Page 1

Operating Instructions

Hydrostatic pressure transmitters

D76 and D77

Level and Pressure

p

Page 2

Contents

Safety information ........................................................................ 2

Note Ex area ................................................................................ 2

1 Product description

1.1 Function and configuration .................................................. 4

1.2 Types and versions ............................................................. 4

1.3 Electronics version without adjustment.............................. 5

1.4 Electronics version with integrated adjustment in

connection housing.............................................................. 6

1.5 Electronics for connection to VEGADIS 12 ........................ 6

2 Technical data

2.1 Data ....................................................................................... 7

2.2 Approvals and certificates ................................................ 10

2.3 Dimensions ......................................................................... 11

Contents

Safety information

Please read this manual carefully, and also take

note of country-specific installation standards

(e.g. the VDE regulations in Germany) as well

as all prevailing safety regulations and accident prevention rules.

For safety and warranty reasons, any internal

work on the instruments, apart from that involved in normal installation and electrical connection, must be carried out only by qualified

VEGA personnel.

2 Pressure transmitters D76 and D77

Note Ex area

Please note the approval documents (yellow

binder), and especially the included safety

data sheet.

Page 3

Contents

3 Mounting

3.1 Mounting instructions ......................................................... 13

3.2 Compensation of the atmospheric pressure ................... 13

4 Electrical connection

4.1 Connection instructions ..................................................... 14

4.2 Terminal assignment .......................................................... 15

4.4 Connection examples ........................................................ 16

4.3 Connection to VEGABOX 01 ............................................. 16

5 Setup

5.1 Sensor without adjustment ................................................ 18

5.2 Adjustment with the adjustment insert in the sensor ...... 18

6 Diagnostics

6.1 Maintenance ....................................................................... 20

6.2 Failure rectification ............................................................. 20

7 Instrument modification

7.1 Retrofitting of adjustment insert ........................................ 21

Pressure transmitters D76 and D77 3

Page 4

1 Product description

Product description

1.1 Function and configuration

The pressure transmitters D76 and D77 are

efficient, modular instruments for hydrostatic

level measurement. A dry, metallic-capacitive

cell or the dry, ceramic-capacitive measuring

cell CERTEC

element.

The hydrostatic pressure of the product

causes a capacitance change via the metallic

or ceramic diaphragm. This capacitance

change is detected by an ASIC (Application

specific integrated circuit) and converted by

the integrated sensor electronics into a pressure-proportional signal. Precise, high-resolution digital processing of measured data

ensures excellent technical data.

The sensor is powered by a separate VEGA

signal conditioning instrument, a stabilised

power supply unit or a PLC (active). After

adjustment, a standardised 4 … 20 mA current signal is available.

To improve reliability, the functionality of important electronic components is constantly

checked, and internal parameters such as

sensor value, temperature and operating

voltage are closely monitored.

Output signal

An analogue level or pressure-proportional

signal current is used as output signal:

- 5 … 19 mA not standardised (in conjunction with VEGA signal conditioning instrument)

- 4 … 20 mA standardised

®

is used as pressure sensor

Adjustment

The sensors are available with or without

integrated adjustment functions:

- without adjustment (version A, adjustment

via signal conditioning instrument)

- without adjustment (version C)

- with integrated adjustment (version D)

- with adjustment from external indicating

instrument (version E)

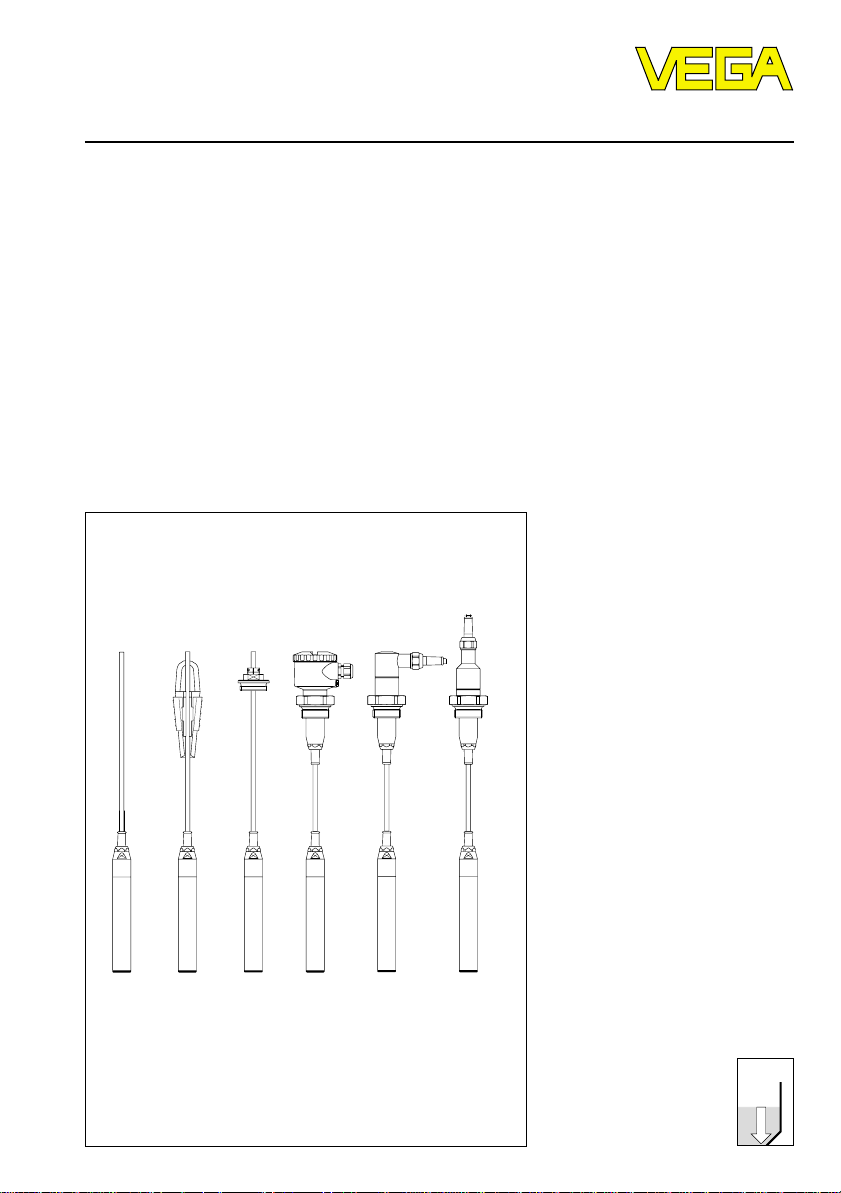

1.2 Types and versions

Suspension pressure transmitter D76

with CERTEC

Features

- Compact instrument with integrated electronics

- Diameter of the transmitter 32 mm

- Connection housing in protection IP 66/IP

67/IP 68

- Electronics as two-wire system 4 … 20 mA

- Power supply 12 … 36 V

- Adjustment/indication in separate housing

VEGADIS 12 possible

Applications

- Level and gauge measurements in water

sewage water, flumes, basins, deep wells,

vessels and tanks

Suspension pressure transmitter D77

with Duratherm 600 diaphragm

Features

- Compact instrument with integrated electronics

- Diameter of the transmitter 32 mm

- Connection housing in protection IP 66/

IP 67/IP 68

- Electronics as two-wire system 4 … 20 mA

- Power supply 12 … 36 V

- Adjustment/indication in separate housing

VEGADIS 12 possible

Applications

- Level and gauge measurements in water/

sewage water, flumes, basins, deep wells,

vessels and tanks

®

4 Pressure transmitters D76 and D77

Page 5

Product description

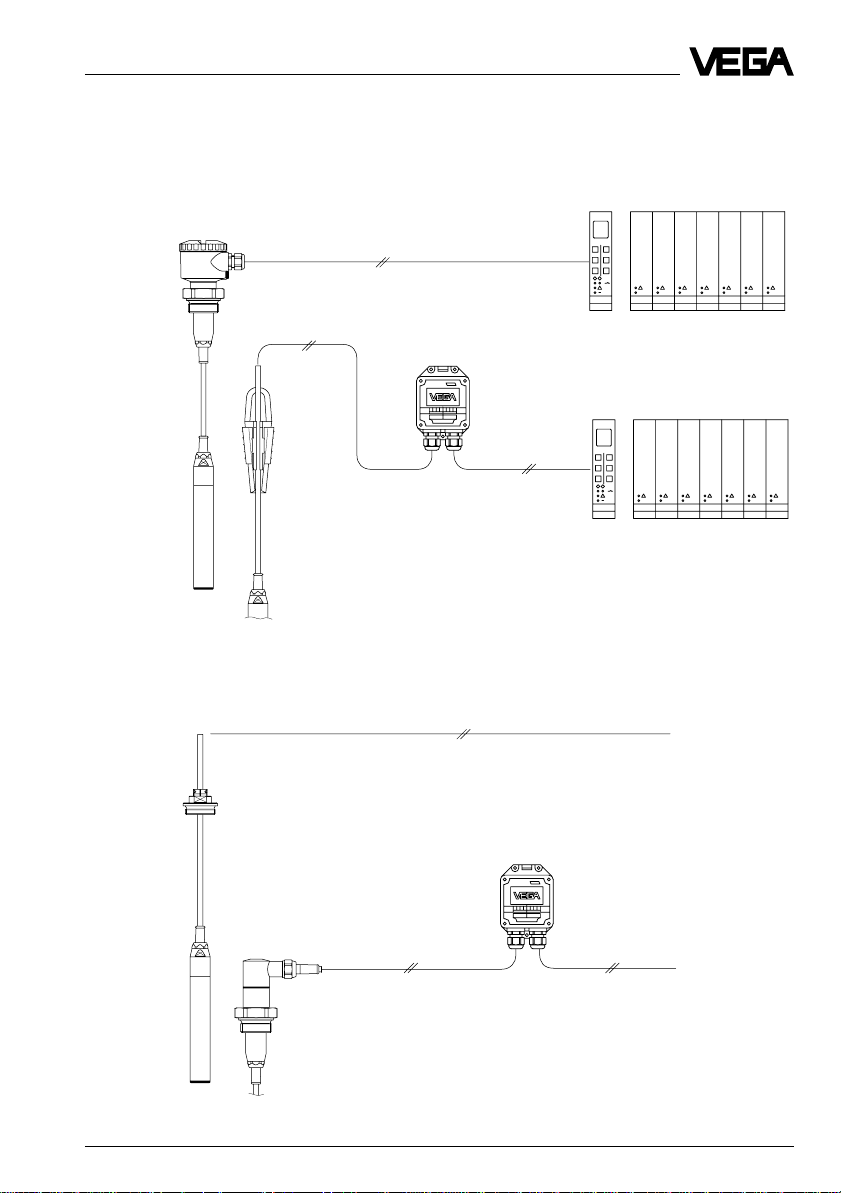

1.3 Electronics version without adjustment

Electronics version A:

Pressure transmitter for connection to VEGA signal conditioning instruments

VEGAMET

VEGABOX 01

VEGALOG

Electronics version C:

Pressure transmitter 4 … 20 mA

VEGABOX 01

VEGAMET

VEGALOG

PLC/DCS

PLC/DCS

Pressure transmitters D76 and D77 5

Page 6

Product description

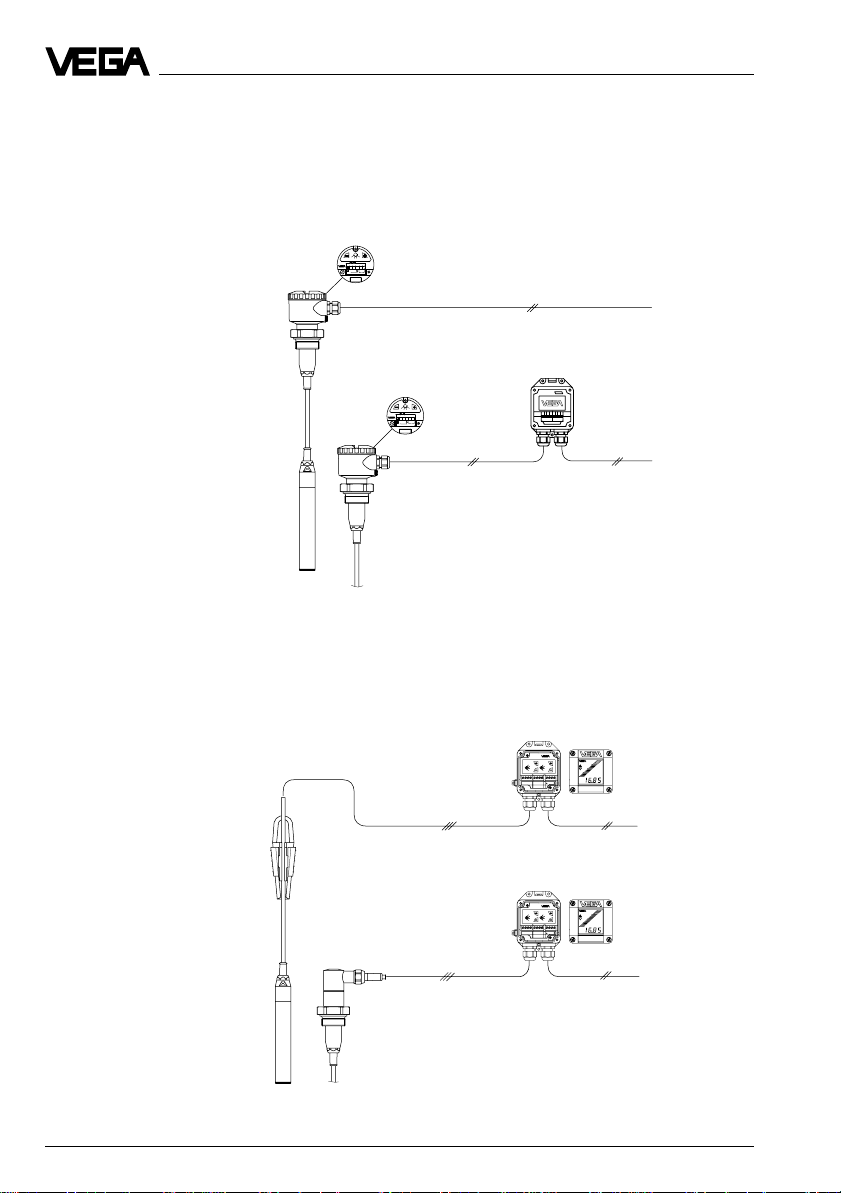

1.4 Electronics version with integrated adjustment in connection housing

Electronics version D:

Pressure transmitter 4 … 20 mA adjustable

Adjustment in connection housing

S

Op

Zt

i

43215

+

-

4...20mA

12V...36V DC

Bedieneinsatz

operating unit

PLC/DCS

VEGABOX 01

S

Op

Zt

i

43215

+

-

4...20mA

12V...36V DC

Bedieneinsatz

operating unit

PLC/DCS

1.5 Electronics for connection to VEGADIS 12

Electronics version E:

Pressure transmitter 4 … 20 mA

Adjustment in VEGADIS 12

6 Pressure transmitters D76 and D77

VEGADIS 12

DISPLAY

TRANSMITTER

DISPLAY

TRANSMITTER

OPERATE

OPERATE

OPERATE

OPERATE

ti

ti

ZERO

ZERO

END

END

ZERO

ZERO

POINT

SPAN

POINT

SPAN

VEGADIS 12

DISPLAY

DISPLAY

TRANSMITTER

TRANSMITTER

OPERATE

OPERATE

OPERATE

OPERATE

ti

ti

ZERO

ZERO

END

END

ZERO

ZERO

POINT

POINT

SPAN

SPAN

PLC/DCS

PLC/DCS

Page 7

12

300

600

900

18 24 30 36

Product description

2 Technical data

2.1 Data

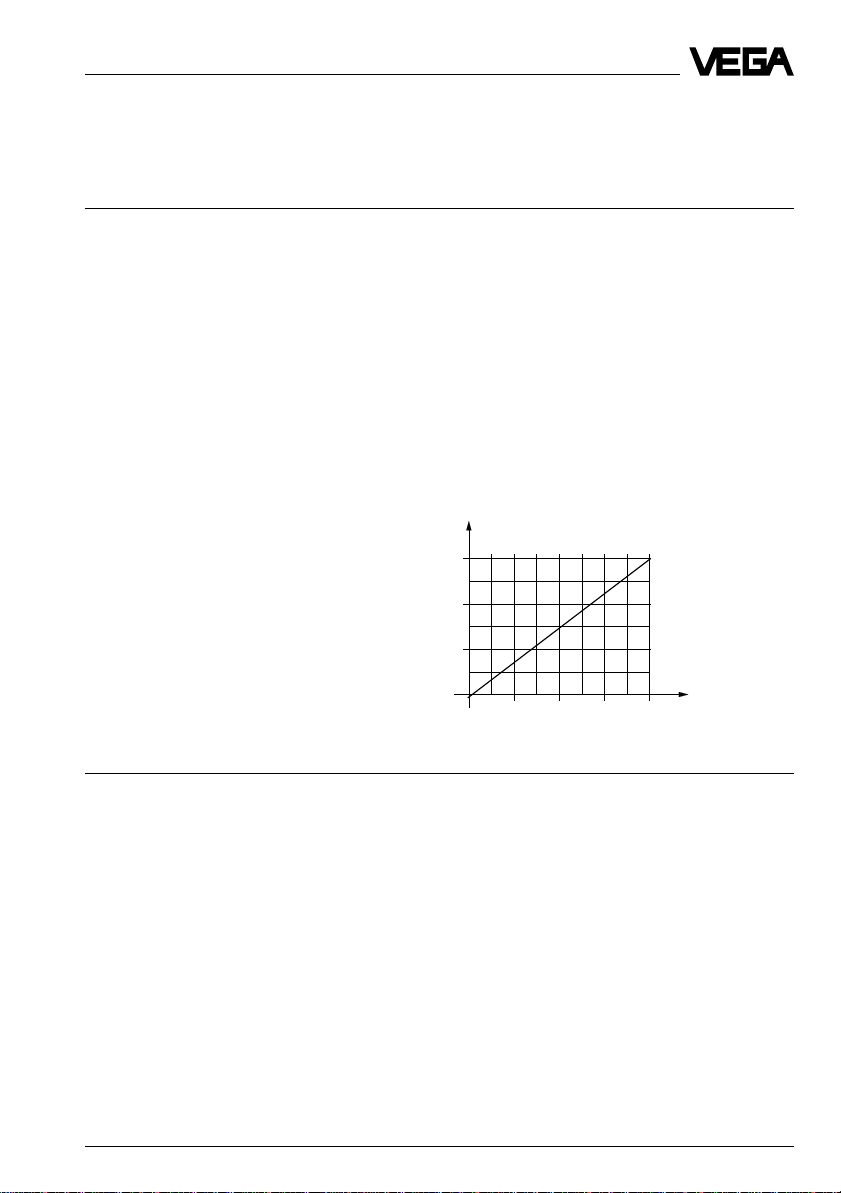

Supply and signal current circuit (analogue transmission, 4 … 20 mA)

Power supply 12 … 36 V DC

Residual ripple of the power supply no influence at U

Output signal

- terminal insert analogue transmission (not standardised)

4 … 20 mA

- adjustment insert 4 … 20 mA (adjustable)

Current limitation approx. 22 mA

Fault signal 22 mA

Integration time 0 … 10 s (adjustment time from 10 % … 90 %

of measuring range final value)

Average delay time 85 ms

Connection cable 2-wire

Max. permissible load depending on power supply

see following load diagram

Load in W

< 100 mV

SS

Integrated overvoltage protection (option)

Pressure transmitters D76 and D77 7

Nominal d.c. spark-over voltage

- protective diode 40 V

- gas separator 650 V

Nominal discharge current

- gas separator 20 kA

Supply voltage

in V

Page 8

Product description

Measuring ranges

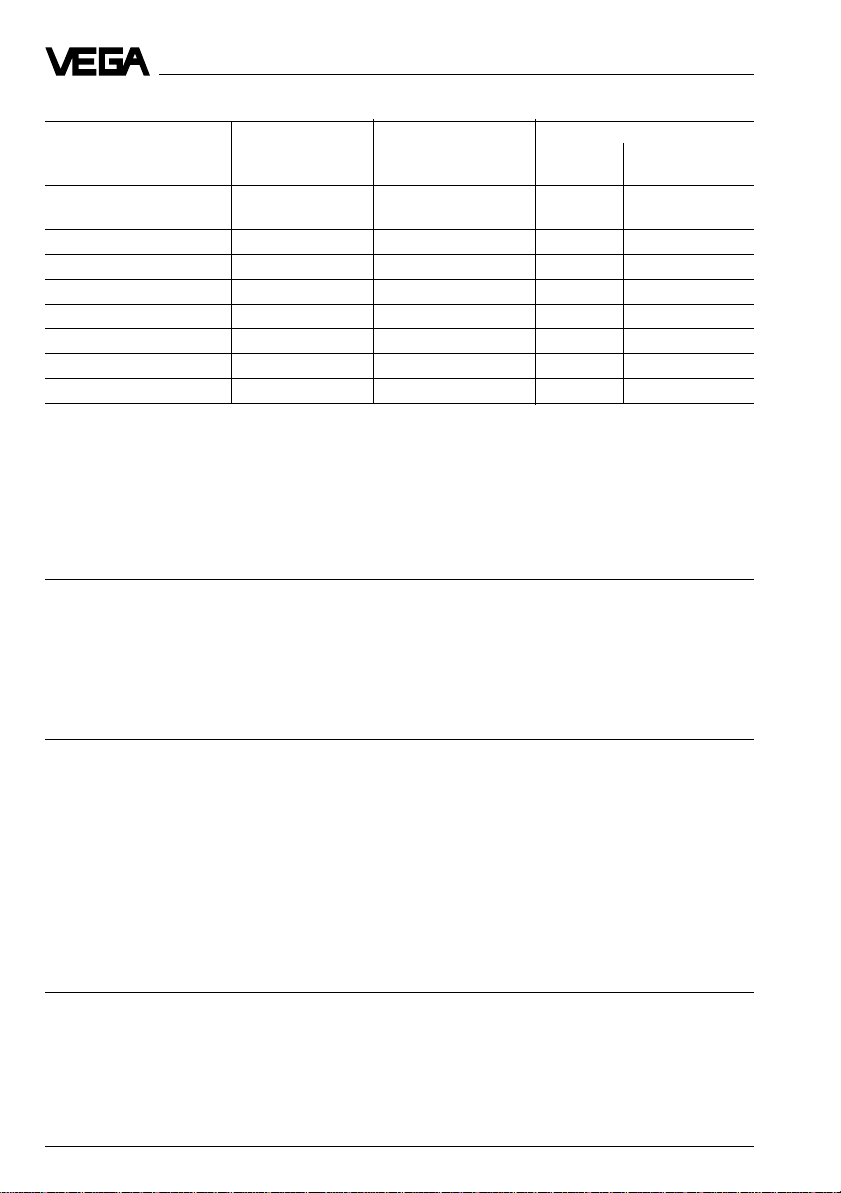

Nominal meas. range Gauge pressure Low pressure Pressure transmitters

resistance resistance D76 D77

D76 / D77

Gauge pressure

0 … 0.1 bar 10 bar / – -0.1 bar • –

0 … 0.2 bar 15 bar / – -0.2 bar • –

0 … 0.4 bar 20 bar / 10 bar -0.4 bar • •

0 … 1.0 bar 25 bar / 25 bar -1.0 bar • •

0 … 2.5 bar 35 bar / 25 bar -1.0 bar • •

0 … 5.0 bar 45 bar / 25 bar -1.0 bar • •

0 … 10.0 bar 60 bar / 25 bar -1.0 bar • •

0 … 20.0 bar 90 bar / 25 bar -1.0 bar • •

Zero -20 % … +95 % of nominal measuring range

adjustable

Span 3.3 % … 120 % of nominal measuring range

adjustable

Recommended turn down with

accuracy class 0.25 up to 1 : 5

Adjustment elements

Pressure transmitters

- terminal insert without adjustment elements

- adjustment insert 2 keys, 1 rotary switch

Measuring accuracy (similar to DIN 16 086, DIN V 19 259-1 and IEC 770)

Deviation

Reference conditions acc. to IEC 770

- temperature 15°C … 35°C

- moisture 45 % … 75 %

- air pressure 860 mbar … 1060 mbar

Determination of characteristics limit point adjustment acc. to DIN 16 086

Characteristics linear

Deviation in characteristics

Hysteresis

Repeatability

1)

1)

Influence of the ambient temperature in general

Average temperature coefficient

of the zero signal

1) 2)

1)

< 0.25 % with accuracy class 0.25

< 0.02 % ceramic measuring cell

< 0.05 % metallic measuring cell

< 0.02 % ceramic measuring cell

< 0.05 % metallic measuring cell

< 0.15 %/10 K with accuracy class 0.25

1)

Relating to the nominal measuring range.

2)

In the compensated temperature range of 0°C … +80°C, reference temperature 20°C.

8 Pressure transmitters D76 and D77

Page 9

Product description

Long-term stability

Longterm drift of the zero signal

1)

- D76 (ceramic measuring cell) < 0.1 %/year

- D77 (metallic measuring cell) < 0.25 %/year

Other actuating variables

Calibration position upright, diaphragm points downwards

Influence of the mounting location

- ceramic measuring cell < 0.2 mbar

- metallic measuring cell < 5.0 mbar

Vibration resistance mechanical vibrations with 4 g and

5 … 100 Hz, tested acc. to the regulations of

German Lloyd, GL regulation 2

Operating conditions

Ambient conditions

Ambient temperature -40°C … +60°C

Storage and transport temperature -40°C … +60°C

Product temperature -40°C … +60°C

Protective measures

Transmitter IP 68

Housing

2)

IP 66 or IP 67, IP 68 (by fixed connected

PE-cable, cable length min. 5 m)

General data

Connection cables

Cable entry

- in connection housing 2 x M20 x 1.5 (for cable ø 5 … 9 mm)

- external housing VEGABOX 01 2 x M20 x 1.5 (for cable ø 5 … 9 mm)

Screw terminals

- terminal, adjustment insert for conductor cross-sections up to 2.5 mm

- external connection housing

VEGABOX 01 for conductor cross-sections up to 2.5 mm

1)

Acc. to IEC 770, item 6.1.2 relating to the nominal measuring range.

2)

Use of suitable seal in the PG is necessary for maintaining the housing protection IP 65 or IP 67.

Pressure transmitters D76 and D77 9

2

2

Page 10

Product description

Materials, wetted parts

Pressure transmitters D76

- transmitter stainless steel 1.4571

- diaphragm ceramic (99.9 % Oxideceramic)

- suspension cable PE-LD

cable bushing CSM

- measuring cell seal Viton

Pressure transmitters D77

- transmitter stainless steel 1.4571

- diaphragm Duratherm 600

- suspension cable PE-LD

cable bushing CSM

Materials, non-wetted parts

Pressure transmitters D76, D77

- housing Alu (sea-water resistant) and powder-

- straining clamp galvanised steel

- closing screw stainless steel 1.4305

Weight

Basic weight without housing

- D76 approx. 0.7 kg

- D77 approx. 0.7 kg

VEGABOX 01 approx. 400 g

Suspension cable approx. 0.1 kg/m

coated, stainless steel 1.4571

2.2 Approvals and certificates

Ex approvals

When using pressure transmitters in Ex areas, the instruments must be suitable and approved for these explosion zones and application areas. Special type approvals are available

for the use on ships. The suitability is checked by approval authorities and certified by approval documents. Please note the attached approval documents when using a sensor in Ex

areas.

Pressure transmitters D7. Ex are approved for Ex Zone 1.

CE conformity

Pressure transmitters D76 and D77 meet the protective regulations of EMC (89/336/EWG)

and NSR (73/23/EWG). Conformity has been judged acc. to the following standards:

EMC Emission EN 50 081 - 1: 1992

NSR EN 61 010: 1993

NAMUR regulations

Full compliance with the NAMUR regulations NE 21, May 1993.

10 Pressure transmitters D76 and D77

Susceptibility EN 50 082 - 2: 1995

Page 11

Product description

2.3 Dimensions

C1

52

1

1

R

49

175

41

14

25

X4 A4 V4

ø 8

SW 30

G 1½ A

A1, A2, B1, B2 C3 D3

66

ø 76

77

ø 41,6 ø 41,6 ø 41,6

39

20

77

SW 60 SW 60

G 1½ A

100

39

20

G4 N4

139

1½" NPT

D77: 247

D76: 230

ø 32

D77: 267

D76: 250

ø 32

D77: 285

D76: 268

ø 36

XVP

Pressure transmitters D76 and D77 11

Page 12

VEGABOX 01 (connection housing with breather facility)

85

108

118

135

38 72

ø 5

Zum Anschluss an

For connection to

Druckmessumformer mit

pressure transmitters with

analogem Ausgangsignal

analog output

-

+

-

TRANSMITTER

VEGABOX 01

+

M20 x 1.5 (cable ø 5 … 9 mm)

with optional protective cover

Product description

72100

139

12 Pressure transmitters D76 and D77

130

Page 13

Mounting

3 Mounting

3.1 Mounting instructions

Cable entry

The pressure transmitters can be mounted in

any position. Cable entries must point downwards to avoid moisture ingress. For this

purpose, the housing can be rotated by 330°

in relation to the mounting part.

A seal, appropriate for connection, must be

used for mounting. This seal is either supplied with the pressure transmitter or must be

provided by the customer.

3.2 Compensation of the atmospheric pressure

On instruments for gauge pressure measurement, the atmospheric pressure is compensated in different ways, depending on the

pressure transmitter version.

Pressure transmitters with housing

- via an integrated breather facility below the

cable entry (PTFE insert

IP 66

- via the capillary tubes of the special ca-

2)

ble

, used with the pressure transmitter,

protection IP 67

Pressure transmitters with direct cable

outlet

- via the capillary tubes of the connected

special cable

2)

, protection IP 68

External housing VEGABOX 01

We recommend leading the special cable to

the external housing VEGABOX 01 (accessory) and carrying out the pressure compensation via the integrated breather facility.

Keep the following instructions in mind:

- the same atmospheric pressure as on the

pressure transmitter must also be present

on the external housing VEGABOX 01

- the pressure compensation must be made

in a dry environment

- for vertical wall mounting, the cable entries

must point downwards to avoid moisture

ingress.

1)

), protection

1)

Air permeable and moisture-blocking

2)

Cable length 5 m (supplied cable)

Pressure transmitters D76 and D77 13

Page 14

4 Electrical connection

Electrical connection

4.1 Connection instructions

The electronics in the pressure transmitter

requires a supply voltage of 12 … 36 V DC. It

is provided by two-wire technology, i.e. supply voltage and measuring signal are transmitted via the same two-wire connection

cable.

The supply voltage is provided via a power

supply unit, e.g.:

- power supply unit VEGASTAB 690

- processing unit with integrated DC current

source (e.g. active PLC input)

- VEGAMET, VEGALOG or VEGADIS 371

Make sure that the supply voltage is reliably

separated from the mains circuits acc. to DIN

VDE 0106, part 101. VEGA instruments meet

this requirement and protection class III is

therefore ensured.

The terminal voltage on the transmitter depends on the following factors:

- output voltage U

under nominal load.

- electrical resistance of the connected instruments in the circuit.

Note the following instructions for electrical

connection:

- Connection must be made according to the

specific installation standards (e.g. in Germany acc. to the VDE regulations).

- Terminal voltage must not exceed 36 V, to

avoid damage to the electronics.

- Electrical connection must have a preventative measure against inadvertent

polarity reversal.

- The pressure transmitter can be connected

with standard two-wire cable.

- Screened cable is recommended, if strong

electromagnetic interference is to be expected. The screening must be grounded

at both ends. Please note the installation

regulations for mounting in Ex areas.

of the power supply

H

- If overvoltages are expected, we recommend pressure transmitters with integrated

overvoltage arrester or the installation of

VEGA overvoltage arresters.

- In the cable connection, a seal must be

used which fits the cable.

Safety information for Ex applications

As a rule, do all work in the complete absence of line voltage. Always switch off the

power supply before you carry out connecting work on the sensors. Protect yourself and

the instruments.

Qualified personnel

Instruments which are operated in Ex areas,

must be connected only by qualified personnel. The qualified personnel must observe

and understand the installation regulations

and the attached type approval and conformity certificates.

In hazardous areas, the required regulations

and conformity and type approval certificates

of the sensors and separators or safety

barriers must be observed (e.g. DIN VDE

0165). Sensors used in Ex areas must be

operated only on intrinsically safe circuits.

The permissible electrical values are stated in

the type approval or conformity certificate.

Intrinsically safe circuits with more than one

active instrument (delivering electrical en-

14 Pressure transmitters D76 and D77

Page 15

Electrical connection

ergy) must not connected in series. The

special installation regulations (DIN VDE

0165) must be observed.

Pressure transmitters in certain versions are

equipped with a warning label, informing of

measures to be taken to avoid electrostatic

discharge. Keep the contents of the warning

label in mind.

Connection cable

Make sure that the connection cable is specified for the expected operating temperatures

in your systems. The cable must have an

outer diameter of 5 … 9 mm. Otherwise the

seal effect of the cable connection will not be

ensured.

Cables for intrinsically safe circuits must be

marked with a blue colour and must not be

used for other circuits.

Direct cable outlet

4.2 Terminal assignment

Screen

Breather capillaries

Suspension

cable

12 … 36 V DC

br

+

for supply or to the process-

bl

ing system (4 … 20 mA)

-

ge

only used in conjunction with

VEGADIS 12, if not used,

connect to minus

Electronics version A

5 … 19 mA output signal for connection to

VEGA signal conditioning instruments

Zum Anschluss an

For connection to

VEGA-Auswertgeräte

VEGA-signal conditioning instruments

51234

-

+

Klemmeinsatz

terminal

-

Control instrument

(5 … 19 mA measurement)

+

Supply or for evaluation

+

of VEGAMET signal

conditioning instrument

-

12 … 36 V DC

Electronics version C

4 … 20 mA output signal

4-20mA

-

+

4...20mA

12V...36V DC

Klemmeinsatz

terminal

51234

+

Control instrument

4 … 20 mA

-

-

Power supply

12 … 36 V DC

+

Electronics version D

4 … 20 mA output signal with integrated

adjustment

S

Zt

+

-

4...20mA

12V...36V DC

Bedieneinsatz

operating unit

Op

i

43215

-

Control instrument

4 … 20 mA

+

-

Power supply

12 … 36 V DC

+

Electronics version E

4 … 20 mA output signal with operatability

from VEGADIS 12

Zum Anschluss an

For connetction to

VEGADIS 12

51234

-

+

12V...36V DC

Klemmeinsatz

terminal

Terminal assignment

Ground, cable screen

1 Power supply [+]

2 Power supply [–]

3 Control instrument [–] / VEGADIS 12

4 not assigned, connect via wire bridge

5 not assigned, connect via wire bridge

ge

for indicating instru-

-

ment VEGADIS 12

+

Pressure transmitters D76 and D77 15

Page 16

4.3 Connection to VEGABOX 01

Pressure transmitters with direct

cable outlet

Screen

Pressure transmitters with

terminal insert in housing

Breather capillaries

Suspension cable

br

+

bl

-

ge

Zum Anschluss an

For connection to

Druckmessumformer mit

pressure transmitters with

analogem Ausgangssignal

analog output

1

231011 12

TRANSMITTER

VEGABOX 01

-

+

-

+

Electrical connection

For supply or to the

+

processing system

-

(4 … 20 mA,

12 … 36 V DC)

4-20mA

-

+

4...20mA

12V...36V DC

Klemmeinsatz

terminal

+

-

51234

+

Control instrument

-

(4 … 20 mA measurement)

4.4 Connection examples

The following connection examples are valid for direct connection to the terminals of the pressure transmitter. When using the external connection housing, the connection is made to the

respective terminals of the housing.

Powered by a power supply unit

Processing via an indicating instrument.

Ammeter for local control

analogue / digital indicat-

+ - -

1 2 3

Pressure transmitter

terminals

U

K

ing instrument

U

4 … 20 mA

External energy source

A

-

U

H

~

+

16 Pressure transmitters D76 and D77

Page 17

Electrical connection

Powered by a VEGA signal conditioning instrument

Standard wiring for nonstandardized output.

Ammeter for local control

+ - -

1 2 3

Pressure transmitter

terminals

U

K

Analogue transmission, not

standardised

0/4 … 20 mA

U

H

DISBUS

!

Powered by a PLC with active input circuit

Processing via PLC.

Ammeter for local control

+ - -

Pressure transmitter

terminals

PLC

1 2 3

U

K

4 … 20 mA

U

-

H

+

Note:

An ammeter for local control of the output current can be connected to terminals 1 and 3. This

measurement can be carried out during operation, without interrupting the supply cable.

Pressure transmitters D76 and D77 17

Page 18

5 Setup

Setup

5.1 Sensor without adjustment

Sensors with electronics version A and C

have no adjustment possibility and are permanently adjusted to the stated measuring

range.

5.2 Adjustment with the adjustment insert in the sensor

Sensors with electronics version D are

equipped with a 2-key adjustment insert.

1

2

3

S

Zti

+

Op

-

Procedure

• Select the required function with the rotary

switch.

• With the "+“ and "–“ key you modify the

signal current to the required values or set

the suitable integration time.

• Then, you set the rotary switch to position

"OPERATE“. The set values are transferred

to the EEPROM memory and remain there

even in case of voltage failure.

Adjustment

For adjustment of zero and span, first of all

connect terminals 1 and 3 to an ammeter. The

measured value is identical to the output

current.

First of all adjust zero (empty vessel)

• Set the rotary switch to "zero“. Empty the

vessel.

• Adjust a current of 4 mA by pushing the "+“

and "–“ keys.

The adjustment range of zero can be between -20 % and +95 % of the nominal measuring range.

12345

+-

4...20mA

12...36 V DC

Then adjust span (full vessel)

• Set the rotary switch to "span“. Completely

fill the vessel.

• Adjust a current of 20 mA by pushing the

"+“ and "–“ keys.

The adjustment range of span can be between 3.3 % and 120 % of the nominal meas-

1 Reduce value

2 Rotary switch

3 Increase value

uring range.

With the rotary switch you can select four

switch positions:

S - Span (pressure measuring range)

Z - Zero (zero adjustment)

ti - Time (integration time)

Op - Operate (operating status)

18 Pressure transmitters D76 and D77

Page 19

Setup

Adjustment information:

- A modification of zero does not influence

the adjusted span.

- It is also possible to adjust currents for

partial fillings, e.g. 8 mA for 25 % and

16 mA for 75 %. Then the electronics automatically calculates the current values for

0 % and 100 % (only possible with a difference ³ 3.3 %).

- If the current values react to the key pressing with a time delay, there can be two

reasons:

- the last adjustment was carried out with a

level deviating considerably from the

actual level.

Integration time

For damping level fluctuations, an integration

time ti of 0 … 10 sec. can be adjusted.

Adjust integration time

• Set rotary switch to "ti“.

• By pressing the "-“ key 10 times make sure

that the integration time is set to 0 sec.

• Per 1 sec. requested integration time, the

"+“ key has to be pushed once.

The integration time is the time required by

the current output signal to reach 90 % of the

actual level after a sudden change of the

level.

Pressure transmitters D76 and D77 19

Page 20

6 Diagnostics

Diagnostics

6.1 Maintenance

Pressure transmitters D76 and D77 are maintenance-free.

6.2 Failure rectification

Due to continuous self-monitoring, series D70

pressure transmitters offer maximum reliability. However, should failures occur, check the

following before removing the pressure

transmitter:

- the atmospheric pressure compensation,

- the electrical connections.

Checking atmospheric pressure compensation

First open the cover of the housing, in which

the atmospheric breather facility is located.

The displayed measured value must not

change. However, if the displayed value

changes, compensation of the atmospheric

pressure is not ensured, which will lead to

distortion of the measured value. Therefore

check:

- the breather facility on the housing

- VEGADIS 12 or VEGABOX 01

- the capillary tubes in the special cable.

Note:

There must always be the same atmospheric

pressure on the breather facility as in the

open vessel.

Checking electrical connections

Pressure transmitter

terminals

1 2 3

mA

Current

Voltage Current

V

mA

External

energy source

-

~

+

Voltage

- the terminal voltage on the pressure transmitters must be at least 12 V DC

Current

Current value Condition

3.8 … 20.5 mA standard range for the output

0 mA signal cable interrupted

< 3.6 mA sensor electronics or pressure

22 mA sensor electronics or pressure

Note for Ex applications

Deviating from above regulation, here terminals 1 and 3 (on VEGADIS 12 terminals 10

and 12) are used only for brief connection to

a certified active, floating measuring instrument (max. value: 470 mW) or an individual

passive, floating ammeter. When connecting,

the regulations for wiring of intrinsically safe

circuits (measuring instrument, supply and

signal circuit) have to be observed.

current

sensor element defective

sensor element defective

20 Pressure transmitters D76 and D77

Page 21

Instrument modification

7 Instrument modification

7.1 Retrofitting of adjustment insert

Such a retrofitting can be necessary, e.g. if

you want to adapt a pressure transmitter to

different measurement conditions.

Remove existing terminal insert

1 Disconnect pressure transmitter from

power supply.

2 Unscrew cover of the connection hous-

ing.

3 Remove cover.

4 Pull out connection cables from the termi-

nal insert.

5 Loosen the three screws on the terminal

insert.

6 Remove terminal insert and plug connec-

tion (carefully bend the locking clip to-

ward the centre of the housing).

Fitting new adjustment insert

7 Push plug connection into the adjustment

insert (must snap in).

8 Place adjustment insert in the housing

and fasten with three screws.

9 Reconnect the connection cables to the

terminals.

10 Fasten the cover.

11 Reconnect the pressure transmitter to

power supply.

For setup of pressure transmitters, see

chapter "5 Setup“.

Pressure transmitters D76 and D77 21

Page 22

Notes

22 Pressure transmitters D76 and D77

Page 23

Notes

Pressure transmitters D76 and D77 23

Page 24

VEGA Grieshaber KG

Am Hohenstein 113

D-77761 Schiltach

Phone (0 78 36) 50 - 0

Fax (0 78 36) 50 - 201

e-mail info@vega-g.de

ISO 9001

The statements on types, application, use and operating conditions of

the sensors and processing systems correspond to the latest information at the time of printing.

Technical data subject to alterations

2.22 064 / March 2000

Loading...

Loading...