Page 1

Operating Instruction

Conductive electrodes

Level and Pressure

5

100

1

5

10

0

2

on

532 Ex

Page 2

Safety information

Safety information

The described module must only be installed

and operated as described in this operating

instruction. Please note that other action can

cause damage for which VEGA does not take

responsibility.

2 Conductive measuring system

Page 3

Contents

Contents

Safety information ........................................................................ 2

1 Product description

1.1 Function and configuration .................................................. 4

1.2 Types and version ............................................................... 4

1.3 Technical data....................................................................... 5

1.4 Dimensions ......................................................................... 14

1.5 Approvals ........................................................................... 18

2 Mounting instructions

2.1 Conductive electrodes ...................................................... 19

2.2 VEGATOR 256C ................................................................. 20

2.3 VEGATOR 532 Ex ............................................................... 20

2.4 VEGATOR 631 Ex ............................................................... 22

3 Electrical connection

3.1 VEGATOR 256C ................................................................. 23

3.2 VEGATOR 532 Ex ............................................................... 23

3.3 VEGATOR 631 Ex ............................................................... 25

4 Set-up

4.1 VEGATOR 256C ................................................................. 27

4.2 VEGATOR 532 Ex ............................................................... 28

4.3 VEGATOR 631 Ex ............................................................... 32

5 Diagnosis

5.1 Fault signal on VEGATOR 532 Ex ..................................... 36

5.2 Fault signal on VEGATOR 631 Ex ..................................... 37

Conductive measuring system 3

Page 4

1 Product description

Product description

1.1 Function and configuration

The conductive measuring principle is used

for level detection of conductive liquids.

Function

When the probe (s) is covered by the

medium, conductive electrodes detect the

product resistance.

A low alternating current flows which is

measured by the electronics of the signal

conditioning instrument on amplitude and

phase position and converted into a

switching command.

The switching signal is determined by the

length or the mounting position of the

appropriate electrode (s).

Configuration

One or two conductive electrodes and a

signal conditioning instrument VEGATOR

256C, 532 Ex or 631 Ex are required to

implement a measuring system.

1.2 Types and version

VEGATOR 256C and electrode

Application:

- level detection, pump control (Min-Max)

Series:

- module unit

Power supply:

- 200 … 250 V AC

- 24 V, 42 V, 48 V, 100 … 130 V AC

Input:

- 1 channel for probes with 1 … 3 electrodes

Output:

- 1 relay (spdt)

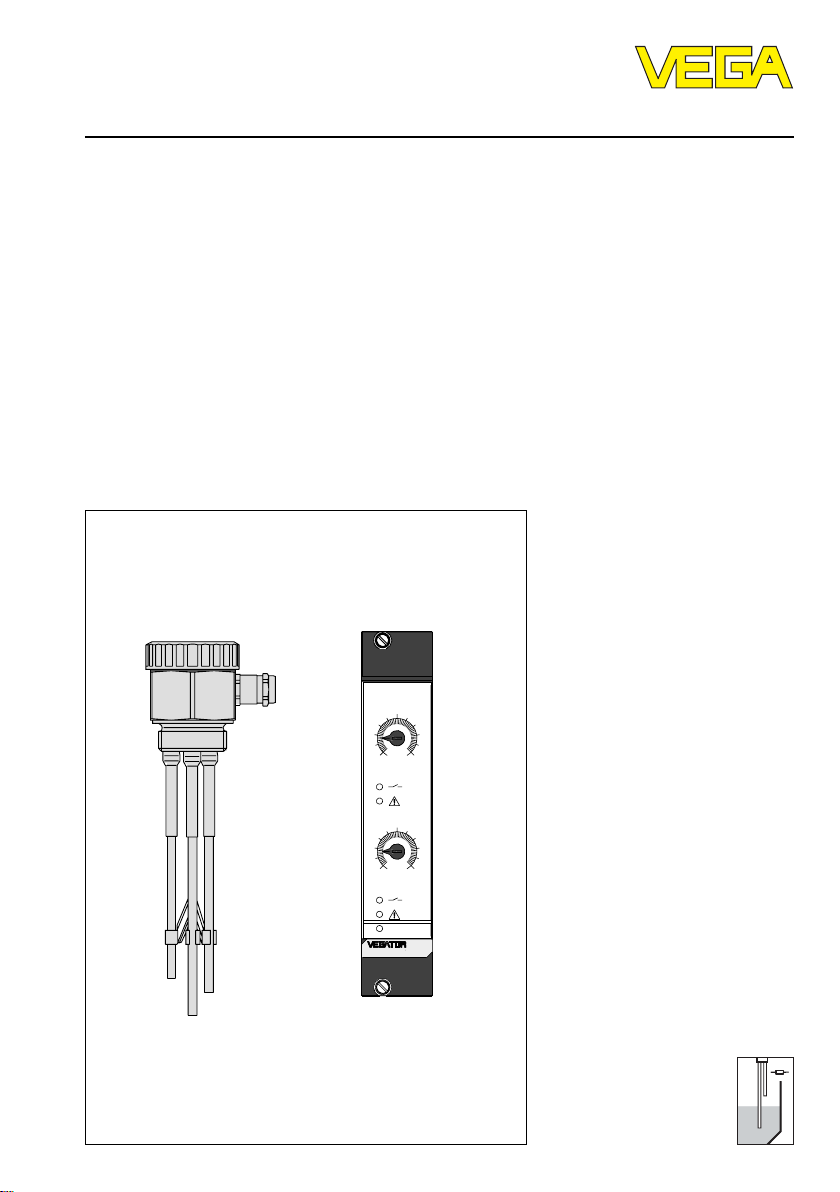

VEGATOR 532 Ex and electrode

Application:

- 2 level detections, pump controls

(Min-Max)

Series:

- 19"-module card, 5 TE

Power supply:

- 20 … 53 V AC

- 20 … 72 V DC

Inputs:

- 2 channels for probes with 1 … 5

electrodes

Outputs:

- 2 relays (1 spdt each)

- 2 transistors

Classification:

- [EEx ia] IIC

Approvals:

- CENELEC

- WHG

Fault monitoring:

- detection of line break

VEGATOR 631 Ex and electrode

Application:

- level detection, pump control (Min-Max)

Series:

- module unit

Power supply:

- 20 … 250 V AC

- 20 … 72 V DC

Input:

- 1 channel for probes with 1 … 3 electrodes

Output:

- 1 relay (1 spdt)

- 1 transistor

Classification:

- [EEx ia] IIC

Approvals:

- CENELEC

- WHG

Fault monitoring:

- detection of line break

4 Conductive measuring system

Page 5

Product description

1.3 Technical data

Conductive electrodes

Conductive electrode type EL 1 and EL 2

Material

- connection housing 1.4571

- thread 1.4571

- welded socket (only with type EL 2) 1.4571

- rod electrode 1.4571 or Hastelloy C4

- isolation of the rod electrode PTFE

Size of the thread G

Length of the rod electrode

- type EL 1 40 … 4000 mm

- type EL 2 60 … 2000 mm

Protection IP 67

Temperature range -50°C … +130°C

Max. permissible vessel pressure 63 bar

Electrical connection Pg 11

Basic weight

- type EL 1 approx. 0,4 kg

- type EL 2 approx. 0,7 kg

Additional weight of the rod electrode approx. 0,04 kg per 100 mm

Conductive rod electrode type EL 1 Ex and EL 2 Ex

Temperature range -20°C … +100°C

Classification EEx ia IIC T6

Max. permissible ambient temperature

- temperature class T6 85°C

- temperature class T5 100°C

all other technical data like EL 1 and EL 2

1

/2 A

Conductive multiple rod electrode type EL 3 (2 … 5 rod electrodes)

Material

- connection housing 1.4571

- thread 1.4571

- rod electrodes 1.4571, Hastelloy C4 or Titanium

- isolation of the rod electrodes PTFE

- distance holder PP

Size of the thread G 1

1

/2 A

Length of the rod electrodes 100 … 4000 mm

Number of rod electrodes 2 … 5

Protection IP 67

Temperature range -50°C … +130°C

Max. permissible vessel pressure 63 bar

Electrical connection Pg 16

Basic weight approx. 0,9 kg

Additional weight of the rod electrodes approx. 0,04 kg per 100 mm

Conductive measuring system 5

Page 6

Conductive multiple rod electrode type EL 3 Ex (2 … 5 rod electrodes)

Temperature range -20°C … +100°C

Classification EEx ia IIC T6

Max. permissible ambient temperature

- temperature class T6 85°C

- temperature class T5 100°C

all other technical data like type EL 3

Conductive multiple rod electrode type EL 4 (2 … 5 rod electrodes)

Material

- connection housing PP

- thread PP

- rod electrodes 1.4571, Hastelloy C4 or Titanium

- isolation of the rod electrodes PP

- distance holder PP

Size of the thread G 1

1

/2 A

Length of the rod electrodes 100 … 4000 mm

Number of rod electrodes 2 … 5

Protection IP 67

Temperature range -20°C … +100°C

Max. permissible vessel pressure 6 bar

Electrical connection Pg 16

Basic weight approx. 0,4 kg

Additional weight of the rod electrodes approx. 0,04 kg per 100 mm

Conductive multiple cable electrode type EL 5 (2 … 5 cable electrodes)

Material

- connection housing 1.4571

- thread 1.4571

- cable electrodes 1.4571

- isolation of the cable electrodes PTFE / FEP

- gravity weight 1.4571

Size of the thread G 1

1

/2 A

Length of the cable electrodes 300 … 20000 mm

Number of cable electrodes 2 … 5

Protection IP 67

Temperature range -50°C … +100°C

Max. permissible vessel pressure 63 bar

Electrical connection Pg 16

Basic weight approx. 1 kg

Additional weight of the cable electrodes approx. 0,01 kg per 100 mm

Product description

Conductive multiple cable electrode EL 5 Ex (2 … 5 cable electrodes)

Temperature range -20°C … +100°C

Classification EEx ia IIC T6

Max. permissible ambient temperature

- temperature class T6 85°C

- temperature class T5 100°C

all other technical data like type EL 5

6 Conductive measuring system

Page 7

Product description

Conductive multiple cable electrode type EL 6 (2 … 5 cable electrodes)

Material

- connection housing PP

- thread PP

- cable electrodes 1.4571

- isolation of the cable electrodes PP / FEP

- gravity weight 1.4571

Size of the thread G 1

1

/2 A

Length of the cable electrodes 300 … 20000 mm

Number of cable electrodes 2 … 5

Protection IP 67

Temperature range -20°C … +120°C

Max. permissible vessel pressure 6 bar

Electrical connection Pg 16

Basic weight approx. 0,5 kg

Additional weight of the cable electrodes approx. 0,01 kg per 100 mm

Conductive rod electrode type EL 8

Material

- connection housing plastic

- thread 1.4305

- rod electrode 1.4571

- isolation of the rod electrode PE

Size of the thread G

1

/2 A

Length of the rod electrode 30 … 1000 mm

Protection IP 50

Temperature range -10°C … +60°C

Max. permissible vessel pressure 6 bar

Basic weight approx. 0,1 kg

Additional weight of the rod electrode approx. 0,04 kg per 100 mm

Conductive cable electrode type EL 9

Material

- connection housing 1.4571

- thread 1.4571

- cable electrode 1.4571

- isolation of the cable electrode FEP

- gravity weight 1.4571

Size of the thread G

1

/2 A

Length of the cable electrode 500 … 25000 mm

Protection IP 67

Temperature range -50°C … +100°C

Max. permissible vessel pressure 63 bar

Electrical connection Pg 11

Basic weight approx. 0,6 kg

Additional weight of the cable electrode approx. 0,01 kg per 100 mm

Conductive measuring system 7

Page 8

Conductive cable electrode type EL 9 Ex

Temperature range -20°C … +100°C

Classification EEx ia IIC T6

Max. permissible ambient temperature

- temperature class T6 85°C

- temperature class T5 100°C

all other technical data like type EL 9

Signal conditioning instrument VEGATOR 256C

General

Series module unit

Mounting 2 holes for M3 or carrier rail mounting

acc. to DIN 46 277, Bl. 3

Dimensions W = 37 mm, H = 69 mm, D = 80 mm

Weight approx. 160 g

Power supply

Operating voltage

- standard 200 … 250 V AC, 50/60 Hz

- option 24 V, 42 V, 48 V, 100 … 130 V AC

+10 %, –15 %, 50/60 Hz

Power consumption 1 VA

Product description

Measuring data input

Number 1 (1 x level detection or

Response resistor 1 … 200 kOhm adjustable

Meas. circuit approx. 12 V eff, approx. 1 mA

Switching hysteresis approx. 20 %

Relay output

Number 1 (1 x level detection)

Mode overfill protection (A)

Contact spdt

Contact material

Turn-on voltage min. 10 mV

Switching current min. 10 µA

Breaking capacity max. 750 VA or 54 W

Integration time

Fixed value approx. 500 ms

8 Conductive measuring system

1 x pump control -Min-Max.)

max. 250 V AC or 250 V DC

max. 5 A AC or 1 A DC

Page 9

Product description

Ambient conditions

Permissible operating temperature -20°C … +50°C

Storage and transport temperature -40°C … +70°C

Electrical protective measures

Protection IP 20

Protection class II

Electrical connection

Screw terminal max. for 1,5 mm

2

CE-conformity

VEGATOR 256C signal conditioning instrument meets the protective regulations of EMVG

(89/336/EWG) and NSR (72/23/EWG). The conformity has been judged acc. to the following

standards:

EMVG Emission EN 50 081 - 1

Susceptibility EN 50 082 - 2

NSR EN 61 010 - 1

Signal conditioning instrument VEGATOR 532 Ex

General

Series 19"-module card, multipoint connector acc. to

Dimensions B = 25,4 mm (5 TE), H = 128,4 mm, D = 162 mm

Weight approx. 170 g

DIN 41 612 incl. transparent cover

Power supply

Operating voltage 20 … 53 V AC, 50/60 Hz

20 … 72 V DC

Power consumption max. 2 W, 3 VA

Fuse

- supply range T 1 A, 250 V

- switching power min. 35 A at 250 V AC or 125 V DC

Measuring data input (channel)

Number 2 (2 x level detection or

2 x pump control -Min-Max)

Response resistor 1 … 200 kOhm adjustable

Parallel resistor

- for fault monitoring 220 kOhm

Meas. circuit max. 5 V eff, max. 1 mA

Permissible line capacitance 1 x 100 nF or

2 x 70 nF with Min-Max.-control

Switching hysteresis approx. 15 %

Conductive measuring system 9

Page 10

Product description

Measuring data input, Ex-technical data

Signal circuits in classification intrinsic safety EEx ia IIC

Max. values

-U

O

-I

K

- P 20 mW

10,6 V

8 mA

Characteristics linear

Inner effective inductance negligible

Inner effective capacitance negligible

Max. permissible outer inductance 5 mH

Max. permissible outer capacitance 570 nF

The intrinsically safe circuits are reliably galvanically separated from the not-intrinsically

safe circuits up to a peak value of the nominal voltage of 375 V.

The intrinsically safe circuits of channel 1 and channel 2 are reliably galvanically isolated.

Relay outputs

Number 2

Mode overfill protection (A) and dry run protection (B)

changeover for each output (channel) separately

Contact 1 spdt per output

Contact material AgCdO and Au plated

Turn-on voltage min. 10 mV

max. 250 V AC or 250 V DC

Switching current min. 10 µA

max. 3 A AC or 1 A DC

Breaking capacity max. 750 VA or 54 W

Transistor outputs

Number 2 (synchronously switching with relay outputs)

Galvanic isolation floating

Turn-on voltage U

Switching current IB = max. 60 mA

Voltage loss on the transistor U

Blocking current I

= max. 36 V DC

B

= approx. 1,5 V at IB = 60 mA

CE

< 10 µA

O

Integration time

Fixed value approx. 500 ms

Ambient conditions

Permissible ambient temperature -20°C … +60°C

Storage and transport temperature -40°C … +70°C

10 Conductive measuring system

Page 11

Product description

Electrical protective measures

Protection

- not mounted IP 00

- mounted into

carrier BGT 596 Ex front side completely equipped IP 30

upper and lower side IP 20

wiring side IP 00

- mounted into

housing type 505 Ex IP 30

Protection class II

Overvoltage category II

Electrical connection

Mounted into

- carrier BGT 596 Ex 33-pole multipoint connector, series F (d, b, z)

- housing type 505 Ex screw terminal, max. for 1,5 mm

with coding holes

2

CE-conformity

VEGATOR 532 Ex signal conditioning instrument meets the protective regulations of EMVG

(89/336/EWG) and NSR (72/23/EWG). The conformity has been judged acc. to the following

standards:

EMVG Emission EN 50 081 - 1

Susceptibility EN 50 082 - 2

NSR EN 61 010 - 1

Signal conditioning instrument VEGATOR 631 Ex

General

Series module unit with plug-in socket including

Dimensions W = 36 mm, H = 118,5 mm, D = 134 mm

Weight approx. 170 g

Mounting carrier rail mounting acc. to DIN 46 277, Bl 3

Power supply

Operating voltage 20 … 250 V AC, 50/60 Hz

Power consumption max. 1,5 W, approx. 1 … 9 VA

Fuse

- supply range T 315 mA, 250 V

- switching power min. 35 A at 250 V AC or 125 V DC

Conductive measuring system 11

transparent cover, cover of the probe

terminals,

coded pin, 2 bridges

20 … 72 V DC

Page 12

Product description

Measuring data input (channel)

Number 1 (1 x level detection or

1 x pump control -Min-Max)

Response resistance 1 … 200 kOhm adjustable

Parallel resistance

- for fault monitoring 220 kOhm

Meas. circuit max. 5 V eff, max. 1 mA

Permissible line capacitance 1 x 100 nF or

2 x 70 nF at Min-Max.-control

Switching hysteresis approx. 15 %

Measuring data input, Ex-technical data

Signal circuit in classification intrinsic safety EEx ia IIC

Max. values

-U

O

-I

K

- P 20 mW

10,6 V

8 mA

Characteristics linear

Inner effective inductance negligible

Inner effective capacitance negligible

Max. permissible outer inductance 5 mH

Max. permissible outer capacitance 570 nF

The intrinsically safe circuits are reliably galvanically isolated from the not-intrinsically safe

circuits up to a peak value of the nominal voltage of 375 V.

Relay outputs

Number 1

Mode overfill protection (A) and dry run protection (B)

changeable

Contact 1 spdt per output

Contact material AgCdO and Au plated

Turn-on voltage min. 10 mV

max. 250 V AC or 250 V DC

Switching current min. 10 µA

max. 3 A AC or 1 A DC

Breaking capacity max. 750 VA or 54 W

Transistor outputs

Number 1 (synchronuously switching with relay outputs)

Galvanic isolation floating

Turn-on voltage U

Switching current I

Voltage loss on transistor U

Blocking current IO < 10 µA

= max. 36 V DC

B

= max. 60 mA

B

= approx. 1,5 V at IB = 60 mA

CE

Integration time

Adjustable 0,2 … 20 s

12 Conductive measuring system

Page 13

Product description

Ambient conditions

Permissible operating temperature -20°C … +60°C

Storage and transport temperature -40°C … +70°C

Electrical protective measures

Protection IP 20

Protection class II

Overvoltage category II

Electrical connection

Screw terminals max. for 1,5 mm

2

CE-conformity

VEGATOR 631 Ex signal conditioning instrument meets the protective regulations of EMVG

(89/336/EWG) and NSR (72/23/EWG). The conformity has been judged acc. to the following

standards:

EMVG Emission EN 50 081 - 1

Susceptibility EN 50 082 - 2

NSR EN 61 010 - 1

Conductive measuring system 13

Page 14

1.4 Dimensions

Conductive electrodes

Type EL 1 (Ex) Type EL 2 (Ex)

~43

ø46

~43

ø46

Product description

56

18

L (max. 4000 mm)

SW 41

G 1/2 A

ø10

ø8

Pg 11

~114

60

Pg 11

SW 41

ø34

ø10

ø11

Type EL 3 (Ex) Type EL 4

SW 60

58

~58

ø66

Pg 16

20

1

/2 A

G 1

SW 60

54

22

78

ø66

~58

G 1

1

Pg 16

/2 A

L1

L3

L2

L1

L3

L2

ø6

L1 = Longest rod electrode, L2 = Shortest rod electrode

L1 = Longest rod electrode, L2 = Shortest rod electrode

ø4

14 Conductive measuring system

Page 15

Product description

Type EL 5 (Ex) Type EL 6

SW 60

~58

ø66

SW 60

~58

ø66

58

Pg 16

20

1

/2 A

65

ø2,5

G 1

PTFE

1.4571

FEP

L3

L2

L1

80

L1 = Longest cable electrode, L2 = Shortest cable electrode

54

Pg 16

22

G 1

1

/2 A

78

PP

ø2,5

1.4571

FEP

L1 = Longest cable electrode, L2 = Shortest cable electrode

L3

L2

L1

Conductive measuring system 15

Page 16

Type EL 8 Type EL 9 (Ex)

ø24

9,3

30

12

27

L (max. 1000 mm)

SW 24

56

ø6,8

ø4

ø46

18

80

40

Product description

~43

Pg 11

SW 41

G 1/2 A

ø10

VEGATOR 256C

66

L

ø4,6

200

ø15

4

min.

1

max.

2

3

10

0

68

4

5

200...250VAC 3VA

6

R

L1

N

ax 250V,5A,750VA

7

power supply

Relais: m

8

37

22

60

7,5

16 Conductive measuring system

Page 17

Product description

VEGATOR 532 Ex

5,5

9

15

3

VEGATOR 631 Ex

162

Carrier rail 35 x 7,5 or

35 x 15 acc. to EN 50 022

Multiple plug

5 TE

100

on

25,4

128,4

Transparent cover

12 34

5

118,5

010

on

54,5

134

631Ex

56 78

9 1011121314

36

Conductive measuring system 17

Page 18

Product description

1.5 Approvals

If measuring systems are installed according to the following approvals, the appropriate legal

documents and their regulations must be noted. The documents are supplied with the

appropriate measuring system.

WHG-approval

Signal conditioning instrument VEGATOR 532 Ex, VEGATOR 631 Ex, (VEGATOR 535 Ex)

together with conductive electrodes type EL 1 Ex, EL 2 Ex, EL 3 Ex, EL 5 Ex, EL 9 Ex as part

of an overfill protection acc. to WHG, no. Z-65.13-7.

Ex-approval

For measuring systems in hazardous areas, certificate acc. to CENELEC.

Conductive electrodes

- Type EL 1 Ex

- Type EL 3 Ex (2 … 5 rod electrodes)

- Type EL 5 Ex (2 … 5 cable electrodes)

- Type EL 9 Ex

defined in conformity certificate PTB-no. Ex-93.C.4048 X

Signal conditioning instrument VEGATOR 532 Ex

Conformity certificate PTB-no. Ex-96.D.2055 X

Signal conditioning instrument VEGATOR 631 Ex

Conformity certificate PTB-no. Ex-96.D.2064

CE-approval

- VEGATOR 256C

- VEGATOR 532 Ex

- VEGATOR 631 Ex

see the appropriate technical data

18 Conductive measuring system

Page 19

Mounting instructions

2 Mounting instructions

2.1 Conductive electrodes

General

When mounting the electrodes it should be

noted that the rod or cable electrodes do not

touch the vessel wall.

Lateral load

Note that the electrode is not subjected to

strong lateral forces.

Mount the electrode on a position in the

vessel where no interferences such as e.g.

by stirrers, vessel openings etc. occur. This

is mainly valid for very long rod and cable

electrodes.

If a modification of the installation place

should not be possible for you, it would be

necessary that the rod or cable electrodes

must be stabilized by an isolated holder.

Pressure

In case of gauge or low pressure in the

vessel, the mounting boss must be sealed on

the thread. Use the attached seal ring. Check

if the seal ring is resistant against the

medium.

Note for electrodes with earth rod (e.g. EL 1,

EL 2, EL 8) that the thread of the electrode is

electrically conductive connected with the

vessel to ensure a sufficient ground.

Use conductive seals such as e.g. copper,

lead etc. Isolating measures such as e.g.

covering the thread with Teflon tape or a

paper seal can interrupt the necessary

electrical connection.

In this case connect the earth connection

terminal on the electrode housing via an

external earth cable to the vessel.

Ex-measuring systems

Important instruction for multiple rod or multiple cable electrodes type … Ex, VEGATOR

532 Ex and VEGATOR 631 Ex. To implement

a line monitoring, a resistor of 220 kOhm is

mounted between terminal 1 and terminal 2 in

the connection housing. Please note that in

case you want to adap the rod or cable

electrode by yourself, i.e. shortening so that

L1 or terminal 1 corresponds to the longest

and L2 or terminal 2 to the shortest rod or

cable electrode (see also paragraph "Fault

signal").

Probe with 3 rod or cable

2

1

3

Conductive measuring system 19

electrodes

Page 20

Mounting instructions

4

60

7,5

22

Probe with 4 rod or cable

3

2

1

4

electrodes

Probe with 5 rod or cable

3

2

4

5

1

electrodes

2.2 VEGA TOR 256C

The signal conditioning instrument VEGATOR

256C can be either mounted directly to the

wall via two screws or plugged to a carrier

rail 35 x 7,5 acc. to DIN EN 50 022.

Carrier rail mounting

Place VEGATOR 256C from the bottom to the

carrier rail and push the instrument to the rail

until snap-in.

Wall mounting

Fasten the instrument directly to the wall by

means of two screws (ø max. 3 mm).

2.3 VEGA T OR 532 Ex

VEGATOR 532 Ex can be either mounted in a

single housing type 505 Ex or into a carrier

BGT 596 or BGT 596 Ex by means of a

module.

- Module consisting of:

Multipoint connector DIN 41 612, series F,

33-pole (d, b, z) with coded pin and

mounting material for mounting in carrier

BGT 596

- Ex-module consisting of:

Multipoint connector DIN 41 612, series F,

33-pole (d, b, z) with coded pins, Exseparating chamber and mounting material

for mounting in carrier BGT 596 Ex

- Single housing

Plastic housing type 505 Ex for single

mounting of signal conditioning instrument

with instrument width 5 TE (25,4 mm)

Mounting carrier

Mount the appropriate module (standard or

Ex-version) on your carrier BGT 596 or BGT

596 Ex. Wire the connection of the multipoint

connector acc. to section "3 Electrical

connection".

The multipoint connector is available as

follows:

- Wire-Wrap standard connection

1,0 x 1,0 mm

- Plug connection 2,8 x 0,8 mm

- Termi-Point standard connection

1,6 x 0,8 mm

- Soldering connection

- Screw terminals 2 x 0,5 mm

2

For further information concerning mounting

see the operating instruction of the carrier.

When mounting VEGATOR 532 with Exapproval into a carrier, you have to use a

VEGA-Ex-module. Keep a distance of at least

10 mm (2 TE) to instruments of other

manufacturers. When you want to mount

VEGATOR completely to the left in the carrier,

you have to mount a blind cover of at least

20 mm (4 TE) in front of the module of the

instrument.

20 Conductive measuring system

Page 21

o 31 o

o 29 o

o 27 o

o 25 o

o 23 o

o 21 o

o 19 o

o 15 o

o 11 o

o 7 o

o 3 o

o 1 o

o 5 o

o 9 o

o 13 o

o 17 o

a c

Mounting instructions

2

on

VEGATOR

Instrument type coding Function coding

c7 VEGATOR

VEGATOR 532 Ex a20

Blindcover

c23 Ex-module

card

Ex-separating chamber

To ensure sufficient "Air and creeping

distances" an Ex-separating chamber must

be mounted for the measuring data inputs in

case of Ex-applications. First of all loop the

lines through the Ex-separating chamber and

connect the lines. When using a multipoint

connector type "Screw terminals" the lower

wall on the Ex-separating chamber must be

broken away acc. to the notches. Fasten the

Ex-separating chamber with the lower screw.

Transparent cover

To protect the instrument against

unauthorized adjustment, the front plate of

VEGATOR 532 Ex can be provided with a

lockable transparent cover.

Note the operating instruction of the carrier.

Mounting single housing type 505 Ex

Coding

To exclude interchanging of the module card

VEGATOR 532 Ex, the multipoint connector of

the housing or the carrier rail is provided with

pins and the multiple plug of the module card

with holes (mechanical coding).

A function coding with fixed coded pin

ensures that not-Ex and Ex-module cards

The socket can be either screwed directly to

the mounting plate or plugged on a carrier

rail (TS 35 x 7,5 acc. to EN 50 022 or TS 32

acc. to EN 50 035).

Connect the terminals of the basic plate acc.

to paragraph "3 Electrical connection". Further information on mounting is stated in the

operating instruction of the housing.

are not interchanged.

An instrument coding with the coded pins

attached to the housing or module ensures

that the signal conditioning instruments are

not interchanged.

Insert the two coded pins into the determined

holes of the multipoint connector.

Conductive measuring system 21

Protection with Ex-applications

For Ex-applications a protection of IP 20 must

be maintained. Therefore cover the gaps or

not coordinated modules from the front by

appropriate blind covers.

Page 22

Mounting instructions

2.4 VEGA T OR 631 Ex

Connect the signal conditioning instrument as

follows:

- Mount the plug-in socket to the carrier rail.

- Wire the socket acc. to your requirements,

see paragraph "3 Electrical connection".

- Close the upper terminals with the supplied

covers.

- Insert the supplied coded pin into the

determined hole no. 3.

- Connect, if requested, the neighbouring

series 600 signal conditioning instrument

via the supplied plug (L1 and N).

- Choose mode A or B on the slide switch

(laterally on top).

- Mount VEGATOR 631 Ex to the plug-in

socket (2 screws).

Cover

4321

Function coding

Ex-version

Instrument coding

VEGATOR 631

A

B

C

1

2

3

-

+

Mounting of the covers

12 43

Transparent cover

To protect the instrument against

unauthorized adjustment, the front plate of

VEGATOR 631 Ex can be provided with a

lockable transparent cover, see following

figure.

7

8

9

Plug

N

L

1

56 78

14131211109

22 Conductive measuring system

Page 23

Electrical connection

3 Electrical connection

3.1 VEGATOR 256C

Level detection

Mass

12

Relay output

Power supply

Electrode

e.g. type EL 1

Pump control

(Min-Max-control)

Mass

Max

Min

2

3

1

Relay output

Power supply

Connect several VEGATOR 256 C absolutely

identical, i.e. the first supply line to all

terminals no. 7 and the second supply line to

all terminals no. 8. An interchanging of no. 7

and no. 8 or the connection of different

phases is not permitted.

3.2 VEGATOR 532 Ex

min.

1

max.

2

3

10

0

4

5

200...250VAC 3VA

6

R

L1

7

power supply

Relais: max 250V,5A,750VA

8

N

min.

1

max.

2

3

10

0

4

5

200...250VAC 3VA

6

R

L1

7

power supply

Relais: max 250V,5A,750VA

8

N

To avoid interferences by capacitive

couplings, use from a line length of 50 m an

own cable for each signal conditioning

instrument VEGATOR 532 Ex or for each

channel.

When you want to use a commen cable, note

that the lines of the max. and min. signal are

screened. Connect the screens to mass.

Double level detection

d b z

+-

2

Power

supply

Transistor output 1

Meas. data input 1

(channel 1)

2

1

L (+)

N (-)

6

10

12

16

18

20

22

24

Mass

28

Max

30

Min

3

32

+

+

-

-

Relay output 1

Relay output 2

Transistor output 2

Meas. data input 2

(channel 2)

2

3

1

Electrode

e.g. type EL 3

Note

Multiple rod electrodes which are connected

to several signal conditioning instruments or

a multiple channel instrument, require an

earth rod to avoid influencing among the

signal conditioning instruments.

Conductive measuring system 23

1

2

3

Electrode

e.g. type EL 3

Page 24

Electrical connection

Pump control

(Min-Max-control)

3

Electrode

e.g. type EL 3

L (+)

N (-)

Mass

Max

Min

Power

supply

Transistor output 1

Meas. data input 1

(channel 1)

2

3

1

2

1

d b z

+-

2

6

10

12

16

18

+

20

-

22

24

28

30

32

Relay output 1

Relay output 2

+

-

Transistor output 2

Meas. data input 2

(channel 2)

Double pump control

For a double pump control e.g. with EL 5 you

require a VEGATOR 532 Ex.

d b z

+-

Power

supply

Transistor output 1

Mass

Max

Min

3

4

2

1

5

L (+)

N (-)

2

6

10

12

16

18

+

20

-

22

24

28

30

32

Relay output 1

Relay output 2

+

-

Transistor output 2

Max

Min

Note

Multiple rod electrodes which are connected

to several signal conditioning instruments or

a multiple channel instrument require an earth

rod to avoid influencing among the signal

conditioning instruments.

24 Conductive measuring system

2

Electrode

5

4

e.g. type EL 5

3

1

Page 25

Electrical connection

VEGATOR 532 Ex with housing

type 505

The terminal designation for the power

supply and the relay or transistor output

corresponds to that of the multipoint

connector. Just the connection of the

electrodes must be made as follows.

Double Pump control

level detection (Min-Max-control)

1 2 3 1 2 3

2

3

1

1 2 3 1 2 3

2

3

1

3.3 VEGA T OR 631 Ex

To avoid interferences due to capacitive

coupling, use from a line length of 50 m an

own cable for each signal conditioning

instrument VEGATOR 631 Ex.

When you want to use a commen cable, note

that the lines of the max. and min. signal are

screened. Connect the screens to mass.

Level detection

Mass

Pump control

(Min-Max-control)

Mass

Max

Min

2

3

1

2

3

1

132 4

5 6

9 10

7 8

131412

Relay output

Power supply

Electrode

e.g. type EL 3

Transistor output

Note

Multiple rod electrodes which are connected

to several signal conditioning instruments or

a multiple channel cable require an earth rod

to avoid influencing among the signal

conditioning instruments.

Pump control (Min-Max) with overfill

protection

Max-ÜFS

2

3

1

Min

4

Max

Mass

12

Electrode

e.g. type EL 1

56

910

21

43

141312

Relay output

Power supply

2

3

4

1

1 32 4

5 6

9 10 131412

L

N

(+)

(–)

1

32 4

5 6

7 8

9 10 131412

L

N

(+)

(–)

7 8

Transistor output

Conductive measuring system 25

Page 26

Coordination of the transistor outputs

VEGATOR 532 Ex and 631 Ex

R

S

+

U

CE

-

R

S

+

U

CE

-

+

+

-

Electrical connection

VEGATOR 532 Ex

(VEGATOR 631 Ex)

DCS

The resistor RS is used as shortcircuit

protection.

R

S

P

47 Ohm 0,25 W

150 Ohm 0,75 W

330 Ohm 1,5 W

560 Ohm 2,2 W

26 Conductive measuring system

Page 27

Set-up

4 Set-up

4.1 VEGATOR 256C

Indicating and adjustment elements

Potentiometer

The switch point or the adaption to the

product conductivity can be adjusted via a

potentiometer. Use a small screwdriver to

carry out the adjustments on the

potentiometer.

Yellow control lamp

lights when the relay is energized,

extinguishes when the relay is deenergized.

min.

1

max.

2

3

LED relay output

AC 3VA

10

0

4

5

6

L1

7

8

N

Switch point adjustment

Level detection

- Connect the signal conditioning instrument

- Turn the potentiometer anticlockwise up to

complete left position

- Fill the vessel until the max. electrode is

covered by approx. 1 cm

- Turn the potentiometer slowly clockwise

until the yellow LED lights

Potentiometer for switch point

adjustment

200...250V

R

power supply

Relais: max 250V,5A,750VA

Pump control (Min-Max-control)

Pre-requirements

- First of all connect only the mass and max.

electrode to the signal conditioning

instrument terminal 2 and 3

- Connect the signal conditioning instrument

to the power supply

Adjust switch point

- Turn the potentiometer anticlockwise up to

complete left position

- Fill the vessel until the max. electrode is

covered by approx. 1 cm

- Turn the potentiometer slowly clockwise

until the yellow LED lights

- Now connect the min. electrode to terminal

1 of the signal conditioning instrument

The switching sensitivity of the signal

conditioning instrument is adapted to the

product conductivity, i.e. the relay of the

output deenergizes at max. level and the

yellow LED extinguishes.

This condition remains until the level

decreases the position of the min. electrode,

i.e. the relay of the output energizes at min.

level and the yellow LED lights.

The relay of the output energizes again at

max. level etc.

The switching conductivity of the signal

conditioning instrument is adapted to the

product conductivity.

Conductive measuring system 27

Page 28

4.2 VEGA T OR 532 Ex

Set-up

B A

B A

18

1 Ex-fuse T50 mA / 250 V

2 Mains fuse T 1 A / 250 V

3 Connection plan

4 Lockable screw

5 Potentiometer for switch point

adjustment for channel 1

6 LED output 1

1

17

14

7 LED fault signal channel 1

8 Potentiometer for switch point

adjustment for channel 2

9 LED output 2

10LED fault signal channel 2

11LED supply voltage

12 Screw

13 Multiple plug

3

2

BR1

BR2

15

1316

4

5

5

6

010

7

8

9

10

11

12

1

5

010

2

on

532 Ex

14Soldering bridge for fault signal

adjustment channel 1

15Soldering bridge for fault signal

adjustment channel 2

16Selection switch mode A/B for

channel 1

17Selection switch mode A/B for

channel 2

18Transparent cover

Indicating and adjustment elements

Potentiometer

The switch point or the adaption to the

product conductivity can be adjusted via

potentiometer separately for each channel.

Use a small screwdriver to carry out the

adjustments on the potentiometer.

Control lamps

LED in the front plate indicate

operation, switching condition of the relay

outputs and fault signals.

Two yellow LED (6 and 9) for status

indication of the relay or transistor outputs

1 and 2 (LED lights = relay energizes,

transistor conductive, LED extinguished =

relay deenergizes, transistor blocked)

Two red LED (7 and 10) for failure

indication of channel 1 and 2 (LED lights =

channel interferred).

One green LED (11) for indication

operating voltage "on".

28 Conductive measuring system

Page 29

Set-up

Selection of mode A/B

A slide switch (16 and 17) per channel is

located on the circuit board of the signal

conditioning instrument. Position A

corresponds to overfill protection, position B

to dry run protection.

Failure adjustment (soldering bridges)

For monitoring of the electrodes and their

circuits, a resistor of 220 kOhm must be

mounted between connection 1 and

connection 2 in the connection housing of the

electrode, i.e. with single point control

measuring and mass electrodes are

monitored and with double point control max.

and mass electrode.

For electrodes without 220 kOhm resistor, a

soldering bridge must be closed on the

circuit board on the multipoint connector of

the signal conditioning instrument

- relating to channel 1 = bridge BR1 (14)

- relating to channel 2 = bridge BR2 (15).

Note

With closed soldering bridge the line

monitoring and appropriate fault signal are

inactive.

If a measuring system is used as part of an

overfill protection, the appropriate soldering

bridge must not be closed.

With Ex-electrodes of VEGA this resistor is

already available as a standard feature.

Selection of the mode

By means of the two selection switches (16

and 17) mode A or B can be adjusted

separately for each channel.

means with uncovered max.-electrode (level

detection) or min.-electrode (pump control)

- relay of output 1 energizes,

connection d10 - z10 is connected through

relays

- transistor output 1 is conductive

- LED relay output 1 lights

2

3

1

Mode B

preferably as dry run protection

means with covered max.-electrode

- relay of output 1 energizes,

connection d10 - z10 is connected through

relays

- transistor output 1 is conductive

- LED output 1 lights

means with uncovered max.-electrode (single point control) or min.-electrode (double

point control)

- relay of output 1 deenergizes,

connection d10 - b10 is connected through

relays

- transistor output 1 blocks

- LED output 1 extinguishes

Mode A

preferably as overflow protection

compulsorily as overfill protection

2

3

means with covered max.-electrode

1

- relay of output 1 deenergizes,

connection d10 - b10 are connected

through relays

- transistor output 1 blocks

- LED output 1 extinguishes

Conductive measuring system 29

Page 30

Set-up VEGATOR 532 Ex

Switch point adjustment

Double single point control

Min.-/Max.-signal separately

Pre-requirements

- Coordinate channel 1 to the max.-signal

- Coordinate channel 2 to the min.-signal

- Set the selection switch of channel 1 (16) to

mode A

- Set the selection switch of channel 2 (17) to

mode B

- Connect the signal conditioning instrument

to power supply

- Turn the potentiometer (5) to position 0

Switch point max.-signal

- Fill the vessel until the max. electrode is

covered by approx. 1 cm

- Turn the potentiometer (5) slowly clockwise

until the yellow LED of channel 1

extinguishes.

The max. electrode is now adapted to the

product conductivity, i.e. the relay of output 1

deenergizes at max. level and the transistor

of output 1 blocks.

Switch point min.-signal

- Turn the potentiometer (8) to position 10

- Empty the vessel until the min. electrode is

covered by approx. 1 cm

- Turn the potentiometer (8) slowly

anticlockwise until the yellow LED of

channel 2 extinguishes.

The min. electrode is now adapted to the

product conductivity, i.e. the relay of output 2

deenergizes at min. level and the transistor of

output 2 blocks.

Pump control, mode A

Overflow protection (channel 1)

Pre-requirements

- First of all connect only the mass and the

max. electrodes to the signal conditioning

instrument (connection points d28 and

d30)

- Set the selection switch of channel 1 (16) to

mode A

- Connect the signal conditioning instrument

to power supply

- Turn the potentiometer (5) to position 0

Adjust switch point

- Fill the vessel until the max. electrode is

covered by approx. 1 cm

- Turn the potentiometer (5) slowly clockwise

until the yellow LED of channel 1

extinguishes

- Now connect the min. electrode to

connection point d32 of the signal

conditioning instrument

The pump control is adapted to the product

conductivity, i.e. the relay of output 1

deenergizes at max. level and the transistor

of output 1 blocks.

This switching condition remains until the level

decreases the position of the min. electrode,

i.e. the relay of output 1 energizes at min.

level and the transistor of output 1 is

conductive.

Only at max. level, the relay of output 1

deenergizes again and the transistor of

output 1 blocks.

30 Conductive measuring system

Page 31

Set-up VEGATOR 532 Ex

Pump control, mode B

Dry run protection (channel 1)

Pre-requirements

- First of all connect only the mass and the

max. electrodes to the signal conditioning

instrument (connection points d28 and

d30)

- Set the selection switch of channel 1 (16) to

mode B

- Connect the signal conditioning instrument

to power supply

- Turn the potentiometer (5) to position 10

Adjust switch point

- Fill the vessel until the max. electrode is

covered by approx. 1 cm

- Turn the potentiometer (5) slowly

anticlockwise until the yellow LED of

channel 1 extinguishes

- Now connect the min. electrode to the

connection point d32 of the signal

conditioning instrument

The pump control is adapted to the product

conductivity, i.e. the relay of output 1

energizes at max. level and the transistor of

output 1 is conductive.

This switching condition remains until the level

decreases the position of the min. electrode,

i.e. the relay of output 1 deenergizes at min.

level and the transistor of output 1 blocks.

Note

For all switch point adjustments it must be

generally noted that between reaching of the

switch point and triggering of the switching

function an integration time of 0,5 s is

effective. The potentiometer must therefore

be turned slowly.

In all applications in conjunction with an integral resistor of 220 kOhm a line monitoring of

the mass and max. electrode must be

guaranteed.

Only at max. level the relay of output 1

energizes again and the transistor of output 1

is conductive.

These set-up examples relate to channel 1,

the same procedure is valid for channel 2.

Conductive measuring system 31

Page 32

4.3 VEGA T OR 631 Ex

12 34

!

5

010

on

631Ex

56 78

91011121314

1

2

3

4

A

B

C

1

2

3

7

8

9

N

L

1

56 78

Set-up

12

sec t

6

off

1234

B

R

VEGA TOR 631 EX

U

L

< x,xxV,

o

o

< x mH

C

< x mA

I

o

o

< xxx nF

P

< xxmW

o

Sensor

Terminal

maximum

minimum

34

12

out

max: 36V

+

56

13

CE

: -20É+60¡C

a

IP 30

nsp. I

power supply

20É250 VAC

max.250VAC

60mA

-

20É72VDC

125VA

1...8 VA

2A

L

N

+

-

12 13

14

910

15

2

5

4321

A

6

7

8

+

PTB-Nr.: Ex-96.D.2064

Sensorstromkreis EEx ia IIC

9

10

11

14131211109

12

14

1 LED fault signal

2 Potentiometer for switch point

adjustment

3 LED output

4 LED supply voltage

5 Bridge for failure adjustment

6 Terminal for electrode

7 Function coding Ex-version

8 Instrument coding VEGATOR

631 Ex

Indicating and adjustment elements

Potentiometer

The switch point or the adaption to the

product conductivity can be adjusted via a

potentiometer.

Use a small screwdriver to carry out

adjustments on the potentiometer.

9 Sockets for connection bridges

10Transistor output

11Relay output

12 Power supply

13DIL-switch block

14Type plate

15Transparent cover

Control lamps

LED in the front plate indicate

operation, switching condition of the relay

output and fault signal.

One yellow LED (3) for status indication of

the relay or transistor output (LED lights =

relay energized, transistor conductive,

LED extinguished = relay deenergized,

transistor blocks)

One red LED (1) for failure indication (LED

lights = fault signal).

One green LED (4) for indication operating

voltage "on".

32 Conductive measuring system

Page 33

Set-up

DIL-switch block

A DIL-switch block with 4 switches is located

laterally on top (covered in mounted

condition). The individual switches are

coordinated as follows:

1 A/B-mode

A - Max. detection or overfill protection

B - Min. detection or dry run protection

2 Integration time 2 s

3 Integration time 6 s

4 Integration time 12 s

With switch 1 the mode (A - overfill protection

or B - dry run protection) can be adjusted.

In the example in the figure mode A (max.

detection or overfill protection) is selected

(switch 1). The integration time is adjusted to

8 seconds (switch 2, 3 and 4).

1 A/B-mode

sec t

2 Integration time +2 s

3 Integration time +6 s

4 Integration time +12 s

62A

1234

off

B

12

With switches 2, 3 and 4 the integration time

can be appropriately adjusted. The times of

the activated timer sum up. The adjusted time

is valid for the switch on and off delay.

Switch 1234

Time 2 s 6 s 12 s

0,2 s A/B off off off

2 s A/B on off off

6 s A/B off on off

8 s A/B on on off

12 s A/B off off on

14 s A/B on off on

18 s A/B off on on

20 s A/B on on on

Failure adjustment, bridge (5)

For monitoring of the electrodes and their

circuit a resistor of 220 kOhm must be

mounted between connection 1 and

connection 2 in the connection housing of the

electrode, i.e. with single point control

measuring and mass electrode are

monitored and with double point control max.

and mass electrode.

For electrodes without 220 kOhm resistor a

bridge (5) must be provided on the signal

conditioning instrument between terminals 3

and 4.

Note

With this bridge, the line monitoring and the

fault signal are inactive.

If a measuring system is used as part of an

overfill protection, the bridge must not be

closed.

On Ex-electrodes of VEGA this resistor is

already available as factory setting.

Selection of mode

Mode A or B can be adjusted by means of

the selection switch (13).

Mode A

preferably as overflow protection

compulsorily as overfill protection

means with covered max.-electrode

- relay deenergizes, connection 12 - 13 is

connected through relay

- transistor output blocks

- LED output extinguishes

means with uncovered max.-electrode (level

detection) or min.-electrode (pump control)

- relay energizes, connection 12 - 14 is

connected through relay

- transistor output is conductive

- LED output lights

Conductive measuring system 33

Page 34

2

3

1

Mode B

preferably as dry run protection

means with covered max.-electrode

- relay energizes, connection 12 - 14 is

connected through relay

- transistor output is conductive

- LED output lights

means with uncovered max.-electrode (level

detection) or min.-electrode (pump control)

- relay deenergizes, connection 12 - 13 is

connected through relay

- transistor output blocks

- LED output extinguishes

Set-up VEGATOR 631 Ex

Switch point adjustment

Level detection for max.-signal

Pre-requirements

- Set the selection switch (13) to mode A

- Connect the signal conditioning instrument

to power supply

- Turn the potentiometer (2) to position 0

Switch point max.-signal

- Fill the vessel until the max. electrode is

covered by approx. 1 cm

- Turn the potentiometer (2) slowly clockwise

until the yellow LED extinguishes

The max. electrode is now adapted to the

product conductivity, i.e. the relay

deenergizes at max. level and the transistor

blocks.

Level detection for min.-signal

Pre-requirements

- Set the selection switch (13) to mode B

- Connect the signal conditioning instrument

to power supply

- Turn the potentiometer (2) to position 10

Switch point min.-signal

- Empty the vessel until the min. electrode is

covered by approx. 1 cm

- Turn the potentiometer (2) slowly

anticlockwise until the yellow LED

extinguishes

The min. electrode is now adapted to the

product conductivity, i.e. the relay

2

3

1

34 Conductive measuring system

deenergizes at min. level and the transistor

blocks.

Page 35

Set-up VEGATOR 631 Ex

Pump control (Min-Max), mode A

Overflow protection

Pre-requirements

- First of all connect only the mass and max.

electrodes to the signal conditioning

instrument (terminal 1 and 3)

- Set the selection switch (13) to mode A

- Connect the signal conditioning instrument

to voltage supply

- Turn the potentiometer (2) to position 0

Adjust switch point

- Fill the vessel until the max. electrode is

covered approx. 1 cm

- Turn the potentiometer (2) slowly clockwise

until the yellow LED extinguishes

- Now connect the min. electrode to terminal

2 of the signal conditioning instrument.

The pump control is adapted to the product

conductivity, i.e. the relay deenergizes at

max. level and the transistor blocks.

This switching condition remains until the level

decreases the position of the min. electrode,

i.e. the relay energizes at min. level and the

transistor is conductive.

Only at max.-level the relay deenergizes

again and the transistor blocks.

Adjust switch point

- Fill the vessel until the max. electrode is

covered by approx. 1 cm

- Turn the potentiometer (2) slowly

anticlockwise until the yellow LED

extinguishes

- Now connect the min. electrode to terminal

2 of the signal conditioning instrument

The pump control is adapted to the product

conductivity, i.e. the relay energizes at max.

level and the transistor is conductive.

This switching condition remains until the level

has decreased the position of the min.

electrode, i.e. the relay deenergizes at min.

level and the transistor blocks.

Only at max. level the relay energizes again

and the transistor is conductive.

Note

For all switch point adjustments it must be

generally noted that between reaching of the

switch point and triggering of the switching

function an integration time of 0,5 s is

effective. The potentiometer must therefore

be turned slowly.

A probable additional integration time should

only be switched after the adjustment.

Pump control (Min-Max), mode B

Dry run protection

In all applications in conjunction with an integral resistor of 220 kOhm a line monitoring of

the mass and the max. electrode is ensured.

Pre-requirements

- First of all connect only the mass and max.

electrodes to the signal conditioning

instrument (terminal 1 and 3)

- Set the selection switch (13) to mode B

- Connect the signal conditioning instrument

to power supply

- Turn the potentiometer (2) to position 10

Conductive measuring system 35

Page 36

5 Diagnosis

5.1 Fault signal on VEGA T OR 532 Ex

BR1

Diagnosis

BR2

Soldering bridge for failure

adjustment of channel 1

The connection line from the mass and max.

electrode to the signal conditioning

instrument is generally monitored on line

break with Ex-measuring systems and

overfill protections.

If both channels are used for two separate

measurements (no double point control) the

electrodes are monitored, e.g. mass and

max. electrode of channel 1 to connection

point d30 and d32, mass and min. electrode

of channel 2 to connection point z30 and z32.

This division effects a channel specific fault

signal. This means in case of failure:

- The channel specific failure-LED lights

- The relay and the transistor output of the

failed channel deenergize and block

- The functions of the failed channel remain.

Soldering bridge for failure

adjustment of channel 2

If conductive electrodes are used without Exversion (measuring system without Exrequirements) a resistor of 220 kOhm must

be mounted between mass and max.

electrode (between connection 1 and 2 ) for

monitoring of the connection line in the

connection box of the electrodes.

If this is not possible, it is necessary to close

a soldering bridge on the circuit board of the

signal conditioning instrument

- for channel 1 soldering bridge BR1 (14)

- for channel 2 soldering bridge BR2 (15)

Note

In this case the monitoring of the mass and

max. electrodes and the connection lines are

inactive. Therefore also the fault signal is

ineffective.

36 Conductive measuring system

Page 37

Diagnosis

5.2 Fault signal on VEGA T OR 631 Ex

2

3

1

321

4

Measuring system with monitoring of the

mass and max. electrode and their

3

3

connection lines

Bridge between

4321

terminal 3 and 4

Measuring system without monitoring of

the mass and max. electrode and their

connection lines

2

1

2

3

1

2

1

Note

In this case the monitoring of the mass and

max. electrodes and the connection lines are

inactive. Therefore also the fault signal is

ineffective.

The connection line from the mass and max.

electrode to the signal conditioning

instrument is generally monitored on line

break with Ex-measuring systems and

overfill protections.

If conductive electrodes without Ex-version

are used (measuring system without Exrequirements) a resistor of 220 kOhm must

be mounted between mass and max.

electrode (between connection 1 and 3) for

monitoring of the connection line in the

connection box of the electrodes.

If this is not possible, it is necessary to

provide a bridge between terminal 3 and 4.

Conductive measuring system 37

Page 38

Notes

38 Conductive measuring system

Page 39

Notes

Conductive measuring system 39

Page 40

1

VEGA Grieshaber KG

Am Hohenstein 113

D-77761 Schiltach

Phone (0 78 36) 50 - 0

Fax (0 78 36) 50 - 201

e-mail info@de.vega.com

ISO 900

The statements on types, application, use and operating conditions of

the sensors and processing systems correspond to the actual

knowledge at the date of printing.

Technical data subject to alteration.

11947-EN-050123

Loading...

Loading...