Page 1

Foreword

This booklet is part of a complete service manual. Read the

foreword in the service manual.

WARNING

Always read the booklet Safety before proceeding.

PUB 2012.10

1

Page 2

Page 3

Table of contents

03 SPECIFICATIONS

030 General

Tightening torque, cylinder head ................................................................ 6

Engine, specification

General ..................................................................................................... 6

Cylinder block, specifications ...................................................................... 7

Engine transmission, tightening torque ....................................................... 7

Tightening torques .................................................................................... 7

Timing gear casing ................................................................................... 9

Tightening torques, flywheel housing WLO/EXC .................................... 11

Tightening torques, timing gear plate ..................................................... 11

Engine transmission, specification ............................................................ 12

Rocker arm shaft, tightening torques ........................................................ 13

Valve mechanism, specifications .............................................................. 14

Valve mechanism, tightening torques ....................................................... 16

Tightening torques, valve cover ................................................................ 16

Oil sump, tightening torque ....................................................................... 16

Oil cooler, tightening torques .................................................................... 17

Oil cooler ................................................................................................. 17

Oil cooler, cover ...................................................................................... 17

Cylinder block, tightening torques ............................................................. 18

Engine mount incl. bracket ..................................................................... 18

Ladder frame .......................................................................................... 19

Inlet ......................................................................................................... 19

Tightening torque, fuel system .................................................................. 21

Exhaust manifold, tightening torques ........................................................ 21

Turbocharger, tightening torques .............................................................. 21

Crank mechanism, specifications ............................................................. 23

Crankshaft, tightening torques .................................................................. 25

Flywheel, tightening torques ..................................................................... 26

Belt pulley/vibration damper, tightening torques ....................................... 27

................................................................................... 6

21 ENGINE

210 General, common info about 211 - 218

Engine, mounting in work stand ................................................................ 28

Engine, dismantling .................................................................................. 32

Cylinder liners, removing ........................................................................ 39

Engine, assembling .................................................................................. 40

Cylinder liners, installing ......................................................................... 41

Crankshaft, installing .............................................................................. 43

Pistons, installing .................................................................................... 44

Installing timing gear plate ...................................................................... 45

Flywheel housing .................................................................................... 49

Crankshaft seal, rear .............................................................................. 50

Front crankshaft seal .............................................................................. 51

Speed (rpm) sensor, adjusting ................................................................ 54

Engine, removing from work stand ........................................................... 56

211 Cylinder head

Cylinder head, removing ........................................................................... 59

Cylinder head, reconditioning ................................................................... 62

Installing in work stand ........................................................................... 62

Valves, removing .................................................................................... 63

Sleeve for unit injector, removing ........................................................... 64

Tap out with drift ..................................................................................... 65

Pull out with puller ................................................................................... 65

Valve guide, checking ............................................................................. 67

Valve guides, changing ........................................................................... 68

3

Page 4

Injector sleeve, installing ......................................................................... 69

Cylinder head, checking for leaks

Valve seat, checking ............................................................................... 73

Valve seat, cleaning soot and grinding ................................................... 73

Valve seat, changing .............................................................................. 73

Valves, grinding ...................................................................................... 74

Cylinder head, assembling ..................................................................... 74

Cylinder head, fitting ................................................................................. 76

212 Cylinder block with crankcase ventilation

Cylinder block, liners removed, milling of all liner locations ...................... 82

214 Valve mechanism

Valves, adjusting ....................................................................................... 88

Inlet valves, checking and adjusting ....................................................... 89

Unit injectors, adjusting ........................................................................... 89

Exhaust valves, checking and adjusting ................................................. 90

...........................................................

22 LUBRICATING SYSTEM

223 Oil cooler

Oil cooler, leakage check .......................................................................... 91

71

4

Page 5

GENERAL

03 SPECIFICATIONS

030 General

5

Page 6

13

36 35

9

28 27

6

22 21

1

15 16

3

23 24

7

31 32

11

14

38 37

10

30 29

4

18 17

2

19 20

5

25 26

8

33 34

12

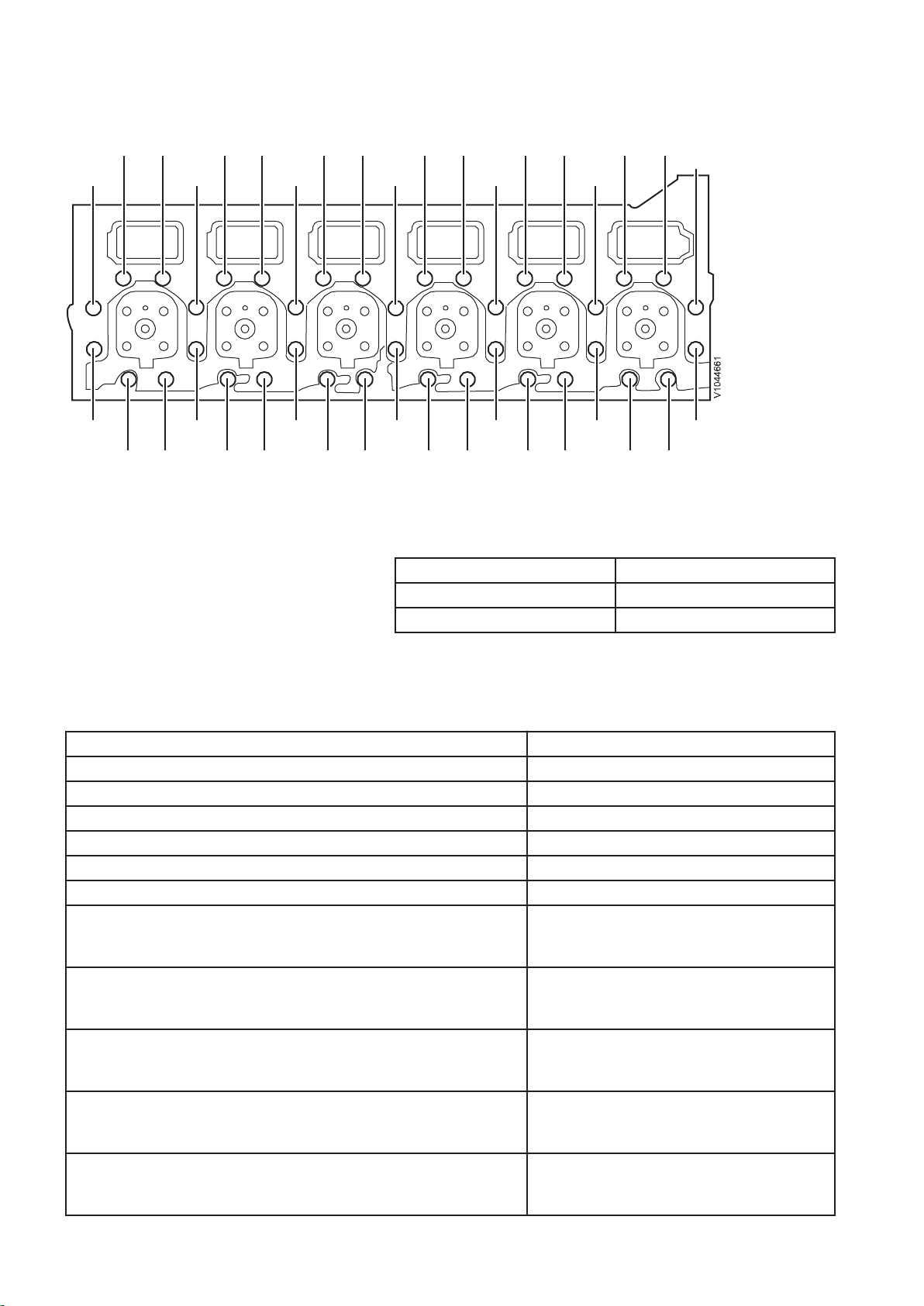

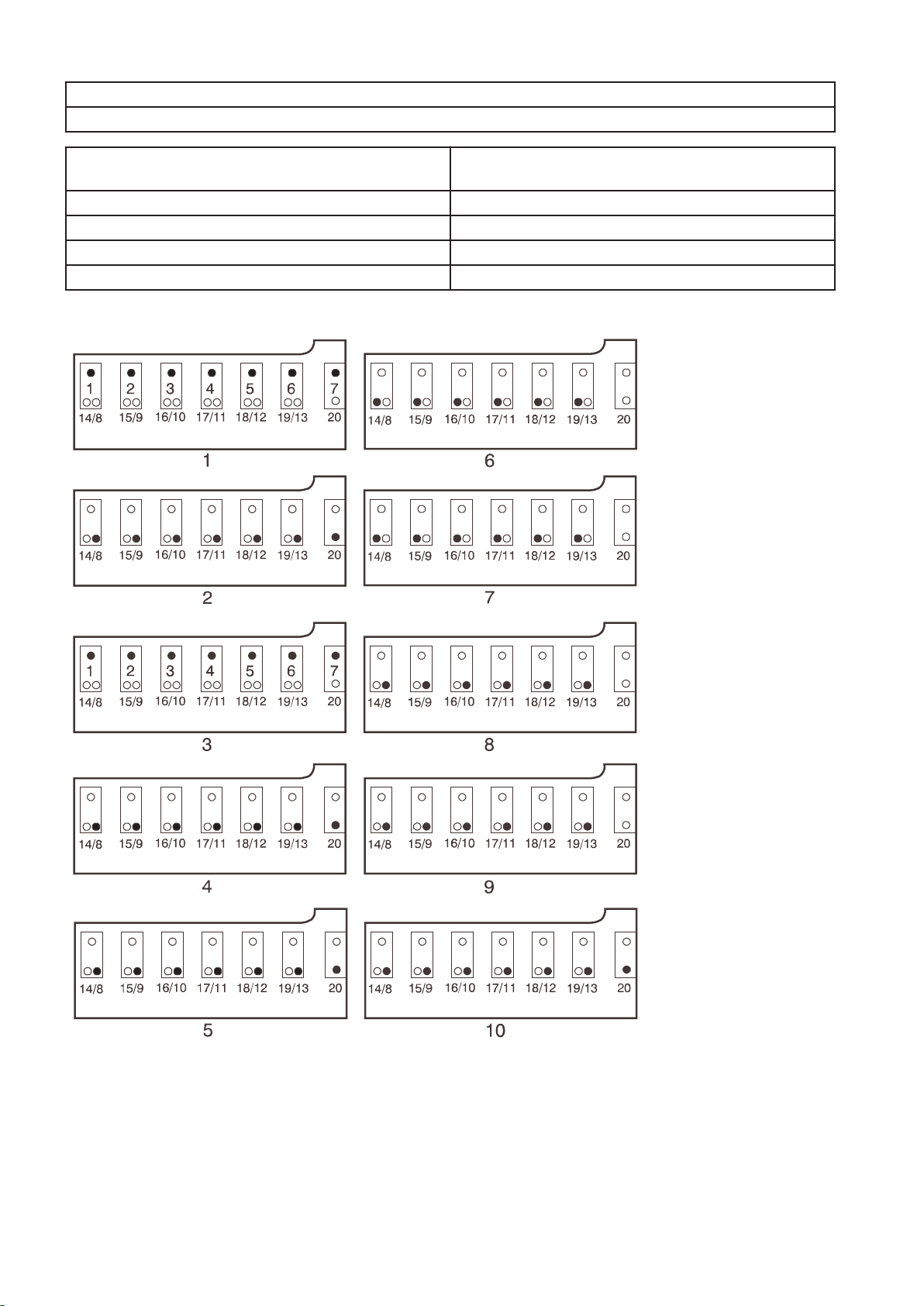

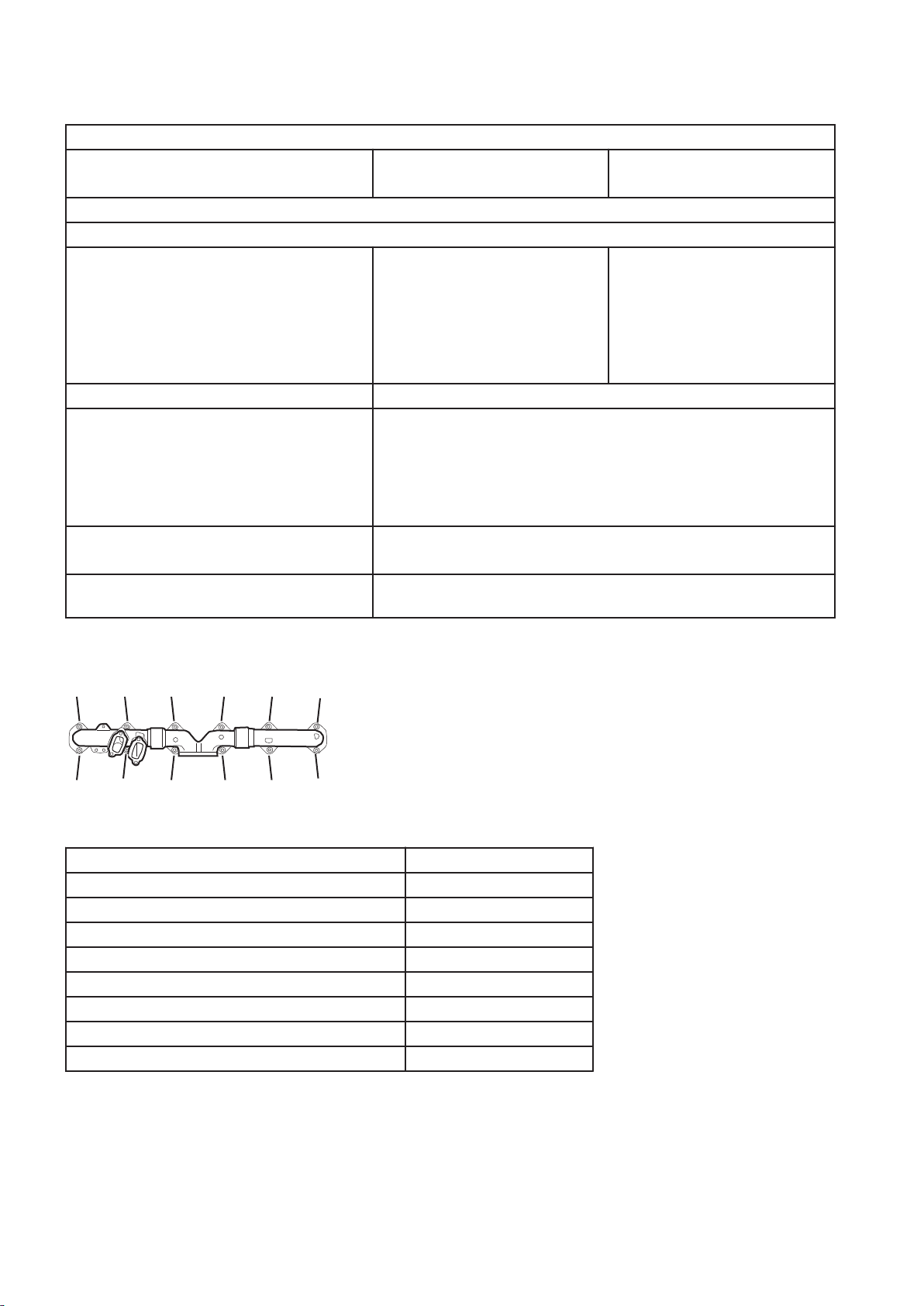

Fig.1 Cylinder head, D13

Tightening torque, cylinder head

NOTE!

Tighten the bolts in the sequence shown in the figure.

Step 1 100±5Nm(74±3.7 lbf ft)

Step 2 120±5° Angle-tightening

Step 3 90±5° Angle-tightening

Engine, specification

General

D13 F

Number of cylinders 6

Cylinder bore 131 mm (5.16 in)

Stroke 158 mm (6.22 in)

Displacement 12.78 litres (3.38 US gal)

Injection order 1–5–3–6–2–4

Compression ratio 18, 5:1

Low idle

EXC

WLO

High idle

EXC

WLO

Max. full load rpm

EXC

WLO

Weight, engine

EXC

WLO

Total length

EXC

WLO

13.33 r/s (800 rpm)

11.67 r/s (700 rpm)

28.33 r/s (1700 rpm)

31.67 r/s (1,900 rpm)

31.67 r/s (1,900 rpm)

35 r/s (2,100 rpm)

1,330 kg (3,042 lbs)

1,330 kg (3,042 lbs)

1 585 mm (62.4 in)

1460 mm (57.5 in)

6

Page 7

D13 F

Width

EXC

WLO

Height

EXC

WLO

789 mm (31.1 in)

1077 mm (42.4 in)

1 250 mm (49.2 in)

1 215 mm (47.8 in)

Cylinder block, specifications

Length 1 052 mm (41.42 in)

Height, upper block face-crankshaft centre 422 mm (16.6 in)

Height, lower block face-crankshaft centre 120 mm (4.72 in)

Cylinder liners

Type Wet, replaceable

Sealing surface's height over cylinder block's face 0.15 – 0.21 mm (0.0059 — 0.0083 in)

Number of seal rings per cylinder liner 3

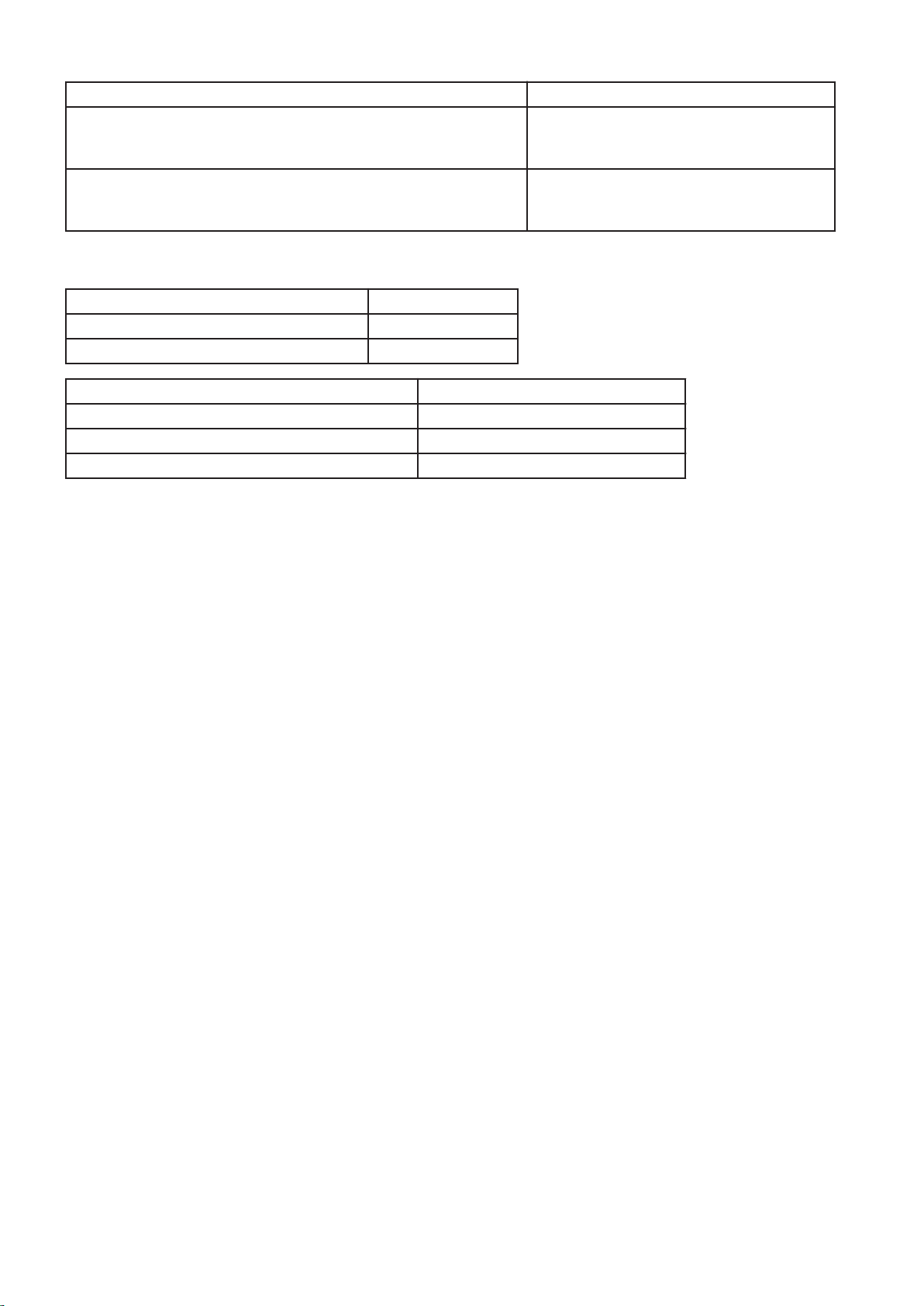

Engine transmission, tightening torque

Tightening torques

NOTE!

Tighten in the order shown in the figure.

7

Page 8

V1071860

Fig.2

Gears: Tightening torque:

1. Drive gear, crankshaft 24±4 Nm (18±3 lbf ft)

2. Transfer gear, outer gear:

step 1: 25±3 Nm (18.4±2.2 lbf ft)

step 2: angle-tightening 110±5°

3. Transfer gear, adjustable:

step 1: 35±4 Nm (25.8±2.95 lbf ft)

step 2: angle-tightening 120° ±5°

4. Gear, camshaft: Vibration damper's 8.8-bolts may not

be reused.

temporarily: 10 Nm (7.5 lbf ft)

step 1: 45±5 Nm (33±4 lbf ft)

step 2: Angle-tightening 90° ±5°

5. Transfer gear 140±10 Nm (103±7.4 lbf ft)

6. Drive gear, lubrication oil pump for power take-off and

100±10 Nm (74±7.4 lbf ft)

fuel feed pump

8

Page 9

7. Drive gear, compressor 200+50/-0 Nm (148+37/-0 lbf ft)

V1088409

8. Not used

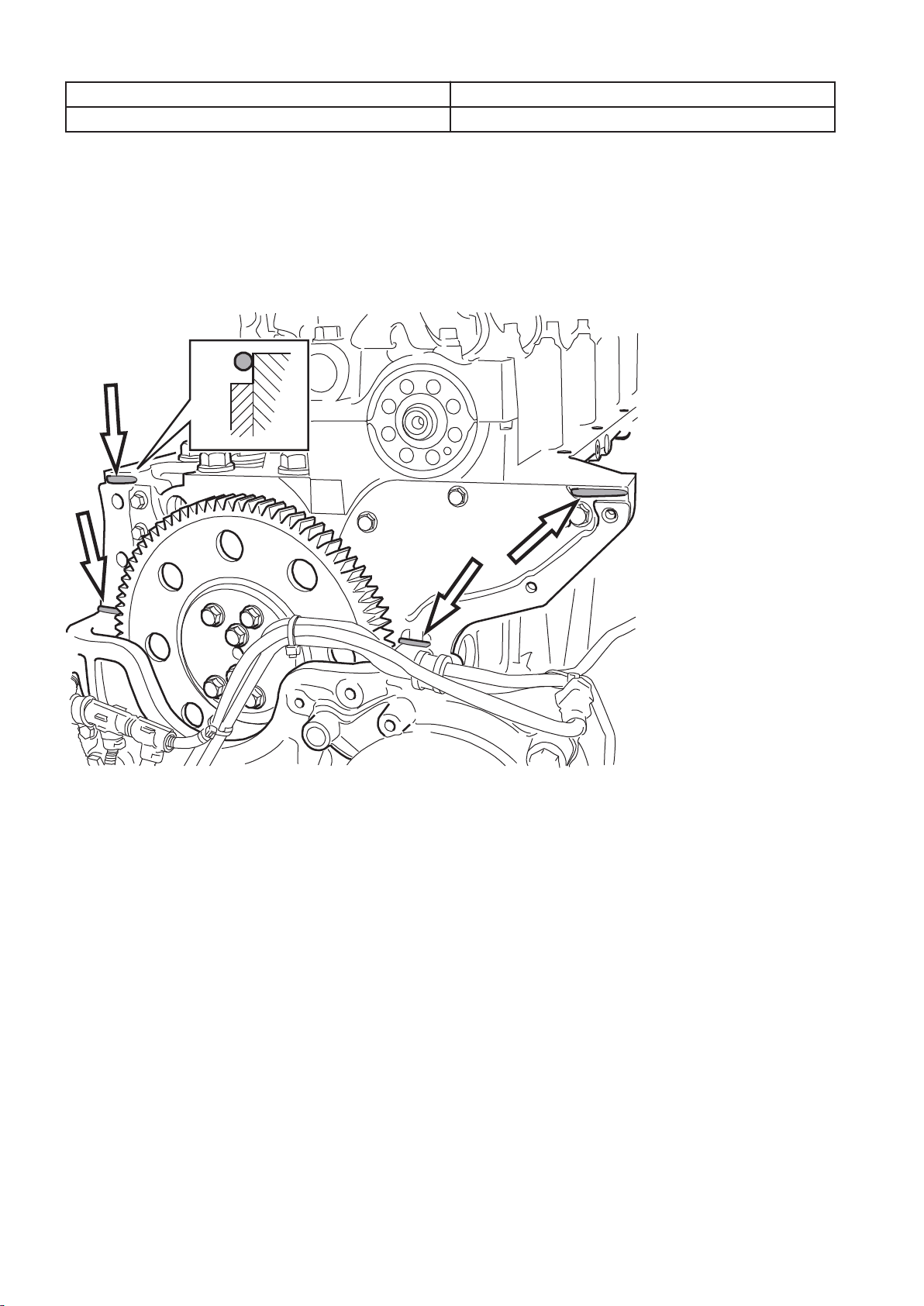

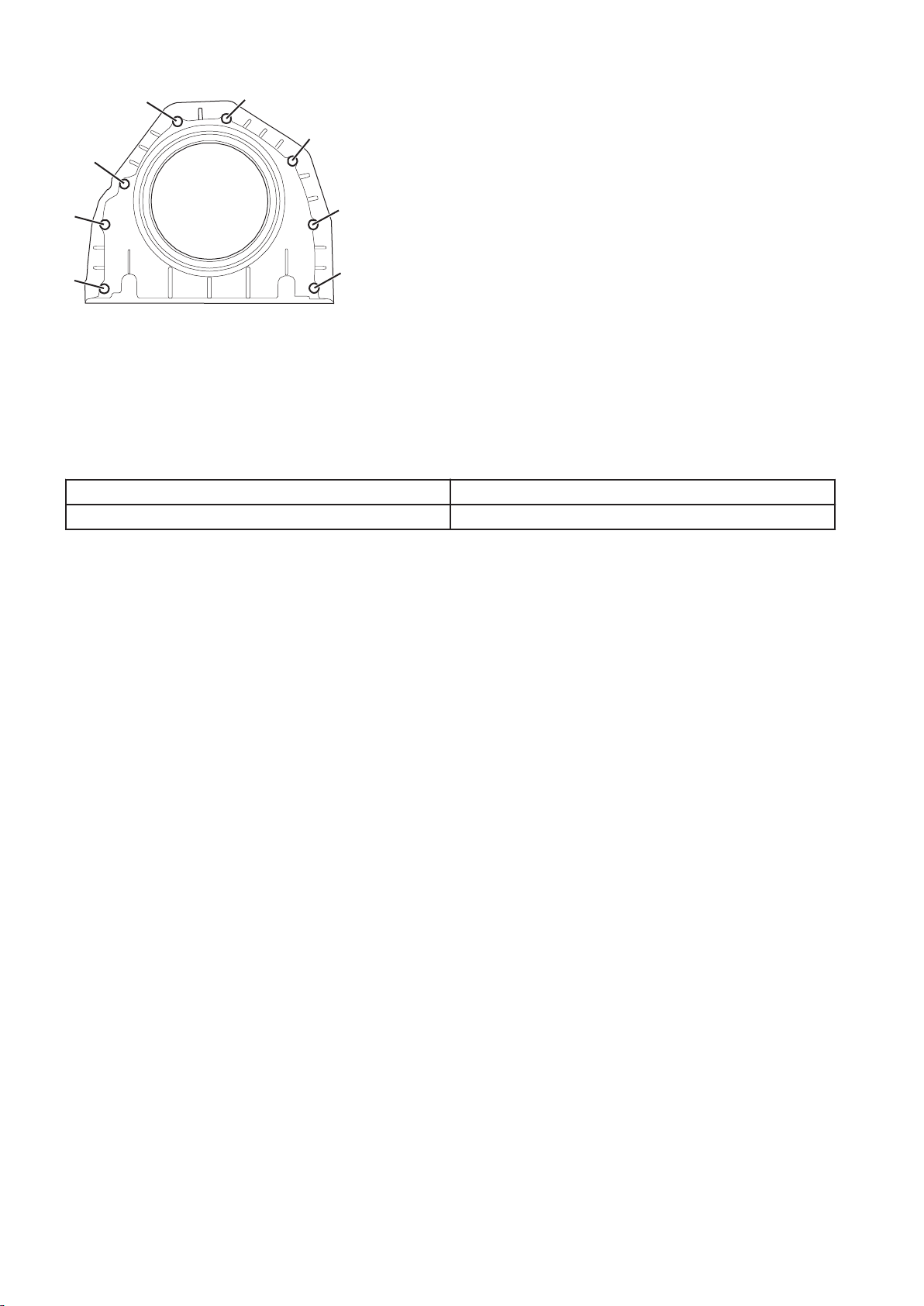

Timing gear casing

Apply a

2 mm (0.08 in) thick bead of sealant (part no. 11713514)

as shown in the figures on the timing gear casing's contact face

against the cylinder head. Install the rubber seals.

NOTE!

The timing gear casing must be installed and torque-tightened

within 20 minutes of applying the sealant.

Fig.3

9

Page 10

V1088411

Fig.4

V1088408

Fig.5 Tightening torques, upper timing gear casing

Timing gear casing (upper)

Step 1: Fasten the casing with the bolts 1 and 2. 4±1 Nm (3±0.74 lbf ft)

Tighten the bolts in the order shown in the above

24±4 Nm (18±3 lbf ft)

figure.

10

Page 11

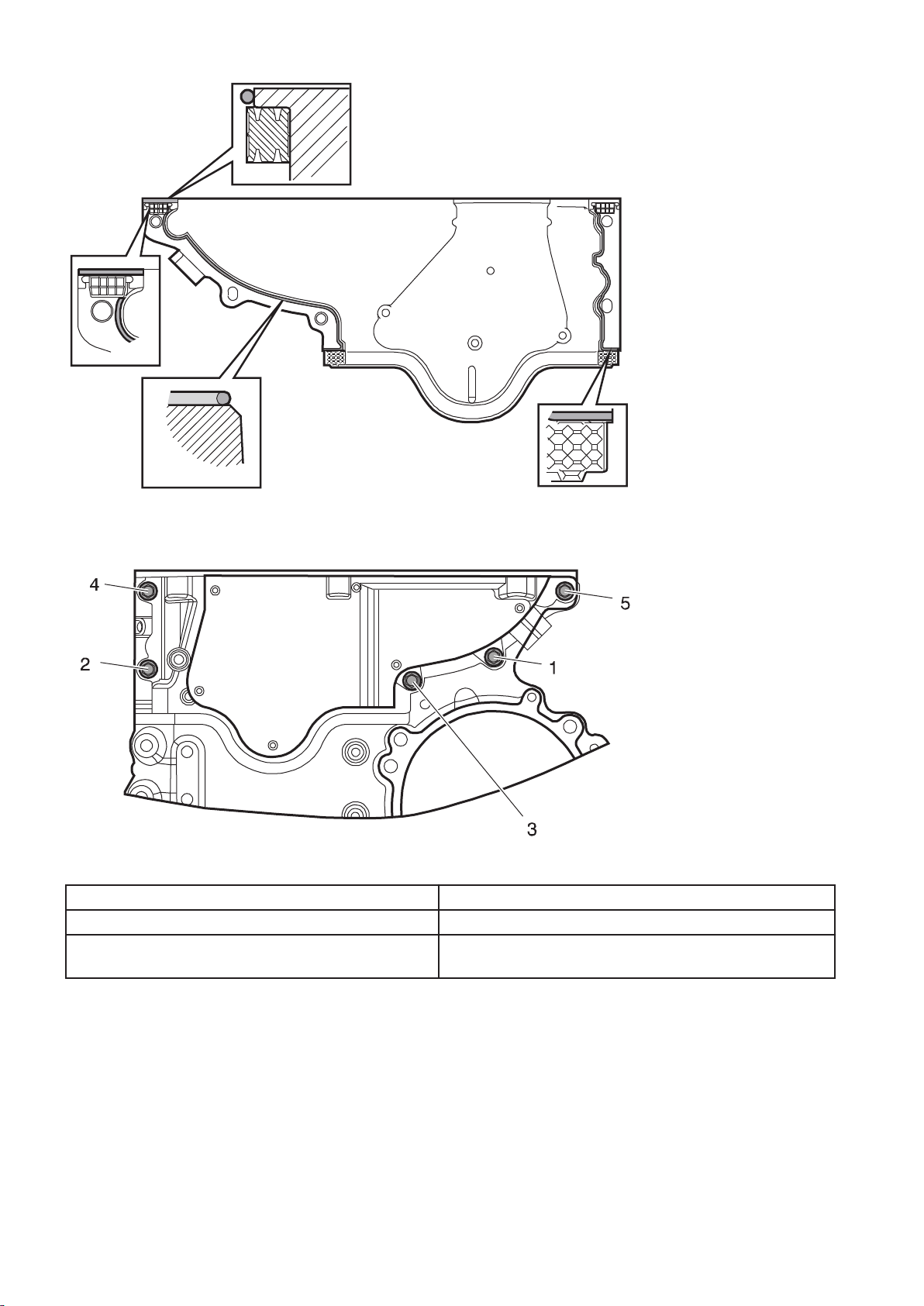

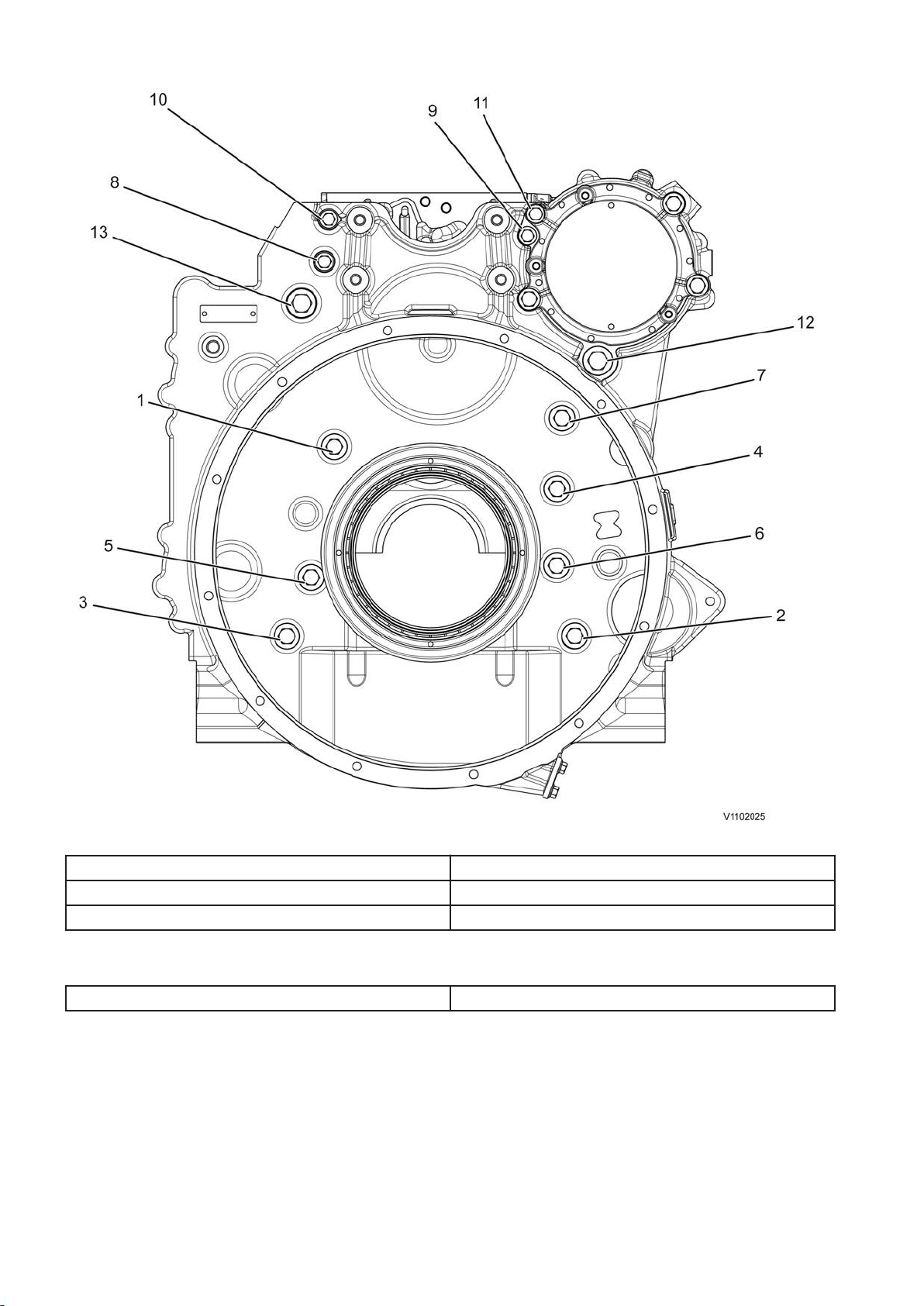

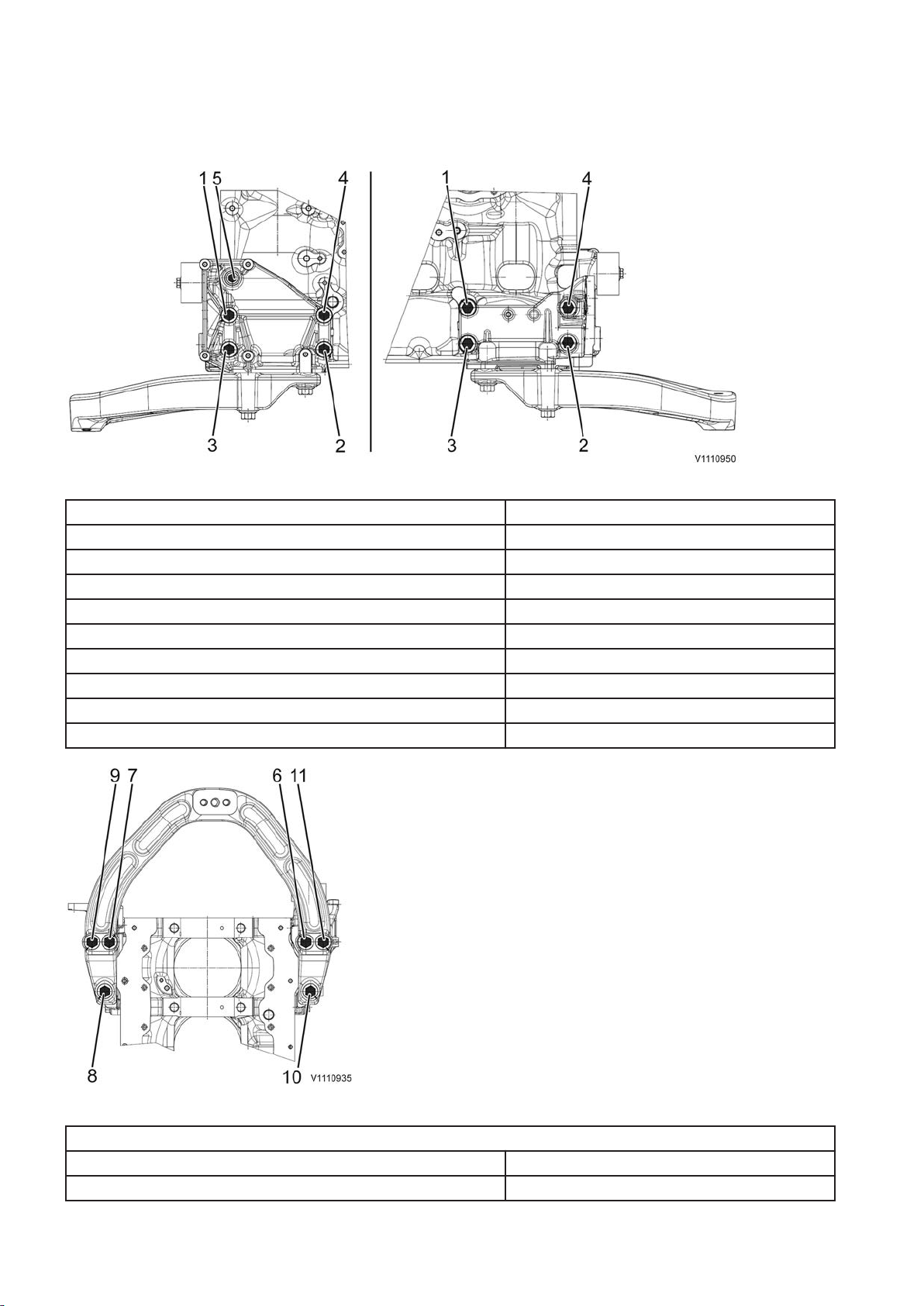

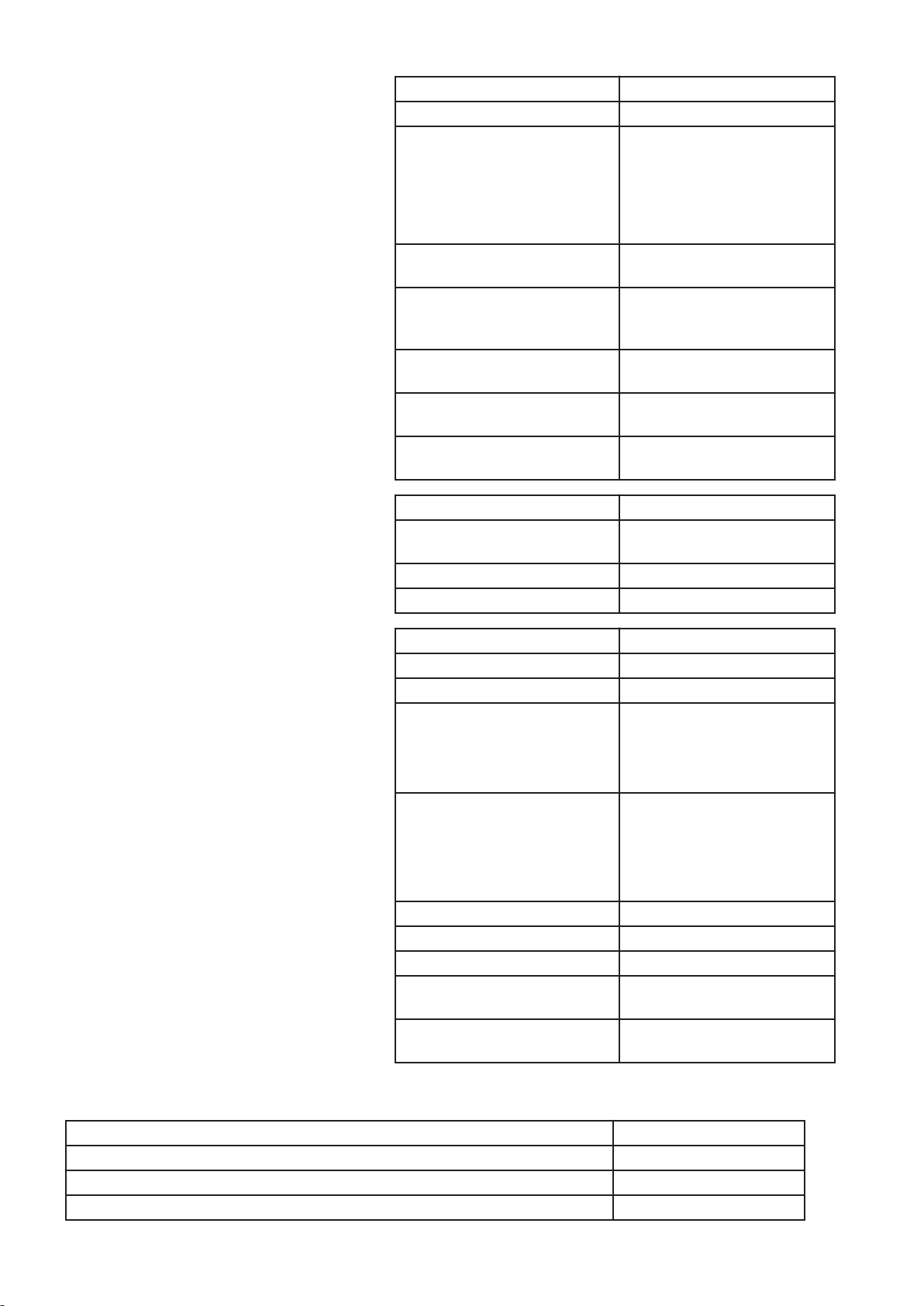

Tightening torques, flywheel housing WLO/EXC

Fig.6 Flywheel housing, WLO/EXC

M14-bolts 160 ± 10 Nm (118 ± 7.4 lbf ft)

M10-bolts 48 ±8 Nm (35.4 ±5.9 lbf ft)

M16-bolts 100±5 Nm (74±3.7 lbf ft)

Tightening torques, timing gear plate

M8-bolts 28±4 Nm (21±3 lbf ft)

11

Page 12

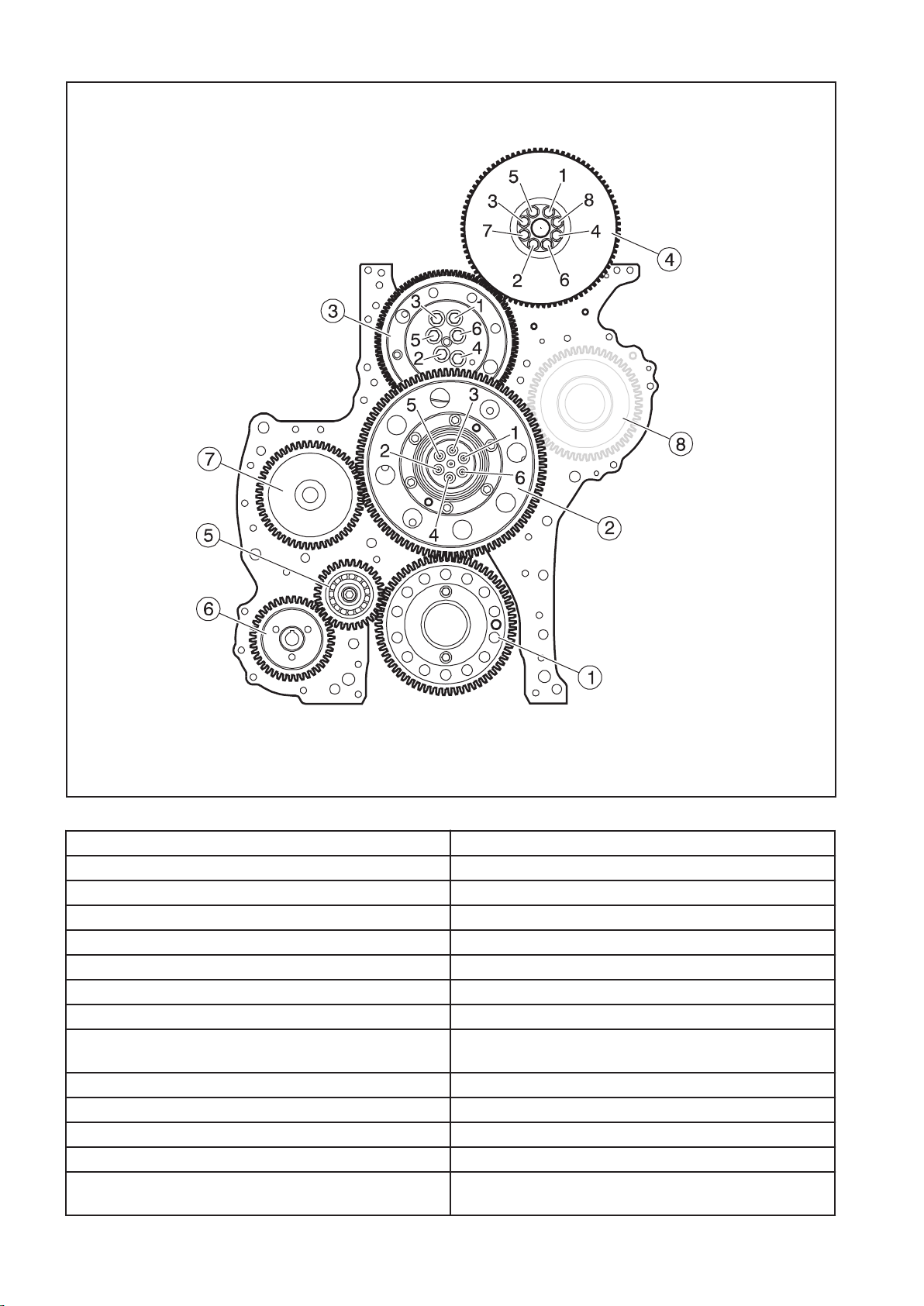

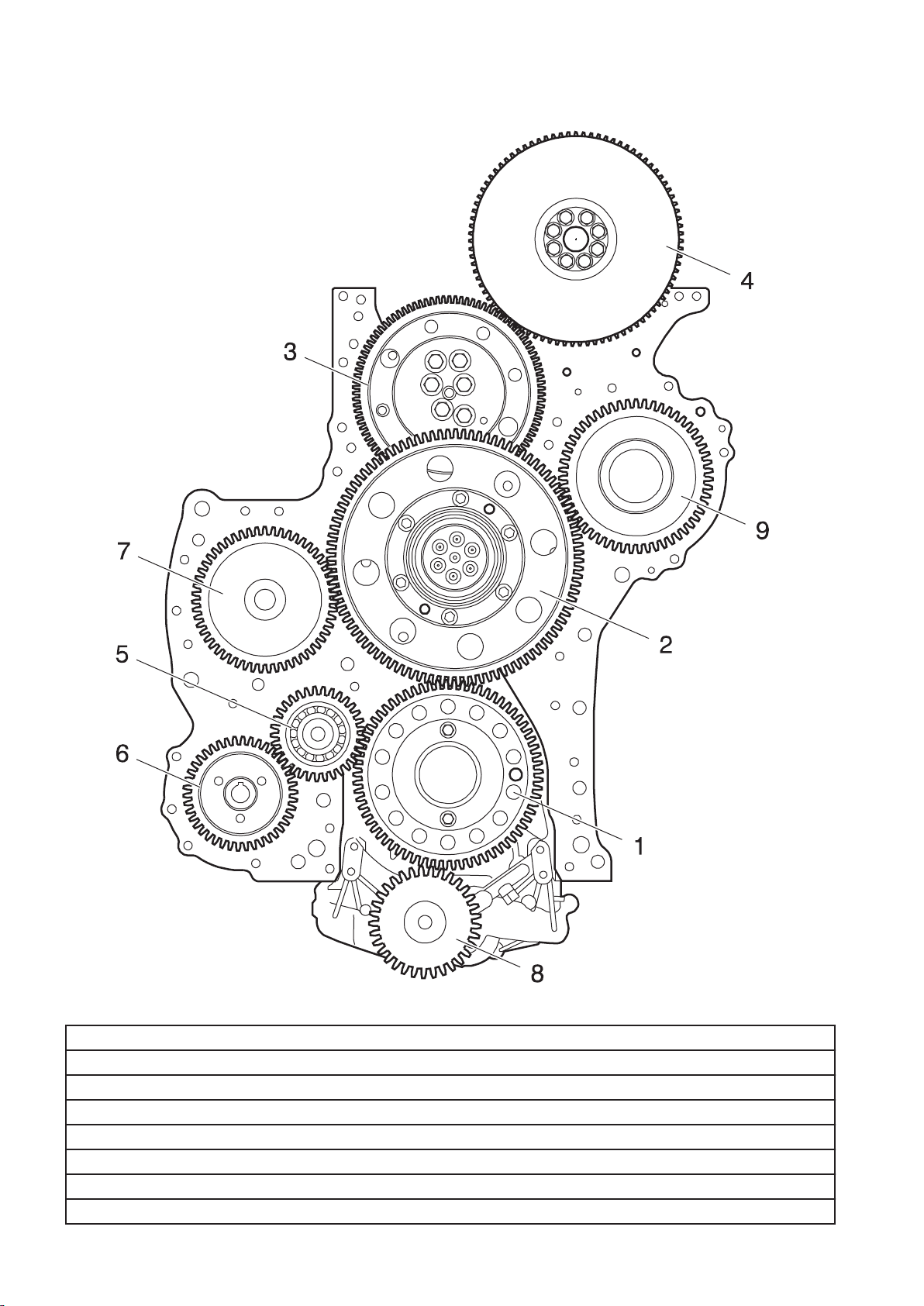

Engine transmission, specification

V1071840

Fig.7

Gears:

1. Drive gear, crankshaft

2. Transfer gears: outer and inner gear

3. Transfer gear (adjustable)

4. Drive gear and vibration damper, camshaft

5. Transfer gear

6. Drive gear, lubrication oil pump for fuel feed pump

7. Drive gear, compressor

12

Page 13

8. Drive gear, lubrication oil pump

V1082177

9. Not used

Gear flank clearance (backlash), adjustable transfer

0.05–0.15 mm (0.0019–0.0059 in)

gear to camshaft's drive gear

Gear flank clearance (backlash), oil pump's drive gear 0.05–0.41 mm (0.0019–0.016 in)

Gear flank clearance (backlash), other drive gears 0.05–0.20 mm (0.0019–0.0078 in)

For checking camshaft installation:

Valve lift, inlet valve, cylinder 1 at 6° after TDC 1.6 ± 0.3 mm (0.063 ± 0.012 in)

Rocker arm shaft, tightening torques

Fig.8

13

Page 14

Camshaft: (camshaft and bearing caps in place)

Fit a mandrel to the number 7 bearing bracket to protect the

guide sleeve.

Step 1: Tighten screws 1–7 25±3 Nm (18±2.2 lbf ft)

Step 2: (with shorter additional screws) Tighten screws 8–13 and

60±5 Nm (44±3.7 lbf ft)

20..... 60±5 Nm

Step 3: Angle tighten screws 1-7 90°±5°

Step 4: Remove the extra screws 8–13 and 20

Remove the mandrel from the number 7 bearing bracket.

Rocker arm shaft: (Rocker arm shaft in place)

Step 5: Tighten screws 8 - 13 and 20 in steps in the order 11,

60±5 Nm (44±3.7 lbf ft)

10, 12, 9, 13, 8, 20.

Step 6: Tighten screws 14–19 25±3 Nm (18±2.2 lbf ft)

Step 7: Angle tighten screws 14-19 120°±5°

Step 8: Untighten bolts 8–13

Step 9: Tighten screws 8-13 25±3 Nm (18±2.2 lbf ft)

Step 10: Angle tighten bolts 8 – 13 and 20 120°±5°

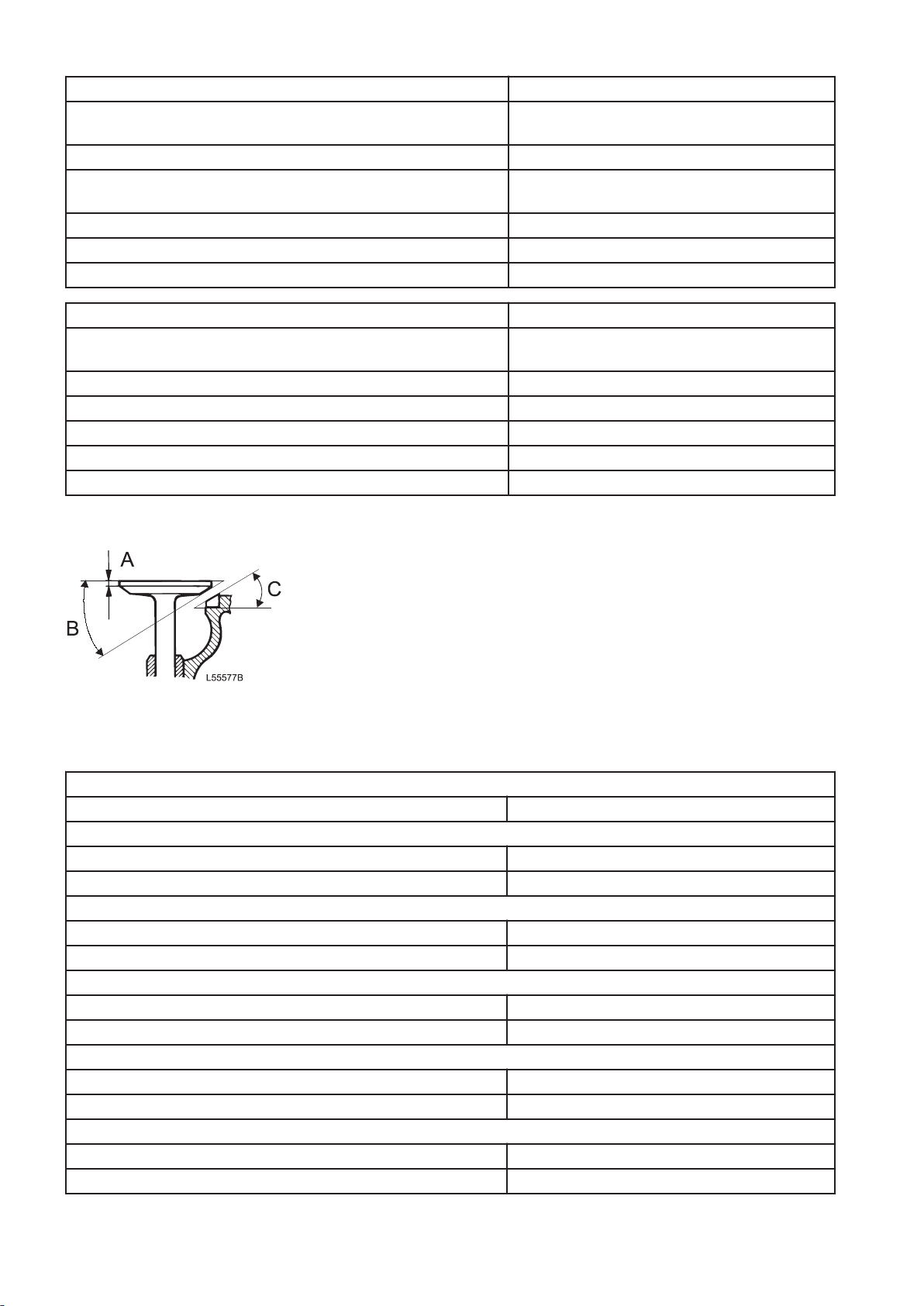

Valve mechanism, specifications

Fig.9

1 Valve disc, thickness (A)

2 Valve's seat angle (B)

3

Valve seat's angle (C)

Valves

Valve arrangement Top valves

Valve disc, diameter

Inlet 42 mm (1.65 in)

Exhaust 40 mm (1.57 in)

Valve stem, diameter

Inlet 7.968 mm (0.3137 in)

Exhaust 7.955 mm (0.3131 in)

Valve's seat angle

Inlet 24.5°

Exhaust 39.5°

Seat's angle in cylinder head

Inlet 25°

Exhaust 40°

Valve disc, thickness

Inlet 2.766 mm (0.108 in)

Exhaust 2.163 mm (0.085 in)

14

Page 15

Valve clearance, cold engine

Inlet valves, checking value 0.15 — 0.25 mm (0.0059 — 0.0098 in)

Inlet valves, setting value 0.20 mm (0.0079 in)

Exhaust valves, checking value 0.75 — 0.85 mm (0.029 — 0.033 in)

Exhaust valves, setting value 0.8 mm (0.031 in)

Brake rocker arm, checking value 2.78 – 2.92 mm (0.109 – 0.114 in)

Brake rocker arm, setting value 2.85 mm (0.112 in)

Checking value without feeler gauge on valve yoke Min. 3.20 mm (0.126 in)

Distance between valve disc and cylinder head's face:

Inlet

Max. 1.85 mm (0.072 in)

Min. 1.0 mm (0.039 in)

Exhaust

Max. 2.2 mm (0.086 in)

Min. 1.4 mm (0.055 in)

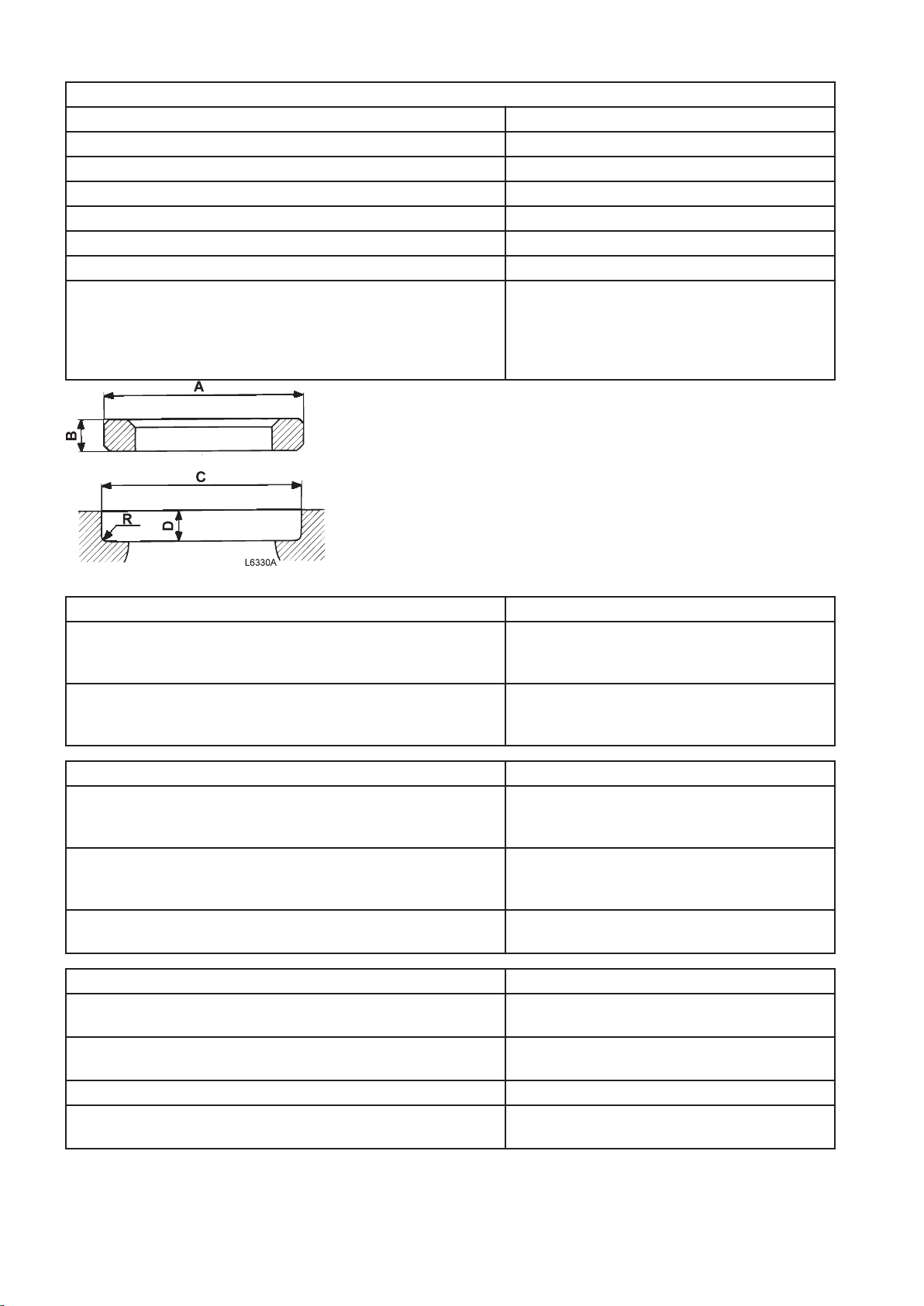

Fig.10 Valve seat and valve seat's position

Valve seats

Outside diameter (A) standard:

Inlet

Exhaust

Ø45 (+0.065+0.081) mm (1.78 in)

Ø43 (+0.07+0.086) mm (1.70 in)

Height (B):

Inlet

Exhaust

7.1 ±0.04 mm (0.279 ±0.0016 in)

7.25 ±0.025 mm (0.285 ±0.001 in)

Valve seat position

Diameter (C) standard:

Inlet

Exhaust

Ø45 H7 (0/+0.025) mm (1.77 in)

Ø43 H7 (0/+0.025) mm (1.69 in)

Depth (D):

Inlet

Exhaust

11.8 ±0.13 mm (0.46 ±0.005 in)

11.2 ±0.13 mm (0.44 ±0.005 in)

Seat's bottom radius (R):

Inlet/exhaust max. 0.8 mm (0.031 in)

Valve guides

Diameter:

Inlet/exhaust Ø8 0/+0.015 mm (0.31 in)

Height above cylinder head's spring face:

Inlet/exhaust 24.5 ±0.2 mm (0.96 ±0.008 in)

Wear value

Clearance, valve stem - guide

Inlet/exhaust max. 0.7 mm (0.028 in)

15

Page 16

Valve spring

10 1 15 1612 1113

14

6 2 38 79 4

5

19

20

18

17

V1083869

V1063169

16 15 14 13 17 6 71 8

12 11 10 9 18 3 42 5

Inlet

Length, unloaded 73.8 mm (2.90 in)

Exhaust

Outer valve spring:

Length, unloaded 73.8 mm (2.90 in)

Valve mechanism, tightening torques

Tightening torques

Lock nut, inlet valves 38 ± 4 Nm (28 ± 2.9 lbf ft)

Lock nut, floating valve bridge (exhaust) 38 ± 4 Nm (28 ± 2.9 lbf ft)

Lock nut, brake rocker arm 38 ± 4 Nm (28 ± 2.9 lbf ft)

Spring plate (tab) 25±3 Nm (18.5± 2.2 lbf ft)

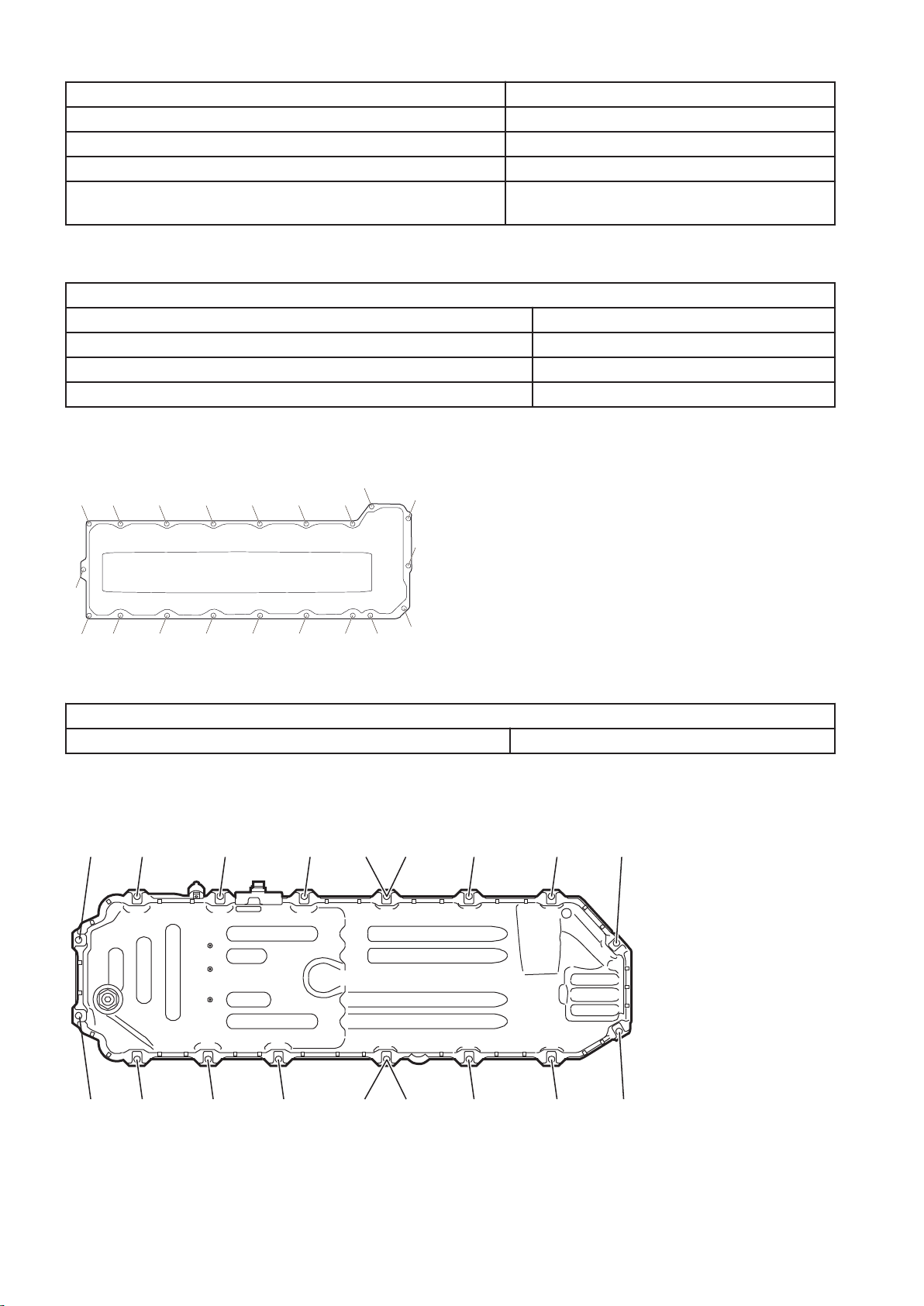

Tightening torques, valve cover

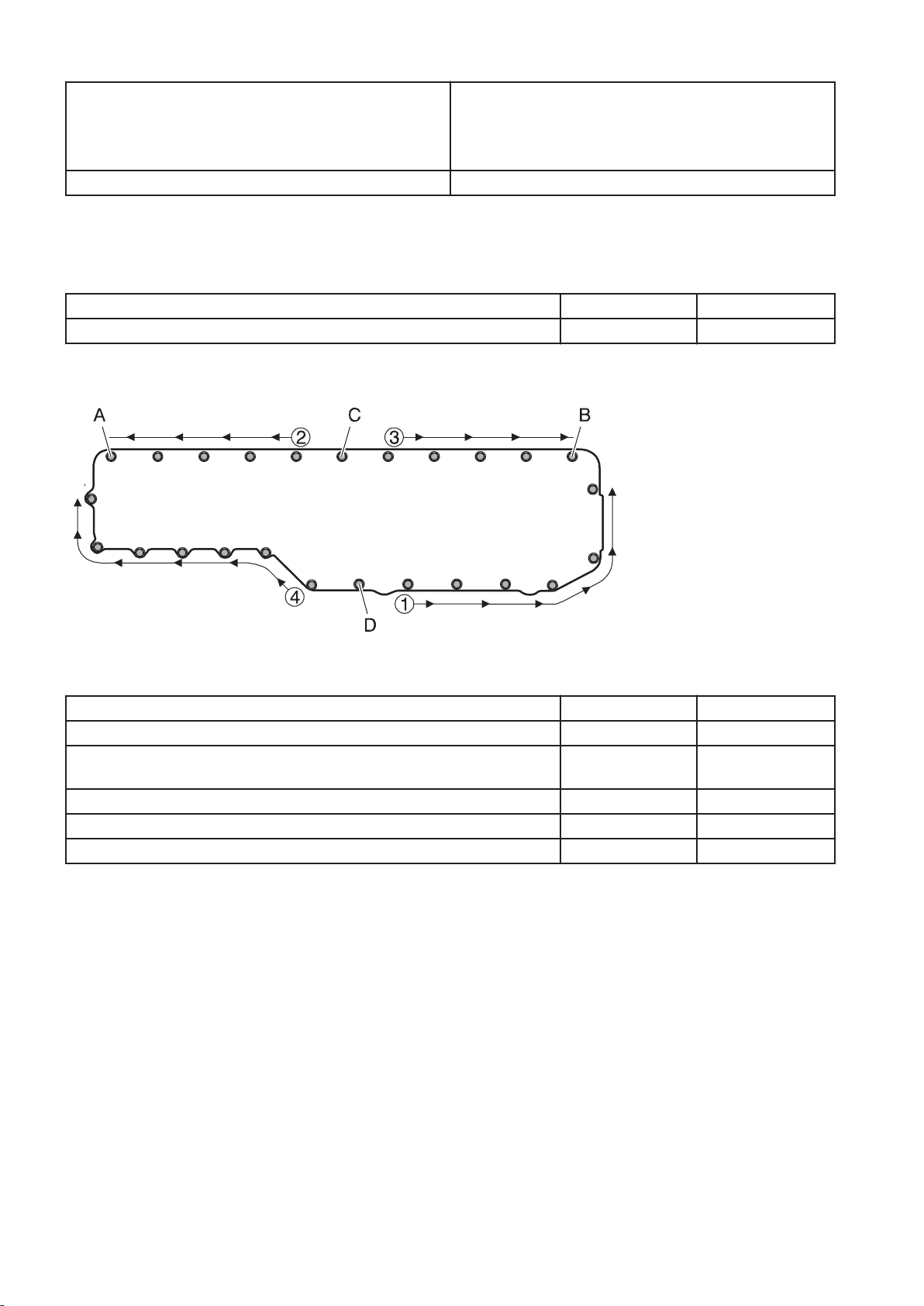

Fig.11 Figure 1 Tightening diagram, valve cover

Valve cover

Valve cover, screws 25 ± 3 Nm (18 ± 2 lbf ft)

Oil sump, tightening torque

Oil sump, tightening diagram

Fig.12 The illustration shows the oil sump for engine D13H, there may be some differences.

16

Page 17

Oil sump

V1089423

NOTE!

Tighten the bolts in the numerical order shown in the

figure.

Drain plug, oil sump 52±8 Nm (38±6 lbf ft)

24±4 Nm (18±3 lbf ft)

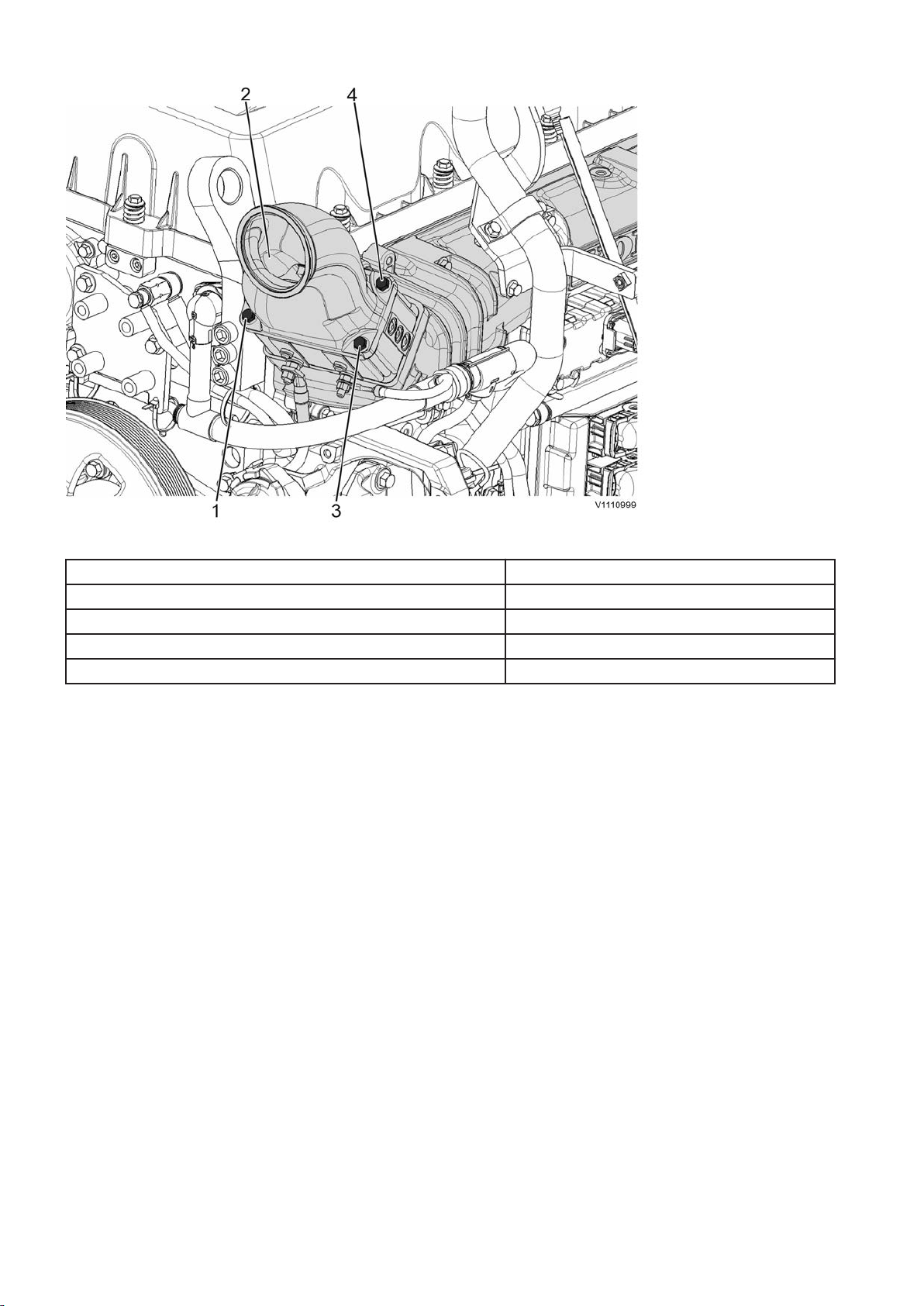

Oil cooler, tightening torques

Oil cooler

Oil cooler, attaching bolts Nm lbf ft

Tighten the bolts crosswise 27 ±4 19,9 ±2,95

Oil cooler, cover

Fig.13

Oil cooler, cover: Nm lbf ft

Install the cover on the engine block and fit bolt A in the oval hole

Press the cover against the coolant pump housing with the special tool

and install bolt B

Install bolts C and D and tighten them 24 ±4 17.7 ±2.95

Tighten the cover's bolts in order, according to diagram 24 ±4 17.7 ±2.95

Finish by tightening bolts C and D again 24 ±4 17.7 ±2.95

17

Page 18

Cylinder block, tightening torques

Engine mount incl. bracket

Fig.14 Front engine mount bracket

Front engine mount bracket, cylinder block:

Step 1: Tighten bolt 1. 80 ±15 Nm (59 ±11 lbf ft)

Step 2: Tighten bolts 2 — 4. 105±15 Nm (77.4±11 lbf ft)

Step 3: Angle-tighten bolts 2 — 4 in numerical order 60 ±5°

Step 4: Tighten bolt 1 105±15 Nm (77.4±11 lbf ft)

Step 5: Angle-tighten bolt 1 60 ±5°

Step 6: Tighten bolt 5 Standard bolt tightening torque

Front engine mount to frame 140±25 Nm (103.3±18.4 lbf ft)

Rear engine mount, flywheel housing:

EXC 262±26 Nm (193.2±19 lbf ft)

Fig.15 Front engine mount

Front engine mount to engine mount bracket

Step 1: Tighten bolts 6 – 11 5 ±2 Nm (3.7 ±1.5 lbf ft)

Step 1: Tighten bolts 6 – 11 275 ±45 Nm (203 ±33 lbf ft)

18

Page 19

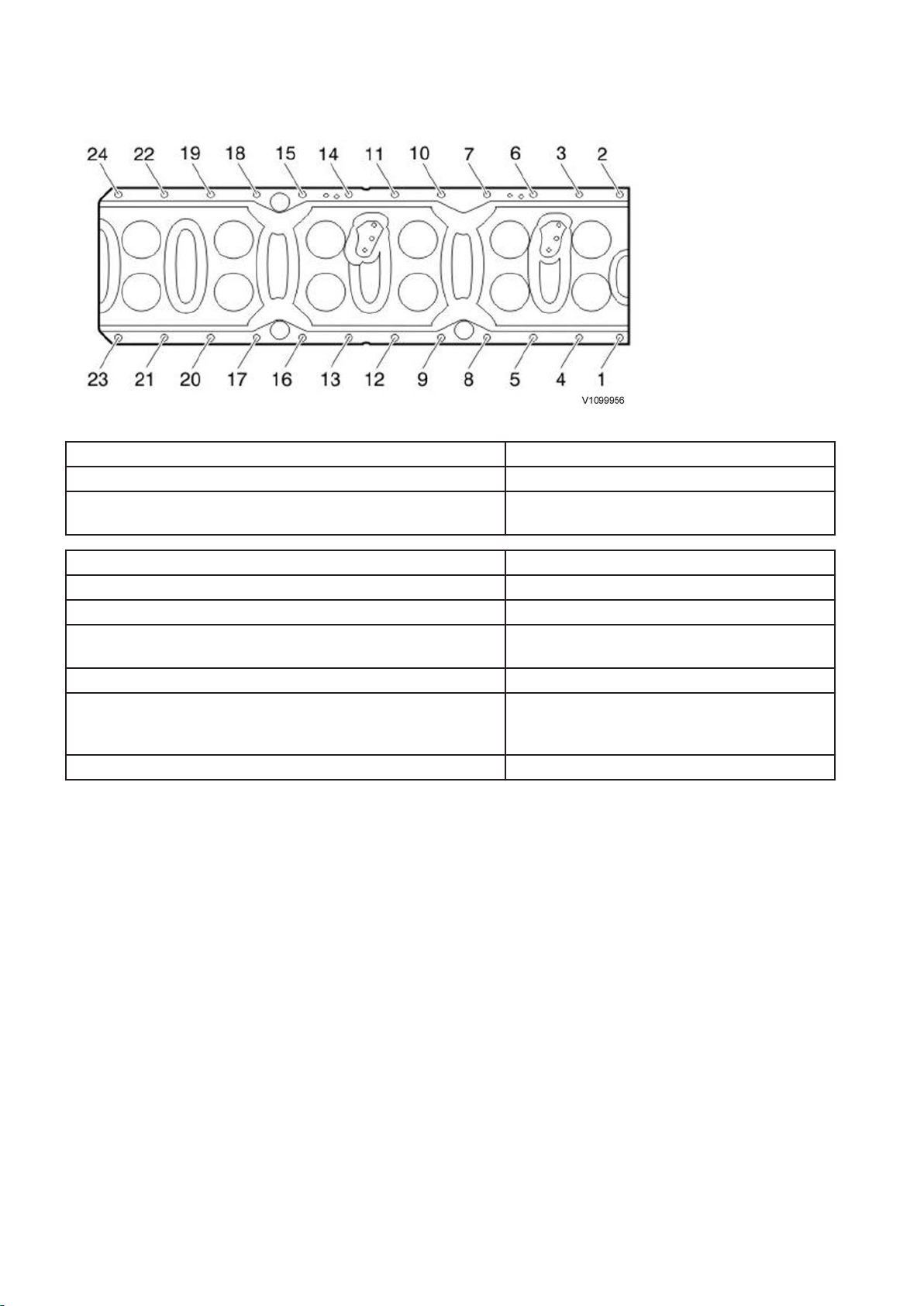

Ladder frame

Fig.16 Ladder frame

Ladder frame

Step 1: Tighten bolts 1 — 24 in numerical order 45±5 Nm (33.19±3.69 lbf ft)

Step 2: Tighten bolts in numerical order 1 — 24 (angletightening)

60 ±5°

Timing gear plate:

M8-bolts 28±4 Nm (20.7±2.95 lbf ft)

Main bearing caps:

Step 1

Step 2 (angle-tightening)

Connecting rod (big-end) caps:

Step 1

Step 2

Step 3 (angle-tightening)

Press tool for measuring liner height 40 Nm (29.5 ft lbf)

150±20 Nm (110.6±14.8 lbf ft)

120 ±5°

20±3 Nm (14.8±2.2 lbf ft)

60±3 Nm (44.3±2.2 lbf ft)

90 ±5°

Inlet

NOTE!

Tighten the bolts according to the numerical order in the figure.

The bolts shall not be reused.

19

Page 20

Fig.17 WLO, EXC: Mixing chamber, preheater

Inlet pipe

Mixing chamber, preheater:

Step 1 10±2 Nm (7.38±1.48 lbf ft)

Step 2 24±3 Nm (17.7±2.21 lbf ft)

Plug, M10 (inlet pipe) 20±3 Nm (14.8±2.2 lbf ft)

NOTE!

Torque-tighten the bolts diagonally as shown in the figure.

20

Page 21

Tightening torque, fuel system

1

3 5 7 9

11

12

108

2

4

6

V1100866

Bolt, fastener yoke, unit injectors. Copper sleeve Steel sleeve

step 1 25 +5/-0 Nm (18.4 +3.7/-0 lbf ft) 20 Nm +5/-0 (14.8 +3.7/-0 lbf ft)

step 2 90° ±5° 90° ±5°

New sleeve or new cylinder head

Bolt, fastener yoke, unit injectors Copper sleeve Steel sleeve

step 1 30 +5/-0 Nm (22 +3.7/-0 lbf ft) 20 +5/-0 Nm (14.8 +3.7/-0 lbf ft)

step 2 150° ±5° 180° ±5°

Step 3: Loose the yoke's bolt until the torqueis10–15 Nm (7.4–11 lbf ft) 10–15 Nm (7.4–11 lbf ft)

step 4 25 +5/-0 Nm (18.4 +3.7/-0 lbf ft) 20 +5/-0 Nm (14.8 +3.7/-0 lbf ft)

step 5 90° ±5° 90° ±5°

Lock nut for adjusting screw, unit injectors 52 ±4 Nm (38.4 ±lbf ft)

Banjo screw, fuel hose

M10 18 ±3 Nm (13.3 ±2.2 lbf ft)

M12 26 ±4 Nm (19.2 ±2.9 lbf ft)

M14 38 ±6 Nm (28 ±4.4 lbf ft)

M16 48 ±8 Nm (35.4 ±6 lbf ft)

Fuel pump (mounted on oil pump) 8 +2/–0 Nm (5.9 +1.5/-0 lbf ft)

Oil pump 24 ±2 Nm (17.7 ±1.5 lbf ft)

Unit injectors, preload Tighten the adjusting screw to zero clearance against the camshaft,

then turn it 240° ±20°

Exhaust manifold, tightening torques

Fig.18

Step 1:

Tighten bolts 1, 4, and 5, 8, and 9, 12 to contact 10±1.5 Nm (7.4±1.1 lbf ft)

Step 2:

Tighten bolts 3 and 2 48±8 Nm (35.4±5.9 lbf ft)

Tighten bolts 7 and 6 48±8 Nm (35.4±5.9 lbf ft)

Tighten bolts 11 and 10 48±8 Nm (35.4±5.9 lbf ft)

Tighten bolts 1 and 4 48±8 Nm (35.4±5.9 lbf ft)

Tighten bolts 5 and 8 48±8 Nm (35.4±5.9 lbf ft)

Tighten bolts 9 and 12. 48±8 Nm (35.4±5.9 lbf ft)

Turbocharger, tightening torques

21

Page 22

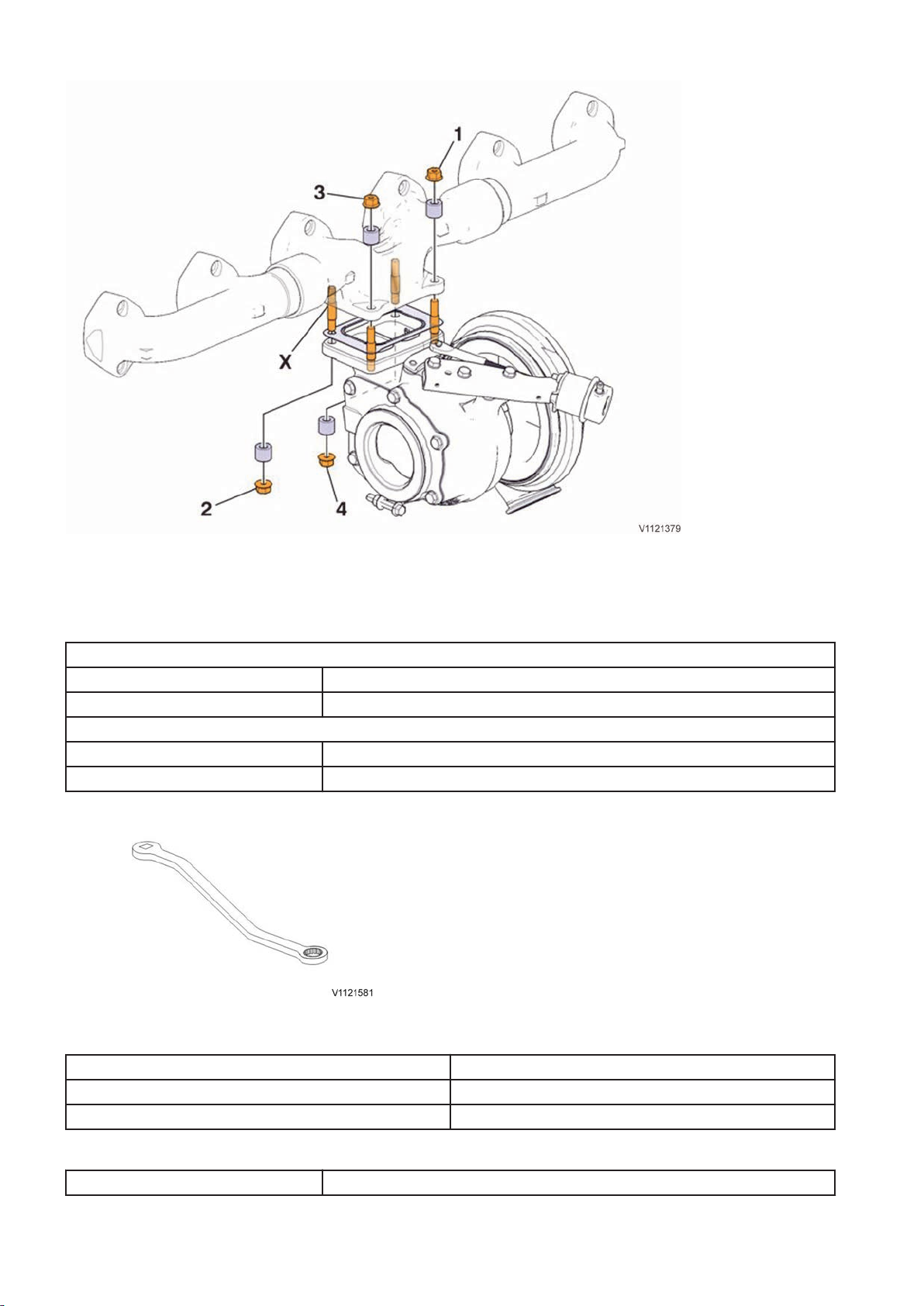

Fig.19 Bolts for installing the turbocharger to the exhaust manifold.

NOTE!

Torque-tighten bolts diagonally as shown in the figure.

Table. Against exhaust manifold

Position 1 and 3

step 1 20 ±4 Nm (14.8 ±3 lbf ft)

step 2 48 ±8 Nm (35.4 ±6 lbf ft)

Position 2 and 4 — using the tool 88830179 Wrench

step 1 16,8 Nm (12.2 lbf ft)

step 2 40,2 Nm (29.6 lbf ft)

Fig.20 88830179 Wrench, for position 2 and 4

Table. Connections for coolant and lubrication oil

Tightening torques, turbo

Coolant lines 38±6 Nm (28±4.4 lbf ft)

Oil lines 48±5 Nm (35.5±3.7 lbf ft)

Table. Charge-air cooler pipe

Clamps 8,5±0,8 Nm (6.3±0.6 lbf ft)

22

Page 23

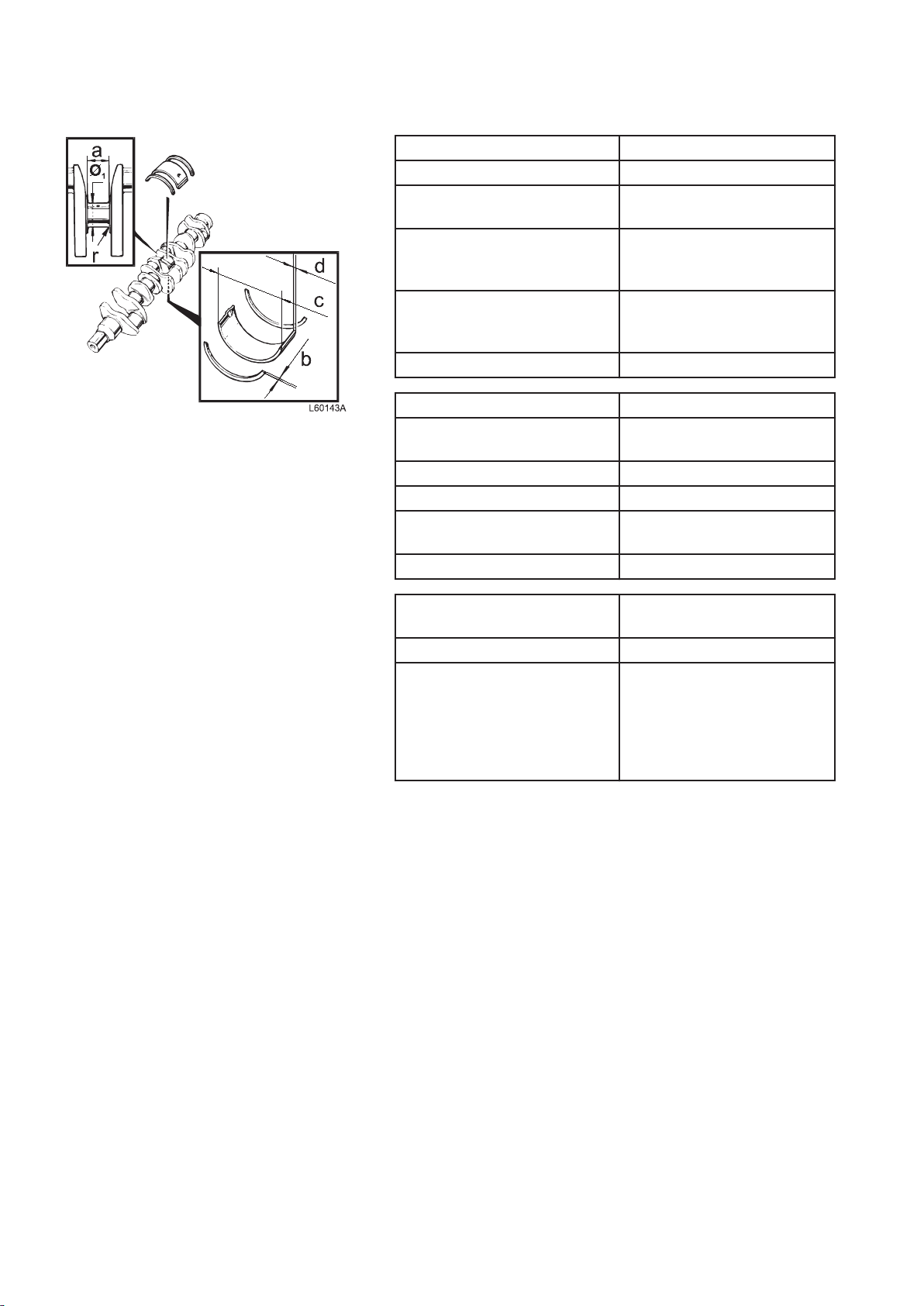

Fig.21

Crank mechanism, specifications

Crankshaft

Length 1 153.8 mm (45.4 in)

Crankshaft, max. axial

clearance

Max. permitted ovality of main

bearing and big-end bearing

pins

Max. permitted conicity of main

bearing and big-end bearing

pins

Max. run-out of middle bearing 0.15 mm (0.0059 in)

Main bearing pin

Diameter (Ø) for reworking,

standard

surface finish, main bearing pin Ra 0.25 mm (0.00098 in)

surface finish, radius Ra 0.4 mm (0.00044 in)

Width, thrust bearing pin (a),

standard

Fillet radius (r) 4.0 mm (0.157 in)

0.4 mm (0.016 in)

0.006 mm (0.00024 in)

< 0.02 mm (< 0.0008 in)

108.0 mm (4.25 in)

47.0 mm (1.85 in)

Thrust washers (thrust

bearings)

Width (b), standard 3.18 mm (0.125 in)

Oversize:

0.1 mm (0.0039 in) 3.28 mm (0.129 in)

0.2 mm (0.0079 in) 3.38 mm (0.133 in)

0.3 mm (0.0118 in) 3.48 mm (0.137 in)

0.4 mm (0.0157 in) 3.58 mm (0.141 in)

23

Page 24

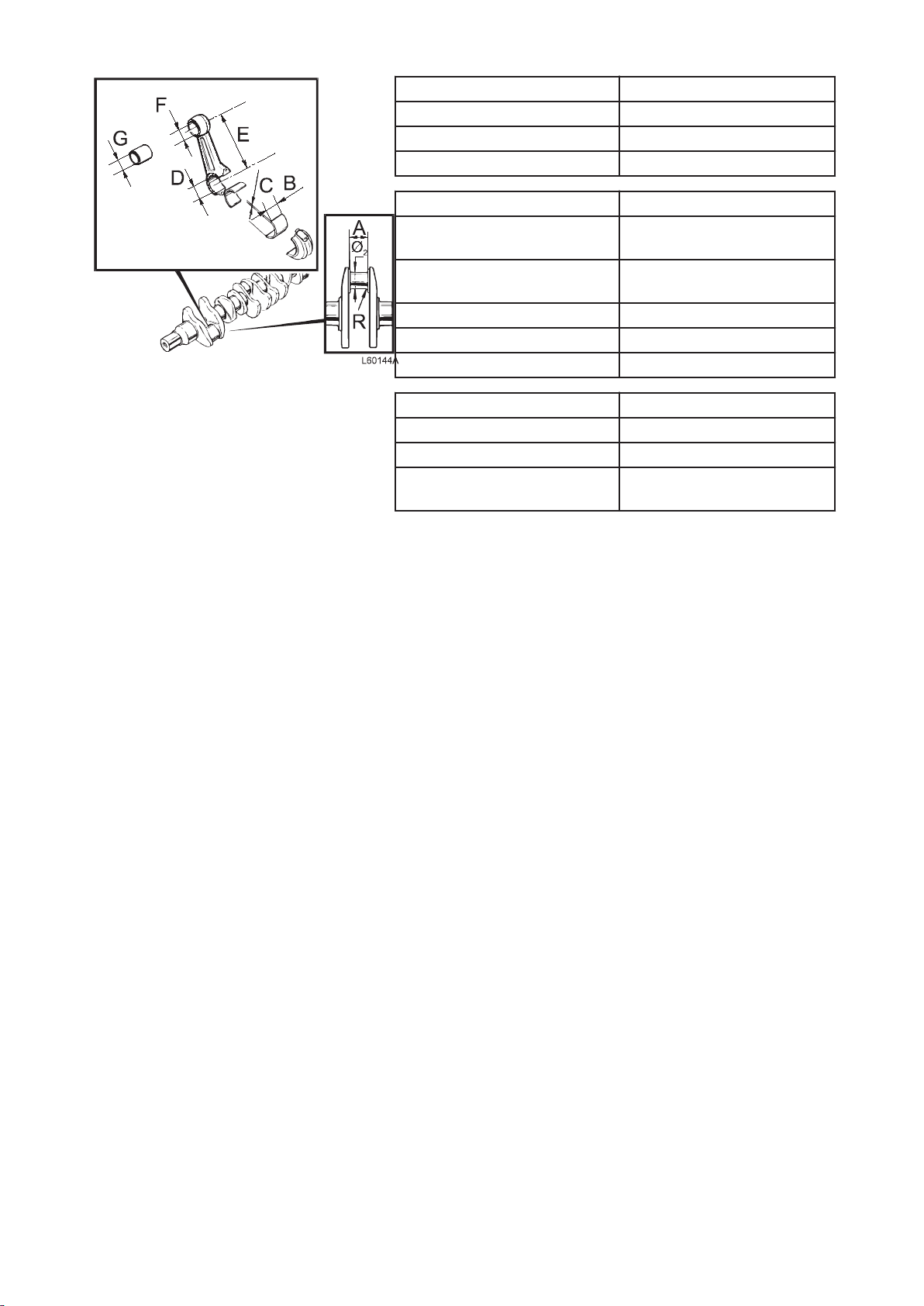

Fig.22

Main bearing shells

Type Replaceable

Outer diameter (c) 113.065 mm (4.451 in)

Thickness (d), standard 2.485 mm (0.098 in)

Crankshaft bearing pins

Diameter (Ø) for reworking,

99 mm (3.897 in)

standard

Surface finish, crankshaft

Ra 0.25

bearing pin

Surface finish, radius Ra 0.4

Width (A) 57 mm (2.244 in)

Fillet radius (r) 4.0 mm (0.157 in)

Connecting rods' bearing shells

Outer diameter (B) 103.85 mm (4.088 in)

Thickness (C), standard 2.389 mm (0.094 in)

Diameter, bearing shell's

103.835 mm (4.088 in)

bearing seat (D)

24

Page 25

Connecting rod

Length, centre – centre (E) 267.5 mm (10.53 in)

Marking:

"FRONT" on

to face the front.

Connecting rods and caps are

pair-marked with a three-digit

running number.

Connecting rod bushing's

internal diameter (G)

Axial clearance, connecting rod

– crankshaft, with marking

directly opposite each other

Big-end bearing, radial

clearance, oiled part

Straightness (max.) deviation

per 100 mm measured length

Twisting (max.) deviation per

100 mm measured length

Piston

Height above cylinder block

face

Number of ring grooves 3

Front marking Arrow facing forward

rod shall be turned

58 mm (2.283 in)

< 0.35 mm (<0.014 in)

< 0.10 mm (0.0039 in)

0.06 mm (0.0024 in)

0.15 mm (0.0059 in)

0.15–0.21 mm (0.006– 0.008

in)

Piston rings

Compression rings

Quantity 2

Piston ring clearance in groove:

upper compression ring Trapezius-shaped profile

lower compression ring 0.09–0.14 mm (0.003– 0.005

in)

Piston ring gap in ring opening:

upper compression ring 0.40–0.55 mm (0.0157–

0.0216 in)

lower compression ring 1.30–1.50 mm (0.051– 0.059

in)

Oil scraper ring

Quantity 1

Width incl. spring 3.41 mm (0.134 in)

Piston ring clearance in groove 0.05–0.10 mm (0.019– 0.039

in)

Piston ring gap in ring opening 0.30–0.55 mm (0.011– 0.021

in)

Crankshaft, tightening torques

Cover, crankshaft seal

Step 1: Fasten the cover with the bolts 2 and 7 and tighten to contact.

Step 2: Tighten bolts 2 and 7 24±4 Nm (17.7±2.95 lbf ft)

Step 3: Tighten the bolts in numerical order 1, 3 — 6, 8 as shown in the figure. 24±4 Nm (17.7±2.95 lbf ft)

25

Page 26

V1048013

1

2

3

4

5

6

7

8

Fig.23

Flywheel, tightening torques

NOTE!

The bolts

Tighten the bolts in the order shown in the following figure. All

bolts are tightened in two steps:

Step 1 60±5 Nm (44±3.7 lbf ft)

Step 2, angle-tightening 120°±10°

may only be reused twice, then new bolts shall be used.

26

Page 27

Fig.24 Flywheel

Belt pulley/vibration damper, tightening torques

Fig.25 Belt pullet/vibration damper

Vibration damper and belt pulley

Step 1, according to numerical order in figure: 35±5 Nm (25.8±3.7 lbf ft)

Step 2, according to numerical order in figure: 90±10 Nm (66.4±7.4 lbf ft)

27

Page 28

ENGINE WITH MOUNTING AND EQUIPMENT

21 ENGINE

210 General, common info about 211 218

Engine, mounting in work stand

Op. no. 210-081

Tools:

9986485 Support

88800345 Fixture

88800123 Fixture

Lifting eye, 2 pcs.

Sling 3 m (118 in)

Ratchet block 1,500 kg (3307 lbs)

NOTE!

Since the engine illustrations in the service publications are

reused for different engine versions, some parts may vary from

the version

illustrations is always correct.

in question. However, the essential information in the

Engine D13F, weight:

WLO approx. 1,330 kg (3,932 lbs)

EXC approx. 1,330 kg (3,932 lbs)

1 Unplug the sensors and the cable harness. Unplug the

connectors from the E-ECU. Remove the cable channel.

28

Page 29

V1044013

1

2

3

4

5

6

7

8

10

11

9

Fig.26 Sensor, control system

1 Sensor for coolant level, SE2603

Sensor for coolant temperature, SE2606

2

3 E-ECU

4 Cable channel

5 Camshaft sensor, engine position, SE2703

6 Sensor for boost pressure/charge-air temperature, SE2507/SE2508

7 Sensor for air pressure/air temperature, SE2501/SE2502

8 Speed (rpm) sensor, flywheel, SE2701

9 Sensor for oil pressure, SE2203

10 Sensor for oil level/oil temperature, SE2205/SE2202

11 Sensor for crankcase pressure, SE2509

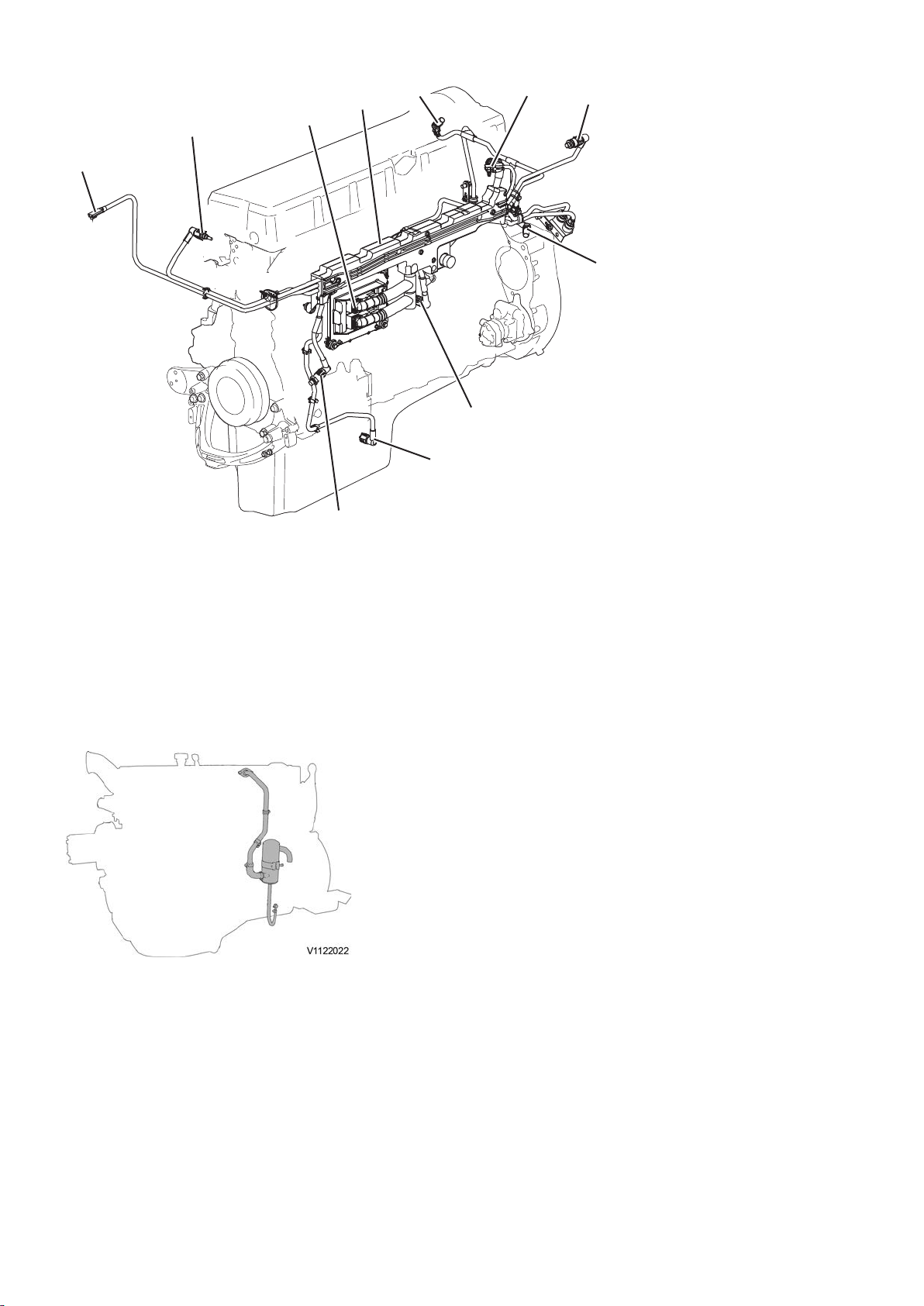

2 Disconnect the oil trap hose from the oil sump. Disconnect

the oil trap pipe from the valve cover. Remove the oil trap,

pipe and hose.

Fig.27 Oil trap with hose and pipe

NOTE!

Collet the waste oil in a suitable container.

29

Page 30

1

2

3

V1045797

Fig.28 Fuel lines

V1111475

1

2

1 Cooling circuit, E-ECU

2 Bracket — different location for EXC

Fuel pump

3

3 Disconnect the fuel lines from the cylinder block, E-ECU,

cylinder head, and the fuel pump. Remove the bracket (for

the fuel connections, also know as fuel interface).

4 Remove the E-ECU.

Install 88800123 Fixture and 88800345 Fixture and tighten

5

with torque.

Fig.29

1 88800345 Fixture

2 88800123 Fixture

Fig.30

1 Ratchet block

2 Sling

6 Install the ratchet block and sling on the engine and connect

the engine to the lifting device.

Install the engine in 9986485 Support.

30

Page 31

Secure the engine by placing three axle stands under the

engine.

NOTE!

If the engine is heavier than the stand's weight-bearing

classification the engine must rest on three axle stands that are

placed under the engine before the lifting device is removed.

31

Page 32

Engine, dismantling

Op. no. 210-077

Tools:

11666054 Jack

88830175 Pump

9990114 Puller

88800352 Lifting tool

9990262 Adapter

9992955 Puller plate

9993590 Gear wheel

9993717 Quick nut

9993717 Quick nut

9993722 Support

9993791 Puller bolt

9996400 Impact puller

9998267 Guide

88830179 Wrench

Sling 1 m (39 in)

Feeler gauge

NOTE!

Since the engine illustrations in the service publications are

reused for different engine versions, some parts may vary from

the version

illustrations is always correct.

in question. However, the essential information in the

This operation also includes tools and times necessary for

applicable parts of the following actions:

Cylinder head, removing page 59

-

-

Valves, adjusting page 88

32

Page 33

Fig.31

1 Bolts connecting the turbo with the exhaust

manifold

2 Coolant line for turbo cooling

Coolant line

3

4 Oil pressure hose

5 Oil return hose

6 Charge-air cooler pipe

7 Clamp for charge-air cooler

1 - Remove the

clamps and hose for the charge-air cooler.

- Remove the charge-air cooler pipe.

- Remove the coolant lines for turbo cooling.

- Loosen the end of the oil pressure and return hoses at

the turbocharger.

- Loosen the rear bolts for the turbocharger.

- Connect a lifting device to the turbocharger.

- Drain the oil.

- Remove the front bolts and remove the turbocharger

with the lifting device. For WLO — remove the

turbocharger including the waste gate.

- Remove the rear bolts for the turbocharger and the

gasket.

- Remove the oil hoses.

Turbo, weight: approx. 28 kg

NOTE!

Collect the waste oil in a suitable container.

2 Remove the exhaust manifold.

3 Remove the coolant pipe between the cylinder head and the

coolant pump.

4 - Remove the lower bolt for the oil filler pipe.

- Remove the oil filler pipe.

- Remove the oil dipstick.

- Remove the inlet manifold with the preheating coil.

Fig.32 Oil filler pipe, oil dipstick, inlet manifold with

preheating coil.

5 Remove the lift plate.

6 Remove the valve cover.

33

Page 34

7 - Remove the upper timing gear casing.

- Remove the vibration damper and the camshaft gear.

Fig.33

1 Upper timing gear casing

2 Vibration damper

Camshaft gear

3

Remove the cylinder head according to

8

removing page 59

.

Cylinder head,

9 Remove the oil filters and the pipes for the oil filters. — only

WLO

NOTE!

Collect the waste oil in a suitable container.

10 - For EXC — remove the fan hub. For WLO — Remove

the upper belt pulley.

- Remove the lower belt pulley.

- Remove the tensioner pulleys.

- Remove the vibration damper.

11 Remove the coolant pump.

Fig.34

1 Coolant pump

2 EXC: Fan hub / WLO: Upper belt pulley

3

Tensioner pulleys

4 Vibration damper

5 Lower belt pulley

34

Page 35

Fig.35

1 Bracket for AC compressor and alternator

2 Bracket with belt tensioner

Bracket for belt tensioners

3

4 Front engine mount

12 - Remove the front engine mount.

- Remove the belt tensioners, idlers and brackets.

Remove the filter housing and the pipes.

13

Fig.36

1 Pipe

2 Filter housing

Fig.37 Fuel pump

14 Remove the fuel pump.

15 Disconnect the lubrication oil lines from the oil sump.

16 Remove the oil sump.

17 Install 9993590 Gear wheel in the flywheel housing to

prevent the crankshaft from rotating.

18 Loosen the bolts for the flywheel (12 pcs.).

35

Page 36

Fig.38

1 Sling 1 metre

2 M10 Lifting eye

19 Remove the flywheel.

Weight:

WLO approx. 40 kg (88 lbs)

EXC approx. 75 kg (165 lbs)

20 Install lifting eyes on the flywheel housing and secure it.

Loosen the bolts on the flywheel housing and then lift away

21

the flywheel housing.

Flywheel housing, weight: approx. 200 kg (441 lbs)

22 Rotate the engine 180°.

23 - Remove the strainer and the pipes for the lubrication

oil pump.

- Remove the ladder frame.

24 Rotate back the engine 180°.

Fig.39

1 Ladder frame

2 Pipes for lubrication oil pump

3

Strainer

Fig.40

1 Oil cooler

25 Remove the oil cooler.

26 Rotate the engine 180°.

27 Remove the casing with the front crankshaft seal.

28 Remove the lubrication oil pump.

29 Remove the transfer gear for the fuel pump.

30 Loosen and remove the bolts that hold the double gear (6

pcs.). Remove the double gear.

Fig.41

36

Page 37

Fig.42

1 Internal puller

31 - Remove the rest of the bolts for the crankshaft gear.

- Install an internal puller as shown in the figure.

Pull out and remove the gear.

-

32 - Install 9998267 Guide (2 pcs.) and remove the bracket

and bolts (23 pcs.) that hold the timing gear plate.

- Carefully remove the timing gear plate.

Fig.43

1 9998267 Guide.

2 Bracket

Fig.44

1 Piston cooling nozzle

33 Remove the piston cooling nozzles.

37

Page 38

V1022057

Fig.45

34 - Remove the bolts (4 pcs.), the caps, and carefully tap

loose the piston and connecting rod.

NOTE!

Avoid striking

on the connecting rod's mating surfaces.

- Repeat for the rest of the pistons and connecting rods.

35 - Remove the bolt and remove the main bearing cap.

- Repeat for the rest of the main bearing caps. Note

position of the main bearing caps for reinstalling later

on.

NOTE!

Save and keep track of the thrust bearings located on

the 4th cylinder's main bearing.

Fig.46

1 9996400 Impact puller, 9990114 Puller and

9990262 Adapter

Fig.47

36 Turn the crankshaft so that the 1st cylinder's and 6th

cylinder's bellcranks are positioned straight up. Secure with

lift slings in the lifting device and lift away the shaft.

Crankshaft, weight: approx. 125 kg (275 lbs).

Remove the main bearings.

38

Page 39

Fig.48

1 9993791 Puller bolt

2 9993717 Quick nut

11666054 Jack

3

4 88830175 Pump

5 9993722 Support (Use the long support legs)

6 9992955 Puller plate and 9993717 Quick nut

Cylinder liners, removing

37 Mark the position of the liners in the cylinder block and pull

out the cylinder liners with the tools shown in the figure.

Remove the old seals.

38

NOTE!

Work carefully so that the block is not damaged.

Thoroughly clean the grooves for the seals and the cylinder

liner's sealing faces against the cylinder block. Thoroughly

clean the sealing face on the liner shelf from rust, grease,

and deposits.

NOTE!

Do not use any scraper tools made of metal.

39 Check the rest of the engine block's seals, connections,

channels, etc. Clean, and replace any damaged parts.

39

Page 40

Engine, assembling

Op. no. 210-078

Tools:

885812 Timing tool

88800021 Installation tool

88800031 Setting tool

88800123 Fixture

88800318 Piston ring compressor

88800345 Fixture

88830179 Wrench

88880003 Bracket

9812524 Milling tool

88800352 Lifting tool

9990166 Installation tool

9992000 Handle

9992479 Retainer

9992663 Sealing plate

9992955 Puller plate

9993590 Gear wheel

9996662 Pressure gauge

9996684 Sealing plate

9996966 Press tool

9996966 Press tool

9996966 Press tool

9996966 Press tool

9996966 Press tool

9996966 Press tool

9996966 Press tool

9998143 Sealing plate

9998238 Drift

9998267 Guide

9998267 Guide

9998288 Sealing plate

9998318 Press tool

9998601 Installation tool

Sealant 1161231

Feeler gauge

Sling 1 m (39 in)

Sling 3 m (118 in)

Lifting eye 2 pcs.

Lifting eye M10, 2 pcs.

Dial indicator with magnetic stand

This operation also includes tools and times necessary for

applicable parts of the following actions:

Cylinder block, liners removed, milling of all liner

-

locations page 82

-

Cylinder head, fitting page 76

-

Oil cooler, leakage check page 91

-

Engine, removing from work stand page 56

40

Page 41

V1094730

Fig.49

Fig.50

1 9992479 Retainer

2 Dial indicator

Cylinder liners, installing

1 Check the cylinder block's liner shelves for any damage.

If the liner shelf is damaged it must be overhauled. See

Cylinder block, liners removed, milling of all liner

locations page 82

.

Install the cylinder liners without O-rings and fixate them with

9996966 Press tool.

Tightening torque press tools, see

torques page 18

.

Cylinder block, tightening

2 Install a dial indicator in 9992479 Retainer. Place the holder

with the dial indicator across the cylinder liner. Reset the dial

indicator to zero with a couple of millimetres preload against

the cylinder block's face.

3 Measure the height between the cylinder liner and the

cylinder block's face. Measure the liner's height at two

different points diagonally opposite to each other.

NOTE!

The sealing face is convex. Always measure at the highest

point on the sealing face.

Calculate the average value of both measurements.

For correct liner height over the block face, see

block, specifications page 7

.

Cylinder

If the liner's height over the block face is higher than the

stated tolerance, then the liner shelf in the cylinder block has

to be milled. Milling should take place at an authorized

workshop.

See

Cylinder block, liners removed, milling of all liner

locations page 82

.

Mark the liner's position in the cylinder block with a magic

marker, so that it ends up in the same position when

installing. Repeat the procedure for the rest of the cylinder

liners.

Fig.51

1 9992479 Retainer

2 Dial indicator

4 Remove the press tools.

Pull the cylinder liners out of the block with 9992955 Puller

plate. Place the cylinder liners in the same order that they

were installed, together with their adjusting shims.

Adjusting shims for adjusting cylinder liner height are available in

different thicknesses, see the Parts catalogue.

41

Page 42

V1022235

Fig.52

V1028446

5 Lube the seal rings with the lubricant that is supplied with the

liner kit and install them on the cylinder liner.

NOTE!

The violet seal ring shall be installed in the bottom groove.

If the cylinder liner is installed without shims, a uniform

6

sealant bead approx. 0.8 mm (0.031 in) thick shall be applied

on the underside of the cylinder liner's collar. Leave a gap

of 1-2 mm (0.039-0.079 in) in the bead. Note that when

replacing cylinder liners, use the sealant that is supplied in

the cylinder liner kit.

Fig.53 Applying sealant

Fig.54 Applying sealant when adjusting shims are

used

7 If adjusting shims are used, apply the sealant bead on the

liner shelf in the cylinder block.

NOTE!

No sealant between the adjusting shims and the cylinder

liner collar.

8 Install one of the cylinder head's bolts. Place 9992955 Puller

plate on top of the cylinder liner together with a 90 mm (3.54

in) spacer. Press down the cylinder liner with a pry bar. Install

two 9996966 Press tool to lock the cylinder liner in the

cylinder block. Repeat the procedure for the rest of the

cylinder liners.

Fig.55 Installing cylinder liner

42

Page 43

V1101075

Fig.56 Main bearing shells

V1001310

V1094739

V1022255

1

Fig.57 Crankshaft

Crankshaft, installing

9 Install and check that the main bearing shells end up in the

correct position in the engine block. Oil in the main bearing

shells and the main bearing journal with engine oil.

NOTE!

Check that each main bearing shell's pressed-out lug ends

in the correct position in the bearing position's slot. Check

up

that the upper bearing shells are provided with oil holes.

10 Check that the crankshaft is free from damage.

Carefully lift the crankshaft into place in the engine block.

Weight: approx. 125 kg (275 lbs)

NOTE!

Make sure that the crankshaft faces the right way in relation

to the block.

11 When the crankshaft is lowered against the main bearings,

check that they are still in correct position. Install the thrust

bearing washers so that the guide pin ends up in the

intended slot.

Fig.58 Thrust bearing washers

Fig.59

1 Thrust bearing washer

12 Fasten the other two thrust bearing washers with grease on

the corresponding main bearing cap. Turn the washers so

that the surfaces with oil grooves face the crankshaft's axial

bearing surfaces.

NOTE!

The thrust bearing washers are available in three different

oversizes, see

Crank mechanism, specifications page 23

NOTE!

The fixing slots mean that the thrust bearing washers can

only be installed in one position.

13 Check that the slots in the main bearings shells are located

directly opposite each other on the main bearings in the

cylinder block and bearing caps, respectively.

43

Page 44

V1001270

Fig.60

1

2

V1024326

1 Torque multiplier

14 Install the main bearing caps.

Tighten down the main bearing caps according to

block, tightening torques page 18

.

Cylinder

NOTE!

The bearing caps are marked. The arrow shall point in the

direction of the engine's inlet side.

Pistons, installing

15 Assemble the piston and connecting rod.

NOTE!

Turn the piston rings so that they face according to their

marking.

16 Rotate the engine to horizontal position. Oil in the piston.

Check that the piston rings' gap are displaced 120° in

relation to each other. Install the piston and connecting rod

with arrow and front marking facing the front, towards the

coolant pump. Use 88800318 Piston ring compressor to

guide down the piston rings in the cylinder liner.

NOTE!

9996966 Press tool shall be removed temporarily when

88800318 Piston ring compressor is used. When the piston

is in place, reinstall the press tool.

Fig.61 Marking on piston and connecting rod

Fig.62

1 88800318 Piston ring compressor

2 9996966 Press tool

44

Page 45

Fig.63 Tightening down bearing cap

V1094740

17 Install the

connecting rod (big-end) bearing caps. Check that

the connecting rod and bearing cap are marked with the

same number. Install two of the flywheel's bolts as a

counterhold when rotating the crankshaft. Rotate the

crankshaft until pistons 1 and 6 are in their bottom position.

Tighten down the bearing caps with 885812 Timing tool for

pistons 1 and 6. Repeat the procedure for the rest of the

bearing caps.

Tightening torque: see

Cylinder block, tightening

torques page 18

18 Install the piston cooling nozzles. Check that the nozzles are

directed at the pistons when they are in their bottom position.

NOTE!

Degrease the bolts and make sure that the threads and bolts

are dry before installing. Use thread locker fluid, medium

strength. Check that the nozzles are free from damage and

that the fastener plate is flat against the cylinder block after

tightening.

Fig.64

1 Piston cooling nozzle

Installing timing gear plate

NOTE!

The timing gear plate should only be installed if it is absolutely

necessary.

New cylinder block is delivered as spare part without timing gear

plate.

19 Apply a 2 mm thick bead of sealant all the way around on

the cylinder block and by the marked hole, as shown in the

figure.

NOTE!

The sealant against the cylinder head is applied later on.

NOTE!

The timing gear plate must be installed within 20 minutes

since the sealant hardens.

Fig.65

45

Page 46

Fig.66

22

21

16

20

19

23

18

17

2

10

11

12

13

14

3

4

5

6

7

8

9

15

1

V1094741

1 9998267 Guide

20 Place the

were installed earlier, 9998267 Guide.

21 Install and tighten the bolts in the correct order as shown in

the figure. Tighten the bolts according to:

timing gear plate in position using the guides that

Engine

transmission, tightening torque page 7

Fig.67

Fig.68

1 Adjustable gear

2 Double gear, cannot be overhauled

Transfer gear

3

4 Crankshaft gear

46

22 Install the O-ring on the crankshaft and lube it with lubricant.

Lube the inside of the gear with the same lubricant. Align the

gear's guide pin with the crankshaft's hole. Install the

crankshaft gear.

23 Install the adjustable gear with its slide bearing. Fasten the

bolts loosely.

24 Install the transfer gear.

Tightening torques, see

Engine transmission, tightening

torque page 7

Page 47

Fig.69

25 Install the double gear.

Use 885812 Timing tool and tighten the bolts according to

specifications.

Tightening torques, see

torque page 7

.

Engine transmission, tightening

NOTE!

Rotate the crankshaft gear so that the drilled markings

match the figure.

26 Remove the guide sleeves.

27 Rotate the engine.

Install the engine oil pump.

Fig.70

1 Engine oil pump

47

Page 48

28 Install the ladder frame and the pipes for the oil pump.

Tightening torques, see

torques page 18

.

Cylinder block, tightening

Install 885812 Timing tool and tighten the bolts according to

Cylinder block, tightening torques page 18

.

Fig.71

1 Ladder frame

2 Pipes for oil pump

29 Change O-rings and install the pipe with the strainer for the

oil pump.

30 Secure the engine by placing three axle stands under the

engine.

31 Install the cylinder head according to

fitting page 76

.

Cylinder head,

Fig.72

1 Pipe with strainer

48

Page 49

V1088409

Fig.73

1 Sealant around bolt holes

Flywheel housing

32 Remove the crankshaft seal.

Check that the housing is free from damage.

Apply a 1.6 mm (0.06 in) thick bead of sealant as shown in

the figure.

Apply sealant around the bolt holes as shown in the figure.

Install the timing gear casing using a lifting device.

the bolts and tighten down according to the diagram.

Install

Tightening torques and diagram, see

tightening torque page 7

.

Weight: 70 kg (154 lbs)

33 Apply sealant as shown in the figure.

Engine transmission,

Fig.74

34 Install the rubber seals and install the upper timing gear

casing.

Fig.75

35 Install the casing with the two bolts that are located in the

oval holes.

49

Page 50

1

2

V1045853

Fig.76

V1043275

1 9998601 Installation tool

2 9998318 Press tool

36 Install 9998601 Installation tool and 9998318 Press tool.

Press down

the casing so that it ends up at the same height

as the top of the cylinder head.

37 Install the rest of the bolts.

Tighten the bolts in numerical order as shown in the figure.

Tightening torques, see

Engine transmission, tightening

torque page 7

Remove the press tool.

Fig.77 Upper timing gear casing

1 Camshaft sensor with heat shield

38 Install the camshaft sensor and heat shield.

Crankshaft seal, rear

39 Clean the seal position on the crankshaft and in the casing.

40 Install the new seal ring on 9990166 Installation tool.

41 Remove the tool and check that the seal is installed

correctly.

Fig.78

NOTE!

Check that the tool does not bottom out against the guide pin in

the crankshaft.

50

Page 51

Fig.79

1 Sling 1 metre

2 M10 Lifting eye

42 Install the flywheel.

Install 9993590 Gear wheel.

Tighten the bolts according to the diagram.

Tightening torque: see

Flywheel, tightening

torques page 26

Weight: WLO: 40 kg (88 lbs), EXC: 76 kg (168.55 lbs)

NOTE!

Make sure that the flanges on the bolts are dry and clean.

Front crankshaft seal

43 Press in the crankshaft seal in the casing using

88800021 Installation tool and 9992000 Handle.

Try to install the seal so that it does not end up in the same

groove as before.

Fig.80

Fig.81

44 Apply a bead of sealant on the casing as shown in the figure.

Install the casing.

Tightening torques, see

Crankshaft, tightening

torques page 25

45 Rotate the engine 180°.

51

Page 52

Fig.82

1 Seal

46 Scrape off surplus sealant from the crankshaft casing and

the timing gear casing.

Install a new seal on the oil sump.

Install the oil sump.

Tightening torques, see

Oil sump, tightening

torque page 16

47 Remove the plate and the oil cooler from the coolant casing.

Pressure-test (pressurize) the oil cooler according to

cooler, leakage check page 91

.

Oil

If needed, replace the oil cooler.

48 Install new seals and the oil cooler in the coolant casing.

Tighten the bolts according to the diagram.

Tightening torques, see

Oil sump, tightening

torque page 16

Install the plate.

Fig.83

1 Plate

2 Oil cooler

3

Seal

Fig.84

1 Seal, oil filter bracket

49 Install a new seal on the coolant casing.

Install the coolant casing on the engine.

Tighten the bolts according to the diagram.

Tightening torques, see

Oil sump, tightening

torque page 16

50 Rotate back the engine 180°.

51 Install a new seal on the oil filter bracket.

Install the oil filter bracket.

Install new seals and connect the pipes.

52 Install the engine mount brackets on the right and left side.

Tightening torques, see

Cylinder block, tightening

torques page 18

Fig.85

1 Engine mount bracket

2 Engine mount

Engine mount bracket

3

52

53 Install the engine mount.

Tightening torques, see

torques page 18

Cylinder block, tightening

Page 53

Fig.86

1 Coolant pump

54 Install new seals on the coolant pump.

Install the coolant pump.

55 Install the vibration damper and belt pulley.

Tightening torques, see

Belt pulley/vibration damper,

tightening torques page 27

56 Install the upper hub centre's fan drive and the belt pulley.

For EXC — install the fan hub.

57 Change the seals and install the bracket for the coolant

housing.

Connect the coolant pipe between the coolant pump and

cylinder head.

Fig.87

1 Vibration damper

2 Belt pulley

58 For WLO — Install the oil filter housing.

Change the seals and connect the oil pipes.

53

Page 54

Fig.88

1 Bolts connecting the turbo to the exhaust

manifold

2 Coolant line for turbo cooling

Coolant line

3

4 Oil pressure hose

5 Oil return hose

6 Charge-air cooler pipe

7 Clamps and hose for charge-air cooler

59 - Connect a lifting device to the turbo.

- Install the turbo with a new seal.

Turbo, weight: approx. 28 kg (62 lbs)

Install the rear bolts for the turbo.

-

- Install the front bolts.

- Install the clamps and the hose for the charge-air

cooler.

- Connect the oil pressure and return hoses for the turbo.

- Connect the coolant lines for turbo cooling.

Tightening torques, see

torques page 21

. Use 88830179 Wrench.

Turbocharger, tightening

Speed (rpm) sensor, adjusting

Fig.89

60 Rotate the crankshaft with 9993590 Gear wheel so that a

gear tooth on the vibration damper stands directly opposite

the camshaft sensor's hole. Feel with a finger or use a mirror

to check when the gear tooth is centred in the hole.

54

Page 55

V1049790

Fig.90

V1047889

61 Install 88800031 Setting tool and tighten the lock bolt.

62 Check the distance to the gear teeth on the vibration

damper.

Install a new O-ring on the sensor and lube the O-ring with

63

vaseline. Install the new sensor with spacers as needed.

64 Repeat the same adjustment procedure for the speed (rpm)

sensor on the crankshaft.

Fig.91 88800031 Setting tool

1 No lug outside = No spacer

2 One lug outside = One spacer

3

Two lugs outside = Two spacers

Fig.92

1 Lift plate

2 Coolant pipe

Speed (rpm) sensor

3

65 Install the lift plate.

Connect the coolant pipe to the coolant casing.

55

Page 56

Fig.93

1 Bracket for AC-compressor and alternator

66 Install the

bracket for the AC-compressor and the alternator.

67 Change seals and install the fuel pump.

68 Change seal on the inlet manifold.

Install the inlet manifold and connect to the mixing chamber.

Tightening torques, see

Cylinder block, tightening

torques page 18

Fig.94

1 Seal

Fig.95 Inlet manifold with preheating coil, oil filler

pipe, oil dipstick.

69 Install the oil filler pipe and oil dipstick.

70 Remove the engine from the work stand according to

Engine, removing from work stand page 56

.

Engine, removing from work stand

Op. no. 210-082

56

Tools:

9986485 Support

88800345 Fixture

88800123 Fixture

Lifting eye, 2 pcs.

Sling 3 m (118 in)

Ratchet block 1,500 kg (3307 lbs)

NOTE!

Since the engine illustrations in the service publications are

reused for different engine versions, some parts may vary from

the version in question. However, the essential information in the

illustrations is always correct.

Engine D13F, weight:

WLO approx. 1,330 kg (3,932 lbs)

Page 57

EXC approx. 1,330 kg (3,932 lbs)

V1111475

1

2

1

2

3

V1045797

Fig.96

1 Ratchet block

2 Sling

1 Install the

ratchet block and sling on the engine and connect

the engine to the lifting device.

Remove the engine from 9986485 Support.

2 Remove 88800123 Fixture and 88800345 Fixture.

3 Install the E-ECU.

Fig.97

1 88800345 Fixture

2 88800123 Fixture

Fig.98 Fuel lines

1 Cooling circuit, E-ECU

2 Bracket — different location for EXC

Fuel pump

3

4 Install the fuel lines on the cylinder block, E-ECU, cylinder

head, and the fuel pump. Install the bracket (for the fuel

connections, also known as the fuel interface).

57

Page 58

5 Install the sensors and the cable harness. Plug in the

V1044013

1

2

3

4

5

6

7

8

10

11

9

connectors for the E-ECU. Install the cable channel.

Fig.99 Sensor, control system

1 Sensor for coolant level, SE2603

Sensor for coolant temperature, SE2606

2

3 E-ECU

4 Cable channel

5 Camshaft sensor, engine position, SE2703

6 Sensor for boost pressure/charge-air temperature, SE2507/SE2508

7 Sensor for air pressure/air temperature, SE2501/SE2502

8 Speed (rpm) sensor, flywheel, SE2701

9 Sensor for oil pressure, SE2203

10 Sensor for oil level/oil temperature, SE2205/SE2202

11 Sensor for crankcase pressure, SE2509

6 Install the

Connect oil trap pipe to the valve cover.

oil trap. Connect the oil trap hose to the oil sump.

Fig.100 Oil trap with hose and pipe

58

Page 59

211 Cylinder head

Cylinder head, removing

Op. no. 211-079

Tools:

88800352 Lifting tool

9993590 Gear wheel

This operation also includes tools and times necessary for

applicable parts of the following actions:

-

214, Rocker arm mechanism, checking and repairing

1 - Remove the valve housing.

- Remove the plates and the attaching bolts for the

rocker arm bridge.

Fig.101

1 Valve housing

2 Plate

2 Check the rocker arms' clearance according to

arm mechanism, checking and repairing

.

214, Rocker

59

Page 60

Fig.102

V110182 8

1

1 Rocker arm bridge

2 88800352 Lifting tool

3 Connect 88800352 Lifting tool and remove the rocker arm

bridge.

Rocker arm bridge, weight: approx. 48 kg (106 lbs).

Fig.103

1. Lifting tool

Fig.104

1 Bolt behind adjustable transfer gear

2 Paper

Plate

3

60

4 -

Rotate the engine to reach the bolt behind the

adjustable transfer gear.

- Put some paper in place to prevent dropping bolts

down in the timing gear.

- Remove the bolts from the plate.

- Remove the bolts from the adjustable transfer gear.

Page 61

Fig.105

1 Coolant temperature sensor

5 - Remove all

bolts for the cylinder head and remove the

cylinder head.

- Remove the coolant temperature sensor.

- Connect a lifting device and lift away the cylinder head.

- Place the cylinder head on wooden blocks or similar so

that the injector nozzles are not crushed and damaged.

Cylinder head, weight, including camshaft and lifting device:

approx. 240 kg (530 lbs).

61

Page 62

Cylinder head, reconditioning

Op. no. 211-069

Tools:

11666043 Jack

88800058 Fixture

88800064 Drift

88800127 Drift

88800137 Drift

88800151 Drift

88800196 Flaring tool (copper sleeve)

88830175 Pump

88800342 Puller

9986173 Puller

9986485 Support

9990106 Sealing plate

9990107 Connection plate

9990176 Press tool

9990210 Valve spring compressor

9996239 Lifting chain

9996159 Pin

9996662 Pressure gauge

9998250 Ring

9998251 Sealing plug

9998251 Sealing plug

9998251 Sealing plug

9998251 Sealing plug

9998251 Sealing plug

9998251 Sealing plug

9998264 Lifting tool

9998266 Sealing plate

9998580 Socket

9998599 Cleaning tool

9998666 Connection plate

Dial indicator with magnetic stand

10 mm (0.39 in) drift

Installing in work stand

1 Install 88800058 Fixture

on the cylinder head.

62

Page 63

2

V1028012

1 2

WARNING

Risk of crushing injuries

Fig.106

1 88800058 Fixture

2 9986485 Support

Lift up the cylinder head with 9996239 Lifting chain

and

secure it to 9986485 Support.

Cylinder head, weight approx. 240 kg (530 lbs)

NOTICE

It is important that the greatest cleanliness is exercised when

working with the cylinder head.

Dirt particles in fuel and oil ducts may cause breakdown of the

unit injectors.

3 Connect 9998264 Lifting tool to the camshaft and lift away

the camshaft.

Camshaft, weight: approx. 34 kg (75 lbs).

Fig.107

1 Thermostat

2 Thermostat cover

Fig.108

1 Manifold

4 Remove the thermostat cover and the thermostat.

5 Remove the unit injectors.

6 Remove the manifold.

Manifold, weight: approx. 15 kg (33 lbs)

Valves, removing

7 Remove 9998251 Sealing plug from the cylinder head.

63

Page 64

V1029997

1

Fig.109

V1038723

1 9990210 Valve spring compressor

8 Install 9990210 Valve spring compressor in the sleeve and

fasten it in the holes for the unit injector's attaching bolts.

9 Press down the valve washer and remove the collets.

Remove the valve washer, springs, and valves.

10

11 Remove the rest of the valves in the same way.

NOTE!

Place the valves together with their associated springs so

that they can be reinstalled in the same place in the cylinder

head when assembling.

12 Remove the valve seals.

Fig.110

Fig.111

Sleeve for unit injector

Sleeve for unit injector, removing

NOTE!

The injector sleeve must be free from soot.

There are two methods for removing the injector sleeve.

1. Tap out with drift

2. Pull out with 88800342 Puller and 9986173 Puller.

64

Page 65

Tap out with drift

V1028024

V1035391

1

V1103063

1

2

Fig.112

Fig.113

1 9998250 Ring

13 Tap out the injector sleeve with a 10 mm (0.394 in) drift

.

14 Install two 9998250 Ring in the cylinder head's fuel channel

to protect against dirt.

Pull out with puller

Fig.114

1 Puller, included in kit 88800342 Puller.

2 Support ring, included in kit

88800342 Puller

.

15 Install 88800342 Puller and press down so that it bottoms

out in the sleeve, a 'click' sound can be heard. On the tool

there is a line marking at a depth of 66 mm. If the tool sinks

down so deep that the line cannot be seen, it may be difficult

to pull up the sleeve since it indicates that it has been

deformed. Tighten down the tool. Tighten the expander by

tightening the nut until it stops.

65

Page 66

16 Then install 9986173 Puller. Tighten down the puller.

V1103064

1

V1103065

1

Fig.115

1 9986173 Puller

17 Pull up the injector sleeve with the puller.

NOTE!

deformed sleeve may be difficult to pull up. Try to remove

A

9986173 Puller, loosen, 88800342 Puller and try to find a

new grip for the jaws. Install the counterhold and pull up the

sleeve again.

Fig.116

1 Injector sleeve

66

Page 67

1

2

3

V1039171

4

5

6

Fig.117

1

2

3

V1039172

1

2

3

V1039173

1 9808616

2 9808607

9998580

3

4 9808613

5 9808615

6 9808614

18 Remove the

seal rings 9998250 Ring from the fuel channels.

Clean the injector sleeve's seat in the cylinder head with

cleaning kit 9998599 Cleaning tool. Use the included tools

9998580 Socket, 9808607, 9808613, 9808614, 9808615,

and 9808616.

19 Clean the cylinder head's walls for the injector sleeve with

9998599 Cleaning tool. Use the included tools 9808607,

9808618, and 9998580.

NOTE!

9808607 and 9998580 shall be used to prevent dirt from

entering the fuel channel.

Fig.118

1 9808618

2 9808607

3

9998580

Fig.119

1 9808617

2 9808607

9998580

3

20 Clean the cylinder head's holes with 9998599 Cleaning

tool. Use the included tools 9808607, 9808617, and

9998580.

NOTE!

9808607 and 9998580 shall be used to prevent dirt from

entering the fuel channel.

21 Remove the rest of the unit injectors' injector sleeves, one

at a time, in the same way.

Valve guide, checking

22 Turn the cylinder head with the valve seats facing up.

23 Place a new valve in the valve guide, so that the valve

spindle's end is flush with the guide's edge.

67

Page 68

Fig.120

1 Dial indicator

24 Place the dial indicator with magnetic stand so that the dial

indicator's styles has contact with the valve disc's edge.

Move the

valve sideways in the direction of the exhaust and

inlet channels.

Read off the value on the dial indicator.

25 Check all valve guides.

If the measured values exceed the highest permitted value

according to

Valve mechanism, specifications page 14

the

valve guides shall be changed.

Valve guides, changing

26 Install 9990176 Press tool in the holes for the cylinder head's

attaching bolts.

Install 11666043 Jack in 9990176 Press tool and press out

the valve guide using 88800137 Drift, 9996159 Pin and

88830175 Pump.

Press out the rest of the valve guides in the same way.

Fig.121

1 88830175 Pump

2 11666043 Jack

3

9990176 Press tool

4 9996159 Pin

5 88800137 Drift

27 Oil in the outside of the valve guides with engine oil before

installing.

68

Page 69

WARNING

Use safety glasses.

Fig.122

1 88830175 Pump

2 11666043 Jack

9990176 Press tool

3

4 9996159 Pin

5 88800064 Drift (inlet valves) / 88800127 Drift

(exhaust valves)

28 Press in the valve guides with

88800064 Drift (inlet valves)

and 88800127 Drift (exhaust valves).

Press until the tool bottoms out against the cylinder head's

face. The rest of the valve guides are pressed in in the same

way. After changing valve guides the cylinder head shall be

cleaned to prevent particles from entering the fuel chamber

or oil channels. Dirt particles can cause failure of the unit

injectors.

Injector sleeve, installing

Fig.123

Sleeve

29 NOTE!

Always use a new O-ring.

Lube the O-ring on the injector sleeve with soapy water.

69

Page 70

V1099411

Fig.124 Flaring pin

V1099397

1

V1034126

The measurement X shall be 7.9 ±0.05 mm (0.311

±0.00197 in)

30 Check that the correct flaring pin is used. Measure the pin,

see figure.

31 Place the injector sleeve on the

88800196 Flaring tool

(copper sleeve) (A).

Grease the threads and also grease under the nut on the

tool (A). Screw in the tool (B) until it reaches the bottom of

the sleeve and then turn it back up half a revolution.

Oil in the pin on the tool (B).

Fig.125

A Flaring tool

B Drift pin (replaceable)

Fig.126

1 88800196 Flaring tool (copper sleeve)

32 Flare the injector sleeve by screwing on the nut at the same

time as the spindle is held in place until the drift pin has been

tightened all the way through.

70

Page 71

1

Fig.127

1 9998251 Sealing plug

33 Install the protective tool 9998251 Sealing plug in the hole

for the unit injector. Fasten the tool in the hole for the unit

injector's fastener yoke.

Cylinder head, checking for leaks

34 Clean the contact faces on the cylinder head.

Install:

35

- The L-shaped connecting plate from the tool kit

9998666 Connection plate and 9998266 Sealing

plate on the cylinder head. Use cylinder head bolts and

nuts M16.

- 9990107 Connection plate for the thermostat housing.

- Plug M12x1.5 in the temperature sensor hole

- 9990106 Sealing plate on the side of the cylinder head

- 9996239 Lifting chain

Fig.128

1 9998666 Connection plate

2 9998266 Sealing plate

9990106 Sealing plate

3

4 9990107 Connection plate

36 Connect 9996662 Pressure gauge. Connect the hose to the

connecting plate (9990107).

37 Connect the pressure gauge to the workshop's compressed

air system. Adjust the pressure to 100 kPa (14.5 psi) with

the reduction valve.

Fig.129 Reduction valve

71

Page 72

Fig.130 Shut-off valve

38 Close the

shut-off valve for 2 minutes. The pressure should

not drop during this time.

39 Immerse the cylinder head in water with the temperature 70

°C (158 °F).

40 Screw out the pressure gauge's reduction valve.

41 Set the reduction valve so that the pressure becomes 50 kPa

(7.3 psi). Let that pressure act for 1 minute.

Fig.131

1 70 °C (158 °F)

Fig.132 Reduction valve

42 Increase the pressure to 150 kPa (21.8 psi) . Lock the

reduction valve's knob with the lock ring and close the valve.

Check after 2 minutes. If the pressure drops, check where

the bubbles come from.

43 Lower the pressure in the cylinder head with the reduction

valve.

44 Lift up the cylinder head from the water. Remove the sealing

plates and the tools. Blow the water off the cylinder head.

72

Page 73

Fig.133

V1033041

V1033042

1 9992479 Retainer

2 Dial indicator

Valve seat, checking

45 Check the valve seat's depth against the cylinder head.

The valve seats shall be changed when distance (A)

measured

to

Valve mechanism, specifications page 14

with a new valve exceeds the tolerance according

, otherwise

clean the soot off and grind them.

Valve seat, cleaning soot and grinding

46 When valve seats are ground do not remove too much

material, only enough so that the valve seat has the correct

shape and the valve disc has a good contact surface.

47 A new valve seat is ground down so that distance (A)

between the cylinder head's face and the valve disc's face,

measured with a new valve, is according to specifications.

Fig.134

Valve seat, changing

48 Grind down two edges on the disc of a discarded valve.

49 Weld the valve in the valve seat.

Fig.135

73

Page 74

V1033043

Fig.136

50 Place a suitable sleeve as protection over the valve/valve

guide. Carefully tap out the valve and valve seat with a

hammer.

NOTE!

Work carefully so that the cylinder head is not damaged.

51 Clean the seat's position thoroughly and check the cylinder

head for cracks.

cracks are permitted on the cylinder head.

No

52 Measure the diameter of the valve seat's position. Check if

a seat of standard dimension should be used. If needed,

rework the valve seat's position.

53 Cool the seat in dry ice to a temperature between -60 °C and

-70 °C (-76 °F and -94 °F) .

Warm the cylinder head with a hot-air gun or in another way.

Press in the valve seat with a suitable drift.

NOTE!

Risk of frostbite. Use protective gloves.

54 Rework the seat to correct angle and width according to

Valve mechanism, specifications page 14

.

Valves, grinding

Fig.137 Inlet valve

A Valve disc's edge thickness

B Valve's seat angle

C

Valve seat's angle

Fig.138 Exhaust valve

A Valve disc's edge thickness

B Valve's seat angle

Valve seat's angle

C

55 Check the valve disc's edge thickness (A). If the

measurement is less than according to

specifications page 14

the valve should be changed.

Valve mechanism,

56 Check the valves' sealing with marking paint.

In case of leakage, grind the valve seat again, but not the

valve, then check again.

57 The sealing face should be ground as little as possible,

however, enough to grind off all damage.

74

Cylinder head, assembling

58 Install the valves.

Page 75

Fig.139

V1029997

1

1 88800147 Drift

59 NOTE!

Before installing the new valve seals, thoroughly clean the

valve seals' contact face with degreaser or similar.

Install the new oil seals over the valve guides with

88800151 Drift.

NOTE!

sure that the oil seals are pressed all the way down so

Make

that the seals' undersides seal tight against the valve guides.

60 Install the valve washers on the springs.

Install the springs.

61 Fasten 9990210 Valve spring compressor in the hole for the

unit injector's fastener yoke. Compress the valve washer

and spring with 9990210 Valve spring compressor.

Install the collets.

Fig.140

1 9990210 Valve spring compressor

Fig.141

1 Thermostat

2 Thermostat cover

62 Install the thermostat and the thermostat cover.

75

Page 76

Fig.142

1 Seal rings

2 Seals

Fig.143 Unit injector with copper sleeve

1 Seals

2 Seal ring

63 Install the new seals and rings on the manifold.

Turn the steel side of the seals to face the manifold.

64 Install the manifold.

Tighten the bolts according to the diagram, see

manifold, tightening torques page 21

.

Exhaust

65 Remove 9998251 Sealing plug.

Copper sleeve

66 Install new seals and seal ring on the injectors. Install the

injectors.

Tightening torques, see

system page 21

.

Tightening torque, fuel

WARNING

Risk of crushing injuries

67 Lift away the cylinder head from the work stand with

9996239 Lifting chain.

Cylinder head, weight approx. 240 kg (530 lbs)

Cylinder head, fitting

Op. no. 211-081

Tools:

885811 Timing tool

88880003 Bracket

88800352 Lifting tool

9993590 Gear wheel

9998264 Lifting tool

Feeler gauge

This operation also includes tools and times necessary for

applicable parts of the following actions:

Valves, adjusting page 88

-

1 Clean contact face and sealing faces on the cylinder block

and cylinder head.

Fig.144

1 Guides for cylinder head

76

2 Install a new cylinder head gasket and align with the cylinder

liners. Install the bolts with washers that work as guides for

the cylinder head.

Page 77

Fig.145

3 Immerse the entire length of the cylinder head's bolts in

rustproofing agent.

NOTE!

The component must be installed within 20 minutes of applying

sealant.

4 Apply sealant outside of the timing gear plate's groove.

Loosen the bolts (2) with washer to get extra space for the

5

cylinder head.

Connect a lifting device and lower the cylinder head.

Cylinder head, weight approx. 240 kg (530 lbs).

Make sure that the washer ends up outside of the engine

block's edge. Then tighten the bolt (1) so that the washer

pulls the cylinder head sideways until it contacts the two

washers located on the side of the block. Tighten the bolts

(2) a revolution or two.

Fig.146

Fig.147

A 5–10 mm (0.2–0.4 in)

6 Leave a distance of 5–10 mm (0.2–0.4 in) to the timing gear

plate.

77

Page 78

7 Install a bolt in the upper timing gear and tighten it so that

the cylinder head is pulled against the timing gear plate.

Loosen the bolt approx. one revolution.

Now the cylinder head is in the correct position to be

tightened down with the cylinder head bolts.

Fig.148

1 Bolt

Fig.149

8 Install the

cylinder head bolts. Use 885811 Timing tool when

tightening.

Tightening torques, see

Tightening torque, cylinder

head page 6

9 Install the bolts for the timing gear plate. Rotate the timing

gear so that the bolt behind the upper timing gear can be

reached.

Tighten all bolts for the timing gear plate in numerical order.

Tightening torques, see

torques page 18

.

Cylinder block, tightening