Page 1

S

E

E

O

C

T

M

E

A

N

T

O

U

O

0

D

A

W

W

0

VT

SOLD

SOLD

STATI

ESTA

LÖTS

SC70

RING STA

ERSTATIO

N DE SO

IÓN DE S

ATION - 8

ION 80W

N - 80W/2

DAGE - 80

LDADURA

W/230V

/230V

30V

/230V

- 80W/23

V

USER

GEBRU

NOTIC

MANU

BEDIE

ANUAL

IKERSHAN

D’EMPLOI

L DEL USU

UNGSANLE

LEIDING

RIO

ITUNG

3

7

1

1

1

6

2

0

Page 2

C

a

VTSS

70

18.02.2010

2

©Vellem

n nv

Page 3

t

e

a

u

o

I

S

f

K D

v

DsI Apa

N

c

t

m

a

a

d

e

e

o

d

s

o

h

o

a

S

i

c

e

r

m

o

e

e

i

d

d

e

t

®

o

s

t

e

c

e

t

c

d

c

e

g

r

i

o

y

e

a

t

i

e

w

e

c

o

Q

e

j

y

o

o

f

d

r

b

C

n

r

t

s

h

u

x

i

g

e

s

a

a

d

a

e

f

g

s

a

w

s

c

o

y

n

p

o

e

r

s

e

w

r

a

a

i

r

d

e

h

e

e

y

n

t

k

m

s

b

d

b

a

t

g

e

o

n

a

t

u

1. In

To all r

Import

If in do

Thank y

service.

The VTS

2. Sa

roduction

sidents of th

nt environme

This symbol

lifecycle coul

Do not dispo

specialized c

This device s

Respect the l

bt, contact y

u for choosing

f the device w

C70 comes w

1x sold

1x sold

ety Instru

European Un

ntal informati

n the device o

harm the env

e of the unit (

mpany for rec

ould be return

ocal environme

ur local wast

Velleman! Ple

s damaged in

th:

ering station +

ering iron + tip

tions

VTSS

User m

ion

on about this

the package i

ronment.

r batteries) as

cling.

ed to your dist

ntal rules.

disposal au

se read the ma

ransit, don't in

power cord

and stand wit

70

anual

product

dicates that di

unsorted muni

ibutor or to a l

horities.

nual thoroughl

tall or use it a

tip cleaner

posal of the d

ipal waste; it s

cal recycling s

before bringin

d contact your

vice after its

ould be taken

rvice.

g this device in

dealer.

to a

o

3. Ge

Refer to

•

Fami

•

All

to th

•

Only

warr

•

Dam

the

•

Do n

Prot

eep this devic

o not use nea

entilated roo

o not touch th

oldering iron t

ncorrect use

lways disconn

erformed. Han

gainst damag

Do not

regulati

ever use the

apacitors are

neral Guid

he Velleman

Indo

liquid

Keep

liarise yourself

odifications of

e device is not

use the device

ealer will not a

ot switch the d

ct the device a

are cl

Prote

devic

nty.

ge caused by

away from ch

inflammable p

s.

e shaft or sold

its stand bet

may cause fir

ct mains powe

dle the power

. Have an auth

nhale solder fu

ons.

evice on live el

ischarged.

lines

Service and

r use only. K

. Never put ob

his device awa

ar at all times.

t this device fr

.

with the functi

he device are

overed by the

for its intende

isregard of ce

cept responsi

vice on immed

ainst damage

ldren and una

roducts or in e

ring tip as this

een uses; alwa

.

r when the dev

ord by the plu

rised dealer r

mes. Dispose o

ectronic circuit

uality Warr

ep this device

ect filled with li

from dust an

m shocks and

ns of the devic

orbidden for sa

warranty.

purpose. Usin

tain guidelines

ility for any en

iately after it h

by leaving it s

thorized users.

plosive atmos

can cause seri

ys let it cool do

ce is not in us

only. Do not c

place it if nece

f solder residu

. Make sure po

nty on the last

way form rain,

quid on top.

extreme heat.

buse. Avoid b

before actuall

ety reasons. D

the device in

in this manual

uing defects o

s been expose

itched off until

heres. Only us

us burns. Alwa

wn after use a

or when main

imp the power

sary.

in accordance

er to the wor

pages of this

moisture, spla

Make sure the

ute force when

y using it.

mage caused

n unauthorise

s not covered

problems.

to changes in

it has reached

in properly

s return the

d before stora

enance activiti

cord(s) and pr

with local

piece is cut a

anual.

hing and dripp

ventilation ope

operating the

y user modific

way will void

y the warranty

temperature.

room temperat

e.

s are

tect

d

ing

nings

tions

he

and

re.

18.02.201

0

3

©Vellem

n nv

Page 4

VTSSC70

4. Features

• electronic temperature control

• password lock

• sensor and heater fail notification

• LCD display with digital temperature scale (°C or °F)

• with on/off switch

• ceramic heating element with temperature sensor

• HEATER/SENSOR FAILED DETECTION: if the sensor circuit fails, the display reads “S--E” and heater

power is cut. If heater circuit fails the display will read “H--E” and heater power is cut.

• TEMPERATUE “LOCK-OUT” FEATURE: the temperature can be locked with a password which might be

useful in a production line.

• ESD SAFE AND SPIKE FREE CIRCUITRY: the “Zero Voltage” electronic switching design also protects

voltage and current sensitive components (CMOS devices, etc.) against overcurrent and transient

voltage spikes.

• LIGHTWEIGHT SOLDERING IRON: ergonomic mini handle that stays cool and prevents operator

fatigue.

• isolated power supply: high-quality 32Vac transformer designed for lead-free soldering

• temperature stability: tip temperature accurate to within ±3°C (6°F)

• available options:

o spare soldering bits: 0.4mm (BITC03), 0.8mm (BITC201)

o spare soldering iron: VTSSC7/SP1

5. Overview

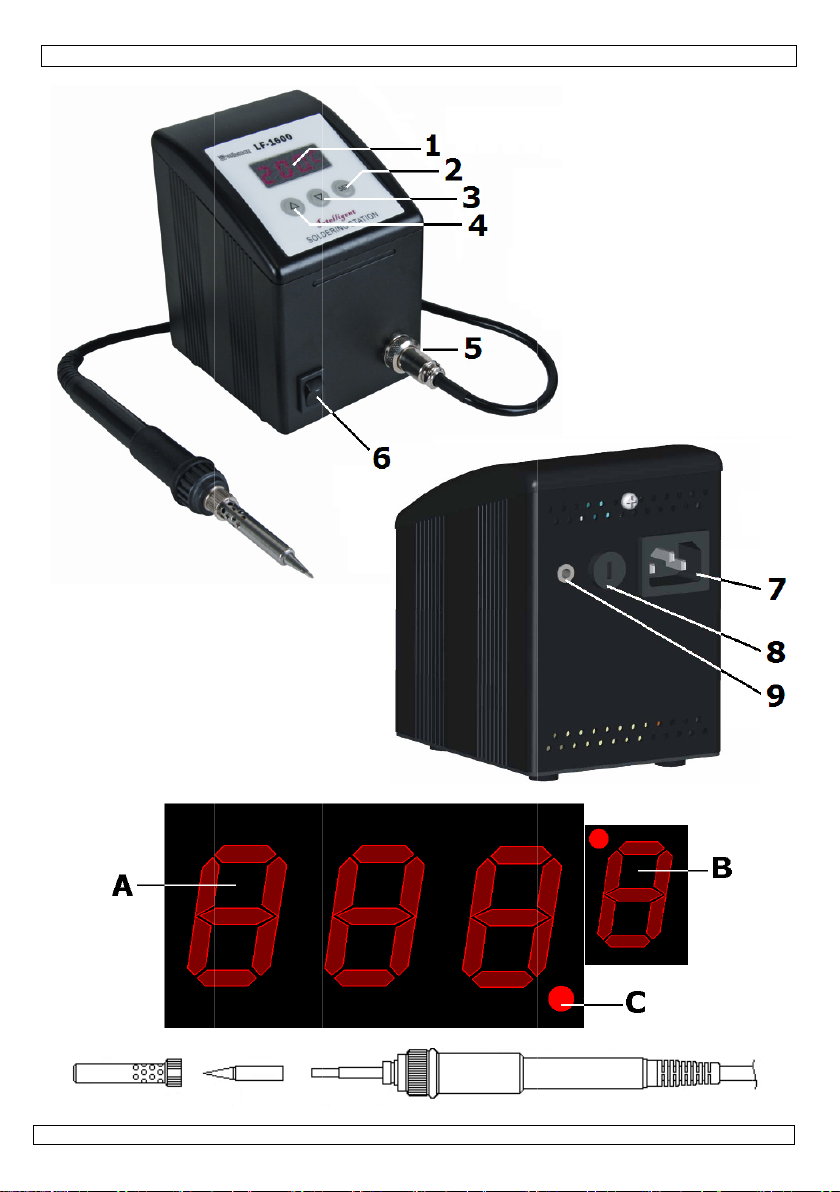

Refer to the illustrations on page 2 of this manual.

VTSSC70 5 soldering iron connection

1 display 6 power switch

2 SET-button 7 power connector

3 down-button (▼) 8 fuse

4 up-button (▲) 9 earth jack

display B temperature unit (°C or °F)

A temperature indication C heating indication

6. Description

• This soldering station is designed to meet the present and future needs of the electronic production

industry. The VTSSC70 is engineered to meet the stringent demands of hobbyists, maintenance

personnel and production people alike.

• A high-quality sensor and heat transfer technology ensure precise temperature regulation which is

essential for making consistent, reliable soldered connections.

• The aluminium alloy housing has several advantages: strong, good heat sink and very resistant to

electro-magnetic interference.

• The VTSSC70s’ electronic circuitry enables the user to set soldering temperatures between 200 and

480°C (392 to 896°F) without having to replace the tip or the heating element. The temperature is

maintained to within ± 3°C (± 6°F) of the normal operating temperature by a thermocouple sensor

placed in the head of the heating element. The 80W power results in a rapid heat-up and fast

recovery.

• The revolutionary "zero voltage" switching design also protects voltage- and current-sensitive

components (CMOS devices, etc.) against the damaging current and transient voltage spikes

commonly produced by less efficient, mechanically switched stations. The heating elements are

galvanically isolated from the electrical supply by an isolating transformer that prevents the system

from using a max. tension higher than a (safe) 32VAC.

18.02.2010 ©Velleman nv

4

Page 5

VTSSC70

7. Operating Temperature

The most common soldering alloys used in the electronics industry consist of 60% tin and 40% lead. The

operating temperature of this type of solder is detailed below and can vary from manufacturer to

manufacturer. However, to meet RoHS requirements, these solders are no longer allowed and are

replaced by lead-free solders that require a working temperature which is ±30°C (54°F) higher.

leaded solder lead-free

Melting point 215°C (419°F) 220°C (428°F)

Normal Operation 270-320°C (518-608°F) 300-360°C (572-680°F)

A good joint is assured if the iron's operating temperature is set within the parameters suitable for the

Production Line Operation 320-380°C (608-716°F) 360-410°C (680-770°F)

type of solder being used. The solder will flow too slowly if the temperature is too low; if the temperature

is too high, the flux in the solder may burn which will give rise to billowing white smoke. In turn, this will

result in a dry joint or in permanent damage to the PCB.

8. Operating instructions

Refer to the illustrations on page 2 of this manual.

Verify whether the operating voltage of the unit is identical to that of the electrical supply.

GENERAL

• Make sure the unit's power switch [6] is in the "OFF"-position.

• Plug in the soldering iron [5]. Note that the connector has a notch so it only fits in one way. Do not

• Connect the AC power cord to the power connector [7]. Connect the other end to a suitable mains

• When applicable, connect an earth wrist strap to the earth jack [9] at the back of the station.

PARAMETER SETTINGS

• Switch on the station [6]

• Press the SET-button [2] and hold for at least 5 seconds until the display shows “— — —”

• In the setup menu, the display will show “F-0”. Press the ▲[4]- or ▼ [3]-button to select modes. If

force.

outlet.

(flashing).Use the ▲-button [4] to enter the mode lock password “010” (default) and press the set-

button [2] to go into setup menu. A wrong password will return to normal working mode

(temperature indication).

no button is pressed within 15 seconds the device will return to normal operation mode.

• F-0: exit menu mode

Press the SET-button [2] when the display shows F-0 to exit the setup menu and return to

temperature indication.

• F-1: password mode

When password mode is enabled, the user can not change the temperature settings on the

station unless he or she knows the password.

Press the set-button [2] once to enter password mode. Press the ▲[4]- or ▼ [3]-button to

change display between 000 and 100, with 000 indicating password mode disabled and 100

indicating password enabled. Press the set-button [2] to return to the setup menu.

• F-2: temperature correction mode

Press the set-button [2] once to enter temperature correction mode. Press the ▲[4]- or ▼ [3]-

button to enter a correction factor for the temperature, e.g. when the display shows 300°C but

the actual temperature is only 290°C, add 10°C to the shown correction value.

When in °C negative values are indicated with a minus in front; in °F negative values are

indicated by a blinking display (5s interval). Press the set-button [2] to return to the setup

menu.

• F-3: unit of temperature

Press the set-button

[2] once to enter temperature mode. Press the ▲[4]- or ▼ [3]-button to

change between °C and °F. Press the set-button [2] to return to the setup menu.

18.02.2010 ©Velleman nv

5

Page 6

VTSSC70

SOLDERING

IMPORTANT NOTE

Do not use temperatures in excess of 410°C (770°F) for normal soldering and desol

The device can be used at higher temperatures for short periods of time. EXERCISE GREAT CAUTION

WHEN DOING SO.

CAUTION

Do not touch the metal parts of the soldering iron while the unit is being used or while it is cooling in

order to avoid burns.

• Set the power switch [6] to the “ON”-position.

• Press the up-button (▲) [4] until the display [1] indicates 250°C (or 482°F). The unit [B] is shown

next to the temperature [A]. When the temperature is stable, the heating indication [C] is off.

Note: to change the indicated unit, see § parameter settings above.

• Tin the surface of the soldering tip by applying a new protective layer of solder.

• Set the iron to the desired working temperature.

• Always return the soldering iron to its stand between uses.

dering purposes.

9. Common causes for tip failure

• The temperature of the tip exceeds 410°C (770°F)

• The tip is not sufficiently tinned

• Wiping the tip on a surface with a high sulphur content or on a dirty or dry sponge

• Contact with organic or chemical substances such as plastic, resin, silicone and grease

• Impurities in the solder and/or a low tin content

10. Tip maintenance

The soldering uses extremely high temperatures. Make sure that the unit is switched off for maintenance

purposes.

Remove the tip and clean it after heavy or moderate use. We recommend cleaning the tip daily if the

station is used frequently.

The supplied soldering tip is made of copper covered with a layer of iron. It will retain its projected life

span if used properly.

• Always tin the tip before returning it to the holder, prior to turning off the station or to storing it for

long periods of time. Wipe the tip on a wet sponge or use our tip cleaner before activating the device.

• Using excessive temperatures (more than 400°C or 750°F) will shorten the life span of the tip.

• Do not exercise excessive pressure on the tip while soldering, as this may cause damage to the tip.

• Never clean the tip with a file or with abrasive materials.

• Do not use flux containing chloride or acid. Use only resinous fluxes.

• If an oxide film has formed, you should remove it by buffing carefully with a 600-800 grit emery

cloth or by using isopropyl alcohol and consequently applying a new protective layer of solder.

• Set the desired temperature after allowing the unit to idle at 250°C for three minutes. The station

will be ready for use once the set temperature is reached.

IMPORTANT

Remove and clean the tip daily. Remove excess solder from the barrel nut assembly when installing a

new tip, otherwise the tip may be fused to the heating element or to the retaining assembly.

11. Maintenance

• Soldering tips can be replaced simply by unscrewing the barrel nut assembly. Turn off the station and

allow it to cool down first. Damage to the soldering station may occur if the system is left on and the

removed tip has not been replaced.

• After removing the tip, you should blow out any oxide dust that may have formed in the tip

receptacle. Be careful not to get dust in your eyes. Replace the tip and tighten the screw. Pliers can

be used to avoid contact with hot surfaces BUT SHOULD BE USED WITH CAUTION because overtightening may cause damage to the element or fuse the tip to the element.

• The outer cover of the iron and station may be cleaned with a damp cloth using small amounts of

liquid detergent. Never submerse the unit in liquid or allow any liquid to enter the case of the station.

Never use any solvent to clean the case.

• If the iron or station should become faulty or, for some reason does not operate normally, the

system should be returned to the service department of your authorized dealer or service agent.

18.02.2010 ©Velleman nv

6

Page 7

c

a

t

a

o

s

f

e

n

s

c

e

e

v

v

e

l

e

e

e

s

o

n

u

h

t

t

h

v

f

p

t

c

p

n

t

n

b

e

h

b

g

v

o

a

h

n

s

e

l

t

U

v

e

e

d

a

e

e

a

t

o

t

n

t

m

t

g

a

e

n

o

t

C

82311

e

a

a

d

e

A

o

g

n

e

s

s

t

d

t

n

e

c

e

a

e

i

e

a

9

0

n

s

n

o

d

h

D

i

e

t

r

o

a

e

o

o

e

e

e

n

n

e

m

o

n

d

l

e

o

e

e

k

l

e

t

o

h

g

l

i

a

t

c

w

r

t

j

k

e

e

j

12. Te

max. he

tempera

low-volt

weight

dimensi

Use thi

event o

concern

www.v

© COPY

This ma

rights re

electroni

hnical sp

ter power for

ure range

ge iron

ns

device with

damage or i

ing this prod

lleman.eu. T

RIGHT NOTIC

ual is copyrigh

erved. No par

medium or ot

cifications

oldering iron

riginal acces

jury resulted

ct and the lat

e information

E

ed. The copyr

of this manua

erwise withou

VTSS

ories only. V

from (incorre

st version of

in this manu

ight to this m

may be copie

the prior writt

70

0W

00 - 480°C (3

2V AC

.58kg

85 x 100 x 17

lleman nv ca

ct) use of thi

this user ma

l is subject t

nual is owne

, reproduced, t

n consent of t

2 - 896°F)

mm

not be held r

device. For

ual, please vi

change with

by Vellema

ranslated or re

e copyright ho

sponsible in

ore info

sit our websit

ut prior noti

nv. All world

uced to any

der.

he

e

e.

ide

1. Inl

Aan all

Belangr

Hebt u

Dank u

toestel b

Inhoud:

2. Vei

3. Alg

Raadple

18.02.201

iding

ingezetenen

ijke milieu-in

Dit symbool o

weggeworpen,

batterijen) nie

terechtkomen

recyclagepunt

ragen, conta

oor uw aankoo

schadigd tijde

1x sold

1x sold

igheidsins

Houd buite

Vermijd ge

een goed g

Raak de sc

gebruik de

verkeerd

Ontkoppel

Neem de v

beschadigd

Adem

milieu

Gebruik di

voeding v

mene ric

g de Vellema

0

GEBR

an de Europ

ormatie betr

het toestel of

dit toestel sch

bij het gewon

voor recyclage.

brengen. Resp

teer dan de p

! Lees deze h

s het transpor

eerstation + v

eerbout + pun

ructies

het bereik va

ruik in de buur

ventileerde rui

acht of de pun

out altijd teru

ebruik ontsta

an het lichtnet

edingskabel en

zijn. Laat uw d

de vrijgekome

wetgeving.

t toestel nooit

n het circuit ui

tlijnen

®

service- en

IKERSH

se Unie

ffende dit pr

e verpakking

de kan toebre

huishoudelijk

U moet dit toe

cteer de plaat

laatselijke au

ndleiding gron

, installeer het

edingskabel

en houder me

kinderen en o

van brandbar

te.

van een inges

in de houder

t brandgeva

na gebruik of a

kel bij de stekk

aler zo nodig

dampen nooit

p een elektron

en ontlaad all

kwaliteitsgar

7

NDLEI

duct

eeft aan dat, a

gen aan het m

afval; het mo

tel naar uw ve

elijke milieuwe

oriteiten bet

ig voor u het t

dan niet en ra

puntreiniger

bevoegden.

producten of

hakelde (de)s

n laat afkoelen

r.

lvorens onderh

er vast. De voe

en nieuwe kab

in. Gooi solde

sch circuit ond

condensatore

ntie achteraa

ING

ls het na zijn l

lieu. Gooi dit t

t bij een gesp

rdeler of naar

geving.

effende de ve

estel in gebrui

dpleeg uw dea

xplosieve gass

ldeerbout nooi

alvorens hem

udswerkzaam

dingskabel ma

l plaatsen.

rresidu weg vo

r spanning. Sc

.

deze handleid

venscyclus wo

estel (en even

cialiseerd bedri

en lokaal

rwijdering.

neemt. Werd

er.

n. Gebruik en

aan. Plaats na

p te bergen. B

eden uit te vo

niet omgeploo

gens de plaats

hakel eerst de

ng.

©Vellem

dt

uele

f

het

el in

ij

ren.

id of

lijke

n nv

Page 8

v

u

r

a

a

e

t

r

o

m

R

t

G

p

O

k

o

i

eo ro r

e

0

l

e

n

n

p

s

o

t

e

k

p

t

t

e

e

e

e

n

g

e

e

r

n

e

e

a

i

O

-

A

L

u

g

e

e

o

d

e

e

g

m

f

o

t

e

w

e

E

h

a

A

d

s

e

e

r

m

P

a

p

n

u

g

C

h

n

t

d

r

s

e

o

w

s

e

L

o

c

o

,

h

p

u

t

a

k

e

h

a

g

e

a

e

1

a

a

u

g

t

d

f

o

e

e

n

v

d

i

t

r

t

a

e

C

o

w

o

e

r

a

r

n

g

s

e

n

• Leer

• Om

gebr

• Geb

• De g

uw d

verb

4. Eig

• elek

• verg

• verkl

• LCD

• met

• kera

• STO

geef

verw

• VER

tem

• STR

dan

• LICH

voor

• Geïs

zond

• Stab

• Opti

5. Om

Raadple

VTSSC7

1 disp

2 inst

3 ▼-k

4 ▲-k

display

A tem

6. Be

• Dit s

elek

ond

• Dan

tem

• De b

elek

Gebru

opspa

Besch

eerst de functi

eiligheidsrede

uik het toestel

ealer zal de ve

gerak

Besch

iker heeft aan

rantie geldt ni

nd mee houde

nschappe

ronische temp

endeling van d

ikker bij defect

display met dig

n/off schakela

isch verwarm

INGSDETECT

de display ‘S-

armingselemen

RENDELING V

eratuursinstelli

OMPIEKVRIJ C

zij het geaarde

TGEWICHT SO

langdurig gebr

leerde voedin

er lood.

liteit van temp

s:

eservedesolde

eservesoldeerb

schrijving

g de figuren

ay

lknop SET

op

op

eratuuraandui

chrijving

ldeerstation w

ronica-industri

rhoudspersone

zij de hoogwaa

eratuurregelin

ehuizing in alu

romagnetische

ik het toestel e

tende vloeisto

rm tegen stof

n

rm tegen sch

s van het toes

en mag u geen

ebracht valt ni

nkel waarvoor

t voor schade

antwoordelijkh

n.

ratuurregeling

e temperatuurr

sensor of ver

itale temperatu

ngselement m

R VOOR HET V

E’ weer en zal

t geeft de displ

N DE TEMPER

ng via paswoor

IRCUIT: Geen

ontwerp en de

DEERBOUT: H

ik.

: hoogwaardig

ratuur: tempe

rpunten: 0,4

out: VTSSC7/S

p pagina 2 v

ing

erd ontworpen

. De VTSSC70

l en productie

rdige sensor e

, kunt u betro

inium is stevi

stralen tegen.

VTSS

nkel binnens

fen. Plaats gee

en extreme hit

kken en vermij

el kennen voor

wijzigingen aa

et onder de ga

het gemaakt i

door het neger

id afwijzen vo

egeling via pas

armingseleme

urschaal (°C of

t temperatuur

RWARMINGSE

et verwarming

y ‘H--E’ weer

TUURSINSTEL

. Dit is handig

toring van gev

nuldoorgangss

t kleine, ergon

transformator

atuur van de p

m (BITC03), 0

1

n deze handle

met het oog op

voldoet dus ru

ersoneel.

hitteoverdrac

wbare soldeer

, de koelt het t

70

uis. Bescherm

objecten gev

e. Zorg dat de

brute kracht

u het gaat geb

nbrengen. Sch

antie.

. Bij onoordeel

n van bepaald

r defecten of p

oord

nt

°F)

ensor

LEMENT EN DE

selement uitsc

n zal het verw

ING: Dit statio

aan de monta

elige onderdel

hakeling.

mische handv

van 32 VAC sp

unt is nauwkeu

8 mm (BITC20

iding.

5 aansluiting

6 aan-uitsch

7 voedingsa

8 zekering

9 aardingsaa

B temperatu

C opwarmin

de huidige en

imschoots aan

ttechnologie, d

unten maken.

oestel op een e

tegen regen, v

ld met vloeisto

verluchtingsop

ijdens de bedi

ruiken.

de door wijzigi

undig gebruik

richtlijnen in

roblemen die h

SENSOR: Bij s

akelen. Bij sto

rmingselemen

n heeft een ver

elijn.

n zoals CMOS-

t wordt niet w

ciaal ontworp

rig tot op ± 3°

)

soldeerbout

kelaar

nsluiting

nsluiting

reenheid (°C

saanduiding

oekomstige k

e eisen van h

ie zorgen voor

ficiënte manie

chtigheid en

f op het toestel

ningen niet ve

ning.

gen die de

ervalt de gara

eze handleidin

er rechtstreek

oring van de s

ing van het

uitschakelen.

grendelbare

componenten

rm en is gesch

n voor het sold

(6°F).

f °F)

aliteitseisen va

bbyisten,

en precieze

en houdt

.

stopt

tie.

en

nsor

ikt

eren

de

18.02.201

0

8

©Vellem

n nv

Page 9

VTSSC70

• Dankzij het elektronische systeem van de VTSSC70 kunt u soldeertemperaturen instellen van 200

tot 480°C (392 tot 896°F) waarbij u noch de punt, noch het verwarmingselement hoeft te vervangen.

De temperatuur wordt binnen een marge van ± 3°C (± 6°F) van de normale bedrijfstemperatuur

gehouden dankzij het thermokoppel in verwarmingselement. Het vermogen van 80 W zorgt voor een

snelle ideale bedrijfstemperatuur.

• De revolutionaire ‘nuldoorgangsschakeling’ beschermt gevoelige componenten (CMOS-apparaten,

enz.) tegen de stroomstoten en spanningpieken die bij minder efficiënte, mechanisch geschakelde

stations dikwijls leiden tot beschadiging. De verwarmingselementen zijn galvanisch gescheiden van

het net door een scheidingstransformator die het systeem een veilige maximale spanning van 32 VAC

laat gebruiken.

7. Bedrijfstemperatuur

De meest gebruikte soldeerlegeringen in de elektronica-industrie bestaan uit 60% tin en 40% lood.

Hieronder vindt u de werktemperatuur van dit type soldeer. Die temperatuur kan verschillen van

fabrikant tot fabrikant. De Europese RoHS-standaard verbiedt echter het gebruik en de verkoop van

loodsoldeer. Het toegelaten loodvrije soldeer smelt aan een temperatuur die gemiddeld 30°C (54°F)

hoger ligt dan dat van loodsoldeer.

loodsoldeer loodvrij soldeer

Smeltpunt 215°C (419°F) 220°C (428°F)

Normale werking 270-320°C (518-608°F) 300-360°C (572-680°F)

Een goede verbinding is verzekerd indien de werktemperatuur van de soldeerbout is afgestemd op de

Productiedoeleinden 320-380°C (608-716°F) 360-410°C (680-770°F)

werktemperatuur van het type soldeer dat u gebruikt. Het soldeer zal te traag vloeien bij een te lage

temperatuur; een te hoge temperatuur verbrandt de flux in het soldeer en veroorzaakt een hevige

rookontwikkeling. Dit leidt dan weer tot een droge verbinding of tot permanente beschadiging van de

printplaat.

8. Bedieningsinstructies

Raadpleeg de figuren op pagina 2 van deze handleiding.

Controleer of de werkspanning van het toestel identiek is aan die van de stroomvoorziening. Ga na of het

toestel niet werd beschadigd tijdens het transport.

ALGEMEEN

1. Plaats de voedingsschakelaar [6] op OFF.

2. Plug voorzichtig de soldeerbout [5] in. Door de inkeping kunt u ze op slechts een enkele manier

3. Sluit de voedingskabel aan op de voedingsaansluiting [7]. Steek de stekker in het stopcontact.

4. Sluit indien gewenst een antistatische armband aan de aardinsaansluiting [9] achteraan het toestel.

INSTELLINGEN

• Schakel het station in [6].

• Houd SET [2] gedurende minstens 5 seconden ingedrukt tot ‘— — —’ op de display knippert. Geef

• In het instelmenu zal de display ‘F-0’ weergeven. Selecteer de modus met ▲ [4] of ▼ [3]. Na 15

aansluiten.

het paswoord (het standaard paswoord is ‘010’) in met ▲ [4] en druk op SET [2] om het instelmenu

weer te geven. Bij het invoeren van een ongeldig paswoord keert u terug naar de normale

werkmodus (temperatuuraanduiding).

seconden keert het station terug naar de normale werkmodus.

• F-0: verlaten van het menu

Verlaat het instelmenu met SET [2]. U keert terug naar de temperatuurweergave.

• F-1: instellen van het paswoord

Wanneer de paswoordmodus ingeschakeld is, kan de gebruiker de temperatuursinstelling niet

wijzigen zonder eerst het paswoord ingevoerd te hebben.

Druk op SET [2] om het paswoordmenu weer te geven. Selecteer nu 000 (paswoord

uitgeschakeld) of 100 (paswoord ingeschakeld) met ▲ [4] of ▼ [3]. Druk opnieuw op SET [2]

om naar het instelmenu terug te keren.

• F-2: temperatuursinstelling

Druk op SET [2] om het instelmenu voor de temperatuur weer te geven. Geef de correctiemarge

in met ▲ [4] of ▼ [3]. Wanneer de weergegeven temperatuur afwijkt van de reële temperatuur

18.02.2010 ©Velleman nv

9

Page 10

VTSSC70

van de punt, kunt u de weergave hier ijken. Voorbeeld: weergegeven temperatuur = 300°C,

reële temperatuur van de punt = 290°C, voeg 10°C toe.

Een negatieve Celsiuswaarde wordt aangeduid met een minteken; een negatieve

Fahrenheitwaarde zal knipperen. Druk op SET [2] om naar het algemeen instelmenu terug te

keren.

• F-3: selecteren van de temperatuureenheid

Druk op SET [2] om het instelmenu weer te geven. Selecteer nu de eenheid (°C of °F ) met

▲[4] of ▼ [3]. Druk op SET [2] om naar het algemeen instelmenu terug te keren.

SOLDEREN

BELANGRIJKE OPMERKING

OPGELET

• Plaats de voedingsschakelaar op ON.

• Druk op ▲[4] onderaan de soldeerdisplay tot deze display de waarde 250°C weergeeft.

• Opmerking: Houd ▲[4] of ▼ [3] ingedrukt om de waarde sneller te wijzigen. Tijdens het opwarmen

• Vertin het oppervlak van de soldeerpunt en de desoldeerpunt door een nieuw beschermend laagje

• Stel de gewenste temperatuur in.

• Plaats na gebruik de soldeerbout altijd terug in de houder.

Bij het solderen mag u geen temperaturen gebruiken die de 410°C (770°F) overstijgen. U kunt het

toestel wel kortstondig gebruiken bij hogere temperaturen, maar dan moet u heel voorzichtig zijn.

Om brandwonden te vermijden mag u de metalen delen van de soldeer- en de desoldeerbout niet

aanraken tijdens gebruik of wanneer ze aan het afkoelen zijn.

van de bout zal de opwarmingsaanduiding op de display [C] knipperen.

soldeer aan te brengen.

9. Defecte punt: mogelijke oorzaken

• De temperatuur van de punt is hoger dan 410°C (770°F).

• De stiftpunt is onvoldoende vertind.

• De punt is in contact gekomen met een vuile of droge spons of met een oppervlak met een te hoog

zwavelgehalte.

• Contact met organische of chemische stoffen zoals plastic, hars, vetten en siliconen.

• Onzuiverheden in het soldeer en/of soldeer met een te laag tingehalte.

10. Tips voor het onderhoud van de punt

De soldeerbout maakt gebruik van extreem hoge temperaturen. Schakel het toestel uit wanneer u het wil

reinigen.

Verwijder en reinig de punt na intensief gebruik. U moet de punt dagelijks reinigen indien u het toestel

frequent gebruikt.

De meegeleverde soldeerpunt is vervaardigd uit koper bekleed met ijzer. De levensduur blijft enkel

behouden indien u ze gebruikt zoals het hoort.

• U moet de punt altijd vertinnen vóór u hem terug in de houder plaatst, vóór u het apparaat

uitschakelt of bij lange periodes van inactiviteit. Veeg de punt schoon met een natte spons vóór u

begint of gebruik onze reinigingsspons.

• De levensduur van de punt vermindert indien u te hoge temperaturen gebruikt (hoger dan 400°C of

750°F).

• Duw niet te hard op de punt tijdens het solderen om beschadiging te vermijden.

• Gebruik geen vijlen of schurende materialen om de punt te reinigen.

• Gebruik geen vloeimiddelen die chloride of zuur bevatten. Gebruik enkel harshoudende

vloeimiddelen.

• Verwijder eventuele oxidelaagjes door voorzichtig te polijsten met een amarildoek met korrel 600 –

800. U kunt ook isopropylalcohol gebruiken en vervolgens een nieuw laagje soldeer aanbrengen.

• Laat het toestel opwarmen tot 250°C (482°F) en stel na een drietal minuten de gewenste

temperatuur in. Het toestel is gebruiksklaar wanneer de ingestelde temperatuur wordt bereikt.

BELANGRIJK

Reinig de punt dagelijks. Verwijder overtollig soldeer van de stiftvergrendeling en de stiftpunt, anders

kan de punt samensmelten met het verwarmingselement of met de stiftvergrendeling.

18.02.2010 ©Velleman nv

10

Page 11

d

t

s

s

n

k

g

e

c

r

t

o

k

h

a

g

U

e

n

t

i

o

d

u

l

u

n

G

t

v

i

a

k

o

e

p

e

t

e

t

n

r

k

i

i

s

m

c

à

o

k

n

m

e

r

s

g

t

a

t

n

g

O

n

e

u

e

o

n

a

g

n

n

C

s

r

E

e

v

s

f

s

d

e

e

e

s

d

m

e

a

v

e

t

e

I

n

k

e

7

m

o

e

o

I

c

m

c

à

i

n

v

s

r

u

e

d

e

k

e

d

m

v

d

o

p

r

e

v

o

a

m

e

t

e

D

a

v

n

t

v

o

e

11. On

• Om

toes

inge

• Blaa

tege

met

aans

word

• Maa

reini

in d

• Bren

12. Te

max. ve

tempera

soldeerb

gewicht

afmeting

Gebrui

voor sc

over dit

inform

kennis

© AUTE

Vellema

Alle wer

over te

voorafga

derhoud

e soldeerpunt

el eerst uit om

chakeld en de

het oxidestof

dit stof. Verv

hete oppervlak

pant, kan het v

en samengesm

de soldeerbou

ingsmiddel. D

behuizing kan

g een defect to

hnische s

mogen van het

uurbereik

ut

en

dit toestel

ade of kwe

product en d

tie in deze h

eving.

RSRECHT

n nv heeft he

ldwijde rechte

emen, te kopië

ande sch

iftelij

e vervangen h

het te laten af

erwijderde pu

n de stifthoude

ng de punt en

en te vermijde

erwarmingsele

olten.

t en het toestel

mpel het toest

binnensijpelen.

stel terug naa

ecificatie

verwarmingsel

nkel met ori

suren bij (ve

meest recen

andleiding k

auteursrech

voorbehouden

ren, te vertale

e toestemmin

VTSS

eft u enkel de

oelen. Het toe

t niet werd ve

r weg wanneer

draai de schroe

n. WEES ECHT

ent worden b

schoon met ee

l nooit in een

Gebruik geen

uw verdeler o

ement

inele acces

rkeerd) gebr

e versie van

n te allen tij

voor deze ha

. Het is niet to

, te bewerken

van de rechth

70

stiftvergrendeli

tel kan worden

vangen.

u de punt heef

f vast. U kunt

R VOORZICHT

schadigd of ku

n vochtige doe

loeistof onder

olventen.

agent.

80 W

200 - 480°C

32 VAC

1,58 kg

185 x 100 x 1

oires. Velle

uik van dit t

eze handleid

de worden g

ndleiding.

gestaan om de

n op te slaan

bbende.

ng los te schro

beschadigd in

verwijderd. B

en tang gebrui

G: indien u de

nen het eleme

een kleine ho

n zorg ervoor

0 mm

an nv is niet

estel.

Voor

ing, zie www.

wijzigd zon

ze handleiding

p een elektroni

ven. Schakel h

ien het systee

scherm uw og

en om elk con

schroef te hard

nt en de punt

veelheid mild

at er geen vlo

aansprakelij

eer informati

elleman.eu.

er voorafga

f gedeelten er

sch medium zo

et

is

n

act

istof

k

e

e

nde

an

der

1. In

Aux rés

Des inf

En cas

Nous vo

l’apparei

revende

Contenu

2. Co

18.02.201

roduction

dents de l'Un

rmations env

Ce symbole

peut polluer

éventuelles)

l’appareil en

de recyclage

l’environne

e questions,

s remercions d

. Si l’appareil a

r.

:

1x stat

1x fer

signes de

arder hors de

0

N

on européen

ronnemental

ur l'appareil o

l'environnemen

parmi les déch

question. Renv

local. Il convie

ent.

ontacter les

e votre achat !

été endomma

ion de soudage

souder + pan

sécurité

la portée des e

TICE D

e

s importante

l'emballage in

t. Ne pas jeter

ts municipaux

yer les équipe

t de respecter

utorités local

Lire la présent

é pendant le tr

avec cordon d’

e et support a

fants et des p

11

’EMPLO

concernant

ique que l’éli

un appareil éle

non sujets au t

ents usagés

la réglementat

es pour élimi

notice attenti

ansport, ne pa

limentation

ec laine d’acie

rsonnes non a

e produit

ination d’un ap

trique ou élect

ri sélectif ; une

votre fourniss

on locale relati

ation.

ement avant la

l’installer et c

pour le nettoy

torisées.

areil en fin de

onique (et des

déchèterie trai

ur ou à un ser

e à la protecti

mise en servic

nsulter votre

age

©Vellem

vie

piles

era

ice

n de

de

n nv

Page 12

É

e Ndi DdD

r

e

m

s

r

e

r

a

o

c

h

P

a

m

P

e

n

T

t

A

o

e

i

n

t

p

t

m

c

i

n

e

d

e

d

u

é

n

m

ÉT

d

’

R

m

n

R

r

E

,

a

r

n

è

e

a

c

s

e

u

r

a

s

e

o

n

n

n

o

c

u

S

n

a

C

à

s

u

é

C

r

e

a

u

r

u

e

o

r

a

o

a

r

n

e

q

d

M

é

é

U

c

T

o

a

n

z

t

a

t

t

s

é

t

e

c

o

c

o

h

ÉM

f

s

p

o

r

i

ç

a

t

k

e

a

s

c

,

o

s

e

d

F

a

c

n

a

±

a

r

e

é

e

e

T

e

u

e

e

b

viter l’usage à

ndroit bien ve

e pas toucher

essouder dans

ncorrect peu

proximité de p

tilé.

la tige ni la pa

le support apr

engendrer d

VTSS

oduits inflamm

ne afin d’évite

s usage. Laiss

s risques d’in

70

ables ou de ga

tout risque de

r refroidir le fe

cendie.

explosifs. N’u

brûlures. Place

r avant le stoc

iliser que dans

le fer à soude

age. Un usag

un

ou à

3. Di

Se référ

•

Se fa

•

Toute

modifi

•

N’utili

•

La ga

notice

résult

4. Ca

• régl

• verr

• déte

• affic

• avec

• élém

• DIS

L’affi

du c

l’ali

• DIS

du f

chaî

• PRO

d’au

• FER

prol

• Alim

• Stab

éconnecter la

’alimentation

emander à vo

Ne ja

respe

Ne jamais util

vers le circuit

ectives gé

r à la garanti

Utiliser

projecti

Protége

fentes

Protége

iliariser avec l

modification es

cations par le c

er qu’à sa fonc

antie ne s’appli

et votre reven

nt.

actéristiq

ge de la tempé

uillage de la te

teur en cas de

eur LCD avec

interrupteur o

ent d'échauffe

OSITIF DE D

cheur affiche «

pteur. En cas

entation vers l

OSITIF DE VE

r à l’aide d’un

e de productio

ECTION CONT

res appareils g

SOUDER LÉG

ngée. En outre

ntation isolée

lité de tempér

station du rése

ar la fiche. Le

re revendeur d

ais respirer le

tant la réglem

ser la station s

et de décharge

érales

de service et

cet appareil un

ons d’eau. Ne j

r contre la pou

e ventilation n

r contre les ch

fonctionneme

t interdite pour

lient ne tombe

tion prévue. U

que pas aux do

eur déclinera t

es

rature électroni

mpérature ave

dérèglement d

chelle de temp

/off

ent céramique

ECTION EN CA

S--E » et l’alim

’un dérègleme

élément de ch

ROUILLAGE DE

ot de passe.

.

E LES CRÊTES

âce à la mise

: Les forme

le manche ne

: transformate

ture : la temp

u après usage

âble d’aliment

e renouveler le

fumées de so

ntation locale

r un circuit so

les condensat

de qualité Ve

iquement à l'i

mais placer d’

sière. Protége

soient pas blo

cs et le traiter

t avant l’empl

des raisons de

t pas sous la g

usage improp

mmages surve

ute responsab

que

mot de passe

capteur ou d

érature numéri

avec capteur

DE DÉRÈGLE

entation vers l’

t de l’élément

uffe sera coup

LA TEMPÉRAT

eci est une fon

DE TENSION E

la terre et la c

ergonomiques

se réchauffe p

r de 32 VCA ha

rature de la pa

ou avant tout

tion ne peut p

câble d’alimen

dure. Éliminer

elative à la pro

s tension. Il e

urs au préalab

lleman® à la fi

ntérieur. Prot

bjet contenan

contre la chal

quées.

vec circonspe

i.

sécurité. Les d

rantie.

e annule d'offi

us en négligea

ilité pour les pr

l’élément d’éc

ue (°C ou °F)

e température

ENT DE L’ÉL

lément de cha

de chauffe, l’af

e.

RE : Il est pos

tion pratique

LES POINTES

nnexion « zer

du fer à soude

s pendant l’util

ute qualité con

ne est réglée

ravail d’entreti

s être replissé

ation si nécess

les résidus de

ection de l’env

t important de

le.

n de cette noti

ger de la pluie

un liquide sur

ur extrême. Ve

tion pendant l’

mmages occa

e la garantie.

nt certaines dir

blèmes et les

auffement

ENT DE CHAU

uffe est coupée

icheur afficher

ible de verrouil

our toute appli

DE COURANT :

cross ».

permettent u

sation.

u pour le soud

vec précision

n. Manier le co

ou endommag

ire.

oudure en

ironnement.

couper l’alimen

e.

de l’humidité

l’appareil.

iller à ce que le

pération.

ionnés par des

ctives de cett

éfauts qui en

FE ET DU CAP

dès un dérègl

« H--E » et

ler la températ

ation dans un

Pas d’interfér

e utilisation

ge sans plom

3°C (6°F).

rdon

.

tation

t des

s

EUR :

ment

re

nce

.

18.02.201

0

12

©Vellem

n nv

Page 13

VTSSC70

r

• Options

o pannes de rechange: 0,4mm (BITC03), 0,8mm (BITC201)

o fer à souder de rechange : VTSSC7/SP1

5. Description

Se référer aux illustrations à la page 2 de cette notice.

VTSSC70 5 connexion du fer à soude

1 afficheur 6 interrupteur marche/arrêt

2 bouton SET 7 prise d’alimentation

3 bouton ▼ 8 fusible

4 bouton ▲ 9 prise de terre

afficheur B unité de température (°C ou °F)

A indication de la température C indication de réchauffement

6. Emploi

• Cette station de soudage/dessoudage a été conçue afin de satisfaire aux exigences présentes et

futures du monde de l'électronique. La VTSSC70 convient donc parfaitement pour les hobbyistes

comme pour les services d'entretien et les ouvriers de production.

• Le capteur haute qualité et la technologie de transfert thermique efficace garantissent un réglage de

la température en précision, ce qui permet de réaliser de points de soudure fiables et consistantes.

• Le boîtier en aluminium est résistant, dissipe la chaleur et retient les interférences

électromagnétiques.

• La VTSSC70 est équipée d'une régulation électronique de la température de soudage entre 200 et

480°C (392 à 896°F) sans nécessiter un remplacement de la panne ou de l'élément d'échauffement.

La température est maintenue dans une marge de ± 3°C (± 6°F) de la température de service

normale à l’aide d’un thermocouple placé dans l’élément de chauffe. La puissance de 80 W suffit à

amplement à atteindre la température de service idéale.

• La connexion « zero cross » (quand le réseau passe par o) protège les composants sensibles (p.ex.

les appareils CMOS, etc.) contre les pointes de courant et les crêtes de tension qui, souvent, causent

des dégâts dans des stations commutées mécaniquement. Les éléments d'échauffement sont isolé

galvaniquement de la source d'alimentation par un transformateur de séparation qui permet au

système d'utiliser un maximum (sans risque) de 32 VCA.

7. Température de travail

La plupart des alliages de soudure dans le monde de l'électronique sont des alliages 60/40 (étain 60% plomb 40%). Ci-dessous vous trouverez la température de travail de ce type de soudure, une

température qui varie selon le fabricant. Cependant, la vente et l’utilisation d’étain avec plomb est, par la

norme RoHS, interdite en Union européenne. L’étain sans plomb nécessite une température plus élevée

de quelque 30°C (54°F).

Une bonne connexion est assurée si la température de travail du fer à souder correspond à la

température de travail du type de soudure employée. Une température trop basse amène une coulée

trop lente : le flux de la soudure risque de brûler en cas d'une température trop élevée, ce qui donne lieu

à une fumée dense. Cette fumée peut aboutir à une connexion sèche ou peut même occasionner un

endommagement permanent du circuit imprimé.

étain avec plomb étain sans plomb

Point de fusion 215°C (419°F) 220°C (428°F)

Opération normale 270-320°C (518-608°F) 300-360°C (572-680°F)

Usage dans la production 320-380°C (608-716°F) 360-410°C (680-770°F)

8. Instructions d'opération

Se référer à l’illustration à la page 2 de cette notice.

Vérifiez si la tension de travail de l'appareil est identique à celle de l'alimentation en électricité. Vérifiez si

l'appareil n'a pas été endommagé pendant le transport.

EN GÉNÉRAL

• Mettez l'interrupteur d'alimentation [6] dans la position OFF.

18.02.2010 ©Velleman nv

13

Page 14

VTSSC70

• Branchez les fers à souder [5] et à dessouder [4]. Notez que les fiches de connexion ont un cran et

qu’elles ne peuvent être insérées que d’une seule façon dans la connexion.

• Connectez le cordon d’alimentation à la prise [7]. Insérez la fiche d’alimentation dans une prise de

courant.

• Si nécessaire, connectez un bracelet antistatique à la prise de terre [9] à l’arrière de la station.

PARAMÉTRAGE

• Allumez la station [6]

• Maintenez enfoncé le bouton SET [2] pendant au moins 5 secondes jusqu’à ce que « — — — »

clignote sur l’afficheur. Entrez le mot de passe (010 par défaut) avec le bouton ▲ [4] et renfoncez le

bouton SET [2] pour accéder au menu. Vous reviendrez au mode d’utilisation (affichage de la

température) lors de la saisie d’un mot de passe invalide.

• Une fois accédé au menu, l’afficheur affichera « F-0 ». Enfoncez le bouton ▲ [4] ou ▼ [3] pour

sélectionner le mode. La station revient au mode d’utilisation après une période de repos de 15

secondes.

• F-0 : quitter le menu

Enfoncez le bouton SET [2] lorsque l’afficheur affiche F-0 quitter le menu et revenir à l’affichage

de la température.

• F-1 : le mot de passe

Une fois le mot de passe activé, vous ne pourrez plus modifier la température de la panne.

Enfoncez le bouton SET [2] pour accéder au menu. Sélectionnez 000 (mot de passe désactivé)

ou 100 (mot de passe activé) avec le bouton ▲ [4] ou ▼ [3]. Renfoncez le bouton SET [2] pour

revenir au menu principal.

• F-2 : instauration de la température

Enfoncez le bouton SET [2] pour accéder au menu. Entrez la valeur corrective avec le bouton

▲ [4] ou ▼ [3]. Cette fonction permet détalonner l’afficheur lorsque la température affichée ne

correspond pas avec la température réelle de la panne. Exemple : température affichée = 300°C,

température réelle : 290°C, ajouter 10°C.

Une température °C négative est indiquée par un signe moins devant la valeur ; une température

°F négative clignotera. Renfoncez le bouton SET [2] pour revenir au menu principal.

• F-3 : unité de température

Enfoncez le bouton SET [2] pour accéder au menu. Sélectionnez l’unité de température (°C ou

°F) avec le bouton ▲

principal.

SOUDAGE

REMARQUES IMPORTANTES

ATTENTION

• Placez l'interrupteur d'alimentation [1] en position OFF.

• Enfoncez le bouton ▲ [4] sous l’afficheur gauche jusqu’à ce qu’il affiche 250°C.

• Remarque : Maintenez enfoncé le bouton ▲ [4] ou ▼ [3] pour modifier la température plus

• Étamez la surface de la panne de soudage en appliquant une nouvelle couche protectrice de soudure.

• Réglez la température de service.

• Placez le fer à souder dans le support après chaque usage.

Évitez des températures supérieures à 410°C (770°F) lors du soudage. L'appareil se laisse

néanmoins utiliser à des températures plus élevées pendants des intervalles de courte durée.

AGISSEZ AVEC CIRCONSPECTION DANS CE CAS.

Évitez les brûlures: ne touchez pas les parties métalliques du fer à souder lors de l'usage ou lorsqu'ils

sont en train de refroidir.

rapidement. L’indication de réchauffement [C] clignote sur l’afficheur clignote lorsque la panne se

réchauffe.

[4] ou ▼ [3]. Renfoncez le bouton SET [2] pour revenir au menu

9. Panne défectueuse : causes possibles

• La température de la panne dépasse 410°C (770°F)

• La panne n'est pas suffisamment étamée.

• La panne est entré en contact avec une éponge sèche ou sale ou avec une surface trop sulfureuse.

• Du contact avec des matières organiques ou chimiques comme le plastique, la résine, les graisses et

les silicones.

• Des impuretés dans la soudure et/ou de la soudure avec une teneur d'étain trop basse.

18.02.2010 ©Velleman nv

14

Page 15

VTSSC70

10. Entretien de la panne

Les fers à souder et à dessouder utilisent des températures très élevées. Débranchez l'appareil avant de

le nettoyer.

Enlevez et nettoyez la panne après chaque usage intensif. Nettoyez la panne chaque jour en cas d'une

utilisation fréquente.

Les pannes incluses sont faites en cuivre avec une couche de fer. Leur durée de vie reste optimale en cas

d'une utilisation appropriée.

• N'oubliez pas d'étamer la panne avant de la replacer dans son support, avant de débrancher

l'appareil ou lors d'une longue période d'inactivité. Avant de commencer, vous devez nettoyer la

panne à l'aide d'une éponge mouillée ou de notre nettoyant.

• La durée de vie de la panne sera raccourcie si vous employez des températures excessives (qui

dépassent donc 400°C ou 750°F).

• N'appuyez pas trop fort sur la panne pendant le soudage pour éviter tout endommagement.

• Évitez l'usage de limes et de matières abrasives lors du nettoyage de la panne.

• Évitez l'usage de fondants acidifères ou de fondants qui contiennent de la chlorure. N'utilisez que des

fondants résineux.

• Enlevez des couches d'oxyde en polissant prudemment avec du papier d'émeri avec un grain de 600

à 800. Vous pouvez également utiliser de l'alcool iso propyle et appliquer par la suite une nouvelle

couche protectrice de soudure.

• Vous pouvez instaurer la température désirée trois minutes après que l'appareil à atteint une

température de 250°C (482°F). La station de soudage/dessoudage est prêt à l'emploi dès que la

température instaurée est atteinte.

IMPORTANT

Nettoyez la panne journellement. Enlevez toute soudure superflue de la panne et du dispositif de

verrouillage. Sinon, vous risquez de faire fondre soit la panne et l'élément d'échauffement, soit la panne

et son dispositif de verrouillage.

11. Entretien

• La panne de soudage est facile à remplacer : vous n'avez qu'à dévisser le dispositif de verrouillage.

Débranchez d'abord l'appareil afin de garantir un refroidissement adéquat avant de remplacer la

panne. Vous risquez d'endommager l'appareil s'il reste branché sans que la panne soit remplacée.

• Une fois la panne enlevée, vous devez souffler la poussière du support de la panne. N'oubliez pas de

protéger vos yeux ! Remplacez la panne et serrez la vis au moyen d'une pince afin d'éviter tout

contact avec des surfaces chaudes. ATTENTION : si la vis est trop serrée, vous risquez

d'endommager l'élément ou de faire fondre l'élément et la panne.

• Nettoyez le fer à souder et la station à l’aide d’un chiffon humide et un peu de détergent. Ne jamais

immerger les composants dans un liquide quelconque et veillez à ce qu’aucun liquide ne pénètre à

l’intérieur du boîtier. Ne pas utiliser de solvants.

• Contactez votre revendeur ou votre agent en cas d’une station de soudage défectueuse.

12. Spécifications techniques

puissance max. du corps de chauffe 80 W

plage de température 200 - 480°C (392 - 896°F)

fer à souder 32V AC

poids 1,58 kg

dimensions 185 x 100 x 170 mm

N’employer cet appareil qu’avec des accessoires d’origine. SA Velleman ne sera aucunement

responsable de dommages ou lésions survenus à un usage (incorrect) de cet appareil. Voor

meer informatie omtrent dit product en de meest recente versie van deze handleiding, zie

www.velleman.eu. Toutes les informations présentées dans cette notice peuvent être

modifiées sans notification préalable.

© DROITS D’AUTEUR

SA Velleman est l’ayant droit des droits d’auteur pour cette notice.

Tous droits mondiaux réservés. Toute reproduction, traduction, copie ou diffusion, intégrale ou partielle,

du contenu de cette notice par quelque procédé ou sur tout support électronique que se soit est interdite

sans l’accord préalable écrit de l’ayant droit.

18.02.2010 ©Velleman nv

15

Page 16

t

u

a

p

d

s

r

a

c

n

d

n

a

c

d

a

e

c

a

s

p

á

e

U

d

y

p

a

m

e

c

r

e

n

p

i

u

t

N

e

e

o

p

e

t

7

e

u

d

l

e

e

r

c

b

m

c

s

o

a

E

o

f

t

c

e

C

L

e

i

v

m

o

e

m

r

c

u

s

u

o

z

r

j

s

®

s

n

s

n

u

s

a

n

n

R

e

u

n

u

c

d

e

r

a

d

e

m

e

e

e

é

o

u

a

o

o

s

d

o

n

c

s

a

s

s

u

u

u

r

y

r

o

u

a

o

s

r

d

n

n

a

a

s

1. In

A los ci

Import

Si tiene

Gracias

Si el apa

distribui

Incluye:

2. In

roducción

dadanos de l

ntes informa

Este símbolo

dañar el me

No tire este

empresa esp

reciclaje loca

Respete las l

dudas, conta

or haber comp

rato ha sufrido

or.

1x est

1x sold

truccione

MA

Unión Europ

iones sobre

en este aparat

io ambiente.

parato (ni las

ecializada en r

l.

yes locales en

te con las au

rado la VTSSC

algún daño en

ción de soldad

ador + punta y

de seguri

VTSS

UAL DE

a

l medio ambi

o el embalaje

ilas, si las hub

ciclaje. Devuel

relación con el

oridades loca

0! Lea atenta

l transporte n

ra con cable d

soporte con li

ad

70

USUA

nte concerni

indica que, si t

era) en la basu

a este aparato

medio ambient

les para resid

ente las instru

lo instale y pó

alimentación

piador para p

IO

nte a este pr

ira las muestra

ra doméstica;

a su distribuid

e.

os.

cciones del ma

gase en conta

ntas

ducto

inservibles, p

ebe ir a una

r o a la unidad

ual antes de u

to con su

drían

de

arla.

3. No

Véase la

• Fami

• Por

caus

• Utili

gara

• Los

gara

Mantenga el a

No utilice el a

aireado.

No toque el v

(de)soldador

almacenarlo.

Desconecte el

enchufe para

alimentación

es necesario,

Nunca utilice

circuito y des

rmas gene

Garantía de s

liarícese con el

azones de seg

dos por modifi

e sólo el apara

tía completam

años causados

tía y su distrib

parato lejos de

arato cerca de

stago ni la pun

n el soporte d

n uso incorr

aparato de la

esconectar el

protéjalo cont

ida a su distri

respire los hu

Nunc

regla

entación local

l aparato si el

argue todos lo

ales

rvicio y calid

el aparato sól

Utilice

tipo de salpic

ningú

No ex

onga este equ

Asegú

rese de que los

No ag

te el aparato.

funcionamient

ridad, las modi

caciones no au

o para las apli

ente.

por descuido d

uidor no será r

alcance de pe

productos infla

ta para evitar

spués del uso.

cto puede ca

ed eléctrica de

able de red, n

ra posibles dañ

uidor reempla

os de soldadu

con respecto a

ircuito está ba

condensadore

ad Velleman

en interiore

dura o goteo.

ipo a polvo. No

orificios de ve

vite usar exce

del aparato a

icaciones no a

orizadas, no e

aciones descrit

e las instruccio

sponsable de

sonas no capa

mables o de ga

ualquier riesgo

Deje que el sol

sar peligro d

pués del uso o

nca del propio

s causados po

ar el cable de

a. Tire los resi

la protección d

o tensión. Pri

.

al final de est

. No exponga

exponga este

tilación no est

iva fuerza dura

tes de utilizarl

torizadas del a

tán cubiertos p

s en este man

es de segurid

ingún daño u

itadas y niños.

s explosivo. Uti

de quemadura

ador se enfríe

incendio.

antes de limpi

cable. No apla

algún tipo de

limentación.

uos de soldad

l ambiente.

ero desconecte

manual del us

ste equipo a ll

quipo a tempe

n bloqueados.

nte el manejo

.

parato están p

or la garantía.

al. Su uso inc

d de este man

tros problemas

lice sólo en un

. Ponga el

antes de

rlo. Tire siemp

te el cable de

uperficie afila

ra al respetar l

la alimentació

ario.

via, humedad

aturas extrem

la instalación.

ohibidas. Los d

rrecto anula la

al invalidarán

resultantes.

lugar

e del

a. Si

a

del

i a

s.

ños

u

18.02.201

0

16

©Vellem

n nv

Page 17

VTSSC70

r

4. Características

• ajuste de la temperatura electrónico

• bloqueo de la temperatura con contraseña

• detector en caso de mal funcionamiento del elemento calentador y el sensor

• display LCD con escala digital de la temperatura (°C o °F)

• con interruptor ON/OFF

• elemento calentador cerámico con sensor de temperatura

• DETECTOR EN CASO DE MAL FUNCIONAMIENTO DEL ELEMENTO CALENTADOR Y EL SENSOR: Se

visualiza « S--E » en la pantalla y se desactiva el elemento calentador si el sensor no funciona

correctamente. Si el elemento calentador no funciona correctamente, aparece « H--E » en la pantalla

y se desactiva el elemento calentador.

• BLOQUEO DEL AJUSTE DE LA TEMPERATURA: Es posible bloquear la temperatura del soldador con

una contraseña. Esto es una función práctica para cualquier aplicación de una cadena de producción.

• PROTECCIÓN CONTRA LAS CRESTAS DE TENSIÓN Y LOS PICOS DE CORRIENTE: no hay

interferencias de otros aparatos gracias al diseño completamente puesto a tierra y la conmutación de

tensión « cruce de cero » (zero cross).

• SOLDADOR LIGERO: Las formas ergonómicas del soldador permiten un uso prolongado. Además, el

mango no se calienta durante el uso.

• alimentación aislada : transformador 32VAC de alta calidad diseñada para soldar sin plomo/desoldar

• estabilidad de la temperatura : precisión de la temperatura de la punta hasta ±3°C

• opción

o puntas de soldadura de recambio: 0.4mm (BITC03), 0.8mm (BITC201)

o soldador de recambio: VTSSC7/SP1

5. Descripción

Véase las figuras en la página 2 de este manual del usuario.

VTSSC70 5 conexión del soldado

1 pantalla 6 interruptor ON/OFF

2 botón SET 7 entrada de alimentación

3 botón ▼ 8 fusible

4 botón ▲ 9 conexión a tierra

pantalla B unidad de temperatura (°C o °F)

A indicador de la temperatura C indicación de recalentamiento

6. Descripción

• Esta estación de soldadura ha sido diseñada para cumplir con los requisitos presentes y futuros del

mundo de la electrónica. La VTSSC70 resulta idónea no sólo para los aficionados sino también para

los servicios de mantenimiento y la producción.

• El sensor de alta calidad y la tecnología de transferencia de calor

temperatura muy preciso, lo que permite realizar puntas de soldadura fiables y consistentes.

• La caja de aluminio es robusta, disipa el calor y retiene las interferencias electromagnéticas.

• La VTSSC70 está equipada con una regulación electrónica de la temperatura de soldadura entre 200

y 480°C (de 392 a 896°F) sin necesidad de cambiar la punta o el elemento calentador. La

temperatura se mantiene en un margen de ± 3°C (± 6°F) de la temperatura de funcionamiento

normal gracias al termopar colocado en el elemento calentador. La potencia de 80W asegura un

alcance rápido de la temperatura de funcionamiento ideal.

• La conexión "cruce de cero" (si la red pasa por cero) protege los componentes sensibles (por ejemplo

los aparatos CMOS, etc.) contra los picos de corriente y las crestas de tensión que causan

normalmente daños en las estaciones conmutadas mecánicamente. Los elementos calentador están

aislados galvánicamente de la fuente de alimentación por un transformador de separación que

permite al sistema usar un máximo (sin riesgo) de 32VCA. Los soldadores y desoldadores están

equipados con un ajuste de temperatura que está en el panel frontal. Gracias a este ajuste, el

usuario puede ajustar la temperatura de manera fácil y eficaz.

eficaz garantizan un ajuste de la

18.02.2010 ©Velleman nv

17

Page 18

VTSSC70

7. Temperatura de funcionamiento

La mayoría de las aleaciones de soldadura en el mundo de la electrónica son aleaciones "60/40" (estaño

60% - plomo 40%). Véase abajo para la temperatura de trabajo de este tipo de soldadura, una

temperatura que varia según el fabricante. Sin embargo, la norma RoHS prohíbe la venta y el uso de

estaño con plomo en la Unión Europea. El estaño sin plomo necesita una temperatura más elevada de

unos 30°C (54°F).

estaño con plomo estaño sin plomo

Punta de fusión 215°C (419°F) 220°C (428°F)

Funcionamiento normal 270-320°C (518-608°F) 300-360°C (572-680°F)

Se asegura una buena soldadura si la temperatura de trabajo del soldador corresponde con la

Uso en la producción 320-380°C (608-716°F) 360-410°C (680-770°F)

temperatura de trabajo del tipo de estaño usado. Tenga en cuenta que una temperatura demasiada baja

causa un flux demasiado lento: a temperaturas muy elevadas, el flux del estaño se quema, lo que da

lugar a un humo denso. Este humo puede tener como resultado una soldadura seca o puede dañar

permanentemente el circuito impreso.

8. Instrucciones de funcionamiento

Véase la figura en la página 2 de este manual del usuario.

Verifique si la tensión eléctrica es la adecuada para el aparato. Verifique si el aparato no ha sido dañado

durante el transporte.

GENERAL

• Ponga el interruptor de alimentación [6] en la posición "OFF".

• Conecte el soldador [5] A causa de la muesca sólo puede conectarlos de una sola manera.

• Conecte el cable de alimentación a la entrada [7]. Conecte el aparato a la red eléctrica.

• Si fuera necesario, conecte una pulsera antiestática a la conexión a tierra [9] de la parte trasera de

AJUSTES

• Active la estación [6]

• Mantenga pulsado el botón SET [2] durante al menos 5 segundos hasta que « — — — » parpadee en

• Después de haber entrado en el menú, la pantalla visualiza « F-0 ». Pulse el botón ▲ [4] o ▼ [3]

la estación.

la pantalla. Introduzca la contraseña (010 por defecto) con el botón ▲ [4] y vuelva a pulsar el botón

SET [2] para entrar en el menú. Volverá al modo de funcionamiento (visualización de la

temperatura) al introducir una contraseña inválida.

para seleccionar el modo. La estación vuelve al modo de funcionamiento después de 15 segundos.

• F-0 : salir del menú

Pulse el botón SET [2] si la pantalla visualiza F-0 para salir del menú y volver a la visualización

de la temperatura.

• F-1 : la contraseña

Después de haber activado la contraseña, ya no puede modificar la temperatura de la punta.

Pulse el botón SET [2] para entrar en el menú. Seleccione 000 (contraseña desactivada) o 100

(contraseña activada) con el botón ▲ [4] o ▼ [3]. Vuelva a pulsar el botón SET [2] para volver

al menú principal.

• F-2 : ajustar la temperatura

Pulse el botón SET [2] para entrar en el menú. Introduzca el valor de corrección con el botón

▲ [4] o ▼ [3]. Esta función permite calibrar la pantalla si la temperatura visualizada no coincide

con la temperatura real de la punta. Ejemplo: temperatura visualizada = 300°C, temperatura

real: 290°C, añadir 10°C.

Una temperatura °C negativa está indicada por signo negativo delante del valor; una

temperatura °F negativa parpadeará. Vuelva a pulsar el botón SET [2] para volver al menú

principal.

• F-3 : unidad de temperatura

Pulse el botón SET [2] para entrar en el menú. Seleccione la unidad de temperatura (°C o °F)

con el botón

▲ [4] o ▼ [3]. Vuelva a pulsar el botón SET [2] para volver al menú principal.

18.02.2010 ©Velleman nv

18

Page 19

VTSSC70

SOLDAR

OBSERVACIONES IMPORTANTES

¡OJO!

• Ponga el interruptor de alimentación en la posición "ON".

• Pulse el botón ▲ [4] en la parte inferior izquierda de la pantalla hasta que visualiza 250°C.

• Observación: Mantenga pulsado el botón ▲ [4] o ▼ [3] para modificar la temperatura de manera

• Aplique una nueva capa de protección de estaño en la superficie de la punta del soldador.

• Ajuste la temperatura de funcionamiento.

• Ponga el soldador en el soporte después de cada uso.

Evite temperaturas superiores a 410°C (770°F) al soldar. No obstante, puede usar el aparato a

temperaturas muy elevadas durante períodos cortos. EN ESTE CASO: SEA EXTREMADAMENTE

CUIDADOSO.

Evite quemaduras: no toque las partes metálicas del soldador durante el uso o la refrigeración.

más rápida. La indicación de recalentamiento [C] parpadea si la punta se recalienta.

9. Punta defectuosa: causas posibles

• La temperatura de la punta sobrepasa 410°C (770°F)

• La punta no tiene suficiente estaño

• La punta ha tocado una esponja seca o sucia o una superficie demasiado sulfúrica.

• El contacto con materias orgánicas o químicas como el plástico, la resina, las grasas y las siliconas.

• Impurezas en la soldadura y/o soldadura con insuficientemente estaño.

10. Mantenimiento de la punta

El soldador alcanza temperaturas muy elevadas. Desconecte el aparato antes de limpiarlo.

Quite y limpie la punta después de cada uso intensivo. Limpie la punta cada día en caso de uso

frecuente.

La punta incluida es de cobre con una capa de hierro. Usándolas correctamente, aumentará su larga

duración.

• No se olvide de estañar la punta antes de colocarla en el soporte, antes de desactivar el dispositivo o

durante un largo periodo de inactividad. Antes de empezar, limpie la punta con una esponja húmeda

o con nuestro limpiador.

• Se disminuye la duración de vida de la punta al utilizar temperaturas excesivas (más de 400°C o

750°F).

• No apoye excesivamente la punta durante la soldadura para evitar daños.

• Nunca limpie la punta con una lima o materiales abrasivos.

• Nunca use flux conteniendo cloruro o ácido. Sólo use flujos que contienen resina.

• Si se ha formado una película de óxido, quítela cuidadosamente puliéndola con papel de lija con un

grano de 600 a 800. Puede usar también alcohol isopropilo al aplicar después una nueva capa de

protección de soldadura.

• Ponga la temperatura deseada 3 minutos después de que el aparato haya alcanzado una temperatura

de 250°C (482°F). La estación de soldadura está lista para usar después de haber alcanzado la

temperatura deseada.

IMPORTANTE

Limpie la punta diariamente. Elimine todo exceso de soldadura de la punta y del dispositivo de

bloqueo. Si no, se arriesga a que se funda, bien la punta y el elemento calentador, bien la punta y el

dispositivo de bloqueo.

11. Mantenimiento

• Es fácil de cambiar la punta: desatornille sólo el dispositivo de bloqueo. Ante todo, desconecte el

aparato para garantizar un enfriamiento adecuado antes de reemplazar la punta. Es posible dañar la

estación de soldadura al dejarla activada sin reemplazar la punta.

• Una vez extraída la punta, elimine el polvo del soporte de la punta. ¡Proteja sus ojos! Introduzca la

nueva punta y apriete el tornillo con una pinza para evitar todo contacto con las superficies calientes.

¡OJO!: Puede dañar el elemento o puede hacer fundir el elemento y la punta al apretar demasiado el

tornillo.

• Limpie el soldador y la estación con un paño húmedo y un poco de detergente. Nunca sumerja el

aparato en un líquido y asegúrese de que no pueda entrar ningún líquido en el interior de la caja. No

utilice disolventes.

• Contacte con su distribuidor o representante en caso de una estación de soldadura defectuosa.

18.02.2010 ©Velleman nv

19