Viking Pump TSM1470 User Manual

Electronic copies of the most current TSM issue can be found on the Viking Pump website at www.vikingpump.com

TECHNICAL SERVICE MANUAL

INSTALLATION, START UP, TROUBLESHOOTING,

PREVENTIVE MAINTENANCE, DO’S & DON’TS

GP-04, GP-05 & GP-07 HI-LO DOUBLE PUMPS

CONTENTS

Introduction . . . . . . . . . . . . . . . . . . . . . . . 1

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Information. . . . . . . . . . . . . . . . . . . . 2

Installation. . . . . . . . . . . . . . . . . . . . . . . . 3

Start Up . . . . . . . . . . . . . . . . . . . . . . . . . 4

Troubleshooting. . . . . . . . . . . . . . . . . . . . . 4

Miscellaneous. . . . . . . . . . . . . . . . . . . . . . 5

Do’s and Don’ts . . . . . . . . . . . . . . . . . . . . . 6

INTRODUCTION

General

The following items must be considered prior to pump

installation:

1. Location - locate the pump as close as possible to the

supply of the liquid being pumped. If possible, locate

the pump below the liquid supply. Viking pumps are self

priming; but, the better the suction conditions, the better

the pump will perform.

2. Accessibility - the pump must be accessible for

inspection, maintenance and repair.

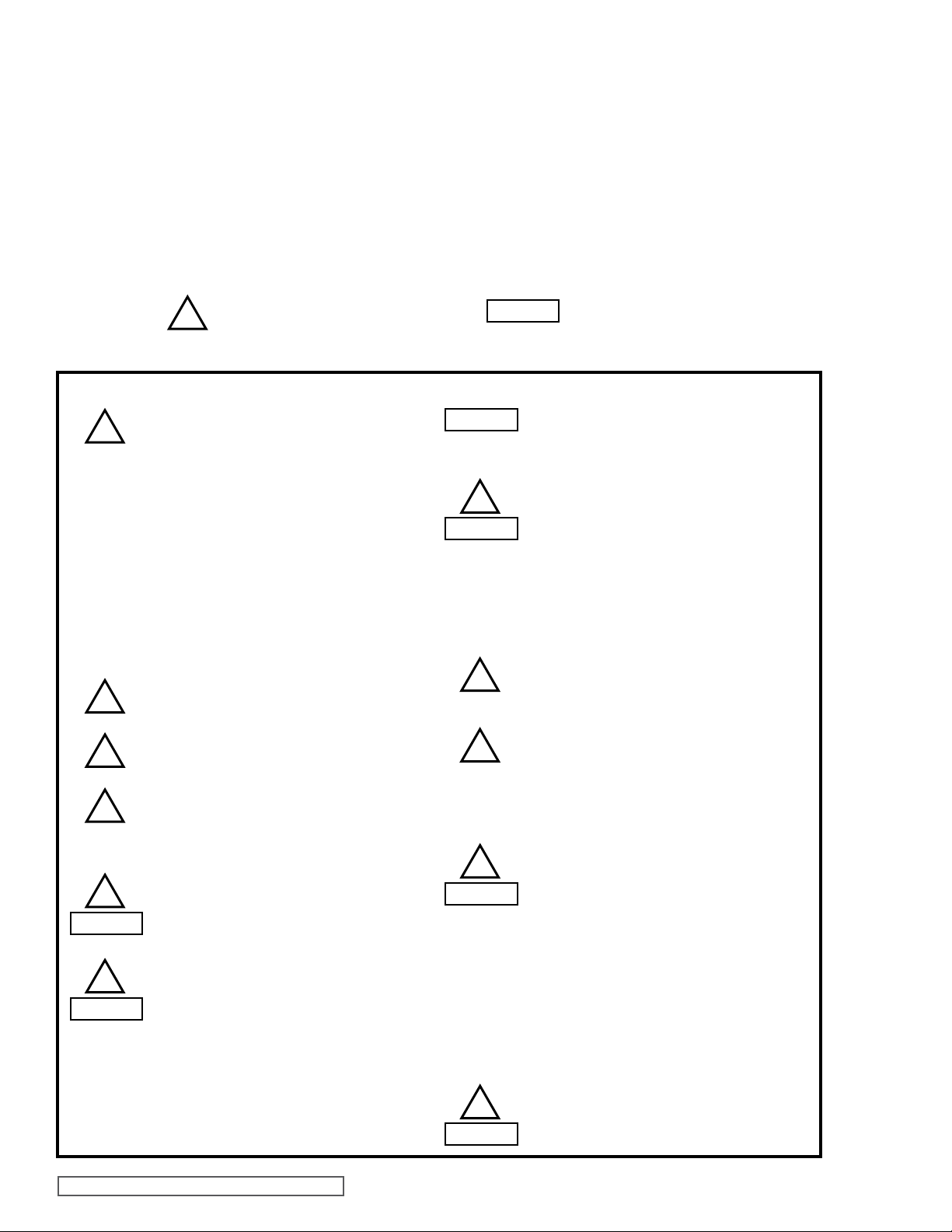

3. Suction/Discharge - Hi-Low Double pumps are

designed for clockwise rotation only (viewed from shaft

end). Refer to Figure 1.

4. Pump Life - pump life is a factor of many parameters,

mainly pressure, speed and duty cycle. Temperature,

contamination and type of hydraulic oil also have a

definite effect.

5. Hydraulic Oil - Viking recommends using industrial

grade hydraulic oil. Temperature must not exceed 150

ºF for optimum life of hydraulic oil. Operating viscosity

must be between 100 and 300 SSU.

6. Filter / Strainer - on a hydraulic system, use a return

line filter with a maximum 10 micron rating to keep the

system clean and free of contaminating elements. A 100

mesh strainer is recommended in the suction line.

7. Pressure Relief Valve - a pressure relief device must

be installed in the system to provide over-pressure

protection. If a line is blocked or closed, pressure builds

up until the motor stalls, drive equipment fails, a pump

part breaks or piping bursts.

8. Discharge Line - select discharge piping, hoses and

fittings rated for maximum system pressure.

9. Storage - if the pump is to be stored, drain the pump and

apply a light coat of non-detergent SAE 30 weight oil to

all internal pump parts. Apply grease to the pump shaft

extension. Viking suggests rotating the pump shaft by

hand one complete revolution every 30 days to circulate

the oil.

SECTION TSM 1470

PAGE 1 Of 8

ISSUE f

FIGURE 2

GP-05 HI-LO

DOUBLE PUMP

REPAIR

1. Parts For A Preventative Maintenance Program -

- Mechanical Seal or Lipseal(s) (Not applicable for Mag

Drive pumps)

- O-rings

2. Parts For A Major Overhaul - The Viking Spur Gear

series pumps have very tight clearances and precision

machining tolerances, and wear on any of the parts will

typically indicate that most of the critical parts are worn.

Therefore, if wear is found on any of the pump parts,

Viking recommends replacing the entire pump. Always

supply the serial number from your pump nameplate

when requesting a replacement.

S

S

FIGURE 1

D

D

VIKING PUMP, INC. • A Unit of IDEX Corporation • Cedar Falls, IA 50613 USAVIKING PUMP, INC. • A Unit of IDEX Corporation • Cedar Falls, IA 50613 USA

SAFETY INFORMATION AND INSTRUCTIONS

IMPROPER INSTALLATION, OPERATION OR MAINTENANCE OF PUMP MAY CAUSE SERIOUS INJURY

OR DEATH AND/OR RESULT IN DAMAGE TO PUMP AND/OR OTHER EQUIPMENT. VIKING’S WARRANTY

DOES NOT COVER FAILURE DUE TO IMPROPER INSTALLATION, OPERATION OR MAINTENANCE.

THIS INFORMATION MUST BE FULLY READ BEFORE BEGINNING INSTALLATION, OPERATION OR

MAINTENANCE OF PUMP AND MUST BE KEPT WITH PUMP. PUMP MUST BE INSTALLED, OPERATED

AND MAINTAINED ONLY BY SUITABLY TRAINED AND QUALIFIED PERSONS.

THE FOLLOWING SAFETY INSTRUCTIONS MUST BE FOLLOWED AND ADHERED TO AT ALL TIMES.

Symbol

Legend :

!

!

!

!

!

WARNING

!

WARNING

Danger - Failure to follow the indicated

instruction may result in serious injury

!

or death.

BEFORE opening any liquid chamber (pumping

chamber, reservoir, relief valve adjusting cap fitting,

etc.) be sure that :

● Any pressure in the chamber has been completely

vented through the suction or discharge lines or

other appropriate openings or connections.

● The pump drive system means (motor, turbine,

engine, etc.) has been “locked out” or otherwise

been made non-operational so that it cannot be

started while work is being done on the pump.

● You know what material the pump has been

handling, have obtained a material safety data

sheet (MSDS) for the material, and understand

and follow all precautions appropriate for the safe

handling of the material.

BEFORE operating the pump, be sure all drive guards

are in place.

DO NOT operate pump if the suction or discharge

piping is not connected.

DO NOT place fingers into the pumping chamber or

its connection ports or into any part of the drive train

if there is any possibility of the pump shafts being

rotated.

DO NOT exceed the pumps rated pressure, speed, and

temperature, or change the system/duty parameters

from those the pump was originally supplied, without

confirming its suitability for the new service.

BEFORE operating the pump, be sure that:

● It is clean and free from debris

● all valves in the suction and discharge pipelines

are fully opened.

● All piping connected to the pump is fully supported

and correctly aligned with the pump.

● Pump rotation is correct for the desired direction

of flow.

WARNING

WARNING

!

WARNING

!

!

!

WARNING

!

WARNING

Warning - In addition to possible serious

injury or death, failure to follow the

indicated instruction may cause damage

to pump and/or other equipment.

INSTALL pressure gauges/sensors next to the

pump suction and discharge connections to monitor

pressures.

USE extreme caution when lifting the pump. Suitable

lifting devices should be used when appropriate. Lifting

eyes installed on the pump must be used only to lift

the pump, not the pump with drive and/or base plate.

If the pump is mounted on a base plate, the base plate

must be used for all lifting purposes. If slings are used

for lifting, they must be safely and securely attached.

For weight of the pump alone (which does not include

the drive and/or base plate) refer to the Viking Pump

product catalog.

DO NOT attempt to dismantle a pressure relief valve

that has not had the spring pressure relieved or is

mounted on a pump that is operating.

AVOID contact with hot areas of the pump and/or

drive. Certain operating conditions, temperature

control devices (jackets, heat-tracing, etc.), improper

installation, improper operation, and improper

maintenance can all cause high temperatures on the

pump and/or drive.

THE PUMP must be provided with pressure protection.

This may be provided through a relief valve mounted

directly on the pump, an in-line pressure relief valve,

a torque limiting device, or a rupture disk. If pump

rotation may be reversed during operation, pressure

protection must be provided on both sides of pump.

Relief valve adjusting screw caps must always point

towards suction side of the pump. If pump rotation is

reversed, position of the relief valve must be changed.

Pressure relief valves cannot be used to control pump

flow or regulate discharge pressure. For additional

information, refer to Viking Pump’s Technical Service

Manual TSM 000 and Engineering Service Bulletin

ESB-31.

THE PUMP must be installed in a matter that allows

safe access for routine maintenance and for inspection

during operation to check for leakage and monitor

pump operation.

SECTION TSM 1470 ISSUE F PAGE 2 OF 8

INSTALLATION

Mounting

1. Surfaces to which the pump mounts against must be

clean and flat.

2. Use SAE Grade 5 or better capscrews to mount the

pump.

3. The 4 mounting capscrews for GP-04 and GP-05 pumps

must have a minimum of ½ inch engagement and must

be torqued evenly to 12-15 ft.-lbs.

4. The 2 mounting capscrews for the SG-07 pumps must

have a minimum of ½ inch thread engagement and must

be torqued evenly to 50-55 ft.-lbs.

5. Do not strike or press the pump drive coupling half to

install on the pump shaft. Damage to the pump or

coupling may result. If the coupling does not slide onto

the pump shaft, inspect the coupling bore, shaft and key

for nicks or burrs and remove if present.

6. Once the pump has been mounted, place a small amount

of compatible liquid into the suction port and turn by hand

to ensure the pump turns freely.

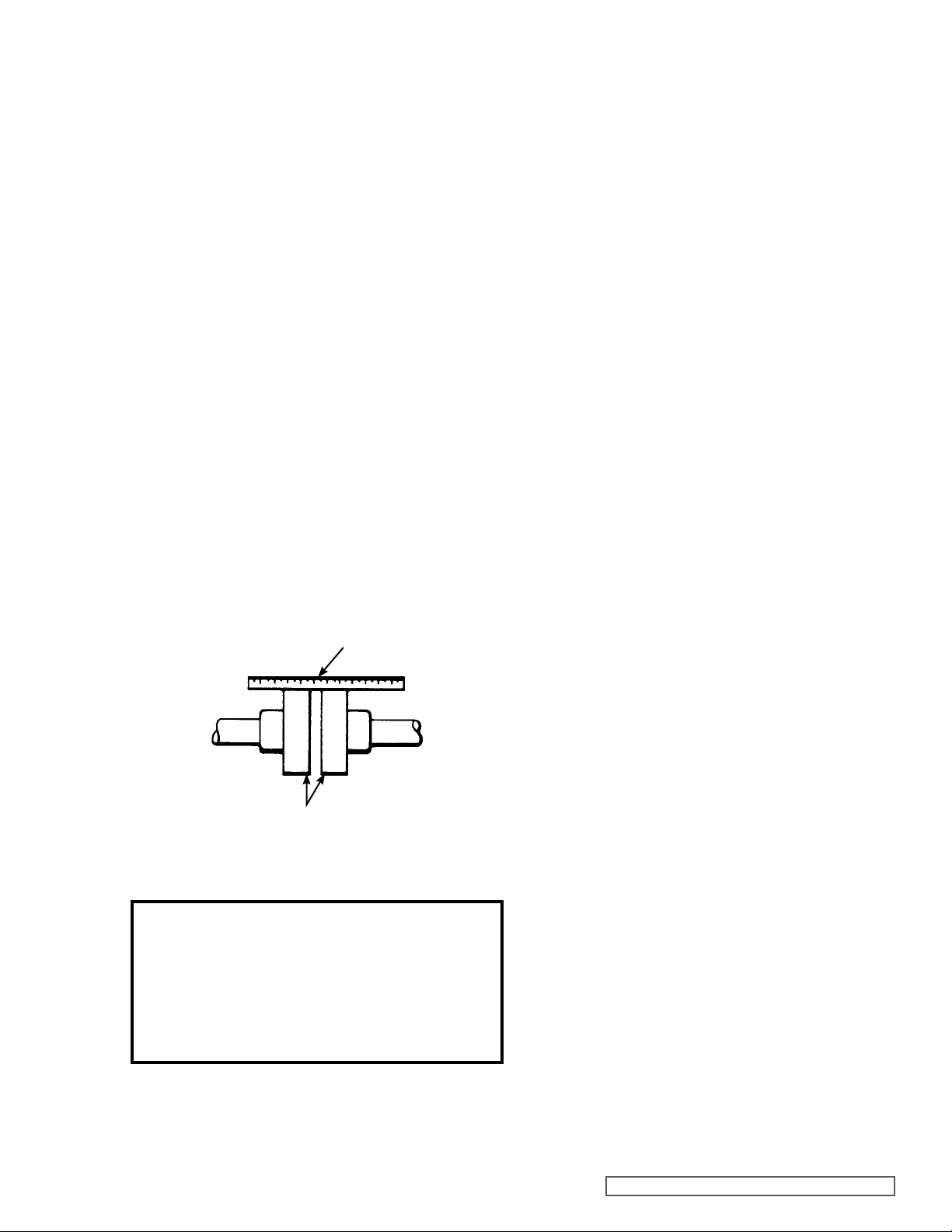

Alignment

Check alignment after mounting.

If the unit has a flexible coupling, remove any coupling guards

or covers and check alignment of coupling halves. A straight

edge (a piece of key stock will work) across the coupling

must rest evenly on both rims at the top, bottom and sides.

See Figure 3.

USE STRAIGHT EDGE.

THESE SURFACES

MUST BE PARALLEL.

CHECK WIDTH BETWEEN THESE SURFACES WITH INSIDE CALLIPERS OR FEELER

GAUGE TO BE CERTAIN THE FACES ARE EQUAL DISTANCE APART AND PARALLEL.

FIGURE 3

Danger !

Before starting pump, be sure all drive equipment

guards are in place.

Failure to properly mount guards may result in serious injury or death.

Piping/Hose

The cause of many pumping problems can be traced to the

suction piping. It should always be as large in diameter and

as short in length as possible.

Before starting the layout and installation of your piping

system, consider the following points:

1. Never use piping smaller than the pump port

connections. Piping larger in diameter than the port

connection is sometimes required to reduce friction

losses.

2. Be sure the inside of the pipe is clean before installing.

3. Do not use galvanized piping.

4. When approaching an obstacle in the suction line,

go around instead of over it. Going over an obstacle

may create an air pocket. Where practical, slope the

piping so no air or liquid pockets will be formed. Air

pockets in the suction line make it hard for the pump

to prime.

5. Viking recommends using a strainer on the suction

side of the pump. The strainer will keep foreign

objects from going into the pump. A 100 mesh

strainer is recommended. Provisions must be

made for cleaning the strainer. Use of a strainer is

particularly important at start up to help clean the

system of weld beads, pipe scale and other foreign

objects.

6. On a hydraulic system, it is recommended that a

return line filter be installed having a maximum 10

micron rating.

7. A pressure relief valve is required in the discharge

line. See Pressure Relief Valves, General page 1

item 7.

8. The pump must not be used to support piping.

Weight of the pipe must be carried by hangers,

supports, stands, etc.

9. When fastening to the pump do not impose any

strain on the pump casing. “Springing” or “drawing”

piping up to the pump will cause distortion, possible

misalignment and probable rapid wear of the pump.

Do not use the pump to correct errors in the piping

layout or assembly.

10. All joints of piping system must be tight; liquid thread

sealant will help assure leak free threaded joints.

Loose joints result in liquid leaks or suction side

leaks. Air leaks make the pump noisy and reduce

flow. CAUTION: Be careful not to over tighten

fittings as this can cause cracked joints. Do not use

PTFE / plumber’s tape. Reduced friction makes

over tightening very easy and will result in cracked

ports.

11. Drive alignment must be checked after the piping is

hooked up.

SECTION TSM 1470 ISSUE F PAGE 3 OF 8

Loading...

Loading...