Volkswagen Beetle 2012, Caddy 2004, Caddy 1997, Bora 1999, Caddy 2011 Workshop Manual

...

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Service

Workshop Manual

Amarok 2011 ➤ , Beetle 2012 ➤ ,

Bora 1999 ➤ , CC 2010 ➤ , CC 2012 ➤ ,

Caddy 1997 ➤ , Caddy 2004 ➤ ,

Caddy 2011 ➤ ,

Caddy Kasten/Kombi 1996 ➤ ,

Caddy Pickup 1997 ➤ ,

California 2004 ➤ , California 2010 ➤ ,

Caravelle 2004 ➤ , Caravelle 2010 ➤ ,

Crafter 2006 ➤ , Eos 2006 ➤ ,

Fox 2005 ➤ , Golf 1992 ➤ , Golf 1998 ➤ ,

Golf 2004 ➤ , Golf 2009 ➤ ,

Golf 2013 ➤ , Golf Cabriolet 2012 ➤ ,

Golf Plus 2005 ➤ , Golf Plus 2009 ➤ ,

Golf Sportsvan 2015 ➤ ,

Golf Variant 1998 ➤ ,

Golf Variant 2007 ➤ ,

Golf Variant 2010 ➤ ,

Golf Variant 2014 ➤ , Jetta 2005 ➤ ,

Jetta 2011 ➤ , LT 1997 ➤ ,

Lupo 1999 ➤ , Lupo 3L 1999 ➤ ,

Multivan 2004 ➤ , Multivan 2010 ➤ ,

New Beetle 1999 ➤ ,

New Beetle Cabrio 2003 ➤ ,

Passat 1994 ➤ , Passat 1997 ➤ ,

Passat 2006 ➤ , Passat 2011 ➤ ,

Passat 2015 ➤ ,

Passat (NMS - US) 2012 ➤ ,

Passat CC 2009 ➤ ,

Passat Variant 1997 ➤ ,

Passat Variant 2011 ➤ ,

Service Department. Technical Information

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Service

Passat Variant 2015 ➤ , Phaeton 2003 ➤ ,

Polo 1995 ➤ , Polo 2002 ➤ ,

Polo 2010 ➤ , Polo 2014 ➤ ,

Polo Classic 1996 ➤ ,

Polo KH IN 2010 ➤ , Polo KH IN 2015 ➤ ,

Polo KH MY 2014 ➤ ,

Polo KH MY 2015 ➤ ,

Polo Lim IN 2011 ➤ ,

Polo Lim MY 2014 ➤ ,

Polo Lim RUS 2011 ➤ ,

Polo Variant 1998 ➤ , Scirocco 2009 ➤ ,

Scirocco 2015 ➤ , Sharan 1996 ➤ ,

Sharan 2011 ➤ , Tiguan 2008 ➤ ,

Touareg 2003 ➤ , Touareg 2010 ➤ ,

Touareg 2015 ➤ , Touran 2003 ➤ ,

Transporter 1996 ➤ ,

Transporter 2003 ➤ ,

Transporter 2004 ➤ ,

Transporter 2010 ➤ , XL1 2015 ➤ ,

e-Golf 2014 ➤ , e-up! 2014 ➤ ,

up! 2012 ➤

Air conditioning system with refrigerant R134a

Edition 10.2014

Service Department. Technical Information

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Service

List of Workshop Manual Repair GroupsList of

Workshop Manual Repair GroupsList of Workshop

Manual Repair Groups

Re pa ir G ro up

00 - Technical data

Technical information should always be available to the foremen and mechanics,

because their careful and constant adherence to the instructions is essential to

ensure vehicle road-worthiness and safety. In addition, the normal basic safety

precautions for working on motor vehicles must, as a matter of course, be

observed.

All rights reserved.

No reproduction without prior agreement from publisher.

Copyright © 2014 Volkswagen AG, Wolfsburg D4B8027068B

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Service

All rights reserved.

No reproduction without prior agreement from publisher.

Copyright © 2014 Volkswagen AG, Wolfsburg D4B8027068B

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Amarok 2011 ➤ , Beetle 2012 ➤ , Bora 1999 ➤ , CC 2010 ➤ , CC 2012 ➤ , ...

Air conditioning system with refrigerant R134a - Edition 10.2014

Contents

00 - Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1 General notes on air conditioning systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Additional information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3 Basics of air conditioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.4 Vapour pressure table for refrigerant R134a . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.5 Refrigerant R134a . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.6 Characteristics of refrigerant R134a . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.7 Refrigerant machine oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.8 Comfort . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.9 How air conditioning works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.10 General safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.11 Safety precautions for when working on vehicles with air conditioning and when handling

refrigerant R134a . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.12 Basics for working on refrigerant circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2 General information on refrigerant circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.1 Refrigerant circuit components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.2 Design of refrigerant circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.3 Evacuation and charging valves for quick-release couplings of air conditioner service station

on refrigerant circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.4 Switch and sender in refrigerant circuit and related connections . . . . . . . . . . . . . . . . . . . . 27

2.5 Electrical components not installed in refrigerant circuit . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.6 Pressures and temperatures in the refrigerant circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2.7 Refrigerant circuit with expansion valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2.8 Refrigerant circuit with restrictor and reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2.9 Test and measurement work that can be performed using a pressure gauge . . . . . . . . . . 36

2.10 Air conditioner service and recycling equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2.11 Notes to repairs on refrigerant circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3 Statutory texts and instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.1 Statutes and regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.2 Recycling and refuse law . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3.3 Converting R12 refrigerant circuits to R134a refrigerant circuits and repairing them

(retrofitting) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

3.4 Maintaining records on refrigerant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4 Refrigerant circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.1 Important repair notes on air conditioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.2 Retrofitting refrigerant circuit from R12 refrigerant to R134a refrigerant . . . . . . . . . . . . . . 46

5 Working with the air conditioner service station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.1 Important notes for working with the air conditioner service station . . . . . . . . . . . . . . . . . . 48

5.2 Connecting air conditioner service station for measuring and checking . . . . . . . . . . . . . . 48

5.3 Draining refrigerant circuit using air conditioner service station . . . . . . . . . . . . . . . . . . . . . . 49

5.4 Evacuating refrigerant circuit using air conditioner service station . . . . . . . . . . . . . . . . . . . . 50

5.5 Charging refrigerant circuit using air conditioner service station . . . . . . . . . . . . . . . . . . . . 51

5.6 Bringing air conditioning system into service after charging . . . . . . . . . . . . . . . . . . . . . . . . 52

5.7 Charging container in air conditioner service station with refrigerant . . . . . . . . . . . . . . . . . . 53

5.8 Draining air conditioner service station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6 Detecting leaks in refrigerant circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

6.1 Leak detection in refrigerant circuit using compressed air or nitrogen . . . . . . . . . . . . . . . . 56

6.2 Searching for leaks in refrigerant circuits using leak detector V.A.G 1796 . . . . . . . . . . . . 58

6.3 Detecting leaks in refrigerant circuit using leak detecting system VAS 6196 or leak detecting

system VAS 6201 or a later model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

7 Clearing refrigerant circuit of contaminants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

7.1 Blowing through refrigerant circuit with compressed air and nitrogen . . . . . . . . . . . . . . . . 65

Contents i

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Amarok 2011 ➤ , Beetle 2012 ➤ , Bora 1999 ➤ , CC 2010 ➤ , CC 2012 ➤ , ...

Air conditioning system with refrigerant R134a - Edition 10.2014

7.2 Purging (cleaning) refrigerant circuit with refrigerant R134a . . . . . . . . . . . . . . . . . . . . . . . . 67

8 Complaints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

8.1 Possible complaints about refrigerant circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

8.2 Smells from heater and air conditioner unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

9 Connecting air conditioner service station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

9.1 For vehicles that have connections on both low-pressure and high-pressure sides of

refrigerant circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

10 Checking pressures on vehicles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

10.1 Checking pressures in refrigerant circuit (using air conditioner service station) . . . . . . . . 127

10.2 Checking systems with a restrictor and collector (with internally regulated air conditioner

compressor) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

10.3 Checking systems with an expansion valve and reservoir (with internally regulated air

conditioner compressor) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

10.4 Checking systems with an expansion valve and reservoir (without regulated air conditioner

compressor) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

10.5 Checking systems with a restrictor and reservoir and air conditioner compressor regulating

valve N280 (with externally regulated air conditioner compressor) . . . . . . . . . . . . . . . . . . 143

10.6 Checking systems with an expansion valve, receiver and air conditioner compressor

regulating valve N280 (with externally regulated air conditioner compressor) . . . . . . . . . . 148

10.7 With expansion valve, receiver and electrical air conditioner compressor . . . . . . . . . . . . . . 158

11 Renewing components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

11.1 In the event of leaking or damaged components (apart from the air conditioner compressor,

receiver or reservoir) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

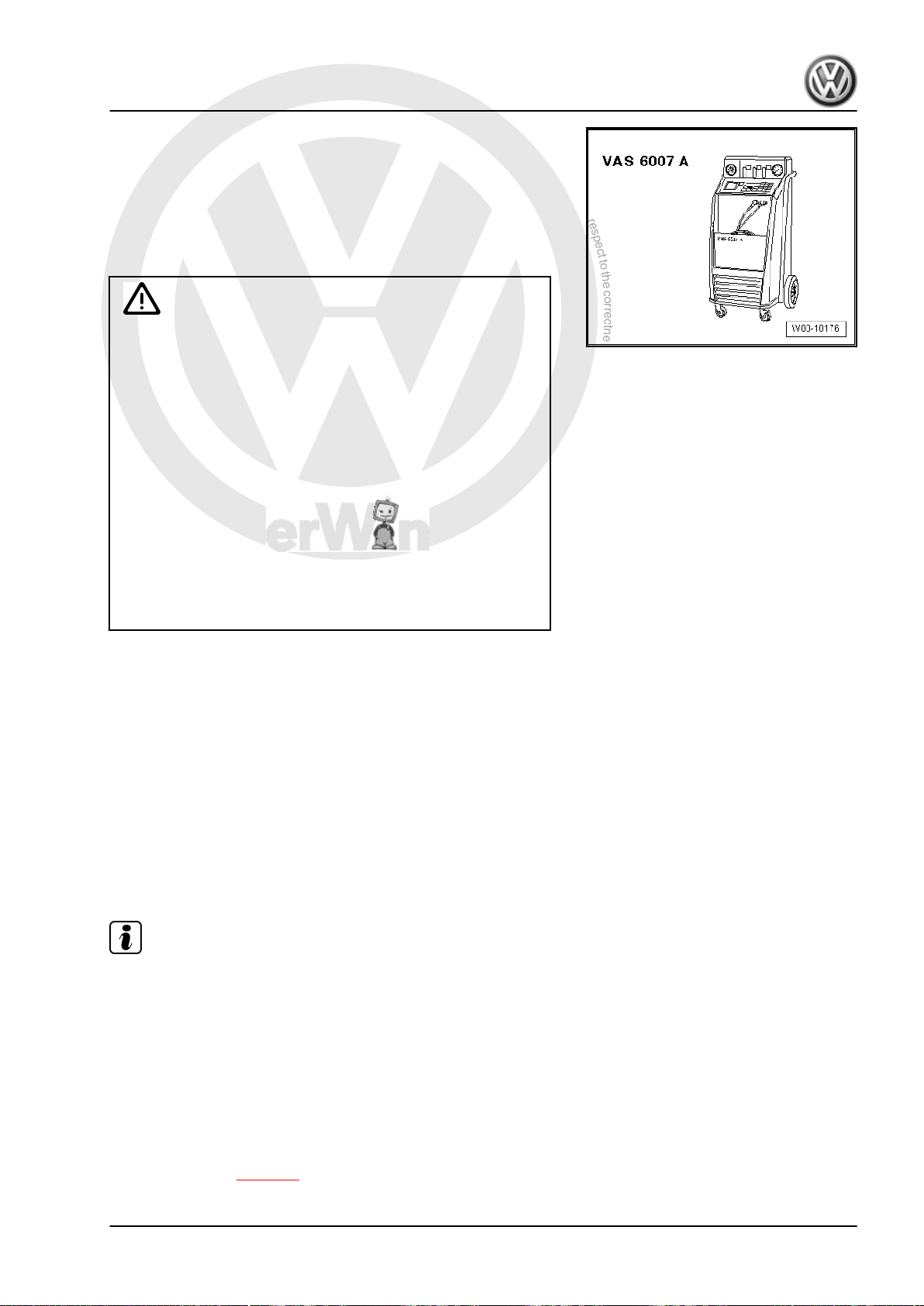

11.2 Renewing air conditioner compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

11.3 Renewing receiver or reservoir, and restrictor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

12 Testing equipment and tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

12.1 List of test equipment, tools and materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

ii Contents

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Amarok 2011 ➤ , Beetle 2012 ➤ , Bora 1999 ➤ , CC 2010 ➤ , CC 2012 ➤ , ...

Air conditioning system with refrigerant R134a - Edition 10.2014

00 – Technical data

1 General notes on air conditioning

systems

(VRL007231; Edition 10.2014)

1.1 Introduction

This repair manual is intended to provide technicians and fitters

with the basic knowledge required for performing trained work on

these systems.

Note

♦

Successful completion of a training course such as AB160 or

ST160 Air conditioning systems including "technical informa‐

tion" is required.

♦

This repair manual is a part of the training material.

It should also be available to the responsible supervisory author‐

ities upon request.

Caution

Non-authorised tools or materials (e.g. leak inhibitor additive)

may cause damage or adversely influence the system.

Only tools and materials approved by the manufacturer may

be used.

Use of non-approved tools or materials will render the warranty

void.

1.2 Additional information

♦ Technical Service Handbook with measures for rectifying lat‐

est malfunctions.

♦ Workshop manual for service work specific to model ⇒ Heat‐

ing, air conditioning; Rep. gr. 87 .

♦ ⇒ Current flow diagrams, Electrical fault finding and Fitting lo‐

cations

♦ Self-study programme No. 208 is no longer up-to-date in some

sections. E.g. the statement “The receiver must be renewed

each time the refrigerant circuit is opened”. The following con‐

ditions apply ⇒ page 159

♦ Video programs for staff training.

♦ Catalogue of special tools / workshop testing.

♦ Service Organisation Volume 1 Additional equipment.

♦ Workshop manual for air conditioning system with R12 refrig‐

erant (for vehicles that were manufactured up to model year

1993). This workshop manual is only available as a hard copy.

1. General notes on air conditioning systems 1

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Amarok 2011 ➤ , Beetle 2012 ➤ , Bora 1999 ➤ , CC 2010 ➤ , CC 2012 ➤ , ...

Air conditioning system with refrigerant R134a - Edition 10.2014

1.3 Basics of air conditioning

1.3.1 Physical basics:

The four known physical states of water also apply to air condi‐

tioning refrigerants.

1 - Gas (invisible)

2 - Vapour

3 - Liquid

4 - Solid

When water is heated in a container (heat absorption), the rising

water vapour is visible. If the vapour is heated by further heat

absorption, the visible vapour becomes invisible gas. This proc‐

ess is reversible. If heat is extracted from gaseous water, it

changes first to vapour, then to water and finally to ice.

A - Heat absorption

B - Heat dissipation

1.3.2 Heat always flows from warmer to colder material

Every material consists of a mass of moving molecules. The fast

moving molecules of a warmer material loose part of their energy

to slower molecules possessing less heat. This slows down the

molecules of the warmer material and accelerates those with less

heat. This continues until the molecules in both materials are

moving at the same speed. They have the same temperature, and

no further exchange of heat occurs.

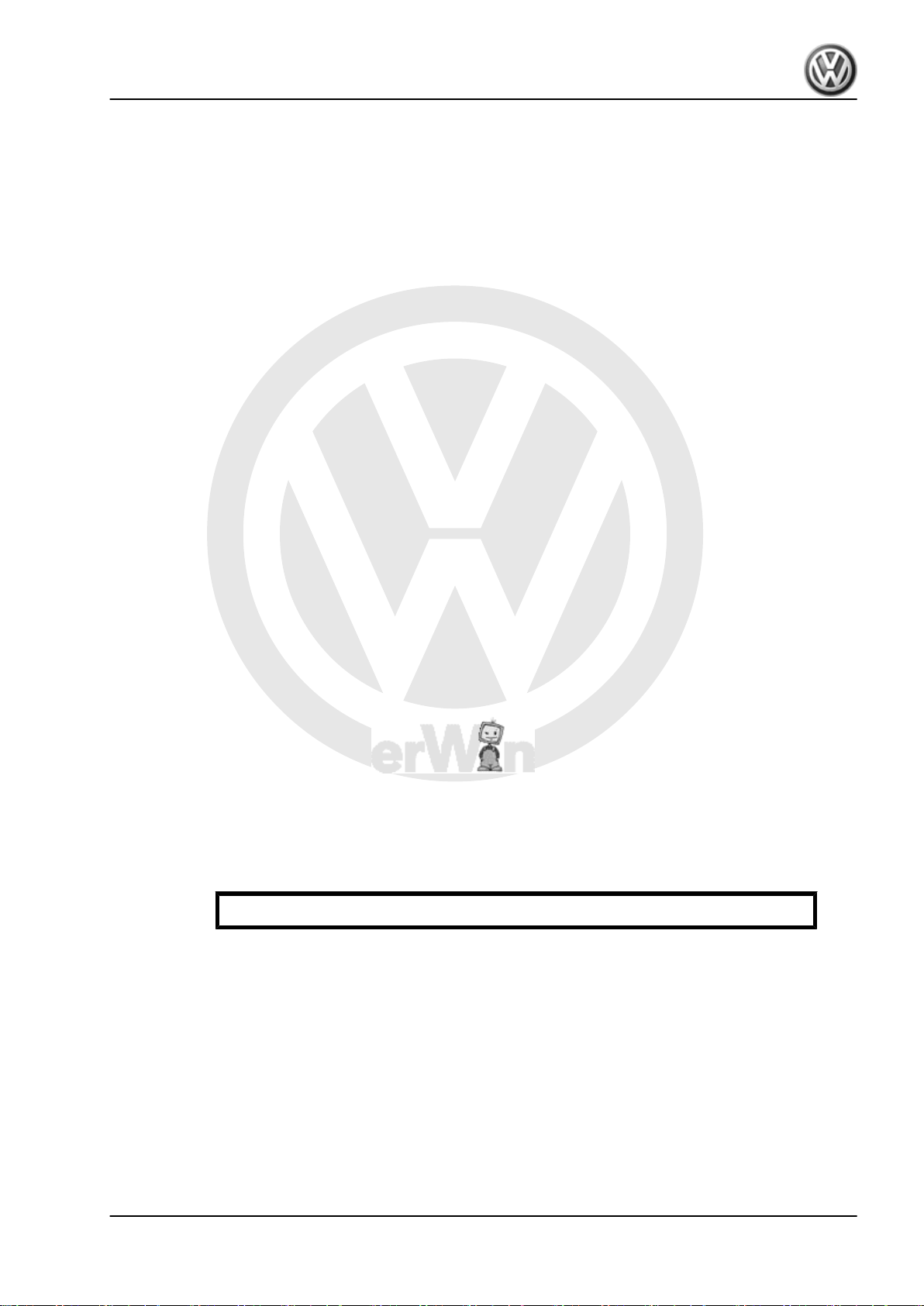

1.3.3 Pressure and boiling point

The boiling points given in the table below are always based on

an atmospheric pressure of 1 bar. If the pressure on a liquid is

changed, its boiling point changes also.

It is well known that, for example, the lower the pressure, the lower

the temperature at which water boils.

The vapour pressure curves for water and for refrigerant R134a

show that at constant pressure and falling temperature the vapour

becomes liquid (in the condenser), and that when pressure drops,

the refrigerant changes from liquid into the vapour state (evapo‐

rator).

2 Rep. gr.00 - Technical data

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Amarok 2011 ➤ , Beetle 2012 ➤ , Bora 1999 ➤ , CC 2010 ➤ , CC 2012 ➤ , ...

Air conditioning system with refrigerant R134a - Edition 10.2014

Vapour pressure curve for water

A - Liquid

B - Gaseous

C - Vapour pressure curve for water

1 - Pressure on the liquid in bar (absolute)

2 - Temperature in °C

Vapour pressure curve for refrigerant R134a

A - Liquid

B - Gaseous

D - Vapour pressure curve for refrigerant R134a

1 - Pressure on the liquid in bar (absolute)

2 - Temperature in °C

1.4 Vapour pressure table for refrigerant R134a

The vapour pressure table for each refrigerant is published in the

literature for refrigeration engineers. This table shows the vapour

pressure exerted on the liquid column in the container for a given

temperature of the container.

Since a characteristic vapour pressure table is known for every

refrigerant, one can determine what refrigerant is present by

measuring pressure and temperature.

Note

Absolute pressure means that 0 bar corresponds to an absolute

vacuum. The normal ambient pressure (positive pressure) corre‐

sponds to 1 bar absolute pressure. On most pressure gauges, a

reading of 0 bar corresponds to an absolute pressure of one bar

(which is confirmed by the existence of a -1 bar marking beneath

the 0 scale marking).

Temperature in °C Pressure in bar (positive pres‐

sure) R134a

-45 -0.61

-40 -0.49

-35 -0.34

-30 -0.16

-25 0.06

-20 0.32

-15 0.63

-10 1.00

-5 1.43

0 1.92

1. General notes on air conditioning systems 3

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Amarok 2011 ➤ , Beetle 2012 ➤ , Bora 1999 ➤ , CC 2010 ➤ , CC 2012 ➤ , ...

Air conditioning system with refrigerant R134a - Edition 10.2014

Temperature in °C Pressure in bar (positive pres‐

sure) R134a

5 2.49

10 3.13

15 3.90

20 4.70

25 5.63

30 6.70

35 7.83

40 9.10

45 10.54

50 12.11

55 13.83

60 15.72

65 17.79

70 20.05

75 22.52

80 25.21

85 28.14

90 31.34

1.5 Refrigerant R134a

Air conditioners in vehicles use the evaporation and condensation

process. The system contains a liquid with a low boiling point,

called the refrigerant.

The refrigerant used is tetrafluoroethane R134a, which boils at

-26.5°C with vapour pressure of 1 bar.

1.5.1 Physical data of refrigerant R134a

Chemical formula CH2F–CF3 or CF3–CH2F

Chemical designation Tetrafluoroethane

Boiling point at 1 bar -26.5℃

Freezing point -101.6℃

Critical temperature 100.6℃

Critical pressure 40.56 bar (technical) pressure

equates to 39.5 bar (standard)

pressure

1.5.2 Critical point

Critical point (critical temperature and critical pressure) means the

point above which there is no longer a surface of separation be‐

tween liquid and gas.

Above its critical point, a substance is always gaseous.

At temperatures below the critical point, all types of refrigerant

contained within a pressure tank exhibit a liquid phase and a gas

phase, so that there is a gas cushion above the liquid.

As long as there is gas in the pressure vessel alongside the liquid,

the pressure depends directly on the ambient temperature

⇒ page 3 .

4 Rep. gr.00 - Technical data

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Amarok 2011 ➤ , Beetle 2012 ➤ , Bora 1999 ➤ , CC 2010 ➤ , CC 2012 ➤ , ...

Air conditioning system with refrigerant R134a - Edition 10.2014

Note

Different types of refrigerants must not be mixed with each other.

Only refrigerants specified for the respective air conditioning sys‐

tem may be used.

1.5.3 Environmental aspects of refrigerant R134a

♦ R134a is a fluorocarbon and contains no chlorine.

♦ R134a has a shorter atmospheric persistence than refrigerant

R12.

♦ R134a does not damage the ozone layer, the potential to re‐

duce the amount of ozone is zero.

♦ The Global Warming Potential (GWP) of R134a lies by ap‐

prox. 1430 (the GWP for carbon dioxide lies by 1).

♦ The contribution of R134a to the greenhouse effect is less by

a factor of 10 than that of refrigerant R12.

1.6 Characteristics of refrigerant R134a

1.6.1 Trade names and designations

Refrigerant R134a is currently available under the following trade

designations:

♦ H-FKW 134a

♦ SUVA 134a

♦ KLEA 134a

Note

♦

Other trade designations may be used in other countries.

♦

Among the large selection of various refrigerants, only this one

may be used for vehicles. The designations Frigen or Freon

are trade names. They apply also to refrigerants which must

not be used in vehicles.

1.6.2 Colour

Like water, the refrigerant is colourless both in the vapour state

and the liquid state. Gases are invisible. Only the boundary layer

between gas and liquid is visible. (Fluid level in indicator tube of

charging cylinder for bubbles in sight glass.) Liquid refrigerant

R134a may appear coloured (milky) in a sight glass. This cloudi‐

ness is caused by partially dissolved refrigerant oil and does not

indicate a fault.

1.6.3 Vapour pressure

In an enclosed container that is not completely full, refrigerant

evaporates as vapour at the surface in a quantity sufficient to form

an equilibrium between vapour and liquid. This equilibrium de‐

velops under pressure and is often called vapour pressure. The

vapour pressure is temperature-dependant ⇒ page 3 .

1. General notes on air conditioning systems 5

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Amarok 2011 ➤ , Beetle 2012 ➤ , Bora 1999 ➤ , CC 2010 ➤ , CC 2012 ➤ , ...

Air conditioning system with refrigerant R134a - Edition 10.2014

1.6.4 Physical properties of R134a

Because the vapour pressure curves of R134a and other refrig‐

erants are in part very similar, unique identification on the basis

of pressure alone is not possible.

The air conditioner compressor used for R134a is lubricated with

special synthetic refrigerator oils, such as PAG oils (polyalkylene

glycol oils).

1.6.5 Effects on metal

In its pure state, refrigerant R134a is chemically stable and does

not attack iron or aluminium.

However, impurities such as chlorine compounds in the refriger‐

ant do attack certain metals and plastics. This can lead to block‐

ages, leaks and deposits on the air conditioner compressor

piston.

1.6.6 Critical temperature and critical pres‐

sure

Up to a gas pressure of 39.5 bar positive pressure (corresponding

to a temperature of 101°C) the refrigerant R134a remains chem‐

ically stable; however, above this temperature the refrigerant

decomposes (see Combustibility).

1.6.7 Water content

Only very small amounts of water are soluble in liquid refrigerant.

On the other hand, refrigerant vapour and water vapour mix in

any proportion.

Any water present in the refrigerant circuit will be carried along as

droplets. The dryer, dryer bag or dryer cartridge in the receiver or

reservoir are capable of holding approx. 7 grams of water before

they are full and cannot absorb any more water. If there is further

water in the circuit, it will flow to the expansion valve jet or to the

restrictor and becomes ice.

The air conditioning system will stop cooling.

Water destroys the air conditioner because at high pressures and

temperatures it combines with other impurities to form acids.

1.6.8 Combustibility

Refrigerant is non-flammable. On the contrary, it has a fire-inhib‐

iting or fire-extinguishing effect. Refrigerant decomposes when

exposed to flames or incandescent surfaces. UV light can also

decompose refrigerants (UV is emitted by electric arc welding).

Products of this decomposition are poisonous and must not be

inhaled. However, these chemicals irritate the mucous mem‐

branes, giving adequate warning of their presence.

1.6.9 Charge factor

There must be space both for liquid and vapour in a container. As

the temperature rises, the liquid expands. The space occupied by

the vapour becomes smaller. Eventually, there will only be liquid

in the container. After that time, even a small increase in temper‐

ature will result in a very large increase in pressure, since the

liquid is seeking to expand further but there is no space for it to

do so. The resulting forces are sufficient to burst the container.

To prevent containers from being overcharged, regulations gov‐

erning the storage of compressed gases specify how many kilo‐

grams may be charged into a container for every litre of container

volume. This charge factor multiplied by the internal volume gives

the permissible charge quantity. The charge factor for the refrig‐

erants used in cars is 1.15 kg/l.

6 Rep. gr.00 - Technical data

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Amarok 2011 ➤ , Beetle 2012 ➤ , Bora 1999 ➤ , CC 2010 ➤ , CC 2012 ➤ , ...

Air conditioning system with refrigerant R134a - Edition 10.2014

1.6.10 Detecting leaks

External damage can cause leaks in the refrigerant circuit. Be‐

cause a small leak will involve only small quantities of refrigerant,

leaks should be checked for using an electronic leak detector or

by introducing a leak detection additive to the refrigerant circuit.

Electronic leak detectors can detect leakage rates of less than 5

grams loss of refrigerant per year. The leak detector should be

specific to the composition of the particular refrigerant in use. For

example, a leak detector for R12 refrigerant is not appropriate for

R134a refrigerant because R134a refrigerant has no chlorine

atoms to which the lead detector responds.)

1.7 Refrigerant machine oil

Refrigerant machine oil is miscible (approx. 20%–40% depending

on the type of air conditioner compressor and the quantity of re‐

frigerant) in the refrigerant. It circulates continuously in the circuit

and lubricates the moving parts.

Special synthetic refrigerant machine oils such as polyalkylene

glycol (PAG) oil are used in conjunction with R134a air condition‐

ing systems. This is necessary because ordinary mineral oils are

immiscible in R134a. In addition the materials of the R134a air

conditioning system could be attacked if the mixture circulated

within the refrigerant circuit under pressure and at high tempera‐

tures, or the lubricant film in the air conditioner compressor broke

down. The use of unapproved oils can lead to the failure of the air

conditioning system, so only approved oils must be used.

⇒ Parts catalogue

Type of oil for R134a in cars: PAG

1. General notes on air conditioning systems 7

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Amarok 2011 ➤ , Beetle 2012 ➤ , Bora 1999 ➤ , CC 2010 ➤ , CC 2012 ➤ , ...

Air conditioning system with refrigerant R134a - Edition 10.2014

Note

♦

Do not store refrigerant machine oils open to the atmosphere

since they are very hygroscopic (they readily absorb water).

♦

Always keep oil containers tightly sealed.

♦

Do not reuse used refrigerant machine oil.

♦

Disposing of used oil: Volkswagen InfoNet; Operation; Man‐

uals and dealership documentation; Service handbook;

15. Environmental Protection; Follow link “Environmental pro‐

tection in the dealership and in the workshop” in "General

notes"; 4. Waste disposal; 6. Disposal channels; g. Disposal

of used oil; Refrigerant oils

♦

Used refrigerant machine oils from systems with halogenated

hydrocarbons (at least one hydrogen atom has been replaced

by e.g the halogens fluorine, chlorine, bromine or iodine) must

be disposed of as waste requiring particular care. It is imper‐

missible to mix such oils with other oils or materials. Proper

storage and disposal must be performed according to guide‐

lines in the country where the work is being performed. Ob‐

serve, for example in the Federal Republic of Germany, the

climate protective regulation concerning chemicals; closed

substance cycle waste management and ensuring environ‐

mentally compatible waste disposal (in other countries other

statutes and regulations may apply)

♦

Reference sources for technical rules and safety at work / ac‐

cident prevention for the Federal Republic of Germany

♦

Sources in other countries may be obtained from the respon‐

sible authorities

♦

Ester-based oils are suitable only for larger systems (not for

air conditioning systems in cars).

1.7.1 Properties of refrigerant oils

The most important properties are high solubility in refrigerants,

good lubrication characteristics, freedom from acid and very low

water content. For this reason, only certain oils may be used. A

list of approved refrigerant oils and quantities can be found in the

vehicle-specific workshop manuals in ⇒ Rep. gr. 00 or ⇒ Rep.

gr. 87 .

The PAG oils suitable for refrigerant R134a are strongly hygro‐

scopic and are immiscible with other oils. Therefore, opened

containers should be closed again immediately to protect them

from moisture. Refrigerant oils age under the influence of mois‐

ture and acids; they become dark, viscous and aggressive to‐

wards metals.

Note

♦

For refrigerant circuits with refrigerant R134a, use only the oil

approved for the air conditioner compressor. See ⇒ Rep. gr.

00 or ⇒ Rep. gr. 87 in the repair manual for the specific ve‐

hicle.

♦

Disposing of used oil: Volkswagen InfoNet; Operation; Man‐

uals and dealership documentation; Service handbook;

15. Environmental Protection; Follow link “Environmental pro‐

tection in the dealership and in the workshop” in "General

notes"; 4. Waste disposal; 6. Disposal channels; g. Disposal

of used oil; Refrigerant oils

8 Rep. gr.00 - Technical data

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Amarok 2011 ➤ , Beetle 2012 ➤ , Bora 1999 ➤ , CC 2010 ➤ , CC 2012 ➤ , ...

Air conditioning system with refrigerant R134a - Edition 10.2014

1.8 Comfort

A basic requirement for concentrated and safe driving is the feel‐

ing of comfort in the passenger compartment. Especially when it

is hot and humid, comfort can be attained only through the use of

air conditioning. Of course, open windows, an open sunroof or

increased air ventilation can contribute to comfort, but they all

have certain disadvantages within the vehicle interior, such as

additional noise, draughts, exhaust gases, unfiltered entry of pol‐

len (unpleasant for allergy sufferers).

A well regulated air conditioning system in conjunction with a well

thought-out heating and ventilation system can create a feeling

of well-being and comfort by regulating the interior temperature,

humidity and rate of air change, regardless of the external con‐

ditions. This must be available whether the vehicle is moving or

not.

Other important advantages of air conditioning are

♦ The cleansing of the air directed into the passenger compart‐

ment. (Dust and pollen, for example, are washed out by the

moist fins of the evaporator and carried off with the conden‐

sation water.)

♦ Temperatures in a mid-range car (for example, after a short

period of driving, ambient temperature 30°C in the shade and

the vehicle in direct sunlight).

Head region 23℃ 42℃

Chest region 24℃ 40℃

Footwell 30℃ 35℃

1.8.1 Environmental aspects

Since about 1992, the air conditioning systems of newly manu‐

factured cars have been successively changed to refrigerant

R134a. This refrigerant contains no chlorine and thus does not

damage the ozone layer.

Up until about 1992, air conditioning systems were charged with

refrigerant R12. Due to its chlorine atoms, this CFC has a high

potential for destroying ozone and, in addition, a potential for in‐

creasing the greenhouse effect.

There are programs for exchanging old air conditioning systems

containing the ozone-damaging refrigerant R12.

⇒ Repair manual for air conditioning systems with refrigerant

R12 . This workshop manual is only available as a hard copy.

To protect the environment, no refrigerant should be released into

the atmosphere ⇒ page 39 (statutory texts and instructions).

1.9 How air conditioning works

The temperature in the passenger compartment depends on the

With air conditioning

system

amount of heat radiated through the windows and conducted by

the metal parts of the body. In order to maintain comfortable tem‐

peratures for the occupants on very warm days, part of the

available heat must be pumped away.

Since heat spreads towards cooler bodies, a unit that can create

low temperatures is fitted in the vehicle interior. Refrigerant is

constantly being evaporated in it. The latent heat of evaporation

is taken from the air passing through the evaporator.

The refrigerant carries the heat with it as it is pumped away by the

air conditioner compressor. The work performed by the air con‐

Without air condi‐

tioning system

1. General notes on air conditioning systems 9

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Amarok 2011 ➤ , Beetle 2012 ➤ , Bora 1999 ➤ , CC 2010 ➤ , CC 2012 ➤ , ...

Air conditioning system with refrigerant R134a - Edition 10.2014

ditioner compressor on the refrigerant increases its heat content

and its temperature. Its temperature is now considerably higher

than that of the ambient air.

The hot refrigerant flows with its heat content to the condenser.

There the refrigerant looses its heat through the condenser to the

surrounding air due to the temperature gradient between the re‐

frigerant and the surrounding air.

Thus, the refrigerant is a means of heat transport. Because it will

be needed again, it returns to the evaporator.

All air conditioning systems basically depend on the circulation of

refrigerant. However, there are differences in the construction of

the system.

1.10 General safety

♦ In accordance with VBG 20, the Federation of Employers Li‐

ability Insurance Associations.

♦ Observe instructions specific to the workplace; ⇒ Volkswagen

ServiceNet; Handbooks; Service handbook; Environmental

protection . Refrigerant from air conditioning systems / refrig‐

erant oils - to be displayed at refrigerant designated working

area.

1.10.1 Product characteristics

Refrigerants used in car air conditioning systems belong to the

new generation of refrigerants, the chlorine-free, partially-fluori‐

dated hydrocarbons (H-CFC, R134a).

In regard to their physical behaviour, they are refrigerants which

can be liquefied under pressure. They are subject to Regulations

for Pressure Tanks and may be charged only into approved and

identified pressurised gas containers.

Specific conditions which apply for safe and proper use must be

maintained.

1.10.2 Handling refrigerants

WARNING

Danger of freezing injuries.

The refrigerant can emerge as liquid or as vapour.

Do not open containers in which this refrigerant is present.

If refrigerant containers are opened, the contents may escape in

liquid or vapour form. The higher the pressure in the container,

the more energetic the emergence will be.

How high the pressure is depends on two factors:

• What type of refrigerant is in the container. “This is because

the lower the boiling point, the higher the pressure.”

• How high the temperature is. “This is because the higher the

temperature, the higher the pressure.”

1.10.3 Wear protective glasses

Put on protective glasses. This will prevent the refrigerant enter‐

ing the eyes, which in certain circumstances can cause severe

injury due to frostbite.

10 Rep. gr.00 - Technical data

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Amarok 2011 ➤ , Beetle 2012 ➤ , Bora 1999 ➤ , CC 2010 ➤ , CC 2012 ➤ , ...

Air conditioning system with refrigerant R134a - Edition 10.2014

1.10.4 Wear protective gloves and apron

Refrigerants dissolve fats and oils very well. Therefore, when they

come in contact with the skin, they take away the protective layer

of fat. Skin from which the natural oil and fat have been removed

is vulnerable to cold and germs.

Note

contact with the skin

systems

1.10.5 Do not allow liquid refrigerant to come in

The refrigerant will draw its latent heat of evaporation from its

surroundings. That can be your skin. This can result in very low

temperatures. The result is local frostbite (boiling point of R134a

is -26.5°C at normal atmospheric pressure).

1.10.6 Do not breath in refrigerant vapour

In high concentrations, emerging refrigerant vapours can mix with

the air and displace the oxygen necessary for breathing.

1.10.7 Absolutely NO SMOKING

Refrigerant can decompose in a burning cigarette. The resulting

substances are poisonous and must not be breathed in.

1.10.8 Welding and soldering on refrigeration

Before welding and brazing on vehicles (in the vicinity of the air

conditioning system components), extract the refrigerant and

then purge the system by blowing through with compressed air

and using nitrogen.

The products of decomposition of refrigerants under heat are not

only poisonous but are strongly corrosive, so that pipework and

system parts could be attacked. This refers primarily to hydrogen

fluoride.

1.10.9 Pungent smell

A pungent odour indicates that the products of decomposition

mentioned above are already present. Breathing in these sub‐

stances must be avoided under all circumstances, or the bron‐

chial tubes, lungs and other organs could be injured.

1.10.10 First aid

• In the event of contact with the eyes or mucous membranes,

wash immediately with copious running water and summon an

eye specialist.

• In the event of contact with the skin, remove wetted clothing

and wash the affected skin with copious water.

• If refrigerant vapours are breathed in high concentrations, take

the patient immediately into the fresh air. Summon a doctor. If

the patient has trouble breathing, administer oxygen. If the

patient's breathing is restricted or stops, bend the head at the

neck and commence resuscitation.

1.10.11 Handling pressure tanks

• Secure vessels against falling over!

Secure standing cylinders against falling over and lying cylinders

from rolling away.

1. General notes on air conditioning systems 11

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i