Page 1

OPERATOR’S MANUAL

VHD

New Roads.

TM

Page 2

Foreword

This manual contains information concerning the safe operation of your

vehicle. It is extremely important that this information is read and understood before the vehicle is operated. This manual also contains a

considerable amount of information concerning the vehicle, such as vehicle identification, Preventive Maintenance recommendations and a log

for your service records. Please keep this in the vehicle at all times. Information from other component manufacturers is supplied in separate

manuals in the Owner’s Package.

NOTE! It is important that this manual stays with the vehicle when it

is sold. Important safety information must be passed on to the new customer. The service information contained in this manual gives the

owner important information about maintaining the vehicle but is not

intended as a substitute for the Preventive Maintenance Service Manual

and must not be regarded as such.

The National Highway Traffic Safety Administration (NHTSA) and

Volvo Trucks North America, Inc. should be informed immediately

if you believe that the vehicle has a defect that could cause a crash,

injury or death.

Contact NHTSA by calling the Auto Safety Hotline at 1 (800) 424–

9393 (or 366–0123 in the Washington, DC area) or by writing to:

NHTSA, U.S. Department of Transportation, Washington, DC 20590.

Volvo Trucks North America, Inc.

Greensboro, NC USA

Order number: PV776-20 139484

© 2000 Volvo Trucks North America, Inc., Greensboro, NC USA

All rights reserved. No part of this publication may be reproduced,

stored in retrieval system, or transmitted in any forms by any means,

electronic, mechanical, photocopying, recording or otherwise, without

the prior written permission of Volvo Trucks North America, Inc..

Page 3

Contents

General Information ............................. 1

Information For the Owner ................... 1

General Safety Information .................. 3

Modifications to Vehicle ....................... 7

Exhaust and Noise Emissions ............... 8

Vehicle Data ........................................ 16

Vehicle Access ...................................... 19

Cab Doors and Door Lock ................. 19

Cab Entry and Exit ............................. 21

Hood .................................................... 26

Pre-Trip Inspection and Daily Mainte-

nance ..................................................... 28

General ................................................ 28

Pre-Trip Inspection Quick List ........... 29

Daily Maintenance .............................. 41

Additional Safety Features ................. 46

Safety Belts ......................................... 46

SRS Airbag ......................................... 55

Safety Equipment ................................ 62

VORAD Collision Warning System ... 63

Instruments and Controls ................... 64

Dash Overview .................................... 64

Instrument Cluster Overview .............. 65

Telltale Overview ................................ 66

Graphic Display Telltale Overview .... 67

Left Instrument Section ...................... 68

Main Instrument Section ..................... 76

Right Instrument Section .................... 83

Changing Telltale Bulbs In Cluster .... 89

Steering Column Switches .................. 91

Left Switch Cluster ............................. 94

Driving Light Switches ....................... 98

Right Switch Cluster ......................... 100

Pneumatic Switch Cluster ................. 104

Optional Switch Cluster .................... 106

Miscellaneous Switches .................... 107

Graphic Display ................................. 108

Graphic Display Overview ............... 108

Graphic Display Controls ................. 109

Graphic Display Telltales .................. 111

Information and Stop Messages ....... 112

Information Telltale ........................... 113

Stop Telltale ...................................... 120

Acknowledge Information and Stop

Messages ........................................... 124

Main Menu: Set-Up Mode ............... 126

Main Menu: System Diagnostic ....... 131

Main Menu: Data Log Mode (Volvo

Engine Only) ..................................... 146

Main Menu: Password Input ............ 152

Main Menu: Gauge ........................... 153

Main Menu: Fuel Economy (option) 157

Main Menu: Time/Distance .............. 159

Main Menu: FAULTS? ..................... 164

Heating and Air Conditioning ......... 168

General .............................................. 168

Climate Unit Main Control Panel .... 169

Cab Ventilation .................................. 177

Cab Air Filter .................................... 178

A/C Diagnostic Module .................... 179

Seats ..................................................... 180

General .............................................. 180

National Standard Seat Adjustments 181

Volvo Standard Seat Adjustments .... 182

National Stationary Seat ................... 183

Cab Interior ....................................... 184

Interior/Reading Lights ..................... 184

Communication and Entertainment 187

Antennas ............................................ 187

Page 4

Stereo/Radio ...................................... 188

Communication Equipment .............. 189

Fuel Economy Driving ...................... 190

Fuel Economy ................................... 190

General .............................................. 256

Axles and Wheels ............................... 258

Axles .................................................. 258

Wheels ............................................... 261

Engine Start and Operation ............. 197

Starting the Engine ........................... 197

Cold Weather Start and Operation ... 202

Engine Operation .............................. 209

Cruise Control ................................... 218

Fuel Tank(s) ...................................... 220

Clutch and Transmission .................. 222

Clutch ................................................ 222

Brakes ................................................. 223

Brakes ................................................ 223

Electrical System ............................... 244

Electrical System ............................... 244

Power Steering ................................... 256

Fifth Wheel Instructions ................... 264

Fifth Wheel General Information ..... 264

Fifth Wheel ....................................... 265

Fifth Wheel Slider (option) .............. 267

Unlocking the Fifth Wheel ............... 268

Trailer Coupling Procedures ............. 270

Trailer Uncoupling Procedures ......... 275

Operating the Fifth Wheel Slider ..... 280

Emergency Information .................... 282

Towing Procedure ............................. 282

Service Information ........................... 287

Service Assistance and Manuals ...... 287

Index .................................................... 289

Page 5

Warning Label Information

IMPORTANT

Before driving this vehicle, be certain that you have read and that

you fully understand each and every step of the driving and handling information in this Operator’s Manual. Be certain that you

fully understand and follow all safety warnings. It is extremely important that this information is read and understood before the

vehicle is operated.

IT IS IMPORTANT THAT THE FOLLOWING INFORMATION CONCERNING

LABELS BE READ, UNDERSTOOD

AND ALWAYS FOLLOWED.

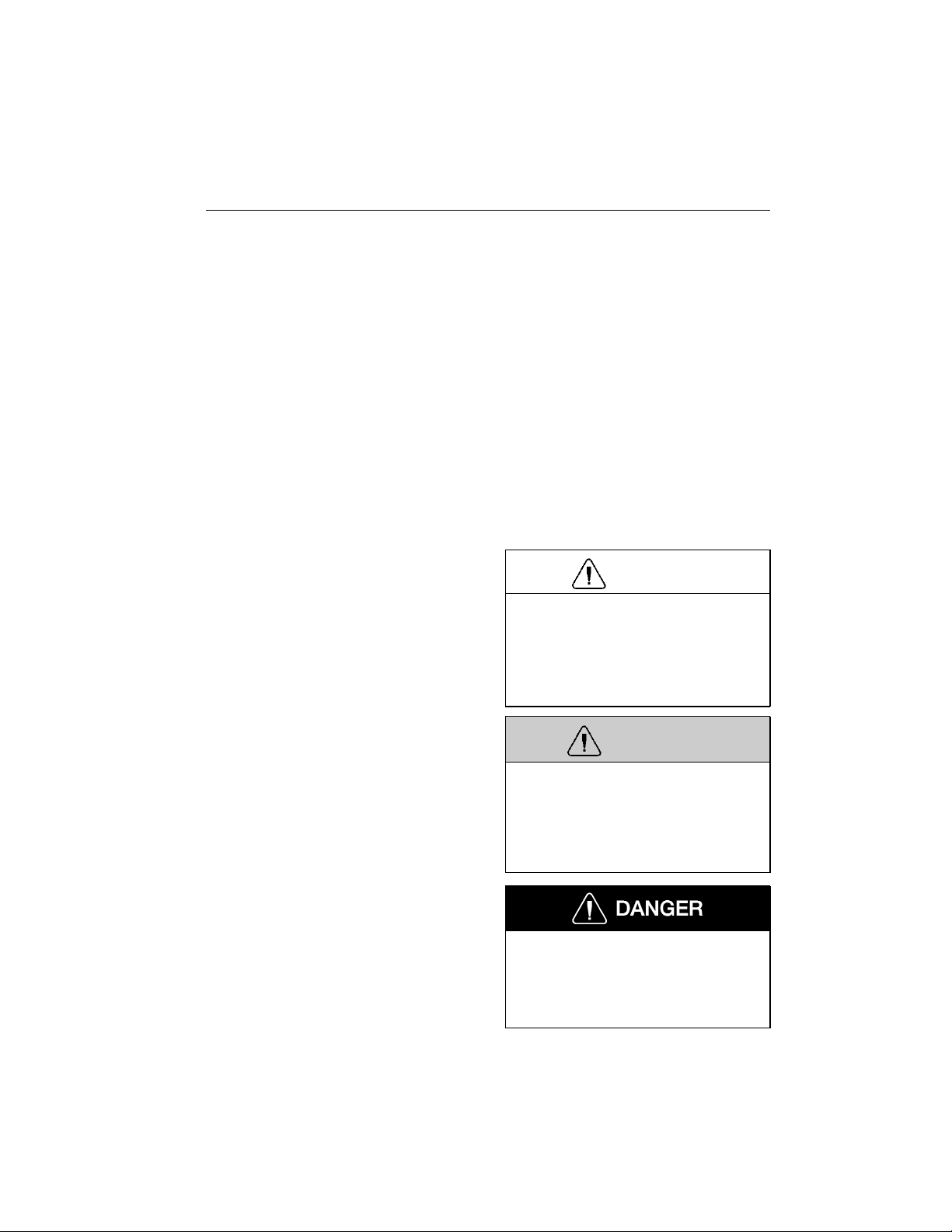

The following types of labels are used

throughout this manual:

NOTE! A note defines an operating procedure, practice, condition, etc., which is

essential to proper operation of the vehicle.

CAUTION

A caution label directs the operator’s

attention to unsafe practices where personal injury is not likely but property

damage could occur. The caution label is

in black type on a white background

with a black border.

WARNING

A warning label directs the operator’s

attention to unsafe practices which could

result in personal injury or severe damage to the vehicle. The warning label is

in black type on a gray background

with a black border.

A danger label directs the operator’s attention to unsafe practices which could

result in serious personal injury or death.

The caution label is in white type on a

black background with a black border.

Page 6

Page 7

Information For the Owner

If there are questions on the maintenance

and performance of your vehicle, please

discuss them with your Volvo Truck dealer.

Your authorized dealer is required to have

trained mechanics, special tools and spare

parts to fully service your vehicle. If

necessary, your dealer will contact the manufacturer for any assistance.

In addition to this Operator’s Manual, there

may be additional instruction/operator’s

manuals supplied by component manufacturers. These manuals are placed in the

Owner’s Package and placed in the cab. Be

sure to read all the manuals thoroughly before operating the vehicle.

Also, various safety labels may be placed

on components by the component manufacturer. Be sure to read and follow these

labels to prevent damage to the vehicle,

personal injury or even death.

Information in this manual refers to Volvo

components and Volvo drivetrain. Information concerning non-Volvo engines and/or

drivetrains can be obtained by contacting

the respective manufacturer.

General Information 1

Various truck warranty coverage plans, contingent on application and weight class, are

available. Please contact an authorized

Volvo Truck Dealer for complete details.

Replacement warranty certificates for Volvo

Trucks are available from Volvo dealers.

For trucks placed in service after August 1,

2000 and operating in the USA and

Canada, Volvo dealers can print copies of

the Standard Truck Warranty Certificate

and the Premium (Purchased) Truck Coverage Certificate. Copies are available in

either English or Canadian French at the

dealer communication system (DCS) website. Look in the Service/Warranty folder.

NOTE! Federal law requires manufacturers

to notify owners of its products in the event

of a non-compliance to a Federal Motor

Vehicle Safety Standard or if a safety related defect is discovered. If you are not

the original owner of this vehicle, please

notify us about the change in ownership at

the address below or through an authorized

Volvo Truck dealer. This is the only way

we will be able to contact you if necessary.

Establish a Preventive Maintenance Program with the help of your local Volvo

Truck dealer. A Preventive Maintenance

Program makes it possible to maximize the

amount of time your vehicle is up and running, resulting in longer component life.

This makes for a safer vehicle by reducing

any mechanical failures due to poor maintenance practices.

Volvo Trucks North America, Inc.

Att: Vehicle Registration dept.

P. O. Box 26115

Greensboro, NC 27402–6115

United States of America

Page 8

2 General Information

Do Not Remove this manual from the vehicle. It contains important operational and

safety information that is needed by all

drivers and owners of this vehicle.

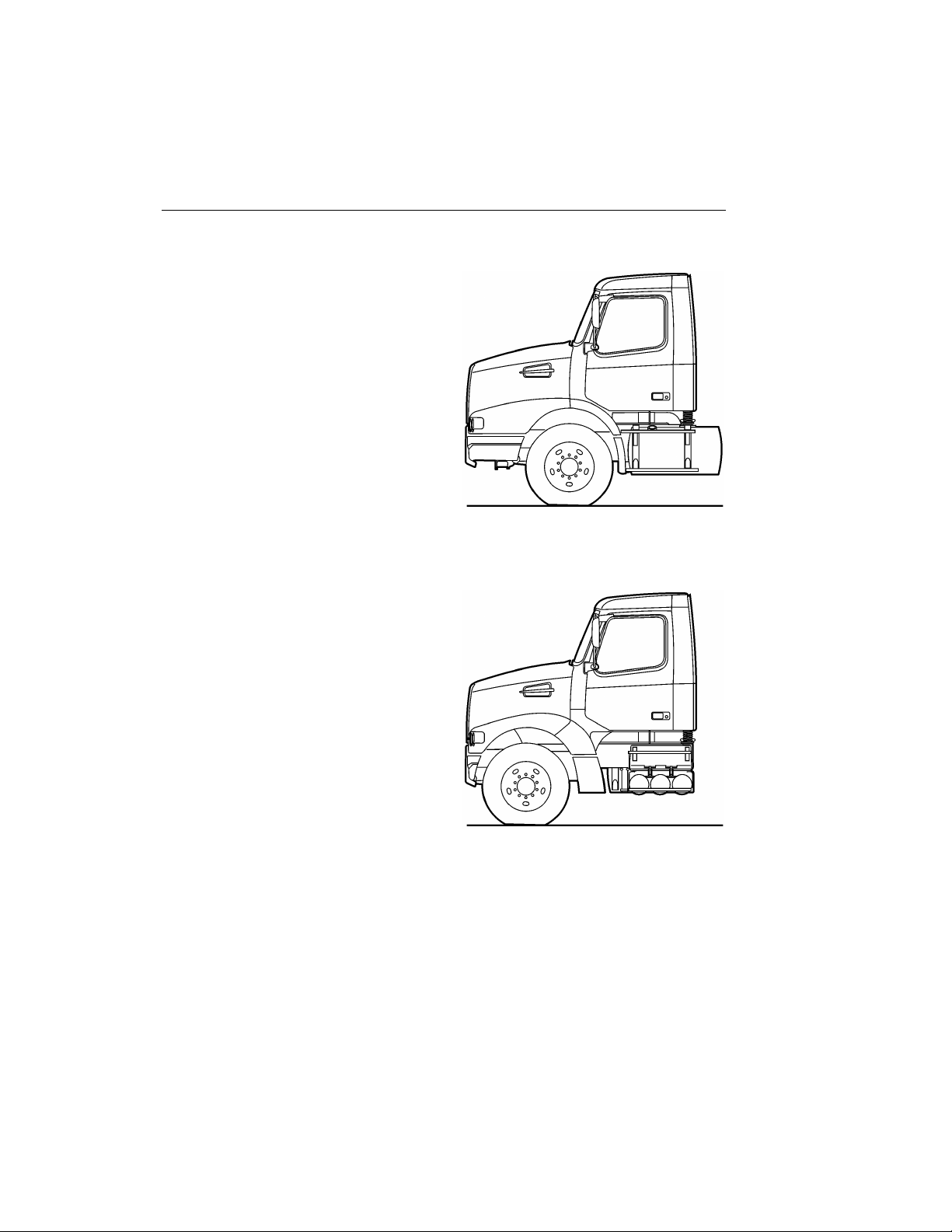

This Operator’s Manual covers Volvo

VHD-series vehicles manufactured by

Volvo Trucks North America, Inc. with any

of the following designations:

VHD42 VHD64 VHD84 VHD104

VHD124 VHD42T VHD64T VHD84T

T=tractor, F=forward position axle

B=back position axle

Explanation: The first number after the

model designation (4, 6, 8, 10 or 12) represents the total number of wheels (hubs) per

vehicle. The last number (2 or 4) represents

the number of wheels (hubs) that drive the

vehicle.

W8002807

Back position axle

This manual, together with manuals for

specific components, for example, Volvo

engine, Cummins engine, Eaton transmission, etc., contain important information for

you to be able to operate this vehicle

safely. They contain advice and instructions

which will enable you to get the operating

economy and performance that you expect

from this quality vehicle.

All information, illustrations and specifications contained in this manual are based

upon the latest product information available at the time of publication. If any

questions arise concerning the current status of Federal or state laws, the appropriate

Federal or state agency should be contacted.

Volvo Trucks North America, Inc. reserves

the right to make changes at any time or to

change specifications or design without notice and without incurring obligation.

W0001920

Forward position axle

Page 9

General Safety Information

Operating the Vehicle

Every vehicle, including heavy duty vehicles, has blind spots. The size of blind

spots varies from driver to driver and from

situation to situation. As a skilled, professional driver,

avoid accidents in turns, lane changes or

other maneuvers. Volvo Trucks North

America, Inc. provides standard equipment

(such as cabs, windshields, window sizes

and mirrors), preferred by most owners and

drivers under most conditions and in most

applications.

However, due to differences in the size of

drivers, their seating positions, the way that

they use and operate their vehicles, personal preferences and other factors, no

combination of mirrors and other visibility

enhancement devices will eliminate all

blind spots in every situation.

you are in the best position to

General Information 3

Never try to operate or work on this

vehicle while under the influence of alcohol. Your reflexes can be affected by

even a small amount of alcohol. Drinking and operating this vehicle can lead

to an accident, causing serious personal

injury or death.

The safe operation of this vehicle is up to

you. Because of your special preferences,

needs and circumstances, you may want to

add extra mirrors and/or other visibility enhancement devices. If so, you should

contact an authorized Volvo Truck dealer to

obtain those parts which best fit your own

personal needs and preferences.

WARNING

All items within the cab must be secured

before the vehicle is set in motion. This

includes, but is not limited to, drinks,

clothes, books, televisions, etc. In the

event of a collision, loose items could

fly around inside the cab. This could

cause personal injury.

Page 10

4 General Information

Operating In Bobtail Mode

Tractors are equipped with a bobtail air

brake proportioning valve which automatically redistributes the braking force between

front and rear axles when not hooked up to

a semitrailer (bobtail operation).

When operating in bobtail mode, the rear

brake chambers receive reduced or proportional brake air pressure. When the tractor

is towing a trailer, the rear brake chambers

will receive full (normal) brake pressure.

NOTE! When operating bobtail, be certain

that glad hands, trailer air hoses, electrical

cable and connectors are properly stowed

and secure. Do not allow them to rub or

chafe on other components.

WARNING

When operating bobtail, the brake

system on the vehicle reduces the possibility of rear wheel brake lockup, except

on full pedal application. When bobtailing, be certain that adequate pedal

pressure is applied. There is no need to

reduce pedal effort. Failure to do so may

result in increased stopping distances.

Page 11

Do Not Overload

This vehicle has been designed and assembled for a maximum gross vehicle weight

rating (GVWR) and a maximum front and

rear axle weights rating (FAWR and

RAWR). The actual rating for this vehicle

can be found on the label attached to the

door frame on the driver’s side. If any of

these three ratings is exceeded and overloading occurs, instability, poor handling,

failure of parts and accelerated wear can

occur.

Under no circumstances should the published GVWR, FAWR, and/or RAWR be

exceeded. Failure to observe these precautions can lead to the loss of vehicle

control, resulting in a crash causing serious personal injury or death.

General Information 5

W0001210

Do not exceed the load rating of the

tires or the vehicle weight ratings. Overloading may result in tire failure causing

loss of vehicle control, leading to an accident resulting in severe personal injury

or death.

Operating

Before driving this vehicle, locate the instruments and controls, and become

thoroughly familiar with their operation.

After starting and when driving, always

check to make sure that the instrument

readings are normal.

Page 12

6 General Information

Reporting Safety Defects

USA

The National Highway Traffic Safety Administration (NHTSA) and Volvo Trucks

North America, Inc. should be informed

immediately if you believe that the vehicle

has a defect that could cause a crash, injury

or death.

Contact NHTSA by calling the Auto Safety

Hotline at 1 (800) 424–9393 (or 366–0123

in the Washington, DC area) or by writing

to: NHTSA, U. S. Department of Transportation, Washington, DC 20590.

Canada

Refer consumer complaints to Volvo Trucks

Canada, Inc. or to the Transport Canada Department of Public Complaints, Recalls

and Investigations.

Mexico

Volvo Trucks of Mexico, S.A. de C.V.

should be informed immediately if you believe the vehicle has a defect that could

cause a crash, injury or death. Contact

Volvo Trucks de Mexico by calling or by

writing to: Volvo Trucks de Mexico, S.A.

de C.V., Prol. Paseo de la Reforma 600,

1er. Piso — 121, Col. Santa Fe Peña

Blanca, C.P. 01210, México, D.F.

NOTE! For a listing of other contacts for

information or help, see page 287.

1 (800) 424-9393

1 (905) 795-1555

01 (800) 90 94 900

Page 13

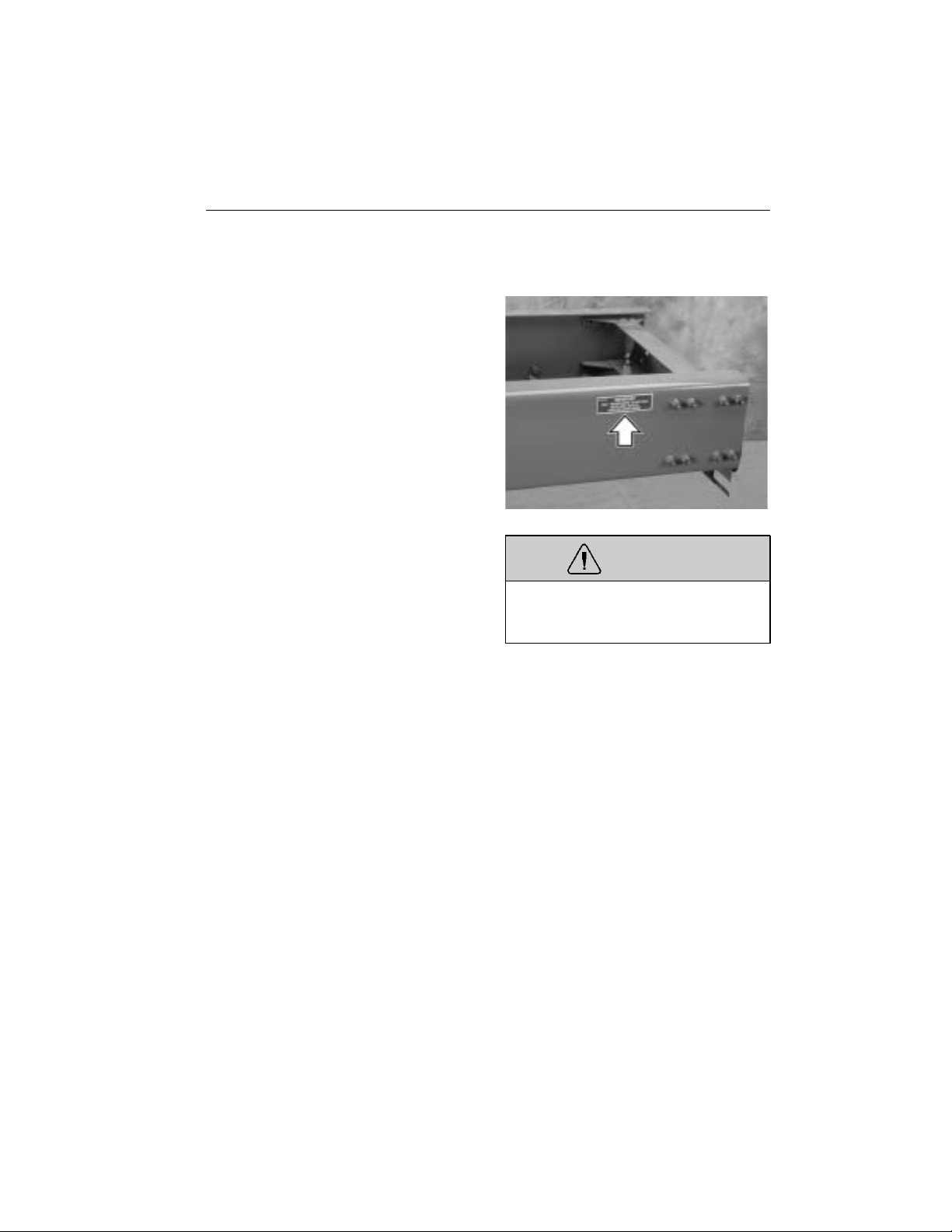

Modifications to Vehicle

Chassis Frame

Frame side rails are heat treated. No welding is permitted because structural failure

may result. Do not drill through either top

or bottom flanges. A warning label is also

attached to the frame for information.

Drilling is permitted in the frame web in

accordance with a specified hole spacing

pattern. Consult a Volvo Truck dealer to

obtain approved hole spacing dimensions or

refer to the Frame Rail and Cross Member

Service Manual.

Frame rail and cross member nuts and bolts

should be checked periodically and tightened to the specified torque if necessary.

General Information 7

W7001174

WARNING

Do not weld on any part of the frame or

drill holes in the top or bottom flanges.

Serious structural damage could occur.

Frame Alterations

Under no circumstances can the frame be

cut and an extension piece added to increase the wheelbase. The only alteration

allowed is wheel base shortening, where

the only change in the frame rail is a new

hole pattern drilled for the new location of

the rear suspension.

Welding In Vehicle

Do not weld anywhere in or on the vehicle

before disconnecting batteries, all electronic

control units (ECU) and instrument cluster.

See page 249 for more information. Do not

use oxy/acetylene welding to repair cab

panels. Refer to the service manuals for

specific information.

Page 14

8 General Information

Exhaust and Noise Emissions

General

USA

The Federal Clean Air Act, Section 203 (a)

(3), states the following concerning the removal of air pollution control devices or

modification of a certified engine to a noncertified configuration:

“The following acts and the causing thereof

are prohibited:

(3) For any person to remove or render inoperative any device or element of design

installed on or in a motor vehicle or motor

vehicle engine in compliance with regulations under this part prior to its sale and

delivery to the ultimate purchaser, or for

any manufacturer or dealer knowingly to

remove or render inoperative any such design after sale and delivery to the ultimate

purchaser.”

Specifically, please note that no person may

make such changes prior to the sale and

delivery of the vehicle to the ultimate purchaser, and, in addition, no manufacturer or

dealer may take such action after sale and

delivery of the vehicle to the ultimate purchaser. The law provides a penalty of up to

$10, 000 for each violation.

Canada

The same conditions that apply in the USA

apply to Canada, with one exception. After

the vehicle is sold to a retail customer, that

is, the end user, the jurisdiction controlling

the emission control devices becomes the

province in which the vehicle is licensed.

No changes should be made that render any

or all of the devices inoperative.

Should the owner/operator wish to make

any changes to the emission control devices, check with the provincial authority

before making any such changes.

Mexico

The same conditions that apply in the USA

apply to Mexico. Refer to the Mexican

Federal Law for Emission Control which

adheres to EPA regulations. No changes

should be made that render any or all of

the emissions control devices inoperative.

Should the owner/operator wish to make

any changes to the emission control devices, check with the state authority before

making any such changes.

Page 15

General Information 9

California Emission Control Warranty Statement

YOUR WARRANTY RIGHTS AND OBLIGATIONS

The California Air Resources Board and Volvo Trucks North America , Inc. (VTNA) are

pleased to explain the emission control system warranty on your vehicle. In California,

new motor vehicles must be designed, built and equipped to meet the State’s stringent

anti-smog standards. Volvo Trucks North America, Inc. must warrant the emission control

system on your vehicle for the periods of time listed listed below provided there has been

no abuse, neglect or improper maintenance of your vehicle.

Your emission control system may include parts such as carburetor or fuel injection system

and engine computer. Also included may be hoses, belts, connectors and other emissionrelated assemblies.

Where a warrantable condition exists, Volvo Trucks North America, Inc. will repair your

vehicle at no cost to you including diagnosis, parts and labor.

MANUFACTURER’S WARRANTY COVERAGE

This warranty is applicable for a period of five years, 100 000 miles or 3 000 hours of operation, whichever first occurs. If an emission-related part of your vehicle is defective, the

part will be repaired or replaced by Volvo Trucks North America, Inc.

This is your emission control system DEFECTS WARRANTY.

OWNER’S WARRANTY RESPONSIBILITIES

As the vehicle owner, you are responsible for the performance of the required maintenance

listed in your owner’s manual. Volvo Trucks North America, Inc. recommends that you retain all receipts covering maintenance on your truck but Volvo Trucks North America, Inc.

cannot deny warranty solely for the lack of receipts or for your failure to ensure the performance of all scheduled maintenance.

You are responsible for presenting your vehicle to a Volvo Trucks North America, Inc.

dealer as soon as a problem exists. The warranty repairs should be completed in a reasonable amount of time, not to exceed 30 days.

As the vehicle owner, you should also be aware that Volvo Trucks North America, Inc.

may deny you warranty coverage if your vehicle or a part has failed due to abuse, neglect,

improper maintenance or unapproved modifications.

If you have any questions regarding your warranty rights and responsibilities, you should

contact Volvo Trucks North America, Inc., Warranty Administration, (336) 393-2000 or

the California Air Resources Board at 9480 Telstar Avenue, El Monte, CA 91731.

Page 16

10 General Information

EMISSION CONTROL SYSTEM WARRANTY

Volvo Trucks North America, Inc. WARRANTS TO THE ORIGINAL OWNER, AND

EACH SUBSEQUENT OWNER, OF A NEW TRUCK POWERED BY A VOLVO

DIESEL ENGINE THAT THE EMISSION CONTROL SYSTEM OF YOUR TRUCK:

1 Is designed, built and equipped so as to conform at the time of sale to all regulations

of the U.S. Environmental Protection Agency and the California California Air Resources Board applicable at the time of the manufacture; and

2 Is free from defects in material and workmanship which will cause the emission con-

trol components not to function as designed for a period of use of 5 years or 100 000

miles or 3 000 hours of engine operation, whichever comes first.

The 5 years/100 000 miles/3 000 hour warranty period shall begin on the date the vehicle

is first delivered to the first retail purchaser or if the vehicle is placed in service as a

demonstrator company vehicle prior to the sale at retail, on the date the vehicle is the first

placed in service.

The emission control system of your new Volvo engine was designed, built and tested using genuine Volvo parts, and the engine is certified as being in conformity with Federal

and California emission control regulations. Accordingly, it is recommended that any replacement parts used for maintenance, replacement or repair without invalidating this

warranty; the cost of such services or or parts, however, will not be covered under the warranty except in an emergency situation. A part not being available or a repair not being

completed within 30 days also constitutes an emergency.

Use of replacement parts which are not of equivalent quality may impair the effectiveness

of emission control systems. If other than Volvo parts are used for maintenance, owner

should obtain assurances that suck parts are warranted by their manufacturer to be equivalent to genuine Volvo parts. However, the use of other than Volvo replacement parts does

not invalidate the warranty on other components, unless such parts cause damage to warranted parts.

Repairs and service covered by the warranty will be performed by an authorized Volvo

Trucks North America, Inc. dealer at his place of business with no charge for parts or labor (including diagnosis) using Volvo parts for the emission control system, that requires

replacement and is covered by the warranty and found defective. In case of an emergency,

where an authorized Volvo Trucks North America, Inc. dealer is not available, repairs may

be performed at any available service establishment or by the owner, using any equivalent

replacement parts and Volvo Trucks North America, Inc. will reimburse the owner for such

repairs (including diagnosis) not to exceed Volvo Trucks North America, Inc’s suggested

retail retail price for the warranted parts and the labor rate appropriate for the geographical

area and the tasks performed.

Replaced parts and paid invoices must be presented to a Volvo Trucks North America, Inc.

dealer for reimbursement.

Page 17

General Information 11

The emissions control parts covered by this Emission Control System Warranty are listed

under "What Is Covered by the Emissions Warranty." You are responsible for the performance of all required maintenance on your new Volvo engine, including maintenance or

repairs needed due to severe operating conditions. Volvo Trucks North America, Inc. will

not deny a warranty claim solely because you have no record of maintenance. However,

Volvo Trucks North America, Inc. may deny a warranty claim if your failure to perform

required maintenance resulted in the failure of a warranted part. Receipts covering the

performance of regular maintenance should be retained in the event questions arise concerning maintenance. The receipts should be transferred to each subsequent owner of the

vehicle with the emission warranted engine.

CUSTOMER ASSISTANCE

Volvo Trucks North America, Inc. wishes to help to assure that the Emission Control System Warranty is properly administered. In the event that you do not receive the warranty

service to which you believe you are entitled under the Emission Control System Warranty,

you should contact Volvo Trucks North America, Inc. Warranty Administration, (336) 393-

2000. The address and telephone number of each Regional Office is in your vehicle

owner’s manual. If you need additional assistance or information concerning the Emission

Control System Warranty, contact: Volvo Trucks North America, Inc., Warranty Administration, (336) 393-2000.

WHAT IS NOT COVERED BY THE EMISSION WARRANTY

This warranty does not cover:

1 Malfunctions in any part caused by any of the following: misuse, abuse, improper

adjustments unless performed by a Volvo Trucks North America, Inc. dealer, modifications, alterations, tampering, disconnection, improper or inadequate maintenance, or

use of fuels not recommended for the engine as described in the owner’s manual.

2 Damage resulting from accident, acts of nature or other events beyond the control of

Volvo Trucks North America, Inc.

3 The replacement of expendable maintenance items such as filters, hoses, belts, oil,

thermostat and coolant made in connection with scheduled maintenance services once

these parts have been replaced. Any parts replaced under warranty before the first required replacement point are warranted for the remainder of the warranty period.

4 Replacement items which are not genuine Volvo parts or not authorized by Volvo

Trucks North America, Inc.

5 Loss of time, inconvenience, loss of use of vehicle or engine, or commercial loss.

6 Any vehicle on which the odometer or hourmeter has been disconnected or the

mileage (or hours) has been altered so the actual usage cannot be readily be deter-

mined.

7 Any vehicle registered and normally operated outside the United States.

Page 18

12 General Information

WHAT IS COVERED BY THE EMISSION WARRANTY

The following is a list of the items that are considered a part of the Emission Control Systems and are covered by the Emission Warranty when installed as original equipment by

Volvo Trucks North America, Inc. on vehicles which were built to conform to Environmental Protection Agency and California Air Resources Board regulations

IMPORTANT - This may not include expendable maintenance items. Emission related

parts requiring scheduled maintenance are warranted until their first scheduled replacement

point.

I. Fuel Injection System

II. Air Induction System

A. Intake Manifold

B. Turbocharge System

C. Charge Air Cooler (Intercooler)

III. Exhaust Manifold

IV. Miscellaneous Items Used in Above Systems

A. Hose, clamps, fittings and tubing

B. Pulleys, belts and idlers

C. Vacuum, temperature, and time sensitive valves and switches

D. Mounting hardware, sealing gaskets and PVC (if applicable)

THIS CALIFORNIA EMISSION CONTROL WARRANTY STATEMENT IN NO WAY

REPLACES, MODIFIES, ALTERS OR SUPERSEDES THE TRUCK WARRANTY CER-

TIFICATE, ITS TERMS AND CONDITIONS, AND ITS

LIMITATIONS AND EXCLUSIONS.

BE CERTAIN YOU READ AND UNDERSTAND ALL WARRANTIES WHICH

ACCOMPANIED YOUR VEHICLE.

NOTE! Warranty coverage is subject to

change without notice. Contact your Volvo

Truck dealer for the current warranty

statement.

Page 19

Noise Emissions

Volvo Trucks North America, Inc. warrants

to the first person who purchases this vehicle for purposes other than resale and to

each subsequent purchaser, that this vehicle

as manufactured by Volvo Trucks North

America, Inc. was designed, built and

equipped to conform, at the time it left the

control of Volvo Trucks North America,

Inc., with all applicable U.S. EPA Noise

Control Regulations.

This warranty covers this vehicle as designed, built and equipped by Volvo Trucks

North America, Inc., and is not limited to

any particular part, component or system of

the vehicle manufactured by Volvo Trucks

North America, Inc. Defects in design, assembly or in any part, component or system

of the vehicle as manufactured by Volvo

Trucks North America, Inc., which, at the

time it left the control of Volvo Trucks

North America, Inc. caused noise emissions

to exceed Federal standards, are covered by

this warranty for the life of the vehicle.

General Information 13

Page 20

14 General Information

Tampering with Noise Control System

Federal law prohibits the following acts or

the causing thereof:

(1) The removal or rendering inoperative by

any person, other than for purposes of

maintenance, repair, or replacement, of any

device or element of design incorporated

into any new vehicle for the purpose of

noise control prior to its sale or delivery to

the ultimate purchaser or while it is in use;

or

(2) the use of the vehicle after such device

or element of design has been removed or

rendered inoperative by any person.

Among those acts presumed to constitute

tampering are the acts listed below:

Air Intake System

Removing or rendering inoperative the air

cleaner or intake piping.

Engine Cooling Fan

Removing or rendering inoperative the fan

clutch.

Removing the fan shroud.

Engine

Removing or altering engine speed programming so as to allow engine speed to

exceed manufacturer’s specifications.

Modifying the parameters of the Engine

Electronic Control Unit.

Page 21

Fuel System

Removing or altering engine speed programming so as to allow engine speed to

exceed manufacturer’s specifications.

Inner Fender Shields and Cab Skirts

Removing shields or skirts.

Cutting away parts of shields, skirts or dam-

aged or loose portions of shields or skirts.

General Information 15

Page 22

16 General Information

Vehicle Data

Identification and Labels

It is extremely important that the correct

vehicle model and serial number are given

whenever replacement parts or service literature are ordered. Using these numbers, as

well as giving the major component model

and serial numbers, will prevent delay and

errors in obtaining the correct material.

Space is given on the rear inside cover of

this manual for noting the main component

model and serial numbers.

The full 17–digit Vehicle Identification

Number (VIN) is shown on the Vehicle

Identification label located in the door

opening on the driver’s side (see next

page). The 8–digit chassis number is

stamped into the right-hand frame rail underside and the left-hand frame rail topside,

42 inches (1065 mm) back from the front

edge of the frame rail. The use of this number is very helpful when ordering parts for

your vehicle.

W0001732

Vehicle Order

The Vehicle Order is a complete and detailed record of all data pertaining to the

assembly of the vehicle. It should be filed

in the Owner’s office where it will be readily available for reference. Any changes

made to the vehicle must become a part of

the Vehicle Order and must comply with all

applicable Federal Motor Vehicle Safety

Standards.

Page 23

Identification and Certification Labels

There are two labels that are located on the

rear, lower face of the driver side door

frame. These should be part of the vehicle

at all times.

The VIN is shown on the Vehicle Identification label. The VIN includes the vehicle

make, model series, weight class, engine

model, where the vehicle was built and the

vehicle serial number. This label also

shows the truck model designation, major

component model and serial number, cab

model and serial number, cab and chassis

paint colors, and color numbers.

On the upper part of the door frame is the

Certification label showing the axle and

load ratings for the vehicle as it was built.

Do not exceed these ratings by overloading.

NOTE! To deter tampering with the original build information, the information on

the label will be destroyed if label is

removed. If for any reason a label is damaged, contact your Volvo Truck dealer for a

replacement.

General Information 17

W0001210

Noise Emission Control Label

A Noise Emission Control label is located

in the rear of the door frame. It is the

Owner’s responsibility to maintain the vehicle so that it conforms to EPA regulations.

Refer to page 14 for a listing on what constitutes tampering with the Noise Emissions

Control.

Page 24

18 General Information

Components

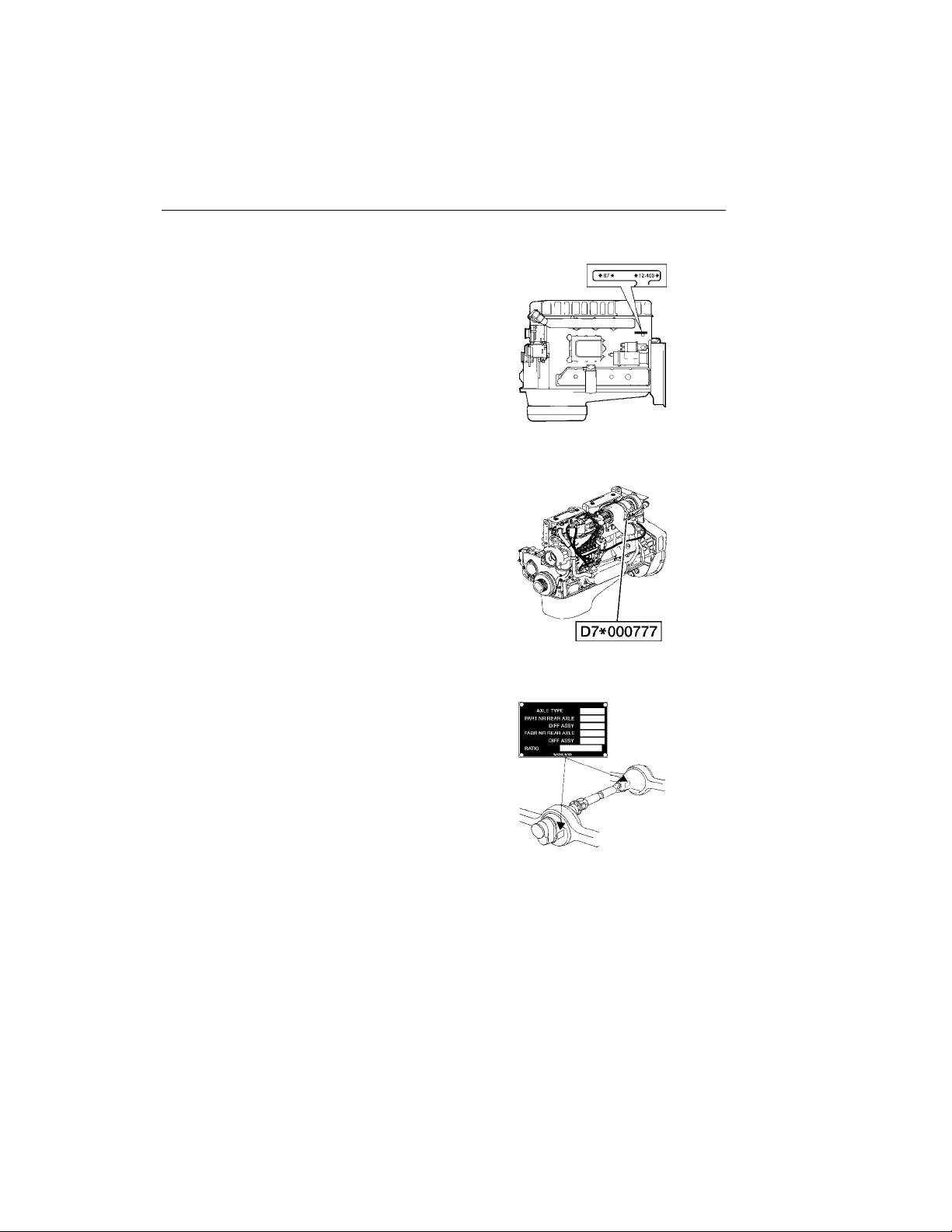

The Volvo D12 engine serial number is located on the rear, left side of the cylinder

block.

There is also a label on the engine electronic control unit that shows the engine

serial number.

The Volvo D7 engine serial number is located on the rear, left side of the cylinder

block.

There is also a label on the rear valve cover

that shows the engine serial number.

W0001529

The Volvo rear axle model and serial number is located on the right side of the

transfer gear housing on the tandem front

axle. It is located on the left side of the differential housing on the tandem rear axle

and on the right side of the single axle.

W2002707

W4000894

Page 25

Cab Doors and Door Lock

The cab door is unlocked with the same

key used for the ignition lock. Keys can be

made to fit only one vehicle or all the vehicles in a fleet of Volvos. A tool for

changing bulbs in the instrument cluster is

included on the keychain.

The key fits in the door lock either way.

Insert the key and turn it 1/4 turn counterclockwise to unlock or clockwise to lock

the door.

NOTE! The vehicle is delivered with 2

identical keys. If more keys are needed,

order them through your Volvo Truck authorized dealer. The keys are laser cut and

require a special machine for copying,

available through the dealer. Record the key

code and keep it in a secure place. A new

key can be made if the keys are lost.

The door locks are mechanically or electrically operated. The lock is activated by

either the key from the outside or the door

lock handle from the inside. With mechanical locks, only one door can be

locked/unlocked at a time. With electrical

locks, both doors will be locked/unlocked

by operating either the key or the inner

door lock handle on either side.

Vehicle Access 19

W0001231

Key code on tag of keychain

To lock either door from the inside, push

the door lock handle forward. The handle

will stay in place, indicating the door is

locked. It can be unlocked without opening

the door by moving the door lock handle to

the middle position.

No door can be locked while it is still

open. The door must be closed for the lock

to work. In the event of a power failure the

electrical lock system reverts back to a mechanically functioning system.

W8001462

Page 26

20 Vehicle Access

The door has a position lock that enables

the door to remain open in two different

positions. An indented bar is holding the

door at approximately 30

open position at approximately 85

To close the door from the inside, place the

hand in the handhold and pull the door in.

To lessen the chance of being thrown

from the vehicle in case of an accident,

always lock the door and wear the safety

belt while driving. Failure to do so can

cause serious personal injury or death if

involved in an accident.

and in the fully

.

W8001854

CAUTION

Do not shut the door by pushing on the

door panel. Hard pushing may distort

the metal in the door panel.

To close the door from the outside, place

the hand flat against the door lock area and

push the door shut.

W8001853

Page 27

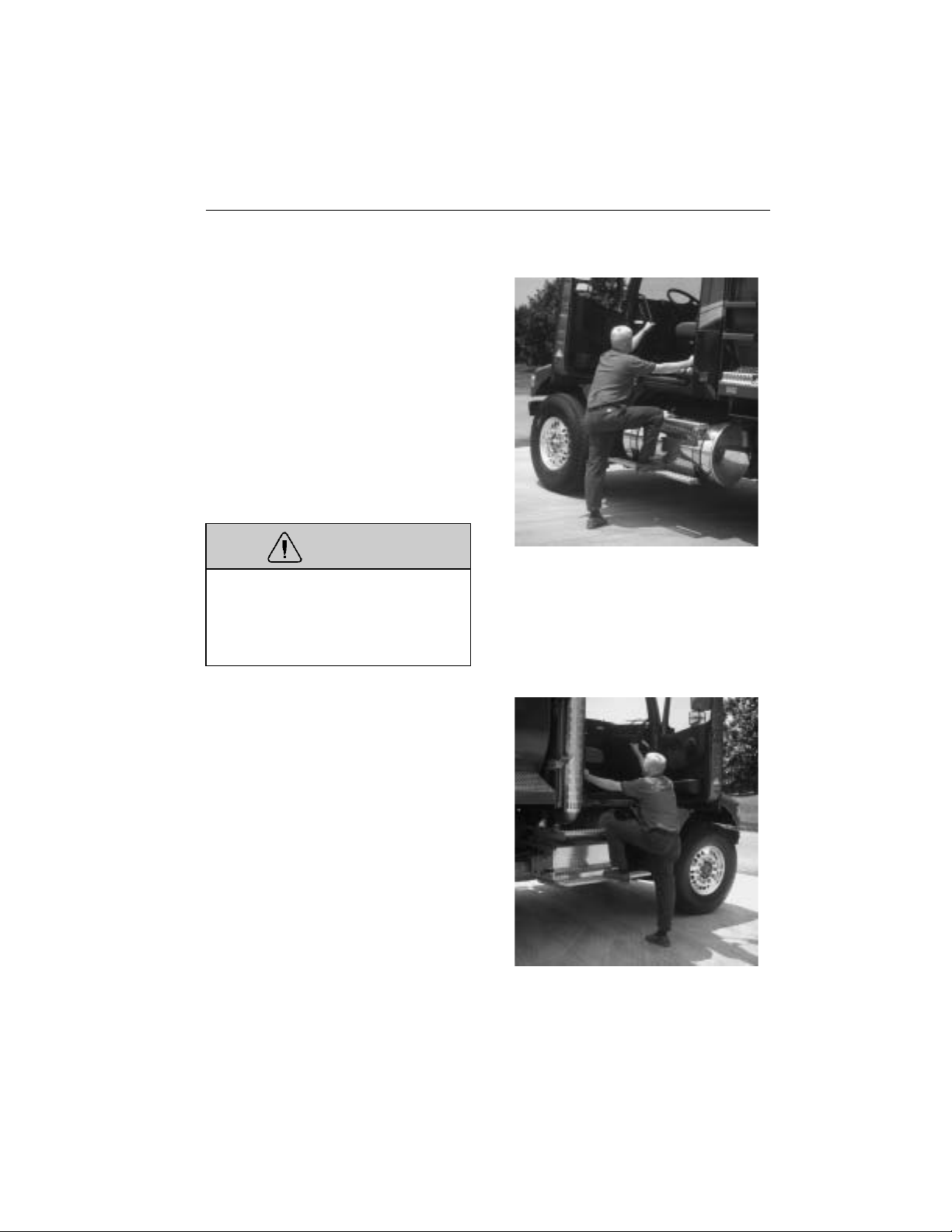

Cab Entry and Exit

General

To avoid personal injury due to a slip

and/or fall, observe all the guidelines explained in this section marked Cab Entry

and Exit.

Vehicle Access 21

WARNING

Wearing shoes with soles that are dirty

or wet increases the chance of slipping

and falling. Be careful when entering the

cab with dirty or wet soles.

WARNING

Do not stand on the steps or any other

part of the vehicle while it is in motion.

The steps and the back of cab access

deck plates are

the vehicle and not for riding on. Failure

to heed this warning can result in serious personal injury or death.

Steps are designed to be slip resistant

and to provide a stable surface for

entering or exiting the cab. However, accumulation of ice, dirt, lubricants, etc.

on the steps can make entering or exiting hazardous. Always make sure the

steps are free from slippery substances.

Failure to follow this guideline may result in a fall that can cause serious

personal injury or death.

only for entering/exiting

Both the operator and passenger should

exercise caution when entering or exiting

the cab. Use the steps and grab handles

to safely get in and out of the cab.

W8002808

Page 28

22 Vehicle Access

General Entry Guidelines

To avoid personal injury due to a slip

and/or fall, observe the following guidelines.

1 Always have three limbs (one foot and

two hands or two feet and one hand)

in contact with the vehicle at all times

when entering or exiting the cab or the

area behind the cab.

2 Be certain you have a firm handhold

and/or stable foot position before

transferring weight to that position. For

example, do not start to put weight on

a foot until you are certain your foot is

properly on the step and will not slip

when you transfer your weight.

3 Do not climb on top of the frame, fuel

tanks or storage boxes to make trailer

hook-ups.

4 If the vehicle is equipped with air fair-

ings, do not use the side mounted

fairing (wind deflector) brackets and

braces as steps or grab handles.

5 Be certain that the grab handles are

clear of snow, mud, ice or other substances that could make them slippery

before using them. Do not use steps or

grab handles if they are slippery or

damaged.

6 Be certain that all grab handles, steps

and related parts are in good working

condition. Any defects should be reported and repaired before using the

grab handles and steps.

8 If a step is mounted to the top of the

battery box, be certain that the battery

box cover is properly fastened before

stepping.

9 Do not jump from the cab or from the

steps to the ground.

10 Always face the cab when entering or

exiting.

11 Do not hold anything in your hands

when entering or exiting the cab or the

area behind the cab. Log books, cups,

clipboards, jackets, luggage and the

like can be placed on the cab floor or

rear deck plate before entering or exiting.

12 Be sure to disconnect the safety belt

before exiting the cab.

13 Be sure that the safety belt is fully re-

tracted and out of the way prior to

entering or exiting the cab.

14 Do not put your foot on any surface

that does not have slip resistant, selfcleaning material. If there is no step

material, the surface may be slippery

and you could fall.

15 Before entering or exiting, be certain

that the soles of your shoes/boots are

free from grease, mud or any other

substance which could make them

slippery.

16 Always put the foot flat on the top of

the step. Do not place your foot on the

side or edge of the step.

7 Do not step on the curved surface of

the fuel tanks. They may be slippery

from snow, mud, ice, water, spilled

fuel or other slippery substances.

BE SURE TO FOLLOW ALL OF

THESE INSTRUCTIONS BEFORE ENTERING O

THE AREA BEHIND THE CAB.

R EXITING THE CAB OR

Page 29

Driver Side Entry/Exit

Open the door. Place any hand-carried

items on the cab floor. Grasp the right grab

handle with your right hand and the left

grab handle with your left hand. Put the

right foot fully on the bottom step and pull

yourself up to the opening.

Slide hands up on the handles, if necessary.

Put the left foot on the top step and step up.

Step into the cab with the right foot first.

To exit, reverse the process. Do not attempt

to exit the cab while carrying any items in

your hands.

Vehicle Access 23

WARNING

On vehicles without side fairings, always make sure that the battery box

cover is securely fastened before stepping up. Failure to fasten the cover may

lead to personal injury.

Passenger Side Entry/Exit

Open the door. Place any hand-carried

items on the cab floor. Grasp the left grab

handle with your left hand and the right

grab handle with your right hand. Put the

left foot fully on the bottom step and pull

yourself up to the opening.

Slide hands up on the handles, if necessary.

Put the right foot on the top step and step

up.

Step into the cab with the left foot first.

To exit, reverse the process. Do not attempt

to exit the cab while carrying any items in

your hands.

W0001911

W0001910

Page 30

24 Vehicle Access

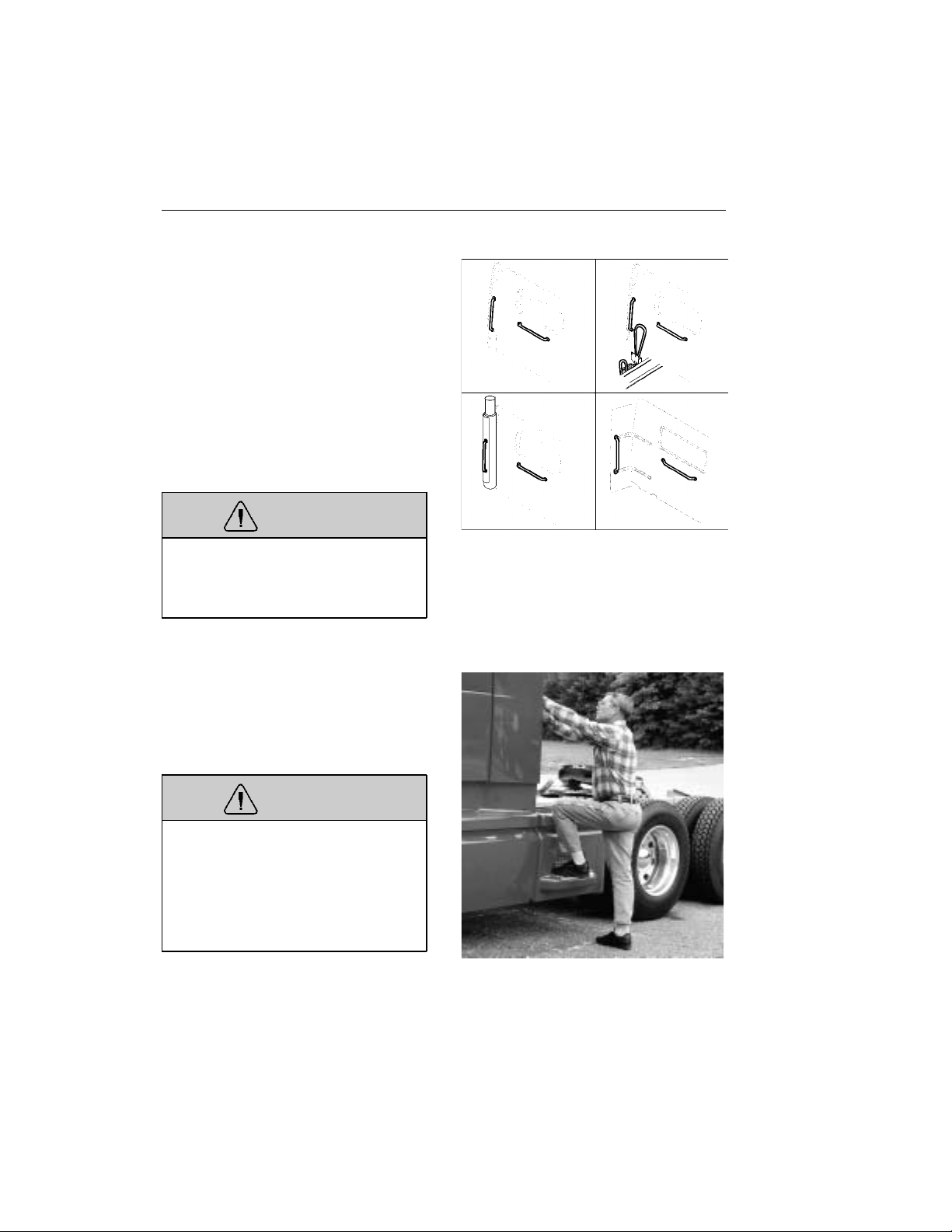

Behind the Cab Entry

When trailer air and electrical connections

can not be coupled from the ground, Federal Regulations require commercial

carriers to provide back-of-cab access steps,

grab handles and plates.

Depending on what option is chosen, grab

handles are available in many variations. In

each case, make sure to always have three

limbs (one foot and two hands or two feet

and one hand) in contact with the vehicle at

all times when entering or exiting the area

behind the cab.

WARNING

Wearing shoes with soles that are dirty

or wet increases the chance of slipping

or falling. Be careful when entering the

back-of-cab area with dirty or wet soles.

W8001363

Grasp the grab handle to the left with both

hands. Put the left foot onto the bottom

step and pull yourself up. Put the right foot

on the top step and step onto the deck plate

with the left foot.

WARNING

Always perform trailer hook-ups while

standing on the ground. Do not climb

on top of fuel tanks or frame rails to

hook up or disconnect trailer air lines

and electrical cord. Use only the metal,

slip resistant steps provided to prevent a

slip and fall injury.

W9000077

Page 31

Stand on the ground when connecting the

air and electrical connections to the trailer.

Vehicle Access 25

W5000713

Page 32

26 Vehicle Access

Hood

The hood is locked down by two latches,

one on each side of the back end of the

hood. The latches are operated by a handle

on the bottom edge of the dashboard.

Pull the bottom of the handle out to release

hood. The hood will be raised about two

inches off its resting position and remain

there.

Make sure the hood can be opened fully

without hitting anything. Stand sideways in

front of the hood with feet in line with the

vehicle. Place feet well apart and grasp the

recessed handle in the front part of the

hood. Transfer the body weight by leaning

away from the hood. Lift the hood until it

is past the balance point. Release the hood

and let it complete the opening movement

unaided.

Two restraint cylinders will engage during

the last part of the opening. The cylinders

will slow and dampen the hood down to its

resting position.

WARNING

Make sure that no one is in the way of

the hood when closing. The hood could

injure a person in the way while being

lowered.

To close the hood, stand with feet well

apart and place the hands along the front

edge of the hood. Bend the knees and let

the leg muscles do the work when lifting.

W8000986

W0001912

Raise the hood up to the halfway point.

Carefully guide the hood down with

enough speed that the hood latches lock the

hood in place when it comes to its normal

resting position.

W0001913

Page 33

Manual Hood Opening

In the event of a malfunction in the hood

opening mechanism, the hood latches can

be manually operated through an opening

in the wheelwell splash shield. The opening

is normally covered by a plate.

To access the opening, remove the two

screws using a T30 Torx screwdriver. Remove the cover plate.

The hood latch can now be accessed

through the hole. Operate the latch manually by pushing the lever in towards the

engine. Do the same on the other side.

Vehicle Access 27

W8002389

W8000981

Page 34

28 Pre-Trip Inspection and Daily Maintenance

General

Before working on or inspecting a vehicle, set the parking brakes, place the

transmission in neutral and block the

wheels. Failure to do so can result in unexpected vehicle movement and can

cause serious personal injury or death.

Safety is the most important and obvious

reason for doing a pre-trip inspection. Federal and state laws require inspection done

by the driver. Federal and state inspectors

also inspect commercial vehicles. An unsafe vehicle can be placed “out of service”

until the driver or owner corrects the

deficiency. Owners and operators should familiarize themselves with sections 49 CFR

396.11 and 396.13 concerning Federal requirements for vehicle inspection. Certain

other laws may also apply.

Section 49 CFR 396.13 states that all motor

carrier drivers must complete a written report at the end of each work day for each

vehicle operated, covering most of what is

covered in the pre-trip list. The report

should list all defects or deficiencies discovered by the driver. Doing a pre-trip

inspection prepares for the end-of-work report.

Starting on the next page are suggested

guidelines to be used in performing truck,

tractor and trailer pre-trip inspections. De-

pending on the application of the vehicle

being used, these guidelines should be

modified to include other necessary inspection points. For example, steps and grab

handles should be checked daily on refuse

trucks because the operator is getting in

and out of the cab more frequently.

If any component or system does not pass

this inspection, it must be corrected before

operating the vehicle. Whenever equipment

requires adjustment, replacement, repair or

lubrication, refer to the Service Manuals or

contact a Volvo Truck dealer for the correct

procedures, specifications and intervals.

Take your time going through the pre-trip

inspection. Remember that a careful pre-trip

inspection saves time by eliminating unscheduled stops for correcting a faulty item.

The following information has been

provided by the American Trucking Association as developed by the D.O.T. Office of

Motor Carriers (BMCS).

Page 35

Pre-Trip Inspection and Daily Maintenance 29

Pre-Trip Inspection Quick List

Inspect the vehicle in a circular manner as shown in the

illustration. Numbers between parentheses in the list, refer to pages in this manual where component function

and necessary inspection is explained in greater detail.

W1000145

Approaching the Vehicle

Check under the vehicle for oil, fuel,

•

coolant leaks or other signs of damage.

Check body surfaces for signs of

•

breaks or damage.

Preparation

Open drain cocks on air tanks to let

•

the tanks drain ( page 234).

Chock wheels on vehicle and, if

•

hooked up, trailer.

Close air tank drain cocks.

•

Start the engine and let the air pres-

•

sure build up to normal ( page 224).

Stop engine.

Switch on parking lights and four-way

•

flashers ( page 94).

Apply parking brakes ( page 229).

•

Release the hood latches ( page 26).

•

Raise hood.

Step 1: Left Side Of the Cab

Left Front Wheel

Check condition of wheel rim. Espe-

•

cially look for cracks, missing

lockrings, bent or broken studs,

clamps or lugs.

Check condition of tire: properly in-

•

flated, no serious cuts, bulges, tread

wear or any signs of misalignment;

valve stem not touching wheel, rim or

brake drum; valve cap in place.

Check wheel bearing and hub: no ob-

•

vious leaking on outside or inside

wheel. Verify correct oil level in hub.

Left Front Suspension

Check condition of spring, spring

•

hangers, shackles, U-bolts: no cracks,

breaks or shifting.

Check shock absorber condition.

•

Page 36

30 Pre-Trip Inspection and Daily Maintenance

Step 1: Left Side Of the Cab (cont.)

Left Front Brake

Condition of brake drum. With brakes

•

released, look for a noticeable gap between lining and drum (This check

cannot be made if dust covers are in

place).

Condition of brake air hose.

•

Check brake chamber mounting bolts

•

and bracket.

Check slack adjuster and chamber

•

pushrod travel.

Condition of Front Axle and Steering System, Left Side

No loose, worn, bent, damaged or

•

missing parts.

Under Hood, Left Side

Check coolant hose condition.

•

Check condition of fan drive belts.

•

Check engine and surrounding areas

•

for coolant, oil and fuel leaks.

Check wiring harnesses for signs of

•

damage.

Step 2: Front Of Cab Area

Condition of Windshield

Check for damage and clean if dirty

•

( page 44 ).

Check windshield wiper arms for

•

proper spring tension.

Check wiper blades for any damage,

•

“dead” rubber and securement to arm.

Lights and Reflectors

Lower hood and inspect parking,

•

clearance and identification lights on

hood and cab. They should be clean,

operating and of the proper color.

Reflectors clean and proper color.

•

Turn on headlights. High and low

•

beams should be operating and lenses

clean. If equipped, check daytime running lights.

Left and right front turn signal lights

•

clean, operating and proper color.

Raise hood.

Grille

Check that charge air cooler and radia-

•

tor or bugscreens are clean and

undamaged.

Step 3: Right Side Of Cab Area

Right Front Wheel

Check condition of wheel rim. Espe-

•

cially look for cracks, missing

lockrings, bent or broken studs,

clamps or lugs.

Check condition of tire: properly in-

•

flated, no serious cuts, bulges, tread

wear or any signs of misalignment;

valve stem not touching wheel, rim or

brake drum; valve cap in place.

Check wheel bearing and hub: no ob-

•

vious leaking on outside or inside

wheel. Verify correct oil level in hub.

Page 37

Pre-Trip Inspection and Daily Maintenance 31

Step 3: Right Side Of Cab Area (cont.)

W1000145

Under Hood, Right Side

Right Front Suspension

Check condition of spring, spring

•

hangers, shackles, U-bolts: no cracks,

breaks or shifting.

Shock absorber condition.

•

Right Front Brake

Condition of brake drum. With brakes

•

released, look for a noticeable gap between lining and drum (This check

cannot be made if dust covers are in

place).

Condition of brake air hose: check for

•

any chafing.

Check brake chamber mounting bolts

•

and bracket.

Check slack adjuster and chamber

•

pushrod travel. With brakes applied or

released, look for conspicuously different positions of the slack adjusters.

Condition of Front Axle and Steering System, Right Side

No loose, worn, bent, damaged or

•

missing parts.

Check condition of coolant and heater

•

hoses.

Check condition of fan drive belts.

•

Check engine and surrounding areas

•

for coolant, oil and fuel leaks.

Check fuel separator sight glass and

•

drain if necessary. Check for leaks.

Check wiring harnesses for signs of

•

damage.

Check air filter with brackets and

•

hoses for loose connections or damage. Check filter gauge, if mounted on

the filter.

Step 4: Right Saddle Tank Area

Right Fuel Tank(s)

Securely mounted and not damaged or

•

leaking.

Fuel lines secure and not leaking.

•

Check that shut-off valves are open.

Tank(s) full of fuel. Cap on and secure.

•

Page 38

32 Pre-Trip Inspection and Daily Maintenance

Condition of Visible Components

Rear of engine: not leaking.

•

Transmission: not leaking. If equipped

•

with oil cooler, check for leaks or that

air-to-air cooler is not blocked.

Check drive shaft.

•

Exhaust system: secure, not leaking,

•

not touching wires, fuel or air tubing.

Frame and cross members: no bends,

•

cracks or breaks.

Air tubing and electrical wiring: se-

•

cured against snagging and chafing.

Step 5: Right Rear Vehicle Area

Dual Wheels, One Or Two Axles

Check condition of wheels and rims.

•

Especially look for cracks, missing

lockrings, bent or broken spacers,

studs, clamps or lugs.

Check condition of tires: properly in-

•

flated, no serious cuts, bulges, tread

wear or any signs of misalignment;

valve stems not touching wheels, rims

or brake drums; valve caps in place

and no objects stuck between the

wheels.

Check that both tires are of same type,

•

for example, not mixed radial and bias

type and that their circumferences are

matched.

Check wheel bearing and hub: no obvi-

•

ous leaking on outside or inside wheel.

Suspension

Check condition of springs (leaf or

•

air), spring hangers, shackles and Ubolts.

Axle alignment.

•

Brakes

Condition of brake drums. With brakes

•

released, look for a noticeable gap between lining and drum (This check

cannot be made if dust covers are in

place).

Condition of brake hoses: check for

•

any chafing.

Check brake chamber mounting bolts

•

and brackets.

Check slack adjusters and chamber

•

push rod travel. With brakes applied or

released, look for conspicuously different positions of the slack adjusters.

Check spring brakes.

•

Step 6: Rear Of Vehicle Area

Frame Area

Frame or cross members not bent,

•

cracked or otherwise damaged or

missing.

Check that air tubing and electrical

•

lines are properly secured to the frame

with no damage or chafing.

Lights and Reflectors

Tail lights, brake lights and turn signal

•

lights: operating, clean and proper

color.

Page 39

Pre-Trip Inspection and Daily Maintenance 33

Step 7: Coupling System Area

Fifth Wheel

Securely mounted to the frame.

•

No missing or damaged parts.

•

Check that trunnion and plate are

•

properly lubricated ( page 265).

Sliding Fifth Wheel

Mechanism not worn, bent, damaged

•

or parts missing ( page 267).

Properly lubricated.

•

All locking pins present and locked in

•

place.

If air operated: no air leaks.

•

Air Tubing and Electric Lines Visible From

This Point

Should be secure from dangling.

•

Both air lines and electric line should

•

be free from damage, oil and grease.

W1000145

Step 8: Left Saddle Tank and Left Rear

Vehicle Wheels Area

Dual Wheels, One Or Two Axles

Check condition of wheels and rims.

•

Especially look for cracks, missing

lockrings, bent or broken spacers,

studs, clamps or lugs.

Check condition of tires: properly in-

•

flated, no serious cuts, bulges, tread

wear or any signs of misalignment;

valve stems not touching wheels, rims

or brake drums; valve caps in place

and no objects stuck between the

wheels.

Check that both tires are of same type,

•

for example, not mixed radial and bias

type and that their circumferences are

matched.

Check wheel bearing and hub: no obvi-

•

ous leaking on outside or inside wheel.

Suspension

Check condition of springs (leaf or

•

air), spring hangers, shackles and

U-bolts, no cracks, breaks or shifting.

Page 40

34 Pre-Trip Inspection and Daily Maintenance

Brakes

Condition of brake drums. With brakes

•

released, look for a noticeable gap between lining and drum (This check

cannot be made if dust covers are in

place).

Condition of brake hoses: check for

•

any chafing.

Check brake chamber mounting bolts

•

and brackets.

Check slack adjusters and chamber

•

push rod travel. With brakes applied or

released, look for conspicuously different positions of the slack adjusters.

Check spring brakes.

•

Condition of Visible Components

Transmission: not leaking.

•

Drive shaft: looks OK.

•

Exhaust system: secure, not leaking,

•

not touching wires, fuel or air tubing.

Left Fuel Tank(s)

Securely mounted and not damaged or

•

leaking.

Fuel lines secure and not leaking.

•

Check that shut-off valves are open.

Tank(s) full of fuel. Cap on and secure.

•

Battery Area

Open the battery box ( page 245). Bat-

•

tery box securely mounted to vehicle.

Batteries secured against movement

•

( page 245).

Battery cases not broken or leaking.

•

Battery cables free from damage.

Tops of batteries and terminals clean

•

and free from foreign material.

If equipped, replace battery lid and

•

make sure it is securely fastened

( page 245).

Frame and cross members: no bends,

•

cracks or breaks.

Air tubing and electrical wiring: se-

•

cured against snagging and chafing.

Page 41

In the Cab

Pre-Trip Inspection and Daily Maintenance 35

W1000145

Check steps and grab handles for

•

looseness or breakage ( page 22).

Also, clean them if there is any substance that makes them slippery, which

makes cab entry/exit hazardous.

Start the engine. If equipped, check

•

that exhaust rain cap opens when accelerating engine.

Check gauges and telltale light func-

•

tion ( page 79).

Check function of low air warning

•

( page 85). Check the Graphic Display

for any fault codes ( page 108).

Check clutch function ( page 222). If

•

equipped, check for clutch brake function.

Check windshield wipers and washers

•

( page 43) and horns, including backup alarm, if equipped.

Clean inside windshield, door win-

•

dows and instruments. Clean mirrors.

Check climate control and defroster

•

( page 168). If equipped, check mirror

heater.

Check condition of warning triangles,

•

fire extinguisher and flares ( page 62).

Adjust the seat ( page 180). Check

•

mirror adjustment.

Check safety belts for function and

•

damage ( page 49).

Apply service brakes. After initial

•

drop, pressure should hold steady, or

increase slightly, with engine at idle.

Check steering wheel for excessive

•

free play.

Check for loose items in the cab. Se-

•

cure them if necessary.

Page 42

36 Pre-Trip Inspection and Daily Maintenance

Hooking Up To Trailer

Hook-up Preparation

Check kingpin and mounting plate on

•

trailer, free from wear, bends or damage.

Chock trailer wheels.

•

Fifth Wheel Or Trailer Hitch

No visible space between fifth wheel

•

and trailer ( page 273).

Locking jaws around the shank and

•

not the head of kingpin ( page 273).

Release lever properly seated and

•

safety latch/lock engaged ( page 274).

Check all connections to dolly or

•

trailer hitch and safety chains are secured.

Check function of trailer air supply

•

valve and trailer brakes.

Sliding Fifth Wheel

Check that fifth wheel is not so far

•

forward that the tractor frame will

strike the landing gear during turns.

Page 43

Pre-Trip Inspection and Daily Maintenance 37

NOTE! Refer to the trailer manufacturer’s

manual for specific information on the

trailer checks.

W0001919

Step 9: Trailer Front Area

Air and Electrical Connections

Glad hands properly mounted, free

•

from damage and not leaking.

Trailer cord receptacle properly

•

mounted, free of damage; plug properly seated and safety catch engaged

to prevent accidental disconnect.

Air and electrical lines properly se-

•

cured against tangling, snagging and

chafing with sufficient slack for turns.

Step 10: Right Side of Trailer Area

Landing Gear or Dolly Area

Fully raised; no missing or damaged

•

parts.

Crank handle present and secured.

•

If power operated, no air/hydraulic

•

leaks.

Spare Wheel(s)

Carrier or rack not damaged.

•

Spare wheel securely mounted in rack.

•

Tire and wheel condition adequate for

•

a spare: proper size, properly inflated.

Lights and Reflectors

Trailer side clearance lights: clean, op-

•

erating and proper color.

Reflectors clean and proper color.

•

Frame and Body

Frame and crossmembers not bent,

•

cracked, damaged or missing.

Proper placarding.

•

Body parts not damaged or missing.

•

Page 44

38 Pre-Trip Inspection and Daily Maintenance

Step 11: Right Rear Trailer Wheel

Dual Wheels, One Or Two Axles

Check condition of wheels and rims.

•

Especially look for cracks, missing

lockrings, bent or broken spacers,

studs, clamps or lugs.

Check condition of tires: properly in-

•

flated, no serious cuts, bulges, tread

wear or any signs of misalignment;

valve stems not touching wheels, rims

or brake drums; valve caps in place

and no objects stuck between the

wheels.

Check that both tires are of same type,

•

for example, not mixed radial and bias

type and that their circumferences are

matched.

Check wheel bearing and hub: no obvi-

•

ous leaking on outside or inside wheel.

Suspension

Condition of springs (leaf or air),

•

spring hangers, shackles and U-bolts.

tween lining and drum (This check

cannot be made if dust covers are in

place).

Condition of brake hoses: check for

•

any chafing.

Check brake chamber mounting bolts

•

and brackets.

Check slack adjusters and chamber

•

push rod travel. With brakes applied or

released, look for conspicuously different positions of the slack adjusters.

Check spring brakes.

•

Step 12: Rear of Trailer Area

Lights and Reflectors

Rear clearance, identification and tail

•

lights clean, operating and proper

color.

Reflectors clean and proper color.

•

Cargo Securement

Axle alignment.

•

Condition of torque rod arms.

•

If equipped with sliding axles, check

•

position and alignment. Look for damaged, worn or missing parts, all locks

present, fully in place and locked.

Flexible air tubing not cracked, cut,

•

crimped or otherwise damaged. Secured against tangling, dragging and

chafing.

Brakes

Condition of brake drums. With brakes

•

released, look for a noticeable gap be-

Cargo properly blocked, braced, tied,

•

chained, etc.

Tailboard up and properly secured.

•

End gates free from damage, properly

secured in stake pockets.

Canvas or tarp (if required) properly

•

latched down to prevent water damage,

tearing, billowing or blockage of either

mirrors or tail lights.

Rear doors securely closed, latched or

•

locked; required security seals in place.

Underside guard in place: not cracked,

•

bent or broken.

Page 45

Pre-Trip Inspection and Daily Maintenance 39

NOTE! Refer to the trailer manufacturer’s

manual for specific information on the

trailer checks.

W0001919

Step 13: Left Rear Trailer Wheels Area

Dual Wheels, One Or Two Axles

Check condition of wheels and rims.

•

Especially look for cracks, lockrings

missing, bent or broken spacers, studs,

clamps or lugs.

Check condition of tires: properly in-

•

flated, no serious cuts, bulges, tread

wear or any signs of misalignment;

valve stems not touching wheels, rims

or brake drums; valve caps in place

and no objects stuck between the

wheels.

Check that both tires are of same type,

•

for example, not mixed radial and bias

type and that their circumferences are

matched.

Check wheel bearing and hub: no obvi-

•

ous leaking on outside or inside wheel.

Suspension

Condition of springs (leaf or air),

•

spring hangers, shackles and U-bolts.

Axle alignment.

•

Condition of torque rod arms.

•

If equipped with sliding axles, check

•

position and alignment. Look for damaged, worn or missing parts, all locks

present, fully in place and locked.

Flexible air tubing not cracked, cut,

•

crimped or otherwise damaged. It

should be secured against tangling,

dragging and chafing.

Brakes

Condition of brake drums. With brakes

•

released, look for a noticeable gap between lining and drum (This check

can not be made if dust covers are in

place).

Condition of brake hoses: check for

•

any chafing.

Check brake chamber mounting bolts

•

and brackets.

Check slack adjusters and chamber

•

push rod travel. With brakes applied or

released, look for conspicuously different positions of the slack adjusters.

Check spring brakes.

•

Page 46

40 Pre-Trip Inspection and Daily Maintenance

Step 14: Left Side of Trailer Area

Landing Gear or Dolly Area

Fully raised; no missing or damaged

•

parts.

Crank handle present and secured.

•

If power operated, no air/hydraulic

•

leaks.

Spare Wheel(s)

Spare wheel securely mounted in rack

•

with no damage to rack.

Tire and wheel condition adequate for

•

a spare: proper size, properly inflated.

Lights and Reflectors

Trailer side clearance lights: clean, op-

•

erating and proper color.

Reflectors clean and proper color.

•

Frame and Body

Frame and crossmembers not bent,

•

cracked, damaged or missing.

Before Leaving the Parking Area

Remove chocks from the wheels.

•

Test trailer hook-up by slowly pulling

•

while applying the trailer brakes with

the trailer brake hand control valve.

Test the service brakes before leaving

•

the parking area.

Test parking brakes by stopping on a

•

20% grade and applying the parking

brakes. The parking brakes shall hold

the combined vehicle and trailer without moving.

Proper placarding.

•

Body parts not damaged or missing.

•

Page 47

Pre-Trip Inspection and Daily Maintenance 41

Daily Maintenance

The following should be checked daily in

addition to doing the pre-trip inspection of

the truck or tractor and trailer.

While checking the fluid levels, visually inspect hoses, pipes and their connections for

signs of leakage. Inspect the ground under

engine, transmission and rear axle(s) for

signs of leakage.

Check coolant level in the coolant tank.

The level should be above the minimum

mark shown on the side of the tank.

WARNING

Do not remove the cap to the surge tank

while the engine and radiator are still

hot and under pressure. Scalding fluid

and/or steam may be blown out under

pressure if the cap is taken off too soon.

If the coolant level is low, add more

coolant to the tank so the level is above the

minimum mark. Coolant should be filled

through the cap in the middle of the tank.

Before working on or inspecting a vehicle, set the parking brakes, place the

transmission in neutral and block the

wheels. Failure to do so can result in unexpected vehicle movement and can

cause serious personal injury or death.

W2003475

CAUTION

Add only pre-mixed coolant made up of

50% clean water and 50% antifreeze.

See the “Operator’s Manual, Mainte-

nance & Engine” for more detailed

information.

CAUTION

Engines equipped with automatic start

systems can start automatically. Alarm

sounds before automatic start. Failure to

turn off ignition before working on fan

or belts can result in personal injury.

Page 48

42 Pre-Trip Inspection and Daily Maintenance

WARNING

Keep yourself clear of all moving or hot

engine parts. A hot engine can cause serious burns.

Check oil level in the engine with the dipstick. The oil level should be between the

minimum and maximum marks on the dipstick. Do not overfill!

See the “Operator’s Manual, Maintenance

and Engine” for correct types of oil used in

Volvo engines.

CAUTION

If the vehicle is equipped with an aerodynamic bumper, do not step on or press

in between the bumper and the wheel.

Breakage or damage may result.

To add oil to a D12 engine, remove oil cap

on the valve cover and fill through the hole.