Operating Instructions

VEGACOM 557

Profibus DP

Level and Pressure

BA

on

PC

557

out

in

Contents

Safety i nformation ........................................................................ 2

Note Ex a rea ................................................................................ 2

1 Product description

1.1 Application ............................................................................ 4

1.2 Configuration ........................................................................ 4

1.3 Functions .............................................................................. 5

1.4 Type plate and or der code ................................................. 9

1.5 Technical data ..................................................................... 10

1.6 Dimensions ......................................................................... 12

1.7 Indicating and adjustment elements ................................ 13

2 Mounting and electrical connection

2.1 Mounting instructions ......................................................... 14

2.2 Mounting in carrier and housing ....................................... 15

2.3 Wiring plan VEGACOM 557 .............................................. 15

2.4 Mounting and installation instructions with

VEGACOM 557AP ............................................................. 16

Contents

3 Switch settings on VEGACOM 557

3.1 Adjustment of the PC interface ......................................... 19

3.2 Adjustment of the Profibus DP interface .......................... 20

Safety information

Please read this manual carefully, and also take

note of country-specific installation standards

(e.g. the VDE regulations in Germany) as well

as all prevailing safety regulations and accident prevention rules.

For safety and warranty reasons, any internal

work on the instruments, apart from that involved in normal installation and electrical connection, must be carried out only by qualified

VEGA personnel.

2 VEGACOM 557 Profibus DP

Note Ex area

Please note the approval documents (yellow

binder), and especially the included safety

data sheet.

Contents

4 Measurement loop in VEGAMET/VEGALOG

4.1 PC/DCS output .................................................................... 23

5 Transfer of measured value

5.1 Format for transfer of measured value ............................ 25

6 Operating mode VEGACOM 557

6.1 Mode 50E2A ....................................................................... 26

6.2 Mode 6 E6A ......................................................................... 26

6.3 Selection of the operating mode ....................................... 26

7 Data image in VEGACOM 557

7.1 Image of measured value when connecting to DISBUS 28

7.2 Measured value image when connecting to LOGBUS ... 38

7.3 Overview of the operating modes and control

commands .......................................................................... 45

8 Setup

8.1 Setup check list .................................................................. 46

8.2 Setup SIEMENS S7 automation system .......................... 46

8.3 Setup SIEMENS S5 with IM308C ...................................... 49

9 Parameter adjustment via Profibus DP ............................... 50

10 Utility diskette for VEGACOM 557 Profibus DP ................. 51

Supplem. A ...................................................................................... 52

Supplement B ................................................................................ 58

Supplement C ................................................................................. 74

1 General information on PROFIBUS ................................... 74

2 Special information on Profibus DP .................................. 77

3 Short description of the interface RS 485 ........................ 81

VEGACOM 557 Profibus DP 3

1 Product description

Product description

1.1 Application

The VEGACOM 557 is an efficient and easyto-use interface converter (Gateway) for your

measurement applications. It is used for

conversion of the VEGA-specific protocols of

DISBUS and LOGBUS into standard data

formats.

The existing version is used for connection of

level or pressure measuring systems to

Profibus DP systems such as

- processing systems (DCS)

- personal computers (PC)

- stored program control (PLC).

In addition, it is used for connecting a PC for

configuration or visualisation via the VEGA

adjustment software.

If connection is made to Profibus DP systems, there is the possibility of calling up

measurement data and status information of

the measuring systems via the master of the

Profibus DP system. The coupling of the

Profibus DP is made via the connections on

the rear of the instrument. This data traffic

requires that special measures (described in

this manual) be taken in setting up the master

of the Pr ofibus DP. The data r eceived in the

master can be visualised there or further

processed for control purposes. In restricted volume, signal conditioning instrument-specific parameters can be outputted,

modified and returned again.

Via the PC interface on the front of VEGACOM 557, the VEGA visualisation software

„Visual VEGA“ or the VEGA configuration

software „VEGA Visual Operating“ (VVO) can

be operated. For these applications, the

coupling between VEGACOM 557 and a PC

is made directly with the connection cable

between the RS 232 interface (PC) on the

front of VEGACOM 557 and a standard Port

(e.g. COM1) of your PC. There is also the

possibility to provide a connection via modems.

1.2 Configuration

The component VEGACOM 557 is designed

in 19" technology with 5 TE width (1 TE = 5.08

mm) acc. to DIN 41 494. It can be used:

- in carrier BGT 596

- in VEGALOG 571 carrier BGT LOG 571

- in housing type 505.

The electrical connection of supply voltage,

DISBUS and Profibus DP is made via a plug

connection acc. to DIN 41 612 on the rear of

the component. The connection to LOGBUS

is made via an additional 5-pole plug-connector mounted to the DIN-socket.

A 9-pole SUB-D plug marked “PC” is located

on the front panel of VEGACOM 557. It is

used for connection of a PC via RS 232C to

VEGACOM 557.

The component consists of two boards:

- the basic board

- the additional board.

Basic board Additional board

PC

interface

VEGACOM 557 connections

On the basic board, you will find the power

supply unit, the PC interface, the DISBUS/

LOGBUS interface as well as the connections

for the P rofibus DP.

The additional board is screwed to the basic

board and includes the hardware of the Profibus DP interface as well as the protocol specific programs.

Supply

DISBUS

LOGBUS

Profibus DP

4 VEGACOM 557 Profibus DP

Product description

1.3 Functions

The VEGACOM 557 interface converter can

be integrated into the VEGA level or pressure measuring system in two different ways:

either

- as DISBUS participant

or

- as LOGBUS participant.

In both cases, VEGACOM 557 operates as

passive participant and provides measured

data and status information of the connected

VEGA signal conditioning instruments via the

Profibus DP. By the use of a standar dised

protocol (Profibus DP), it is possible to connect via this interface any individual Profibus

DP compatible processing system.

Alternatively, it is possible to connect a PC

with VEGA adjustment software via the SUBD-plug marked “PC” on the front panel of

VEGACOM 557. VEGA adjustment software

is actually available as two different Windows

applications.

VVO = VEGA Visual Operating

For configuration and parameter adjustment of the connected VEGAMET or VEGALOG processing systems

VV = Visual VEGA

For visualising and recording of measured

values of complete (multiple) vessel installations.

The following pictures show the basic connection possibilities of VEGACOM 557.

VEGAMET

DISBUS

%

100

+

-

ESC OK

CONNECT

!

on

VEGAMET

513

VEGACOM 557

PC

BA

!

on

VEGACOM

557

VVO

VEGA adjustment software

PC connection

Profibus

DP

Profibus DPMaster

VEGACOM 557 as DISBUS participants

VEGALOG 571

VVO

BA

!

on

VEGACOM

PC connection

LOGBUS

VEGACOM 557

PC

557

Profibus

DP

PC

!

on

VEGALOG

571

VEGA adjustment software

Profibus DPMaster

VEGACOM 557 as LOGBUS participant

VEGACOM 557 Profibus DP 5

Product description

VEGACOM 557 on DISBUS

VEGAMET series 500/600 signal conditioning

instruments transmit via the DISBUS cyclically measured data and status information,

so called PC/DCS telegrams. VEGACOM 557

receives as participant on the DISBUS these

data and makes them available (in buffer

memory) for collection via the Pr ofibus DP.

DISBUS Prof ibus DP

%

%

100

100

+

-

-

ESC OK

ESC OK

CONNECT

!

!

on

on

VEGAMET

VEGAMET

513

VEGAMET

%

100

+

+

-

ESC OK

CONNECT

CONNECT

!

on

VEGAMET

513

513

PC

BA

!

on

VEGACOM

557

VEGACOM Pro fibus

Profibus DPSlave

DPMaster

Connection VEGACOM 557 to DISBUS

If a PC is connected to the PC interface (front

interface) of VEGACOM 557, this instrument

transfers acyclically (on request by the

VEGA configuration software VVO) measurement loop parameters fr om or to VEGAMET .

Max. two VEGACOM 557 can be connected

to the same DISBUS. For clear identification,

different instrument addresses should be

depending on both instruments.

VEGACOM 557 on LOGBUS

Data are exchanged continuously on the

LOGBUS between the individual components

of VEGALOG 571. VEGACOM 557 receives

as participant of this LOGBUS PC/DCS telegrams including the measured values and

status information and makes them available

(in buffer memory) for collection via the Profibus DP.

LOGBUS

on

PC

!

on

VEGALOG

571

VEGALOG

Connection VEGACOM 557 to LOGBUS

Profibus DP

PC

BA

!

on

VEGACOM

557

VEGACOM

Profibus DPSlave

Profibus

DPMaster

If a PC is connected to the PC interface (front

interface) of VEGACOM 557, this instrument

transfers acyclically (on request by the

VEGA configuration software VVO) measurement loop parameters from or to VEGALOG

571.

Max. two VEGACOM 557 can be connected

to the same LOGBUS. The addressing for

clear identification is made automatically on

LOGBUS.

6 VEGACOM 557 Profibus DP

Product description

VEGACOM 557 on Profibus DP

The data communication between VEGACOM

557 and Profibus DP-Master is only carried

out if initiated by the master , which can enquire the requested information by means of

special control commands.

The data from DISBUS/LOGBUS are first

written in a buffer memory of VEGACOM 557.

The data set is transferred from this buffer

memory into a process image. The protocol

conversion software enquires the stored data

cyclically from the individual storage areas.

The data sets are checked and converted

into the Profibus DP data format. After the

conversion, the data are transferred into the

emission memory and are sent from there to

the Pr ofibus DP. The PROFIBUS DP transmits

the data to the DP-Master .

DISBUS

LOGBUS

Function VEGACOM 557

Buffer

memory

Process

image

Test

conversion

Emission

memory

Profibus

DP

VEGACOM 557 with VVO or VV

connected to VEGACOM 557. The adjustment concept includes the user -friendly configuration and parameter adjustment of the

measuring system or the sensor with the

following instruments:

- VEGAMET series 500/600 signal conditioning instruments

- VEGALOG 571 processing system

- VBUS ultrasonic/radar sensors.

The adjustment is menu-driven and window

orientated. No matter if a radar sensor , several connected signal conditioning instruments or a VEGALOG should be adjusted via

the PC, the procedure is always the same.

As another possibility , measured values and

fault signals of the entire processing facility

can be recorded and shown graphically by

means of the visualisation software VISUAL

VEGA (VV). T ools for pr ocessing and analysis of history data are also available.

The configuration of the measurement loop

comprises, depending on the connected

instruments, e.g. the determination of output

functions or the configuration of individual

outputs or inputs. The user orientated editing

of measurement loops is supported by

graphic means, such as e.g. vessel drawings and pictographs that adapt to the selected general conditions and options.

With the graphic support also more complex

parameter adjustments such as e.g. the input

of a linearisation curve by means of index

markers can be done with ease.

Direct connection

As an alternative to the Profibus DP communication, a PC can be connected via the PC

interface (SUB-D-plug in the front panel of

VEGACOM 557). By means of the adjustment

and indicating software VEGA Visual Operating (VVO), the parameter adjustment can be

made on the signal conditioning instruments

Connection via modem

The PC interface supports, beside the direct

connection of a PC, also the operation via

modems. With this additional function, remote

parameter adjustment or remote diagnostics

of VEGA systems via VVO are possible.

Together with the visualisation softwar e V isual

VEGA, even remote visualisations can be

carried out.

VEGACOM 557 Profibus DP 7

Product description

Complete measuring system with digital communication and networking

DISBUS

%

%

%

100

100

+

-

-

ESC OK

ESC OK

CONNECT

!

!

on

on

VEGAMET

VEGAMET

513

%

%

%

100

100

100

+

+

-

-

ESC OK

ESC OK

CONNECT

CONNECT

!

!

on

on

VEGAMET

VEGAMET

513

513

100

+

+

-

-

ESC OK

ESC OK

CONNECT

CONNECT

!

!

on

on

VEGAMET

VEGAMET

513

513

on

%

%

100

100

+

+

+

-

-

ESC OK

ESC OK

CONNECT

CONNECT

CONNECT

!

!

on

on

VEGAMET

VEGAMET

513

513

513

4

O

V

V

LOGBUS

1

4

PC

!

on

VEGALOG

571

Measuring system with digital communication and networking

Explanation:

3 VEGACOM 557

Interface converter for conversion of VEGA

1 VEGA Visual Operating (VVO)

Adjustment software for the PC for the

user-friendly configuration and parameter

adjustment of VEGA instruments

- VEGALOG 571 directly via RS 232

specific pr otocols into standar d data for mats. Suitable for connection to the DISBUS output of VEGAMET series 500/600

signal conditioning instrument or the LOG-

BUS of VEGALOG 571 processing system.

connection cable on the CPU card or

VEGACOM 557

- several VEGAMET via VEGACOM 557

or individually via VEGACONNECT

- VEGASON, VEGAPULS via VEGACONNECT on the signal line or on the sensor

4 VEGACONNECT 2

Connection cable (interface converter)

between VEGA instruments (VEGASON,

VEGAPULS or VEGAMET) and a PC in

conjunction with the adjustment software

VEGA Visual Operating.

2 Visual VEGA (VV)

PC visualisation software for presentation

of measurement data from VEGA instruments in a graphical or tabular form. Inte-

5 RS 232 connection cable (interlink cable)

Connection cable between PC and VEGA-

LOG 571-CPU or VEGACOM 557

gration of individual measurement loops

into groups, saving of fault signals and

measured values (recorder function).

Suitable for networks

Profibus DP system

3

PC

BA

!

on

VEGACOM

557

5

V

5

V

2

1

8 VEGACOM 557 Profibus DP

Product description

1.4 Type plate and order code

Type plate

Before mounting and electrical connection,

please check if you are using the correct

version of VEGACOM 557. Please note the

type plate, located below the multiple plug.

Type plate on

multiple plug

The type plate contains important data required for electrical connection. The configuration and the components of the type plate

are explained in the illustration below .

Note:

The serial number of your VEGACOM is on

the rear of the plug connector .

1

®

RS 485

DATA

/DATA

d32 z28d30

557

Profibus DP

DISBUS

GND

+5V

d28

-+

z22z24

a: -20 ... +60°C

IP 40 (front)

Insp.

power supply

20 ... 53V AC

20 ... 72 V DC

N-L+

6 VA

z2d2

3 2

1 Version: Profibus DP

2 Supply voltage

3 Terminal assignments Profibus DP interface (RS 485)

VEGACOM 557 Profibus DP 9

Product description

1.5 T echnical data

Power supply

Supply voltage U

Power consumption approx. 6 VA

Fuse 1 A, slow-blow

Electrical connection

Component multiple plug acc. to DIN 41 612, series F

Module in carrier

BGT 596 or BGT LOG 571 suitable multipoint connector acc. to DIN 41 612

Housing type 505 via screw terminals max. 1 x 1.5 mm

Indicating elements

LED on front panel green „BA“: Profibus activity

Meas. data input DISBUS

Data transmission DISBUS (digital data transmission)

Connection cable 2-wire standard cable (shielded)

Cable length max. 1000 m

Measuring data input LOGBUS

Data transmission LOGBUS (digital data transmission)

Connection cable connection via BUS-plug

= 24 V AC (20 … 53 V), 50/60 Hz or

nom

= 24 V DC (20 … 72 V)

48 pole (d, b, z) with coding holes

with connection via standard technologies

2

red: failure, freeze mode

green „on“: operating mode

PC interface

Interface standard RS 232C

Cable length max. 15 m

Transmission rate in baud 300, 600, 1200, 2400, 4800,

9600

, 19200, 38400

Transmission format 8 data bits, 1 stop bit, no parity or even

parity

Plug on front panel SUB-D-plug connector, 9 pole, pins

10 VEGACOM 557 Profibus DP

Product description

Profibus DP interface (RS 485)

Standards conformity to DIN 19 245, part 3

Interface standard RS 485

Network topology linear bus (active bus connection on both

ends)

Bus access hybrid bus access protocol acc. to DIN 19 245,

part 1

Max. number of bus participants 126 master and slave instruments

Communication structure point-to-point or multicast

Communication procedure cyclical or acyclical

Max. cable length

- without repeater

1)

Baud rate (kBit/s) 9.6 19.2 93.75 187.5 500 1500 12000

cable length (m) 1200 1200 1200 1000 400 200 100

- with repeater can be extended to the km-range

Connection cable screened 2-wire, twisted in pairs

Transmission half-duplex, serially asynchronous,

Transmission rate

2)

slip resistant synchronization

9.6; 19.2; 45.45; 93.75; 187.5; 500; 1500; 3000;

6000; 12000 Kbits/s

Telegraph formats acc. to DIN 19 245, part 1

E/A-data per DP-Slave VEGACOM 50E/2A Byte or 6E/6A Byte

Data backup Hamming distance HD = 4

Fuse +5V 100 mA, slow-blow

Electrical protective measures

Protection:

not mounted IP 00

in carrier BGT 596

or BGT LOG 571

- front side completely equipped IP 40

- upper and lower side

BGT 596 IP 00

BGT LOG 571 IP 20

- wiring side IP 00

in housing type 505

- front side IP 40

- other sides IP 30

Protection class II (in housing type 505)

Overvoltage category II

Electrical separation measures

Reliable separation acc. to VDE 0106, part 1 between power supply, LOGBUS, DISBUS,

PC-connection and respective interface

- reference voltage 250 V

- test voltage 2 kV

1)

Repeater = line amplifier

2)

Baud rate is automatically adjusted

VEGACOM 557 Profibus DP 11

Product description

CE conformity

VEGACOM 557 meets the protective regulations of EMC (89/336/EWG) and NSR

(73/23/EWG). The conformity has been judged acc. to the following standards:

EMC Emission EN 50 081 - 2: 1993

Susceptibility EN 50 082 - 2: 1995

NSR EN 61 010 - 1: 1993

Ambient conditions

Permissible ambient temperature -20°C … +60°C

Storage and transport temperature -20°C … +85°C

Humidity 93 %, T = 40°C acc. to DIN/IEC 68-2-3

Shock 2 … 100 Hz, 0.7 g

Mechanical data

Series module unit for

- carrier BGT 596

- carrier BGT LOG 571

- housing type 505

Dimensions, not mounted W = 25.4 mm (5 TE), H = 128.4 mm, D = 166 mm

Weight approx. 550 g

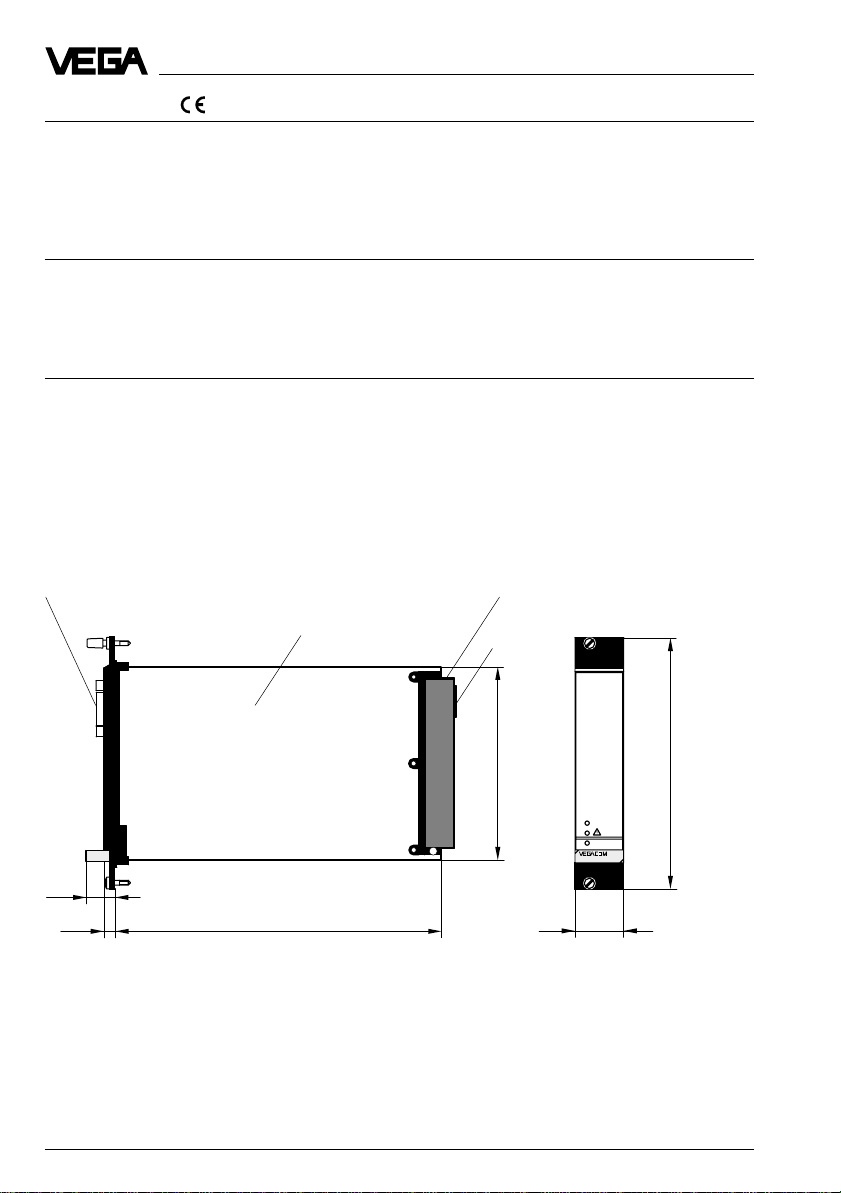

1.6 Dimensions

front RS 232C interface (PC)

Multipoint connector

100 x 160 x 1.5

European size

Multiple plug

LOGBUSplug

100

5 TE

BA

on

128,4

557

15

1625,5

25,4

12 VEGACOM 557 Profibus DP

Product description

1.7 Indicating and adjustment elements

As diagnostic aid, VEGACOM 557 is

equipped with three LEDs. These are located

on the instrument front panel. In addition, the

basic board, as well as the additional board

of VEGACOM 557 are equipped with

switches (DIP switch or hook switch) for

configuration of the available interfaces.

Indicating elements/Diagnostics LEDs

PC

Modbus activity

BA

on

557

Front of VEGACOM 557

Meaning of the LEDs:

VEGA ASCII active:

- green LED lights in case of valid data ex-

change

Fault signal:

- red LED flashing: DISBUS/LOGBUS-error

- irregularly flashing: no PC/DCS outputs

assigned

- permanent light: hardware error or special

function „Freeze Mode“

Voltage supply:

- green LED lights, operating voltage on.

Fault signal

Voltage supply

Adjustment elements

The adjustment elements are located on the

basic board or on the additional board.

A 6-pole DIL switch block on the basic board

is used for adjustment of the fr ont PC interface. The DIL switch and hook switch on the

additional board are used for adjustment of

the Profibus interface.

Basic board

2 3 4ON1

DIL switch

on basic board

Side view of VEGACOM 557

Additional

board

DIL switch

on additional board

Special function “Freeze Mode“

For diagnostic purposes on VEGA processing systems VEGAMET and VEGALOG, the

process image can be “frozen“ in VEGACOM

557 with the adjustment software VVO. This

enables the possibility of carrying out maintenance work on the VEGA system, without

disturbing the higher -priority pr ocessing

system.

For activating the Freeze Modes, a PC must

be connected directly to the PC interface of

VEGACOM 557 and the Freeze Mode must

be switched on under VVO in the menu „Configuration - Measuring system “.

Attention:

Before activating this function, it must be

ensured that during this mode, no disastrous

consequences are to be expected for production processes (during this mode, no

level values etc. are updated).

VEGACOM 557 Profibus DP 13

2 Mounting and electrical

connection

Mounting and electrical connection

2.1 Mounting instructions

The gateway VEGACOM 557 can process

measured data and status information in two

different ways:

- via DISBUS (from measuring systems with

VEGAMET)

- via LOGBUS (from measuring systems

with VEGALOG).

For DISBUS configurations, VEGACOM 557

can be either mounted into carrier BGT 596

or housing type 505.

In conjunction with LOGBUS, VEGACOM 557

in is mounted into carrier BGT LOG 571. The

location is individually selectable, the system

adapts automatically when rebooting

(autoconfiguation).

Coding

A mechanical coding system prevents mixing

up the different module cards in the carrier or

in the housing.

The coding system consists of:

- three coded pins in the multipoint connector

- three holes in the multiple plug of VEGACOM 557.

Instrument Function

coding coding

VEGACOM 557 a27 c3/c11

Instrument coding

d b z

a c

1

3

5

7

9

11

13

15

17

19

21

23

VEGACOM 557

Positioning of the coded pins

a27

25

27

29

31

Function coding

c3

VEGALOG card

c11

Interface card

The coded pins are attached to the module

or the housing. The plug-in socket must be

equipped by the user with the coded pins

according to the following table and diagram.

Coded pin

Plug-in socket of VEGACOM 557

14 VEGACOM 557 Profibus DP

Mounting and electrical connection

2.2 Mounting in carrier and housing

BGT 596 or BGT LOG 571

For mounting, a slot module must be provided at the location. A slot module consists

of:

- a multipoint connector acc. to DIN 41 612,

series F, 33-pole (d, b, z)

- two screws

- three coded pins

- two guide rails.

The multipoint connector is available in the

following versions:

- Wire-Wrap, standard connection

1.0 mm x 1.0 mm

- plug connection

2.8 mm x 0.8 mm

- Termi-Point standard connection

1.6 mm x 0.8 mm

- soldering connection

- screw terminals 0.5 mm

For mounting the module, please note the

operating instructions of the carrier .

Housing type 505, type 506

This housing is already equipped with a

multipoint connector. Before mounting, please

check if the housing is equipped with a

power supply unit or not.

The connection is made via screw terminals

with max. 1.5 mm

in the operating instructions “Housing type

505, type 506 “.

2

2

.

. Further details are stated

2.3 Wiring plan VEGACOM 557

PC interface in front panel (SUB-Dplug)

The PC interface of VEGACOM 557 is used

exclusively for connection of computer systems with VEGA adjustment software via a

COM-Port. The PC interface is based on the

RS 232C standard and is assigned as follows.

1

6

2

7

3

8

4

9

5

Pin assignments of the PC interface of VEGACOM 557

Pin Description I/O

2 RxD receive data I

3 TxD transmit data O

5 GND ground –

Note:

With a direct connection to the computer

system, VEGACOM 557 works without hardware handshake.

Direct connection

For direct connection of a PC to the PC inter face of VEGACOM 557, the interlink (or a

standard) cable available from VEGA with 9pole plugs on both ends should be used.

The pin assignments of the interlink cable are

shown in the diagram.

RxD

TxD

GND

1

6

2

7

3

8

4

9

5

Wiring proposal for interlink cable

1

2

3

4

5

VEGACOM 557 Profibus DP 15

6

7

8

9

Mounting and electrical connection

Connection via modem

For remote parameter adjustment, it is possible to connect the PC interface via a modem.

In such a case, the modem cable that comes

with the respective modem should be used.

Modem operation is supported by VEGACOM 557 from software version 2.11. Further

information on the remote parameter adjustment is stated in the operating instructions

„Remote parameter adjustment “.

Connections of the multiple plug (rear)

For connection of VEGACOM 557 to the existing Profibus DP system, a RS 485 interface

is available. The following diagram shows the

connections of the RS 485 interface, the

power supply of the instrument and the connection to the VEGA system.

dbz

Supply voltage

DISBUS (not

used on VEGALOG)

Multiple plug (rear of VEGACOM 557)

+

2

-

4

6

8

10

12

14

16

18

20

+

22

-

24

26

28

30

32

Profibus DP via RS 485

GND (

DGND

+5V (VP)

DATA (

/DATA (

)

RxD/TxD-P

RxD/TxD-N

)

)

2.4 Mounting and installation instructions with VEGACOM 557AP

As an option, VEGACOM 557 can be extended with the adapter print VEGACOM

557AP. The adapter print VEGACOM 557AP

consists of a module card with 5 TE width

and two modules connected to a back-panel

print for carrier BGT 596 or BGT LOG 571.

BA

on

557AP

557

With the adapter print card it is possible to

put the Profibus DP interfaces of VEGACOM

557 at the front of the carrier . On the fr ont of

the adapter print car d, the Pr ofibus DP interface is available as a 9-pole SUB-D-plug and

as 9-pole SUB-D-socket. The r equired interface type must be stated when ordering

VEGACOM 557AP.

The following interface types are available:

- RS 485 (Profibus DP)

Keep in mind that for Profibus, the interface

type RS 485 is necessary!

The pin assignments of the SUB-D-plug and

the SUB-D-socket are stated in the schedules.

16 VEGACOM 557 Profibus DP

Mounting and electrical connection

Pin assignments VEGACOM 557AP

Pin-Nr.

1

2

3

4

5

6

7

8

9

9-pole SUB-D-plug

Pin-Nr.

1

2

3

4

5

6

7

8

9

9-pole SUB-D-socket

RS 485

-

-

DATA (RxD/TxD-P)

-

GND (DGND)

+5V (VP)

-

/DATA (RxD/TxD-N)

-

RS 485

-

-

DATA (RxD/TxD-P)

-

GND (DGND)

+5V (VP)

-

/DATA (RxD/TxD-N)

-

Mounting instructions for VEGACOM

557AP

The two modules connected to the backpanel print consist of:

- two multipoint connector acc. to DIN 41

612, series F, 48-pole (d, b, z) connected

via the back-panel print

- four screws

- four coded pins

- four guide rails

Module position

BGT LOG 571

The module position is individually selectable,

the VEGALOG 571 processing system

adapts automatically through

autoconfiguration during the first booting.

After autoconfiguration, the slot location of the

cards must never be changed.

BGT 596

The module position is individually selectable.

Please note that the two connected modules

cover a width of 10 TE (5 TE for VEGACOM

557 plus 5 TE for the adapter board

VEGACOM 557AP).

Connection VEGACOM 557AP

BGT LOG 571

With the bus board (part of the carrier BGT

LOG 571) connection to LOGBUS is made

automatically when inserting VEGACOM 557.

The voltage supply of the card must be provided separately. For this r eason, a 2-pole

terminal with tension spring connection,

called U

print. The permissible operating voltage of

VEGACOM 557 should be observed. In case

of DC voltage supply , the corr ect polarity

should be noted!

is available on the back-panel

b,

Coding

The coding should be carried out for both

modules as described in chapter “2.1 Mounting in carrier and housing “. The coded pin c3

BGT 596

When operating VEGACOM 557 as

DISBUS participant, the DISBUS must be

wired in addition to the supply voltage.

will not be inserted.

For the two cables of the DISBUS, a 2-pole

terminal with tension spring connection is

available. Make sur e that the polarity is cor rect!

VEGACOM 557 Profibus DP 17

Terminals

for supply voltage

Terminals

for DISBUS

Ub+

View of back-panel board (rear of the carrier)

Modbus interface

PC interface of

VEGACOM 557

of VEGACOM 557

as SUB-D-plug

Mounting and electrical connection

PC

BA

on

557

Modbus interface

of VEGACOM 557

as SUB-D-socket

557AP

Front view with SUB-D-connections of VEGACOM 557

and VEGACOM 557AP

18 VEGACOM 557 Profibus DP

Switch adjustments on VEGACOM 557

3 Switch settings on VEGACOM

557

For adjustment of the interfaces or the BUS

parameters of the PC interface and the Modbus interfaces, various DIL switches are

provided on VEGACOM 557. Before inserting

VEGACOM 557 into the carrier or the housing, the DIL switches must be set according

to the user-specific data. The data of these

settings will be effective with the next initialization (switching on of voltage).

3.1 Adjustment of the PC interface

For adjustment of the RS 232 PC interface in

the front panel of VEGACOM 557, a 6-pole

DIL switch block is located on the basic

board. The PC interface is used for communication between a PC and VEGACOM 557, by

means of the adjustment software VVO or the

visualisation software VV.

Instrument number

Only relevant when operating two

VEGACOM 557 on the same DISBUS. If

two VEGACOM 557 are operated on the

DISBUS, then different instrument numbers

have to be assigned.

Not relevant for operation on LOGBUS.

Automatic modem initialization

In position „ON“ the modem will be initialized automatically when connecting it to the

VEGACOM interface.

Transmission rate

For VVO or VV , the transmission rate must

be set to 9600 baud.

In the following diagram, you see all possible

adjustment possibilities for configuration of

the PC interface.

ON

Basic board

2 3 4ON1

DIL switch

on basic board

Side view of VEGACOM 557

Additional

board

DIL switch

below additional

board

The following adjustments are carried out via

the above mentioned DIL switch block.

Data format

Parity can be switched from even to no

parity (note for VVO including version 2.15,

even parity is compulsory).

123 4 5 6

Data format

8 data bits, 1 stop bit, even parity

8 data bits, 1 stop bit, no parity

Instrument number

1. instrument

2. instrument

Automatic modem initialization

On

Off

Transmission rate (baud)

300

600

1200

2400

Adjustment possibilities of the DIL switch on the

basic board

4800

9600

19200

38400

VEGACOM 557 Profibus DP 19

Switch adjustments on VEGACOM 557

3.2 Adjustment of the Profibus DP interface

A 8-pole DIL switch block as well as two hook

switches for configuration of the Profibus DP

interface to the DCS or the PLC are located

on the additional board.

DIL switch blocks

additional board

1 2 3

Basic board

Front

plate

Additional

board

DIL switch

basic board

Bottom view of VEGACOM 557

1 2 3 4 5 6 7 8

L RL R

12

Hook switches

additional

board

2 1

Multiple plug

DIL switch additional board

The DIL switch is used to select the slave

address of VEGACOM 557 on the Profibus

DP.

DIL-switch block

(Additional board)

ON

12345678

Factory setting:

Slave address = 12

DIL switch block on the additional board for selecting

the Slave address

Profibus Slave address of VEGACOM 557

SW 8 SW 7 SW 6 SW 5 SW 4 SW 3 SW 2 SW 1

off 2625242322212

SW 8 is reserved and must be set to position

“off“. Permitted address range 0 … 126.

Example:

Address 32 corresponds:

SW 8 SW 7 SW 6 SW 5 SW 4 SW 3 SW 2 SW 1

off off on off off off off off

0

Bottom view of the additional board

ON

12345678

Slave address = 32

20 VEGACOM 557 Profibus DP

Switch adjustments on VEGACOM 557

Hook switches additional board

The hook switches are used to switch on the

bus terminator resistors.

Switch positions

Hook switch closed:

Bus terminator "On"

1

2

Hook switch open:

1

Example 1:

VEGACOM 557 PLC

Both hook switches are

closed

If a VEGACOM 557 is connected to a PLC,

both hook switches have to be closed (bus

terminator ON).

Bus terminator "Off"

2

Example 2:

VEGACOM 557

Both hook switches Both hook switches

closed open open closed

PLC

VEGACOM 557

If several VEGACOM 557 are connected to a

PLC, both hook switches have to be closed

on VEGACOMs located at the beginning and

end of the connecting line, and open on

VEGACOM 557s located in between.

VEGACOM 557 Profibus DP 21

Measurement loop in VEGAMET/VEGALOG

4 Measurement loop in VEGAMET/VEGALOG

Generally a measurement loop in VEGAMET/VEGALOG processing systems is structured as

follows:

A sensor delivers the sensor value to the input of the processing system. This sensor value is

then further processing in the processed system (.e.g. empty/full adjustment, linearisation ...).

The processed values are outputted (e.g. via current outputs, relay outputs ...). The PC/DCS

output is available as gateway for VEGACOM 557, i.e. the processing system transmits the

PC/DCS output value via the DISBUS or LOGBUS to VEGACOM 557. This values are accessible to the PC/DCS system via the field bus.

Sensors

VBUS, 4...20mA

Sensor value

VEGALOG/

VEGAMET input

VEGALOG / VEGAMET

(Resolution= 0...10000)

(Resolution= 0...1000)

Empty/

adjustment

Linear-

full

isation

Unit: 0,00%

Unit: 0,0%

Unit: 0,00%

Unit: 0,0%

Scaling

DISBUSLOGBUS

VEGALOG/VEGAMET

PC/DCS output

Parameter

selection

DISBUS

or

LOGBUS

LOGBUS/

DISBUS

Fieldbus

PC/DCS value

Fieldbus PC/DCS

PC/DCS systemVEGACOM 557

system

Parameter: Percent

mA

bar

m

Volume

percent

Scaled

selected

parameter+

unit

Fundamental configuration of a measurement loop

22 VEGACOM 557 Profibus DP

Measurement loop in VEGAMET/VEGALOG

4.1 PC/DCS output

Max. 255 PC/DCS outputs are available,

depending on the processing system. The

configuration or parameter setting of the PC/

DCS outputs is done with the adjustment

software VVO or via keyboard (VEGAMET) in

the processing system. Several PC/DCS

outputs can be allocated to each measurement loop. This enables the possibility of

transmitting the measured value, e.g. as

“Percentage value“ and “Scaled“, e.g. in

“Liters“ to the Pr ofibus master.

Processing system No. of PC/DCS outputs

VEGAMET 509 3

VEGAMET 512 3

VEGAMET 513 3

VEGAMET 514(V) 3 ( 7)

VEGAMET 515(V) 7(7)

VEGAMET 614(V) 3(7)

VEGALOG 571 max. 255

Automatic allocation of a PC/DCS output

It is possible to allocated another or further

PC/DCS outputs to a measurement loop later

on.

Via the menu items „

ment loop, Modify

outputs

“, you reach the window “PC/DCS

Configuration, Measure-

“ and the button “

PC/DCS

coordination“.

Existing PC/DCS outputs

Configuration of the PC/DCS output via

VVO

A PC/DCS output is automatically allocated to

each measurement loop created in the

processing system. As a standard feature,

the PC/DCS output number is assigned automatically. The next fr ee PC/DCS output

number is always used. If, e.g. the PC/DCS

outputs 3, 4, 5 and 6 are still free, the PC/

DCS output number 3 is automatically allocated to the new measurement loop. Which

output number will be allocated, is shown in

VVO during creation of a new measurement

loop in the window „Create new measurement

loop - Measurement loop designation “. By

pushing the button „

PC/DCS address

“, a

new window opens in which the allocation of

the output number can be carried out manually.

VEGACOM 557 Profibus DP 23

PC/DCS output coordination

Parameter settings of the PC/DCS output via VVO

The following parameter settings can be

made for the PC/DCS output:

- parameters to be transferred, e.g. percent

- unit in which the parameter should be

transferred, e.g. 0.00 %

- transfer error code in the PC/DCS value

(from VVO 2.60)

- measured value limitation

Measurement loop in VEGAMET/VEGALOG

Examples of parameter settings: parameter, unit

Percent is chosen as parameter and 0.0% as

unit. The measured value 0.0 … 100.0 % is

transferred with these parameters as PC/

DCS value 0 … 1000.

Percent is chosen as parameter and 0.00%

as unit. The measured value

0.00 … 100.00 % is transferred with these

parameters as PC/DCS value 0 … 10000.

Note

The PC/DCS value is always transferred

without decimal point!

The adjustment of the parameter and the unit

can be made separately for each PC/DCS

output and has no influence on the other

outputs of the measurement loop. The parameter settings are done in the window

„PC/DCS“. This window is reached under

VVO via the menu items „

Parameter adjustment,

measurement loop, „

measured value

,“ button „

measured value and PC/DCS

Instrument data,

“ choose requested

Outputs, Display of

Outputs, Display of

“.

In the window „PC/DCS“, „scaled“ must be

chosen as parameter after the scaling.

Note

The scaling is used by each output of the

measurement loop that applies the parameter

„scaled“. Modifications in the scaling will then

affect all connected indicating instruments!

Transfer error code in the PC/DCS value

From VVO version 2.60, it is possible to

transfer an error code if there is interference

in a measurement loop. The error code is

then transferred in the PC/DCS value instead

of the measur ed value. To have the err or

code transferr ed in this way , “Transfer failure

messages to PC/DCS “ must be activated in

the window “PC/DCS“.

Adjust limitation of measured values

Further optional parameter settings can be

found in the window „Limitation of measured

values“.

In this window, it is possible to suppr ess

negative measured values, i.e. measured

values <0% are limited to 0%.

As another option, measured values <-10 %

and >110 % can be outputted as a fault signal.

Note

These options influence all outputs of the

measurement loop!

Parameter setting PC/DCS outputs

Scaled is selected as parameter . The measured value 0 … 100 % shall be transferred to

the PC/DCS system as PC/DCS value

10 … 5000. First of all, a scaling must be

The window can be reached via the following

menu items: „

adjustment,

loop, button „

measured values

Instrument data, Parameter

“ select requested measurement

Conditioning and Limitation of

“.

carried out for the measurement loop. Via the

menu items „

adjustment,

ment loop, button „

Parameter setting of the scaling

Instrument data, Parameter

“ choose the requested measure-

Conditioning and scaling

“.

Limitation of measured values

24 VEGACOM 557 Profibus DP

Transfer of measur ed value

5 Transfer of measured value

As DP norm slave, the VEGACOM 557 DP

gateway is either configured with 50 Byte

consistent input data and 2 Byte consistent

output data or with 6 Byte consistent input

data and 6 Byte consistent output data (see

chapter „6 Operating mode VEGACOM

557“)

.

The DP master transmits via the inputs

control information to VEGACOM 557, to

which VEGACOM 557 r esponds accor dingly,

making the data available to the DP master

as input information.

5.1 Format for transfer of measured

value

Measured values and PC/DCS values

The measured values of the VEGA processing systems (VEGAMET or VEGALOG) connected to VEGACOM 557 are reproduced on

the input bytes of the Profibus master as

described in chapter 4. They are available in

VEGACOM 557 as so-called PC/DCS values.

A PC/DCS value consists of 6 Byte.

Structure of a measured value

Measured values of VEGALOG or VEGAMET

processing system are transferred to VEGACOM 557 as 2 Byte signed data. This means

that the value range comprises max.

+32.768 up to -32.767.

Structure of a PC/DCS value

An individual PC/DCS value in VEGACOM

557 consists of 6 Byte and is structured as

follows:

PC/DCS value

Measured value

Additional info. High word Low word

Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6

Index Status

high

low high low

The real measured value is in the low word of

the measured value and with a length of 2

Byte and signed, this means that the value

range is +32768 up to -32767.

The 2 Byte of the high word of the measured

value are not used at present - they are filled

with the value zero.

In addition to the measured value, VEGACOM 557 provides per DCS value one Byte

for the PC/DCS index and another Byte for

information on the current measured value

status.

The PC/DCS output number is transferred in

the byte index. The status describes the

conditions of the respective measured value.

The contents of the measured value is only

valid if the respective status has the value

zero.

If the status value is not equal to zero, the

status value and the respective value in the

measured value field must be taken into

account for a detailed error diagnosis. The

following list explains the possible errors:

Status M eas. valueMeaning

0x00 0xXXXX valid measured value

0x01 0xXXXX simulated meas. value

(only on VEGAMET 509

and 512)

0x80 0xXXXX old meas. value (prob-

ably connection separated)

0xFE 0x0000 there is no meas. value

available (not configured)

0xFF 0xFFFF there is no VEGAMET or

VEGALOG connected

0xFF 0x00XX failure message of an

individual meas. loop

XX = error type

0xFF 0x8000 failure message of an

individual meas. loop

Error type not defined

VEGACOM 557 Profibus DP 25

6 Operating mode VEGACOM 557

Operating mode VEGACOM 557

Two dif ferent operating modes ar e available

for VEGACOM 557.

Depending on the operating mode, VEGACOM 557 reserves a different number of

input and output bytes in the Profibus-Master.

6.1 Mode 50E2A

In this mode, VEGACOM 557 reserves 50

input bytes and 2 output bytes.

The Profibus-Master has to process 50 Bytes

of data consistently .

How it works

A control command and a block number (1

byte each) are written into the 2 Byte output

data. After VEGACOM 557 has received

these two Bytes via Pr ofibus DP, it answers

by sending the data of the required block these 50 Byte are then available to the Profibus-Master as input bytes.

Since a maximum of 255 PC/DCS values and

up to 32 relay status are available in VEGACOM, but only 50 bytes at a time can be

transferred on the Profibus, the data are

multiplexed on the bus.

To facilitate this, the data ar e divided in

VEGACOM 557 into blocks. The requested

block can be enquired by the Profibus-Master with the control command and the block

number.

8 PC/DCS values (6 Byte each), the control

command (1 Byte) and the block number (1

Byte) decremented by the value 1 are returned in a block.

6.2 Mode 6E6A

In this mode, VEGACOM 557 reserves 6

input byte and 6 output byte.

The Profibus-Master must process 6 Byte

data consistently.

How it works

A control command and a PC/DCS value

number (1 Byte each) is written by the Profibus-Master into the 6 Byte output data, the

remaining 4 Byte must be filled with the value

0xFF.

After VEGACOM 557 has received these 6

Byte via the Pr ofibus DP, it answers by sending the data of the enquired PC/DCS value.

These 6 Byte are then available as input

bytes to the Pr ofibus-Master.

Since a maximum of 255 PC/DCS values and

up to 32 relay status are available in VEGACOM, but only 6 bytes at a time can be

transferred on the Profibus, the data on the

bus are multiplexed.

To facilitate this, the data in VEGACOM 557

are divided into single PC/DCS values. With

the control command and the PC/DCS value

number, the Pr ofibus-Master can enquir e t he

respective PC/DCS value.

6.3 Selection of the operating mode

To select the operating mode, it is necessar y,

to choose the respective configuration when

creating the bus configuration. The GSD file

provides both operating modes as options.

The selection is made with the respective

configuration tool, e.g. HW-Config for SIEMENS S7 systems or COM PROFIBUS for

SIEMENS S5 systems.

Depending on the configuration tool, a window is opened in which the desired operating mode can be selected when adding a

VEGACOM 557 slave to the bus configuration.

26 VEGACOM 557 Profibus DP

Loading...

Loading...