Page 1

Service Manual

Trucks

Group 330–500

Starting and Charging

VN, VHD

PV776-TSP146025

Page 2

Page 3

Foreword

The descriptions and service procedures contained in this manual are based on designs and methods studies carried out up to March 2001.

The products are under continuous development. Vehicles and components produced

after the above date may therefore have different specifications and repair methods.

When this is believed to have a significant bearing on this manual, supplementary service bulletins will be issued to cover the changes.

The new edition of this manual will update the changes.

In service procedures where the title incorporates an operation number, this is a refer-

ence to an S.R.T. (Standard Repair Time).

Service procedures which do not include an operation number in the title are for gen-

eral information and no reference is made to an S.R.T.

The following levels of observations, cautions and warnings are used in this Service

Documentation:

Note: Indicates a procedure, practice, or condition that must be followed in order to

have the vehicle or component function in the manner intended.

Caution: Indicates an unsafe practice where damage to the product could occur.

Warning: Indicates an unsafe practice where personal injury or severe damage to the

product could occur.

Danger: Indicates an unsafe practice where serious personal injury or death could oc-

cur.

Volvo Trucks North America, Inc.

Greensboro, NC USA

Order number: PV776-TSP146025

© 2001 Volvo Trucks North America, Inc., Greensboro, NC USA

All rights reserved. No part of this publication may be reproduced, stored in

retrieval system, or transmitted in any forms by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior written

permission of Volvo Trucks North America, Inc..

Page 4

Page 5

Contents

General .................................................................................................... 3

Starting and Charging ........................................................................... 3

Tools ........................................................................................................ 5

Special Tools ......................................................................................... 5

Design and Function ............................................................................. 9

Starting and Charging System Indicator Lights .................................... 9

Battery ................................................................................................... 9

Cold Cranking Amps ....................................................................... 10

Reserve Capacity ............................................................................ 10

Open Circuit Voltage ....................................................................... 10

Battery Locations .............................................................................. 10

Battery Cables ................................................................................... 11

Battery Disconnect Switch ................................................................ 11

Starting System ................................................................................... 12

Starting Circuit ................................................................................... 12

Starter ................................................................................................ 13

Preheat System ................................................................................... 13

Preheat Circuit ................................................................................... 13

Preheater Assembly .......................................................................... 14

Charging System ................................................................................. 15

Charging Circuit ................................................................................. 15

Alternator ........................................................................................... 16

Troubleshooting ................................................................................... 17

Battery Troubleshooting ....................................................................... 17

Battery State of Charge .................................................................... 18

Battery Surface Charge Removal ..................................................... 19

Load Testing Batteries ....................................................................... 20

Electronic Battery Testing .................................................................. 21

Starting System Troubleshooting ......................................................... 22

Troubleshooting Simplified Schematic, Starting System ................... 23

Troubleshooting Ignition Switch with VCADS Pro Tool ..................... 24

Troubleshooting Battery/Starter Cables With Digital Multimeter ....... 25

Troubleshooting Ignition Switch/Starter Relay Circuit With Digital

Multimeter .......................................................................................... 26

Troubleshooting Starter with Digital Multimeter ................................ 27

Preheat System Troubleshooting ........................................................ 28

Troubleshooting Preheater with VCADS Pro Tool ............................. 29

Troubleshooting Preheater with Fault Codes .................................... 29

Troubleshooting Simplified Schematic, D7 Preheater ....................... 30

Troubleshooting Simplified Schematic, D12 Preheater ..................... 31

Troubleshooting Preheater with Digital Multimeter ............................ 32

Charging System Troubleshooting ...................................................... 33

Troubleshooting Simplified Schematics, Charging System ............... 34

Troubleshooting Charging System with Digital Multimeter ................ 35

Troubleshooting Charging Indicator (Telltale) Lamp .......................... 37

Troubleshooting — Alternator Output Test with BVA-34 Tester ........ 38

Troubleshooting Starting and Charging System with The Accu-

racy Plus Tester ................................................................................. 39

Service Procedures ............................................................................. 41

Battery Cables, Removal and Installation ........................................... 41

All Cables .......................................................................................... 41

1

Page 6

Ground Cables .................................................................................. 42

Battery Jump Starting .......................................................................... 43

Battery, Replacement (One or Two) .................................................... 44

Battery Cables to Starter, Replacement ............................................. 45

Battery Inter-connection Cables, Replacement ................................... 47

Starter Motor, Replacement ................................................................ 49

Volvo D12B or D12C Engine ............................................................. 49

Starter Motor, Replacement ................................................................ 51

Volvo D7C Engine ............................................................................. 51

Starter Motor, Replacement ................................................................ 53

Cummins or Detroit Diesel Engine .................................................... 53

Preheater Fuse, Replacement ............................................................ 55

Preheater Relay, Replacement ............................................................ 56

Volvo D12B or D12C Engine ............................................................. 56

Preheater Relay, Replacement ............................................................ 58

D7C Engine ....................................................................................... 58

Preheater Element, Replacement ....................................................... 59

D12B or D12C Engine ...................................................................... 59

Preheater Element, Replacement ....................................................... 60

D7C Engine ....................................................................................... 60

Alternator, Replacement (Adjustable Mount) ...................................... 62

Alternator, Replacement (Fixed Mount) .............................................. 63

Feedback

Operation Numbers

2

Page 7

Group 33 Starting and Charging VN, VHD General

General

Starting and Charging

The starting and charging system on the VN/VHD series vehicles is comprised of batteries, the starter, alternator and

all the connecting wiring, cables and switches. Vehicles equipped with Volvo engines may also have preheaters installed in the intake manifold to assist starting. For maximum efficiency, all parts of the system must function properly.

Note: The information in this manual pertains specifically to the Volvo VN/VHD series vehicles.

For more general information on the starting and charging system, including test, refer to:

Vendor

Information

Delco Remy DRA/DP1029

Diagnostic Procedures For Heavy Duty Electrical Systems

Starting and Charging Circuit, Simplified Schematic.

This simplified schematic should only be used to clarify the design features of the VN/VHD starting and charging circuit. For detailed vehicle-specific schematics, refer to:

Service

Manual

IMPACT Function Group: 370

Electrical Schematics VN, VHD

Information Type: Schematics

W3004734

3

Page 8

4

Page 9

Group 33 Starting and Charging VN, VHD Tools

Tools

Special Tools

The tools referenced in this manual are listed below. They can be obtained by contacting your local Volvo Trucks parts

dealer, Kent-Moore at 1–800–328–6657, or you may call a local listed tool vendor.

Note: For VCADS Pro tooling refer to:

Service

Manual

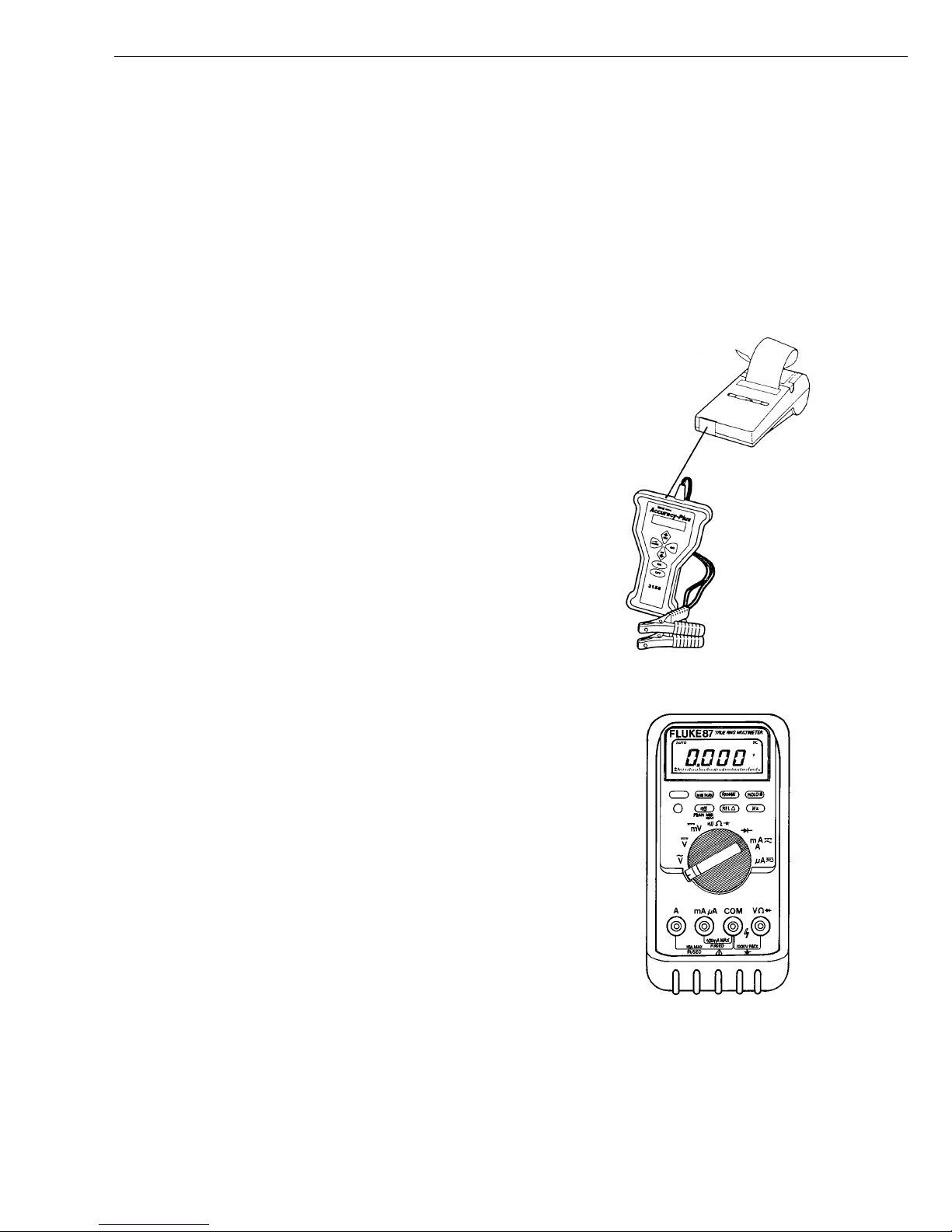

Battery tester kit. Includes: Tester J-44700 and Printer

238598, available from Kent-Moore (telephone: 800–

328–6657).

J-44701

VCADS Pro User’s Manual

Group Number 030–600

Fluke 87 digital multimeter, available from Volvo or KentMoore (telephone: 800–328–6657).

J-39200

W0001836

W2001014

5

Page 10

Group 33 Starting and Charging VN, VHD Tools

Relay puller tool, available from Kent-Moore (telephone:

800–328–6657).

J-43244

W0001917

VCADS Pro

For VCADS Pro tooling refer to:

Service

Manual

VCADS Pro User’s Manual

Group Number 030–600

Fan Belt Tensioner Tool, available from Volvo or KentMoore (telephone: 800–328–6657).

J-44392

W0001632

W0001817

(BT-33–73F) Belt Tension Gauge, available from KentMoore (telephone: 800–328–6657).

J-23600–B

6

W0001844

Page 11

Group 33 Starting and Charging VN, VHD Tools

BVA-34 System Analyzer

The BVA-34 System Analyzer is a digital, carbon pile,

battery load tester and starting/charging system analyzer. It is portable and designed for use in the heavy

truck market. Optional tester stand, part number ES-2, is

also available . For more information contact Auto-

®

Meter

at www.autometer.com.

(telephone: 435–283–4142) or visit their web site

W3004737

7

Page 12

8

Page 13

Group 33 Starting and Charging VN, VHD Design and Function

Design and Function

Starting and Charging System Indicator Lights

When the ignition key is turned “ON,” the Charging Indicator (telltale) lamp (1) will momentarily illuminate for a

bulb test. The lamp will remain on until the engine is

started. With the engine running and the alternator properly charging, the Charging telltale light should go off.

The instrument cluster left module is equipped with a

graphics display (2) that includes a voltmeter function.

With the voltmeter function active, the display will show a

battery icon and display the battery/charging voltage.

W3004552

If the battery/charging voltage exceeds 17 volts, the yellow “INFO” lamp (3) will illuminate and the graphic

display will show the voltage reading with the text message “TOO HIGH.”

T3008832

TOO HIGH

17.9 V

Battery

The battery is an electrochemical device for converting

chemical energy into electrical energy. The battery, or

battery pack, performs four basic functions:

1 It supplies energy for starting the engine.

2 It supplies energy to operate all the vehicles electri-

cal systems and accessories.

3 It acts as a voltage stabilizer for the electrical sys-

tem.

4 It supplies additional energy to operate the electrical

system during peak demands, for instance, when

the alternator is already at maximum output.

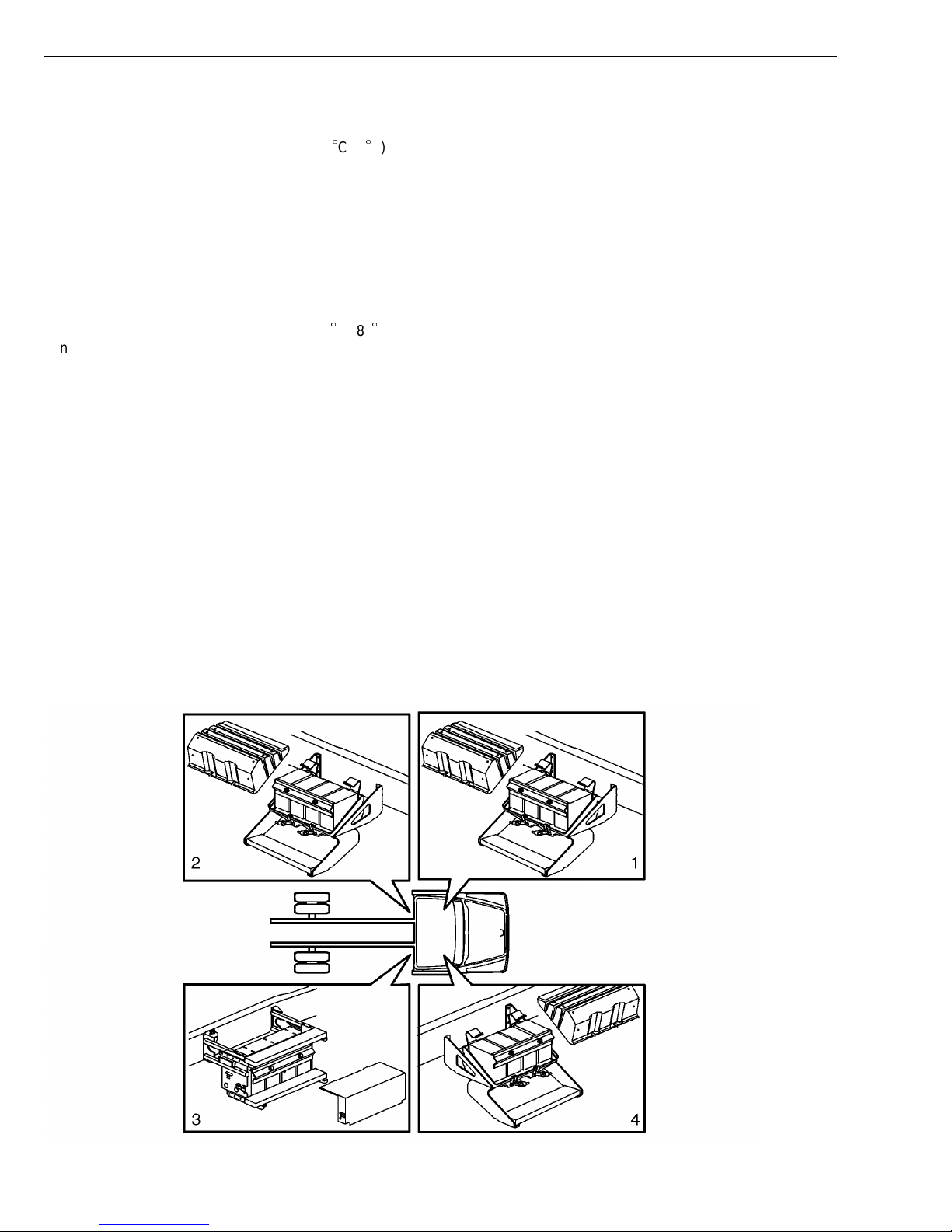

The battery case (1) is made of a strong, lightweight material, commonly polypropylene, to withstand shock and

vibration. The cover is vented to allow chemical gases to

escape. Each battery cell (2) is constructed of positive

and negative plates (3) that are insulated from each

other by a porous separator (4). Plate straps (5) connect

the positive and negative plates and provide a means of

interconnecting the cells. The cell is immersed in an

electrolyte solution of sulfuric acid and water. The electrical energy is produced in the battery by the chemical

reaction of the active materials that comprise the positive

and negative plates and the electrolyte. Each cell will

produce approximately 2.1 volts. The six cells that comprise the battery are connected in series to deliver

approximately 12.6 volts at the battery post (6).

W3004553

9

Page 14

Group 33 Starting and Charging VN, VHD Design and Function

Cold Cranking Amps

The “Cold Cranking Amps” rating is the amount of amperage load that can be maintained at –18

without the post voltage falling below 7.2 volts. This

rating is useful in determining the battery’s ability to

start an engine in cold weather conditions. The cold

cranking amp rating is determined by the amount of

plate surface area in each cell.

C(0

F)

Reserve Capacity

The “Reserve Capacity” is the number of minutes that

a battery can sustain a 25 Amp load at 27

until the post voltage drops to 10.5 volts. This rating is

useful in determining the battery’s ability to supply

operating power in the event of a vehicle charging system failure. The reserve capacity is determined by the

amount of active plate material in each cell.

C (80

F)

Open Circuit Voltage

The “Open Circuit Voltage” is the voltage at the battery

post with no loads applied.

Battery Locations

Battery box locations vary per application. The standard mounting location (1) is on the left frame rail

under the cab steps. This is the mounting location for

all VN and some VHD vehicles. Depending on the

equipment ordered, there are three optional battery

box mounting locations for the VHD vehicle. See illustration for locations: (2), (3) and (4).

10

W3004555

Page 15

Group 33 Starting and Charging VN, VHD Design and Function

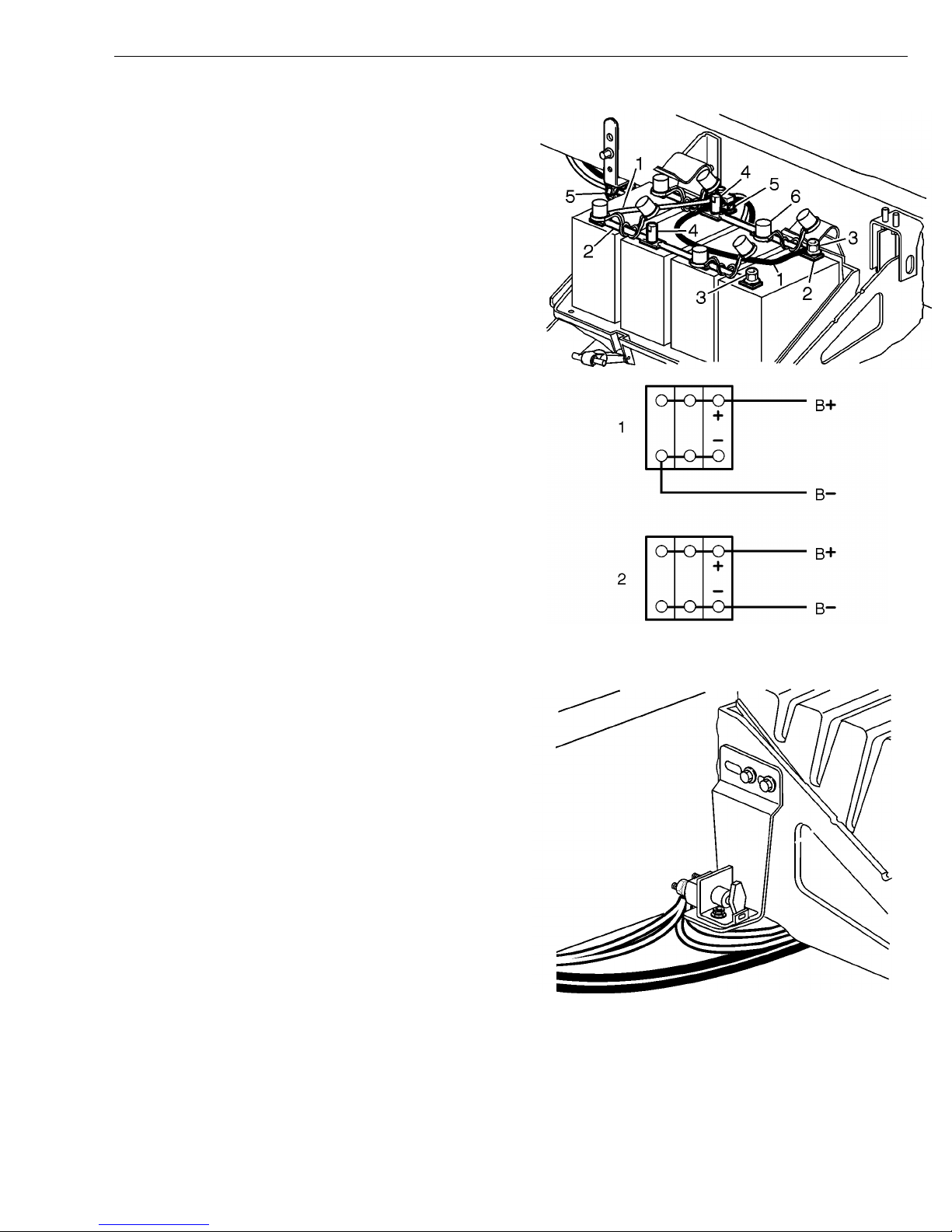

Battery Cables

All copper, 3/0 battery cables (1) are used on VN/VHD

vehicles. Single cables are used if the batteries are

mounted in the standard location. If the batteries are

mounted in optional locations, dual cables are used to

prevent excessive voltage drop due to cable length. Battery inter-connection cables (2) are 2/0 size. Some

applications may use interconnection bars instead of cables. All battery cables are sealed with polyvinyl chloride

(PVC) insulation to resist abrasion and the elements.

The battery cable terminals are secured to the batteries

with either stainless steel terminal nuts (3) or brass

jumper studs (4). Some applications may be equipped

with insulated terminal nuts that are made of plastic with

a brass insert. Protective covers (6) are installed on all

uninsulated battery cable terminal nuts/studs. Mounting

brackets (5) support and secure the battery cables at approximately 300 mm (12 in.) to 600 mm (24 in.) intervals

to avoid damage from abrasion, vibration, heat and

strain.

Ideally, battery sets should be connected to the battery/starter cables in a diagonal pattern (1) rather than

both cables being connected to one battery at the end of

the set (2). The diagonal connection will help assure that

all batteries in the set are cycled at the same rate, extending service life.

W3004556

Battery Disconnect Switch

As an option, some vehicles may have a master battery

disconnect switch (main switch). The switch will be

mounted on or near the battery box in all applications.

The battery disconnect switch should not be used as a

substitute for removing battery cables to prevent damage

to the vehicle when welding.

W3004557

W3004404

11

Page 16

Group 33 Starting and Charging VN, VHD Design and Function

Starting System

Starting Circuit

When the ignition switch is turned to the “START” position, power to energize the starter relay coil is supplied

on wire number 284. The starter relay coil is grounded

through the overcrank protection switch (OCP) or a

shorting jumper.

The OCP switch is located inside the starter. This switch

is optional. Where the OCP switch is not used, a shorting jumper is used to complete the starter relay coil

ground circuit.

When the starter relay is energized, a connection is

made from the starter solenoid BATT terminal (wire

285A) to the starter solenoid SW terminal (wire 285).

When the solenoid pulls in, a connection is made internally in the solenoid, which connects the battery terminal

to the motor terminal, then the starter begins to crank

the engine.

For more details see schematic in “Starting and Charging” page 3.

W3004339

overcrank protection (OCP) input switch.

12

W3003757

Starter Relay.

Page 17

Group 33 Starting and Charging VN, VHD Design and Function

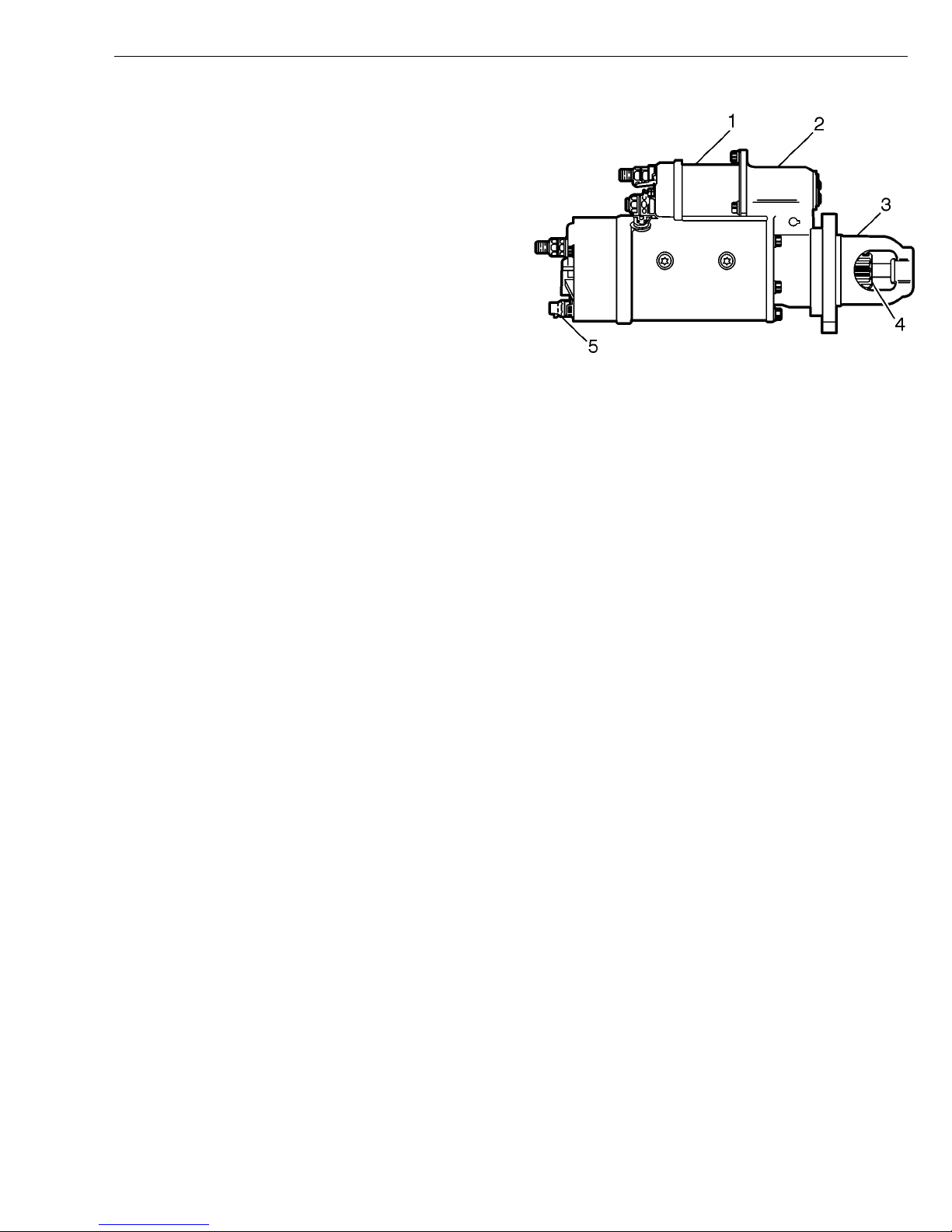

Starter

Volvo VN/VHD vehicles are equipped with Delco Remy42MT starters for most applications. If the vehicle is

equipped with a Volvo D7 engine, it will be equipped with

a Delco-Remy 37MT starter. These starters, sometimes

referred to as starting motors, have a shift lever and solenoid housing that is totally enclosed to protect them

from the elements. The nose housing can be rotated to

“clock” the solenoid to accommodate various engine

mounting locations. A positive engagement shift mechanism moves the pinion into mesh with the engine

flywheel ring gear prior to cranking to minimize gear

tooth damage. An optional overcrank protection (OCP)

switch protects the starter in adverse starting conditions,

such as cold weather starting or operator misuse. The

OCP switch is a temperature sensitive circuit breaker

that prevents overcrank heat damage by opening the

starter relay ground, then automatically resetting when

the starter has cooled sufficiently.

1 Solenoid

2 Shift Lever Housing

3 Nose Housing

4 Pinion

5 Overcrank Protection Input Switch

W3004558

Preheat System

Preheat Circuit

Vehicles equipped with Volvo engines may be equipped

with intake air preheaters to assist in cold weather starting.

Preheating is standard on the D7 engine with one preheat relay/element, and optional on the D12 engine with

two preheat relays/elements.

In normal operation, the ignition switch is turned to the

“preheat” position then released back to the “On”

position. The Vehicle Electronic Control Unit (VECU) recognizes the preheat request and sends the request to the

Engine Electronic Control Unit (EECU), via the J-1939

Control Data Link. The EECU will supply a ground to the

preheat relay(s), and the preheater will begin to operate.

Based on engine temperature, the EECU will time the interval for preheater operation. The operator may also

hold the ignition switch in the “preheat” position if additional preheat is desired after the timed preheat period.

The preheat relay(s) coil is supplied ignition power via a

fuse in the Truck Electrical Center (TEC) panel. The relay(s) is energized when a ground is supplied by the

EECU. When the relay(s) is energized, an internal connection is made that connects the preheater element

power supply from the alternator cable to the fuse that

connects to the preheat element(s). The preheat element(s) are case grounded.

page 3.

A “sense” circuit(s) provides information to the EECU to

confirm that the preheat circuit is intact. If the EECU determines that the circuit is not intact, a fault code(s) will

be generated.

For simplified schematic see: “Starting and Charging”

13

Page 18

Group 33 Starting and Charging VN, VHD Design and Function

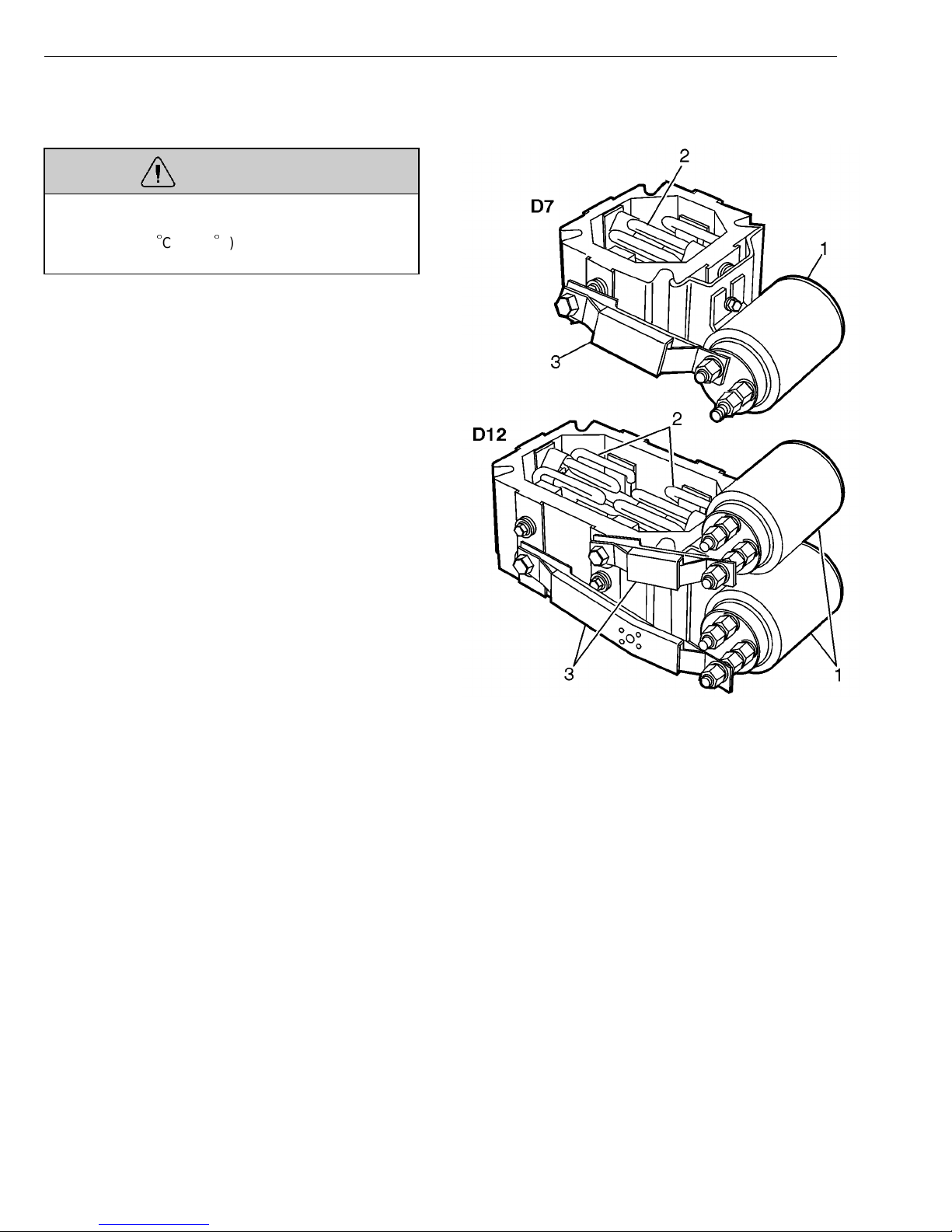

Preheater Assembly

WARNING

Use caution when working around the preheat

elements. When active, the elements will heat to approximately 705

the elements to cool to avoid severe burns.

The preheater assembly on a D7 engine is standard with

one relay element and fuse. The preheater assembly on

a D12 engine is optional with two relays, elements and

fuses.

C (1300F). Allow sufficient time for

1 Relay

2 Element

3 Fuse Assembly

W3004559

14

Page 19

Group 33 Starting and Charging VN, VHD Design and Function

Charging System

Charging Circuit

With the engine running, DC voltage is generated at the

alternator output (B+) terminal and supplied to the vehicles electrical system through wire no. 8. The alternator

is grounded by a wire from the ground terminal (B-) on

the alternator case to the engine ground terminal. A

fusible link in the ground circuit is designed to protect the

vehicle electrical system if a short in the alternator, alternator cable or battery cable occurs.

A wire from the alternator indicator light terminal to the

instrument cluster sends a signal to indicate that the

alternator is not charging. Vehicles with body builder applications may also have a wire from the alternator relay

terminal to provide engine speed information for PTO operation. Also see Starting and Charging Simplified

Schematic in “Starting and Charging” page 3.

W3004731

1 Output Terminal (B+)

2 Ground Terminal (B-)

3 Relay Terminal

4 Indicator Light Terminal

5 Ground Terminal (B-) 34SI only

15

Page 20

Group 33 Starting and Charging VN, VHD Design and Function

Alternator

The alternator converts the mechanical energy supplied

by the engine via drive belts into electrical energy that is

used to recharge the batteries and operate the electrical

devices on the vehicle. The alternator produces alternating current (AC), which is converted to direct current

(DC) by the diodes in the rectifier bridge. The rectifier

bridge also has design features to “clamp” voltage spikes

that may damage vehicle electronics. An internal voltage

regulator limits the charging voltage from 13.8 to 14.2

volts. Volvo VN/VHD vehicles currently are equipped with

one of three different Delco Remy alternators:

33SI — The 33SI alternator is a brushless design

•

for longer operating life. It is the standard alternator

used in most applications. It is available with 110

and 135 amp output ratings.

22SI — The 22SI alternator is a smaller, standard

•

brush type alternator. It is available with 100, 130

and 145 amp output ratings.

34SI — The 34SI alternator is internally identical to

•

the 33SI. The major difference is that the housing

has a fourth mounting lug to withstand higher vibration applications. The 34SI is currently only used in

VN vehicles equipped with Detroit Diesel engines.

16

W3004561

Page 21

Group 33 Starting and Charging VN, VHD Troubleshooting

Troubleshooting

Battery Troubleshooting

Before working on a vehicle, set the parking brakes,

place the transmission in neutral, and block the

wheels. Failure to do so can result in unexpected

vehicle movement and can cause serious personal injury or death.

WARNING

Always wear eye protection when working around batteries to prevent the risk of injury due to contact with

sulfuric acid or an explosion. (Important: If contacted

with sulfuric acid, flush immediately with water and

get medical attention).

WARNING

Batteries may contain explosive gases. To help minimize the risks of explosion, avoid sparks or open

flames near batteries. Do not smoke when servicing

batteries.

CAUTION

If there are other ground cables connected to the battery (such as engine ECU’s, satellite system, etc.),

disconnect those grounds first, then remove the main

battery ground cable. Electronic modules may be

damaged when additional grounds are connected/disconnected without the main battery ground

connected. Disconnect the main battery ground last.

CAUTION

In vehicles with a Supplemental Restraint System

(SRS), turn the ignition switch ON before connecting

the battery. Failure to do so may result in permanent

damage to the instrument cluster or other electronic

circuits within the vehicle. (This applies only to vehicles with SRS and a Cummins or Detroit Diesel

engine.) Always check for fault codes after repairs are

completed.

CAUTION

Possible damage to electronic components. Turn the

vehicle ignition switch OFF before disconnecting or

connecting any electronic components. Failure to

de-energize circuits may result in permanent damage

to electronic components.

17

Page 22

Group 33 Starting and Charging VN, VHD Troubleshooting

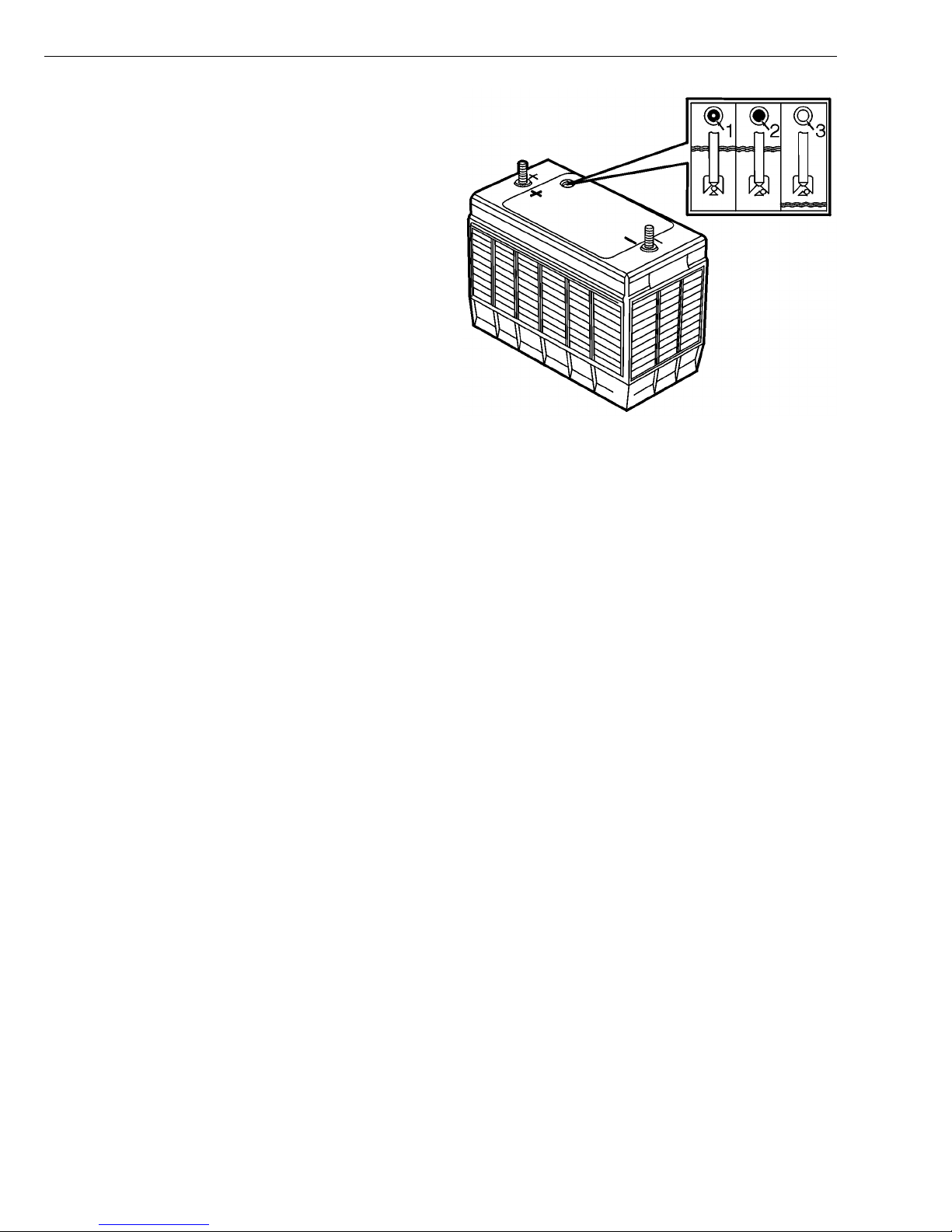

Battery State of Charge

The battery state of charge must be determined before

battery testing. Battery hydrometers that measured battery acid specific gravity were used to determine the

state of charge in earlier battery designs with removable

filler caps. In current “maintenance free” design batteries

the state of charge is determined by a built-in hydrometer or an open circuit voltage test.

The battery may have a special temperature compensated hydrometer built into the cover to show at a glance

the battery’s state-of-charge. The hydrometer has a

green ball within a cage which is attached to a clear,

plastic rod. The green ball will float at a predetermined

specific gravity of the electrolyte that represents about

65% state-of-charge. When the green ball floats, it rises

within the cage and positions itself under the rod.

Visually a green dot then shows in the center of the hydrometer. The built-in hydrometer provides a guide for

battery testing and charging.

In testing, the green dot means the battery is charged

enough for testing. If the green dot is not visible, it

means the battery must be charged before the test procedure is performed.

1. State of charge 65% or above

2. Below 65% state of charge

3. Low electrolyte level

W3004562

In charging, the appearance of the green dot means that

the battery is sufficiently charged.

The hydrometer on some batteries may be clear or light

yellow. This means the fluid level is below the bottom of

the rod and attached cage. This may have been caused

by excessive or prolonged charging, a broken case, excessive tipping or normal battery wear out.

If a battery displays a clear eye, it must be replaced.

Do not attempt to charge, test or jump start the battery.

Note: The built-in hydrometer only monitors one battery

cell. Low state of charge in other cells will not be indicated by the built-in hydrometer.

The battery state of charge may also be checked by

reading the open circuit voltage. To check, connect a

voltmeter to the positive and negative battery post. If the

reading is below 12.40 volts, the battery is too low for

proper testing and must be recharged. If the reading is

above 12.66 volts, the surface charge must be removed

before testing. See: “Battery Surface Charge Removal”

page 19.

18

Page 23

Group 33 Starting and Charging VN, VHD Troubleshooting

Battery Surface Charge Removal

When a battery is charged, very small hydrogen gas

bubbles form on the surface of the battery plates, causing what is known as “surface charge.” When a voltmeter

is connected to the battery post, it may give a false reading if the surface charge is not removed.

Before testing a battery, the surface charge must be removed by one of the following methods:

Turn on the headlights for 2–3 minutes. Then allow

•

the battery to stabilize for 1 minute before testing.

Remove the Engine ECU fuse in the battery box to

•

prevent the engine from starting. Start the engine

for 5–10 seconds. Then allow the battery to stabilize

for 1 minute before testing.

Use BVA-34 System Analyzer or equivalent tool to

•

load the battery to 300 amps for 5–10 seconds.

Then allow the battery to stabilize for 1 minute before testing.

Note: The open circuit voltage must be at least 12.4

volts after the surface charge has been removed to continue battery testing.

19

Page 24

Group 33 Starting and Charging VN, VHD Troubleshooting

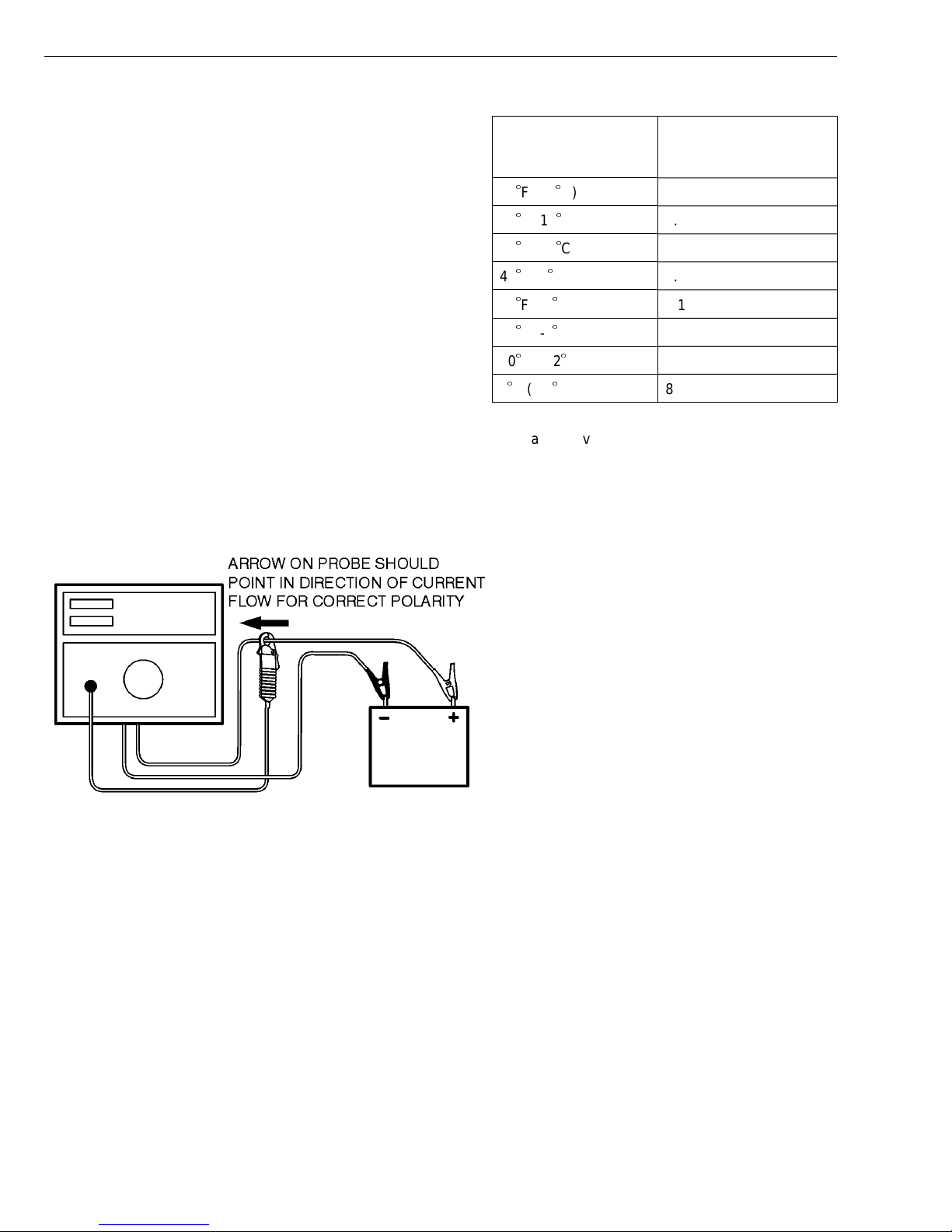

Load Testing Batteries

The BVA-34 System Analyzer is a digital, carbon pile,

battery load tester and starting/charging system analyzer. It is portable and designed for use in the heavy

truck market. The test that follows may be performed

with the BVA-34 System Analyzer, or equivalent carbon

pile type tester, and should be used as a general guide

for performing a battery load test. Read and follow the

test instructions supplied with the tester used to perform

battery testing.

1 Batteries must be tested individually. Remove

battery cables as described in “Battery Cables, Removal and Installation” page 41.

2 Visually inspect the battery for corroded terminals,

damage or a clear built-in hydrometer eye, if

equipped. Clean the terminals if needed. Replace

damaged batteries or batteries with clear hydrometer eyes (indicates electrolyte loss).

3 Screw the brass “jumper studs” onto the positive

and negative terminal before connecting the tester.

Do not connect the tester leads directly to the battery terminal post.

4

7

ESTIMATED

ELECTROLYTE

TERMPERATURE

70F (21C) and above 9.6

60F (16C) 9.5

50F (10C) 9.4

40F(4C) 9.3

30F (-1C) 9.1

20F (-7C) 8.9

10F (-12C) 8.7

0F (-18C) 8.5

Compare the voltage reading obtained to the temperature compensated chart above. If the battery

does not meet or exceed the minimum voltage required, replace the battery.

MINIMUM REQUIRED

VOLTAGE UNDER 15

SECOND LOAD

Connect the BVA-34 System Analyzer (or equivalent

tool) to the battery as shown. Set the voltmeter to

the “INTERNAL” setting. Zero the ammeter.

5 Check the battery open circuit voltage. The reading

must be between 12.40 and 12.66 volts to proceed.

If not, see “Battery State of Charge” page 18.

6 Adjust the load control knob to equal one half the

battery’s Cold Cranking Amp (CCA) rating. The battery CCA specification can be found on the battery

label. Maintain the load for 15 seconds then note

the battery voltage (with load applied).

20

W3004563

Page 25

Group 33 Starting and Charging VN, VHD Troubleshooting

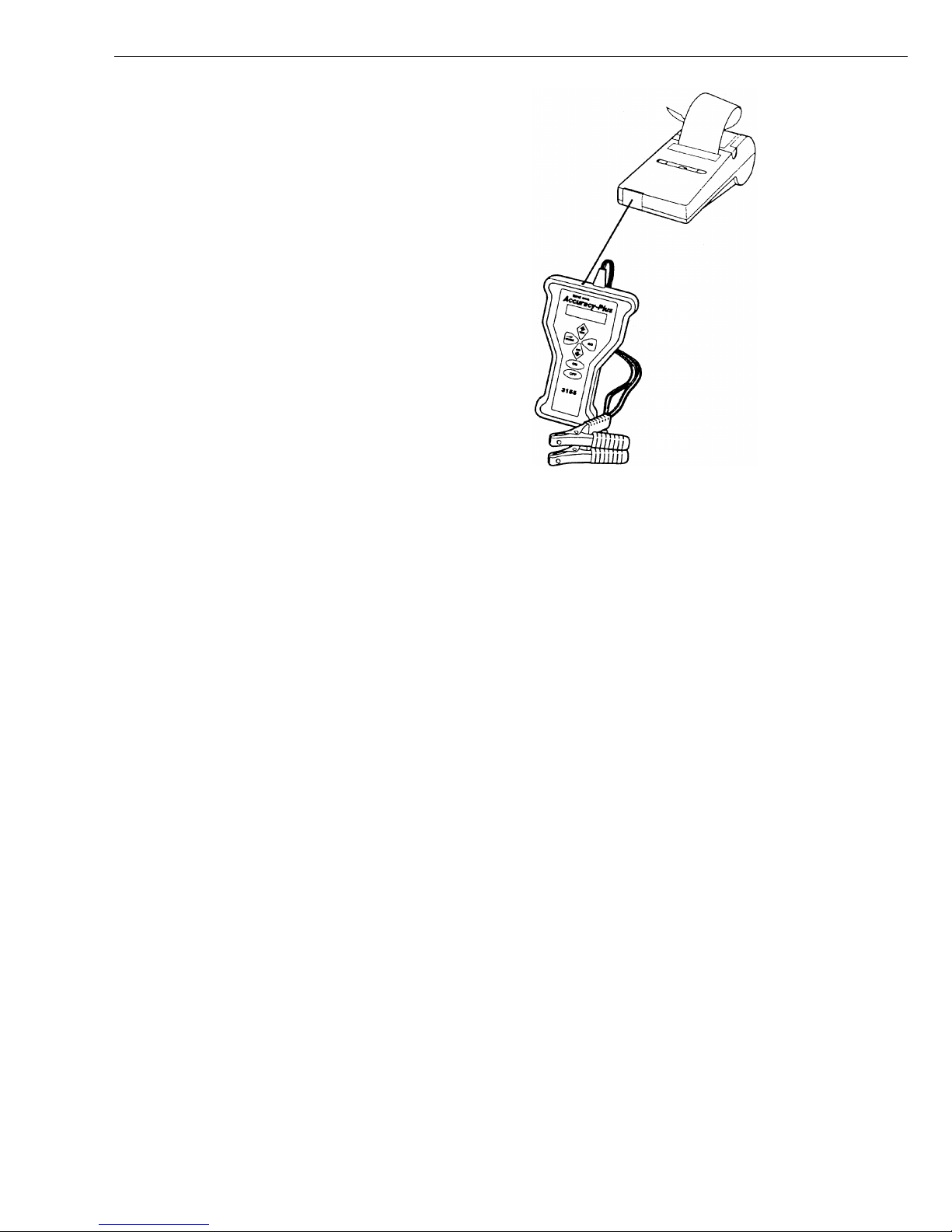

Electronic Battery Testing

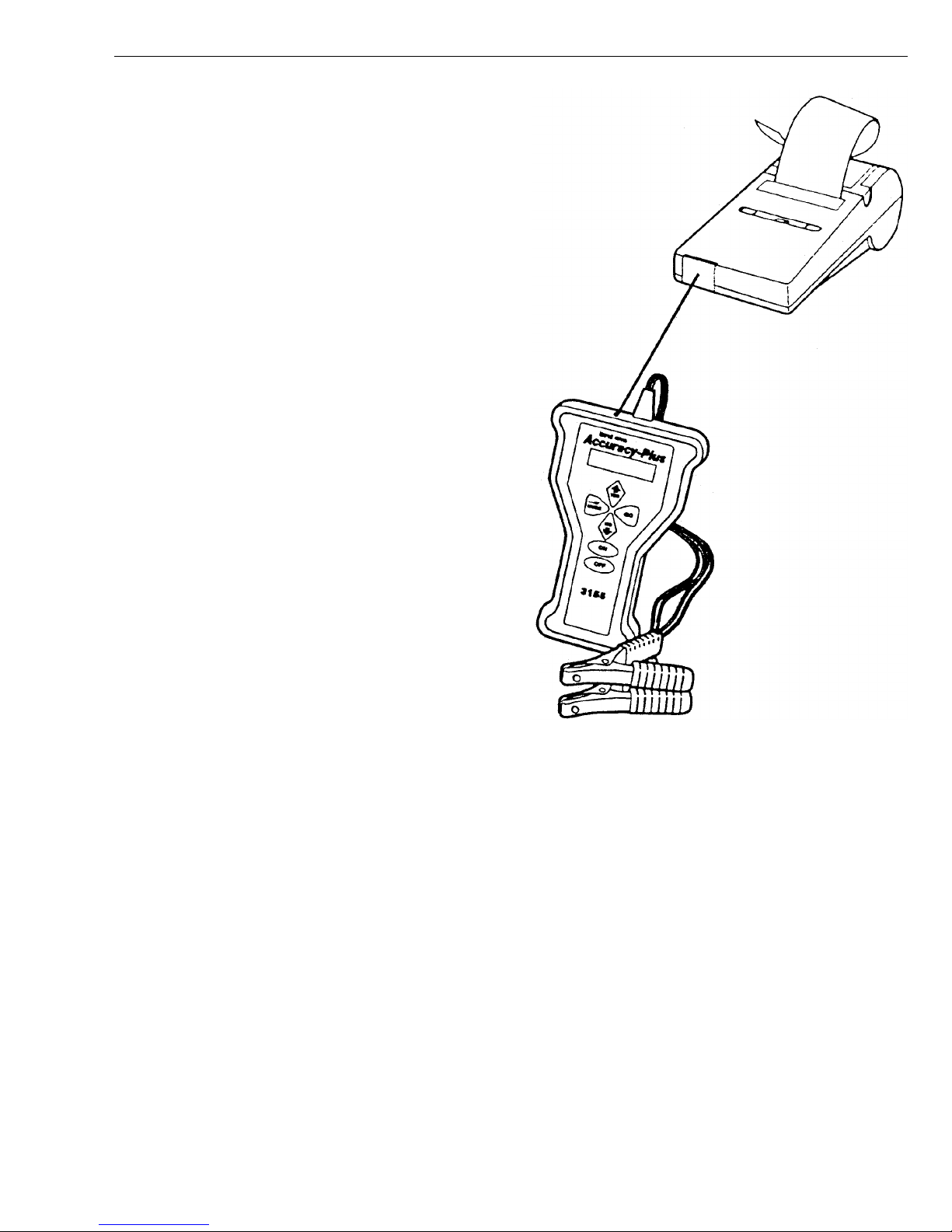

The J-44700 Accuracy Plus HD Battery Tester is a hand

held electronic battery diagnostic tester. The tester applies variable loads to the battery and measures the

battery’s response. Results are then displayed and may

be printed if desired with the optional printer number

238598. Both the J-4477 Accuracy Plus tester and the

238598 printer are available in kit part number J-44701.

The test that follows may be performed with the J-44770

Accuracy Plus HD Battery Tester, or equivalent electronic testers, and should be used as a general guide for

performing electronic battery testing. Read and follow

the test instructions supplied with the electronic test

equipment used to perform battery testing.

1 Batteries must be tested individually. Remove

battery cables as described in “Battery Cables, Removal and Installation” page 41.

2 Visually inspect the battery for corroded terminals,

damage, or a clear built-in hydrometer eye if

equipped. Clean the terminals if needed. Replace

damaged batteries or batteries with clear hydrometer eyes (indicates electrolyte loss).

J-44700 Accuracy Plus HD Battery Tester.

W0001836

3 To operate the Accuracy Plus tester, connect the

positive and negative tester leads to the battery stud

posts. Select the “Battery Test” and follow the on

screen prompts until the test is complete. Test results will appear on screen.

21

Page 26

Group 33 Starting and Charging VN, VHD Troubleshooting

Starting System

Troubleshooting

Before working on a vehicle, set the parking brakes,

place the transmission in neutral, and block the

wheels. Failure to do so can result in unexpected

vehicle movement and can cause serious personal injury or death.

WARNING

Always wear eye protection when working around batteries to prevent the risk of injury due to contact with

sulfuric acid or an explosion. (Important: If contacted

with sulfuric acid, flush immediately with water and

get medical attention).

WARNING

WARNING

HOT ENGINE! Keep clear of all moving parts or hot

engine parts and/or fluids. A hot engine an/or fluids

can cause burns.

CAUTION

Possible damage to electronic components. Turn the

vehicle ignition switch OFF before disconnecting or

connecting any electronic components. Failure to

de-energize circuits may result in permanent damage

to electronic components.

CAUTION

Never use the ohmmeter mode of the DMM in a powered circuit, or as a substitute for a voltmeter or

ammeter, since this will result in damage to the instrument. Use the ohmmeter mode only when power is

removed from the circuit.

Batteries may contain explosive gases. To help minimize the risks of explosion, avoid sparks or open

flames near batteries. Do not smoke when servicing

batteries.

22

Page 27

Group 33 Starting and Charging VN, VHD Troubleshooting

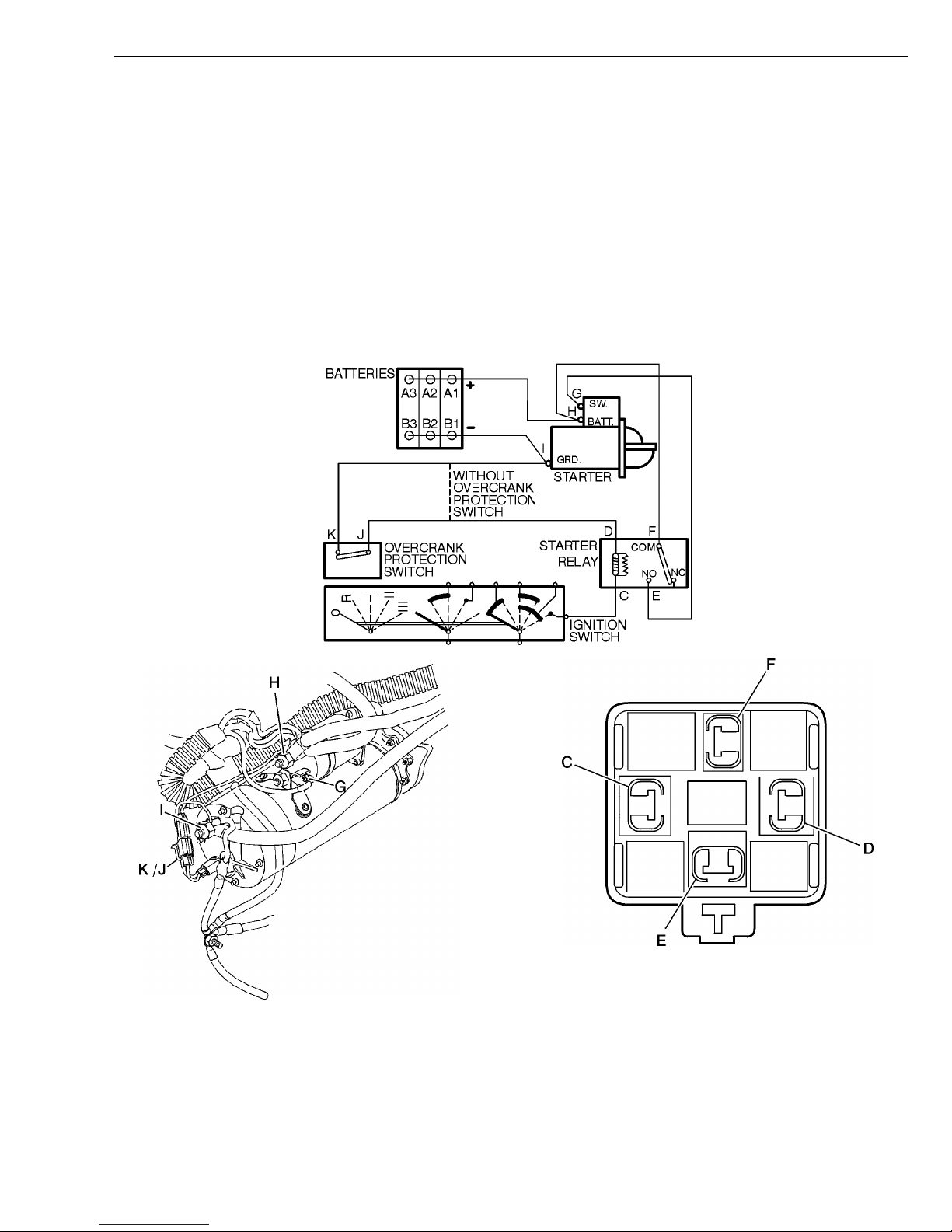

Troubleshooting Simplified

Schematic, Starting System

The simplified schematic and illustration below should be used to clarify the troubleshooting procedures in

“Troubleshooting Battery/Starter Cables With Digital Multimeter” page 25 , “Troubleshooting Ignition Switch/Starter

Relay Circuit With Digital Multimeter” page 26 and “Troubleshooting Starter with Digital Multimeter” page 27. For detailed, vehicle-specific schematics refer to:

Service

Manual

IMPACT Function Group: 370

Electrical Schematics VN, VHD

Information Type: Schematics

W3003745

Starter

Motor

H, I, J and K are measuring points. For details see

“Troubleshooting Battery/Starter Cables With Digital

Multimeter” page 25.

W3004564

W3003744

Starter

Relay

Switch

The connector is illustrated from the relay insertion side.

C=86 12V from Ignition Switch

D=85 Coil Ground

E=87 12V to Starter Solenoid

F=30 12V Supply

23

Page 28

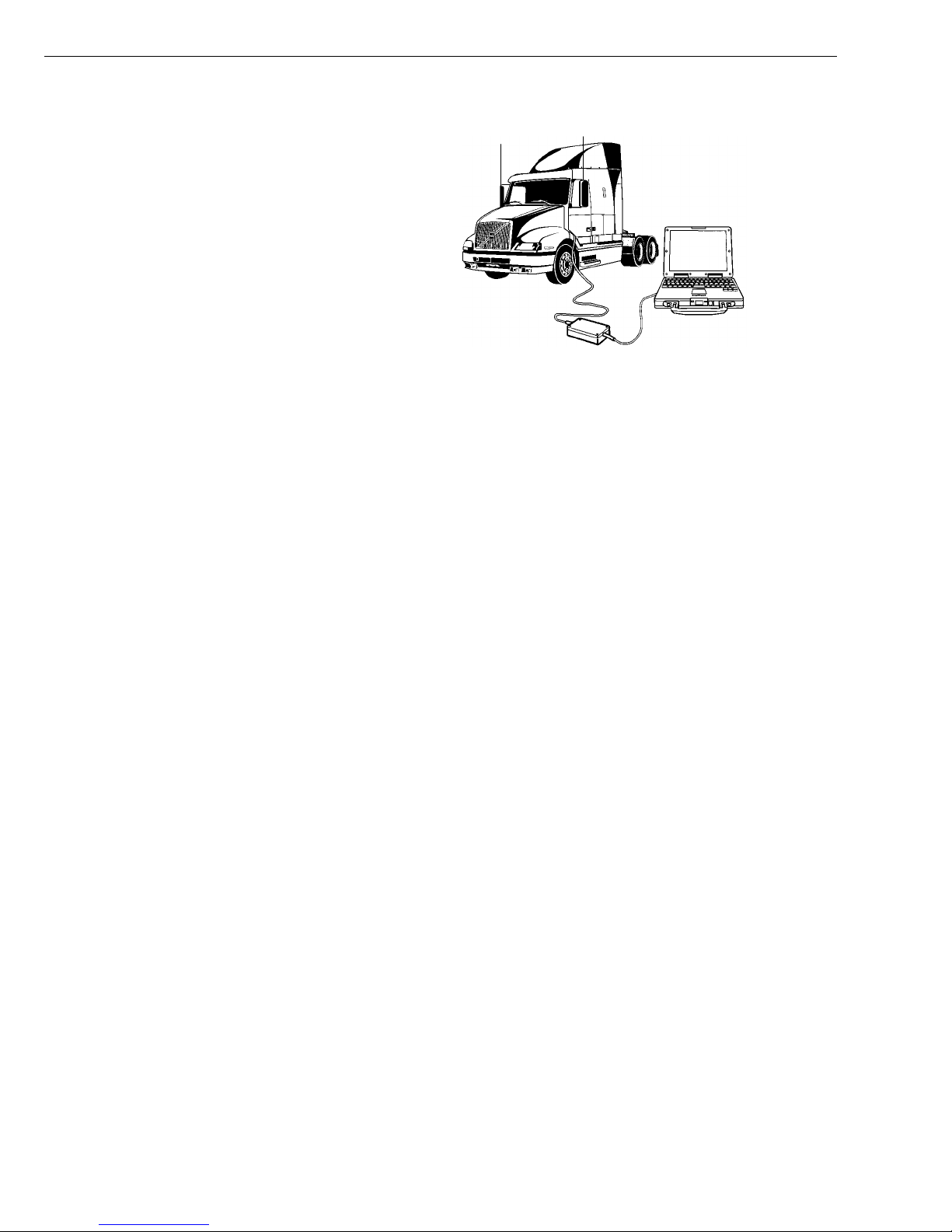

Group 33 Starting and Charging VN, VHD Troubleshooting

Troubleshooting Ignition Switch

with VCADS Pro Tool

The VCADS Pro Tool is a Windows 95 based PC tool

that can be used to perform some ignition switch testing.

The following is a brief description of tests that are currently available.

Test number 3340–08–02–01, “Ignition Switch, test”

Indicators on the VCADS Pro Screen will illuminate green

when the ignition key is turned to the “Start” position.

For detailed information about the VCADS Pro Tool op-

eration see refer to:

Service

Manual

VCADS Pro User’s Manual

Group Number 030–600

Note: This test only applies to vehicles with a Vehicle

ECU (Volvo engines).

W0001632

24

Page 29

Group 33 Starting and Charging VN, VHD Troubleshooting

Troubleshooting Battery/Starter

Cables With Digital Multimeter

The starter is supplied power and ground through cables

connected directly to the batteries. Excessive resistance

in the cables or connectors will cause decreased current

flow to the starter.

Due to the high current flow demands of the starting

circuit, voltage drop tests are more effective than ohmmeter tests in determining if excessive resistance exists

in the cable assemblies.

1 Check for 12.4V at the battery cable terminals (A1 &

B1) to the starter motor. If 12.4 V is not present or if

a weak battery(s) is suspected, see: “Battery Troubleshooting” page 17 for battery testing information.

2 Test complies with SAE J541 (10/96) or 0.1 volts

per 100 amps current draw. Specification assumes a

typical 700 amps starting current draw.

Function Key Position Measuring Point Approximate

Value

Positive

Cable

Start Battery positive-

post (A1)/Starter

"BATT" post (H)

<0.7 V drop. See

Note 2 above.

3 Confirm that the cables between batteries are clean,

tight and in proper working order.

4 Remove engine ECU fuses, located in the battery

box, to prevent the engine from running during the

tests.

Use the digital multimeter J-39200 or equivalent tool to

perform the test in the table below. The measuring

points referenced in the tables as A,B,C etc. correspond

to measuring points that are illustrated in the simplified

schematics and drawing. See: “Troubleshooting Simplified Schematic, Starting System” page 23.

Note: Due to battery mounting locations some vehicles

will have dual positive and negative cables. This test assumes that both cables are connected.

Note: Test complies with SAE J541 (10/96) of 0.1 volts

per 100 amp current draw. Specification assumes a

maximum of 700 amps starting current draw and normal

circuit temperature of 20

Note Possible Cause (if ex-

Starter cranking

engine

C (68

F).

pected value not correct)

Positive battery cable or

connectors

Negative

cable

Positive

InterConnect

Cables

Negative

InterConnect

Cables

Start Battery negative

post (B1)/Ground

post at starter (I)

Start Individual Battery

Positive Post

A1/A2; A2/A3;

etc.

Start Individual Battery

Negative Post

B1/B2;B2/B3;

etc.

<0.7 V drop. See

Note 2 above.

<0.1 V drop

between any terminals

<0.1 V drop

between any terminals

Starter cranking

engine

Starter cranking

engine

Starter cranking

engine

Negative battery cable or

connectors

Positive battery interconnect cable or connections

Negative battery interconnect cable or connections

25

Page 30

Group 33 Starting and Charging VN, VHD Troubleshooting

Troubleshooting Ignition

Switch/Starter Relay Circuit With

Digital Multimeter

When the “start” position is selected at the ignition

switch, 12 volts are supplied to the starter relay coil. If

the starter relay coil is properly grounded, either directly

or through the overcrank protection switch, the starter relay will energize and close the contacts between the

“common” and “normally open” terminals.

This creates a connection between the battery that connects to the “common” terminal, and the starter solenoid

switch feed, that connects to the “normally open” terminal. With this connection made, 12 volts are supplied to

the starter solenoid, which engages, and the starter motor begins to crank the engine.

The overcrank protection switch is designed to open and

prevent the starter from turning if the starter becomes

excessively hot. It should reset when the starter cools

sufficiently.

Function Key

Position

Measuring Point Expected

Value

1 Check for 12.4V at the battery cable terminals (A1 &

B1) to the starter motor. If 12.4 V is not present or if

a weak battery(s) is suspected, see: “Battery Troubleshooting” page 17 for battery testing information.

2 Confirm that the cables between batteries are clean,

tight and in proper working order.

3 Remove the engine ECU fuses located in the bat-

tery box to prevent the engine from running during

the tests.

4 Unplug the starter relay from the connector.

Use digital multimeter J-39200 or equivalent tool to per-

form the test in the table below. The measuring points

referenced in the tables as A,B,C, etc. correspond to

measuring points that are illustrated in the starting system simplified schematics and drawing. See

“Troubleshooting Simplified Schematic, Starting System”

page 23.

Note Possible Cause (if

expected value not correct)

Start signal to

starter relay

Ground to

starter relay

Battery signal

to starter relay

Start signal to

starter solenoid

Start Ignition switch ter-

minal at the starter

relay (C)/alternate

ground

Off Ground terminal

at starter relay

(D)/alternate

ground

Off Battery terminal at

starter relay

(F)/alternate

ground

Start SW terminal at

starter solenoid

(G)/alternate

ground

12V 1 Power supply to igni-

tion switch

2 Connectors/ wiring

fault in circuit from ignition switch to starter

relay

3 Ignition switch

<1

12V 1 Power supply to

12V Reinstall

relay to connector.

Starter relay

should

"click" when

energized.

1 Connectors/ wiring

fault in ground circuit

from starter relay

2 Overcrank protection

switch open (if

equipped)

starter "batt" post

2 Connectors/ wiring

fault in circuit from

starter "batt" post to

starter relay

1 Connectors or wiring

faults in starter relay/starter solenoid

circuit

2 If values in previous

test OK, probably

starter relay failure

Overcrank

Protection

(OCP) Switch

26

Off OCP Switch con-

nector (K/J)

<1

Not

equipped on

all engines

1 Starter overheated

2 OCP Switch failure

Page 31

Group 33 Starting and Charging VN, VHD Troubleshooting

Troubleshooting Starter with

Digital Multimeter

The starter motor/solenoid is supplied power and ground

through cables connected directly to the batteries. The

starter solenoid is engaged when a 12 volt signal is delivered to the “SW” terminal via the starter relay. When

the starter solenoid engages, a connection is made internally in the solenoid that connects the battery and

motor terminals and the starter cranks the engine.

1 Check for 12.4V at the battery cable terminals (A1 &

B1) to the starter motor. If 12.4 V is not present or if

a weak battery(s) is suspected, see: “Battery Troubleshooting” page 17 for battery testing information.

Function

Power supply

from batteries

Ground from

batteries

Key Position Measuring

Point

Off Starter "Batt"

post (H) / alternate

ground

Off Ground post

at starter (I) /

alternate

ground

Expected

Value

12V 1 Positive battery cable or con-

<1

2 Confirm that the cables between batteries are clean

tight and in proper working order.

3 Remove the engine ECU fuses located in the battery

box to prevent the engine from running during tests.

Use a digital multimeter J-39200 or equivalent tool to

perform the test in the table below. The measuring

points referenced in the tables as A, B, C etc. correspond to measuring points that are illustrated in the

starting system simplified schematics and drawing. See:

“Troubleshooting Simplified Schematic, Starting System”

page 23.

Note Possible Cause (if expected

value not correct)

nectors. See: “Troubleshooting

Battery/Starter Cables With

Digital Multimeter” page 25.

1 Negative battery cable or con-

nectors. See: “Troubleshooting

Battery/Starter Cables With

Digital Multimeter” page 25.

Start signal

from starter

relay.

If all the measurements are correct and the starter

•

will not engage, the starter is probably defective.

If all the measurements are correct and the starter

•

engages, but will not crank or the engine cranks

slowly, perform the following checks before replacing

starter:

Start Starter "SW"

terminal (G)

/alternate

ground

12V Starter

should

crank with

terminal energized

1 Check that the engine can be manually turned with

2 Check the starting system with the engine at operat-

3 Perform the test “Troubleshooting Battery/Starter

1 Starter relay.

2 Connectors or wiring faults in

starter relay/ignition switch circuit. See: “Troubleshooting

Ignition Switch/Starter Relay

Circuit With Digital Multimeter”

page 26.

a reasonable amount of effort to eliminate the possibility of a mechanical engine fault.

ing temperature. Extreme cold will make the engine

more difficult to turn and will reduce the batteries

output.

Cables With Digital Multimeter” page 25.

27

Page 32

Group 33 Starting and Charging VN, VHD Troubleshooting

Preheat System Troubleshooting

Before working on a vehicle, set the parking brakes,

place the transmission in neutral, and block the

wheels. Failure to do so can result in unexpected

vehicle movement and can cause serious personal injury or death.

CAUTION

Use caution when working around the preheat

elements. When active, the elements will heat to approximately 705

the elements to cool to to avoid severe burns.

C (1300

F). Allow sufficient time for

Possible damage to electronic components. Turn the

vehicle ignition switch OFF before disconnecting or

connecting any electronic components. Failure to

de-energize circuits may result in permanent damage

to electronic components.

Never use the ohmmeter mode of the DMM in a powered circuit, or as a substitute for a voltmeter or

ammeter, since damage to the instrument will result.

Use the ohmmeter mode only when power is removed

from the circuit.

CAUTION

CAUTION

CAUTION

Do not keep the ignition key in the preheating position

longer than approx. 15 seconds. Allow the starting

heater to cool between each activation or damage to

the preheater can occur.

28

Page 33

Group 33 Starting and Charging VN, VHD Troubleshooting

Troubleshooting Preheater with

VCADS Pro Tool

The VCADS Pro tool is a Windows 95 based PC tool

that can be used to perform some preheater testing. The

following is a brief description of tests that are currently

available.

Test number — 3330–08–02–01, preheat test.

Indicators on the VCADS Pro screen will illuminate

green when the ignition key is turned to the preheat position and when the preheat relay 1 and/or 2 is activated.

The VCADS Pro Tool also displays the engine coolant

temperature.

For detailed information about the VCADS Pro Tool operation, refer to:

Service

Manual

VCADS Pro User’s Manual

Troubleshooting Preheater with

Fault Codes

Check for stored fault codes when beginning troubleshooting procedures for preheating. If any of the

following fault codes is present, refer to:

Group Number 030–600

W0001632

Service

Information

IMPACT Function Group: 0

MID 128 — PID 45, preheating

•

MID 128 — SID 70, preheating element 1

•

MID 128 — SID 71, preheating element 2

•

Fault Tracing Information

Diagnostics Binder

Information Type: Diagnostics

29

Page 34

Group 33 Starting and Charging VN, VHD Troubleshooting

Troubleshooting Simplified

Schematic, D7 Preheater

The simplified schematic and lllustration below should clarify the procedures in “Troubleshooting Preheater with Digital

Multimeter” page 32. For detailed, vehicle-specific schematics refer to Function Group 370, Service Manual: Electrical

Schematics VN, VHD. Information Type: Schematics.

W3003776

Wire color codes in schematic:

SB Solid Black

BL/R Blue/Red

R Red

R/W Red/White

Y Yellow

GN Green

W3003778

A, B, C and D are measuring points. See:

“Troubleshooting Preheater with Digital Multimeter” page

32 for more information.

30

Page 35

Group 33 Starting and Charging VN, VHD Troubleshooting

Troubleshooting Simplified

Schematic, D12 Preheater

The simplified schematic and lllustration below should clarify the procedures in “Troubleshooting Preheater with Digital

Multimeter” page 32. For detailed, vehicle-specific schematics refer to Function Group 370, Service Manual: Electrical

Schematics VN, VHD. Information Type: Schematics.

Wire color codes in Schematic:

SB Solid Black

BL/R Blue/Red

R/W Red/White

Y Yellow

GN Green

W3003779

A, B, C and D are measuring points. See:

“Troubleshooting Preheater with Digital Multimeter” page

32 for more information. 1: Relay 1, 2: Relay 2.

W3003777

31

Page 36

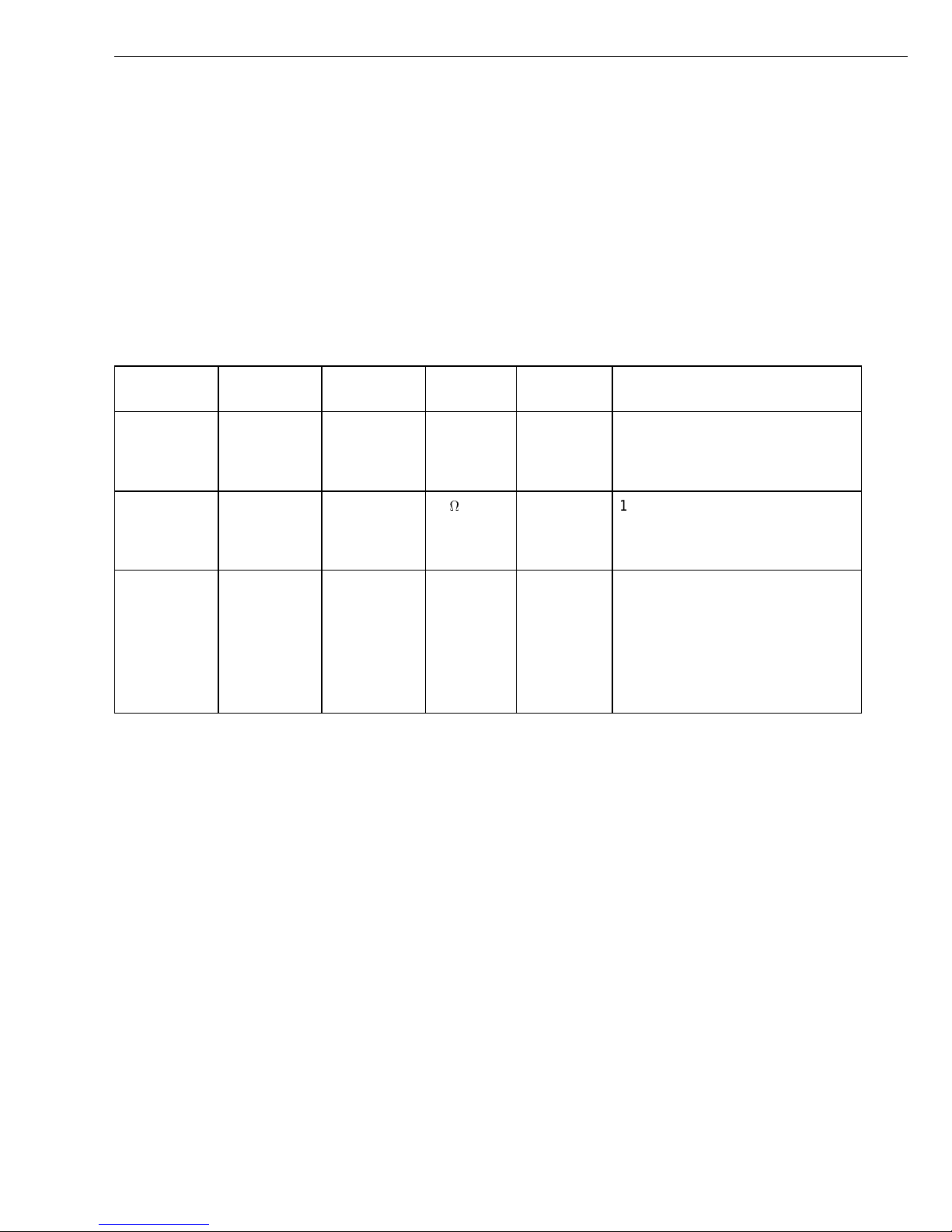

Group 33 Starting and Charging VN, VHD Troubleshooting

Troubleshooting Preheater with

Digital Multimeter

Use digital Multimeter J-39200 or equivalent tool to perform the test in the table below. The measuring points referenced in the table as A, B, C, etc. correspond to measuring points that are illustrated in the preheat simplified

schematics and drawings in “Troubleshooting Simplified Schematic, D7 Preheater” page 30 and “Troubleshooting

Simplified Schematic, D12 Preheater” page 31.

These measuring points should not be confused with the wire color codes that are listed beside each schematic.

Each preheat relay, fuse and element must be checked independently on D12 engines.

Function Key

Position

Power Supply to

Relay Coil

Ground to Relay

Coil

Control Signal Preheat Control Wire (B) to al-

Relay Coil Function Test

Power Supply

for Pre-heater

Elements

Ground through

Preheater Elements

On Relay coil positive

Off Control Wire (B) to al-

On Control Wire (B) to al-

Off Relay "Common" (C)

Off Relay "NO" (D) termi-

Measuring Points Expected

connector (A) to alternate ground.

ternate ground

ternate ground

ternate ground

terminal to alternate

ground

nal to alternate ground

Note Possible Cause (if ex-

Value

12V Fuse, connectors or

180 k± 20% Disconnect

control wire at

relay

<1V Relay(s) click in 1 Connectors or

Relay(s) click

in

12V Connectors or wiring

<1

pected value not

correct)

wiring fault in power

supply circuit.

Connectors or wiring

fault in ground circuit

through EECU.

wiring fault in

ground circuit

through EECU

2 Preheat relay(s).

If values above are

correct probably relay

fault.

fault in power supply

circuit from alternator.

1 Preheater fuse.

2 Preheater ele-

ment.

Relay Function

Test

Preheat Fuses Preheat Preheat element

Preheater Elements

32

Preheat Relay "NO" (D) termi-

nal to alternate ground

connection (E) to alternate ground

Preheat Preheat element

connection (E) to alternate ground

9V - 12V Relay(s) click in If power supply for pre-

heater elements

correct, probable relay

fault.

9V - 12V Relay(s) click in If relay function cor-

rect, probable pre-heat

fuse fault

9V - 12V With relay(s)

clicked in elements should

produce heat

If values above correct,

probable pre-heater element fault

Page 37

Group 33 Starting and Charging VN, VHD Troubleshooting

Charging System

Troubleshooting

Before working on a vehicle, set the parking brakes,

place the transmission in neutral, and block the

wheels. Failure to do so can result in unexpected

vehicle movement and can cause serious personal injury or death.

Never use the ohmmeter mode of the DMM in a powered circuit or as a substitute for a voltmeter or

ammeter, since this will damage the instrument. Use

the ohmmeter mode only when power is removed

from the circuit. (If contacted with sulfuric acid, flush

immediately with water and get medical attention).

CAUTION

WARNING

CAUTION

Possible damage to electronic components. Turn the

vehicle ignition switch OFF before disconnecting or

connecting any electronic components. Failure to

de-energize circuits may result in permanent damage

to electronic components.

Always wear eye protection when working around batteries to prevent the risk of injury due to contact with

sulfuric acid or an explosion. (Important: If contacted

with sulfuric acid, flush immediately with water and

get medical attention).

WARNING

HOT ENGINE! Keep clear of all moving parts or hot

engine parts and/or fluids. A hot engine and/or fluids

can cause burns.

33

Page 38

Group 33 Starting and Charging VN, VHD Troubleshooting

Troubleshooting Simplified

Schematics, Charging System

The simplified schematic and illustration below should be used to clarify the procedures in “Troubleshooting Charging

System with Digital Multimeter” page 35. For detailed, vehicle-specific schematics refer to:

Service

Manual

IMPACT Function Group: 370

Electrical Schematics VN/VHD

Information Type: Schematics.

W3004567

H, I and Q are measuring points, for more information see page 37.

W3004739

W3004566

X Output Terminal (B+)

Y Ground Terminal (B-)

W Relay Terminal

Z Indicator Light Terminal

Y(1) Ground Terminal (B-) 34SI only

34

Page 39

Group 33 Starting and Charging VN, VHD Troubleshooting

Troubleshooting Charging System

with Digital Multimeter

One or more of the following conditions will generally indicate charging systems problems:

Undercharged or overcharged batteries.

•

Charging indicator telltale lamp “on” with the engine

•

running.

Charging indicator telltale lamp “off” with the ignition

•

switch on and the engine not running.

The voltmeter in the graphic display showing a

•

charging rate outside the normal range.

Incorrect or no operation of accessories connected

•

to the “Relay” terminal.

Short life of light bulbs or other electrical compo-

•

nents due to unusually high system voltage.

Prior to troubleshooting, visually check the cables and

connections for obvious problems. Check the drive belt

tension and adjust if necessary.

Use the digital multimeter J-39200 or equivalent tool to

perform the test in the following table. The measuring

points referenced in the table as X, Y, Z, etc. correspond

to measuring points that are illustrated in the charging

system simplified schematics and drawings. See:

“Troubleshooting Simplified Schematics, Charging Sys-

tem” page 34.

35

Page 40

Group 33 Starting and Charging VN, VHD Troubleshooting

Funtion

Alternator

Charging

Voltage

Charging

Voltage at

Batteries

Relay Terminal

Signal

Ins. Cluster

Indicator

Lamp Operation

Positive

Cables

Key Position

ON/ Engine

Running

ON/ Engine

Running

ON/ Engine

Running

ON/ Engine

Running

ON/ Engine

Running

Measuring Point Expected

Value

Output Terminal (X)/

13.8 - 14.2 V Accessories

Ground Terminal Y

or Ground Terminal

Y(1)

Batt (+) Terminal

13.8 - 14.2 V Accessories

(A)/ Batt (-) Terminal

(B)

Relay Terminal (W)/

Ground Terminal (Y)

Approx. 1/2

Charging Voltage

Ind. Light Terminal

(Z)/ Terminal (Y)

Approx.

Charging Voltage

Output Terminal (X)/

Batt + Terminal (A)

<0.5 total

voltage drop

= positive and

negative voltage drops

combined

Note Possible Cause (if expected

valve not correct

1 Power circuit from battery

Off

2 Ground circuit from battery

3 Alternator belt

loose/missing

4 Alternator failure

If alternator charging voltage

Off. Reading

may be slightly

OK, probable power or ground

cable fault.

less than at

alternator.

Accessories

Off.

1 Probable alternator failure.

2 Check for broken or loose

no. 19 ire at the alternator

terminal.

Accessories

Off. Indicator

Lamp Off.

A/C On,

Blower Motor

on High,

Headlamps on

See: “Troubleshooting Charging

Indicator (Telltale) Lamp” page

37.

Excessive resistance in positive

cables. Check measuring points

X/H and A/H to help isolate

problem cable/ connectors.

Bright

Ground Cables

ON/ Engine

Running

Ground Terminal (Y)

Batt - Terminal (B)

<0.5 total

voltage drop

= positive and

negative voltage drops

combined

A/C On,

Blower Motor

on High,

Headlamps on

Bright

Excessive resistance in negative cables. Check measuring

points Y/Q, Y1/Q, Q/I and I/B to

help isolate problem cable/ connectors.

36

Page 41

Group 33 Starting and Charging VN, VHD Troubleshooting

Troubleshooting Charging Indicator (Telltale) Lamp

When the ignition key is turned “ON”, the Charging Indicator (telltale) lamp will momentarily illuminate for a bulb

test. The lamp will remain on until the engine is started.

With the engine running and the alternator properly

charging, the wire at the indicator light terminal from the

instrument cluster and the indicator light terminal on the

alternator (Z) should be at approximately the same voltage. With the voltages equal, the Charging telltale light

should go out.

To clarify the procedures below refer to: “Troubleshooting

Simplified Schematics, Charging System” page 34.

Instrument cluster and bulb check: Test the Charging

•

Indicator (telltale) lamps ability to function by running

the “Bulb Test” from the instrument cluster self test

menu. Use the graphic display control buttons to access the “System Diagnostics” menu, select “Cluster

Self Test,” then “Bulb Test.” With the bulb test active,

all the telltale and LED indicator lamps, including the

Charging telltale, will illuminate for approximately 5

seconds. With the bulb test active, the charging indicator wiring is ignored and the test is operated by

the instrument cluster internal electronics. If the indicator does not illuminate properly, refer to:

Service

Manual

Instrumentation, VN from 3/99,

VHD

telltale should be illuminated. Disconnect the wire at

the indicator light terminal (Z). The Charging telltale

should go off. If not, check for a grounded circuit between the alternator and instrument cluster. If a

grounded circuit is indicated, refer to manual below

for detailed vehicle-specific schematics:

Service

Manual

IMPACT Function Group: 370

Wiring check — open circuit: With the ignition key

•

“ON” and the engine not running, the Charging tell-

tale should be illuminated. Disconnect the wire at

the indicator light terminal (Z). Use a jumper wire to

ground the removed indicator light wire. The Charging telltale should illuminate. If not, check for an

open circuit between the alternator and the instrument cluster. If an open circuit is indicated, refer to:

Service

Manual

IMPACT Function Group: 370

Electrical Schematics VN, VHD

Information Type: Schematics

Electrical Schematics VN, VHD

Information Type: Schematics

IMPACT Function Group: 381

Information Type: Diagnostics

”Instrument Cluster Tests”

Wiring check — grounded circuit: With the ignition

•

key “ON” and the engine not running, the Charging

Alternator check: With the engine running and the

•

alternator properly charging, remove the wire at the

indicator light terminal. The indicator light terminal

on the alternator (Z) should be at approximately

charging voltage. If not, the alternator is probably

defective.

37

Page 42

Group 33 Starting and Charging VN, VHD Troubleshooting

Troubleshooting — Alternator

Output Test with BVA-34 Tester

Before beginning the alternator output test, visually check the cables and connections for obvious problems. Check the

drive belt tension and adjust if necessary.

Use BVA-34 System Analyzer or equivalent tool to perform the test below. Read and follow the directions with

the test equipment used. The test outlines below should

be used as a general guide for performing an alternator

output test. The measuring points referenced in the text

as A, B, X etc. correspond to measuring points that are

illustrated in the alternator output test simplified

schematics above.

1 Set the volt switch to the “INTERNAL VOLTS” posi-

tion. Connect the clamps from the tester to the

positive and negative (A& B) battery jumper stud

posts.

2 “Zero” the ammeter if neccessary.

3 Clamp the inductive amp probe around the output

cable from the B+ post (X) at the alternator. Be sure

that the inductive amp probe is pointing the proper

direction.

4 Turn the ignition key to “ON” and note the amps

draw.

W3004738

5 Start the engine and run at high idle.

Note: Engine speed must be above approximately

1700 RPM to achieve maximum alternator output.

6 While observing the volt and amp gauges on the

meter, adjust the load knob to obtain maximum alternator output. Use caution not to go below 12 volts

when applying the load. Also note the red “STATOR

DIODE” LED. If the LED glows steady red, it indicates that a diode or the stator is faulty.

7 Note the maximum alternator output (observe in step

6). Add the current draw obtained in step 4. This is

the total alternator output, which should be a minimum of 85 percent of the rated alternator output.

Note: The rated alternator output can be found on

the alternator identification tag.

38

Page 43

Group 33 Starting and Charging VN, VHD Troubleshooting

Troubleshooting Starting and

Charging System with The

Accuracy Plus Tester

The J-44700 Accuracy Plus Tester will test the starting

and charging system for the following:

Battery open circuit voltage

•

Cranking voltage

•

Charging voltage

•

Regulator voltage

•

Diode condition

•

To operate the Accuracy Plus tester, connect the positive

and negative tester leads to the battery jumper stud

posts. Select the “System Test” and follow the on screen

prompts until the tests are complete. The test results

may be printed if desired with the optional printer number

238598. Both the J-44700 Accuracy Plus tester and the

238598 printer are available in kit part number J-44701.

See the tools section of this manual for more information.

Note: Enter the combined CCA rating of all batteries

when prompted.

Note: If the results of this test indicate a faulty battery,

the batteries must be disconnected and tested individually. See section: “Battery Troubleshooting” page 17.

W0001836

J-44700 Accuracy Plus HD Battery Tester.

39

Page 44

40

Page 45

Group 33 Starting and Charging VN, VHD Service Procedures

Service Procedures

3714-19-03-01

Battery Cables, Removal and

Installation

Before working on a vehicle, set the parking brakes,

place the transmission in neutral, and block the

wheels. Failure to do so can result in unexpected

vehicle movement and can cause serious personal injury or death.

WARNING

Always wear eye protection when working around batteries to prevent the risk of injury due to contact with

sulfuric acid or an explosion (If contacted with sulfuric

acid, flush immediately with water).

WARNING

Batteries may contain explosive gases. To help minimize the risks of explosion, avoid sparks or open

flames near batteries. Do not smoke when servicing

batteries.

CAUTION

If there are other ground cables connected to the battery (such as engine ECU’s, satellite system, etc.),

disconnect those grounds first, then remove the main

battery ground cable. Electronic modules may be

damaged when additional grounds are connected/disconnected without the main battery ground

connected. Disconnect the main battery ground last.

CAUTION

Possible damage to electronic components. Turn the

vehicle ignition switch OFF before disconnecting or

connecting any electronic components. Failure to

de-energize circuits may result in permanent damage

to electronic components.

All Cables

Volvo VN/VHD vehicles are equipped with 2, 3 or 4 batteries depending on the engine and options ordered.

The batteries are connected together, in parallel, with

battery interconnecting cables. The batteries cannot be

tested or serviced as a set, but must be tested or serviced individually.

To test or service the batteries, all battery cables and

wiring connected directly to the batteries must be removed. If the battery cables and wiring are not removed

and installed in the proper order, damage to sensitive

electronic equipment may occur. To properly remove and

install the battery cables, proceed as follows:

Removal

1

Turn the ignition key to the “OFF” position.

2

Disconnect the ground wiring from

electrical equipment connected directly

to the batteries, such as ECU’s, satellite systems, etc.

3

Disconnect the main ground cable(s).

4

Disconnect the positive wiring from the

electrical equipment connected directly

to the batteries.

CAUTION

In vehicles with a Supplemental Restraint System

(SRS), turn the ignition switch ON before connecting

the battery. Failure to do so may result in permanent

damage to the instrument cluster or other electronic

circuits within the vehicle. (This applies only to vehicles with SRS and Cummins or Detroit Diesel engine.)

Always check for fault codes after repairs are completed.

5

Disconnect the main positive cables(s).

6

Disconnect the battery interconnecting

cables.

7

Perform battery test or service as

needed.

41

Page 46

Group 33 Starting and Charging VN, VHD Service Procedures

Installation

8

Connect the battery interconnection

cables.

9

Connect the main positive cable(s).

10

Connect the positive wiring from the

electrical equipment connected directly

to the batteries.

11

If the vehicle is equipped with a Supplemental Restraint System (SRS) and

a Cummins or Detroit Diesel engine,

turn the ignition switch to the “ON” position. If not, leave the ignition switch

in the “OFF” position.

12

Connect the main ground cable(s).

Turn the ignition switch back to “OFF”

if necessary.

3

Disconnect the main ground cable(s).

4

Perform service operations as needed.

Installation

5

If the vehicle is equipped with a Supplemental Restraint System (SRS) and

a Cummins or Detroit Diesel engine,

turn the ignition switch to the “ON” position. If not, leave the ignition switch

in the “OFF” position.

6

Connect the main ground cable(s).

Turn the ignition switch back to “OFF”

if necessary.

7

Connect ground wiring from the electrical equipment connected directly to

the batteries.

13

Connect ground wiring from the electrical equipment connected directly to

the batteries.

14

Secure all battery terminal nuts.

Battery terminal torque =

3.7 ± 5.7 Nm

(10 –15 ft-lb)

3.7 ± 5.7 Nm

(10 –15 ft-lb)

Ground Cables

Many service operations require the removal of the battery ground (negative) cables as a safety measure. If the

battery ground cable(s) and wiring are not removed and

installed in the proper order, damage to sensitive electronic equipment may occur. To properly remove and

install the battery ground cables and wiring, proceed as

follows:

Removal

1

Turn the ignition key to the “OFF” position.

8

Secure all battery terminal nuts. Battery terminal torque =

13 ± 20 Nm

(10 –15 ft-lb)

13 ± 20 Nm

(10 –15 ft-lb)

2

Disconnect the ground wiring from

electrical equipment connected directly

to the batteries, such as ECU’s, satellite systems, etc.

42

Page 47

Group 33 Starting and Charging VN, VHD Service Procedures

Battery Jump Starting

Before working on a vehicle, set the parking brakes,

place the transmission in neutral, and block the

wheels. Failure to do so can result in unexpected

vehicle movement and can cause serious personal injury or death.

CAUTION

Do not use a “Hot Shot” type starting cart, as most

use extremely high voltages. Use of “Hot Shot” device

to jump start the vehicle will seriously damage the

ECU’s and other electrical equipment.

CAUTION

Do not attempt to jump-start a vehicle equipped with

Delco Maintenance Free batteries, if the test indicator

light is yellow. Replace the battery instead.

WARNING

Always wear eye protection when working around batteries to prevent the risk of injury due to contact with

sulfuric acid or an explosion (If contacted with sulfuric

acid, flush immediately with water and get medical attention).

WARNING

Batteries may contain explosive gases. To help minimize the risks of explosion, avoid sparks or open

flames near batteries. Do not smoke when servicing

batteries.

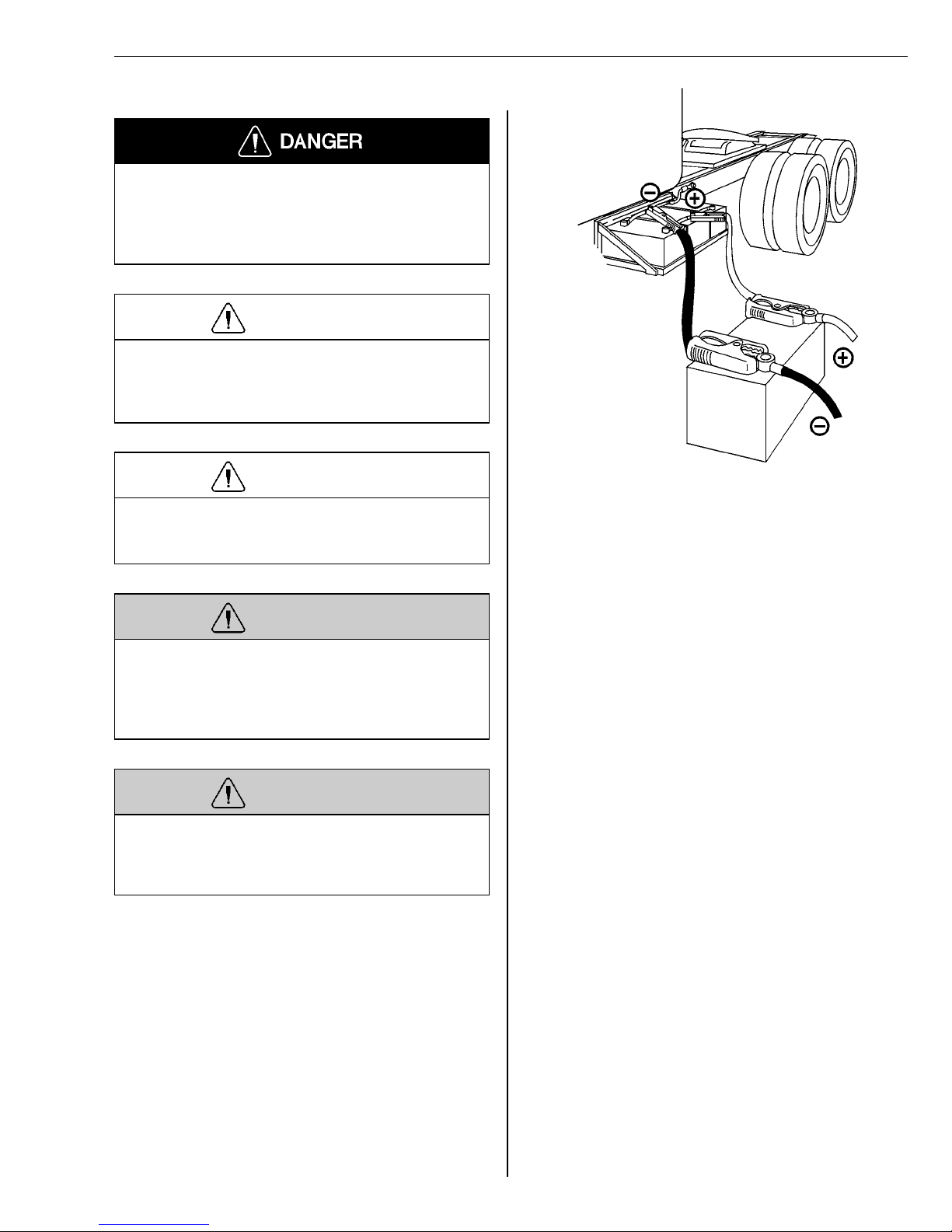

W3002432

If the vehicle needs to be jump started, use starting batteries. DO NOT use battery chargers with “boosting”

capability. These utilize a high voltage that will cause

damage to the vehicle electrical and electronic components.

When jumping batteries to start an engine, it is important

that the jumper cables are connected directly from one

set of batteries in one vehicle to the other set of batteries in the other vehicle. This is so the cranking current is

carried through the proper starter wiring.

To access the batteries on a vehicle equipped with side

fairings, open the fairing access cover. “Jumper Studs”,

which are longer and made of brass, are factory installed

on one battery positive and negative post. These jumper

studs are designed to accept the jumper cable claws.

Connect the jumper cables to the positive, or “hot”

terminal first and the ground terminal last. When disconnecting the cables, disconnect the ground terminal first.

Connect the jumper cable clamps to the discharged battery first and to the booster battery last. Avoid creating

sparks by making all connections quickly and firmly. Do

not permit the vehicles to touch each other when jump

starting.

43

Page 48

Group 33 Starting and Charging VN, VHD Service Procedures

3111-03-02-02

Battery, Replacement (One or

Two)

Possible damage to electronic components. Turn the

vehicle ignition switch OFF before disconnecting or

connecting any electronic components. Failure to

de-energize circuits may result in permanent damage

to electronic components.

CAUTION

Before working on a vehicle, set the parking brakes,

place the transmission in neutral, and block the

wheels. Failure to do so can result in unexpected

vehicle movement and can cause serious personal injury or death.

WARNING

Always wear eye protection when working around batteries to prevent the risk of injury due to contact with

sulfuric acid or an explosion (If contacted with sulfuric

acid, flush immediately with water and get medical attention).

WARNING

Batteries may contain explosive gases. To help minimize the risks of explosion, avoid sparks or open

flames near batteries. Do not smoke when servicing

batteries.

Note: Some applications will require the removal of air

fairings, battery box covers, or other components to access the batteries.

Removal

1

Turn the ignition key to the “OFF” position.

2

Disconnect ground wiring from electrical equipment connected directly to

the batteries, such as ECU’s, satellite

systems, etc.

3

Disconnect the main ground cable(s)

at the batteries.

4

Disconnect the positive cable(s) at the

batteries.

CAUTION

If there are other ground cables connected to the battery (such as engine ECU’s, satellite system, etc.),

disconnect those grounds first, then remove the main

battery ground cable. Electronic modules may be

damaged when additional grounds are connected/disconnected without the main battery ground

connected. Disconnect the main battery ground last.

CAUTION

In vehicles with a Supplemental Restraint System

(SRS), turn the ignition switch ON before connecting

the battery. Failure to do so may result in permanent

damage to the instrument cluster or other electronic

circuits in the vehicle. This applies only to vehicles

with SRS and Cummins or Detroit Diesel engines.

Check for fault codes after repairs are complete.

5

Remove the battery nuts on all battery

connections and remove all cables

and wiring.

6

Loosen the battery hold down clamp

nuts enough to allow removal of the

hold down clamp assembly.

7

Remove the defective battery(s).

8

Clean any battery post or cable terminals as necessary.

Installation

9

Install the replacement battery(s). Observe that the battery positive and

negative posts are oriented properly

when installed.

44

Page 49

Group 33 Starting and Charging VN, VHD Service Procedures

10