Page 1

Operating Instructions

Hydrostatic pressure

transmitters D84

p

Page 2

Contents

Safety information ........................................................................ 2

Note Ex area ................................................................................ 2

1 Product description

1.1 Function and configuration .................................................. 4

1.2 Electronics version without adjustment .............................. 5

1.3 Electronics version with integrated adjustment

in connection housing .......................................................... 7

1.4 Electronics for connection to VEGADIS 12 ........................ 8

1.5 Technical data ....................................................................... 9

1.6 Approvals and certificates ................................................ 13

1.7 Dimensions ......................................................................... 14

2 Mounting

2.1 Mounting instructions ......................................................... 18

2.2 Compensation of the atmospheric pressure ................... 18

Contents

Safety information

Please read this manual carefully, and also take

note of country-specific installation standards

(e.g. the VDE regulations in Germany) as well

as all prevailing safety regulations and accident prevention rules.

For safety and warranty reasons, any internal

work on the instruments, apart from that involved in normal installation and electrical connection, must be carried out only by qualified

VEGA personnel.

2 Pressure transmitter D84

Note Ex area

Please note the attached safety instructions

containing important information on installation

and operation in Ex areas.

These safety instructions are part of the

operating instructions and come with the Ex

approved instruments.

Page 3

Contents

3 Electrical connection

3.1 Connection instructions ..................................................... 19

3.2 Terminal assignment .......................................................... 20

3.3 Connection to external connection housing

VEGABOX 01 ..................................................................... 21

3.4 Connection examples ........................................................ 22

4 Setup

4.1 Adjustment structure ......................................................... 23

4.2 Sensor without adjustment ................................................ 24

4.3 Sensor with adjustment insert, adjustment

in the sensor ....................................................................... 24

4.4 Setup with HART® handheld ............................................. 26

5.5 Adjustment with PC directly on the sensor ...................... 32

6 Diagnostics............................................................................... 40

7 Instrument modification

7.1 Retrofitting the adjustment insert ...................................... 41

7.2 Exchange of hygienic form seal on D84 .......................... 41

Pressure transmitter D84 3

Page 4

1 Product description

Product description

1.1 Function and configuration

The pressure transmitter D84 is an efficient

instrument for hydrostatic level measurement.

A dry ceramic-capacitive CERTEC

measuring cell is used as pressure sensor

element.

Pressure transmitter D84

Measuring cell: dry, ceramic-capacitive

Diaphragm: flush, ceramic

Series: flanged version

Standard application: All kind of level

measurements, best suited for food

processing and pharmaceutical industries.

The pressure effects a capacitance change

on the measuring cell. This capacitance

change is detected by an ASIC (Application

Specific Integrated Circuit) and converted

into a pressure-proportional signal by the

integrated electronic module with

microcontroller. Precise, high-resolution digital processing of measurement data ensures

excellent technical data.

To improve reliability, the functionality of important electronic components is continuously checked, and internal parameters such

as sensor value, temperature and operating

voltage are closely monitored.

®

Output signal

The output signal is transferred as a digital or

analogue signal from the pressure transmitter

to the signal conditioning instrument:

• analogue output signal

- unstandardised (in conjunction with

VEGA signal conditioning instrument)

- 4 … 20 mA standardised

• digital output signal (VBUS) for connection

to a digital VEGA signal conditioning instrument (VEGAMET 514V, 515V or VEGALOG

571)

4 Pressure transmitter D84

Page 5

Product description

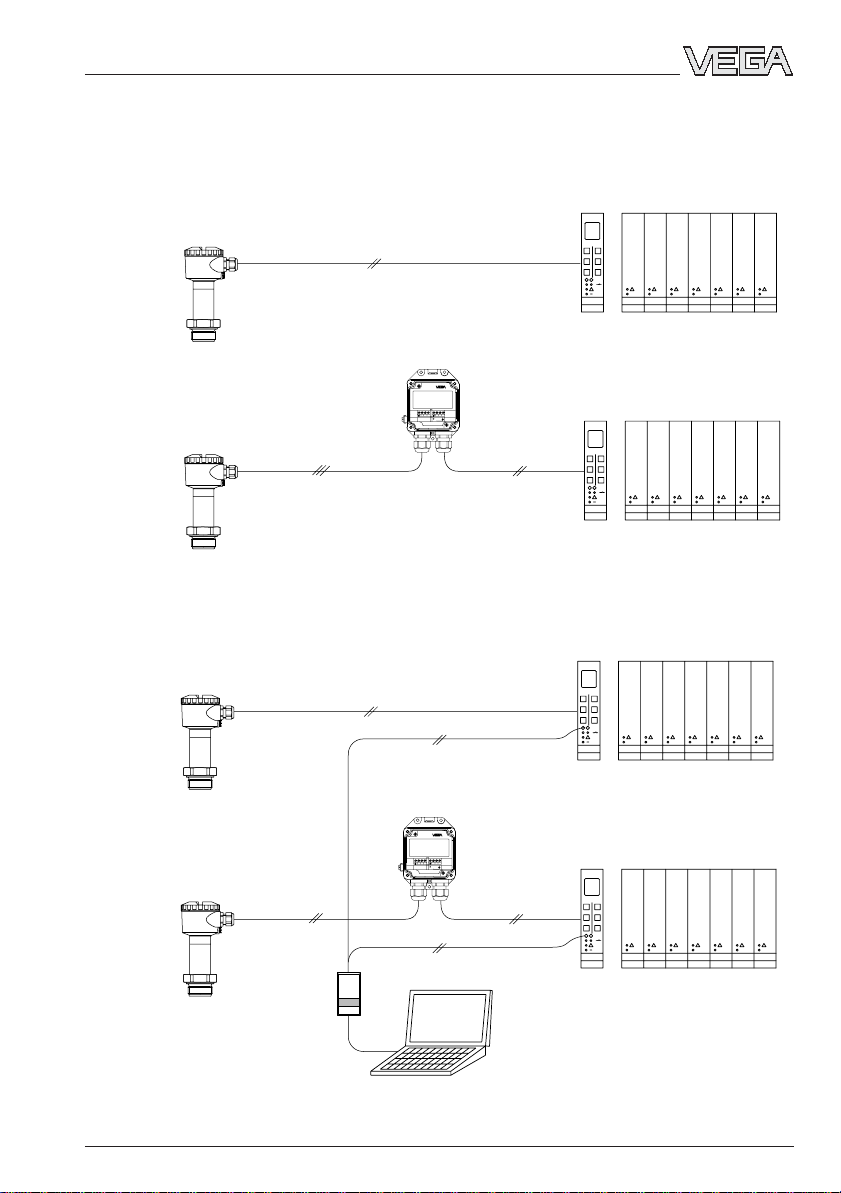

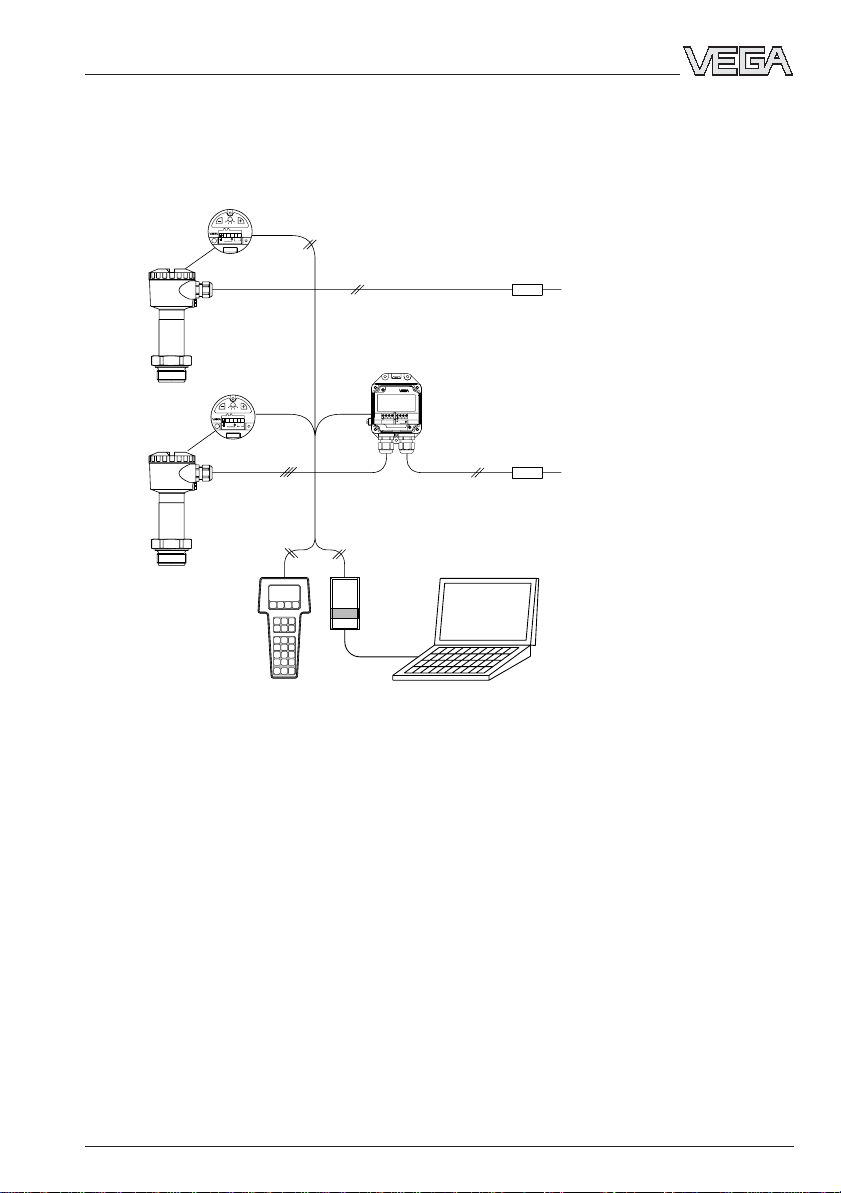

1.2 Electronics version without adjustment

Electronics version A:

Pressure transmitter for connection to VEGA signal conditioning instruments

e.g. IP 66

VEGABOX 01

VEGAMET

VEGALOG

Zum Anschluss an

For connection to

Druckmessumformer mit

pressure transmitters with

analogem Ausgangssignal

analog output

12310

TRANSMITTER

VEGABOX 01

11 12

-

+

-

+

VEGAMET

VEGALOG

e.g. IP 67

Electronics version B:

Pressure transmitter for connection to VEGA signal conditioning instruments (digital

transmission VBUS)

e.g. IP 66

e.g. IP 67

VEGABOX 01

Zum Anschluss an

For connection to

Druckmessumformer mit

pressure transmitters with

analogem Ausgangssignal

analog output

12310

11 12

-

+

-

TRANSMITTER

+

VEGABOX 01

VEGAMET

VEGAMET

VEGALOG

VEGALOG

Pressure transmitter D84 5

Page 6

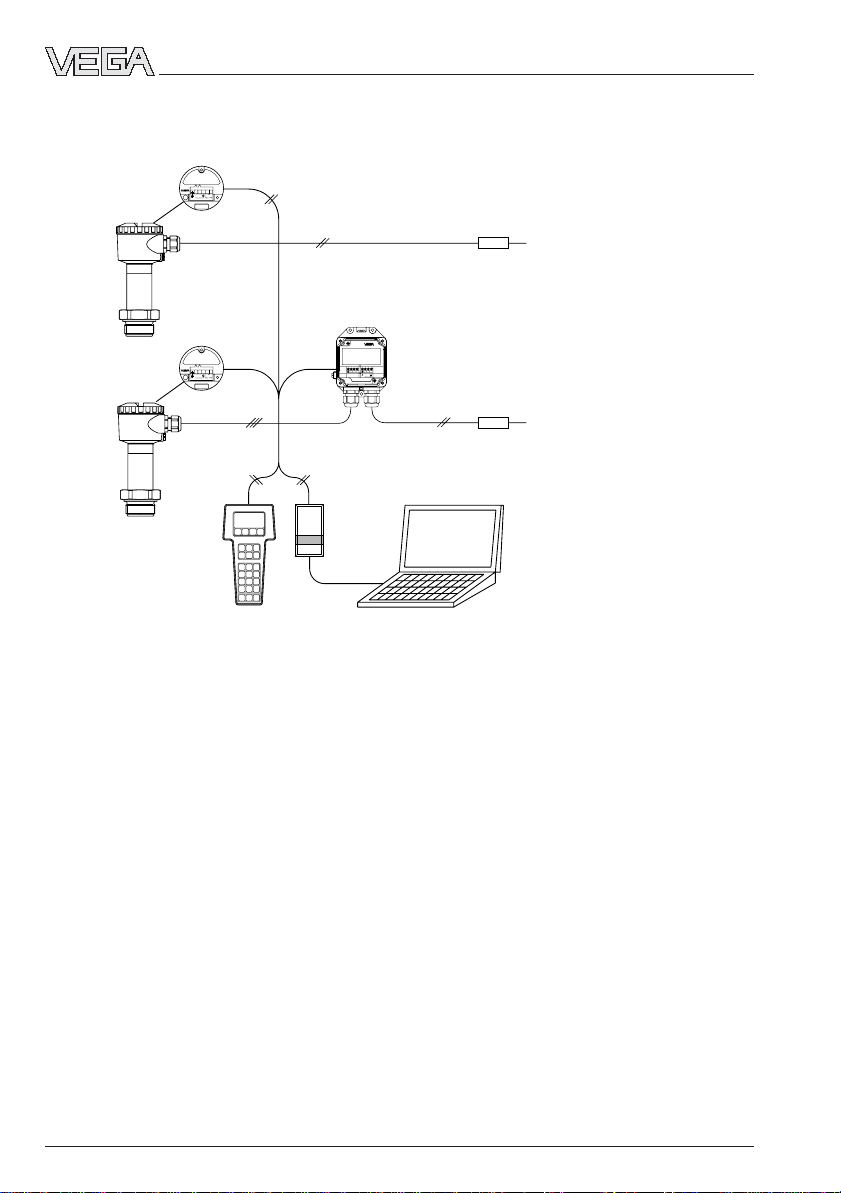

Electronics version I:

Pressure transmitter 4 … 20 mA, HA RT®, VVO

4-20mA

51234

-

+

4...20mA

12V...36V DC

Klemmeinsatz

terminal

e.g. IP 66

VEGABOX 01

Zum Anschluss an

For connection to

Druckmessumformer mit

pressure transmitters with

analogem Ausgangssignal

analog output

12310

TRANSMITTER

VEGABOX 01

11 12

-

+

-

+

e.g. IP 67

HART® handheld

4-20mA

+

4...20mA

51234

-

12V...36V DC

Klemmeinsatz

terminal

VVO

250 Ω

250 Ω

Product description

PLC/DCS

PLC/DCS

6 Pressure transmitter D84

Page 7

Product description

1.3 Electronics version with integrated adjustment in connection housing

Electronics version K:

Pressure transmitter 4 … 20 mA, HART®, VVO adjustable

S

Op

Zt

i

43215

+

-

4...20mA

12V...36V DC

Bedieneinsatz

operating unit

PLC/DCS

e.g. IP 66

e.g. IP 67

S

+

4...20mA

12V...36V DC

Bedieneinsatz

HART® handheld

VEGABOX 01

Zum Anschluss an

For connection to

Druckmessumformer mit

pressure transmitters with

Op

Zt

i

43215

-

operating unit

analogem Ausgangssignal

analog output

12310

TRANSMITTER

VEGABOX 01

11 12

-

+

-

+

250 Ω

PLC/DCS

250 Ω

VVO

Pressure transmitter D84 7

Page 8

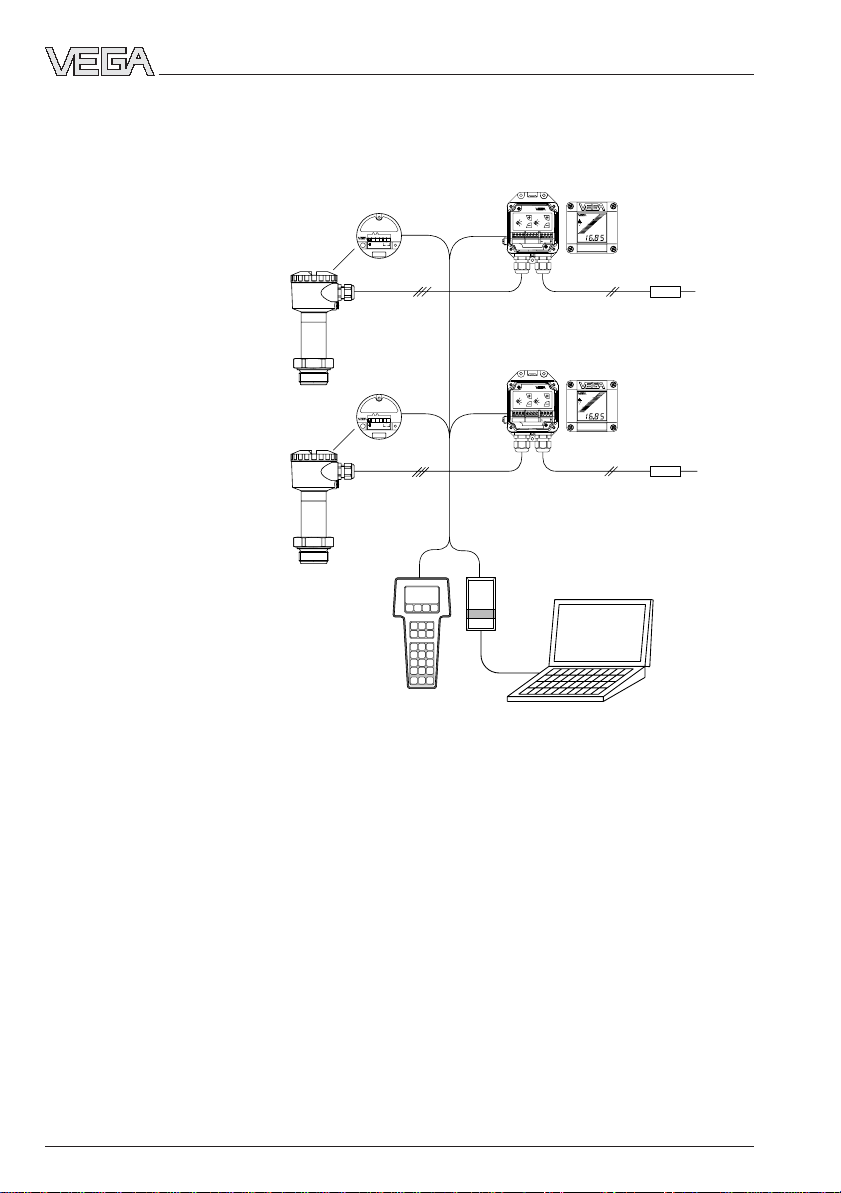

1.4 Electronics for connection to VEGADIS 12

VEGADIS 12

DISPLAY

+ -

TRANSMITTER

5876321101112

OPERATE

POINT

DISPLAYTRANSMITTER

END

ZERO

OPERATE

POINT

END

ZERO

VEGADIS 12

DISPLAY

+ -

TRANSMITTER

5876321101112

OPERATE

POINT

DISPLAYTRANSMITTER

END

ZERO

OPERATE

POINT

END

ZERO

51234

VEGADIS 12

Zum Anschluß an

For connection to

+

-

12V...36V DC

terminal

Klemmeinsatz

51234

VEGADIS 12

Zum Anschluß an

For connection to

+

-

12V...36V DC

terminal

Klemmeinsatz

Electronics version L:

Pressure transmitter 4 … 20 mA, HA RT®, VVO

e.g. IP 66

e.g. IP 67

HART® handheld

VEGADIS 12

VEGADIS 12

Product description

250 Ω

250 Ω

VVO

PLC/

DCS

PLC/

DCS

8 Pressure transmitter D84

Page 9

Product description

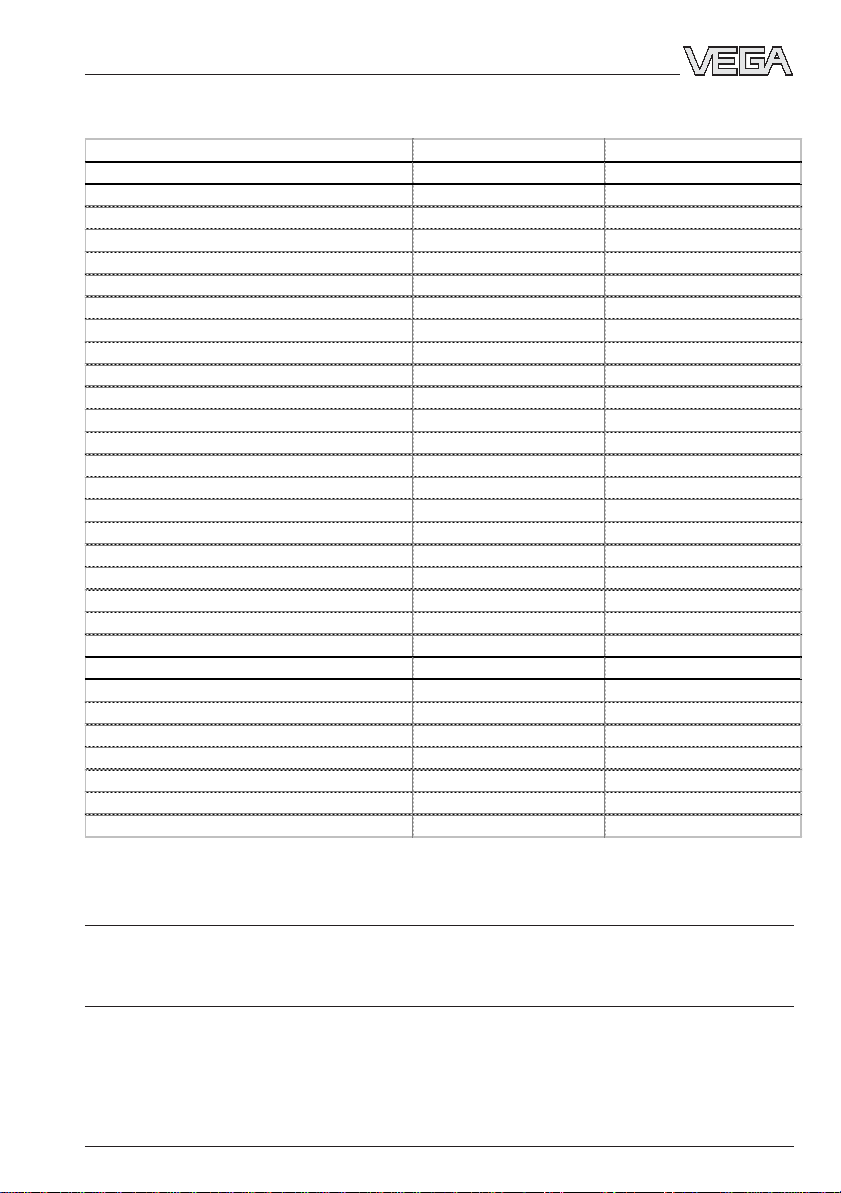

1.5 Technical data

Nominal measuring range Gauge pr. resistance Low pr. re sistance

Gauge pressure

0…0.1 bar / 0…10 kPa 15 bar / 1 500 kPa -0.2 bar / -20 kPa

0…0.2 bar / 0…20 kPa 20 bar / 2 000 kPa -0.4 bar / -40 kPa

0…0.4 bar / 0…40 kPa 30 bar / 3 000 kPa -0.8 bar / -80 kPa

0…1.0 bar / 0…100 kPa 35 bar / 3 500 kPa -1.0 bar / -100 kPa

0…2.5 bar / 0…250 kPa 50 bar / 5 000 kPa -1.0 bar / -100 kPa

0…5.0 bar / 0…500 kPa 65 bar / 6 500 kPa -1.0 bar / -100 kPa

0…10.0 bar / 0…1 000 kPa 90 bar / 9 000 kPa -1.0 bar / -100 kPa

0…20.0 bar / 0…2 000 kPa 130 bar / 13 000 kPa -1.0 bar / -100 kPa

0…40.0 bar / 0…4 000 kPa 200 bar / 20 000 kPa -1.0 bar / -100 kPa

0…60.0 bar / 0…6 000 kPa 300 bar / 30 000 kPa -1.0 bar / -100 kPa

-0.05…+0.05 bar / -5…+5 kPa 15 bar / 1 500 kPa -0.2 bar / -20 kPa

-0.1…+0.1 bar / -10…+10 kPa 20 bar / 2 000 kPa -0.4 bar / -40 kPa

-0.2…+0.2 bar / -20…+20 kPa 30 bar / 3 000 kPa -0.8 bar / -80 kPa

-0.5…+0.5 bar / -50…+50 kPa 35 bar / 3 500 kPa -1.0 bar / -100 kPa

-1.0…0.0 bar / -100…0 kPa 35 bar / 3 500 kPa -1.0 bar / -100 kPa

-1.0…+1.5 bar / -100…+150 kPa 50 bar /5 000 kPa -1.0 bar / -100 kPa

-1.0…+4.0 bar / -100…+400 kPa 65 bar / 6 500 kPa -1.0 bar / -100 kPa

-1.0…+10.0 bar / -100…+1 000 k Pa 90 bar / 9 000 kPa -1.0 b ar / -100 k Pa

-1.0…+20.0 bar / -100…+2 000 kPa 130 bar / 13 000 kPa -1.0 bar / -100 kPa

-1.0 …+40.0 bar / -100…+4 000 kPa 200 bar / 20 000 kPa -1.0 bar / -100 kPa

-1.0…+60.0 bar / -100…+6 000 kPa 300 bar / 30 000 kPa -1.0 bar / -100 kPa

Absolute pressure

0…1.0 bar / 0…100 kPa 35 bar / 3 500 kPa

0…2.5 bar / 0…250 kPa 50 bar / 5 000 kPa

0…5.0 bar / 0 …500 kPa 65 bar / 6 500 kPa

0…10.0 bar / 0…1 000 kPa 90 bar / 9 000 kPa

0…20.0 bar / 0…2 000 kPa 130 bar / 13 000 kPa

0…40.0 bar / 0…4 000 kPa 200 bar / 20 000 kPa

0…60.0 bar / 0…6 000 kPa 300 bar / 30 000 kPa

Mechanical data

Materials, wetted parts

Process connection stainless steel 1.4435 or 1.4571

Diaphragm saphire-ceramic

Materials, non-wetted parts

Housing Alu (seawater resistant) Pe-powder coated,

stainless steel 1.4571

External connection housing high resistance plastic PBT (Polyester)

Ground terminal stainless steel 1.4305

Window of the display module safety glass

Pressure transmitter D84 9

®

Page 10

Product description

Weights

Basic weight without housing approx. 1.6 kg

External housing approx. 400 g

Adjustment and display elements

Pressure transmitter

- terminal insert without adjustment elements

- adjustment insert 2 keys, 1 rotary switch

Electrical data

Adjustment ranges

Zero adjustable from -20 … +95 % of nominal range

Span adjustable from 3.3 … 120 % of nominal range

Supply and signal circuit (analogue transmission, 4 … 20 mA),

electronics version A, C, I and K

Supply voltage 12 … 36 V DC

permissible residual ripple U

- at 100 Hz … 10 kHz U

Output signal

- terminal insert - analogue transmission (not standardised)

- adjustment insert 4 … 20 mA (adjustable)

Current limitation approx. 22 mA

Fault signal 22 mA (3.6 mA)

Integration time 0 … 10 s

Rise time 70 ms (ti = 0 sec; 0 … 63 %)

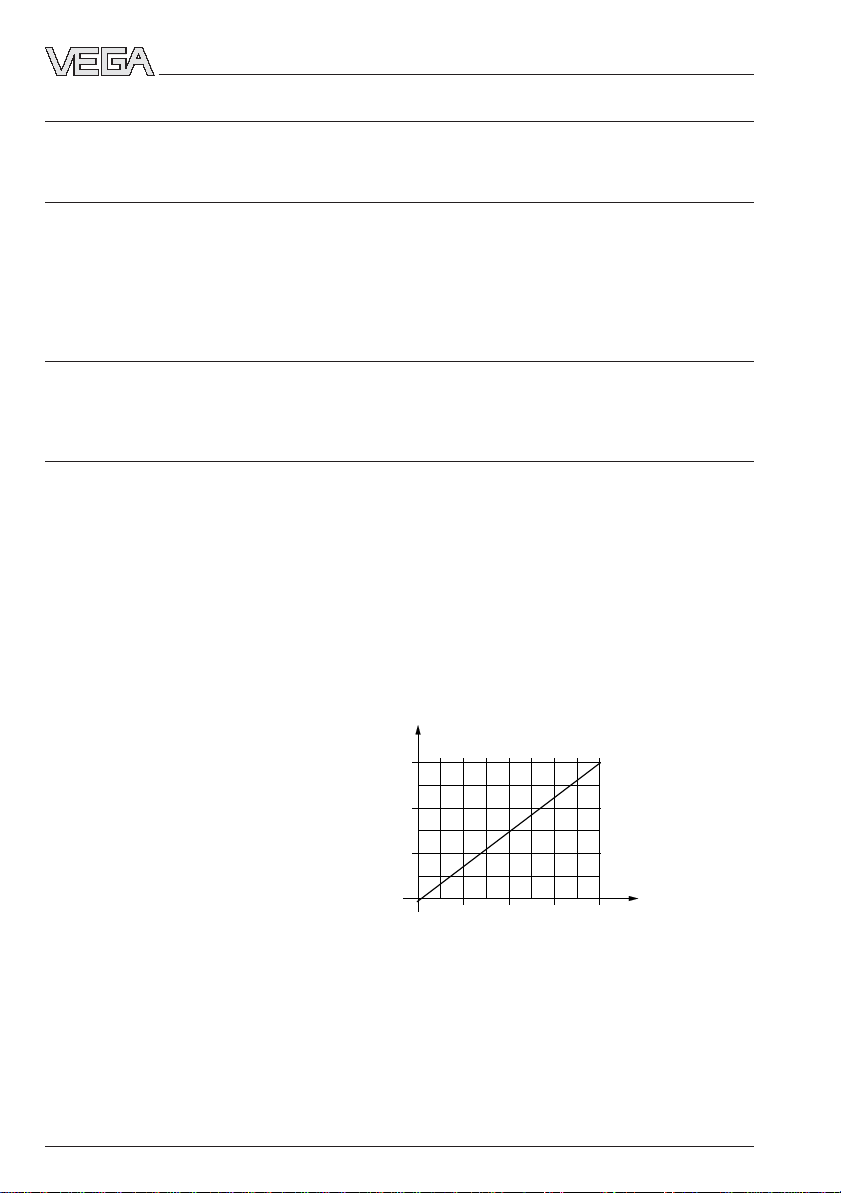

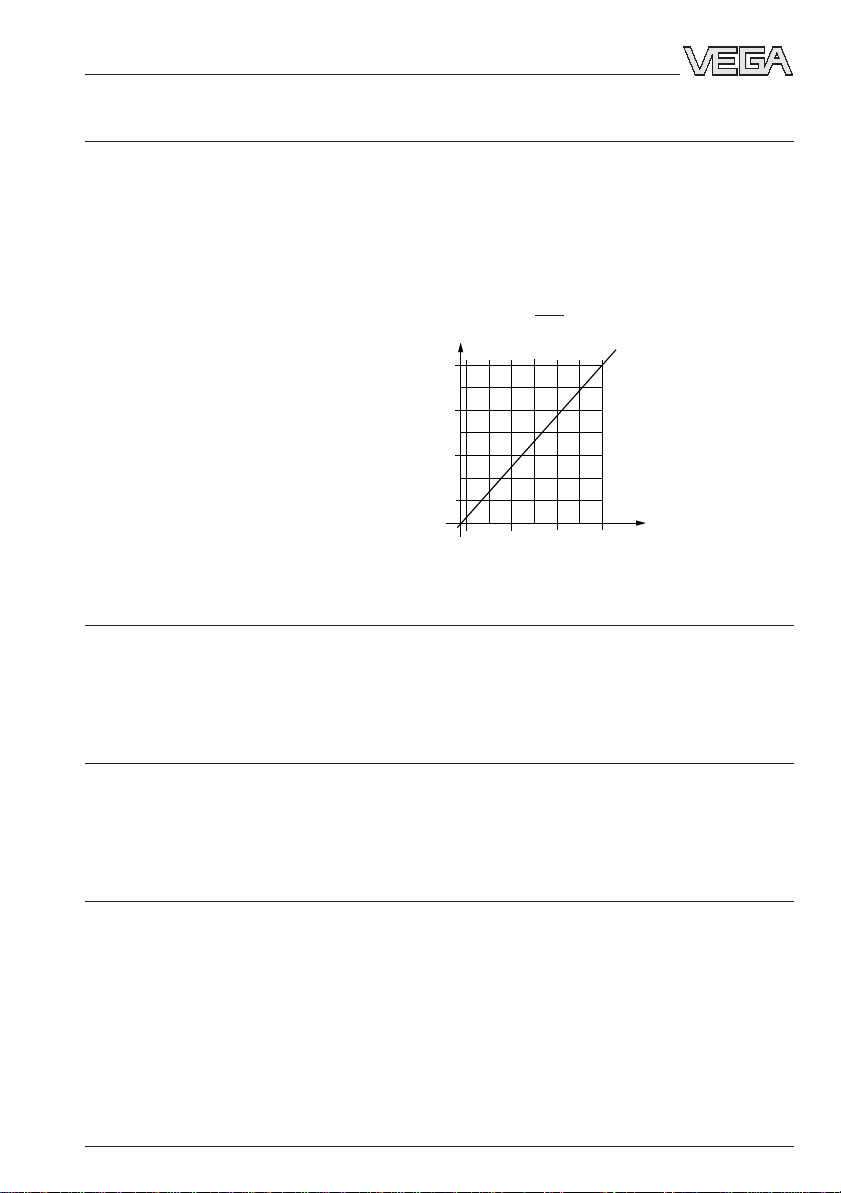

Max. permissible load see load diagram:

≤ 1 V

SS

≤ 10 mV

SS

- 4 … 20 mA

Load in Ω

900

600

300

Supply voltage

12

18 24 30 36

10 Pressure transmitter D84

in V

Page 11

Product description

Supply and signal circuit (analogue transmission, 4 … 20 mA),

additional data for electronics version L

Supply voltage for pressure transmitters

in conjunction with VEGADIS 12

- without display 12 … 36 V DC

- with display 17 … 36 V DC

Max. input current 150 mA

Current signal range 3.5 … 22 mA

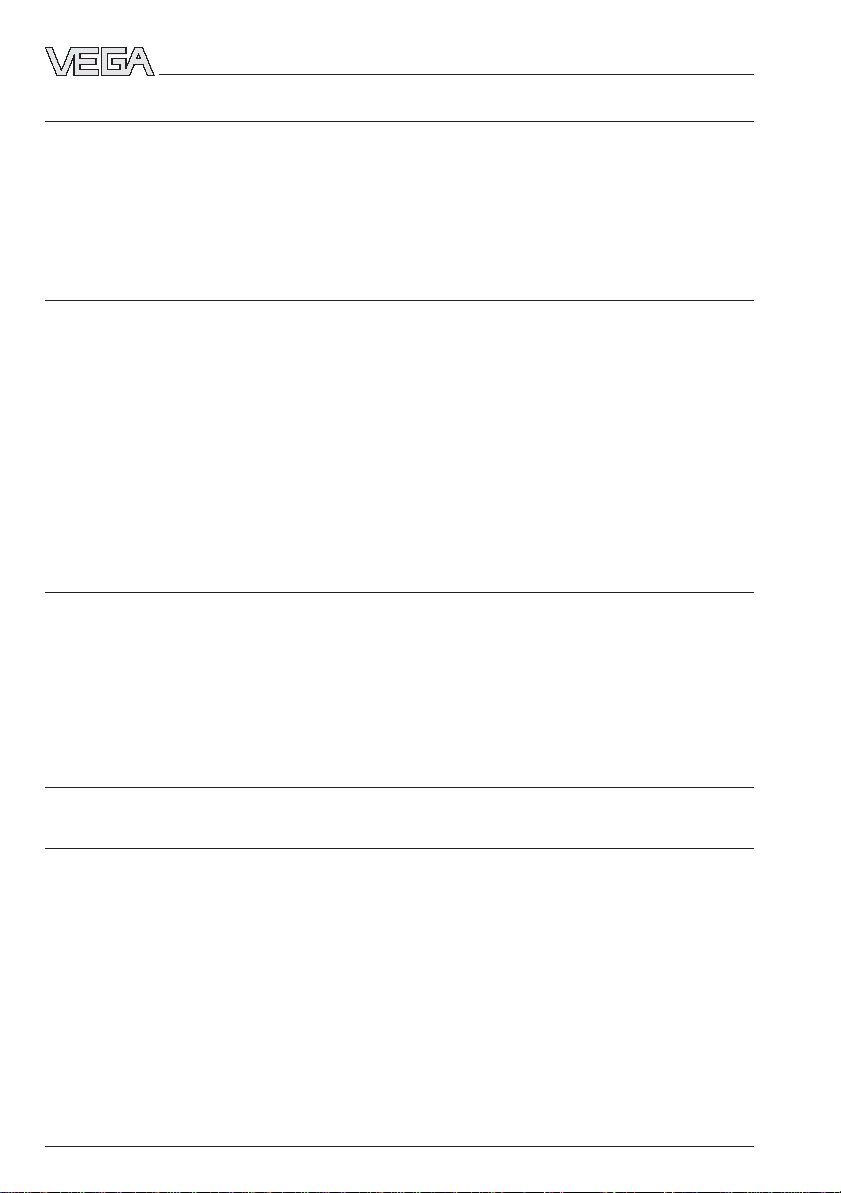

Max. permissible load see load diagram:

Load diagram with display

Load in Ω

700

500

300

100

18

24 30 36

Supply voltage

in V

Supply and signal circuit on VEGA signal conditioning instruments (digital signal

transmission VBUS), additional data for electronics version B

Supply voltage 25 … 36 V DC, from VEGAMET (VBUS) or

from VEGALOG 571 with EV input card

Data transmission digital (VBUS)

Connection cable 2-wire screened

Cable length max. 1000 m

Integrated overvoltage protection (option)

Nominal response DC voltage

- protective diode 40 V

- gas separator 650 V

Nominal leakage current

- gas separator 20 kA

Connection cables

Cable entry

- housing 2 x M20x1.5 (for cable ø 5…9mm or 9…12mm)

- external connection housing 2 x M20x1.5 (for cable ø 5…9mm or 9…12mm)

Screw terminals

- sensor for wire cross-sections of up to 2.5 mm

- external connection housing for wire cross-sections of up to 2.5 mm

2

2

Pressure transmitter D84 11

Page 12

Product description

Protective measures

1)

Protection IP 66, IP 67, IP 68

VEGABOX 01 IP 66 and IP 67

Protection class III

Overvoltage category III

Accuracy (similar to DIN 16 086, DIN V 19 259 - 1 and IEC 770)

Deviation

Reference conditions (acc. to IEC 770)

- temperature 15°C … 30°C

- humidity 45 % … 75 %

- air pressure 86 kPa … 106 kPa

Determination of characteristics limit point adjustment acc. to DIN 16 086

Characteristics linear

Deviation in characteristics incl. hysteresis and repeatability

- Turn Down 1 : 1 < 0.25 % with accuracy class 0.25

- Turn Down up to 1 : 5 typ. < 0.3 % with accuracy class 0.25

- Turn Down up to 1 : 10 typ. < 0.4 % with accuracy class 0.25

Influence of the ambient temperature

Average temperature coefficient

of the zero signal

2)

- Turn Down 1 : 1 < 0.15 %/10 K with accuracy class 0.25

- Turn Down up to 1 : 5 typ. < 0.225 %/10 K with accuracy class 0.25

- Turn Down up to 1 : 10 typ. < 0.3 %/10 K with accuracy class 0.25

< 0.1 % with accuracy class 0.1

typ. < 0.1 % with accuracy class 0.1

typ. < 0.2 % with accuracy class 0.1

< 0.05 %/10 K with accuracy class 0.1

typ. < 0.075 %/10 K with accuracy class 0.1

typ. < 0.1 %/10 K with accuracy class 0.1

Long-term stability

Long-term stability of the zero signal

3)

< 0.1 % per 2 years

Other actuating variables

Calibration position upright, diaphragm points downwards

Influence of the installation position < 0.2 mbar/20 Pa

Vibration resistance mechanical vibrations with 4 g and

5 … 100 Hz, tested acc. to the regulations of

German Lloyd GL-characteristics 2

1)

Maintaining the housing protection IP 66 or IP 67 requires the use of a seal that correctly fits the cable in

the cable entry. If the supplied seal does not fit, a suitable seal must be provided by the customer.

2)

In compensated temperature range of 0°C … +80°C, reference temperature 20°C.

3)

Acc. to IEC 770, item 6.3.2 relating to the nominal range.

12 Pressure transmitter D84

Page 13

Product description

Operating conditions

Ambient conditions

Ambient temperature -40°C … +85°C

- with indicating module -10°C … +60°C

Storage and transport temperature -50°C … +100°C

Product temperature

- Viton seal -20°C … +100°C

- EPDM seal -40°C … +100°C

- Kalrez seal 0°C … +100°C

1.6 Approvals and certificates

Approvals

- Ex Zone 2

- CENELEC EEx ia IIC

- ATEX II 1G EEx ia IIC

If the use of approved instruments is required for certain applications, the appropriate

official documents (test reports, test certificates and conformity certificates) must be observed. These are supplied with the respective instrument.

CE conformity

D84 pressure transmitters meet the requirements of EMC (89/336/EWG) and NSR

(73/23/EWG). Conformity has been judged acc. to the following standards:

EMC Emission EN 50 081 - 1: 1992

NSR EN 61 010: 1993

Susceptibility EN 50 082 - 2: 1995

NAMUR regulations

Full compliance with the NAMUR regulations NE21 and NE 43.

Pressure transmitter D84 13

Page 14

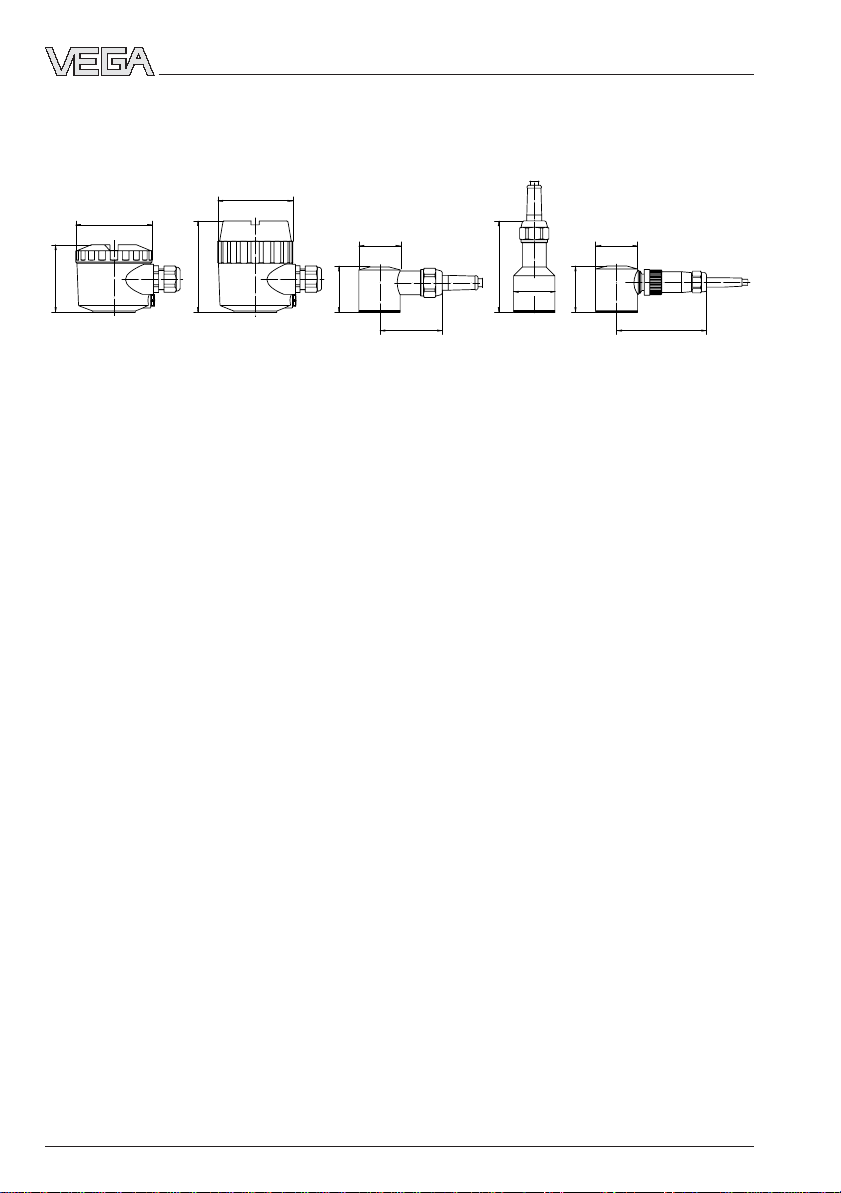

1.7 Dimensions

Housings

ø 76

67

Product description

ø 75

ø 41,6

91

46

63

93

ø 41,6

ø 41,6

46

90

14 Pressure transmitter D84

Page 15

Product description

Process connections D84

Ø 41,6

Ø 41,6

Ø 41,6

76,5 (115*)

121 (160*)

121 (160*)

SW 46

SW 46

121 (160*)

SW 60

24,5

Ø 41,6

Ø 78

LA

Ø 41,6

Ø 78

RA

Ø 41,6

G 1½ A

Ø 55

GG

72,5 (111*)

121 (160*)

121 (160*)

SW 46

SW 46

121 (160*)

Ø 41,6

Ø 90

LB

Ø 41,6

Ø 92

RB

SW 60

25

1½ " NPT

GN

Ø 41,6

SW 46

121 (160*)

SW 46

121 (160*)

Ø 41,6

Ø 64

CA

Ø 41,6

Ø 65,8

Ø 105

AA

121 (160*)

SW 46

21

M44 x 1,25

BA

SW 46

121 (160*)

SW 46

121 (160*)

Ø 41,6

Ø 84

TA

Ø 41,6

Ø 100

PA

120

42,5

160

Ø 48

Ø 115

23

FT4

Ø 38

Ø 115

FG4

*) VBUS version

Pressure transmitter D84 15

Page 16

Pressure transmitter accessory

Welded socket

G 1½

19

ø 65

GG

Product description

Rd 65 x

1/

6

21

ø 60

BA

40

ø 79,6

LA

ø 72/6xM6

40

ø 79,6

LB

Rd 78 x

1/

6

35

ø 50

ø 55

RB

21,5

ø 48,6

ø 51,6

CA

ø 84/4xM10

20

ø 125

AA

33

20

Rd 65 x

ø 38

ø 43

RA

ø 82/4xM8

ø 165

PA

1/

6

16 Pressure transmitter D84

Page 17

Product description

VEGABOX 01

38 72

ø 5

M20x1,5

with protective cover

135

118

108

139

85

72100

130

Pressure transmitter D84 17

Page 18

2 Mounting

Mounting

2.1 Mounting instructions

The pressure transmitter can be mounted in

any position. Cable entries must point downwards to avoid moisture ingress. For this

purpose, the housing can be rotated by 330°

in relation to the mounting part.

An appropriate connection seal must be

used for mounting. This seal is either supplied with the pressure transmitter or must be

provided by the customer.

2.2 Compensation of the atmospheric pressure

On instruments for gauge pressure measurement, the atmospheric pressure is compensated via a breather facility integrated in

the housing.

Pressure transmitter with housing

- via an integrated breather facility (PTFE

use 1)), protection IP 66

- via the capillaries of a special cable con-

nected to the terminals, protection IP 67

Pressure transmitter with direct cable

outlet

- via the capillaries of a special cable con-

nected to the terminals, protection IP 68

We recommend leading the special cable into

the external connection housing VEGABOX

01 (accessory) and carrying out the pressure compensation via the integrated

breather facility there.

External connection housing

Observe the following instructions:

- as a rule, there must be the same atmos-

pheric pressure on the breather facility as

on the vessel

- the pressure compensation must be done

in a dry environment

- with vertical wall mounting, cable entries

must point downward to avoid moisture

ingress and buildup on the breather facility.

1)

air permeable and humidity blocking

18 Pressure transmitter D84

Page 19

Electrical connection

3 Electrical connection

3.1 Connection instructions

The electronics in the pressure transmitter

requires a supply voltage of 12 … 32 V DC. It

is designed in two-wire technology, i.e. the

supply voltage and the digital output signal

are led via the same two-wire cable to the

terminals.

This external energy is provided via a separate power supply unit, e.g.:

- power supply unit VEGASTAB 690

- processing unit with integrated DC voltage

source (e.g. active PLC input)

- VEGAMET, VEGALOG or VEGADIS 371

Make sure that the external energy source is

reliably separated from the mains circuits

acc. to DIN VDE 0106, part 101. The abovementioned VEGA devices meet this requirement and protection class III is therefore

guaranteed.

The external energy source must provide a

terminal voltage of at least 12 V on the transmitter. The actual terminal voltage on the

transmitter depends on the following factors:

- output voltage UH of the external energy

source under nominal load.

- electrical resistance of the connected instruments in the circuit (see connected

instruments, load resistance).

Note the following instructions for electrical

connection:

- Connection must be made according to the

country-specific installation standards (e.g.

in Germany acc. to the VDE regulations).

- The terminal voltage must not exceed 36 V,

to avoid damage to the electronics.

- The electrical connection must have a protective measure against polarity reversal.

- Connection of Ex sensors only by qualified

personnel.

- The wiring between pressure transmitter

and power supply can be made with

standard two-wire cable.

- If strong electromagnetic interference is

expected, screened cable is recommended. The screening must be done on

both ends. Note the installation regulations

for use in Ex areas.

- In case of overvoltages, we recommend

the use of pressure transmitters with integrated overvoltage protection or the installation of VEGA overvoltage arresters.

- In the cable entry, a seal correctly fitting the

cable should be used.

Safety information for Ex applications

As a rule, do all connecting work in the complete absence of line voltage. Always switch

off the power supply before you carry out

connecting work on the sensors. Protect

yourself and the instruments.

Qualified personnel

Instruments used in Ex areas must be

installed only by qualified personnel. The

qualified personnel must observe and understand the mounting regulations and the

supplied type approval certificates and

conformity certificates.

If an instrument is used in hazardous areas,

the respective regulations, conformity certificates and type approvals of the sensors,

separators or safety barriers must be noted

(e.g. DIN VDE 0165).

Pressure transmitter D84 19

Page 20

Electrical connection

Sensors used in Ex areas must be connected only to intrinsically safe circuits. The

permissible electrical values are stated in the

conformity certificate or the type approval

certificate.

Intrinsically safe circuits with more than one

active instrument (instrument delivering electrical energy) are not allowed. Please note the

special installation regulations (DIN VDE

0165).

Certain pressure transmitters are provided

with a warning label informing of measures to

be taken to avoid the danger of electrostatic

discharge. Note the content of the warning

label.

3.2 Terminal assignment

Direct cable outlet

Breather capillaries

Suspension cable

br

For supply or to the process-

+

bl

ing system (4 … 20 mA,

-

12 … 36 V DC or VBUS)

ge

Screen

(only for adjustment insert in

external housing)

Electronics version B

Digital output signal for connection to a digital

VEGA signal conditioning instrument (VBUS)

Zum Anschluss an

For connection to

VBUS-Auswertgeräte

VBUS-signal conditioning instruments

1234

-+

-+

Klemmeinsatz

terminal

V

Field

Communication

BUS

Internal connection

Supply and digital

measuring signal from

and to the digital

VEGAMET 514V and

515V signal condition-

–

ing instrument or

VEGALOG 571

+

processing system

Electronics version I

4 … 20 mA output signal, remote parameter

setting through PC and HART® handheld

4-20mA

-

+

4...20mA

12V...36V DC

Klemmeinsatz

terminal

51234

+

–

–

Power supply

+

12 … 36 V DC

Electronics version A

for connection to VEGA signal conditioning

instruments

Zum Anschluss an

For connection to

VEGA-Auswertgeräte

VEGA-signal conditioning instruments

51234

-

+

Klemmeinsatz

terminal

+

–

Supply or processing

from the VEGAMET

–

signal conditioning

instrument

+

12 … 36 V DC

Electronics version K

4 … 20 mA output signal with integrated

adjustment and remote parameter setting

through PC and HART® handheld

S

Zt

+

-

4...20mA

12V...36V DC

Bedieneinsatz

operating unit

Op

i

43215

+

–

–

Power supply

12 … 36 V DC

+

20 Pressure transmitter D84

Page 21

Electrical connection

Electronics version L

4 … 20 mA output signal with adjustability via

the external connection housing VEGADIS

12, as well as remote parameter adjustability

via PC and HART® handheld

Zum Anschluss an

For connection to

VEGADIS 12

51234

-

+

12V...36V DC

Klemmeinsatz

terminal

Connection housing

VEGADIS 12

3.3 Connection to external connection housing VEGABO X 01

Adjustment insert in external

connection housing

Zum Anschluss an

For connection to

Druckmessumformer mit

pressure transmitters with

analogem Ausgangssignal

analog output

1

Pressure transmitter with direct cable

outlet

231011 12

TRANSMITTER

VEGABOX 01

+

4... 20mA

-

+

+

For supply or to the processing

system (4 … 20 mA, 12 … 36 V DC)

–

Breather capillaries

Suspension cable

+

br

bl

–

ge

+

Control instrument (4 … 20 mA

measurement)

–

Screen

Pressure transmitter D84 21

Page 22

Electrical connection

3.4 Connection examples

Note:

An ammeter for local control of the output current can be connected to terminals 1 and 3. This

measurement can be carried out during operation without interrupting the supply cable.

The following connection examples are valid for direct connection to the terminals of the pressure transmitter. When using the external connection housing, the connection is made to the

respective terminals of the housing.

Supply through a power supply unit

Processing is done by an indicating instrument.

Ammeter for local control

analogue / digital indicating

+ - -

1 2 3

Pressure transmitter terminals

instrument

External energy source

U

U

K

4 … 20 mA

A

-

U

H

~

+

Supply through a VEGA signal conditioning instrument

Standard wiring for non-standardised output.

Ammeter for local control

+ - -

1 2 3

Pressure transmitter

terminals

U

K

Analogübertragung,

unnormiert

0/4 … 20 mA

DISBUS

!

Supply through a PLC with active input circuit

Processing is done by the PLC

Ammeter for local control

+ - -

1 2 3

Pressure transmitter

terminals

U

K

4 … 20 mA

PLC

+

22 Pressure transmitter D84

Page 23

Setup

4 Setup

4.1 Adjustment structure

The hydrostatic pressure transmitters come

with or without adjustment capability.

After connection to the supply voltage, the

electronics carries out a self-test (approx.

2 sec.) and the current in this signal circuit

(sensors with analogue output signal) takes

on a value of > 21.6 mA.

Sensors with adjustment

(electronics version A and C)

Sensors with electronics version A deliver a

pressure-proportional current as measured

value and are not adjustable. All settings

such as adjustment, density correction etc.

are carried out via the signal conditioning

instrument. The sensors with electronics

version C come preadjusted according to the

measuring range of the sensor (factory setting). In unpressurised condition, they consume a current of 4 mA. With a pressure at

the measuring range final value, they consume a current of 20 mA.

Sensors with adjustment insert in the

sensor (electronics version K)

The adjustment insert with selection switch

allows:

- zero adjustment

"z" = empty adjustment

- span adjustment

"s" = full adjustment

- adjustment of an integration time (time) "ti"

Adjustment in external connection housing VEGADIS 12 (electronics version L)

The adjustment insert with selection switch

(VEGADIS 12 with display) allows:

- zero adjustment

- span adjustment

- adjustment of an integration time (time)

- adjustment of a value for zero point

(empty)

- adjustment of a value for span (full)

- adjustment of the decimal point for the

displayed value

Adjustment with HART® handheld

(electronics version I, K and L)

The hydrostatic pressure transmitters with

electronics version I, K and L can be adjusted with the HART® handheld like other

HART® capable instruments. A manufacturer

specific DD (Device Description) is not necessary. The sensors work with the HART

standard menus.

Adjustment of VEGA signal conditioning

instrument VEGAMET (electronics version

A and B)

Electronics version A delivers a non-standardised output signal to a VEGAMET with

analogue input.

Electronics version B transfers the measured

value digitally (VBUS) to a digital VEGAMET

(514V, 515V, 614V).

The signal conditioning instrument itself, as

well as the pressure transmitter, can be operated by means of the standard six-key adjustment field (with clear dialog text display)

on the signal conditioning instrument.

®

Pressure transmitter D84 23

Page 24

Setup

Adjustment with PC and adjustment

program VVO (electronics version B, I, K

and L)

With the adjustment program VVO (VEGA

Visual Operating) on the PC you can conveniently adjust the pressure transmitters with

electronics version B, I, K and L. The PC

communicates with the sensor through the

interface converter VEGACONNECT 2 or the

standard RS 232 interface cable. A digital

adjustment signal is superimposed on the

signal and supply cable. The adjustment can

be carried out from any location on the signal

cable, on the sensor directly, on the signal

conditioning instrument or on the VEGALOG

processing system.

4.2 Sensor without adjustment

Sensors with electronics version C have no

adjustment capability and come preset to the

stated measuring range.

4.3 Sensor with adjustment insert, adjustment in the sensor

Sensors with electronics version D and K are

equipped with an adjustment insert.

2

1

1 Reduce value

2 Rotary switch

3 Increase value

S

Zt

+

-

4...20mA

12V...36V DC

Bedieneinsatz

operating unit

Op

i

43215

3

With the rotary switch you can select four

switch positions:

s - span

z - zero

ti - time (integration time)

Op - operate (operating status)

24 Pressure transmitter D84

Page 25

Setup

S

Op

Zt

i

43215

+

-

4...20mA

12V...36V DC

Bedieneinsatz

operating unit

Adjustment

For adjustment of zero and span, an ammeter must be connected to terminals 1 and 3.

The measured value is identical to the output

current.

1 Adjustment of zero

(e.g. process pressure zero or empty vessel)

• Set rotary switch to zero.

• By pushing the "+" and "–" keys simultaneously, the current jumps directly to 4 mA or

you can adjust a current of 4 mA with the

"+" and "–" keys.

Adjustment range of zero:

-20 % … +95 % of nominal measuring range

(corresponds to a turn up of up to +95 %)

Note:

- A modification of zero does not influence

the span, i.e. the measuring range final

value is simply shifted.

- It is also possible to adjust currents for

partial fillings or partial pressures, e.g.

8 mA for 25 % and 16 mA for 75 %.The

pressure transmitter then automatically

calculates the values for 0 % or 100 %

(only possible with a level difference

>3.3 %).

Integration time

An integration time ti of 0 … 10 s can be adjusted to damp pressure shocks.

Procedure

• Set rotary switch to ti.

• By pushing the "-" 10 times, make sure that

the integration time is set to 0 s.

• For each 1 s of requested integration time,

the "+" key has to be pushed once.

2 Adjustment of span

(e.g. process pressure or level at maximum)

• Set rotary switch to span.

• By pushing the "+" and "–" keys simultaneously, the current jumps directly to 20 mA

or you can adjust a current of

20 mA with the "+" and "–" keys.

Adjustment range of span:

3.3 % … 120 % of nominal measuring range

(corresponds to a turn down 1 : 30)

Pressure transmitter D84 25

Page 26

Setup

4.4 Setup with HART® handheld

Sensors with electronics versions I, K and L

can be set up with the HART® handheld. A

special DD (Data Device Description) is not

necessary. Just connect the HART® handheld

to the sensor signal cable after you have

connected the sensor to supply voltage.

250 Ω

Note:

If the resistance of the voltage supply is less

than 250 Ω, a resistor must be looped into the

signal/connection cable during adjustment.

The digital adjustment and communication

signals would otherwise be short-circuited

through insufficient resistance of e.g. the

supply voltage source or the processing

system. In such case, communication with

the sensor would not be ensured. Simply

connect the adjustment resistor in parallel to

the connection socket of the HART

®

handheld.

+

PLC

-

Ri < 250 Ω

26 Pressure transmitter D84

Page 27

Setup

The most important adjustment steps

On the following four pages you see a menu

schematic of the HART® handheld in conjunction with pressure transmitters D80 … D87.

The most important adjustment steps are

marked in the menu schematic with the letters

A … D. If you are not familiar with HART

handheld, please note:

After entering a parameter, first push the

"

ENTER

" key. The adjustment is saved in the

handheld, but not in the sensor itself.

Generic: SENSOR

PV LVR

0.000 mbar

10.000 mbar

HELP DEL ESC ENTER

Empty adjustment without

medium

After you have pushed "

push "

SEND

" (here in the example for the

4.1

(5.1)

ENTER

", you have to

min. adjustment), to transfer the input to the

sensor.

Generic: SENSOR

1PV LRV

2 PV URV

®

After a moment, you are asked to switch the

system from manual to automatic operation.

Confirm with "OK"

Generic: SENSOR

– WARNING –

Return control loop to

automatic control

OK

and then with "

Generic: SENSOR

1PV LRV

2 PV URV

HELP HOME

HOME

".

You are now in the initial menu.

Generic: SENSOR

Online (general)

1 Sensor unit

2 P V 80.945 mbar

3 PV Analog output

4PVLRV

5 PV URV

HELP SAVE

HELP SEND HOME

After pushing "

SEND

", a warning is displayed

that you are about to change device output

and for safety reasons, you should switch

your system to manual operation. Push "OK"

and the adjustment is now transferred to the

sensor.

Generic: SENSOR

– WARNING –

Pressing „OK“ will

change device output

Put loop in manual

ABORT OK

Pressure transmitter D84 27

Page 28

HART® menu schematic

Switch on:

Hart Communicator

Self T est

in Progress

Firmware Rev: F2.2

Module Rev: 3.6

01992-96 FRSI

after approx.

20 s

Generic: D84

Online(Generic)

1 Device setup

2 P V 80.007 mbar

3 P V AO 17.594 mA

4 PV LRV 0.000 mbar

5 URV 100.000mbar

HELP SAVE

Set up the sensor in the sequence of the

letters A, B, C and D (adjustment without

medium).

For the adjustment with medium you set

up the sensor in the sequence A1, B1, C

and D.

Generic: D84

Device setup

1 Process variables

2 Diag/Service

3 Basic setup

4 Detailed setup

5 Review

SAVE HOME

Generic: D84

PV

84.558 mbar

HELP EXIT

Generic: D84

AO1

17.518 mA

HELP EXIT

1

2

3

Generic: D84

Process variables

1 Snsr 84.293 mbar

2 AI % rnge 84.265 %

3 AO1 17.478 mA

HELP SAVE HOME

Generic: D84

1 PV LRV 0.000 mbar

2 URV 100.000 mbar

HELP HOME

Generic: D84

– WARNING –

Return control loop to

automatic control

Generic: D84

– WARNING –

Pressing „OK“ will

change device output

Put loop in manual

ABORT OK

Generic: D84

1 PV LRV 0.000 mbar

2 URV 100.000 mbar

Setup

1.1

OK

HELP SEND HOME

4.1

(5.1)

4.2

(5.2)

Important and

required menu

windows

Less important

menu windows

Not required, unimportant

or blocked menu windows

Generic: D84

1 PV LRV 0.000 mbar

2 URV 100.000 mbar

HELP HOME

Generic: D84

1 PV LRV 0.000 mbar

2 URV 100.000 mbar

HELP HOME

continue like under 4

Generic: D84

PV LRV

AA

A

AA

4

BB

B

BB

5

0.000 mbar

0.000 mbar

HELP DEL ESC ENTER

Empty adjustment without

medium

Generic: D84

PV URV

100.000 mbar

100.000

HELP DEL ESC ENTER

Full adjustment without

medium

continue like under

A figure 4.1(5.1)

28 Pressure transmitter D84

Page 29

Setup

Generic: D84

PV

83.454 mbar

HELP EXIT

Generic: D84

PV % rnge

83.385 %

HELP EXIT

Generic: D84

AO1

17.327 mA

HELP EXIT

Generic: D84

Diag/Service

1 Test device

2 Loop test

3 Calibration

4 D/A trim

SAVE HOME

Generic: D84

Basic setup

1Tag

2 PV Unit

3 Range values

4 Device information

5 PV Xfer fnctn

HELP SAVE HOME

6 PV Damp

1.1.1

Safety

enquiry

acknowledgement

1.1.2

1.1.3

1.2

Blocked menu. The

following menu window is

indicated but not supported

by the sensor. Therefore

saving of adjustments

carried out here is not

possible.

1.3

T r ansmission function

(linear)

Generic: D84

Choose analog output

level

14 mA

2 20 mA

3 Other

4End

ABORT ENTER

Generic: D84

Calibration

1 Apply values

2 Enter values

HELP SAVE HOME

Generic: D84

Tag

DD

D

DD

CC

C

CC

BAR 20

BAR 20

HELP DEL ESC ENTER

Generic: D84

PV Snsr unit

mbar

mbar

g/cm2

kg/cm2

Pa

Generic. D84

Range values

1 PV LRV 0.000 mbar

2 URV 100.000 mbar

3 PV LSL 0.000 mbar

4 USL 100.000 mbar

HELP HOME

Generic: D84

Device information

1 Distributor

2 Model Generic

3 Dev id 11017815

4Tag D84

5 Date 10/01/97

HELP SAVE HOME

6 Write protect None

7 Description

8 Message

9 PV Snsr. s/n

Generic: D84

PV Damp

1.2.2

Input of individual current

values for test purposes

(simulation of measured

value)

1.2.3

ESC ENTER

Final asmbly num 0

Revision #’s

1.000 s

1 .000 s

A1A1

A1

A1A1

B1B1

B1

B1B1

1.3.1

1.3.2

1.3.3

1.3.4

1.3.6

Empty and full

adjustment

with medium

}

(see next page)

Newly assigned

measurement loop

designation to be

saved with ENTER

and SEND

see

next

}

page

see

next

}

page

HELP DEL ESC ENTER

Generic: D84

Review

Model

Generic

HELP PREV NEXT EXIT

Pressure transmitter D84 29

NAE CH VERL.

1.5

Generic: D84

Detailed setup

1 Sensors

2 Signal condition

3 Output condition

4 Device information

SAVE HOME

1.4

}

see

next

page

Page 30

HART® menu schematic (continuation)

Generic: D84

Calibration

1 Apply values

2 Enter values

HELP SAVE HOME

Generic: D84

Range values

1 PV L RV 0.000mbar

2 PV URV 95.981mbar

3 PV LSL 0.000mbar

4 USL 100.000mbar

HELP HOME

Menu fields (broken line):

repetition of previous page

1.2.3

1.2.3.1

Generic: D84

Enter values

HELP HOME

1.3.3

}

Safety

enquiry

acknowledgement

1 PV LRV 0.000 mbar

2 URV 100.000 mbar

3 PV USL

4 PV LSL 0.000 mbar

Indication of the

sensor measuring

range limits

Generic: D84

Set the:

14 mA

2 20 mA

3Exit

ABORTENTER

1.2.3.2

like display 4.1

like display 4.2

Indication of the

}

sensor measuring

range limits

Generic: D84

PV LRV

0.000 mbar

0.000

HELP DEL ESC ENTER

Generic: D84

PV URV

100.000 mbar

100.000 mbar

1.2.3.1

A1A1

A1

A1A1

B1B1

B1

B1B1

1.3.3.1

1.3.3.2

Setup

Empty adjustment with

medium

Generic: D84

Apply new 4 mA input

ABORT OK

Generic: D84

Apply new 20 mA input

Full adjustment with

medium

ABBR. OK

Generic: D84

Device information

1 Distributor

2 Model Generic

3 Dev id 11017815

4Tag D84

5 Date 01/01/97

HELP SAVE HOME

6 Write protect None

7 Descriptor

8 Message

9 PV Snsr s/n

Final asmbly num 0

Revision #’s

Generic: D84

Detailed setup

1 Sensors

2 Signal condition

3 Output condition

4 Device information

SAVE HOME

like menu 1.3.4

1.3.4

Unknown Enumerator

General

(1.3.4.3) Indication of the sensor serial number

(1.3.4.4) Measurement loop designation as under menu window 1.3.1

(1.3.4.5) Date adjustment

None

individual text adjustment

individual text adjustment

Indication of the sensor serial number (as under menu window 1.3.4.3)

Generic: D84

Sensors

1.4

1 PV 97.214 mbar

2 PV Snsr unit mbar

3 Sensor information

HELP SAVE HOME

Generic: D84

Signal condition

1 Snsr Damp 1.000 s

2 URV 100.000 mbar

3 AI L R V 0.000 mbar

4 Xfer fnctn Linear

5 AI % rnge 97.101 %

HELP SAVE HOME

Generic: D84

Output condition

1 Analog output

2 HART output

HELP DEL ESC ENTER

SAVE HOME

1.4.1

Measured value

Modification of the unit

Info on lower and upper measur-

ing range limit as well as min.

span (also the sensor characteris-

1.4.2

1.4.3

tics values)

Adjustment of the integration time

Adjustment of zero and span

Adjustment of zero and span

linear

Indication of the level in % of the

adjusted span

30 Pressure transmitter D84

Page 31

Setup

Generic: D84

Current applied

process value: 97.112

mbar

1 Set as 4 mA value

2 Read new value

3 Leave as found

ABORTENTER

Generic: D84

Current applied

prosess value :96. 262

mbar

1 Set as 20 mA value

2 Read new value

3 Leave as found

Generic: D84

Analog output

1 AO1 19.920 mA

2AO Alrm typ

3 Loop test

4 D/A trim

5 Scaled D/A trim

HELP SAVE HOME

1.2.3.1.1

ABORT ENTER

1.2.3.1.2

1.4.3.1

Generic: D84

Set the:

14 mA

2 20 mA

3 EXIT

Generic: D84

Set the:

14 mA

2 20 mA

3Exit

Generic: D84

AO Alrm typ

Lo

Generic: D84

WARN - Loop should be

removed from

automatic control

Menu windows are displayed but not

}

supported by the sensor.

Saving of adjustments carried out here is

therefore not possible.

1.2.3.1.1.1

ABORT ENTER

ABORT ENTER

1.2.3.1.2.1

1.4.3.1.2

EXIT

1.4.3.1.3

ABORT OK

1.4.3.1.3

Generic: D84

Current applied

process value: 96.549

mbar

1 Set as 4 mA value

2 Read new value

3 Leave as found

Generic: D84

Current applied

process value: 95.703

mbar

1 Set as 20 mA value

2 Read new value

3 Leave as found

Generic: D84

Fld dev output is

fixed at 4.000 mA

Generic: D84

Apply new 4 mA input

ABORT OK

Generic: D84

Apply new 20 mA input

ABORT OK

Low : In case of failure, current output

goes to 22 mA

High: In case of failure, current output

goes to < 3.6 mA

Generic: D84

Choose analog output

level

14 mA

2 20 mA

3 Other

4End

ABORTENTER

ABORT ENTER

ABORT ENTER

1.4.3.1.3.1

ABBR. OK

1.4.3.2.3

ESC ENTER

1.4.3.2.4

Off

On

Not used

None

Unknown

Special

Leave the Burst-mode in

OFF position

Choice is not supported

Sensor signals measured values only on

request

Sensor signals measured values

unrequested

Choice is not supported

Generic: D84

HART output

1 Poll addr 0

2 Num req preams 5

3 Burst mode Off

4 Burst option

HELP SAVE HO M E

1.4.3.2

Generic: D84

Burst mode

Off

Off

On

Not Used

None

Generic: D84

Burst option

*********

PV

% range/current

Process vars/crnt

HELP ESC ENTER

Note:

After entering a parameter, push "

ENTER

" and then "

SEND

".

Confirm the message to switch over to manual operation with "OK".

Confirm the message to reset to automatic operation also with "OK".

Only then will the adjustment be stored in the sensor and take effect.

Pressure transmitter D84 31

Page 32

Setup

5.5 Adjustment with PC directly on the sensor

(electronics versions I, K and L)

For connection of the PC to the sensor, the interface converter VEGACONNECT 2 is required.

Connection of the PC to the sensor

Insert VEGACONNECT into the serial interface of the PC and insert the two-wire cable of

VEGACONNECT into the CONNECT socket of the sensor.

Connection of the PC to the signal cable

Connect the two-wire cable of VEGACONNECT 2 to the signal cable leading to the sensor.

Connection configuration with pressure transmitter directly on active PLC

(electronics versions I, K and L)

• Two-wire technology, power supply from active PLC.

• Output signal 4 … 20 mA (passive).

• Adjustment with PC, HART® handheld or adjustment insert located in the sensor or in the

external connection housing.

1)

2

4 ... 20 mA

2

VEGACONNECT 2

32 Pressure transmitter D84

2

1)

If the resistance of the processing system (PLC)

connected to the 4 … 20 mA signal output is less

than 200 Ω, a resistor of 250 Ω must be connected

to the connection cable during adjustment.

The digital adjustment signal would be considerably

damped or short-circuited through insufficient

resistance of a connected processing system, and

digital communication with the PC would not be

ensured.

PLC

Ri < 250 Ω

Page 33

Setup

If you have already connected the PC with

the adjustment software VVO to your measuring system,

• first switch on the power supply of the

connected sensor

• switch on the PC and start the adjustment

software VVO.

• Choose with the arrow keys or the mouse

the item "

and click to "

You are asked for user identification.

PlanningPlanning

Planning

PlanningPlanning

OKOK

OK

".

OKOK

" on the entrance screen

The adjustment program (VVO), called in the

following VVO, gets into contact with the

connected sensor…

…and indicates after a few seconds if and

with which sensor a connection exists.

The preset user identification can be modified

later in the menu "

User access

".

• Enter under name "

• Also enter "

Pressure transmitter D84 33

VEGAVEGA

VEGA

VEGAVEGA

VEGAVEGA

VEGA

" under password.

VEGAVEGA

".

Page 34

Note:

If you connect the adjustment software (VVO)

to a sensor from which data has already

been saved, you are asked if the saved data

should be transferred to the sensor or if you

want to transfer the sensor data to the

database of VVO (the available data of the

current sensor will be overwritten).

If you don’t get communication with the sensor, check the following:

- Is the sensor being supplied with sufficient

voltage (min. 12 V)?

- When VEGACONNECT 2 is connected to

the signal cable, is the load resistance

250 … 350 Ω?

Configuration

• Choose the menu "

system

", to get further information on the

sensor type, the software version of the

sensor, measuring unit, the measurement

loop designation etc.

Configuration/Measuring

Setup

In the menu "

you can give a name (e.g. vessel 10) and a

description (e.g. cleaning detergent) to the

measurement loop in place of the sensor

number. This will make your entire measuring

system more understandable.

• Now enter in this menu whether a level, a

distance or a gauge should be measured.

Modify meas. loop configuration

"

• Click to "

• Click to the menu "

ment loop/Modifyment loop/Modify

ment loop/Modify

ment loop/Modifyment loop/Modify

sensor setup.

34 Pressure transmitter D84

QuitQuit

Quit

QuitQuit

".

Configuration/Measure-Configuration/Measure-

Configuration/Measure-

Configuration/Measure-Configuration/Measure-

". This is the first step of

• Confirm the adjustment with "

saving you are again in the initial menu.

OKOK

OK

" and after

OKOK

Page 35

Setup

Parameter adjustment/Adjustment

In the menu "

adjustment

sor adjustments.

• Choose the menu "

eter adjustment

Instrument data/Parameter

" you carry out all important sen-

Instrument data/Param-

".

• Choose in the menu window "

data parameter adjustment

AdjustmentAdjustment

"

Adjustment

AdjustmentAdjustment

• In the menu window "

Min/Max-adjustmentMin/Max-adjustment

to "

Min/Max-adjustment

Min/Max-adjustmentMin/Max-adjustment

You can carry out the min./max. adjustment

with or without medium. Generally you will

carry out the adjustment without medium.

".

Adjustment

Instrument

" the menu item

" you click

" (zero/span).

The adjustment can be quickly and conveniently carried out without medium, as shown

in the example.

• Choose in which unit you want to carry out

the adjustment.

• Enter the pressures corresponding in your

• Confirm the warning with "

In the heading you now see the previously

entered measurement loop name and the

measurement loop description.

Pressure transmitter D84 35

OKOK

OK

OKOK

".

application to 0 % and 100 % and push

OKOK

"

OK

".

OKOK

Page 36

Setup

The example shows an absolute pressure

transmitter with a measuring range of

0 … 1000 mbar, with which low pressures

(partial vacuum) are measured. The min.

value was set to 50 mbar and the max. value

(span) to 1000 mbar (i.e. the final value of the

measuring range).

QuitQuit

Quit

QuitQuit

OKOK

OK

" and

OKOK

" and you

• Confirm your adjustments with "

after a short data transmission to the

sensor, you are again in the menu window

"

Adjustment

• Quit all menu windows with "

are again in the initial menu.

Offset correction (not possible with absolute pressure transmitters)

With this menu you can carry out a zero point

correction/position correction (unpressurized

sensor).

".

• Click to "

• When the sensor is unpressurised and in

installation position, confirm the safety

enquiry with "

You see the actual measured value from the

sensor.

• Click to "

Offset correctionOffset correction

Offset correction

Offset correctionOffset correction

OKOK

OK

".

OKOK

CorrectCorrect

Correct

".

CorrectCorrect

".

• Choose in the initial menu "

Parameter adjustment

functionsfunctions

functions

functionsfunctions

36 Pressure transmitter D84

".

Instrument data/

" the item "

AdditionalAdditional

Additional

AdditionalAdditional

Page 37

Setup

Again choose the menu "

and you see the corrected zero value.

Note:

The menu item "

bles the correction of the actual pressure by

means of a reference value. This corrects the

measuring characteristics in a way similar to

the offset correction.

Real value correction

Offset correction

" ena-

"

Conditioning/Linearisation

In the menu "

adjustment/Conditioning/Linearisation

allocated a filling quantity (volume) to the level

(filling height). The correlation between level

and volume is described with so-called

linearisation curves.

• Click to "

mentment

ment

mentment

LinearisationLinearisation

"

Linearisation

LinearisationLinearisation

Instrument data/Parameter

" you

Instrument data/Parameter adjust-Instrument data/Parameter adjust-

Instrument data/Parameter adjust-

Instrument data/Parameter adjust-Instrument data/Parameter adjust-

", then to "

ConditioningConditioning

Conditioning

ConditioningConditioning

".

" and finally to

You can choose four linearisation curves:

linear, horiz. cylindrical tank, spherical tank

and user programmable curve.

Under "

User programmable curve

enter your own linearisation curve as a correlation between the level in % or pressure in %

(percentage value) and the volume

(linearised).

• Choose "

then "

User programmable curveUser programmable curve

User programmable curve

User programmable curveUser programmable curve

EditEdit

Edit

".

EditEdit

" you can

" and

First of all, a linear correlation is displayed

(the function is a straight line).

Pressure transmitter D84 37

Page 38

Setup

In the field "

Transfer measured value

" the

current pressure as a percentage of the

adjusted span is displayed. The measuring

span has already been adjusted with the

min./max adjustment. In our example this is in

the range between 50 … 1000 mbar.

The user-programmable linearisation curve is

generated by index markers, consisting of

the value pairs "

the selected unit) and "

Linearised

Percentage value

" (volume in % or in

"

(level or filling height in %).

Defining the linearisation curve by incremental filling

In the characteristics of the example (evacuated vessel), you see four index markers or

value pairs. There is always a linear interpolation between the index markers.

• Click in the check box "

ues

", to have the selected unit of measure-

Show scaled val-

ment displayed on the y-axis (left bottom

part in the menu window).

Index marker 1 is at 0 % level or pressure

(percentage value [%]), corresponding to an

actual pressure of 0 mbar.

1000 mbar

= 100 liters

700 mbar

= 35 liters

300 mbar

= 5 liters

0 mbar

= 0 liters

Pressure

transmitter

Vacuum

Saline

solution

Max. 32 index markers (value pairs) can be

entered.

• Quit the menu with "

• Confirm the message with "

OKOK

OK

OKOK

".

OKOK

OK

" and your

OKOK

individual linearisation curve will be saved

in the sensor.

Again in the menu window "

Conditioning

" you

can enter a measured value integration with

the menu item "

Integration time

". This is useful

for fluctuating product surfaces to smooth the

display and output of measured values. As a

standard feature, the integration time is

preset to 0 seconds.

Index marker 2 is at 30 % level or pressure

and 5 % filling volume.

Index marker 3 is at 70 % level or pressure

• Quit the menu with "

You are again in the menu window "

ment data parameter adjustment

OKOK

OK

OKOK

".

Instru-

".

and 35 % filling volume.

Index marker 4 is at 100 % level or pressure

and 100 % filling volume (100 litres).

38 Pressure transmitter D84

Page 39

Setup

Meas. data information

• Click to "

All available sensor information is displayed.

With the button "

pressure and temperature history saved in

the sensor.

Meas. data info

reset

" you can delete the

".

Backup

In the menu window "

its serial number is displayed. You can save

the sensor data in the PC individually or in

groups with all adjustments in a directory of

your choice. A small text message can be

added to each backup.

Backup

" the sensor with

Saved sensor data can be transferred later

on to other sensors.

For example, if you have a system with several of the same storage vessels and

identical sensors, it is sufficient to configure

one sensor and then transfer the settings to

the other sensors.

In this menu window, the actual setting (data

base) with date and time of the last system

configuration is displayed in the yellow window field. If you click on the serial number of

the sensor from which you want to adopt the

adjustments (in the yellow field), these sensor

settings will be transferred to the currently

connected sensor with "

Restore to

".

Pressure transmitter D84 39

Page 40

6 Diagnostics

Diagnostics

Maintenance

The pressure transmitter D84 is maintenance

free.

Should dismounting of the pressure transmitter (e.g. for vessel cleaning) be necessary,

we recommend the use of new seals. Use

only original seals from VEGA.

Remedying faults

Through continuous self-monitoring, series 80

pressure transmitters offer maximum

reliability. However, if faults occur, please

check the following before removing the

pressure transmitter:

- the atmospheric pressure compensation

(only with gauge pressure measuring

ranges),

- the electrical connections.

Checking atmospheric pressure compensation

First of all, open the cover of the housing in

which the atmospheric breather facility 1) is

located. The displayed measured value must

not change. If, however, the displayed value

changes, the compensation of the atmospheric pressure does not function correctly

and the measured value will be distorted.

Therefore check:

- the breather facility on the housing

- the external connection housing

VEGADIS 12

- the capillaries in the special housing.

Note:

The same atmospheric pressure must be

acting on the breather facility and the open

vessel.

Checking electrical connections

Pressure

transmitter

terminals

1 2 3

mA

Current

Voltage

V

Current

mA

External

energy source

-

~

+

Checking the voltage

- The terminal voltage on the pressure transmitter must be at least 12 V DC.

- The terminal voltage on VEGADIS 12 must

be at least 12 V DC or 17 V DC (with display).

- The supply voltage for the pressure transmitter through a VEGAMET signal conditioning instrument must be approx.

18 V DC (on VBUS 25 V DC).

Checking the current

These values are only valid for pressure

transmitters with analogue signal transmission, not for pressure transmitters with digital

output signal (VBUS).

• Initial current with uncovered diaphragm of

the pressure transmitter: approx. 4 mA

(5 mA when operated on a VEGA signal

conditioning instrument)

• Measuring current during operation:

4 … 20 mA (5 … 19 mA when operated on

a VEGA signal conditioning instrument)

• Exceeding or falling short of the specified

measuring range: 20.5 mA or 3.8 mA

• Pressure transmitter defective or shortcircuit: current 22 mA or 3.6 mA

1)

It consists of a black plastic screwed insert with

integrated filter element.

40 Pressure transmitter D84

Page 41

Instrument modification

7 Instrument modification

7.1 Retrofitting the adjustment insert

Such a retrofitting can be necessary, e.g.

when a pressure transmitter with factory

settings must be adapted to changed measurement conditions.

Note the following retrofit procedure:

• remove the outdated terminal insert

• mount new adjustment insert

• set up pressure transmitter acc. to chapter

"5 Setup"

Remove the outdated terminal insert

1 Separate pressure transmitter from

power supply.

2 Unscrew cover of the connection housing

or loosen the screws on the cover of the

external housing.

3 Remove cover.

4 Loosen connection cables on the terminal

insert.

5 Loosen the three screws of the terminal

insert.

6 Remove terminal insert and pull out plug

connection (to do this, bend locking nose

carefully towards housing centre).

Mount new adjustment insert

7 Plug the connection into the adjustment

insert (must snap in).

8 Place adjustment insert in the housing

and fasten with three screws.

9 Connect the connection cables to the

terminals.

10 Fasten the cover.

11 Reconnect the pressure transmitter to

power supply.

Setup of pressure transmitter

see chapter "5 Setup".

7.2 Exchange of hygienic form seal on D84

On the hygienic connections AA, CA, LA, LB,

RA, RB, TA of pressure transmitter D84, the

ceramic measuring cell is radially, gaplessly

sealed with a form seal. This form seal (material EPDM-FDA) can be exchanged by the

user without the need of a fresh adjustment.

The criteria and the time intervals for such an

exchange of the seal are generally defined

by the process and hygienic requirements.

Important:

Use only original replacement seals from

VEGA!

Please note the following exchange procedure.

Removal procedure:

• Pressure transmitter should be unpressu-

rized (switch off process pressure or

empty vessel).

• Loosen the hexagon pressure screw (4)

(width across flats, 46 mm) by turning to

the left.

Note!

The process connection (6) (e.g. compression nut) must not be loosened!

• Turn the adapter (3) below the pressure

transmitter housing with a wrench (with

across flats, 36 mm) briefly to the left (to

loosen the seal).

• Pull the complete pressure transmitter on

the housing (1) out of the process connection by carefully turning to the left.

• Slightly lift the form seal (5) and loosen

from the ceramic measuring cell.

• If the form seal (5) does not completely

encircle the measuring cell, it must be

carefully removed from the process

connection.

Pressure transmitter D84 41

Page 42

Installation procedure:

• Place the new form seal (5) over the measuring cell (the conical end must point to the

process connection!).

• Carefully insert pressure transmitter into

the process connection by turning clockwise.

• Tighten hexagon pressure screw (4) (width

across flats, 46 mm) (45 Nm).

• Turn the housing (1) of the pressure

transmitter to the original position.

The exchange of the form seal is now finished; the removed seal must be properly

disposed of.

1

2

3

4

Instrument modification

5

6

1 Pressure transmitter

2 Headless screw (prevents overwinding and must not be

removed)

3 Adapter

4 Hexagon screw

5 Form seal

6 Process connection

42 Pressure transmitter D84

Page 43

Notes

Pressure transmitter D84 43

Page 44

VEGA Grieshaber KG

Am Hohenstein 113

77761 Schiltach/Germany

Phone +49 (0) 7836 50-0

Fax +49 (0) 7836 50-201

E-Mail info@de.vega.com

www.vega.com

ISO 9001

All statements concerning scope of delivery, application, practical

use and operating conditions of the sensors and processing systems correspond to the latest information at the time of printing.

Technical data subject to alterations

24981-EN-021217

Loading...

Loading...