Page 1

Operating Instructions

VEGADIF 34 … 51

Level and Pressure

p

Page 2

Contents

Safety information ......................................................................... 3

Note Ex-area ................................................................................ 3

1 Product description

1.1 Function and configuration ................................................... 4

1.2 Types and versions .............................................................. 5

1.3 Type plate ............................................................................. 7

1.4 Technical data ....................................................................... 8

1.5 Dimensions ......................................................................... 15

1.6 Approvals ........................................................................... 20

2 Mounting

2.1 Verifying operating conditions ........................................... 21

2.2 Pre-installation ..................................................................... 22

2.3 Mounting .............................................................................. 24

3 Electrical connection

3.1 Connection instructions ...................................................... 28

3.2 Load resistance .................................................................. 28

3.3 Connections ........................................................................ 29

3.4 Ex-applications ................................................................... 30

Contents

4 Setup

4.1 Adjustment structure .......................................................... 32

4.2 Adjustment with 4-key adjustment element ....................... 32

4.3 Adjustment with HART® handheld ...................................... 38

4.4 Adjustment with PC ............................................................ 46

2 VEGADIF 34 … 51

Page 3

Contents

5 Typical installation connections

5.1 Valves .................................................................................. 53

5.2 Impulse lines ....................................................................... 54

5.3 Differential pressure measurement ................................... 55

5.4 Level measurement ............................................................ 57

5.5 Flow measurement ............................................................. 65

6 Diagnostics

6.1 Failure codes ...................................................................... 69

7 Instrument modification ......................................................... 70

Safety information

The described module must only be installed

and operated as described in these operating

instructions. Please note that other action can

cause damage for which VEGA does not take

responsibility.

VEGADIF 34 … 51 3

Note Ex-area

Please note the approval documents (yellow

binder), and especially the included safety data

sheet.

Page 4

1 Product description

Product description

1.1 Function and configuration

Function

VEGADIF 34 … 51 differential pressure transmitters are an efficient, modular instrument

series for differential pressure, level and flow

measurement.

The sensor element of VEGADIF 34 and 44 is

a single-chamber ceramic measuring cell. It

consists of a disk-shaped ceramic body with

ceramic diaphragms on both sides. According to the pressure the diaphragms move and

the capacitances change. The difference of

the individual capacitances is reciprocally

proportional to the difference of the pressures.

The sensor element of VEGADIF 35, 45 and 51

is a silicium plate with pressure sensitive resistors. The differential pressure to be measured is received via separating diaphragms

and transmitted to the sensor element via

incompressible oil (silicone oil or inert oil). The

silicium plate moves according to the differential pressure. The values of the resistors

change (piezoresistive principle).

The capacitance or resistance values are

detected by the integral electronics and converted into a 4 … 20 mA output signal. This

output signal is proportional to the difference

of the pressures. Precise digital processing of

measured data with maximum resolution ensures excellent technical performance.

The external power supply is provided via a

separate supply instrument, e.g.:

- power supply instrument

(e.g. VEGASTAB 690)

- processing unit with integral direct voltage

source (e.g. active DCS-input)

- VEGAMET series 500 or 600 signal conditioning instrument, VEGALOG 571 processing system or VEGADIS 371 indicating

instrument

Configuration

Each VEGADIF consists of only two modular

components:

- the electronics housing

- the measuring cell housing.

Sensor specific data are permanently stored

in an ASIC in the sensor. Hence the measuring

cell modules can be changed, e.g. ceramic for

silicium and vice versa. The electronics can be

changed, e.g. from 4 … 20 mA standard to

4 … 20 mA with HART®-communication protocol, without dismounting the transmitter.

The electronics in the pressure transmitter

requires a supply voltage of 11.5 … 45 V DC.

4 VEGADIF 34 … 51

Page 5

Product description

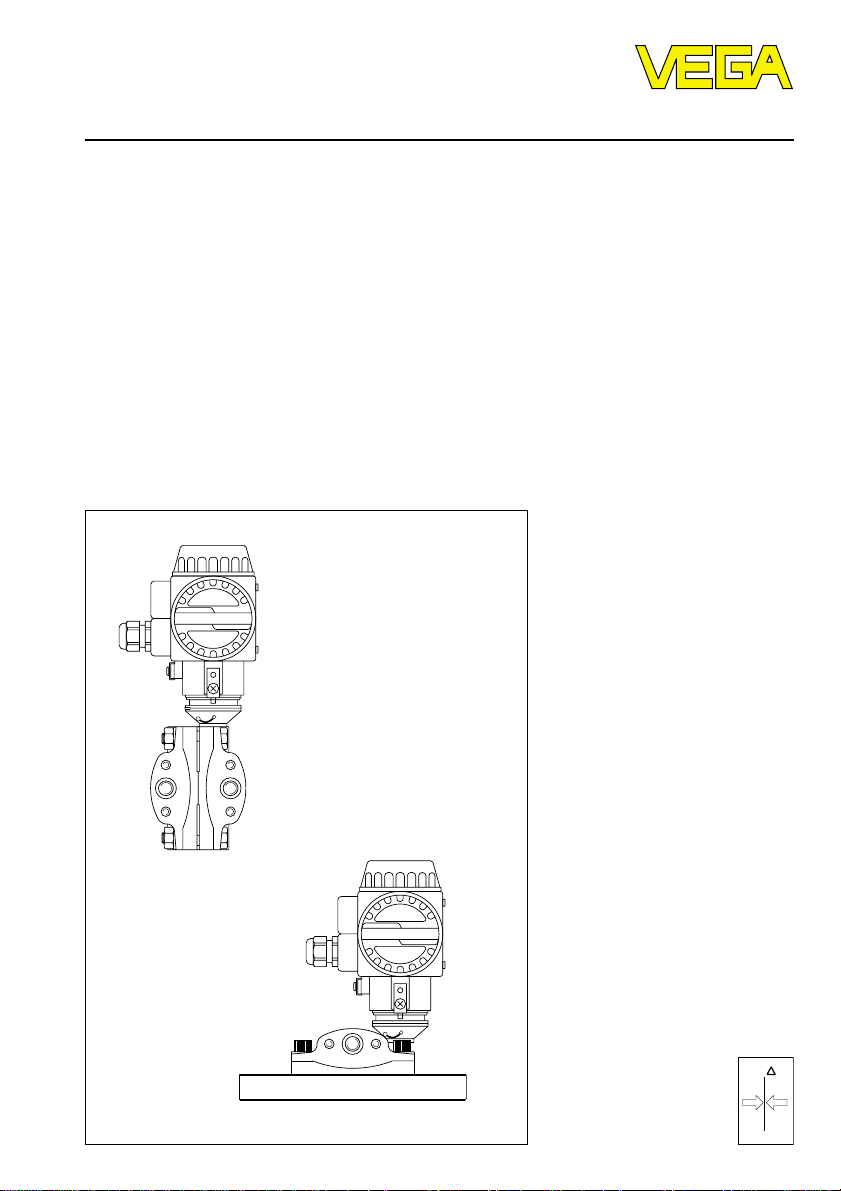

1.2 T ypes and versions

VEGADIF 34

Measuring cell:

ceramic-capacitive

Process connection:

acc. to DIN 19 213

Standard application:

Differential pressure and flow measurement

with gases, vapours and liquids

VEGADIF 35

Measuring cell:

silicium-piezoresistive with metal separating

diaphragms

Process connection:

acc. to DIN 19 213

VEGADIF 34

Standard application:

Differential pressure and flow measurement

with gases, vapours and liquids, with differential pressure up to 40 bar and static pressures up to 420 bar

VEGADIF 35

VEGADIF 44

Measuring cell:

ceramic-capacitive

Process connection:

Plus side flange,

minus side acc. to DIN 19 213

Standard application:

Level measurement in pressurized vessels,

even with suspended solids, abrasive or high

viscosity products

VEGADIF 34 … 51 5

VEGADIF 44

Page 6

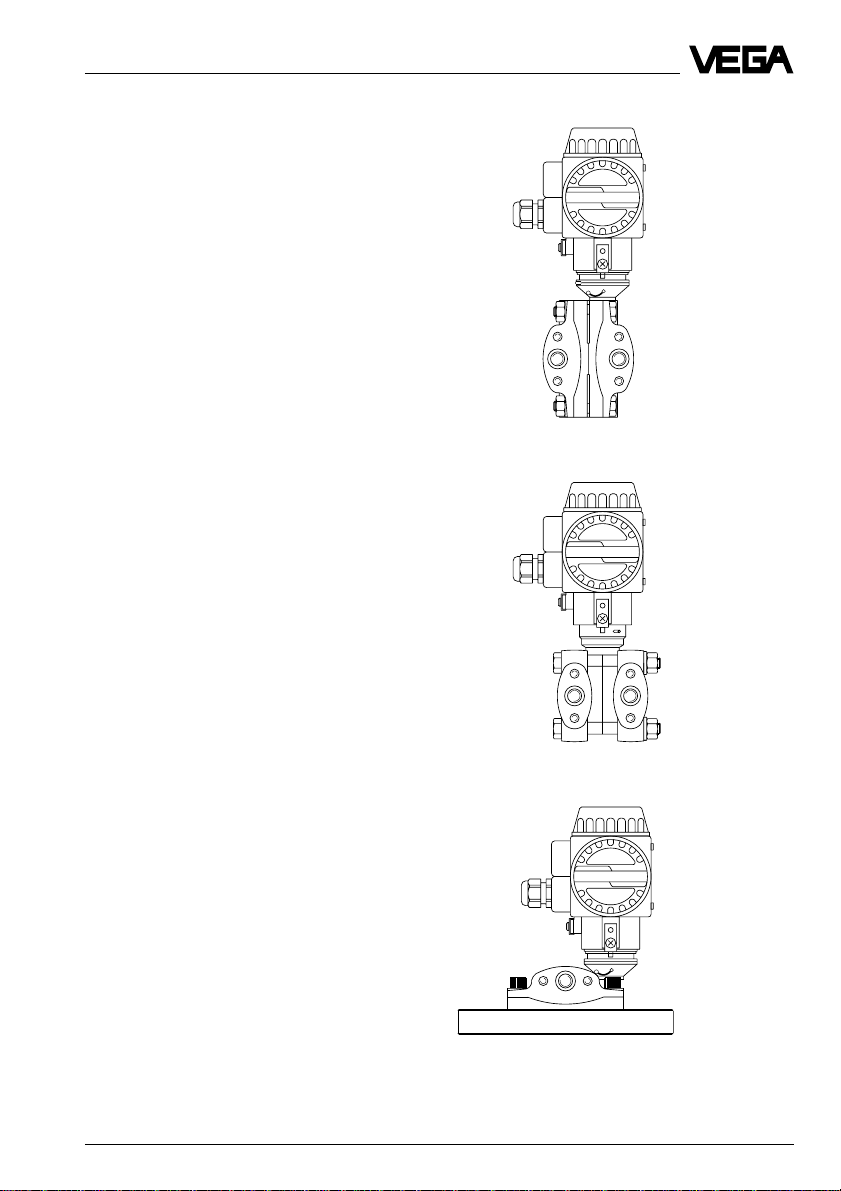

VEGADIF 45

Measuring cell:

silicium-piezoresistive with metal separating

diaphragm

Process connection:

Plus side flange,

minus side acc. to DIN 19 213

Standard application:

Level measurement in pressurized vessels,

even with product temperatures up to 400°C

VEGADIF 51

Measuring cell:

silicium-piezoresistive with metal separating

diaphragms

Product description

VEGADIF 45

Process connection:

Cell isolating diaphragm in standard series,

connected via capillary lines

Standard application:

Level, differential pressure and flow measurement especially with high-viscosity products,

high temperatures and in food processing

industries

For applications in hazardous areas as well as

overfill protection acc. to WHG certified instruments are available

6 VEGADIF 34 … 51

VEGADIF 51

Page 7

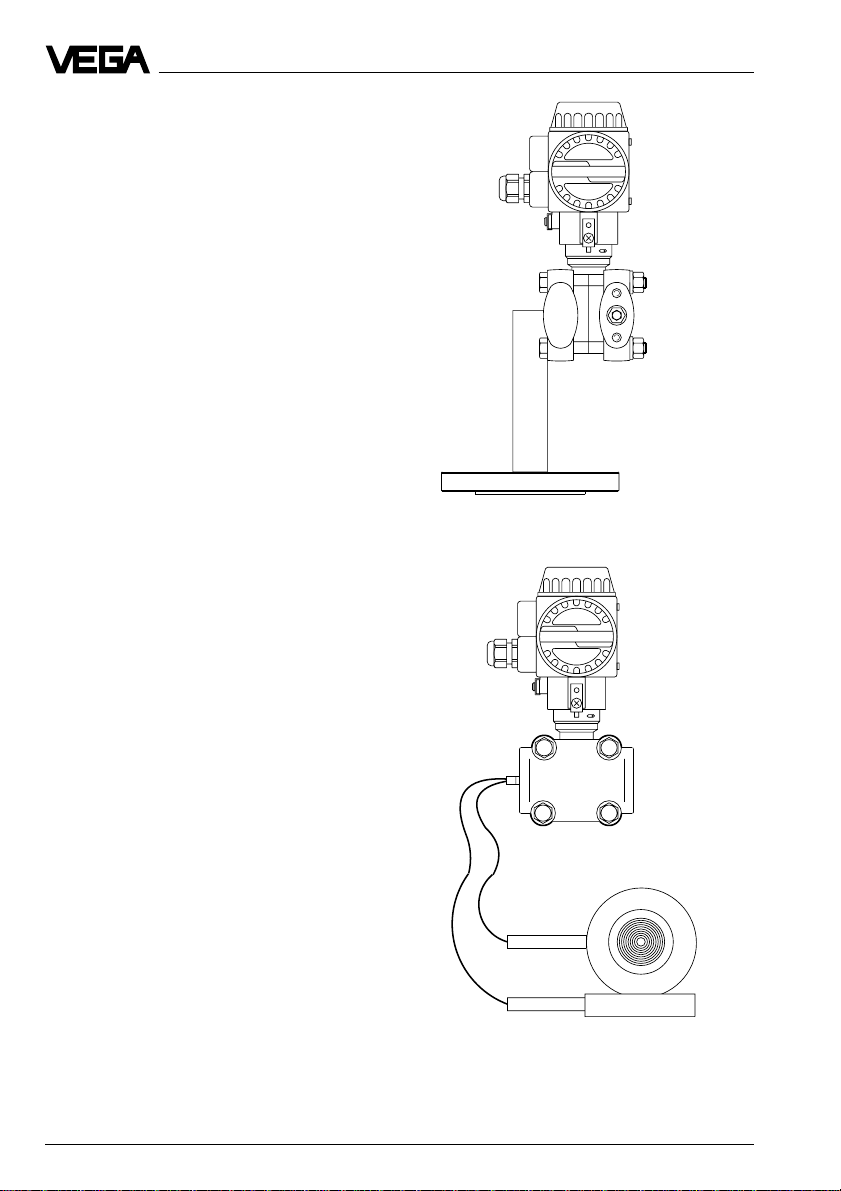

Product description

1.3 T ype plate

Check before mounting and electrical connection that you are using a suitable differential

pressure transmitter. Observe type and calibration plate which are located as follows:

Calibration plate

Both plates include important data required for

mounting and connection. The configuration

and contents of the plates are explained in the

following example.

Type plate

Product coding example

type DIF35AC4E1VH3C

Process connection flange

1.4435

Measuring cell seal PTFE

2 ventilation valves,

1 mounting loop

Nominal value calibration

in mbar/bar

Nom. meas. range 160 mbar,

static pressure max. 140 bar

LC-indication top

Cable entry Pg 13.5

Configuration of the calibration plate

(example)

Cal.

Adj. 0 … 160 MBAR

Calibration range 0 … 160 mbar

Configuration of the type plate (example)

1

2

Order Code

Ser.-No.

p

Pmax

4…20mA U

Mat.

1 Basic data of the order no.

2 Serial number

VEGADIF 34 … 51 7

DIF35 AC4E1 VH 3C

10612892

-160 … 160 mbar

140 bar

1.4571 PTFE

VEGA VEGADIF

Made in

Germany

11,5 … 45 V DC

Page 8

Product description

1.4 T echnical data

Mechanical data

Materials, wetted parts

VEGADIF 34

- Diaphragm Aluminiumoxideceramic (Al2O3)

- Process seal FPM, Hastelloy C4 PTFE-plated, EPDM,

- Process connection carbon steel C22.8 chromized 1.0460,

- Ventilation valves stainless steel 1.4571 or 1.4404, Hastelloy C276

VEGADIF 35

- Separating diaphragms stainless steel 1.4401

- Process seal FPM, NBR, PTFE, FPM for oxygen

- Process connection carbon steel C22.8 chromized 1.0460

- Ventilation valves stainless steel 1.4571 or 1.4404, Hastelloy C276

VEGADIF 44

- Diaphragm Aluminiumoxideceramic (Al2O3)

- Process seal FPM, Hastelloy C-4 PTFE-plated, EPDM,

- Process connection (plus side) carbon steel C22.8 chromized 1.0460,

- Process connection (minus side) carbon steel C22.8 chromized 1.0460,

FPM for oxygen application, Kalrez

stainless steel 1.4571 or 1.4404, Hastelloy C276

2.4819, PVDF (PN 10)

2.4819 (only with process connection Hastelloy)

applications

stainless steel 1.4571 or 1.4404, Hastelloy C276

2.4819

2.4819 (only with process connection Hastelloy)

FPM for oxygen application, Kalrez

stainless steel 1.4571, stainless steel 1.4571

PTFE coated

Hastelloy C276 2.4819

stainless steel 1.4571 or 1.4404, Hastelloy C276

2.4819

VEGADIF 45

- Isolating diaphragm stainless steel 1.4435

- Process flange (plus side) stainless steel 1.4435

- Process flange (minus side) carbon steel C22.8 chromized 1.0460,

VEGADIF 51

- Isolating diaphragm stainless steel 1.4435

- Process connection carbon steel C22.8 chromized 1.0460,

8 VEGADIF 34 … 51

stainless steel 1.4571 or 1.4404, Hastelloy C276

2.4819

stainless steel 1.4571 or 1.4404, Hastelloy C276

2.4819

Page 9

Product description

Materials, non-wetted parts

Common components

- Electronics housing and cover Al-casting (Cu-free), protective coating

Polyester based, colour yellow RAL 1018,

black RAL … (cover)

- Type plates stainless steel 1.4301

- O-rings for cover seal NBR

- Screws and nuts

for measuring cell housing or

process connection carbon steel C22.8

- Mounting loop corresponding to process connection

carbon steel C22.8, stainless steel 1.4571

1)

VEGADIF 34

- Fill fluid of the measuring cell silicone oil, mineral oil, Voltalef 1 A

VEGADIF 35

- Measuring cell housing stainless steel 1.4571

- Fill fluid of the measuring cell silicone oil, Fluorlube

2)

VEGADIF 44

- Fill fluid of the measuring cell silicone oil, mineral oil, Voltalef 1 A

VEGADIF 45 and VEGADIF 51

- Measuring cell housing stainless steel 1.4571

- Fill fluid of the measuring cell silicone oil, vegetable oil, glycerine, high

temperature oil, oil for oxygen applications

- Capillary line stainless steel 1.4571

- Fill fluid of the measuring cell silicone oil, Fluorlube

2)

Weights

VEGADIF 34 approx. 5 kg

VEGADIF 35 4 … 6 kg, depending on version

VEGADIF 44 8 … 10.5 kg, depending on flange size

VEGADIF 45 6 … 12 kg, depending on flange size and

extension length

VEGADIF 51 4 kg plus capillaries and flange isolating

diaphragm

Isolating diaphragm see tables in "1.5 Dimensions - Isolating

diaphragm"

2)

2)

1)

Sea water resistance (salt spray test acc. to DIN 50 021 passed for 504 h)

2)

for applications in pure gases

VEGADIF 34 … 51 9

Page 10

Electrical data

Product description

Connection

Cable entry Pg 13.5 (for cable-ø 9 … 12 mm)

1)

Screw terminals for conductor cross-sections up to 2.5 mm

Earth terminal for conductor cross-sections up to 4 mm

Supply and signal circuit (4 … 20 mA-signal)

Supply voltage

- not Ex-instruments 11.5 … 45 V DC

- Ex-instruments 11.5 … 30 V DC

Residual ripple no influence at USS £ 4.5 V

Output signal 4 … 20 mA linear (differential pressure proportio

nal) or square root (flow proportional changeable)

Resolution better than 6 µA

Current limitation approx. 23 mA

Measuring range decrease 2.8 mA (standard) or 4 mA

Measuring range exceed 20.5 mA acc. to NAMUR

Fault signal (adjustable) 3.6 mA, 21.5 mA, current value

Integration time

2)

0 … 16 s with keys on the instrument

0 … 40 s with HART® handheld

Adjustment period 0.5 … 2.0 s depending on measuring range

Raising time 0.4 … 1.6 s depending on measuring range

Heating time 2 s

Connection line 2-wire

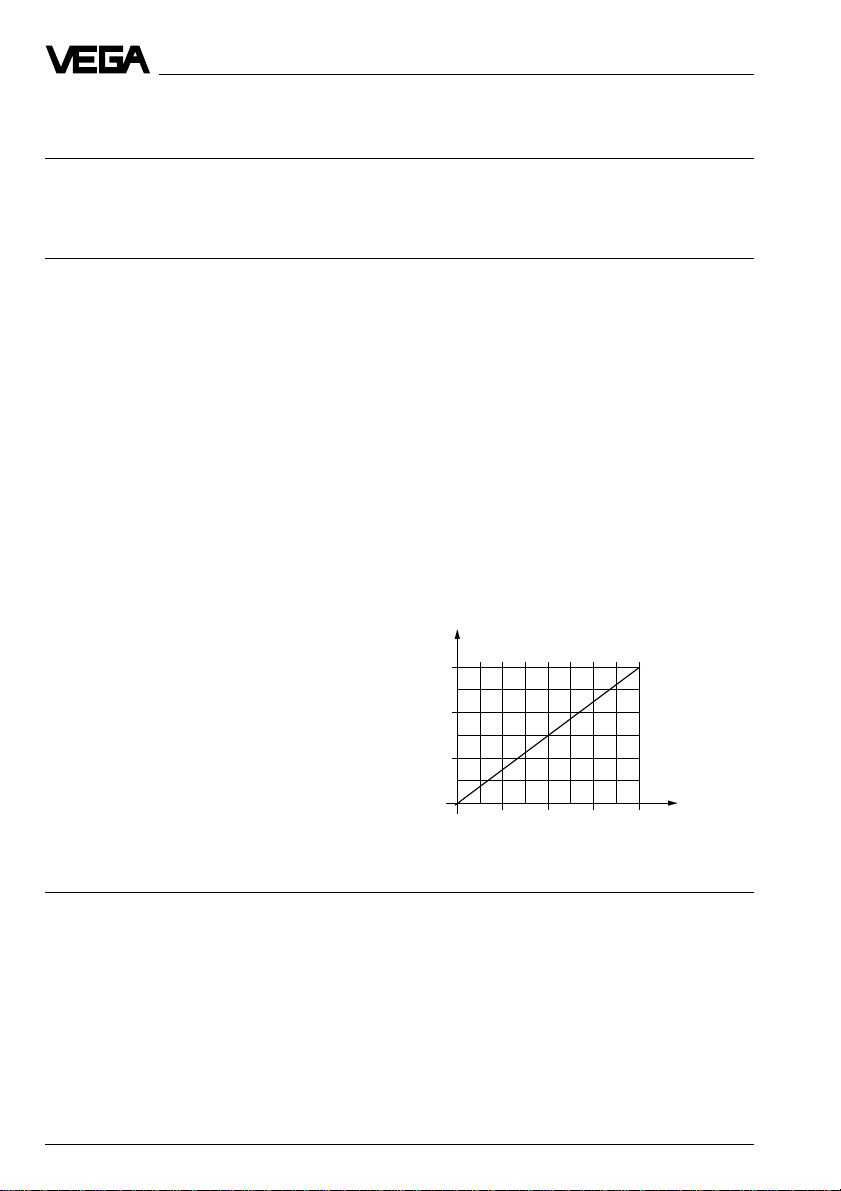

Max. permissible load depending on supply voltage

1560

1000

in Ohm

R total

500

Load

0

20 28,5 37 4511,5

Voltage of the external energy UH in Volts

Supply and signal circuit (digital communication signal HART®)

Connection line 2-wire (the communication must not be influenced

by unshielded cables)

Line resistance £ 25 W/km

Total resistance higher than 250 W (communication resistance of

min. 250 W required)

Total capacitance smaller than 180 nF

Max. length 1000 m

2

2

1)

with smaller cable diameter a suitable seal must be provided by the customer

2)

adjustment time of 10 % … 63 % of the measuring range final value

10 VEGADIF 34 … 51

Page 11

Product description

Protective measures

Protection IP 65

IP 68 (option for VEGADIF 35, 45 and 51)

Protection class III

CE-protective measures

VEGADIF 34, VEGADIF 35, VEGADIF 44, VEGADIF 45 and VEGADIF 51 differential pressure

transmitters meet the protective regulations of EMC (89/336/EWG) and NSR (73/23/EWG).

The conformity has been judged acc. to the following standards:

EMC Emission EN 50 081 - 1

Susceptibility EN 50 082 - 2

NSR EN 61 010

NAMUR-regulations

Full compliance with the NAMUR-regulations NE21, May 1993.

Transmission reaction

Measuring ranges

VEGADIF 34 and VEGADIF 44

Features Limits Span System pressure Pressure transmission

Nom. liquid

meas. Initial Final value minimum maximum Overload Overload in the sensor

ranges value unilateral bilateral

25 mbar -25 mbar 25 mbar 5 mbar 25 mbar 10 bar 10 bar silicone oil

100 mbar -100 mbar 100 mbar 5 mbar 100 mbar 16 bar 2)25 bar 2)silicone oil

500 mbar -500 mbar 500 mbar 25 mbar 500 mbar 100 bar 2)140 bar 2)mineral oil

3000 mbar -3000 mbar 3000 mbar 150 mbar 3000 mbar 100 bar 2)140 bar 2)mineral oil

1)

1)

1)

1)

VEGADIF 35, VEGADIF 45 and VEGADIF 51

Features Limits Span System pressure Pressure transmission

Nom. liquid

meas. Initial Final value minimum maximum Overload Overload in the sensor

ranges value unilateral bilateral

3)

10 mbar

40 mbar

160 mbar -160 mbar 160 mbar 10 mbar 160 mbar 140 bar 140 bar silicone oil

1000 mbar -1000 mbar 1000 mbar 50 mbar 1000 mbar 420 bar 4)420 bar 4)silicone oil

6000 mbar -6000 mbar 6000 mbar 300 mbar 6000 mbar 420 bar 4)420 bar 4)silicone oil

40000 mbar3)-40000 mbar 40000 mbar 2000 mbar 40000 mbar 100 bar 420 bar 4)silicone oil

-10 mbar 10 mbar 2 mbar 10 mbar 140 bar 140 bar s ilicone oil

3)

-40 mbar 40 mbar 5 mbar 40 mbar 140 bar 140 bar s ilicone oil

1)

1)

1)

1)

1)

1)

Minimum pressure

VEGADIF 34, 35 and 44 1 mbar

VEGADIF 45 and 51 10 mbar

1)

in applications with pure gases Voltalef 1 A

2)

10 bar with process connection PVDF for VEGADIF 34; 40 bar with process flange for VEGADIF 44

3)

only VEGADIF 35

4)

note nominal pressure of the flanges

VEGADIF 34 … 51 11

abs

abs

Page 12

Product description

Output characteristics

Determination of characteristics fixed point method acc. to VDI/VDE 2600, sheet 4

(corresponds to the limit point adjustment acc. to

DIN 16 086)

Characteristics linear (differential pressure proportional),

changeable to square root (flow proportional)

Accuracy data

1)

Feature Accuracy

2)

Hysteresis Repeatability

Instrument

VEGADIF 34 better than 0.1 % better than 0.05 % better than 0.05 %

VEGADIF 35 better than 0.1 % better than 0.1 % better than 0.1 %

VEGADIF 44 better than 0.1 % better than 0.05 % better than 0.05 %

VEGADIF 45 better than 0.2 % better than 0.1 % better than 0.1 %

VEGADIF 51 better than 0.2 % better than 0.1 % better than 0.1 %

Long-term stability of the zero signal

3)

better than 0.1%/12 months (VEGADIF 34 and 44)

better than 0.2%/12 months (VEGADIF 35, 45, 51)

Influence of other actuating variables

Influence of the static pressure

to zero and span better than 0.2 %/PN (VEGADIF 34 and 44)

better than 0.2 %/100 bar (VEGADIF 35, 45, 51)

Electromagnetic compatibility (EMC) interference immunity to NAMUR: 30 V/m

Influence of vibration

5) 6)

better than ±0.1 % acc. to DIN/IEC 68, part 2 - 6

Climatic class GPC acc. to DIN 40 040

Calibration position upright

Influence of the mounting position max. 2 mbar

Temperature influence

Average temperature influence of the

zero signal

3) 4)

or the output span better than 0.02 %/10 K (+10 … +60°C)

better than 0.1 %/10 K (-40 … + 10°C a.

60°C…85°C)

1)

Similar to DIN 16 086

2)

relating to the nominal measuring range with recommended turn-down limit of 20 : 1

3)

relating to the nominal measuring range, reference temperature 25°C, with recommended turn-down limit of

20 : 1

4)

with VEGADIF 45 and 51 without isolating diaphragm or capillaries, see temperature influence

5)

relating to the nominal measuring range

6)

with silicium measuring cell measured on 6000 mbar sensor

12 VEGADIF 34 … 51

Page 13

Product description

Additional temperature influence 1) with VEGADIF 45:

- by isolating diaphragm

Process connection effective Temperature coefficient

diaphragm-ø [mbar/10 K]

Flange DN 50 PN 40 acc. to DIN 2501,

Seal surface acc. to DIN 2526 form D 46 mm 5.0

Flange DN 80 PN 40 acc. to DIN 2501,

Seal surface acc. to DIN 2526 form D 70 mm 3.0

Flange DN 80 PN 40 with extension 50 mm 70 mm 3.0

Flange DN 80 PN 40 with extension 100 mm 70 mm 3.0

Flange DN 80 PN 40 with extension 150 mm 70 mm 3.0

Flange DN 80 PN 40 with extension 200 mm 70 mm 3.0

Additional temperature influence

1)

with VEGADIF 45:

- by isolating diaphragm

Isolating diaphragm series effective Temperature coefficient

diaphragm-ø [mbar/10 K]

unilateral bilateral

Cell DN 50 PN 16/400 46 mm 3.0 0.5

Cell DN 80 PN 16/400 70 mm 0.7 0.1

Cell DN 100 PN 16/400 70 mm 0.7 0.1

Cell 3" class 150/2000 2

3

/4" 0.7 0.1

Cell 4" class 150/2000 23/4" 0.7 0.1

DIN 11 851, nut DN 50 PN 25 46 mm 3.0 0.5

DIN 11 851, nut DN 65 PN 25 52 mm 1.0 0.2

DIN 11 851, nut DN 80 PN 25 71.5 mm 0.7 0.1

DIN 11 851, socket DN 50 PN 25 46 mm 3.0 0.5

DIN 11 851, socket DN 65 PN 25 52 mm 1.0 0.2

DIN 11 851, socket DN 80 PN 25 71.5 mm 0.7 0.1

Clamp 2" PN 25 45 mm 3.0 0.5

Clamp 3" PN 25 71.5 mm 0.7 0.1

DRD-flange DN 25 46 mm 1 .5 0.25

- by capillary line 2) per m 0.5 mbar/10 K (unilateral)

0.12 mbar/10 K (bilateral)

Operating conditions

Product features

Aggregate gaseous, vapour, liquid to high viscosity

Condition also abrasive or aggressive with suitable

1)

standard values relating to isolating liquid silicone oil

2)

both capillary lines are supplied with the same length

VEGADIF 34 … 51 13

material selection of wetted parts acc. to

order code

Page 14

Product description

Temperatures

Ambient temperature -40°C … +85°C (for indication: -20°C … +85°C)

Medium temperature

- VEGADIF 34 and VEGADIF 44

FPM (Viton, Fluor-caoutchouc) -20°C … +85°C

PTFE (Hastelloy C4, from p

EPDM -40°C … +85°C

³ 900 mbar) -40°C … +85°C

abs

FPM (Viton for oxygen, oil and grease free) -10°C … +85°C

Kalrez -10°C … +85°C

- VEGADIF 35 and minus side VEGADIF 45

FDM (Viton, Fluor-caoutchouc) -20°C … +85°C

NBR -20°C … +85°C

PTFE, from p

FPM (Viton for oxygen, oil and grease free) -10°C … +85°C

³ 1 mbar -40°C … +85°C

abs

- Plus side VEGADIF 45 and VEGADIF 51

Isolating liquid: p

- silicone oil -40°C … +200°C / -40°C … +180°C

³ 1 bar / 0.05 bar £ p

abs

- vegetable oil -10°C … +200°C / -10°C … +120°C

- glycerine +15°C … +200°C / – ––

- high temperature oil -10°C … +350°C / -10°C … +200°C

- oil for oxygen application -40°C … +175°C / -40°C … +80°C

Storage and transport temperature -40°C … +100°C (VEGADIF 34 and 44)

-50°C … +100°C (VEGADIF 35, 45 and 51)

Ex-technical data CENELEC

General data

Classification mark EEx ia IIC T4/T6

Intrinsically safe supply and signal circuit

Classification EEx ia IIC

Only for connection to certified, intrinsically

safe circuits with the max. values:

- voltage UO = 30 V

- current IK = 300 mA

- efficiency P = 1 W

Inner effective capacitance C

Inner effective inductance L

Ambient conditions

Ambient temperature around the

oscillator

- temperature class T6 -40°C … +40°C

- temperature class T5 -40°C … +55°C

- temperature class T4 -40°C … +85°C

= 11.2 nF

int

= 0.2 mH

int

1)

abs

< 1 bar

1)

at p

< 1 bar (vacuum range) the isolating liquid boils already at lower temperatures

abs

14 VEGADIF 34 … 51

Page 15

Product description

0-500 mbar

2 5 0

39

Z S

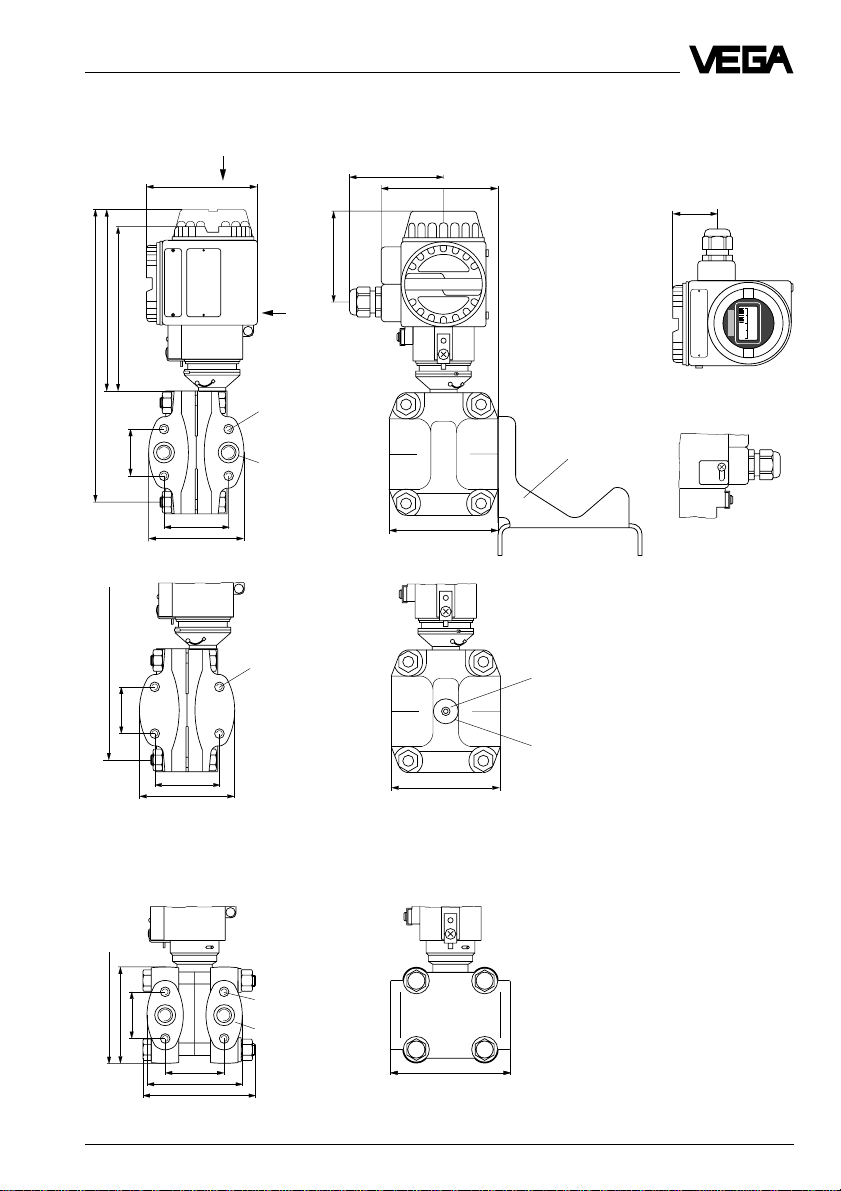

1.5 Dimensions

VEGADIF 34

104

x

81

104

80

View x

150

136

255

41,3

255

41,3

with PVDF-flange

VEGADIF 35

y

M10

7

/16 - 20 UNF

1

/4" - 18 NPT

54

82

M10

7

/16 - 20 UNF

54

82

96

96

Mounting loop

(optional)

PVDF

1

/4" - 18 NPT

View y

235

41,3

85 (93)

54

85

100 (135)

The values in brackets relate to PN 420

VEGADIF 34 … 51 15

M10 (M12)

7

/16 - 20 UNF

1

/4" - 18 NPT

106 (110)

Page 16

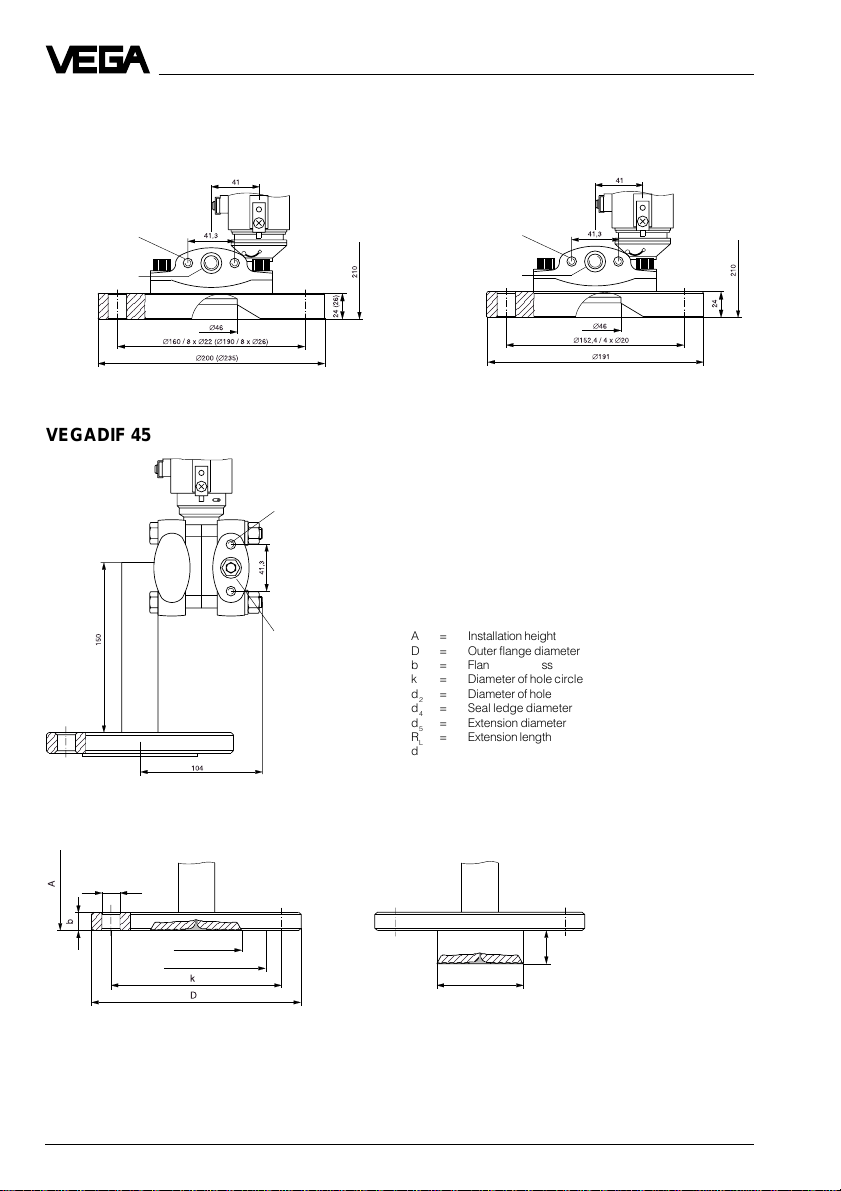

VEGADIF 44

;

;;;;;;;

DIN-flange DN 80/DN 100 ANSI-flange 3"

Product description

M10

7

/16 - 20 UNF

1

/4" - 18 NPT

VEGADIF 45

M10

7

/16 - 20 UNF

1

/4" - 18 NPT

M10

7

/16 - 20 UNF

1

/4" - 18 NPT

A = Installation height

D = Outer flange diameter

b = Flange thickness

k = Diameter of hole circle

d2= Diameter of hole

d4= Seal ledge diameter

d5= Extension diameter

RL= Extension length

dM= Diaphragm diameter

d

2

d

M

d

4

d

5

L

R

16 VEGADIF 34 … 51

Page 17

Product description

Flange connection acc. to DIN 2501, seal ledge acc. to DIN 2526 form D

Order Flange Holes Seal ledge Dia. Extension Install.

code Size/Nominal pressure D b k No. d2d

dMR

4

d5dMheight A

L

B DN 50 / PN 40 165 20 125 4 18 102 46 –– –– –– 360

C DN 80 / PN 40 200 24 160 8 22 138 70 –– –– – – 360

D DN 80 / PN 40 200 24 160 8 22 138 –– 50 76.5 70 360

E DN 80 / PN 40 200 24 160 8 22 138 –– 100 76.5 70 360

F DN 80 / PN 40 200 24 160 8 22 138 –– 200 76.5 70 360

G DN 100 / PN 40 235 26 190 8 26 162 70 –– 76.5 70 360

Flange connection acc. to ANSI B 16.5

Order Flange Holes Seal ledge Dia. Extension Install.

code Size/Nominal press. D b k No. d

in lb/sq in in/mm in/mm in/mm in/mm in/mm in/mm in/mm in/mm in/mm A

3

P 2 / 150 6/152

/4 /43/4/43/4/35/8/13/4/ –– –– –– 14.2/

19.5 120.7 20 92 46 360

15

R 3 / 150 8.25/

/16 /6/ 43/4/5 /23/4/ –– –– –– 14.2/

191 24 152.4 20 127 70 360

15

S 3 / 150 8.25/

/16 /6/ 43/4/5/–– 2/ 3/23/4/ 14.2/

191 24 152.4 20 127 50.8 76.5 70 360

15

T 3 / 150 8.25/

/16 /6/ 43/4/5/–– 4/ 3/23/4/ 14.2/

191 24 152.4 20 127 101.6 76.5 70 360

15

U 3 / 150 8.25/

/16 /6/ 43/4/5/–– 8/ 3/23/4/ 14.2/

191 24 152.4 20 127 203.2 76.5 70 360

1

W 4 / 300 10/ 1

/2 /78/9/814/16/62/9/23/4/ –– –– –– 14.2/

254 32 200.1 23 158 70 360

d4d

2

R

M

d5d

L

height

M

VEGADIF 34 … 51 17

Page 18

;

;;;;;;;

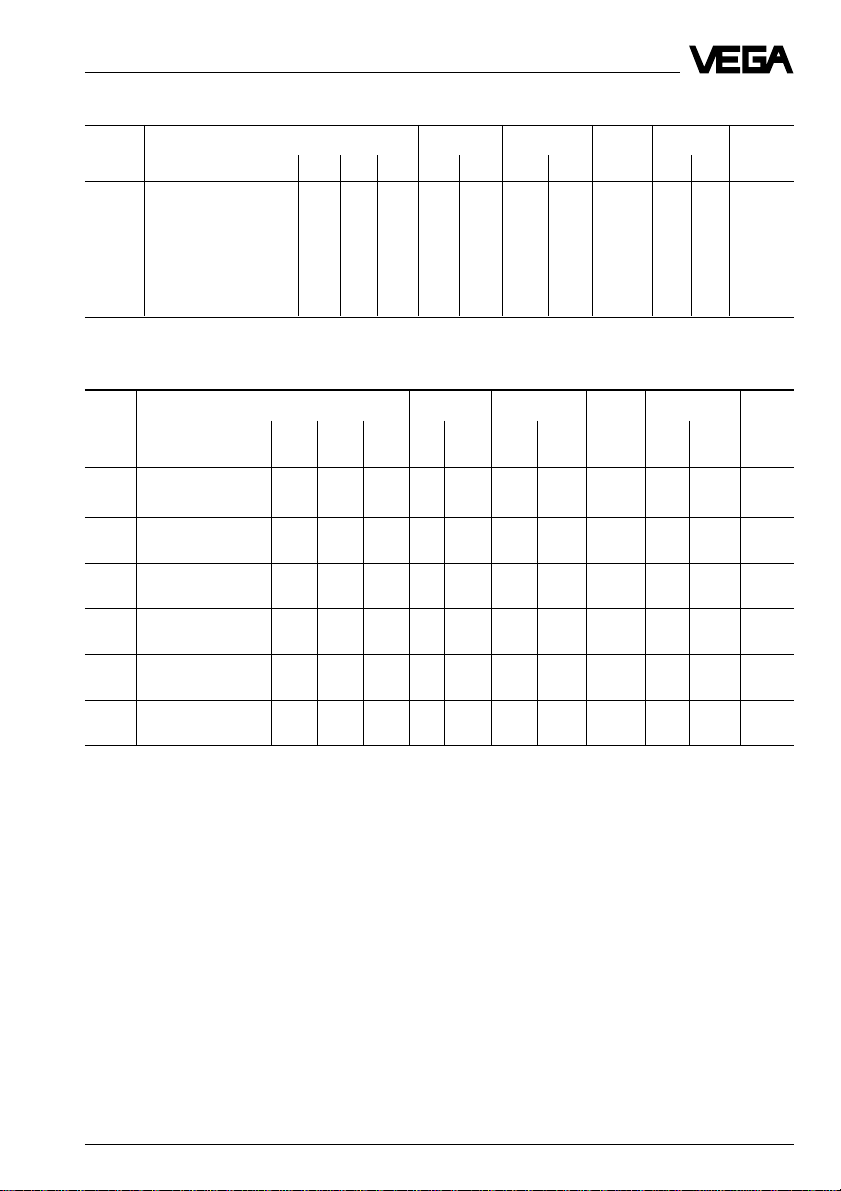

VEGADIF 51

;

7

/16 - 20 UNF

1

/4" -

18 NPT

Isolating diaphragm as cell version, AA … CR

Product description

d

M

acc. to DIN 2501

Order Socket Cell Min. mounting Max. Weight

code Size/Nominal pressure D b d

distance A pressure approx.

M

AA DN 50 PN 16 102 20 46 130 400 bar 2.6 kg

AK DN 80 PN 16 138 20 70 130 400 bar 4.6 kg

AM DN 80 PN 16 PTFE 138 20 70 130 400 bar 4.6 kg

AN DN 80 PN 16 Hastelloy 138 20 70 130 400 bar 4.6 kg

AR DN 100 PN 16 158 20 70 130 400 bar 6.2 kg

acc. to ANSI 16.5

Order Socket Cell Min. mounting Max. Weight

code Size/Nom. pr. D b d

in / lb sq in in/mm in/mm in/mm A in/mm lb/sq in

M

CK 3 / 150 71/2 / 1343/4 / 20 23/4 / 70 5 / 130 –– 4.5 kg

CR 4 / 150 81/4 / 1583/4 / 20 23/4 / 70 5 / 130 2500 6.2 kg

18 VEGADIF 34 … 51

distance pressure approx.

Page 19

Product description

;;;;;;;;;;

;;;;;;;;;;

;;;;;;;;;;

;;;;;;;;;;

;;;;;;;;;;

;;;;;;;;;;

;;;;;;;;;;

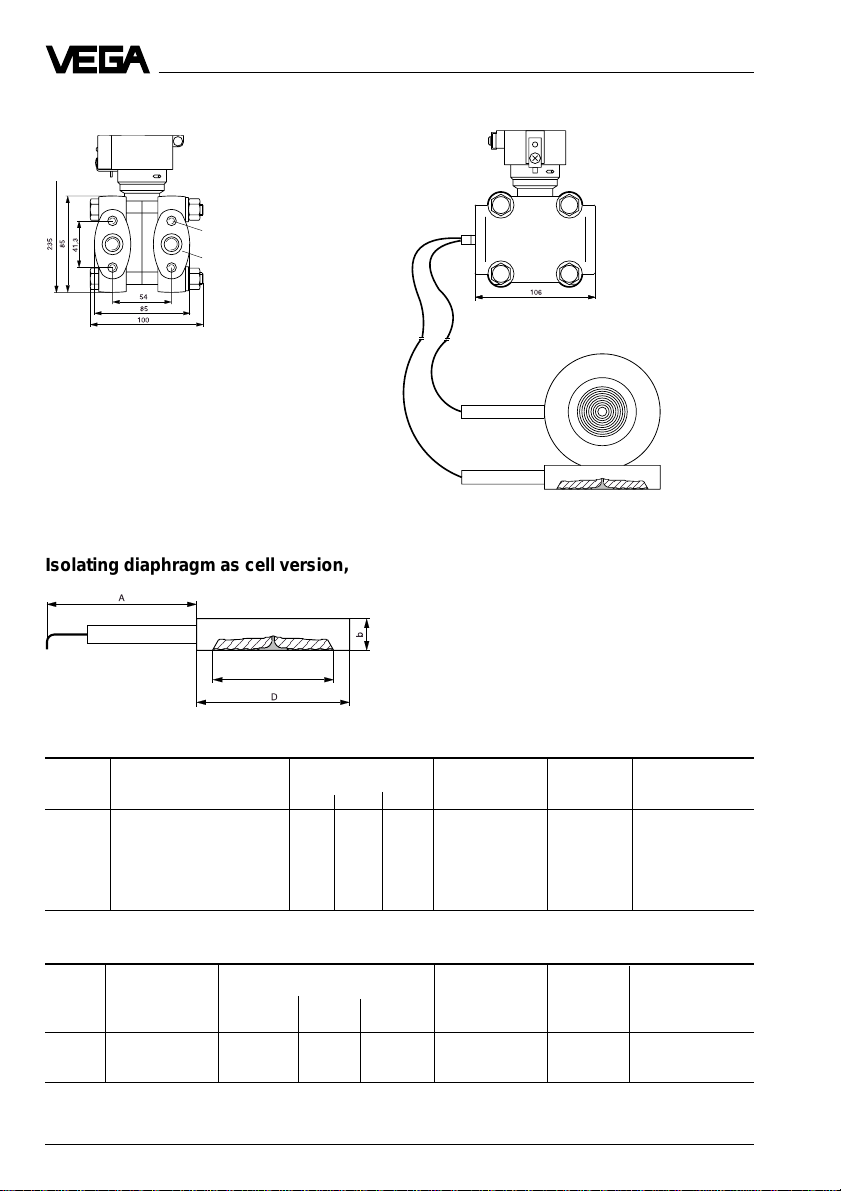

Isolating diaphragm as cone socket with compression nut, FA … FK

d

M

acc. to DIN 11 851

Order Socket Cell Compression nut Min. mount. Weight

code Size/Nominal pr. D f dMG k m distance A approx.

FA DN 50/PN 25 68 11 46 Rd78x

FE DN 65/PN 25 86 12 52 Rd95x1/6" 25 21 120 4.0 kg

FK DN 80/PN 25 100 12 71.5 Rd110x1/4" 29 25 120 5.1 kg

1

/6" 22 19 120 2.2 kg

Isolating diaphragm as threaded socket, GA … GK

acc. to DIN 11 851

Order Socket Threaded socket Min. mounting Weight

code Size/Nominal pres. d1GdMdistance A approx.

d

1

d

M

GA DN 65/PN 25 66 Rd95x1/6" 52 110 3.4 kg

GK DN 80/PN 25 91 Rd110x1/6" 71.5 110 4.0 kg

GA DN 50/PN 25 60 Rd78/

1

/6" 46 110 1.8 kg

Isolating diaphragm as Clamp, HA and HK

Order Socket Terminal socket Min. mounting Weight

code Size/Nominal pres. D d

d

M

HA DN 2" PN 40 64 46 100 1.4 kg

HK DN 3" PN 40 91 71.5 100 2.4 kg

M

distance A approx.

Isolating diaphragm as DRD-flange, KE

Order Socket Dimensions Min. mounting Weight

code Nominal pr. dMdistance A approx.

A

d

M

˘64

˘84

˘105

VEGADIF 34 … 51 19

KE PN 25 see drawing 46 100 1.5 kg

Page 20

Product description

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

105

119

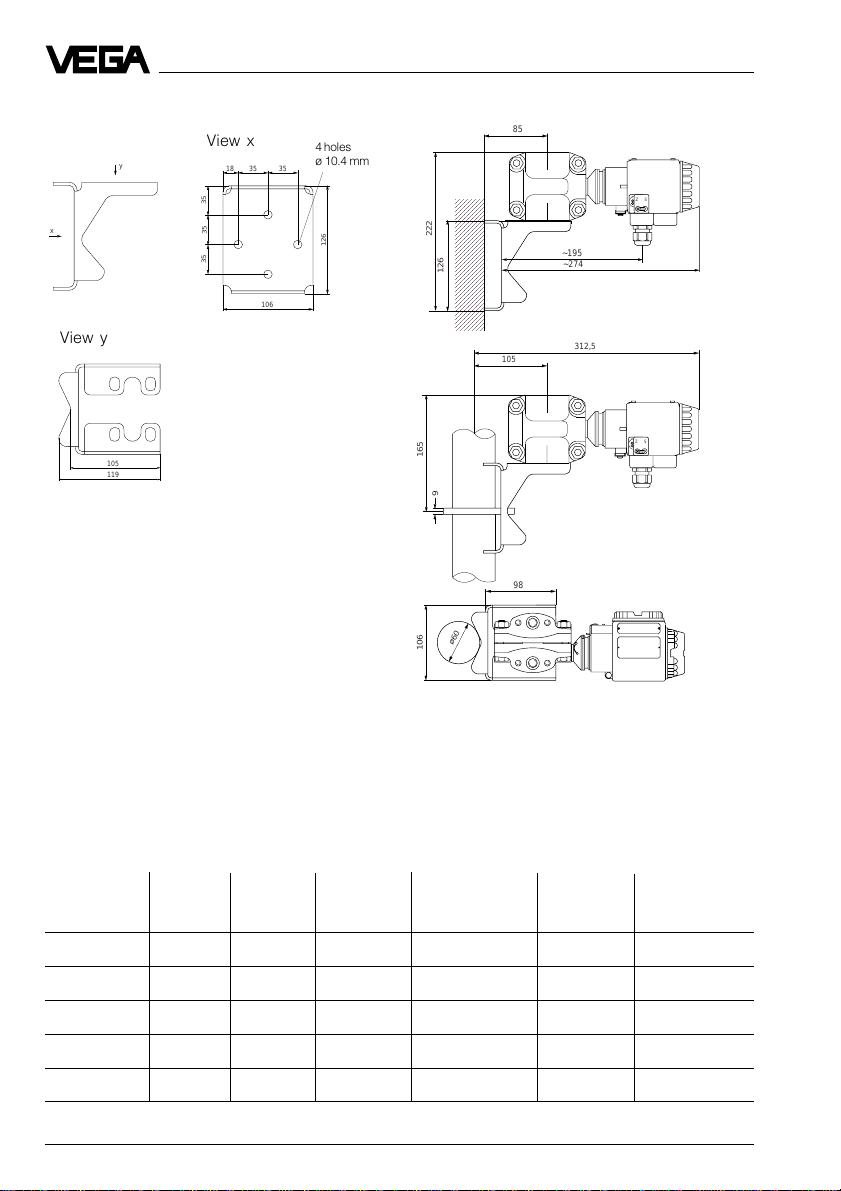

Mounting bracket Installation instructions

;;;;;;

;;;;;;

;;;;;;

;;;;;;

;;;;;;

;;;;;;

;;;;;;

;;;;;;

;;;;;;

;;;;;;

;;;;;;

;;;;;;

;;;;;;

;;;;;;

;;;;;;

;;;;;;

;;;;;;

;;;;;;

;;;;;;

;;;;;;

;;;;;;

;;;;;;

;;;;;;

;;;;;;

;;;;;;

;;;;;;

;;;;;;

;;;;;;

;;;;;;

;;;;;;

;;;;;;

ø60

85

~195

~274

105

312,5

98

x

View y

View x

y

18

35 35

4 holes

ø 10.4 mm

35

35

126

35

222

126

106

165

9

106

+

Z S

-

+

Z S

-

1.6 Approvals

For these applications the appropriate official documents (test reports, test certificates and

conformity certificates) have to be noted. These are supplied with the appropriate instrument.

Survey on the approvals which are in preparation or for which we applied

Approval CENELEC CENELEC PTB-Zone 0 FM FM WHG

Type and non incentive safe

VEGADIF 34 • • • • • •

VEGADIF 35 • • • • • •

VEGADIF 44 • • • • • •

VEGADIF 45 • • • • • •

VEGADIF 51 • • • • • •

20 VEGADIF 34 … 51

EEx ia IIC EEx d IIC EEx ia IIC Explosion proof Intrinsically

Page 21

Mounting

2 Mounting

2.1 Verifying operating conditions

VEGADIF is a rugged transmitter for precise

differential pressure, level and flow measurement. The accuracy of the measurement

mainly depends on the correct installation and

the connection of the impulse lines.

Detailed information for differential pressure

measurement in aggressive products as well

as further information on wiring and coordination of valves, measuring lines and components is given in the VDI/VDE-regulations 3512

as well as DIN 19 201 and DIN 1952. Further

information on level measurement is stated in

the VDI/VDE-regulations 3519.

The differential pressure transmitter used

must meet the technical and safety requirements of the application. Therefore check from

the type plate, calibration plate and order

code the following data:

Nominal pressure

The pressure stage rating of VEGADIF must

be above the operating pressure of the process.

Measuring range

The measuring range is calibrated (factory

set) acc. to the order. The pressure values

adjusted for zero and span are documented

on the calibration plate. The values must cover

the application. If an adaptation is necessary,

this should be carried out acc. to section

4 Setup.

Materials of wetted parts

The material of the wetted parts must be sufficiently resistant. Use the respective material

tables for control. A table is given in the product information to VEGADIF, for more information we recommend the VEGA-resistance lists.

Ambient temperature

The ambient temperature in the installation

place must be in the range of -40°C … +85°C.

The surface temperature of the electronics

housing must not exceed +85°C. Hence it

should be noted that the electronics housing

should not be heated to more than +85°C due

to radiation by neighbouring instruments or

systems. If temperatures below -40°C are

expected at the installation, the transmitter

should be installed in a temperature isolated

and heated protection box. If there is danger

that measured product or condensate freezes

in the process connection or on the measuring

cell, the transmitter must be installed in a

warmer place or in a heated protection box for

process connections and process seals.

Similar measures should be taken to protect

the impulse lines.

Medium temperature

The permissible medium temperature depends on the process seal, the measuring cell

and the isolating liquid. When VEGADIF 45 or

51 are used, note that the product temperature can differ between plus and minus side.

Moisture

Mount horizontally installed instruments such

that the cable entry points to the bottom to

avoid moisture ingress. The sensor housing is

therefore rotational by approx. 350°. For vertically installed instruments loop the connection

lines in a bow pointing to the bottom to the

instrument housing, so that rain or condensation

water can drain off the cable. This is mainly

valid for mounting outside, in humid areas (e.g.

by cleaning processes) or on cooled or heated

vessels.

VEGADIF 34 … 51 21

Page 22

Mounting

2.2 Pre-installation

Selection of the installation location

The selection of a suitable installation location

under extreme ambient conditions is needed

for

- quality of the measurement

- a long lifetime of the transmitter

- low maintenance expenses.

Note the following regulations:

Installation level

• For level measurements install below the

minimum level (the diaphragm or the isolating diaphragm must be completely covered).

• For measurement of gases, install transmit-

ter above the pressure tapping points.

• For the measurement of vapours and liq-

uids, install transmitter below the pressure

tapping points.

Mounting locations

• Mount the transmitter as near as possible to

the pressure tapping points.

• Keep impulse lines as short as possible.

• Mounting and maintenance work should be

carried out without obstruction.

• The transmitter, the tapping points, the

impulse lines and the valves should be

easily accessible.

• If available, the mounting place should provide a good view to the LC-display.

Adaptation of the transmitter

For optimum adaptation of your VEGADIF to

the installation place the following measures

can be carried out:

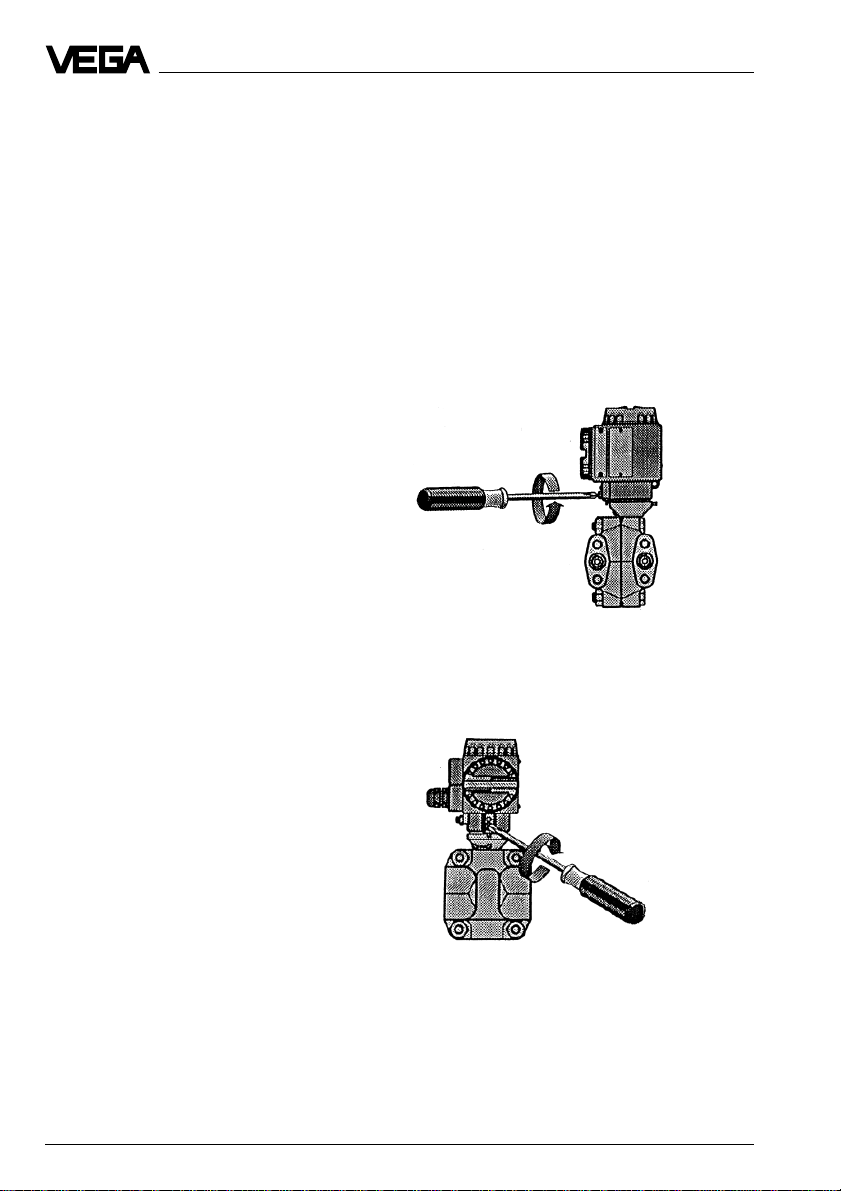

Rotate the electronics housing

After loosening the locking screw below the

electronics housing, the housing can be rotated by approx. 330°. A stop prevents further

turning. Hence the terminal compartment can

be set to an optimum position for cable entry

or the LC-display into an optimum reading

position.

Fig. 2.1 Loosen the locking screw

When the best position is reached, tighten the

locking screw again.

Ambient influences

• Keep the vibration and shock effect to a

minimum.

• Avoid corrosive ambient atmosphere.

• Reduce condensation to a minimum.

Note:

Under arduous ambient conditions, a protective housing is recommended.

22 VEGADIF 34 … 51

Fig. 2.2 Fastening of the locking screw

Page 23

Mounting

Rotating the display

If the integrated display is not correctly positioned it can be rotated in 90°-steps after

opening the housing cover.

Avoid exposure of the electronics compartment and carry out these measures if possible

in a workshop.

1 Unscrew the display cover

2 Push the protruding clamp with a screw-

driver outwards

3 Tilt the display in this position and take

out

Note

Do not turn more than 2 x 90° to the left or

right, otherwise the connection cable may be

damaged.

5 Insert the display into the clamp and

snap-in

6 Replace the outer cover

Remove the protective plugs

Transmitter or isolating diaphragm are provided with protective plastic plugs. Remove

them before installation.

4 Rotate display as needed

VEGADIF 34 … 51 23

Page 24

Mounting

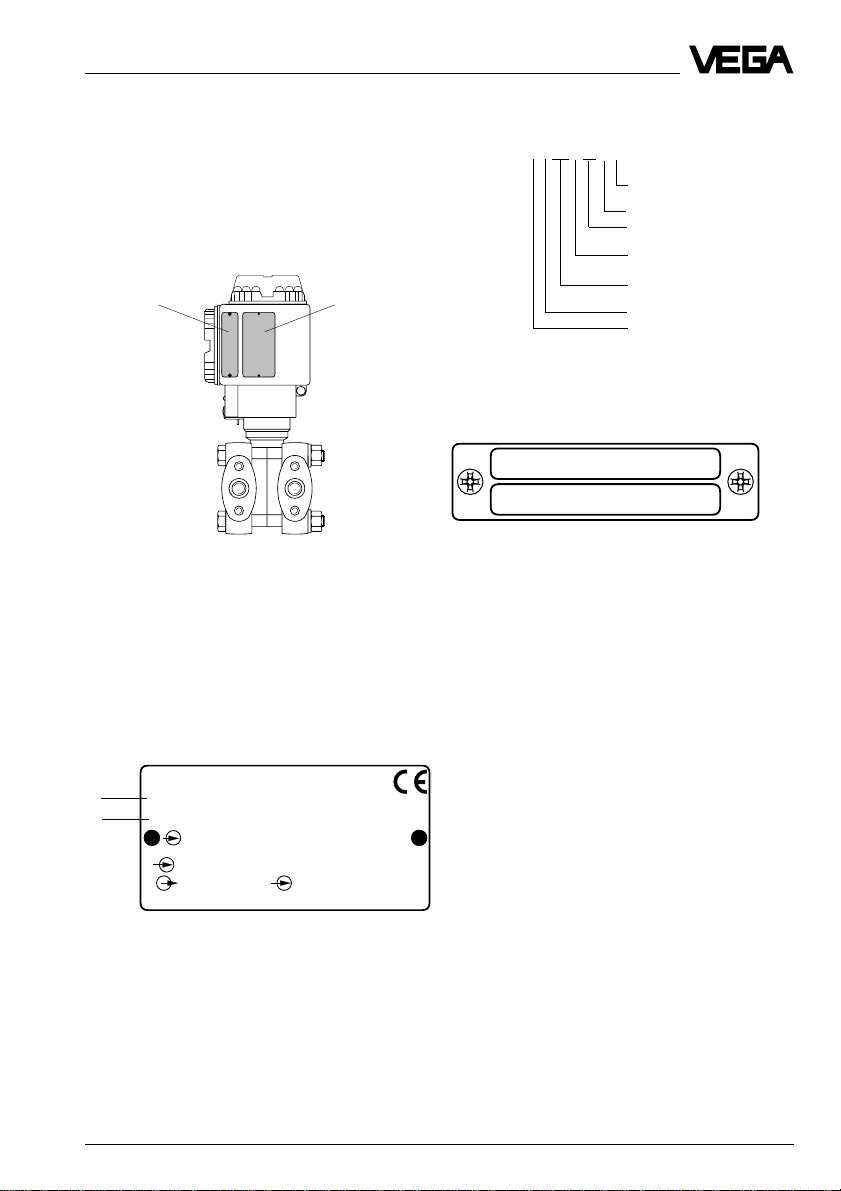

2.3 Mounting

2.3.1 VEGADIF 34, 35 and 51

The differential pressure transmitter mounting

is generally fixed. There are three versions

with VEGADIF 34, 35 and 51:

- pipe mounting (2“-pipe)

- wall mounting

- mounting on a valve block

Hanging the transmitter on the impulse lines is

not recommended, nor with capillary lines.

For correct mounting VEGA offers a universal

mounting kit consisting of:

- a mounting bracket

- a pipe shackle for 2“-pipes (up to outer-ø

63 mm)

- two hexagon nuts M8 with plain washers

- four hexagon screws (7/16 UNF or

M10 x 182))

For easy removal of the transmitter a three or

five valve manifold can be mounted to the

transmitter 1).

In this case the valve block can be mounted

with the mounting kit to a pipe or wall instead

of the transmitter. The impulse lines can be

sealed via valves and the manifold with the

connected impulse lines can be left in place

after removal of the transmitter.

1)

Pipe mounting

Use the complete mounting kit and note the

following procedure:

1 Hold the mounting bracket in the required

direction on the pipe.

2 Insert the u-bolt via the pipe through the

holes of the mounting bracket.

3 Screw two hexagon nuts to the u-bolt and

fasten the bracket by fastening the nuts on

the pipe.

4 Fasten the transmitter to the bracket (the

screws with plain washers pass through the

holes of the bracket into the thread).

Mounting on vertical pipe

approx. dimensions in mm

105

165

9

312,5

+

Z S

-

+

Z S

-

1)

not with VEGADIF 51

2)

M12 x 18 with 420 bar-version of VEGADIF 35

24 VEGADIF 34 … 51

Page 25

Mounting

Mounting on horizontal pipe

Z S

-

+

Wall mounting

Use the following material of the mounting kit:

- bracket

- four hexagon screws

Provide the following material:

- four screws with suitable plugs

Note the following procedure:

1 Screw the bracket by means of the screws

and suitable plugs to the wall.

2 Screw the transmitter to the bracket (the

screws with plain washers pass via the

holes of the bracket to the thread).

Mounting with valve block

1)

The valve block is fastened as described

before by tube or wall mounting.

Procedure:

1 Fasten bracket to a tube or wall.

2 Screw the valve block to the mounting

bracket with two hexagon screws and plain

washers.

The transmitter is normally flanged to the valve

block just before setup of the measurement

loop.

2.3.2 VEGADIF 44 and 45

The following instructions are given for VEGADIF 44 however are also valid for VEGADIF

45.

Open vessel

The minus side of the transmitter is open to

atmospheric pressure. Therefore the open

process connection of the minus side should

point downwards.

Max.

Min.

P

atm

Atmospheric pressure on the minus

side of the transmitter

1) not with VEGADIF 51

VEGADIF 34 … 51 25

Page 26

Mounting

Closed vessel

The minus side of the transmitter is connected

via an impulse line with the vessel and feels

the pressure. The pressure must be above

the maximum level. The impulse line should

have a block valve.

Block

valve

Steam trap

Block

valve

If the static pressure is caused by steam above

the product the minus side is connected via a

condensation leg. Before opening the block

valve the impulse line must be filled via the

condensation pot.

2.3.3 Isolating diaphragm mounting on

VEGADIF 51

The two isolating diaphragms connect the

pressure transmitter with the process. The

dimensions of the cell isolating diaphragm are

dependent to the respective standard flange.

The fastening is made by means of a suitable

blind flange. Depending upon the flange a

seal acc. to DIN 2690 or ANSI B 16.5 must be

used.

Mounting

Blind flange

Isolating diaphragm

Seal

Measuring point

connection flange

Vessel wall

Level measurement

Block

Condensation pot

valve

Condensate

Steam

Max.

Min.

Min.

Recommended mounting

Block

valve

26 VEGADIF 34 … 51

Condensation outlet

Page 27

Mounting

Only permitted with continuous positive pressures.

Differential pressure measurement

-+

Flow measurement

+

-

Avoid buildup on the isolating diaphragm of

solids or by sticky materials. If possible position the flange connections on top of the pipe.

VEGADIF 34 … 51 27

Page 28

3 Electrical connection

Electrical connection

3.1 Connection instructions

The electronics of the pressure transmitters

requires a supply voltage of 11.5 … 45 V DC.

Supply voltage (DC voltage) and current

signal are on the same two-wire connection

cable to the terminals.

This external supply can be provided via a

separate instrument:

- power supply

(e.g VEGASTAB 690)

- processing unit with integral DC voltage

source (e.g. active DCS-input)

- VEGAMET series 500 or 600 signal conditioning instrument, VEGALOG 571 processing system or VEGADIS 371 indication

Note that the external supply source is reliably

isolated acc. to DIN VDE 0106, part 101 from

the mains circuits. The above mentioned systems meet these requirements and protection

class III is therefore ensured.

For electrical connection note the following

instructions:

- The connection must be made acc. to the

specific national installation standards (e.g.

in Germany acc. to the VDE-regulations).

- The wiring between pressure transmitter

and supply can be made by standard twowire cable.

- If strong electromagnetic interference is

expected, use screened cable. The screening must be earthed at the sensor end.

- The connection cable for the external supply

must never be connected to terminal 3 of

the terminal block or to the test plug connection via terminal 1 of the terminal block

(danger of damage to the electronics).

- Housing cover and cable entry must be

tight after electrical connection, so that humidity ingress to the terminal compartment

is avoided.

3.2 Load resistance

Various instruments can be connected to the

signal output of the pressure transmitter, e.g.:

- remote transmission systems

- computers

- indicating instruments

- recorders

- controllers etc.

The total resistance of the connected instruments and the connection cable must not

exceed the value of the max. load resistance.

The load resistance consists of the line resistance RL, the adjustment resistance RX, and the

resistance of the processing system and/or

indicating instrument.

This max. load resistance depends on the

voltage of the external supply and can be

calculated acc. to the following formula:

US – U

R

= –––––––––

Lmax

R

Lmax

US= supply voltage

UKl= terminal voltage

I

max

The following load diagram is used for simplified determination of this value:

1560

1000

in Ohm

500

total

Load R

K

I

max

= max. load resistance

1)

= max. current (approx. 23 mA)

0

20 28,5 37 4511,5

Supply voltage US in Volts

28 VEGADIF 34 … 51

Page 29

Electrical connection

3.3 Connections

Electronics powered by the power supply unit

Processing via an indicating instrument.

Ammeter for local testing

1+2–3

–

+

U

Transmitter

terminals

R

Kl

L

analogue / digital

indicating instrument

e.g. VEGADIS

U

A

4 … 20 mA

U

S

+

~

–

Voltage supply

US= power supply

UA= voltage loss in the indication instrument

UKL= terminal voltage (supply voltage)

RL= resistance processing systems and connec-

tion cable (load resistance)

Electronics powered by a VEGA-signal conditioning instrument or a PLC with active

input circuit

Processing is made via the PLC or the VEGAMET signal conditioning instrument.

Ammeter for local testing

–

+

1+2–3

Transmitter

terminals

U

Kl

R

L

4 … 20 mA

PLC active

or

0/4 … 20 mA

U

S

DISBUS

!

Note:

An ammeter for local testing of the output current can be connected between terminal 1 and its

tag. This measurement can be made during operation without interrupting the supply line.

VEGADIF 34 … 51 29

Page 30

Electrical connection

3.4 Ex-applications

Applications in Ex-areas require the use of

approved instruments.

For these applications the appropriate documents (test reports, test and conformity certificates) should be noted. These are supplied

with the appropriate instrument.

Therefore note the attached approval documents (yellow binder) and especially the attached safety data sheet.

The voltage supply in Ex-applications must be

only made via an intrinsically safe circuit.

There are the following possibilities:

- VEGAMET signal conditioning instrument in

Ex-version

- not certified signal conditioning instrument

VEGAMET with VEGA-safety barrier type

145

- Ex-separator (e.g. VEGATRENN 149 Ex)

- indicating and supply instrument VEGADIS

371 in Ex-version.

The legal documents of these instruments

must also be noted.

Application with supply by Ex-separator,

e.g. VEGATRENN 149 Ex

The processing is made by an indicating

instrument in the non-Ex-area.

-

+

1+2-3

U

Kl

Ex-area

Terminals

VEGADIF

Non-Ex-area

e.g. Ex-separator

VEGATRENN

149 Ex

-

U

S

+

4…20 mA

=

~

Ex-application with supply via a VEGA

non-Ex-signal conditioning instrument

with safety barrier type 145

The processing is made via the signal conditioning instrument in the non-Ex-area.

Non-Ex-area

Safety barrier

type 145

VEGAMET in

non-Ex-version

-

+

Ex-area

1+2-3

Terminals

VEGADIF

U

Kl

Note

- Carry out the adjustment only with connected safety barrier (reason: the current

consumption of approx. 300 µA is considered).

- When connecting a VEGADIS 11 Ex the

regulations for wiring of intrinsically safe

circuits should be noted.

Determination of the line length in the

ia-IIC-circuit

The sum of the inner capacitances and inductances of the components must not exceed

the max. permissible values of the ia-IICcircuit.

Example:

ia-IIC-circuit Pressure 1 pce. Line

max. total transmitter overv.arrester L

L

ext/Cext

L

int/Cint

L

int/Cint

0.5 mH 0.2 mH 0.13 mH 0.17 mH

56 nF 11.2 nF 1 nF 44.8 nF

1)

int/Cint

VEGADIS 11

Processing e.g.

indicating instrument

1)

Typical values for unshielded two-wire lines:

L‘ = 0.00065 mH/m; C‘ = 0.00012 nF/m

30 VEGADIF 34 … 51

Page 31

Electrical connection

Calculation of L

L

(cable) = L

int

transmitter) – L

of the cable:

int/Cint

(ia-IIC-circuit) – L

ext

(overvoltage arrester)

int

(pressure

int

= 0.5 mH – 0.2 mH - 0.13 mH

= 0.17 mH

C

(cable) = C

int

sure transmitter) – C

(ia-IIC-circuit) – C

ext

(overvoltage arrester)

int

(pres-

int

= 56 nF – 11.2 nF - 1 nF

= 44.8 nF

Calculation of the cable length:

0.17 mH

I = –––––––––– • m = 262 m

0.65 µH

44.8 nF

I = ––––––––––– • m = 373 m

120 pF *

To be on the safe side, the cable length in this

example should not exceed a value of 250 m.

VEGADIF 34 … 51 31

Page 32

4 Setup

Setup

4.1 Adjustment structure

The differential pressure transmitters can be

setup

- with the PC and the VEGA-adjustment program VVO,

- with the HART® handheld or

- with the integral 4-key adjustment elements.

Adjustment program VVO

With the adjustment program VVO (VEGA

Visual Operating) on the PC you adjust the

sensors in a very comfortable way. The PC

communicates via the interface converter

VEGACONNECT 2 with the sensor. The signal

and supply line is therefore superimposed by

a digital adjustment signal. The adjustment

can be made in any position of the signal line,

naturally also directly on the sensor.

HART® handheld

Beside the PC and the 4-key adjustment elements, the sensors can be also adjusted with

the HART® handheld.

4-key adjustment elements with LCdisplay

If you have neither a PC nor a HART® handheld,

the sensors can also be setup directly with the

integral 4-key adjustment elements.

4.2 Adjustment with 4-key adjustment element

LC-display in operating mode

According to the ordered version your VEGADIF is provided with an integral LC-display.

This display can be retrofitted or removed.

The display is located below the upper housing cover behind a glass pane.

The LC-display provides the following information in the adjustment mode:

Span indication during

full adjustment

Appropriate

pressure value

s

5 .0 0 0

z

Zero indication during

empty adjustment

Position of

zero

Bar graph for measuring span =

span – zero

LC-display

The following examples show possible indication

values.

Example 1: Meas. range -0.5 … 1.5 bar, LCD

in operating mode

Position of

span

D p

-0,5 bar

0 bar

1,5 bar

32 VEGADIF 34 … 51

Display I

- 0 .5 0 0

4 mA

- 0 .0 0 0

8 mA

1 .5 0 0

20 mA

Page 33

Setup

Example 2: Measuring range 0 … 10 bar

D p

0 bar

2,5 bar

10 bar

Display I

0 .0 0

4 mA

2 .5 0

8 mA

1 0 .0 0

20 mA

4-key adjustment elements

Your VEGADIF is provided with the following

direct adjustment elements:

- four adjustment keys

- one step switch

The adjustment keys are located below a slide

laterally on the electronics housing. The slide

is marked with z (zero) and s (span) and can

be moved after loosening of the recessed

head screws. When moving the slide, two adjustment keys are released, when then rotating

the slide, all four adjustment keys are released.

+

Z S

-

First of all the slide releases 2 keys and then

all four keys

Via these four keys in conjunction with the LCdisplay you can carry out the most important

adjustments such as zero, span and bias pressure directly on the transmitter.

++

ZS

-

If you have a VEGADIF without LC-display,

connect to the terminal and to tag 1 an ammeter

with measuring range 0 … 20 mA (e.g. digital

multimeter). For the exact adjustment connect a

precision ammeter. Push the keys with a small

screwdriver.

The second adjustment element, the step

switch, is located below the LC-display; therefore remove the display, as described under

"2.2 Pre-installation“.

The step switch below LC-display

The adjustments on the step switch mean:

- 0 Adjustment with PC or HART®, therefore

damping adjustable from 0 … 40 s

- 2 Damping 0.5 s linear

- 3 Damping 1.0 s linear

- 4 Damping 2.0 s linear

- 5 Damping 4.0 s linear

- 6 Damping 8.0 s linear

- 7 Damping 16.0 s linear

- 8 Adjustment with PC or HART®, there-

fore damping adjustable from 0 … 40 s

- 9 Damping 0 s extracted by root

- A Damping 0.5 s extracted by root

- B Damping 1.0 s extracted by root

- C Damping 2.0 s extracted by root

- D Damping 4.0 s extracted by root

- E Damping 8.0 s extracted by root

- F Damping 16.0 s extracted by root

Current I

Current I

Dp

linear extracted by root

VEGADIF 34 … 51 33

Dp/p

Page 34

Setup

Display zero

1 Push +z or –z key

2 Monitor the displayed value and release the

key again.

After approx. 2 s the indication resets automatically to operating mode.

Example for display of zero:

Meas. range Display

-3…0 bar

0…1,5 bar

2,5…-0,5 bar

Display span

1 Push +s or –s key

2 Monitor the displayed value for s and re-

lease the key again

The display resets automatically to operating

mode after approx. 2 s.

Examples for display of span:

Meas. range Display

-3…0 bar

1)

z

- 3 .0 0 0

z

0 .0 0 0

z

2 .5 0 0

s

0 .0 0 0

Data of the factory setting

Measuring range

Your VEGADIF is calibrated acc. to the order.

The calibration data is stated on the calibration

plate, e.g. 0 … 1000 mbar.

For this measuring range:

- The 4 mA-signal is coordinated to the first

pressure value (in the example 0 mbar).

- The 20 mA-signal is always coordinated to

the second pressure value (in the example

1000 mbar).

Check if the calibrated measuring range corresponds to the application and if necessary

readjust, see the following section "Adjustment“.

Integration time

A factory set integration time of 0 s is supplied. Via the step switch this time can be

changed from 0 … 16 s, with the PC to

0 … 40 s, to achieve an increased smoothing

of the output signal.

Output characteristics

As factory setting a linear characteristics is

adjusted. A square root output can be selected with the step switch.

Electronics replacement

The calibration data is stored in the EEPROMmemory of the electronics. Always check the

data when replacing the electronics and

modify if necessary.

Adjustment

0…1,5 bar

2,5…-0,5 bar

1)

This adjustment effects an inversion of the current

output

34 VEGADIF 34 … 51

s

1)

1 5 0 0

- 5 0 0 .0

First note the adjustment ranges for zero and

span. The values are stated under "1.4 Technical data - Transmission reaction“. Make sure

that your requested values are within the

possible adjustment range.

Page 35

Setup

Two methods are available for adjustment

- adjustment without pressure (dry)

- adjustment with pressure (wet)

The dry adjustment can be made before

mounting in the workshop or after mounting at

the measuring point. Note with the adjustment

before mounting, that the position of the transmitter corresponds to the intended installation

position. This is particularly necessary for

VEGADIF 45 and 51 with isolating system or

capillaries. Use for sensors without display a

precision ammeter (class 0.03 or better) to

adjust the current output.

Adjustment without pressure (dry)

Reduce zero

1 Push key z– twice and hold.

2 Note the change of the current.

3 When the requested current value is

reached, release z–.

4 The display resets automatically to operat-

ing mode after approx. 2 s and the adjusted

value is saved.

Example:

given: 0 … 1000 mbar, (z = 0 mbar,

s = 1000 mbar)

z to be changed to: z = -500 mbar

Example:

given: 0 … 1000 mbar, (z = 0 mbar,

s = 1000 mbar)

to be changed to: s = 500 mbar

Push the key s– twice and hold until 500 mbar

are adjusted.

Adjustment with pressure (wet)

For the adjustment with pressure, VEGADIF

must be connected to a variable pressure

source, e.g.:

- a pressure calibrator

- directly to the process

Adjust zero with display

1) Set pressure precisely for zero (e.g.

0 bar) and check via the display.

2) Push key z+ and z– together.

The pressure (e.g. 0 bar) corresponds to the

output current 4 mA.

Adjust span with display

1) Set pressure precisely for span (e.g.

1 bar) and check via the display.

2) Push key s+ and s– together.

Increase zero

Push the key z+ twice and hold. The procedure is the same as above.

Reduce span

1 Push key s– twice and hold.

2 Note the change of the current.

3 When the requested current value is

reached, release s–.

4 The display resets automatically to operat-

ing mode after approx. 2 s and the adjusted

value is saved.

VEGADIF 34 … 51 35

The pressure (e.g. 1 bar) corresponds to the

output current 20 mA.

Adjust zero without display

1) Set pressure precisely for zero (e.g.

0 bar) and check via an external pressure

calibrator.

2) Push key z+ and z– together.

The pressure (e.g. 0 bar) corresponds to the

output current 4 mA.

Page 36

Setup

Adjust span without display

1) Set pressure precisely for span (e.g.

1 bar) and check via an external pressure

calibrator.

2) Push key s+ and s– together.

The pressure (e.g. 1 bar) corresponds to the

output current 20 mA.

Adjust zero/span without display however

with current meter

For adjustment a control instrument with measuring range 0 ... 20 mA is connected to terminal 1 and tag 1.

1) Set pressure precisely for zero (e.g.

0 bar) and check via an external pressure

calibrator.

2) Adjust with keys z+ and z– a current of

4 mA.

The pressure (e.g. 0 bar) corresponds to an

output current 4 mA.

3) Set pressure precisely for span (e.g.

1 bar) and check via an external pressure

calibrator.

4) Adjust with the keys s+ and s– a current

of 20 mA.

Example:

Meas. range 0 … 1000 mbar

Reference pressure span ps = 1000 mbar,

zero pz = 0 mbar, reference pressure

p = 250 mA (750 mbar)

250 mbar – 0 mbar

Iz = 4 mA + 16 mA • ––––––––––––––––––––

1000 mbar – 0 mbar

Iz = 8 mA

750 mbar – 0 mbar

Is = 4 mA + 16 mA • –––––––––––––––––––

1000 mbar – 0 mbar

Is = 16 mA

Bias pressure

Bias pressure is the pressure indicated although a differential pressure of 0 mbar is

present at the pressure tappings. The bias

pressure is caused by unequal hydrostatic

pressures 1) on the measuring cell.

The following relation is valid:

Pressure indication = Sensor pressure – Bias

pressure

The pressure (e.g. 1 bar) corresponds to an

output current 20 mA.

Example:

Pressure indication: 0.025 bar

Sensor pressure: 0.035 bar

Bias pressure: 0.010 bar

Note:

When only intermediate values are available

0.025 bar = 0.035 bar – 0.010 bar

for the reference pressures, the current to be

adjusted can also be calculated:

Note:

p – p

I = 4 mA + 16 mA • –––––––––

p = reference pressure

ps= pressure at span

pz= pressure at zero

ps – p

z

z

- The adjustment of the bias pressure must

be carried out before the adjustment of zero

and end, as these values had been modified.

- The adjustment of the bias pressure does

not influence the current output. The signal

current and its characteristics are not modified.

1)

This can be caused e.g. by non-level pressure tappings and therefore different needs in the impulse lines, by

the installation of the capillary lines or the position of the measuring cell itself (max. 2 mbar when tipped by

90°).

36 VEGADIF 34 … 51

Page 37

Setup

Indicate bias pressure

1) Push keys z+ and s+ once together.

2) Adjusted bias pressure is indicated.

3) After approx. 2 s the display resets automatically to operating mode.

Save/take over bias pressure

1) Push keys z+ and s+ twice together. The

available pressure value is taken over as

bias pressure.

2) After approx. 2 s the display resets automatically to operating mode and shows

0.000 bar. Therefore the available pressure (0 bar) was taken over as bias pressure (correction value).

Delete bias pressure

1) Push the keys z– and s– twice together.

2) After approx. 2 s the display resets automatically to operating mode and shows

the value of the uncorrected bias pressure.

Lock/unlock keys

Lock

1) Push keys z+ and s– once together.

2) "Prot“ = protected appears (locked).

3) After approx. 2 s the display resets automatically to operating mode.

Unlock

1) Push keys z– and s+ once together.

2) "Free“ = unlocked appears.

3) After approx. 2 s the display resets automatically to operating mode.

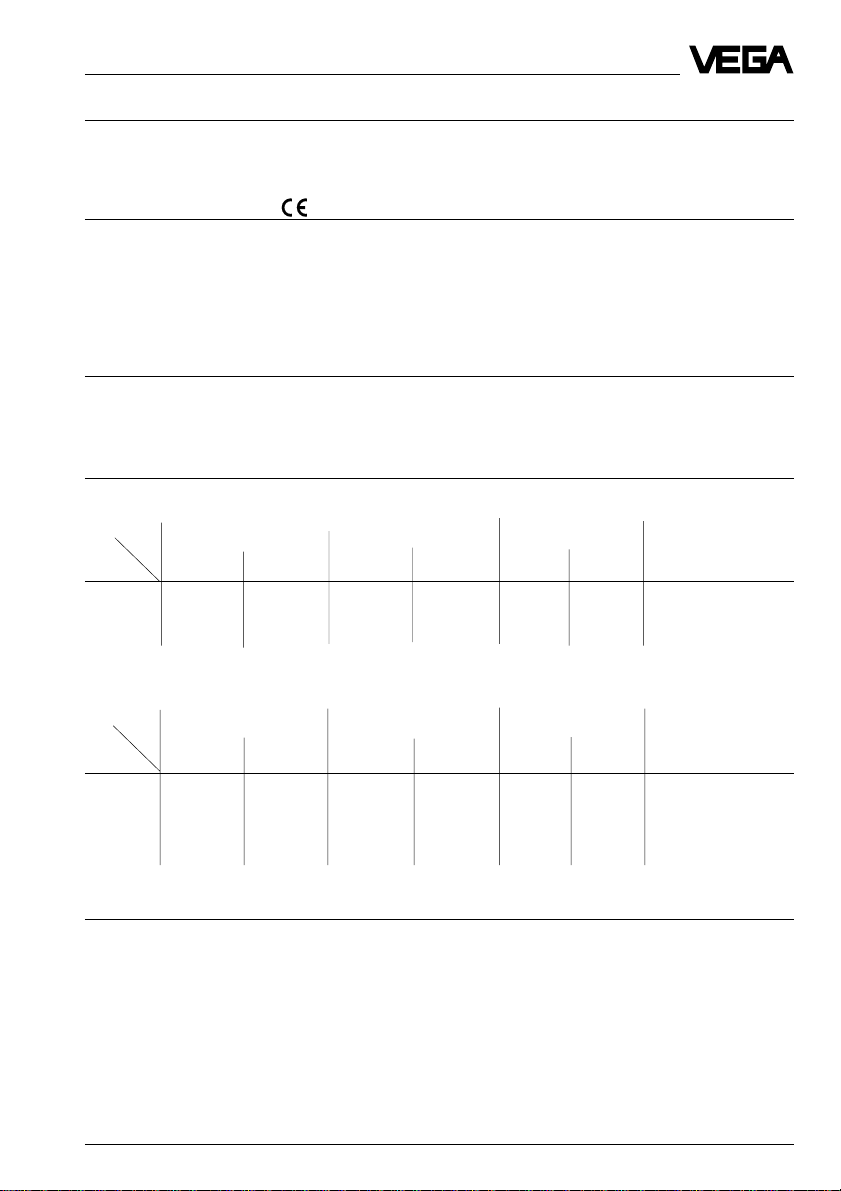

Integration time and output characteristics

An integration time of 0, 1, 2, 4, 8, 16 s can be

adjusted via the step switch to smooth the

output signal of your VEGADIF. The output

characteristics for pressure, level and flow

can be selected as line or square root.

The integration time is the time required by the

output to reach 63 % of the actual change

after a step change of the differential pressure. After three times the adjusted integration

time, the current output signal will have

reached 95 % of the step change.

Explanation:

- an integration time of 0 s means tracking of

the current output without additional delay

- an integration time of 16 s means that the

output has reached its final value only after

more than one minute.

Adjust the integration time and the output

characteristics acc. to the table. All figures

indicate the switch positions:

Characteristics linear by root

Integration time

0 s 1 9

0.5 s 2 A

1 s 3 B

2 s 4 C

4 s 5 D

8 s 6 E

16 s 7 F

I ~ DpI ~ ÖDp/Dp

I

Dp

I

max.

Dp

The positions 0 and 8 enable the adjustment

with PC (VVO) or with HART® handheld by which

you can also adjust the integration time of

0 … 40 s.

VEGADIF 34 … 51 37

Page 38

Setup

4.3 Adjustment with HART® handheld

Beside the adjustment with the 4-key adjustment element in the sensor and the adjustment with

the PC and the adjustment software VVO a VEGADIF can be also operated with a HART® handheld. If

the inner resistance of the voltage supply is less than 250 W, a resistor of RX = 250 W 1/4 W must be

looped into the signal/connection line during adjustment.

The digital adjustment and communication signals would be shortcircuited via too small resistances of the supply current source or the processing system so that the sensor communication

would not be assured.

Electronics powered by PLC with active input circuit

+

PLC

-

Ri > 250

+

PLC

250

-

Ri < 250

38 VEGADIF 34 … 51

Page 39

Setup

Electronics powered by power supply unit

Ammeter for local testing

analogue / digital indicating instrument

-

+

1+2-3

Transmitter

terminals

U

S

-

~

+

Supply voltage

(Ri < 250 W)

U

Kl

U

4 … 20 mA

U

A

K

R

X

Note:

An ammeter for local testing of the output current can be connected between terminal 1 and its

tag. This measurement can be made during operation without interrupting the supply line.

Electronics powered by a VEGA-signal conditioning instrument

Ammeter for local testing

Transmitter

terminals

1+2-3

-

+

U

U

Kl

4 … 20 mA

K

U

S

R

X

0/4 … 20 mA

DISBUS

!

If the differential pressure transmitters are operated on a VEGA-signal conditioning instrument, you

have to connect the sensor via a resistor acc. to the following schedule to the signal conditioning

instrument during the HART® adjustment. Together with the inner resistor of the signal conditioning

instrument, the resistance value of 250 W required for the HART® instrument is reached.

If the resistor of the processing system or the voltage supply is more than 250 W, there is no

"Adjustment resistor“ required.

VEGADIF 34 … 51 39

Page 40

Setup

+

PLC

-

Ri > 250

VEGALOG VEGAMET

Rx

VEGA-signal conditioning instr. R

X

VEGAMET 513, 514, 515, 602

VEGATRENN 544

VEGATOR 521…527 50 … 100 Ohm

VEGAMET 614 no additional

VEGADIS 371 resistance

required

VEGAMET 601 200 … 250 Ohm

VEGASEL 643 150 … 200 Ohm

VEGAMET 513 S4, 514 S4

515 S4,

VEGALOG EA-card 100 … 150 Ohm

40 VEGADIF 34 … 51

Page 41

Setup

The most important adjustment steps

On the following two pages you see the

HART®-menu plan to differential pressure

transmitter VEGADIF.

The most important adjustment steps are

marked in the menu plan with the figures

A … F. Setup the sensor in the sequence

A…F.

A: Empty adjustment without medium

(

zero

– dry)

B: Full adjustment without medium

(

span

– dry)

A1: Empty adjustment with medium

(

zero

)

B1: Full adjustment with medium

(

span

)

C: LOW/HIGH SENSOR CAL.

(only if required, see following diagram)

Here the proportionality defined by the

empty and full adjustment between pressure and signal current (characteristics)

can be shifted in the position (vertically).

The characteristics can be quasi hold or

shifted in the range of the zero point or the

range of the measuring range final value

(see right diagram), to get a requested

signal current in the zero point or at the

measurement end.

Adjustment characteristics

(e.g. -70 … 80 mbar) after

LOW/HIGH SENSOR CAL.

was carried out (point C)

LOW SENSOR CAL.

-100

mbar

zero

- 50

D: BIAS PRESSURE AUTOM.

Means that the indication can be set to

zero, to suppress a certain pressure in

the indication. The output characteristics

and the signal current are not concerned.

E: Damping of the signal output.

The pressures on the measuring cell are

integrated and averaged in the given

times, to get a stable indication and signal

current output even in case of quick pressure fluctuations.

F: Selection of the physical unit

mA

HIGH SENSOR CAL.

○ ○ ○ ○ ○ ○

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

0

Adjustment characteristics

(e.g. -70…80 mbar)

after empty/full adjustment

50 100

○ ○ ○ ○ ○ ○ ○ ○○○○○○○○○○○○○○○○○○○○○

span

mbar

VEGADIF 34 … 51 41

Page 42

HART® menu plan VEGADIF

Setup

Switch on:

Hart Communicator

Self T est

in Progress

Firmware Rev: F2.2

Module Rev: 3.6

01992-96 FRSI

after approx. 20 s

Generic: 10956186

Online (Generic)

1 Device setup

2 PV 2.633 mbar

3 PV AO 4.014 mbar

4 PV LRV 0.000 mbar

5 URV 3000.000 mbar

HELP SEND

Setup the sensor in the sequence of the letters A,

B, C and D (dry adjustment: adjustment without

medium).

For the adjustment with medium, setup the

sensor in the sequence A1, B1, C and D

Generic: 10956186

Device setup

1 Process variables

2 Diag/Service

3 Basic setup

4 Detailed setup

5 Review

SAVE HOME

Generic: 10956186

PV

2.405 mbar

HELP EXIT

Generic: 10956186

A01

3.987 mA

HELP EXIT

1

2

3

Generic: 10956186

Process variables

1 Snsr 2.684 mbar

2 AI % rnge 0.090

3 AO1 4.014

HELP SAVE HOME

Generic: 10956186

1 PV LRV 0.000 mbar

2 URV 3000.000 mbar

HELP HOME

Generic: 10956186

– WARNING –

Return control loopo

to automatic control

OK

Generic: 10956186

– WARNING –

Pressing ÒK`will

change device output.

Put loop in manual.

ABORT OK

Generic: 10956186

1 PV LRV 0.000 mbar

2 URV 3000.000 mbar

1.1

Important menu

windows

Less important

menu windows

Dry adjustment:

Empty and full adjustment

without medium

(with medium see next

page)

Generic: 10956186

1 PV LRV 0.000 mbar

2 URV 3000.000 mbar

HELP HOME

Generic: 10956186

1 PV LRV 0.000 mbar

2 URV 3000.000 mbar

HELP HOME

4

5

HELP SEND HOME

Generic: 10956186

PV LRV

A

B

0.000 mbar

0.000 mbar

HELP DEL ESC ENTER

Empty adjustment without

medium

Generic: 10956186

PV URV

3000.000 mbar

900.300 mbar

HELP DEL ESC ENTER

Full adjustment

without

medium

continue as under A

(figure 4.1 or 5.1)

4.2 (5.2)

4.1

(5.1)

42 VEGADIF 34 … 51

Page 43

Setup

1.2.2

Simulation:

Output of individual current

values for test purposes

1.2.3

A1

B1

Generic: 10956186

Tag

10956776

LEV 34

HELP DEL ESC ENTER

Generic: 10956186

PV Snsr unit

mbar

mbar

g/Sqcm

kg/Sqcm

Pa

Generic: 10956186

Range values

1 PV LRV 0.000 mbar

2 URV 3000.000 mbar

3 LSL -3000.000 mbar

4 USL 3000.000 mbar

HELP HOME

Generic: 10956186

Device information

1 Distributor

2 Model

3 Dev id

4Tag

5 Date **/**/**

HELP SA VE HOME

6 Schreibgeschützt

7 Beschreibung

8 Nachricht

9 PV Sens. Seriennr.

Werknummer

Revisionsnummer

1.4.1

ESC ENTER

Measured value

Change measuring unit

Info on lower and upper

measuring range limit as well

as the min. span (also the

sensor characteristics values)

1.4.2

Adjustment of the integration time

Adjustment of zero and span

Adjustment of zero and span

linear

Display of the level in % of the

adjusted span

Wet adjustment:

Empty and full adjustment

with medium

(see next page)

1.3.1

New measurement

loop designation to

save with ENTER

and SEND

1.3.2

1.3.3

Display of the used

}

measuring range

Display of

}

measuring

range

1.3.4

see next

page

Generic: 10956186

PV

2.676 mbar

HELP EXIT

Generic: 10956186

PV % rnge

0.086 %

HELP EXIT

Generic: 10956186

AO1

4.014 mA

HELP EXIT

Generic: 10956186

Diag/Service

1 Test device

2 Loop test

3 Calibration

4 D/A trim

HELP SAVE HOME

Generic: 10956186

Basic setup

1Tag

2 PV Unit

3 Range values

4 Device information

5 PV Xfer fnctn

HELP SA VE HOME

6 PV Damping

Generic: 10956186

Dateiled setup

1 Sensors

2 Signal condition

3 Output condition

4 Device information

SAVE HOME

1.1.1

Safety

enquiry

Acknowledge-

1.1.2

1.1.3

1.2

Correction possibility of the

digital/analogue converter in

conjunction with a prevision

ammeter as reference

instrument (only for service

purposes).

1.3

1.4

as menu

1.3.4

ment

Transmission function (linear)

Adjustment of the integration time

Generic: 10956186

Sensors

HELP SAVE HOME

Generic: 10956186

Choose analog output

level

14 mA

2 20 mA

3 Other

4 End

ENTER

Generic: 10956186

Calibration

HELP SEND HOME

ABORT

1 Apply values

2 Enter values

D

C

1 PV 2.601 mbar

2 PV Snsr unit

3 Sensor information

Generic: 10956186

Signal condition

1 Snsr Damp 0.000s

2 URV 3000.000 mbar

3 AI LRV 0.000 mbar

4 Xfer fnctn Linear

5 AI % rnge 0.082 %

HELP SAVE HOME

VEGADIF 34 … 51 43

Page 44

Continuation HART® menu plan VEGADIF

Wet adjustment

Generic: 10956186

Set the:

Generic: 10956186

Calibration

1 Apply values

2 Enter values

HELP SAVE HOME

1.2.3

Safety

enquiry

Acknowledge

1 4mA

2 20mA

3 Exit

ABORT ENTER

1.2.3.1

Empty adjustment with

medium

Generic: 10956186

Apply new 4ma input

ABORT OK

Full adjustment with

medium

Generic: 10956186

Apply new 20ma input

ABORT OK

Setup

Generic: 10956186

Analog output

1 AO1 4.014 mA

2 AO Alrm typ Hi

3 Loop test

4 D/A trim

5 Skaled D/A trim

HELP SAVE HOME

Dry adjustment

Generic: 10956186

Enter values

HELP HOME

Generic: 10956186

AO Alrm typ

Hi

1.4.3.1

Generic: 10956186

WARNING–Loop should be

removed from

automatic control

}

1.2.3.2

1 PV LRV 0.000 mbar

2 URV 3000.000 mbar

3 PV USL

4 PV LSL

1.4.3.1.2

EXIT

ABORT OK

Correction possibility of the digital/analogue

converter in conjunction with a precision

ammeter as reference instrument (only for

service purposes)

Empty adjustment without medium (as

menu 4.1 or 4.2 on previous page)

Display of the

}

measuring

range

Low: In case of failure current output

High: In case of failure current output

Generic: 10956186

Choose analog output

level

14 mA

2 20 mA

3 Other

4 End

ABORT

ENTER

goes to 22 mA

goes to < 3.6 mA

1.4.3.1.3

Full adjustment

without medium

Set signal current

for test purposes

to a certain value.

1.4.3.2

from menu window

1.4.

menu point 3

Condition output

Generic: 10956186

Output condition

1 Analog output

2 HART output

SAVE HOME

1.4.3

Generic: 10956186

HART output

1 Poll addr

2 Num req preams 0

3 Burst mode Off

4 Burst option

HELP SAVE HOME

44 VEGADIF 34 … 51

Page 45

Setup

A1

B1

Generic: 10956186

Current applied

Process value: 2.492

mbar

1 Set as 4mA value

2 Read new value

3 Leave as found

ABORT ENTER

Generic: 10956186

Current applied

process value: 2.498

mbar

1 Set as 4mA value

2 Read new value

3 Leave as found

ABORT ENTER

Generic: 10956186

PV LRV

A

B

2.547 mbar

2.547 mbar

HELP DEL ESC ENTER

Generic: 10956186

PV LRV

2.547 mbar

2.547 mbar

HELP DEL ESC ENTER

1.2.3.1.1

1.2.3.1.2

1.2.3.2.1

1.2.3.2.1

1.2.3.1.1.1

Generic: 10956186

Set the:

14 mA

2 20 mA

3 Exit

ABORT

ENTER

Generic: 10956186

Set the:

14 mA

2 20 mA

3 Exit

ABORT ENTER

Generic: 10956186

Enter values

HELP SEND HOME

Generic: 10956186

Enter values

HELP SEND HOME

Quit the menu with

„3 Quit“

1.2.3.1.2.1