Page 1

Operating instructions

Pressure transmitter D98

p

Page 2

Contents

Safety information ........................................................................ 2

1 Product description

1.1 Function and configuration .................................................. 3

2 Technical data

2.1 Data ....................................................................................... 4

2.3 Dimensions ........................................................................... 6

3 Mounting

3.1 Mounting instructions ........................................................... 7

3.2 Compensation of the atmospheric pressure ..................... 7

4 Electrical connection

4.1 Connection instructions ....................................................... 8

4.2 Terminal assignment ............................................................ 9

4.3 Connection example ............................................................ 9

Contents

5 Diagnostics............................................................................... 10

6 Instrument modification

6.1 Exchange of hygienic form seal ....................................... 11

Safety information

Please read this manual carefully, and also

take note of country-specific installation

standards (e.g. the VDE regulations in Germany) as well as all prevailing safety regulations and accident prevention rules.

For safety and warranty reasons, any internal

work on the instruments, apart from that

involved in normal installation and electrical

connection, must be carried out only by

qualified VEGA personnel.

2 Pressure transmitter D98

Page 3

Product description

1 Product description

1.1 Function and configuration

D98 pressure transmitters are efficient modular instruments for pressure and level measurement. A dry ceramic-capacitive CERTEC

measuring cell is used as the pressure sensor element.

®

Pressure transmitter D98 3

Page 4

Technical data

2 Technical data

2.1 Data

Nominal measuring range Gauge pressure resistanLow pressure resistance

Gauge pressure

0…0.4 bar / 0…40 kPa 30 bar / 3 000 kPa -0.8 bar / -80 kPa

0…1.0 bar / 0…100 kPa 35 bar / 3 500 kPa -1.0 bar / -100 kPa

0…2.5 bar / 0…250 kPa 50 bar / 5 000 kPa -1.0 bar / -100 kPa

0…4.0 bar / 0…400 kPa 65 bar / 6 500 kPa -1.0 bar / -100 kPa

0…10.0 bar / 0…1 000 kPa 90 bar / 9 000 kPa -1.0 bar / -100 kPa

0…16.0 bar / 0…1 600 kPa 130 bar / 13 000 kP a -1.0 bar / -100 k Pa

Power supply and signal circuit

Power supply

- without indication 12 … 36 V DC

Residual ripple of the power supply no influence with U

Output signal 4 … 20 mA (factory setting)

Current limitation approx. 22 mA

Fault signal approx. 22 mA

Average delay time 20 ms

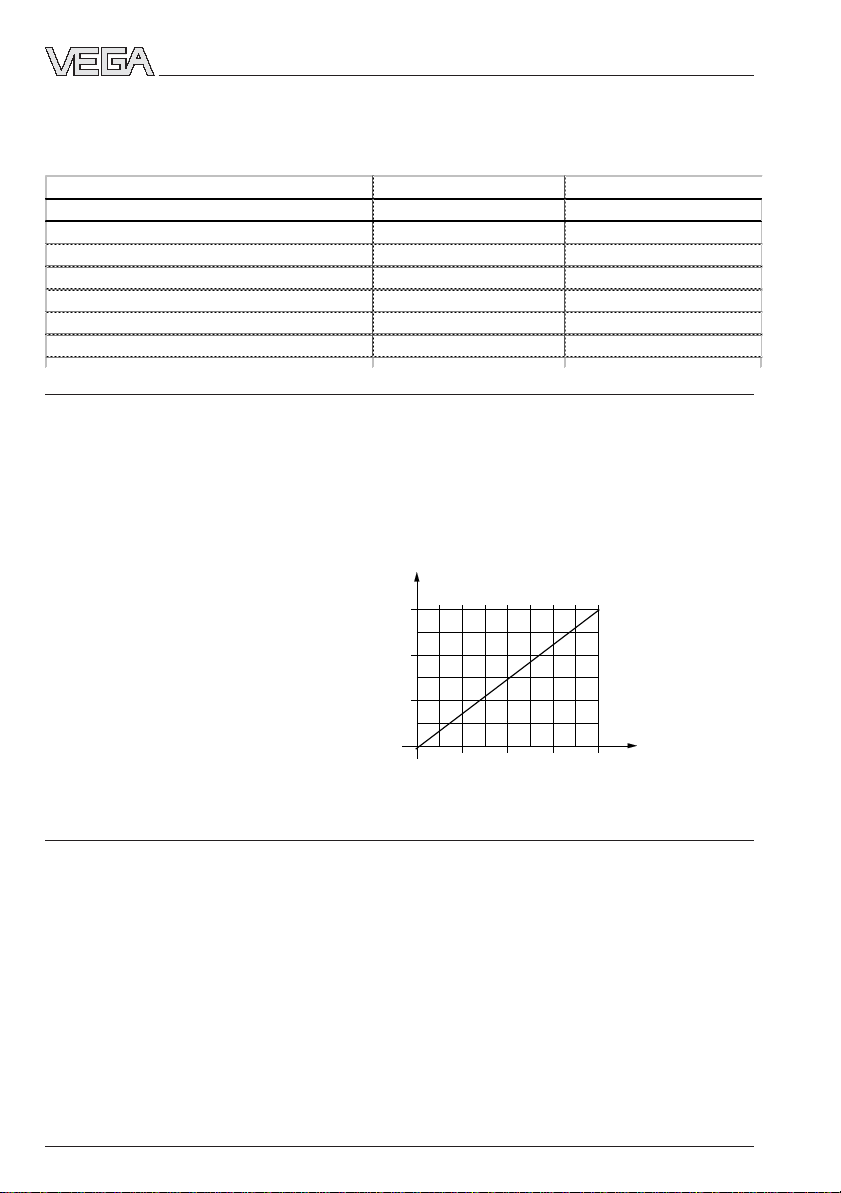

Max. permissible load see load diagram:

load in Ω

900

≤ 1 V

SS

600

300

supply voltage

12

18 24 30 36

in V

Measuring accuracy (according to DIN 16 086, DIN V 19 259-1 and IEC 770)

Measuring deviation

Reference conditions acc. to IEC 770, e.g.

- temperature 15°C … 35°C

- rel. humidity 45 % … 75 %

- air pressure 860 mbar … 1060 mbar

Determination of characteristics limit point adjustment acc. to DIN 16 086

Characteristics linear

Deviation in characteristics

Hysteresis (repeatability)

1)

Relating to the nominal range

2)

In compensated temperature range of 0°C … +80°C, reference temperature 20°C

3)

According to IEC 770, Punkt 6.3.2 related to the nominal range

4)

The use of a properly fitting cable seal in the cable connection is necessary for maintaining the housing

protection IP 66. If the seal used does not fit the cable, it should be replaced by a suitable one.

5)

FDA approved

4 Pressure transmitter D98

1)

1)

< 0.25 %

< 0.02 %

Page 5

Technical data

Influence of the ambient temperature

Average temperature coefficient

of the zero signal

1) 2)

< 0.15 %/10 K

Long-term stability

Long-term stability of the zero signal

1) 3)

< 0.1 %/2 years

Other actuating variables

Vibration resistance mechanical vibration with 4 g and

5 … 100 Hz, tested acc. to the regulations of

German Lloyd, GL-characteristics 2

Ambient conditions

Temperatures

Ambient temperature -40°C … +85°C

Storage and transport temperature -50°C … +85°C

Product temperature -40°C … +100°C (1 h up to +140°C)

Protective measures

Protection class IP 66 (EN 60 529)

Connection cable

Cable entry M20x1.5 (for cable ø 5…9 mm)

Screw terminals for conductor cross-sections of up to 2.5 mm

Materials, wetted parts

Process connection stainless steel 1.4435

Diaphragm sapphire-ceramic® (99.9 % Oxide-ceramic)

Seal, measuring cell

Materials, non-wetted parts

Housing stainless steel 1.4571

Ground terminal stainless steel 1.4305

4)

5)

EPDM

2

Weight

Weight 1.4 kg … 1.6 kg

CE conformity

The pressure transmitter D98 meets the requirements of EMC (89/336/EC) and NSR (73/23/

EWG). Conformity has been judged according to the following standards:

EMC emission EN 50 081 - 1: 1992

susceptibility EN 50 082 - 2: 1995

NSR EN 61 010: 1993

Pressure transmitter D98 5

Page 6

2.3 Dimensions

D98 DN 25 D98 DN 50

Technical data

188

164

200

176

TA

TB

6 Pressure transmitter D98

Page 7

Mounting

3 Mounting

3.1 Mounting instructions

Cable entry

The pressure transmitter can be mounted in

any position.

Cable entries must point downward to avoid

moisture ingress. For this purpose, the housing can be rotated by 330 °. With vertically

mounted sensors, the connection cable to the

housing must point downward so that rain

and condensed water can drip off. This applies especially to outdoor mounting, or

mounting in humid rooms (e.g. caused by

cleaning processes) or on cooled or heated

vessels.

3.2 Compensation of the atmospheric pressure

The atmospheric pressure is compensated

via a breather facility integrated in the housing (air-permeable and moisture-resistant

PTFE insert).

Moisture

Pressure transmitter D98 7

Page 8

4 Electrical connection

Electrical connection

4.1 Connection instructions

The electronics in the pressure transmitter

requires a supply voltage of 12 … 36 V DC.

The electronics is designed in two-wire technology i.e. supply voltage (DC) and measuring signal are led via the same two-wire

connection cable to the terminals. The supply

voltage is provided by an external power

supply unit.

Please note that the external power supply

according to DIN VDE 0106, part 101 must

be reliably separated from the mains circuits.

Note the following instructions for electrical

connection:

- Connection must be made according to

country-specific installation standards (e.g.

in Germany acc. to the VDE regulations).

- The terminal voltage should not exceed 36

V to avoid damage to the electronics.

- The electrical connection is provided with

polarity reversal.

- The wiring between pressure transmitter

and power supply can be carried out with

standard two-core cable.

- Screened cable is recommended in case

of strong electromagnetic interference.

Install the screening on one side of the

sensor.

- In case of overvoltage, we recommend

using a pressure transmitter with integrated overvoltage protection or installing

VEGA overvoltage arresters.

- A seal must be used which correctly fits

the cable in the cable entry.

Connection cable

Please make sure that the connection cables

are specified for the anticipated operating

temperatures in your plant. The cable must

have an outer diameter of 5 ... 9 mm, otherwise the sealing effect of the cable entry

cannot be guaranteed.

8 Pressure transmitter D98

Page 9

Electrical connection

4.2 Terminal assignment

4-20mA

1 2 3 4 5

-

+

4...20mA

12...36 V DC

+

control unit 4 … 20 mA

-

-

energy supply

+

12 … 36 V DC

4.3 Connection example

The following examples are valid for a direct connection to the terminals of the pressure transmitter. When the external connection housing is used, the connections are made to the appropriate terminals of the housing.

The hydrostatic pressure transmitter D98 is adjusted to the indicated measuring range by

VEGA and has no adjustment option.

Oscillator is supplied by a power supply unit

The adjustment is made via the indicating instrument.

Ammeter for on-site

control

+ – –

1 2 3

connection terminals

pressure transmitter

U

K

analogue / digital indicating

instrument

U

A

4 … 20 mA

U

H

power supply unit

–

~

+

Oscillator is supplied by a PLC with active input circuit

Evaluation is carried out via PLC.

Ammeter for on-site check

+ – –

1 2 3

connection terminals

pressure transmitter

U

K

4 … 20 mA

memory programmable control

U

–

H

+

Notes:

An ammeter for on-site check of the output current can be connected to the terminals 1 and 3.

This measurement can be carried out during operation without interruption of the mains supply.

Pressure transmitter D98 9

Page 10

5 Diagnostics

Diagnostics

Maintenance

When properly used, pressure transmitters

D98 are maintenance-free.

Should a dismounting of the pressure transmitter be necessary (e.g. vessel cleaning)

we recommend the use of a new seal. You

should only use VEGA seals.

Troubleshooting

If faults do occur, the following measures

must be taken before dismounting the

pressure transmitter:

- check the atmospheric pressure compensation (only with gauge measuring ranges)

- check the electrical connections.

Check the atmospheric pressure compensation

Open the cover of the housing. The measured value must not change. However, if the

displayed value changes, compensation of

the atmospheric pressure is not ensured,

which can result in distortion of the measured

value. Make sure the breather unit is unobstructed. It consists of a black plastic

threaded insert with integrated filter element.

Check the electrical connections

Terminals

Pressure

transmitter

1 2 3

mA

current

voltage

V

current

mA

external

energy

–

+

~

Check the voltage

- The terminal voltage on the pressure

transmitter must be at least 12 V DC.

Check the current

• Initial current with unimmersed diaphragm

of pressure transmitter: approx. 4 mA

• operating measuring current: 4 … 20 mA

• Exceeding or falling short of the specified

measuring range: 20.5 mA and 3.8 mA

• Pressure transmitter damaged or shortcircuited: current > 22 mA or < 3.6 mA

Note:

The pressure acting on the breather must be

the same as the atmospheric pressure in the

open vessel.

10 Pressure transmitter D98

Page 11

Instrument modification

6 Instrument modification

6.1 Exchange of hygienic form seal

In the hygienic connections of pressure

transmitter D98, the ceramic measuring cell is

gaplessly sealed with a radial, form seal.

This form seal (material EPDM-FDA) can be

exchanged by the user without a fresh adjustment being necessary. The criteria and

the time intervals for such an exchange of the

seal are generally defined by the process

and hygienic requirements.

Important:

Use only original replacement seals from

VEGA, article no. 2.17 775!

Please note the following exchange procedure.

Removal procedure:

1 Pressure transmitter should be

unpressurized (switch off process pressure or empty vessel)

2 Loosen the hexagon pressure screw (4)

(width across flats, 46 mm) by turning to

the left.

Note!

The process connection (6) (e.g. compression nut) must not be loosened!

Installation procedure:

1 Place the new form seal (5) over the meas-

uring cell (the conical side must mate with

the process connection).

2 Turning it lightly clockwise, insert the pres-

sure transmitter carefully into the process

connection.

3 Tighten hexagon pressure screw (4) (width

across flats, 46 mm) (45 Nm).

4 Turn the housing (1) of the pressure trans-

mitter to the original position.

The exchange of the form seal is now finished; the removed seal must be properly

disposed of.

1

2

3

4

3 Turn the adapter (3) below the pressure

transmitter housing with a spanner (with

across flats, 36 mm) slightly to the left

(loosen the seal).

5

4 Hold onto the housing (1), pull the entire

pressure transmitter out of the process

connection by carefully turning to the left.

5 Slightly lift the form seal (5) and loosen it

from the ceramic measuring cell.

6 If the form seal (5) does not completely

encircle the measuring cell, the remaining

part must be carefully removed from the

process connection.

Pressure transmitter D98 11

1 Pressure transmitter

2 Headless screw (avoids overwinding and must not be

removed)

3 Adapter

4 Hexagon screw

5 Form seal

6 Process connection

6

Page 12

VEGA Grieshaber KG

Am Hohenstein 113

D-77761 Schiltach

Phone (07836) 50-0

Fax (07836) 50-201

E-Mail info@de.vega.com

www.vega.com

ISO 9001

All statements concerning scope of delivery, application, use and

operating conditions correspond to the information available at the

time of printing.

Technical data subject to alterations

24336 -EN-021030

Loading...

Loading...