Page 1

Operating Instructions

VEGASCAN 850

Level and Pressure

Page 2

Contents

Safety information ........................................................................ 2

Note Ex area ................................................................................ 2

1 Product description

1.1 Function ................................................................................. 4

1.2 Application features ............................................................. 6

1.3 Adjustment ............................................................................ 6

2 Types and versions

2.1 Type overview, VEGASCAN 850 ........................................ 8

2.2 Type overview, sensors....................................................... 8

2.3 Type code, VEGASCAN 850............................................. 11

2.4 Type code, sensors ........................................................... 12

2.5 Approvals ........................................................................... 13

2.6 Configuration of measuring systems ............................... 13

3 Technical data

3.1 Data ..................................................................................... 18

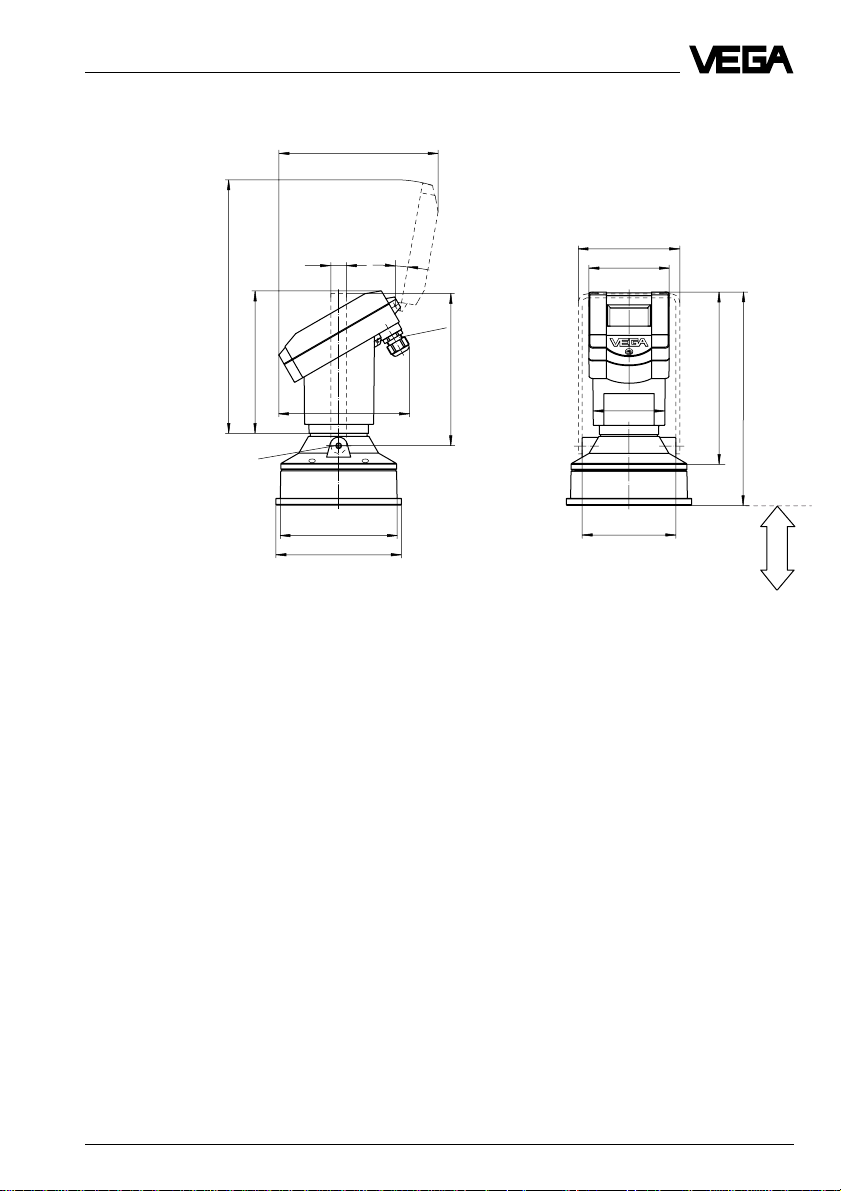

3.2 Dimensions ......................................................................... 25

Contents

Safety information

Please read this manual carefully, and also take

note of country-specific installation standards

(e.g. the VDE regulations in Germany) as well

as all prevailing safety regulations and accident prevention rules.

For safety and warranty reasons, any internal

work on the instruments, apart from that involved in normal installation and electrical connection, must be carried out only by qualified

VEGA personnel.

2 VEGASCAN 850

Note Ex area

Please note the approval documents (yellow

binder), and especially the included safety

data sheet.

Page 3

Contents

4 Mounting and installation

4.1 Mounting VEGASON 54 … 56 .......................................... 34

4.2 General installation instructions ........................................ 36

4.3 Measurement of liquids ..................................................... 39

4.4 Measurement of solids ...................................................... 42

4.5 Socket extensions ............................................................. 44

4.6 Flow measurement ............................................................. 46

4.7 False echoes ...................................................................... 47

4.8 Incorrect mounting ............................................................. 49

5 Electrical connection

5.1 Connection, connection cable and shielding ................... 53

5.2 Connection of the sensor .................................................. 56

5.3 Connection of the external indicating instrument

VEGADIS 50 ....................................................................... 57

5.4 Connection of the sensors to VEGASCAN 850 ............... 58

5.5 Signal output/Interface connection ................................... 59

5.6 Connection of the PC to VEGASCAN 850 ........................ 59

6 Setup

6.1 Adjustment methods .......................................................... 60

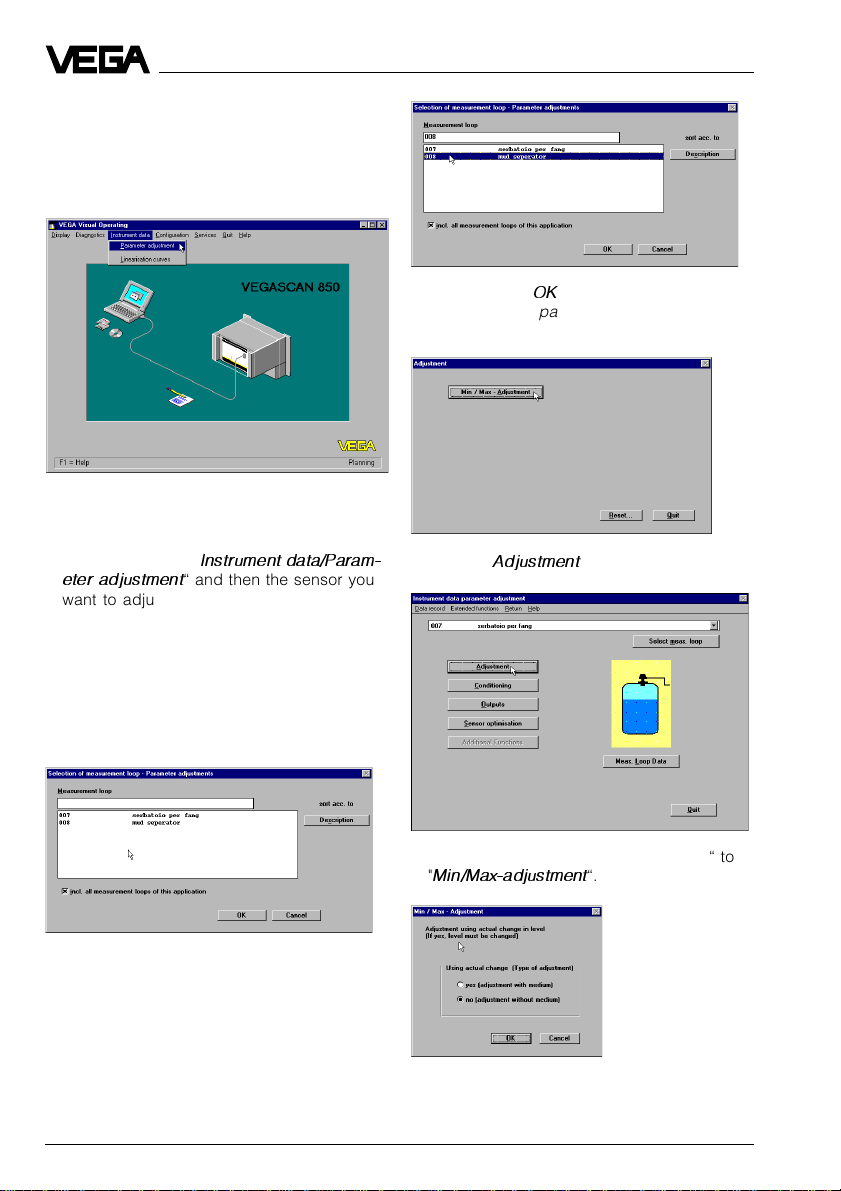

6.2 Adjustment with the PC ...................................................... 61

6.3 Sensor adjustment with the adjustment

module MINICOM............................................................... 86

7 Diagnostics

7.1 Simulation ............................................................................ 90

7.2 Error codes ........................................................................ 90

VEGASCAN 850 3

Page 4

1 Product description

1.1 Function

Continuous level measurement with ultrasonic

sensors is based on the running time measurement of ultrasonic pulses.

VEGASON series 51 … 56 sensors are a

newly developed generation of extremely

compact ultrasonic sensors for level measurement. They were especially developed for

liquids (51 ... 53) and for solids and larger

measuring ranges (54 ... 56).

Due to the small housing dimensions and

process fittings, the compact sensors are a

very reasonable solution for your level measurement applications. With the integrated

display and a special sensor intelligence, in

conjunction with large measuring ranges,

they can be used for applications in which

the advantages of non-contact measurement

could never before be realized.

As output and measuring signal, the sensors

produce a digital output signal which is processed and evaluated in VEGASCAN 850.

VEGASCAN 850 then outputs the processed

measured values as a digital communication

protocol.

Measuring principle

Piezoceramic high-performance transducers

emit focused ultrasonic pulses which are

reflected by the product surface. The measurement electronics prepares a precise image of the environment out of the reflected

ultrasonic pulses. The transducers work both

as transmitter and receiver. As receiver, the

transducers are high-sensitivity piezo microphones.

Product description

Meas. distance

emission - reflection - reception

The measurement electronics precisely calculates the distance between transducer and

medium from the speed of sound and the

measured running time of the emitted sound

impulse. The distance is then converted into

a level-proportional signal, and in conjunction

with the sensor parameter settings, made

available as precise, calibrated level value.

Since the speed of sound is subject to temperature influence, the transducer also continuously detects the ambient temperature,

so that the level is precisely measured even

in case of varying ambient temperature.

4 VEGASCAN 850

Page 5

Product description

Output signal

The level-proportional measuring signal of the

sensors is received, processed and

outputted digitally throughout. VEGASCAN

850 reads in the digital sensor measured

values permanently and processes the individual levels according to the user’s selected

options. Depending on the version of

VEGASCAN, max. 15 sensors can be connected to one screened two-wire cable or 30

sensors on two screened two-wire cables.

The two-wire cable transfers beside the digital level signal and adjustment signals also

the supply voltage of 24 V.

The sensor measured values can be processed and outputted in VEGASCAN as levels

in percent, volume or mass units. In addition,

linked process tasks such as scaling, linearisation, differential generation, addition, tendency processing or limit value processing

can be selected individually. As a result,

VEGASCAN can carry out - decentralised

and without costly programming - the entire

measurement-related arithmetic.

The levels and their processed results are

then outputted in the following field bus protocols and interfaces depending on the ordered version of VEGASCAN 850.

The digital processing of the measured signal ensures an accuracy that an analogue

measuring signal could never reach, as the

digital signal is always transferred without

error right down to the last bit and decimal

point position.

Varying line resistance or small leakage currents do not influence the accuracy (digital

technology). The digital signal is always unambiguous.

Display of measured values

As an option, the series 50 ultrasonic sensors

can be equipped with an indicating instrument for direct, local level survey. The indicating instrument shows the precise level by

means of the analogue bar graph and the

digital number value. In addition to the indication in the sensor, you can have the level

displayed by the VEGADIS 50 external indicating instrument at a distance of up to

25 m from the sensor. The external display of

measured values operates, like the integrated display, independently of the output

signal, can be modified through individual

parameter settings, and is connected to and

powered by the sensor.

Protocol Interface

Siemens 3964 - RS 232

VEGA-ASCII - RS 232

Modbus - RS 232

Profibus DP - RS 485

Profibus FMS - RS 485

VEGASCAN 850 5

- RS 422

- RS 485

- TTY

- RS 422

- RS 485

- TTY

- RS 422

- RS 485

- TTY

Page 6

Product description

1.2 Application features

Applications

• Level measurement of all liquids

• Level measurement of solids (only short

measuring distances) such as e.g. coal,

ore, stones, crushed rocks, cement,

gravel, sand, sugar, salt, cereals, flour,

granules, powder, dusts, sawdust,

sawings.

• Flow measurement on various flumes

• Gauge measurement, distance measure-

ment, object monitoring and conveyor belt

monitoring

Two-wire technology

• Supply and output signal on one two-wire

cable (loop powered).

• Output signal and signal processing completely digital.

Rugged and precise

• Measurement unaffected by substance

properties such as density, conductivity,

dielectric constant…

• Suitable for corrosive substances

• Measuring range 0.25 m … 70 m.

• Precise through digital processing and

transmission of measured values.

Means of adjustment

• With adjustment software VEGA Visual

Operating (VVO) on the PC

• With detachable adjustment module

MINICOM

• With VEGAMET signal conditioning instrument.

1.3 Adjustment

Each measuring situation is unique. For that

reason, every ultrasonic sensor needs some

basic information on the application and the

environment, e.g. an empty vessel profile is

important for a reliable measurement. Beside

this, many other settings and adjustments

are possible on VEGASON ultrasonic sensors.

The adjustment and parameter setting of

VEGASCAN 850 and ultrasonic sensors are

carried out with the PC and the adjustment

program VVO (VEGA Visual Operating).

Only sensor-relevant settings can be carried

out with the adjustment module MINICOM.

Adjustment with PC

The program leads quickly through the adjustment and parameter setting by means of

pictures, graphics and process

visualisations.

The PC is connected with a standard cable

(RS 232) directly to VEGASCAN 850.

The adjustment and parameter data of the

connected sensors and the configuration of

VEGASCAN can be saved with the adjustment software on the PC and can be protected by passwords. On request, the

sensor adjustments can be quickly transferred to other sensors.

Display of measured value

• Display of measured value integrated in

sensor.

• Optional display module separated from

sensor.

Process fittings

• G 1 A, DN 50, DN 80, DN 200, DN 250

• G 11/2A, 11/2“ NPT

• G 2 A, 2“ NPT

• Compression flange DN 100, ANSI 4“

Approvals

• CENELEC, ATEX, PTB, FM, CSA, ABS,

LRS, GL, LR, FCC

6 VEGASCAN 850

Page 7

Product description

Adjustment with adjustment module

MINICOM

With the small (3.2 cm x 6.7 cm) 6-key adjustment module with display, the adjustment

can be carried out in clear text dialogue.

The adjustment program recognises the sensor type

and the location of the connection

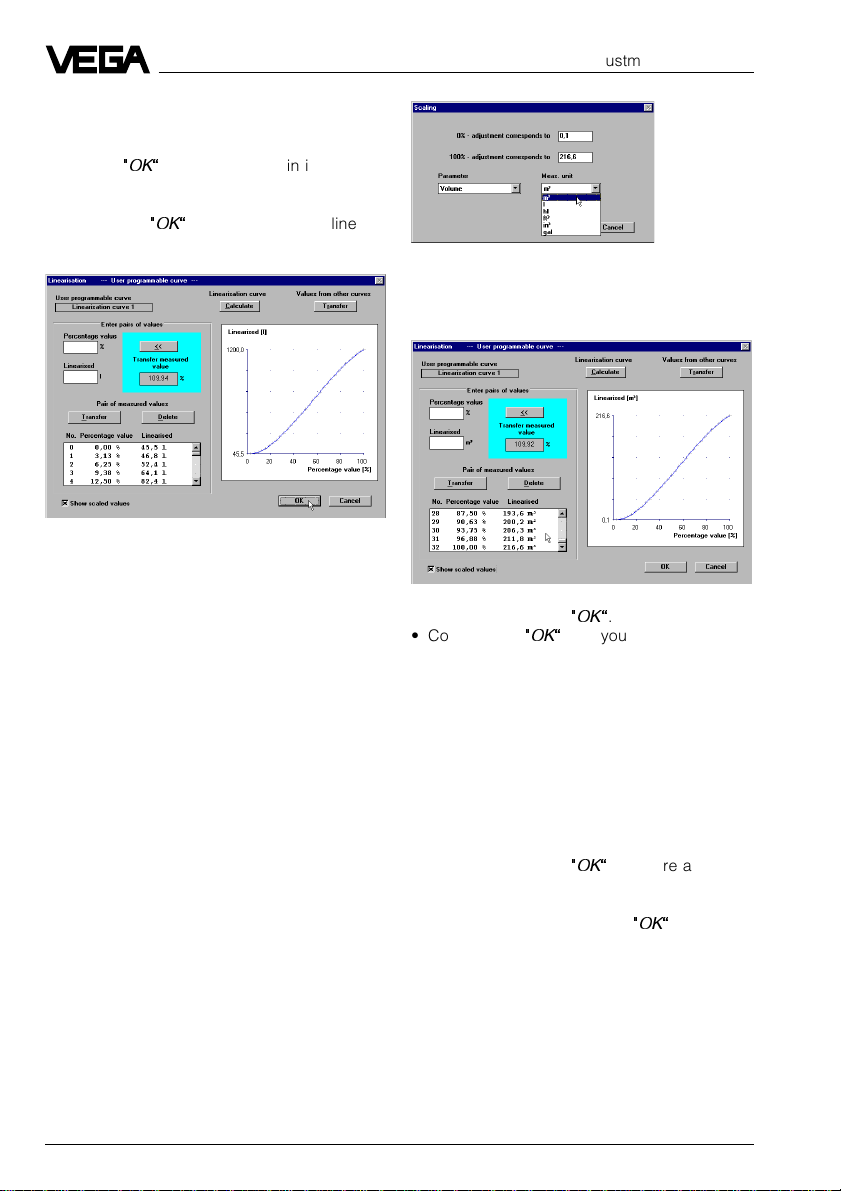

Visualised input of a vessel linearisation curve

2

P

...

C

8

5

0

BA

on

1...15

Tank 1

m (d)

12.345

ESC

+

-

OK

Detachable adjustment module. The adjustment

module can be plugged into the ultrasonic sensor or

onto the external indicating instrument VEGADIS 50.

The adjustment module can be plugged into

the ultrasonic sensor or into the optional,

external indicating instrument. Unauthorised

sensor adjustments can be prevented by

removing the adjustment module.

Adjustment with the PC on VEGASCAN 850 with the

standard cable RS 232 (with VEGASCAN up to 15

sensors can be operated on one two-wire cable)

VEGASCAN 850 7

Page 8

2 Types and versions

Types and versions

2.1 T ype overview, VEGASCAN 850

Either 15 or 30 series 50 ultrasonic sensors

can be connected to VEGASCAN 850. The

measured data are outputted in the ordered

field bus protocol by the ordered interface.

The field bus protocol and interface type are

determined by the ordered version of VEGASCAN. The type label of VEGASCAN contains

the bus protocol and the interface type (see

chapter "2.3 Type code of VEGASCAN 850“).

Optional field bus protocols:

- Siemens 3964

- Modbus

- VEGA-ASCII

- Profibus DP

- Profibus FMS

Optional interface types:

- RS 232

- RS 422

- RS 485

- TTY

2.2 T ype overview, sensors

VEGASON series 51 … 56 sensors are a

newly developed generation of extremely

compact ultrasonic sensors for large measuring ranges (VEGASON 54 ... 56) or for

shorter measuring ranges (VEGASON

51 … 53).

Due to the small housing dimensions and

process fittings, the compact sensors do

your level monitoring inconspicuously, and

above all, at reasonable cost.

Because of price, reliability and easy handling, ultrasonic level measurement can be

now used in applications in which non-contact level measurement could never be used

before.

VEGASON 50 ultrasonic sensors utilise twowire technology perfectly. The supply voltage

and the digital output signals of 15 sensors

are transmitted between VEGASCAN 850

and the sensors via one two-wire cable.

Swivelling holders allow quick alignment of

the transducer to the product and solid surface. Mounting is simplified by the option of

separating the sensor electronics from the

transducer. The sensor electronics can be

mounted at a distance of 300 m from the

transducer. It is then possible to mount the

transducer in environments with an ambient

temperature up to 150°C (type 56).

8 VEGASCAN 850

Page 9

Types and versions

Common features

• Application to solids and liquids.

• Measuring range 0.25 m … 70 m.

• Ex approved in Zone 1 (IEC) and Zone 1

(ATEX) classification EEx ia [ia] IIC T6.

• Display module integrated in the sensor or

in the external indicating instrument separated up to 25 m from the sensor.

VEGASON 51

VEGASON 52

VEGASON 54

Version A Version B Version C Version D

VEGASON 55

Version A Version B Version C Version D

VEGASON 56

VEGASON 53

Version A Version B Version C Version D

VEGASCAN 850 9

Page 10

Types and versions

Short overview of sensor features

• Use in solids and liquids.

• Measuring range 0.25 … 70 m.

• Ex approved in Zone 1 (IEC) or Zone 1 (ATEX) classification.

• Integrated display of measured values.

VEGASON 51V 52V 53V 54V 55V 56V

Signal output

digital meas. signal ••••••

Power supply

- two-wire technology ••••••

Process fitting

- G 1 A, 1“ NPT –––•••

-G 11/2 A, 11/2“ NPT •–––––

- G 2 A, 2“ NPT –•––––

- DN 100 compr. flange ––•–––

- DN 50 –––•••

- DN 80 –––•••

- DN 200 –––•••

- DN 250 –––•••

Adjustment

- with PC and adjustment software ••••••

- with adjustment module in sensor ••••••

- with adjustment module in ext. indicating

instrument ••••••

Meas. range in m

- liquid 0.25 … 4 0.4 … 7 0.6 … 15 1 … 25 0.8 … 45 1.4 … 70

- solid 0.3 … 2 0.5 … 3.5 0.75 … 71 … 25 0.8 … 45 1.4 … 70

10 VEGASCAN 850

Page 11

Types and versions

2.3 T ype code, VEGASCAN 850

VEGASCAN 850 X X X X X

K - Cable entry M20 x 1.5

N - Cable entry

A - 230 V AC power supply

B - 115 V AC power supply

1 - RS 232 interface

2 - RS 422 interface

3 - RS 485 interface

4 - TTY interface

A - Siemens S5 (3964 R procedure with RK 512)

B - Modbus (RTU and ASCII)

S - Profibus FMS

P - Profibus DP

N - VEGA-ASCII

B - up to 15 sensors can be connected

C - up to 30 sensors can be connected

1

/2“ NPT

VEGASCAN 850 11

Page 12

2.4 T ype code, sensors

Types and versions

VEGASON 54 V EX.XX X X X X X X X

K - Plastic housing PBT, M20 x 1.5 cable entry

N - Plastic housing PBT,

1

/2“ NPT cable entry

A - Aluminium housing, M20 x 1.5 cable entry

G - Process fitting G 11/2 A

N - Process fitting 11/2“ NPT

X - Process fitting DN 100 PN (without sleeve nut)

A - Process fitting DN 100 PN (PPH compression flange)

B - Process fitting DN 100 PN (1.4571 compression flange)

C - 1.4301 mounting strap

FEP - Version A, flange DN 200 (PP)

FFA - Version A, flange DN 200 (Aluminium)

SAS - Version B, flange swivelling holder DN 50

SBS - Version B, flange swivelling holder DN 80

GAS - Version C, flange swivelling holder DN 50

GBS - Version C, flange swivelling holder DN 80

RGS - Thread G 1 A

YYY - Other process fittings

X - without display

A - with integral display

X - without adjustment module MINICOM

B - with adjustment module MINICOM (integrated)

A - 20 … 72 V DC; 20 … 250 V AC; 4 … 20 mA (four-wire)

B - 20 … 72 V DC; 20 … 250 V AC; 4 … 20 mA, HART

®

(four-wire)

E - Power supply via signal conditioning instrument

G - Segment coupler for Profibus PA

P - 90 … 250 V AC (only in USA)

N - 20 … 36 V DC, 24 V AC (only in USA)

Z - Power supply via signal conditioning instr. (only in USA)

.X - without approval

EX.X - Ex approved CENELEC EEx ia IIC T6

EXS.X - StEx Zone 10

K - Analogue 4 … 20 mA output signal (two-wire or four-wire

technology)

V - Digital output signal (two-wire technology - VBUS)

P - Digital output signal (two-wire technology - Profibus)

Type 51 - Meas. range 0.25 … 4 m

Type 52 - Meas. range 0.4 … 7 m

Type 53 - Meas. range 0.6 … 15 m

Type 54 - Meas. range 1.0 … 25 m

Type 55 - Meas. range 0.8 … 45 m

Type 56 - Meas. range 1.6 … 70 m

Meas. technology (SON for ultrasonic)

12 VEGASCAN 850

Page 13

Types and versions

2.5 Approvals

When using ultrasonic sensors in Ex areas or

in marine applications, the instruments must

be suitable and approved for the explosion

zones and application areas.

The suitability is tested by approval authorities and is certified in approval documents.

VEGASON 50 ultrasonic sensors are approved for Ex zone 1, 10, 11, 21 and 22.

Please note the attached approval documents when using a sensor in Ex area.

2.6 Configuration of measuring systems

A measuring system consists of one to 15

(30) sensors and a VEGASCAN 850. The

processing unit (VEGASCAN 850 signal

conditioning instrument) evaluates the levelproportional, digital measuring signals in a

number of processing routines and outputs

the levels as process bus signal.

Beside the output of the levels in percent,

cubic meters and other physical units, the

levels can be also processed by linked

processing algorithms. Scaling, linearisation,

calculation of linearisation curves, differential

generation, addition or tendency processing

are implemented in VEGASCAN 850 as intrinsic processing routines and are easily accessible via the menu.

On the following pages you will find three

instrument configurations (measuring systems) consisting of sensor(s) and processing unit.

Note:

It is possible to operate up to 15 sensors on

one two-wire cable, see following page (configuration A). However, it would be more

suitable to plan the measuring system in

such a way that max. five sensors are operated on one two-wire cable. For this reason,

VEGASCAN is equipped with three clamping

positions for a VBUS input. The sensor arrangement can either be made linearly (configuration B) or radially (configuration C).

VEGASCAN 850 13

Page 14

Types and versions

Configuration A

Up to 15 sensors via one two-wire cable on VEGASCAN 850

• Two-wire technology, 15 sensors with power supply and digital output signals via one twowire cable on VEGASCAN 850 possible. However, it is better to wire in groups of five as in

configuration B and C.

2

1)

Sensor cables should be screened. Grounding of

4

2

2

the cable screens at both ends is recommended.

However make sure that no earth compensation

currents flow via the screens (see chapter "5.1

Connection, connection cable and screening“).

Earth compensation currents can be avoided by

potential equalisation lines or if the cable screen is

grounded at both ends - by connecting one end via

a capacitor (e.g. 0.1 µF; 250 V) to earth potential.

4

2

2

VEGACONNECT 2

4

2

14 VEGASCAN 850

Page 15

Types and versions

• Display of measured value integrated in sensor.

• Optional external indicating instrument (can be mounted up to 25 m separated from the

sensor, also in Ex area).

• Adjustment with PC or adjustment module MINICOM (can be plugged into the sensor or the

external indicating instrument VEGADIS 50).

• Max. resistance of the signal cable 10 W per wire or 1000 m cable length.

screened sensor cable 1)

2

4

2

2

2)

4

2

2

4

2

2)

Sensor cables leading to the same VBUS input can

be looped together in a screened multiple wire

cable.

Sensor cables leading to another VBUS connection

must be looped in a separate, screened cable.

VEGASCAN 850 15

Page 16

Types and versions

Configuration B

VEGASCAN 850 B; 15 sensors can be connected

• Two-wire technology, 3 x 5 sensors grouped in line on three two-wire cables.

• Display of measured value integrated in sensor.

• Optional external indicating instrument (can be mounted up to 25 m separated from sensor

also in Ex area).

• Adjustment with PC or adjustment module MINICOM (can be plugged into the sensor or the

external indicating instrument VEGADIS 50).

• Max. resistance of the signal cable 15 W per wire or 1000 m cable length.

PC

8

5

0

BA

on

2

2

2

16 VEGASCAN 850

Page 17

Types and versions

Configuration C

VEGASCAN 850 B; 15 sensors can be connected

• Two-wire technology, 3 x 5 sensors grouped radially on three two-wire cables.

• Display of measured values integrated in the sensor.

• Optional external indicating instrument (can be mounted up to 25 m separated from the

sensor also in Ex area).

• Adjustment with PC or adjustment module MINICOM (can be plugged into the sensor or

external indicating instrument VEGADIS 50).

• Max. resistance of the signal cable 15 W per wire or 1000 m cable length.

PC

8

5

0

BA

on

2

4

2

2

2

4

2

4

2

VEGASCAN 850 17

Page 18

Technical data

3 Technical data

3.1 Data

Power supply

Supply voltage

- VEGASCAN 850 230 V AC, 50/60 Hz

- sensors sensor power supply is provided via the

Min. sensor voltage 17 V

Power consumption

- VEGASCAN 850 max. 70 VA

- VEGASON 51 … 53 81 mW

- VEGASON 54 … 56 max. 1.5 W peak power

Current consumption

- VEGASON 51 … 53 6 mA

- VEGASON 54 … 56 90 mA

Resistance of the signal cable

per measuring data input dependent on the number of connected sensors

115 V AC, 50/60 Hz

VEGASCAN 850

processing system with max.

1 … 15 sensors per two-wire cable

approx. 1 W continuous power

(power) per connection cable, see following

diagram, however max. 15 W per wire

and max. 1000 m cable length

1000 m

900

840

800

700

630

600

500

400

300

200

Length of the connection cable

100

0

0 5 10 15

Total power of all sensors on one

2

1,0 mm

2

0,75 mm

two-wire cable

2,5 mm

1,5 mm

2

2

23W max

20

Note:

If longer signal cables are used, it is a good idea to distribute the sensors over two or three

inputs.

18 VEGASCAN 850

Page 19

Technical data

Measuring range

(reference plane is the transducer end. On VEGASON 54 … 56 in version A the lower flange

side is the reference plane.)

VEGASON 51

- liquids 0.25 … 4 m

- solids 0.3 … 2 m

VEGASON 52

- liquids 0.4 … 7 m

- solids 0.5 … 3.5 m

VEGASON 53

- liquids 0.6 … 15 m

- solids 0.75 … 7 m

VEGASON 54 in general 1.0 … 25 m

VEGASON 55 in general 0.8 … 45 m

VEGASON 56

- version A 1.8 … 70 m

- version B … D 1.4 … 70 m

Output signal of the sensors

Signal output of the sensors digital output signal in two-wire technology

(VBUS): the digital output signal (meas.

signal) is superimposed power supply of

VEGASCAN and further processed in

VEGASCAN

Meas. data inputs on VEGASCAN

Number of inputs 3 meas. data inputs on VEGASCAN 850B

6 meas. data inputs on VEGASCAN 850C

Supply voltage from VEGASCAN approx. 24 V

Output current per meas. data input max. 1 A

Output power

per meas. data input max. 23 W (15 W continuous power)

Resistance of the signal cable max. 15 W per wire or

max. 1000 m cable length

Integration time 0 … 999 seconds (selectable in the sensor)

0 … 600 seconds (selectable in VEGASCAN)

Two-wire technology: The digital output signal (meas. signal) and the power supply are led

through one cable.

VEGASCAN 850 19

Page 20

Technical data

Output signal of VEGASCAN (depending on the ordered instrument version)

Siemens 3964

- interfaces RS 232, RS 422, RS 485, TTY

- transmission rates 110 … 19200 baud

- transmission mode serially asynchronous, half-duplex

- coding system 8 bit binary

- number of bits 1 start , 8 data, 1 parity, 1 stop bit

- parity NONE, ODD, EVEN

- backup BCC

VEGA-ASCII

- interfaces RS 232, RS 422, RS 485, TTY

- transmission rates 300 … 38400 baud

- transmission mode serially asynchronous, half-duplex

- coding system 8 bits ASCII

- number of bits 1 start, 8 (7) data, 1 parity, 1 stop bit

- parity NONE, ODD, EVEN

- backup none

Modbus

- interfaces RS 232, RS 422, RS 485, TTY

- transmission rates 300 … 38400 baud

- transmission mode serially asynchronous, half-duplex

- coding system

RTU-Mode 1 start, 8 data, 1 (0) parity, 1 stop bit

ASCII-Mode 1 start, 8 (7) data, 1 (0) parity, 1 stop bit

- parity NONE, ODD, EVEN

- backup

RTU-Mode CRC-16

ASCII-Mode LRC

Profibus DP and FMS

- interfaces RS 485

- transmission rates

Profibus DP 9.6 … 12000 kbaud

Profibus FMS 9.6 … 500 kbaud

- transmission mode serially asynchronous, half-duplex, slip-free

synchronisation

- coding system NRZ code

- backup Haming distance HD = 4

Galvanic separation galvanic separation between sensor current

circuit, power supply, output signal (Siemens

3964, Modbus etc.) and RS 232 PC adjustment

interface

- reference voltage up to 500 V

- isolation resistance 4 kV

20 VEGASCAN 850

Page 21

Technical data

Display of measured value (optional)

Liquid-crystal display

- in sensor scalable output of measured values as graph

and digital value

- powered externally by the sensor scalable output of measured values as graph

and digital value. Display of measured values

can be mounted up to 25 m separated

from the sensor.

Adjustment

- PC with adjustment software VEGA Visual Operating via RS 232 interface (max. 15 m

cable length)

- adjustment module MINICOM (only the individual sensor is adjustable)

Characteristics

1)

(typical values under reference conditions, all statements relate to the nominal measuring

range)

Min. span

(between empty and full adjustment) > 20 mm (recommended > 50 mm)

Ultrasonic frequency (at 20°C)

- VEGASON 51 70 kHz

- VEGASON 52 55 kHz

- VEGASON 53 38 kHz

- VEGASON 54 30 kHz

- VEGASON 55 18 kHz

- VEGASON 56 10 kHz

Meas. intervals

- VEGASON 51 1.0 s

- VEGASON 52 1.0 s

- VEGASON 53 0.6 s

- VEGASON 54 1.0 s

- VEGASON 55 1.5 s

- VEGASON 56 2.0 s

Beam angle at -3 dB emitted power

- VEGASON 51 5.5°

- VEGASON 52 5.5°

- VEGASON 53 3°

- VEGASON 54 4°

- VEGASON 55 5°

- VEGASON 56 6°

Influence of the process temperature 1.8 %/10 K, however is compensated by a

dynamic temperature detection integrated

in the transducer

Influence of the process pressure negligible within the permitted sensor pressures

Adjustment time

2)

- VEGASON 51 … 54 > 2 s (depending on the parameter setting)

- VEGASON 55, 56 > 4 s (depending on the parameter setting)

1)

Similar to DIN 16 086, reference conditions acc. to IEC 770;

temperature 15°C … 35°C; moisture 45 % … 75 %; pressure 860 mbar … 1060 mbar

2)

The adjustment time is the time required by the sensors for the correct output of the level (with max. 10 %

deviation) after a sudden level change.

VEGASCAN 850 21

Page 22

Technical data

Accuracy

1)

(typical values under reference conditions relating to the nominal measuring range)

Characteristics linear

Deviation in characteristics including

linearity, repeatability and

hysteresis (determined acc. to the

limit point method) < 0.1 %

Linearity better than 0.05 %

Average temperature coefficient of the

zero signal 0.06 %/10 K

Resolution max. 1 mm

Resolution of the output signal

- VEGASON 51 … 54 0.01 % or 1 mm

- VEGASON 55 and 56 0.01 % or 10 mm

Ambient conditions

Ambient temperature (housing) -20°C … +60°C

Process temperature (transducer)

- VEGASON 51 … 55 -40°C … +80°C (StEx: -20°C … +75°C)

- VEGASON 56 version A -40°C … +120°C

- VEGASON 56 version B and C -40°C … +150°C

- storage and transport temperature -40°C … +80°C

Vessel pressure max. (gauge pressure)

- VEGASON 51 and 52 2.0 bar

- VEGASON 53 1.5 bar

- VEGASON 54

Version A 1.5 bar (flange version)

Version B … C 0.5 bar

Version D 3 bar

- VEGASON 55

Version A 1.5 bar (flange version)

Version B … C 0.5 bar

Version D 3 bar

- VEGASON 56

Version A 3 bar (flange version)

Version B … C 0.5 bar

Version D 3 bar

Protection

- sensor IP 67

- transducer, process IP 68

Protection class

- two-wire sensor II

- four-wire sensor I

Overvoltage category III

Selfheating

at 40°C ambient temperature

- sensor 45°C

- transducer, process 55°C

1)

Similar to DIN 16 086, reference conditions acc. to IEC 770;

temperature 15°C … 35°C; moisture 45 % … 75 %; pressure 860 mbar … 1060 mbar

22 VEGASCAN 850

Page 23

Technical data

Ex technical data

(note approval documents)

Classification m (die casting of the transducer)

supply with increased safety

Temperature class (permissible

ambient temperature on the transducer

when used in Ex areas)

-T6 45°C

- T5, T4, T3 60°C

Ex approved in category or zone

- VEGASON 51, 52, 56

ATEX Zone 1 (II 2G)

IEC, CENELEC, PTB Zone 1

- VEGASON 51 … 56

ATEX Zone 21/22 (II 2D/3D)

IEC, CENELEC, PTB Zone 10/11

Process fittings

VEGASON 51 G 11/2A, 11/2“ NPT

VEGASON 52 G 2 A, 2“ NPT

VEGASON 53 DN 100 compression flange

VEGASON 54 G 1 A, 1-11,5 NPT, DN 50, DN 80, DN 200

VEGASON 55 G 1 A, 1-11,5 NPT, DN 50, DN 80, DN 250

VEGASON 56 G 1 A, 1-11,5 NPT, DN 50, DN 80, DN 200

Note:

VEGASON 54 … 56 sensors with process fittings G 1 A, 1-11.5 NPT, DN 50 and DN 80

generally require an additional adapter flange, if no other access to the vessel interior is

available.

Connection cables

Power supply supply and signal via one two-wire cable

Electrical connection

- sensors and VEGASCAN spring terminals, terminal cross-section

generally 2.5 mm

2

- sensor option screw connection

Cable entry in sensor housing

- standard 2 x M20 x 1.5 (cable diameter 5 … 9 mm)

- option 2 x 1/2“ NPT (cable diameter 3.1 … 8.7 mm

or 0.12 … 0.34 inch)

Cable entry in

VEGASCAN 850 4 … 5 x M20 x 1.5

Ground connection max. 4 mm

(cable diameter 6 … 12 mm)

2

Transducer cable (only type 54 … 56

in version C and D)

- VEGASON 54, 55 5 … 300 m (cable diameter 7.2 … 7.6 mm)

- VEGASON 56 5 … 300 m (cable diameter 9.5 … 9.9 mm)

VEGASCAN 850 23

Page 24

Materials

Housing PBT (Valox) or Aluminium

Process fitting

- VEGASON 51, 52 PVDF (thread)

- VEGASON 53 PP or 1.4571 (compression flange)

1.43019 (mounting strap)

- VEGASON 54 … 56 - Alu or PP (version A)

- swivelling holder or thread G 1 A of

galvanized steel (version B, C and D)

Transducer

- VEGASON 51, 52 PVDF

- VEGASON 53 UP

- VEGASON 54 PA (1.4301 with StEx)

- VEGASON 55, 56 UP

Transducer diaphragm

- VEGASON 51, 52 PVDF

- VEGASON 53 1.4571

- VEGASON 54 1.4571

- VEGASON 55 Alu/PE foam

- VEGASON 56 Alu/PTFE coating

Transducer cable (cable cover)

- VEGASON 54, 55 PUR (1.1082)

- VEGASON 56 Silicone (1.1083)

Weight

VEGASON 51 1.2 kg

VEGASON 52 1.6 kg

VEGASON 53 2.3 kg

VEGASON 54

- version A 5.6 … 10.7 kg

- version B 6.9 … 9.7 kg

- version C 7.5 … 10.5 kg

- version D 4.7 … 6.9 kg

VEGASON 55

- version A 8.0 … 13.3 kg

- version B 8.7 … 10.3 kg

- version C 9.2 … 11.1 kg

- version D 6.5 … 7.5 kg

VEGASON 56

- version A 7.3 … 11.3 kg

- version B 8.7 … 10.3 kg

- version C 9.3 … 11.1 kg

- version D 6.5 … 7.5 kg

Technical data

CE conformity

VEGASON series 50 ultrasonic sensors and VEGASCAN 850 meet the protective regulations of EMC (89/336/EWG) and NSR (73/23/EWG). Conformity was judged acc. to the

following standards:

EMC Emission EN 50 081 - 1: 1992

Susceptibility EN 50 082 - 2: 1995

NSR EN 61 010 - 1: 1993

EN 61 326 - 1: 1997/A1:1998

24 VEGASCAN 850

Page 25

Technical data

3.2 Dimensions

VEGASCAN 850

90

80

260235

246

13 90

210

236

VEGASCAN 850 25

Page 26

External indicating instrument VEGADIS 50

Technical data

38

ø5

48

10

Pg 13,5

Mounting on carrier rail 35 x 7 .5 acc. to EN 50 022 or flat

screwed

135

118

108

Adjustment module MINICOM

Tank 1

m (d)

12.345

67,5

ESC

+

-

32,5

OK

Adjustment module for insertion into

VEGASON series 50 sensor or into the external indicating instrument VEGADIS 50

74

82

85

Note:

The diameter of the connection cable must be

5 … 9 mm.

Otherwise the seal effect of the cable entry will

not be ensured.

26 VEGASCAN 850

Page 27

Technical data

VEGASON 51

Housing PBT

201

Housing aluminium

370

322

182

215

185

10˚

165

M20x1,5

SW 60

G 1½ A/

1½" NPT

25

101

90

116

2

ø 40

Min. distance

to the medium

228

315

20

Reference plane

0,25 m

205

M20x1,5

SW 60

102

252

337

2

G 1½ A/

1½" NPT

20

Reference plane

ø 40

Min. distance to

the medium

0,25 m

VEGASCAN 850 27

Page 28

VEGASON 52

Housing PBT

Technical data

201

Housing aluminium

370

322

182

215

185

10˚

165

M20x1,5

SW 60

G 2 A

25

101

90

116

232

2

20

ø 50

Min. distance to

the medium

315

Reference plane

0,4 m

205

M20x1,5

SW 60

102

256

337

2

G 2 A

20

Reference plane

ø 50

Min. distance to

the medium

0,25 m

28 VEGASCAN 850

Page 29

Technical data

VEGASON 53

201

322

M8x10

12 tief

182

20

ø 148

ø 158

10˚

165

M20x1,5

195

130

101

90

118

218

Min. distance to

the medium

270

0,6 m

VEGASCAN 850 29

Page 30

VEGASON 54 … 56 in version A

201

165

Plastic housing

(PBT)

10˚

101

Aluminium

housing (Al)

25

116

Technical data

215

185

VEGASON 54

VEGASON 55

397

257

Min. distance to

the medium

Min. distance to

the medium

1,0 m

0,8 m

90

12xø22

1)

ø190 (ø196)

ø340

ø244

ø405

75

1)

20

110 (126)

12xø26

20

128

12xø22 (12xø26)

445,8

282

Reference plane

Reference plane

20

Reference plane

VEGASON 56

423

Min. distance to

the medium

1,8 m

30 VEGASCAN 850

ø198

2)

ø340 (ø405)

Page 31

Technical data

VEGASON 54 … 56 in version B

486

4xø19

172

386

245

ø165

ø122,8

201

165

10˚

Plug connection

ø 27

> ø200

Plastic housing

(PBT)

11,5

11,5

101

90

503

4xø19

ø165

ø122,8

>ø250

435

270

215

185

65

Plug connection

798

Aluminium

housing (Al)

25

116

ø165

ø122,8

4xø19

>ø210

ø190 (ø196)

VEGASON 54

1,0 m

Reference plane

189,5

ø 244

VEGASON 55

484,5

0,8 m

ø 198

1,4 m

VEGASON 56

VEGASCAN 850 31

Page 32

VEGASON 54 … 56 in V ersion C

Aluminium housing (Al)

Plug

Technical data

215

25

116

185

Plug connection

ø 45

78

68

7

130

150

ø 7

85

65

170

445,8

282

10120

1,0 m

0,8 m

VEGASON 54

VEGASON 55

1,4 m

Reference plane

VEGASON 56

32 VEGASCAN 850

Page 33

Technical data

VEGASON 54 … 56 in version D

Plug connection

3240

214

149

Plastic housing (PBT)

Plug

68

ø 45

78

233

7

3240

167,5

186

101

90

130

150

201

165

10˚

397,2

257,2

ø 7

85

65

120 10

170

3240

527

462,5

Reference plane

1,0 m

0,8 m

1,4 m

VEGASON 54 VEGASON 55 VEGASON 56

VEGASCAN 850 33

Page 34

4 Mounting and installation

4.1 Mounting VEGASON 54 … 56

Mounting and installation

VEGASON 54 … 56, version A

Sensors in version A (flange version) are

supplied completely mounted and ready for

operation. Immediately after mounting on the

vessel and electrical connection, they are

ready for operation.

VEGASON 54 … 56, version B

The sensors in version B are supplied in two

parts (transducer and sensor electronics).

First of all, mount the transducer on the vessel or above the medium. There is a four-pole

jack at the end of the transducer tube. The

respective counterpart to the jack protrudes

out of the lower side of the sensor electronics

housing. Insert the plug of the sensor electronics (only possible in one position) into the

jack of the transducer tube. Continue pushing the electronics housing onto the transducer tube, on which there is a wide and a

narrow groove.

Groove for locking the

headless screw

Mounting groove (must

no longer be visible after

mounting)

The wide groove is used for locking the

headless screws. The narrow groove is a

marking for mounting. Move the electronics

housing farther down over the transducer

tube until the mounting groove is no longer

visible. Fasten the housing with the headless

screws to the transducer tube. Use a 5 mm

hexagon screwdriver (or Allen wrench).

34 VEGASCAN 850

Page 35

Mounting and installation

VEGASON 54 … 56, version C, D

The sensors in version C and D are supplied

in three parts (transducer, sensor electronics

and transducer cable). First mount the transducer (see version B). There is a four-pole

jack at the transducer tube end. A respective

counterpart to the jack is provided in the

connection cylinder of the transducer cable.

Insert the connection cylinder plug into the

jack of the transducer tube.

Connection

cylinder

Mounting

bracket

Connection

cylinder

Transducer

cable

On the end of the transducer tube you find a

wide and a narrow groove. The wide groove

is used for locking the cylinder with the headless screws. The narrow groove is the

mounting mark.

Then push the connection cylinder over the

transducer tube (with a slight swivelling motion) until the mounting mark is no longer

visible.

When the mounting mark is covered by the

cylinder, fasten the cylinder with the two

headless screws. Use a 5 mm hexagon

screwdriver (or Allen wrench).

Now mount the sensor electronics in the

requested location. The sensor electronics is

fastened to a mounting bracket, so that it can

be mounted on a plane surface or on the wall.

Make sure that the sensor housing is

mounted in such a way that there is enough

space above the housing to open the cover.

Now insert the plug at the other end of the

transducer cable into the jack on the electronics housing.

Note:

Avoid bending the transducer cable too

sharply when laying it out. This is a special

cable which could otherwise be damaged.

In addition, make sure that the cable is not

damaged during operation. A signal with a

voltage of approx. 1 kV is transmitted (which

could be a danger in Ex areas if the cable is

damaged).

Groove for locking the

headless screws

Mounting groove (must

no longer be visible after

mounting)

VEGASCAN 850 35

Page 36

Mounting and installation

4.2 General installation instructions

transducer end. For VEGASON 54 ... 56 in

version A the lower flange side on the sensor

Measuring range

Beside other criteria, you select your instrument according to the required measuring

range. The reference planes for the min. and

is the reference plane. Please note the information on the reference planes in chapter

"3.2 Dimensions“. The max. filling depends on

the required min. distance and the mounting

location.

max. distance to the product or solid is the

VEGASON 51

Min.

distance

0.25 m 0.4 m

Full

Empty

1m

max. meas. range

4 m (type 51), 7 m (type 52), 15 m (type 53)

Min. distance, max. measuring range and span (VEGASON 51 … 53)

VEGASON 53 VEGASON 52

Min.

distance

0.75 m

Span

Reference plane

Min.

distance

VEGASON 56

Version B

Reference plane

min. meas. distance 1.4 m

100 %

0 %

Span

0 %

100 %

Span

VEGASON 54

Version A

min. meas.

distance 1.0 m

VEGASON 55

Version B

Reference plane

min. meas. distance 0.8 m

100 %

0 %

max. meas. range

Span

max. meas. distance 25 m (type 54), 45 m (type 55), 70 m (type 56)

Min. distance, max. measuring range, span and reference plane (VEGASON 54 … 56)

36 VEGASCAN 850

Page 37

Mounting and installation

0

0 m

15 m

100 %

50 %

1,2

1,2

m

0,4

0,4

3˚

8˚

Beam angle and false echoes

The ultrasonic impulses are focused by the

transducer. The impulses leave the transducer in conical form similar to the beam

pattern of a spotlight.

Any object inside this emission cone will

cause a false echo. Especially within the first

few meters of the emission cone, pipes,

struts, or other installations can interfere with

the measurement. At a distance of 6 m, the

false echo of a strut has an amplitude nine

times greater than at a distance of 18 m.

At greater distances, the energy of the ultrasonic impulses distributes over a large area,

thus causing weaker echoes from obstructing surfaces. The interfering signals are

therefore less critical than those at close

range.

If possible, orient the sensor axis perpendicularly to the product surface and avoid

vessel installations (e.g. pipes and struts)

within the 100 % area of the emission cone.

The illustrations showing the ultrasonic emission cones are much simplified and represent only the main beam. However, several

weaker beams also exist. The transducer

must therefore be aligned - especially under

difficult measuring conditions - in such a way

that very low false echo values result. Putting

emphasis only on a strong useful echo is not

sufficient under adverse conditions.

Meas.

distance

0 m

Meas.

distance

7 m

Meas.

distance

0 m

4 m

0,4

0,8

0,4

1,2

VEGASON 51

50 %

100 %

5,5˚

0,4

0

0,8

VEGASON 52

5,5˚

100 %

0,4

1,2

0

VEGASON 53

emitted power

emitted power

12˚

m

12˚

emitted power

emitted power

50 %

emitted power

m

emitted power

Under difficult measurement conditions, we

recommend looking for a mounting location

with the weakest possible false echoes. The

useful echo will then often appear automatically with sufficient quality. With the adjustment software VVO on the PC you can have

a look at the echo image and optimise the

mounting location (see chapter "6.2 Adjustment with the PC – Sensor optimisation –

Echo curve“).

VEGASCAN 850 37

Page 38

0 m

Meas.

distance

Mounting and installation

VEGASON 56VEGASON 54

0 m

emitted power

50 %

100 %

4˚

emitted power

25 m

Meas.

distance

45 m

0 m

4

0,9

2,0

5˚

10˚

242

0

8˚

0,9

2,0

0

VEGASON 55

50 %

emitted power

100 %

m

m

emitted power

Meas.

distance

70 m

50 %

emitted power

6˚

100 %

emitted power

12˚

3,7

7,5

3,7

0

m

7,5

38 VEGASCAN 850

Page 39

Mounting and installation

4.3 Measurement of liquids

Flat vessel top

On flat vessels, the mounting is usually done

on a very short DIN socket piece. Reference

plane is the lower edge of the flange. The

transducer should protrude out of the flange

tube.

Reference plane

£ 60 mm

VEGASON 53 on very short DIN socket piece

< 100 mm

Min.

distance

Reference plane

Reference plane

< 400 mm

Min. distance

1.8 m

VEGASON 56 in flange version on short

DIN socket piece

A mounting location directly on the vessel top

is ideal. A round opening in the vessel top is

sufficient to fasten the sensor with the flange,

or version B and C (VEGASON 54 … 56) with

swivelling holder.

Reference plane

Min. distance

Type 54: 1 m

Type 55: 0.8 m

VEGASON 55 in flange version on short

DIN socket piece

VEGASON 53 (compression flange) on flat vessel top

VEGASCAN 850 39

Page 40

Reference

plane

Swivelling

holder

Reference

plane

Mounting and installation

< 60 mm

Reference

plane

Mounting of the transducer with 1“ thread (here

belonging to VEGASON 54 version D)

Min. meas. distance

1.8 m

Min. meas. distance

1.4 m

Flange version and swivelling holder on flat vessel

top

It is also possible to mount the sensors with

11/2“ or 2“ thread to short socket pieces.

£ 60 mm

Reference plane

Mounting on short 11/2“ or 2“ socket pieces (VEGASON 51)

VEGASON 54 … 56 sensors in version C are

mounted in a 1“ thread.

Dished tank ceiling

On dished tank ceilings, please do not mount

the instrument in the centre, but approx. 1/

vessel radius from the centre. Dished tank

ceilings can act as paraboloidal reflectors. If

the transducer is placed at the focal point of

the parabolic ceiling, the transducer receives

amplified false echoes. The transducer

should be mounted outside the focal point.

Amplified echoes caused by parabolic surfaces are thereby avoided.

£ 60 mm

VEGASON 51, 52 on dished tank ceiling

Reference plane

1

/2 vessel radius

2

40 VEGASCAN 850

Page 41

Mounting and installation

£ 60 mm

1

/2 vessel radius

VEGASON 53 on dished tank ceiling

< 400 mm

1

/2 vessel radius

Reference

plane

Reference plane

Reference

plane

< 100 mm

1

/2 vessel radius

VEGASON 54 version A on dished tank ceiling; the

statements are also valid for VEGASON 55

Open vessels

On open vessels, use of instruments on an

extended mounting bracket is recommended. Mount the low-weight sensor onto

such a bracket and ensure a sufficient distance to the vessel wall.

Reference plane

Min. meas.

Reference plane

distance

VEGASON 56 version A on dished tank ceiling

Min. meas.

distance

VEGASON 54 on open vessel

VEGASCAN 850 41

Page 42

Mounting and installation

Pump shaft

Narrow shafts and shaft-like openings (vessel openings) with very rough walls and

shoulders make an ultrasonic measurement

extremely difficult due to strong false echoes.

This problem can be overcome by using an

extended socket piece or a complete measuring tube (see chapter "4.5 Socket extension“).

see “4.5 Socket extension“

Socket piece

≥ 250 mm

min.

distance

Meas. range

4.4 Measurement of solids

Flange mounting

As with applications for liquids, the instrument

can be mounted on a short DIN socket connection on vessels for solids. The transducer

axis, however, should point to the vessel

outlet or should be oriented perpendicularly

to the product surface. The socket length can

be max. 60 … 400 mm, depending on the

sensor type.

Reference plane

Min. distance

Shaft pump

Measuring tube

Example of a socket extension or measuring tube in a

shaft

Shaft pump

VEGASON 53 on inclined vessel flange

Shaft

Very good measuring results can be attained

with a measuring tube in continuous narrow

shafts, see figure. The applied measuring

tube must have smooth walls inside (e.g. PE

sewage pipe) and a diameter of 100 mm. This

arrangement works well as long as the inside

of the measuring tube collects no dirt or

buildup (cleaning necessary). You might

want to consider using hydrostatic pressure

transmitters or capacitive measuring probes.

Either the measuring tube should never be

immersed in the medium, or it must always

Swivelling holder

We offer as an accessory a swivelling holder

(mounting strap) for mounting of VEGASON

53. This simplifies the alignment of the sensor

to the product surface.

Suitable is the use of VEGASON 54 … 56

version B or C. For solids, the swivelling

holder enables an optimum alignment of the

transducer, thus minimising false echoes.

be immersed (so that the measurement is

carried out exclusively in the tube).

42 VEGASCAN 850

Page 43

Mounting and installation

Reference plane

Min. distance

Mounting boss

Reference plane

Min. distance

VEGASON 53 on swivelling holder

Reference plane

Min. distance

VEGASON 54C with adapter flange and swivelling

holder on a DN 200 vessel flange

VEGASON 51 or 52 on the mounting boss. The socket

axis should point directly to the product surface. This

is why VEGASON 51 and 52 are less suitable for

solids.

Reference plane

Min. distance

VEGASON 56 in 1“ mounting boss.

The socket axis should point directly to the

product surface. Much better would be the

use of a swivelling holder version.

VEGASCAN 850 43

Page 44

Mounting and installation

Material heaps

Large material heaps are best detected with

several instruments, which can be mounted

on e.g. traverse cranes. For this type of application, it is advantageous to orient the

sensor directly toward the solid surface.

Transducer on traverse crane above a material heap

(illustration: VEGASON 54 in version B)

4.5 Socket extensions

The ultrasonic sensors require a min. distance to the liquid or solid product. Take the

min. distance into account in your planning. In

some situations, it is possible to reach the

required min. distance, and hence the desired filling height, with a socket extension.

However, the socket extension increases the

noise level of the ultrasonic signal at the extension outlet and can interfere with the

measurement. Only use a socket extension if

all other possibilities have to be excluded.

Carry out the extension as shown in the following illustration.

Socket extensions in liquids

Chamfer and deburr the socket carefully and

make sure it has a smooth inner surface. The

socket should not protrude into the measured product, in case buildup can form on

the socket through pollution or product residues.

Socket piece should not be immersed into adhesive

products (illustration: VEGASON 53)

The socket diameter should be as large and

the socket length as small as possible. Make

sure that the socket outlet is burr-free to

minimise false echoes.

44 VEGASCAN 850

Page 45

Mounting and installation

15˚ 15˚

Type 51/52

LL

45˚

ø

Socket extensions in liquids

Type 53

45˚

ø

Max. socket length in relation to socket diameter

ø in mm L in mm

Type 51 Type 52 Type 53

100 200 300 300

150 300 400 400

200 – 500 500

250 ––600

Type 54

Type 55

Socket extensions for solids

For solids, use a conical socket extension

with a taper of at least 15° … 20°.

Socket extension in solids

Measurement in a tube

For nonadhesive measured products, a

socket extension in the form of a measuring

tube can be permanently submerged in the

product. The ultrasonic measurement is then

made exclusively in the measuring tube and

works very well without interference from

other vessel installations (see "Pump shaft“).

L

45˚

ø

Socket extensions that do not protrude into the

measured product

L

45˚

ø

Max. socket length in relation to socket diameter

ø in mm L in mm

Type 54 Type 55 Type 56

200 400 –– ––

250 500 500 500

300 –– –– 600

VEGASCAN 850 45

Page 46

Mounting and installation

4.6 Flow measurement

The short examples on this page are only

basic information on flow measurement. You

can get complete planning information from

the flume manufacturers and in special literature.

Rectangular flume

- Installation of the sensor on the upstream

side

- Note distance to the overfall edge

(3 … 4 x h

- Installation centered to the flume

- Edge opening ³ 2 x h

- Installation perpendicular to the liquid surface

- Keep min. distance in relation to h

- Min. distance from edge opening to downstream water ³ 50 mm

max

90°

)

from ground

max

max

³ max.

distance

h

max

Khafagi-Venturi flume

- Installation of the sensor on the inlet side

- Note distance to the Khafagi-Venturi flume

(3 … 4 x h

- Installation perpendicular to the liquid surface

- Keep min. distance in relation to the height

of damming h

Khafagi-Venturi flume

max

3 … 4 x h

90°

Sensor

)

max

max

h

max

B

³ 2 x h

Overfall edge

max

Flow measurement on open flumes

Overfall edge

3 … 4 x h

max

90°

³ 5 cm

Upstream water

Downstream water

Flow measurement on open flumes

46 VEGASCAN 850

Page 47

Mounting and installation

4.7 False echoes

The mounting location of the ultrasonic sensor

must be selected such that no installations or

inflowing material are in the path of the ultrasonic impulses. The following examples and

instructions show the most frequent measuring problems and how to avoid them.

Vessel protrusions

Vessel forms with flat protrusions can, due to

their strong false echoes, adversely effect

the measurement. Shields above these flat

protrusions scatter the false echoes and

guarantee a reliable measurement.

Correct Wrong

Vessel protrusions (slope)

Intake pipes, e.g. for the mixing of materials with a flat surface directed towards the sensor - should be covered with a sloping

shield. This shield will scatter false echoes.

Vessel installations

Vessel installations such as, for example, a

ladder, often cause false echoes. Make sure

when planning your measurement loop that

the ultrasonic signals have free access to the

measured product.

Correct Wrong

Ladder

Vessel installations

Ladder

Struts

Struts, like other vessel installations, can

cause strong false echoes that are superimposed over the useful echo signals. Small

shields effectively hinder a direct false echo

reflection. These false echoes are scattered

and diffused in the area and are then filtered

out as "echo noise“ by the measuring electronics.

Correct Wrong

Correct Wrong

Shields

Struts

Vessel protrusions (intake pipe)

VEGASCAN 850 47

Page 48

Mounting and installation

Inflowing material

Do not mount the instrument in or above the

filling stream. Ensure that you detect the

product surface and not the inflowing material.

Correct

Correct

Wrong

Wrong

Correct

Buildup

Wrong

Overflow basin

The expected max. high water determines

the installation height, to ensure the min.

distance of the transducer even with the

highest water level. The low water level

should be covered in the transducer area

with a shield to filter out echoes from exposed basin surfaces.

Correct Wrong

Inflowing material

Min. distance

high water

Buildup

If the sensor is mounted too close to the

vessel wall, buildup and adhesions of the

measured product to the vessel wall can

cause false echoes. Position the sensor at a

sufficient distance from the vessel wall.

Please also note chapter "4.2 General installation instructions“.

48 VEGASCAN 850

60°

Shield

Filtering out of a level echo

Low water

Page 49

Mounting and installation

Strong product movements

Heavy turbulences in the vessel, e.g. by

strong stirrers or strong chemical reactions,

can seriously interfere with the measurement.

A surge or bypass tube of sufficient size

(DN 200, DN 250) always allows, provided

the product causes no buildup in the tube, a

reliable measurement even with strong turbulences in the vessel.

100 %

60 %

0 %

Strong product movements

4.8 Incorrect mounting

Foam generation

Thick foam on the product can cause incorrect measurements. Take measures to avoid

foam, carry out the measurement in a bypass

tube, or use a different measuring technology, e.g. capacitive measuring probes or

hydrostatic pressure transmitters.

Foam generation

Wrong orientation to the product

Weak measuring signals are the result if the

sensor is not directly pointed at the product

surface. Orient the sensor axis perpendicularly to the product surface to achieve optimum measuring results.

Orient the sensor perpendicularly to the product

surface

VEGASCAN 850 49

Page 50

Mounting and installation

Strong heat fluctuations

Strong heat fluctuations, e.g. due to the sun,

cause measuring errors. Please provide a

sun shield.

Shield

Strong heat fluctuations

Min. distance to the medium

If the min. distance to the medium is not maintained, the instruments show wrong measured values. Mount the instrument at the

required min. distance.

Sensor too close to the vessel wall

If the sensor is mounted too close to the

vessel wall (dimension A in diagram), strong

false echoes can be caused. Buildup, rivets,

screws or weld joints on the vessel wall superimpose their echoes onto the product or

useful echo. Please ensure a sufficient distance from the sensor to the vessel wall,

depending on the maximum measuring distance (dimension B in diagram).

In case of good reflection conditions (liquids,

no vessel installations), we recommend determining the sensor distance according to

Diagram curve 1. At a max. meas. distance

of e.g. 10 m, the distance of the transducer

(according to curve 1) should be approx.

1.5 m.

In case of solids with bad reflection properties, determine the distance to the vessel wall

according to Diagram curve 2. Under very

bad measuring conditions (rough vessel

walls, struts), it might be necessary to increase the distance to the vessel wall, or to

additionally filter out the false echoes by

storing them in memory, thereby adapting the

sensor more precisely to the environment.

Correct Wrong

Sensor too close to the vessel wall

50 VEGASCAN 850

Page 51

Mounting and installation

Distance of the

transducer to the

vessel wall

A

1 m 2 m 3 m 4 m 5 m

Curve 1 (liquids)

5 m

B

10 m

15 m

max. meas.

distance

Curve 2 (solids)

Distance from the sensor to the vessel wall, depending on the meas. distance (type 51 … 53)

Distance of the

transducer to the

vessel wall

A

Parabolic effects of rounded or arched

vessel tops

Round or parabolic tank tops act on the signals like a parabolic mirror. If the sensor is

placed at the focal point of such a parabolic

tank top, the sensor receives amplified false

echoes. The optimum location is generally in

the area of half the vessel radius from the

centre.

Correct

< 100 mm

~ 1/

2

vessel

radius

Wrong

2 m 4 m 6 m 8 m

Wrong

Curve 1 (liquids)

10 m

B

20 m

Curve 2 (solids)

Mounting on a vessel with parabolic tank top

30 m

max. meas.

distance

Distance from the sensor to the vessel wall, depending on the meas. distance (type 54 … 56)

VEGASCAN 850 51

Page 52

Socket piece too long

If the sensor is mounted in a socket extension that is too long, strong false echoes are

caused, and measurement is hindered. Make

sure that the transducer protrudes at least

30 mm out of the socket piece.

Reference plane

< 100 mm

Mounting and installation

Correct and wrong length of socket piece

52 VEGASCAN 850

Page 53

Electrical connection

5 Electrical connection

5.1 Connection, connection cable and shielding

Qualified personnel

Instruments which are not operated with

protective low voltage or DC voltage must

only be connected by qualified personnel.

This is especially valid for the connection of

the power supply on VEGASCAN.

Safety information

As a rule, do the work in the complete absence of voltage. Always switch off the power

supply before you carry out connecting

work. Protect yourself and the instruments.

The shielded transducer cables transmit a

signal with a voltage of approx. 1 kV. In Ex

areas, cable damage can be dangerous. Do

not carry out any mounting or connection

work on the transducer when VEGASCAN is

switched on.

Connection cable

Please note that the connection cables are

specified for the expected operating temperatures in your systems. The power supply and

the sensor cables must have an outer diameter of 6 … 12 mm, to ensure the seal effect of

the cable entry.

Transducer cable

When wiring the transducer cable (version C

and D), strong bending of the cable should

be avoided. This is a special cable which can

be damaged.

Make sure when wiring the transducer cable

that no operating influences can damage it.

Earth conductor terminal

The electronics housing of the sensors has a

protective insulation. The earth conductor

terminal and the earth terminal in the electronics housing are galvanically connected with

the metallic transducer diaphragm.

On sensors in version B, the earth conductor

terminal is galvanically connected to the

transducer diaphragm via the transducer

tube when the sensor is completely mounted.

On version C and D, the connection is made

via the cable screen of the transducer cable

and the transducer tube.

Shielding of the sensor cables

The "Electromagnetic pollution“ from electronic actuators, power lines and transmitting

stations is often so considerable that the twowire cable of VEGASCAN to the sensors

must be shielded.

Power supply

For power supply, standard three-wire cable

up to max. 2.5 mm2 can be used. The electrical connection is made via spring terminals.

You open the terminal opening with a small

screwdriver by inserting it into the opening

slot above the terminal position and lever it

upward. This opens the terminal and the

copper core of the connection wire can be

inserted.

VEGASCAN 850 53

Page 54

Electrical connection

We recommend a screening on both ends,

see the following sketch. Screening is a good

preventative measure against future sources

of interference. However, you must make

sure that no ground potential currents flow

through the sensor cable shields. Ground

potential currents can be avoided by potential equalisation cables. When grounding at

both ends, it is possible to connect the cable

Note Ex protection!

In Ex applications, grounding on both ends is

not allowed due to potential losses. If an

instrument is used in hazardous areas, the

respective regulations, conformity certificates

and type approvals for systems in Ex areas

must be noted (e.g. DIN 0165).

Please note the approval documents with the

safety data sheet attached to the Ex sensors.

shield on one side (e.g. in the switching cabinet) via a capacitor (e.g. 0.1 µF; 250 V) to the

ground potential. Use a low-resistance

ground connection (foundation, plate or

mains earth).

Linear (serial) arrangement of sensors

Grounding of the cable screen on both ends, at the end of each sensor line via a ground capacitor.

PC

850

BA

on

2

2

54 VEGASCAN 850

Page 55

Electrical connection

Radial arrangement of sensors

Grounding on at least two ends, on VEGASCAN and once on the sensor star, i.e. on the longest sensor line. If the individual sensor lines are longer than approx. 15 m, a grounding of

each longer line should be made via a ground capacitor.

PC

850

BA

on

Longest stub of the

sensor star

2

4

2

2

4

2

VEGASCAN 850 55

Page 56

Electrical connection

5.2 Connection of the sensor

After mounting the sensor at the measurement location according to the instructions in

chapter "4 Mounting and installation“, loosen

the closing screw on top of the sensor. The

sensor lid with the optional indication display

can then be opened. Unscrew the sleeve nut

and slip it over the connection cable (after

removing about 10 cm of insulation). The

sleeve nut of the cable entry has a self-locking ratchet that prevents it from opening on

its own.

Version with aluminium housing

Voltage supply and digital

meas. signal

M20 x 1.5

(diameter of the

connection

cable 6…9 mm)

+

-

To the indicating instrument in the cover or to the

external indicating

instrument VEGADIS 50

M20 x 1.5

Now insert the cable through the cable entry

into the sensor. Screw the sleeve nut back

onto the cable entry and clamp the stripped

wires of the cable into the proper terminal

positions.

The spring terminals hold the wire without a

screw. Press the white opening tabs with a

small screwdriver and insert the copper core

of the connection cable into the terminal

opening. Check the hold of the individual

wires in the terminals by lightly pulling on

them.

Version with plastic housing

Voltage supply and digital

meas. signal

-

+

To the indicating instrument in

Cable entry

M20 x 1.5

the cover or to the external

indicating instrument

Sockets for

connection of

VEGACONNECT 2

(communication sockets)

12 C 567843

12 C 5 6 7 8

(+) (-)

Communication

Display

ESC

-

+

VBUS

Terminals

(max. 2.5 mm

wire cross-section)

OK

Sockets for connection of the HART

handheld or VEGACONNECT

pluggable

adjustment

module MINICOM

2

12 C 5678

12 C 5678

Commu-

(+) (-)

nication

VBUS

®

Tank 1

m (d)

12.345

Display

+

ESC

-

OK

Opening

tabs

56 VEGASCAN 850

Page 57

Electrical connection

5.3 Connection of the external indicating instrument VEGADIS 50

Loosen the four screws of the housing cover

on VEGADIS 50.

The connection procedure can be facilitated

by fixing the housing cover during connection work with one or two screws on the right

of the housing (figure).

OUTPUT

(to the sensor)

3

2

1

4

5

8

6

7

Adjustment

module

VEGADIS 50

+

-

Tank 1

m (d)

12.345

ESC

OK

Voltage supply and

digital meas. signal

-

+

12 C 5678

2

1

(+) (-)

VBUS

Tank 1

m (d)

12.345

C 5678

Commu

nication

+

-

Display

ESC

OK

DISPLAY

(in the cover of

the indicating

instrument)

Screws

VEGASCAN 850 57

Page 58

Electrical connection

5.4 Connection of the sensors to

VEGASCAN 850

off

on

---

POWER

GNDTxD

N

RxDDTR

FIELDBUS VBUS1 VBUS2

PC2

PE L

VBUS1

Use the terminal VBUS1, when using a

VEGASCAN 850 for 15 sensors. Sensors

16 … 30 are connected to the terminals

VBUS2.

+++

--+++

VBUS2

The electrical connection is made by spring

terminals. The clamping opening can be

opened with a small screwdriver by inserting

it into the opening slot above the clamping

position and pushing upwards. Then the

terminal and the copper core of the connec-

tion wire can be inserted.

Up to 15 sensors can be connected to each

VBUS branch on one two-wire cable.

---

+++

Sensor 1 … 15

VBUS1

It is a good idea to optimise the current distribution by dividing the BUS into three

branches with five sensors each.

Sensor

Sensor

6 … 10

Sensor

11 … 15

1 … 5

---

+++

VBUS1

58 VEGASCAN 850

Page 59

Electrical connection

5.5 Signal output/Interface connection

The connection terminal is labelled for the

field bus cable according to the selected

interface and instrument version.

Modbus, VEGA-ASCII, Siemens 3964

TXRX

DATA

(B/B´)

DATA

(B/B´)

Interface RS 232

/TX/RX

Interface RS 422

Interface RS 485

DATA

(A/A´)

Interface RS TTY

Interface RS 485

DATA

(A/A´)

RxD

GND TxD

FIELDBUS

GND

FIELDBUS

GND

(C/C´)

FIELDBUS

T-

R+ R+

GND T+

FIELDBUS

Profibus DP , Profibus FMS

GND

(C/C´)

FIELDBUS

5.6 Connection of the PC to VEGASCAN 850

The PC with the adjustment software VVO

can be connected in the front panel or in the

terminal compartment of VEGASCAN.

For connection of the PC in the front panel (9pole socket) you require a standard RS 232

DTE-DTE (Data Terminal Equipment) interface cable.

DCD

RxD

TxD

DTR

GND

...

6

...

7

...

8

...

9

For connection of the PC in the terminal compartment, connect the opened PC cable

according to the following sketches to terminal block PC2. For communication, only three

wires of the 9-pole cable are used.

DCD

1

RxD

2

TxD

3

DTR

4

GND

5

...

6

...

7

...

8

...

9

1

DCD1

2

RxD2

3

TxD3

4

DTR4

5

GND5

...

6

...

7

...

8

...

9

GNDTxD

RxD DTR

PC2

Terminal in VEGASCAN

VEGASCAN 850 59

Page 60

6 Setup

Setup

6.1 Adjustment methods

VEGASCAN 850 and the series 50 ultrasonic