Page 1

USER'S GUIDE

Vaisala WINDC AP © Ult raso ni c

Wind Sensor Serie s

WMT700

M211095EN-E

Page 2

Vaisala Oyj Phone (int.): +358 9 8949 1

P.O. Box 26 Fax: +358 9 8949 2227

FI-00421 Helsinki

Finland

Visit our Internet pages at www.vaisala.com.

© Vaisala 2013

No part of this manual may be reproduced, published or publicly displayed in any form

or by any means, electronic or mechanical (including photocopying), nor may its

contents be modified, translated, adapted, sold or disclosed to a third party without prior

written permission of the copyright holder. Translated manuals and translated portions

of multilingual documents are based on the original English versions. In ambiguous

cases, the English versions are applicable, not the translations.

The contents of this manual are subject to change without prior notice.

This manual does not create any legally binding obligations for Vaisala towards

customers or end users. All legally binding obligations and agreements are included

exclusively in the applicable supply contract or the General Conditions of Sale and

General Conditions of Service of Vaisala.

Page 3

_________________________________________________________________________________

Table of Contents

CHAPTER 1

GENERAL INFORMATION .......................................................................... 11

About This Manual ................................................................. 11

Contents of This Manual ..................................................... 11

Version Information ............................................................. 12

Related Manuals ................................................................. 12

Documentation Conventions ............................................... 13

Safety ....................................................................................... 13

Recycling ................................................................................ 14

Regulatory Compliances ....................................................... 15

Trademarks ............................................................................. 16

Warranty .................................................................................. 16

CHAPTER 2

PRODUCT OVERVIEW ................................................................................ 17

Introduction to WMT700 ........................................................ 17

Ordering Options ................................................................. 23

Measurement Range...................................................... 23

Temperature Range ....................................................... 23

Heating ........................................................................... 24

Digital Communication Interface .................................... 24

Digital Communication Profile ........................................ 25

Digital Communication Units .......................................... 25

Analog Output Signal for Wind Speed Channel ............. 26

Analog Output Signal for Wind Direct ion Cha nne l ......... 27

Connection Cables ......................................................... 27

Mounting Adapters ......................................................... 28

Accessories .................................................................... 28

Manual ........................................................................... 29

Example of WMT703 Configuration ............................... 29

Accessories ......................................................................... 30

Bird Cage ....................................................................... 31

WM Verifier .................................................................... 32

Cables ............................................................................ 33

Cable Tightening Tool .................................................... 34

CHAPTER 3

FUNCTIONAL DESCRIPTION ..................................................................... 35

Operating Principle ................................................................ 35

Coordinate Systems: Vector and Polar Calculations ......... 38

Wind Speed and Direction Averaging .................................. 40

Scalar Averaging ................................................................. 40

Wind Direction Coasting ................................................ 41

Vector Averaging ................................................................. 41

Measurement Methods .......................................................... 42

Continuous Measurement ................................................... 42

VAISALA _________________________________________________________________________ 1

Page 4

User's Guide ______________________________________________________________________

Wind Measurement on Request .......................................... 42

Host System Connections and Interfaces ............................ 43

Serial Communication and Analog Output .......................... 45

Serial Communication ............................................................ 45

Digital Communication Interface .......................................... 45

Profiles ................................................................................. 46

Protocols .............................................................................. 47

Measurement and Configuration Modes ............................. 47

Serial Interface Timing ......................................................... 49

Analog Output ......................................................................... 50

Analog Output Types ........................................................... 50

Analog Output Scaling ......................................................... 52

Limitations for Output Signals .............................................. 54

Missing Readings and Error Indication ................................ 55

CHAPTER 4

INSTALLATION ............................................................................................ 57

Maritime Installations ............................................................. 57

Selecting Installation Location .............................................. 58

Installation Procedure ............................................................ 62

Unpacking ............................................................................ 62

Mounting .............................................................................. 63

Mounting on Vertical Pole Mast ...................................... 64

Mounting on Horizontal Cross Arm ................................ 68

Checklist for Connection Cables ......................................... 73

Alignment ............................................................................. 74

Alignment Tuning ............................................................ 75

Installing Bird Cage ............................................................. 75

Wiring ....................................................................................... 77

Cables .................................................................................. 77

Cable 2 m, Cable 10 m, Cable 15 m, and Cable

26 m ..................................................................................... 78

RS485 for COM2 with Cable 2 m and 10 m ................... 79

RS485 Cable 2 m and RS485 Cable 10 m .......................... 80

Connector Signals ............................................................... 81

Heating ..................................................................................... 82

Heated Transducers ............................................................ 82

Heated Transducers and Arms ............................................ 83

Heated Body, Transducers, and Arms ................................ 83

Powering .................................................................................. 84

Operating Power .................................................................. 84

Heating Power ..................................................................... 87

Power and Cable Recommendations for Fully

Heated WMT700 ............................................................ 87

Upgrading from WS425 to WMT700 ...................................... 89

Mounting with WS425 Mounting Kit..................................... 90

Before You Start .................................................................. 94

Mounting Procedure ............................................................ 96

Tightening Connector ..................................................... 97

Checklist for Connection Cables ......................................... 98

Wiring in Retrofit Installations............................................... 99

Using Standard WMT700 Cables ........................................ 99

ROSA Cable 10 m (Analog Outputs) ............................ 100

Using WS425 Cables with Adapters ................................. 101

2 ____________________________________________________________________ M211095EN-E

Page 5

_________________________________________________________________________________

Adapter Cable for WS425 Serial Output ...................... 101

Adapter Cable for WS425 Analog Frequency

Output .......................................................................... 102

Adapter Cable for WS425 Analog Voltage Output ....... 103

Differences between WMT700 and WS425 Analog

Output Signals ................................................................... 104

Powering in Retrofit Installa tions ....................................... 105

CHAPTER 5

OPERATION ............................................................................................... 107

Serial Connection to WMT700 ............................................. 107

Communicating with Terminal Software ........................... 107

Entering and Exiting Configuration Mode ......................... 109

OPEN — Entering Configuration Mode ............................ 109

CLOSE — Exiting Configuration Mode ............................. 109

Configuration ........................................................................ 110

Configuration Overview ..................................................... 110

Parameter Handling Commands ......................................... 111

S — Set Parameter ........................................................... 112

G — Get Parameter .......................................................... 113

Get All Parameters ....................................................... 113

Get Specified Parameters ............................................ 113

BAUD — Display or Set Port Settings .............................. 114

Set Port Settings .......................................................... 114

Display Port Settings .................................................... 114

Wind Measurement Control Commands ............................ 115

MEAS — Single Wind Measurement ................................ 115

START — Start Continuous Measurement ....................... 115

STOP — Stop Wind Measurement ................................... 115

Diagnostics and Support Commands ................................ 116

ERRORS — Get Error Codes and Counts ....................... 116

CLEARERR — Reset Error Codes and Cou nts ................ 117

POLL — Get Message ...................................................... 117

RESET — Reset CPU ....................................................... 117

Information Commands ....................................................... 117

? — Display Command Set ............................................... 117

H — Display Help and Messages ..................................... 117

VERSION — Show Firmware Version .............................. 118

WIND_GET — Get Calibration Data ................................. 118

Configuration Parameters ................................................... 118

User-Configurable Data Messages ..................................... 119

Configuring Data Messages .............................................. 119

Items for Data Messages ............................................. 119

Status Flags ...................................................................... 123

Loading Settings from Configuration File .......................... 124

Operating WMT700 ............................................................... 126

Operating WMT700 with Term inal Progr am ..................... 126

Data Messages ................................................................. 127

WMT700 Data Message 21 ......................................... 129

WMT700 Data Message 22 ......................................... 129

WMT700 Data Message 23 ......................................... 130

WMT700 Data Message 24 ......................................... 131

WMT700 Data Message 25 ......................................... 132

ROSA - MES12 Data Message .................................... 133

VAISALA _________________________________________________________________________ 3

Page 6

User's Guide ______________________________________________________________________

Missing Readings .............................................................. 133

Error Indication .................................................................. 134

Measurement Mode Commands ......................................... 135

WMT700 Profile Commands ............................................. 135

MEAS — Start Measurement ....................................... 136

OPEN — Enter Configuration Mode ............................. 136

POLL — Poll Data ........................................................ 137

SLEEP — Enter Low-Power Mode ............................... 137

ROSA - MES12 Profile Commands ................................... 138

M 12 — Poll MES12 Data Mess age ............................. 138

Operating WMT700 in WS425 Analog Output Mode ......... 139

Analog Output Settings ...................................................... 139

Wind Speed Output .............................................................. 141

Frequency .......................................................................... 141

Voltage ............................................................................... 142

Wind Direction Output .......................................................... 143

Limitations for Output Signals ............................................ 144

Missing Readings and Error Indic ation .............................. 144

Operating WMT700 with WS425 and SDI-12 Profiles ........ 145

Communication Profiles ...................................................... 145

Changing Communication Profile ...................................... 145

Operating WMT700 with Terminal Program ....................... 146

Entering Configuration Mode .............................................. 147

WS425 F/G ASOS Profile ...................................................... 148

Configurable Parameters ................................................... 148

WS425 F/G ASOS Commands ......................................... 149

WA — Fetch Averaged Wind Speed and

Direction ....................................................................... 150

WS — Fetch Internal Diagnostics Information ............. 150

WS425 F/G ASOS Data Message..................................... 152

WS425 A/B NMEA Standard Profile .................................... 154

Configurable Parameters ................................................... 154

WS425 A/B NMEA Standard Data Message ..................... 155

Missing Readings ......................................................... 155

WS425 NMEA Extended Profile (v . 0183) ........................... 156

Configurable Parameters ................................................... 156

WS425 A/B NMEA Extended Commands ......................... 157

WS425 A/B NMEA Extended Data Message .................... 158

Missing Readings ......................................................... 158

WS425 A/B ASCII Profile ...................................................... 159

Configurable Parameters ................................................... 159

WS425 A/B ASCII Commands .......................................... 160

I — Identify Sensor ....................................................... 160

Wx — Start Measurement ............................................ 160

Missing Readings ......................................................... 162

WS425 A/B WAT11 Profile ................................................... 163

Configurable Parameters ................................................... 163

WS425 A/B WAT11 Commands ........................................ 163

Missing Readings ......................................................... 164

SDI-12 Profile (v 1.3) ............................................................. 165

Configurable Parameters ................................................... 166

SDI-12 Commands ............................................................ 167

?! — Address Query ..................................................... 168

a! — Acknowledge Active ............................................. 169

4 ____________________________________________________________________ M211095EN-E

Page 7

_________________________________________________________________________________

aAb! — Change Address ............................................. 170

aC! — Start Concurrent Measurement ........................ 171

aD0! — Send Data ....................................................... 172

aI! — Send Identification .............................................. 172

aM! — Start Measurement ........................................... 173

aV! — Start Verification ................................................ 175

SDI-12 Data Messages ..................................................... 176

WS425 A/B SDI-12 Message for C and M

Command ..................................................................... 176

Missing Readings .................................................... 176

WS425 A/B SDI-12 Message for V Command ............ 177

Requesting Cyclic Redundancy Check ........................ 177

CHAPTER 6

MAINTENANCE ......................................................................................... 179

Periodic Maintenance .......................................................... 180

Visual Inspection .................................................................. 180

Cleaning ................................................................................ 180

Testing Proper Operation .................................................... 181

CHAPTER 7

TROUBLESHOOTING ............................................................................... 183

Problem Situations ............................................................... 183

Error and Event Messages .................................................. 185

Restoring Serial Port Settings ............................................ 186

Technical Support ................................................................ 188

Product Returns ................................................................... 188

CHAPTER 8

TECHNICAL DATA .................................................................................... 189

Dimensions ........................................................................... 193

APPENDIX A

COMPLETE COMMAND SET FOR WMT700 ........................................... 195

APPENDIX B

TYPICAL SYSTEM ENVIRONMENTS ....................................................... 197

APPENDIX C

DEFAULT SETTINGS FOR DIFFERENT COMMUNICATION

PROFILES .................................................................................................. 201

APPENDIX D

CONFIGURATION PARAMETERS ........................................................... 205

VAISALA _________________________________________________________________________ 5

Page 8

User's Guide ______________________________________________________________________

APPENDIX E

WMT700 NMEA MWV PROFILE ................................................................ 209

Configurable Parameters ................................................... 210

WMT700 NMEA MWV Commands ................................... 211

WMT700 NMEA MWV Data Message .............................. 212

Missing Readings ......................................................... 212

APPENDIX F

ACCESSORIES .......................................................................................... 213

APPENDIX G

CERTIFICATES .......................................................................................... 217

6 ____________________________________________________________________ M211095EN-E

Page 9

_________________________________________________________________________________

List of Figures

Figure 1 WMT700 Wind Sensor ............................................................. 18

Figure 2 WMT700 Wind Sensor from Below .......................................... 19

Figure 3 FIX70 Mounting Kit ................................................................... 20

Figure 4 WS425FIX60-POM ................................................................... 21

Figure 5 WMT70FIX60-POM .................................................................. 21

Figure 6 WS425FIX60-RST and WS425FIX60 ...................................... 22

Figure 7 WMT70FIX60-RST ................................................................... 22

Figure 8 Bird Cage ................................................................................. 31

Figure 9 WM Verifier ............................................................................... 32

Figure 10 Cable Tightening Tool .............................................................. 34

Figure 11 Ultrasonic Measurement Principle ........................................... 36

Figure 12 Measurement Paths of WMT700 ............................................. 37

Figure 13 Different Wind Speed and Direction Pres ent ati ons

(Direction Offset Is 0) ............................................................... 39

Figure 14 Example of Wind Direction Averaging ...................................... 41

Figure 15 External Interfaces of WMT700 ................................................ 44

Figure 16 Configuration and Measurement Modes .................................. 48

Figure 17 Timing for RS-232, RS-485, and RS-422 Interfaces ................ 49

Figure 18 Frequency Output ..................................................................... 51

Figure 19 Recommended Location in Open Area .................................... 59

Figure 20 Recommended Mast Length on Top of Building ...................... 60

Figure 21 Minimum Distance between Two WMT700 Devices

Installed at Same Height .......................................................... 61

Figure 22 Sensor Handling ....................................................................... 62

Figure 23 WMT700 and Transportation Damper ...................................... 63

Figure 24 Inserting Cable in Cable Tightening Tool ................................. 64

Figure 25 Attaching Connector to WMT700 ............................................. 65

Figure 26 WMT700 on Side of Pole Mast ................................................ 66

Figure 27 WMT700 on Top of Pole Mast ................................................. 67

Figure 28 WMT700 on Cross Arm with Array Facing Up ......................... 69

Figure 29 WMT700 on Cross Arm with Array Facing Down .................... 70

Figure 30 Tightening Connector with Cabl e Tight eni ng Tool ................... 71

Figure 31 Tightening Connector without Cable Tightening Tool .............. 72

Figure 32 Correctly Aligned WMT700 ...................................................... 74

Figure 33 Incorrectly Aligned WMT700 and Resulting Offset Error ......... 75

Figure 34 Bird Cage and Bird Cage Straps .............................................. 76

Figure 35 COM2 RS485 Wiring ................................................................ 79

Figure 36 Pins for 17-Pin M23 Connector ................................................ 81

Figure 37 Wiring of Non-heated WMT700 Versions ................................. 85

Figure 38 Operating Supply Current Consumption .................................. 86

Figure 39 Operating Supply Power Cons umption .................................... 86

Figure 40 Wiring of Heated WMT700 Versions, Part 1 ............................ 88

Figure 41 Wiring of Heated WMT700 Versions, Part 2 ............................ 88

Figure 42 Retrofit Installation to Pole Mast .............................................. 91

Figure 43 Retrofit Installation to Cross Arm with Array Facing Up ........... 92

Figure 44 Retrofit Installation to Cross Arm with Array Facing

Down ........................................................................................ 93

Figure 45 FIX30, WS425FIX60-RST, and WS425FIX60-POM ................ 94

Figure 46 Mounting Adapter for FIX30, WS425FIX60 (Left), and

Mounting Adapter for FIX70 (Right) ......................................... 95

Figure 47 WS425 Adapter Cable .............................................................. 96

Figure 48 Wind Speed Frequency Analog Output with WS425

Cable and Adapter Cable for Analog Frequency Output ....... 141

VAISALA _________________________________________________________________________ 7

Page 10

User's Guide ______________________________________________________________________

Figure 49

Figure 50 Wind Direction Voltage Output with WS425 Cable and

Figure 51 Testing WMT700 with WM Verifier ......................................... 182

Figure 52 WMT700 Dimensions in Millimeters ....................................... 193

Figure 53 FIX70 Mounting Kit Dimensions in Millimeters ....................... 194

Figure 54 System Environment with Serial Port COM1 Only ................. 197

Figure 55 System Environment with Analog Output Only....................... 198

Figure 56 System Environment with Serial Ports COM1 and

Figure 57 System Environment with Backup Battery .............................. 200

Figure 58 Complete Set of Accessories.................................................. 214

Wind Speed Voltage Analog Output with WS425 Cable

and Adapter Cable for Analog Voltage Output ....................... 142

Adapter Cable ......................................................................... 143

COM2 ...................................................................................... 199

8 ____________________________________________________________________ M211095EN-E

Page 11

_________________________________________________________________________________

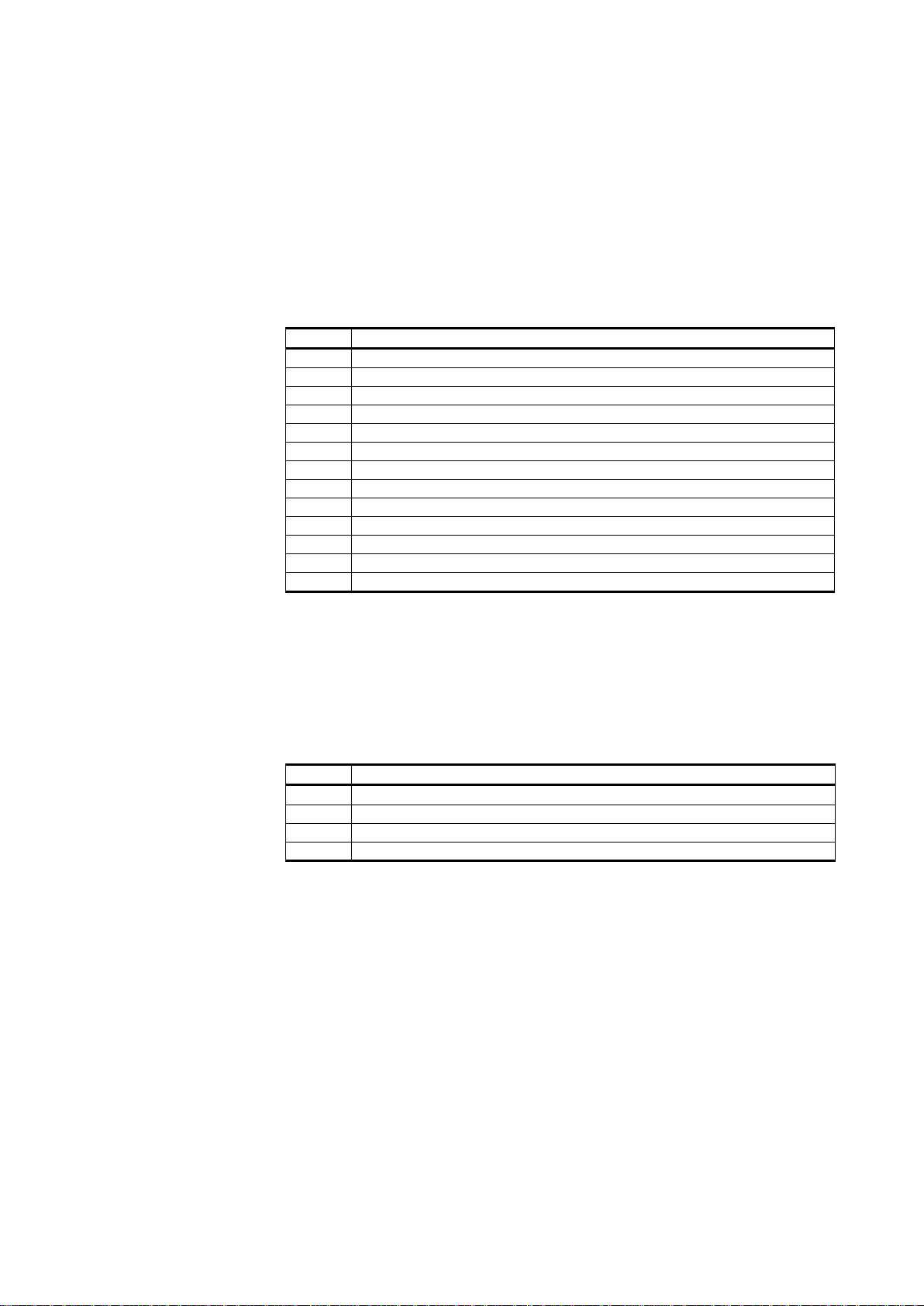

List of Tables

Table 1 Manual Revisions ..................................................................... 12

Table 2 Related Manuals ...................................................................... 12

Table 3 Environmental Tests ................................................................. 15

Table 4 Electromagnetic Compatibility Tests ........................................ 16

Table 5 Measurement Ranges of Different Sensor Types .................... 23

Table 6 Temperature Ranges ............................................................... 23

Table 7 Heating ..................................................................................... 24

Table 8 Digital Communication Interface .............................................. 24

Table 9 Digital Communication Profile .................................................. 25

Table 10 Digital Communication Options ................................................ 25

Table 11 Output Configuration ................................................................ 26

Table 12 Analog Output Signal for Wind Direction .................................. 27

Table 13 Analog Output Configuration .................................................... 28

Table 14 Mounting Adapters ................................................................... 28

Table 15 Accessories .............................................................................. 28

Table 16 Manual ...................................................................................... 29

Table 17 Cables ...................................................................................... 33

Table 18 Factory Settings for Analog Wind Speed Output ..................... 52

Table 19 Factory Default Settings for Analog Wind Direction

Output ....................................................................................... 52

Table 20 Common Transfer Function Settings for AOUT1 (WS) ............ 53

Table 21 Common Transfer Function Settings for AOUT2 (WD) ............ 53

Table 22 Connecting Cable 2 m (227567SP),

Cable 10 m (227568SP), Cable 15 m (237890SP), and

Cable 26 m (237889SP) ........................................................... 78

Table 23 COM2 RS485 Wiring ................................................................ 79

Table 24 Connecting RS485 Cable 2 m (228259SP) and

RS485 Cable 10 m (228260SP) ............................................... 80

Table 25 Pin-Out for 17-Pin M23 Co nnec tor ........................................... 81

Table 26 Operating Power Supply Voltage Requirements ..................... 84

Table 27 Heating Power Supply Requirements ...................................... 87

Table 28 Heating Power and Extension Cable ....................................... 87

Table 29 Mounting Kits and Cable Codes ............................................... 95

Table 30 ROSA Cable 10 m (231425SP) ............................................. 100

Table 31 Pin-Outs for WS425 Serial Adapter Cable (227569SP) ......... 101

Table 32 Pin-Outs for WS425 Analog Frequency Output Adapter

Cable ...................................................................................... 102

Table 33 Pin-Outs for WS425 Analog Voltage Output Adapter

Cable ...................................................................................... 103

Table 34 Analog Output Connections ................................................... 104

Table 35 List of Configuration Mode Commands .................................. 111

Table 36 Wind Measurement Items for Data Messages ....................... 120

Table 37 Control Character and Checksum Items for Data

Messages ............................................................................... 120

Table 38 Monitoring Items for Data Messages ..................................... 121

Table 39 Status Flags ........................................................................... 123

Table 40 Data Messages ...................................................................... 128

Table 41 Measurement Mode Commands ............................................ 136

Table 42 Required Parameters for WS425 Analog Output

Operation Mode ...................................................................... 140

Table 43 Configurable Parameters for WS425 F/G ASOS Profile ........ 148

Table 44 WS425 F/G ASOS Commands .............................................. 149

Table 45 WS425 F/G ASOS Data Message ......................................... 152

VAISALA _________________________________________________________________________ 9

Page 12

User's Guide ______________________________________________________________________

Table 46

Table 47 Configurable Parameters for WS425 A/B NMEA

Table 48 Checksum Table ..................................................................... 157

Table 49 Configurable Parameters for WS425 A/B ASCII Profile ......... 159

Table 50 WS425 A/B ASCII Commands ............................................... 160

Table 51 WS425 A/B ASCII Data Message .......................................... 161

Table 52 Configurable Parameters for WS425 A/B WAT11 Profile ...... 163

Table 53 Configurable Parameters for SDI-12 Profile ........................... 166

Table 54 SDI-12 Commands ................................................................. 167

Table 55 Some Problem Situations and Their Remedies...................... 183

Table 56 Error and Event Messages ..................................................... 185

Table 57 Restored Serial Port Settings ................................................. 187

Table 58 Wind Speed ............................................................................ 189

Table 59 Wind Direction ........................................................................ 189

Table 60 Outputs ................................................................................... 190

Table 61 General ................................................................................... 191

Table 62 Accessories............................................................................. 192

Table 63 Command Set for All Profiles.................................................. 195

Table 64 Default Settings for Different Digital Communication

Table 65 Parameters without Protocol-Specific Default Value .............. 203

Table 66 Parameter Descriptions .......................................................... 205

Table 67 Configurable Parameters for WMT700 NMEA

Configurable Parameters for WS425 A/B NMEA

Standard Profile ...................................................................... 154

Extended Profile ..................................................................... 156

Profiles .................................................................................... 202

MWV Profile ............................................................................ 210

10 ___________________________________________________________________ M211095EN-E

Page 13

Chapter 1 _________________________________________________________ General Information

CHAPTER 1

GENERAL INFORM ATION

This chapter provides general notes for the manual and the

WMT700 series.

About This Manual

This manual provides information for installing, operating, and

maintaining Vaisala WINDCAP® Ultrasonic Wind Sensors

WMT701, WMT702, and WMT703, commonly referred to as

WMT700.

Contents of This Manual

This manual consists of the following chapters:

- Chapter 1, General Information, provides general notes for the

manual and the WMT700 series.

- Chapter 2, Product Overview, introduces the features,

advantages, and product nomenclature of WMT700.

- Chapter 3, Functional Description, describes the functionality

of WMT700.

- Chapter 4, Installation, contains information that is needed to

install WMT700.

- Chapter 5, Operation, contains information on WMT700

configuration, operating commands, protocols, and data

messages.

- Chapter 6, Maintenance, contains information on performing

visual inspection, cleaning, and verifying the operation of

WMT700.

- Chapter 7, Troubleshooting, describes common problems, their

probable causes and remedies, and provides contact

information for technical support.

- Chapter 8, Technical Data, provides the technical data of

WMT700.

- Appendix A, Complete Command Set for WMT700, lists all

the commands available for WMT700.

VAISALA ________________________________________________________________________ 11

Page 14

User's Guide ______________________________________________________________________

Manual Code

Description

M211095EN-E

August 2013. This manual. Combined User’s Guide

Options and Accessories.

M211095EN-D

Previous version.

M211095EN-A

First version of this manual.

Manual Code

Manual Name

M211218EN

Vaisala WINDCAP© Ultrasonic Wind Sensor Series

WMT700 Quick Reference Guide

- Appendix B, Typical System Environments, lists the most

typical WMT700 system environments.

- Appendix C, Default Settings for Different Communication

Profiles, lists the default settings for different digital

communication profiles.

- Appendix D, Configuration Parameters, lists the WMT700

configuration parameters.

- Appendix E, WMT700 NMEA MWV Profile, lists the

configurable parameters, commands, and data messages of the

WMT700 NMEA MWV profile.

- Appendix F, Accessories, lists all the accessories available for

WMT700.

- Appendix G, Certificates, contains copies of certificates issued

for WMT700.

Version Information

Table 1 Manual Revisions

and Technical Reference. Updated Heating with

new fully heated WMT700. Updated Ordering

Related Manuals

Table 2 Related Manuals

12 ___________________________________________________________________ M211095EN-E

Page 15

Chapter 1 _________________________________________________________ General Information

Warning alerts you to a serious hazard. If you do not read and follow

instructions very carefully at this point, there is a risk of injury or even

death.

Caution warns you of a potential hazard. If you do not read and follow

instructions carefully at this point, the product could be damaged or

important data could be lost.

Note highlights important information on using the product.

To protect personnel (and the wind sensor)

installed with the tip at least one meter above WMT700. The rod must be

properly grounded, compliant with all local applicable safety regulations.

Do not install the wind sensor above the top of the lightning protection

rod.

If ice or snow accumulates on WMT700 or the mast, it can fall and cause

injury to persons below.

Some WMT700 product versions provide heating for transducers and/or

array arms. To avoid injury, do not touch the heated parts of the wind

se

Documentation Conventions

Throughout the manual, important safety considerations are

highlighted as follows:

WARNING

CAUTION

NOTE

Safety

WARNING

WARNING

Vaisala WINDCAP® Ultrasonic Wind Sensor WMT701,

WMT702, or WMT703 delivered to you has been tested for safety

and approved as shipped from the factory. Note the following

precautions:

, a lightning rod must be

WARNING

nsor when the heating is enabled.

VAISALA ________________________________________________________________________ 13

Page 16

User's Guide ______________________________________________________________________

Make sure that you connect only de

Using a long cable between different units (sensors, transmitters, power

supplies, and displays) can cause a lethal surge voltage, if a lightning

st

and follow the requirements of the local Electrical Code.

Do not install WMT700 when there is a risk of thunderstorm or lightning

activity in the area.

Do not

Improper modification can damage the product or lead to malfunction.

When handling WMT700, do not rotate, pull, strike, bend, scrape or

touch the transducers with sharp objects. Any impact on the wind sensor

array

The heating

each

both must be connected to each other. Leaving one terminal unconnected

or connecting it to the ground may cause a WMT700 malfunction or a

short circuit in the power supply.

Recycle all applicable material.

Dispose of batteries and the unit according to statutory regulations.

Do

WARNING

WARNING

WARNING

CAUTION

-energized wires.

rike occurs in the vicinity. Always apply proper grounding procedures

modify the unit. There are no user-serviceable parts inside.

CAUTION

CAUTION

Recycling

may damage the device.

power supply wires of WMT700 are internally connected to

other. If the connection cable has two positive heating supply wires,

not dispose of with regular household refuse.

14 ___________________________________________________________________ M211095EN-E

Page 17

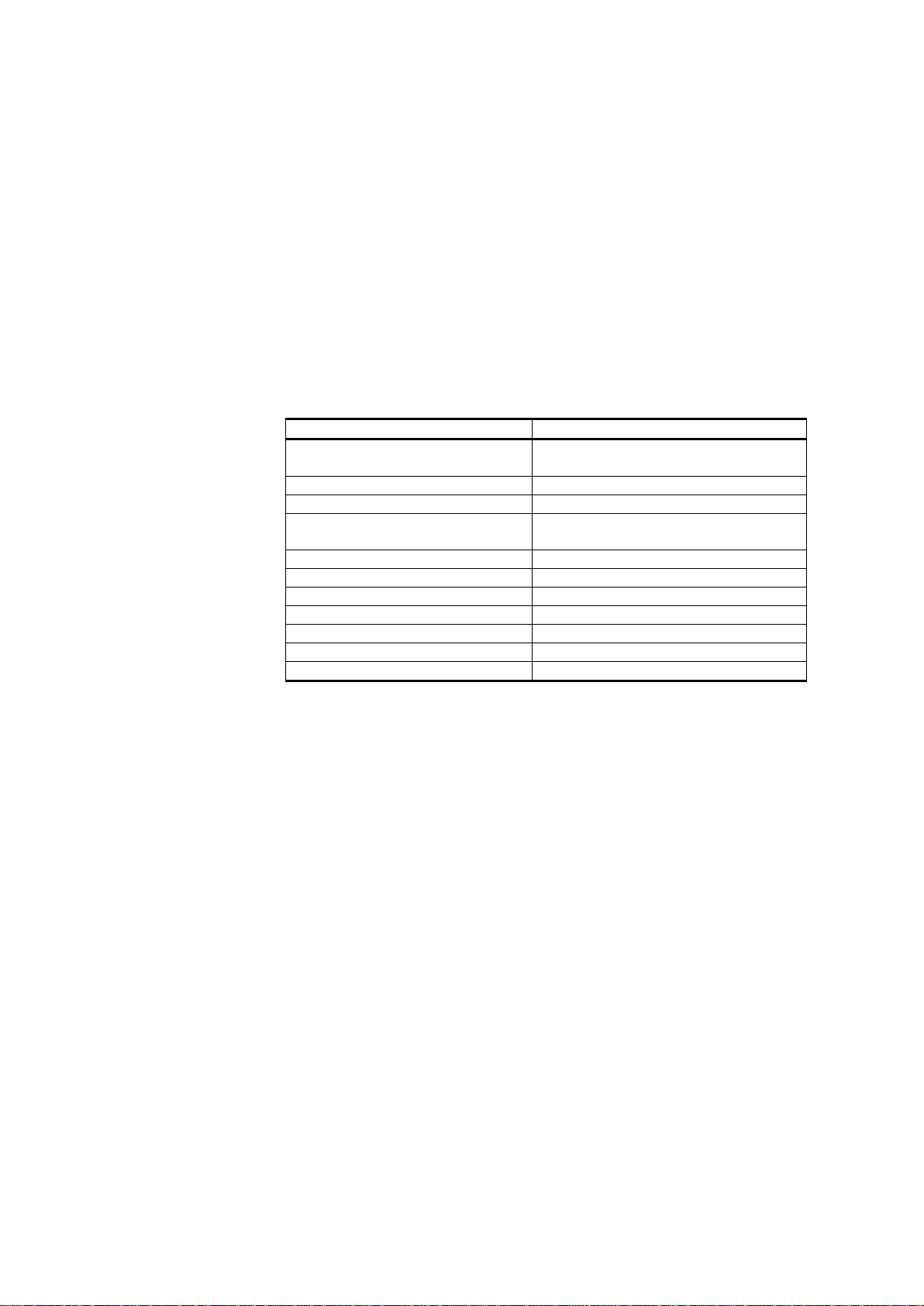

Chapter 1 _________________________________________________________ General Information

Test

Setup According to

Wind driven rain

MIL-STD 810G Method 506.5 and

Telcordia GR-487-Core

Salt fog

VDA 621 - 415 / IEC 60068-2-52

Leak test (Ingression Protection)

IEC 60529 class IP67

Vibration

IEC 60068-2-6 / IEC 60945 /

Lloyd's test

Shock

MIL-STD-202G, Method 213B, cond. J

Dry heat

IEC 60068-2-2 / IEC 60068-2-48

Damp heat cyclic

IEC 60068-2-30, Test Db

Damp heat

IEC 60068-2-78

Low temperature

IEC 60068-2-1 Test Ab/Ad

Free fall (rough handling)

IEC 60068-2-31

Change of temperature

IEC 60068-2-14

Regulatory Compliances

Vaisala WINDCAP® Ultrasonic Wind Sensor WMT701,

WMT702, and WMT703 comply with the performance and

environmental test standards listed in Table 3 below.

Wind tunnel tests have been performed according to Sonic

anemometers/thermometers - Acceptance test methods for mean

wind measurements ISO 16622:2002 and Measnet Anemometer

Calibration Procedure Version 2, October 2009.

Table 3 Environmental Tests

EMC tests are based on a European product family standard:

EN 61326-1:2006 (Electrical equipment for measurement, control

and laboratory use - EMC requirements for use in industrial

locations) and EN 60945:2002 (Maritime Navigation and

Radiocommunication Equipment and Systems - General

Requirements - Methods of Testing and Required Test Results).

VAISALA ________________________________________________________________________ 15

Page 18

User's Guide ______________________________________________________________________

Test

Setup According to

Conducted RF immunity

IEC 61000-4-6

EFT immunity

IEC 61000-4-4

Surge immunity

IEC 61000-4-5

ESD immunity

IEC 61000-4-2

High voltage (Dielectric tests)

IEC 60947-2

Conducted emissions

1)

CISPR 22

Radiated emissions

CISPR 22

RF field immunity

IEC 61000-4-3

Insulation resistance

IEC 60092-504

1)

equipment and systems

required test results. 4th edition, 200 2

Appendix

Table 4 Electromagnetic Compatibility Tests

Limits according to IEC 60945: Maritime navigation and radiocommunication

- General requirements - Methods of testing and

-08. See Det Norske Veritas Certificate in

G on page 217.

Trademarks

Warranty

The WMT700 series wind sensors are based on the advanced,

patented Vaisala WINDCAP®wind measurement technology that

ensures accurate results in all wind directions. The effects of

temperature, humidity, and pressure are also fully compensated.

Windows®is a registered trademark of Microsoft Corporation in

the United States and/or other countries.

Visit our Internet pages for our standard warranty terms and

conditions: www.vaisala.com/warranty.

Please observe that any such warranty may not be valid in case of

damage due to normal wear and tear, exceptional operating

conditions, negligent handling or installation, or unauthorized

modifications. Please see the applicable supply contract or

Conditions of Sale for details of the warranty for each product.

16___________________________________________________________________ M211095EN-E

Page 19

Chapter 2 ___________________________________________________________ Product Overview

CHAPTER 2

PRODUCT OVERVIE W

This chapter introduces the features, advantages, and product

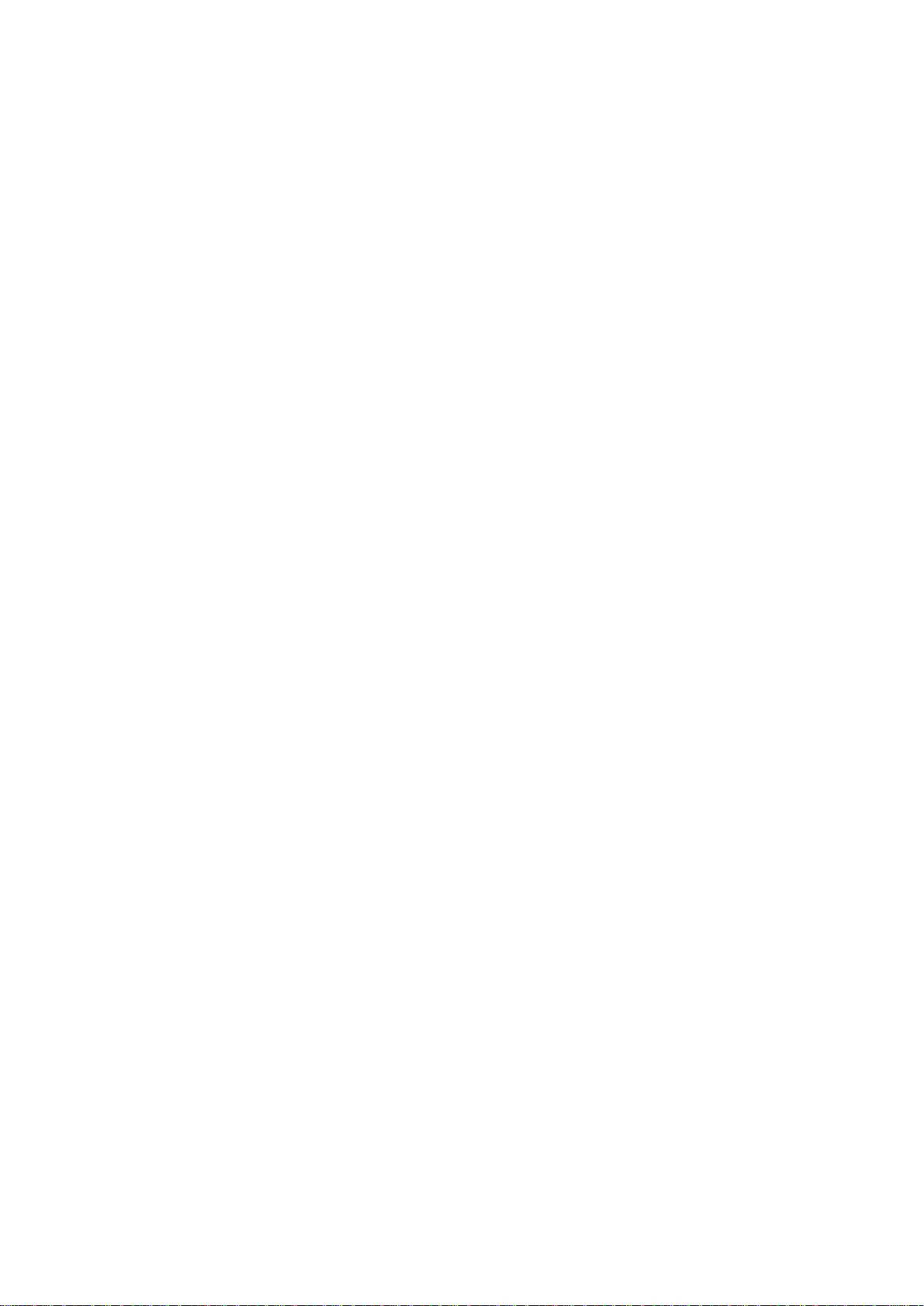

nomenclature of WMT700.

Introduction to WMT700

Vaisala WINDCAP® Ultrasonic Wind Sensor WMT700 measures

wind speed and direction, and sends the measurement results to

data acquisition systems. WMT700 forms part of the Vaisala

weather measurement offering suitable for systems and standalone installations.

The WMT700 series consists of three product types with different

measurement ranges: WMT701, WMT702, and WMT703.

Additionally, you can select heating functions that shield the array

and/or the transducers and the sensor body from ice and snow

buildups in cold climates.

The WMT700 series wind sensors are based on the advanced,

patented Vaisala WINDCAP® wind measurement technology that

ensures accurate results in all wind directions. The effects of

temperature, humidity, and pressure are also fully compensated.

Since the WMT700 series wind sensors have no moving parts,

they are virtually maintenance-free. The performance of the

sensors does not degrade with wear nor is it affected by natural

contaminants such as salt, dust, or sand.

The WMT700 series wind sensors support a wide range of

communication options. You can connect the wind sensors

directly to a variety of data acquisition systems without additional

converters or adapters.

VAISALA ________________________________________________________________________ 17

Page 20

User's Guide ______________________________________________________________________

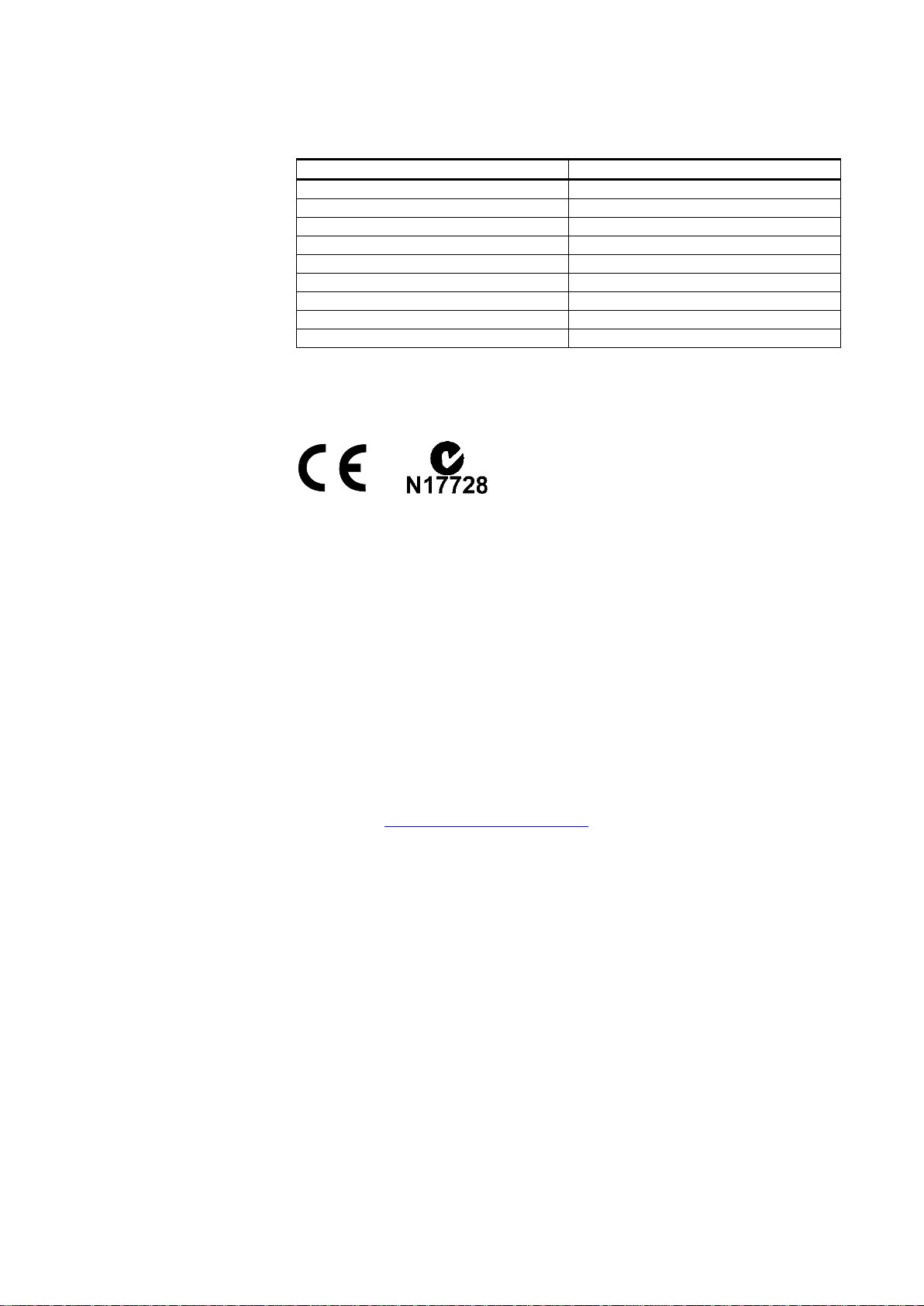

The following numbers refer to Figure 1 above:

The array consists of 1, 2, and 3:

1 = Transducers (3 pcs)

2 = Top of WMT700. There is a north arrow on top of WMT700.

3 = Transducer arms (3 pcs)

4 = Enclosure

5 = Mounting screw

6 = Mounting adapter

7 = Type label

WMT700 is configured at the factory according to the customer's

order, and it is ready for operation directly after the installation. If

required, the user also has a wide range of configuration options

for the wind sensor and the measurement settings.

WMT700 can be equipped with accessories to tailor the

instrument to match different user-specific needs. The accessories

include a bird deterrent solution and a field-usable calibration

verifier.

1003-005

Figure 1 WMT700 Wind Sensor

18 ___________________________________________________________________ M211095EN-E

Page 21

Chapter 2 ___________________________________________________________ Product Overview

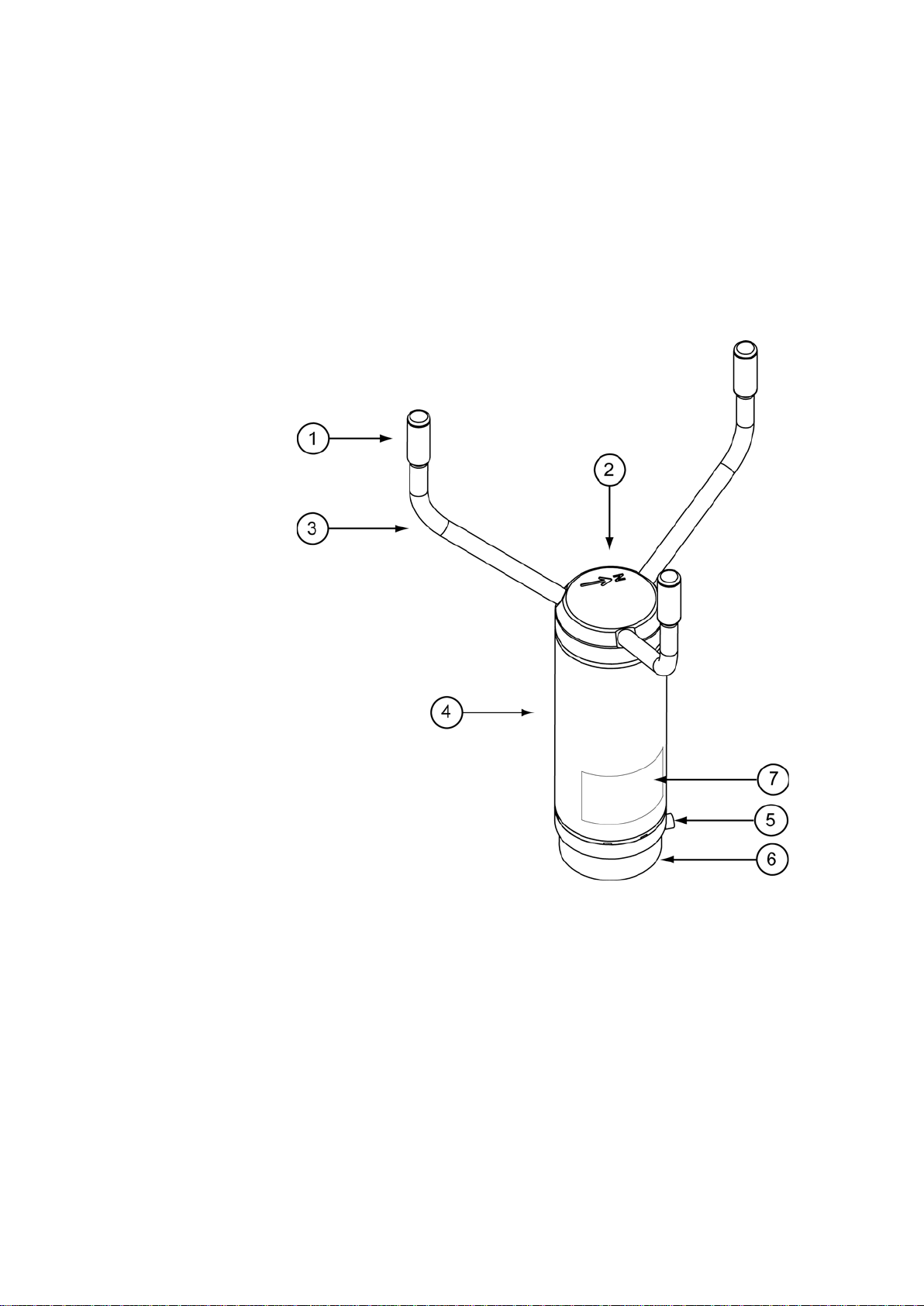

The following numbers refer to Figure 2 above:

1 = Waterproof vent

2 = Mounting adapter screw (3 pcs; use Allen key 4 mm)

3 = 17-pin M23 male connector

Do not open the sensor. There are no user

1104-065

Figure 2 WMT700 Wind Sensor from Below

NOTE

-serviceable parts inside.

VAISALA ________________________________________________________________________ 19

Page 22

User's Guide ______________________________________________________________________

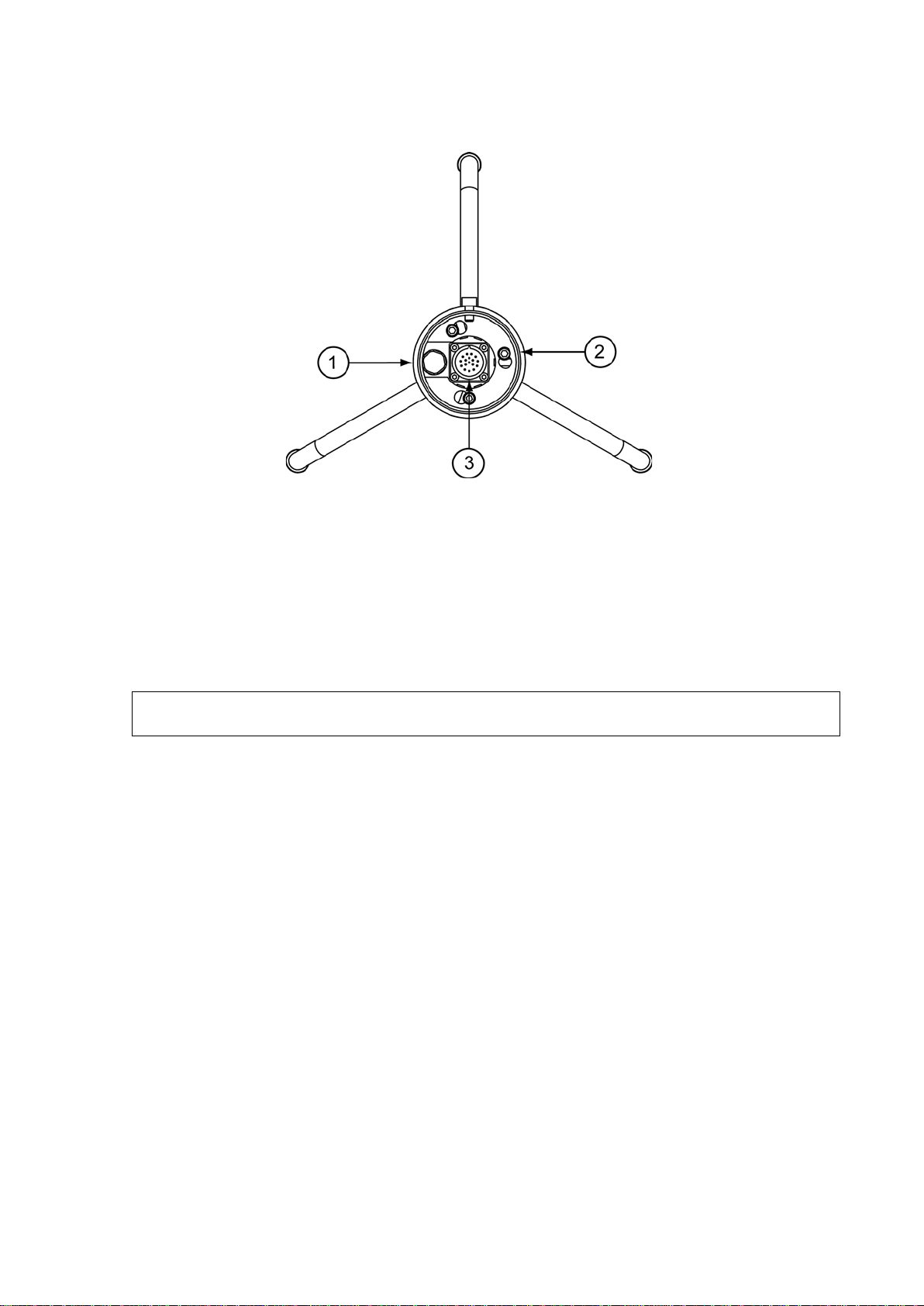

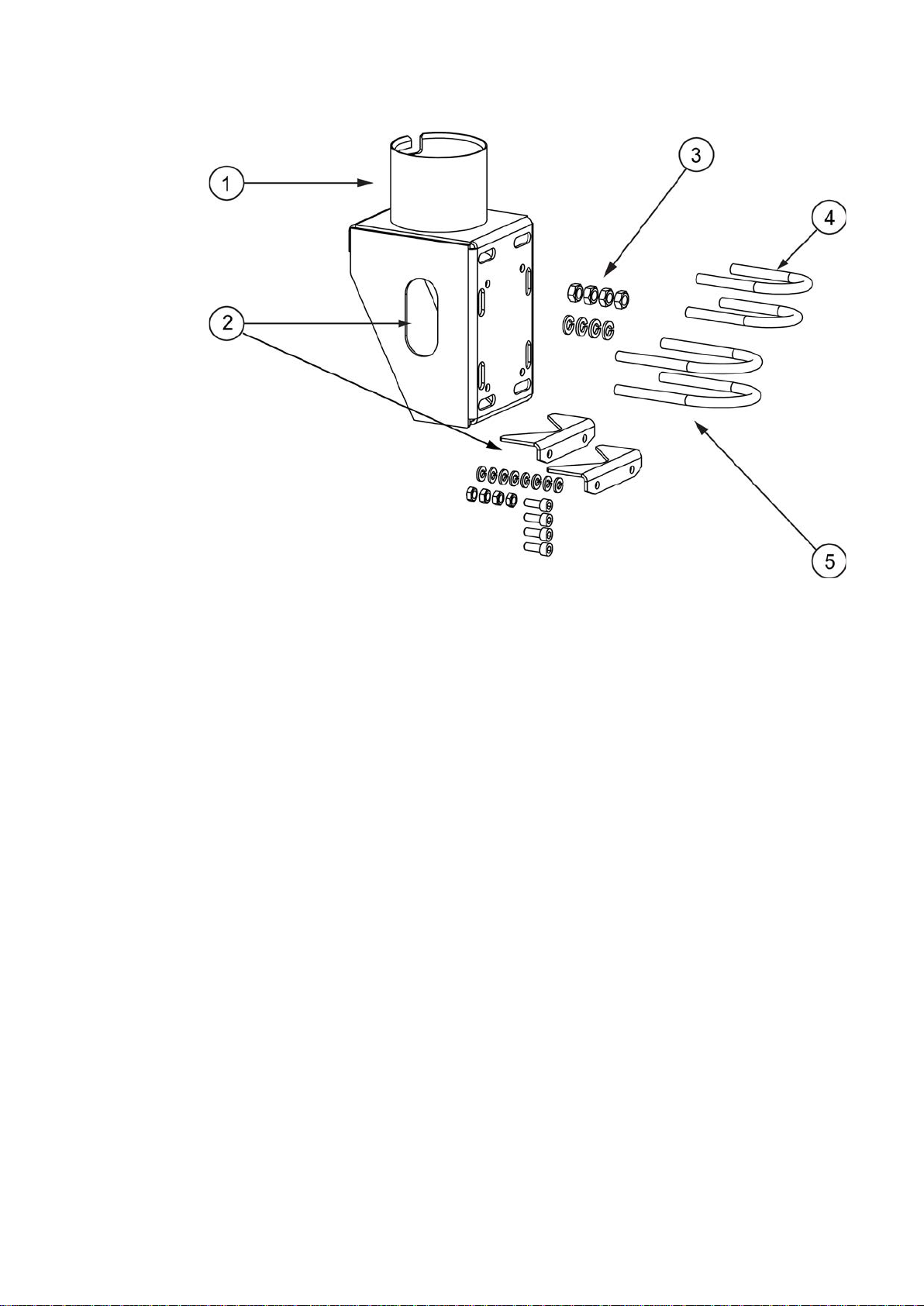

The following numbers refer to Figure 3 above:

FIX70 consists of :

1 = Fix body

2 = Removable mast guide with mounting hardware

3 = Mounting hardware (M6 nuts, washers)

4 = U bolts for ø30 mm mast (2 pcs)

5 = U bolts for ø60 mm mast (2 pcs)

1104-064

Figure 3 FIX70 Mounting Kit

20 ___________________________________________________________________ M211095EN-E

Page 23

Chapter 2 ___________________________________________________________Product Overview

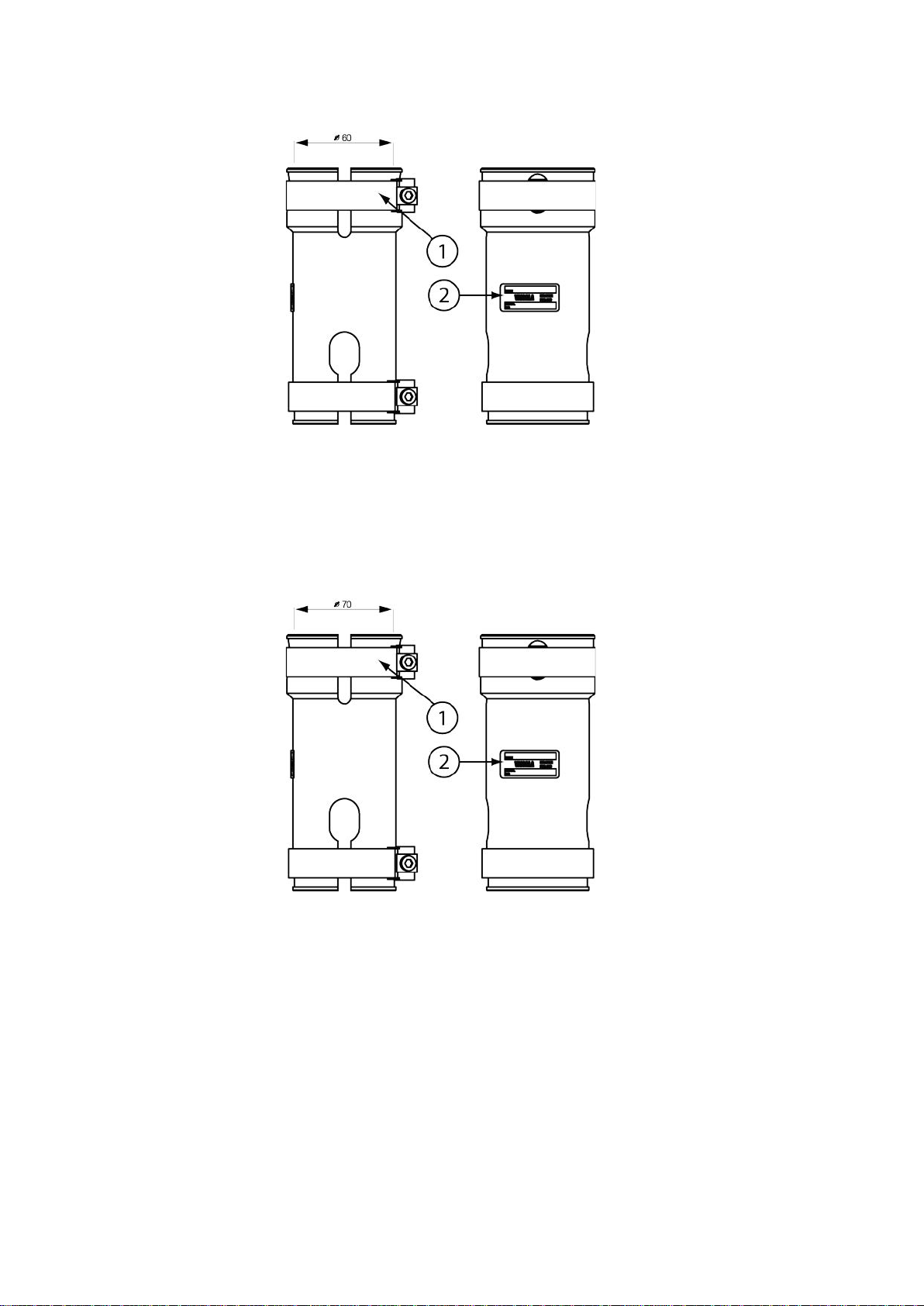

The following numbers refer to Figure 4 above:

1=Clamp

2=Label

The following numbers refer to Figure 5 above:

1=Clamp

2=Label

1305-001

Figure 4 WS425FIX60-POM

Figure 5 WMT70FIX60-POM

VAISALA________________________________________________________________________ 21

1305-002

Page 24

User's Guide ______________________________________________________________________

The following numbers refer to Figure 6 above:

1=Screw hole

2=Label

3=Clamp

The following numbers refer to Figure 7 above:

1=Screw holes

2=Label

3=Clamp

1305-003

Figure 6 WS425FIX60-RST and WS425FIX60

Figure 7 WMT70FIX60-RST

22___________________________________________________________________ M211095EN-E

1305-004

Page 25

Chapter 2 ___________________________________________________________ Product Overview

Sensor Type

Measurement Range

1

WMT701 up to 40 m/s

2

WMT702 up to 65 m/s

3

WMT703 up to 75 m/s

A

WMT701 up to 40 m/s + Accredited Wind Calibration

B

WMT702 up to 65 m/s + Accredited Wind Calibration

C

WMT703 up to 75 m/s + Accredited Wind Calibration

Option

Temperature Range

A

-10 ... +60 °C

B

-40 ... +60 °C

C

-55 ... +70 °C

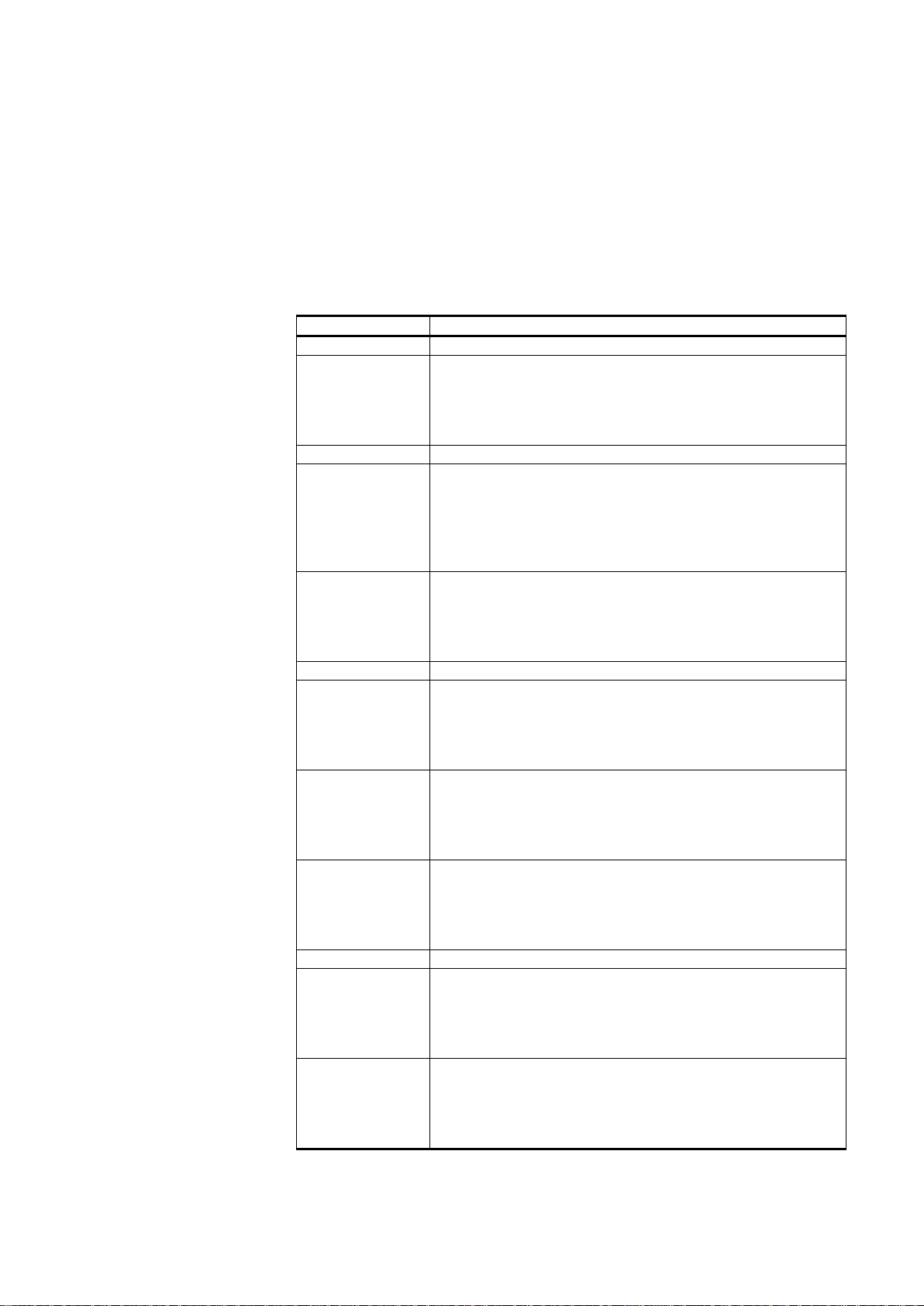

Ordering Options

A WMT700 unit can be configured by ordering options to suit

versatile customer needs. You can reconfigure the following

options:

- Digital communication interface

- Digital communication profile

- Digital communication units

- Analog output signals for wind speed channel

- Analog output signals for wind direction channel

Measurement Range

Ordering option 1, Measurement Range, defines the wind speed

operation range for the sensor. The maximum reported value of

wind speed 40, 65, or 75 m/s, depending on the selected option as

shown in Table 5 below.

Table 5 Measurement Ranges of Different Sensor Types

Temperature Range

Ordering option 2, Temperature Range, defines the operating

temperature range for the sensor as shown in Table 6 below.

Table 6 Temperature Ranges

Note that the temperature range is not connected to heating in any

way. If you operate in a demanding environmental climate where

ice accumulation is expected, Vaisala recommends that you use a

heated sensor; see Option 4 in Table 7 on page 24.

VAISALA ________________________________________________________________________ 23

Page 26

User's Guide ______________________________________________________________________

Option

Heating

1

Non-heated

2

Heated transducers (Min. 30 W power supply is needed)

3

Heated transducers and arms (Min. 200 W needed)

4

Heated transducers, arms, and body (Min. 350 W needed)

Option

Hardware Interface

A

RS-485 isolated (1 pair)

B

RS-422 isolated

C

RS-232 isolated

D

SDI-12 isolated

Heating

Ordering option 3, Heating, defines if the sensor is equipped with

extra heating for demanding environmental conditions. Option 4

providing full sensor heating is best suited for most demanding

environments. Note that power consumption requirement depends

on the selected heating option.

Table 7 Heating

Digital Communicati on Interface

Ordering option 4, Digital Communication Interface, defines the

serial line physical interface. Four different standard

communication interfaces are available.

Table 8 Digital Communication Interface

24 ___________________________________________________________________ M211095EN-E

Page 27

Chapter 2 ___________________________________________________________ Product Overview

Option

Communication Profile

0

WMT70 - default mode

9600, 8, N, 1

Polled

1

WS425 - ASCII

2400, 8, N, 1

Polled

2

WS425 - NMEA Extended (v 0183)

9600, 8, N, 1

Auto send 1/s

3

WS425 - SDI-12 (v 1.3)

1200, 7, E, 1

Polled

4

WS425 - ASOS

2400, 8, N, 1

Polled

5

ROSA - MES12

9600, 8, N, 1

Polled

6

US AWOS - NMEA Standard

2400, 8, N, 1

Autosend 5/s

7

FAA - Federal

9600, 8, N, 1

Polled

8

AWS520 - NMEA Extended (v 0183)

4800, 8, N, 1

Auto send 1/s

A

MARINE1 (v 0183)

4800, 8, N, 1

Auto send 1/s

B

MARINE2 (v 0183)

9600, 8, N, 1

Auto send 1/s

C

WIND TURBINE1 (default)

9600, 8, N, 1

Polled

D

WIND TURBINE2 (v 0183)

9600, 8, N, 1

Auto send 1/s

Option

Unit Used

A

Meters per second

B

Knots

C

Miles per hour

D

Kilometers per hour

Digital Communicati on Pr of ile

Ordering option 5, Digital Communication Profile, defines the

communication protocol used for the sensor. WS425 options are

usable and backwards compatible when replacing WS425 sensor

with a WMT700 unit. MARINE and WIND TURBINE options

are customer-specific profiles.

Table 9 Digital Communication Profile

Digital Communicati on Units

Ordering option 6, Unit Definition for Digital Communication,

offers four different digital communication options.

Table 10 Digital Communication Options

VAISALA ________________________________________________________________________ 25

Page 28

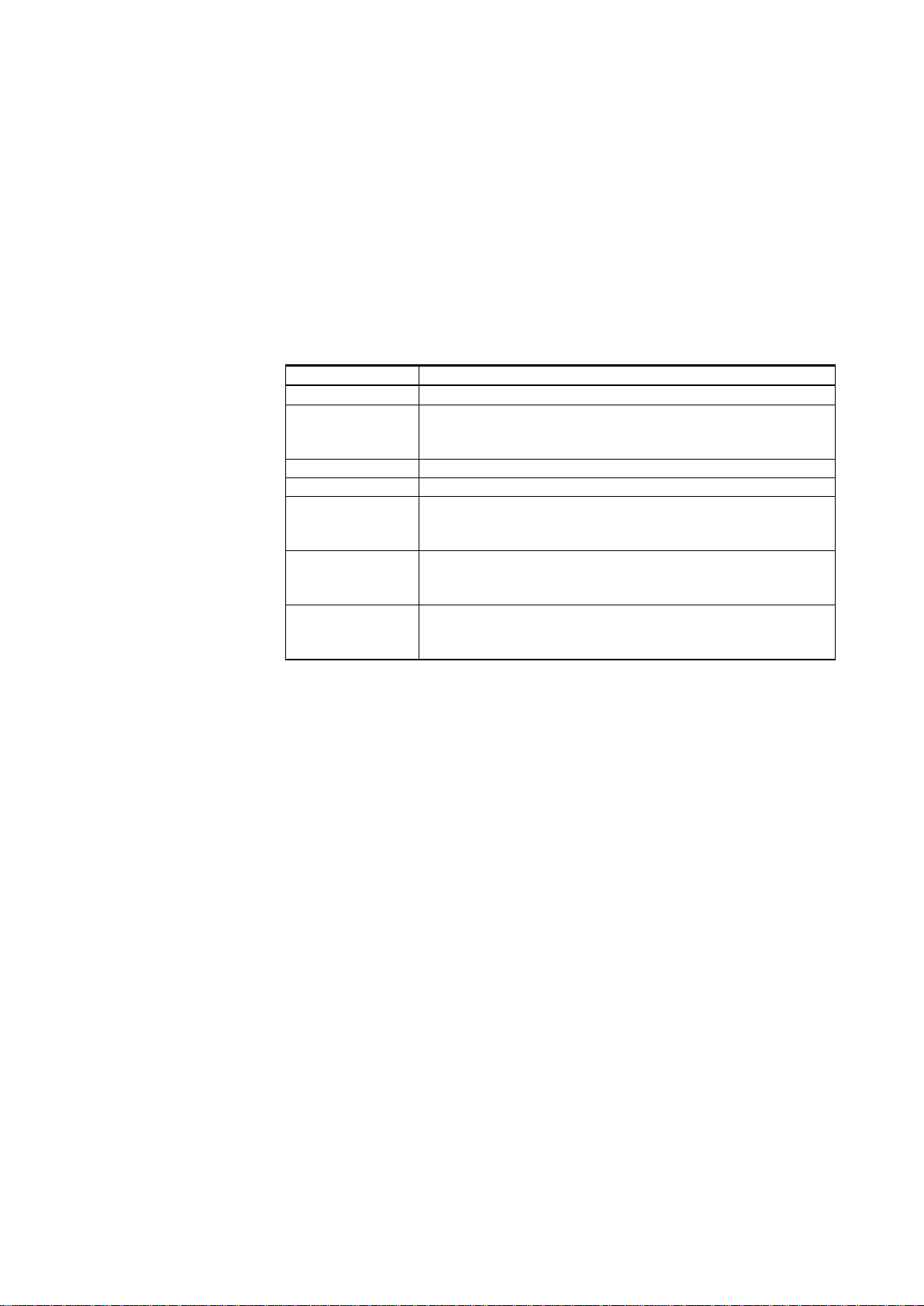

User's Guide ______________________________________________________________________

Option

Output Configuration

0

Disabled

1

Voltage output 100 mV/m/s

7500 mV = 75 m/s (WMT703 maximum wind speed)

2

Reserved for future use

3

Current output 4…20 mA, offset 4 mA

Error indication sets output to 2 mA

4

Current output 0.2 mA/m/s

15 mA = 75 m/s (WMT703 maximum wind speed)

5

Reserved for future use

6

Frequency output 10 Hz/m/s

750 Hz = 75 m/s (WMT703 maximum wind speed)

7

WS425 voltage output 8 mV/mph

1344 mV = 168 mph (WMT703 maximum wind speed)

8

WS425 frequency output 5 Hz/m ph

840 Hz = 168 mph (WMT703 maximum wind speed)

9

Reserved for future use

A

Push up output, 10 Hz/m/s

750 Hz = 75 m/s (WMT703 maximum wind speed)

B

Pull down output 10 Hz/m/s

750 Hz = 75 m/s (WMT703 maximum wind speed)

Analog Output Signal for Wi nd S peed Channel

Ordering option 7, Analog Output for Wind Speed, can be

disabled or factory-configured for 8 different modes. WS425

options are usable and backwards compatible when replacing

WS425 sensor with a WMT700 unit.

Table 11 Output Configuration

0 mV = 0 m/s

4000 mV = 40 m/s (WMT701 maximum wind speed)

6500 mV = 65 m/s (WMT702 maximum wind speed)

4 mA = 0 m/s

20 mA = 40 m/s (WMT701, 0.4 mA/m/s)

20 mA = 65 m/s (WMT702, 0.24615 mA/m/s)

20 mA = 75 m/s (WMT703, 0.21333 mA/m/s)

0 mA = 0 m/s

8 mA = 40 m/s (WMT701 maximum wind speed)

13 mA = 65 m/s (WMT702 maximum wind speed)

0 Hz = 0 m/s

400 Hz = 40 m/s (WMT701 maximum wind speed)

650 Hz = 65 m/s (WMT702 maximum wind speed)

0 mV = 0 m/s

716 mV = 89.5 mph (WMT701 maximum wind speed)

1116 mV = 145 mph (WMT702 maximum wind speed)

0 Hz = 0 m/s

447.5 Hz = 89.5 mph (WMT701 maximum wind speed)

725 Hz = 145 mph (WMT702 maximum wind speed)

0 Hz = 0 m/s

400 Hz = 40 m/s (WMT701 maximum wind speed)

650 Hz = 65 m/s (WMT702 maximum wind speed)

26 ___________________________________________________________________ M211095EN-E

0 Hz = 0 m/s

400 Hz = 40 m/s (WMT701 maximum wind speed)

650 Hz = 65 m/s (WMT702 maximum wind speed)

Page 29

Chapter 2 ___________________________________________________________ Product Overview

Selection

Output Configuration

0

Disabled

A

Voltage output 20 mV/degree

7200 mV = 360 degree

B

Reserved for future use

C

Reserved for future use

D

Current output 50 uA/degree

18 mA = 360 degree

E

Current output 4…20 mA (44.444 uA/degree)

20 mA = 360 degree km/h

F

WS425 Potentiometer output

100% of V

ref

= 360 degree

Analog Output Signal for Wi nd Direction Channel

Ordering option 8 defines Analog Output Signal for Wind

Direction.WS425 Potentiometer output is backward compatible

when replacing WS425 with a WMT700 unit. For different wind

speed and direction representations, see Figure 13 on page 39.

Note that the wind direction offset must be 0 for the for the

readings to correspond with Figure 13.

Table 12 Analog Output Signal for Wind Direction

0 mV = 0 degree

0 uA = 0 degree

4 mA = 0 degree

0% of V

= 0 degree

ref

Connection Cables

Ordering option 9 defines connection cables. There are several

different cables of different lengths for different purposes, as

shown in Table 13 on page 28.

VAISALA ________________________________________________________________________ 27

Page 30

User's Guide ______________________________________________________________________

Selection

Cable type

1

No cables

2

Cable 2 m, cable connector, open leads on one end

3

Cable 10 m, cable connector, open leads on one end

4

MAWS cable 10 m

5

AWS520 cable 10 m. Shield connected to PE pin

6

Adapter cable for WS425 serial

7

Adapter cable for WS425 analog frequency output

8

RS485 cable 2 m, cable connector, open leads on one

end

9

RS485 Cable 10 m, cable connector, open leads on one

end A Adapter cable for WS425 analog voltage output

B

AWS520 cable 10 m. Shield not connected to PE pin.

C

ROSA analog cable 10 m, cable connector, open leads on

one end

D

Junction Box with Cable 2 m

E

Cable 15 m, cable connector, open leads on one end

F

Cable 26 m, cable connector, open leads on one end

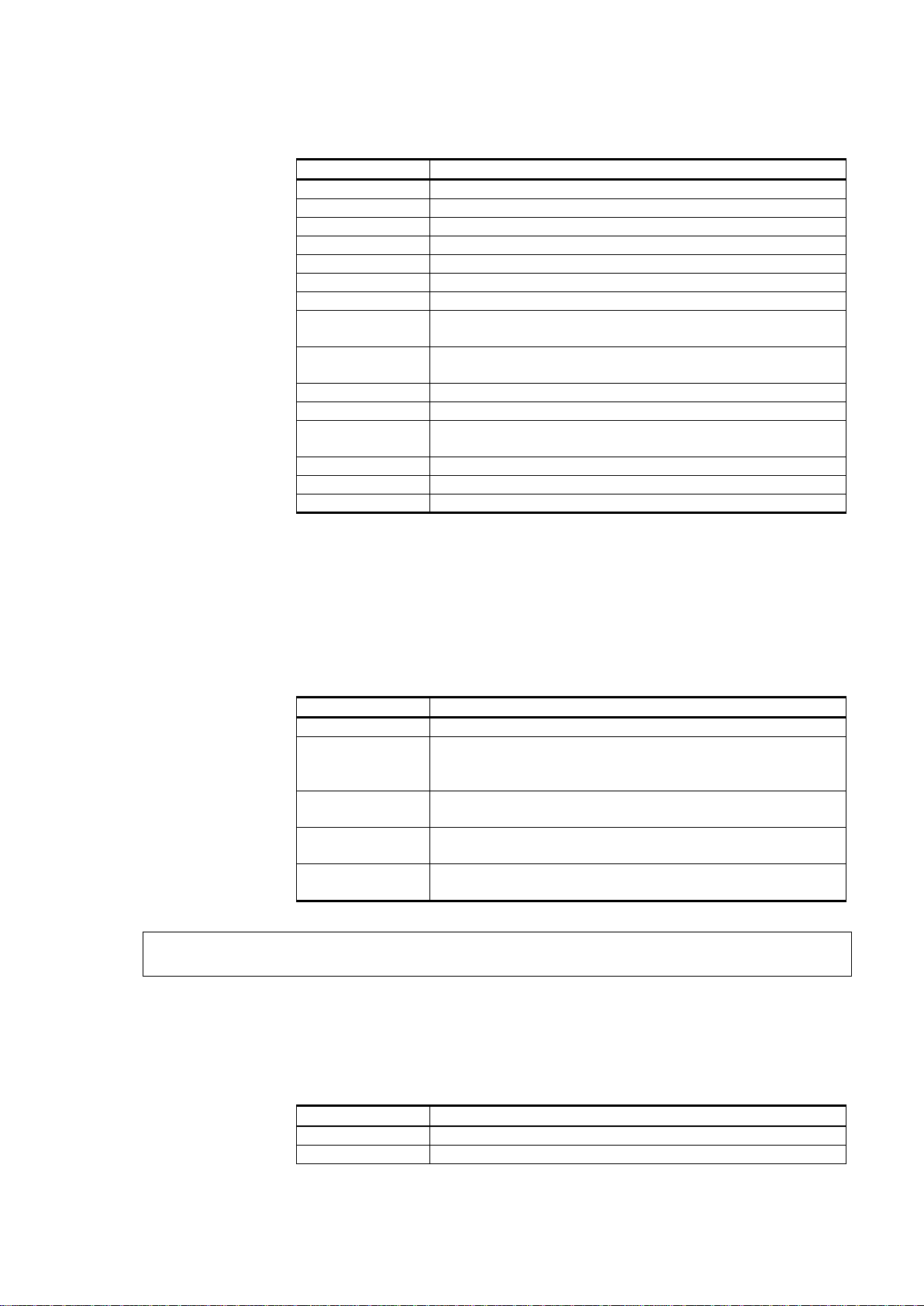

Option

Adapter Type

A

Adapter 228869 only. Standard adapter, no fix

B

Adapter 228869 with WMT70FIX70 fixing mechanics. Also

general purpose

C

Adapter 228869 with WMT700FIX60-POM. Standard

adapter with plastic fix for 60 mm pole

D

Adapter 228869 with WMT700FIX60-RST Standard

adapter with stainless steel fix for 60 mm pole

E

Adapter 22877 only (used for old WS425

FIX30/WS425FIX60), WS425-compatible adapter, no fix

Ordering option 11 is reserved for future use.

Option

Accessories

A

No accessories

B

Bird cage WMT70BirdKit

Table 13 Analog Output Configuration

NOTE

Mounting Adapters

Ordering option 10 defines mounting adapters. There are several

different mounting adapters for different purposes, as shown in

Table 14 below.

Table 14 Mounting Adapters

suitable for inverted mounting. Standard adapter for

Accessories

Ordering option 12 defines WMT700 accessories.

Table 15 Accessories

28 ___________________________________________________________________ M211095EN-E

Page 31

Chapter 2 ___________________________________________________________ Product Overview

Option

Manual

1

No manual

2

English manual

3

Japanese manual

4

Chinese manual

5

Russian manual

6

Deif manual and packing

Vaisala recommends using heated versions of WMT700 in

environmental conditions where snow and ice build

For

page 82

If required, you can change

communication profile, digital communication units, an

signals for wind speed channel, and analog output signals for wind

direction channel.

Table

Manual

Ordering option 13, Manual, defines available manual version and

possible special package design.

Table 16 Manual

Example of WMT703 Configuration

WMT703 C4A2A003B1A2

| | | | | | | | | | | | |_English ma n u a l in c l uded

| | | | | | | | | | | |__No acces s o r i e s

| | | | | | | | | | |___Option 11 not in use

| | | | | | | | | | ____FIX70 mounting adapter included

| | | | | | | | |_____ C a b l e 10 m included

| | | | | | | |_____ _ A nalog signal for wind direction disabled

| | | | | | |_______ Analog signal for wind speed disabled

| | | | | |________ Used unit: m/s

| | | | |__________WS425 NMEA Extended messaging in use

| | | |___________Physical serial line interface is RS-485

| | |____________Transducers, arms, and body are heated

| |______________-55 to +70° temperature range model

|________________WMT703 measurement range up to 75 m/s

NOTE

more information on the heating functionality, see section Heating on

.

NOTE

To change the product version characteristics listed in

9 on page 25, contact Vaisala Service Center.

VAISALA ________________________________________________________________________ 29

-up is possible.

the digital communication interface, digital

alog output

Page 32

User's Guide ______________________________________________________________________

Accessories

WMT700 can be tailored to your needs with several accessories.

The accessories include, for example, mounting adapters for

different mast diameters, cables for different host systems and

preferred communication types, a bird prevention kit, and a field

calibration kit.

When specifying your WMT700, you can order the optional

FIX70 universal mounting adapter, a bird cage, WM Verifier, and

cables as accessories for WMT700.

For the codes of the accessories that you need to order separately,

see Table 62 on page 192. For a complete list of accessories, see

Appendix F, Accessories, on page 213.

30 ___________________________________________________________________ M211095EN-E

Page 33

Chapter 2 ___________________________________________________________ Product Overview

Bird Cage

Vaisala recommends using the optional bird cage in areas with

large bird populations. The cage is designed to prevent large birds

from disturbing the measurement. It has been tested in a wind

tunnel with wind speeds of up to 40 m/s without noticeable effects

on the wind speed and direction measurement.

You can install the bird cage on a mounted WMT700 series wind

sensor without dismounting the wind sensor itself. In cold

climates, take into account that accumulated snow or ice on the

bird cage can disturb the measurement. In such conditions,

consider performing frequent visual inspections of WMT700 to

avoid ice or snow build-ups.

1005-028

Figure 8 Bird Cage

VAISALA ________________________________________________________________________ 31

Page 34

User's Guide ______________________________________________________________________

WM Verifier

The optional WM Verifier is a small echo-free chamber for

testing the mechanical integrity of WMT700 and performing onepoint calibration. The verifier ensures that the array is undamaged

and the transducers are parallel to each other. You can perform

the verifier test in a laboratory or in the field.

For instructions on performing the verifier test, see section

Testing Proper Operation on page 181.

1004-119

Figure 9 WM Verifier

32 ___________________________________________________________________ M211095EN-E

Page 35

Chapter 2 ___________________________________________________________ Product Overview

Order Code

Description

Purpose

WMT70Conn

Cable connector

Cable

227567SP

Cable 2 m, cable connector, open leads

on one end

Used for analog output or serial

communication with two serial ports.

227568SP

Cable 10 m, cable connector, open

leads on one end

Used for analog output or serial

communication with two serial ports.

237890SP

Cable 15 m, cable connector, open

leads on one end

Used for analog output or serial

communication with two serial ports.

237889SP

Cable 26 m, cable connector, open

leads on one end

Used for analog output or serial

communication with two serial ports.

228259SP

RS485 cable 2 m, cable connector,

open leads on one end

Used for serial communication with RS485 interface.

228260SP

RS485 Cable 10 m, cable connector,

open leads on one end

Used for serial communication with RS485 interface.

227565SP

MAWS cable 10 m

Used for connecting WMT700 to

MAWS.

229807SP

AWS520 cable 10 m, shield connected

Used for connecting WMT700 to

AWS520.

227566SP

AWS520 cable 10 m, shield not

Used for connecting WMT700 to

AWS520.

231425SP

ROSA analog cable 10 m, cable

connector, open leads on one end

Used for connecting WMT700 to

Vaisala Road Weather System ROSA.

227569SP

Adapter cable for WS425 serial

Used for connecting the WS425 cable

installations.

227570SP

Adapter cable for WS425 analog

Used for connecting the WS425 cable

installations.

227571SP

Adapter cable for WS425 analog

Used for connecting the WS425 cable

installations.

ASM210719SP

Junction Box with Cable 2 meters

Used when a cable longer than 10

2-meter cable to a needed length.

Cables

Select the required cables according to your operating

environment.

Table 17 Cables

Vaisala Automatic Weather Station

to PE pin

connected to PE pin

frequency output

voltage output

Vaisala Fixed Site Observation System

Vaisala Fixed Site Observation System

to WMT700. Only applicable for retrofit

to WMT700. Only applicable for retrofit

to WMT700. Only applicable for retrofit

meters is needed. Junction Box

contains terminal blocks that extend the

VAISALA ________________________________________________________________________ 33

Page 36

User's Guide ______________________________________________________________________

Cable Tightening Tool

WMT700 is shipped with a cable tightening tool (237888SP).

When a cable is inserted in the cable tightening tool, it is easier to

grip and rotate the cable when connecting it to WMT700. After

tightening, the cable tightening tool can be left in place.

1306-028

Figure 10 Cable Tightening Tool

34___________________________________________________________________ M211095EN-E

Page 37

Chapter 3 _______________________________________________________ Functional Description

CHAPTER 3

FUNCTIONAL DESCRIPTION

This chapter describes the functionality of WMT700.

Operating Principle

WMT700 uses the Vaisala WINDCAP® ultrasonic sensor

technology in wind measurement. The sensor has an onboard

microcontroller that captures and processes data and

communicates over serial interfaces.

The wind sensor has an array of three equally spaced ultrasonic

transducers on a horizontal plane. Wind speed (WS) and wind

direction (WD) are determined by measuring the time it takes the

ultrasound to travel from each transducer to the other two.

The wind sensor measures the transit time (in both directions)

along the three paths established by the array of transducers. This

transit time depends on wind speed along the ultrasonic path. For

zero wind speed, both the forward and reverse transit times are

the same. With wind along the sound path, the upwind direction

transit time increases and the downwind transit time decreases.

Figure 11 on page 36 shows how the time shift of the ultrasonic

signals is measured and how tail wind and forward wind affect the

measurement.

VAISALA ________________________________________________________________________ 35

Page 38

User's Guide ______________________________________________________________________

The following numbers refer to Figure 11 above:

1 = Ultrasonic measurement with zero wind

2 = Impact of tail wind on ultrasonic measurement

3 = Impact of head wind on ultrasonic measurement

1005-007

Figure 11 Ultrasonic Measurement Principle

36 ___________________________________________________________________ M211095EN-E

Page 39

Chapter 3 _______________________________________________________ Functional Description

)t/1(1/tL5.0V

rfW

−⋅⋅=

where

Vw = Wind velocity

L = Distance between two transducers

tf = Transit time in the forward direction

tr = Transit time in the reverse direction

where

1–6

=

Measurement paths 1 to 6 of WMT700

La, Lb, Lc

=

Distance between two transducers

The microcontroller calculates WS from the measured transit

times using the following formula:

Measuring the six transit times allows Vw to be computed for each

of the three ultrasonic paths. Using Vw values of two array paths

is enough to compute WS and WD.

Figure 12 below shows the different paths of WMT700 and the

vectors provided by the wind sensor:

VAISALA ________________________________________________________________________ 37

1104-066

Figure 12 Measurement Paths of WMT700

Page 40

User's Guide ______________________________________________________________________

)A/1(1/A5.0V

21a

−⋅⋅=

a

L

)A/1(1/A5.0V

43

−⋅⋅=

bb

L

)A/1(1/A 5.0V

65

−⋅⋅=

cc

L

The vectors are calculated as follows:

The equation depends on the accurate distance of the

measurement path (L). The computed wind speeds are

independent of altitude, temperature, and humidity, which are

canceled out when the transit times are measured in both

directions, although the individual transit times depend on these

parameters.

Coordinate Systems: Vector and Polar Calculations

The triangular geometry of the sensor is converted to orthogonal

coordinates to achieve the x and y components. Then the sensor

converts the wind vectors into polar coordinates.

The measurement results are reported as follows:

- WMT700 reports WS (x, y) as two scalar speeds, one parallel

to the N-S direction (x) and the other (y) parallel to the W-E

direction. The speed unit may be m/s, kt, mph, or km/h.

x = WS × cos (WD)

y = WS × sin (WD)

- WMT700 reports polar wind speed as a scalar speed in

selected units (m/s, kt, mph, km/h).

Polar wind direction is expressed in degrees (°). WMT700

indicates the direction that the wind comes from. North is

represented as 0°, east as 90°, south as 180°, and west as 270°.

38 ___________________________________________________________________ M211095EN-E

Page 41

Chapter 3 _______________________________________________________ Functional Description

Figure 13 below shows examples of wind speed and direction

presentations.

Figure 13 Different Wind Speed and Direction

Presentations (Direction Offset Is 0)

0212-044

VAISALA________________________________________________________________________ 39

Page 42

User's Guide ______________________________________________________________________

Wind Speed and Direction Averaging

WMT700 provides average values for wind speed and direction

using either scalar or vector averaging. With both methods, the

average is determined according to the user-configurable

averaging time. The averaging time affects serial communication

and analog output similarly.

You can also configure the gust averaging time for calculating

wind extreme values. The default gust averaging interval is 3

seconds, as recommended by World Meteorological Organization

(WMO).

If scalar averaging is selected, you can also enable wind direction

coasting to ensure consistent direction measurement results at low

wind speeds.

Scalar Averaging

When scalar averaging is selected, WMT700 calculates wind

speed and direction averages by adding up each wind

measurement from the averaging time and dividing the sum by

the number of measurements. The time between each consecutive

wind speed and wind direction measurement is 0.25 seconds.

Wind direction is a circular function with a discontinuity at the

north, where 360 degrees is equal to zero degrees. For example:

359° + 5° = + 4°

0° - 5° = 355°

WMT700 translates wind direction to a linear function to

determine the wind direction average. For instance:

359° + 5° is translated to 364°, which is then further converted to

+4° for output.

0° - 5° is translated to 355°.

This ensures that the wind direction average stays representative

of the true situation even if individual samples occur on both sides

of the zero direction.

If the data acquisition system requests data before the initial

averaging time completes, the sensor returns the most recent

complete measurement data.

40 ___________________________________________________________________ M211095EN-E

Page 43

Chapter 3 _______________________________________________________ Functional Description

Figure 14 below shows an example of averaging wind direction

when the measured wind values are 355° and 10°. The resulting

average is 2.5°.

1005-024

Figure 14 Example of Wind Direction Averaging

Wind Direction Coasting

Accurate wind direction measurement requires that the wind

speed is sufficient. If you enable wind direction coasting,

WMT700 does not calculate wind direction when the wind speed

drops below the selected wind direction coasting threshold. The

last calculated direction output remains until the wind speed

increases enough to reach the threshold and WMT700 returns to

normal operation.

Vector Averaging

When vector averaging is selected, WMT700 calculates wind

speed and direction averages by adding up each x velocity and y

velocity measurement from the averaging time and then dividing

the sum by the number of measurements. WMT700 converts the

resultant average x velocity and average y velocity to polar

direction and magnitude, which returns the wind direction average

in degrees and wind speed average in the chosen units.

If the data acquisition system requests data before the initial

averaging time completes, the sensor returns the most recent

complete measurement data.

VAISALA ________________________________________________________________________ 41

Page 44

User's Guide ______________________________________________________________________

Measurement Methods

WMT700 measures wind speed and direction either continuously

or for the duration of the user-configurable averaging time. You

can select the measurement mode over the serial interface.

Continuous Measurement

You can set WMT700 to measure wind data continuously until

the sensor receives the STOP command.

The following data communication methods are available:

- Poll Mode: You can fetch the most recent data from WMT700

with the POLL command. You must specify the data message

identification number in the command.

- Automatic Messaging Mode: If the automatic message interval

is configured, WMT700 sends automatic data messages at

selected intervals. The data message is user-configurable.

For information on response delay and timing, see section Serial

Interface Timing on page 49.