Page 1

Operating Instruction

VEGAPULS 51 V … 54 V

Level and Pressure

Page 2

Contents

Safety information ........................................................................ 2

1 Product description

1.1 Function ................................................................................. 4

1.2 Application features ............................................................. 6

1.3 Adjustment ............................................................................ 6

2 Types and versions

2.1 Type survey ........................................................................... 9

2.2 Configuration of measuring systems ............................... 13

3 Technical data

3.1 Data ..................................................................................... 18

3.2 Dimensions ......................................................................... 22

3.3 Approvals ........................................................................... 25

Contents

4 Mounting and installation

4.1 General installation instructions ........................................ 26

Safety information

The described module must only be installed

and operated as described in this operating

instruction. Please note that other action can

cause damage for which VEGA does not take

responsibility.

2 VEGAPULS 51 V … 54 V

Page 3

Contents

4.2 Measurement of liquids ..................................................... 28

4.3 Measurement in standpipe ............................................... 30

4.4 False echoes ...................................................................... 36

4.5 Installation error .................................................................. 38

5 Electrical connection

5.1 Connection and connection cable .................................... 41

5.2 Connection of the sensor .................................................. 42

5.3 Connection of the external indicating instrument

VEGADIS 50 ....................................................................... 43

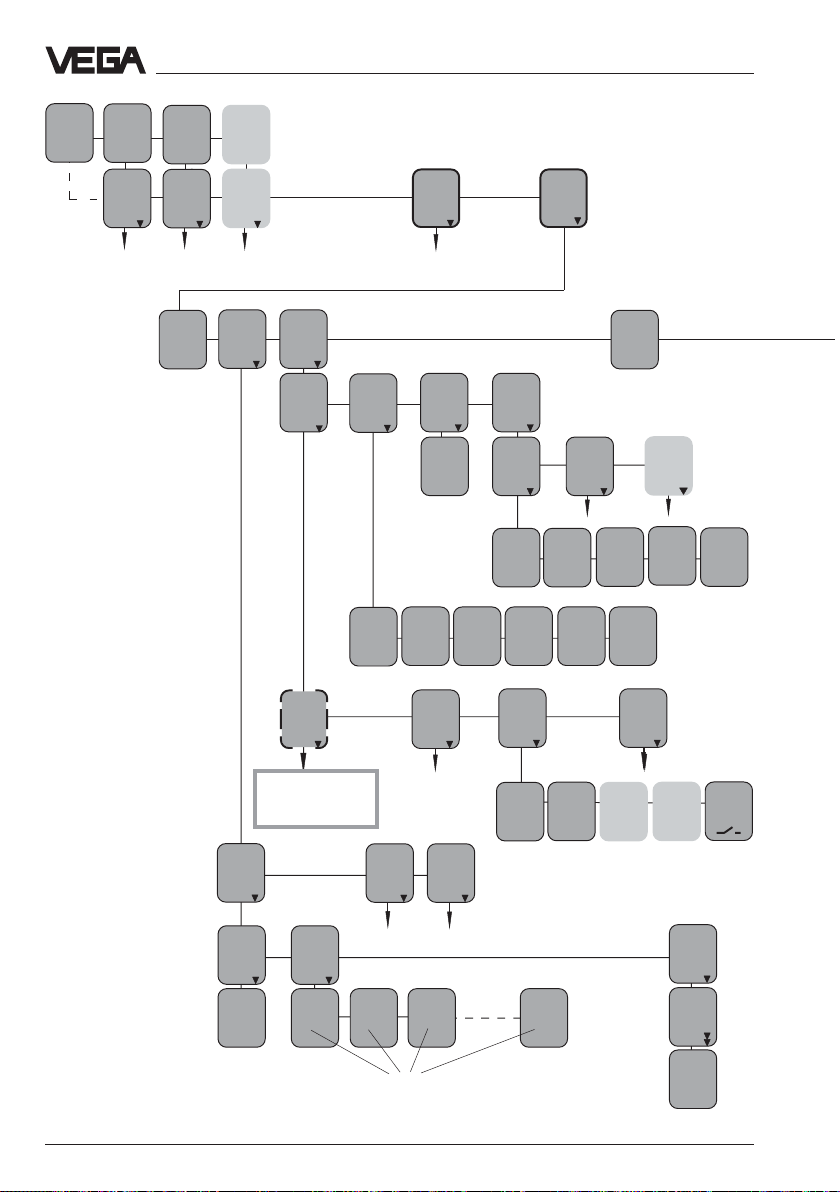

6 Set-up

6.1 Adjustment structure ......................................................... 44

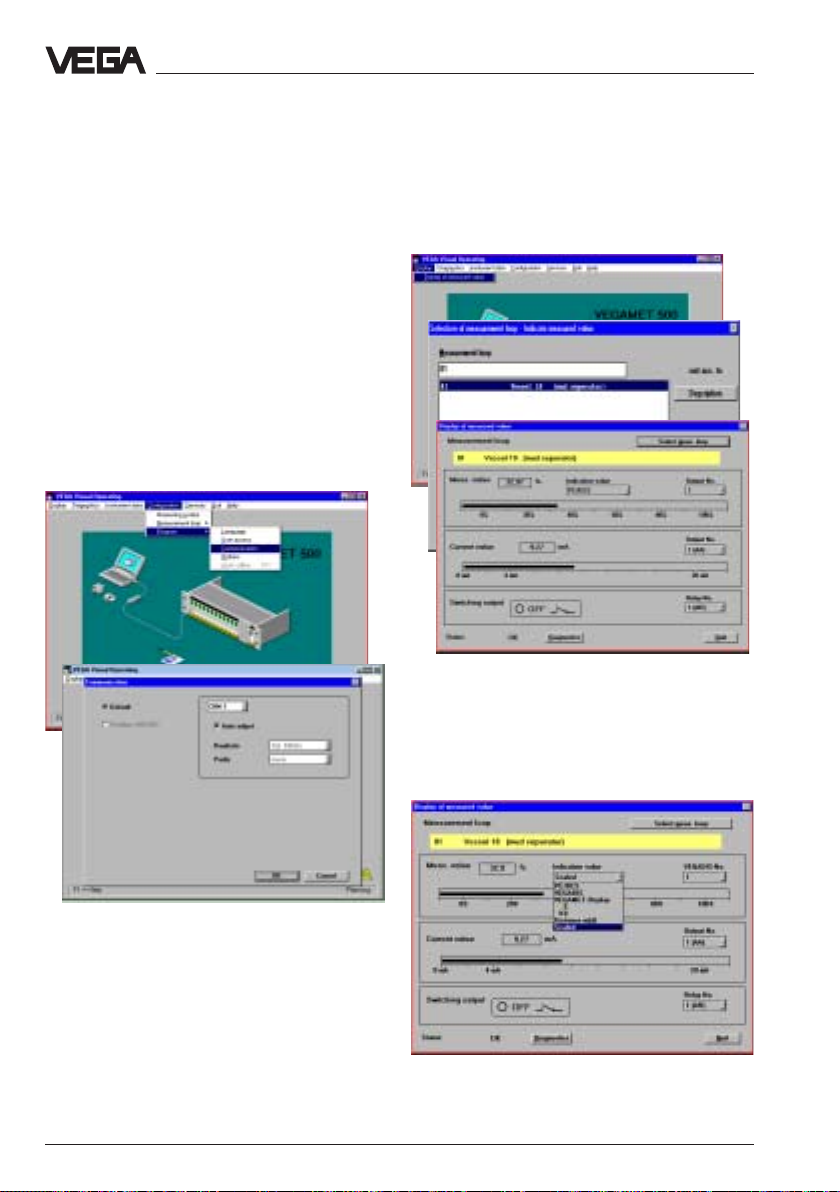

6.2 Adjustment with PC on VEGAMET .................................... 45

6.3 Adjustment with MINICOM or VEGAMET ........................ 63

6.4 Adjustment with the PC on VEGALOG ............................ 76

VEGAPULS 51 V … 54 V 3

Page 4

1 Product description

1.1 Function

Radio detection and ranging: Radar.

VEGAPULS radar sensors are used for noncontact and continuous distance

measurement. The measured distance

corresponds to a filling height and is

provided as level.

Product description - Function

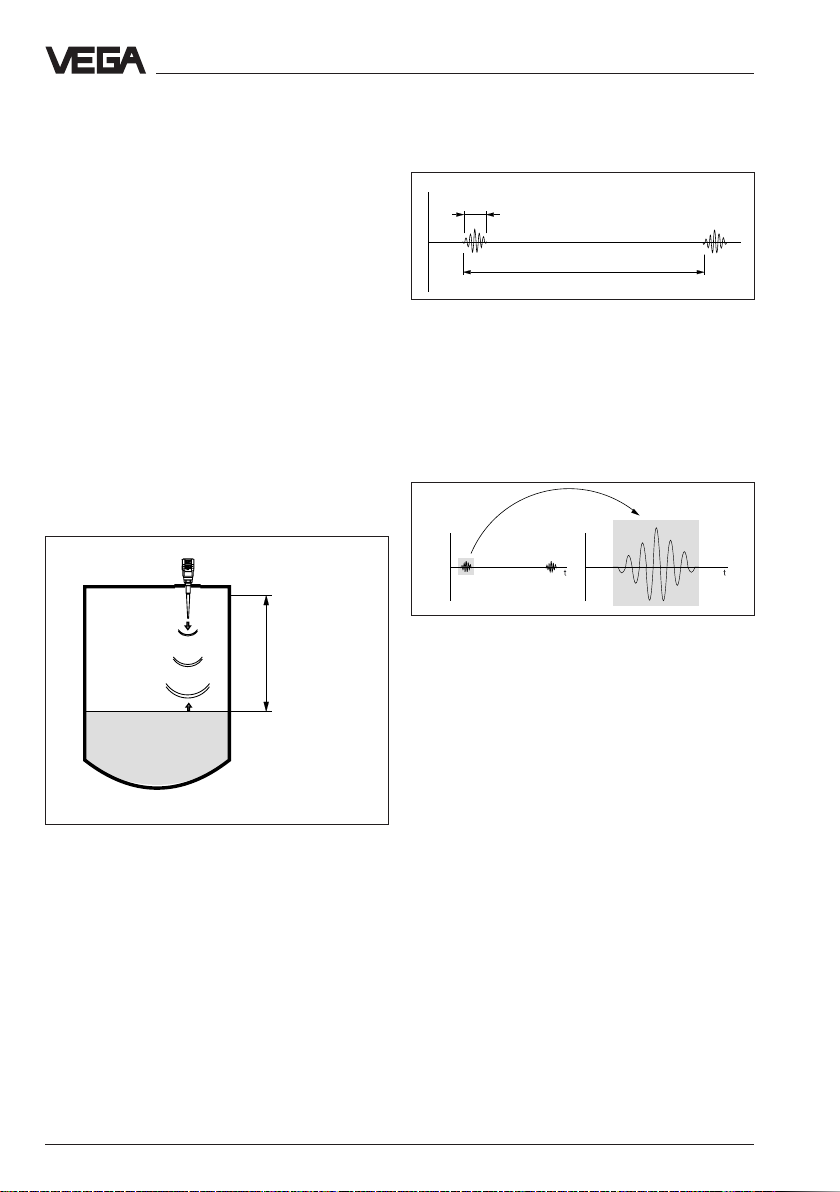

1 ns

278 ns

Meas. principle:

emission – reflection – receipt

Smallest 5,8 GHz radar signals are emitted

from the antenna of the radar sensor as short

pulses. The radar impulses reflected by the

sensor environment and the product are

received by the antenna as radar echoes.

The running period of the radar impulses

from emission to receipt is proportional to the

distance and hence to the level.

Meas.

distance

emission - reflection - receipt

The radar impulses are emitted by the

antenna system as impulse packets with a

pulse duration of 1 ns and pulse breaks of

278 ns; this corresponds to a pulse package

frequency of 3,6 MHz. In the impulse breaks

the antenna system operates as receiver. Signal running periods of less than one millionth

of a second must be processed and the

echo pictures must be evaluated in a fraction

of a second.

Pulse sequence

VEGAPULS radar sensors can reach this in a

special procedure of time transformation

which spreads more than 3,6 million echo

pictures per second in a slow-motion picture,

then freezes and processes them.

Time transformation

Hence it is possible for the VEGAPULS 50

radar sensors to process the slow-motion

pictures of the sensor environment precisely

and in detail in cycles of 0,5 to 1 second

without using very time consuming frequency

analysis (e.g. FMCW) necessary for other

radar principles.

Virtually all products can be measured

Radar signals physically react similar to

visible light. According to the quantum theory

they penetrate empty space. Hence they are

not bound such as e.g. sound to conductive

product (air) and spread like light with light

velocity.

4 VEGAPULS 51 V … 54 V

Page 5

Product description - Function

Radar signals react to two electrical primary

quantities:

- the electrical conductivity of a substance.

- the dielectric constant of a substance.

All products which are electrically conductive

reflect radar signals very well. Even only

slightly conductive products ensure a

sufficient reflection for a reliable

measurement.

All products with a dielectric constant figure ε

of more than 2,0 reflect radar impulses

sufficiently (note: air has a dielectric constand

figure ε

The signal reflection increases with the

of 1).

r

conductivity or with the dielectric constant

figure of the product. Hence virtually all

products can be measured.

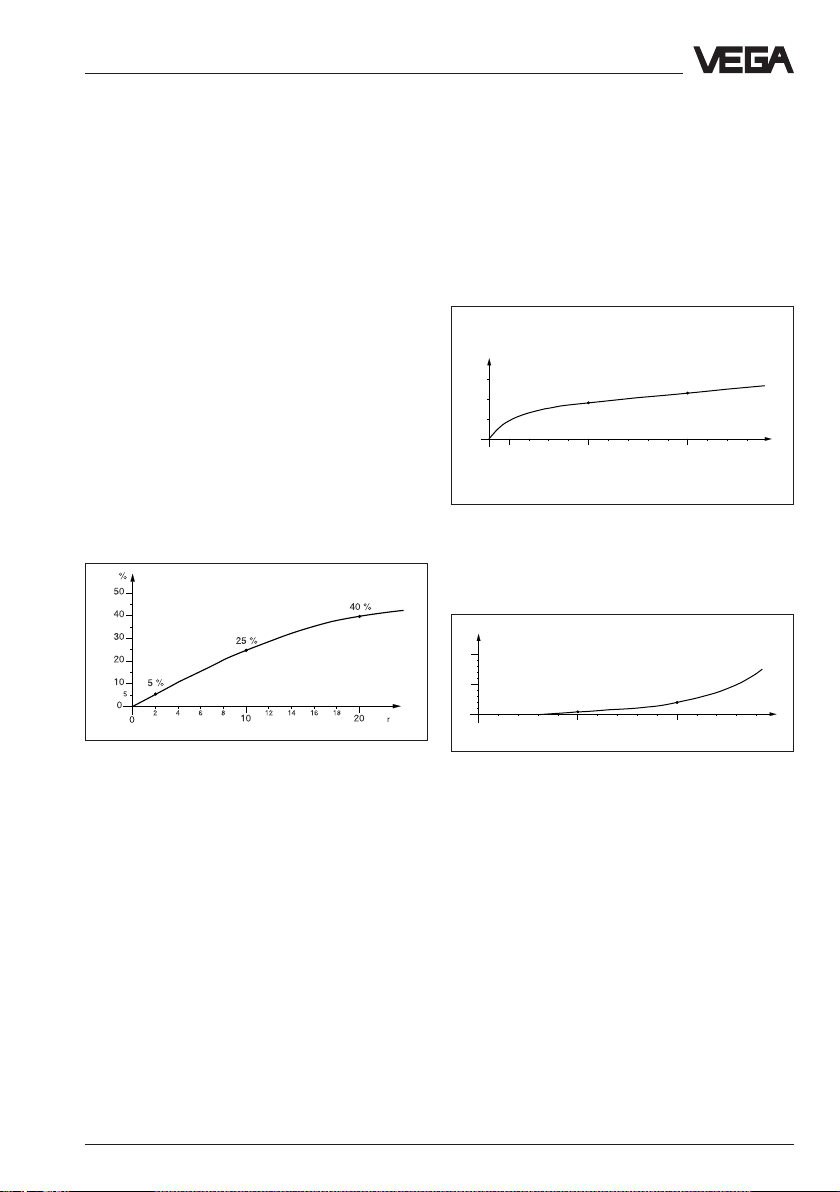

ε

Reflected radar power dependent on the

dielectric constant figure of the measured

product

Continuous and reliable

Unaffected by temperature, pressure and

individual gas atmospheres, VEGAPULS

radar sensors are used for quick and reliable

continuous level measurement of various

products.

%

0,03

r

0,02

0,01

0

100 500 1000 1300 °C

0

0,018 %

Temperature influence: Temperatur error

absolutely zero (e.g. at 500°C 0,018 %)

%

10

5

0

10

0

0,8 %

20 30 40 60

50

Pressure influence: Error with pressure

increase very low (e.g. at 50 bar 0,8 %)

0,023 %

3 %

70 80 90 110 120 130 140

100

bar

Due to the standard flanges from DN 50 to

DN 250, ANSI 2" to ANSI 10" or G 11/2 A and

11/2" NPT the sensor antenna systems are

adapted to the various measured products

and measurement environments.

VEGAPULS 50 enable level measurement

with radar sensors on systems where radar

sensors had not been used before due to

price reasons.

High-quality materials withstand also

extremely chemical and physical conditions.

The sensors deliver reliably, precisely and

longterm stable, reproducible analogue or digital level signals.

VEGAPULS 51 V … 54 V 5

Page 6

Product description

1.2 Application features

Applications

• Level measurement of liquids, limited use in

solids

• Measurement also in vacuum

• All slightly conductive materials and all

substances with a dielectric constant figure

εr > 2,0 can be measured

• Measuring ranges 0 … 20 m

Two-wire technology

• Supply and output signal on one two-wire

line

• Output signal and signal processing

completely digital, hence maximum

accuracy

Rugged and abrasionproof

• Non-contact

• High resistance materials: PTFE, 1.4571

Exact and reliable

• Resolution 1 mm

• Unaffected by noise, vapours, dusts, gas

compositions and inert gas layering

• Unaffected by varying density and

temperature of the product

• Measurement of pressures up to 40 bar

and product temperatures up to 200°C

Communicative

• Individually connectable, with 15 sensors

on one two-wire line (digital output signal)

• Integral indication of measured values

• Optionally indication separated from the

sensor

• Connection to all BUS-systems: Interbus S,

Modbus, Siemens 3964R, Profibus DP,

Profibus FMS, ASCII

• Adjustment from the DCS-stage

Ex-approvals

• CENELEC, FM, CSA, ABS, LRS, GL, LR

1.3 Adjustment

Each measuring distance is different, hence

each radar sensor must be given some

basic information on the application and the

environment.

The adjustment and parameter adjustment of

the radar sensors is hence carried out with

- the PC and adjustment program VVO

- the detachable adjustment module

MINICOM

- the signal conditioning instrument

VEGAMET

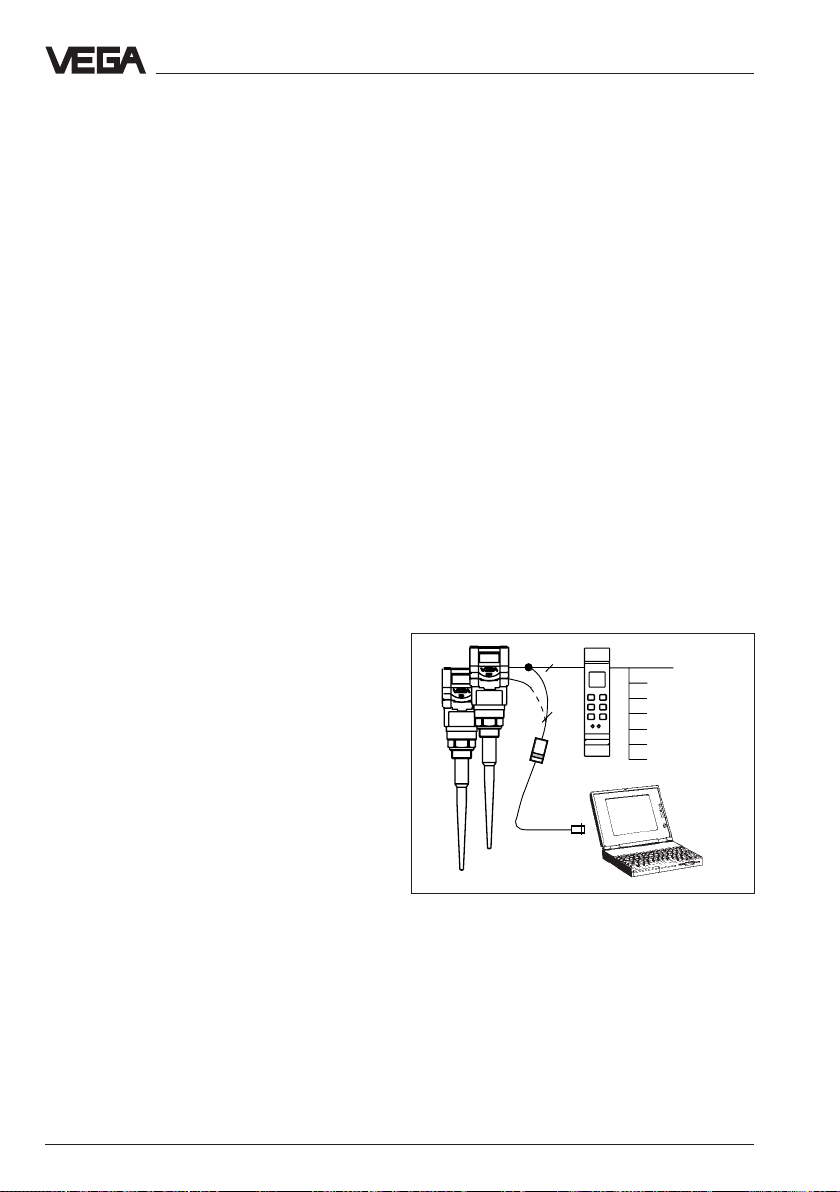

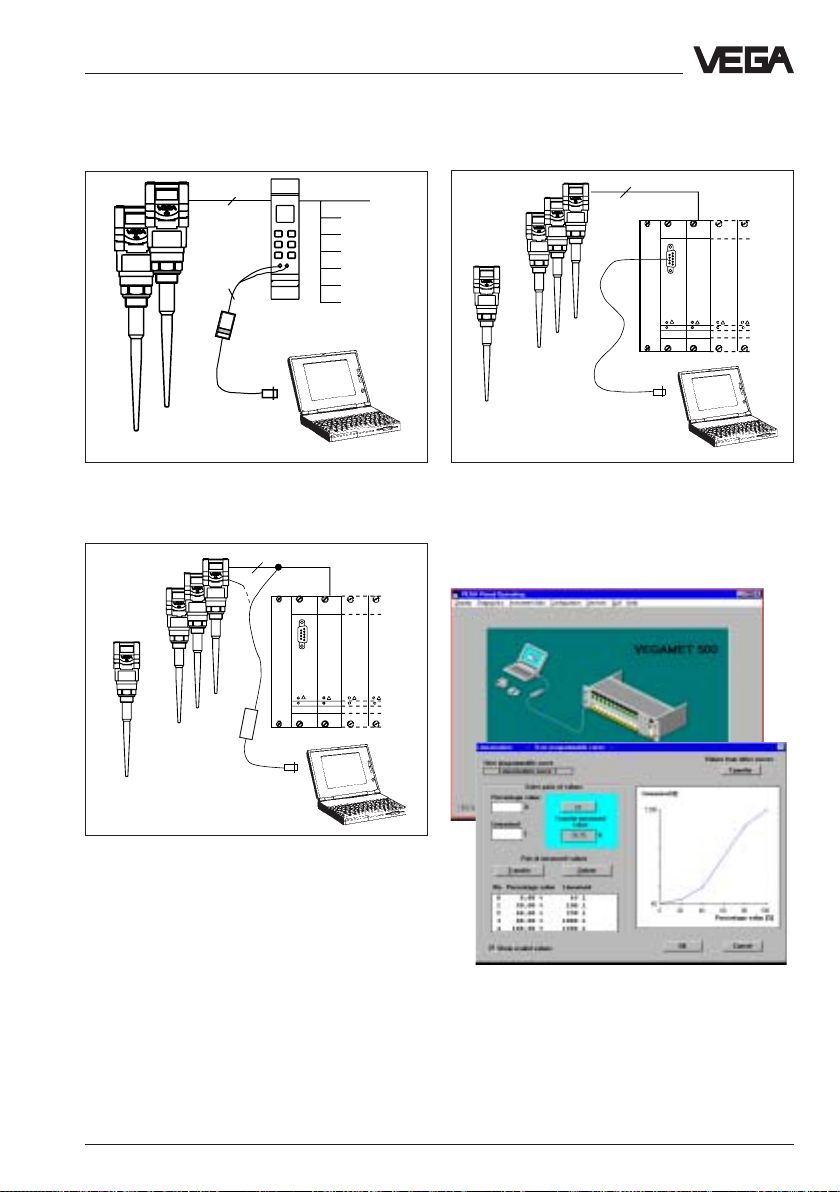

Adjustment with PC

The set-up and adjustment of the radar

sensors is generally made on PC with

adjustment program VVO (VEGA Visual Ope-

rating) under Windows®.

The program leads quickly through the

adjustment and parameter adjustment via

pictures, graphics and process

visualisations.

2

2

Adjustment with the PC on the digital signal

and supply line between the sensors and the

signal conditioning instrument VEGAMET

The PC can be connected to any individual

position of the system or the signal line. It is

hence connected with the two-wire PCinterface converter VEGACONNECT 2 to the

sensor, to the signal line or to the signal

conditioning instrument.

6 VEGAPULS 51 V … 54 V

Page 7

Product description - Adjustment

2

2

One or two sensors on the signal

conditioning instrument; adjustment with the

PC on the signal conditioning instrument

2

……

VEGALOG

VEGALOG

571 CPU

571 EA

1 … 15

2

……

VEGALOG

VEGALOG

571 CPU

571 EA

1 … 15

Adjustment with the PC and the standard

cable RS 232 directly on the processing

system

If required the adjustments can then be

quickly transferred to other sensors.

1…15 sensors on the processing system

VEGALOG. Adjustment with the PC on the digital signal and supply line to the processing

system or directly on the sensor

With the standard cable (RS232) the PC is

directly connected to the processing system

VEGALOG.

The adjustment and parameter adjustment

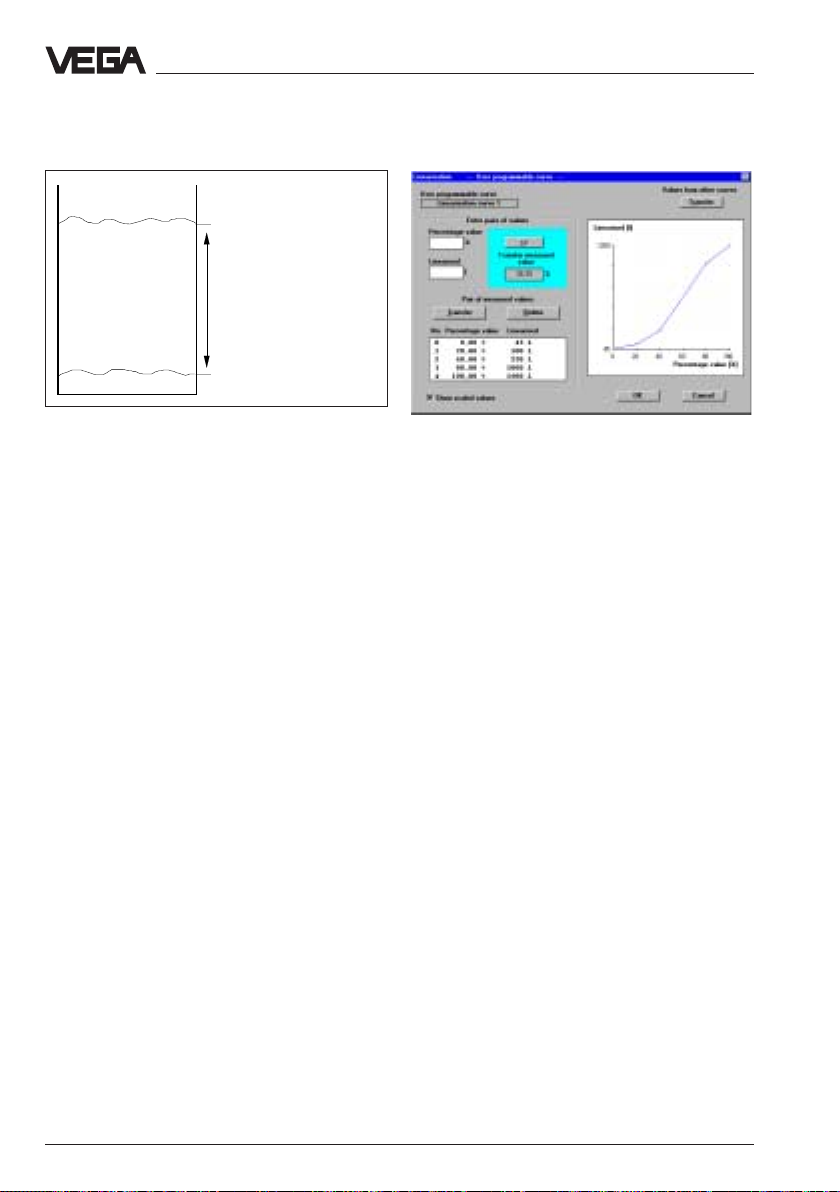

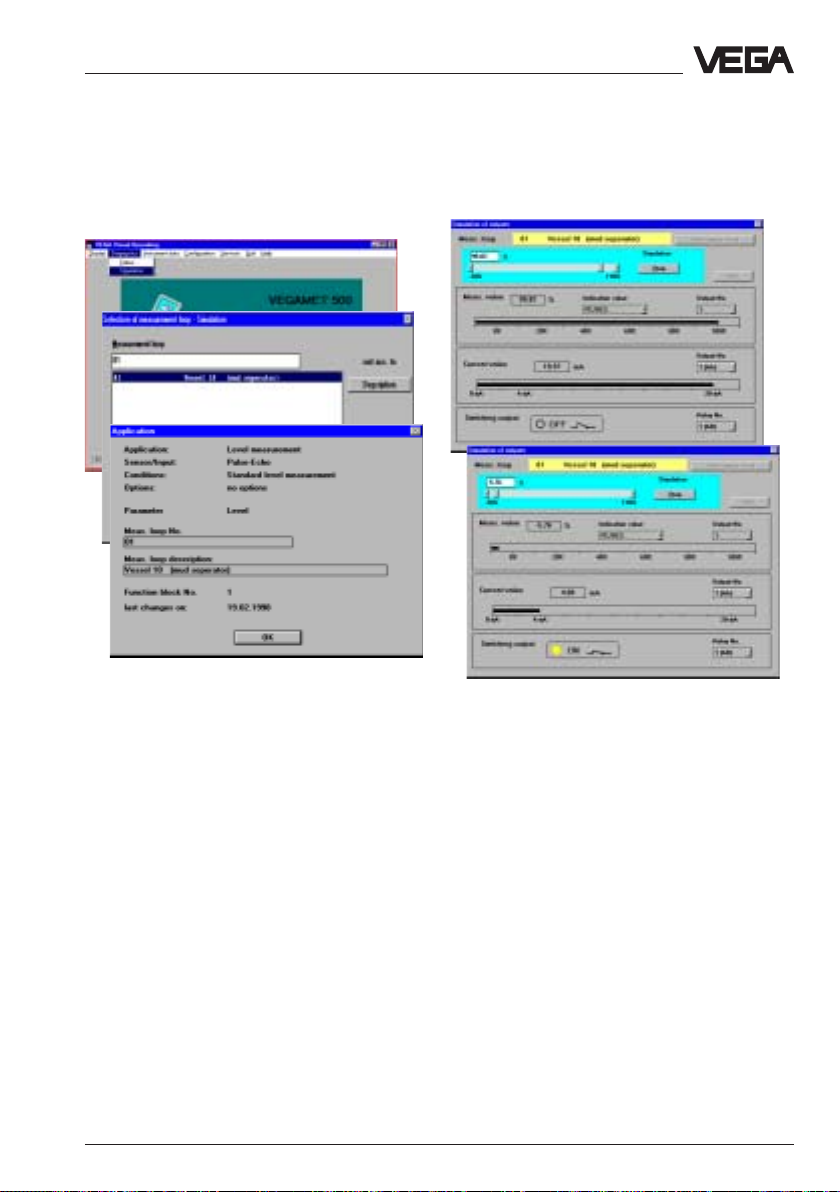

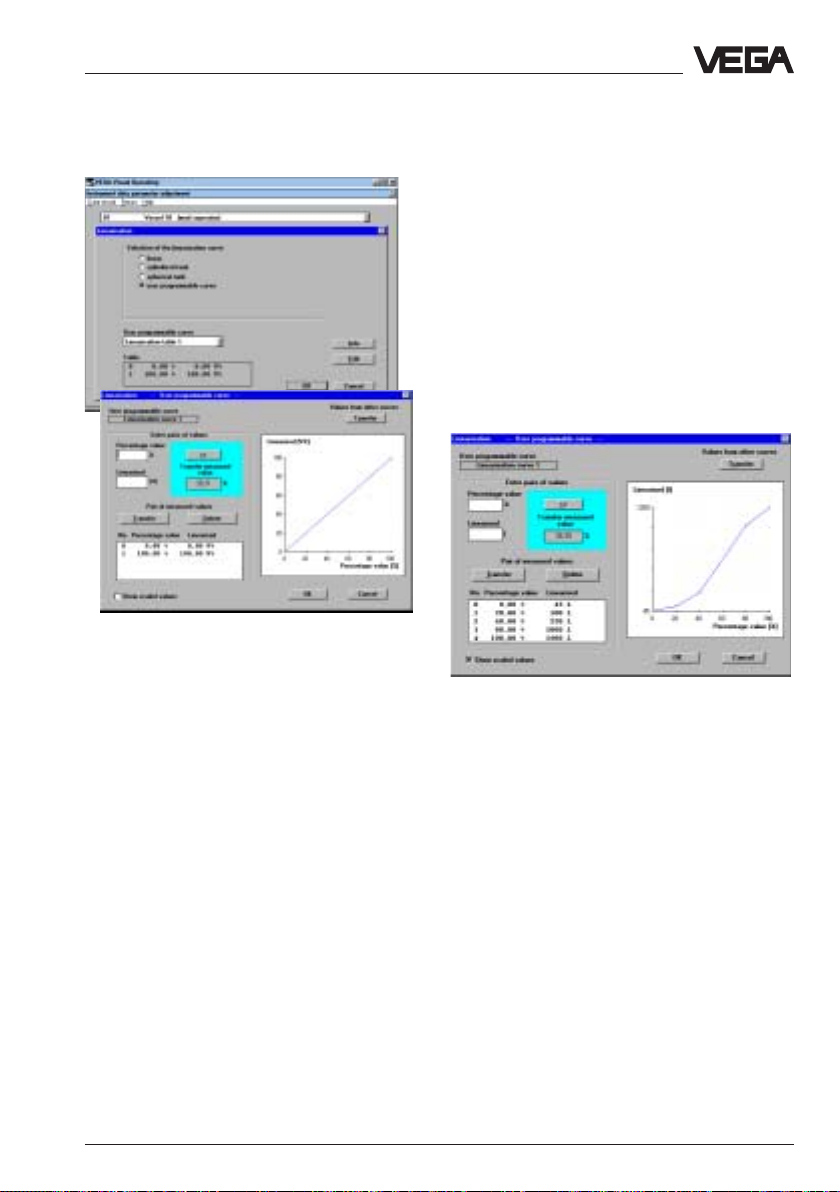

Automatic sensor recognition (top figure) and

visualized input, e.g. of a vessel linearisation

curve (bottom figure)

data can be at any time saved on the PC and

protected by passwords by means of the

adjustment software.

VEGAPULS 51 V … 54 V 7

Page 8

ESC

OK

-

+

1

2

on

100

%

CONNECT

514 Ex

Product description - Adjustment

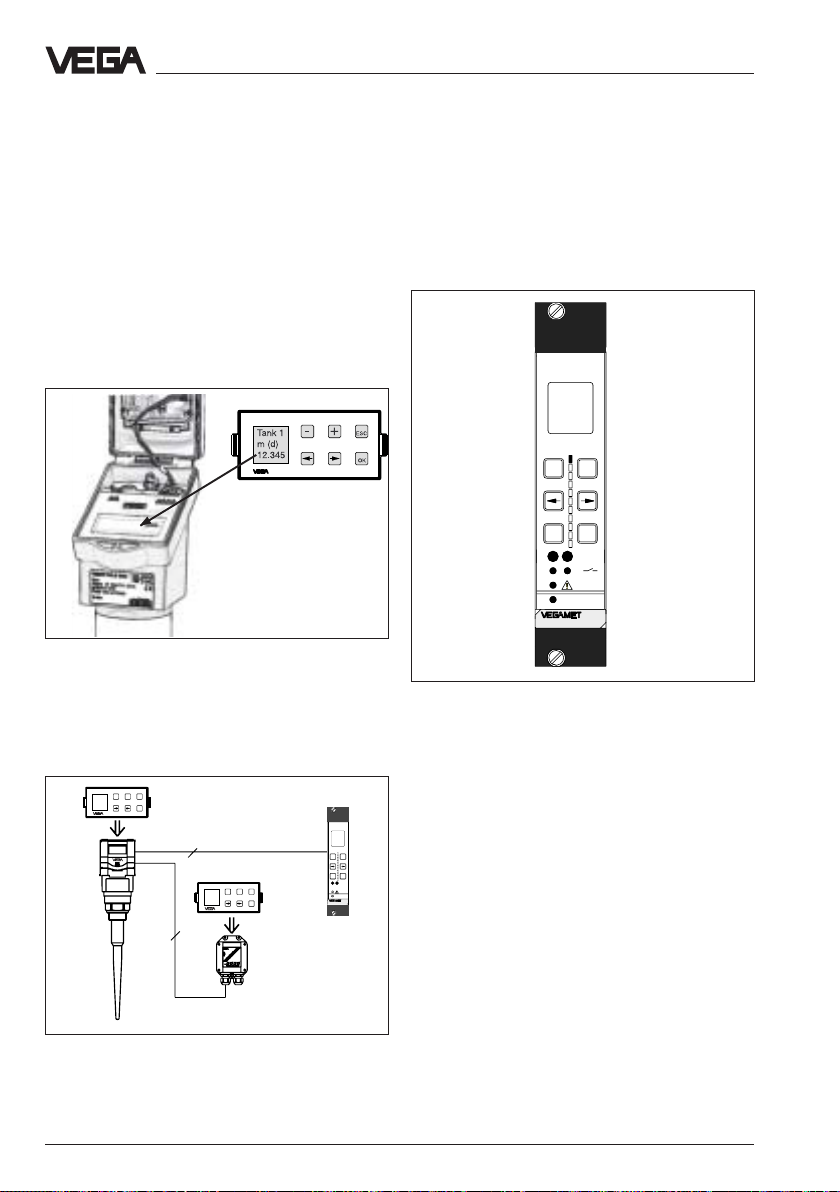

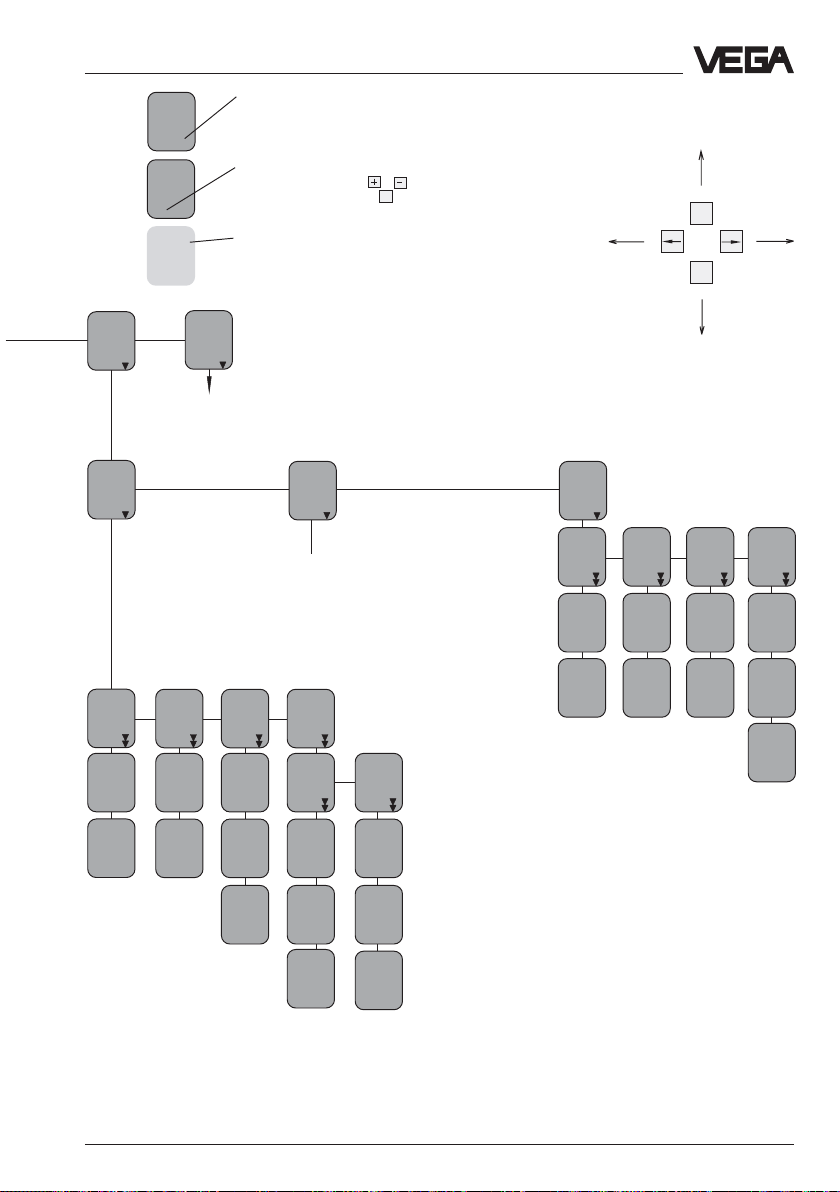

Adjustment with adjustment module

MINICOM

The adjustment with the small

(3,2 cm x 6,7 cm) 6-key adjustment module

with display can be compared with the

adjustment with the signal conditioning

instrument. You can carry out some sensor

relevant adjustments directly at the meas.

point which can naturally also be carried out

with the signal conditioning instrument.

Detachable adjustment module MINICOM

The adjustment module can be plugged into

or removed from the radar sensor or the

optionally external indicating instrument.

ESC

+

Tank 1

-

m (d)

12.345

OK

2

ESC

+

Tank 1

-

m (d)

12.345

OK

4

Adjustment with signal conditioning

instrument VEGAMET

Beside the PC the radar sensors with digital

output signal can be also adjusted with the

signal conditioning instrument VEGAMET.

6-key adjustment field on the instrument front

of a signal conditioning instrument VEGAMET

For adjustment the digital signal conditioning

instruments VEGAMET 514 V and 515 V are

provided with a 6-key adjustment field with

%

100

+

-

OK

ESC

CONNECT

on

513

display. Here you can carry out the

parameter adjustment in clear text.

The adjustment structure corresponds to the

adjustment on the adjustment module

MINICOM.

Adjustment with the detachable adjustment

module on the radar sensor or on the

external indicating instrument VEGADIS 10.

8 VEGAPULS 51 V … 54 V

Page 9

Types and versions

2 Types and versions

VEGAPULS series 50 sensors are a new

developed generation of very compact, small

radar sensors. With only very narrow space

requirements they are developed for short

meas. distances (0 … 20 m) and for

standard applications such as storage tanks

and buffer tanks.

Due to the small housing dimensions and

process connections, the compact sensors

monitor your levels very price favourably.

With the integral indication and the many

features of the "big brothers" of VEGAPULS

series 64 and especially of VEGAPULS

series 81, they open the advantages of a

radar level measurement for applications in

which the special adavantages of radar were

not possible, due to price reasons.

VEGAPULS 50 radar sensors dominate the

two-wire technology perfectly. They are the

first radar sensors transmitting supply

voltage and output signal via one two-wire

line. As output or meas. signal they provide a

digital output signal.

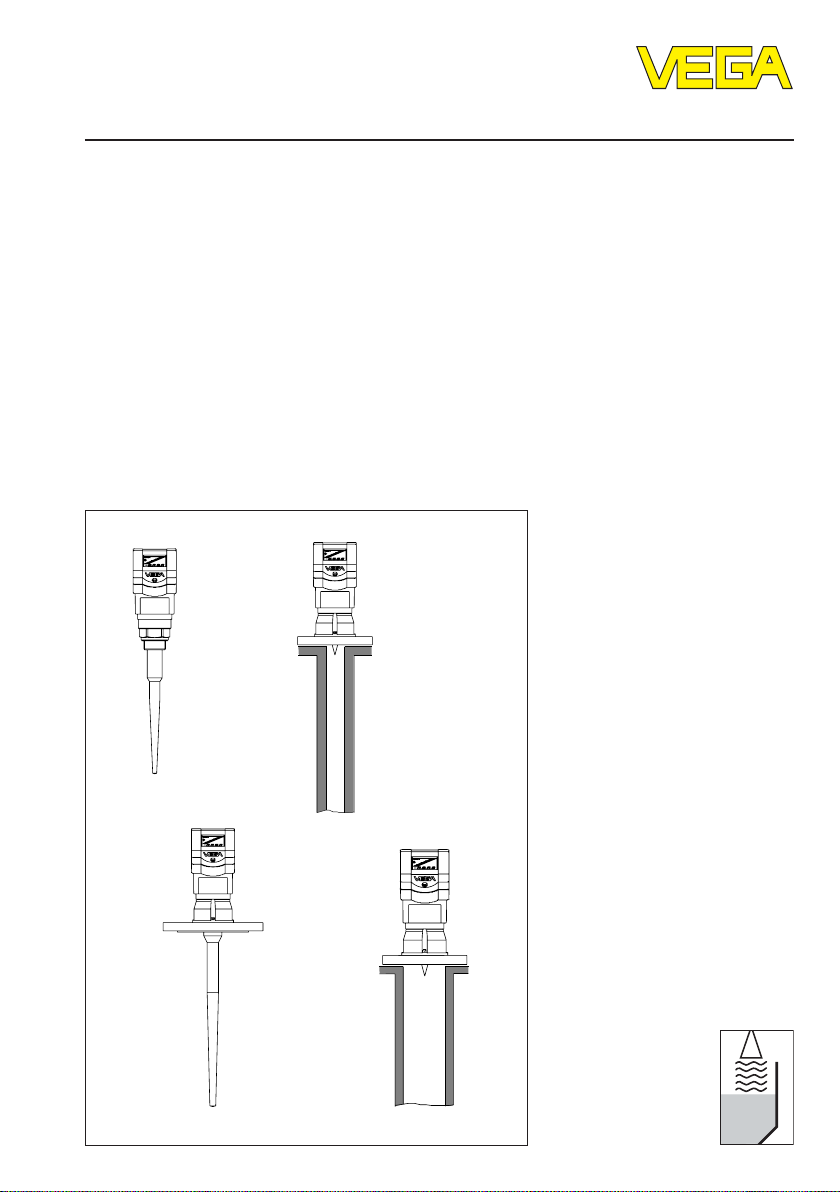

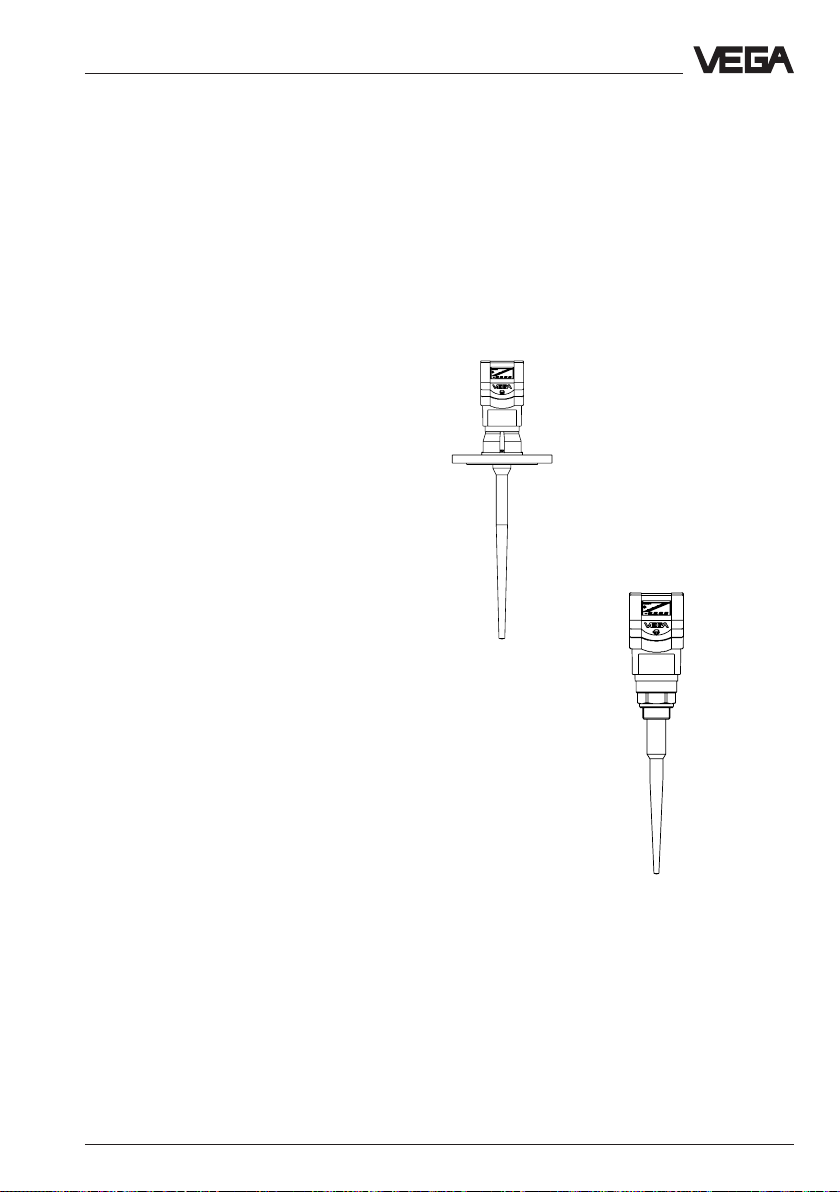

2.1 Type survey

The antenna is the eye of the radar sensor.

Four antenna systems are available for different applications and process requirements.

Each system differs in the physical features.

Rod antenna

Rod antennas with high

chemical resistance require

smallest flange dimensions

(DN 50). The antenna rod and

the wetted flange parts are

made of PTFE, PP or PPS so

that the rod antenna can be

easily cleaned and is

insensitive to condensation.

The rod antenna is suitable for

pressures up to 16 bar and

temperatures up to 150°C.

VEGAPULS 53

VEGAPULS 51/52

VEGAPULS 51 V … 54 V 9

Page 10

Types and versions - Survey

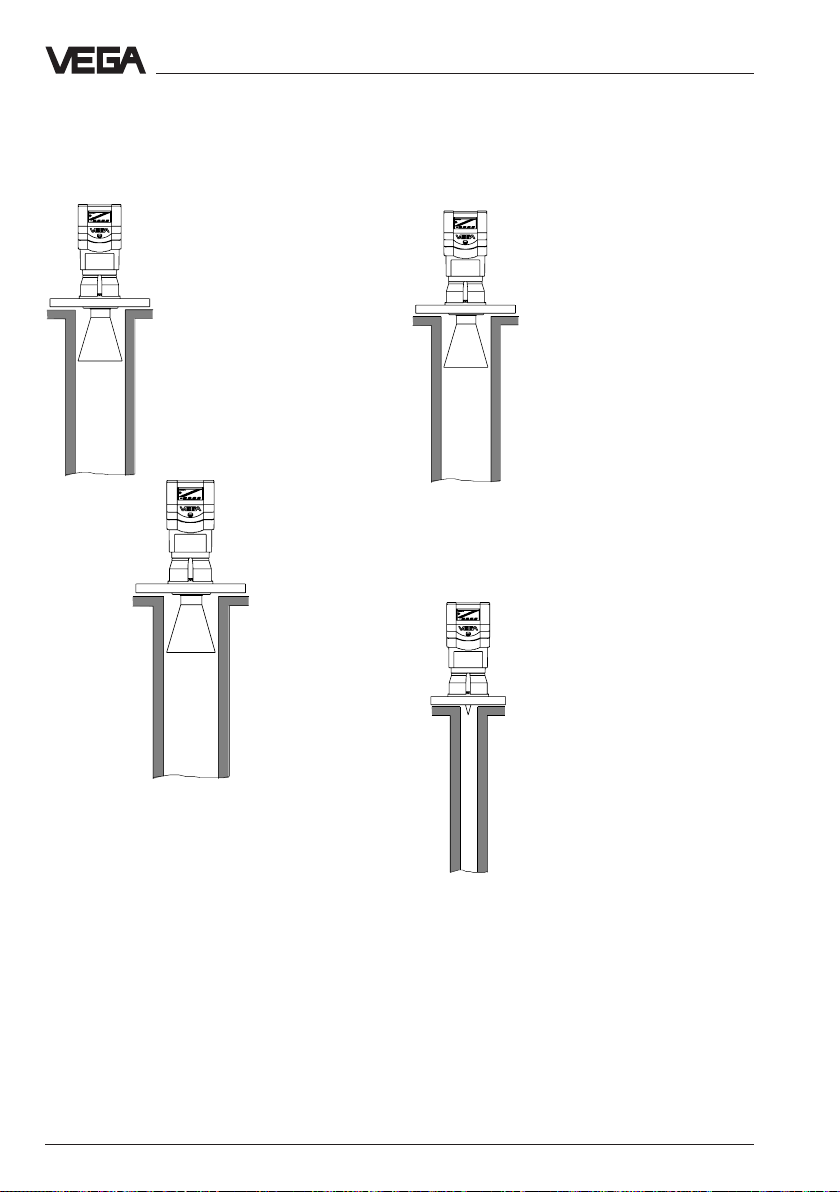

Horn antenna

VEGAPULS 54

Horn antennas are best

suited for most applications.

They focus the radar signals

very well. Manufactured of

1.4571 (stst) they are very

rugged and physically as well

as chemically resistant. They

are suitable for pressures up

to 40 bar and for product

temperatures up to 150°C.

VEGAPULS 54

(pipe antenna/

standpipe)

Pipe antenna

VEGAPULS 54

(pipe antenna/

standpipe)

Pipe antennas on surge or

bypass pipes only form a

complete antenna system in

conjunction with a measuring

pipe which can also be bent.

Pipe antennas are especially

suitable for products with

heavy product movements or

products with low dielectric

constant figure.

The antenna can be with or

without horn. Versions with

horn characterize by very

good antenna gain. A very

good reliability can be

achieved even in case of

products with very bad

reflection features.

The meas. pipe means a

conductor for radar signals.

The running period of the

radar signals changes in the

pipe and depends on the

pipe diameter. The pipe inner

diameter must be

programmed in the

electronics so that the running

period can be compensated.

VEGAPULS 54 without horn

(pipe antenna/standpipe)

10 VEGAPULS 51 V … 54 V

Page 11

Types and versions - Survey

Survey of features

• Application preferably of liquids in storage

tanks or vessels

• Meas. range 0 …20 m

• Ex-approved in IEC or ATEX

classification EEx ia [ia] IIC T 6

• Integral measured value indication

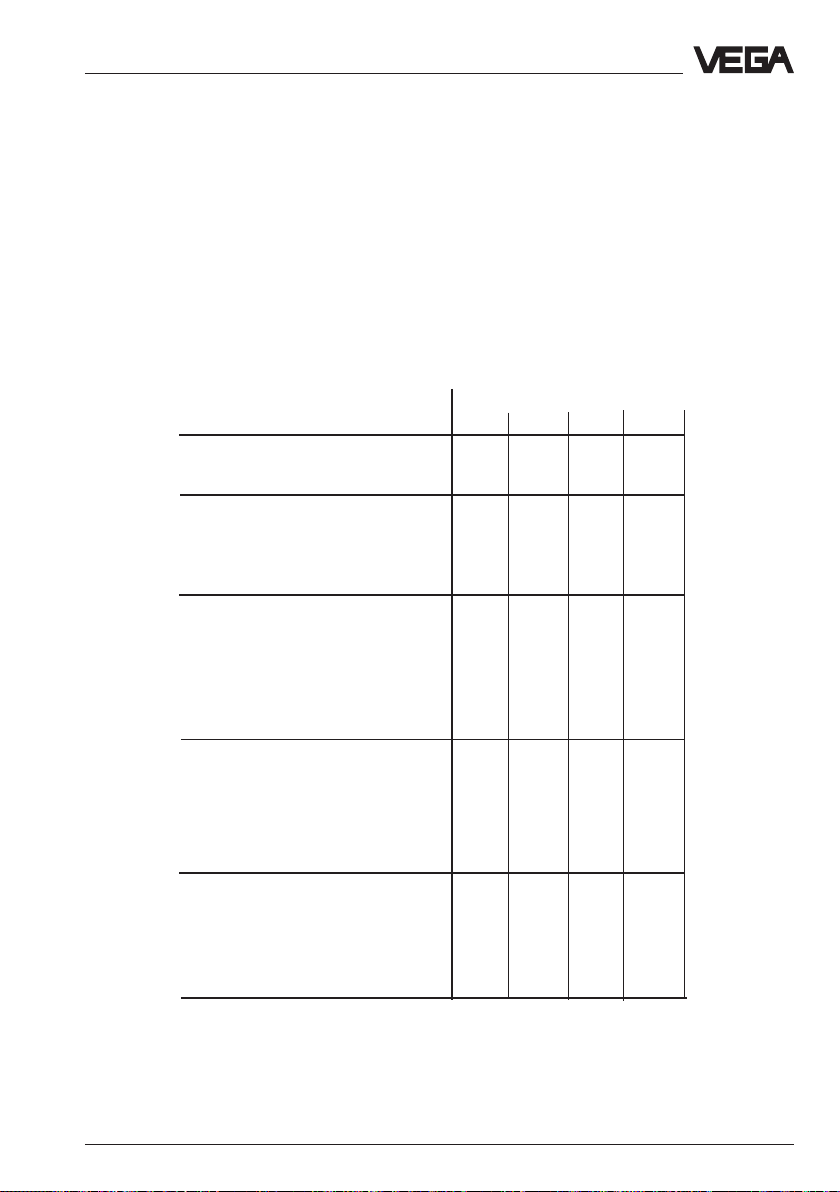

Survey

51 V 52 V 53 V 54 V

VEGAPULS …

Signal output

digital meas. signal • • • •

Voltage supply

– two-wire technology (voltage

supply and signal output

via one two-wire line) • • • •

Process connection

– G11/2 A; 11/2" NPT • • – –

– DN 50; ANSI 2" – – • •

– DN 80; ANSI 3" – – • •

– DN 100; ANSI 4" – – • •

– DN 150; ANSI 6" – – – •

Adjustment

– with PC • • • •

– with adjustment module in sensor • • • •

– with adjustment module in external

indicating instrument • • • •

– with signal conditioning instrument • • • •

Antenna material

– PP • – – –

– PPS/StSt • – – –

– PTFE/StSt – • – –

– PTFE – – • –

– StSt – – – •

VEGAPULS 51 V … 54 V 11

Page 12

Types and versions - Survey

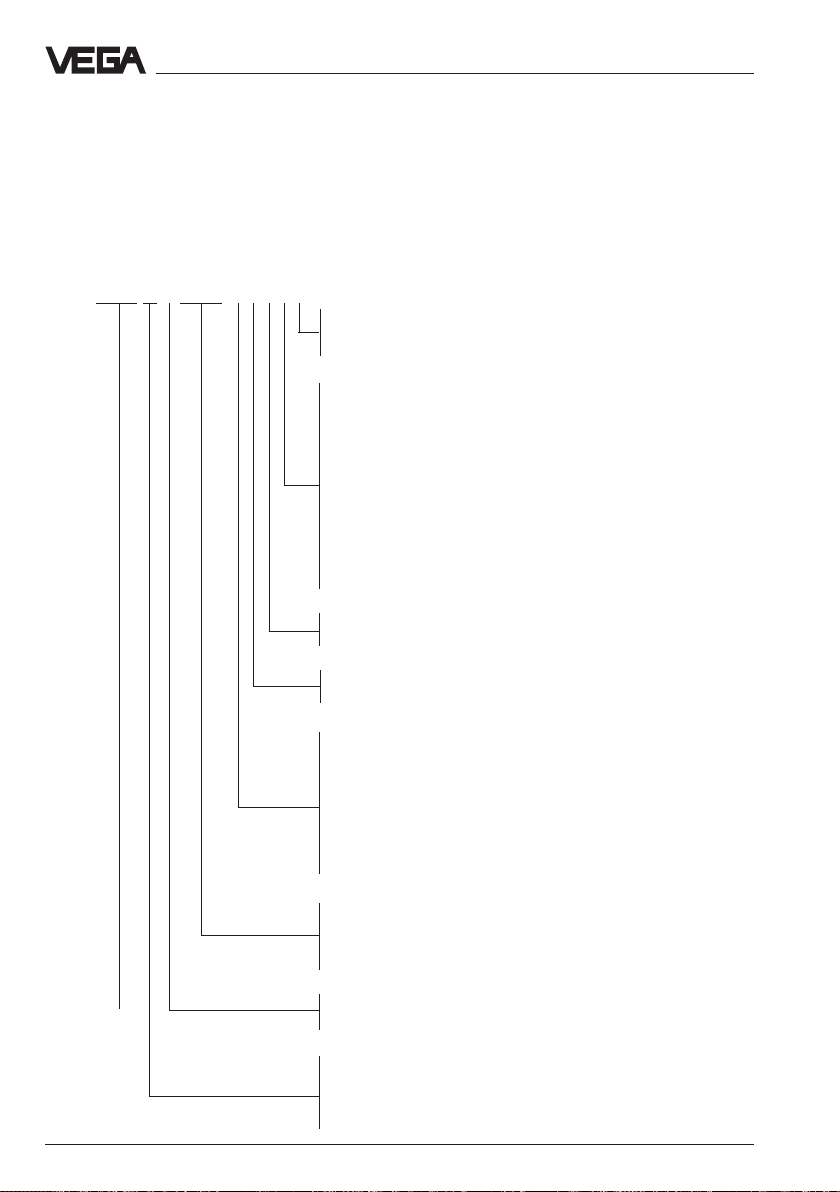

Type code

The second figure of the type designation,

e.g. VEGAPULS 5[1]… differentiates the

instruments acc. to process connection and

antenna material.

VEGAPULS 51 V EXXX X X X X X

1 for measurement in standpipe (d = 50 mm)

3 for socket lengths up to 100 mm

9 for socket lengths up to 250 mm

G - Process connection G 11/2 A

N - Process connection 11/2 NPT

K - Process connection DN 50 PN 16

L - Process connection DN 80 PN 16

E - Process connection DN 100 PN 16

F - Process connection DN 150 PN 16

S - Process connection ANSI 2" 150 PSI

W - Process connection ANSI 3" 150 PSI

P - Process connection ANSI 4" 150 PSI

V - Process connection ANSI 6" 150 PSI

Y - other process connections

X - without indication

A - with integral indication

X - without MINICOM adjustment module

B - with MINICOM adjustment module (pluggable)

A - 20 … 72 V DC; 20 … 250 V AC; 4 … 20 mA

B - 20 … 72 V DC; 20 … 250 V AC; 4 … 20 mA; HART

C - Two-wire (loop powered); 4 … 20 mA

D - Two-wire (loop powered); 4 … 20 mA; HART

E - Supply via signal conditioning instrument

P - 90 … 250 V AC (only in USA)

N - 20 … 36 V DC, 24 V AC (only in USA)

Z - Supply via signal conditioning instrument (only in USA)

The letter e.g. VEGAPULS 51[V]

characterizes the output signal:

V stands for a digitial output signal (VBUS), K

stands for an analogue 4 … 20 mA output

signal (compact instrument).

®

®

.X - FTZ approval (BRD)

EX.X - Ex approved CENELEC EEx ia IIC T6, FTZ

.U - FCC approval (US)

EX.U - FM, CLASS 1, DIV 1; FCC (US)

K - Analogue 0 … 20 mA output signal

PULS V - Digital output signal (two-wire technology)

for radar

Type 51: 1 1/2 PP or PPS/StSt rod antenna

Type 52: 1 1/2 PTFE or PTFE/StSt rod antenna

Type 53: DN 50 … DN 150 PTFE rod antenna

Type 54: DN 50 … DN 100 for mounting on standpipe

12 VEGAPULS 51 V … 54 V

Page 13

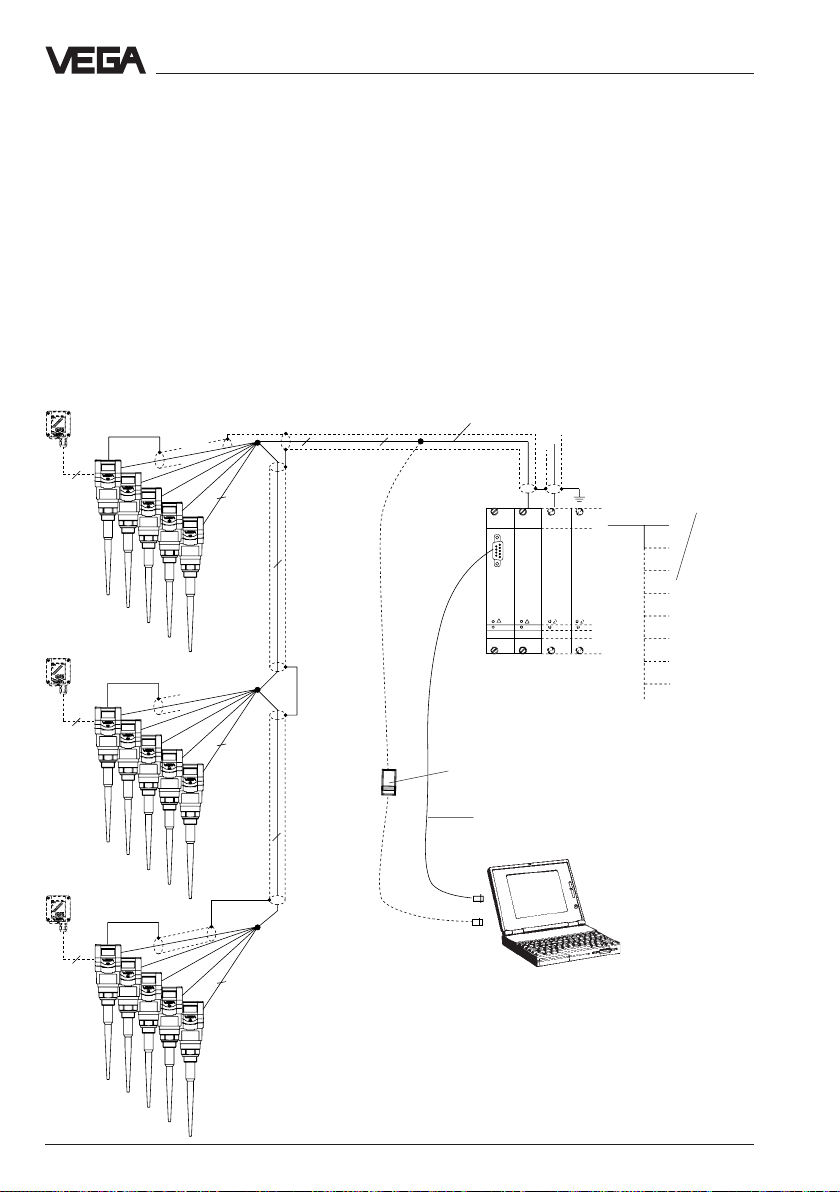

Types and versions - Configuration of meas. systems

2.2 Configuration of measuring systems

Which radar sensor you use depends on

your process requirements and installation

conditions as well as on the requirements of

your control or processing system.

On sensors with digital output signal like

VEGAPULS 51 V … 54 V a meas. system

consists of a sensor and a processing unit.

The processing unit (the signal conditioning

instrument VEGAMET or the processing

system VEGALOG) evaluates the level proportional digital meas. signal in a number of

routines and provides then the levels as

individual current, voltage or switching

signals.

On the following pages you find the various

instrument configurations which are called in

the following meas. system and which are

partly shown with a signal processing.

• 2 sensors on one two-wire line

(page 14)

• 2 sensors in Ex on one two-wire line

(page 15)

• 15 sensors on one two-wire line

(page 16)

• 3 sensors in Ex on one two-wire line

(page 17)

Ex

Series 50 sensors require for operation in Exareas Ex-separator VEGATRENN 548 V Ex,

providing intrinsically safe Ex-circuits to the

sensors.

On the Ex-separtor VEGATRENN 548 V up to

9 sensors can be connected in groups with

three sensors each (see page 17).

Note to page 15…17:

2)

Sensor lines should be looped in screened cables.

It is recommended to earth the cable screens on

both ends. However it must be noted that no earth

compensation currents flow over the screen. Earth

compensation currents are avoided in case of

earthing on both ends by connecting the cable

screen on one earth side (e.g. in the switching

cabinet) via a capacitor (e.g. 1 µF; 100 V) with the

earth potential.

Sensor lines leading to the same separator card,

can be looped together in one screened multiple

wire cable.

Sensor lines leading to other separator cards must

be looped in separate screened cables.

VEGAPULS 51 V … 54 V 13

Page 14

Types and versions - Configuration of meas. systems

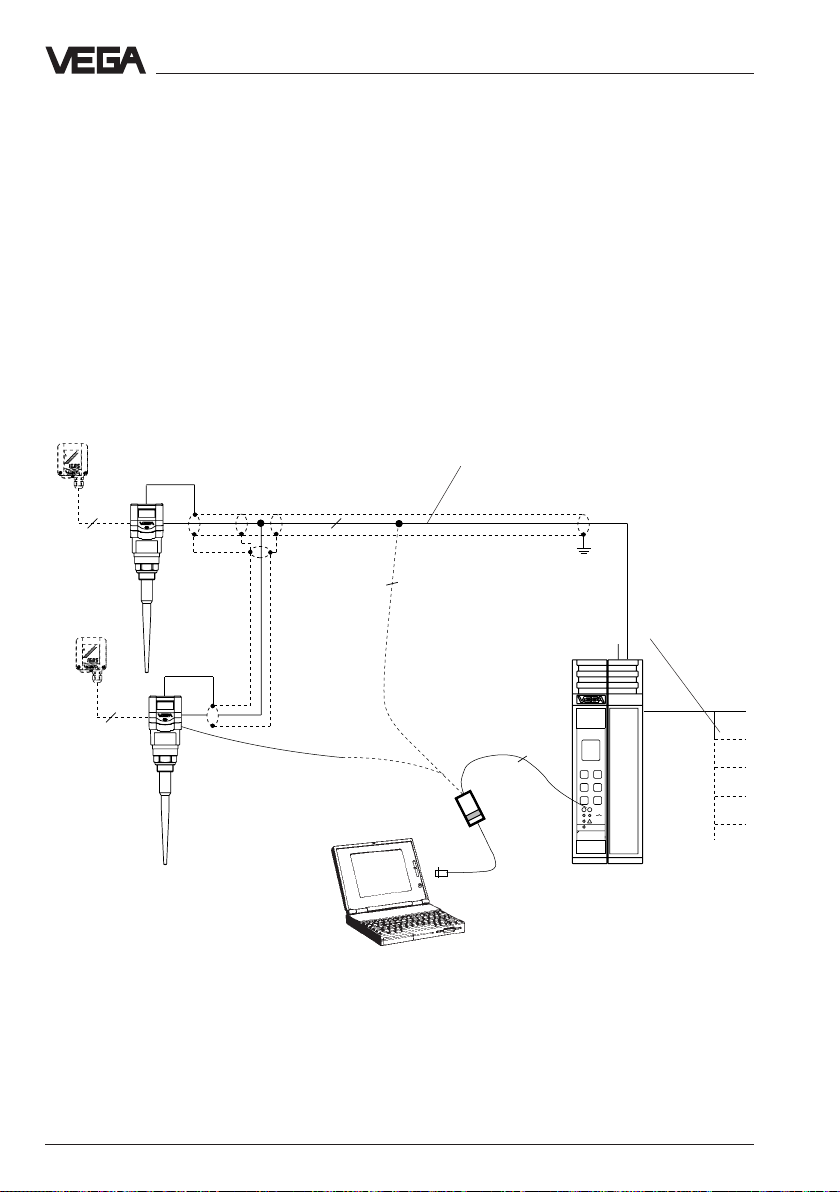

1 … 2 sensors on the signal conditioning instrument VEGAMET 515 V

• Two-wire technology, supply from the signal conditioning instrument.

Output signals and supply voltage via a two-wire line.

• Digital output signal, two sensors on one line.

• Measured value indication in the sensor and in the signal conditioning

instrument.

• Optionally external indicating instrument

(can be mounted up to 25 m separated from the sensor in Ex-area).

• Adjustment with PC, the signal conditioning instrument or the

adjustment module (can be plugged in the sensor or in the external

indicating instrument)

• Max. resistance of the signal line 15 Ω per wire or 1000 m cable length

VEGADIS 50

Screened line in case of

electromagnetic interferences

1)

4

VEGADIS

10/50

2

2

Current outputs

Voltage outputs

Relay

Digital wiring

Fault signals

4

2

VEGACONNECT 2

VEGAMET

515V

Signal conditioning

instrument VEGAMET 515 V

in housing type 505

1) Sensor lines should be looped in screened

cables. It is recommended to earth the cable

Processings see product information "Signal

conditioning instruments series 500"

screens on both ends. However it must be

noted that no earth compensation currents

flow over the screen. Earth compensation

currents are avoided in case of earthing on

both ends by connecting the cable screen on

one earth side (e.g. in the switching cabinet)

via a capacitor (e.g. 1 µF; 100 V) with the

earth potential.

14 VEGAPULS 51 V … 54 V

Page 15

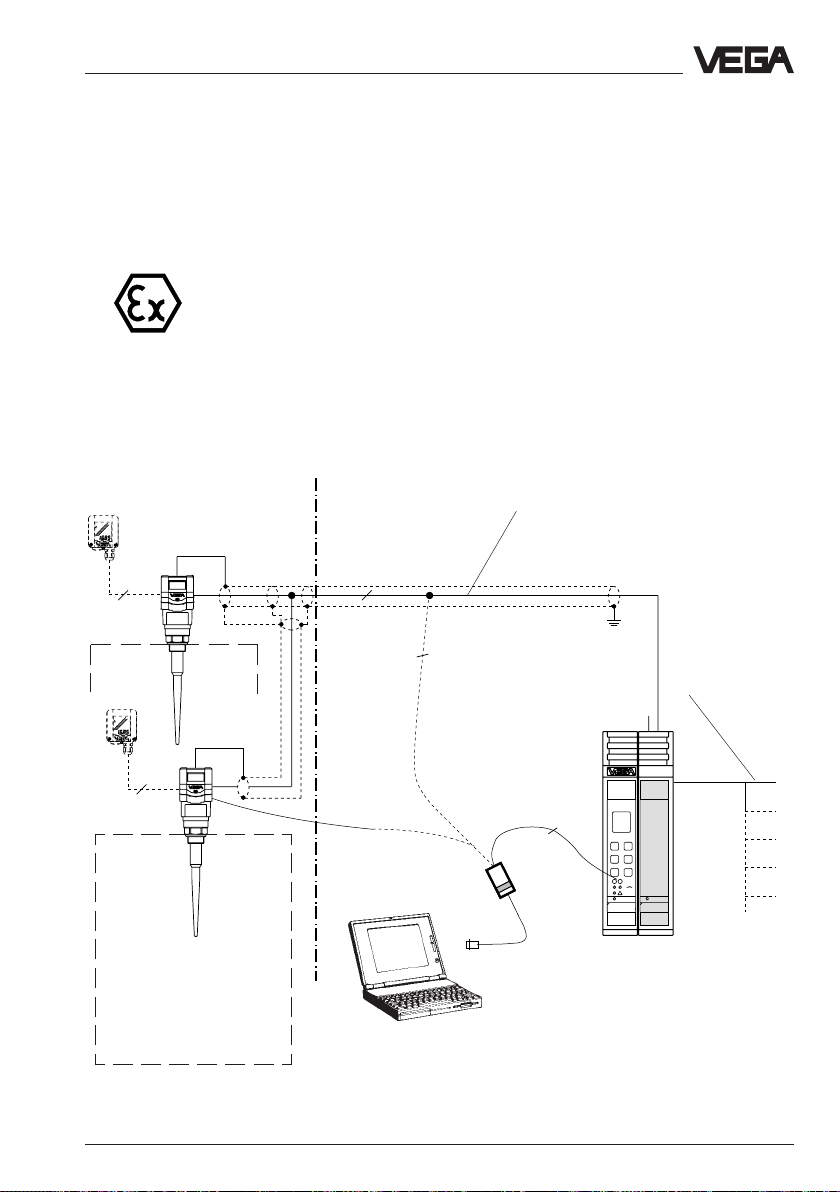

Types and versions - Configuration of meas. systems

1 … 2 sensors in Ex-area via separator

VEGA TRENN 548 V Ex on signal conditioning instrument VEGAMET 515 V

• Two-wire technology, supply from separator.

Output signals and voltage supply via one two-wire line

• Ex-area acc. to CENELEC and ATEX

• Digital output signal, two sensors on one line

• Meas. value indication in the sensor or in the signal conditioning

instrument

• Optionally external indicating instrument

(can be mounted up to 25 m separated from the sensor in Ex-area)

• Adjustment with PC, signal conditioning instrument or adjustment

module (can be plugged in the sensor or in the external indicating

instrument)

• Max. resistance of the signal line 15 Ω per wire or 1000 m cable length

(see also approval certificates of the separators)

VEGADIS 50

4

Ex-area

Zone 1

or

Zone 0

4

Zone 1 or Zone 0

Not Ex-area

2

2

VEGACONNECT 2

Screened line in case of electromagnetic

interferences

2) see note on page 13

Current outputs

Voltage outputs

Relays

Digital wiring

Fault signals

2

VEGAMET

VEGATRENN

515V

547

Signal conditioning instrument VEGAMET

515 V with Ex-separator VEGATRENN

548 V Ex in housing type 506

Processings see product information "Signal

conditioning instruments series 500"

VEGAPULS 51 V … 54 V 15

Page 16

Types and versions - Configuration of meas. systems

15 sensors via one two-wire line on the processing system VEGALOG 571

• Two-wire technology, voltage supply and digital output signals via one

two-wire line from the processing system VEGALOG 571.

• Up to 15 sensors on one two-wire line

• Meas. value indication integrated in the sensor

• Optionally external indicating instrument (can be mounted up to 25 m

separated from the sensor in Ex-area).

• Adjustment with PC or adjustment module (pluggable in sensor or in

external indicating instrument)

• Max. resistance of the signal line 15 Ω per wire or 1000 m cable length.

4

VEGADIS 50

4

4

Screened line in case of electromagnetic

2

2

2

2

2

interferences

1)

2

CPU

VEGALOG

571 CPU

Processing system VEGALOG 571

with input cards in 19"-rack. 15

sensors on one module card and

two-wire line

VEGACONNECT 2

Interface cable

RS 232

VEGALOG

571 EV

Processings see product information

"Signal conditioning instruments

series 500"

Current outputs

Voltage outputs

Relays

Digital wiring

Fault signals

Connection to all

Bus-systems

Transistor outputs

2

1) Sensor lines should be looped in screened cables.

It is recommended to earth the cable screens on

both ends. However it must be noted that no earth

compensation currents flow over the screen. Earth

VEGAPULS 51 … 53

(15 sensors per two-wire line,

individual grouping)

compensation currents are avoided in case of

earthing on both ends by connecting the cable

screen on one earth side (e.g. in the switching

cabinet) via a capacitor (e.g. 1 µF; 100 V) with the

earth potential.

16 VEGAPULS 51 V … 54 V

Page 17

Types and versions - Configuration of meas. systems

3 sensors per two-wire line via

separator VEGATRENN 548 V Ex on the processing system VEGALOG 571

• Two-wire technology, voltage supply and digital output signals via one

two-wire line from the separator

• Three sensors on one two-wire line

• Meas. value indication integrated in the sensor

• Optionally external indicating instrument (can be mounted up to 25 m

separated from the sensor in Ex-area).

• Adjustment with PC or adjustment module (pluggable in the sensor or in

external indication instrument)

• Max. resistance of the signal line 7,5 Ω per wire or 1000 m cable length

(see approval certificates of the separators).

Ex-area Not Ex-area

VEGADIS 50

2

2

2

2

Screened line in case of electromagnetic

interferences

2

2

2

2

2

2

2

2

2

CPU

VEGALOG

VEGALOG

571 CPU

2) see note page 13

Processing system

VEGALOG 571

(19" module card)

VEGATRENN

VEGATRENN

571 EV

VEGATRENN

548

548

VEGALOG

VEGATRENN

VEGATRENN

571 EV

548

548

Current and voltage

outputs

Digital wiring

Fault signals

Transistor outputs

Relays, connection to

all Bus-systems

548

Separator VEGATRENN 548 V Ex

22

2

(max. 9 sensors per card)

Input card of VEGALOG 571

(max. 15 sensors per card)

VEGACONNECT 2

Interface cable RS 232

2

2

VEGAPULS 51 … 53

3 sensors per two-wire line,

individual grouping

VEGAPULS 51 V … 54 V 17

Page 18

Technical data

3 Technical data

3.1 Data

Power supply

Supply voltage from signal conditioning instrument VEGAMET or

Current consumption max 22,5 mA

Power consumption max. 80 mW 0,45 VA

processing system VEGALOG 571

(max. 36 V DC)

fuse 0,5 A (slow-blow)

Meas. range

1)

Standard 0 … 20 m

Measurement in standpipe

- VEGAPULS 54 on DN 50 0 … 16 m

- VEGAPULS 54 on DN 100 0 … 19 m

Output signal (see "Outputs and processings")

Digital meas. signal (VBUS)

Adjustment

- PC with adjustment software VEGA Visual Operating

- adjustment module MINICOM

Accuracy (typical values under reference conditions)

2)

Linearity error < 0,1 % (relating to max. meas. range)

Average temperature error 0,03 %/10 K

Accuracy of the 4 … 20 mA 0,25 %

output signal

Resolution 1 mm

Characateristics

Meas. frequency 5,8 GHz (USA 6,3 GHz)

Meas. intervals 1 s

Min. span between

full and empty adjustment > 10 mm (recommended >50 mm)

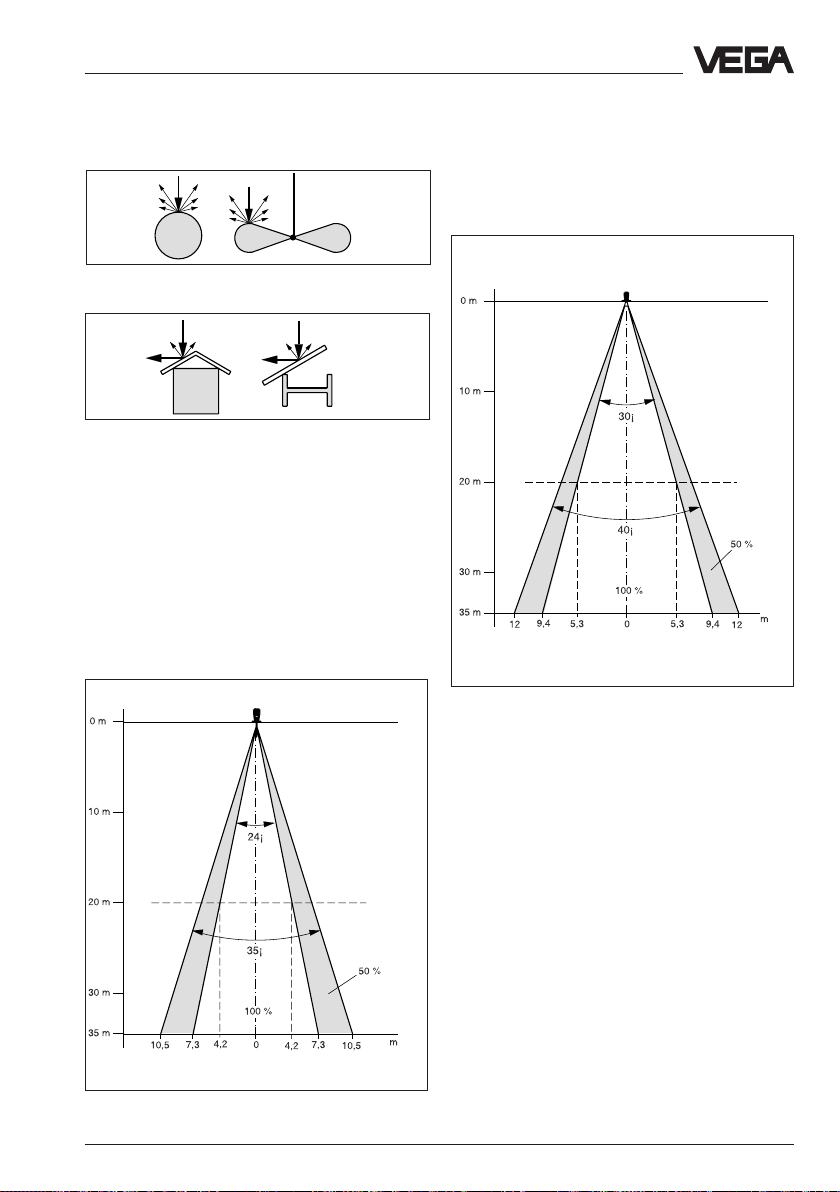

Beam angle (at –3 dB)

- VEGAPULS 51 … 53 < 24°

- VEGAPULS 54 with DN 80 38°

- VEGAPULS 54 with DN 100 30°

- VEGAPULS 54 with DN 150 20°

1)

Min. distance of the antenna to the medium 5 cm

18 VEGAPULS 51 V … 54 V

2)

Reference conditions acc. to IEC 770:

e.g. temperature 18 … 30°C

Page 19

Technical data

Ambient conditions

Vessel pressure

- VEGAPULS 51 (process connection PVDF) -1 … 3 bar

- VEGAPULS 51 (process connection StSt) -1 … 16 bar

- VEGAPULS 52 (process connection PVDF) -1 … 3 bar

- VEGAPULS 52 (process connection StSt) -1 … 16 bar

- VEGAPULS 53 -1 … 16 bar

- VEGAPULS 54 -1 … 40 bar

Ambient temperature on the housing -20°C … +60°C

Flange temperature (process temperature)

- VEGAPULS 51 (process connection PVDF) -20°C … +80°C

- VEGAPULS 51 (process connection StSt) -40°C … +150°C

- VEGAPULS 52 (process connection PVDF) -20°C … +120°C

(shortterm 130°C)

- VEGAPULS 52 (process connection StSt) -40°C … +150°C

- VEGAPULS 53 (process connection StSt) -40°C … +150°C

- VEGAPULS 54 (process connection StSt) -40°C … +150°C

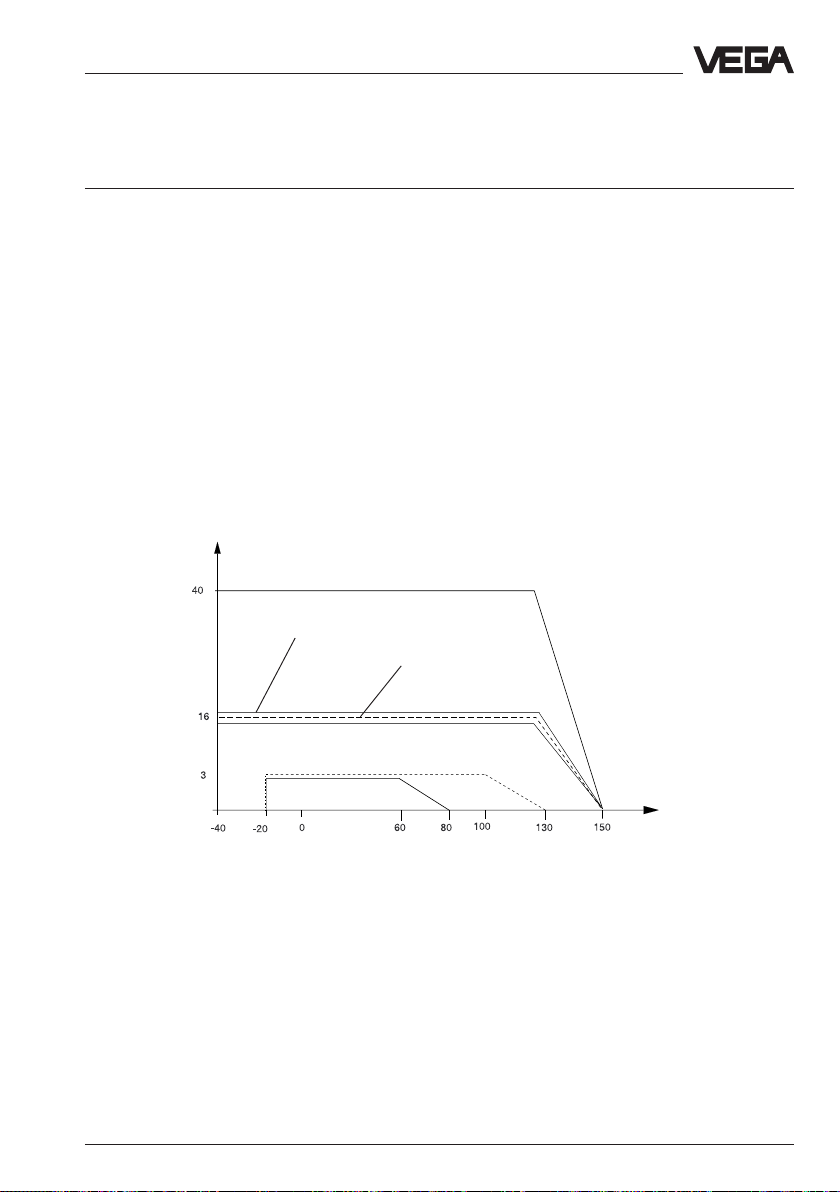

Diagram of the flange temperature dependent on the process pressure

bar

Type 54

Type 53

Type 52 with

StSt process

connection

Type 51 with

StSt process connection

Type

51

Type

52

°C

Storage and transport temperature -40°C … +80°C

Protection IP 66/67

Protection class

- two-wire sensor II

- four-wire sensor I

Overvoltage category III

VEGAPULS 51 V … 54 V 19

Page 20

Technical data

Ex-technical data (note approval documents)

Flame proofing ia (intrinsically safe in conjunction with

a safety barrier or separator)

Classification EEx ia IIC T6

Perm. housing ambient temperature T6: 45°C T5: 58°C T4/T3: 60°C

Temperature class (permissible ambient temperature on the antenna system)

- T6 80°C

- T5 95°C; type 51: 80°C

- T4 130°C; type 51: 80°C

- T3 150°C; type 51: 80°C; type 52: 130°C

Ex-approved in category or zone

- EC-type approval Type 5*V Ex: Zone 1 (II 2 G)

Type 5*V Ex 0: Zone 0 (II 1 G)

- conformity certificate Type 5*V Ex: Zone 1

Type 5*V Ex 0: Zone 0

Process connections

VEGAPULS 51, 52 G 11/2 A, 11/2" NPT (rod antennas on plastic

or StSt thread)

VEGAPULS 53 DN 50, DN 80, DN 100, DN 150 (rod antennas)

VEGAPULS 54 DN 50, DN 80, DN 100, DN150

ANSI 2", 3", 4" and 6"

(up to DN 100 or 4" mounting on surge pipe)

Connection lines

Two-wire sensors, supply and signal via one two-wire line

Line resistance max. 15 Ω per wire or 1000 m cable length

Cross-section area of conductor generally 2,5 mm

Earth connection max. 4 mm

2

2

Cable entry 2 x M20 x 1,5 (cable diameter 5 … 9 mm)

Materials

Housing PBT (Valox)

Flange / process connection

- VEGAPULS 51 PVDF or StSt

- VEGAPULS 52 PVDF or StSt

- VEGAPULS 53, 54 1.4571

Antenna

- VEGAPULS 51 PP or StSt / PPS

- VEGAPULS 52 PTFE or StSt / PTFE

- VEGAPULS 53 PTFE

- VEGAPULS 54 1.4571, 1.4071

Flange coating (only VEGAPULS 53) PTFE

20 VEGAPULS 51 V … 54 V

Page 21

Technical data

Weights

Dependent on the kind of process connection or the flange size

- Screw connection G 11/2 A, 11/2" NPT 1,3 kg

- DN 50 6 kg

- DN 80 8 kg

- DN 100 9,5 kg

- DN 150 13,5 kg

- ANSI 2" 5,8 kg

- ANSI 3" 7 kg

- ANSI 4" 11 kg

- ANSI 6" 15,5 kg

CE-conformity

VEGAPULS series 50 radar sensors meet the protective regulations of EMC (89/336/EWG)

and NSR (73/23/EWG) and R & TTE directive (1999/5/EC).

Conformity was judged acc. to the following standards:

EN 300 683-1: 1997

EN 300 440-1: 1995

I-ETS 300-440

Expert opinion No. 0043052-01/SEE, Notified Body No. 0499

EN 61 326: 1997/A1: 1998 (EMC Emission/Susceptibility)

EN 61 010 - 1: 1993 (NSR)

EN 50 020: 1994 (ATEX)

EN 50 018: 1994

EN 50 014: 1997

Outputs and processings

Display indication

Optionally mounted, scalable analogue and digital meas. value indication as well as

additionally up to 25 m separated from the sensor, meas. value indication powered by the

sensor.

Signal output

Signal output digital output signal in two-wire technology

Two-wire technology:

The digital output signal (meas. signal) is modulated to the power supply and processed in

the signal conditioning instrument or processing system.

VEGAPULS 51 V … 54 V 21

(VBUS)

Page 22

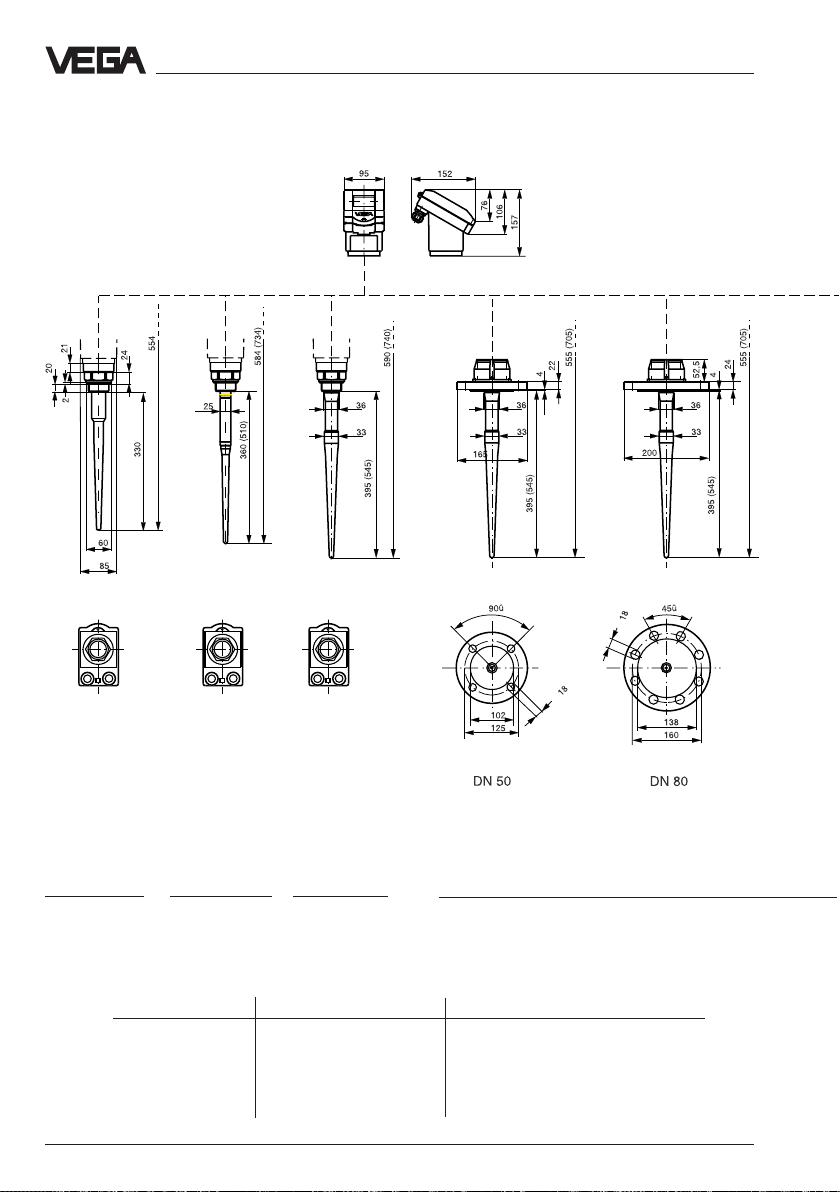

3.2 Dimensions

Technical data - Dimensions

∅

∅

G 11/2 A o.

11/2" NPT

thread

VEGAPULS 51

VEGAPULS 52

∅

G 11/2 A o.

11/2" NPT

thread

∅

∅

G 11/2 A o.

11/2" NPT

thread

Rod antennaRod antennaRod antenna

VEGAPULS 51 VEGAPULS 52

∅

∅

∅

∅

∅

∅

∅

∅

∅

∅

∅

∅

Rod antenna Rod antenna

VEGAPULS 53

Rod length max. socket length

VEGAPULS 51 330 50 mm

VEGAPULS 51 360 (option 510) 100 mm (option 250 mm)

VEGAPULS 52 330 50 mm

VEGAPULS 52 395 (option 545) 100 mm (option 250 mm)

VEGAPULS 53 395 (option 545) 100 mm (option 250 mm)

22 VEGAPULS 51 V … 54 V

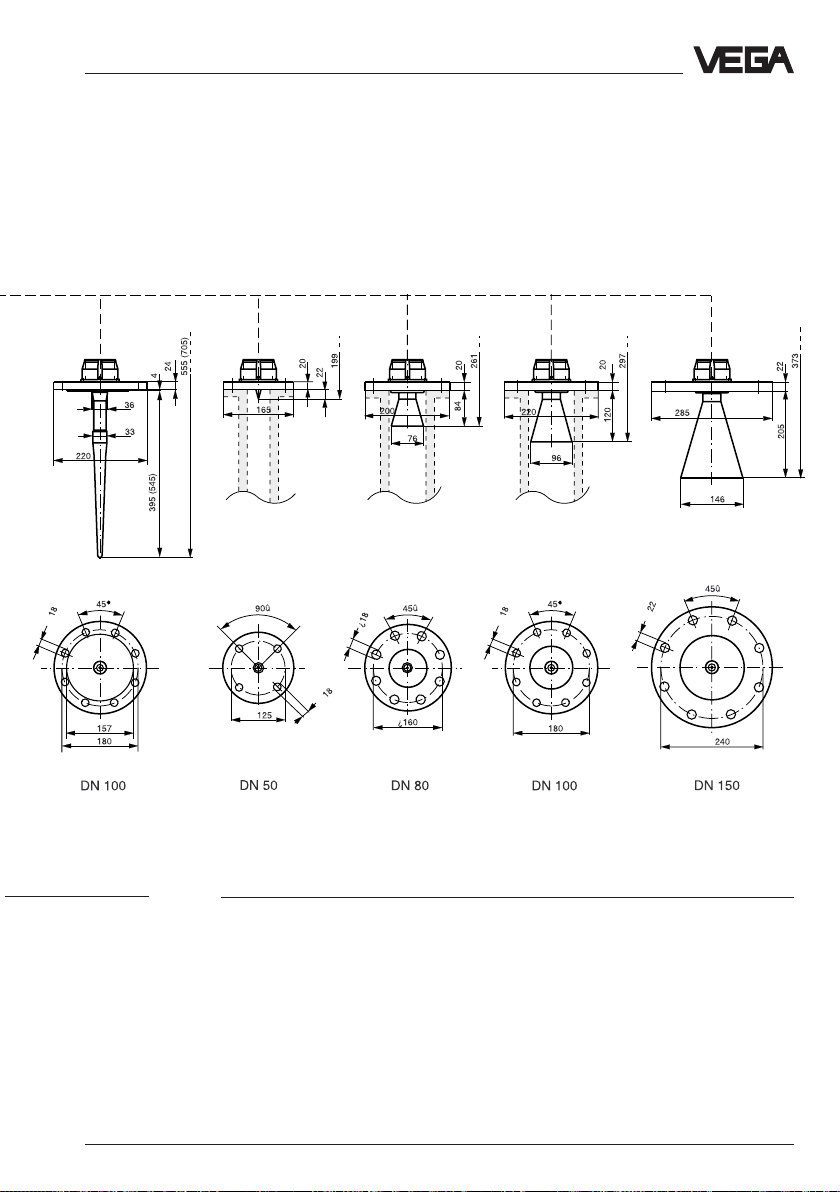

Page 23

Technical data - Dimensions

∅

∅

∅

∅

∅

∅

∅

∅

∅

∅

∅

∅

∅

∅

∅

Rod antenna Pipe antenna Pipe antenna Pipe antenna

VEGAPULS 54

∅

∅

∅

∅#

Pipe antenna

(horn antenna)

VEGAPULS 51 V … 54 V 23

Page 24

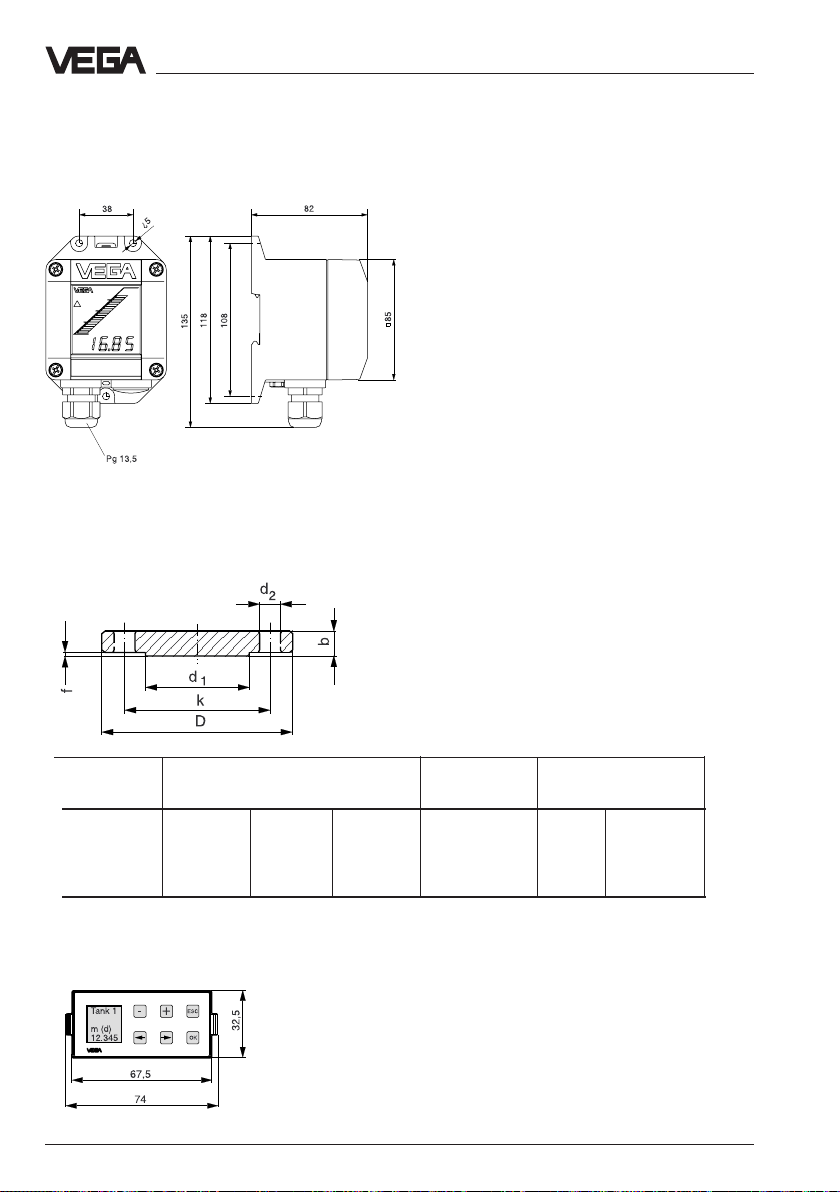

External indicating instrument VEGADIS 50

Mounting on carrier rail 35 x 7,5 acc. to EN 50 022 or flat

screwed

Flange dimensions acc. to ANSI

Technical data - Dimensions

Note:

Cable diameter of the connection cable min.

5 mm and max. 9 mm.

Otherwise the seal effect of the cable entry will

not be ensured.

D = outer flange diameter

b = flange strength

k = diameter of hole circle

d1= seal ledge diameter

f = seal ledge strength

1

/16" = ca. 1,6 mm

d2= diameter of holes

Size Flange Seal ledge Holes

Db k d1No. d

2

2" 150 psi 152,4 20,7 120,7 91,9 4 19,1

3" 150 psi 190,5 25,5 152,4 127,0 4 19,1

4" 150 psi 228,6 25,5 190,5 157,2 8 19,1

6" 150 psi 279,4 27,0 241,3 215,9 8 22,4

Adjustment module MINICOM

Adjustment module for insertion in series 50

sensors or into the external indicating

instrument VEGADIS 50

24 VEGAPULS 51 V … 54 V

Page 25

Technical data - Approvals

3.3 Approvals

When using radar sensors in Ex and St-Exareas, the instrument must be suitable and

approved for these explosion zones and

applications.

For the use on ships, special type approvals

are available.

The suitability is tested by the approval

authorities and certified by approval

documents.

VEGAPULS 51 V Ex (0) to 54 V Ex (0)

sensors must be supplied from one

intrinsically safe circuit when used in Exareas. This is ensured by the separators

VEGATRENN 548 V Ex.

The separator provides intrinsically safe (ia)

circuits.

The resistance of the signal line must not

exceed 15 Ω per wire.

VEGAPULS 51 V Ex … 54 V Ex sensors are

approved for Ex-Zone 1.

VEGAPULS 51 V Ex 0 … 54 V Ex 0 sensors

are approved for Ex-Zone 0.

Please note the attached approval

documents when you want to use a sensor in

Ex-environment.

Test and approval authorities

VEGAPULS radar sensors are tested and

approved by the following monitoring and

approval authorities:

- PTB

(Physikalisch Technische Bundesanstalt Physical Technical Approval Authority)

- FM

(Factory Mutual Research)

- ABS

(American Bureau of Shipping)

- LRS

(Lloyds Register of Shipping)

- GL

(German Lloyd)

- CSA

(Canadian Standards Association)

VEGAPULS 51 V … 54 V 25

Page 26

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

Mounting and installation - General installation instructions

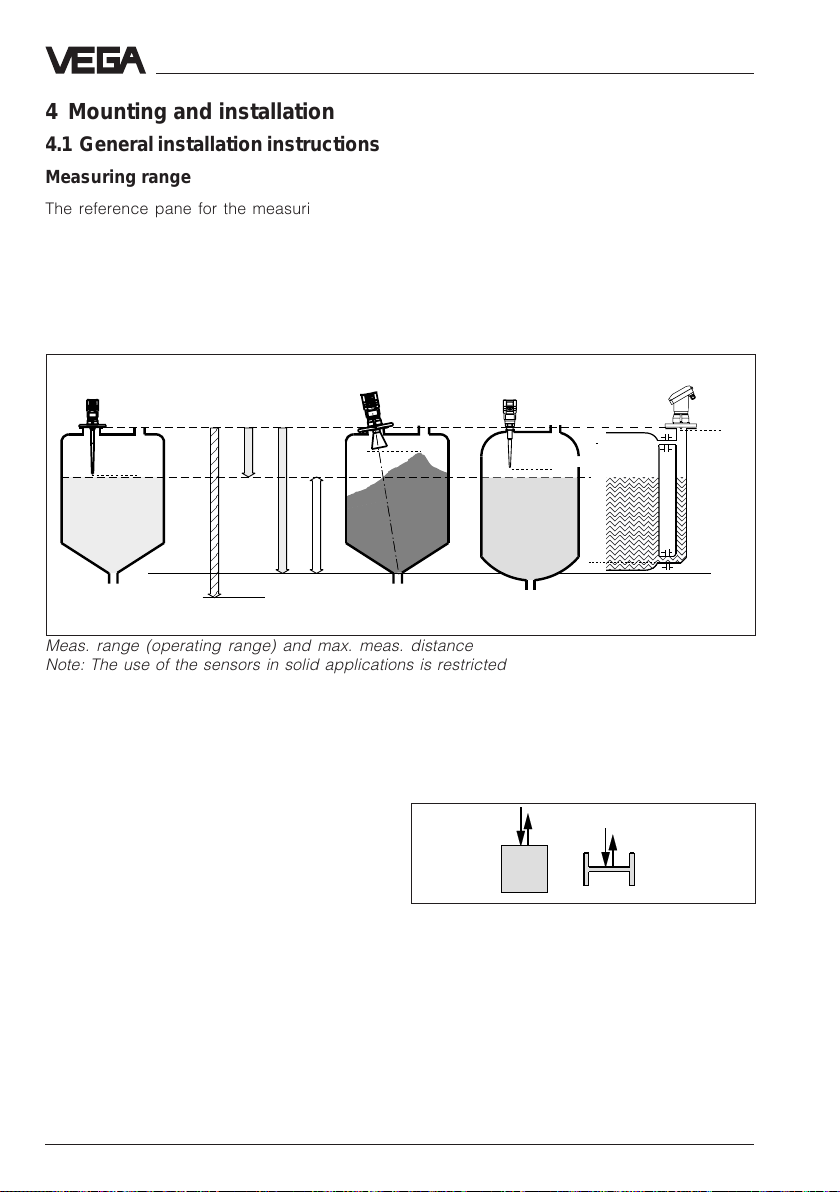

4 Mounting and installation

4.1 General installation instructions

Measuring range

The reference pane for the measuring range

is the flange face (type 53/54) or the seal

shoulder of the thread (type 51/52). The max.

measuring range is 0 … 20 m, dependent on

the sensor type. The min. distance to the

medium must be 5 cm.

For measurements in surge or bypass pipes

(pipe antenna), the max. meas. distance is

reduced.

Note that for measurements where the

medium reaches the antenna, build-up on the

antenna is possible which can cause

measurement errors.

Type 53

Reference pane

Max.

Type 54

full

empty

Max.

Type 51/52 Type 54

Max.

Meas. range

max. meas. distance 20 m

Meas. range (operating range) and max. meas. distance

Note: The use of the sensors in solid applications is restricted

False reflections

Flat obstructions and struts cause large false

reflections. They reflect the radar signal with

high amplitude.

Round profile interfering surfaces have a diffuse reflection of the radar signals and cause

false reflections with low density. Hence they

are less critical than reflections from a flat

surface.

If flat obstructions in the range of the radar

signals cannot be avoided, it is

recommended to reflect the interfering

signals with a deflector.

26 VEGAPULS 51 V … 54 V

Profiles with smooth interfering surfaces

cause large false signals

Due to this scattering the interfering signals

will be low in amplitude and diffuse so that

they can be filtered out by the sensor.

Max.

Page 27

Mounting and installation - General installation instructions

This emission cone depends on the antenna

used.

Round profiles diffuse the radar signals

Meas. distance

A deflector causes signal scattering

Emission cone and false reflections

The radar signals are focused by the

antenna system. The signals leave the

antenna in conical form, similar to the beam

pattern of a spotlight.

DN 100 horn antenna

Series 50

Series 64

and 81

Meas. distance

Rod antenna

Series 50

Series 64

and 81

Emission cone of a DN 100 horn antenna

Emission cone of a rod antenna (independent

on the process connection)

VEGAPULS 51 V … 54 V 27

Page 28

If possible provide a "clear view" inside the

emission cone to the product and avoid

obstructions in the first third of the cone.

Optimum measuring conditions exist when

the emission cone reaches the measured

product vertically and when the emission

cone is free from obstructions.

Mounting and installation - Measurement of liquids

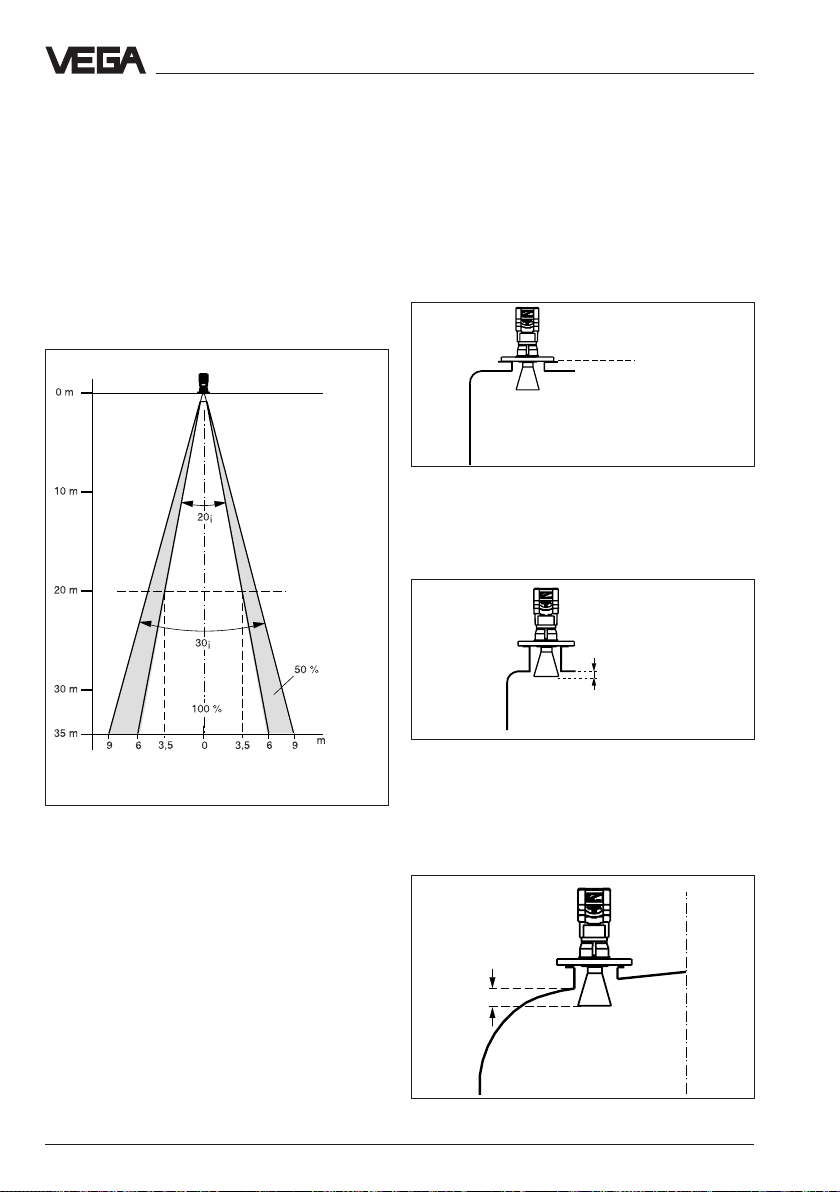

4.2 Measurement of liquids

Horn antenna

Most of the time the mounting of radar

sensors is made on short DIN-socket pieces.

The instrument flange is the reference pane

of the measuring range. The antenna should

always protrude out of the flange pipe.

Meas. distance

DN 150 horn antenna

Series 50

Series

64

and 81

Emission cone of a DN 150 horn antenna

Reference pane

Mouning on short DIN-socket piece

When the DIN-socket piece is longer, please

note that the horn antenna must protrude at

least 10 mm out of the socket.

> 10 mm

Mounting on longer DIN-socket

When mounting on dished end vessels the

antenna has to protrude at least 10 mm.

> 10 mm

Mounting on a dished end vessel

28 VEGAPULS 51 V … 54 V

Page 29

Mounting and installation - Measurement of liquids

Do not mount the transmitter in the centre of

the dished end of the tank or close to the

outer wall of the vessel, but approx. 1/2 vessel

radius from the middle or from the outer wall.

Dished tank ends can act as paraboloidal

reflectors. If the radar sensor is placed in the

"focus" of a parabolic tank end, the sensor

receives amplified false echoes. The radar

sensor must be mounted outside the "focus"

hence parabolic amplified echoes are

avoided.

Reference pane

1

/2 vessel radius

Mounting on dished vessel end

Horn antenna directly on the vessel top

Dependent on the construction of the vessel,

flat mounting directly on the vessel top would

be a favourable solution. The top side of the

vessel is the reference pane.

Rod antenna

The PTEF (Teflon) rod antenna is well suited

to chemically aggressive products such as

lyes and acids. Applications in the food

processing industry with aseptic vessel

conditions are catered for with the Teflon rod

antenna close tolerance and crevice free

construction.

For measurements of liquids with the Teflon

rod antenna, the mounting is made on a

straight DIN-socket piece. The socket

however must not be longer than 150 mm

(when using a longer antenna, not longer

than 250 mm). The rod antenna is available in

flange sizes of DN 50, DN 80 and DN 100.

≤ 100 or 250 mm

Rod antenna on DIN-socket piece

Reference pane

Opening

ø 50 mm

Mounting directly on the flat vessel top

VEGAPULS 51 V … 54 V 29

Rod antenna directly on vessel opening

Page 30

Alternatively to the socket mounting, the rod

antenna can also be mounted on round

vessel openings (holes). Rod antennas are

available for the following openings: 11/2" NPT,

G11/2 A, DN 50, DN 80, DN100 and DN 150.

Note that the PTFE-rod antenna can only

carry limited mechanical load. When

subjected to lateral power, deformation or

even break will be the cause.

Mounting and installation - Measurement of liquids

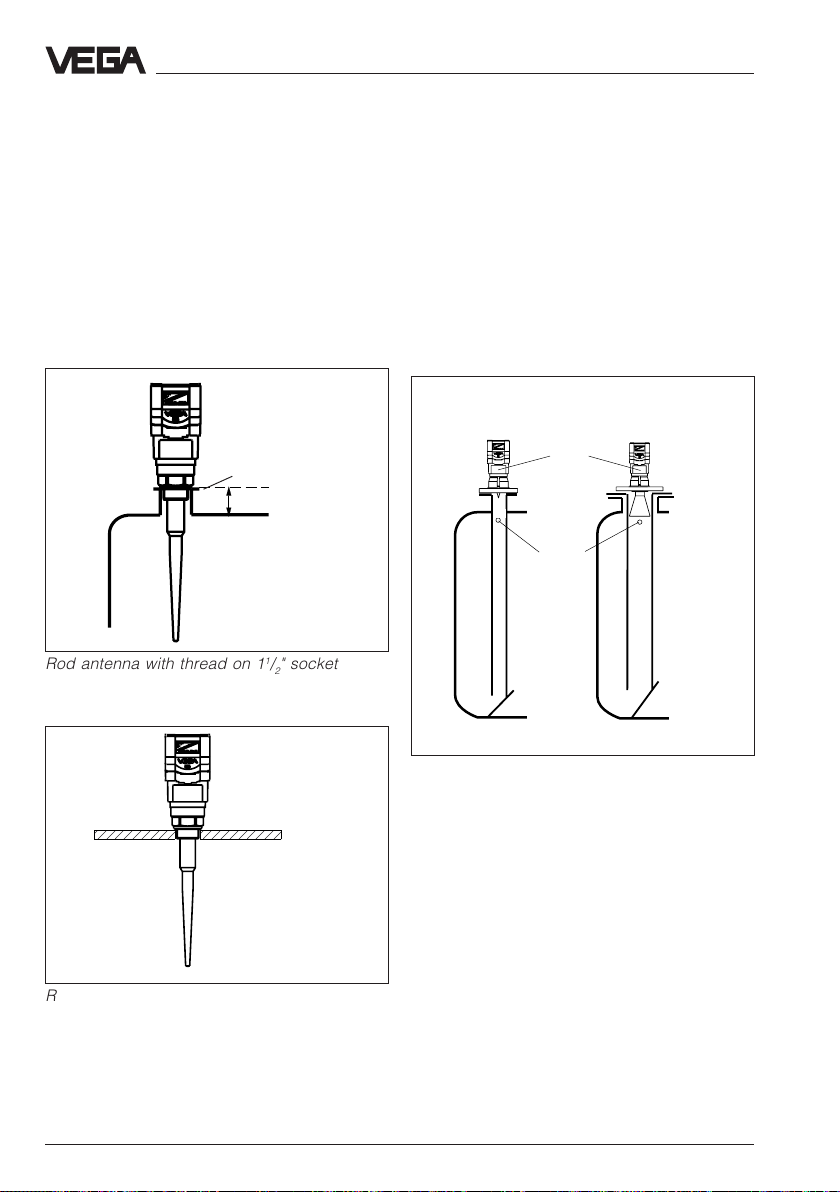

4.3 Measurement in standpipe

General instructions

Pipe antennas are an option in vessels which

are mechanically complex or where the

product surface is very turbulent.

By focusing of the radar signal within the

measuring pipe, also products with small

dielectric constants (εr= 1,6 to 3) can be

reliably measured.

Reference pane

< 50 mm or 100 mm

or 250 mm

Rod antenna with thread on 11/2" socket

Surge pipe welded

to the tank

Type plate

Vent

Surge pipe in the

socket piece

Pipe antenna systems in the tank

Surge pipes which are open at the bottom

must extend over the full measuring range

(i.e. down to 0% level). Ventilation and surge

holes must be in one axis with the type plate.

Rod antenna with thread on 11/2" threaded

hole

30 VEGAPULS 51 V … 54 V

Page 31

;;;

;;;

;

;

;

;

;

Mounting and installation - Measurement in standpipe

As an alternative to the surge pipe in the

vessel, a pipe antenna outside the vessel is

possible as bypass pipe. Direct the sensor

such that the type plate is in one axis with the

pipe holes or the pipe connection openings.

The polarization of the radar signals enables

considerably more stable measurements with

this directing.

Note that with a measurement in the surge or

bypass pipe the max. measuring range is

reduced by 5 … 20 % (e.g. DN 50: 16 m

instead of 20 m and DN 100 only 19 m

instead of 20 m).

Casting nose

;

;

;

;

;

Pipe flange system as bypass pipe

Adhesive products

When measuring adhesive products, the

inner diameter of the surge pipe must have a

larger nominal width so that build-up does

not cause measuring errors. Surge pipe

diameters of DN 50 to DN 150 can be

connected.

∅

∅

100 %

∅

∅

75 %

Pipe antenna with DN 50, DN 80, DN 100 and

DN 150

0 %

Extended bypass pipe

VEGAPULS 51 V … 54 V 31

Page 32

Mounting and installation - Measurement in standpipe

Standpipe measurement in

inhomogeneous products

If you want to measure inhomogeneous products

or laminated products in surge pipe it must

have long holes or slots. These openings ensure

that the liquid is mixed and balanced at the

correct level.

homogeneous

liquids

slightly inhomogeneous

liquids

The more inhomogeneous the measured

product, the closer the openings should be.

For reasons of radar signal polarization the

holes and slots must be positioned in two

rows displaced by 180°.

The mounting of the radar sensor is then

such that the type plate is in one axis with the

row of holes.

Type plate

Row of holes in one axis with the type plate

inhomogeneous liquids

Openings in a surge pipe for mixing of

inhomogeneous products

32 VEGAPULS 51 V … 54 V

Page 33

Mounting and installation - Measurement in standpipe

Surge pipe with ball valve

When using a ball valve in a surge pipe, it is

possible to carry out maintenance and

service work without opening the vessel (e.g.

with liquid gas or toxic products).

DN 50

Ball valve

ø50

Surge pipe lockable with ball valve

The ball valve diameter must correspond to

the pipe size and provide a flush surface

when in the open position.

Installation error in surge pipe

Missing ventilation hole

Pipe antenna systems must be provided with

a vent at the upper end of a surge pipe. A

missing hole causes wrong measurements.

Correct

The surge pipe open to the bottom must

have a ventilation hole on top

Wrong polarization direction

When measuring in a surge pipe, especially

when there are holes for mixing, it is

important that the radar sensor is directed to

the rows of holes. The two rows of holes of

the surge pipe displaced by 180° must be in

one pane with the polarization direction of the

radar signals. The polarization direction is in

the pane of the type plate.

Wrong

Type plate

The polarization direction is in one pane with

the type plate. The sensor must be directed

with the type plate to the rows of holes or the

openings

VEGAPULS 51 V … 54 V 33

Page 34

;

;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

Mounting and installation - Measurement in standpipe

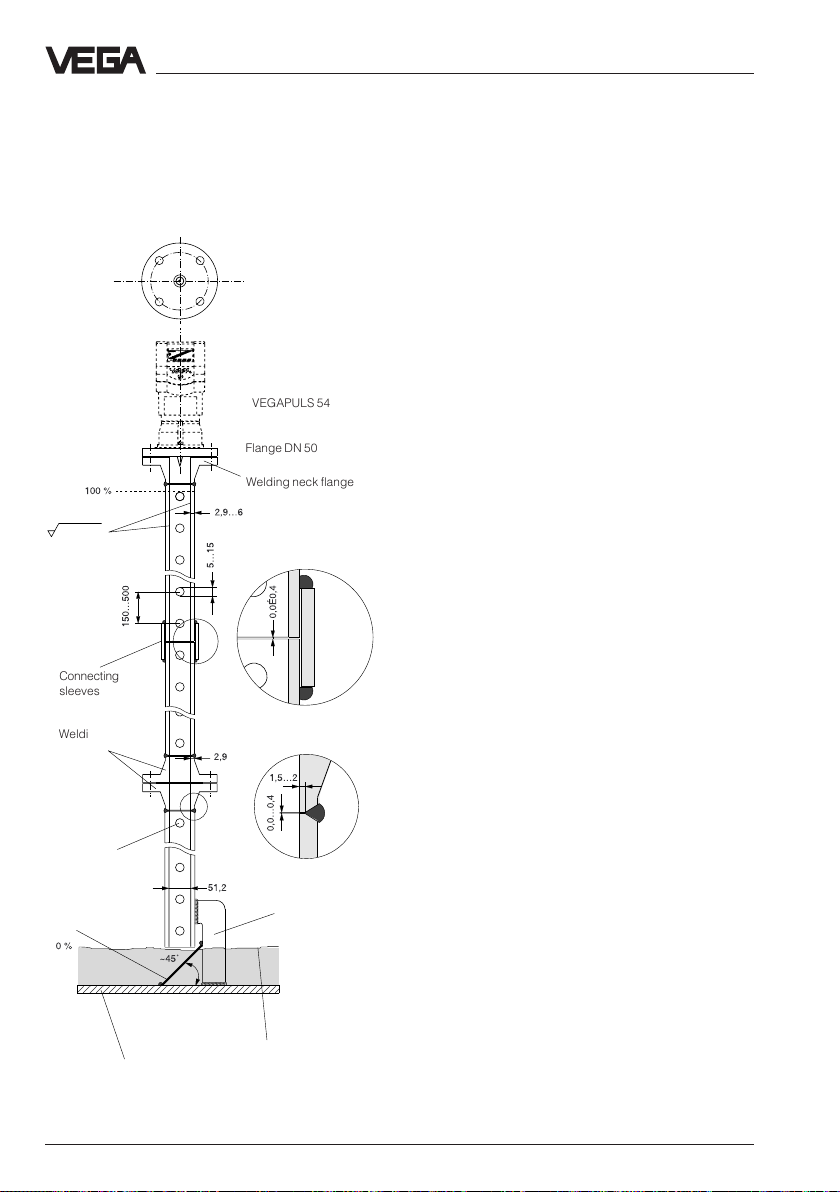

Construction instructions for the surge pipe

Radar sensors for measurement on surge or

bypass pipes are used in flange sizes

DN 50, DN 80, DN 100 and DN 150.

On the left is the construction of a measuring

pipe (surge or bypass pipe) on the example

of a sensor with a DN 50 flange.

Rz ≤ 30

Connecting

sleeves

Welding neck

flanges

Burr the

holes

Deflector

VEGAPULS 54

Flange DN 50

Welding neck flange

Welding of the

connecting sleeve

Welding of the

welding neck flange

Fastening of meas.

pipe

The radar sensor with a DN 50 flange is only

in conjunction with a measuring pipe a

functional system.

The measuring pipe must be smooth inside

(average roughness Rz - 30). Use as

measuring pipe a stainless steel pipe without

joint. Extend the measuring pipe to the

required length with welding neck flanges or

with connecting sleeves. Note that no

shoulders are caused in the pipe during

welding. Fasten the pipe and the flange

before welding in alinement with the inner

sides.

Do not just weld through the pipe wall. The

pipe must be smooth inside. Roughnesses or

joints must be removed carefully as

otherwise strong false echoes and build-up

will be caused.

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

Min. product level to be

Vessel bottom

measured (0 %)

34 VEGAPULS 51 V … 54 V

Page 35

Mounting and installation - Measurement in standpipe

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

On the left you see the contruction of a

measuring pipe on the example of a radar

sensor with a DN 100 flange.

Radar sensors with flanges of DN 80,

DN 100 and DN 150 are equipped with a

VEGAPULS 54

horn antenna. Instead of the welding neck

flange also a smooth welding flange can be

used on the sensor side of these sensors.

Smooth welding flange

In agitated products, fasten the measuring

pipe to the vessel bottom. Provide additional

Flange DN 100

fastenings for longer measuring pipes.

With the deflector on the measuring pipe end,

the radar signals are reflected from the

Burr the

holes

Welding of the smooth

welding neck flange

vessel bottom. This avoids that in nearly

empty vessel and products with low

dielectric constant figures, not the measured

product but the vessel bottom is detected. In

products with low dielectric constant figure

the product is penetrated by radiation and

the vessel bottom delivers at low level

considerably clearer radar echoes than the

product surface.

Connection

sleeves

Welding neck

flanges

Welding of the

welding neck flange

Due to the deflector, the useful signal remains

and hence the measured value can be

clearly detected in nearly empty vessel and

the 0 % level is reliably detected.

Rz ≤ 30

Deflector

VEGAPULS 51 V … 54 V 35

Measuring pipe

fastening

Vessel bottom

Page 36

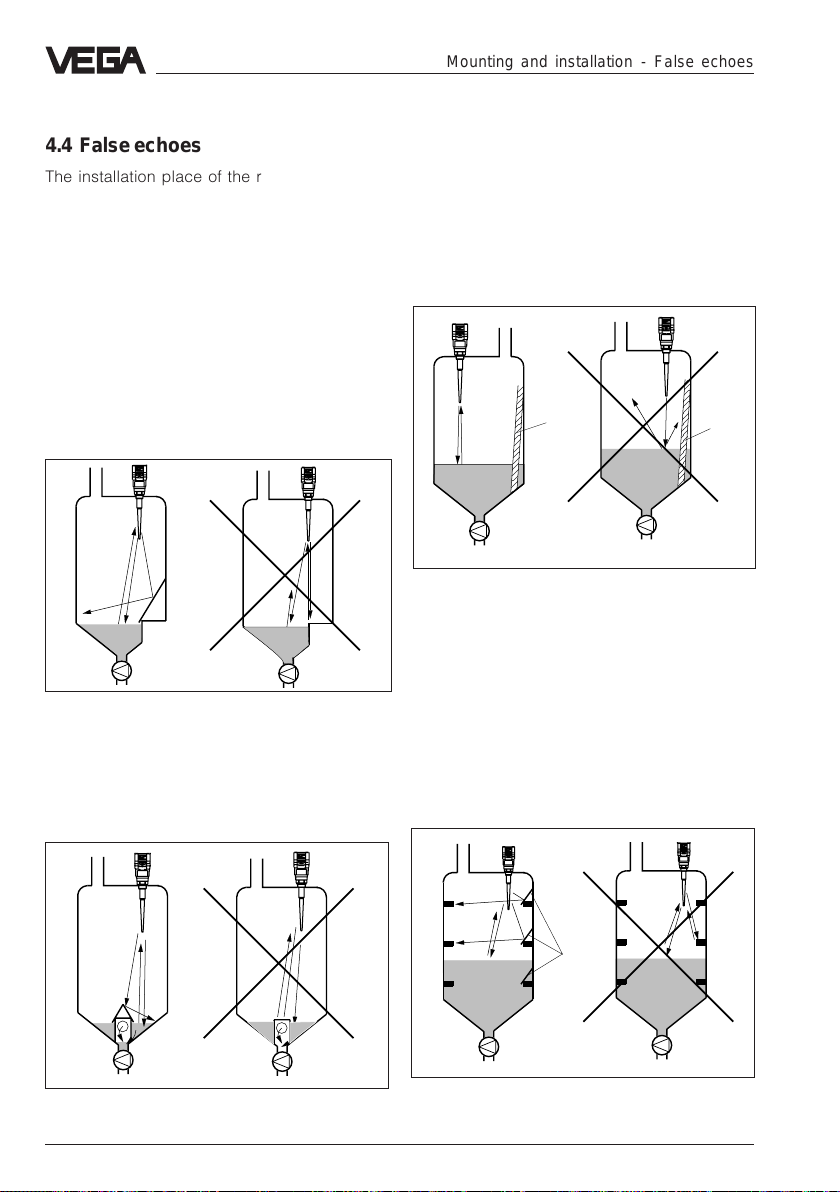

4.4 False echoes

The installation place of the radar sensor

must be selected such that no struts or

inflowing material cross the radar signals.

The following examples show frequent meas.

problems and how they can be avoided.

Shoulders

Vessel forms with flat shoulders pointing to

the antenna can influence the measurement

due to their hard false echoes. Deflectors

above these flat shoulders diffuse the false

echoes and ensure a reliable measurement.

Correct Wrong

Mounting and installation - False echoes

Vessel installations

Struts, such as e.g. a ladder often cause

false echoes. Note when planning a

measurement loop that the radar signals

reach the measured products without

problems.

Correct Wrong

Ladder

Vessel installations

Ladder

Struts

Flat shoulders

Inlets, e.g. for material mixing with flat surface

pointing to the radar sensor, should be

covered by a screen. False echoes are

hence gated out.

Correct Wrong

Shoulders (inlets)

36 VEGAPULS 51 V … 54 V

Struts such as vessel installations can cause

strong false echoes which can overlay the

useful echo. Small shields avoid a direct false

echo reflection. The false echoes are diffused

and filtered out by the meas. electronics as

"echo noise".

Correct Wrong

Shields

Struts

Page 37

Mounting and installation - False echoes

;;

;;

;;

;;

;;

;;

Strong product movements

Heavy turbulences in the vessel, e.g. by

strong stirrers or strong chemical reactions

influence the measurement. A surge or

bypass pipe (figure) of sufficient size allows,

provided that the product causes no buildup in the pipe, always a reliable

measurement even with strong turbulences in

the vessel.

Correct Wrong

Strong product movements

Products which can cause slight build-up

can be measured by using a meas. pipe with

100 mm nominal width and more. In a meas.

pipe of this size, slight build-up is not a

problem.

Build-up

If the radar sensor is mounted too close to

the vessel wall, build-up on the vessel walls

causes false echoes. Position the radar

sensor in a sufficient distance to the vessel

wall. Also note chapter "4.1 General

installation instructions".

Correct Wrong

Build-up

Inflowing material

Do not mount the instruments in or above the

filling stream. Ensure that you detect the

product surface and not the inflowing

material.

Correct

Wrong

Inflowing liquid

VEGAPULS 51 V … 54 V 37

Page 38

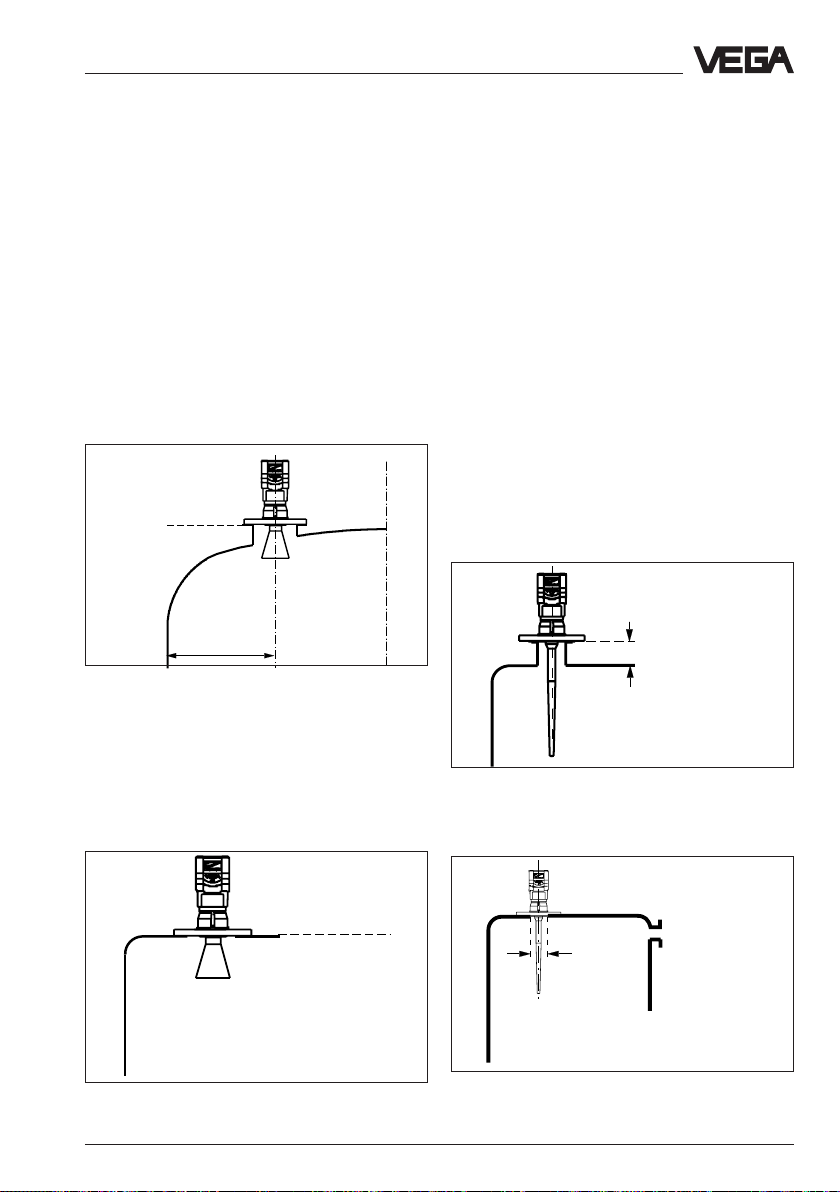

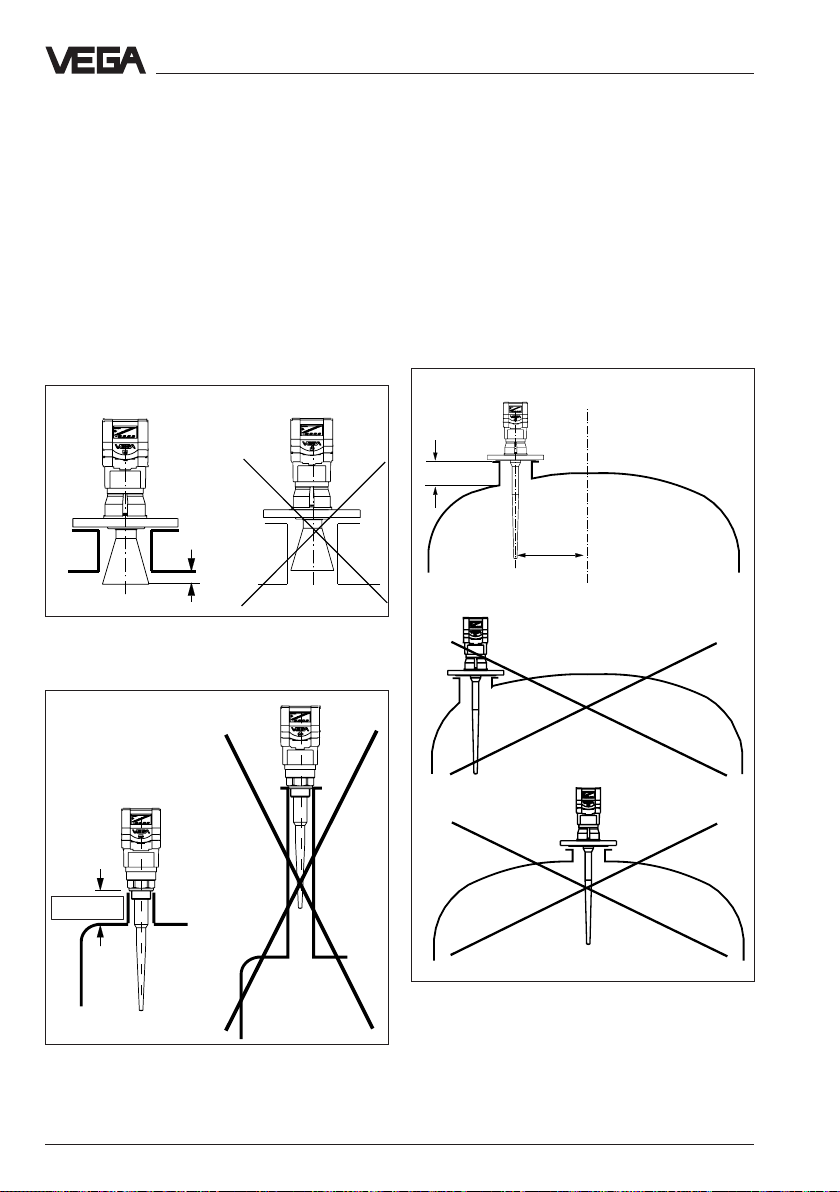

4.5 Installation error

Socket piece too long

When mounting the antenna in a too long

socket piece, strong false reflections are

caused, aggravating a measurement. Note

that the horn antenna protrudes at least

10 mm out of the socket piece. When using a

rod antenna, the socket piece must have a

length of max. 100 or 60 mm (with a rod

length of 545 mm the length of the socket

piece must be max. 250 mm).

Correct Wrong

> 10 mm

Horn antenna: Correct and wrong length of

the socket piece

Mounting and installation - Installation error

Parabolic effect on dished boiler head

or basket arch vessel

Round or parabolic tank tops act for the

radar signal like a parabolic mirror. If the

radar sensor is placed to the focus of such a

parabolic tank top the sensor receives

amplified false echoes. The optimum

mounting is generally in the range of the half

vessel radius from the centre.

Correct

< 100 mm

(250 mm)

~ 1/

2

vessel

radius

Wrong

Wrong

Correct

Wrong

< 100 mm

(250 mm)

Mounting on a vessel with parabolic tank top

Rod antenna: Correct and wrong length of

the socket piece

38 VEGAPULS 51 V … 54 V

Page 39

Mounting and installation - Installation error

Surge pipe without ventilation hole

A surge pipe, also called pipe antenna, must

be provided with a breathing hole on the

upper edge of the surge pipe. A missing hole

will cause faulty measurements.

Correct Wrong

Pipe antenna: The surge pipe open to the

bottom must have a ventilation hole on top

Sensor in wrong polarization direction

on the surge pipe

When measuring in a surge pipe, especially if

there are holes in the pipe for mixing, it is

important that the radar sensor is directed to

the row of holes.

The two rows of holes of the surge pipe

displaced by 180° must be in line with the

polarization direction of the radar signals. The

polarization direction is in line with the type

plate.

Correct Wrong

Type plate

VEGAPULS 54 on a surge pipe: The

polarization direction is in line with the type

plate. The sensor must be directed with the

type plate to the rows of holes

VEGAPULS 51 V … 54 V 39

Page 40

Mounting and installation - Installation error

Wrong directing to the product surface

A directing of the sensor which does not

point to the product surface will cause a

weak measuring signal. If possible direct the

sensor axis vertically to the product surface,

to reach optimum measuring results.

Correct Wrong

Ladder

Direct sensor vertically to the product

surface

Ladder

Sensor too close to the vessel wall

If the radar sensor is mounted too close to the

vessel wall, strong interfering signals can be

caused. Build-up, rivets, screws or weld

joints superimpose their echoes to the useful

signal or useful echo. Hence note a sufficient

distance of the sensor to the vessel wall.

In case of good reflection conditions (liquids

without vessel installations) we recommend to

select the sensor distance so that there is no

vessel wall within the inner emission cone. For

liquids with worse reflection conditions it is

useful that there are also no interfering

installations within the outer emission cone.

Note chapter "4.1 General installation

instructions".

Foam generation

Strong, dense and creamy foam on the

product can cause faulty measurements.

Provide measures to avoid foam or measure

in a bypass pipe. Check if necessary the use

of another measuring principle, e.g.

capacitive electrodes or hydrostatic pressure

transmitters.

40 VEGAPULS 51 V … 54 V

Page 41

Electrical connection

5 Electrical connection

5.1 Connection and connection

cable

Safety information

Ensure that the instrument is unpressurized

before you start work. Always switch off the

power supply before you carry out clamping

work on the radar sensors. Protect yourself

and the instruments. Especially when you

use sensors which do not work with low

voltage.

Skilled staff

Instruments operated in Ex-areas must only

be connected by skilled staff. This staff must

note the installation regulations and the

attached type approvals and conformity

certificates.

Connection

A standard two-wire cable with max. 2,5 mm

can be used for connection. Very often

"Electromagnetic pollution" by electronic

actuators, energy lines and transmitting

stations is so considerable that the two-wire

line must be screened.

We recommend to use a screening. This

screening prevents against future

interferences. It is useful to earth the cable

screens on both ends, however it must be

noted that no earth compensation currents

flow via the sensor cable screens. You avoid

earth compensation currents by connecting

the cable screen on one earth side (e.g. in

the switching cabinet) via a capacitor (e.g.

1 µF; 100 V) with earth potential in case of

earthing on two ends. Use a very low

impedance earth connection (foundation,

plate or mains earth).

Ex-protection

If an instrument is used in hazardous areas

the appropriate regulations, conformity

certificates and type approvals for sensors

and separators or safety barriers must be

noted (e.g. DIN VDE 0165).

Sensors used in Ex-area must only be

operated on intrinsically safe circuits. The

permissible electrical values are stated in the

conformity certificate or the type approval.

Connection cable

Note that the connection cables must be specified

for the expected operating temperatures in your

systems. The cable must have an outer diameter

of 5 … 9 mm. Otherwise the seal effect of the

cable entry will not be ensured.

2

Cables for intrinsically safe circuits must be

marked blue and must not be used for other

circuits.

Earth conductor terminal

On VEGAPULS 51/52 sensors with a 11/2"

thread of plastic, the earth conductor terminal

is galvanically isolated.

On all VEGAPULS 53/54 sensors as well as

VEGAPULS 51/52 sensors with metal thread,

the earth conductor terminal is galvanically

connected with the metal process

connection.

VEGAPULS 51 V … 54 V 41

Page 42

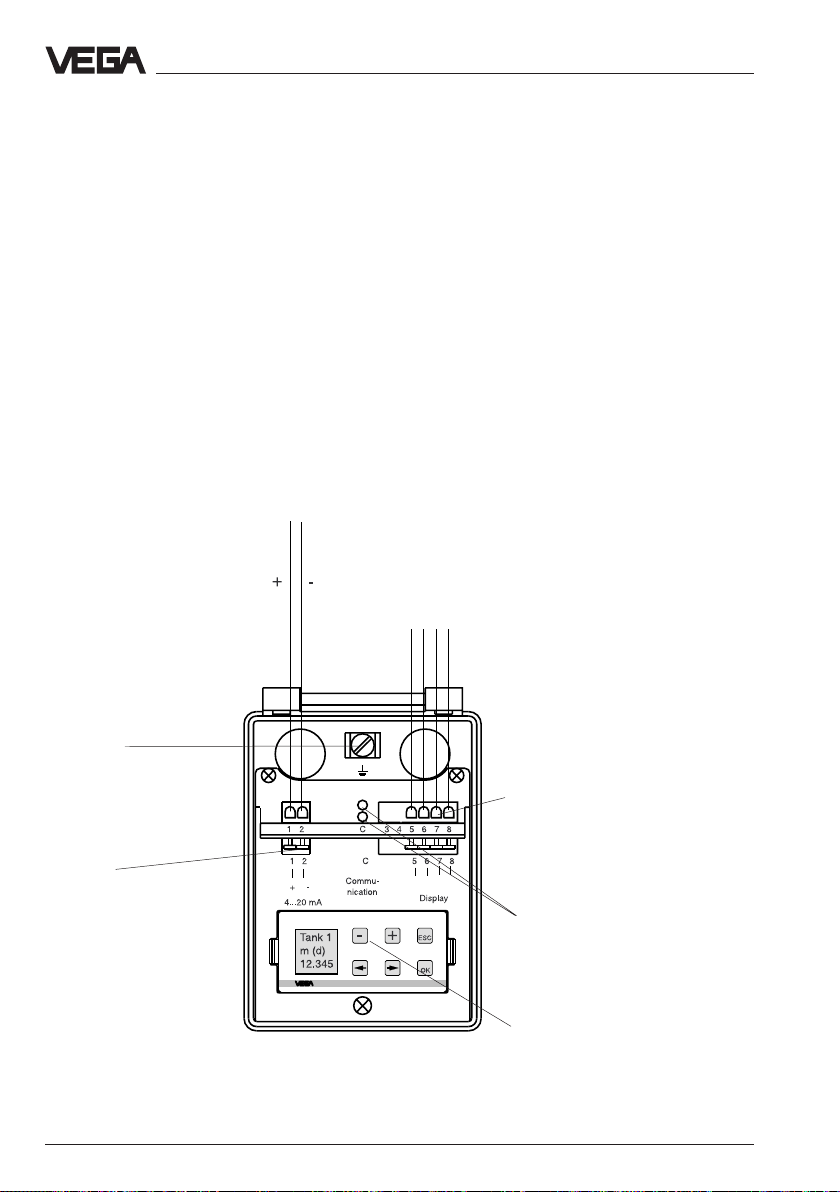

5.2 Connection of the sensor

After having mounted the sensor in the

measuring position acc. to the instructions in

chapter "4 Mounting and installation", loosen

the closing screw on the top of the sensor.

The sensor cover with the optional indicating

display can then be opened. Unscrew the

compression screw and shift the screw over

the approx. 10 cm dismantled connection

cable. The compression screw is protected

with a safety lock-in position against

automatic loosening.

Voltage supply

and digital measuring signal

Electrical connection - Connection of the sensor

Now loop the cable through the cable entry

into the sensor. Screw the compression

screw again to the cable entry and clamp the

dismantled wires of the cable to the

appropriate terminal positions.

The terminals operate without terminal screw.

Press the white opening buckets with a small

screwdriver and insert the copper core of the

connection line into the terminal opening.

Check the position of the lines in the terminal

position by slightly pulling on the connection

lines.

To the indicating instrument in the

sensor cover or to the external

indicating instrument VEGADIS 50

Earth terminal

The earth terminal must be

connected to system earth

Spring terminals

Tw o-wire technology

42 VEGAPULS 51 V … 54 V

Spring terminals to

VEGADIS

(max. 2,5 mm

cross-section area

of conductor)

Sockets for connection of the

interface adapter

VEGACONNECT

Pluggable

adjustment module

MINICOM

2

Page 43

Electrical connection - Connection of the external indicating instrument

5.3 Connection of the external indicating instrument VEGADIS 50

Loosen the four screws of the housing cover

on VEGADIS 50.

You can facilitate the connection procedure

by fastening the housing cover during

connection with two screws on the right of the

housing (figure).

Terminal board VEGADIS 50

3

2

1

4

5

to DISPLAY in the cover of

VEGADIS 50

8

6

7

Adjustment module

-

Tank 1

m (d)

12.345

3215678

-

+

OUTPUT

+

DISPLAY

VEGADIS 50

ESC

OK

16.85

Voltage supply

and

digital measuring signal

+

-

12 C 567843

Screws

Sensor terminal box

-

+

+

ESC

-

Tank 1

m (d)

12.345

OK

VEGAPULS 51 V … 54 V 43

(open)

Page 44

6 Set-up

6.1 Adjustment structure

Series 50 radar sensors can be adjusted

with

- PC (adjustment program VVO)

- detachable adjustment module MINICOM

- signal conditioning instrument VEGAMET.

The adjustment must be only carried out with

one adjustment medium.

Adjustment program VVO

With the adjustment program VVO

sual Operating System) on the PC you can

adjust the radar sensors very comfortably.

The PC communicates via the interface

adapter VEGACONNECT 2 or the standard

RS232 interface cable digitally with the

sensor. The adjustment can be hence carried

out directly on the sensor, in any individual

position of the signal line or on the

processing system VEGAMET/VEGALOG.

Note:

The adjustment with PC via the interface

adapter VEGACONNECT 2 directly on the

sensor or on the signal line enables only the

"parameter adjustment" and corresponds to

the adjustment with PC on VEGAMET or

VEGALOG on the following pages.

Adjustments to "

not possible when the VEGACONNECT 2 is

connected directly to the sensor or the signal

line and hence not described separately in

this operating instruction.

Configuration

(VEGA Vi-

" however are

Set-up - Adjustment structure

Signal conditioning instrument VEGAMET

The signal conditioning instrument VEGAMET

enables with the 6-key adjustment field with

text display the parameter adjustment in the

same functional volume than the adjustment

program VVO on the PC.

Adjustment module MINICOM

With the adjustment module MINICOM you

can adjust in the sensor or in the external

indicating instrument VEGADIS 50. The

adjustment module enables with the 6-key

adjustment field with text display the

parameter adjustment in the same functional

volume than the adjustment program VVO or

the 6-key adjustment field with text display on

the signal conditioning instrument VEGAMET.

The configuration adjustments however are

only possible with the adjustment program

VVO or the 6-key adjustment field with text

display on the signal conditioning instrument

VEGAMET.

The adjustment is always the same, whether

you set-up a measuring sytem (unit

consisting of sensor and signal conditioning

instrument VEGAMET or sensor and

processing system VEGALOG) with the

adjustment software VVO, with the signal

conditioning instrument or with the adjustment

module MINICOM:

- first of all configure in the menu

a meas. system and

- carry out the parameter adjustment of the

sensors in the menu "

"Configuration"Configuration

"Configuration

"Configuration"Configuration

Instrument dataInstrument data

Instrument data

Instrument dataInstrument data

".

"

44 VEGAPULS 51 V … 54 V

Page 45

Set-up - Adjustment structure

Configuration Configuration

Configuration means to coordinate or

Configuration Configuration

determine once. In the menu Configuration

the signal conditioning instrument is informed

about the general configuration:

- which kind of sensor is connected (radar,

ultrasonic, process pressure…),

- what kind of parameter or application is

concerned (level, gauge, distance…)

- to which input the sensor is connected

- which outputs (current, voltage, relay, fault

signals, indication…) should be

coordinated to which input in which way

(inverted, threshold value controlled…).

After these adjustments (configuration) had

been carried out, the meas. system goes to

operating condition and the signal

conditioning instrument will display a

measured value. Now the sensor parameter

adjustment (adjustment, unit, linearisation

curve, sensor adaption…) can be carried

out.

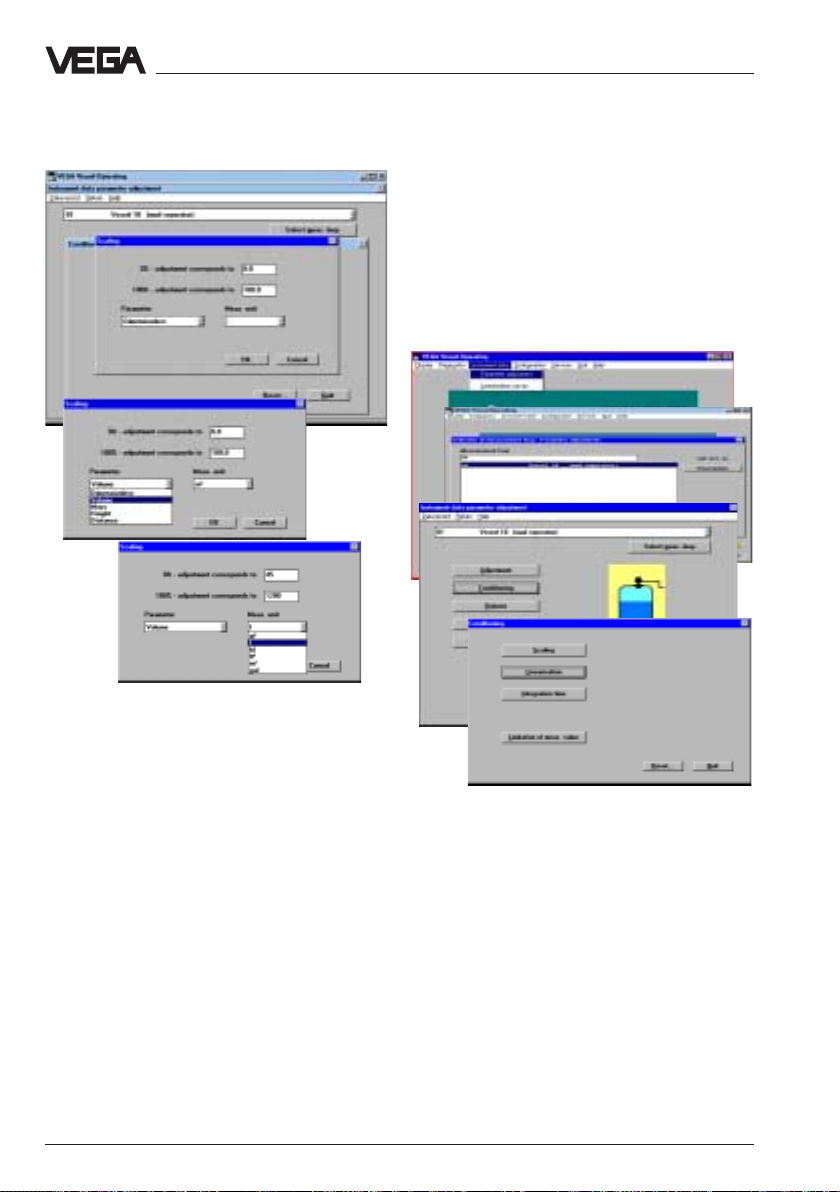

Parameter adjustment Parameter adjustment

Parameter adjustment means to enter values.

Parameter adjustment Parameter adjustment

Parameters are entered in the signal

conditioning instrument as well as in the

connected sensors. For example:

- Min. and max. adjustment

- Meas. range limits

- Physical unit, decimal point

- Linearisation curves

- Integration time

- Meas. environment (solid, liquid,

foam generation, operating range…)

- False echo memory

- Inversion of the measured value etc.

Now all required adjustments for a precisely

adapted sensor are carried out for a reliable

measurement.

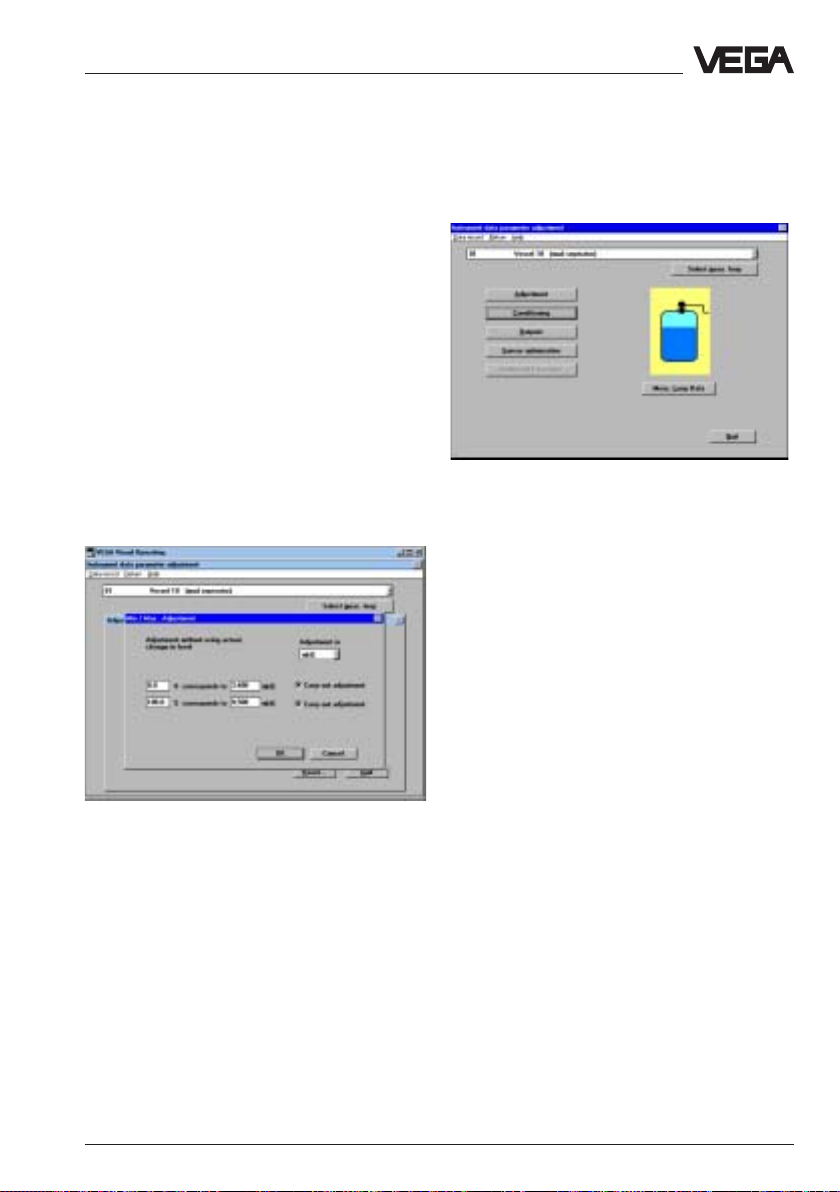

6.2 Adjustment with PC on VEGAMET

The PCThe PC

The PC with the adjustment program VVO

The PCThe PC

VV

VV

(

VEGA

VV

- to the sensor

- to the signal line

to the signal conditioning instrumentto the signal conditioning instrument

-

to the signal conditioning instrument

to the signal conditioning instrumentto the signal conditioning instrument

VEGAMET VEGAMET

VEGAMET 514V/515V

VEGAMET VEGAMET

- to the processing system VEGALOG 571

For connection of a PC to a signal

conditioning instrument you require the

interface adapter VEGACONNECT 2. The PC

communicates via the interface adapter

VEGACONNECT 2 with the signal

conditioning instrument and the sensor.

Hence a digital adjustment signal is

superimposed to the signal and supply line

between sensor and signal conditioning

instrument. In chapter "2.2 Configuration of

measuring systems" the connection of the PC

in different coordinations is shown.

In any case you are requested to enter or

enquire something, this is marked in the

following with a dot, such as e.g.:

• Choose …

• Start …

• Click to …

Now start to

• Connect the standard plug of

VEGACONNECT 2 (9-pole) with the

interface COM 1 or COM 2 of your PC.

• Plug the two small pin plugs of

VEGACONNECT 2 into the CONNECTsocket of the signal conditioning

instrument.

• Now switch on the voltage supply of the

signal conditioning instrument.

OO

Visual

Operating) can be connected:

VV

OO

After approx. 1…2 minutes (selfcheck) the

meas. system is generally ready for

operation and indicates measured values or

a failure.

VEGAPULS 51 V … 54 V 45

Page 46

Set-up - Adjustment with the PC on VEGAMET

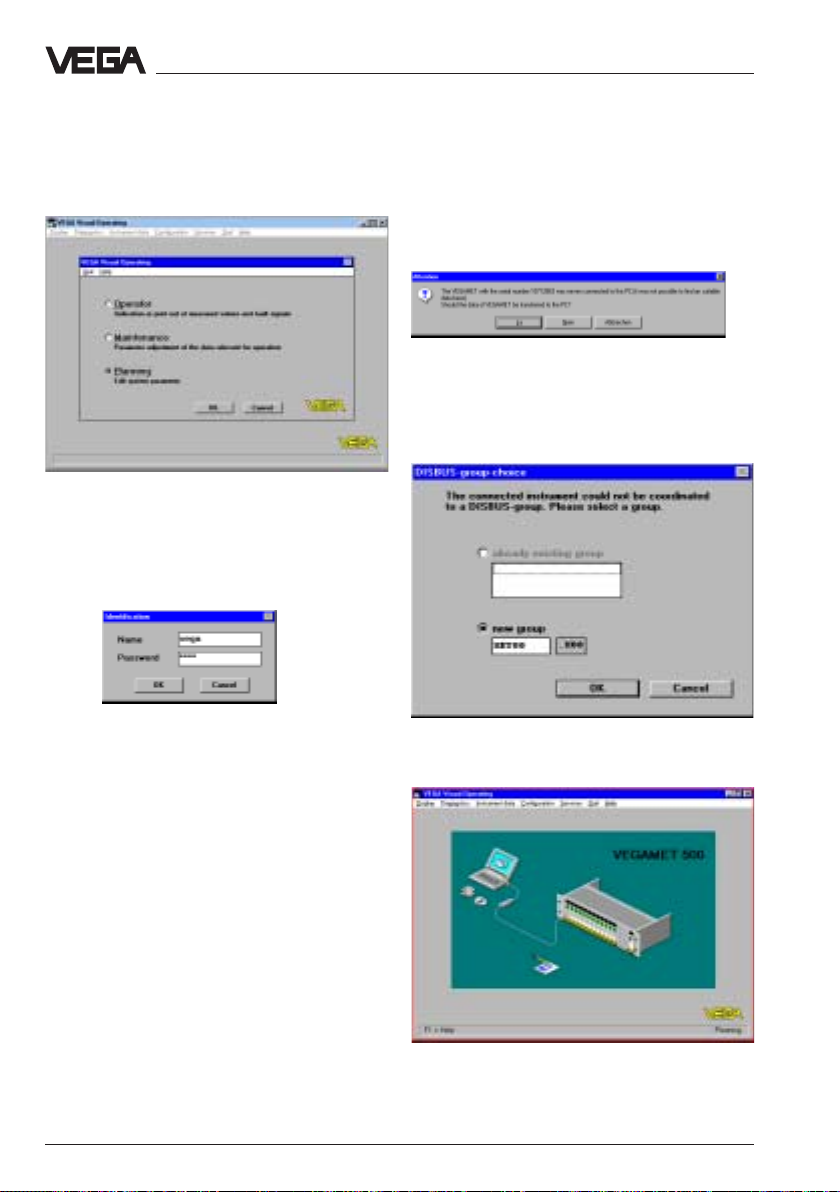

• Now start the adjustment software VVO on

your PC.

• In the entrance screen you choose with the

arrow keys or the mouse the item

PlanningPlanning

"

Planning

PlanningPlanning

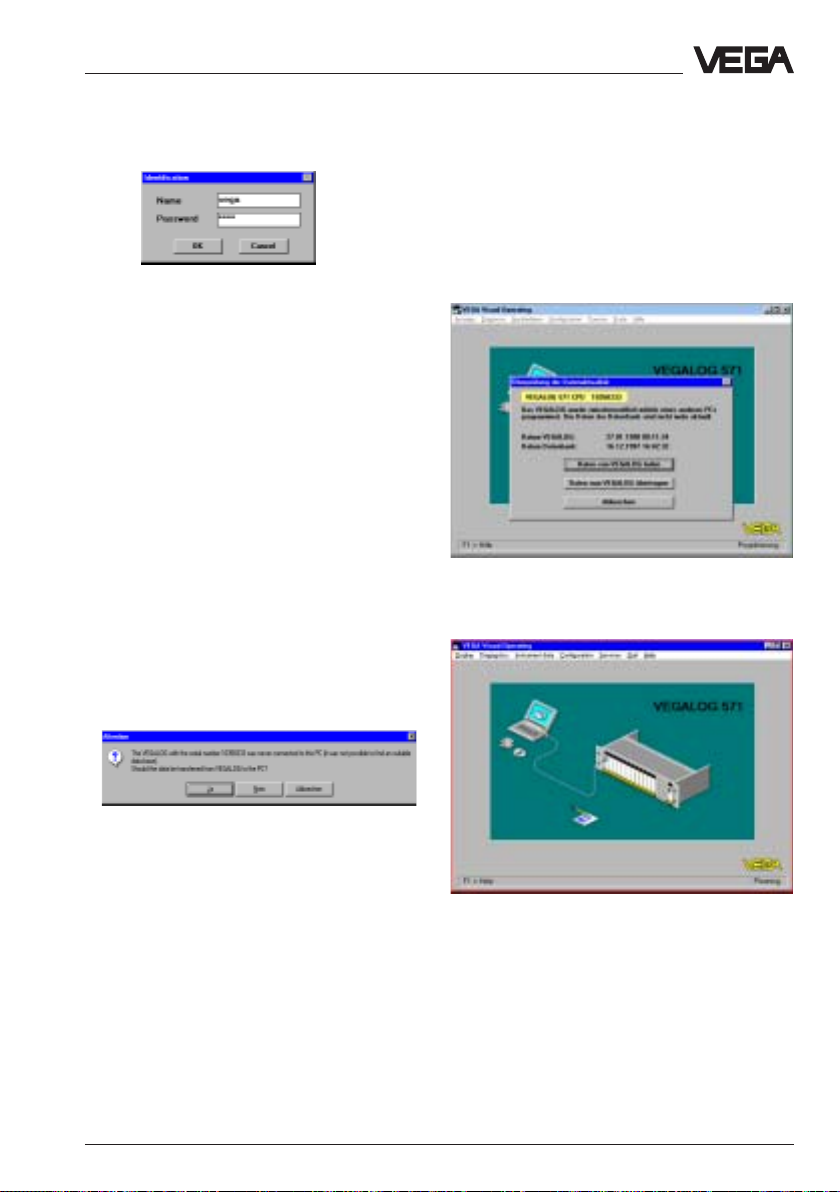

In the next window you are asked for the

identification.

• Enter under the name "

• Also enter under the password

The adjustment program, in the following

called VVO, gets in contact with the

connected coordination/sensor …… and

displays after a few seconds whether and

with which coordination/sensor a connection

exists.

" and click to "

OKOK

OK

".

OKOK

VEGAVEGA

VEGA

VEGAVEGA

".

VEGAVEGA

"

VEGA

VEGAVEGA

".

If VVO (adjustment software) gets in contact

with the signal conditioning instrument for the

first time, you are asked if the data should be

transmitted from the signal conditioning

instrument to the PC.

YY

• Click to "

In the following menu window "

choice

or keep the suggested file name.

• Click to "

window.

eses

Y

es

"

YY

eses

DISBUS-group

" you can give a name to the database

OKOK

OK

", and you are in the main menu

OKOK

Note:

If you do not get a sensor connection, please

check:

- is the sensor fed with power supply (min.

20 V)?

- do you use VEGACONNECT instead of the

new VEGACONNECT 2 ?

46 VEGAPULS 51 V … 54 V

Page 47

Set-up - Adjustment with the PC on VEGAMET

User access

The preadjusted identification can be

modified later in the menu "

Before starting the configuration:Before starting the configuration:

Before starting the configuration:

Before starting the configuration:Before starting the configuration:

The signal conditioning instruments are

preconfigured depenpent on the sensor type

you have ordered with the signal conditioning

instrument.

User accessUser access

User access

User accessUser access

".

Configuration

Before starting the set-up:Before starting the set-up:

Before starting the set-up:

Before starting the set-up:Before starting the set-up:

Take some time to carry out the set-up stepby-step with the PC and soon you will no

more require the following pages.

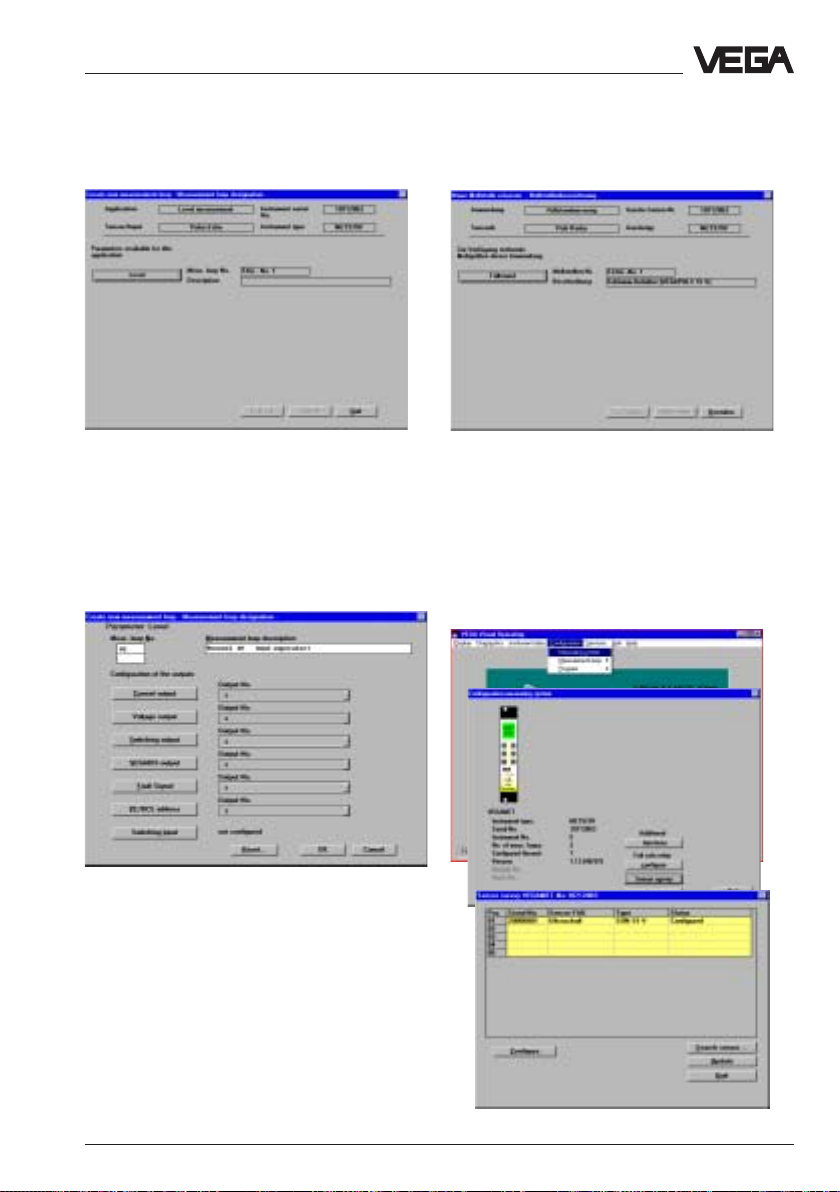

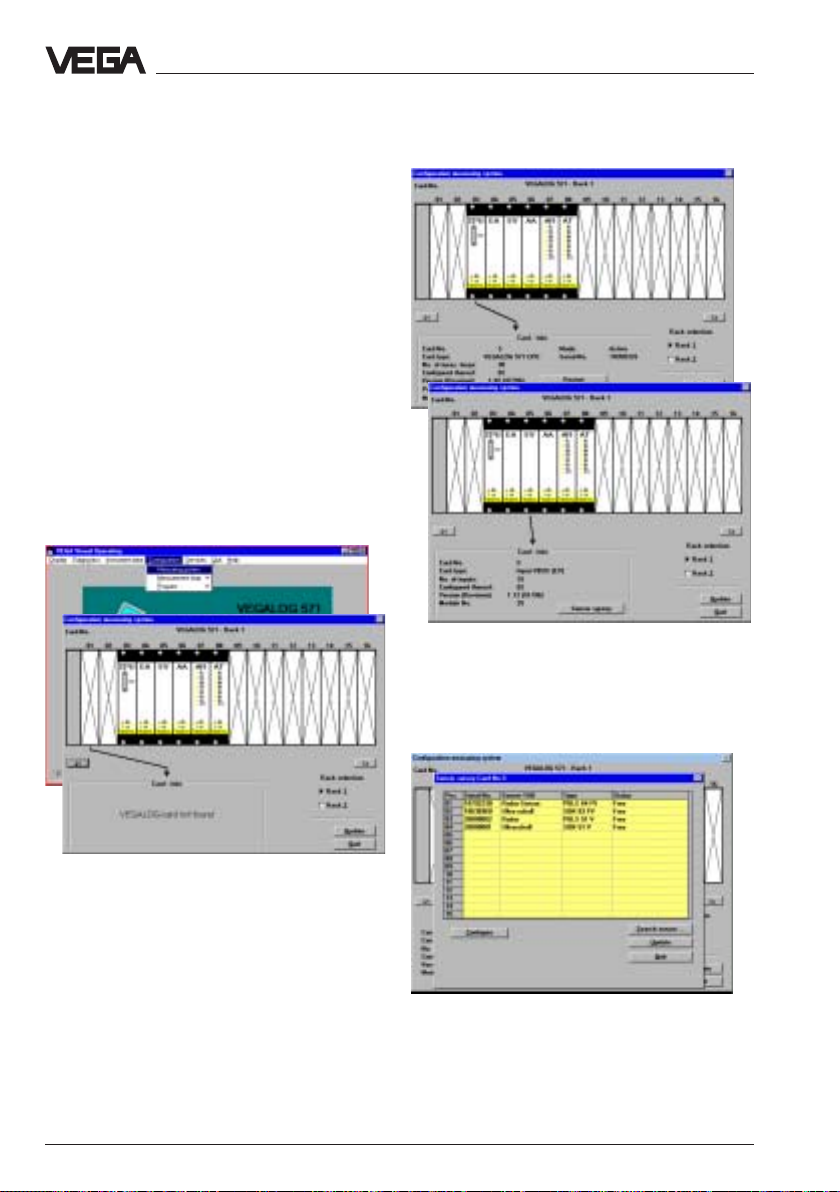

Create new measurement loop

• Choose the menu "

Measurement loop/Create newMeasurement loop/Create new

Measurement loop/Create new" and you

Measurement loop/Create newMeasurement loop/Create new

are in the menu window

measurement loop - Application"

Configuration/Configuration/

Configuration/

Configuration/Configuration/

"Create new

Generally you will use a preconfiguredGenerally you will use a preconfigured

Generally you will use a preconfigured

Generally you will use a preconfiguredGenerally you will use a preconfigured

signal conditioning instrument.signal conditioning instrument.

signal conditioning instrument.

signal conditioning instrument.signal conditioning instrument.

Hence you normally do not have to make anyHence you normally do not have to make any

Hence you normally do not have to make any

Hence you normally do not have to make anyHence you normally do not have to make any

adjustments in the menu "Configuration"adjustments in the menu "Configuration"

adjustments in the menu "Configuration"

adjustments in the menu "Configuration"adjustments in the menu "Configuration"

beginning on this page and in this case youbeginning on this page and in this case you

beginning on this page and in this case you

beginning on this page and in this case youbeginning on this page and in this case you

can directly choose the menu "Parametercan directly choose the menu "Parameter

can directly choose the menu "Parameter

can directly choose the menu "Parametercan directly choose the menu "Parameter

adjustment" (on page 50).adjustment" (on page 50).

adjustment" (on page 50).

adjustment" (on page 50).adjustment" (on page 50).

If as an exception your signal conditioning

instruments are not preconfigured, then start

with the following chapter "

this page and continue with the adjustments

in the chapter "Parameter adjustment" on

page 50.

VEGAPULS 51 V … 54 V 47

Configuration

" on

• Choose the parameter

measurement"measurement"

measurement" (gauge or distance) and the

measurement"measurement"

sensor type (

• Click to "

"pulse radar""pulse radar"

"pulse radar"

"pulse radar""pulse radar"

ContinueContinue

Continue

ContinueContinue

"

"Level "Level

"Level

"Level "Level

for radar).

Page 48

Set-up - Adjustment with the PC on VEGAMET

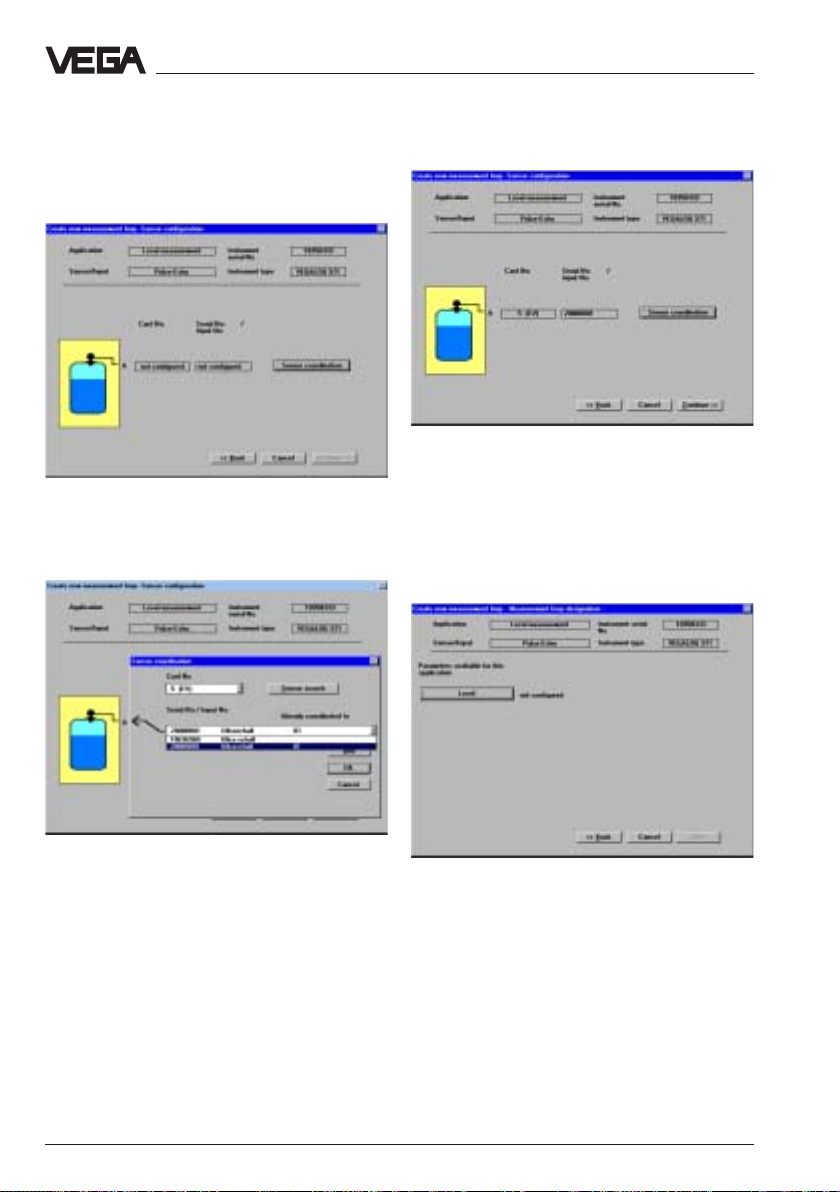

• Choose "

"

no options

• Click to "

"New application - select meas. loop"

opens

• Choose one of the two inputs of the signal

conditioning instrument VEGAMET

(VEGAMET 514 V has just one sensor

input) and click to "

After a few seconds the menu window

"Create new measurement loop - Sensor

configuration" opens.

• Click in the menu window "Create new

measurement loop - Sensor configuration"

to "

The menu window "

opens.

Standard level measurementStandard level measurement

Standard level measurement" and

Standard level measurementStandard level measurement

no optionsno options

no optionsno options

Sensor coordinationSensor coordination

Sensor coordination

Sensor coordinationSensor coordination

"

ContinueContinue

Continue

ContinueContinue

Sensor coordination

", and the menu window

OKOK

OK

"

OKOK

".

"

• Click to "

• Then click to "

number of the sensor which you want to

coordinate e.g. to input 1.

• Confirm with "

• Click in the menu window "Sensor

coordination" again to "

You are again in the menu window

Sensor searchSensor search

Sensor search

Sensor searchSensor search

InputInput

Input

" and choose the serial

InputInput

OKOK

OK

".

OKOK

".

OKOK

OK

OKOK

".

"Create

new measurement loop - Sensor

configuration"

• Click to "

48 VEGAPULS 51 V … 54 V

ContinueContinue

Continue

ContinueContinue