Page 1

V

N

S

D

E

&

S

N

I

FRA-R

TS

IR

D SMD

BGA REWORK

TATIO

U

ER MAN

UAL

3

Page 2

VTSDIR

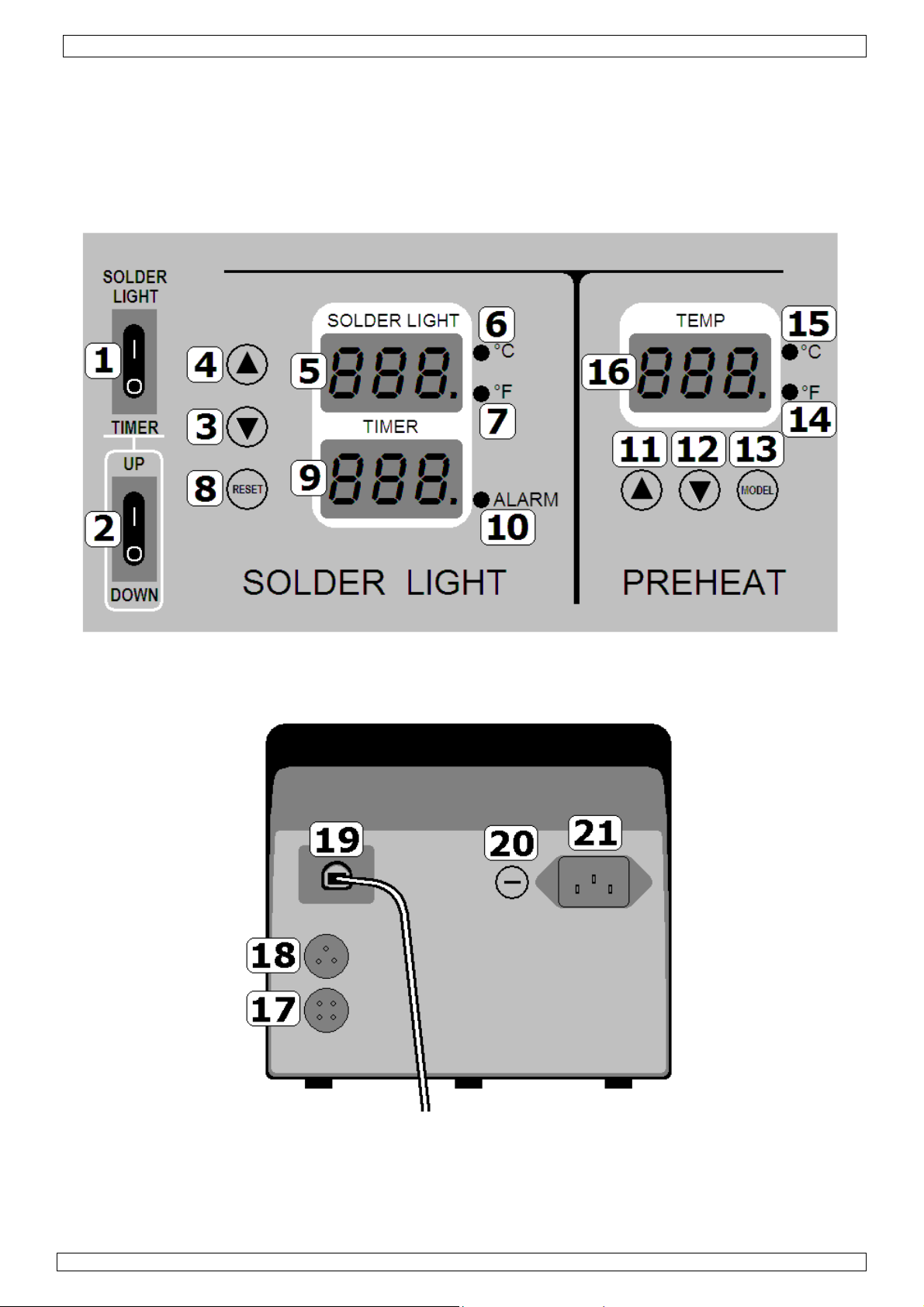

Main station front panel

Main station rear panel

Figure

21.03.2011 ©Velleman nv

2

Page 3

.

oIm

e

mPlekeeFowe

.

o

u

n

n

s

k

o

d

s

o

w

I

d

s

r

r

m

e

e

p

o

f

e

i

a

l

e

e

u

h

h

x

p

o

a

o

n

e

t

t

m

o

E

t

h

t

V

n

a

a

n

W

r

r

y

e

y

c

h

e

e

e

f

c

A

u

e

m

h

i

n

c

t

e

a

i

n

t

o

m

e

o

e

r

m

d

G

d

u

u

a

t

b

l

r

l

w

r

A

r

u

e

r

m

e

m

h

b

l

y

s

e

t

e

f

c

o

r

U

p

w

o

g

v

y

e

u

t

h

e

t

r

o

h

C

e

d

r

e

o

e

o

VTSDIR

n

c

h

r

u

o

c

s

r

o

w

m

i

b

n

m

n

n

o

e

t

d

s

t

y

w

e

a

u

s

f

o

o

L

d

n

h

n

i

a

w

g

o

d

n

g

t

e

u

w

c

t

r

c

n

g

r

D

n

A

e

t

l

f

n

c

m

o

t

.

a

t

b

c

r

R

f

w

d

s

e

K

n

u

e

s

e

s

a

t

e

.

a

o

a

n

d

u

n

u

a

a

n

a

i

n

y

I

c

1

Introd

T

all reside

portant e

Th

ank you for

th

device wa

Th

is appliance

co

ponents.

ase read th

p this man

r more inf

bsite ww

2

Safety

Warning an

significant

1.

Ensure th

2.

Check ca

3.

Put the p

resistant

4.

During th

Use glov

5.

Do not us

6.

Turn the

or prior t

7.

Keep the

amount o

use any s

Quartz h

8.

9.

This unit

used for

10

. Keep the

play with

prevent e

T

1.

Make sur

2.

Do not pr

3.

Do not b

damage t

4.

To isolate

electric s

5.

Do not e

6.

Turn the

will remai

7.

Do not m

This

harm

be ta

to a l

If in

ction

ts of the

vironmen

ymbol on t

the environ

en to a spe

cal recyclin

oubt, con

buying the

damaged i

is specially

is manual c

ual readily

concerni

.velleman

nstruct

:

Caution a

afety conce

e voltage ra

efully of an

oducts on a

aterial du

operation,

s and/or an

e the produ

ower switc

storing th

appliance cl

liquid dete

olvent to cl

ater is fragi

s designed

ny other pu

unit out of t

the applian

ectrical sh

the unit is

ssure the

mp, hit, po

e quartz h

the equipm

ock. This

pose the un

ower switc

n unused fo

dify the un

uropean U

al informa

e device or

ment. Do n

cialized co

g service. R

act your l

TSDIR! Pl

transit, do

designed fo

refully to

ccessible fo

g this pro

.eu.

ions

ARNIN

e positione

ns. Be sure

ting of the

damage d

safe and st

to the unit

the heater

heat resis

t near com

OFF and a

unit.

aning espe

rgent. Neve

an the case

le, be slight

or SMD re

rpose witho

he reach of

e.

ock, be su

grounded.

C power co

r water/liq

ater.

ent from th

ay result in

it to moistu

off and re

r a longer p

t.

Us

ion

ion about

the packag

t dispose o

pany for re

spect the l

cal waste

ase read th

not install o

SMD/BGA

aximize the

r reference.

uct and th

and CA

at critical

to comply

nit and you

ring transp

ble workin

can reach

is extremel

ant tools to

ustible gas

low the hea

cially the q

submerse

.

y moving t

ork, BGA re

ut first cons

children. Yo

e to take t

lways conn

d. Be sure

ids or othe

mains bef

Death or se

e nor use t

ove the A

riod of tim

r ma

his produ

indicates t

the unit (o

ycling. This

cal environ

disposal a

e manual th

use it and

rework and

advantage

e latest ve

TION

oints in the

ith the foll

r mains po

rtation.

table. Tabl

ery high te

hot, and w

pick up the

s or flamm

ter to cool

artz heater.

he unit in li

e station if

-balling and

ulting the

ung Childre

he followi

ct power t

he work ar

wise subjec

re commen

rious injury.

e unit with

power cor

.

ual

t

at disposal

batteries)

device sho

mental rule

thorities.

roughly be

ontact your

also very c

of using y

sion of thi

: E

manual to

wing warni

er supply is

e surface s

perature a

ll cause ser

PCB assem

able materi

efore check

This may b

quid or allo

ecessary.

pre-heatin

anufacturer

should be

g precauti

a grounde

a is well ve

the heatin

cing repairs

wet hands.

by pulling

of the devi

s unsorted

ld be retur

.

ore bringin

dealer.

nvenient fo

ur new SM

s user ma

ECTRIC

raw the us

gs and cau

identical pr

ould be con

d potential

ous burns i

bly to elimi

ls.

ing or repla

e used with

any liquid

PCB asse

or its auth

supervised

ns:

receptacle

tilated.

surface to

or making

he plug (no

e after its li

municipal

ed to your

this device

re-balling

/BGA rewo

ual, pleas

L SHOC

r’s attentio

ions for yo

ior to use.

sisted of fir

y dangerou

contacted

ate the pos

ing heater

a damp clo

to enter th

bly and sho

rized agent

o ensure th

physical sh

ny mainten

the cable)

ecycle coul

aste; it sho

istributor o

into service.

maller BGA

rk system a

visit our

to

r safety.

and heat

.

xposed ski

ibility of b

nd other p

h using sm

station. Ne

uld not be

t they do

ck. This m

ance to avo

when the u

ld

r

If

nd

.

rns.

rts,

ll

ver

ot

y

d

it

•

This syste

other purp

The IR ha

•

without bei

hand tool,

not switch

may resul

Do not ai

•

or via mirr

21

.03.2011

W

rnings

m is desig

se without

d tool is d

ng allowed

nsure that

he IR Hand

in damag

the IR h

r) to shine

ed to be u

onsulting

esigned fo

o cool. It s

it is placed

tool on whi

to the IR

nd tool at

nto the eye

sed for sol

anufacture

r intermitt

ould be use

ack in its c

e it is in th

hand tool

our eyes.

as serious

ering/de

or its agen

d use onl

d a maximu

oling stand

cooling sta

r the cool

Do not allo

eye damag

3

oldering S

s.

. It is not d

m of 5 min

to cool do

nd. Fail to

ing stand.

the IR spo

may occu

MDs and sh

signed to

tes before

n between

omply wit

from the I

.

ould not be

e used cont

ooling. Afte

ework oper

h there ins

hand tool

used for an

inuously

using the

tions. Also,

tructions

(either dire

©Vellema

R

do

tly

nv

Page 4

•

.

.

a

a

a

.

osol

eNoPro

m

s

o

e

a

o

h

n

e

I

n

i

“

“

d

T

T

i

e

h

o

p

m

e

t

e

e

o

u

a

o

f

S

e

e

r

r

e

:

a

p

e

a

e

a

s

e

e

h

t

e

o

R

s

g

e

n

t

e

k

f

n

o

s

c

y

c

d

p

f

o

f

n

d

r

y

w

o

d

d

d

r

r

s

t

l

e

s

a

n

m

a

e

t

W

n

e

U

n

s

o

e

e

F

”

c

s

r

t

c

e

e

e

t

e

a215

e

e

c

q

h

s

v

m

s

m

o

r

n

i

o

5

)

0

1

m

e

t

h

g

c

g

n

t

m

n

r

b

t

a

n

m

g

y

y

e

0360

R

e

m

e

e

f

d

e

e

8

2

0

n

e

t

n

r

The syste

pre-heater,

for the equ

Death or

•

equipment

•

Do not all

result. Due

Keep this d

•

3

Genera

Re

fer to the V

can prod

to contact

ipment to c

erious inj

from the m

w the spil

to the use

evice away

l Guideli

lleman®

uce a lot o

xposed ski

ol before c

ry may re

ins before

lage of an

f glass opti

rom childre

nes

ervice an

heat. Do

as burning

mmencing

ult from el

ommencing

liquid to f

al compon

n and unau

Quality

VTSDIR

ot allow th

may occur.

aintenanc

ectric sho

repairs.

ll on the

nts, the IR

horized use

arranty on

IR spot fro

To eliminat

.

k. It is ther

uartz emi

hand tool s

rs.

the last pa

the IR ha

e the possi

fore essen

ter (pre-he

ould be ha

es of this

nd tool or I

ility of burn

ial to isolat

ter) as da

dled with r

anual.

from the P

, allow tim

the

age may

asonable ca

CB

re.

•

Familiarise

•

All modific

device is n

•

Only use t

•

Damage ca

dealer will

4

Overvi

Re

fer to the ill

M

in station

1.

SOLDERL

2.

Time cou

3.

“▼” key:

4.

“▲” key:

5.

IR Tempe

6.

Celsius (°

7.

Fahrenhe

8.

RESET”:

9.

TIMER”

10

. “ALARM”:

M

in station

11

. “▲” key:

12

. “▼” key:

13

. “MODEL”:

14

. Fahrenhe

15

. Celsius (°

16

. Preheat t

M

in station

17

. Solderlig

18

. DC12V C

19

. Output to

20

. Fuse Hold

21

. AC power

Indoor us

Keep this d

Protect this

yourself wit

tions of the

t covered b

e device fo

used by dis

ot accept r

w

ustrations o

– solderlig

GHT/Timer

ting switch

Time count

Time count

rature displ

C): IR Tem

t (°F): IR T

Offset forw

isplay: Tim

alarm indic

– Preheat

Temperatur

Temperatur

Actual tem

t (°F): Pre-

C): Pre-hea

mperature

- rear pan

t Foot switc

oling fan s

PREHEATE

er

inlet (Main

only. Kee

vice away

device from

h the functi

device are

y the warra

its intende

egard of ce

sponsibilit

n page 2 of

ht section

alternate s

I = time c

ing / Actual

ing / Actual

y / IR han

erature in

mperature

rd counting

counting

tor

ection

pre-heate

pre-heate

perature off

eater temp

er tempera

setting disp

l

h socket (4

cket (3 pin)

inlet)

this device

rom dust a

shocks and

ns of the d

orbidden fo

ty.

purpose.

tain guideli

for any en

this manual

itch: I = S

unting up,

temperatur

temperatur

tool power

egrees Cels

in degrees

for “TIMER

isplay / Pro

up (increa

down (dec

et pre-hea

erature indi

ure in degr

ay (3 segm

pin)

away form

d extreme

abuse. Avo

vice before

r safety rea

sing the de

es in this

uing defect

.

lderlight te

O = time c

decrease

increase

ius indicato

ahrenheit i

ess timer

e)

ease)

er

ating light

es Celsius

nts)

rain, moistu

eat.

id brute for

actually usi

ons. Dama

ice in an u

anual is no

or proble

perature c

unting dow

dicator

ndicator

re, splashin

e when ope

ng it.

e caused b

authorised

covered b

s.

ontrolled, O

and drippi

rating the d

user modi

way will voi

the warran

= time cou

ng liquids.

vice.

ications to

the warra

ty and the

nting.

he

ty.

5

Workin

Th

e most com

op

erating tem

H

wever, to

ders that r

M

lting point

rmal Opera

duction Lin

21

.03.2011

Temp

mon solderi

erature of

eet RoHS r

quire a wor

ion

Operation

rature

g alloys us

his type of

quirements

ing temper

d in the el

older is de

, these sold

ture which

270-32

320-38

ctronics ind

ailed below

rs are no l

is ±30°C (

le

ded solder

°C (419°F

0°C (518-6

0°C (608-7

4

ustry consis

and can va

nger allowe

4°F) higher

8°F)

6°F)

t of 60% tin

y from man

d and are r

.

30

and 40% l

ufacturer to

placed by l

lead-fre

220°C (42

-360°C (57

-410°C (68

ad. The

manufactu

ad-free

°F)

-680°F)

-770°F)

©Vellema

er.

nv

Page 5

VTSDIR

6. Setup

Refer to the illustrations on page 2 of this manual.

Note: never unplug any connection during operation.

• The equipment must be sited on a firm surface at least 1.2M x 0.75M and at a height to suit the operator.

The location should be chosen to suit the flow of work.

• Plug the solder light plug into the socket on the front of the main station.

• Plug the solder light fan into the cooling fan socket [18] and place the solder light in the holder.

• Plug the footswitch into the foot switch socket [17].

• The quartz heaters are secured against shocks with a metal bar and plastic tubes. Remove these and mount

the metal grid in place (refer to Appendix 1).

• Mount the PCB holder (refer to Appendix 2).

• Plug the power cord into the AC power inlet [21].

7. Operation

• The principle of operation of IR rework system is that whilst being heated from above and below, a single

SMD is subjected to similar temperature/time profile during rework as it experiences during reflow in the

original production process.

Note: wait about 5 minutes for the system to warm up after changing a setting.

IR hand tool operation:

• Set the “SOLDERLIGH/TIMER” switch [1] to the SOLDERLIGHT position (I).

• Set the IR Lamp temperature using the “▼” [3] and “▲” [4] keys. Press and hold ±2s to increase

setting speed. Read the temperature on the display [5].

Note: the temperature depends on the type of work (normally about 240°C)

Standard operation

• Press on the footswitch to start the IR heating; release to stop IR heating.

Timer-up operation

• Set the “SOLDERLIGH/TIMER” switch [1] to the TIMER position (O).

• Set the “Time counting” switch [2] to the UP position (I).

• Press on the footswitch to start IR heating; release to stop IR heating. The timer display [9] will count

the number of seconds that the IR heating was on.

Timer-down operation

• Set the “SOLDERLIGH/TIMER” switch [1] to the TIMER position (O).

• Set the “Time counting” switch [2] to the DOWN position (O).

• Set the timer using the “▼” [3] and “▲” [4] keys. Press and hold ±2s to increase setting speed. Read

the time (in seconds) on the display [9].

• Press on the footswitch to start IR heating; release to stop IR heating. The timer display will count

down the number of seconds that the IR heating was on. When 000 is reached, a warning signal

sounds.

Notes:

• Press the reset switch [8] to return the display to 000.

• To determine the reflow time of a new component, first use the timer up operation until it reflows, than

use the timer value for timer-down operation.

Pre-heater operation:

• Set the pre-heater temperature using the “▼” [12] and “▲” [11] keys. Press and hold ±2s to increase

setting speed. Read the temperature on the display [16].

Note: the temperature depends on the type of work (normally about 220°C)

Actual temperature compensation value

• Press on the MODEL button [13] until the display shows “---” (±4s). The temperature compensation is

shown for ±2s.

• To change the value, press the MODEL button [13] again. The value on the display starts to flash and

can be set using the “▼” [12] and “▲” [11] keys.

Note: when the display shows “00” or “-00” the compensation is “+10”.

E.g. When the temperature is set at 200°C and the measured temperature is only 190°C, then the

value must be set to “00” or “-00”. If the measured value is 180°C, than the compensation value must

be set to “+10” (-20 + 10 = 10).

General operation:

CAUTION: to avoid burns, do not touch the heater or PCB directly, use clips or tweezers to pick up or align

components.

CAUTION: do not allow water/liquids/solvents to touch the heater surface to avoid temperature drop cracks

while the unit is still hot. Such cracks can lead to electrical shorts or failure of the heater.

CAUTION: Do not touch the PCB holder to avoid burning your skin during preheat!

21.03.2011 ©Velleman nv

5

Page 6

P T

.

n

h

o

o

n

w

i

o

r

o

t

o

u

y

A

o

s

o

P

R

n

e

S

C

n

A

o

P

R

n

S

C

u

o

H

n

m

e

n

r

g

x

t

e

m

d

m

r

o

e

e

w

m

s

r

e

e

w

s

w

f

8

t

0

g

9

w

.

r

t

I

h

n

o

p

e

m

n

t

h

n

e

p

m

n

t

h

d

o

c

u

a

s

a

G

m

e

d

e

g

o

p

t

g

B

r

e

t

r

s

B

r

e

l

t

o

VTSDIR

n

d

p

e

a

d

o

o

m

t

m

C

e

B

s

g

n

m

C

e

s

8

d

o

t

e

y

m

e

m

p

C

o

o

m

n

d

C

o

8

o

w

u

b

t

o

a

e

(

u

r

m

n

P

t

u

r

m

e

n

n

s

d

e

c

o

r

I

m

s

d

e

I

m

h

s

c

n

h

a

n

a

a

n

reparatio

The proced

• Switc

• Set ‘c

• Sort t

The followi

• SMT T

• Flux d

• Low s

emperatu

In normal

system is d

150W shor

maximum

In normal

provided b

ure for prep

on and wa

ntrol settin

ols and flu

g tools are

eezers, fin

spenser bo

lids and gel

e profile

peration th

esigned for

wave IR la

f 650W me

se, approxi

the back h

aring to re

m up.

s’ required

es required

required fo

e tipped

tle

/paste flux

componen

rework sing

p focused

ium wave

ately 25%

eater (pre-

ork SMT/B

for PCB/co

use in sold

is first put

le/double si

through a r

R.

of the ener

eater). Figu

A compone

ponent

ring/desol

through a

e and mix

flective ch

y is prove

re below sh

ts is as foll

ering opera

reheat stag

d technolog

mber syste

by the top

ws how th

ws:

ions:

, followed

PCB. The

. The bott

heater, and

energy is

y a reflow

op heat is

m heater d

75% of the

pplied to a

tage. The

erived from

livers a

energy is

omponent.

a

Soldering

• PREPAR

centre

thickne

apply s

o [A]

o [B]

the c

duri

phas

o [C]

o [D]

Desolderi

• PREPAR

centre

o [A]

o [B]

the c

duri

time

o [C]

o [D]

Aftercare

• Clean fl

• Check s

• Test

TION: plac

f the PCB p

s). Place an

lder paste t

REHEAT th

EFLOW: us

omponent u

g the reflo

time (nor

OAK for a

OOL: allow

g

TION: plac

f the PCB p

REHEAT th

EFLOW: us

omponent u

g the reflo

(normally 3

OAK for a

OOL – allo

x residue o

lder joints

e the PCB i

e-heater. F

d align com

the PCB b

fluxed co

the IR ha

p to reflow

phase so t

ally 30-45

hort period

the compo

e PCB in th

e-heater. A

fluxed co

the IR ha

p to reflow

phase so t

0-45 secon

hort period

the comp

f PCB if ne

the PCB h

r BGAs, ap

onent. No

fore placin

ponent/PC

d tool (ope

emperatur

erefore we

seconds for

soak (abou

ent to cool

PCB holde

ply a very

ponent/PC

d tool (ope

emperatur

erefore we

s for a sma

soak (abou

nent to coo

essary

lder, positi

ly a very s

e – dependi

componen

to approxi

ated by pre

(200-225°

use the tim

a small PC

10 second

to below 18

, positionin

mall amou

to approxi

ated by pre

(200-225°

use the tim

l PCB).

10 second

l to below 1

ning the co

all amount

ng on the a

.

ately 120°

ssing the fo

). It is not

r on the IR

).

) the comp

0°C before

the compo

t of flux un

ately 120°

ssing the fo

). It is not

r on the IR

) the comp

0°C before

ponent sit

of gel flux

plication, y

(as meas

tswitch) fo

so easy to

810 control

nent allowi

oving the

ent site to

er/around

(as meas

tswitch) fo

so easy to

10 controll

nent allowi

moving the

to be rew

approx. 0.1

ou may be

red by the

the reflow

easure te

ler to limit t

g the joint

CB.

be reworke

he compon

red by the

the reflow

easure te

er to limit t

g the joint

PCB.

rked over t

- 0.15mm)

equired to

R sensor).

phase to he

perature

he reflow

to fully bo

over the

nt.

R sensor).

phase to he

perature

e reflow ph

to fully bo

e

t

d.

t

se

d.

8

Q&A

•

What Top

Betwee

•

What’s the

Approxi

Move th

compon

•

What pre-h

Betwee

21

.03.2011

eat setting

220 and 3

working dis

ately 5~1

e hand tool

nt.

eater settin

200 and 2

should you

0°C. Norm

ance of the

mm when

in a scannin

should I u

0°C. Norm

se?

l setting is

IR Hand to

reworking a

g motion to

e?

l setting is

240°C.

l and how

nd move up

heat leads,

240°C.

6

o I move it

to 30mm

taking abo

for rework?

hen removi

t one secon

g compone

d for each s

nts.

an of the

©Vellema

nv

Page 7

VTSDIR

• How long do I preheat the PCB?

Always preheat the PCB (up to 120°C or between 45 – 90 seconds) to allow the heat to conduct through

to the component before introducing the top heat. With the 700W pre-heater the top of a small PCB will

reach 120°C in approximately 45 – 90 seconds. Larger PCBs will take longer to pre-heat. To check the

PCB/component temperature, use the hand-held IR temperature sensor to ‘look’ down at the

PCB/component from about 60mm away and at about 45° angle.

• How long does it take to reach reflow temperature?

After preheating the PCB up to 120°C, it should normally take about 30 – 45 seconds of heating with the

IR hand tool to reach reflow temperature (200-220°C). It is not so easy to measure temperature during

the reflow phase so therefore we use the electronic process timer to warn us when the reflow phase time

is over.

9. Technical specifications

mains power 230VAC

power 150W

IR solderlight

pre-heater

dimensions

weight ±7kg

Use this device with original accessories only. Velleman nv cannot be held responsible in the event

of damage or injury resulted from (incorrect) use of this device.

The information in this manual is subject to change without prior notice.

© COPYRIGHT NOTICE

The copyright to this manual is owned by Velleman nv. All worldwide rights reserved.

No part of this manual or may be copied, reproduced, translated or reduced to any electronic medium or otherwise without

the prior written consent of the copyright holder.

temperature range 45 ~ 350°C

time setting 0 ~ 900s

power 650W

temperature range 100 ~ 350°C

controller 170 x 158 x 137 mm

pre-heater 280 x 90 x 260 mm

21.03.2011 ©Velleman nv

7

Page 8

VTSDIR

Appendix 1

Remove screws [X], remove metal bar [Y] and remove plastic tubes [Z].

21.03.2011 ©Velleman nv

8

Page 9

VTSDIR

Place the metal grid and secure it with the two screws [X].

21.03.2011 ©Velleman nv

9

Page 10

VTSDIR

Appendix 2

21.03.2011 ©Velleman nv

10

Page 11

VTSDIR

21.03.2011 ©Velleman nv

11

Page 12

Velleman® Service and Quality Warranty

Velleman® has over 35 years of experience in the electronics

world and distributes its products in more than 85 countries.

All our products fulfil strict quality requirements and legal

stipulations in the EU. In order to ensure the quality, our

products regularly go through an extra quality check, both by

an internal quality department and by specialized external

organisations. If, all precautionary measures

notwithstanding, problems should occur, please make appeal

to our warranty (see guarantee conditions).

General Warranty Conditions Concerning Consumer

Products (for EU):

• All consumer products are subject to a 24-month warranty

on production flaws and defective material as from the

original date of purchase.

• Velleman® can decide to replace an article with an

equivalent article, or to refund the retail value totally or

partially when the complaint is valid and a free repair or

replacement of the article is impossible, or if the expenses

are out of proportion.

You will be delivered a replacing article or a refund at the

value of 100% of the purchase price in case of a flaw

occurred in the first year after the date of purchase and

delivery, or a replacing article at 50% of the purchase price

or a refund at the value of 50% of the retail value in case of

a flaw occurred in the second year after the date of purchase

and delivery.

• Not covered by warranty:

- all direct or indirect damage caused after delivery to the

article (e.g. by oxidation, shocks, falls, dust, dirt,

humidity...), and by the article, as well as its contents (e.g.

data loss), compensation for loss of profits;

- frequently replaced consumable goods, parts or accessories

such as batteries, lamps, rubber parts, drive belts...

(unlimited list);

- flaws resulting from fire, water damage, lightning, accident,

natural disaster, etc. …;

- flaws caused deliberately, negligently or resulting from

improper handling, negligent maintenance, abusive use or

use contrary to the manufacturer’s instructions;

- damage caused by a commercial, professional or collective

use of the article (the warranty validity will be reduced to six

(6) months when the article is used professionally);

- damage resulting from an inappropriate packing and

shipping of the article;

- all damage caused by modification, repair or alteration

performed by a third party without written permission by

Velleman®.

• Articles to be repaired must be delivered to your

Velleman® dealer, solidly packed (preferably in the original

packaging), and be completed with the original receipt of

purchase and a clear flaw description.

• Hint: In order to save on cost and time, please reread the

manual and check if the flaw is caused by obvious causes

prior to presenting the article for repair. Note that returning

a non-defective article can also involve handling costs.

• Repairs occurring after warranty expiration are subject to

shipping costs.

• The above conditions are without prejudice to all

commercial warranties.

The above enumeration is subject to modification

according to the article (see article’s manual).

Loading...

Loading...