Page 1

Operating Instructions

Hydrostatic pressure transmitters

PROF I

D94 (Profibus PA)

PROCESS FIELD BUS

BUS

0 - 20 bar

Level and Pressure

p

Page 2

Safety information, note Ex area

Safety information

Please read this manual carefully, and also take

note of country-specific installation standards

(e.g. the VDE regulations in Germany) as well

as all prevailing safety regulations and accident prevention rules.

For safety and warranty reasons, any internal

work on the instruments, apart from that involved in normal installation and electrical connection, must be carried out only by qualified

VEGA personnel.

2 Pressure transmitter D94 (Profibus PA)

Note Ex area

Please note the attached safety instructions

containing important information on installation

and operation in Ex areas.

These safety instructions are part of the

operating instructions and come with the Ex

approved instruments.

Page 3

Contents

Contents

Safety information ........................................................................ 2

Note Ex area ................................................................................ 2

1 Product description

1.1 Function and configuration .................................................. 4

1.2 Types and versions ............................................................. 5

1.3 Technical data ....................................................................... 6

1.4 Approvals and certificates .................................................. 9

1.5 Dimensions ......................................................................... 10

2 Mounting

2.1 Mounting instructions ......................................................... 12

2.2 Compensation of the atmospheric pressure ................... 12

3 Electrical connection

3.1 Connection instructions ..................................................... 13

3.2 Wiring plan .......................................................................... 14

4 Setup

4.1 Setting the Profibus PA address ...................................... 15

4.2 Setup with module

"Menu-driven adjustment with additional functions" ........ 17

4.3 Setup with adjustment software

VEGA Visual Operating (VVO) ......................................... 23

5 Diagnostics

5.1 Maintenance ....................................................................... 31

5.2 Failure rectification ............................................................. 31

6 Instrument modification

6.1 Exchange of adjustment modules

in the processing unit ........................................................ 32

6.2 Exchange of hygienic form seal on D94 .......................... 33

Pressure transmitter D94 (Profibus PA) 3

Page 4

1 Product description

Product description

1.1 Function and configuration

D94 pressure transmitters are efficient instruments for hydrostatic level measurement. A

dry ceramic-capacitive CERTEC® measuring

cell is used as the pressure sensor element.

The hydrostatic pressure effects a capacitance change on the ceramic diaphragm.

This capacitance change is detected by an

ASIC (Application Specific Integrated Circuit)

and converted into a pressure-proportional

signal by the integrated electronic module

with microcontroller. Precise, high-resolution

digital processing of measurement data

ensures excellent technical data.

The electronics module is powered by a

Profibus DP - PA segment coupler. The

measured pressure is transmitted via the

bus cable as digital signal to the processing

system and can be displayed on the indicating module.

To improve reliability, the functionality of important electronic components is continuously checked, and internal parameters such

as sensor value, temperature and operating

voltage are closely monitored.

The pressure transmitters with ceramic

CERTEC® measuring cell offer the advantage

of continuous self-monitoring: the measuring

and reference capacitances of the measuring

cell constitute a predefined ratio over the

entire measuring range. Any deviation from

these data is a reliable indicator of a malfunction of the measuring cell. If errors or malfunctions are detected during these routines,

fault signals are triggered according to the

Profibus PA specification.

The pressure transmitter D94 consists of two

parts, the transmitter and the processing

unit. Both parts are connected via a threewire screened cable (depending on the version, with or without breather capillaries). The

processing unit contains the adjustment

elements (address switch, keys and LCD)

and the terminals for the Profibus PA cable.

Transmitter

Processing unit

0 - 20 bar

Profibus PA

cable

Profibus PA version

The instrument profile of the pressure transmitter D94 is according to the profile specification version 3.0. The instrument master file

(GSD) is supplied with the pressure transmitter D94. In addition, the GSD is available as a

download file from the VEGA homepage

(www.vega.com).

Adjustment and indication

The following adjustment versions are available:

- menu-driven adjustment (4 keys and DOTMatrix) in the processing unit

- via PC with the adjustment software VEGA

Visual Operating (VVO)

- optional, processing unit equipped with an

indicating module.

4 Pressure transmitter D94 (Profibus PA)

Page 5

Product description

1.2 Types and versions

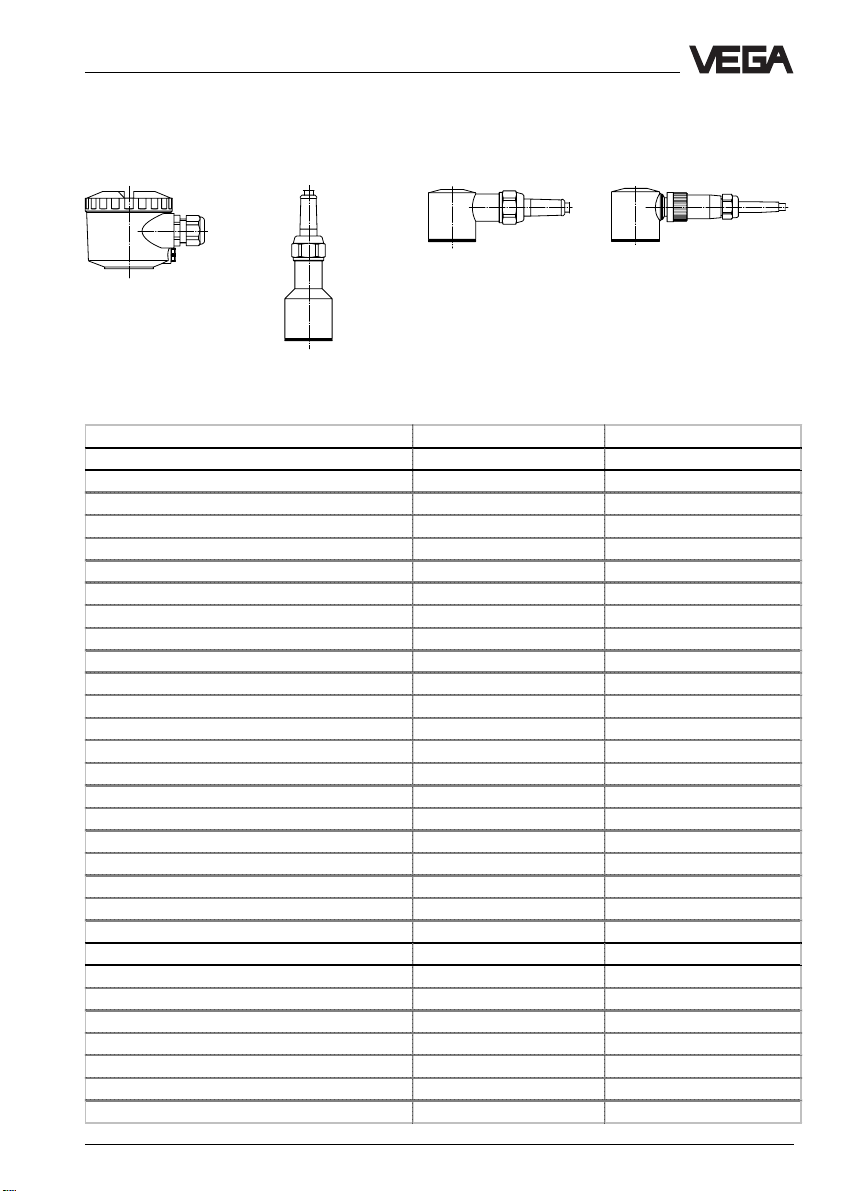

Housing with terminals

Nominal measuring range Gauge pressure resistanLow pressure resistance

Gauge pressure

0…0.1 bar / 0…10 kPa 15 bar / 1 500 kPa -0.2 bar / -20 kPa

0…0.2 bar / 0…20 kPa 20 bar / 2 000 kPa -0.4 bar / -40 kPa

0…0.4 bar / 0…40 kPa 30 bar / 3 000 kPa -0.8 bar / -80 kPa

0…1.0 bar / 0…100 kPa 35 bar / 3 500 kPa -1.0 bar / -100 kPa

0…2.5 bar / 0…250 kPa 50 bar / 5 000 kPa -1.0 bar / -100 kPa

0…5.0 bar / 0…500 kPa 65 bar / 6 500 kPa -1.0 bar / -100 kPa

0…10.0 bar / 0…1 000 kPa 90 bar / 9 000 kPa -1.0 bar / -100 kPa

0…20.0 bar / 0…2 000 kPa 130 bar / 13 000 kPa -1.0 bar / -100 kPa

0…40.0 bar / 0…4 000 kPa 200 bar / 20 000 kPa -1.0 bar / -100 kPa

0…60.0 bar / 0…6 000 kPa 300 bar / 30 000 kPa -1.0 bar / -100 kPa

-0.05…+0.05 bar / -5…+5 kPa 15 bar / 1 500 kPa -0.2 bar / -20 kPa

-0.1…+0.1 bar / -10…+10 kPa 20 bar / 2 000 kPa -0.4 bar / -40 kPa

-0.2…+0.2 bar / -20…+20 kPa 30 bar / 3 000 kPa -0.8 bar / -80 kPa

-0.5…+0.5 bar / -50…+50 kPa 35 bar / 3 500 kPa -1.0 bar / -100 kPa

-1.0…0.0 bar / -100…0 kPa 35 bar / 3 500 kPa -1.0 bar / -100 kPa

-1.0…+1.5 bar / -100…+150 kPa 50 bar /5 000 kPa -1.0 bar / -100 kPa

-1.0…+4.0 bar / -100…+400 kPa 65 bar / 6 500 kPa -1.0 bar / -100 kPa

-1.0…+10.0 bar / -100…+1 000 kPa 90 bar / 9 000 kPa -1.0 bar / -100 kPa

-1.0…+20.0 bar / -100…+2 000 kPa 130 bar / 13 000 kPa -1.0 bar / -100 kPa

-1.0 …+40.0 bar / -100…+4 000 kPa 200 bar / 20 000 kPa -1.0 bar / -100 kPa

-1.0…+60.0 bar / -100…+6 000 kPa 300 bar / 30 000 kPa -1.0 bar / -100 kPa

Absolute pressure

0…1.0 bar / 0…100 kPa 35 bar / 3 500 kPa

0…2.5 bar / 0…250 kPa 50 bar / 5 000 kPa

0…5.0 bar / 0 …500 kPa 65 bar / 6 500 kPa

0…10.0 bar / 0…1 000 kPa 90 bar / 9 000 kPa

0…20.0 bar / 0…2 000 kPa 130 bar / 13 000 kPa

0…40.0 bar / 0…4 000 kPa 200 bar / 20 000 kPa

0…60.0 bar / 0…6 000 kPa 300 bar / 30 000 kPa

Cable outlet

axial

Cable outlet lateral Plug connection

lateral

Pressure transmitter D94 (Profibus PA) 5

Page 6

Product description

1.3 Technical data

Mechanical data

Transmitter materials, wetted parts

Process connection stainless steel 1.4435 or 1.4571

Diaphragm sapphire-ceramic® (99.9 % Oxide-ceramic)

Seal, measuring cell Viton, EPDM, Hifluor, Kalrez

Transmitter materials, non-wetted parts

Transmitter housing - Alu die casting, powder-coated

Materials of the processing unit

Housing high resistance plastic PBT (Polyester)

Ground terminal stainless steel 1.4305

Window of the indication module Lexan

Adjustment and indicating elements (in the processing unit)

Menu-driven adjustment with

additional functions

- adjustment elements 4 keys

- indicating elements DOT-matrix display, 3 lines with 7 digits each

Version without adjustment module

- adjustment element 8-pole mini coding switch for adjustment of the

Indication module LC-display with

- stainless steel 1.4571

bus address

- bar graph (20 segments)

- digital value (4 digits)

- tendency indicators for rising or falling values

Weight

Transmitter approx. 1.4 kg

Processing unit approx. 480 g

6 Pressure transmitter D94 (Profibus PA)

Page 7

Product description

Electrical data

Adjustment ranges

Zero adjustable from -20 … +95 % of nominal range

Span adjustable from 3.3 … 120 % of nominal range

Supply and signal circuit

Supply voltage 9 … 32 V DC

Current consumption 10 mA ± 1 mA

Integration time 0 … 50 s

Rise time 70 ms (ti = 0 sec; 0 – 63 %)

Connection cable, processing unit – Profibus PA

Cable entry M20 x 1.5 (for cable ø 5 … 9 mm)

Screw terminals for conductor cross-sections of up to 2.5 mm

Recommended bus cable types - SINEC 6XV 830-5AH10 (Siemens AG)

Connection cable, processing unit – Transmitter

Cable entry M20 x 1.5 (for cable ø 5 … 9 mm)

Screw terminals for conductor cross-sections of up to 2.5 mm

Transmitter

- with fixed cable outlet 3-wire screened with breather capillaries

- with cable connection terminals 3-wire screened

Protective measures

1)

Protection

- transmitter with fixed cable outlet IP 68

- transmitter with terminal housing IP 66/IP 67

- transmitter with plug connection IP 66/IP 67

- processing unit IP 66/IP 67

Protection class III

Overvoltage category III

(delivered by the segment coupler)

- SINEC L2 6XV1 830-35H10 (Siemens AG)

- 3079 A (Belden)

2

2

1)

The use of a properly fitting cable seal in the cable connection is necessary for maintaining the housing

protection. If the seal used does not fit the cable, it should be replaced by a suitable one.

Pressure transmitter D94 (Profibus PA) 7

Page 8

Product description

Accuracy (similar to DIN 16 086, DIN V 19 259 - 1 and IEC 770)

Deviation

Reference conditions (acc. to IEC 770)

- temperature 15°C … 35°C

- rel. humidity 45 % … 75 %

- air pressure 860 mbar … 1060 mbar/86 kPa … 106 kPa

Determination of characteristics limit point adjustment acc. to DIN 16 086

Characteristics linear

Deviation in characteristics incl. hysteresis and repeatability

- Turn Down 1 : 1 < 0.25 % with accuracy class 0.25

- Turn Down up to 1 : 5 typ. < 0.3 % with accuracy class 0.25

- Turn Down up to 1 : 10 typ. < 0.4 % with accuracy class 0.25

Influence of the ambient temperature

Average temperature coefficient

of the zero signal

1)

- Turn Down 1 : 1 < 0.15 %/10 K with accuracy class 0.25

- Turn Down up to 1 : 5 typ. < 0.225 %/10 K with accuracy class 0.25

- Turn Down up to 1 : 10 typ. < 0.3 %/10 K with accuracy class 0.25

< 0.1 % with accuracy class 0.1

typ. < 0.1 % with accuracy class 0.1

typ. < 0.2 % with accuracy class 0.1

< 0.05 %/10 K with accuracy class 0.1

typ. < 0.075 %/10 K with accuracy class 0.1

typ. < 0.1 %/10 K with accuracy class 0.1

Long-term stability

Long-term drift of the zero signal

2)

< 0.1 % per 2 years

Other actuating variables

Vibration resistance mechanical vibrations with 4 g and

5 … 100 Hz, tested acc. to the regulations of

German Lloyd GL-characteristics 2

1)

In compensated temperature range of 0°C … +80°C, reference temperature 20°C.

2)

Acc. to IEC 770, item 6.1.2 relating to the nominal range.

8 Pressure transmitter D94 (Profibus PA)

Page 9

Product description

Operating conditions

Ambient conditions

Ambient temperature -40°C … +85°C

- with indicating module -20°C … +70°C

Storage and transport temperature -40°C … +85°C

Product temperature, depending on

seal material of the measuring cell

- Viton -20°C … +100°C (1 h up to +150°C)

- EPDM -40°C … +100°C (1 h up to +150°C)

- Hifluor -10°C … +100°C (1 h up to +150°C)

- Kalrez 0°C … +100°C (1 h up to +150°C)

1.4 Approvals and certificates

Approvals

- Ex Zone 2

- CENELEC EEx ia IIC

- ATEX II 1G EEx ia IIC

If the use of approved instruments is required for certain applications, the appropriate

official documents (test reports, test certificates and conformity certificates) must be observed. These are supplied with the respective instrument.

CE conformity

The pressure transmitter D94 meets the requirements of EMC (89/336/EWG) and NSR

(73/23/EWG). Conformity has been judged acc. to the following standards:

EMC Emission EN 50 081 - 1: 1992

NSR EN 61 010 - 1: 1993

Susceptibility EN 50 082 - 2: 1995

NAMUR regulations

Full compliance with the NAMUR regulations NE 21, May 1993.

Pressure transmitter D94 (Profibus PA) 9

Page 10

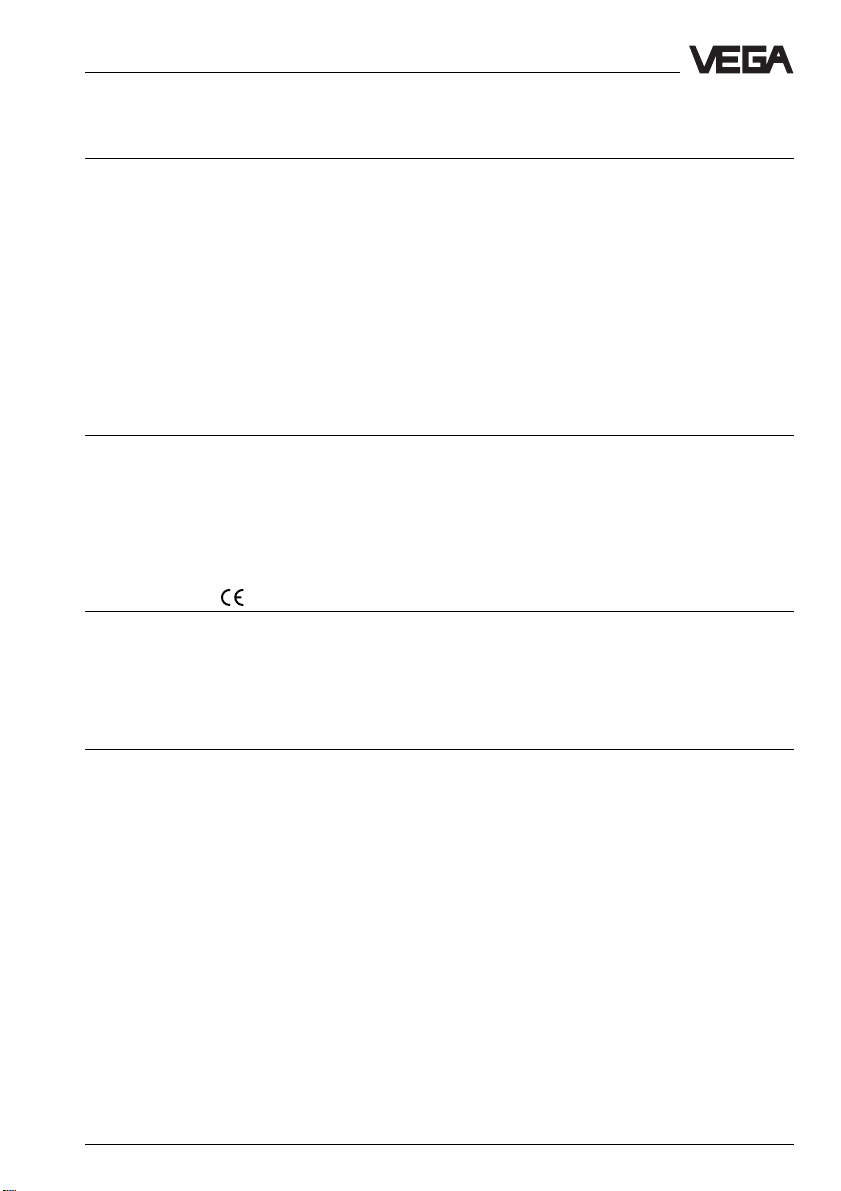

1.5 Dimensions

Transmitter housing

ø 76

67

Product description

ø 41,6

93

46

ø 41,6

ø 41,6

46

Processing unit

with display module

38 82

∅

M20x1,5

with protective cover

63

5

135

118

108

72100

85

90

139

130

10 Pressure transmitter D94 (Profibus PA)

Page 11

Product description

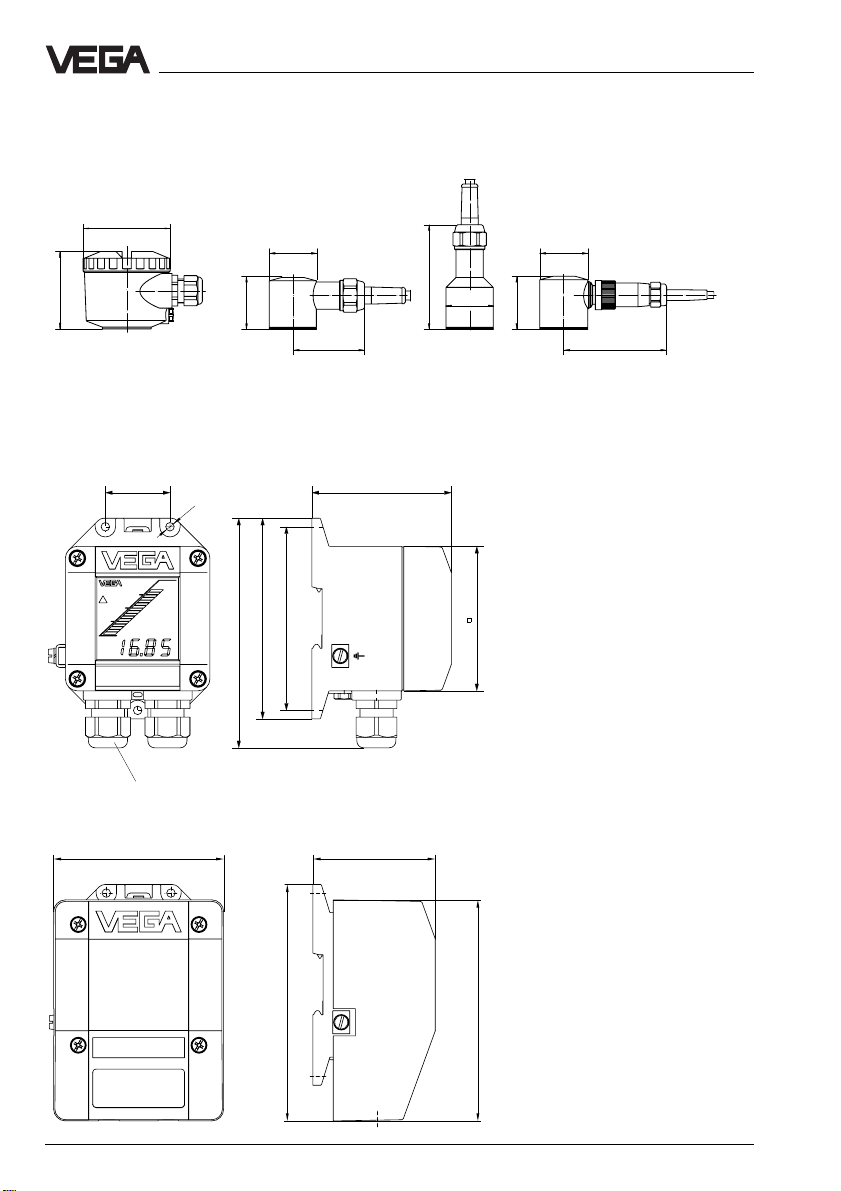

Process connections

Ø 41,6

Ø 41,6

Ø 41,6

76,5 (115*)

121 (160*)

121 (160*)

SW 46

SW 46

121 (160*)

SW 60

24,5

Ø 41,6

Ø 78

LA

Ø 41,6

Ø 78

RA

Ø 41,6

G 1½ A

Ø 55

GG

72,5 (111*)

121 (160*)

121 (160*)

SW 46

SW 46

121 (160*)

Ø 41,6

Ø 90

LB

Ø 41,6

Ø 92

RB

SW 60

25

1½ " NPT

GN

Ø 41,6

SW 46

121 (160*)

SW 46

121 (160*)

Ø 41,6

Ø 64

CA

Ø 41,6

Ø 65,8

Ø 105

AA

121 (160*)

SW 46

21

M44 x 1,25

BA

SW 46

121 (160*)

SW 46

121 (160*)

Ø 41,6

Ø 84

TA

Ø 41,6

Ø 100

PA

120

42,5

160

Ø 48

Ø 115

23

FT4

Ø 38

Ø 115

*) VBUS version

FG4

Pressure transmitter D94 (Profibus PA) 11

Page 12

2 Mounting

Mounting

2.1 Mounting instructions

The pressure transmitter can be mounted in

any position. Cable entries must point downward to avoid moisture ingress. For this purpose, the housing can be rotated by 330° in

relation to the mounting part.

An appropriate connection seal must be

used for mounting. This seal is either supplied with the pressure transmitter or must be

provided by the customer.

2.2 Compensation of the atmos-

pheric pressure

On instruments for gauge pressure measurement, the atmospheric pressure is compensated via a breather facility integrated in

the housing.

Pressure transmitter with housing

- via an integrated breather facility (PTFE

use 1)), protection IP 66

- via the capillaries of a special cable connected to the terminals, protection IP 67

Pressure transmitter with direct cable

outlet

- via the capillaries of a special cable connected to the terminals, protection IP 68

We recommend leading a special cable to

the processing unit and carrying out the

pressure compensation via the integrated

breather facility there.

Processing unit

Observe the following instructions:

- as a rule, there must be the same atmospheric pressure on the breather facility as

on the vessel

- the pressure compensation must be made

in dry environment

- with vertical wall mounting, cable entries

must point downward to avoid moisture

ingress and buildup on the breather facility.

1)

air permeable and humidity blocking

12 Pressure transmitter D94 (Profibus PA)

Page 13

Electrical connection

3 Electrical connection

3.1 Connection instructions

The electronics in pressure transmitter D94

requires a supply voltage of 9 … 32 V DC.

The supply voltage and the digital output

signal are led via the same two-wire cable to

the terminals. The external energy is provided via a segment coupler.

Note the following instructions for electrical

connection:

- Connection must be made according to

country-specific installation standards (e.g.

in Germany acc. to the VDE regulations).

- The electrical connection must have a protective measure against polarity reversal.

- The connection of field instruments is generally made via T-adapters on stubs..

- Screened cable is recommended for connection (cable types, see chapter "1.3

Technical data"). The shielding must be

grounded on both ends (on the T-adapter

and on the connection housing of D94).

- For use in Ex areas, the installation regulations must be observed.

Safety information for Ex applications

As a rule, do all connecting work in the complete absence of line voltage. Always switch

off the power supply before you carry out

connecting work on the sensors. Protect

yourself and the instruments.

Qualified personnel

Instruments used in Ex areas must be installed only by qualified personnel. The qualified personnel must observe and understand

the mounting regulations and the supplied

type approval certificates and conformity

certificates.

If an instrument is used in hazardous areas,

the respective regulations, conformity certificates and type approvals of the sensors,

separators or safety barriers must be noted

(e.g. DIN VDE 0165).

Sensors used in Ex areas must be connected only to intrinsically safe circuits. The

permissible electrical values are stated in the

conformity certificate or the type approval

certificate.

Intrinsically safe circuits with more than one

active instrument (instrument delivering electrical energy) are not allowed. Please note the

special installation regulations (DIN VDE

0165).

Certain pressure transmitters are provided

with a warning label informing on measures to

be taken to avoid the danger of electrostatic

discharge. Note the content of the warning

label.

Pressure transmitter D94 (Profibus PA) 13

Page 14

3.2 Wiring plan

TT

ransmitter with dirransmitter with dir

T

ransmitter with dir

TT

ransmitter with dirransmitter with dir

cable outletcable outlet

cable outlet

cable outletcable outlet

Screen

TT

ransmitter with terransmitter with ter

T

ransmitter with ter

TT

ransmitter with terransmitter with ter

housinghousing

housing

housinghousing

Zum Anschluß an

TransmitterTransmitter

Breather capillaries

For connection to

E21 PA

4321543215

Klemmeinsatz

terminal

ectect

ect

ectect

Suspension cable

br

bl

ge

minalminal

minal

minalminal

Processing unitProcessing unit

Processing unit

Processing unitProcessing unit

Transmitter

E21PA

bl

br

ge

Electrical connection

Display moduleDisplay module

Display module

Display moduleDisplay module

OK

121110231

PA+PA

AM10

-

4

PA +

Profibus PA cable

PA -

14 Pressure transmitter D94 (Profibus PA)

Page 15

Setup

4 Setup

4.1 Setting the Profibus P A address

Since each bus participant must have its own

address by which it is identified on the bus,

the address must be adjusted before setup

of the transmitter. Depending on the instrument version, this is done either with the

module "Menu-driven adjustment" or the

address switch.

Address adjustment with the address

switch

Address

12345678

on

off

The transmitter is delivered with the address

set as shown (all switches position "on").

If the mini coding switch is set to address

126 and higher (factory setting), the address

can be modified via software (with VVO).

However, this is only possible if the transmitter is connected as the only participant with

address 126 on the bus. For this reason, we

recommend adjusting the address of the

sensor via the hardware (switch) before

connecting to the bus.

Example:

To select address 37, set switch 1 (value 1),

switch 3 (value 4) and switch 6 (value 32) to

position "on". Set all other switches to position

"off".

Address

12345678

on

off

1 2 4 81632 64 128

1+4+32=37

S

H

S

H

value

Address adjustment with the module

"Menu-driven adjustment with additional functions"

The Profibus PA transmitter is delivered with

the address set to "126". To modify the address via the keyboard, the transmitter must

be connected to the power supply. This does

not have to be over the bus cable. You can

use a standard power supply unit or a battery (9 … 32 V DC, 10 mA).

OK

121110231

PA+PA

Transmitter

With the arrow key and the "OK" key, you

move to the menu item "Instrument address".

There you can adjust the address (0 … 125)

with the "+" and "–" key. Save the adjusted

address with the "OK" key.

Operate

0.123

bar

Ad-

just-

ment

E21PA

U

Calcu-

lation

AM10

-

–+

B

Output

Station

address

126

Simula-

tion

Addi-

tional

funct.

Escape

Pressure transmitter D94 (Profibus PA) 15

Page 16

Further adjustment steps (adjust PA output,

adjustment etc.) can also be carried out if the

processing unit is connected to a power

supply unit. However, adjustment is also

possible at a later time (when the processing

unit is connected to the bus cable).

Adjustment can be simplified by temporarily

mounting the cover or the display module on

the processing unit laterally or displaced

downwards.

Processing unit

Display module

OK

121110231

PA+PA

Transmitter

AM10

-

E21PA

0 - 20 bar

Setup

Tighten screws lightly

16 Pressure transmitter D94 (Profibus PA)

Page 17

Setup

4.2 Setup with module "Menu-driven adjustment with additional functions"

Adjustment elements

Indication of:

- measured value

- functions in menu

t Jump to the menu below

with the "OK" key

s Return to the menu above

with the "OK" key

Depending on parameter:

change value (increase) or

choose out of a list

+

OPERATE

3.00

mbar

Depending on the parameter: change value (decrease) or choose out of a

list

–>

OK

–

Adjustment with the multifunctional module is

menu-orientated and is made via the four

keys in conjunction with the text display. The

switchover from the measured value indication to the main menu is made with the "OK"

key. Use the "→" key to change within a menu

from one menu item to another.

Branching points

A branching point is shown by the t symbol

and enables a jump to the menu below with

the "OK" key. In this menu you can find parameters which belong together according to

function (possibly in other submenus).

Choose menu item or interrupt

adjustment

Depending on the menu item, save

the adjusted value or change the

menu level

Reset

A reset is indicated by the s symbol and

enables a jump up to the menu above with

the "OK" key.

An automatic jump back to measured value

indication is triggered 60 minutes after the

last key push.

Parameters have no s or t symbol. The

value of the parameters can be modified with

the "+" and "–" keys or chosen from a list.

When these keys are pushed once, the value

flashes first. When pushed again, the value is

modified. The modified value can be saved

with the "OK" key. Push the "→" key to cancel

input (without saving the modification).

Certain parameters can be displayed but not

modified.

Pressure transmitter D94 (Profibus PA) 17

Page 18

Menu schematic

Operate

0,0

skal

Measured value

indication

Setup

Adjust-

ment

Calcu-

lation

Lin.-

curve

activ

with PA

output "Pressure"

Output

PA-

output

Lin%

pressure

is only displayed if a

linearisation curve was

activated with VVO and

the PA output is set to

Lin%

with PA output

"%" or "Lin%"

Adjust

with

pres.

%

ti

1

s

Scalint

out

0

%=

0

Unit

0,0

skal

mbar

psi

kPa

%

Lin%

inHg

Adjust

without

pres.

Zurück

100

%=

1000

Escape

Decimal

Escape

point

888,8

Unit

0,0

%

mbar

psi

kPa

m

ft

inch

inHg

Simula-

tion

Sim.

x,xx

bar

Escape

Escape

Zero

0,0

%

Offset

correc-

tion

Offset

corr.

OK?

Sensor

un-

pres.?

18 Pressure transmitter D94 (Profibus PA)

Escape

Only on pressure transmitter

for relative pressure measurement

Span

100

%

Escape

Unit

0,0

bar

psi

kPa

inHg

on sensors with a measuring range <1 bar

the unit

mbar

Offset

correc-

tion

Offset

corr.

OK?

Sensor

un-

pres.?

is displayed instead of

Zero

0,0

bar

Span

1,000

bar

bar

Escape

Page 19

Setup

Addi-

tional

funct.

Station

address

126

Escape

Sensor

data

Fabr.

date

49.98

Lan-

guage

English

Reset

Escape

Franc.

Ital.

Español

Deutsch

P min

-0,3

bar

1) 1) 1) 1)

1)

The min. and max. values can be set to the actual value

Reset

OK ?

Reset

Now !

OK ?

P max

15,0

bar

T emp.

30,7

°C

T min

23,5

°C

T max

36,2

°C

by pushing the "+" and "–" keys simultaneously.

Diagno-

se no.

- - -

Escape

White letters indicate the parameters

which can be modified with the "+"or "–

" key and saved with the "OK" key.

bar

Sensors or measured value information which cannot be modified in these

positions are in italics..

List

These options can be selected with

the "+" or "–" key and saved with the

"OK" key.

Adjust

with

pres.

Escape

Use the arrow key to move to

the right in the menu schematic.

In menu items with these symbols, you can move to the top

or bottom with the "OK" key.

Span

100,0

Lan-

guage

English

Franc.

Ital.

Español

Deutsch

Pressure transmitter D94 (Profibus PA) 19

Page 20

Setup

Adjust P A output

Operate

0,0

skal

Adjust-

ment

The PA output is factory-set to "Lin%". With

this adjustment it is possible to carry out an

adjustment and a volume measurement ( to

measure the volume of a non-linear vessel,

the linearisation curve of the vessel also has

to be programmed into the D94 with the software VVO). The adjustment "%" enables a

level measurement (also with adjustment). If

only a pressure value should be outputted,

the PA output must be set to "Pressure". An

adjustment is then not possible. Move with

the arrow and "OK" key to the menu item "PA

output", choose there the requested option

with the "+" or "–" key and save with the "OK"

key.

Under "Scaling out." you can modify the

number values (min/max), the position of the

decimal point and the unit (with the "+" or "–"

key the values can be modified, with the "OK"

key the adjustments are saved).

%=

Calcu-

lation

0

0

100

%=

1000

Output

PA-

output

Lin%

pressure

%

Decimal

point

888,8

Scaling

out.

Unit

0,0

%

mbar

psi

kPa

m

ft

inch

inHg

Escape

Escape

Adjustment

(only possible, if "%" or "Lin%" has been chosen for the PA output)

Adjustment taking the current pressure into account (live adjustment)

Live adjustment comprises two steps:

1 Adjustment of zero

2 Adjustment of span

1 Adjustment of zero

(e.g. process pressure zero or vessel

empty)

Set the percentage value to 0.0 %

Zero

0,0

with the "+" or "–" key. Then push the

%

"OK" key.

2 Adjustment of span

(e.g. process pressure zero or vessel level

max.)

Set the percentage value to 100 %

Span

100

with the "+" or "–" key. Then push the

%

"OK" key.

Note:

- A modification of zero does not influence

the adjusted span, i.e. the final value of the

measuring range is shifted.

- Push the "+" and "-" key simultaneously for

standard adjustment of zero/span. The

value jumps directly to 0 %/100 %.

- When pushing the "+" or "–" keys individually, the output signal remains at the last

value; it takes on the adjusted value only

after saving with the "OK" key.

- It is also possible to set values for partial

fillings or partial pressures, e.g. 25 % and

75 %. The pressure transmitter then automatically calculates the values for 0 % or

100 % (only possible with a level difference

>3.3 %).

20 Pressure transmitter D94 (Profibus PA)

Page 21

Setup

Adjustment without taking the current

pressure into account (dry adjustment)

Adjustment without pressure comprises four

steps:

1 Selection of the unit in which the adjustment

is to be carried out

2 Offset correction

3 Adjustment of zero

4 Adjustment of span

The offset correction (only in gauge pressure

mode) defines the reference positions for the

measurement. It can be carried out:

- before or after adjustment of zero and

span

- before or after installation of transmitters.

The transmitter must be unpressurised for

the offset correction!

Adjustment without pressure can be carried

out with the instrument mounted or dismounted (e.g. workroom). Any ambient pressure has no effect on the adjustment.

1 Selection of the unit

Choose the unit with the "+" or "–"

Adjust

without

key. Save the selected unit with

pres.

the "OK" key.

Unit

0,0

mbar

psi

kPa

inHg

2 Adjustment of zero

Adjust zero with the "+" or "–" key

Zero

0,0

and save with the "OK" key.

mbar

4 Adjustment of span

Span

Adjust span with the "+" or "–" key

100,0

and save with the "OK" key.

mbar

Note:

- A modification of zero does not influence

the span.

- By pushing the "+" and "–" keys, the output

remains on the last value - only after saving

with the "OK" key will the output take on the

adjusted value.

Evaluation

Linearisation curve

Is only displayed if a linearisation

Lin.-

curve

curve has been activated with VVO.

activ

Adjustment of the integration time

An integration time ti of 0 s … 50 s can be

the "OK" key.

Selection of the indicated unit

adjusted with the "+" or "–" key for

ti

1

damping of pressure shocks. The

s

adjusted value can be saved with

Unit

The measurement unit for the dis-

0,0

play of measured values as well as

skal

for the display module can be

psi

selected here (with the "+" or "–"

kPa

key and the "OK" key). If you select

%

m

"scal.", the scaled PA output value

ft

will be displayed (as adjusted

inch

under "Scaling outp.").

mbar

Pressure transmitter D94 (Profibus PA) 21

Page 22

Setup

Simulation

Simula-

You can adjust with the "+" or "–"

tion

keys an individual pressure or %

value to check the outputs of the

pressure transmitter and the con-

Sim.

nected components. The adjusted

xx,x

mbar

value flashes during activated simulation. The simulation can be

stopped with the "OK" key.

Additional functions

Sensor data

Important sensor data can be displayed via

the DOT-matrix for information and diagnostic

purposes:

- manufacturing date

- pointer function (p

- pointer function (p

- actual temperature value (Temp)

- pointer function (T

- pointer function (T

- diagnostic number

Additional

funct.

min

max

min

max

)

)

)

)

Language

Lan-

guage

English

Franc.

Ital.

Español

Deutsch

Reset

Reset

Reset

Now?

Reset

Now !

OK ?

The pressure transmitter comes

adjusted to the language in which

it is ordered. The languages German, English, French, Italian or

Spanish can be chosen with the

"+" or "–" key and the "OK" key.

The reset function deletes the adjusted values and resets the parameters to the default values. The

adjustment data again correspond

to the nominal measuring range. The

following data are not reset:

- instrument address

- language

- diagnostics number

- offset correction

- pointer

Station

address

Fabr.

date

49.98

1)

The min. and max. values can be set to the actual

value by pushing the "+" and "–" keys simultaneously.

22 Pressure transmitter D94 (Profibus PA)

xxx

Sensor

data

P min

P max

-0,3

150

mbar

mbar

1)

1) 1) 1)

Temp.

30,7

°C

T min

23,5

°C

T max

36,2

°C

Diagno-

se no.

- - -

Page 23

Setup

4.3 Setup with adjustment software VEGA Visual Operating (VV O)

VVO connection to the b us cable

To operate the sensor with the adjustment

software VVO, you require a Profibus DP

interface card (from Messrs. Softing) in your

PC. This card must be used to provide the

connection between computer and Profibus

DP cable (a connection directly to the sensor

or to the Profibus PA cable is not possible).

The computer with VVO then has the status

"Master, class 2".

Segment

coupler

Profibus PA

cable

VVO

DP cable

Profibus DP

interface card

(Messrs. Softing)

Field distributor

Sensor Sensor Sensor Sensor

If the computer is connected to the Profibus

DP cable, you can start VVO. If the following

presentation is shown on the monitor, you

have to modify the communication settings in

VVO. To do this, click to Configuration, point

to Program and click to Communication.

First click in the window "Communication" to

Profibus DP for PA sensors. Then select the

Profibus card installed in your PC. It is also

possible to modify the settings for baud rate,

further bus parameters and master address.

Note:

Make sure that the master address you are

using is not assigned to another bus participant!

Click to OK, if you have finished the communication setting. Then you have to restart

VVO.

Pressure transmitter D94 (Profibus PA) 23

Page 24

Setup

Sensor configuration

After starting VVO as previously described

or having made connection to the Profibus,

the following presentation will be displayed

on the monitor. Click to Configuration, then

to Measuring system.

If you have already connected several VEGA

sensors to the bus, you can select the sensor to be configured, in this case pressure

transmitter D94. The serial number and the

bus address of the sensors are displayed to

enable clear identification.

The menu language of the sensor can be

selected (only relevant with a sensor with

menu-driven adjustment) and the units for the

output of sensor values can be set. If address 126 is adjusted on the sensor, you can

assign a bus address to the sensor in the

field "Sensor address". Then click to Save.

Information about the sensor identification number:

You do not have to modify the adjustment

"VEGA specific No.". Only if you want to make

sure that the pressure transmitter can be

replaced on the Profibus by a sensor of

another manufacturer do you have to choose

the option "Profile specific No.".

Configuration measurement loop

Click to Configuration, point to Measurement loop, then click to Modify.

Now all instruments which are connected to

the bus are shown (identifiable by the bus

address and the serial number). Notice that

in this example the same serial number appears twice. This is a sensor with a measurement loop for pressure and a second measurement loop for temperature. Choose the

sensor (the measurement loop) with which

you want to create a measurement loop and

click to OK.

24 Pressure transmitter D94 (Profibus PA)

Page 25

Setup

In the window "Modify meas. loop configuration" you can assign a name and a description to the measurement loop. State under

"Application" if you want to create a process

pressure or level measurement. With OK you

return again to the window "VEGA Visual

Operating". In the following explanations, we

assume that you have chosen the application

"Level measurement". The adjustment "Process pressure measurement" differs only

slightly from the following presentation.

Sensor parameter setting – Adjustment

Click to Instrument data, then to Parameter

adjustment.

From the window "Instrument data parameter

adjustment" you reach all submenus of the

sensor. To get familiar with the available options, try out the buttons one after the other.

You will automatically return to this window. To

carry out the adjustment, click the button

Adjustment.

Click in the window "Adjustment" to Min/Max

adjustment.

Choose the measurement loop in which you

want to make the parameter adjustment and

click to OK.

Pressure transmitter D94 (Profibus PA) 25

Then in the window "Min/Max adjustment" you

have to choose the type of adjustment. If you

want to carry out the "Adjustment without

taking the actual product into account" (dry

adjustment), click to no, then to OK.

Page 26

Setup

Here you can choose in which unit the adjustment should be made (mbar or bar, psi, kPa,

inHg). Then you enter the pressure values

corresponding to 0 % and 100 %. Then click

to OK. The adjustment is now finished.

If you want to carry out the "Adjustment taking the actual product into account" (live

adjustment), click in this window to yes, then

to OK.

Click to Min-Adjustment or to Max-Adjust-

ment to carry out the respective adjustment.

In the window "Min-Adjustment" you choose in

which unit the adjustment should be carried

out (bar, mbar, psi, kPa, inHg). Then click to

Save. The min. adjustment is finished.

In the window "Max-Adjustment" you choose

in which unit the adjustment should be carried out (bar, mbar, psi, kPa, inHg). Then

click to Save. The max. adjustment is finished.

Sensor parameter setting – Linearisation curves

Click in the window "Instrument data parameter adjustment" to Conditioning.

Note:

For min. adjustment and max. adjustment,

defined levels (e.g. 0 % and 100 % or e.g.

20 % and 80 %) have to be present in the

vessel.

26 Pressure transmitter D94 (Profibus PA)

Page 27

Setup

Click in the window "Conditioning" to Lineari-

sation.

In the window "Linearisation" you can choose

the linearisation curves of a cylindrical or a

spherical tank. If you choose a user-programmable curve, you can then click to Edit

and open the program "Tank Calculation".

With this program you can calculate the

curves of different tank shapes (see the

manual "VEGA Visual Operating"). After selection of the curve, click to OK.

Click in the window "Outputs" to Profibus

output.

In the window "Profibus output" you can determine the options for the Profibus output

(acc. to Profibus PA instrument profile). Confirm your adjustments with OK.

Sensor parameter setting – Outputs

Click in the window "Instrument data parameter adjustment" to Outputs.

Pressure transmitter D94 (Profibus PA) 27

Page 28

Setup

Sensor parameter setting – Integration

time

Click in the window "Instrument data parameter adjustment" to Conditioning.

Click in the window "Conditioning" to Integra-

tion time. In the window "Integration time"

you can enter a time interval of max. 50 seconds. Then click to OK.

Sensor parameter setting – Offset correction

Click in the window "Instrument data parameter adjustment" to Additional functions,

then in the window "Additional functions" to

Offset correction.

Confirm the question with OK, in case the

conditions are met.

Click in the window "Offset correction" to

Correct.

28 Pressure transmitter D94 (Profibus PA)

Page 29

Setup

Pointer functions

Click in the window "Instrument data parameter adjustment" to Meas. loop data.

In the window "Meas. loop data" all available,

current sensor values and the peak values

(pointer function) are displayed. With the

button reset you can reset all displayed peak

values to the actual value all at once.

Choose the requested measurement loop

and click to OK.

In the window "Simulation of outputs", you

click to Start to begin the simulation. With the

buttons "<–" and "–>" (or the thumb of the

scroll bar) you can adjust values between 10 % and 110 %. Click to Stop to terminate

the simulation.

Simulation

For checking outputs of the pressure transmitter and connected devices and components, a pressure can be simulated. Click to

Diagnostics, then to Simulation.

Note:

The simulation mode is not terminated automatically, but remains active until you switch it

off!

Pressure transmitter D94 (Profibus PA) 29

Page 30

Display of measured values

The current values of the measurement loops

can be displayed from the main menu. Click

to Display and then to "Display of measured

value".

Choose the requested measurement loop

and click to OK.

Setup

In the window "Display of measured value"

you can choose the unit in which the measured value should be displayed. In addition,

you will see the current value. By clicking to

Quit you return to the window "VEGA Visual

Operating".

30 Pressure transmitter D94 (Profibus PA)

Page 31

Diagnostics

5 Diagnostics

5.1 Maintenance

Pressure transmitters D94 are maintenancefree.

5.2 Failure rectification

Fault signals

The pressure transmitter D94 provides maximum reliability through its self-test and continuous self-monitoring. If, however, malfunctions occur, the pressure transmitter D94

diagnosis distinguishes between atypical

process conditions and faults in the pressure

transmitter D94.

Atypical process conditions

Exceeding or falling short of measuring

range limits (fault signal extinguishes when

the measured value is again in the measuring

range).

Failure in the D94 pressure transmitter

Failure in the electronics, interference or

damage in the measuring cell.

The following table assists in the analysis of

fault signals.

Cause of Fault signal via

failure DOT-matrix Bar graph

Clearly "OPERATE Bar graph 0 %

outside ???? or 100 %

measuring bar" digital value

range flashes

Digital indication

On instruments with menu-driven adjustment

with additional functions, the possible causes

are displayed under the menu item "Diagnostics no." in case of failure.

Diagnostics Meaning

no.

1 No frequency from C/D-converter

2 Frequency signal of the capacitor not

within the limit values

3 Frequency signal of the reference

capacitor not within the limit values

4 Frequency signal temperature not

within the limit values

7 Communication with EEPROM dis-

rupted

9 Error in EEPROM CRC-checksum

11 Process connection or electronics

module has been exchanged (appears for approx. 20 s after switching

on for the first time after exchange)

Troubleshooting

If the displayed value does not correspond

to the level in the vessel or to the process

pressure, the following measures must be

taken:

- check the pressure compensation (only

with gauge pressure measuring ranges)

- check the electrical connections.

Overload Bar graph 0 %

range or 100 %,

of the digital value

meas. cell four segments

Failure in all segments

D94 flash

flash "- - - -"

Checking pressure compensation

Open the processing unit of the D94 pressure transmitter. The measured value must

not change. However, if the displayed value

changes, compensation of the atmospheric

pressure is not ensured, which can result

distortion of the measured value. Check the

breather on the processing unit.

Pressure transmitter D94 (Profibus PA) 31

Page 32

6 Instrument modification

6.1 Exchange of adjustment modules in the processing unit

Display

module

Module for

menu-driven

adjustment

Module without

adjustment

Instrument modification

Exchange of the adjustment module

Removal of the adjustment module

• Separate processing unit from the power

supply.

• Remove the screws on the upper side of

the housing and remove the cover or the

display module.

• Disconnect the cables from the terminals,

and if applicable, pull out the plug connection of the display module.

• Remove the two screws of the adjustment

module.

• Remove adjustment module and pull out

plug connection.

Insertion of an adjustment module

• Plug the plug connection of the new adjustment module into the plug-in socket of

the electronics module.

• Fasten the new adjustment module.

• Reconnect the cables, and if applicable,

also the cable from the display module.

• Replace the cover or the display module

of processing unit.

• Reconnect processing unit to power

supply.

Processing unit

The modular construction of the processing

unit allows retrofitting, interchange and removal of the adjustment modules and the

display module. Data previously saved (e.g.

adjustment values) are not stored in the adjustment module but in an EEPROM of the

electronics module and readjustment is

therefore not necessary. The connection of

the modules is made via a 4-pole plug connection.

32 Pressure transmitter D94 (Profibus PA)

Page 33

Notes

6.2 Exchange of hygienic form seal on D94

On the hygienic connections AA, CA, LA, LB,

RA, RB, TA of pressure transmitter D94, the

ceramic measuring cell is radially, gaplessly

sealed with a form seal. This form seal (material EPDM-FDA) can be exchanged by the

user without the need of a fresh adjustment.

The criteria and the time intervals for such an

exchange of the seal are generally defined

by the process and hygienic requirements.

Important:

Use only original replacement seals from

VEGA!

Please note the following exchange procedure.

Removal procedure:

• Pressure transmitter should be unpres-

surized (switch off process pressure or

empty vessel).

• Loosen the hexagon pressure screw (4)

(width across flats, 46 mm) by turning to

the left.

Note!

The process connection (6) (e.g. compression nut) must not be loosened!

• Turn the adapter (3) below the pressure

transmitter housing with a screwdriver

(with across flats, 36 mm) briefly to the

left (to loosen the seal).

• Pull the complete pressure transmitter on

the housing (1) out of the process connection by carefully turning to the left.

• Slightly lift the form seal (5) and loosen

from the ceramic measuring cell.

• If the form seal (5) does not completely

encircle the measuring cell, it must be

carefully removed from the process connection.

Installation procedure:

• Put the new form seal (5) over the measuring cell (the conical end must point to

the process connection!).

• Carefully insert pressure transmitter into

the process connection by turning clockwise.

• Tighten hexagon pressure screw (4)

(width across flats, 46 mm) (45 Nm).

• Turn the housing (1) of the pressure

transmitter into the original position.

The exchange of the form seal is now finished; the removed seal must be properly

disposed of.

1

2

3

4

5

6

1 Pressure transmitter

2 Headless screw (avoids overwinding and must not be

removed)

3 Adapter

4 Hexagon screw

5 Form seal

6 Process connection

Pressure transmitter D94 (Profibus PA) 33

Page 34

Notes

34 Pressure transmitter D94 (Profibus PA)

Page 35

Notes

Pressure transmitter D94 (Profibus PA) 35

Page 36

VEGA Grieshaber KG

Am Hohenstein 113

D-77761 Schiltach

Germany

Phone +49 (0) 7836 50-0

Fax +49 (0) 7836 50-201

E-Mail info@de.vega.com

www.vega.com

ISO 9001

All statements concerning scope of delivery, application, practical

use and operating conditions of the sensors and processing systems correspond to the latest information at the time of printing.

Technical data subject to alteration

2.24 843 / June 2001

Loading...

Loading...