Page 1

Operating instructions

VEGACOM 557

VEGA ASCII protocol

Level and Pressure

BA

on

PC

557

out

in

Page 2

Contents

Safety information ..................................................................................................... 2

Note Ex area ............................................................................................................. 2

1 Product description

1.1 Application ......................................................................................................... 4

1.2 Configuration ..................................................................................................... 4

1.3 Functions ........................................................................................................... 5

1.4 Type plate .......................................................................................................... 9

1.5 Technical data .................................................................................................. 10

1.6 Dimensions ...................................................................................................... 12

1.7 Indicating and adjustment elements ............................................................. 13

2 Mounting and electrical connection

2.1 Mounting instructions ...................................................................................... 14

2.2 Mounting in carrier and housing .................................................................... 15

2.3 Wiring plan VEGACOM 557 ........................................................................... 15

2.4 Mounting and installation instructions with VEGACOM 557AP ................... 17

Contents

Safety information

Please read this manual carefully, and also take

note of country-specific installation standards

(e.g. the VDE regulations in Germany) as well

as all prevailing safety regulations and accident prevention rules.

For safety and warranty reasons, any internal

work on the instruments, apart from that involved in normal installation and electrical connection, must be carried out only by qualified

VEGA personnel.

2 VEGACOM 557 VEGA ASCII

Note Ex area

Please note the approval documents (yellow

binder), and especially the included safety

data sheet.

Page 3

Contents

3 Switch settings on VEGACOM 557

3.1 Adjustment of the PC interface ...................................................................... 20

3.2 Adjustment of the VEGA ASCII interface ...................................................... 21

4 Data image in VEGACOM 557

4.1 Enquiry for VEGAMET with three or less values per instrument ................ 26

4.2 Enquiry for VEGAMET with up to seven values per instrument ................. 28

4.3 Enquiry as block with low resolution ............................................................. 30

4.4 Enquiry as single value with low resolution ..................................................32

4.5 Enquiry as range with low resolution ............................................................ 34

4.6 Enquiry as block with address and low resolution ......................................36

4.7 Enquiry as single value with address and low resolution ........................... 38

4.8 Enquiry as range with address and low resolution ..................................... 40

4.9 Enquiry for the contact inputs and outputs on DISBUS .............................. 42

4.10 Enquiry for the contact inputs and outputs on LOGBUS ............................ 43

4.11 Enquiry for the software version .................................................................... 44

4.12 Error information from VEGACOM 557 .........................................................44

4.13 Parameter adjustment of VEGALOG or VEGAMET via VEGA ASCII ......... 45

5 Setup

5.1 Setup check list: ...............................................................................................46

5.2 Communication structure ................................................................................. 46

5.3 Setup example for the PC ............................................................................... 47

5.4 Example program for the enquiry VEGAMET (QUICK BASIC) .................. 49

5.5 Example program for the enquiry VEGALOG (VISUAL BASIC 4.0) ........... 53

Supplement A ..............................................................................................................56

VEGACOM 557 VEGA ASCII 3

Page 4

1 Product description

Product description

1.1 Application

The VEGACOM 557 is an efficient and easyto-use interface converter (Gateway) for your

measurement applications. It is used for

conversion of the VEGA-specific protocols of

DISBUS and LOGBUS into standard data

formats.

The existing version is used for connection of

level or pressure measuring systems to

Profibus DP systems such as

- processing systems (DCS)

- personal computers (PC)

- stored program control (PLC).

In addition, it is used for connecting a PC for

configuration or visualisation via the VEGA

adjustment software.

If connection is made to external systems,

there is the possibility of calling up measurement data and status information of the measuring systems via the master of the external

system. The coupling of the external system

is made via the connections on the rear of the

instrument. This data traffic requires that

special measures (described in this manual)

be taken in setting up the master of the external system. The data received in the master

can be visualised there or further processed

for control purposes. In restricted volume,

signal conditioning instrument-specific parameters can be outputted, modified and

returned again.

Via the PC interface on the front of VEGACOM 557, the VEGA visualisation software

"Visual VEGA“ or the VEGA configuration

software "VEGA Visual Operating“ (VVO) can

be operated. For these applications, the

coupling between VEGACOM 557 and a PC

is made directly with the connection cable

between the RS 232 interface (PC) on the

front of VEGACOM 557 and a standard Port

(e.g. COM1) of your PC. There is also the

possibility to provide a connection via modems.

1.2 Configuration

The component VEGACOM 557 is designed

in 19" technology with 5 TE width (1 TE = 5.08

mm) acc. to DIN 41 494. It can be used:

- in carrier BGT 596

- in VEGALOG 571 carrier BGT LOG 571

- in housing type 505.

The electrical connection of supply voltage,

DISBUS and Modbus is made via a plug

connection acc. to DIN 41 612 on the rear of

the component. The connection to LOGBUS

is made via an additional 5-pole plug-connector mounted to the DIN-socket.

A 9-pole SUB-D plug marked “PC” is located

on the front panel of VEGACOM 557. It is

used for connection of a PC via RS 232C to

VEGACOM 557.

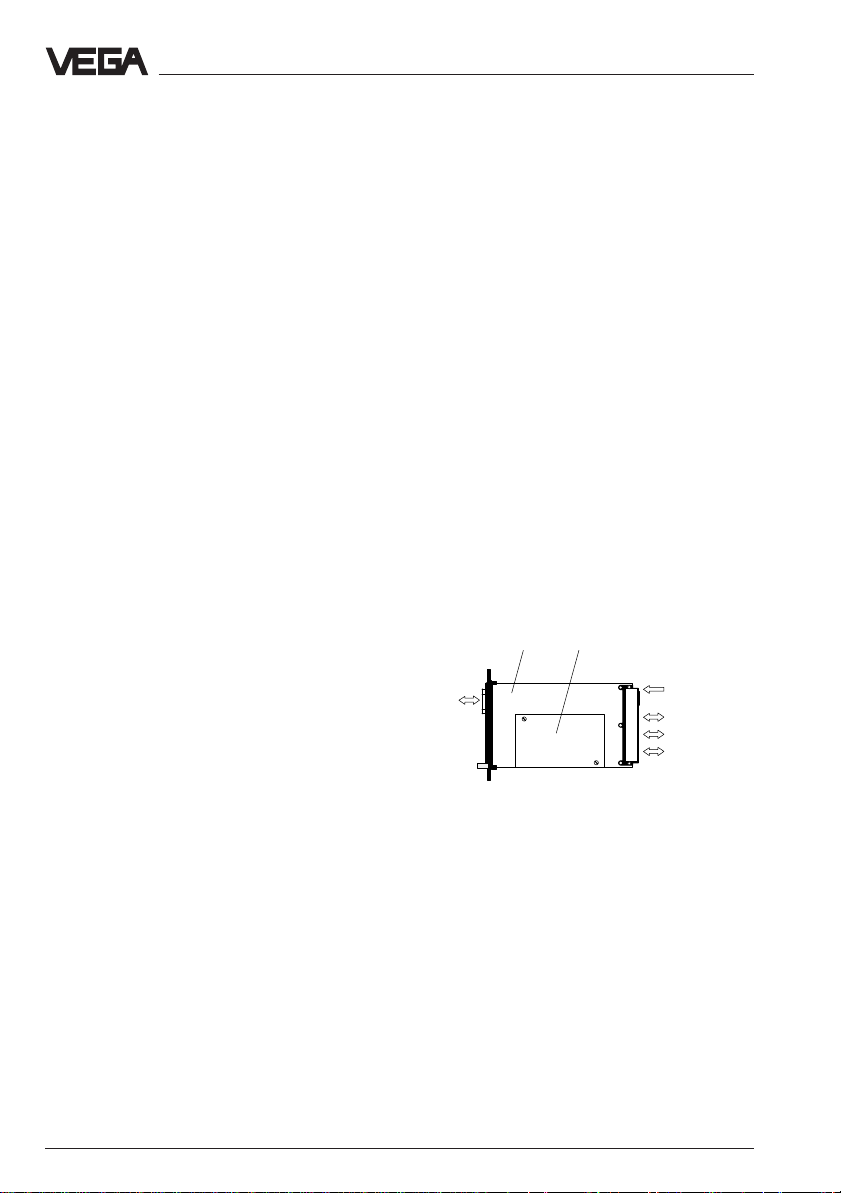

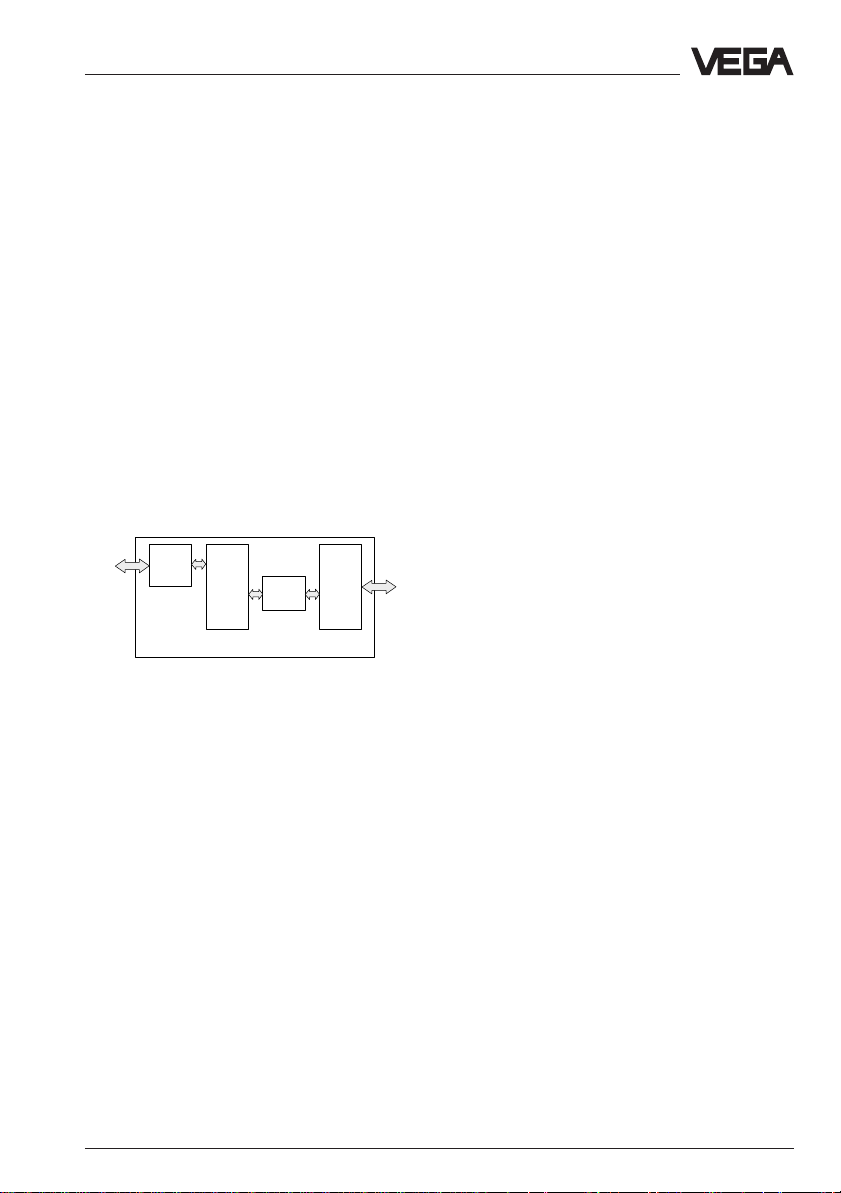

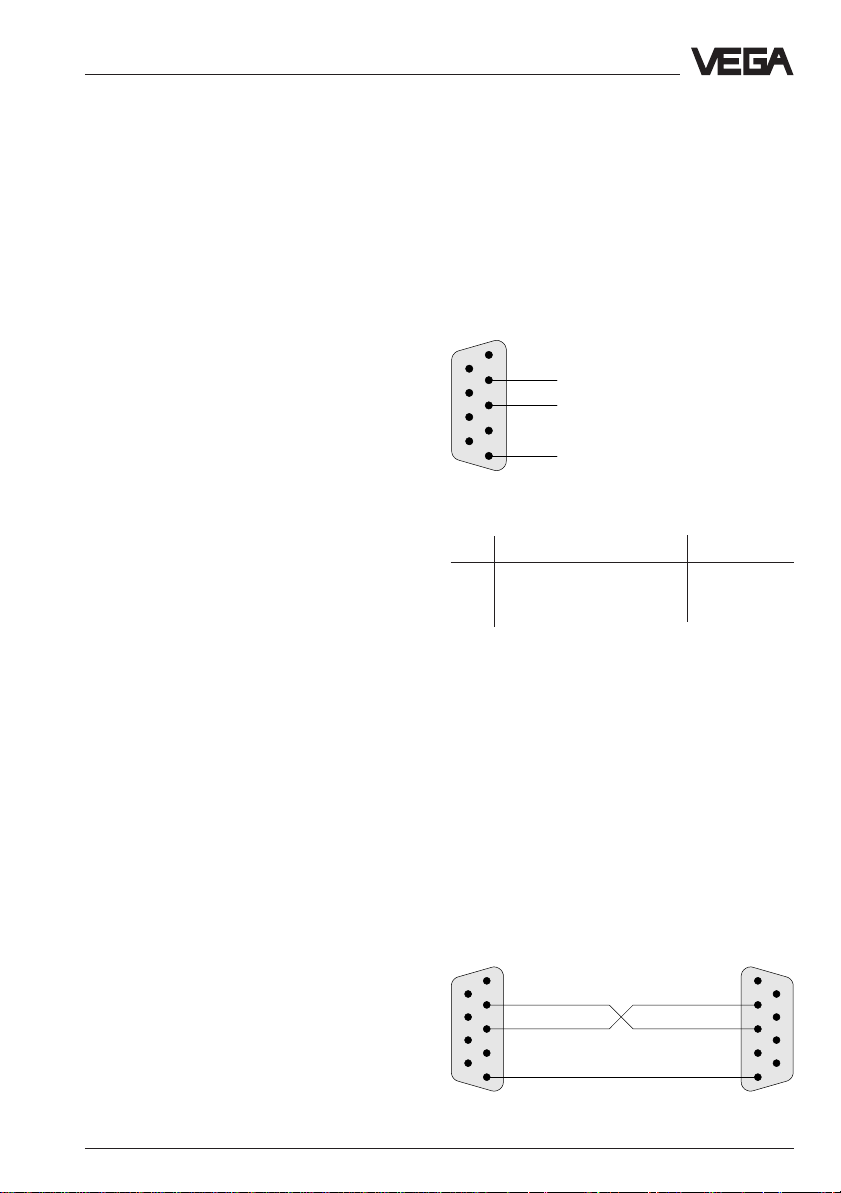

Basic board

PC

interface

VEGACOM 557 connections

The component consists of two boards:

- the basic board

- the additional board.

On the basic board, you will find the power

supply unit, the PC interface, the DISBUS/

LOGBUS interface as well as the connections

for the VEGA ASCII interface.

The additional board is screwed to the basic

board and includes the hardware of the

VEGA ASCII interface as well as the protocol

specific programs.

Additional board

Supply

DISBUS

LOGBUS

Modbus

4 VEGACOM 557 VEGA ASCII

Page 5

Product description

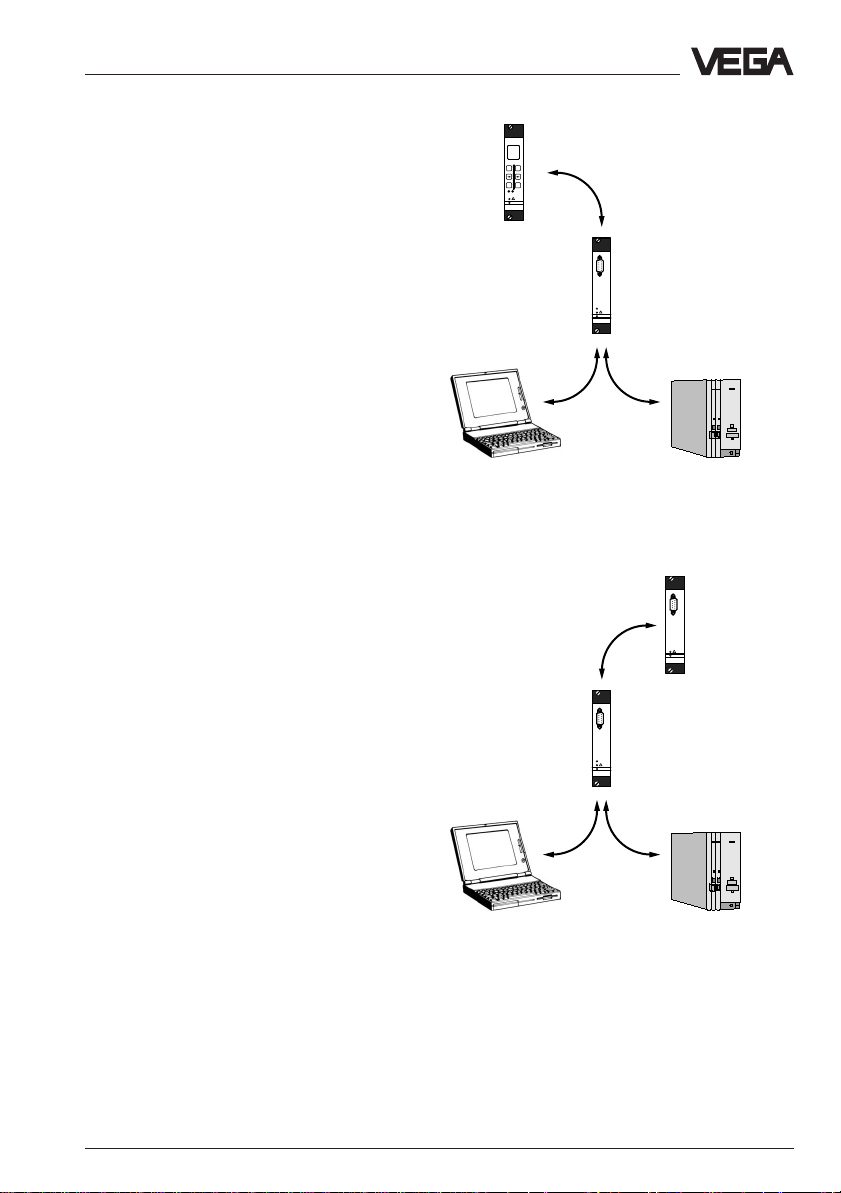

1.3 Functions

The VEGACOM 557 interface converter can

be integrated into the VEGA level or pressure measuring system in two different ways:

either

- as DISBUS participant

or

- as LOGBUS participant.

In both cases, VEGACOM 557 operates as

passive participant and provides measured

data and status information of the connected

VEGA signal conditioning instruments via the

external system. Through the use of readable text, a connection with simple terminal

programs is possible.

Alternatively, it is possible to connect a PC

with VEGA adjustment software via the SUBD-plug marked “PC” on the front panel of

VEGACOM 557. VEGA adjustment software

is actually available as two different Windows

applications.

VVO = VEGA Visual Operating

For configuration and parameter adjustment of the connected VEGAMET or VEGALOG processing systems

VV = Visual VEGA

For visualising and recording of measured

values of complete (multiple) vessel installations.

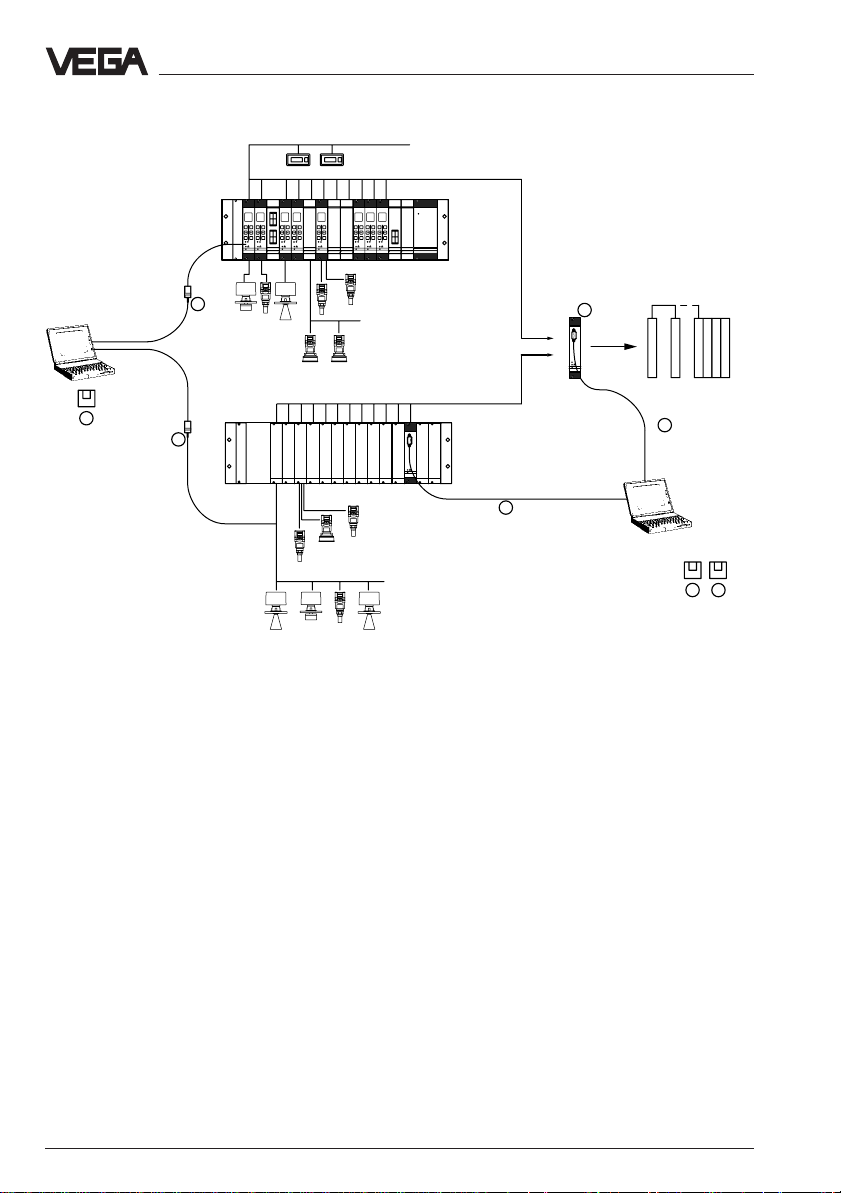

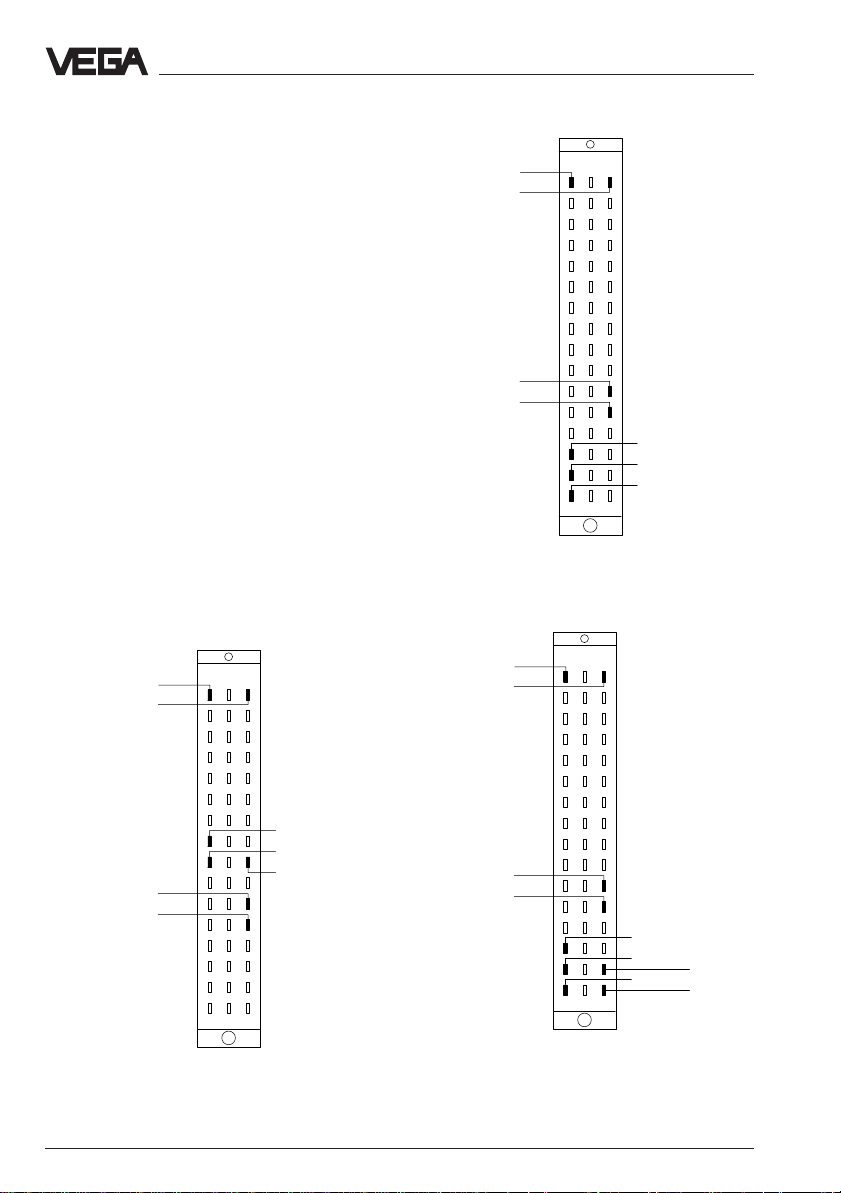

The following pictures show the basic connection possibilities of VEGACOM 557.

VEGAMET

DISBUS

%

100

+

-

ESC OK

CONNECT

!

on

VEGAMET

513

VEGACOM 557

PC

BA

!

on

VEGACOM

557

VVO

VEGA adjustment software

PC connection

VEGA ASCII

External

Master

VEGACOM 557 as DISBUS participants

VEGALOG 571

LOGBUS

PC

VEGACOM 557

BA

!

on

VEGACOM

557

PC

!

on

VEGALOG

571

VVO

VEGA adjustment software

PC connection

VEGA ASCII

External

Master

VEGACOM 557 as LOGBUS participant

VEGACOM 557 VEGA ASCII 5

Page 6

Product description

VEGACOM 557 on DISBUS

VEGAMET series 500/600 signal conditioning

instruments transmit via the DISBUS cyclically measured data and status information,

so called PC/DCS telegrams. VEGACOM 557

receives these data as participant on the

DISBUS and makes them available (in buffer

memory) for collection via the VEGA ASCII

protocol.

DISBUS

-

ESC OK

VEGAMET

100

CONNECT

!

on

+

+

+

-

-

ESC OK

ESC OK

CONNECT

CONNECT

!

!

on

on

VEGAMET

VEGAMET

513

513

513

%

%

%

100

100

VEGAMET

Connection VEGACOM 557 to DISBUS

VEGA ASCII

PC

BA

!

on

VEGACOM

557

VEGACOM

further

VEGACOM

External

Master

If a PC is connected to the PC interface (front

interface) of VEGACOM 557, this instrument

transfers acyclically (on request by the

VEGA configuration software VVO) measurement loop parameters from or to VEGAMET.

Max. two VEGACOM 557 can be connected

to the same DISBUS. For clear identification,

a different instrument address should be

assigned to each instrument.

VEGACOM 557 on LOGBUS

Data are exchanged continuously on the

LOGBUS between the individual components

of VEGALOG 571. VEGACOM 557 receives

as participant of this LOGBUS PC/DCS telegrams including the measured values and

status information and makes them available

(in buffer memory) for collection via the VEGA

ASCII protocol.

LOGBUS

on

PC

!

on

VEGALOG

571

VEGALOG

Connection VEGACOM 557 to LOGBUS

VEGA ASCII

PC

BA

!

on

VEGACOM

557

VEGACOM

further

VEGACOM

External

Master

If a PC is connected to the PC interface (front

interface) of VEGACOM 557, this instrument

transfers acyclically (on request by the

VEGA configuration software VVO) measurement loop parameters from or to VEGALOG

571.

Max. two VEGACOM 557 can be connected

to the same LOGBUS. The addressing for

clear identification is made automatically on

LOGBUS.

6 VEGACOM 557 VEGA ASCII

Page 7

Product description

VEGACOM 557 with VEGA ASCII

The data communication between VEGACOM

557 and a master is only carried out if initiated by the master, which can enquire the

requested information by means of special

commands.

The data from DISBUS/LOGBUS are first

written in a buffer memory of VEGACOM 557.

The data set is transferred from this buffer

memory into a process image. The protocol

conversion software enquires the stored data

cyclically from the individual storage areas.

The data sets are checked and converted

into the VEGA ASCII data format. After the

conversion, the data are transferred into the

emission memory and are sent from there to

the master.

DISBUS

LOGBUS

Function VEGACOM 557

Buffer

memory

Process

image

Test

conversion

Emission

memory

VEGA

ASCII

VEGACOM 557 with VVO or VV

Direct connection

As an alternative to the VEGA ASCII communication, a PC can be connected via the PC

interface (SUB-D-plug in the front panel of

VEGACOM 557). By means of the adjustment

and indicating software VEGA Visual Operating (VVO), the parameter adjustment can be

made on the signal conditioning instruments

connected to VEGACOM 557. The adjustment concept includes the user-friendly configuration and parameter adjustment of the

measuring system or the sensor with the

following instruments:

- VEGAMET series 500/600 signal conditioning instruments

- VEGALOG 571 processing system

- VBUS ultrasonic/radar sensors.

The adjustment is menu-driven and window

orientated. No matter if a radar sensor, several connected signal conditioning instruments or a VEGALOG should be adjusted via

the PC, the procedure is always the same.

As another possibility, measured values and

fault signals of the entire processing facility

can be recorded and shown graphically by

means of the visualisation software VISUAL

VEGA (VV). Tools for processing and analysis of history data are also available.

The configuration of the measurement loop

comprises, depending on the connected

instruments, e.g. the determination of output

functions or the configuration of individual

outputs or inputs. The user-orientated editing

of measurement loops is supported by

graphic means, such as e.g. vessel drawings and pictographs that adapt to the selected general conditions and options.

Thanks to the graphical support, even more

complex parameter adjustments such as e.g.

the input of a linearisation curve by means of

index markers can be done with ease.

Connection via modem

The PC interface supports, beside the direct

connection of a PC, also the operation via

modems. With this additional function, remote

parameter adjustment or remote diagnostics

of VEGA systems via VVO are possible.

Together with the visualisation software Visual

VEGA, even remote visualisations can be

carried out.

VEGACOM 557 VEGA ASCII 7

Page 8

Product description

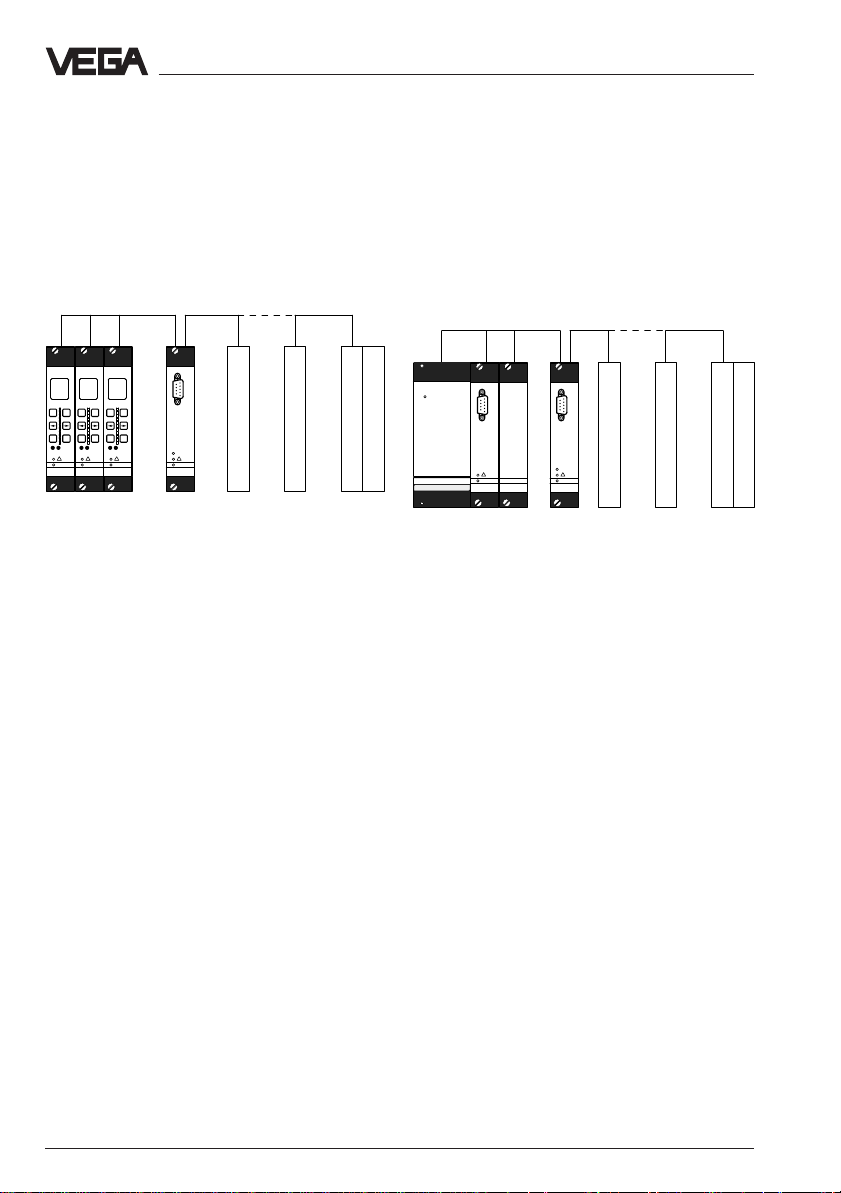

Complete measuring system with digital communication and networking

DISBUS

%

%

%

100

100

+

-

-

ESC OK

ESC OK

CONNECT

!

!

on

on

VEGAMET

VEGAMET

513

%

%

%

100

100

100

+

+

-

-

ESC OK

ESC OK

CONNECT

CONNECT

!

!

on

on

VEGAMET

VEGAMET

513

513

100

+

+

-

-

ESC OK

ESC OK

CONNECT

CONNECT

!

!

on

on

VEGAMET

VEGAMET

513

513

on

%

%

100

100

+

+

+

-

-

ESC OK

ESC OK

CONNECT

CONNECT

CONNECT

!

!

on

on

VEGAMET

VEGAMET

513

513

513

4

O

V

V

LOGBUS

1

4

PC

!

on

VEGALOG

571

Measuring system with digital communication and networking

Explanation:

3 VEGACOM 557

1 VEGA Visual Operating (VVO)

Adjustment software for the PC for the

user-friendly configuration and parameter

adjustment of VEGA instruments

- VEGALOG 571 directly via RS 232

connection cable on the CPU card or

VEGACOM 557

4 VEGACONNECT 2

- several VEGAMET via VEGACOM 557

or individually via VEGACONNECT

- VEGASON, VEGAPULS via VEGACONNECT on the signal line or on the sensor

2 Visual VEGA (VV)

PC visualisation software for presentation

5 RS 232 connection cable (interlink cable)

of measurement data from VEGA instruments in a graphical or tabular form. Integration of individual measurement loops

into groups, saving of fault signals and

measured values (recorder function).

Suitable for networks

3

VEGA

PC

ASCII

BA

!

on

VEGACOM

557

5

V

5

V

2

1

Interface converter for conversion of VEGA

specific protocols into standard data formats. Suitable for connection to the DISBUS output of VEGAMET series 500/600

signal conditioning instruments or the LOGBUS of VEGALOG 571 processing system.

Connection cable (interface converter)

between VEGA instruments (VEGASON,

VEGAPULS or VEGAMET) and a PC in

conjunction with the adjustment software

VEGA Visual Operating.

Connection cable between PC and VEGALOG 571-CPU or VEGACOM 557

External system

8 VEGACOM 557 VEGA ASCII

Page 9

Product description

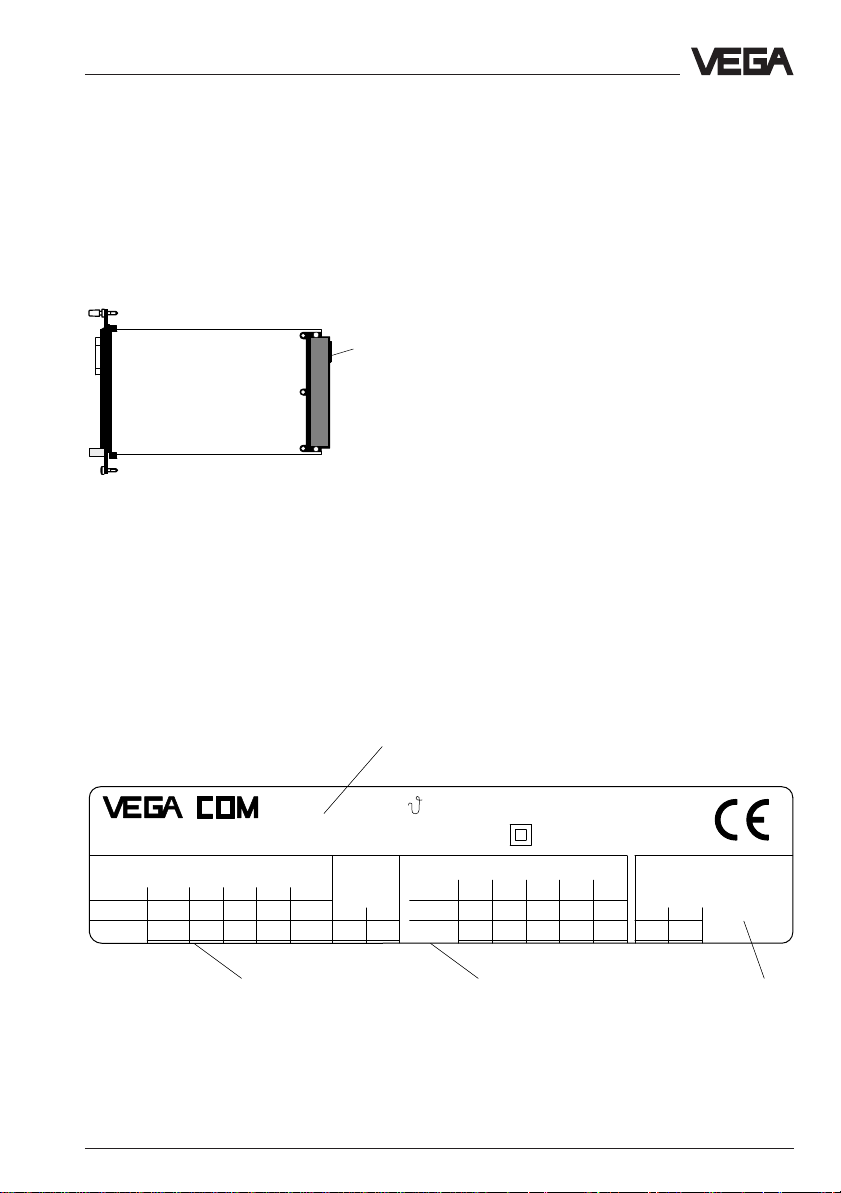

1.4 T ype plate

Type plate

Before mounting and electrical connection,

please check if you are using the correct

version of VEGACOM 557. Please note the

type plate, located below the multiple plug.

Type plate on

multiple plug

The type plate contains important data required for electrical connection. The configuration and the components of the type plate

are explained in the illustration below.

Note:

The serial number of your VEGACOM is on

the rear of the plug connector.

1

®

RS 422 /Rx /Tx GND_1TxRx

RS 485

d32 z32 z30d30

DATA GND_1

557

VEGA ASCII

DIS

-+

d28

z22z24

a: -20 ... +60˚C

IP 40 (front)

TTY

R- T- R+

RS 232

d20 z20 d16d18

Insp.

power supply

z18

GND

GNDRxD

20 ... 53V AC

20 ... 72 V DC

N-L+

6 VA

z2d2

T+

TxD/DATA

33 2

1 Version: VEGA ASCII

2 Supply voltage

3 Terminal assignment of the possible interface to VEGA ASCII

VEGACOM 557 VEGA ASCII 9

Page 10

Product description

1.5 T echnical data

Power supply

Supply voltage U

Power consumption approx. 6 VA

Fuse 1 A, slow-blow

Electrical connection

Component multiple plug acc. to DIN 41 612, series F

Module in carrier

BGT 596 or BGT LOG 571 suitable multipoint connector acc. to DIN 41 612

Housing type 505 via screw terminals max. 1 x 1.5 mm

Indicating elements

LED on front panel green "BA“: VEGA ASCII active

Meas. data input DISBUS

Data transmission DISBUS (digital data transmission)

Connection cable 2-wire standard cable (shielded)

Cable length max. 1000 m

Measuring data input LOGBUS

Data transmission LOGBUS (digital data transmission)

Connection cable connection via BUS-plug

= 24 V AC (20 … 53 V), 50/60 Hz or

nom

= 24 V DC (20 … 72 V)

48 pole (d, b, z) with coding holes

with connection via standard technologies

2

red: failure, freeze mode

green "on“: operating mode

PC interface

Interface standard RS 232C

Cable length max. 15 m

Transmission rate in baud 300, 600, 1200, 2400, 4800,

96009600

9600, 19200, 38400

96009600

Transmission format 8 data bits, 1 stop bit, no parity or even

parity

Plug on front panel SUB-D-plug connector, 9 pole, pins

Modbus interfaces

Interfaces RS 232 RS 422 RS 485 TTY

Cable length 15 m 1200 m 1200 m 1000 m

Connection cable 3-wire 5-wire 3-wire 4-wire

twisted in pairs, shielded

Transmission mode serially asynchronous, half-duplex

Transmission rate 300; 600; 1200; 2400; 4800; 9600; 19200;

38400 baud

Galvanic separation up to 0.5 kV

10 VEGACOM 557 VEGA ASCII

Page 11

Product description

Modbus ASCII-mode

Coding system hexadecimal, ASCII-character

Number of bits 1 start bit, 7 or 8 data bits, 1 (0) parity bit,

Parity NONE, ODD, EVEN

Backup none

Electrical protective measures

Protection:

not mounted IP 00

in carrier BGT 596

or BGT LOG 571

- front side completely equipped IP 40

- upper and lower side

BGT 596 IP 00

BGT LOG 571 IP 20

- wiring side IP 00

in housing type 505

- front side IP 40

- other sides IP 30

Protection class II (in housing type 505)

Overvoltage category II

Electrical separation measures

Reliable separation acc. to VDE 0106, part 1 between power supply, LOGBUS, DISBUS,

PC-connection and respective interface

- reference voltage 250 V

- test voltage 2 kV

1 stop bit

Ambient conditions

Permissible ambient temperature -20°C … +60°C

Storage and transport temperature -20°C … +85°C

Humidity 93 %, T = 40°C acc. to DIN/IEC 68-2-3

Shock 2 … 100 Hz, 0.7 g

Mechanical data

Series module unit for

Dimensions, not mounted W = 25.4 mm (5 TE), H = 128.4 mm, D = 166 mm

Weight approx. 550 g

CE conformity

VEGACOM 557 meets the protective regulations of EMC (89/336/EWG) and NSR

(73/23/EWG). The conformity has been judged acc. to the following standards:

EMC Emission EN 50 081 - 2: 1993

Susceptibility EN 50 082 - 2: 1995

NSR EN 61 010 - 1: 1993

VEGACOM 557 VEGA ASCII 11

- carrier BGT 596

- carrier BGT LOG 571

- housing type 505

Page 12

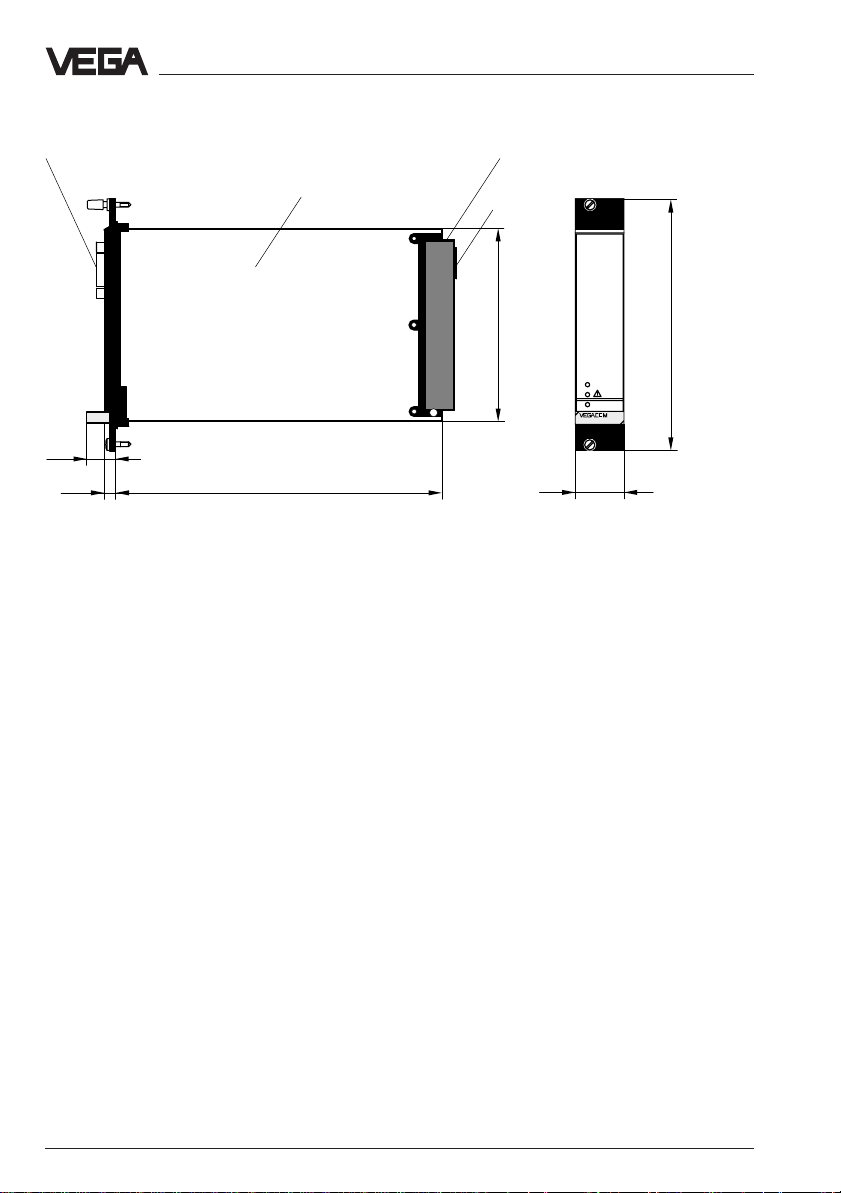

1.6 Dimensions

front RS 232C interface (PC)

Multipoint connector

100 x 160 x 1.5

European size

Multiple plug

LOGBUS

plug

Product description

5 TE

15

100

BA

on

1625,5

25,4

128,4

557

12 VEGACOM 557 VEGA ASCII

Page 13

Product description

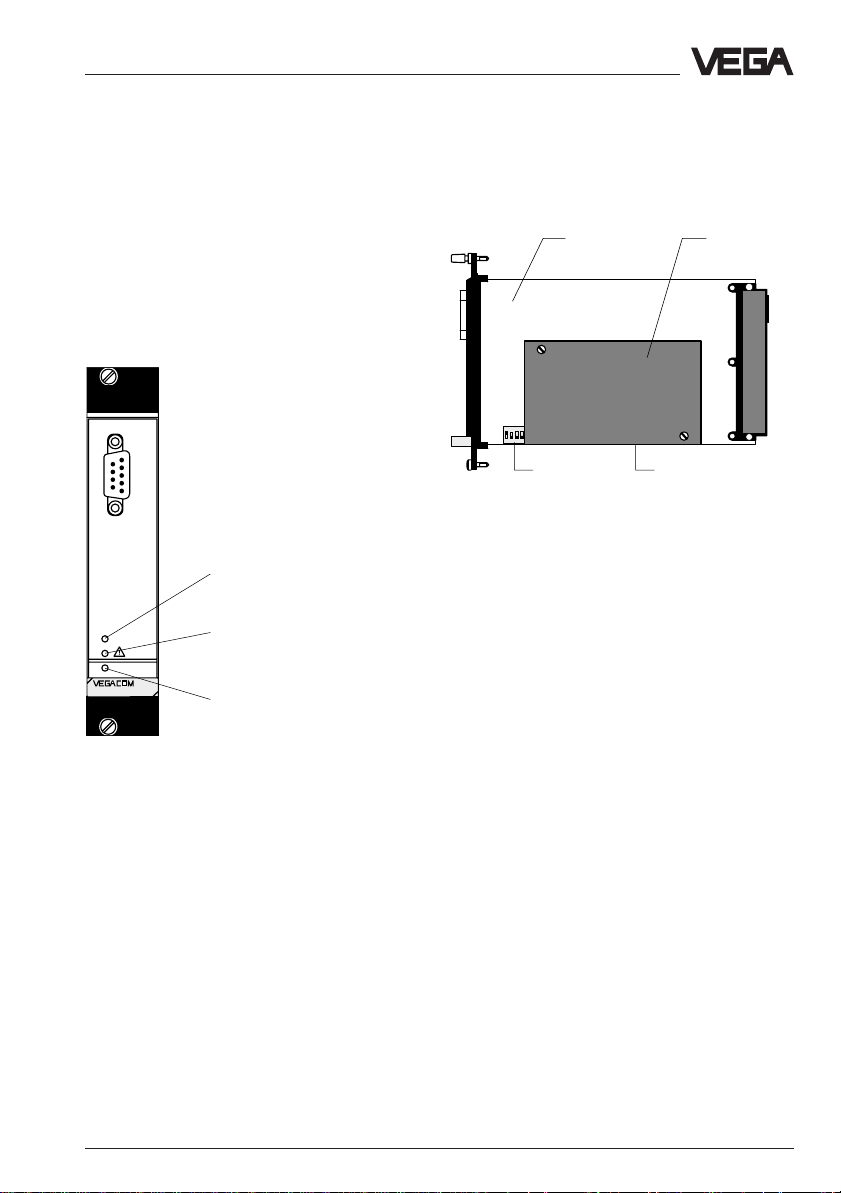

1.7 Indicating and adjustment elements

As diagnostic aid, VEGACOM 557 is

equipped with three LEDs. These are located

on the instrument front panel. In addition, the

basic board, as well as the additional board

of VEGACOM 557 are equipped with a

number of switches (DIP switch or hook

switch) for configuration of the available interfaces.

Indicating elements/Diagnostics LEDs

PC

VEGA ASCII active

BA

on

557

Fault signal

Voltage supply

Adjustment elements

The adjustment elements are located on the

basic board. A 6-pole DIL-switch block on

the basic board is used for adjustment of the

front PC interface.

Additional

Basic board

2 3 4ON1

DIL switch

on basic board

Side view of VEGACOM 557

DIL switch

on additional

board

board

Special function “Freeze Mode“

For diagnostic purposes on VEGA processing systems VEGAMET and VEGALOG, the

process image can be “frozen“ in VEGACOM

557 with the adjustment software VVO. This

enables the possibility of carrying out maintenance work on the VEGA system, without

disturbing the higher-priority processing

system.

Front of VEGACOM 557

Meaning of the LEDs:

VEGA ASCII active:

For activating the Freeze Mode, a PC must

be connected directly to the PC interface of

VEGACOM 557 and the Freeze Mode must

be switched on under VVO in the menu "Configuration - Measuring system“.

- green LED lights in case of valid data ex-

change

Fault signal:

- red LED flashing: DISBUS/LOGBUS-error

- irregularly flashing: no PC/DCS outputs

assigned

- permanent light: hardware error or special

Attention:

Before activating this function, you must

make sure that during this mode no disastrous consequences are to be expected for

production processes (during this mode, no

level values etc. are updated).

function "Freeze Mode“

Voltage supply:

- green LED lights, operating voltage on.

VEGACOM 557 VEGA ASCII 13

Page 14

2 Mounting and electrical

connection

Mounting and electrical connection

2.1 Mounting instructions

The gateway VEGACOM 557 can process

measured data and status information in two

different ways:

- via DISBUS (from measuring systems with

VEGAMET)

- via LOGBUS (from measuring systems

with VEGALOG).

For DISBUS configurations, VEGACOM 557

can be either mounted into carrier BGT 596

or housing type 505.

In conjunction with LOGBUS, VEGACOM 557

is mounted into carrier BGT LOG 571. The

location is individually selectable, the system

adapts automatically when rebooting

(autoconfiguation).

Coding

A mechanical coding system prevents mixing

up the different module cards in the carrier or

in the housing.

The coding system consists of:

- three coded pins in the multipoint connector

- three holes in the multiple plug of VEGACOM 557.

Instrument Function

coding coding

VEGACOM 557 a27 c3/c11

Instrument coding

d b z

a c

1

3

5

7

9

11

13

15

17

19

21

23

VEGACOM 557

Positioning of the coded pins

a27

25

27

29

31

Function coding

c3

c11

VEGALOG card

Interface card

The coded pins are attached to the module

or the housing. The plug-in socket must be

equipped by the user with the coded pins

according to the following table and diagram.

Coded pin

Plug-in socket of VEGACOM 557

14 VEGACOM 557 VEGA ASCII

Page 15

Mounting and electrical connection

2.2 Mounting in carrier and housing

BGT 596 or BGT LOG 571

For mounting, a slot module must be provided at the location. A slot module consists

of:

- a multipoint connector acc. to DIN 41 612,

series F, 33-pole (d, b, z)

- two screws

- three coded pins

- two guide rails.

The multipoint connector is available in the

following versions:

- Wire-Wrap, standard connection

1.0 mm x 1.0 mm

- plug connection

2.8 mm x 0.8 mm

- Termi-Point standard connection

1.6 mm x 0.8 mm

- soldering connection

- screw terminals 0.5 mm2.

For mounting the module, please note the

operating instructions of the carrier.

Housing type 505, type 506

This housing is already equipped with a

multipoint connector. Before mounting, please

check if the housing is equipped with a

power supply unit or not.

2.3 Wiring plan VEGA COM 557

PC interface in front panel (SUB-Dplug)

The PC interface of VEGACOM 557 is used

exclusively for connection of computer systems with VEGA adjustment software via a

COM-Port. The PC interface is based on the

RS 232C standard and is assigned as follows.

1

6

2

7

3

8

4

9

5

Pin assignments of the PC interface of VEGACOM 557

Pin Description I/O

2 RxD receive data I

3 TxD transmit data O

5 GND ground –

Note:

With a direct connection to the computer

system, VEGACOM 557 works without hardware handshake.

RxD

TxD

GND

The connection is made via screw terminals

with max. 1.5 mm2. Further details are stated

in the operating instructions “Housing type

505, type 506“.

Direct connection

For direct connection of a PC to the PC interface of VEGACOM 557, the interlink (or a

standard) cable available from VEGA with 9pole plugs on both ends should be used.

The pin assignments of the interlink cable are

shown in the diagram.

1

6

2

7

3

8

4

9

5

Wiring proposal for interlink cable

1

2

3

4

5

VEGACOM 557 VEGA ASCII 15

6

7

8

9

Page 16

Mounting and electrical connection

dbz

10

8

6

4

2

12

14

16

18

20

22

24

26

28

30

32

Connection via modem

VEGA ASCII via RS 485

For remote parameter adjustment, it is possible to connect the PC interface via a modem.

In such a case, the modem cable that comes

with the respective modem should be used.

Modem operation is supported by VEGACOM 557 from software version 2.11. Further

information on the remote parameter adjustment is stated in the operating instructions

"Remote parameter adjustment“.

Connections of the multiple plug (rear)

For connection of VEGACOM 557 to the existing VEGA ASCII system all standard interfaces are available. The power supply of the

instrument and the connection to the VEGA

system are always the same. The following

illustrations show the respective terminal

assignments depending on the selected

Supply voltage

DISBUS (not

used on VEGALOG)

+

–

+

–

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

dbz

GND (C/C´)

DATA (B/B´)

/DATA (A/A´)

interface type.

Wiring regulation for VEGA ASCII via

VEGA ASCII via RS 232 C

Supply voltage

DISBUS (not

used on VEGALOG)

Wiring regulation for VEGA ASCII via

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

dbz

GND

TxD

RxD

RS 232 CRS 232 C

RS 232 C

RS 232 CRS 232 C

Supply voltage

+

–

DISBUS (not

used on VEGALOG)

Wiring regulation for VEGA ASCII via

16 VEGACOM 557 VEGA ASCII

+

–

VEGA ASCII via RS 422

+

–

+

–

RS 485RS 485

RS 485

RS 485RS 485

GND

RX

/RX

RS 422RS 422

RS 422

RS 422RS 422

TX

/TX

Page 17

Mounting and electrical connection

Modbus via TTY

Supply voltage

DISBUS (not

used on VEGALOG)

+

–

+

–

dbz

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

Wiring regulation for VEGA ASCII via

GND

T+

R-

TTYTTY

TTY

TTYTTY

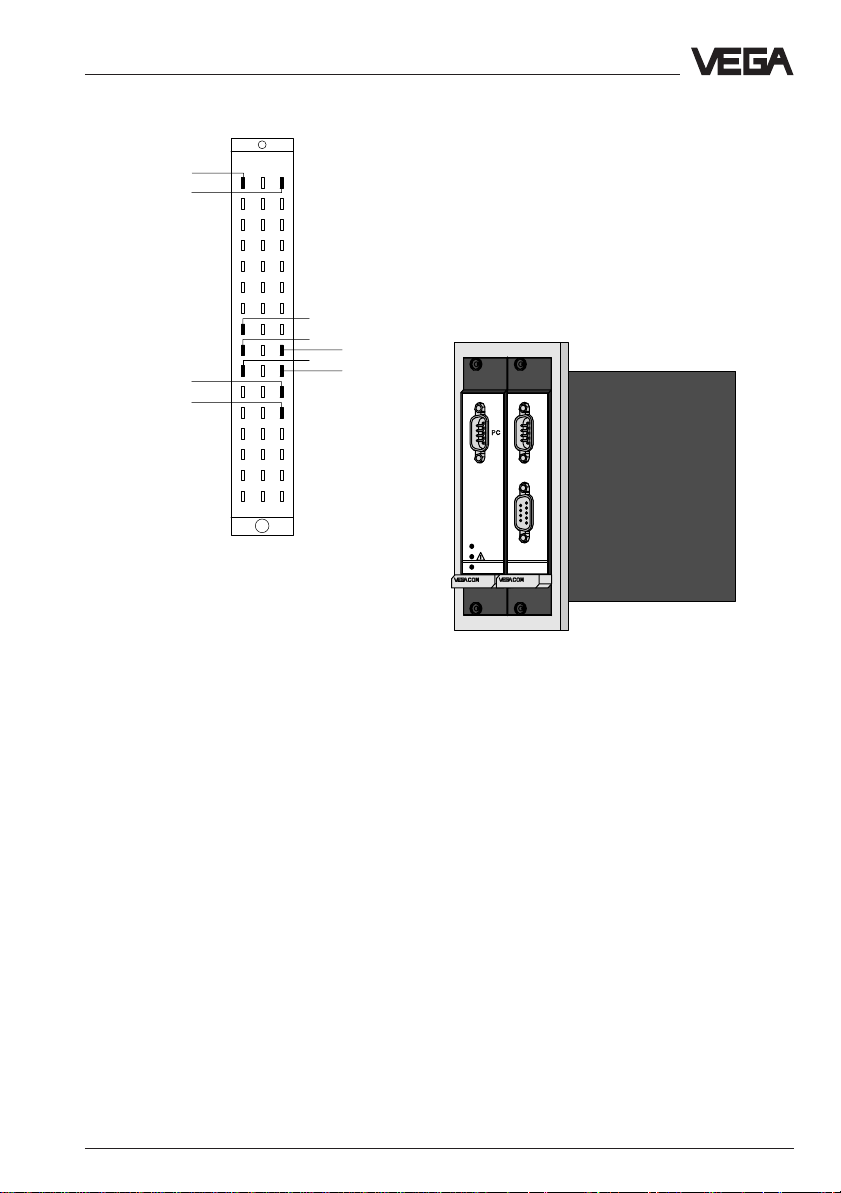

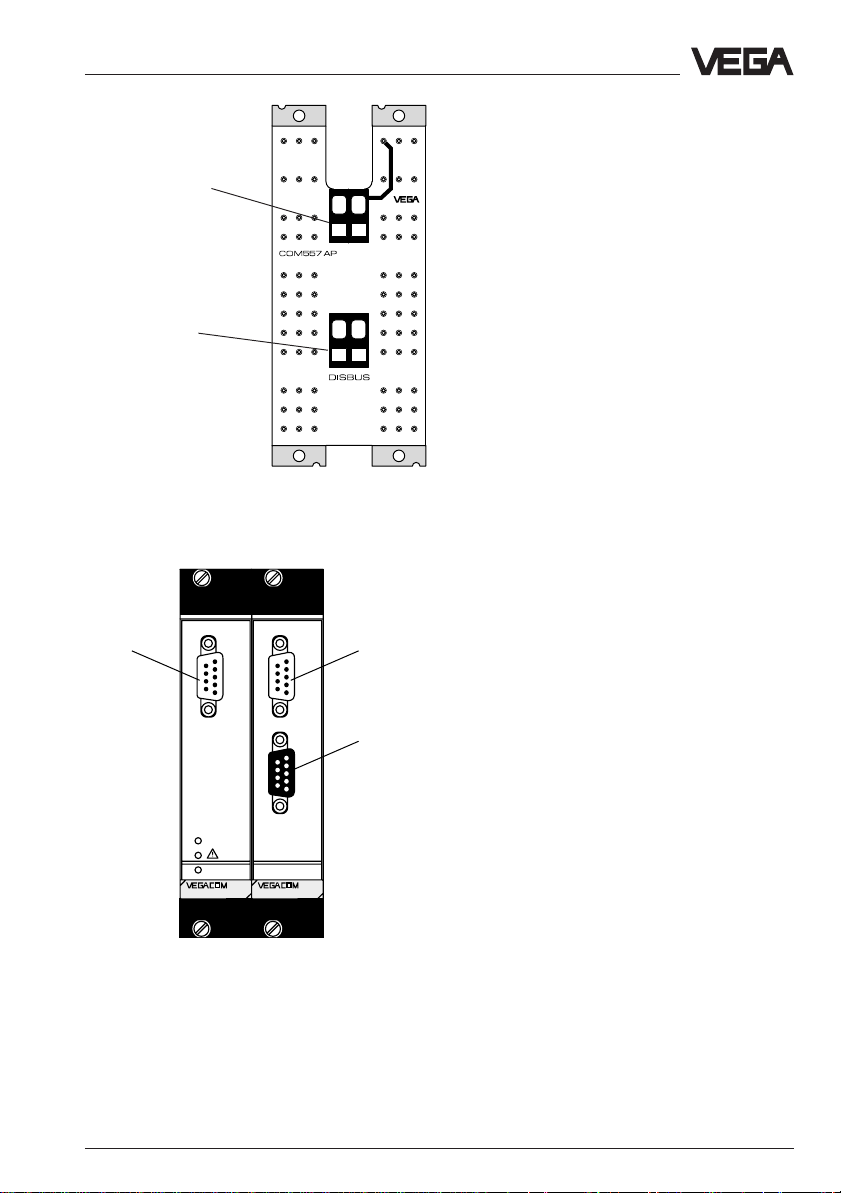

2.4 Mounting and installation instructions with VEGACOM 557AP

As an option, VEGACOM 557 can be extended with the adapter print VEGACOM

557AP. The adapter print VEGACOM 557AP

consists of a module card with 5 TE width

and two modules connected to a back-panel

print for carrier BGT 596 or BGT LOG 571.

R+

T-

BA

on

557AP

557

VEGACOM 557 with adapter print VEGACOM 557AP

With the adapter print card it is possible to

put the interfaces of VEGACOM 557 at the

front of the carrier. On the front of the adapter

print card, the VEGA ASCII interface is available as a 9-pole SUB-D-plug and as 9-pole

SUB-D-socket. The required interface type

must be stated when ordering VEGACOM

557AP.

The following interface types are available:

- RS 232

- RS 422

- RS 485

- TTY

VEGACOM 557 VEGA ASCII 17

Page 18

Mounting and electrical connection

Make sure that also VEGACOM 557 is set to

the same interface type (DIL-switch 1 on the

additional board) as VEGACOM 557AP. The

pin assignments of SUB-D-plug and SUB-Dsocket is listed in the tables.

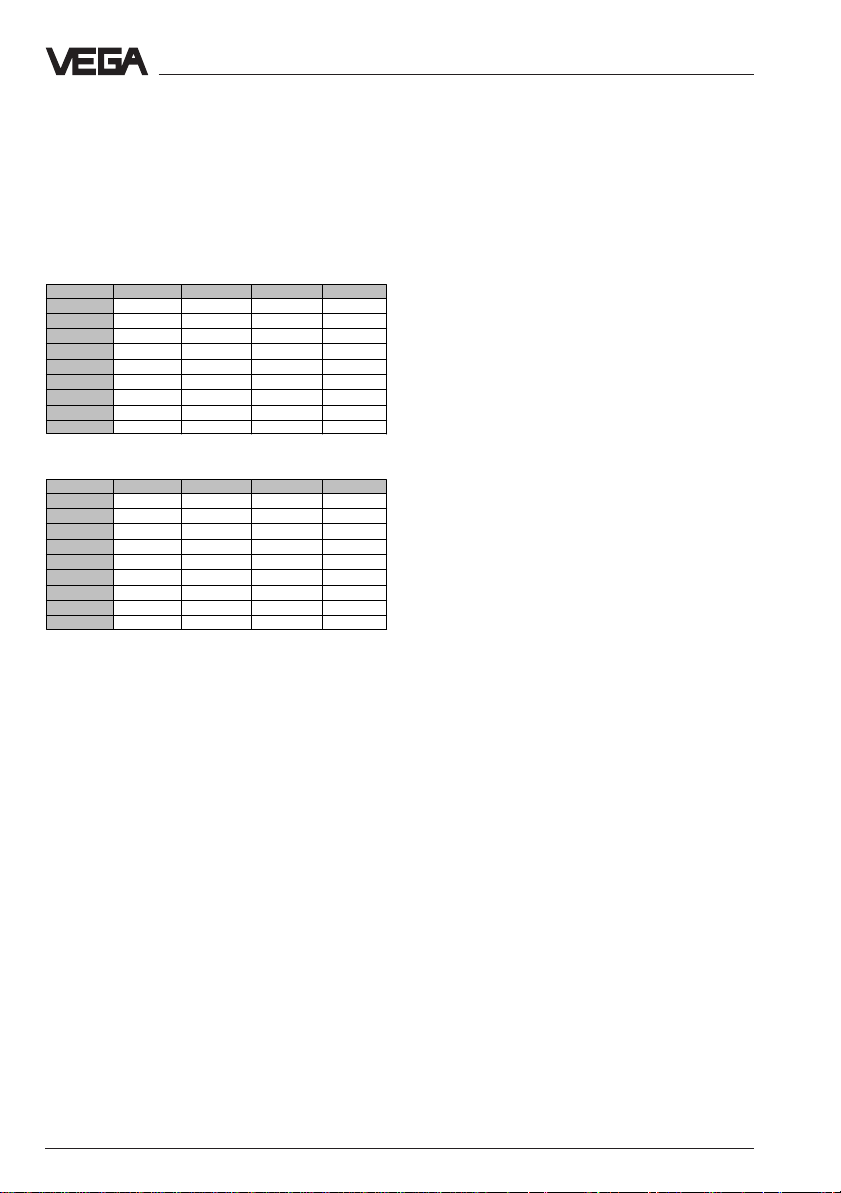

Pin assignments

Pin-Nr. RS 232 RS422 RS485 TTY

1

2 RXD RX

3 TXD TX DATA R+

4

5 GND GND GND GND

6 - - +5V 7-/RX-T8 - /TX /DATA R9-- - -

9-pole SUB-D-plug

Pin-Nr. RS 232 RS422 RS485 TTY

1

2 TXD RX

3 RXD TX DATA R+

4

5 GND GND GND GND

6 - - +5V 789-- - -

9-pole SUB-D-socket

VEGACOM 557APVEGACOM 557AP

VEGACOM 557AP

VEGACOM 557APVEGACOM 557AP

----

----

----

----

/RX

/TX /DATA R-

-

-

-

T+

T+

T-

Mounting instructions for VEGA COM

557AP

The two modules connected to the backpanel print consist of:

- two multipoint connectors acc. to DIN 41

612, series F, 48-pole (d, b, z) connected

via the back-panel print

- four screws

- six coded pins

- four guide rails

Coding

The coding should be carried out for both

modules as described in chapter “2.1“.

Module position

BGT LOG 571

The module position is individually selectable,

the VEGALOG 571 processing system

adapts automatically through

autoconfiguration during the first booting.

After autoconfiguration, the slot location of the

cards must never be changed.

BGT 596

The module position is individually selectable.

Please note that the two connected modules

cover a width of 10 TE (5 TE for VEGACOM

557 plus 5 TE for the adapter board

VEGACOM 557AP).

Connection VEGACOM 557AP

BGT LOG 571

With the bus board (part of the carrier BGT

LOG 571) connection to LOGBUS is made

automatically when inserting VEGACOM 557.

The voltage supply of the card must be provided separately. For this reason, a 2-pole

terminal with tension spring connection,

called U

print. The permissible operating voltage of

VEGACOM 557 should be observed. In case

of DC voltage supply, the correct polarity

should be noted!

BGT 596

When operating VEGACOM 557 as

DISBUS participant, the DISBUS must be

wired in addition to the supply voltage.

For the two cables of the DISBUS, a 2-pole

terminal with tension spring connection is

available. Make sure that the polarity is correct!

is available on the back-panel

b,

18 VEGACOM 557 VEGA ASCII

Page 19

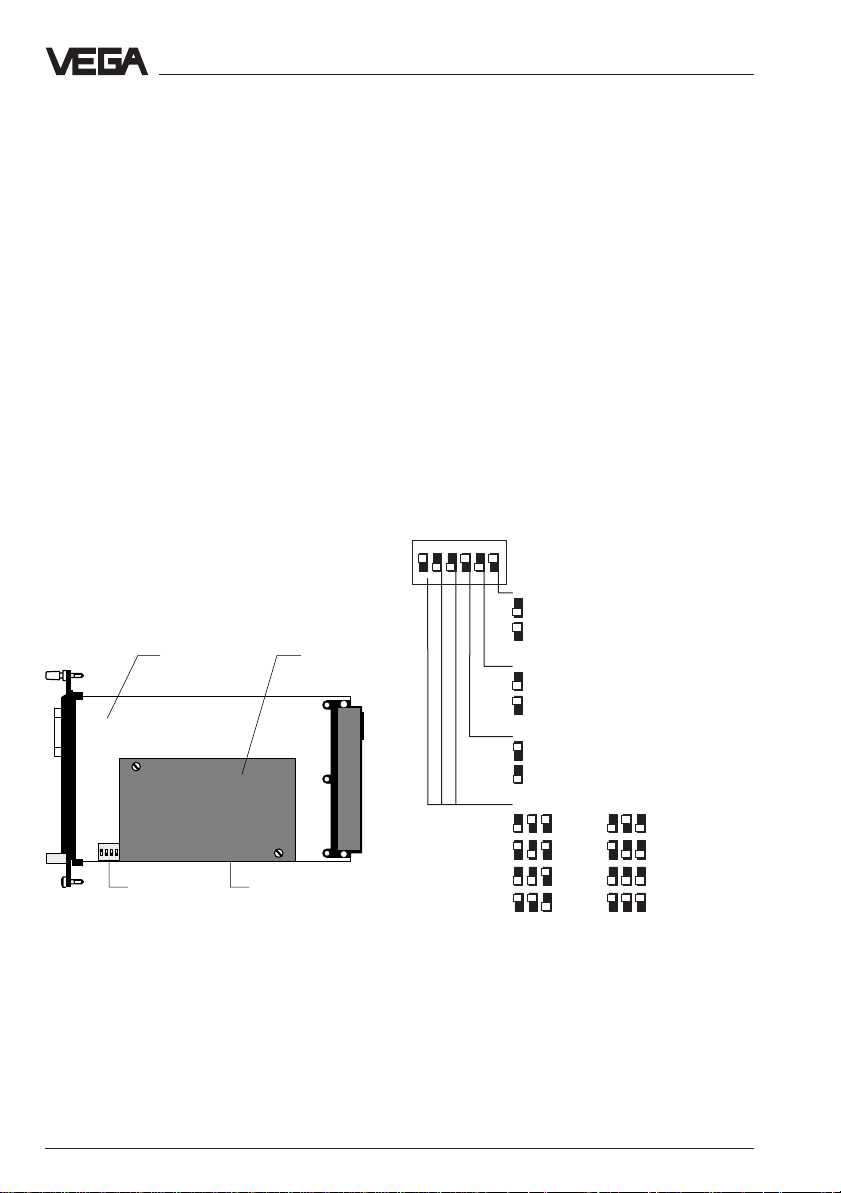

Mounting and electrical connection

Terminals

for supply voltage

Terminals

for DISBUS

View of back-panel board (rear of the carrier)

PC interface of

VEGACOM 557

Ub+

VEGA ASCII

interface of

VEGACOM 557 as

SUB-D-plug

PC

BA

on

557

VEGA ASCII

interface of VEGACOM 557 as SUBD-socket

557AP

Front view with SUB-D-connections of VEGACOM 557

and VEGACOM 557AP

VEGACOM 557 VEGA ASCII 19

Page 20

3 Switch settings on

VEGACOM 557

Switch settings on VEGACOM 557

For adjustment of the interfaces or the BUS

parameters of the PC interface and the VEGA

ASCII interfaces, various DIL switches are

provided on VEGACOM 557. Before inserting

VEGACOM 557 into the carrier or the housing, the DIL switches must be set according

to the user-specific data. The data of these

settings will be effective with the next initialization (switching on of voltage).

3.1 Adjustment of the PC interface

For adjustment of the RS 232 PC interface in

the front panel of VEGACOM 557, a 6-pole

DIL switch block is located on the basic

board. The PC interface is used for communication between a PC and VEGACOM 557, by

means of the adjustment software VVO or the

visualisation software VV.

Basic board

2 3 4ON1

DIL switch

on basic board

Side view of VEGACOM 557

Data format

Parity can be switched from even to no

parity (note for VVO including version 2.15,

even parity is compulsory).

Additional

board

DIL switch

below additional

board

Instrument number

Only relevant when operating two

VEGACOM 557 on the same DISBUS. If

two VEGACOM 557 are operated on the

DISBUS, different instrument numbers

have to be assigned.

Not relevant for operation on LOGBUS.

Automatic modem initialization

In position "ON“ the modem will be initialized automatically when connecting it to the

VEGACOM interface.

Transmission rate

For VVO or VV, the transmission rate must

be set to 9600 baud.

In the following diagram, you see all possible

adjustment possibilities for configuration of

the PC interface.

ON EDG

1

23456

Possible settings of the DIL switch on the basic

board

Factory setting

Data format

8 data bits, 1 stop bit, even parity

8 data bits, 1 stop bit, no parity

Instrument number

1. instrument

2. instrument

Automatic modem initialisation

On

Off

Transmission rate (baud)

300 4800

600 9600

1200 19200

2400 38400

20 VEGACOM 557 VEGA ASCII

Page 21

Switch settings on VEGACOM 557

123

45678

O

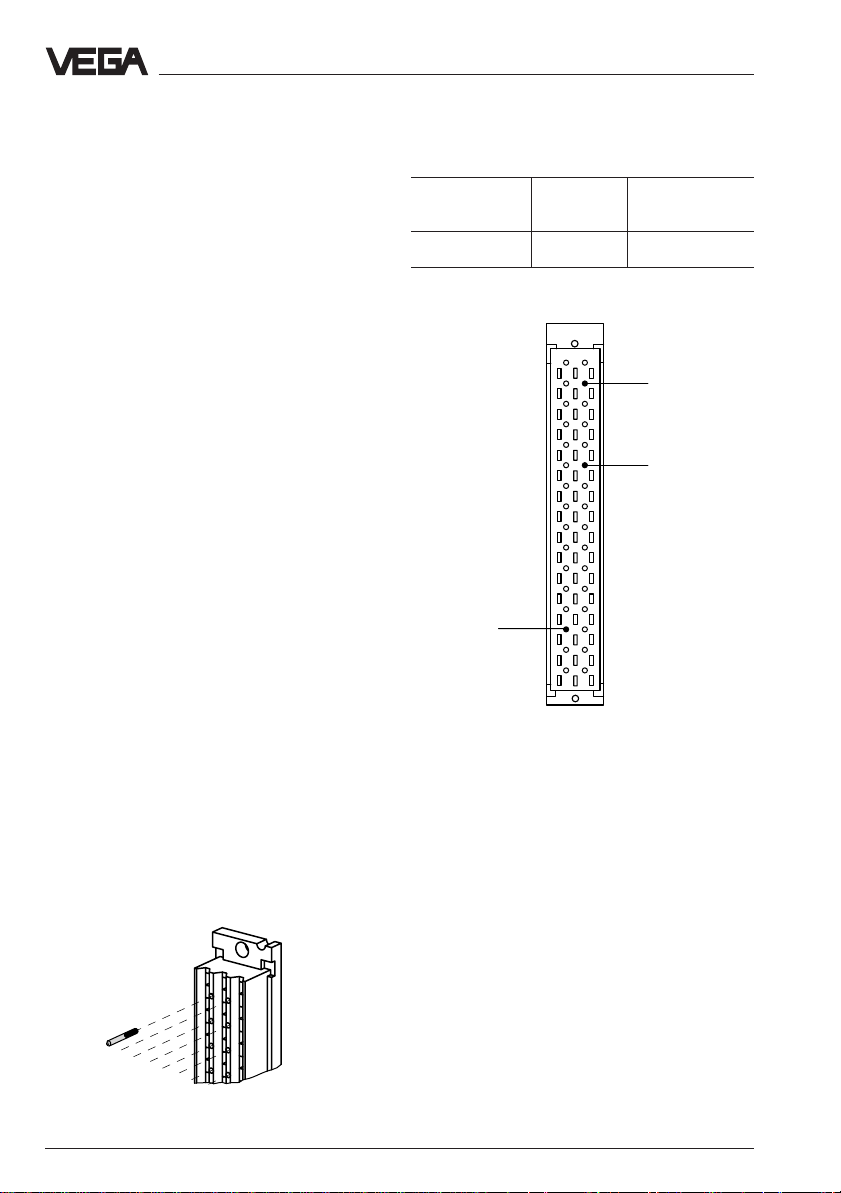

3.2 Adjustment of the VEGA ASCII interface

Three 8-pole DIL switch blocks as well as two

hook switches for configuration of the VEGA

ASCII interface to the DCS or the PLC are

located on the additional board.

DIL switch blocks

Additional

board

Front

DIL switch

plate

basic board

Bottom view of VEGACOM 557

additional board

1 2 3

1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8

Basic board

The following adjustments for the VEGA

ASCII are made through these DIL-switch

blocks:

Switch 1

- selection of the interface type

- activation of the bus termination

- selection of the protocol

Switch 2

- selection of the baud rate

- number of data bits

- mode for parity bit

- resolution

- definition of the measured value image

Hook switches

additional

board

2 1

Multiple plug

DIL switch block 1

(additional board)

N

Factory setting

Protocol selection

VEGA ASCII

Bus termination for RS 485/

422

On

Off

Selection of the interface type

RS 232

RS 422, RS 485

TTY

Possible settings of DIL switch block 1 on the additional board

Note:

When selecting the interfaces TTY and

RS 232, the hook switches must also be set

to the respective position.

Activation of the bus termination on RS 485 is

necessary when VEGACOM 557 is the last

participant. General rule: The first and the last

bus participant must be operated with bus

termination activated.

When using interface RS 422, the bus termination must always be activated on VEGACOM 557.

Switch 3

- VEGA ASCII address of VEGACOM 557

Note:

When holding VEGACOM 557 for adjustment

of the DIL-switches 1 to 3 (shown in illustration 2.10), the following switch representation

can be applied directly.

VEGACOM 557 VEGA ASCII 21

Page 22

Switch settings on VEGACOM 557

123

45678

O

123

45678

O

DIL switch block 2

(additional board)

N

Factory setting

DCS measured value image

(only relevant on VEGAMETs)

all meas. values Met 1,

all meas. values Met 2,

etc.

1. meas. value Met 1,

1. meas. value Met 2,

etc.

Protocol mode

Modbus ASCII

Modbus RTU

Parity

none

odd

even

Number of data bits

8

7

Selection of the baud rate

300

600

DIL switch block 3

(additional board)

N

Factory setting

Bus address

of VEGACOM 557

(Adr. 1 to 9)

not used

e.g.:

Adr.

= 1

Possible settings of DIL switch block 3 on additional

board

Note:

With the switch for the adjustment of the bus

address (DIL-switch block 3), it is theoretically possible to set addresses in the range

of 0 to 15. However, in reality only address 1

to 9 can be directly set. Address settings

outside the range are converted to address

9.

Address 0 cannot be used, as it is used as

broadcast address.

Hook switches (additional board)

The hook switches on the additional board

enable selection between TTY and RS 232

interface. The additional print has to be removed from the basic print to modify the

settings. The following illustration shows the

removed additional print.

1200

2400

4800

9600

19200

38400

Possible settings of DIL switch block 2 on additional

board

DIL switch

123

L RL R

12

Hook switch

View of the dismounted additional print

22 VEGACOM 557 VEGA ASCII

Page 23

Switch settings on VEGACOM 557

Depending on the requirements, the VEGA

ASCII interface can be used as TTY interface

but also as RS 232 interface (using the hook

switches). Illustration 2.15 shows the respective switch positions. As a rule, VEGACOM

557 is delivered with RS 232 activated.

L RL R

= Activation of the TTY-interface

12

L RL R

= Activation of the RS 232-interface

(default)

12

Note:

L = left position, R = right position

Allocation of the switch positions (hook switch on the

additional print)

VEGACOM 557 VEGA ASCII 23

Page 24

4 Data image in VEGACOM 557

Data image in VEGACOM 557

VEGACOM 557 collects the measured values

of the VEGA signal conditioning instruments

VEGAMET 509, 512, 513, 514, 515 and 614

(via DISBUS) or VEGALOG 571 (via LOGBUS) and puts them in the temporary

memory for collection via the VEGA ASCII.

The method of storing the measured values

(for the higher-priority processing systems)

in the VEGACOM 557 temporary memory

differs depending on the selected configuration. It depends on whether VEGACOM 557

is connected to the DISBUS or the LOGBUS,

and if DISBUS, also on the connected instrument type. However, it can be also influenced

by VEGACOM 557 itself via DIL switches.

Note

On the VEGAMET 513, 514, 515 and 614

signal conditioning instruments, as well as on

the VEGALOG 571 processing system, the

individual configuration of the DCS outputs

with the adjustment software VVO is possible.

On VEGAMET 513, 514, 515 and 614 signal

conditioning instruments as well as the VEGALOG 571 processing system, it is additionally possible to enquire the conditions of

the contact inputs and outputs via VEGACOM 557.

Enquiry of DCS values from DISBUS

The addressing of the measured values for

VEGA ASCII is made instrument-orientated

for the DISBUS enquiry. I.e. the measured

values are enquired individually for each

VEGAMET.

Due to these two different series, it is necessary to use two different telegrams for the

enquiry of measured values. With enquiry "P“

3 values are transmitted. With enquiry "M“,

VEGACOM 557 delivers a total of 7 measured values.

If one or several DCS outputs have been

assigned on the instrument, the respective

measured value is provided with an error

information during transmission. It is then

possible to distinguish between valid and

invalid values.

All values of an instrument are placed one

after the other.

Resolution

A selection between two resolutions of the

value range is possible:

1 low resolution: (switch 2.2 = OFF)

between -999.9 and +999.9

2 high resolution: (switch 2.2 = ON)

between -999999 and +999999

(actually only the range between

-32768 and +32767 is used)

In addition to the above mentioned possibilities, the DCS values can be read out as a

block. Here also there are two different possible configurations.

In the first configuration, a total of 16 DCS

values are reserved for each VEGAMET. The

instruments are then imaged in the memory

according to their address.

Series 509 and 512 instruments deliver max.

3 measured values. The number of measured

values can be configured on the instrument.

On series 513, 514, 515 and 614 instruments,

the number of measured values (max. 7) can

be set via the adjustment program VVO or

directly on the instrument.

24 VEGACOM 557 VEGA ASCII

Page 25

Data image in VEGACOM 557

all measured values

of VEGAMET #1

all measured values

of VEGAMET #2

all measured values

of VEGAMET #15

ESC OK

VEGAMET

%

100

+

-

CONNECT

!

on

513

ESC OK

VEGAMET

%

%

100

100

+

+

-

-

ESC OK

CONNECT

CONNECT

!

!

on

on

VEGAMET

513

513

-

ESC OK

VEGAMET

%

100

+

CONNECT

!

on

513

Grouping of measured values acc. to VEGAMET

addresses

The second configuration images first all DCS

values with the number 1, then DCS values

with the number 2 etc.

all DCS output with index =1

Enquiry of DCS values on LOGBUS

The numbering of the DCS values is made for

LOGBUS between 001 and 255. This assignment is prepared via the parameter tool VVO.

Each DCS value is therefore marked clearly.

With the enquiry "%“ and the DCS number,

the values can be read out of VEGACOM 557

as single enquiry, range enquiry or as total

block.

all DCS output with index =2

ESC OK

VEGAMET

%

100

+

-

CONNECT

!

on

513

ESC OK

VEGAMET

%

%

100

100

+

+

-

-

ESC OK

CONNECT

CONNECT

!

!

on

on

VEGAMET

513

513

-

ESC OK

VEGAMET

%

100

+

CONNECT

!

on

513

Grouping of measured values acc. to DCS indices or

channels

VEGACOM 557 VEGA ASCII 25

Page 26

Data image in VEGACOM 557

4.1 Enquiry for VEGAMET with three or less values per instrument

Low resolution = Switch 2.2 = OFF

VEGAMET series 509 and 512 instruments have max. 3 DCS outputs. Series 513, 514 and 515

instruments can assign max. 7 DCS outputs. If max. 3 DCS outputs are used with these instruments, the following telegram can be used for data transmission:

Telegram from processing system to VEGACOM 557

Address Address End

Identifier VEGACOM VEGAMET identification

No. of bytes1121

Range (AS CII) p (P) 0..9 01. . 15 CR

Example p 1 02 CR

Identifier: 1 character, optional "P“ or "p“

End identification: 1 character Chr (13) = CR = Carriage Return

Total length of the telegram: 5 characters

Answer of VEGACOM 557

Addr Addr DCS DCS DCS Error End

S1 COM MET S2 va lue1 T1 value2 T2 v alue3 T3 info identification

No. of bytes11 11717171 1 2

Range (ASCII) = 0.. 9 01. .15 # AS CII p AS CII p ASCII p 0.. 7 CRLF

Example = 1 02 # 17.2 p 38.4 p 45.7 p 0 CRLF

Start character: S1 = 1 character "=“

Start character: S2 = "#“

Separating character: T1, T2, T3 = per 1

character "p“

Total length of the telegram: 32 characters

26 VEGACOM 557 VEGA ASCII

(structure also value for DCS value 2 and 3)

7123456

3 positions in front of the decimal point

1 decimal point

1 position after the decimal point

1 during simulation

" " during operation

"-“ for negative values

" " for positive values

Error information

0: No error

1: Error on DCS 1

2: Error on DCS 2

3: Error on DCS 1+2

4: Error on DCS 3

5: Error on DCS 1 + 3

6: Error on DCS 2 + 3

7: Error on DCS 1,2 + 3

Page 27

Data image in VEGACOM 557

5

High resolution = switch 2.2 = ON

The same enquiry can also be carried out with high resolution. The enquiry to VEGACOM 557

remains the same, in the answer more characters are used for the presentation of the measured value.

Telegram from processing system to VEGACOM 557

Address Address End

Identifier VEGACOM VEGAMET identification

No. of bytes1121

Range (ASCII) p (P) 0. .9 01. .15 CR

Example p 1 02 CR

Identifier: 1 character, optional "P“ or "p“

End identification: 1 character Chr (13) = CR = Carriage Return

Total length of the telegram: 5 characters

Answer of VEGACOM 557

Addr Addr DCS DCS DCS Error End

S1 COM MET S2 Value1T1 Value2 T2 Valu e3 T3 info identification

No.of bytes11117171711 2

Range (ASCII) = 0.. 9 01..1

# ASCII p ASCII p ASCII p 0..7 CRLF

Example = 1 02 # 00172 p 00384 p 00457 p 0 CRLF

Start character: S1 = 1 character "=“

Start character: S2 = "#“

Separating character: T1,T2,T3 = per 1 character "p“

Total length of the telegram: 32 characters

VEGACOM 557 VEGA ASCII 27

(structure also value for DCS value 2 and 3)

123456

6 digit figure

without decimal point

"-“ for negative values

" " for positive values

7

Error information

0: No error

1: Error on DCS 1

2: Error on DCS 2

3: Error on DCS 1+2

4: Error on DCS 3

5: Error on DCS 1 + 3

6: Error on DCS 2 + 3

7: Error on DCS 1,2 + 3

Page 28

Data image in VEGACOM 557

4.2 Enquiry for VEGAMET with up to seven values per instrument

Low resolution = switch 2.2 = OFF

VEGAMET instruments can be provided with up to 7 DCS outputs. With this telegram, it is

possible to read all DCS values from one instrument.

Telegram from processing system to VEGACOM 557

Address Address End

Identifier VEGACOM VEGAME T identification

No. of bytes1121

Range (AS CII) m (M) 0.. 9 01. . 15 CR

Example m 1 2 CR

Identifier: 1 character, optional "M“ or "m“

End identification: 1 character Chr (13) = CR = Carriage Return

Total length of the telegram: 5 characters

Answer of VEGACOM 557

Addr Addr DCS Error End

S1 COM MET S2 value2 T2 T3 info identification

No. of bytes 1 1 1 1 7 X 7 1 1 1 2

Range (ASCII) = 0..9 01..15 # ASCII p p 0..7 CRLF

Example = 1 02 # 38.4 p p 0 CRLF

Start character: S1 = 1 character "=“

Start character: S2 = 1 character "#“

Separating character: Tx = per 1 character "p“

Total length of the telegram: 66 characters

28 VEGACOM 557 VEGA ASCII

(Structure is valid for all DCS values)

123456

3 positions in front of decimal point

1 decimal point

1 position after the decimal point

1 during simulation

" " during operation

"-“ for negative values

" " for positive values

7

Error information

1. position

0: No error on DCS 1,2,3

1: Error on DCS 1

2: Error on DCS 2

3: Error on DCS 1+2

4: Error on DCS 3

5: Error on DCS 1 + 3

6: Error on DCS 2 + 3

7: Error on DCS 1,2 + 3

2. position

0: No error on DCS 4,5,6

1: Error on DCS 4

2: Error on DCS 5

3: Error on DCS 4+5

4: Error on DCS 6

5: Error on DCS 4 + 6

6: Error on DCS 5 + 6

7: Error on DCS 4,5 + 6

3. position

0: No error on DCS 7

1: Error on DCS 7

Page 29

Data image in VEGACOM 557

High resolution = switch 2.2 = ON

The same resolution can also be carried out with high resolution. The enquiry to VEGACOM

557 remains the same, however the answer, has more characters for the presentation of the

measured value.

Telegram from processing system to VEGACOM 557

Address Address End

Identifier VEGACOM VEGAMET identification

No. of bytes1121

Range (ASCII) m (M ) 0..9 01..15 CR

Example m 1 2 CR

Identifier: 1 character, optional "M“ or "m“

End identification: 1 character Chr (13) = CR = Carriage Return

Total length of the telegram: 5 characters

Answer of VEGACOM 557

Addr Addr DCS Error End

S1 COM MET S2 v alue2 T2 T3 info identification

No. of bytes 1 1 1 1 7 X 7 1 1 1 2

Range (ASCII) = 0..9 01.. 15 # ASCII p p 0.. 7 CRLF

Example = 1 02 # -00384 p p 0 CRLF

Start character: S1 = 1 character "=“

Start character: S2 = 1 character "#“

Separating character: Tx = per 1 character "p“

Total length of the telegram: 66 characters

VEGACOM 557 VEGA ASCII 29

(structure is valid for all DCS values)

7123456

6 digit figure

without decimal point

"-“ for negative values

" " for positive values

Error information

1. position

0: No error on DCS 1,2,3

1: Error on DCS 1

2: Error on DCS 2

3: Error on DCS 1+2

4: Error on DCS 3

5: Error on DCS 1 + 3

6: Error on DCS 2 + 3

7: Error on DCS 1,2 + 3

2. position

0: No error on DCS 4,5,6

1: Error on DCS 4

2: Error on DCS 5

3: Error on DCS 4+5

4: Error on DCS 6

5: Error on DCS 4 + 6

6: Error on DCS 5 + 6

7: Error on DCS 4,5 + 6

3. position

0: No error on DCS 7

1: Error on DCS 7

Page 30

Data image in VEGACOM 557

4.3 Enquiry as block with low resolution

Low resolution = switch 2.2 = OFF

This telegram reads in all DCS values, i.e. 255 values are always transferred together. Each

DCS value is provided with a number. Depending on the position of switch 2.1, the DCS values are arranged differently. The assignment of the DCS numbers to the VEGAMET addresses is stated in supplement A.

Telegram from processing system to VEGACOM 557

End

Identifier identification

No. of bytes 1 1

Range (AS CII) % CR

Example % CR

Identifier: 1 character, "%“

End identification: 1 character Chr (13) = CR = Carriage Return

Total length of the telegram: 2 characters

Answer of VEGACOM 557

255 repetitions

DCS DCS End

S1 no. S2 value2 identification

No. of by t es 1 3 1 5-6 2

DCS value or

Range (ASCII) = 001..255 #

fault %CR

Example = 001 # -067.3 %CR

Start character: S1 = 1 character "=“

Start character: S2 = 1 character "#“

Total length of the telegram: 255 * 12 or 13 characters

Fault

12345

‘FAULT’

30 VEGACOM 557 VEGA ASCII

valid measured value

123456

3 positions in front of the decimal point

1 decimal point

1 position after the decimal point

‘-’ with negative values

‘ ‘ with positive values

Page 31

Data image in VEGACOM 557

High resolution = switch 2.2 = ON

The same enquiry can also be carried out with high resolution. The enquiry to VEGACOM 557

remains the same, however in the answer, more characters are used for presentation of the

measured value.

Telegram from processing system to VEGACOM 557

End

Identifier identification

No. of bytes 1 1

Range (AS CII) % CR

Example % CR

Identifier: 1 character, "%“

End identification: 1 character Chr (13) = CR = Carriage Return

Total length of the telegram: 2 characters

Answer of VEGACOM 557

255 repetitions

DCS DCS End

S1 no. S2 value2 identification

No. of by t es 1 3 1 7 2

DCS value of

Range (ASCII) = 001..255 #

fault %CR

Example = 001 # -000673 %CR

Start character: S1 = 1 character "=“

Start character: S2 = 1 character "#“

Total length of the telegram: 255 * 14 characters

Fault

‘FAULT ’

VEGACOM 557 VEGA ASCII 31

valid measured value

12345671234567

6 digit value

‘-’ with negative values

‘ ‘ with positive values

Page 32

Data image in VEGACOM 557

4.4 Enquiry as single value with low resolution

Low resolution = switch 2.2 = OFF

This telegram reads in a DCS value from VEGACOM 557. Depending on the position of switch

2.1., the DCS values are arranged differently. The assignment of the DCS numbers to the

VEGAMET addresses is stated in supplement A.

Telegram from processing system to VEGACOM 557

DCS End

Identifier number identification

No. of byt e s 1 3 1

Range (ASCII) % 001..255 CR

Example % 001 CR

Identifier: 1 character, "%“

End identification: 1 character Chr (13) = CR = Carriage Return

Total length of the telegram: 5 characters

Answer of VEGACOM 557

One repetition

DCS DCS End

S1 no. S2 value2 identification

No. of by t es 1 3 1 5-6 2

DCS value or

Range (ASCII) = 001..255 #

fault %CR

Example = 001 # -067.3 %CR

Start character: S1 = 1 character "=“

Start character: S2 = 1 character "#“

Total length of the telegram: 12 or 13 characters

Fault

12345

‘FAULT’

32 VEGACOM 557 VEGA ASCII

valid measured value

123456

3 positions in front of the decimal point

1 decimal point

1 position after the decimal point

"-“ with negative values

" " with positive values

Page 33

Data image in VEGACOM 557

High resolution = switch 2.2 = ON

The same enquiry can also be carried out with high resolution. The enquiry to VEGACOM 557

remains the same, however in the answer, more characters are used for the presentation of

the measured value.

Telegram from processing system to VEGACOM 557

DCS End

Identifier number identification

No. of bytes 1 3 1

Range (A SCII) % 00 1..255 C R

Exam ple % 001 CR

Identifier: 1 character, "%“

End identification: 1 character Chr (13) = CR = Carriage Return

Total length of the telegram: 5 characters

Answer of VEGACOM 557

One repetition

DCS DCS End

S1 no. S2 value2 identification

No. of by t es 1 3 1 7 2

DCS value or

Range (ASCII) = 001..255 #

fault %CR

Example = 001 # -000673 %CR

Start character: S1 = 1 character "=“

Start character: S2 = 1 character "#“

Total length of the telegram: 13 characters

Fault

‘FAULT ’

VEGACOM 557 VEGA ASCII 33

valid measured value

12345671234567

6 digit figure

"-“ with negative values

" " with positive values

Page 34

Data image in VEGACOM 557

4.5 Enquiry as range with low resolution

Low resolution = switch 2.2 = OFF

This telegram reads in a DCS value from VEGACOM 557. Depending on the position of the

switch 2.1, the DCS values are arranged differently. The assignment of the DCS numbers to

the VEGAMET addresses is stated in supplement A.

Telegram from processing system to VEGACOM 557

DCS End

Identifier number T1 Number identification

No. of bytes 1 3 1 3 1

Range (ASCII) % 001.. 255 L 001. .255 CR

Example % 001 L 001 CR

Identifier: 1 character, "%“

T1 : Separating character = 1 character "L“

End identification: 1 character Chr (13) = CR = Carriage Return

Total length of the telegram: 9 characters

Answer of VEGACOM 557

n (n= stated number) repetitions

DCS DCS End

S1 no. S2 value2 identification

No. of by t es 1 3 1 5-6 2

DCS value or

Range (ASCII) = 001..255 #

fault %CR

Example = 001 # -067.3 %CR

Start character: S1 = 1 character "=“

Start character: S2 = 1 character "#“

Total length of the telegram: 12 or 13 characters

Fault

12345

‘FAULT’

34 VEGACOM 557 VEGA ASCII

valid measured value

123456

3 positions in front of the decimal point

1 decimal point

1 position after the decimal point

"-“ with negative values

" " with positive values

Page 35

Data image in VEGACOM 557

High resolution = switch 2.2 = ON

The same enquiry can also be carried out with high resolution. The enquiry to VEGACOM 557

remains the same, however in the answer, more characters are used for the presentation of

the measured value.

Telegram from processing system to VEGACOM 557

DCS End

Identifier number T 1 Number identification

No. of bytes 1 3 1 3 1

Range (ASCII) % 001. . 255 L 001. . 255 CR

Example % 001 L 001 CR

Identifier: 1 character, "%“

T1 : Separating character = 1 character "L“

End identification: 1 character Chr (13) = CR = Carriage Return

Total length of the telegram: 9 characters

Answer of VEGACOM 557

n (n= stated number) repetitions

DCS DCS End

S1 no. S2 value2 identification

No. of by t es 1 3 1 7 2

DCS value or

Range (ASCII) = 001..255 #

fault %CR

Example = 001 # -000673 %CR

Start character: S1 = 1 character "=“

Start character: S2 = 1 character "#“

Total length of the telegram: n * 14 characters

Fault

‘FAULT ’

VEGACOM 557 VEGA ASCII 35

valid measured value

12345671234567

6 digit figure

"-“ with negative values

" " with positive values

Page 36

Data image in VEGACOM 557

4.6 Enquiry as block with address and low resolution

Low resolution = switch 2.2 = OFF

This telegram reads in all DCS values of VEGACOM 557 with the assigned address, i.e. 255

are always transferred together. Each DCS value is provided with a number. Depending on

the position of switch 2.1, the DCS values are arranged differently. The assignment of the DCS

numbers to the VEGAMET addresses is stated in supplement A.

Telegram from processing system to VEGACOM 557

End

Identifier Address T1 identification

No. of bytes 1 1 1 1

Range (AS CII) % 0..9 , CR

Example % 2 , CR

Identifier: 1 character, "%“

T1: 1 character ",“ (comma)

End identification: 1 character Chr (13) = CR = Carriage Return

Total length of the telegram: 4 characters

Answer of VEGACOM 557

255 repetitions

DCS DCS End

S1 Adr T1 no. S2 value2 identification

No. of bytes 1 1 1 3 1 5-6 2

DCS valu e

Range (ASCII) = 0..9 , 001..255 #

or fault % CR

Example = 2 , 001 # -067.3 %CR

Start character: S1 = 1 character "=“

Address : Addr = 1 character VEGACOM 557 address

Separating character: T1 = 1 character ",“ (comma)

Start character: S2 = 1 character "#“

Total length of the telegram: 255 * 14 or 15 characters

Fault

12345

‘FAULT’

36 VEGACOM 557 VEGA ASCII

valid meas. value

123456

3 positions in front of the decimal point

1 decimal point

1 position after the decimal point

"-“ with negative values

" " with positive values

Page 37

Data image in VEGACOM 557

High resolution = switch 2.2 = ON

The same enquiry can also be carried out with high resolution. The enquiry to VEGACOM 557

remains the same, however in the answer, more characters are used for the presentation of

the measured value.

Telegram of processing system to VEGACOM 557

End

Identifier Address T1 identification

No. of bytes 1 1 1 1

Range (ASCII) % 0.. 9 , CR

Example % 2 , CR

Identifier: 1 character, "%“

T1: 1 character ",“ (comma)

End identification: 1 character Chr (13) = CR = Carriage Return

Total length of the telegram: 4 characters

Answer of VEGACOM 557

255 repetitions

DCS DCS End

S1 Adr T1 no. S2 v alue2 identification

No. of bytes111317 2

DCS value

Range (ASCII) = 0..9 , 001. .255 #

or fault %CR

Example = 2 , 001 # -000673 %CR

Start character: S1 = 1 character "=“

Address: Addr = 1 character VEGACOM 557 address

Separating character: T1 = 1 character ",“ (comma)

Start character: S2 = 1 character "#“

Total length of the telegram: 255 * 16 characters

Fault

‘FAULT ’

VEGACOM 557 VEGA ASCII 37

valid meas. value

12345671234567

6 digit figure

"-“ with negative values

" " with positive values

Page 38

Data image in VEGACOM 557

4.7 Enquiry as single value with address and low resolution

Low resolution = switch 2.2 = OFF

This telegram reads exactly one DCS value. Depending of the position of the switch 2.1, the

DCS values are arranged differently. The assignment of the DCS number to the VEGAMET

addresses is stated in supplement A. In addition to chapter "4.6 Enquiry as block with address and low resolution“, an address from 0 to 9 is transferred so that several VEGACOM

557 can be operated on one BUS system (e.g. via a RS 485 interface)

Telegram from processing system to VEGACOM 557

DCS End

Identifier Address T1 number identification

No. of bytes 1 1 1 3 1

Range (ASCII) % 0. .9 , 001..255 CR

Example % 2 , 001 CR

Identifier: 1 character, "%“

T1: 1 character ",“ (comma)

End identification: 1 character Chr (13) = CR = Carriage Return

Total length of the telegram: 7 characters

Answer of VEGACOM 557

One repetition

DCS DCS End

S1 Addr T1 no. S2 value2 identification

No. of bytes 1 1 1 3 1 5-6 2

DCS valu e

Range (ASCII) = 0..9 , 001..255 #

or fault % CR

Example = 2 , 001 # -067.3 %CR

Start character: S1 = 1 character "=“

Address: Addr = 1 character VEGACOM 557 address

Separating character: T1 = 1 character ",“ (comma)

Start character: S2 = 1 character "#“

Total length of the telegram: 14 or 15 characters

Fault

12345

‘FAULT’

38 VEGACOM 557 VEGA ASCII

valid meas. value

123456

3 positions in front of the decimal point

1 decimal point

1 position after the decimal point

"-“ with negative values

" " with positive values

Page 39

Data image in VEGACOM 557

High resolution = switch 2.2 = ON

The same enquiry can also be carried out with high resolution. The enquiry of VEGACOM 557

remains the same, however in the answer, more characters are used for the presentation of

the measured value.

Telegram from processing system to VEGACOM 557

DCS End

Identifier Address T1 number identification

No. of bytes 1 1 1 3 1

Range (ASCII) % 0..9 , 001.. 255 CR

Example % 2 , 001 CR

Identifier: 1 character, "%“

T1: 1 character ",“ (comma)

End identification: 1 character Chr (13) = CR = Carriage Return

Total length of the telegram: 7 characters

Answer of VEGACOM 557

One repetition

DCS DCS End

S1 Adr T1 no. S2 value2 identification

No. of bytes 1 1 1 3 1 7 2

DCS value

Range (ASCII) = 0. . 9 , 001.. 255 #

or fault %CR

Example = 2 , 001 # -000673 %CR

Start character: S1 = 1 character "=“

Address: Addr = 1 character VEGACOM 557 address

Separating character: T1 = 1 character ",“ (comma)

Start character: S2 = 1 character "#“

Total length of the telegram: 16 characters

Fault

‘FAULT ’

VEGACOM 557 VEGA ASCII 39

valid meas. value

12345671234567

6 digit figure

"-“ with negative values

" " with positive values

Page 40

Data image in VEGACOM 557

4.8 Enquiry as range with address and low resolution

Low resolution = switch 2.2 = OFF

This telegram reads in a range of DCS values. The number is transferred with the enquiry.

Depending on the position of the switch 2.1, the DCS values are arranged differently. The

assignment of the DCS numbers to the VEGAMET addresses is stated in supplement A. In

addition to chapter "4.6 Enquiry as block with address and low resolution“ another address

from 0 to 9 is transferred, so that several VEGACOM 557 can be operated on one BUS system (e.g. via a RS 485 interface).

Telegram from processing system to VEGACOM 557

DCS DCS End

Identifier Address T1 number T1 number identification

No. of bytes1 11313 1

Range (AS CII) % 0.. 9 , 0 01.. 2 55 L 001.. 255 CR

Example % 2 , 001 L 2 CR

Identifier: 1 character, "%“

T1: 1 character ",“ (comma)

T2: 1 character "L“

End identification: 1 character Chr (13) = CR = Carriage Return

Total length of the telegram: 11 characters

Answer of VEGACOM 557

n (n= stated number) repetitions

DCS DCS Ende

S1 Addr T1 no. S2 v alue2 identification

No. of byt es 1 1 1 3 1 5-6 2

DCS value

Range (ASCII) = 0. .9 , 001.. 255 #

or fault %CR

Example = 2 , 001 # -067.3 %CR

Start character: S1 = 1 character "=“

Address: Addr = 1 character VEGACOM 557 address

Separating character: S2 = 1 character ",“ (comma)

Start character: S3 = 1 character "#“

Total length of the telegram: 14 or 15 characters

Fault

1234

‘FAULT’

40 VEGACOM 557 VEGA ASCII

valid meas. value

5

12345

3 positions in front of the decimal point

1 decimal point

1 position after the decimal point

"-“ with negative values

" " with positive values

6

Page 41

Data image in VEGACOM 557

High resolution = switch 2.2 = ON

The same enquiry can also be carried out with high resolution. The enquiry to VEGACOM 557

remains the same, however in the answer, more characters are used for the presentation of

the measured value.

Telegram from processing system to VEGACOM 557

DCS DCS End

Identifier Address T1 number T1 number identification

No. of bytes1 11313 1

Range (ASCII) % 0.. 9 , 001..255 L 001.. 255 CR

Example % 2 , 001 L 2 CR

Identifier: 1 character, "%“

T1: 1 character ",“ (comma)

T2: 1 character "L“

End identification: 1 character Chr (13) = CR = Carriage Return

Total length of the telegram: 11 characters

Answer of VEGACOM 557

n (n= stated number) repetitions

DCS DCS End

S1 Addr T1 no. S2 value2 identification

No. of bytes 1 1 1 3 1 7 2

DCS valu e

Range (ASCII) = 0..9 , 001..255 #

or fault % CR

Example = 2 , 001 # -000673 %CR

Start character: S1 = 1 character "=“

Address: Addr = 1 characters VEGACOM 557 address

Separating character: S2 = 1 character ",“ (comma)

Start character: S3 = 1 character "#“

Total length of the telegram: 16 characters

Fault

‘FAULT ’

VEGACOM 557 VEGA ASCII 41

valid meas. value

12345671234567

6 digit figure

"-“ with negative values

" " with positive values

Page 42

Data image in VEGACOM 557

4.9 Enquiry for the contact inputs and outputs on DISBUS

During operation on DISBUS via VEGACOM 557, the contacts are assigned by means of the

VEGAMET address. The enquiry is then made with the VEGAMET address.

Telegram from processing system to VEGACOM 557 for enquiry of a VEGAMET

Address Address End

Identifier COM MET identification

No. of bytes 1 1 2 1

Range (ASCII) R 0..9 01.. 15 CR

Example R 2 01..15 CR

Telegram from processing system to VEGACOM 557 for enquiry of several VEGAMET

Address Address End

Identifier COM MET T1 No. identification

No. of bytes 1 1 2 1 2 1

Range (ASCII) R 0.. 9 01..15 L 01 ..15 CR

Example R 2 01 L 03 CR

Identifier: 1 character, "R“

T1: 1 character "L“

End identification: 1 character Chr (13) = CR = Carriage Return

Total length of the telegram: 5 or 8 characters

Answer of VEGACOM 557

1 or n (n= stated number) repetitions

Address Address Contact End

S1 COM MET S2 value T Status identification

No. of bytes 1 1 2 1 6 1 1

Range (ASCII) R 0. .9 01..15 # value p 0..3 CRLF

Example R 2 01 # 32896 p 0 CRLF

Start character: S1 = 1 character "=“

Address: Addr = 1 character VEGACOM 557 address

Start character: S2 = 1 character "#“

Status: Validity of the contact value,

0 = Inputs and outputs valid, 1 = output contacts valid,

2 = Input contacts valid, 3 = value invalid.

End identification: CR LF = Carriage Return + Linefeed

Total length of the telegram: 15 characters

Input contacts Output contacts

Meaning S1 reserve 2 1 S2 reserve ST 2 1

Bit position 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

ST : Fail safe relay

S1 : Status for input contacts; value : 0 - input contacts are valid, value :1 - input contacts are not valid.

S2 : Status for output contacts; value : 0 - output contacts are valid, value :1 - output contacts are not valid.

42 VEGACOM 557 VEGA ASCII

Contact value binary coded

32896 = 10000000 10000000

Page 43

Data image in VEGACOM 557

4.10 Enquiry for the contact inputs and outputs on LOGBUS

During operation on LOGBUS via VEGACOM 557, the contacts are assigned by means of the

module address. The enquiry is the made with the module address.

Telegram from processing system to VEGACOM 557 for enquiry of a module

Address Mod- End

Identifier COM ule identification

No. of bytes 1 1 2 1

Range (ASCII) R 0.. 9 01..31 CR

Example R 2 01..15 CR

Telegram of the processing system to VEGACOM 557 for enquiry of several modules

Address Address End

Identifier COM MET T 1 No. identification

No. of bytes 1 1 2 1 2 1

Range (ASCII) R 0..9 01..31 L 01..31 CR

Example R 2 01 L 03 CR

Identifier: 1 character, "R“

T1: 1 character "L“

End identification: 1 character Chr (13) = CR = Carriage Return

Total length of the telegram: 5 or 8 characters

Answer of VEGACOM 557

1 or n (n= stated number) repetitions

Address Mod- Contact End

S1 COM ule S2 value T Status identification

No. of bytes 1 1 2 1 6 1 1

Range (ASCII) R 0..9 01..31 # value p 0..1 CRLF

Example R 2 01 # 32896 p 0 CRLF

Start character: S1 = 1 character "=“

Address: Addr = 1 character VEGACOM 557 address

Start character: S2 = 1 character "#“

Status: Validity of the contact value,

0 = value valid, 1 = value invalid.

End identification: CR LF = Carriage Return + Linefeed

Total length of the telegram: 15 characters

Input contacts Output contacts

Meaning S1 reserve 10 9 8 7 6 5 4 3 2 1

Bit position 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

S1 : Status for contacts; 0 - contact information is valid, 1 - contact information is not valid.

VEGACOM 557 VEGA ASCII 43

Contact value binary coded

32768 = 10000000 00000000

Page 44

Data image in VEGACOM 557

4.11 Enquiry for the software version

With this enquiry, the software version in VEGACOM 557 can be determined.

Telegram from processing system to VEGACOM 557

Address End

Identifier VEGACOM Reserve Enquiry identification

No. of bytes 1 1 2 13 1

Range (ASCII) % 0..9 00 READ VERSION CR

Example % 2 00 READ VERSION CR

Identifier: 1 character, "v“ ("V“)

Request: 13 characters " READ VERSION“ (in front of READ and in front of VERSION with 1 blank character)

End identification: 1 character Chr (13) = CR = Carriage Return

Total length of the telegram: 18 characters

Answer of VEGACOM 557

Address End

Identifier VEGACOM Reserve Enquiry identification

No. of bytes 1 1 2 17 2

Range (ASCII) = 0..9 00 Answer text CRLF

Example = 2 00 VEGACOM557 V2.17 CRLF

Start character: S1 = 1 character "=“

Address: Addr = 1 character VEGACOM 557 address

Reserve: 2 characters here "00“

Answer: 17 characters text

Total length of the telegram: 23 characters

4.12 Error information from VEGA COM 557

If an enquiry of VEGACOM 557 was not understood correctly or the transmission of the enquiry was faulty, VEGACOM sends an error information.

Error text Meaning