Page 1

in

out

Operating Instructions

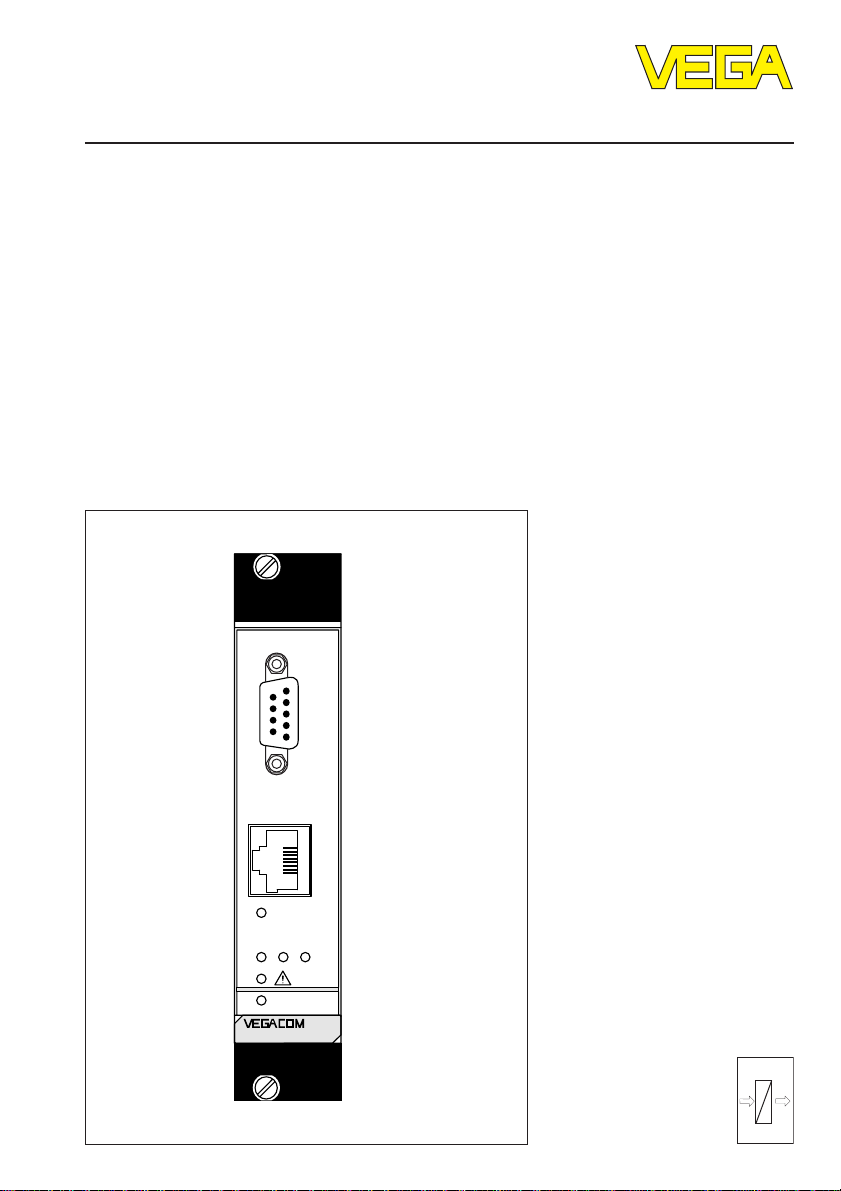

VEGACOM 558 Ethernet

Level and Pressure

PC

Ethernet

321

on

558

out

in

Page 2

Contents

Safety information ........................................................................ 2

Note Ex area ................................................................................ 2

1 Product description

1.1 Function ................................................................................. 4

1.2 Configuration ........................................................................ 4

1.3 Technical data ....................................................................... 5

1.4 Dimensions ........................................................................... 7

2 Mounting..................................................................................... 8

3 Electrical connection

3.1 Connection instruction ......................................................... 9

3.2 Wiring plan ............................................................................ 9

4 Communication with VEGACOM

4.1 Ways to connect ................................................................ 10

4.2 Adjustment software .......................................................... 11

Contents

5 Configuration of VEGACOM 558

5.1 Adjust communication mode with VVO ............................ 15

5.2 IP address.......................................................................... 16

5.3 Connection via modem ...................................................... 17

5.4 VEGACOM 558 on DISBUS .............................................. 19

5.5 Real time clock ................................................................... 20

5.6 Activate password protection ........................................... 21

Safety information

Please read this manual carefully, and also take

note of country-specific installation standards

(e.g. the VDE regulations in Germany) as well

as all prevailing safety regulations and accident prevention rules.

For safety and warranty reasons, any internal

work on the instruments, apart from that involved in normal installation and electrical connection, must be carried out only by qualified

VEGA personnel.

2 VEGACOM 558 Ethernet

Note Ex area

Please note the attached safety instructions

containing important information on installation

and operation in Ex areas.

These safety instructions are part of the operating instructions and come with the Ex approved instruments.

Page 3

Contents

6 VEGACOM 558 as Modbus / TCP server

6.1 Storage of measured values when

connected to DISBUS ........................................................ 23

6.2 Storage of contact inputs/outputs when

connected to DISBUS ........................................................ 26

6.3 Storage of measured values when

connected to LOGBUS ...................................................... 28

6.4 Storage of the contact outputs when

connected to LOGBUS ...................................................... 30

6.5 Format for transfer of measured values .......................... 32

7 VEGACOM 558 as web server

7.1 VEGACOM in the Internet .................................................. 33

7.2 Predefined web pages ...................................................... 33

7.3 Network settings ................................................................ 35

7.4 Web server settings .......................................................... 39

7.5 Send emails ........................................................................ 39

7.6 Language of VEGACOM 558 ............................................ 42

7.7 Real time clock ................................................................... 43

7.8 User Management ............................................................. 44

8 Your own html documents

8.1 Transfer html files ............................................................... 52

8.2 Structure of html files ......................................................... 56

8.3 Key words for output in html files ..................................... 58

9 Diagnosis .................................................................................. 61

Supplement A ................................................................................. 62

Supplement B ................................................................................. 68

VEGACOM 558 Ethernet 3

Page 4

1 Product description

Product description

1.1 Function

The VEGACOM 558 interface converter is

used for conversion of VEGA-specific

protocols of the DISBUS and LOGBUS into

the TCP/IP protocol. It enables the connection

of VEGA signal conditioning instruments

VEGAMET series 500 and 600 and the

VEGALOG 571 processing system, and

through this, the connection of VEGA transmitters to an Ethernet network. When connecting signal conditioning instruments, the

data of the VEGA protocol "DISBUS" are

used, with the processing system, the VEGA

protocol "LOGBUS" is used.

VEGACOM can be used as a web server,

making the measured values of the connected VEGA instruments available in html

format on the Ethernet. At the office level, the

measured values of VEGA instruments can

be displayed with an internet browser on

each computer connected to the network.

The data of VEGACOM 558 can also be

called up via the WWW. Furthermore, it is

possible to send emails containing measured

values at predefined times and dates. For

integration in process control or visualisation

systems, VEGACOM 558 provides a

Modbus / TCP server.

Network participants provided with the adjustment software VVO (VEGA Visual Operating) (e.g. service technicians) can adjust the

VEGA instruments via Ethernet. With the

visualisation software VV (Visual VEGA), it is

also possible to access via network connection VEGACOM 558 and thus the measured

values of the VEGA instruments.

Note:

To enable VEGALOG to work together with

VEGACOM 558, the CPU card of VEGALOG

must be equipped with the software version

1.30 or higher.

VEGAMET

500/600

VVO/

VV/

Webbrowser

%

100

+

-

OKESC

CONNECT

12

on

514

RS 232

LOGBUSDISBUS

PC

Ethernet

321

on

558

Ethernet

VEGACOM 558

VEGALOG

CPU

PC

on

571 CPU

VVO/

VV/

Webbrowser

Modbus / TCP

SPS / PLS

1.2 Configuration

VEGACOM 558 is designed in European size

(5 TE width) and can be mounted into:

- carrier BGT596

- VEGALOG carrier BGT LOG571

- housing type 505.

The electrical connection to the power supply,

DISBUS and LOGBUS is made with plug

connectors. On the front plate of VEGACOM

there are also:

- a nine-pole SUB-D plug (RS232) for direct

connection to a PC with adjustment software VVO (VEGA Visual Operating) or the

visualisation software VV (Visual VEGA)

- an RJ-45 connection for connection to an

Ethernet network.

4 VEGACOM 558 Ethernet

Page 5

Product description

1.3 Technical data

Power supply

Operating voltage U

Power consumption approx. 4 VA

Fuse 1 A, slow-blow

Electrical connection

Component multiple plug acc. to DIN 41 612, series F

Module in carrier

BGT 596 or BGT LOG571 suitable multipoint connector acc. to DIN 41 612

Housing type 505 via screw terminals max. 1 x 1.5 mm

Indicating elements

LEDs in front plate

- on (green) operating condition

- ! (red) failure indication

- Ethernet (green/red) status Ethernet (linked, TX, RX)

- 1 (green/red) save indication

- 2 (green/red) status LOGBUS

- 3 (green/red) status DISBUS

Measured data input DISBUS

Data transmission DISBUS (digital data transmission)

Connection cable connection via 48-pole multipoint connector

Max. cable length 1000 m

= 24 V AC (20 … 53 V), 50/60 Hz or

nom

= 24 V DC (20 … 72 V)

48-pole (d, b, z) with coding holes

with connection via standard technologies

2

2-wire standard cable (screened)

Measured data input LOGBUS

Data transmission LOGBUS (digital data transmission)

Connection cable connection via bus plug

RS 232 interface on front plate

Interface standard RS 232C

Cable length max. 15 m

Transmission rate in baud 9600, 19200, 38400, 57600

Transmission format 8 data bits, 1 stop bit, no parity

Plug in the front plate SUB-D plug connector, 9-pole, pins

VEGACOM 558 Ethernet 5

Page 6

Product description

Ethernet interface on the front plate (mode 10BaseT)

Interface standard Ethernet (IEEE802.3)

Line impedance 100 Ohm +/– 15 %

Cable type Ethernet-Patch cable category 5 (STP)

Wire cross-section 0.2 mm

2

No. of wires 4

Max. transmission rate 10 Mbits/s

Coding Manchester

Topology star

Max. segment length 100 m

Plug version 8-pole RJ45 plug

Frame-Format Ethernet Version 2

Ethernet interface on the front plate (mode 100BaseTX/Fast Ethernet)

Interface standard Ethernet (IEEE802.3)

Line impedance 100 Ohm +/– 15 %

Cable type Ethernet-Patch cable category 5 (STP)

Wire cross-section 0.2 mm

2

No. of wires 4

Max. transmission rate 100 Mbits/s

Coding Manchester with 4B/5B procedure

Topology star

Max. segment length 100 m

Plug version 8-pole RJ45 plug

Frame-Format Ethernet Version 2

Electrical protective measures

Protection

- not mounted IP 00

- in carrier BGT596

or BGT LOG571

- front side completely equipped IP 40

- upper and lower side

BGT596 IP 00

BGT LOG571 IP 20

- wiring side IP 00

- in housing type 505

- front side IP 40

- other sides IP 30

Protection class II (in housing type 505)

Overvoltage category II

Electrical separating measures

Reliable separation acc. to VDE 0106, part 1 between power supply, LOGBUS, DISBUS,

RS 232 and Ethernet

- reference voltage 250 V

- test voltage 2 kV

6 VEGACOM 558 Ethernet

Page 7

Product description

CE conformity

VEGACOM 558 meet the protective regulations of EMC taking the following standard into

consideration:

Emission EN 61 326: 1997/A1: 1998 (class A)

Susceptibility EN 61 326: 1997/A1: 1998

The protective regulations of the low voltage directive are fulfilled acc. to the EN standard

EN 61 010 - 1: 1993

Ambient conditions

Permissible ambient temperature -20 °C … +60 °C

Storage and transport temperature -20 °C … +85 °C

Mechanical data

Series module unit for carrier BGT596,

BGT LOG571 and housing type 505

Dimensions, not mounted W = 25.4 mm (5 TE), H = 128.4 mm, D = 166 mm

Weight approx. 550 g

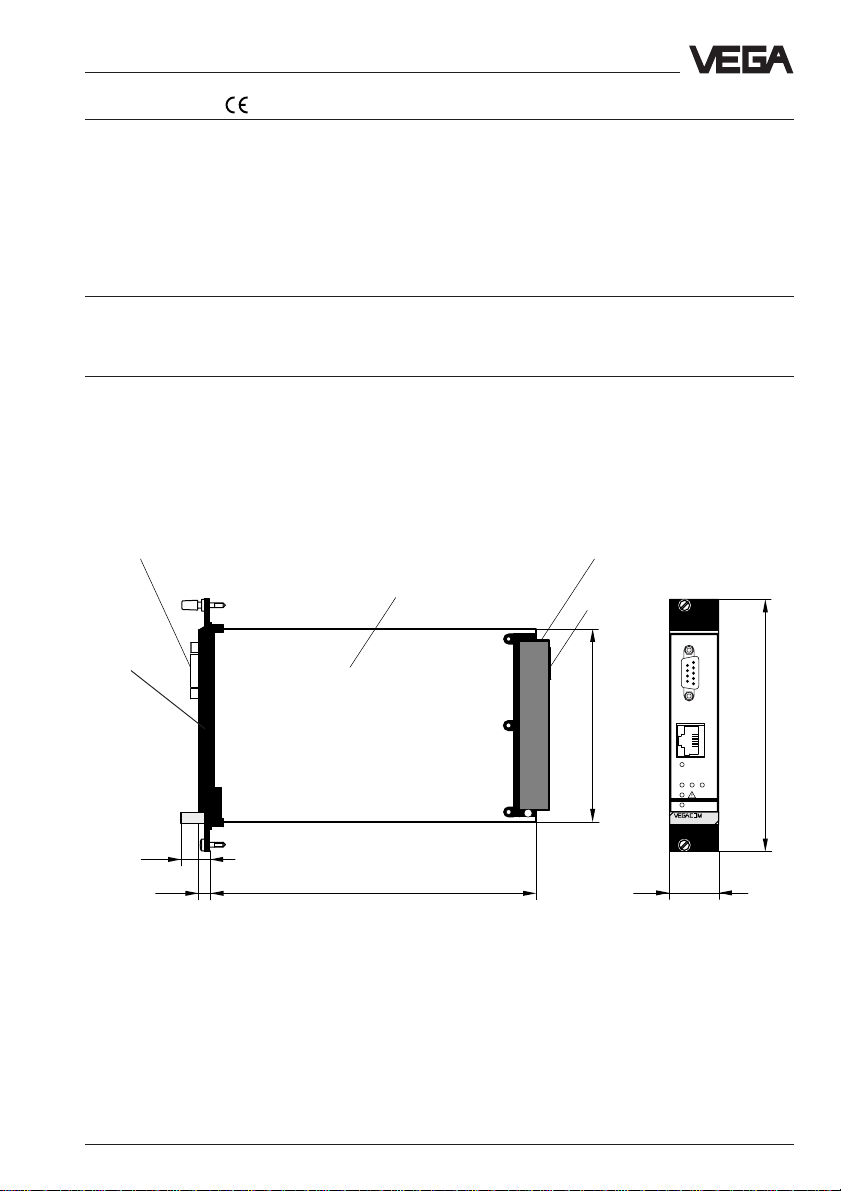

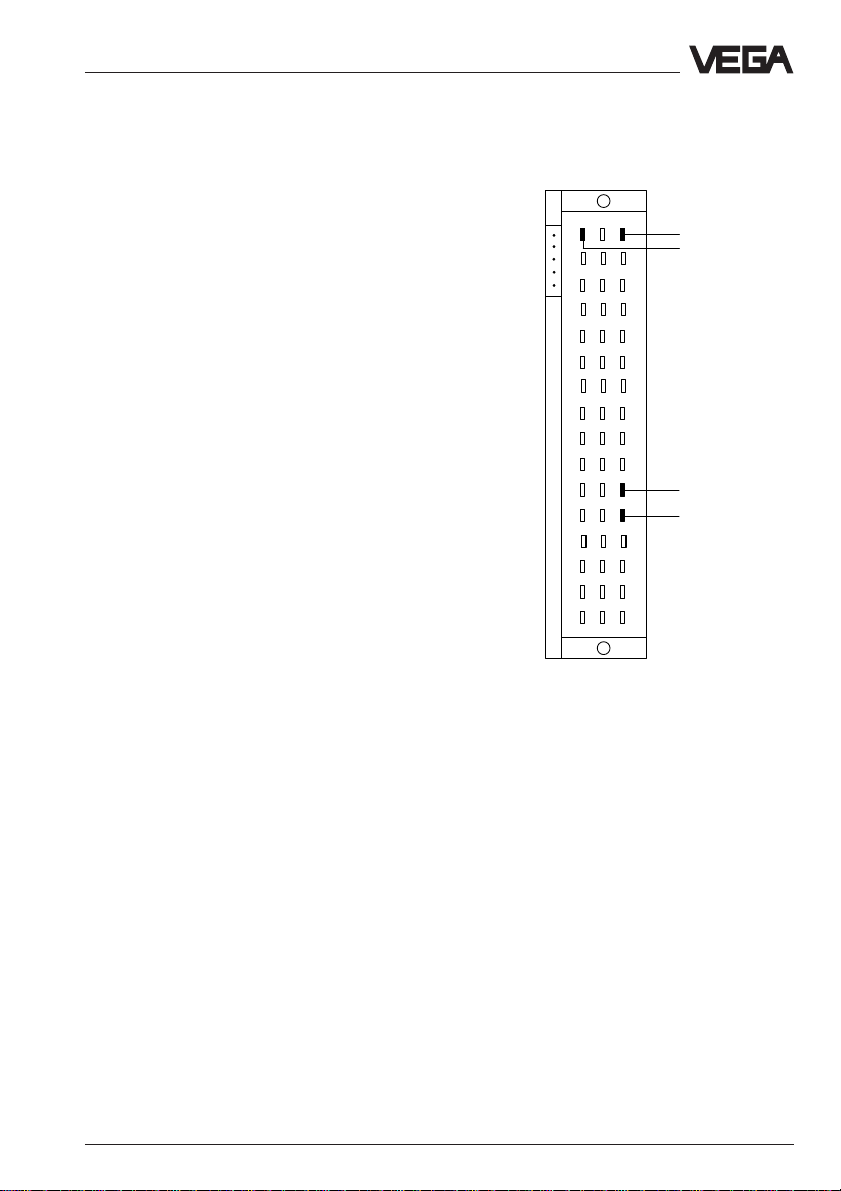

1.4 Dimensions

RS 232C interface

Ethernet

interface

(RJ45)

15

Circuit board 100 x 160 x 1.5

European size

1625,5

Multiple plug

LOGBUSplug

100

5 TE

Ethernet

on

25,4

PC

128,4

321

558

VEGACOM 558 Ethernet 7

Page 8

2 Mounting

Mounting

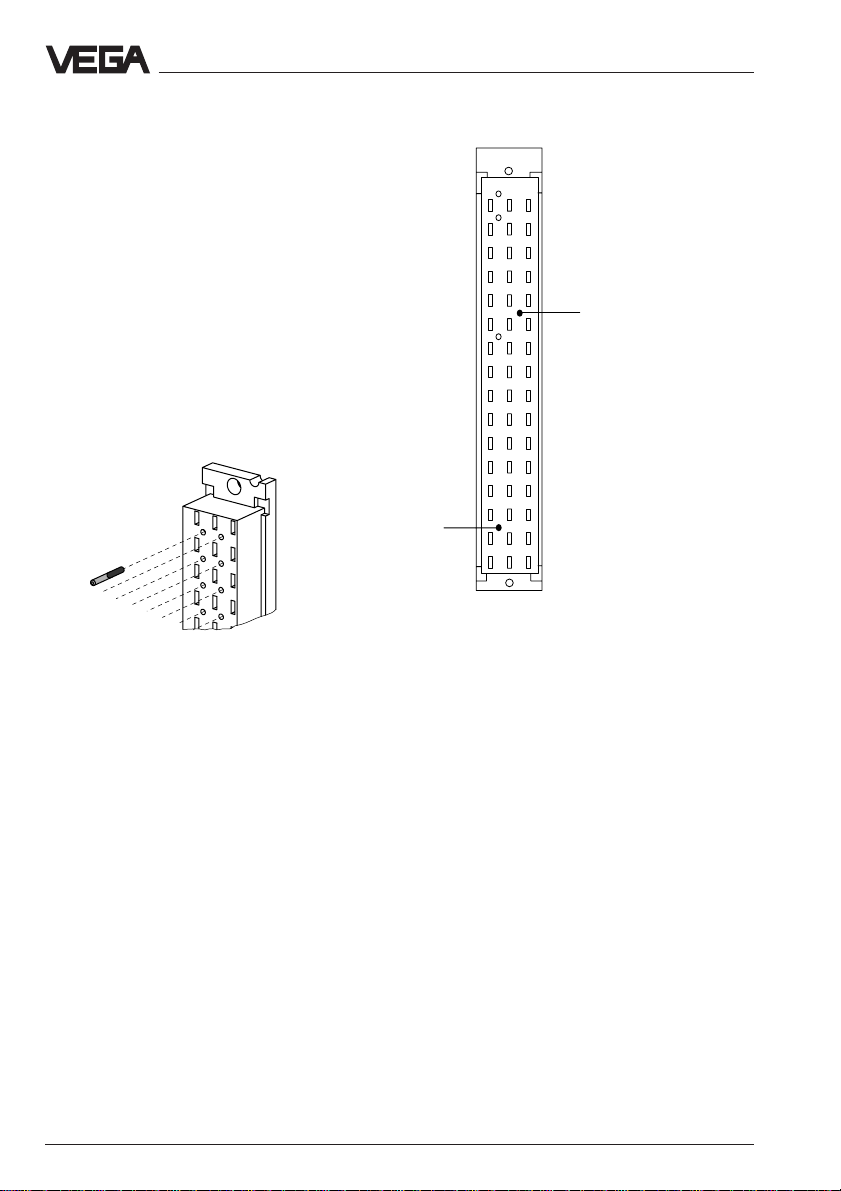

Coding

A mechanical coding system avoids later

interchanging of various module cards in the

carrier or in the housing type 505.

The coding system consists of:

- two coded pins in the multipoint connector

- two holes in the multiple plug of

VEGACOM.

The coded pins are attached to the module

(multipoint connector). The multipoint connector is equipped with the coded pins by the

user according to the following illustrations.

Coded pin

z b d

a c

o 1 o

o 3 o

o 5 o

o 7 o

o 9 o

o11o

o13o

o15o

o17o

o19o

o21o

o23o

o25o

o27o

a29

Positioning of the coded pins on the multipoint connector

o29o

o31o

c11

8 VEGACOM 558 Ethernet

Page 9

Electrical connection

3 Electrical connection

3.1 Connection instruction

Safety information – Qualified

personnel

Instruments which are not operated with

protective low voltage or DC voltage must

only be connected by qualified personnel.

This also applies to the configuration of

measuring systems planned for Ex environment.

As a rule, do all connecting work in the complete absence of line voltage. Always switch

off the power supply before you carry out

connecting work. Protect yourself and the

instruments.

3.2 Wiring plan

LOGBUS

(data from

VEGALOG 571)

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

d b z

–

+

+

DISBUS

(data from

–

VEGAMET)

VEGACOM 558 Ethernet 9

Page 10

4 Communication with VEGACOM

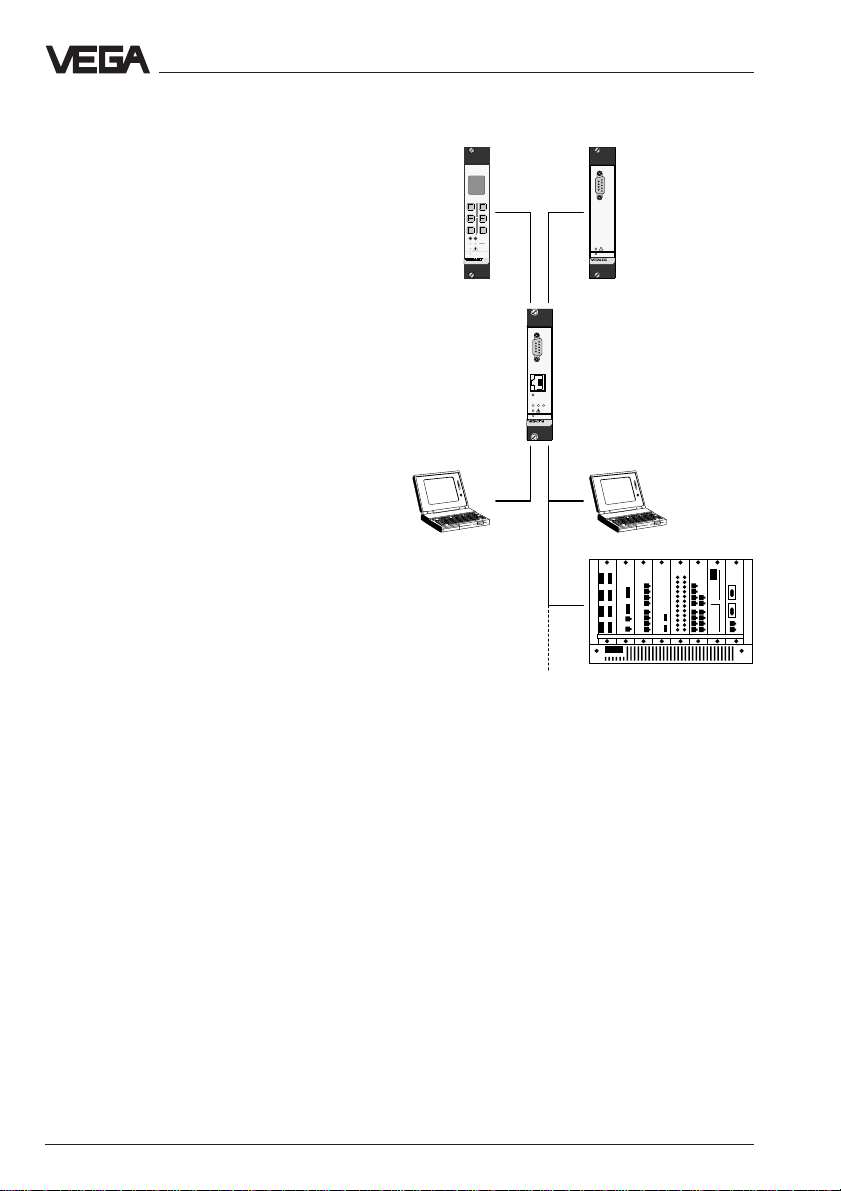

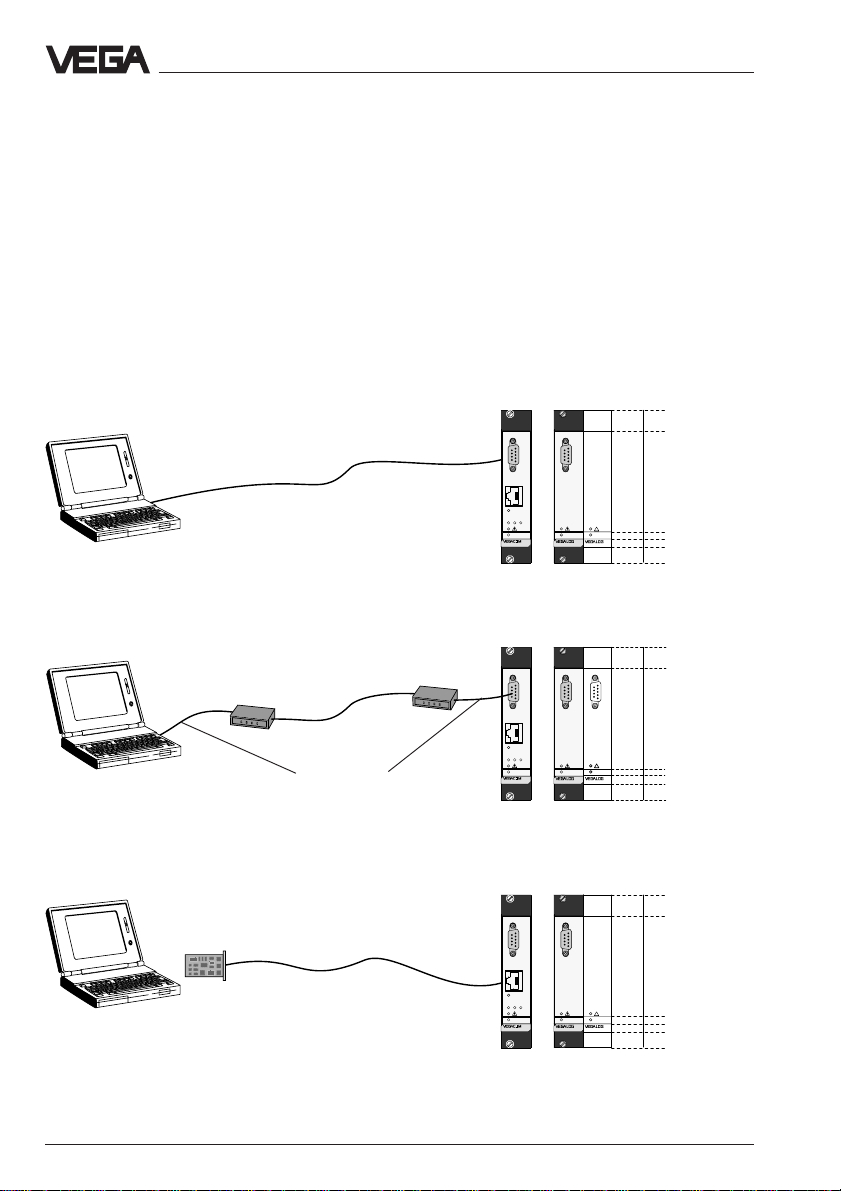

4.1 Ways to connect

There are a number of ways to enable communication with VEGACOM 558:

- a direct standard connection with the PC

(RS232)

- a standard connection via modems and

telephone network with the PC (RS232)

- a connection via a network (Ethernet)

- a connection via internet

Communication with VEGACOM

RS 232 (VVO, VV)

RS 232 (VVO, VV)

Ethernet (HTTP, FTP,

Telnet, VVO, VV)

Ethernet card

Modem

RS 232 connection cable

Telephone

network

RS 232 cable

Cross-over cable

Local

modem

PC

Ethernet

321

on

558

VEGACOM

PC

Ethernet

321

on

558

VEGACOM

PC

Ethernet

321

on

558

on

571 CPU

on

571 CPU 571 CPU

on

571 CPU

571 EV

571 EV

VEGACOM

10 VEGACOM 558 Ethernet

Page 11

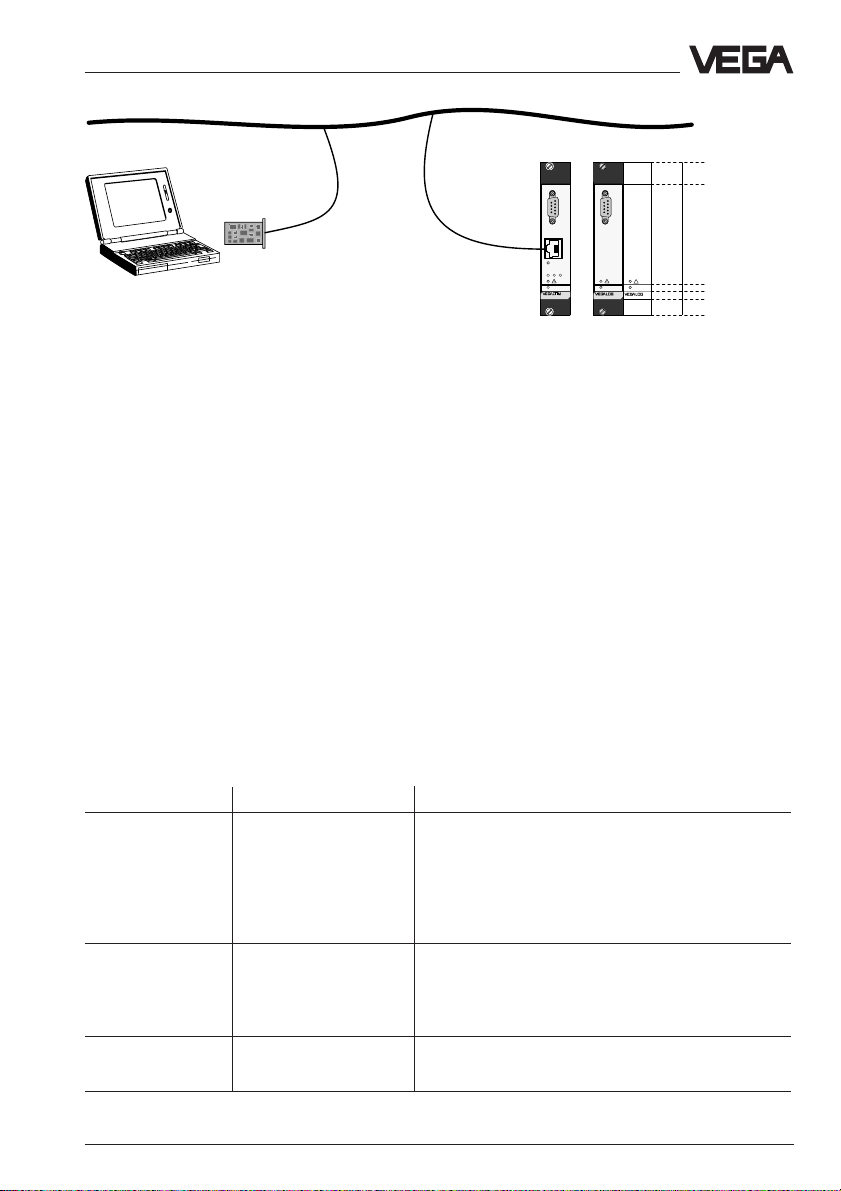

Communication with VEGACOM

Ethernet (HTTP, FTP,

Telnet, VVO, VV)

Ethernet

PC

Ethernet card

Ethernet-Patch cable

category 5 (STP)

Ethernet

321

on

558

VEGACOM

on

571 EV

571 CPU

4.2 Adjustment software

There are two ways to adjust VEGACOM 558

with the adjustment software VVO, either via

the RS232 interface or via the Ethernet interface. In both cases, VVO version 2.80 or

higher is necessary.

For settings on VEGACOM 558 relating to

certain internet services (e.g. web server,

Mail-Client, etc.), an internet browser, e.g.

Internet Explorer or Netscape Communicator,

must be used instead of VVO. Adjustment

with an Internet browser, however, requires

that VEGACOM 558 and the PC be connected via a network (Ethernet).

Software Connection technology Activities

VVO (VEGA - standard (RS232) - complete configuration and parameter setting

Visual Operating) - Ethernet of the connected instruments with LOGBUS

version 2.8 - modem connection and DISBUS (VEGALOG and signal condior higher tioning instruments)

- provide Ethernet access

- load html pages into VEGACOM

Internet browser - Ethernet - configuration of Mail-Client, Web server,

Diagnosis, …

or Netscape - show html pages of VEGACOM

Communicator - generate and send emails

Ping - Ethernet - diagnosis help (search and check network

participants)

VEGACOM 558 Ethernet 11

Page 12

Configuration of VEGACOM 558

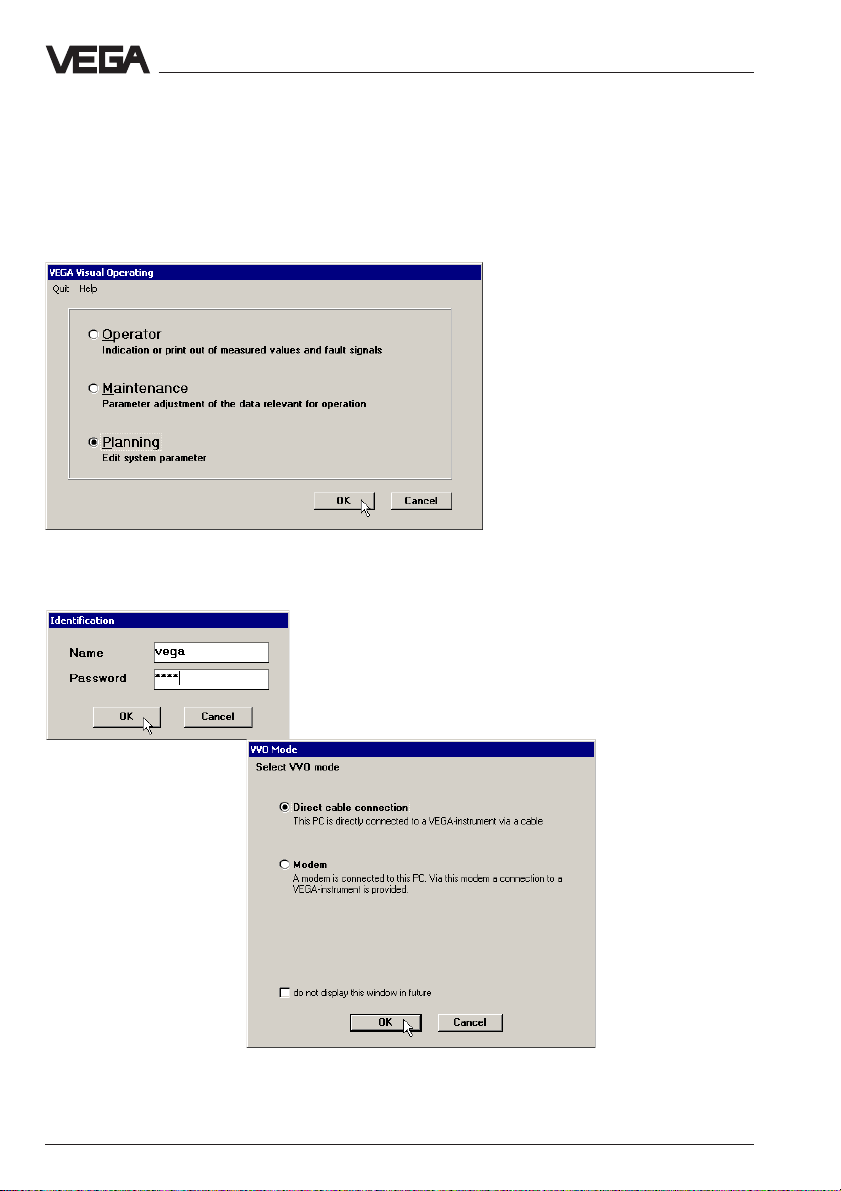

5 Configuration of VEGACOM 558

The configuration of the instrument is done with the adjustment software

VVO (VEGA Visual Operating), version 2.8 or higher, and can be realised via the standard serial interface or Ethernet connection. Connect

VEGACOM 558 to the PC (as described in chapter "4.1 Ways to connect"). Start VVO and choose Planning.

Enter in each of the following fields (name and password) vega and

then choose mode Direct cable connection.

12 VEGACOM 558 Ethernet

Page 13

Configuration of VEGACOM 558

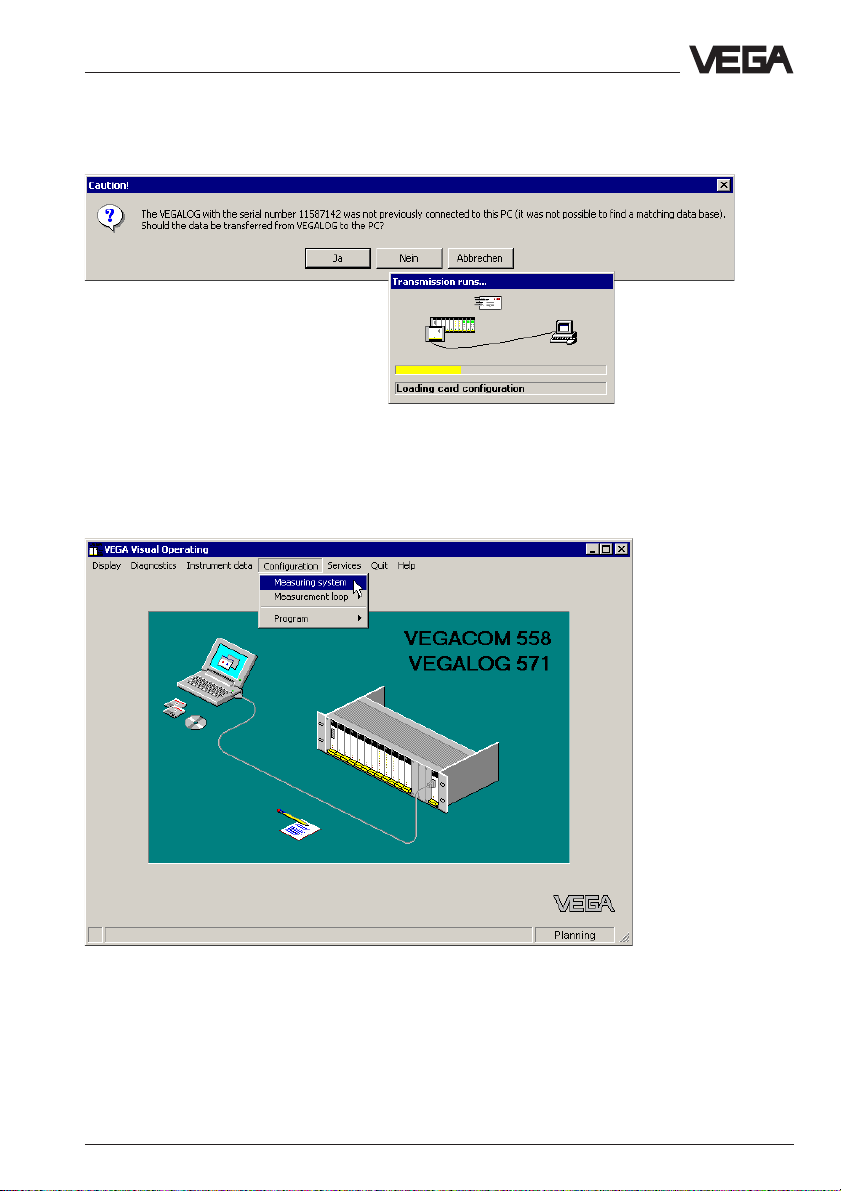

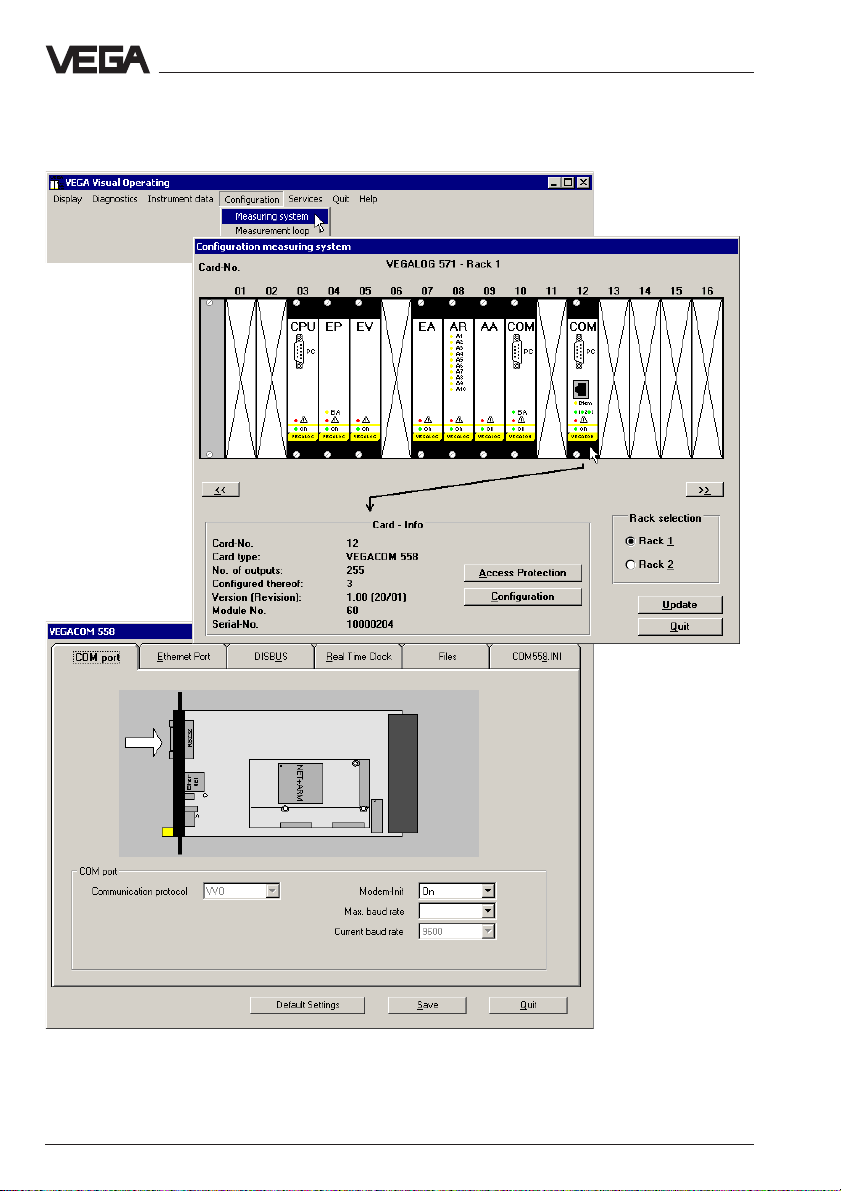

If necessary, confirm the following message (if VEGALOG or VEGAMET

was already previously connected to VVO, another message appears)

and wait until data transmission is finished.

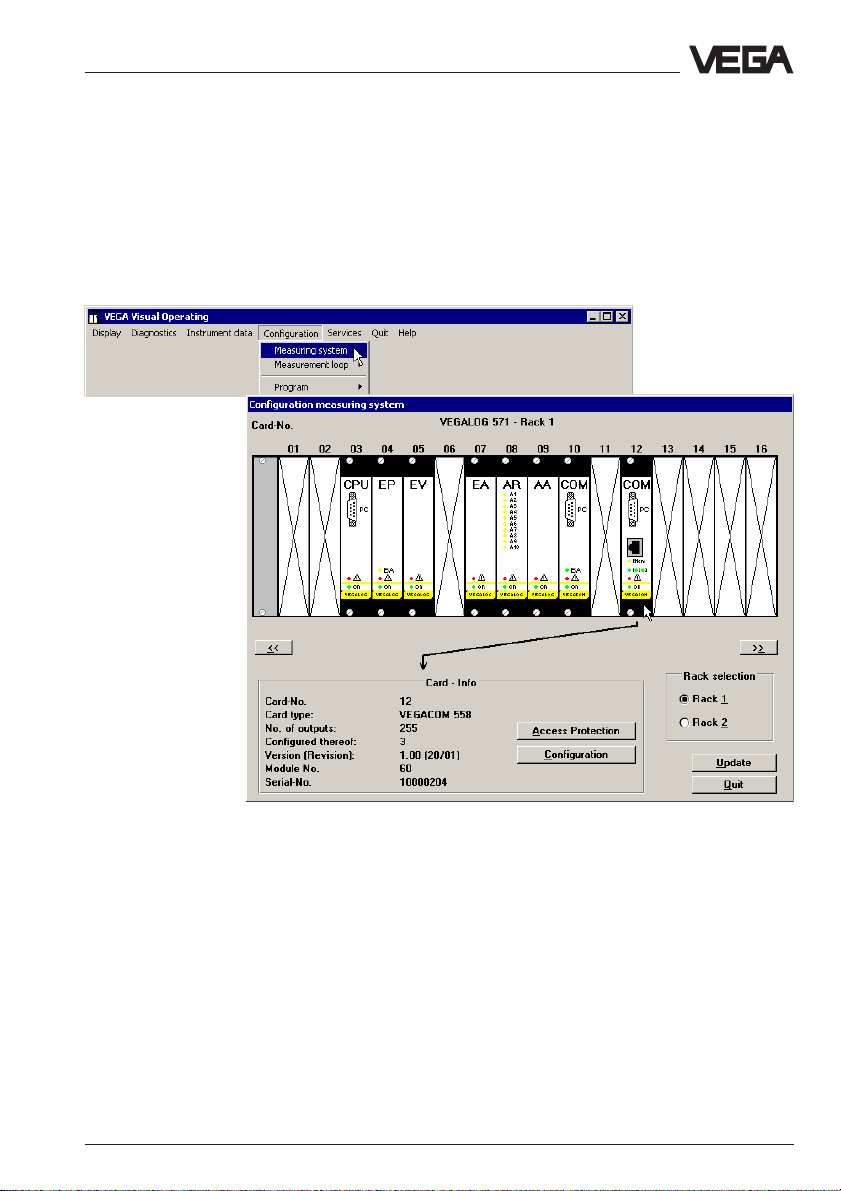

VVO now shows the connected instrument, in this case a VEGALOG with

a VEGACOM 558 which is connected via the standard serial interface to

the PC. Click to Configuration and to Measuring system.

VEGACOM 558 Ethernet 13

Page 14

Configuration of VEGACOM 558

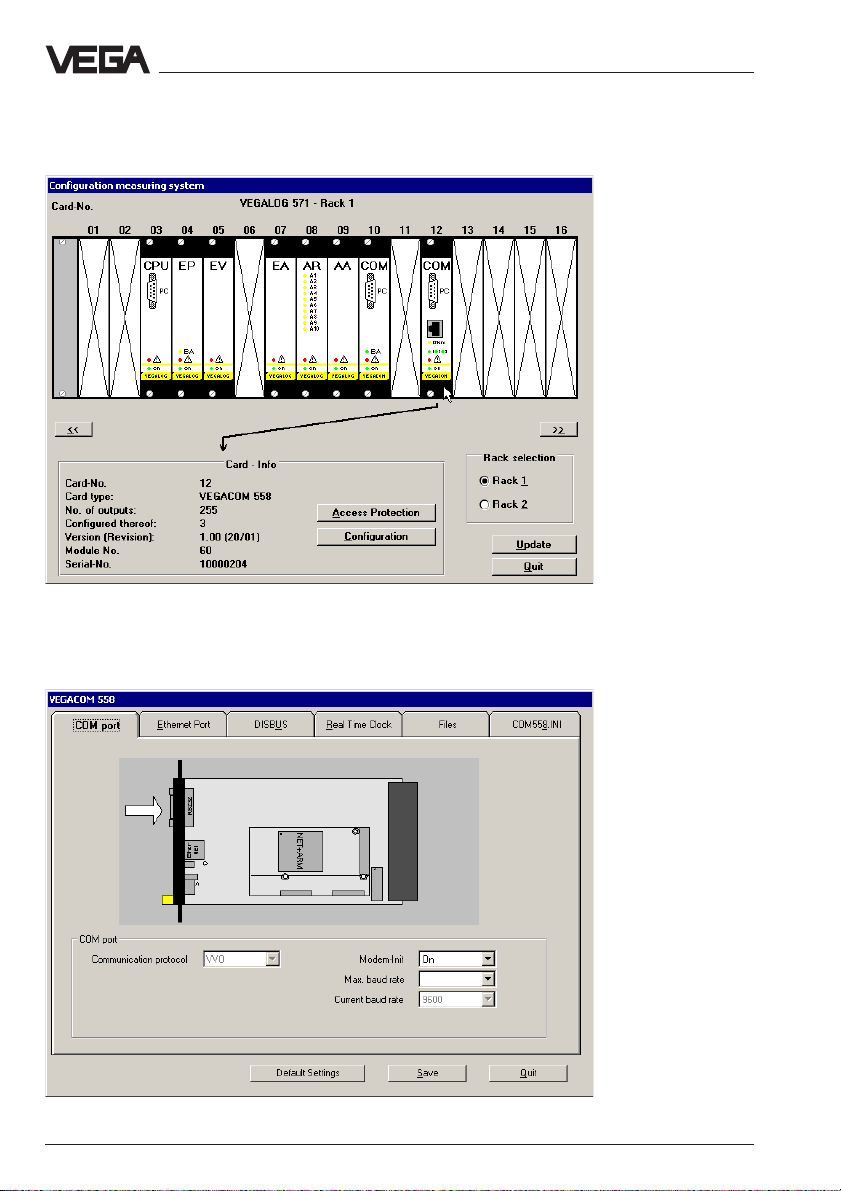

Click in the following window to VEGACOM 558 and then the button

Configuration (VEGACOM can, however, be located in other positions

than shown here).

The following image shows the configuration window of VEGACOM 558.

By clicking different registers, all parameters of VEGACOM 558 can be

reached.

14 VEGACOM 558 Ethernet

Page 15

Configuration of VEGACOM 558

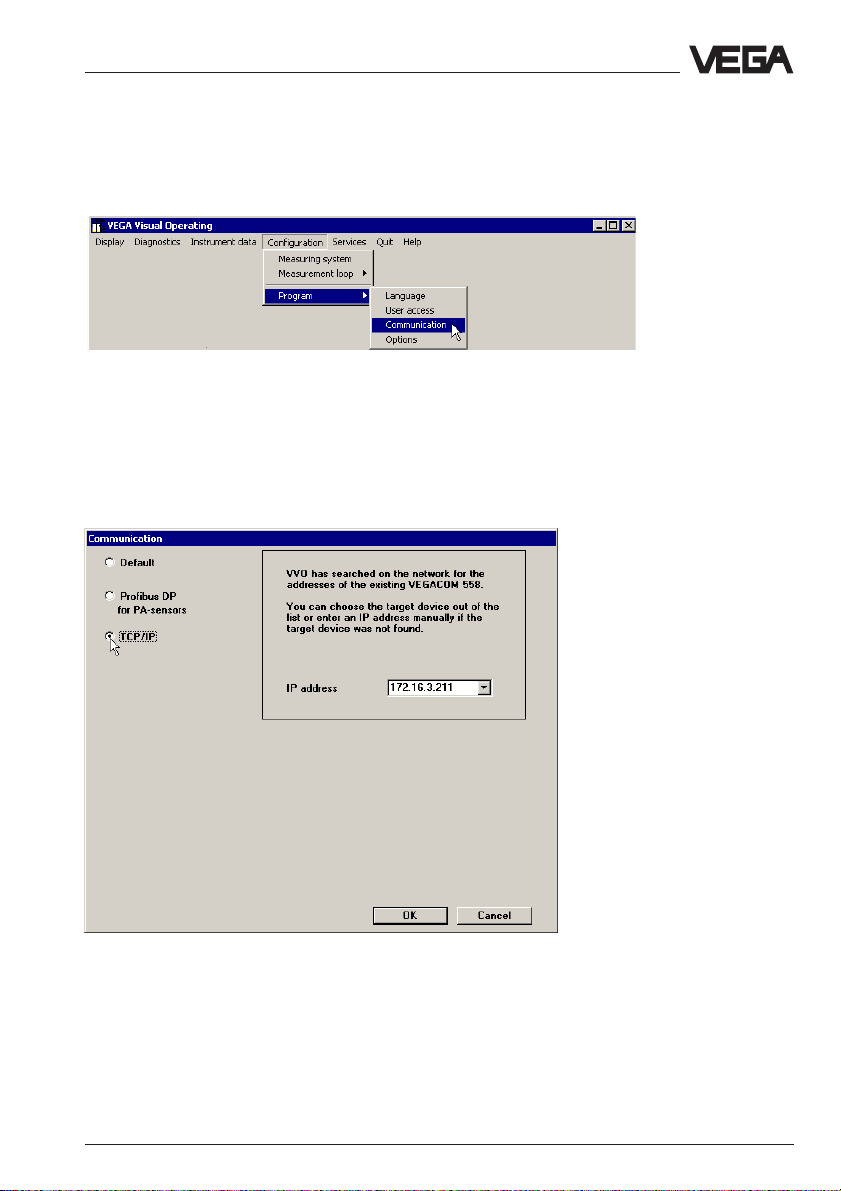

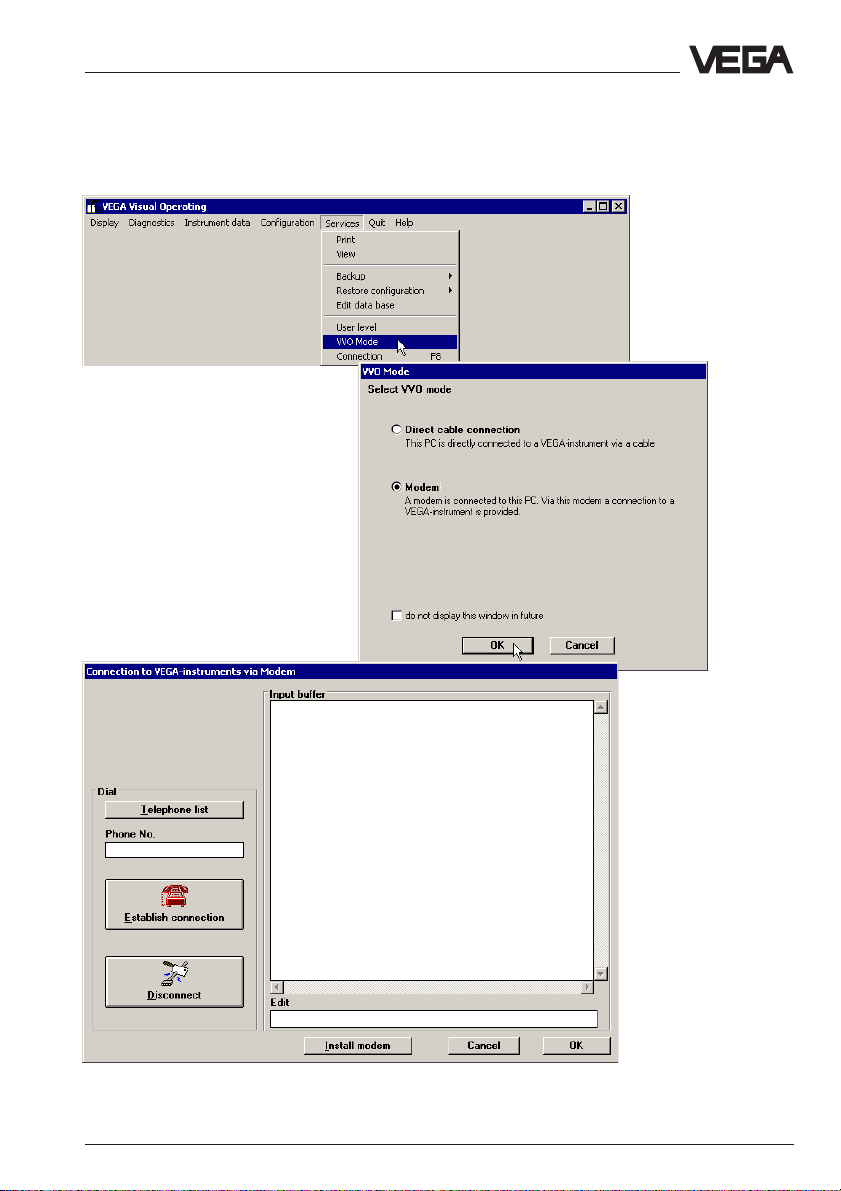

5.1 Adjust communication mode with VV O

During installation, VVO is set to "serial communication" (standard). For

access via Ethernet to VEGACOM, VVO must be switched over. Click in

the VVO main window to Configuration > Program > Communication.

Choose in the window "Communication" TCP/IP. VVO searches the network for existing VEGACOMs and enters the result (IP addresses) in

the list box. Then the requested VEGACOM can be selected out of the

list. If it is not found by VVO (because it is probably switched off or not

already connected), the IP address must be entered manually. After

confirmation with OK, VVO searches the network and makes a connec-

tion to the instrument.

If a connection to a VEGACOM 558 (whose IP address has already

been entered) should be made at a later time, you only have to select it

from the list.

VEGACOM 558 Ethernet 15

Page 16

Configuration of VEGACOM 558

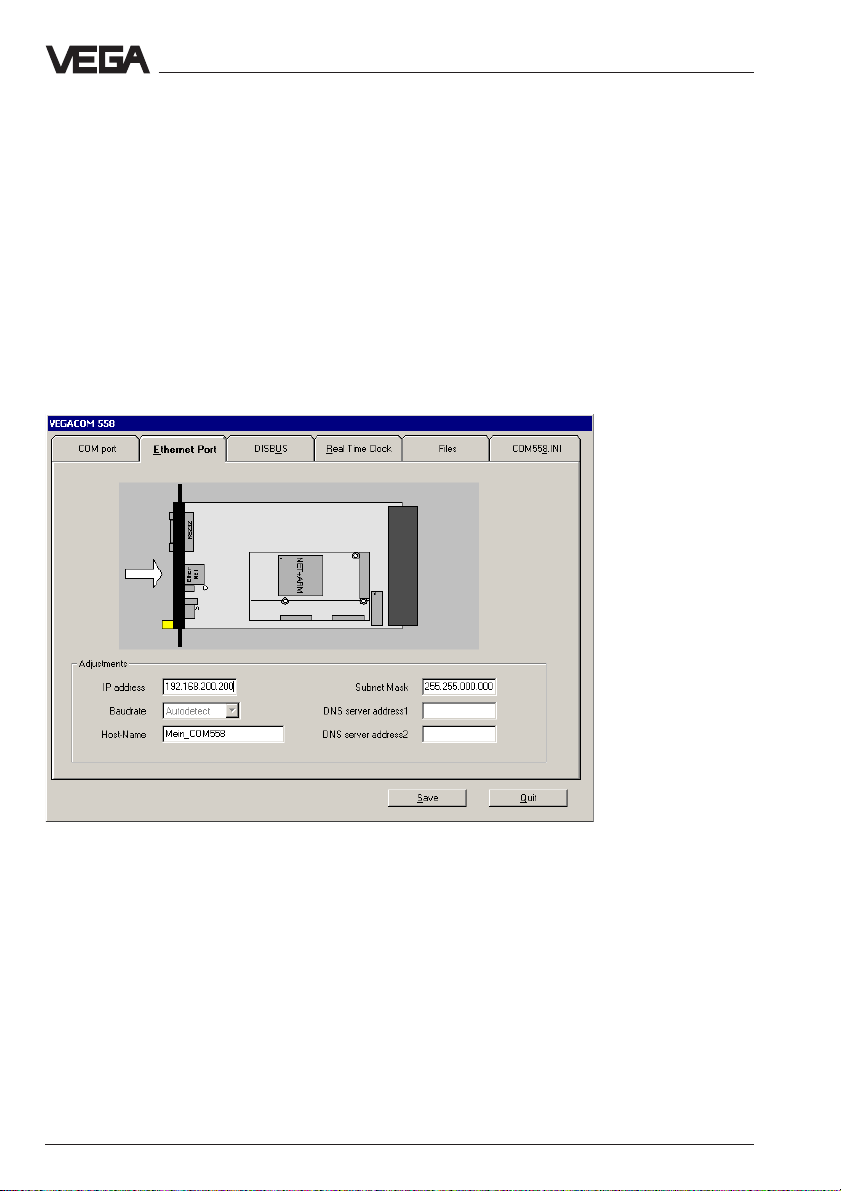

5.2 IP address

If the instrument is to be connected to the network, it must have an IP

address for identification on the net. As default, VEGACOM 558 has IP

address 192.168.200.200.

Generally, the system administrator assigns a unique IP address for

each network participant. To assign this address on VEGACOM 558,

move to the configuration window of VEGACOM (here it doesn’t matter if

a serial or a network connection exists). There you click the register

Ethernet Port. In the fields, you enter the IP address and a host name,

if necessary also the subnet mask and DNS server addresses. Make

sure that the host name does not contain special or blank characters.

The baud rate can remain at Autodetect. Then you have to Save. With

Quit (push twice) you return to the VVO main window.

16 VEGACOM 558 Ethernet

Page 17

Configuration of VEGACOM 558

5.3 Connection via modem

If VEGACOM 558 is to be adjusted via modem, you have to adjust the

mode Modem (as shown in the following three images).

VEGACOM 558 Ethernet 17

Page 18

Configuration of VEGACOM 558

For modem operation, also note the settings in the configuration window

of VEGACOM. As default, the modem initialisation is switched on and the

baud rate is set to 9600. These settings relate to the local modem.

For detailed information on modem operation, see operating instructions

"Remote parameter adjustment".

18 VEGACOM 558 Ethernet

Page 19

Configuration of VEGACOM 558

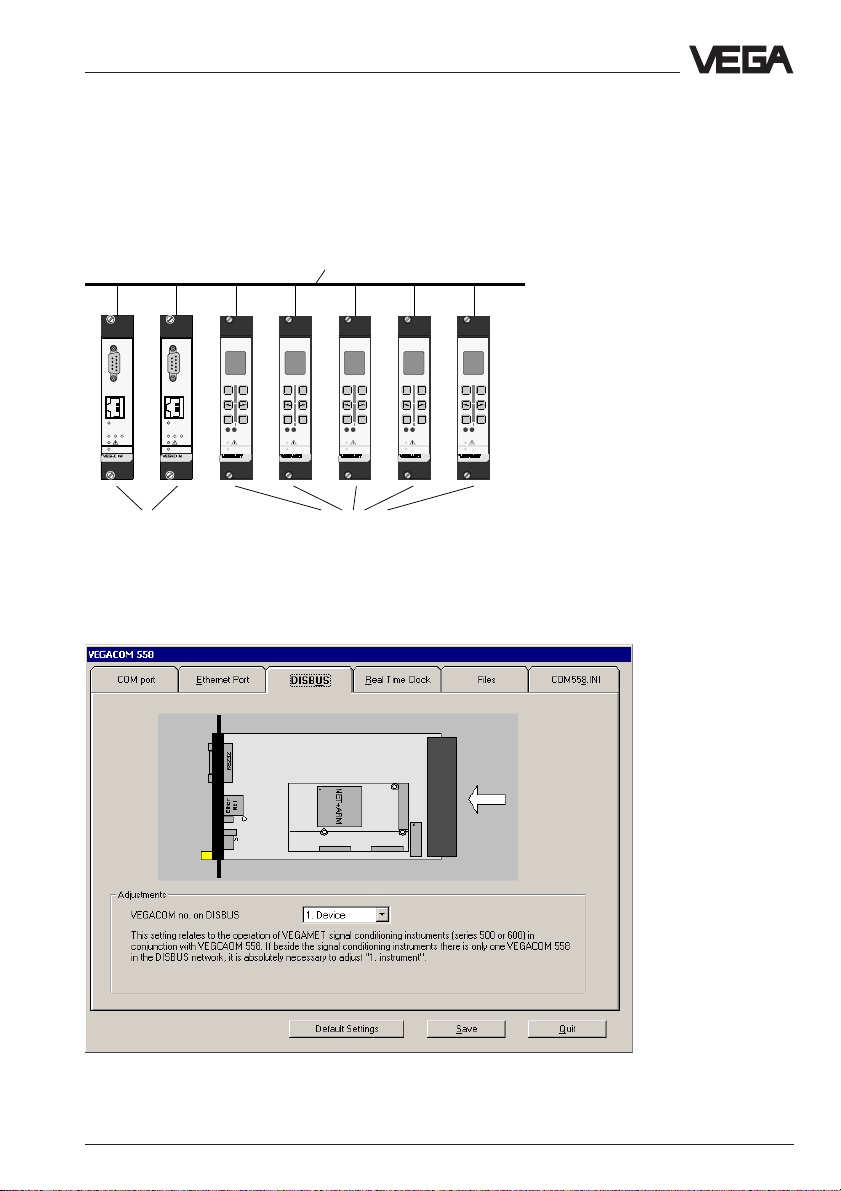

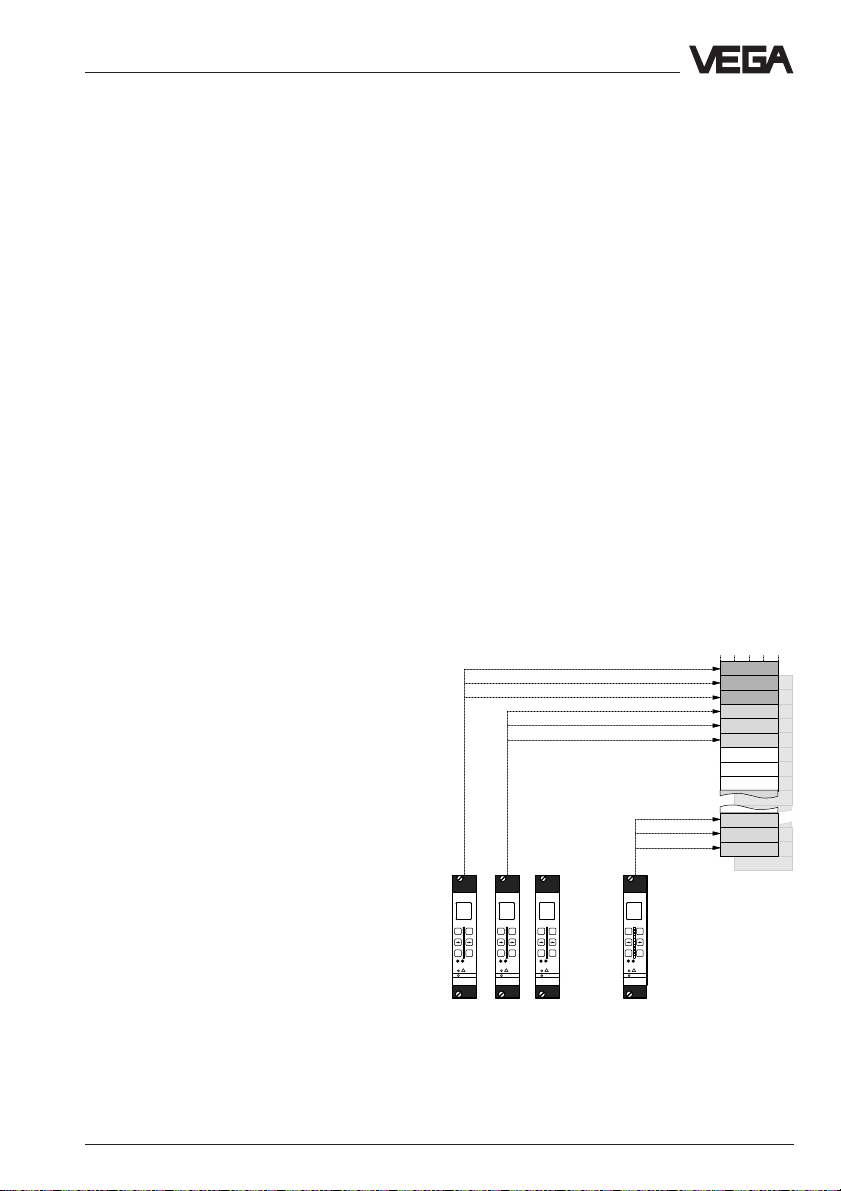

5.4 VEGACOM 558 on DISBUS

If VEGACOM 558 is operated in conjunction with VEGA signal conditioning instruments (e.g. VEGAMET 515, VEGAMET 614), it is a participant

on the DISBUS. Max. 15 VEGAMETs can be connected to the DISBUS,

in addition, two participants can be a VEGACOM 558.

DISBUS

PC

PC

%

%

%

100

100

+

-

Ethernet

Ethernet

321

on

on

558

CONNECT

321

on

558

+

-

-

OKESC

OKESC

CONNECT

on

513

on

513

%

100

100

+

-

OKESC

CONNECT

on

513

%

100

+

+

-

OKESC

CONNECT

OKESC

CONNECT

on

513

513

VEGACOM 558 (max. 2) Signal conditioning instru-

ments (max. 15)

All DISBUS participants must be addressed (1 … 15). On VEGACOM

558, this is done in the configuration window (1. device or 2. device).

VEGACOM 558 Ethernet 19

Page 20

Configuration of VEGACOM 558

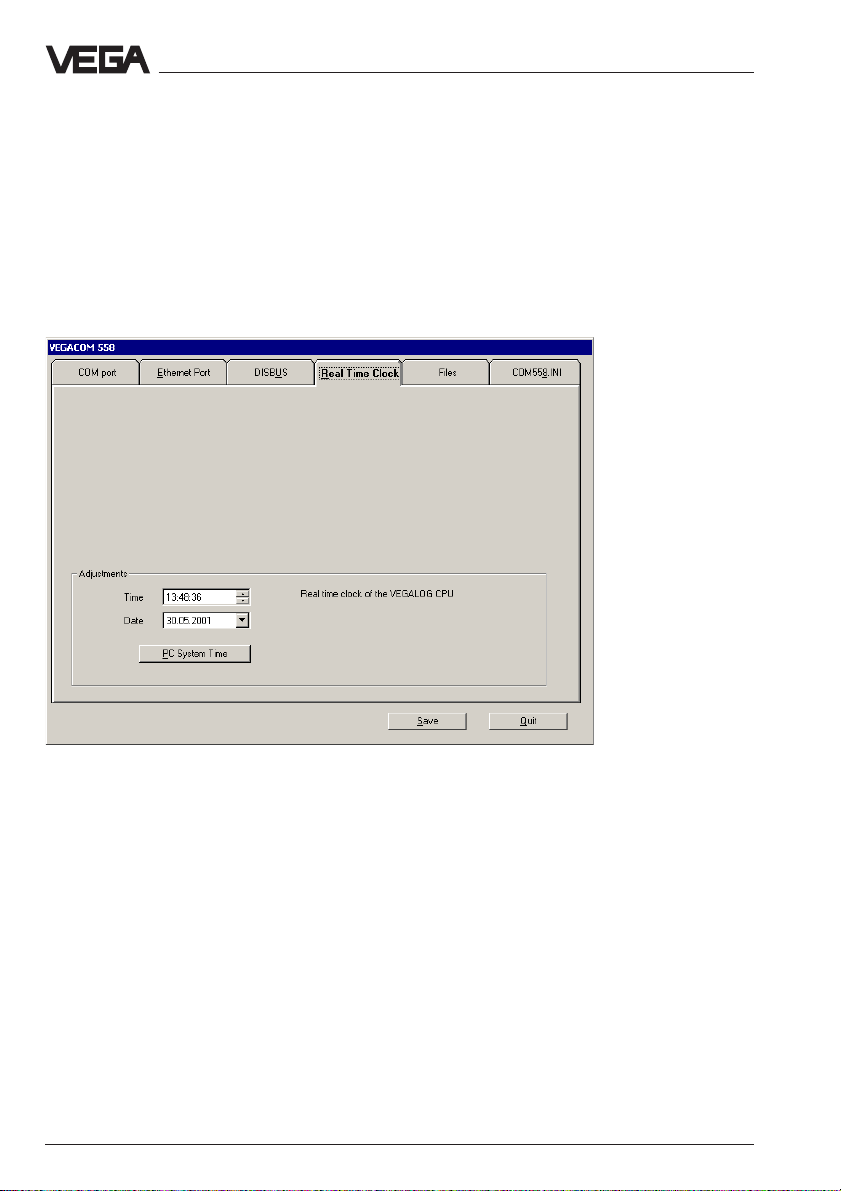

5.5 Real time clock

Since VEGACOM 558 can send time-controlled emails, the current time

must be available. In the CPU card of VEGALOG 571 there is a batterybuffered real time clock which is used by VEGACOM. In the illustrated

configuration window, you can set time and date manually or they can

be transferred with the button PC system time from the PC to the RAM

memory of the CPU card.

With Save, the time is permanently saved and and remains even in case

of mains failure.

Note:

If VEGACOM 558 is used in conjunction with DISBUS, no buffered real

time clock is available. After a supply interruption to VEGACOM, the time

must be readjusted.

20 VEGACOM 558 Ethernet

Page 21

Configuration of VEGACOM 558

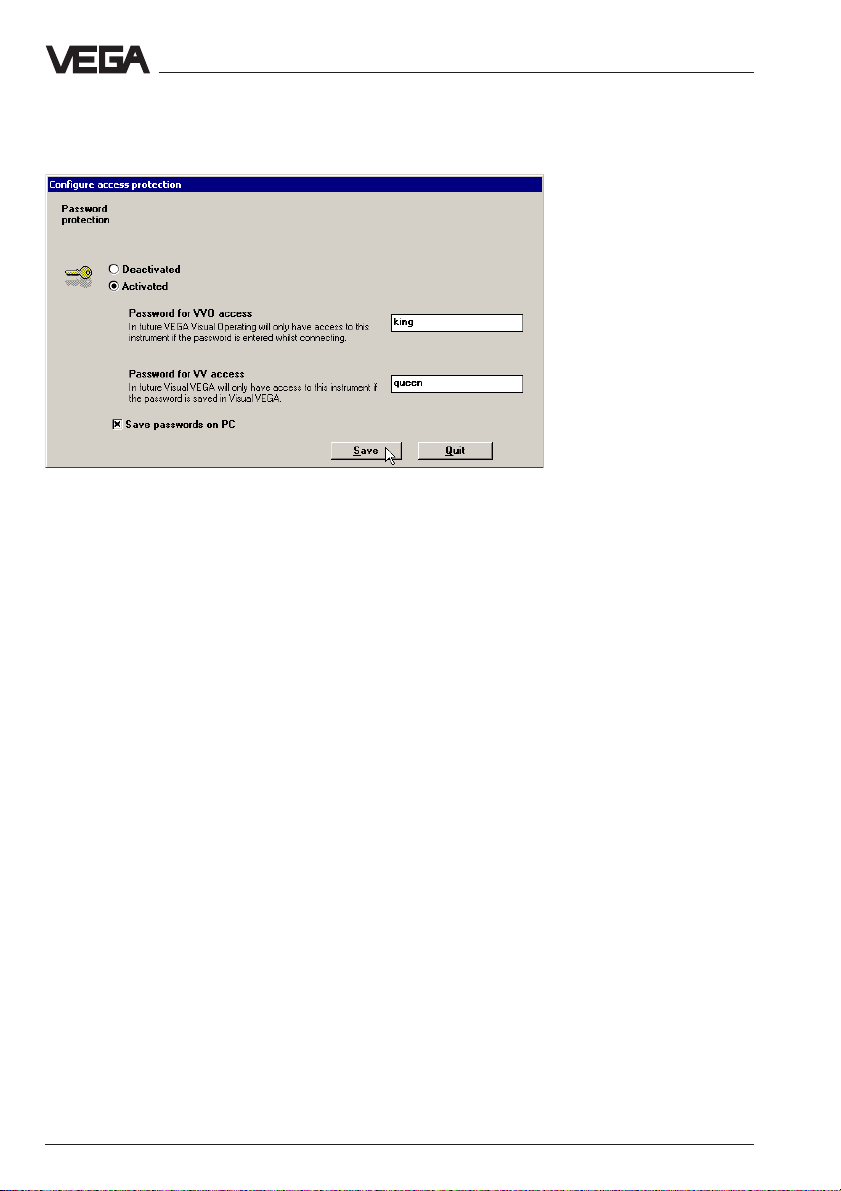

5.6 Activate password protection

To avoid unauthorised access to VEGACOM 558 and the connected

processing systems VEGALOG or VEGAMET, they can be protected

by a password. Especially when VEGACOM is adjusted via network

and is therefore accessible to each network participant, it can be important to preclude unauthorised adjustment. Click to Configuration >

Measuring system, in the window "Configuration Measuring system"

you click to the VEGACOM 558 and then to Access protection.

VEGACOM 558 Ethernet 21

Page 22

Configuration of VEGACOM 558

In the following window, you have to choose Activated and enter a

password for access with VVO as well as with VV (adjustment software

Visual VEGA). Then Save the setting.

However, the access protection is not yet activated, and only with the

next VVO start (and with switch-over of the communication mode from

standard to network and vice versa) will you be asked to enter the

password.

22 VEGACOM 558 Ethernet

Page 23

Data image in VEGACOM 558

6 VEGACOM 558 as Modbus / TCP server

VEGACOM 558 collects measured values of

the VEGAMET 513, 514, 515 and 614 signal

conditioning instruments (via DISBUS) or

VEGALOG 571 (via LOGBUS) and stores

them temporarily for collection via MODBUS /

TCP.

The way the measured values are stored in

the temporary storage of VEGACOM 558 for

the higher-priority processing system depends on the selected configuration. It depends on whether VEGACOM 558 is

connected to DISBUS or LOGBUS.

VEGACOM 558 follows the "Open MODBUS /

TCP Specification" release 1.0 from Schneider Electric. This standard is supported by

many process control systems, remote IO’s,

visualisation programs and OPC servers.

Note:

When connecting to DISBUS, the storage of

measured values can be determined additionally via the HTML configuration page

"General".

Beside the measured values, it is also possible to call up the status of the contact inputs

and outputs via VEGACOM 558.

Call up of the measured values via:

- Function code 04 (= Read Input Registers)

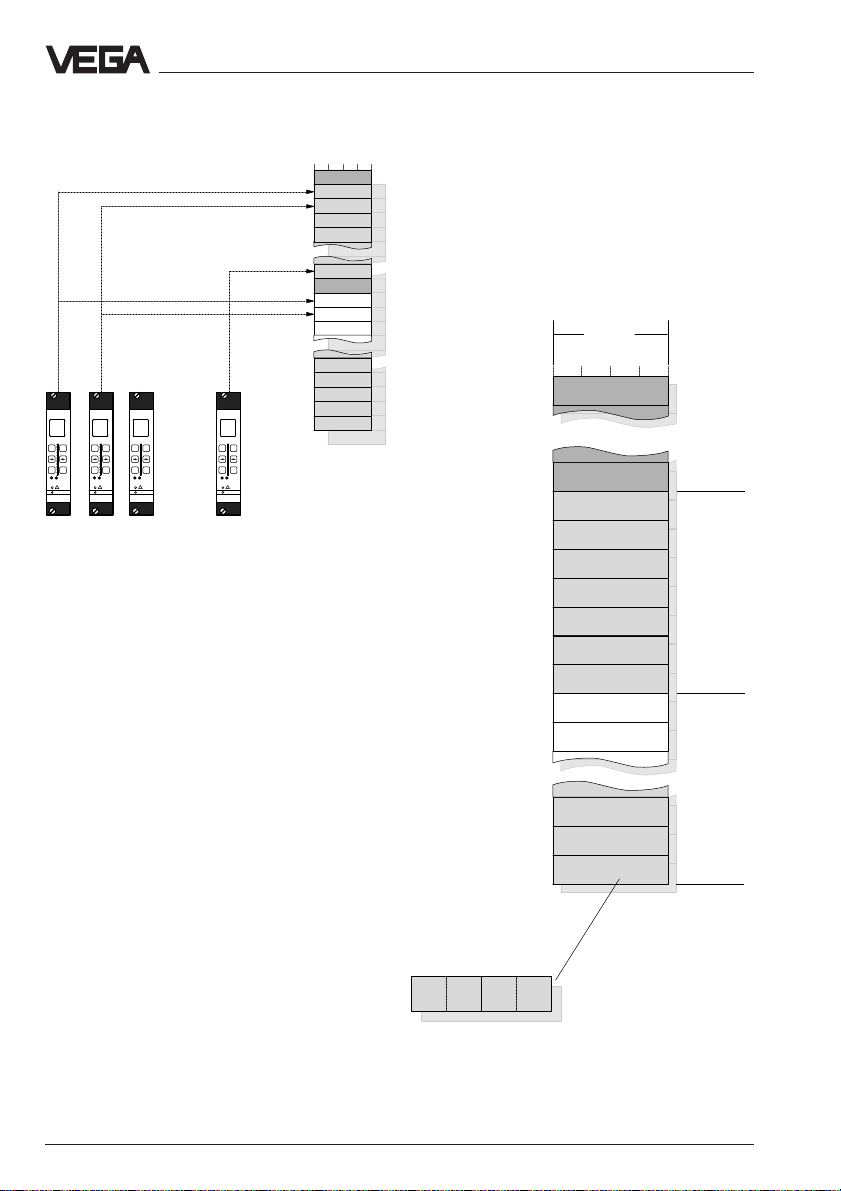

6.1 Storage of measured values when connected to DISBUS

The addressing of the measured values for

Modbus systems is "word-oriented". In

VEGACOM 558, a measured value is represented by two words, the first word includes

the real measured value, the next higher

word the associated status information. In the

standard, the term "register word” is also

used instead of the term "word”. The addressing is done via existing library calls of

the process control system (e.g. Modicon).

As already mentioned, the storage of measured values for VEGAMET signal conditioning

instruments can be influenced by the user.

For this purpose, a connection to VEGACOM

558 must first be provided via a web

browser. By activating the entry "DCS 1-7

from MET 1, …" in the section "storage of

measured values for MODBUS / TCP” in the

HTML page "General", the measured values

are saved in rising sequence acc. to the

VEGAMET addresses.

all measured values

from VEGAMET #1

all measured values

from VEGAMET #2

Call up of the switching conditions via:

- Function code 01 (= Read Coil Status) or

alternatively via

ESC OK

VEGAMET

%

100

+

-

CONNECT

!

on

513

all measured values

from VEGAMET #15

%

100

+

-

ESC OK

CONNECT

!

on

VEGAMET

513

Temporary memory

of VEGACOM 558

- Function code 02 (= Read Input Status).

%

%

100

100

+

+

-

-

ESC OK

ESC OK

CONNECT

CONNECT

!

!

on

on

VEGAMET

VEGAMET

513

513

Grouping of measured values acc. to VEGAMET

addresses

VEGACOM 558 Ethernet 23

Page 24

Data image in VEGACOM 558

If the entry "DCS 1 from MET 1-15, …" is

activated, the measured values will be

grouped acc. to DCS indices or channels.

all DCS outputs with index =1

all DCS outputs with index =2

%

100

+

-

ESC OK

CONNECT

!

on

VEGAMET

513

Grouping of measured values acc. to DCS indices or

channels

-

ESC OK

VEGAMET

%

%

100

100

+

+

-

ESC OK

CONNECT

CONNECT

!

!

on

on

VEGAMET

513

513

ESC OK

VEGAMET

%

100

+

-

CONNECT

!

on

513

Temporary memory

VEGACOM 558

Addressing of measured values when

connected to DISBUS

With grouping acc. to VEGAMET address

(DCS 1 from MET 1, …)

Organisation of the temporary memory for

VEGAMET 513, 514, 515 or 614 signal conditioning instruments

Register

address

in

Modicon

30001

30013

30015

30017

30019

30021

30023

30025

30027

30029

30031

Temporary memory

in VEGACOM 558

4 Byte

reserved

reserved

DCS output 1

DCS output 2

DCS output 3

DCS output 4

DCS output 5

DCS output 6

DCS output 7

DCS output 1

DCS output 2

VEGAMET

with DISBUS

address 1

VEGAMET

with DISBUS

address 2

Sta-

tus

DCS output 5

DCS output 6

DCS output 7

VEGAMET

with DISBUS

address 15

Note:

A complete overview of the process image of

30219

30221

30223

Meas. value

High-

Byte

Grouping of measured values acc. to VEGAMET

addresses on VEGAMET 513, 514, 515 or 614

Low-

Byte

Add. info

Meas.

unit

VEGACOM 558 can be found in supplement

A at the end of this operating instructions

manual

24 VEGACOM 558 Ethernet

Page 25

Data image in VEGACOM 558

Grouping acc. to DCS indices (DCS 1 from MET 1-15, … ):

Organisation of the temporary memory for

VEGAMET 513, 514, 515 or 614 signal conditioning instruments

Register

address

in

Modicon

30001

30003

30005

30007

30009

30031

30033

30035

30037

30039

30215

30217

30219

30221

30223

Temporary memory in

VEGACOM 558

4 Byte

reserved

DCS output 1

DCS output 1

DCS output 1

DCS output 1

DCS output 1

reserved

DCS output 2

DCS output 2

DCS output 2

DCS output 7

DCS output 7

DCS output 7

DCS output 7

DCS output 7

VEGAMET

with

DISBUS

address =

1

2

3

4

15

1

2

3

11

12

13

14

15

Meas. value

High-

Byte

Low-

Byte

Add. info

Meas.

unit

Sta-

tus

Grouping of measured values acc. to DCS indices for

VEGAMET 513, 514, 515 or 614

Note:

A complete overview of the process image of VEGACOM 558 can be found in supplement A at

the end of this operating instructions manual

VEGACOM 558 Ethernet 25

Page 26

Data image in VEGACOM 558

6.2 Storage of contact inputs/outputs when connected to DISBUS

Beside the previously described measured

values, it is also possible to transmit switching conditions of the VEGAMET 513, 514 and

515 signal conditioning instruments via

VEGACOM 558.

This particularly includes:

- status of the contact inputs (key switch

position, etc.)

- status of the contact outputs (relay or tran-

sistor outputs)

16 register bits from VEGAMET #1

In contrast to the image of the measured

values, the image of the switching status is

"bit oriented". In the standard, these status

bits are also called register bits. The addressing of the register bits for Modbus

systems is "bit oriented". In VEGACOM 558,

a switching status is represented as register

bit, whereby all available information of a

VEGAMET is saved in an associated block of

16 register bits. The storage of a 16 register

bit block within VEGACOM 558 is controlled

via the setting of the DISBUS address on

VEGAMET. The addressing by means of the

control system is normally done by existing

library calls of a process control system

(.e.g. Modicon).

16 register bits from VEGAMET #2

16 register bits from VEGAMET #15

Temporary memory

ESC OK

VEGAMET

%

100

+

-

CONNECT

!

on

513

VEGACOM 558

-

ESC OK

VEGAMET

%

100

+

CONNECT

!

on

513

ESC OK

VEGAMET

%

%

100

100

+

+

-

-

ESC OK

CONNECT

CONNECT

!

!

on

on

VEGAMET

513

513

Image of the switching status in VEGACOM 558 for

VEGAMET 513, 514, 515 or 614

26 VEGACOM 558 Ethernet

Page 27

Data image in VEGACOM 558

Addressing of the switching conditions

when connected to DISBUS

Register

address

in

Modicon

10001

10002

10003

10004

10005

10006

10007

10008

10009

10010

10011

10012

10013

10014

10015

10016

10017

10018

10019

Temporary memory in

VEGACOM 558

1 BIT

Input contact 2

Input contact 1

reserved

reserved

reserved

reserved

reserved

Status: Inputs

Relay contact 1

Relay contact 2

Fail safe relay

reserved

reserved

reserved

reserved

Status: Outputs

Input contact 2

Input contact 1

reserved

VEGAMET

with

DISBUS

address =

1

VEGAMET

with

DISBUS

address =

2

If you imagine the 16 register bits belonging

to a VEGAMET as one 16 bit word, the

following graphical repesentation results.

Status of

inputs

Switching

status of

input

no.:

1.

Byte

Status of

outputs

12

456701234567Bit

2.

Byte

Switching

status of

output no:

The meaning of the individual bits is defined

as follows:

Status of inputs:

0 = all inputs OK

1 = input status not available (no inputs

configured or VEGAMET not available)

Switching status of inputs 1 and 2:

0 = input contact is open

1 = input contact is closed

Status of outputs:

0 = all outputs OK

1 = output status not available (no outputs

configured or VEGAMET not available)

123

0123

Switching status of outputs 1, 2 and 3 (output

3 corresponds to fail safe relay):

0 = relay is deenergised

1 = relay is energised

15

10238

10239

10240

reserved

reserved

Status: Outputs

VEGAMET

with

DISBUS

address =

Note:

Addressing of the switching conditions in VEGACOM

558 for VEGAMET 513, 514, 515 or 614

A complete overview of the process images

on the switching status of VEGACOM 558

can be found in supplement B at the end of

this operating instructions manual.

VEGACOM 558 Ethernet 27

Page 28

Data image in VEGACOM 558

6.3 Storage of measured values when connected to LOGBUS

The addressing of measured values for

Modbus systems is "word-oriented". In

VEGACOM 558, a measured value is represented by two words, whereby the first word

includes the real measured value, the next

higher word the associated status information. In the standard, the term "register word”

is also used instead of the term "word”. The

addressing is done via existing library calls

of a PLC (e.g. Modicon).

DCS output 1

DCS output 2

DCS output 3

VEGALOG 571 can administrate up to 255

measurement loops. For the transfer of the

measured values of a measurement loop,

VEGALOG provides up to 255 DCS outputs.

One or several DCS outputs with any index

can be assigned to each measurement loop.

The configuration of VEGALOG 571 is done

with the VEGA adjustment software VVO. The

selected PC/DCS output defines where the

appropriate measured values can be collected from the temporary memory of

VEGACOM 558.

Meas.

value

x

!

on

VEGALOG

Meas.

Meas.

value

y

PC

571

value

DCS output 255

Temporary memory of

VEGACOM 558

Measured value image when connected to

VEGALOG 571

28 VEGACOM 558 Ethernet

Page 29

Data image in VEGACOM 558

Addressing of measured values when

connected to LOGBUS

The measured value image when connected

to LOGBUS is always sorted acc. to the DCS

outputs, the following illustration shows the

addressing of the temporary memory via

Modbus.

Register

address

in

Modicon

30001

30003

30005

30007

30009

30011

30013

30015

30017

30505

30507

30509

Meas.

value

High-

Byte

Low-

Byte

Add. info

Meas.

unit

Temporary memory of

VEGACOM 558

4 Byte

DCS output 1

DCS output 2

DCS output 3

DCS output 4

DCS output 5

DCS output 6

DCS output 7

DCS output 8

DCS output 9

DCS output 253

DCS output 254

DCS output 255

Sta-

tus

Addressing of the measured value when connected to

LOGBUS

Note:

A complete overview of the process image of

the measured values of VEGACOM 558 can

be found in supplement A at the end of this

operating instructions manual.

VEGACOM 558 Ethernet 29

Page 30

Data image in VEGACOM 558

6.4 Storage of the contact outputs when connected to LOGBUS

Beside the previously described measured

values, it is also possible to transfer

switching conditions of the VEGALOG 571

processing system via VEGACOM 558.

This particularly includes:

- status of the contact outputs of the AR

cards (relay contacts)

- status of the contact outputs of the AT

cards (transistor outputs)

Output status of the output card on

module #1

In contrast to the imaging of measured

values, the imaging of switching status is

done "bit-oriented". In the standard, these

status bits are also called "register bits". The

addressing of the register bits for Modbus

systems is therefore "bit-oriented". In

VEGACOM 558, a switching status is

represented by one register bit, whereby all

available information of a VEGALOG output

card type AR or AT is saved within an

associated block of 16 register bits. The

storage of a 16 register bit block within

VEGACOM 558 depends on the module

position in VEGALOG 571.

The addressing by the control system is

done via existing library enquiries of a

process control system (e.g. Modicon).

Output status of the output

card on module #32

Temporary memory of

VEGACOM 558

PC

!

on

VEGALOG

571

Image of the switching status in VEGACOM 558 for

VEGALOG 571

30 VEGACOM 558 Ethernet

Page 31

Data image in VEGACOM 558

Addressing of the output status when

connected to LOGBUS

The image of the output status when

connecting to VEGALOG is always sorted

acc. to the module numbers of the output

cards, the following illustration shows the

addressing of the temporary memory via

Modbus.

Register

address

in

Modicon

10001

10002

10003

10004

10005

10006

10007

10008

10009

10010

10011

10012

10013

10014

10015

10016

10017

Temporary memory of

VEGACOM 558

1 BIT

Output 9

Output 10

reserved

reserved

reserved

reserved

reserved

Status: Card

Output 1

Output 2

Output 3

Output 4

Output 5

Output 6

Output 7

Output 8

Output 9

Values of

VEGALOG

Card on

module =

If you image the 16 register bits belonging to

a module card as one 16 bit word, the

following graphical representation results:

Status of the

output card

Switching status of output no:

8910

01234567Bit

1.

Byte

The meaning of the individual bits is defined

as follows:

Status of the output card:

0 = OK

1 = no values of the output card available

(no outputs configured or card not

available)

Switching status of the inputs with AR or AT

cards:

0 = relay deenergised

1

1 = relay energised

Note:

A complete overview of the process image of

the switching status of VEGACOM 558 can

be found in supplement B at the end of this

operating instructions manual.

4567

2.

Byte

123

4567

0123

50910510

51010511

51110512

Output 6

Output 7

Output 8

Values of

VEGALOG

Card on

module =

32

Addressing of the switching status in VEGACOM 558

for VEGALOG 571

VEGACOM 558 Ethernet 31

Page 32

Format for transfer of measured values

6.5 Format for transfer of measured values

Measured values and DCS values

The measured values of the VEGA

processing systems (VEGAMET or

VEGALOG) connected to VEGACOM 558 are

imaged on the input registers of Modicon 584

as described in chapter 6.1 and 6.3. In

VEGACOM 558, they are available for

collection as so-called DCS values.

One DCS value covers two register

addresses, this means that it consists of two

double words, i.e. 4 bytes.

A complete overview of the image of the DCS

values in the input registers of Modicon can

be found in supplement A of this operating

instructions manual.

Structure of a measured value

Measured values of VEGALOG or VEGAMET

are transferred to VEGACOM 558 as signed

data comprising 2 octets. This means, that

the value range is max. +32.768 to -32.767.

Structure of a DCS value

A single DCS value in VEGACOM 558

consists of 4 octets and consists of the

following:

DCS value

Meas. value Add. info

The octet for the measuring unit is not

presently used and is always filled with the

value zero.

The status describes the condition of the two

associated measured value octets. The

contents of the measured value octet is only

valid if the assigned status has the value

zero.

If you have a status value unequal zero, the

status value and the associated value in the

measured value field must be taken into

account for a detailed failure diagnosis. The

following list explains the possible errors:

Status Meas. Meaning

value

0x00 0x XXXX valid meas. value

0x01 0x XXXX simulated meas. value

(only with VEGAMET

509 and 512)

0x80 0x XXXX old meas. value

(probably interrupted

connection)

0xFE 0x0000 no measured value

available (not

configured)

Octet 1 Octet 2 Octet 3 Octet 4

0xFF 0xFFFF no VEGAMET or

VEGALOG connected

High-Byte Low-Byte

Maßeinheit

Status

XX = type of error

The real measured value has a length of 2

octets and is signed, this means that the

value range is between +32768 and -32767.

In addition to the measured value,

0xFF 0x8000 failure message of an

individual

measurement loop

Type of error is not

defined

VEGACOM 558 provides one octet per DCS

value for measuring unit and another octet for

information on the actual status of the

measured value.

32 VEGACOM 558 Ethernet

Page 33

VEGACOM 558 as web server

7 VEGACOM 558 as web server

7.1 VEGACOM in the Internet

In this document, the function of VEGACOM 558 as web server within

the company network is described. If the Internet can be accessed

from the company network, VEGACOM can also function as web server

in the "World Wide Web". The necessary steps are not part of this document and will be generally done by the system administrator.

7.2 Predefined web pages

If VEGACOM 558 is participant on the network, the measured values of

VEGA sensors can be shown as a Web page and an online overview of

the VEGA measuring systems can be shown with an Internet browser.

For this purpose, VEGACOM contains already predefined web pages.

To show these web pages, the IP address of VEGACOM 558 must be

entered in the browser:

http://http://

xxx.xx.x.xxxxxx.xx.x.xxx

http://

xxx.xx.x.xxx = IP address

http://http://

xxx.xx.x.xxxxxx.xx.x.xxx

The browser then calls up the following html file (start page):

http://xxx.xx.x.xxx/vega/deutsch/process/index.htmhttp://xxx.xx.x.xxx/vega/deutsch/process/index.htm

http://xxx.xx.x.xxx/vega/deutsch/process/index.htm

http://xxx.xx.x.xxx/vega/deutsch/process/index.htmhttp://xxx.xx.x.xxx/vega/deutsch/process/index.htm

VEGACOM 558 Ethernet 33

Page 34

VEGACOM 558 as web server

The html file is configured such that all existing measurement loops,

sorted according to measurement loop names, are automatically displayed (splitting in several pages, switching over via the navigation

board below the measured value tables). By clicking the link Measured

values (No.) the measurement loops will be sorted according to the

number of the DCS output. The html file, however, is not accessible and

cannot be modified.

In addition, it is possible to make different VEGACOM settings and

modifications with the browser on the predefined web pages. For this

purpose, you will find links on the web page which will pass you on to

the appropriate page. For this purpose, the web page is provided with

links leading you the the respective page. These links are not visible on

the start page. The corresponding authorisation level of the user can be

released with "Release settings". Acc. to the factory setting, first of all

each user has access. First of all, everybody can access this function

by factory setting. By activating the user management, access can be

avoided (see chapter "User administration").

- network settings (host name, modification of the IP address,

subnetwork masks and Name-Server addresses)

- web server (updating intervals of the web pages, selection of differ-

ent web pages)

- setup mail server

- definition of the email messages (recipient, documents, transmitting

times)

- title of web pages, date and time in VEGACOM 558 (important for

time-controlled emails)

- language used by VEGACOM 558 (German or English)

- user management.

Note:

Some Internet browsers use the setting

"Use temporary internet files". This

causes the browser to read the file,

once it has been loaded, again and

again from the local hard drive. This

setting should be changed to ensure

that the HTML pages are always up-todate when calling up measured values

or the configuration pages of

Links

VEGACOM.

34 VEGACOM 558 Ethernet

Page 35

VEGACOM 558 as web server

7.3 Network settings

Like with the adjustment software VVO, the IP address, sub net mask,

host name1) and Name-Server addresses of VEGACOM 558 can be also

modified with the Internet browser. An IP address must be assigned

beforehand to VEGACOM so that it can be identified on the network (IP

address set as default: 192.168.200.200).

1)

Approved are alphanumierc characters and stroke. Do not use special characters.

VEGACOM 558 Ethernet 35

Page 36

VEGACOM 558 as web server

Subnets with VEGACOM 558

For the use of subnet masks with VEGACOM 558, the same rules as for

any Ethernet host apply. A host only processes telegrams whose destination addresses have full compliance with their own subnet. A specific

subnet is determined by its own IP address and the subnet mask. By

AND linking of IP address and subnet mask, you will get the appropriate subnet. In other words, all bit positions of the subnet mask set at "1",

determine the NetID, i.e. the subnet. The more bit positions used for the

determination of the NetID, the less combinations remain for the HostID.

Example:

VEGACOM 558 IP address: 192.168.200.1 (Class-C)

Standard masking (subnet mask): 255.255.255.0

This means for VEGACOM 558:

- VEGACOM 558 is in the subnet 192.168.200.0 (with max. 253 partici-

pants)

- VEGACOM 558 processes all telegrams on the Ethernet whose desti-

nation addresses start with 192.168.200.

- VEGACOM 558 itself can only transmit telegrams whose destination

addresses start with 192.168.200

Improved masking by e.g.: 255.255.255.128

This means for VEGACOM 558:

- By setting an additional bit in the subnet mask, the above-mentioned

subnet will be divided into two sections.

- VEGACOM 558 is now in subnet 192.168.200.0 (with max. 126 partici-

pants)

- VEGACOM 558 processes all telegrams on the Ethernet whose desti-

nation addresses are between 192.168.200.1 and 192.168.200.127.

- VEGACOM 558 itself can only drop off telegrams whose destination

addresses are between 192.168.200.1 and 192.168.200.127

36 VEGACOM 558 Ethernet

Page 37

VEGACOM 558 as web server

DNS by means of VEGACOM 558

If an application on a host (with VEGACOM 558 e.g. the Mail Client or

PING in TELNET window) tries to call another network participant with its

host name, the enquiring computer first has to know the IP address of

the destination computer.

The following steps are carried out:

Step 1:

The enquiring computer (VEGACOM 558) first asks via an ARP enquiry

for the MAC address of the entered DomainNameServers in the network. If available, the MAC address is returned.

Step 2:

The enquiring computer (VEGACOM 558) transmits a DNS telegram to

the DomainNameServer asking "which IP belongs to the host name xyz".

If the name server can resolve the host name, it will return the requested

IP directly as answer (probably the enquiry will be transferred to another name server).

Step 3:

The enquiring computer (VEGACOM 558) can now transmit the telegrams directly to the destination computer, the IP of which is known

now.

Note!!!

Conversion of the DNS configuration is currently only effective after a

restart of VEGACOM 558.

VEGACOM 558 Ethernet 37

Page 38

VEGACOM 558 as web server

Determine standard gateway for VEGACOM 558

From Rev. 1.10, VEGACOM 558 supports gateways or routers, whereby

these must be accessible within the subnet with regard to their IP address.

This means:

If a gateway address is entered in VEGACOM 558 which does not fit the

network address and the subnet, VEGACOM 558 will deactivate the

gateway support.

Function:

If a gateway address unequal 0 is entered in VEGACOM 558, the gateway functionality will be activated. The above-mentioned boundary condition, that the used address must be accessible within the subnet /

NetworkID, is a prerequisite.

Example:

If Host A (192.168.200.10) tries to reach a Host B in network

192.168.201, the protocol software in Host A determines by means of

the subnet entry that the destination host is in another network. If an IP

address is defined for a gateway, Host A will transmit an ARP enquiry to

the entered gateway to get its MAC address. Finally Host A transmits

the requested telegram to Host B, whereby the destination IP of the

destination computer (i.e. Host B) is entered, however, as destination

MAC, the destination IP of the gateway is used.

AB

192.168.200.10 192.168.201.4

Gateway / Router

E

t

h

e

r

n

e

t

1

9

2

.

1

6

8

.

2

0

0

192.168.200.1 192.168.201.1

192.168.200.2 192.168.201.6

E

t

h

e

r

n

e

t

1

0

2

.

8

6

1

.

2

9

1

By handing from one network to the other, the router replaces in the

received datagram the destination MAC address, either with the one of

the next router or with the one of the addressee (provided it can be

reached already directly).

On VEGACOM 558, the announcement of a router/gateway is carried

out exclusively by manual configuration.

38 VEGACOM 558 Ethernet

Page 39

VEGACOM 558 as web server

7.4 Web server settings

Here you can adjust the updating intervals of the html page. The empty

field can be used for a file created by yourself (see chapter "8 Your own

html documents"). The field list then always extends itself by one new

position by pushing the button "Save list". If you open a file entered into

the list via an Internet browser, the browser will call up this page cyclically acc. to the set updating period.

7.5 Send emails

First of all, the mail server must be set up so that VEGACOM 558 can

send emails. Enter the IP address of the mail server in the field "IP address of the outbox server (SMTP)" (you will get the IP address from the

network administrator). If the mail server has Internet access, it is possible to send emails worldwide.

VEGACOM 558 Ethernet 39

Page 40

VEGACOM 558 as web server

You must then define the mail recipients1) (in the field "email address”).

Any weekday or exact daily time can be entered as transmission time.

Instead of the entered documents

be sent, e.g.

layouts/val_name.htm layouts/val_name.htm

layouts/val_name.htm (see chapter "8 Your own html

layouts/val_name.htm layouts/val_name.htm

val_name.htmval_name.htm

val_name.htm , your own file can also

val_name.htmval_name.htm

documents").

If you want to send text files instead of the html file by email, you can

enter as attachment document var/pls.csv. Contrary to html files, this file

can be easily integrated into other documents for further processing

(registered…). For this kind of processing, VEGACOM 558 provides in

the directory "var/" two files which will be updated approx. every 5 s.

The file named

var/pls.csvvar/pls.csv

var/pls.csv includes DCS no., Tag names, measured

var/pls.csvvar/pls.csv

values and associated units of all measurement loops of the connected

VEGA system in ASCII format, whereby the individual fields are separated by ";".

The file named

var/rel.csvvar/rel.csv

var/rel.csv includes card number and switching status of

var/rel.csvvar/rel.csv

the associated relay output of all module cards for the connected VEGA

system in ASCII format, whereby the individual fields are separated by

";".

- pls.csv: Includes all measured values of the measurement loops incl.

DCS output number, TAG name and unit configured in the VEGA

processing system connected to VEGACOM 558.

Beispielplot:

#VERSION: 1.0

#FROM: COM558_Mast

#DATE: 05.07.2001 10:05

#FIELDS: Pls;Tag;Value;Unit

001;aa_temperatur ; 96.46;Lin%

002;Grenz_kapazitiv ; ——;Lin%

003;druck_kompakt ; ——;Lin%

1)

Approved are alphanumierc characters and stroke. Do not use special characters.

40 VEGACOM 558 Ethernet

Page 41

VEGACOM 558 as web server

- rel.csv: Includes the switching status of all relay outputs or

contact inputs (only with VEGAMET) of the measurement loop

including all card numbers for VEGALOG or DISBUS addresses

for VEGAMET configured in the VEGA processing system connected to VEGACOM 558.

Example plot on VEGALOG:

#VERSION: 1.0

#FROM: COM558_Mast

#DATE: 05.07.2001 10:14

#FIELDS: Card;R1;R2;R3;R4;R5;R6;R7;R8;R9;R10

01;-;-;-;-;-;-;-;-;-;02;-;-;-;-;-;-;-;-;-;03;-;-;-;-;-;-;-;-;-;04;-;-;-;-;-;-;-;-;-;05;-;-;-;-;-;-;-;-;-;06;-;-;-;-;-;-;-;-;-;07;0;0;0;0;0;0;0;0;0;0

Note: Only the "own" contact inputs will be displayed. If a

VEGAMET uses the inputs of another VEGAMET, these status will

not be shown in the CSV file.

After sending the mails, a status message (confirmation) is made if

the mails are received by the mail server. When clicking the link

Diagnostic buffer, you will see details on sent emails.

Independent of automatic sending of emails, it is always possible to

manually send a message with the current measured values. To do

this, click the link Submit mail.

VEGACOM 558 Ethernet 41

Page 42

VEGACOM 558 as web server

In the following window, you can enter and then send immediately the

email address, a text and an attached file.

7.6 Language of VEGA COM 558

With the selection of the language (German or English), not only the

language of the screen user interface is modified. An important consequence of changing the language is the calling up of a different html

page. With the language English, VEGACOM displays the file http://

xxx.xx.x.xxx/Index_uk.thml when entering the address:

englisch/process/index.htmenglisch/process/index.htm

englisch/process/index.htm..

englisch/process/index.htmenglisch/process/index.htm

/vega//vega/

/vega/

/vega//vega/

42 VEGACOM 558 Ethernet

Page 43

VEGACOM 558 as web server

7.7 Real time clock

Since VEGACOM 558 can send time-controlled emails, the current time

must be available. There is a battery-buffered real time clock in the CPU

of VEGALOG 571 which is used by VEGACOM. In the illustrated configuration window, time and date can be adjusted manually and transferred to the RAM memory of the CPU card.

With Save, the time will be permanently implemented and remains even

in case of mains failure.

Note:

If VEGACOM 558 is used in conjunction with DISBUS, no buffered real

time clock is available. After a supply interruption to VEGACOM, the time

must be readjusted.

VEGACOM 558 Ethernet 43

Page 44

VEGACOM 558 as web server

7.8 User Management

The web server of VEGACOM 558 enables the user to read out all measured values of the level measuring system, or to spy on them, so to

speak to. In addition, fundamental configurations such as authentication,

mailing lists etc. can be modified. To avoid inadvertent or deliberate

manipulation of the data bank of VEGACOM 558, the web service must

be protected against unauthorised access.

For this purpose, the VEGACOM 558 web server offers basic functions

for user management. The user management system works directoryoriented, i.e. access authorisation can be defined for certain directories.

To keep the complexity of user management to a minimum, VEGACOM

558 does not offer the option of defining new user authorisations to create new user groups. Rather, ten fixed user groups with fixed user rights

are stored in VEGACOM 558.

The administrator of VEGACOM 558 can now assign any number of

users with hteir individual passwords to these ten user groups. The

allocations are made via the web browser in the menu item "

agementagement

agement" on the VEGACOM 558 web pages.

agementagement

User man-User man-

User man-

User man-User man-

44 VEGACOM 558 Ethernet

Page 45

VEGACOM 558 as web server

7.8.1 Factory setting

VEGACOM 558 is factory set to user management = Off. If the user

management is activated for the first time (see chapter "7.8.2 User management On/Off"), two users are preconfigured (delivery status).

User Password Group

ADMIN ADMIN ADMINISTRATOR

VEGA VEGA PROJEKTIERER

7.8.2 User management On/Off

As a standard feature, VEGACOM 558 is delivered with status "User

management = INACTIVE". In this setting, access to all web pages of

VEGACOM 558 via the web browser is possible from any computer in

the network without authentication. The current user is displayed as

"– – – –".

In the page "User management", the activation can be carried out with

the push button

Activate user managementActivate user management

Activate user management.

Activate user managementActivate user management

VEGACOM 558 Ethernet 45

Page 46

VEGACOM 558 as web server

7.8.3 Assignment of users to user groups

When the page "User management" is called, VEGACOM 558 automatically generates a complete list of currently defined users. Beside the

existing users, the assigned user groups will also be listed automatically.

All items on this page are defined as "read only"!

To modify this list, the following functions are available via "Push buttons":

- Delete - deletes users from a list

- Modify - opens the menu "Modification of user data", shown

Add userAdd user

With "

Add user", the dialogue for creating a new user is opened. This

Add userAdd user

dialogue generally corresponds to the dialogue "Modify user data".

below

Field user name:

Here, any user name can be entered. The name must be unambiguous,

i.e. it must not be used already and can have between 1 … 16 characters (only a … z, A … Z, 0 … 9).

Field password:

Here you can enter a password belonging to the user. The presentation

is hidden, i.e. one asterix per entered character appears in the entry

field. The password can consist of 1 … 16 characters (only a … z,

A … Z, 0 … 9). The input of a password is not absolutely necessary.

Field user group:

Select the requested user group from the list box.

46 VEGACOM 558 Ethernet

Page 47

VEGACOM 558 as web server

7.8.4 Directories/Areas

When the page "User management" is called, VEGACOM 558 automatically generates a complete list of the current directories in the RAM disk

of VEGACOM 558. Beside the existing directories, the assigned user

groups will also be listed.

With the button "

user group, and therefore user authorisation, can be modified.

Directory name and user group are taken over from the activated line on

the user management page.

ModifyModify

Modify", available for each entry, the assignment of the

ModifyModify

The field of the directory name is still "read only".

The requested user group can be selected from the list box.

VEGACOM 558 Ethernet 47

Page 48

VEGACOM 558 as web server

7.8.5 Selectable user groups and their access authorisation

To give the operator of a VEGA measuring system (in conjunction with

VEGACOM 558) the ability to transmit selective information to certain

subcontractors or company staff, there must be an option for user-dependent access control.

The following user groups are preset in VEGACOM 558. The administrator can assign any user to hte first eight.

All users assigned e.g. to the group "Planning" will have access authorisation for the directories (and the subjacent ones) which are assigned to

"Planning".

The "rights" (write, read) of the first eight user groups are identical. By

means of the group names, a logical, hierarchic graduation is created.

Exactly this hierarchic graduation for assignment of user groups to directories is preset at the factory. If this setting remains unchanged, the

following access options result.

Group Access to own, Access to Access to Access to

ADMINISTRATOR x x x x

PLANNING x x x

MAINTENANCE x x

USER GROUP 1 x

USER GROUP 2 x

USER GROUP 3 x

USER GROUP 4 x

USER GROUP 5 x

ALL

NO ACCESS

also measured value configuration pages "/SYSTEM"

customer-specific, pages (plant) (plant) area

web pages

48 VEGACOM 558 Ethernet

Page 49

VEGACOM 558 as web server

The administrator must determine in the configuration which directories, if

any, the user groups PLANNING to USER GROUP 5 will have access to

(especially in the areas of customer-specific web pages. A possible

version is shown in the illustration.

Group "NO ACCESS"

Users assigned to the group "NO ACCESS" have no access authorisation. This status corresponds to "Deactivation of a user".

The assignment of directories to user group "NO ACCESS" is not recommended and is not accepted by VEGACOM 558.

Group "ALL"

Anyone can access directories assigned to the user group "ALL" without

authorisation.

The assignment of users to group "ALL" is not a good idea and is therefore not allowed by VEGACOM 558.

Generally, web browsers allow the access authorisation settings to be

saved for later program launches.

To facilitate user management, VEGACOM 558 organises the directories

for web pages in such a way that the above-emtioned user groups are

indicated within the directory hierarchy.

This means that the customer can selectively assign access authorisation

by means of a well thought-out directory structure …

VEGACOM 558 Ethernet 49

Page 50

VEGACOM 558 as web server

root

Administrator

Planning

vega

deutsch

english

images

Maintenance

process

config

Maintenance

process

config

Maintenance

The correlation between directory

hierarchy and user groups is shown in

the diagram on the left.

If the preset structures are used for

"customized-Sites", the planning engineer can also control the user authorisation for the "customised area" by

means of a hierarchical system.

The authorisation a user group has is

automatically passed on to hierarichally

"lower" directories. "Planning" for example, with authorisation for the directory

/VEGA, has automatically the same

authorisation fro all subdirectories of /

VEGA.

Note:

When planning, please note that exactly one user group can be assigned

to one area!

Planning

Anyone

Maintenance

user1

user2

user3

Usergroup1

Usergroup2

Usergroup3

custom

process

system

var

images

50 VEGACOM 558 Ethernet

Page 51

Your own html documents

8 Your own html documents

To show the predefined web pages of VEGACOM with an Internet

browser, the IP address of VEGACOM 558 must be stated in the

browser:

http://xxx.xx.x.xxx = IP address

The browser then calls up the following html file (start page):

http://xxx.xx.x.xxx/vega/deutsch/process/index.htm

The directory VEGA with the html files is not visible and cannot be modified. In the configuration window of VEGACOM 558, there is an additional directory called Layouts. This directory contains six files

- BANNER.HTM

- INDEX.HTM

- CONTENT.HTM

- Formate.css

- Val_dcs.htm

- Val_name.htm

To show these files, the following address must be entered in the

browser:

http//xxx.xx.x.xxx/layouts/dateiname.htm

When choosing the file layouts/index.htm, you will find no difference

between it and the respective file in the VEGA directory. The files of the

layout directory, however, can be copied to the PC, processed and

loaded again in the memory of VEGACOM. Independent of this, it is

possible to create your own html pages and load them in VEGACOM.

This feature makes it possible to create individual html documents

adapted to your own requirements.

Note:

- When creating html pages, we recommend that you observe html

standard 4.0.

- The memory space provided in VEGACOM is approx. 180 kByte. A

"flash-disk" is used as storage medium.

VEGACOM 558 Ethernet 51

Page 52

8.1 Transfer html files

To reach the directory "Layouts", you have to go with VVO to the configuration window of VEGACOM 558. Click to Configuration, Measur-

ing systems.

Click in the following windows to VEGACOM 558, then the button Con-

figuration.

Your own html documents

52 VEGACOM 558 Ethernet

Page 53

Your own html documents

In the following window, you click to Files, then double click the directory Layouts (left side of the window). The files in the layout directory

appear.

To transfer these files to the PC, you first have to select a destination

directory (right side of the window). Then choose the files (left side).

Finally click to the "arrow to the right".

VEGACOM 558 Ethernet 53

Page 54

Your own html documents

You now find the directory with the copied files on your PC.

These files can be processed according to your requirements and

retransferred to VEGACOM. If you leave the names of the new files

unchanged and define the directory "Layouts" as destination when

retransferring to VEGACOM, the old VEGACOM files will be overwritten.

It is a good idea to create a new destination directory in VEGACOM.

54 VEGACOM 558 Ethernet

Page 55

Your own html documents

Transferring files from PC to VEGACOM works the same as vice versa.

First of all, choose on the left side of the window the VEGACOM destination folder by double clicking, then on the right side of the window the

html files and then click to the "arrow to the left".

Note:

After transfer, the files are only available in the operating memory of

VEGACOM. After pushing the button Save the files are written in the

hardware memory (flash-disk) of VEGACOM.

VEGACOM 558 Ethernet 55

Page 56

Your own html documents

8.2 Structure of html files

- According to the MS-DOS convention, file names must consist of max.

eight characters and three-digit extension.

- If only a path name (without file name) is stated in the URL when calling up VEGACOM, start page INDEX.HTM must be stated.

- It is also possible to integrate graphics. The formats gif and jpg are

supported.

The following example is a very simple html document

(MESS_RUF.HTM), but it is sufficient as an example of general structure.

This is how the document looks when it is shown with an Internet

browser.

To show variable values, such as e.g. measured values, "key words"

Key words

are used. These key words are part of the html documents. If you load

the document into the memory of VEGACOM, VEGACOM enters the

appropriate value.

This is how the document looks when it is loaded into the memory of

VEGACOM and shown with the browser.

56 VEGACOM 558 Ethernet

Page 57

Your own html documents

html file in source code

<html>

<p align="center"><b>table of readings (arranged by name)</b></p>

<table align="center" border="2" width="90%" height="1" cellspacing="1"

BGCOLOR="#EEEEEE">

<tr BGCOLOR="#FFFF00">

<th align="center" width="30%" height="7%"><font size="2">measurement loop</font>

<th width="15%" height="7%"><font size="2">no. of DCS-outputs</font>

<th width="20%" height="7%"><font size="2">reading</font>

<th width="20%" height="7%"><font size="2">dimension</font>

</tr>

<tr>

<td align=center><font size="2">

<td align=center><font size="2">

<td align=center><font size="2">

<td align=center><font size="2">

</tr>

</table>

<p>

</body></html>

For simplification, the key words are shown in bolt print. In this file, only the most important key

words are used. On the following pages, all possible key words are listed and described in

detail.

?key_list_tag??key_list_tag?

?key_list_tag?</font></td>

?key_list_tag??key_list_tag?

?key_list_output??key_list_output?

?key_list_output?</font></td>

?key_list_output??key_list_output?

?key_list_value??key_list_value?

?key_list_value?</font></td>

?key_list_value??key_list_value?

?key_list_dim??key_list_dim?

?key_list_dim?</font></td>

?key_list_dim??key_list_dim?

VEGACOM 558 Ethernet 57

Page 58

Your own html documents

8.3 Key words for output in html files

To display the measured values via a web browser, VEGACOM knows a set of key words.

Depending on whether the user wants to call up the measured values in the form of lists and

tables or only individual measuring results on his page or within a context, two different categories of key words are available.

Measured value key words for lists or tables

For special applications in lists or tables, the following four key words are provided:

- ?key_list_tag?

- ?key_list_output?

- ?key_list_value?

- ?key_list_dim?

?key_list_tag?

Measurement loop designation ?key_list_tag? stands for listing of short designations of all

?key_list_tag("xyz”)?

Measurement loop designation With ?key_list_tag("xyz”)? the output of a specific measure-

measurement loops in VEGA systems. If ?key_m_tag? is found

within a table or a list, the table/list will be extended by the

number of lines according to the measurement loops available.

Outside a table, ?key_list_tag? just lists all tag names.

1)

ment loop is forced, "xyz" stands for the tag name of the requested measurement loops (e.g. ?m_tag[LI3210+]? =

"LI3210+")

1)

?key_list_tag("a”-"d”)?

Measurement loop designation With ?key_list_tag("abc”-"def”)? the output of a specific

measurement loop is forced, "a" and "d" stands for the first

letters of the requested measurement loops (e.g.

?m_list_tag["a"-"d"]? = "Used oil", "Bier", "Diesel 2")

1)

?key_list_output?

Index (DCS output) ?key_list_output?

stands for listing of all indices of the DCS

values which are transferred to the DCS system. If ?pls_output?

is found within a table or list, the table/list will be extended by

the number of lines according to the measurement loops avail-

1)

able.

?key_list_output(n,m)??key_list_output(n,m)?

?key_list_output(n,m)?

?key_list_output(n,m)??key_list_output(n,m)?

Index (DCS output) ?key_list_output(n,m)?

DCS value which should be listed. Examples: ?pls_output(1,3)?

or ?pls_output(4,8)?

58 VEGACOM 558 Ethernet

stands for the index (number) of the

1) 2)

Page 59

Your own html documents

?key_list_output(n-m)??key_list_output(n-m)?

?key_list_output(n-m)?

?key_list_output(n-m)??key_list_output(n-m)?

Index (DCS output)

?key_list_output(n-m)? ?key_list_output(n-m)?

?key_list_output(n-m)? stands for listing of all indices of the

?key_list_output(n-m)? ?key_list_output(n-m)?

DCS values within the limits "n" to "m". Examples: ?pls_output(1-

15)? or ?pls_output(16-30)?:

1) 2)

?key_list_value?

Value (DCS output) Measured value which should be transferred to a DCS system.

?key_list_value? adds the appropriate measured value to a

previously defined tag or DCS output within a list or table.

?key_list_dim??key_list_dim?

?key_list_dim?

?key_list_dim??key_list_dim?

Unit (DCS output) Measuring unit of a measured value which should be trans-

ferred to a DCS system. ?key_list_value? adds the appropriate measuring unit to a previously defined tag or DCS output

within a list or table.

1)

If both key words ?key_list_tag? and ?key_list_output? are found within a table or list line, the sorting

sequence is determined by the one occurring at first.

Sorting sequence at ?key_list_tag?: rising according to tag names (a, A, b, B, c, C, …)

Sorting sequence at ?key_list_output?: rising according to DCS output numbers (1, 2 3, 4, …)

2)

The statement of the DCS output with VEGAMET is made in format (D.P), for which is valid:

D = DISBUS address

P = DCS output.

The statement of the DCS output with VEGALOG is made in format (P), for which is valid:

P = DCS output.

Measured value key words for specific individual measured values

For special applications in which specific individual measured values are to be presented on

web pages, the following key words are available:

- ?key_tag[]?

- ?key_output[]?

- ?key_value[]?

- ?key_dim[]?

Square brackets must always be entered. By stating a DCS output within a square bracket,

the requested value of the key word is specified.

Special feature:

If several key words of the above-mentioned type are used within a context, the DCS output

must be specified only for the first one. All following key words of the above-mentioned type

use this DCS output until redefinition.

VEGACOM 558 Ethernet 59

Page 60

?key_?key_

?key_tag[]?

?key_?key_

Measurement loop designation

?key_?key_

?key_output[]?

?key_?key_

Measurement loop designation

?key_?key_

?key_value[]?

?key_?key_

Measurement loop designation

?key_?key_

?key_dim[]?

?key_?key_

Measurement loop designation

Your own html documents

?key_?key_

?key_tag[]? stands for the output of a short designation of the

?key_?key_

measurement loop specified by the DCS output.

?key_tag[x]? delivers the tag name belonging to DCS output x.

?key_tag[]? delivers the tag name belonging to the DCS output

specified in one of the previous key words.

?key_?key_

?key_output[]? stands for the output of a DCS output.

?key_?key_

?key_output[x]? delivers the DCS output belonging to DCS

output x, i.e. itself.

?key_output[]? delivers the DCS output belonging to the DCS

output specified in one of the previous key words.

?key_?key_