be somewhat longer than the original to allow for

staggering of the splices.

3

Strip approximately 50 mm (2 in.) of cable jacket and

shield at each end of the splices to expose the wiring.

Use caution not to cut the wire insulation.

4

Slide a piece of heat-shrink tubing over each end of the

cut cablebundle to seal the data link after the wires have

been spliced. The tubing should be approximately 50 mm

(2 in.) longer than the repair area.

/N 982689)

1 Cable bundle, existing

2 Cable bundle, new

3 Heat-shrink tubing

W3004994

Volvo Trucks North America, Inc. Date Group No. Page

Service Bulletin 12.2004 371 44 22(25)

5

Stagger cut the wiring to minimize bulges in the data

link cable. Strip approximately 6.3 mm (0.25 in.) of

wiring insulation at each wire end. Use caution not

to cut the wire strands.

1 Cable bundle, existing

2 Cable bundle, new

1 Wire stop

W3004995

6

Observe polarity when connecting the 406 (CAN-H,

yellow) and 407 (CAN-L, green) wires. Use a heat

shrinkable wiring connector to splice the wires together.

Insert each end of the wire into the connector until it

hits the wire stop.

W3004996

W3004997

7

Insert the connector into the proper anvil on the crimping

tool and crimp. Gently tug on the spliced connection to be

sure the wire is secure.

Volvo Trucks North America, Inc. Date Group No. Page

Service Bulletin 12.2004 371 44 23(25)

8

Use a heat gun to activate the heat shrink. Look for

sealant at each end of the connector as evidence of a

good application. Note: Do not use an open flame to

apply heat shrink.

1 Visible sealant

1 Cable bundle, existing

2 Cable bundle, new

3 Heat shrink tubing

4 Visible sealant

W3004889

W3004883

9

Center the piece of heat shrinkable tubing installed in

step 5 over the entire splice area. There should be

approximately 25 mm (1 in.) overlap at each end of the

splice area. Starting at the center, use a heat gun to

shrink the tubing. Look for sealant at each end of the

connector as evidence of a good application. Note: Do

not use an open flame to apply heat shrink.

10

After both ends of the cable are spliced, install the data

link back into thewiring harness andsecure as necessary.

Volvo Trucks North America, Inc. Date Group No. Page

Service Bulletin 12.2004 371 44 24(25)

Wire Splice, Solder and Seal

You must read and understand the precautions and

guidelines in Service Information, group 30, "General

Safety Practices", before performing this procedure.

If you are not properly trained and certified in this

procedure, ask your supervisor for training before

you perform it.

W3000568

Fig. 1: Wire splicing

1 Strip as necessary

2 Wire

W3000569

1 Solder

2 Soldering iron

3 Heat shrink tubing with sealant

4 Wires twisted

Soldering Procedure

1

Clean and tin the soldering iron tip.

2

Clean the terminal to be soldered.

3

Strip the wire as necessary to fit the terminal. Do not cut

or nick the wire when stripping. Note: The replacement

section of cable (P

than the original to allow for staggering of the splices.

4

Slide a piece of sealant shrink tubing onto the wire.

/N 982689) must be somewhat longer

5

Insert the wire in the terminal and, with a pair of crimpers

(as recommended by the connector manufacturer),

squeeze the small tabs onto the wire insulation. Not all

types of terminals have these tabs. Be certain to use the

crimpers recommended by the connector manufacturer.

With a blunt instrument, form the bare wire so that it will

lay against the soldering area of the terminal.

Volvo Trucks North America, Inc. Date Group No. Page

Service Bulletin 12.2004 371 44 25(25)

6

Using the soldering iron, apply heat to the outside of the

terminal while holding the solder on the wire on the inside

of the terminal. When a sufficient amount of heat has

been transferred from the gun through the terminal and

into the wire, the solder will be melted by the wire. Melt a

sufficient amount of solder on the wire and withdraw

the solder and the tip of the iron.

NOTE: Do not hold the terminal with pliers or anything

metal during the solder operation, as heat will be

1 Solder

W3000571

2 Tabs (crimp over wire insulation)

3 Wire

4 Soldering iron

5 Terminal

conducted away from the terminal.

7

Slide the sealant shrink tubing over the soldered

connection, making sure all exposed wire is covered.

Heat the tubing with a heat gun to shrink. Shrink until the

tubing is tight around the wire and the sealant is visible

out of both ends of the tubing.

Loading...

Loading...