Page 1

Ope

p

rating Instructions

VEGADIF 55

4 … 20 mA/HART

Differe

ntial pressure

Page 2

Contents

Conten

1 About this document

2 For your safety

3 Product description

4 Mounting

ts

1.1 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Target group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Symbolism used . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Authorised personnel . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Appropriate use . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Warning about misuse . . . . . . . . . . . . . . . . . . . . . . .

2.4 General safety instructions . . . . . . . . . . . . . . . . . . . .

2.5 Safety approval markings and safety tips . . . . . . . . .

2.6 Safety approval markings and safety tips . . . . . . . . .

2.7 CE conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8 Safety instructions for Ex areas . . . . . . . . . . . . . . . .

2.9 Environmental instructions . . . . . . . . . . . . . . . . . . . .

3.1 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Principle of operation . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Packaging, transport and storage . . . . . . . . . . . . . . .

4.1 General instructions . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Mounting instructions for flow measurement . . . . . . .

4.3 Mounting instructions for level measurement . . . . . . .

4.4 Mounting instructions with differential pressure

measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 Mounting for instruments with isolating diaphragms ..

4.6 Mounting instructions for seal with flange mounting . .

4.7 Heat insulation of instruments with flange isolating

diaphragm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.8 Mounting instructions for wall or tube mounting . . . . .

4.9 Mounting control . . . . . . . . . . . . . . . . . . . . . . . . . . .

4

4

4

5

5

5

5

6

6

6

6

6

7

8

9

9

11

12

15

20

21

24

24

26

26

5 Connecting to power supply

5.1 Preparing the connection . . . . . . . . . . . . . . . . . . . . .

5.2 Connection procedure . . . . . . . . . . . . . . . . . . . . . . .

5.3 Wiring plan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 Take 4 … 20 mA test signal . . . . . . . . . . . . . . . . . . .

5.5 Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6 Connection control . . . . . . . . . . . . . . . . . . . . . . . . .

5.7 Switch on phase . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Operation

6.1 Short description . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Local indication (optional) . . . . . . . . . . . . . . . . . . . .

6.3 Adjustment elements . . . . . . . . . . . . . . . . . . . . . . . .

6.4 Local adjustment - local indication not connected . . .

2 VEG

27

28

28

30

30

30

31

31731-EN-081119

32

32

35

37

ADIF 55 • 4 … 20 mA/HART

Page 3

Contents

6.5 Loca

6.6 Data memory module (optional) . . . . . . . . . . . . . . . .

6.7 Copy configuration data . . . . . . . . . . . . . . . . . . . . . .

6.8 Adjustment via HART handheld . . . . . . . . . . . . . . . .

6.9 Lock/Unlock adjustment . . . . . . . . . . . . . . . . . . . . . .

6.10 Default setting (reset) . . . . . . . . . . . . . . . . . . . . . . .

6.11 Menu schematic . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Set up

7.1 Warning instructions . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Installation and function control . . . . . . . . . . . . . . . . .

7.3 Select language and measuring mode . . . . . . . . . . .

7.4 Position correction . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5 Flow measurement . . . . . . . . . . . . . . . . . . . . . . . . .

7.6 Level measurement . . . . . . . . . . . . . . . . . . . . . . . . .

7.7 Differential pressure measurement . . . . . . . . . . . . . .

8 Maintenance and fault rectification

8.1 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Remove interferences . . . . . . . . . . . . . . . . . . . . . . .

8.3 Replacement parts . . . . . . . . . . . . . . . . . . . . . . . . .

8.4 Instrument repair . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 Dismounting

9.1 Dismounting steps . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 Supplement

10.1 Technical data and dimensions . . . . . . . . . . . . . . . .

l adjustment - local indication connected . . . . . .

40

44

45

48

48

49

52

57

57

57

58

59

64

74

78

78

78

79

80

80

81

31731-EN-081119

VEGADIF 55 • 4 … 20 mA/HA

Supplementary documentation

tion:

Informa

Supplementary documents appropriate to the ordered version come

with the delivery. You can find them listed in chapter "Product

description".

RT 3

Page 4

1 Abou

t this document

1 Abou

t this document

1.1 Function

This operating instructions manual provides all the information you

need for mounting, connection and setup as well as important

instructions for maintenance and fault rectification. Please read this

information before putting the instrument into operation and keep this

manual accessible in the immediate vicinity of the device.

1.2 Target group

This operating instructions manual is directed to trained personnel.

The contents of this manual should be made available to these

personnel and put into practice by them.

1.3 Symbolism used

Inform

ation, tip, note

This symbol indicates helpful additional information.

Cauti

on: If this warning is ignored, faults or malfunctions can

result.

Warning: If this warning is ignored, injury to persons and/or serious

damage to the instrument can result.

Danger: If this warning is ignored, serious injury to persons and/or

destruction of the instrument can result.

applications

Ex

This symbol indicates special instructions for Ex applications.

l List

The dot set in front indicates a list with no implied sequence.

à Action

Th

is arrow indicates a single action.

1 Sequence

Numbers set in front indicate successive steps in a procedure.

4 VEG

31731-EN-081119

ADIF 55 • 4 … 20 mA/HART

Page 5

your safety

2 For

or your safety

2 F

2.1 Authorised personnel

All operations described in this operating instructions manual must be

carried out only by trained specialist personnel authorised by the plant

operator.

During work on and with the device the required personal protection

equipment must always be worn.

2.2 Appropriate use

VEGADIF 55 is a differential pressure transmitter for measurement of

flow, level or differential pressure.

You can find detailed information on the application range in chapter

"Product description".

Operational reliability is ensured only if the instrument is properly used

according to the specifications in the operating instructions manual as

well as possible supplementary instructions.

For safety and warranty reasons, any invasive work on the device

beyond that described in the operating instructions manual may be

carried out only by personnel authorised by the manufacturer. Arbitrary

conversions or modifications are explicitly forbidden.

2.3 Warning about misuse

Inappropriate or incorrect use of the instrument can give rise to

application-specific hazards, e.g. vessel overfill or damage to system

components through incorrect mounting or adjustment.

31731-EN-081119

VEGADIF 55 • 4 … 20 mA/HA

2.4 General safety instructions

This is a high-tech instrument requiring the strict observance of

standard regulations and guidelines. The user must take note of the

safety instructions in this operating instructions manual, the countryspecific installation standards as well as all prevailing safety

regulations and accident prevention rules.

The instrument must only be operated in a technically flawless and

reliable condition. The operator is responsible for trouble-free

operation of the instrument.

During the entire duration of use, the user is obliged to determine the

compliance of the required occupational safety measures with the

current valid rules and regulations and also take note of new

regulations.

RT 5

Page 6

2 For

your safety

2.5 Safety

The safety approval markings and safety tips on the device must be

observed.

approval markings and safety tips

2.6 Safety approval markings and safety tips

The safety approval markings and safety tips on the device must be

observed.

2.7 CE conformity

VEGADIF 55 is CE conform to EMVG (89/336/EWG), NSR (73/23/

EWG) and corresponds to NAMUR recommendation EMC (NE 21).

Conformity has been judged according to the following standards:

l EMC: Emission EN 61326 instrument B, susceptibility EN 61326

supplement A (industrial area)

l LVD: EN 61010-1

The instrument corresponds to article 3 (3) of EG directive 97/23/EG

pressure device regulation and is designed according to good

engineering experience. VEGADIF 55 as basic instrument with PN 420

withtout isolating diaphragm is suitable for stable gases of group 1,

category 1.

2.8 Safety instructions for Ex areas

Please note the Ex-specific safety information for installation and

operation in Ex areas. These safety instructions are part of the

operating instructions manual and come with the Ex-approved

instruments.

2.9 Environmental instructions

Protection of the environment is one of our most important duties. That

is why we have introduced an environment management system with

the goal of continuously improving company environmental protection.

The environment management system is certified according to DIN

EN ISO 14001.

Please help us fulfil this obligation by observing the environmental

instructions in this manual:

l Chapter "Packaging, transport and storage"

l Chapter "Disposal"

6 VEG

31731-EN-081119

ADIF 55 • 4 … 20 mA/HART

Page 7

+ –

2

1

3

3 Produc

t description

Scope of delivery

Components

3 Produc

t description

3.1 Configuration

The scope of delivery encompasses:

l VEGADIF 55 differential pressure transmitter

l Version with lateral flanges of 316L or C22.8: in addition 2

ventilation valves, 316L

l Version with lateral flanges of 316L or C22.8 and lateral

ventilations: in addition 4 closing screws, 316L

l Optional accessory

l Documentation

- this operating instructions manual

- Short instruction (in housing cover)

- Final inspection protocol

- Supplementary instructions manual - 31732 "Service instruc-

tions for VEGADIF 55"

- Ex-specific "Safety instructions" (with Ex-versions)

- if necessary, further certificates

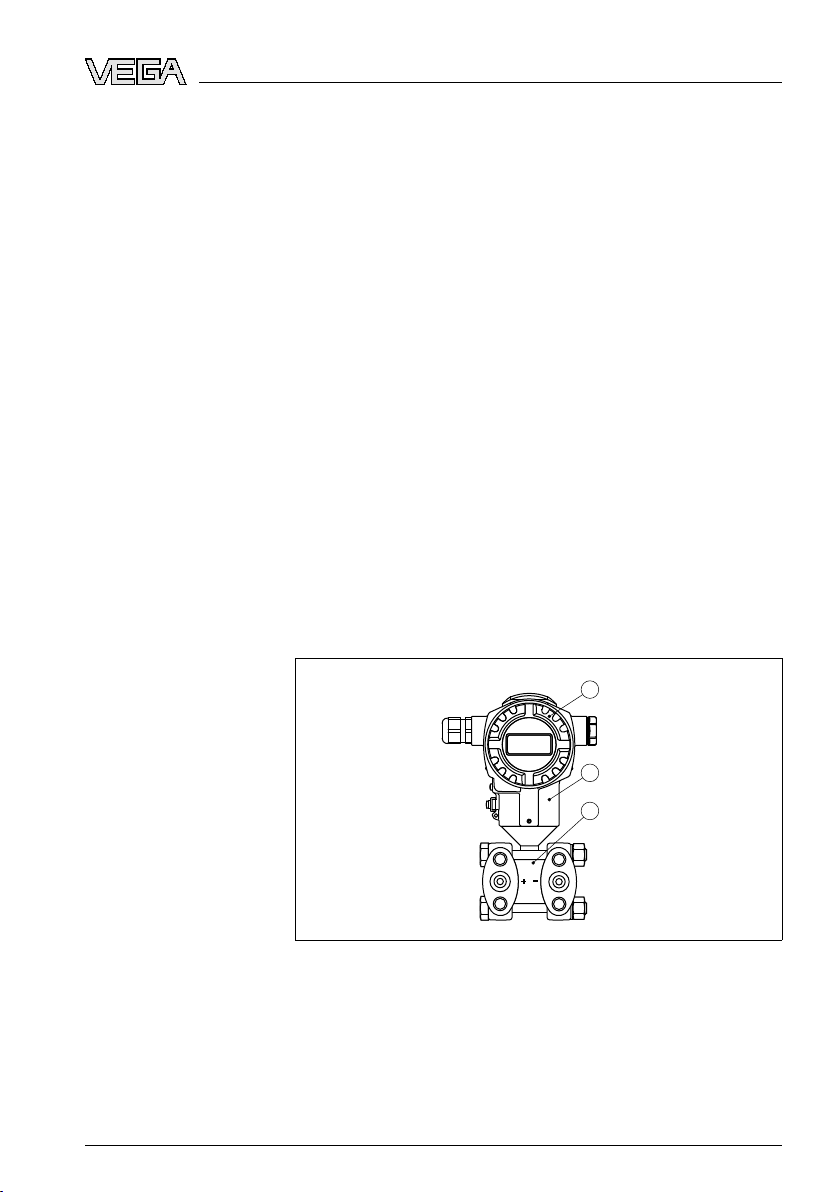

VEGADIF 55 consists of the following components:

l Process fitting w ith measuring cell

l Housing with electronics, optionally available with plug connector

l Housing cover, optionally available with local indication

The components are available in different versions.

Type label

31731-EN-081119

VEGADIF 55 • 4 … 20 mA/HA

Fig. 1: VEGADIF 55 in

1 Housing cover, optionally available with subjacent on-site indication

2 Housing with electronics

3 Process fitting with measuring cell

The type label contains the most important data for identification and

use of the instrument:

l Article number

l Serial number

basic version

RT 7

Page 8

1

2

3

4

5

1

p

2

p

3 Produc

t description

hnical data

l Tec

l Article numbers documentation

With the serial number, you can access the delivery data of the

instrument via "

search". In addition to the type label outside, you can also find the

serial number on the inside of the instrument.

www.vega.com", "VEGA Tools" and "serial number

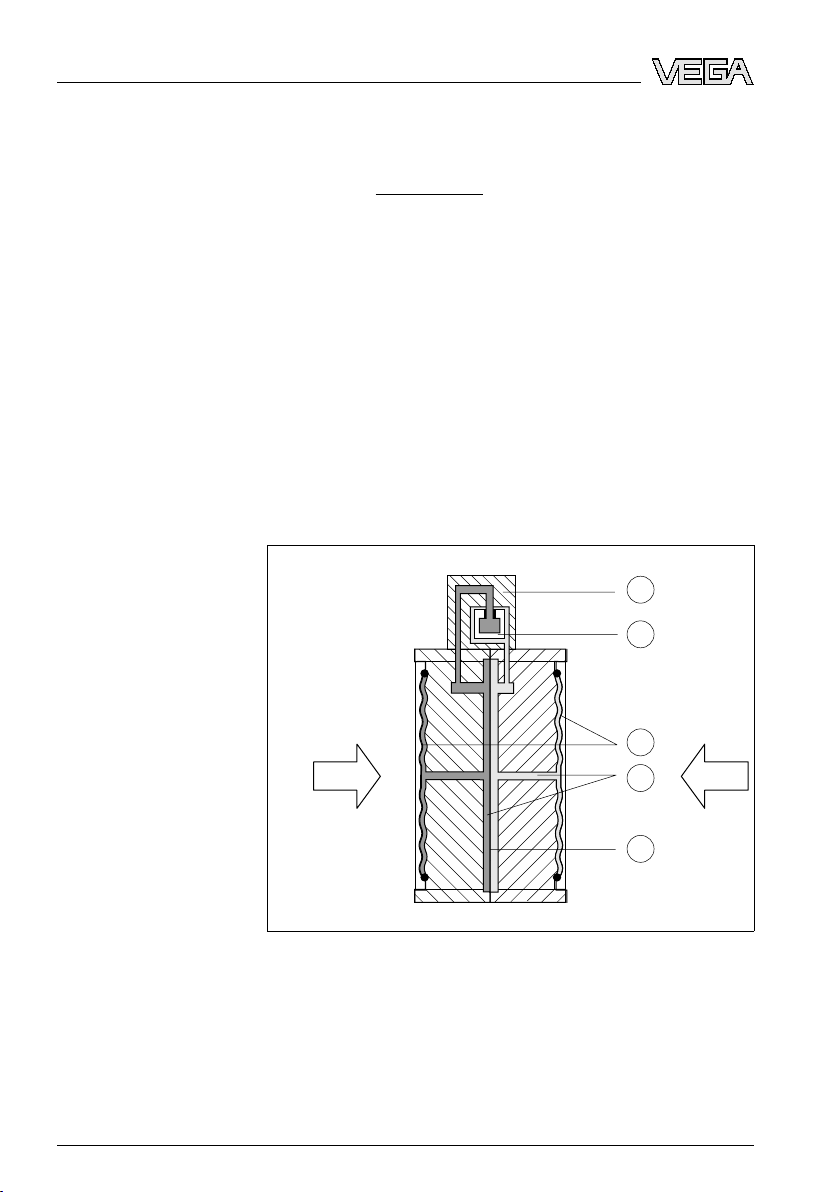

3.2 Principle of operation

Area of application

Functional principle

VEGADIF 55 is a differential pressure transmitter for measurement of

flow, level or differential pressure. Measured products are gases,

vapours and liquids.

The sensor element is a metallic measuring cell. The process pressure

is transmitted via the separating diaphragm and filling oil to the

resistance measuring bridge (semi-conductor technology). The differential-pressure dependent change of the bridge voltage is measured,

further processed and converted into a corresponding output signal.

The configuration of the measuring cell differs depending on the

measuring range:

Fig. 2: Metal

1 Measuring element

2 Silicone diaphragm

3 Separating diaphragm

4 Filling oil

5 Integrated overvoltage arrester

measuring cell 10 mbar and 30 mbar

8 VEG

31731-EN-081119

ADIF 55 • 4 … 20 mA/HART

Page 9

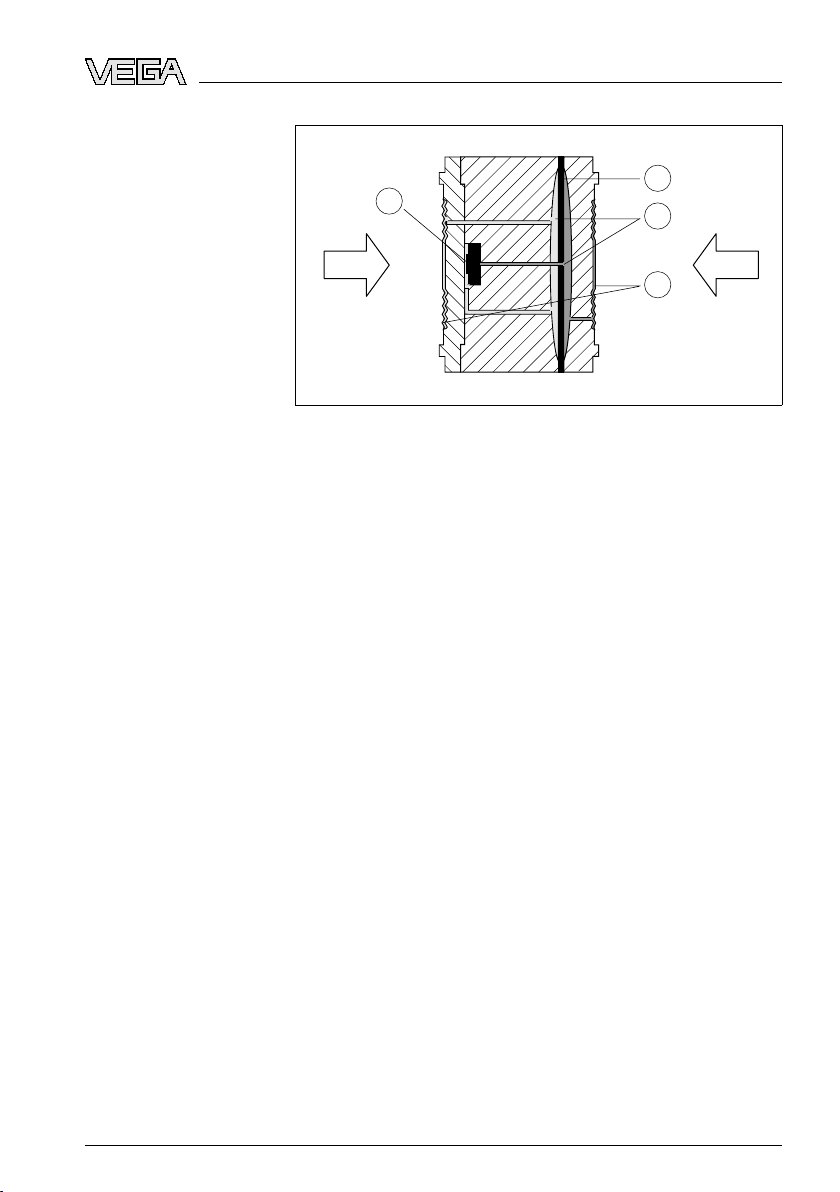

1

2

3

4

1

p

2

p

3 Produc

t description

Voltage supply

Packaging

Fig. 3: Metal

1 Measuring element

2 Overload diaphragm/Middle diaphragm

3 Filling oil

4 Separating diaphragm

Two-wire electronics 4 … 20 mA/HART for power supply and

measured value transmission over the same cable.

The voltage supply range can differ depending on the instrument

version. The exact range is stated in chapter "Wiring plan " or

"Technical data" in the product information manual "VEGADIF 55".

measuring cell from 100 mbar

3.3 Operation

VEGADIF 55 can be adjusted with different adjustment media:

l via integrated adjustment keys and local indication (available as

options)

l an adjustment software according to FDT/DTM standard, e.g.

PACTware and PC

l with manufacturer-specific adjustment programs AMS™ or PDM

l With a HART handheld

The entered parameters are generally saved in VEGADIF 55,

optionally also in PACTware.

3.4 Packaging, transport and storage

Your instrument was protected by packaging during transport. Its

capacity to handle normal loads during transport is assured by a test

according to DIN EN 24180.

The packaging of standard instruments consists of environmentfriendly, recyclable cardboard. For special versions, PE foam or PE foil

is also used. Dispose of the packaging material via specialised

recycling companies.

31731-EN-081119

VEGADIF 55 • 4 … 20 mA/HA

RT 9

Page 10

3 Produc

t description

Transport

Transport inspection

Storage

Storage and transport

temperature

sport must be carried out under consideration of the notes on the

Tran

transport packaging. Nonobservance of these instructions can cause

damage to the device.

The delivery must be checked for completeness and possible transit

damage immediately at receipt. Ascertained transit damage or

concealed defects must be appropriately dealt with.

Up to the time of installation, the packages must be left closed and

stored according to the orientation and storage markings on the

outside.

Unless otherwise indicated, the packages must be stored only under

the following conditions:

l Not in the open

l Dry and dust free

l Not exposed to corrosive media

l Protected against solar radiation

l Avoiding mechanical shock and vibration

l Storage and transport temperature see chapter "Supplement -

Technical data - Ambient conditions"

l Relative humidity 20 … 85 %

10 VEG

31731-EN-081119

ADIF 55 • 4 … 20 mA/HART

Page 11

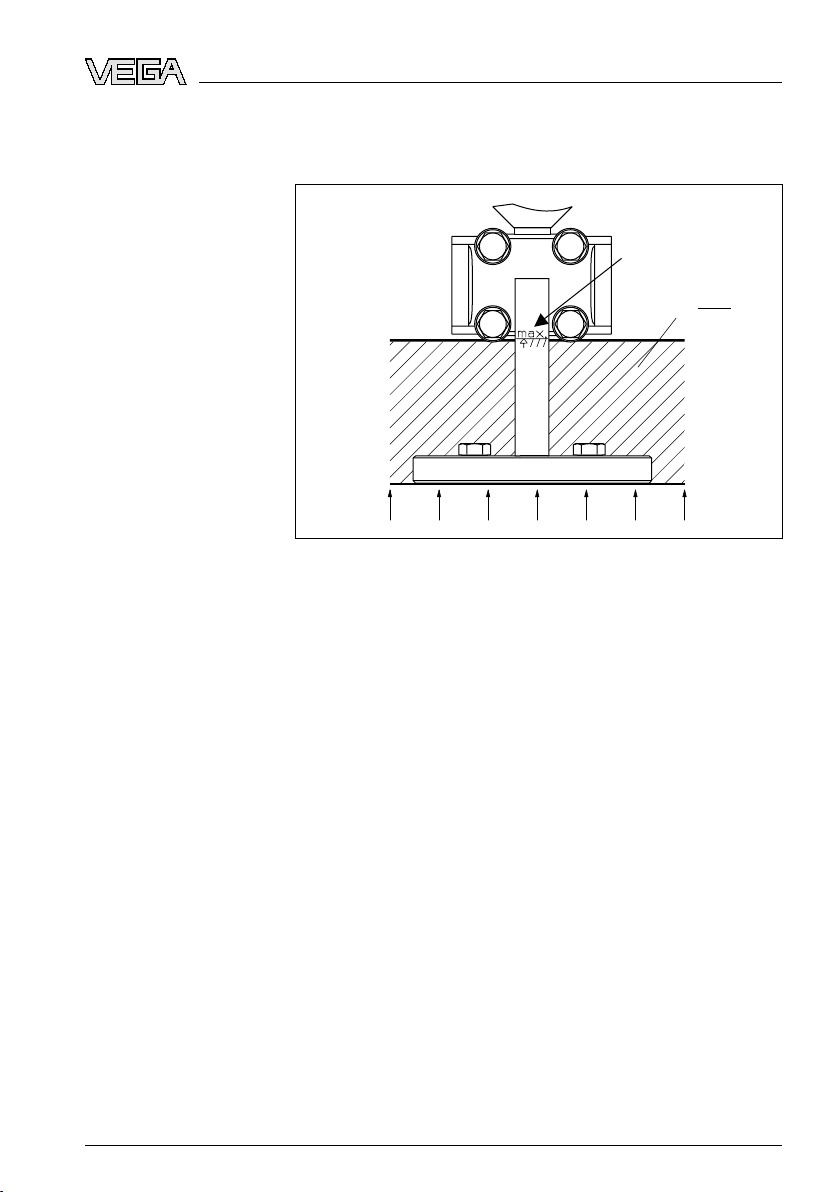

max. 380°

4 M

ounting

Materials, wetted parts

Mounting position

4 Moun

ting

4.1 General instructions

Make sure that the wetted parts of VEGADIF 55, especially the seal

and process fitting, are suitable for the existing process conditions

such as pressure, temperature etc. as well as the chemical properties

of the medium.

You find the specification in the "Product information manual"

VEGADIF 55 in chapter "Technical data".

Select such a mounting position that the instrument is in easy reach

when mounting or connecting as well as for later retrofitting of the

indicating and adjustment module. After loosening the pin, the housing

can be rotated by 380°.

Proceed as follows:

1 Loosen the pin with a 2 mm Allen wrench

2 Rotate the housing (max. up to 380°)

3 Tighten the pin

Installation position

Effective pressure lines

Valve block

31731-EN-081119

VEGADIF 55 • 4 … 20 mA/HA

Fig. 4: Direct

Due to the installation position of VEGADIF 55, a zero point shifting

can be caused, i.e. the measured values is not zero with empty vessel.

You can correct this zero point shoft either directly on the instrument

via the "E" key or the remote adjustment, see chapter "Operating

elements" and "Position adjustment".

You find general recommendations for wiring of effective pressure

lines in DIN 19210 "Effective pressure lines for flow systems" or the

corresponding national or international standards. When wiring

effective pressure lines outdoors, keep in mind to use a suitable

antifreeze, e.g. by using tube heat tracing. Wire effective pressure

lines with a monotonic decrease of at least 10 %.

Using a three-fold or five-fold valve block ensures easy setup,

mounting and maintenance without interrupting the process.

RT 11

the housing

Page 12

+

–

1

2

4

3

ounting

4 M

Oxygen applications

r:

Dange

Instruments for oxygen applications should be unpacked just before

mounting. After removing the protective cover of the process fitting, the

label "O₂" will be visible on the process fitting. Penetration of oil,

grease and dirt should be avoided. Danger of explosion!

Moisture

Flow measurement in

gases

Use the recommended cables (see chapter "Connecting to power

supply") and tighten the cable gland.

You can give your VEGADIF 55 additional protection against moisture

penetration by leading the connection cable downward in front of the

cable entry. Rain and condensation water can thus drain off. This

applies mainly to outdoor mounting as well as installation in areas

where high humidity is expected (e.g. through cleaning processes) or

on cooled or heated vessels.

4.2 Mounting instructions for flow measurement

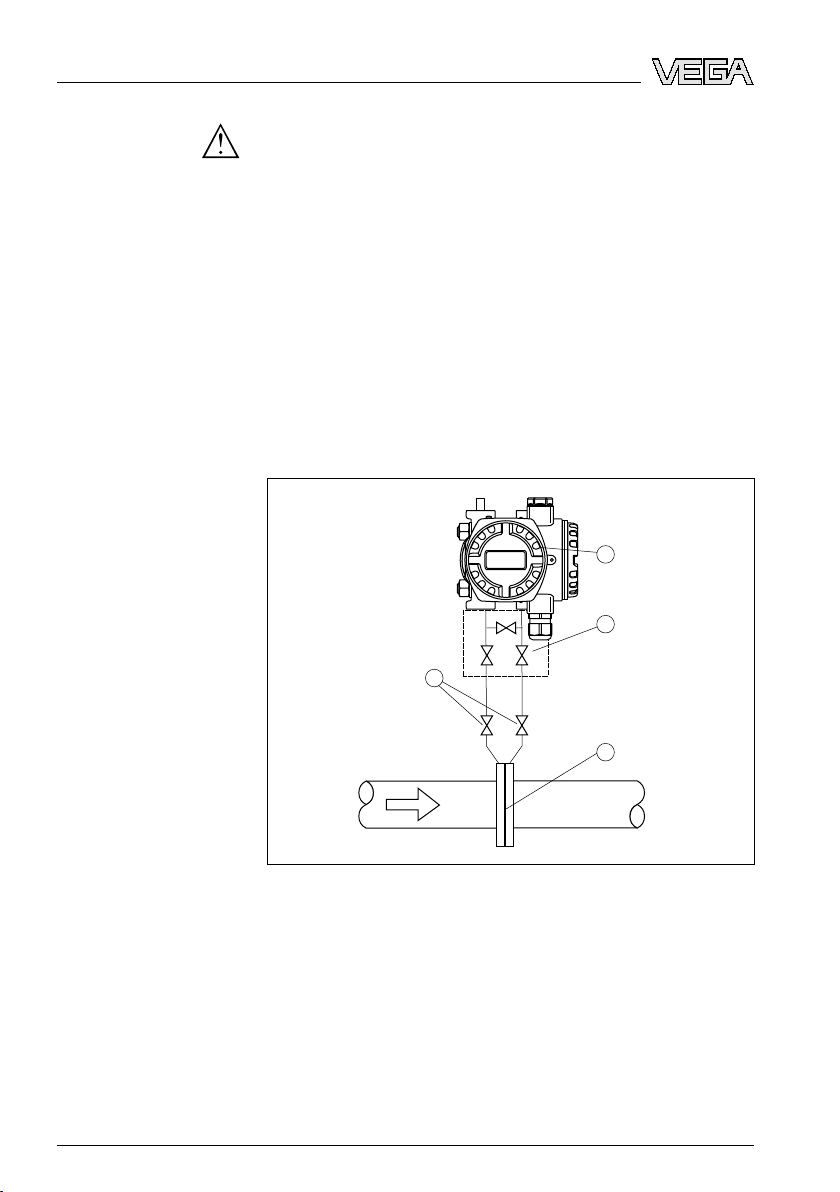

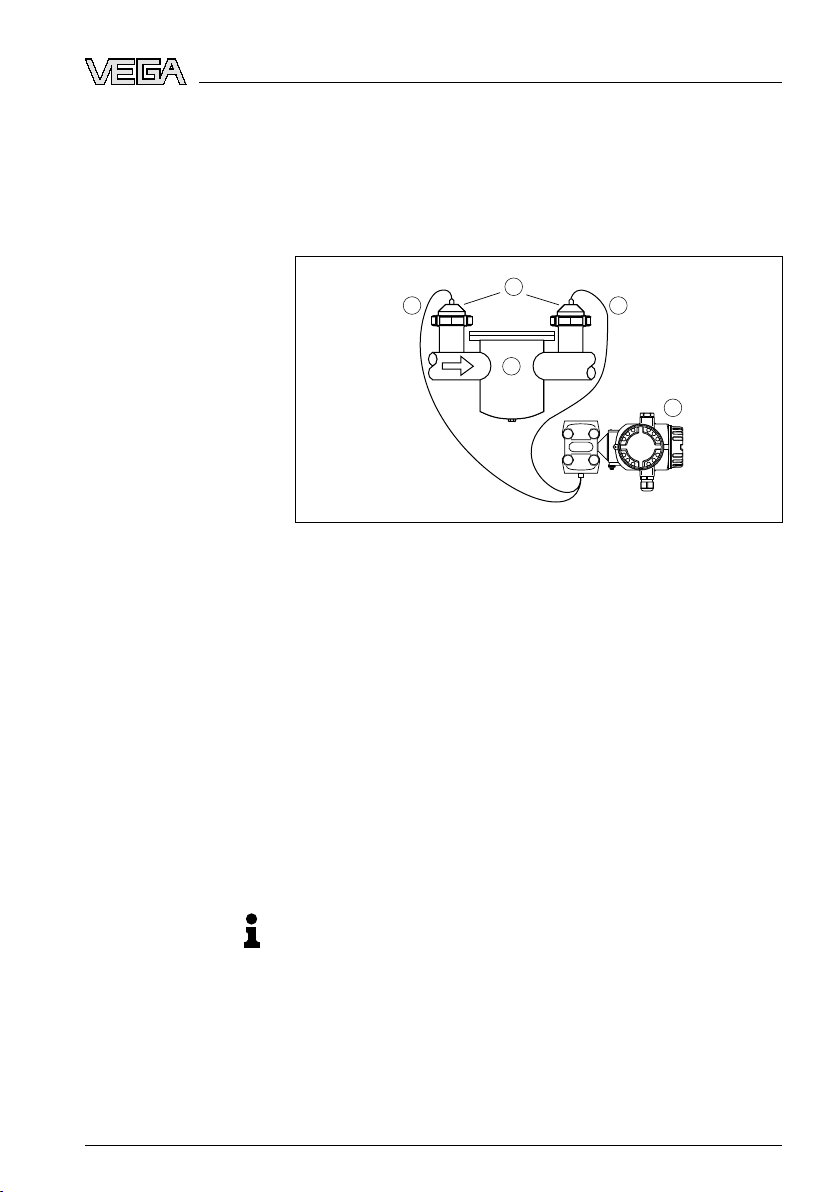

Fig. 5: Measurement

1 VEGADIF 55

2 Three-fold valve block

3 Block valves

4 Orifice or impact pressure probe

setup, flow measurement in gases with VEGADIF 55

à Mount VEGADIF 55 above the measurement loop so that

12 VEG

condensate can drain off in the process cable.

31731-EN-081119

ADIF 55 • 4 … 20 mA/HART

Page 13

+

–

1

2

3 3

5 5

6 6

7

4

Flow measurement in

vapours

4 M

ounting

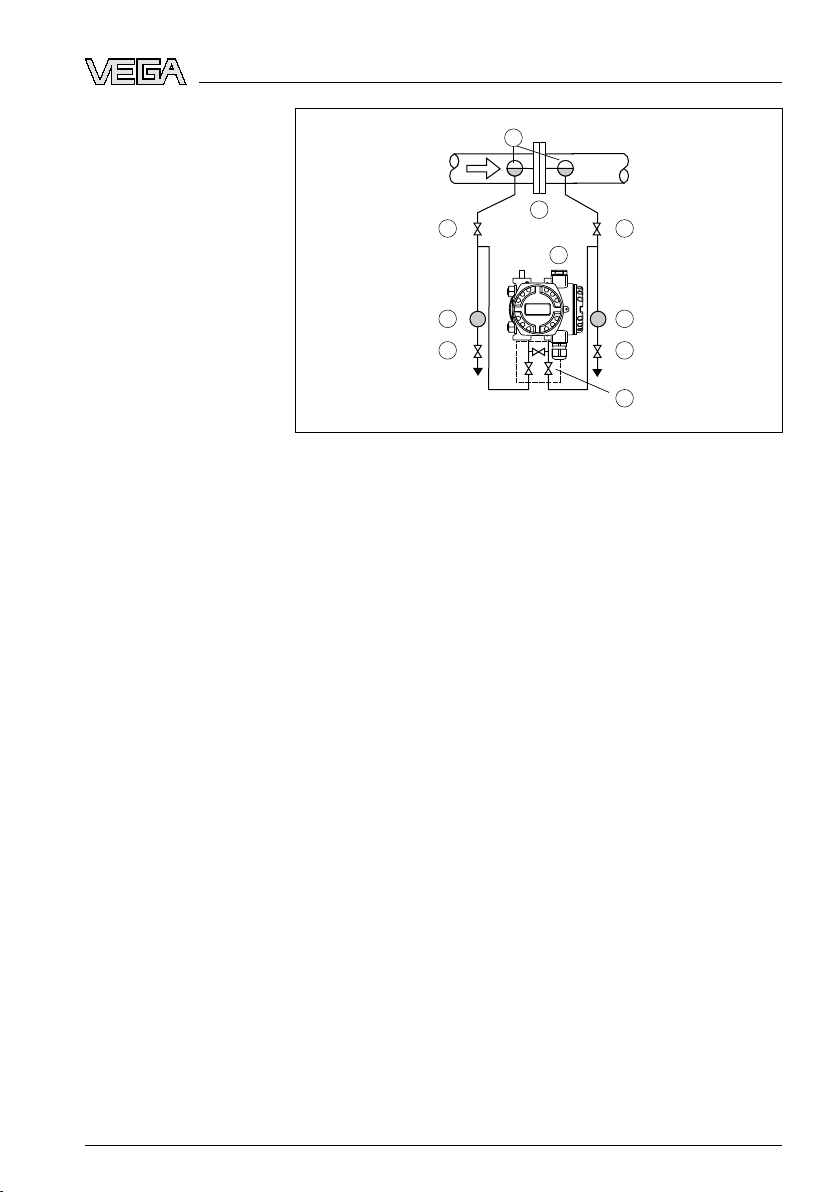

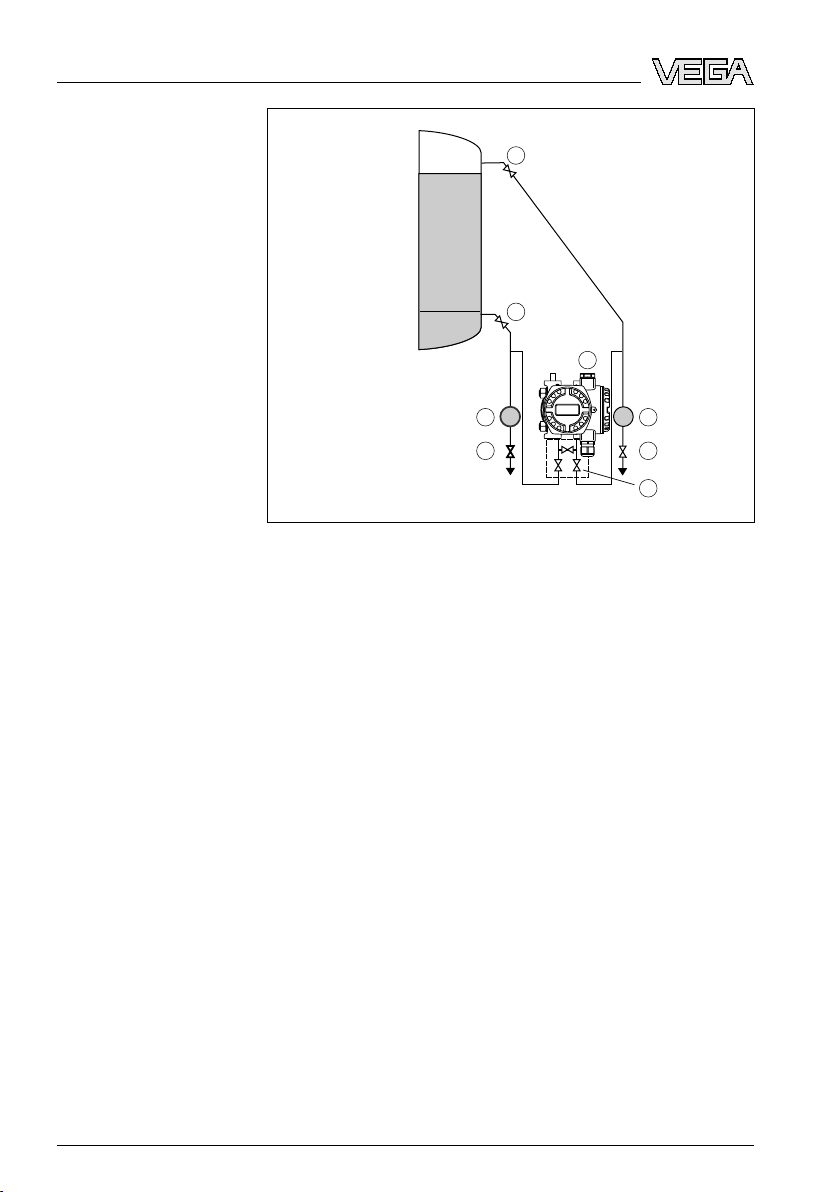

Fig. 6: Measurement

1 Condensate vessels

2 Orifice or impact pressure probe

3 Block valves

4 VEGADIF 55

5 Precipitator

6 Drain valves

7 Three-fold valve block

à Mount VEGADIF 55 below the measurement loop

à Mount condensate vessels at the same height with the discharge

socket and at the same distance to VEGADIF 55

à Fill the effective pressure lines to the height of the condensate

vessels before setup

setup, flow measurement in vapours with VEGADIF 55

31731-EN-081119

VEGADIF 55 • 4 … 20 mA/HA

RT 13

Page 14

+

–

1

2 2

3

5 5

6

4 4

ounting

4 M

Flow measurement in

liquids

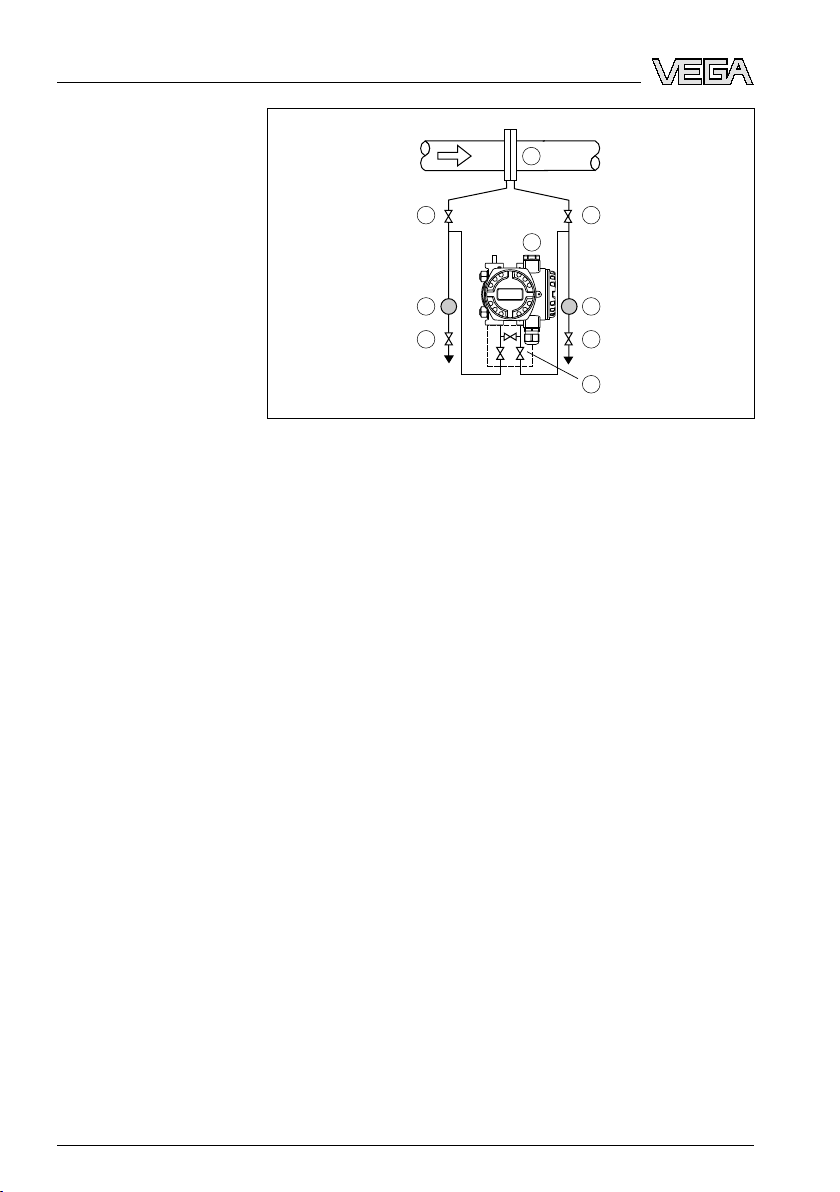

Fig. 7: Measurement

1 Orifice or impact pressure probe

2 Block valves

3 VEGADIF 55

4 Precipitator

5 Drain valves

6 Three-fold valve block

à Mount VEGADIF 55 below the measurement loop so that the

effective pressure lines are always filled with liquid and gas

bubbles can bubble up to the process line

à For measurements in products with solid content such as e.g. dirty

liquids, the installation of separators and drain valves is

recommended to enable collection and removal of debris and

sediment.

à Fill the effective pressure lines to the height of the condensate

vessels before setup

setup, flow measurement in liquids with VEGADIF 55

31731-EN-081119

14 VEG

ADIF 55 • 4 … 20 mA/HART

Page 15

+

p

atm

min.

p

atm

1

2

3

4

5

+

–

min.

p

atm

p

atm

1

2

4 M

ounting

Level measurement in

the open vessel with

effective pressure line

Level measurement in

the open vessel with

flange

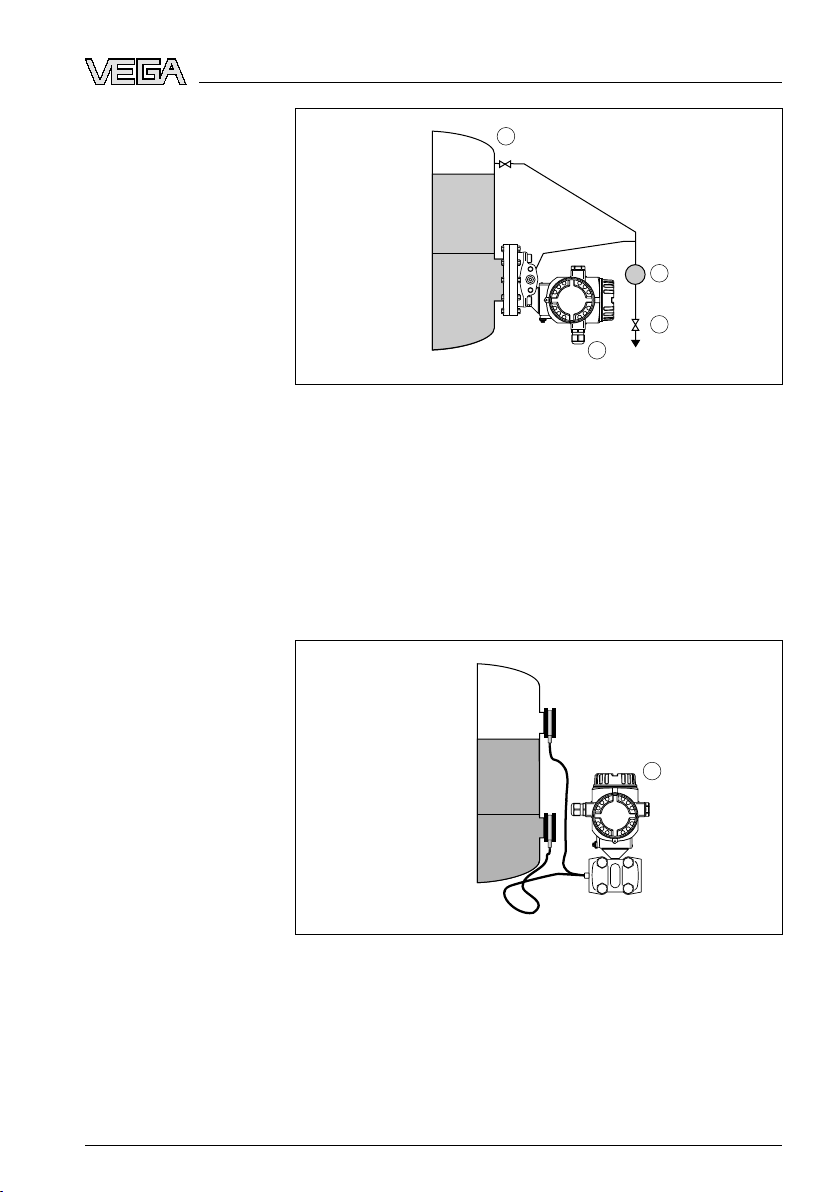

4.3 Mount

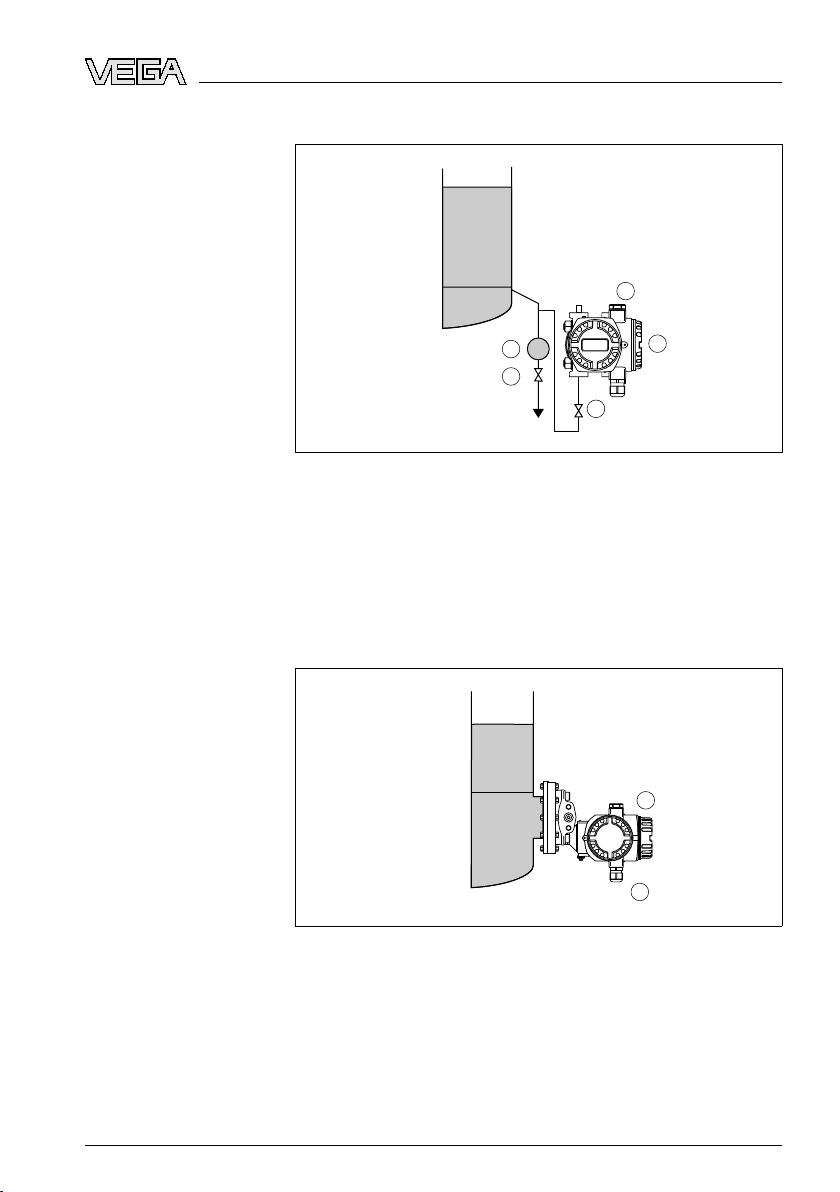

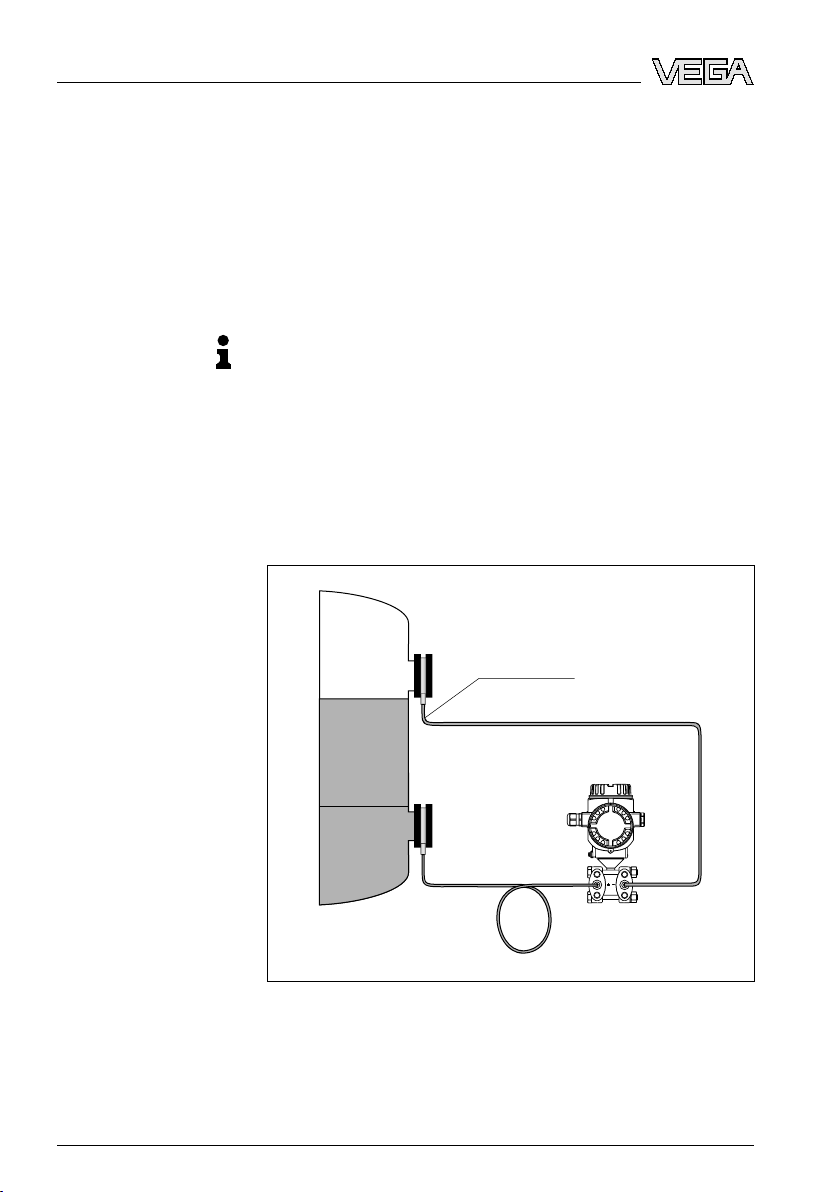

Fig. 8: Measurement

1 Minus side is open to the atmospheric pressure

2 VEGADIF 55

3 Block valve

4 Precipitator

5 Drain valve

à Mount VEGADIF 55 below the lower measurement connection so

that the effective pressure lines are always filled with liquid

à Minus side is open to the atmospheric pressure

ing instructions for level measurement

setup, level measurement in the open vessel

31731-EN-081119

VEGADIF 55 • 4 … 20 mA/HA

Fig. 9: Measurement

1 VEGADIF 55

2 Minus side is open to the atmospheric pressure

à Mount VEGADIF 55 directly to the vessel

à Minus side is open to the atmospheric pressure

setup, level measurement in the open vessel

RT 15

Page 16

+

–

min.

max.

1

3

4

3

4

5

1

2

ounting

4 M

Level measurement in

closed vessel with effective pressure line

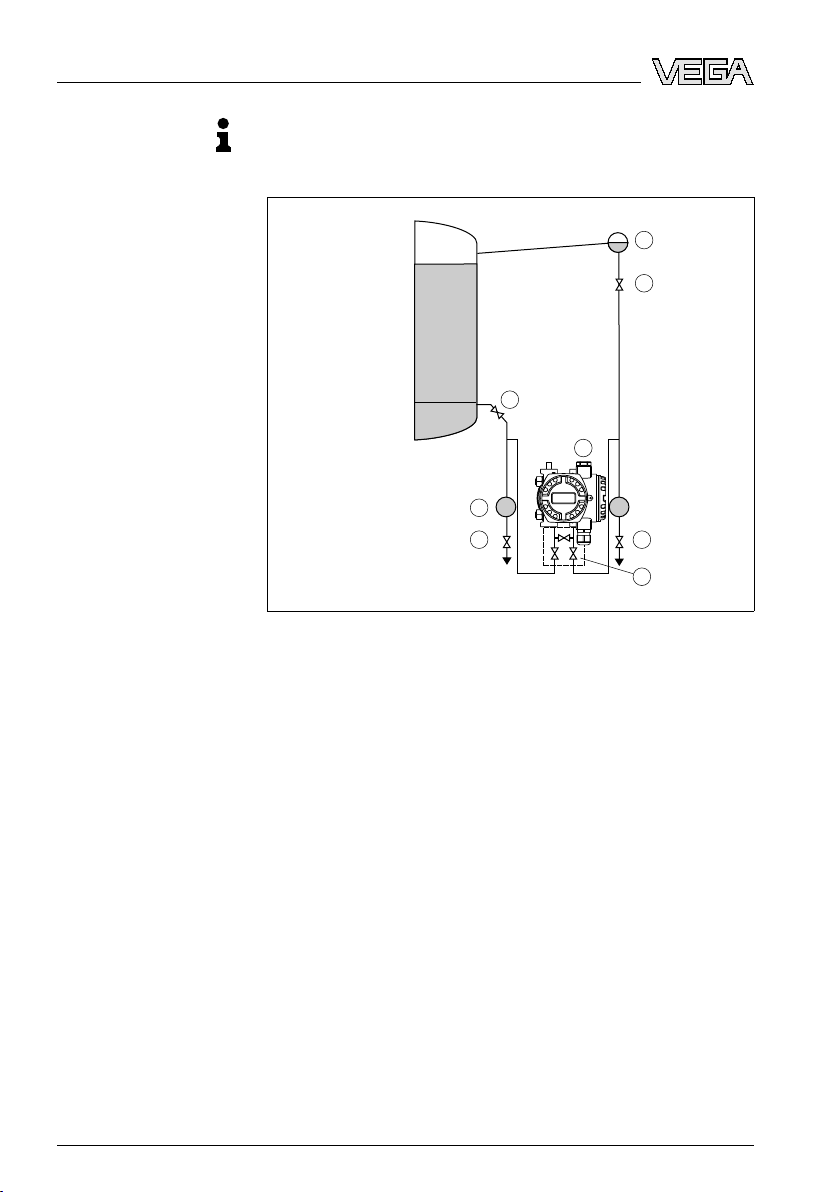

Fig. 10: Measurement

1 Block valves

2 VEGADIF 55

3 Precipitator

4 Drain valves

5 Three-fold valve block

à Mount VEGADIF 55 below the lower measurement connection so

that the effective pressure lines are always filled with liquid

à Connect minus side always above the max. level

à For measurements in products with solid content such as e.g. dirty

liquids, the installation of separators and drain valves is

recommended to enable collection and removal of debris and

sediment.

setup, level measurement in closed vessel

16 VEG

31731-EN-081119

ADIF 55 • 4 … 20 mA/HART

Page 17

+

–

max.

min.

1

2

3

4

+

–

min.

max.

1

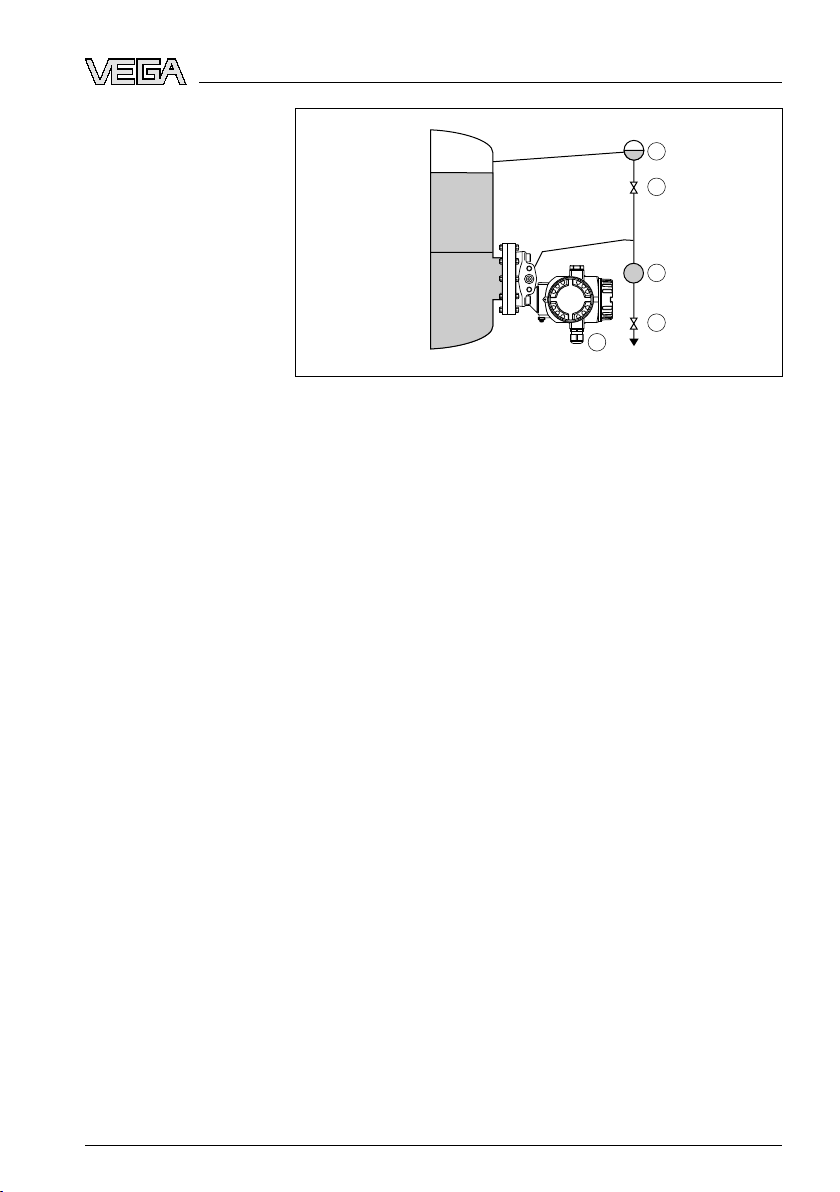

Level measurement in

closed vessel with

flange

4 M

ounting

Level measurement in

closed vessel with cell

isolating diaphragms

Fig. 11: Measurement

1 Block valve

2 Precipitator

3 Drain valve

4 VEGADIF 55

à Mount VEGADIF 55 directly to the vessel

à Connect minus side always above the max. level

à For measurements in products with solid content such as e.g. dirty

liquids, the installation of separators and drain valves is

recommended to enable collection and removal of debris and

sediment.

Fig. 12: Measurement

1 VEGADIF 55

à Mount VEGADIF 55 below the lower isolating diaphragm

à The ambient temperature should be the same for both capillaries

setup, level measurement in closed vessel

setup, level measurement in closed vessel

31731-EN-081119

VEGADIF 55 • 4 … 20 mA/HA

RT 17

Page 18

+

–

min.

max.

1

2

2

3

4

6

5 5

ounting

4 M

Level measurement in

closed vessel with

steam layer with effective pressure line

tion:

Informa

Level measurement is only ensured between the upper edge of the

lower and the lower edge of the upper pressure transmitter.

Fig. 13: Measurement

1 Condensate vessel

2 Block valves

3 VEGADIF 55

4 Precipitator

5 Drain valves

6 Three-fold valve block

à Mount VEGADIF 55 below the lower measurement connection so

that the effective pressure lines are always filled with liquid

à Connect minus side always above the max. level

à The condensate vessel ensures a constant pressure on the minus

side

à For measurements in products with solid content such as e.g. dirty

liquids, the installation of separators and drain valves is

recommended to enable collection and removal of debris and

sediment.

setup in closed vessel with superimposed steam

18 VEG

31731-EN-081119

ADIF 55 • 4 … 20 mA/HART

Page 19

+

–

min.

max.

1

2

3

4

5

Level measurement in

closed vessel with

superimposed steam

with flange

4 M

ounting

Fig. 14: Measurement

1 Condensate vessel

2 Block valve

3 Precipitator

4 Drain valve

5 VEGADIF 55

à Mount VEGADIF 55 directly to the vessel

à Connect minus side always above the max. level

à The condensate vessel ensures a constant pressure on the minus

side

à For measurements in products with solid content such as e.g. dirty

liquids, the installation of separators and drain valves is

recommended to enable collection and removal of debris and

sediment.

setup in closed vessel with superimposed steam

31731-EN-081119

VEGADIF 55 • 4 … 20 mA/HA

RT 19

Page 20

+

➃

1

2

33

+

–

1

2

4

5

6

4

5

2

3

4 M

ounting

Differential pressure

measurement in gases

and vapours

Differential pressure

measurement in liquids

4.4 Mount

ing instructions with differential

pressure measurement

Fig. 15: Measurement

vapours with VEGADIF 55

1 VEGADIF 55

2 Three-fold valve block

3 Block valves

4 E.g. filter

à Mount VEGADIF 55 above the measurement loop so that

condensate can drain off in the process cable.

setup, differential pressure measurement in gases and

Fig. 16: Measurement

1 E.g. filter

2 Block valves

3 VEGADIF 55

4 Precipitator

5 Drain valves

6 Three-fold valve block

setup, flow measurement in liquids with VEGADIF 55

20 VEG

31731-EN-081119

ADIF 55 • 4 … 20 mA/HART

Page 21

+

–

1

4

22

3

4 M

ounting

Differential pressure

measurement in gases,

vapours and liquids

à Moun

à For measurements in products with solid content such as e.g. dirty

Fig. 17: Measurement

vapours and liquids with VEGADIF 55

1 Cell isolating diaphragm

2 Capillaries

3 E.g. filter

4 VEGADIF 55

à Mount isolating diaphragm with capillaries on top or laterally on the

à In vacuum applications: Mount VEGADIF 55 below the measure-

à The ambient temperature should be the same for both capillaries

t VEGADIF 55 below the measurement loop so that the

effective pressure lines are always filled with liquid and gas

bubbles can bubble up to the process line

liquids, the installation of separators and drain valves is

recommended to enable collection and removal of debris and

sediment.

setup, differential pressure measurement in gases,

pipeline

ment loop

31731-EN-081119

VEGADIF 55 • 4 … 20 mA/HA

4.5 Mounting for instruments with isolating

diaphragms

Isolating diaphragm

Note these general instructions to the isolating diaphragms:

Note:

isolating diaphragm together with a pressure transmitter forms

l An

a closed, calibrated system which is filled through openings in the

isolating diaphragm and the measuring element of the pressure

transmitter. These openings are sealed and must not be opened!

l Do not clean or touch the isolating diaphragm with hard or sharp

subjects

l Remove the diaphragm protection just before installation

l When using a mounting strap, there must be sufficient strain relief

for the capillaries to avoid bending them (bendingradius ≥ 100 mm)

RT 21

Page 22

+ –

+

–

≥ 100 mm

4 M

ounting

l Reme

mber that due to the hydrostatic pressure of the liquid

columns in the capillaries, a zero point shift can occur. The zero

point shift can be corrected, see also "Position adjustment".

l Keep the application limits of the isolating diaphragm filling oil in

mind according to the Product Information manual VEGADIF 55,

"Planning instructions isolating diaphragms"

Capillaries

To achieve more precise measuring results and avoid instrument

malfunctions, the capillaries must be mounted as follows:

Note:

l Vibr

ation-free (to avoid additional pressure fluctuations)

l Not close to heating or cooling lines

l Insulate them in cooler or warmer environment

l Lay wire with a bend radius ≥ 100 mm

l With isolating diaphragms on both sides, the ambient temperature

and length of both capillaries should be the same

l Always two identical isolating diaphragms (e.g. diameter, material

etc.) should be used for the minus and plus side (standard

shipment)

Fig. 18: Mounting VEGADIF 55 with

vacuum application: place the pressure transmitter below the lower isolating

diaphragm

22 VEG

isolating diaphragms and capillaries with

31731-EN-081119

ADIF 55 • 4 … 20 mA/HART

Page 23

+ –

+

–

H1

–

+

ounting

4 M

um application

Vacu

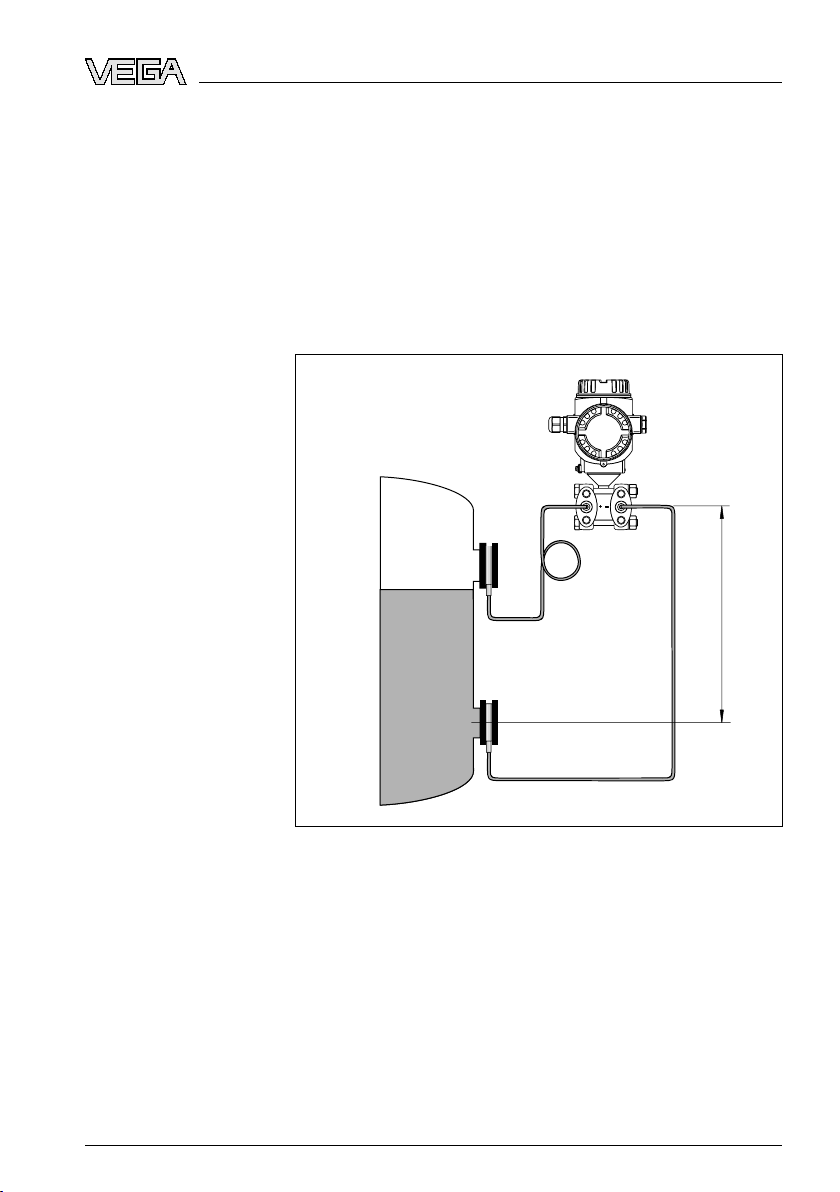

In applications under vacuum, we recommend mounting the pressure

transmitter below the lower isolating diaphragm. A vacuum load on the

isolating diaphragm due to the filling oil in the capillaries is thus

avoided.

When mounting the pressure transmitter above the lower isolating

diaphragm, the max. difference in height H1 must not be exceeded

according to the following illustrations. The max. difference in height

depends on the density of the filling oil and the smallest pressure

which can occur on the plus side of teh isolating diaphragm (empty

vessel), see following illustration.

31731-EN-081119

VEGADIF 55 • 4 … 20 mA/HA

Fig. 19: Mounting

above the lower isolating diaphragm

RT 23

Page 24

0,0

2,0

4,0

6,0

8,0

10,0

12,0

50

100 300 400 500 600 700 800 900 1000

mbar

m

200

2

1

3

4

1 2

4 M

ounting

Fig. 20: Diagram

vacuum applications depending on the pressure on the isolating diaphragm on

the plus side

1 Vegetable oil

2 Silicone oil

3 High temperature oil

4 Inert oil

max. mounting height above the lower isolating diaphragm in

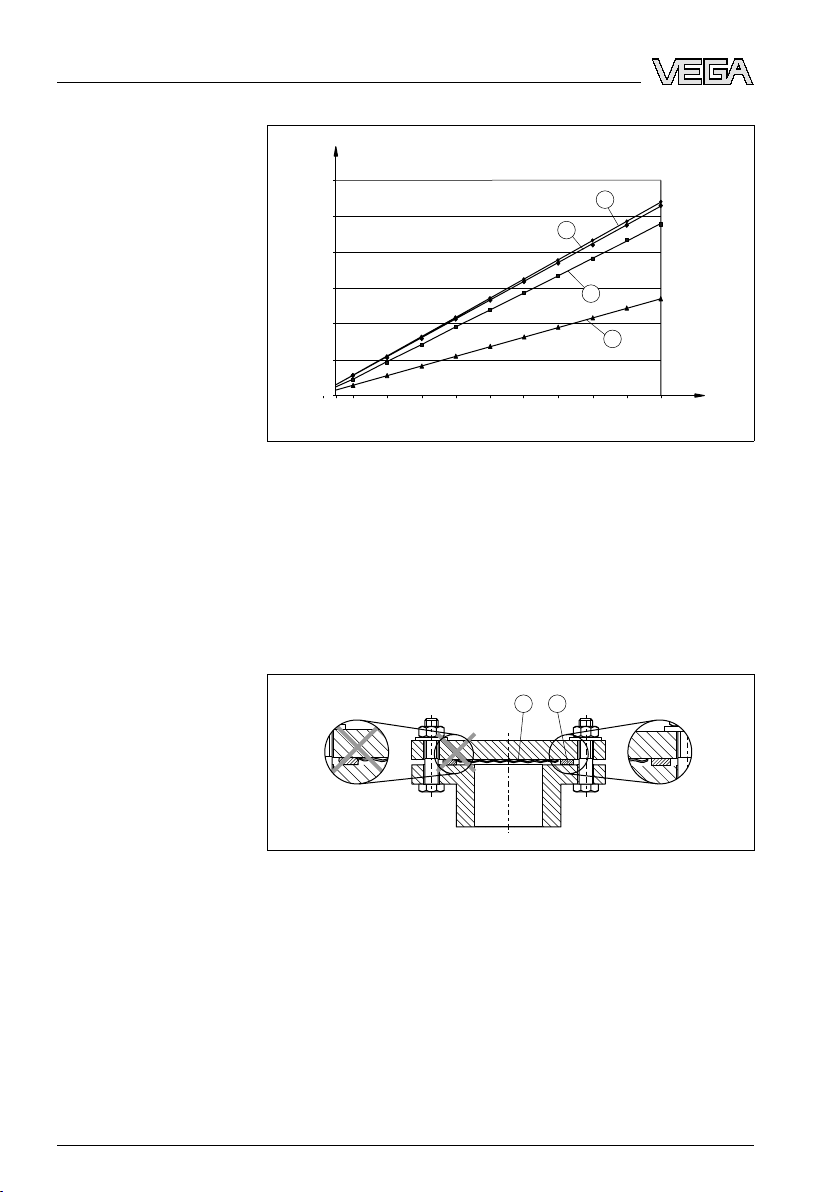

4.6 Mounting instructions for seal with flange

mounting

Fig. 21: Mounting

1 Diaphragm

2 Seal

4.7 Heat insulation of instruments with flange

isolating diaphragm

VEGADIF 55 with unilateral flange isolating diaphragm must only be

isolated up to a certain height. The max. permissible isolating heigth is

marked on the instruments and applies to an isolating material with a

heat conductance ≤ 0.04 W/(m x K) and fa max. permitted ambient

24 VEG

the versions with flange or isolating diaphragm

31731-EN-081119

ADIF 55 • 4 … 20 mA/HART

Page 25

λ 0,04≤

W

m K•

T

A

T

P

4 M

ounting

temperature T

≤ 70 °C (158 °F) and process temperature TP< 350 °C

U

(662 °F). The data were determined under the critical application

"resting air".

Fig. 22: Max. permissible

isolating height

31731-EN-081119

VEGADIF 55 • 4 … 20 mA/HA

RT 25

Page 26

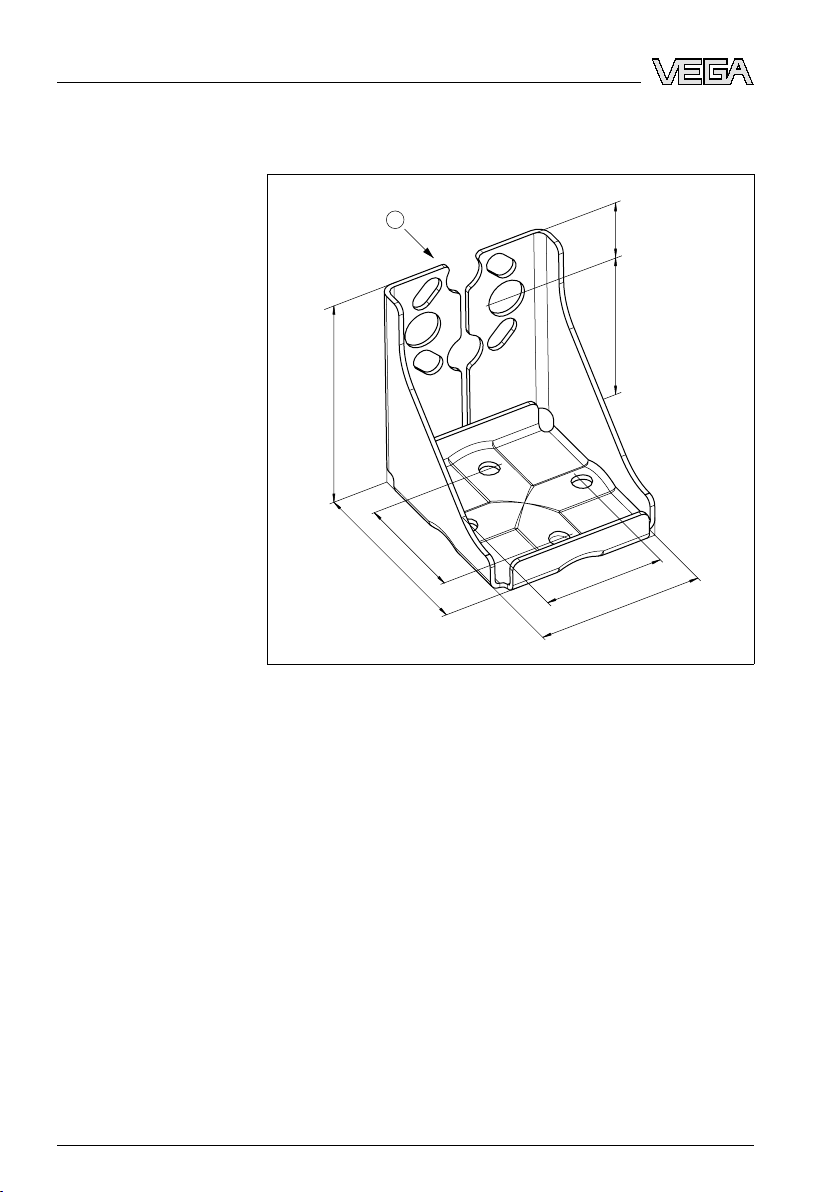

97,5

135

74

124

106

74

37,5

1

4 M

ounting

4.8 Mount

mounting

Fig. 23: Mounting

ing instructions for wall or tube

strap for wall or tube mounting

Take note of the following when mounting:

l Instruments with capillary lines: Mount capillaries with a bending

radius of ≥ 100 mm

l Slightly grease the mounting screws so that the threaded

connetion remains detachable

l For tube mounting, tighten the nuts on the strap with a torque of at

least 30 Nm

4.9 Mounting control

Check the following after mounting the instrument:

26 VEG

l Did you tighten all screws?

l Housing cover tightened?

l Did you tighten the closing screws and the ventilation valves?

31731-EN-081119

ADIF 55 • 4 … 20 mA/HART

Page 27

ecting to power supply

5 Conn

Note safety instructions

Take note of

safety instructions for Ex applications

Select power supply

Selecting connection

cable

5 Conn

ecting to power supply

5.1 Preparing the connection

Always keep in mind the following safety instructions:

l Connect only in the complete absence of line voltage

l If overvoltage surges are expected, overvoltage arresters should

be installed.

Ti

p:

We recommend using VEGA overvoltage arresters B63-48 and

ÜSB 62-36G.X.

In

hazardous areas you should take note of the appropriate

regulations, conformity and type approval certificates of the sensors

and power supply units.

Power supply and current signal are carried on the same two-wire

cable. The voltage supply range can differ depending on the

instrument version.

Data for power supply is specified in chapter "Technical data".

Provide a reliable separation between the supply circuit and the mains

circuits according to DIN VDE 0106 part 101. The VEGA power supply

units VEGATRENN 149AEx, VEGASTAB 690, VEGADIS 371 as well

as all VEGAMETs meet this requirement.

Bear in mind the following factors regarding supply voltage:

l Output voltage of the power supply unit can be lower under

nominal load (with a sensor current of 20.5 mA or 22 mA in case of

fault message)

The instrument is connected with standard, twisted and screened twowire cable with round cross section. An outer cable diameter of 5 ...

9 mm (0.2 ... 0.35 in) ensures the seal effect of the cable gland.

Cable screening and

grounding

Select connection cable for Ex

applications

31731-EN-081119

VEGADIF 55 • 4 … 20 mA/HA

Optimum shielding agains intefering influences can be achieved if the

screening is connected to both sides (in the switching cabinet and on

the instrument). If potential equalisation currents are expected, the

screening must be earthed only on one end, preferably on the

transmitter.

the corresponding regulations when used in hazardous areas. All

Note

Ex instruments are shipped with a separate Ex documentation with

additional technical data and instructions.

Provide potential equalisation inside and outside hazardous areas.

Connect all instruments to the local potential equalisation.

Instruments with integrated overvoltage protection must be grounded.

RT 27

Page 28

Test

Test

4... 20mA

5

4

3

2

1

ecting to power supply

5 Conn

Housing overview

5.2 Conne

ction procedure

Proceed as follows:

1 Unscrew the housing cover

2 Loosen compression nut of the cable entry

3 Remove approx. 10 cm (4 in) of the cable mantle, strip approx.

1 cm (0.4 in) insulation from the ends of the individual wires

4 Insert the cable through the cable gland into the sensor

5 Loosen the screws on the terminals

6 Insert the wire ends into the open terminals according to the wiring

plan

7 Tighten the screws of the terminals

8 Check the hold of the wires in the terminals by lightly pulling on

them

9 Connect the screen to the internal ground terminal, connect the

outer ground terminal with potential equalisation

10 Tighten the compression nut of the cable entry. The seal ring must

completely encircle the cable

11 Screw the housing cover on

The electrical connection is finished.

5.3 Wiring plan

Fig. 24: Housing

1 Housing

2 Bridge for 4 … 20 mA test signal

3 Internal ground terminal

4 External ground terminal

5 4 … 20 mA test signal between plus and test terminal

28 VEG

overview, view to the connection compartment

31731-EN-081119

ADIF 55 • 4 … 20 mA/HART

Page 29

Tes t4... 20mA

4...20 mA

10,5 V DC

11,5 V DC

Tes t

1

2

3

Han7D

–

+

+ –

VEGADIF55

–

+

1

5

4

6

7

8

2

3

VEGADIF55

M12x1

–

+

+–

–

+

Wiring plan

ecting to power supply

5 Conn

Wiring plan, plug connector Harting Han7D

Wiring plan, plug connector M12 x 1

Fig. 25: Wiring

1 Supply voltage/Signal output: min. supply voltage 10.5 V DC, bridge is

plugged according to illustration

2 Supply voltage/Signal output: min. supply voltage 11.5 V DC, position "Test"

is plugged with the bridge

Fig. 26: Wiring

electrical connection in the instrument; on the right, view to the plug on the

instrument

plan VEGADIF 55

plan VEGADIF 55 with plug connector Harting Han7D. On the left,

31731-EN-081119

VEGADIF 55 • 4 … 20 mA/HA

Fig. 27: Wiring

electrical connection in the instrument; on the right, view to the plug on the

instrument

plan VEGADIF 55 with plug connector M12 x 1. On the left,

RT 29

Page 30

Test

Test

1 2

≤

30

20

10,5

U

[V]

40 45

1282

1500

847

413

Test

3

4

Ω

R

Lmax

R

Lmax

U - 10,5 V

23 mA

[ ]

30

20

11,5

U

[V]

40 45

1239

1456

804

369

Test

3

4

≤

R

Lmax

U - 11,5 V

23 mA

Ω

R

Lmax

[ ]

ecting to power supply

5 Conn

5.4 Take 4 … 20 mA test

signal

Without interrupting the measurement you can tap a 4 … 20 mA test

signal via the plug and test terminal. By simply switching the bridges,

you can lower the min. supply voltage of the measuring instrument.

Through this it also possible to operate the instrument with a weaker

voltage source. To keep the measurement error below 0.1 %, the

current meter should show an inner resistance of < 0.7 Ω. Take note of

the bridge position according to the following illustrations.

Fig. 28: Left: Position

voltage 10.5 V DC. Right: Position of the bridge with test signal. Min. supply

voltage 11.5 V DC.

position of the bridge without test signal. Min. supply

5.5 Load

Fig. 29: Load

diagrams: Note position of the bridge and flame proofing. RLmax

max. load resistance, U voltage supply

1 Bridge for 4 … 20 mA test signal plugged in position "Non-test"

2 Bridge for 4 … 20 mA test signal plugged in position "Test"

3 Voltage supply 10.5 (11.5) … 30 V DC for EEx ia, 1/2 D, 1 GD, 1/2 GD, FM

IS and CSA IS

4 Supply voltage 10.5 (11.5) … 45 V DC for instruments for Ex-free area, 1/

3 D, EEx d, EEx nA, FM XP, FM DIP, FM NI, CSA XP and CSA Dust-Ex

30 VEG

5.6 Connection control

Check the following after electrical installation of the instrument:

l Does the supply voltage correspond to the specification on the

type label?

31731-EN-081119

ADIF 55 • 4 … 20 mA/HART

Page 31

ecting to power supply

5 Conn

the instrument connected according to chapter "Connecting to

l Is

power supply"?

l Did you tighten all screws?

l Did you screw up the housing covers?

The green LED on the electronics module lights for a few seconds or

the connected local indication lights if the voltage is switched on on the

instrument.

5.7 Switch on phase

Switch on phase

After VEGADIF 55 is connected to voltage supply or after voltage

recurrence, the instrument carries out a self-check. The following

steps are carried out:

l Internal check of the electronics

l For approx. 3 sec onds, the output signal takes on the value 12 mA

Then the actual measured value is displayed and the corresponding

current is transmitted to the cable.

1)

31731-EN-081119

VEGADIF 55 • 4 … 20 mA/HA

1)

The values correspond to the actual measured value as well as to the

settings already carried out, e.g. default setting.

RT 31

Page 32

6 Operati

on

Function/Configuration

6 Operati

on

6.1 Short description

The following adjustment media are available:

l Order code A - 4 … 20 mA/HART/outside/LCD: Adjustment via

local indication and 3 keys outside on the instrument

l Order code B - 4 … 20 mA/HART/inner/LCD: Adjustment via local

indication and 3 keys in the instrument

l Order code C - 4 … 20 mA/HART/inner/without: Adjustment with

local indication and 3 keys in the instrument

6.2 Local indication (optional)

As indication and adjustment, the 4-line liquid crystal indication (LCD)

is used. The local indication shows measured values, dialogue texts

as well as failure and information messages.

Functions:

32 VEG

31731-EN-081119

ADIF 55 • 4 … 20 mA/HART

Page 33

32 4 5

6

9

12

14

15

11

8

7

10

13

1

E

+

–

6 Operati

on

l 8-digit

measured value indication incl. signs and decimal point,

indication of the units, bar graph for current indication

l Easy and complete menu-guidance through arrangement of the

parameters into several levels and groups

l To enable easy navigation, each parameter is marked with a 3-

digit identification number

l Possibility to configure the indication according to the individual

requirements and requests, such as e.g. language, alternating

indication, contrast setting, indication of other measured values,

such as e.g. sensor temperature

l Comprehensive diagnostic functions (fault and warning message,

pointer etc.)

l Quick and reliable setup by means of quick setup menus

31731-EN-081119

VEGADIF 55 • 4 … 20 mA/HA

Fig. 30: Functions

1 Adjustment keys

2 Measured value indication mode

3 Function name

4 Value

5 Parameter identification number

6 Unit

7 Bar graph

8 Symbol

9 Header

10 Main line

11 Info line

12 Editing mode

13 Selection options

14 Editable value

15 Actual measured value

of the local indication

The following chart shows the possible symbols of the local indication.

Four symbols can appear at once.

RT 33

Page 34

6 Operati

on

Symbol Meaning

Alarm symbol

l Symbol flashes: Warning, instrument continues measuring

l Symbol flashes permanently: Error, instrument does not

continue measuring

Note: Where appropriate, the alarm symbol superimposes the

tendency symbol.

Lock

symbol

Adjustment of the instrument is locked

Note: Unlock instrument, see "Lock/Unlock adjustment".

Communication

Data transmission via communication

Root

symbol

Active mode "Flow measurement"

For the current output, the flow signal extracted by root is used

Tendency

The measured value increases

Tendency

The measured value falls

Tendency

Within the last minutes, the measured value was constant

symbol

symbol (rising)

symbol (falling)

symbol (steady)

34 VEG

31731-EN-081119

ADIF 55 • 4 … 20 mA/HART

Page 35

1

τ

1

4 5

HW-Version:

SW-Version:

250002271-–

HART

R

FIELDCO MMUNICATION PROTOCOL

1

2

21

PC

on

off

6

2

3

6 Operati

on

Position of the adjustment elements

6.3 Adj

ustment elements

The adjustment keys are either outside on the housing below the

protective cover or inside the electronics module. In addition there are

adjustment keys on the optional local indication.

Fig. 38: Adjustment

1 Adjustment keys

elements outside on the housing below the protective cover

31731-EN-081119

VEGADIF 55 • 4 … 20 mA/HA

Fig. 39: Adjustmetn

1 Adjustment keys

2 Module for optional indication

3 Module for optionally available memory module

4 DIP switch for locking/unlocking measured value-relevant parameters

5 DIP switch for damping on/off

6 Green LED for indication when the value is taken over

RT 35

keys inside

Page 36

6 Operati

Function of the

adjustment elements - local indication not

connected

Function of the operating elements - local indication connected

on

tion:

Informa

To carry out the respective function, the key or key combination must

be pushed for at least 3 seconds. For a reset, the key combination

must be pushed for at least 6 seconds.

l "-" key

- Accept me asurement begin, refer

l "+" key

ence pressure is on

- Accept measurement end, reference pressure is on

l "E" key

- Position adjustment

l "+

" key and "-" key and "E" key

- Reset of all parameters. The reset via the keys corresponds to

the software rest code 7864.

l "+" key and "E" key

- Copy

l "-" key and "E" key

configurati

device.

- Copy configurati

module.

l DIP switch 1

on data from optional data memory module to

on data from device to optional data memory

- To lock/unlock measured value-relevant parameters. Default

setting: off (unlocked)

l DIP switch 2

- Damping

l "+" key

- Navigation upward in the selection list

on/off, def

ault setting: on (damping on)

- Editing of the numerical values or signs within a function

l "-" key

- Naviga

tion downward in the selection list

- Editing of the numerical values or signs within a function

l "E" key

- Confirm entry

- Jump to the next menu item

l "+

" key and "E" key

- Contrast setting of the local display: highe

l "-" key and "E" key

- Contrast

setting of the local display: weak

r

er

31731-EN-081119

36 VEG

ADIF 55 • 4 … 20 mA/HART

Page 37

6 Operati

" key and "-" key

l "+

- Quit editing mode without saving the modified value

- In the menu you are within a function group: when pushing the

keys for the first time simultaneously, you jump one parameter

back within the function group. With every further simultaneous pushing you jump one level in the menu to the top

- You

l DIP switch 1

are in the menu on a selection level: With

simultaneous pushing you jump one level in the menu to the

top

every

- To lock/unlock measured value-relevant parameters. Default

setting: off (unlocked)

l DIP switch 2

- Damping on/off, def

6.4 Local adjustment - local indication not

connected

Informa

tion:

For adjustment of the instrument with a data memory module see

"Data memory module".

ault setting: on (damping on)

on

Measuring Mode - Pressure

31731-EN-081119

VEGADIF 55 • 4 … 20 mA/HA

If no local indication is connected, the following functions will be

possible via the three keys on the electronics module or outside on the

instrument:

l Position adjustment (zero point correction)

l Set measurement begin and measurement end

l Instrument reset, see chart in chapter "Operating elements"

tion:

Informa

The adjustment must be unlocked, see chapter "Lock/Unlock adjust-

ment".

By default, the instrument is set to mode Pressure. The mode can be

changed via the parameter "Measuring Mode", see chapter "Select

language and measuring mode".

The existing pressure must be within the nominal pressure limits of the

sensor, see specifications on the "Type label".

Carry out position adjustment:

1 Pressure on the instrument

2 Push "E" key at least for 3 s

3 Does the LED on the electronics module light briefly?

Yes: existing pressure was accepted as position adjustment

No: Existing pressure for position adjustment was not accepted,

note the adjustment limits

Set LRV:

RT 37

Page 38

6 Operati

on

Measuring Mode - Level

1 Pres

sure for LRV is on the instrument

2 Push "-" key at least for 3 s

3 Does the LED on the electronics module light briefly?

Yes: existing pressure was accepted as LRV

No: Existing pressure for LRV was not accepted, note the

adjustment limits

Set URV:

1 Pressure for URV is on the instrument

2 Push "+" key at least for 3 s

3 Does the LED on the electronics module light briefly?

Yes: existing pressure was accepted as URV

No: existing pressure for URV was not accepted, take note of the

adjustment limits

If no local indication is connected, the following functions will be

possible via the three keys on the electronics module or outside on the

instrument:

l Position adjustment (zero point correction)

l Set the lower and upper pressure value and assign a level value to

the lower or upper level value

l Instrument reset, see chart in chapter "Operating elements"

Informa

tion:

The adjustment must be unlocked, see chapter "Lock/Unlock adjust-

ment".

By default, the instrument is set to mode Pressure. The mode can be

changed via the parameter "Measuring Mode", see chapter "Select

language and measuring mode".

If "Level Mode" "Pressure Linearized" or "Height Linearized" or

"Calibration Mode" "dry" are selected, the "-" and "+" keys are without

function.

The existing pressure must be within the nominal pressure limits of the

sensor, see specifications on the "Type label".

See also "Quick setup menu" in chapter "Level measurement"

l Default settings of the parameters in mode "Level":

- LEVEL MODE = Linear

- CALIBRATION MODE = wet

- LIN. MEASURAND = %

- EMPTY CALIB. = 0 %

- FULL CALIB. = 100 %

Carry out position adjustment:

1 Pressure on the instrument

2 Push "E" key at least for 3 s

31731-EN-081119

38 VEG

ADIF 55 • 4 … 20 mA/HART

Page 39

6 Operati

on

Measuring Mode - Flow

3 Does

the LED on the electronics module light briefly?

Yes: existing pressure was accepted as position adjustment

No: Existing pressure for position adjustment was not accepted,

note the adjustment limits

Set lower pressure value:

1 Requested pressure for lower pressure value (EMPTY PRES-

SURE) is on the instrument

2 Push "-" key at least for 3 s

3 Does the LED on the electronics module light briefly?

Yes: Existing pressure was saved as lower pressure value

(EMPTY PRESSURE) and assigned to the lower level value

(EMPTY CALIB.)

No: Existing pressure was not saved as lower pressure value

(EMPTY PRESSURE). Take note of the adjustment limits

Set upper pressure value:

1 Requested pressure for upper pressure value (FULL PRESSURE)

is acting on the instrument

2 Push "+" key at least for 3 s

3 Does the LED on the electronics module light briefly?

Yes: Existing pressure was saved as upper pressure value (FULL

PRESSURE) and assigned to the upper level value (FULL CALIB.)

No: Existing pressure was not saved as upper pressure value

(FULL PRESSURE). Note the adjustment limits.

If no local indication is connected, the following functions will be

possible via the three keys on the electronics module or outside on the

instrument:

l Position adjustment (zero point correction)

l Set the max. pressure value and assign it to the max. flow value

l Instrument reset, see chart in chapter "Operating elements"

31731-EN-081119

VEGADIF 55 • 4 … 20 mA/HA

tion:

Informa

The adjustment must be unlocked, see chapter "Lock/Unlock adjust-

ment".

By default, the instrument is set to mode Pressure. The mode can be

changed via the parameter "Measuring Mode", see chapter "Select

language and measuring mode".

The "-" key is without function

The existing pressure must be within the nominal pressure limits of the

sensor, see specifications on the "Type label".

See also "Quick setup menu" in chapter "Flow measurement".

Carry out position adjustment:

1 Pressure on the instrument

RT 39

Page 40

6 Operati

on

h "E" key at least for 3 s

2 Pus

3 Does the LED on the electronics module light briefly?

Yes: existing pressure was accepted as position adjustment

No: Existing pressure for position adjustment was not accepted,

note the adjustment limits

Adjust max. pressure value:

1 Requested pressure for max. pressure value (MAX. PRESSURE

FLOW) is on the instrument

2 Push "+" key at least for 3 s

3 Does the LED on the electronics module light briefly?

Yes: Existing pressure was saved as max. pressure value (MAX.

PRESSURE FLOW) and assigned to the max. flow value (MAX.

FLOW).

No. Existing pressure for measurement begin was not saved as

max. pressure value. Note the adjustment limits

6.5 Local adjustment - local indication connected

If the local indication is connected, the three adjustment key are used

for navigation in the adjustment menu, see chapter "Function of the

operating elements".

Configuration of the

menu

40 VEG

The menu is divided into four levels. The three upper levels are used

for navigation whereas on the lowest level, numerical values are

entered, options selected and saved. The complete menu is shown in

chapter "Menu schematic". The "Adjustment menu" is composed

according to the selected mode, e.g. when the mode "Pressure" is

selected, only the functions necessary for this mode are displayed.

The parameters LANGUAGE and MODE are shown via the local

indication on the 1. selection level. Via the digital communication, the

parameter LANGUAGE is shown in group INDICATION and the

parameter MODE in the function group BASIC ADJUSTMENT.

31731-EN-081119

ADIF 55 • 4 … 20 mA/HART

Page 41

Measured value

GROUP SELCTION

DISPLAY

SETTINGS

EXTENDED SETUP

POS. ZERO ADJUST

POS INPUT VALUE

CALIB. OFFSET

POSITION ADJUSTMENT BASIC SETUP

OPERATING MENU

QUICK SETUP

MEASURING MODELANGUAGE

1

2

3

4

6 Operati

on

Fig. 40: Configuration

1 1. Selection level

2 2. Selection level

3 Function groups

4 Parameter

Selec

t option

of the menu

Example: Select the menu language "English"

German is selected as language. The active selection is marked by a

check mark in front of the me nu text.

t English with "+" or "-".

Selec

31731-EN-081119

VEGADIF 55 • 4 … 20 mA/HA

RT 41

Page 42

6 Operati

on

Edit

value

1. Confirm

check mark in front of the menu text (the language English is selected).

2. Move to the next menu item with "E".

Exa

chapter "Operating elements".

The local adjustment shows the parameter to be modified. The value

highlighted in black can be modified. The unit is determined "s" and

cannot be modified.

1. Push "+

highlighted in black.

selection with "E". The active selection is marked by a

mple: Set function "Damping value" from 2.0 s to 30.0 s. See also

" or "-" to reach the editing mode. 2. The first position is

the "+" key, you change number "2" to "3". 2. With the "E" key,

1. With

you confirm "3". Cursor jumps to t he next position (hihglighted in

black).

42 VEG

31731-EN-081119

ADIF 55 • 4 … 20 mA/HART

Page 43

6 Operati

e point is highlighted in black, i.e. you can now edit this position.

Th

on

1. Push "+

Cursor jumps to the next position. "↵" is displayed and is highlighted in

black, see next illustration.

With "E" you

illustration.

Th

with "E". You return to the editing mode with "+" or "-".

" or "-" until "0" is displayed. 2. Confirm "0" with the "E" key.

save the new value and quit the editing mode, see next

e new value for the damping is 30 s. You reach the next parameter

the pressure on the

Take

instrument over as value

31731-EN-081119

VEGADIF 55 • 4 … 20 mA/HA

mple: Adjust measurement end - assign 20 mA to the pressure

Exa

value 400 mbar.

The lower line on the local indication shows the existing pressure, here

400 mbar.

RT 43

Page 44

6 Operati

on

Move with "+" or "-" to the option "Confirm". Active selection is

highlighted in black.

Assi

gn value (400 mbar) to the parameter "GET URV" value

(400 mbar) with the key "E". The instrument confirms the adjustment

and jumps back to the parameter, here "GET URV" (see next

illustration).

Move to the next parameter with "E".

6.6 D

ata memory module (optional)

The data memory is a memory module that is plugged to the

electronics module and fulfils the following functions:

l Backup of the configuration data

l Copy the configuration data of a transmitter to another transmitter

l Cyclical recording of pressure and sensor temperature measured

values

l Recording of various events such as e.g. alarm messages,

configuration changes, counter for exceeding and decreasing of

the measuring range for pressure and temperature, exceeding and

decreasing of the user limits for pressure and temperature etc.

ning:

War

Warning! Remove or plug data memory only in idle condition from the

electronics module.

tion:

Informa

The data memory module can be retrofitted any time. After having

plugged to the electronics module and the instrument is powered

again, the data in the data memory module and in the instrument are

checked. The following messages can be displayed "W702, Histo-

ROM data not consistent" and "W706, Configuration in HistoROM and

device not identical". For measures see Additional instructions manual

"Service instructions VEGADIF 55", "Messages".

44 VEG

31731-EN-081119

ADIF 55 • 4 … 20 mA/HART

Page 45

Histo

ROM

2 1

PC

τ

Damping

[

] τ

2

1

on

off

off

on

Sensor

Display

6 Operati

on

Local indication not

connected

31731-EN-081119

VEGADIF 55 • 4 … 20 mA/HA

Fig. 54: Electronics

1 Optionally available data memory module

2 DIP switch

module with optionally available data memory module

6.7 Copy configuration data

Informa

tion:

To copy configuration data from the data memory module in an

instrument, the adjustment must be unlocked.

Copy configuration data from one instrument into a data memory

module:

tion:

Informa

The adjustment must be unlocked. See also chapter "Lock/Unlock

adjustment".

1 Separate instrument from voltage supply

2 Plug data memory module into the electronics module

3 Connect instrument again to voltage supply

4 Push "E" and "-" keys (at least 3 seconds) until the LED on the

electronics module lights

5 Wait approx. 20 seconds. Configuration data are loaded from the

instrument to the data memory module. The instrument does not

carry out a restart.

6 Separate instrument again from voltage supply

7 Remove memory module

8 Connect instrument again to voltage supply

RT 45

Page 46

6 Operati

Local adjustment

through local indication

(optional) or remote adjustment

on

configuration data from a data memory module to an

Copy

instrument:

Information:

The adjustment must be unlocked. See also chapter "Lock/Unlock

adjustment".

1 Separate instrument from voltage supply

2 Plug the data memory module into the electronics module.

Configuration data of a different instrument are saved in the data

memory module.

3 Connect instrument again to voltage supply

4 Push "E" and "+" keys (at least 3 seconds) until the LED on the

electronics module lights

5 Wait approx. 20 seconds. All parameters except DEVICE SERIAL

NO., DEVICE DESIGN., CUST. TAG NUMBER, LONG TAG

NUMBER, DESCRIPTION, BUS ADDRESS and the parameters of

the group POSITION ADJUSTMENT and PROCESS CONNECTION are loaded from the data memory module in the instrument.

The instrument carries out a restart.

6 Before you remove the data memory module from the electronics

module, you have to separate the instrument from the voltage

supply

Copy configuration data from one instrument into a data memory

module:

tion:

Informa

The adjustment must be unlocked. See also chapter "Lock/Unlock

adjustment".

1 Separate instrument from voltage supply

2 Plug data memory module into the electronics module

3 Connect instrument again to voltage supply

4 The selection for the parameter DOWNLOAD SELECT does not

influence an upload from the instrument in HistoROM (menu

path:"Group sel ection - Operating menu - Operating"

5 Select via the parameter HistoROM CONTROL the option

"Instrument - HistoROM" for the transmission direction (menu

path: "Group selection - Operating menu - Operating").

6 Wait approx. 20 seconds. Configuration data are loaded from the

instrument to the data memory module. The instrument does not

carry out a restart.

7 Separate instrument again from voltage supply

8 Remove memory module

9 Connect instrument again to voltage supply

Copy configuration data from a data memory module to an

instrument:

46 VEG

31731-EN-081119

ADIF 55 • 4 … 20 mA/HART

Page 47

6 Operati

tion:

Informa

The adjustment must be unlocked. See also chapter "Lock/Unlock

adjustment".

1 Separate instrument from voltage supply

2 Plug the data memory module into the electronics module.

Configuration data of a different instrument are saved in the data

memory module.

3 Connect instrument again to voltage supply

4 You select via the parameter DOWNLOAD SELECT which

parameter should be overwritten (menu path: "Group selection -

Operating menu - Operating")

Depending on the selection, the following parameters are overwritten:

Copy config.: All parameters except DEVICE SERIAL NO.,

DEVICE DESIGN., CUST. TAG NUMBER, LONG TAG NUMBER,

DESCRIPTION, BUS ADDRESS and the parameters of group

POSITION ADJUSTMENT and PROCESS CONNECTION.

Instrument change: All parameters except DEVICE SERIAL NO.,

DEVICE DESIGN. and the parameters of group POSITION

ADJUSTMENT and PROCESS CONNECTION

Electronics exchange: All parameters except the parameters of

group POSITION ADJUSTMENT. Factory setting: Copy config.

5 Select via the parameter HistoROM CONTROL the option

"HistoROM - Instrument" for the transmission direction (menu

path: "Group selection - Operating menu - Operating").

6 Wait approx. 20 sec. Configuration data are loaded from the data

memory module to the instrument. The instrument carries out a

restart.

7 Before you remove the data memory module from the electronics

module, you have to separate the instrument from the voltage

supply

on

31731-EN-081119

VEGADIF 55 • 4 … 20 mA/HA

RT 47

Page 48

EX EX

4…20 mA

min. 250 Ω

1

# % &

Copy

G H I

P Q R S

, ( )‘

A B C

Paste

Page

On

Page

Up

De

leteBksp

Insert

J K L

T UV

_ < >

D E

F

Hot Key

+ Hot Key

M N O

W XY Z

+ * /

4

7

.

2

5

8

0

375

FIELD COMMUNICATOR

3

6

9

-

9

6

DELTABAR:* * * * * * * *

ONLINE

1 QUICK SETUP

2 OPE

RATING MENU

4 SV 0 °C

3 PV 352 mbar

HELP SAVE

dsdmdm

df das.

asdas fa

asas la.

1

# % &

Copy

G H I

P Q R S

, ( )‘

A B C

Paste

Page

On

Page

Up

De

leteBksp

Insert

J K L

T UV

_ < >

D E

F

Hot Key

+ Hot Key

M N O

W XY Z

+ * /

4

7

.

2

5

8

0

375

FIELD COMMUNICATOR

3

6

9

-

9

6

DELTABAR:* * * * * * * *

ONLINE

1 QUICK SETUP

2 OPE

RATING MENU

4 SV 0 °C

3 PV 352 mbar

HELP SAVE

dsdmdm

df das.

asdas fa

asas la.

1

# % &

Copy

G H I

P Q R S

, ( )‘

A B C

Paste

Page

On

Page

Up

De

leteBksp

Insert

J K L

T UV

_ < >

D E

F

Hot Key

+ Hot Key

M N O

W XY Z

+ * /

4

7

.

2

5

8

0

375

FIELD COMMUNICATOR

3

6

9

-

9

6

DELTABAR:* * * * * * * *

ONLINE

1 QUICK SETUP

2 OPE

RATING MENU

4 SV 0 °C

3 PV 352 mbar

HELP SAVE

dsdmdm

df das.

asdas fa

asas la.

1

# % &

Copy

G H I

P Q R S

, ( )‘

A B C

Paste

Page

On

Page

Up

Del

eteBksp

Insert

J K L

T UV

_ < >

D E

F

Hot Key

+ Hot Key

M N O

W XY Z

+ * /

4

7

.

2

5

8

0

375

FIELD COMMUNICATOR

3

6

9

-

9

6

DELTABAR:* * * * * * * *

ONLINE

1 QUICK SETUP

2 OP

ERATING MENU

4 SV 0 °C

3 PV 352 mbar

HELP SAVE

dsdmdm

df das.

asdas fa

asas la.

1

# % &

Copy

G H I

P Q R S

, ( )‘

A B C

Paste

Page

On

Page

Up

Del

eteBksp

Insert

J K L

T UV

_ < >

D E

F

Hot Key

+ Hot Key

M N O

W XY Z

+ * /

4

7

.

2

5

8

0

375

FIELD COMMUNICATOR

3

6

9

-

9

6

DELTABAR:* * * * * * * *

ONLINE

1 QUICK SETUP

2 OP

ERATING MENU

4 SV 0 °C

3 PV 352 mbar

HELP SAVE

dsdmdm

df das.

asdas fa

asas la.

4...20mA

Test

Test

3

2

1

6 Operati

on

6.8 Adj

ustment via HART handheld

You can adjust, check and use the additional functions of the

transmitter with a HART handheld along the 4 … 20 mA cable.

Fig. 55: Connection HART handheld, here

1 Required communication resistor ≥ 250 Ω

2 HART handheld

3 HART handheld connected directly to the instrument, also in Ex i area

With

protection EExd, do not connect the handheld in hazardous areas.

e.g. Field Communicator DXR375

Do not change battery of the handheld in hazardous areas. For

instruments with FM or CSA certificate, carry out the electrical

connection according to the installation attached in the certificate.

6.9 Lock/Unlock adjustment

After entering all parameters, you can protect your settings against

unauthorised access. You have the following possibilities to lock/

unlock the adjustment:

l via the DIP switch on the electronics module, on site on the

instrument

l via the local indication (optional)

l Via a HART handheld

The locking of the adjustment is marked on the local indication with the

key symbol. Parameters refering to the presentation such as e.g.

language and contrast indication can be still modified.

Note:

the adjustment is locked via the DIP switch, the locking can be ony

If

released via the DIP switch.

If the adjustment is locked via the local indication or remote

48 VEG

adjustment, the locking can be released either via the local indication

or the remote adjustment.

31731-EN-081119

ADIF 55 • 4 … 20 mA/HART

Page 49

Histo

ROM

2 1

PC

Damping

[

] τ

off

on

Sensor

Display

of f

on

2 1

off

on

2 1

Damping

[

]

τ

Damping

[

] τ

1 2 3

6 Operati

on

A modificati

on of the DIP switch "Damping on/off" does not influence

the damping time as long as the adjustment is locked. A modification is

only effective after the adjustment is unlocked again.

The chart gives an overview of the locking function:

Locking via Indication/Re-

ading of the

parameters

DIP switch Yes No No Yes No No

Local indica-

Yes No No No Yes No

tion

Remote adjust-

Yes No No No Yes No

ment

Modifying/Writing via local

indication

Modifying/Writing via remote adjustment

Unlocking via

DIP switch

Unlocking via

local indication

Unlocking via

remote adjustment

Lock/Unlock adjustment

on site via DIP switch

Fig. 56: Position DIP switch "Hardware

1 If necessary, dismount local indication (optional)

2 DIP switch 1 is set to "on": Adjustment is locked.

3 DIP switch 1 is set to "off": Adjustment is unlocked (adjustment possible)

locking" on the electronics module

Lock/Unlock adjustment

via local indication or

remote adjustment

31731-EN-081119

VEGADIF 55 • 4 … 20 mA/HA

The chart gives an overview of the locking/unlocking options:

Description

Lock adjustment Select parameter "Insert pin no.", menu path: "Operating

menu - Operating - Insert pin no.".

To lock the adjustment, you have to enter for the parameter a

number between 0 … 9999 and ≠100.

Unlock adjustment

Select parameter "Insert pin no.", menu path: "Operating

menu - Operating - Insert pin no.".

To unlock the adjustment, enter 100 for the parameter.

6.10 Default setting (reset)

By entering a certain code, you can reset the adjustments for the

parameters completely or only partially to default. You enter the code

via the parameter "ENTER RESET CODE" (menu path: " Group

selection - Operating menu - Operation"). There are different reset

codes for the instrument. The following chart shows the parameters

RT 49

Page 50

6 Operati

on

which can be reset by the respective reset code. T

the adjustment must be unlocked (see chapter "Lock/Unlock adjust-

ment").

Information:

Customer-specific parameter adjustments (default) remain even after

a reset. If you want that the parameters are reset to default, you have

to contact VEGA.

Reset code Description

1846 Indication Reset

l This reset resets all parameters relating to the display (DISPLAY Group)

l If a simulation is running, this will be terminated

l The instrument carries out a restart

62 PowerUp reset (warm start)

l This reset resets all parameters in the RAM. Data are reread from the EEPROM (processor is

re-initialised)

l If a simulation is running, this will be terminated

l The instrument carries out a restart

2710 Reset mode level

l Depending on the settings of the parameters LEVEL MODE and LIN MEASURAND, LINd

MEASURAND or COMB. MEASURAND all parameters necessary for this application are reset.

l If a simulation is running, this will be terminated

l The instrument carries out a restart

333 User reset

This reset resets the following parameters:

l Function group POSITION ADJUSTMENT

l Function group BASIC SETUP, except the customer-specific units

l Function group EXT. SETUP

l Function group: TOTALIZER SETUP

l Group OUTPUT

l Function group HART DATA: BUS ADDRESS and PREAMBLE NUMBER

l If a simulation is running, this will be terminated

l The instrument carries out a restart

o carry out a reset,

50 VEG

31731-EN-081119

ADIF 55 • 4 … 20 mA/HART

Page 51

code Description

Reset

7864 Total reset

8888 Data memory module reset

This reset resets the following parameters:

l Function group POSITION ADJUSTMENT

l Function group BASIC SETUP

l Function group EXT. SETUP

l Function group LINEARIZATION (an existing linearization chart may be deleted)

l Function group: TOTALIZER SETUP

l Group OUTPUT

l Function group HART DATA

l Function group MESSAGES

l All messages to be configured (type "Error") are set to "Warning", see also Supplementary

instruction manual "Service instructions VEGADIF 55", "Messages" and chapter "Fault

rectification"

l Function group USER LIMITS

l Function group SYSTEM 2

l If a simulation is running, this will be terminated

l The instrument carries out a restart

Measured value and event memory will be deleted. The data memory module must be plugged to

the electronics module during the reset.

Example LEVEL MODE = linear a nd LIN. MEASURAND = Height

l HEIGHT UNIT = m

l CALIBRATION MODE = wet

l EMPTY CALIB. = 0

l FULL CALIB. = Sensor final value converted in H²O, e.g. with a

500 mbar sensor: 5.99 mH²O

6 Operati

on

31731-EN-081119

VEGADIF 55 • 4 … 20 mA/HA

RT 51

Page 52

*

*

B B BB

A

B

A

*

1)

1)