Page 1

Supple

mentary information

Recurring function

for VEGAFLEX series 60

test

Document ID:

36552

Page 2

1 Conte

nts

Conten

1 About this document

2 Prerequisites

3 Sequence of the recurring function test

4 Result of the recurring function test

5 Test protocol - Recurring function test

ts

2.1 Authorised personnel . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Required tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Required comparative data . . . . . . . . . . . . . . . . . . . .

2.4 Required plant situation . . . . . . . . . . . . . . . . . . . . . .

3.1 Restart of the sensor . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Verification of the current output . . . . . . . . . . . . . . . .

3.3 Verification of the instrument parameters . . . . . . . . . .

3.4 Verification of echo data . . . . . . . . . . . . . . . . . . . . . .

3.5 Sensor reaction to a level change . . . . . . . . . . . . . . .

5

5

5

5

7

9

10

11

12

2 Recurring

36552-EN-100225

function test • for VEGAFLEX series 60

Page 3

out this document

1 Ab

Why a function test?

Fault detection rate λ

92 %

1 Abou

t this document

The recurring function test serves to check the safety function and

reveal possible undetected, dangerous failures (λ

). The functional

du

capability of the measuring system has to be tested in adequate time

intervals. It is the user's responsibility to select an appropriate type of

testing. The time intervals are subject to the PFD

-value according to

avg

the specifications in the Safety Manual (SIL).

With high demand rate, a recurring function test is not requested in

IEC 61508. The functional efficiency of the measuring system is

demonstrated by the frequent use of the system. In double channel

architectures it is a good idea to verify the effect of the redundancy

through recurring function tests at appropriate intervals.

With this supplementary information you can carry out a recurring

function test of level sensors VEGAFLEX 61, 62, 63, 65 and 66 without

dismounting the instrument or moving the level of the medium to the

switching point.

With this procedure, 88 % or 92 % of all dangerous undetected

instrument failures (λ

) are detected (DC

du

Proof

).

The described function test fulfils the requirements according to SIL.

If you have already created a sensor documentation during setup, you

du

can check the sensor at a detection rate of 92 % of all dangerous

undetected failures.

The remaining dangerous undetected failures are 11 FIT.

FIT = Failure In Time (1 FIT = 1 failure/10

9

h)

Fault detection rate λ

88 %

36552-EN-100225

Recurring

function test • for VEGAFLEX series 60 3

e sure that also a later sensor documentation is possible. This

Mak

sensor documentation of a recurring function test must be at least 6

months old.

If you created no sensor documentation during setup, you can check

du

the sensor only at a detection rate of 88 % of all dangerous undetected

failures.

The remaining dangerous undetected failures are in this case 16 FIT.

9

FIT = Failure In Time (1 FIT = 1 failure/10

h)

Page 4

1 A bou

t this document

ase note the Ex-specific safety information for installation and

Ple

operation in Ex areas. These safety instructions are part of the scope

of delivery and come with the Ex-approved instruments.

Warning:

The recurring function test influences connected devices. Take note

that downstream devices may be activated during the test.

Informa

tion:

Proceed according to the specified, recommended sequence of these

instructions to isolate possible device failures systematically.

Informa

tion:

Document the recurring function test, for example, in the test protocol

in the supplement. To facilitate the recording and for further function

tests, we recommend to copy the empty test protocol before

completing it.

This supplementary information manual can be downloaded from our

download section.

Th

e recurring function test cannot replace the prescribed test

according to WHG (Water Resources Act).

4 Recurring

36552-EN-100225

function test • for VEGAFLEX series 60

Page 5

2 Prer

equisites

2 Prere

quisites

2.1 Authorised personnel

All operations described in this operating instructions manual must be

carried out only by trained specialist personnel authorised by the plant

operator.

During work on and with the device the required personal protective

equipment must always be worn.

2.2 Required tools

l This test instruction

l PACTware

l Actual VEGA DTM Collection

l Device-DTM of the corresponding sensor (part of the VEGA DTM

Collection)

l Communication-DTM (part of the VEGA DTM Collection)

l Interface adapter VEGACONNECT

l mA-meter or PLC resp. DCS (accuracy ≤±0.2 %)

l Operating instructions manual of the sensor

l Safety Manual

2.3 Required comparative data

The setup data should be used for verification of the settings.

The following setup data are required:

l Sensor documentation of the setup with all parameters or a sensor

documentation created at least 6 months ago

l Documentation of all parameter changes since the setup

36552-EN-100225

Recurring

the sensor documentation of the setup or a sensor documentation

If

created at least 6 months ago is not available, then the described

recurring function test (λ

92 %) cannot be carried out completely. In

du

this case, only the test at a detection rate of 88 % of all dangerous,

undetected failures is possible.

2.4 Required plant situation

Caution:

e sure that there are no considerable process-relating changes in

Mak

your plant during the recurring function test. This means also that the

level in the vessel should not change significantly by filling or emptying

during the test. Make sure that also temperature changes, stirrers,

current reactions in the vessel, etc. can cause level changes.

function test • for VEGAFLEX series 60 5

Page 6

0

0

V

dB

3

1

2

2 P rereq

uisites

tion:

Informa

Document the recurring function test, for example, in the test protocol

in the supplement.

The following conditions must be fulfilled when performing the

recurring function test:

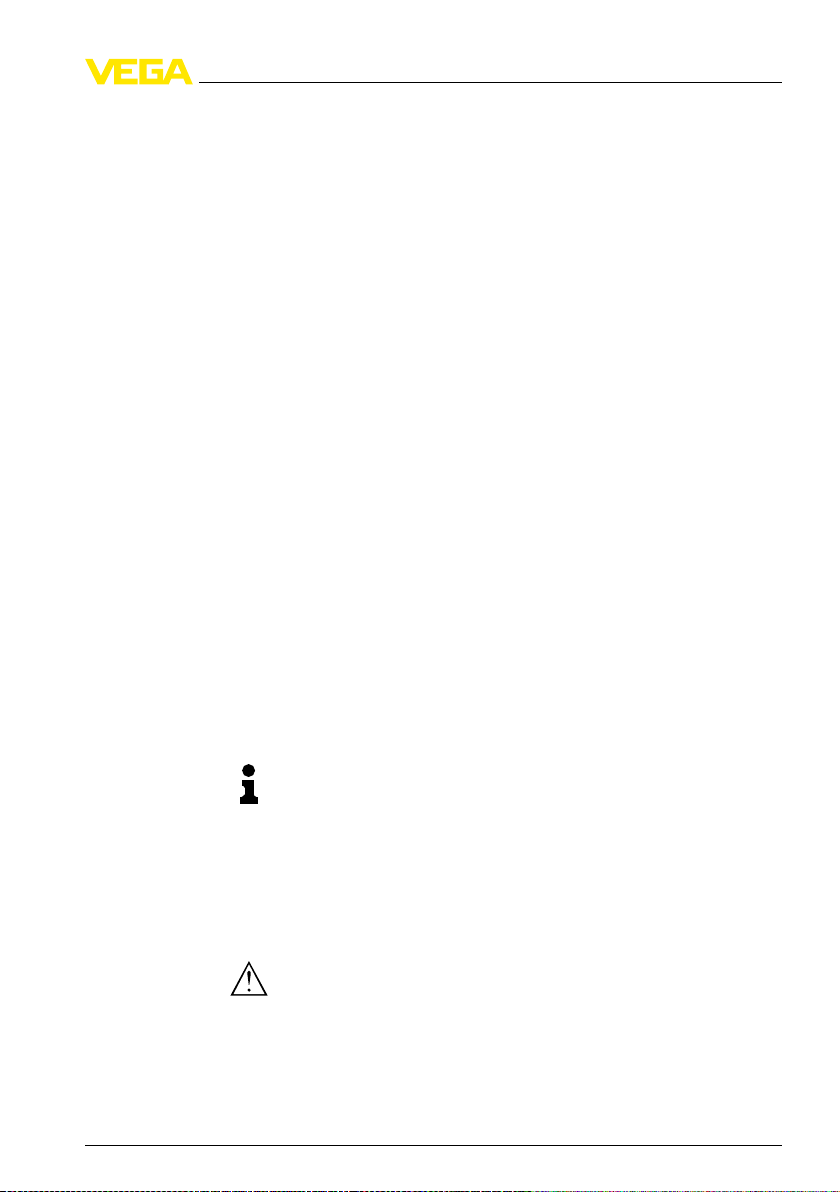

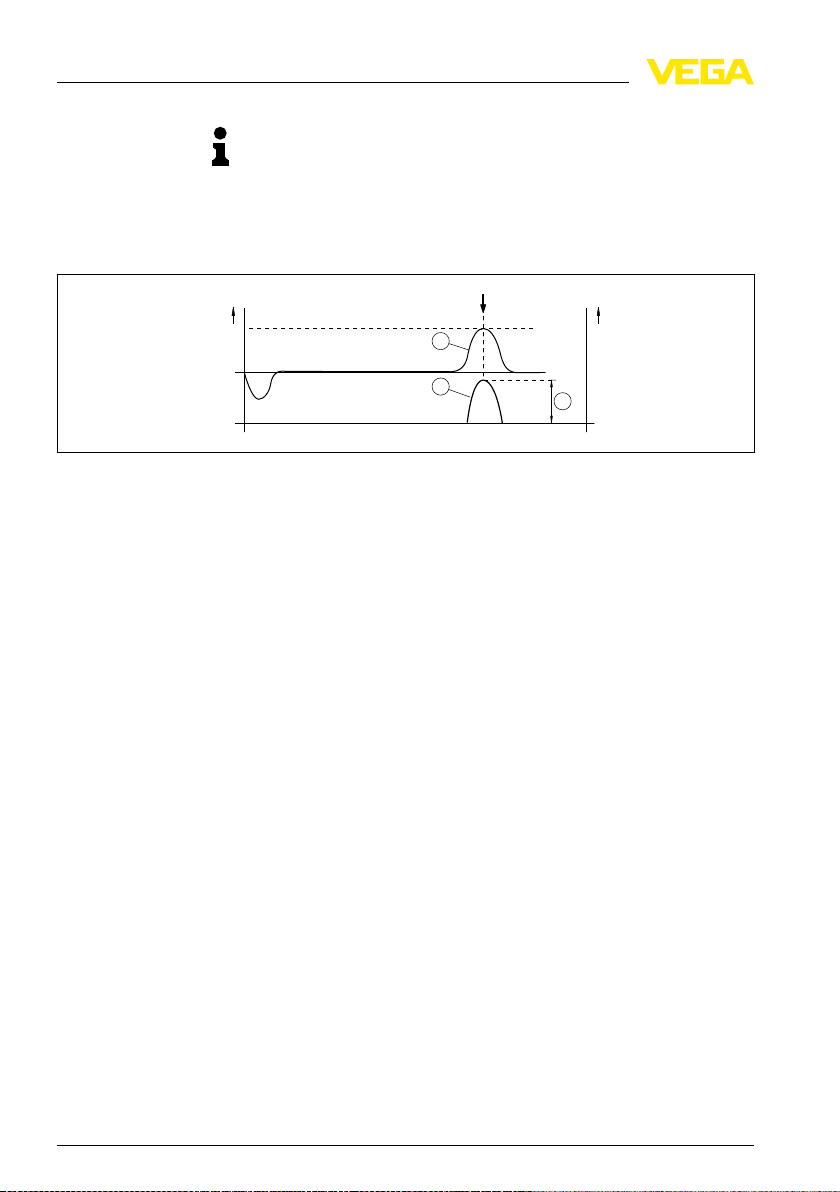

Fig. 1: Level

1 Echo curve

2 Logarithmic echo curve

3 Amplitude of the useful echo (logarithmic echo curve)

echo - VEGAFLEX

l The process conditions must be nearly constant (level, process

pressure, process temperature)

l The medium must be the same as during setup or the medium

must at least belong to the same product group.

- Solvents/Liquid gases/Hydrocarbons/Oils (DK value < 3)

- Chemical mixtures (DK value 3 … 10)

- Water/Acids/Bases (DK value > 10 or conductive)

l The level must be either in the following areas:

- Distance to the process fitting ≥ 200 mm.

- Min. covering of the rod electrode ≥ 100 mm/cable electrode

≥ 250 mm.

-

- or the following requirement must be fulfilled:

-

- Reliability at least 20 dB (amplitude of the useful logarithmic

echo above the noise level). The reliability can be verified

during the test.

36552-EN-100225

6 Recurring

function test • for VEGAFLEX series 60

Page 7

ence of the recurring function test

3 Sequ

Function test not successful

3 Sequen

ce of the recurring function test

Carry out the recurring function test in the following sequence:

l 3.1 Restart the sensor

l 3.2 Verification of the current output

l 3.3 Verification of the instrument parameters (only with sensor

documentation)

l 3.4 Verification of the echo data (only with sensor documentation)

l 3.5 Sensor reaction to a level change

Informa

tion:

Document the recurring function test, for example, in the test protocol

in the supplement

If one of the test points was not terminated successfully, there is

probably an undetected dangerous failure. The recurring function test

has failed.

In this case, proof of functional safety can only be provided by moving

the level to the switching point.

3.1 Restart of the sensor

With this test point, it is possible to check of the sensor ouputs the

same value within the prescribed min. accuravy after a restart.

ning:

War

The recurring function test influences connected devices. Take note

that downstream devices may be activated during the test.

Before the restart

36552-EN-100225

Recurring

function test • for VEGAFLEX series 60 7

Carry out a restart of the sensor. Proceed as follows:

1 Start PACTware and the corresponding sensor DTM.

Make sure that the conditions to the plant situation are maintained.

See "Required plant situation".

(range of the actual level or the reliability at least 20 dB)

2 Set the indication to "Current".

3 The level is subject to plant or process-relevant fluctuations.

Control the indicated current values over an adequate period.

Make sure that a damping is probably adjusted on the sensor.

4 Note the upper and lower limit values of the measured value.

5 Measure the output current of the sensor.

Preferrably use the indication of the input current value in the

processing system.

Page 8

1

2

3

mA

3 Sequenc

e of the recurring function test

you do not have this possibility, connect an mA-meter according

If

to the following illustration.

You require the mA-meter for the verification of the current output

in the next test point. The accuracy of the mA-meter should be

better than 0.2 %. Select the smallest measuring range covering

4 … 20 mA.

After switching on again

Fig. 2: Connection

1 Level sensor

2 Processing system

3 mA-meter

6 Switch off the power supply.

7 Switch the voltage supply on again after approx. 10 s.

If the software signals a communication error during or after

switching off the power supply, you have to acknowledge it.

After connecting the sensor to power supply respectively after the

voltage recurrence, the instrument carries out a self-check for approx.

30 seconds:

l Internal check of the electronics

l The output signal jumps to the set error current

Then the current corresponding to the level is outputted to the cable.

1 The level is subject to plant or process-relevant fluctuations.

Control the indicated current values over an adequate period.

2 Note the upper and lower limit values of the measured value.

3 Compare the actually noted current values with the previously

noted values.

The two values must correspond within the safety accuracy of 2 %

(±0.32 mA).

If the two differential values are within the safety accuracy, then the

test of the restart was successful.

Continue with the next test point.

of the mA-meter

36552-EN-100225

8 Recurring

function test • for VEGAFLEX series 60

Page 9

ence of the recurring function test

3 Sequ

Simulation 4 mA

Simulation 20 mA

3.2 Verificat

In this test point you simulate certain level values via the current

output. With this you can test the reaction of the sensor with different

current output values and the switching behaviour.

Warning:

The recurring function test influences connected devices. Take note

that downstream devices may be activated during the test.

1 Select in the DTM under the menu "Service" the menu item

"Simulation".

2 Select "Current" as measured variable for the simulation.

3 Activate the simulation.

4 Set the simulation value to 4 mA.

Take note that downstream devices may be activated.

5 Accept the simulation value.

Wait approx. 30 s.

The simulation is running and a corresponding current is being

outputted.

6 Note the displayed value (4 mA simulation) of the mA-meter.

The value must correspond with the simulated value within the

safety accuracy of 2 % (±0.32 mA).

Continue with the simulation if the two values correspond.

1 Set the simulation value of the current simulation to 20 mA.

Take note that downstream devices may be activated.

2 Accept the simulation value.

Wait approx. 30 s.

The simulation is running and a corresponding current is being

outputted.

3 Note the displayed value (20 mA simulation) of the mA-meter.

The value must correspond with the simulated value within the

safety accuracy of 2 % (±0.32 mA).

The verification of the current output was successful if the two values

correspond.

ion of the current output

36552-EN-100225

Recurring

Caution:

ate the simulation.

Deactiv

Continue with the next test point.

function test • for VEGAFLEX series 60 9

Page 10

3 Sequenc

e of the recurring function test

Create a current sensor

documentation

3.3 Verificat

For this test point, the sensor documentation of the setup or the last

sensor documentation (at least 6 months old) is required. If a

parameter was changed since then, you also require the protocol or

the sensor documentation of this parameter change.

If this sensor documentation is not available, then the described

recurring function test cannot be carried out completely. In this case,

only the test with a detection rate of 88 % of all dangerous, undetected

failures is possible.

In this case, you continue with the test point "Sensor reaction on level

change" or create an actual sensor documentation and carry out the

function test after at least 6 months. The actual parameter adjustment

must be checked for correctness in the respect.

A sensor documentation was generated directly after the setup or at

least 6 months ago. For assessment of the instrument parameters, this

sensor documentation of the setup, the actual sensor documentation

of the last parameter change or the sensor documentation generation

and checked 6 months ago must be taken into consideration.

Create now a sensor documentation with the current instrument

parameters. Proceed as follows:

1 Select the function "Print" in the DTM.

2 For complete sensor documentation, you have to select all

instrument parameters (except laboratory parameters).

A multiple-page pdf documentation containing all relevant sensor

data is then generated.

3 Save this documentation as pdf document and, where appropriate,

print out the documentation to be on the safe side.

4 Compare the instrument parameters of this actual sensor

documentation with the sensor documentation of the setup or the

last parameter change.

Deviating parameters must be documented, justified and checked

on correctness.

If the actual sensor documentation corresponds to the stored sensor

documentation or if the modified parameters are correct, then the

verification of the instrument parameters was successful.

Continue with the next test point.

ion of the instrument parameters

36552-EN-100225

10 Recurring

function test • for VEGAFLEX series 60

Page 11

ence of the recurring function test

3 Sequ

Exception: Cable probes

> 10 m

3.4 Verificat

ion of echo data

For this test point, you require the sensor documentation of the setup

or a sensor documentation created at least 6 months ago.

If none of these sensor documentations is available, the described

recurring function test (λ

92 %) cannot be carried out.

du

Only the test at a detection rate of 88 % of all dangerous undetected

failures is possible. In this case, just skip this test point.

In this case, continue with the test point "Sensor reaction on level

change".

Use the two pdf files of the sensor documentation again for

assessment of the level echo.

Under chapter "Echo curve" you will find a short chart containing the

"Echo data". The data of this chart are relevant for the assessment.

Compare the values of the two echo data charts. The echo curve itself

cannot be compared.

The following criteria must correspond when comparing the echo data:

l The level echo (highest useful echo probability) is at the top of the

echo data chart.

l The amplitude [dB] of the actual level echo (highest useful echo

probability) corresponds t o the respective value of the level echo

from the setup (tolerance max. -6 dB). This means that the actual

level echo can be higher, but only max. 6 dB lower than the level

echo during setup.

With cable probes > 10 m proceed as follows:

1 Compare the distance [m] of the two level echoes (actual/setup).

2 Calculate the difference of t he distance [m] of the two level echoes

(actual/setup).

Round off this value to the metre (m).

3 Multiply the difference by the factor 0.5.

4 If the distance of the actual level is smaller than the distance

during setup, subtract this value from the amplitude of the actual

level value.

If the distance of the actual level is larger than the distance during

setup, add this value to the amplitude of the actual level value.

5 This corrected value of the amplitude [dB] of the actual level echo

can be higher, but only max. 6 dB lower than the level echo during

setup.

36552-EN-100225

Recurring

function test • for VEGAFLEX series 60 11

Page 12

3 Sequenc

e of the recurring function test

e

Exampl

During setup, the level echo had 32 dB. The distance [m] to the

medium was 12.5 m.

The actual level echo has 25 dB. The distance [m] to the medium is

16.1 m.

Calculation of the difference of the two distance values: 16.1 m -

12.5 m = 3.6 m

Rounding off the calculated difference: 3.6 --> 3

Multiplying the difference with the factor (0.5): 3 * 0 .5 = 1.5

Because the distance of the actual level is larger than the distance

during setup, this value will be added to the amplitude of the actual

level value:

25 dB + 1.5 = 26.5 dB

The result of the example (26.5 dB) is thus within the permissible

tolerance range of - 6 dB (32 dB - 6 dB = 26 dB)

In this example, the test point would be successfully fulfilled.

If all the above conditions are fulfilled, the measurement works

correctly and the verification of the echo data was successful.

Continue with the next test point.

3.5 Sensor reaction to a level change

With this test point, you monitor the reaction of the sensor during a

level change.

1 Set the indication of the sensor DTM to "Distance".

2 Change the filling of your vessel.

It doesn't matter if you fill or empty the vessel.

The filling speed is also not relevant.

The level change must be at least 50 mm.

3 Take note of the sensor reaction.

Does the measured value [m(d)] move in the correct direction

during emptying/filling?

The displayed measured value (distance) is the distance between

seal surface of the sensor and the product surface.

● The measured value will decrease during filling.

● The measured value will increase during emptying.

When the level value changes analogue to the level change, the

measurement works correctly and the assessment of the sensor

reaction was successful.

12 Recurring

36552-EN-100225

function test • for VEGAFLEX series 60

Page 13

ence of the recurring function test

3 Sequ

all function tests were successful, the recurring function test is

If

finished.

If you used an mA-meter for the recurring function test, switch off the

sensor and remove the mA-meter from the sensor cable after finishing

the recurring function test.

36552-EN-100225

Recurring

function test • for VEGAFLEX series 60 13

Page 14

esult of the recurring function test

4 R

esult of the recurring function test

4 R

Function test successful

Function test not suc-

cessful

If all test points could be terminated successfully, then the recurring

function test was successful.

Fulfilled test points

3.1 / 3.2 / 3.3 / 3.4 / 3.5 Fault detection rate λ

3.1 / 3.2 / 3.5 (sensor documentation

of the setup or a sensor documentation created at least 6 months ago, is

not available)

Fault detection rate λdu88 %

du

92 %

The test must be repeated in regular intervals. The time periods

depend on the PFD

value according to the sepcifications in the

avg

Safety Manual (SIL).

If one of the test points (3.1 / 3.2 / 3.5) could not be terminated

successfully, there is probably an undetected dangerous failure. The

recurring function test has failed.

In this case, proof of functional safety can only be provided by moving

the level to the switching point.

14 Recurring

36552-EN-100225

function test • for VEGAFLEX series 60

Page 15

est protocol - Recurring function test

5 T

5 Test

protocol - Recurring function test

If you copy this protocol, please note the date of the function test, the

measurement loop and the sensor serial number on each page.

Specifications VEGAFLEX

Tester

Measurement loop name (sensor-TAG)

Sensor type

Sensor length

Serial number of the sensor

Software version

Required plant situation (according to 2.4) □ maintained

Safety-instrumented system (SIS) □ yes

SIL activated □ yes

Medium or product group

Date of the setup (sensor documentation)

Date of the last function test (if carried out)

Test 3.1 - Restart of the sensor

Measured value before switching off Current value min. in mA Current value max. in mA

Measured value after switching on

again

Difference of the current values Current value min. in mA Current value max. in mA

Duration of the inspection in s

Test result

Min. and max. values

Current value min. in mA Current value max. in mA

□ Deviation ≤ 2 %

(test point successful)

□ Deviation > 2 %

(test point not successful)

Test 3.2 - Verification of the current output

Lower simulation value (4 mA) Indication mA-meter in mA

Intermediate result ≤ 2 % (≤0.32 mA) □ Corresponds □ Does not correspond

Upper simulation value (20 mA) Indication mA-meter in mA

Intermediate result ≤ 2 % (≤0.32 mA) □ Corresponds □ Does not correspond

Test result - Total □ Corresponds □ Does not correspond

36552-EN-100225

Recurring

function test • for VEGAFLEX series 60 15

Page 16

est protocol - Recurring function test

5 T

Test 3.3 - Verification of the instrument parameters

□ Sensor documentation of the

setup available

or

□ Sensor documentation (at least 6

months old) is available

File name:

□ Parameters correspond

□ Parameters do not correspond -

however checked on correctness

□ Parameters do not correspond -

deviation not acceptable

□ Sensor documentation of the

setup not available

□ Parameters checked on correct-

ness and saved (recheck after 6

months necessary)

File name:

File name:

File name:

Test result □ All parameters correct or

□ Parameters not correct

checked on correctness

Tester:

Test 3.4 - Verification of the echo data

Useful echo (completely on top) □ Corresponds □ Does not correspond

Corresponding amplitude □ In the tolerance range □ Not in the tolerance range

Test result □ Corresponds □ Does not correspond

Test 3.5 - Verification of the sensor reaction

Reduction of the level □ Distance value [m] increases □ Other reaction

Increase of the level □ Distance value [m] decreases □ Other reaction

Test result □ Corresponding sensor reaction □ Sensor reaction does not corre-

spond

● Summary 92 % (λ

)

du

Date Signature

Test 3.1 / 3.2 / 3.3 / 3.4 / 3.5 □ All five test points passed □ One or several test points did not

pass

36552-EN-100225

● Summary 88 % (λ

)

du

Date Signature

16 Recurring

function test • for VEGAFLEX series 60

Page 17

est protocol - Recurring function test

5 T

● Summary 88 % (λ

Test 3.1 / 3.2 / 3.5 □ All three test points passed □ One or several test points did not

)

du

pass

Date ___________________________________

Signature ___________________________________

36552-EN-100225

Recurring

function test • for VEGAFLEX series 60 17

Page 18

est protocol - Recurring function test

5 T

18 Recurring

36552-EN-100225

function test • for VEGAFLEX series 60

Page 19

est protocol - Recurring function test

5 T

36552-EN-100225

Recurring

function test • for VEGAFLEX series 60 19

Page 20

VEGA Grieshaber KG

ISO 9001

Am Hohenstein 113

77761 Schiltach

Germany

Phone +49 7836 50-0

Fax +49 7836 50-201

E-mail: info@de.vega.com

www.vega.com

Printing date:

statements concerning scope of delivery, application,

All

practical use and operating conditions of the sensors and

processing systems correspond to the information avail-

able at the time of printing.

© VEGA Grieshaber KG, Schiltach/Germany 2010

Subject to change without prior notice 36552-EN-100225

Loading...

Loading...