Page 1

HMP260 SERIES

TRANSMITTERS

Operating Manual

HMP260-U017en-1.5

5 January 1996

Vaisala 1996

Page 2

This page intentionally left blank.

Back of cover page.

Page 3

HMP260 SERIES

HMP260-U017en-1.5 Operating Manual

Contents

1. PRODUCT DESCRIPTION ......................................................................................... 1

2. TO BE NOTED WHEN M EASURING HUMIDITY........................................................ 3

3. INSTALLATION.......................................................................................................... 4

3.1. Selecting the place of installation ................................................................ 4

3.2. Mounting........................................................................................................ 5

3.2.1. HMP263 transmitter ......................................................................... 6

3.2.2. HMP264 transmitter ......................................................................... 7

3.2.3. HMP265 transmitter ....................................................................... 10

3.3. Grounding .................................................................................................... 11

3.4. Electrical connections................................................................................. 13

4. COMMISSIONING .................................................................................................... 15

4.1. Security lock jumper ................................................................................... 15

4.2. Selecting the analogue outputs .................................................................. 15

4.3. Connecting the RS 232C serial bus............................................................ 17

4.3.1. Reverting to factory settings of the serial port................................. 19

5. COMMANDS ............................................................................................................ 21

5.1. Commands and security lock jumper ......................................................... 21

5.2. LED commands ........................................................................................... 22

5.3. Display/keypad commands......................................................................... 23

5.3.1. Display mode ................................................................................. 23

5.3.2. Command m ode............................................................................. 23

5.3.3. Entering numbers........................................................................... 23

5.3.4. Analogue output commands ........................................................... 24

5.3.4.1. Selecting the output (mA/V)........................................................ 24

5.3.4.2. Selecting and scaling the analogue output quantities.................. 25

5.3.5. Output via the serial bus ................................................................. 26

5.3.5.1. Turning the serial interface echo ON/OFF................................... 26

5.3.5.2. Serial bus settings...................................................................... 26

5.3.5.3. Setting the transmitter address................................................... 27

5.3.5.4. Selecting the output units ........................................................... 27

5.3.6. Output modes................................................................................. 28

5.3.6.1. Setting the serial interface operation mode................................. 28

5.3.7. Others .......................................................................................... 29

5.3.7.1. Setting the measurement integration tim e................................... 29

5.3.7.2. Setting the pressure for m ixing ratio and wet bulb calc ulations ... 29

5.3.7.3. Setting the date .......................................................................... 30

5.3.7.4. Setting the time .......................................................................... 30

1997-11-25 i

Page 4

HMP260 SERIES

Operating Manual HMP260-U017en-1.5

5.4. Serial commands ......................................................................................... 32

5.4.1. Analogue output commands ............................................................ 32

5.4.1.1. Setting the analogue outputs ....................................................... 32

5.4.1.2. Selecting and scaling the analogue output quantities ..................33

5.4.1.3. Scaling the analogue outputs ......................................................33

5.4.2. Output via the serial bus .................................................................34

5.4.2.1. Starting the measurement output ................................................34

5.4.2.2. Stopping the measurement output ............................................... 34

5.4.2.3. Outputting the reading once........................................................ 34

5.4.2.4. Setting the output interval for the RUN mode ..............................35

5.4.2.5. Serial bus settings.......................................................................35

5.4.2.6. Selecting the output units............................................................36

5.4.2.7. Setting the transmitter address ...................................................36

5.4.2.8. Resetting the transmitter.............................................................36

5.4.4. Operating the transmitter via the serial bus.....................................36

5.4.4.1. Setting the serial interface...........................................................36

5.4.4.2. OPEN & CLOSE .........................................................................37

6. CALIBRATION..........................................................................................................38

6.1. Humidity calibration ....................................................................................38

6.1.1. One point humidity calibration.........................................................39

6.1.1.1 Using serial commands...............................................................39

6.1.1.2 Using display/keypad commands ................................................39

6.1.1.3 Using LED commands................................................................. 40

6.1.2. Two point humidity calibration.........................................................40

6.1.2.1 Using serial commands...............................................................40

6.1.2.2 Using display/keypad commands ................................................41

6.1.2.3 Using LED commands................................................................. 41

6.1.3. Calibration procedure after sensor c hange ...................................... 42

6.1.3.1 Using serial commands...............................................................42

6.1.3.2 Using display/keypad commands ................................................43

6.1.3.3 Using LED commands................................................................. 43

6.1.4. Humidity calibration table................................................................44

6.2. Temperature calibration .............................................................................. 44

6.2.1 One point offs et correction..............................................................45

6.2.2.1 Using serial commands...............................................................45

6.2.2.2 Using display/keypad commands ................................................45

6.2.2.3 Using LED commands................................................................. 46

6.2.2 Two point temperature c alibration...................................................46

6.2.2.1 Using serial commands...............................................................46

6.2.2.2 Using display/keypad commands ................................................47

6.2.2.3 Using LED commands................................................................. 47

6.3. Calibration of analogue outputs .................................................................48

6.3.1 Using serial com m ands ................................................................... 48

6.3.2 Using display/keypad commands ....................................................48

6.3.3 Using LED com m ands ....................................................................50

7. MAINTENANCE........................................................................................................50

7.1. Reference measurements............................................................................50

7.2. Self-diagnostics...........................................................................................50

7.3. Changing the HUMICAP® sensor and the filter.......................................... 51

7.4. Measurement of output currents using test points.................................... 51

7.5. Adjusting the contrast of the display..........................................................52

ii 1997-11-25

Page 5

HMP260 SERIES

HMP260-U017en-1.5 Operating Manual

8. TECHNICAL DATA................................................................................................... 53

8.1. Relative humidity......................................................................................... 53

8.2. Temperature................................................................................................. 53

8.3. Calculated variables.................................................................................... 53

8.4. Pressure ....................................................................................................... 55

8.5. Analogue outputs........................................................................................ 55

8.6. Electronics ................................................................................................... 55

8.7. Mechanics.................................................................................................... 56

8.8. Environmental conditions ........................................................................... 58

8.8.1 Emissions ....................................................................................... 58

8.8.2 Imm unity ........................................................................................ 58

9. OPTIONS ................................................................................................................. 59

10. SPARE PARTS......................................................................................................... 59

Appendix 1 Serial commands

Appendix 2 Safety summary

Appendix 3 Installing and using the RS 485/422 serial port module

Appendix 4 Installing and using the digital current loop module

Appendix 5 Error messages

Appendix 6 Calculation formulas: dewpoint, m ixing ratio and abs olute hum idity

Appendix 7 Wiring diagr am MK4462

Appendix 8 Installation diagram MK4461

Appendix 9 Approvals and specifications of the protection unit

Certificates: Technical Research Centre of Finland No. Ex-94.C.016X

No. Ex-94.C.018X

DEMKO No. 94C.115330X

This manual is f or progr am m e vers ion HMPS260 1.01

1997-11-25 iii

Page 6

HMP260 SERIES

Operating Manual HMP260-U017en-1.5

This page intentionally left blank.

iv 1997-11-25

Page 7

HMP260 SERIES

HMP260-U017en-1.5 Operating Manual

1. PRODUCT DESCRIPTION

NOTE

Before installing and using the HMP260 transmitter

study carefully Appendix 2: SAFETY SUMMARY.

The HMP260 series transmitters are associated electrical apparatuses. This

means that the housing of the transmitter is mounted into a safe area and the

sensor head and its cable can go to a potentially explosive environment

(hazardous area). The transmitters incorporate a protective unit which contains

the power limiting components. This unit prevents the entry of any hazardous

energies to the potentially explosive area.

The transmitters are microprocessor based instruments which measure relative

humidity and temperature; from these variables they can calculate dewpoint

temperature, absolute humidity, mixing ratio and wet bulb temperature. The

transmitters have two analogue outputs and can be connected to a serial bus

via the RS 232C interface or through an RS 485/422 serial module or a digital

current loop module.

The series consists of three types of transmitter:

• HMP263, installation in tight places; temperatures up to +120 °C

• HMP264, installation in pressure or vacuum chambers

• HMP265, installation in high temperatures up to +180 °C

There are various possibilities for the configuration of the transmitters. They

can have either a blank cover or a cover with a local display and keypad with

which to operate the transmitter. Two analogue output signals are selected

from the measured and calculated quantities; the signals can be scaled and the

measurement ranges changed within certain limits. The HMP263, HMP264

and HMP265 can be supplied with two, five, ten or 15 metre probe cable.

The humidity measuring range is 0...100 %RH. The temperature is measured

with a Pt 100 sensor. Temperature measurement range depends on the model;

the HMP264 and HMP265 have the widest range, -40...+180 °C. The analogue

temperature output can be scaled quite freely, for example -20...+60 °C can be

set to correspond to 0...10 V. The dewpoint temperature, absolute humidity,

mixing ratio and wet bulb temperature ranges are also scalable.

The HMP260 series units incorporate the HUMICAP® sensor, which uses an

operating principle based on changes in the capacitance of the sensor as its

thin polymer film absorbs water molecules.

1997-11-25 1

Page 8

HMP260 SERIES

Operating Manual HMP260-U017en-1.5

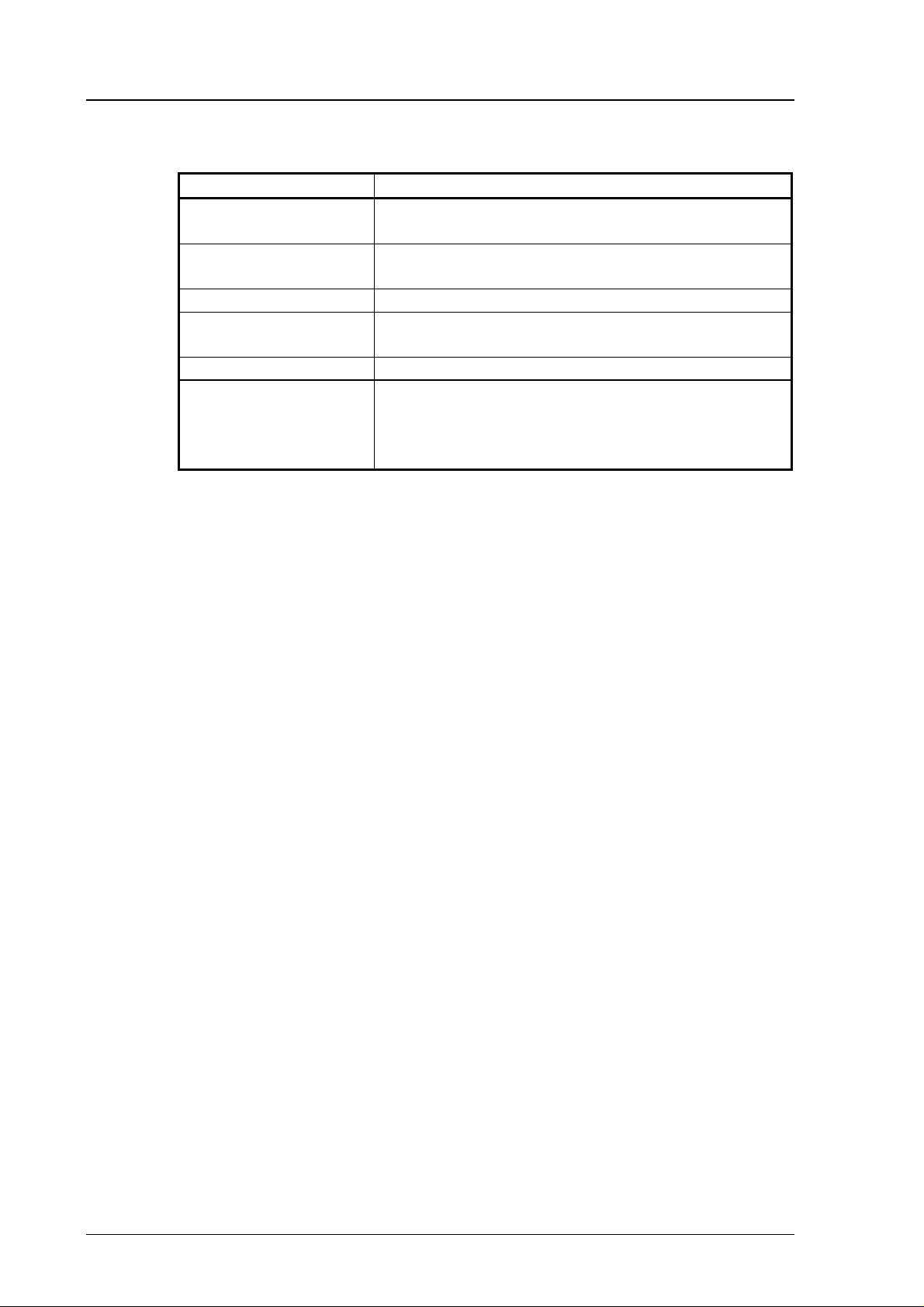

Options

Calculation variables dewpoint temperature, mixing ratio, absolute hu-

midity, wet bulb temperature

Serial interface RS 232C (standard), RS 485/422, digital current

loop

Display cover cover with or without local display & keypad

Filters sintered filter, PPS grid with steel netting, PPS

grid

Cable length 2, 5,10 or 15 metres

Installation aids HMP263: installation kit

HMP264: NPT conical pipe threaded fitting body

(1/2 - 14 NPT)

HMP265: steel and aluminium flanges

2 1997-11-25

Page 9

HMP260 SERIES

HMP260-U017en-1.5 Operating Manual

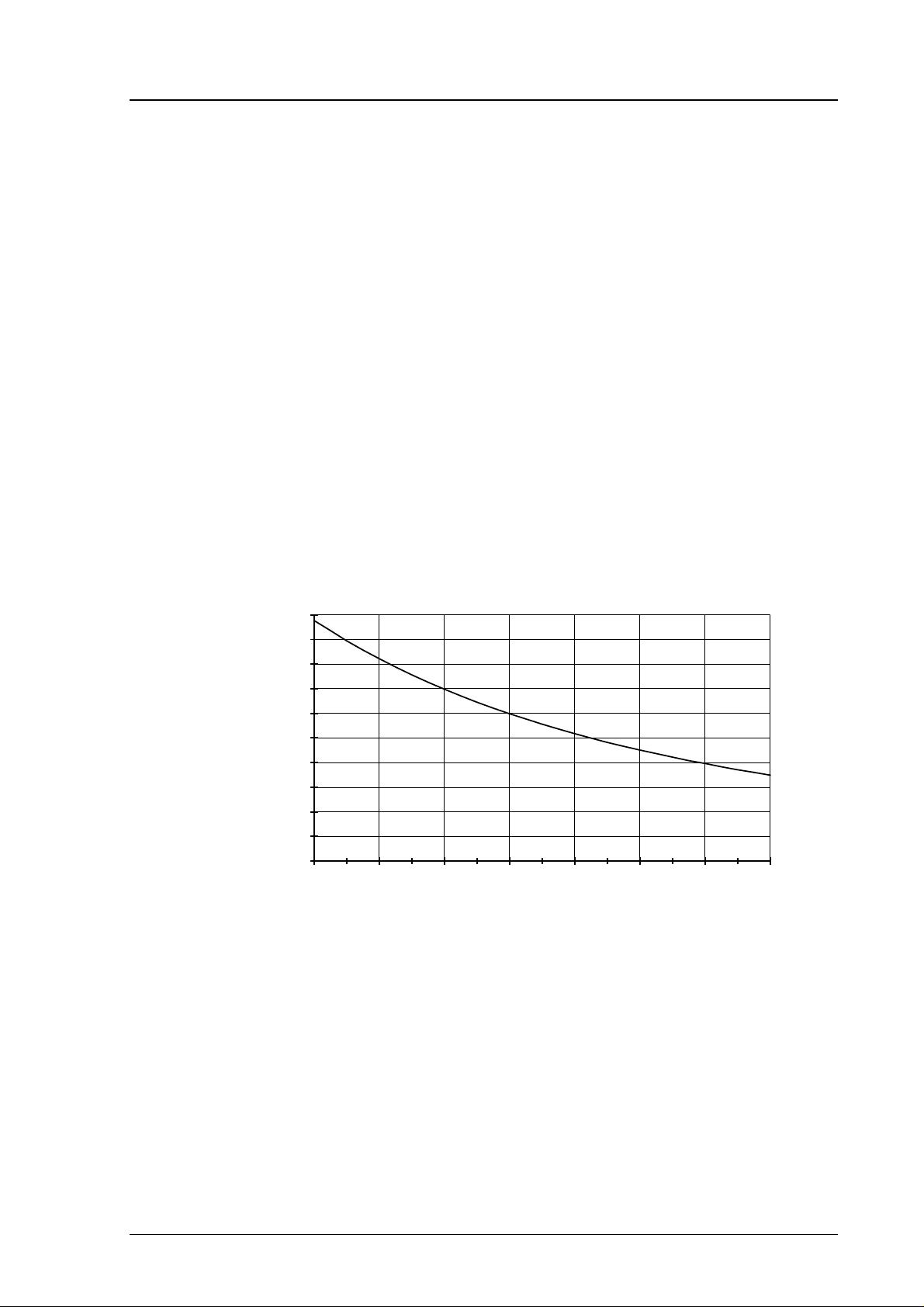

2. TO BE NOTED WHEN MEASURING HUMIDITY

In the measurement of humidity and especially in calibration, it is essential

that temperature equilibrium is reached. Even a small difference in

temperature between the measured object and the sensor causes an error. If the

temperature is +20 °C (+68 °F) and the relative humidity 50 %RH, a

difference of ±1 °C between the measured object and the sensor causes an

error of ±3 %RH. When the humidity is 90 %RH, the corresponding error is

±6 %RH.

The error is at its greatest when the sensor is colder or warmer than the surroundings and the humidity is high. A temperature difference of a few degrees

can cause water to condense on the sensor surface. In an unventilated space

evaporation may take hours; good ventilation accelerates evaporation. The

HUMICAP sensor starts to function normally as soon as the water has evaporated. If the condensed water is contaminated, the life span of the sensor may

shorten and calibration may change.

10

9

8

7

6

5

4

dRH (%RH)

3

2

1

0

-40-200 20406080100

Temperature (°C)

Fig. 2.1 Measurement error at 100 %RH when the difference between the

ambient and sensor temperature is 1 °C

1997-11-25 3

Page 10

HMP260 SERIES

Operating Manual HMP260-U017en-1.5

3. INSTALLATION

3.1. Selecting the place of installation

The transmitters should be installed in a place that gives a true picture of the

environment or process and is as clean as possible. Air should circulate freely

around the sensor. A rapid air flow is recommended; it ensures that the sensor

head and the ambient air are at the same temperat ure.

Install the transmitter in a place where no cold or hot spot can develop. When

the sensor head is installed in a duct or a process channel where the

temperature is different from the ambient temperature, insulate the point of

entry; this is particularly important if the transmitter is installed with the

sensor head pointing downwards. Installing the sensor head vertically is not

recommended. An uninsulated installation could lead to condensation in the

sensor head and even when no condensation occurs, the resultant air flow may

change the temperature near the sensor and distort the readings.

Install the sensor head in the process wherever possible; avoid sample flows

where the gas temperature can drop below dewpoint temperature. Install the

sensor head transversely against the direction of the process flow.

In duct or channel installations drill a hole ready for a reference meter. Plug

the reference hole tightly.

The transmitters are associated electrical apparatuses: the electronics housing

must be in the safe area and only the sensor head and its cable may go into the

hazardous area.

Install the electronics housing away from possible steams escaping from the

process.

NOTE

To ensure an IP 65 class protection:

1. Always mount the transmitter housing with the cable

bushings pointing downwards.

2. Make sure that the connection cable has the right

thickness (∅ 7...10 mm) and that the cable bushing

is carefully tightened.

3. Pay always special attention to closing the

transmitter cover carefully and remember to tighten

all four screws.

4 1997-11-25

Page 11

HMP260 SERIES

HMP260-U017en-1.5 Operating Manual

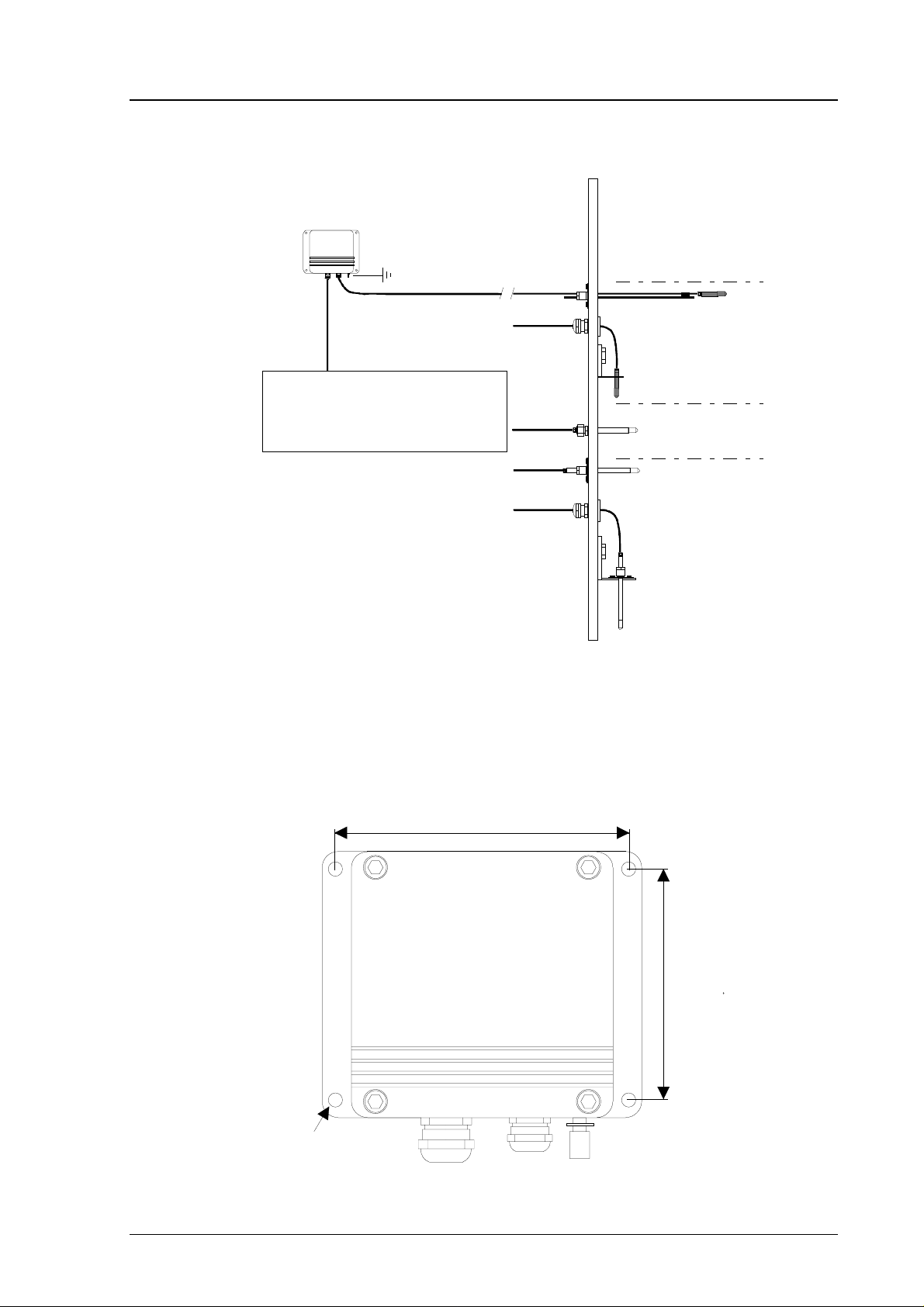

3.2. Mounting

HMP263/264/265

(EEx ia) IIC

Supply voltage 24 VDC

Analog outputs (mA/V)

RS 232C/ RS 485 /digital current loop

SAFE AREA

HAZARDOUS AREA

EEx ia IIC T3/T4

HMP263 sensor head

HMP264 sensor head

for pressurized spaces

HMP265 sensor head

.

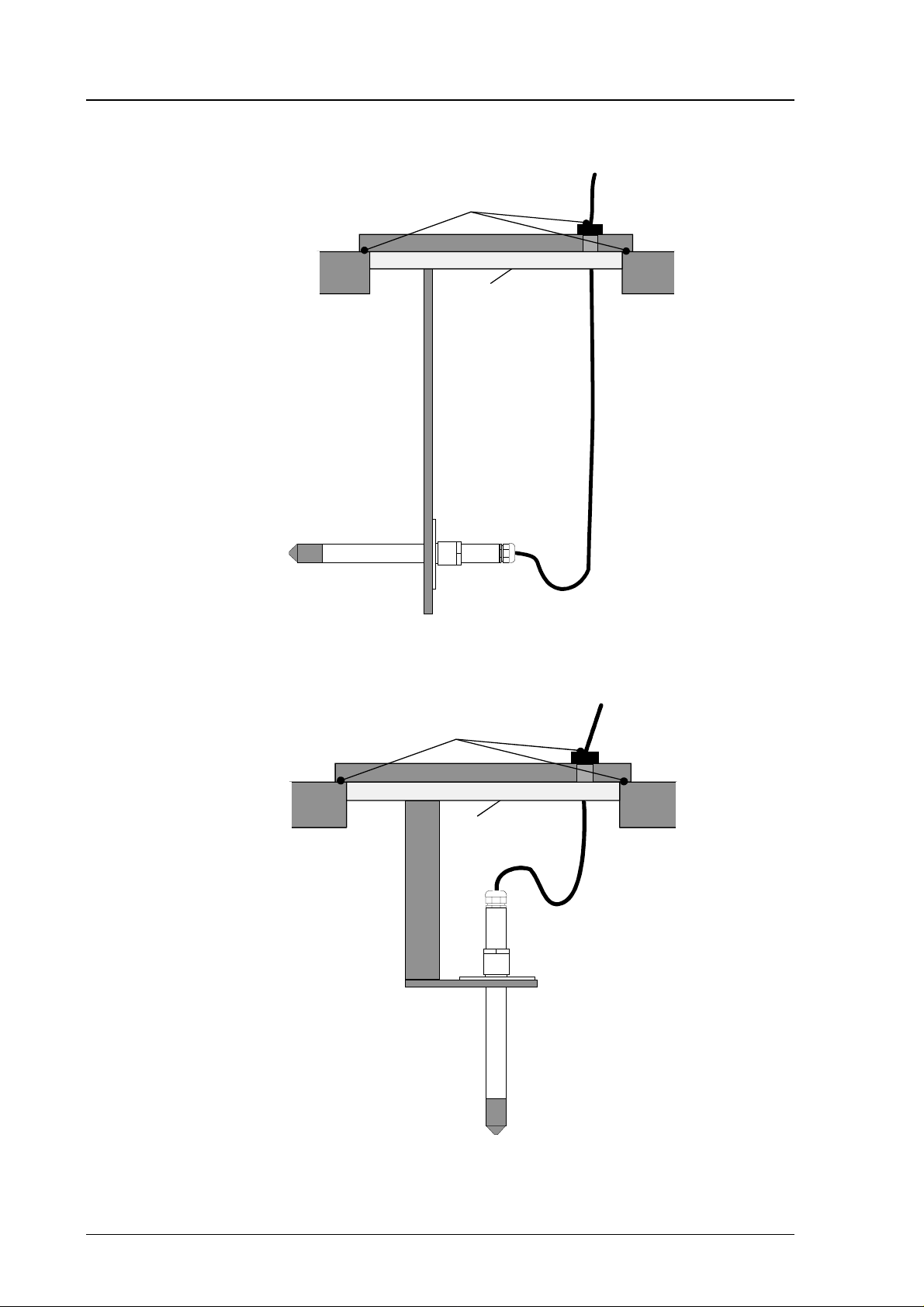

Fig. 3.1 Examples of sensor head mounting

The lead-throughs must be sealed properly to avoid air flowing in or out from

the channel. The sealings must fulfil EEx requirements. When using the

support bar with the HMP263, the lead-through piece must be sealed e.g. with

silicon. See also Appendix 8.

133

104

Ø 6.5

Fig. 3.1 Mounting holes in the HMP260 transmitter housings

1997-11-25 5

Page 12

HMP260 SERIES

Operating Manual HMP260-U017en-1.5

The transmitters should be mounted with the sensor head horizontally; this

way, any water condensing on the tube cannot flow onto the sensors. When

there is no alternative but to install the sensor head in the process vertically,

the point of entry must be carefully insulated. The cable must also be allowed

to hang loosely as in Figure 3.6; this prevents any condensed water from

running onto the sensor head along the cable.

If the process temperature is much higher than that of the environment, the

whole sensor head and preferably part of the cable must be inside the process.

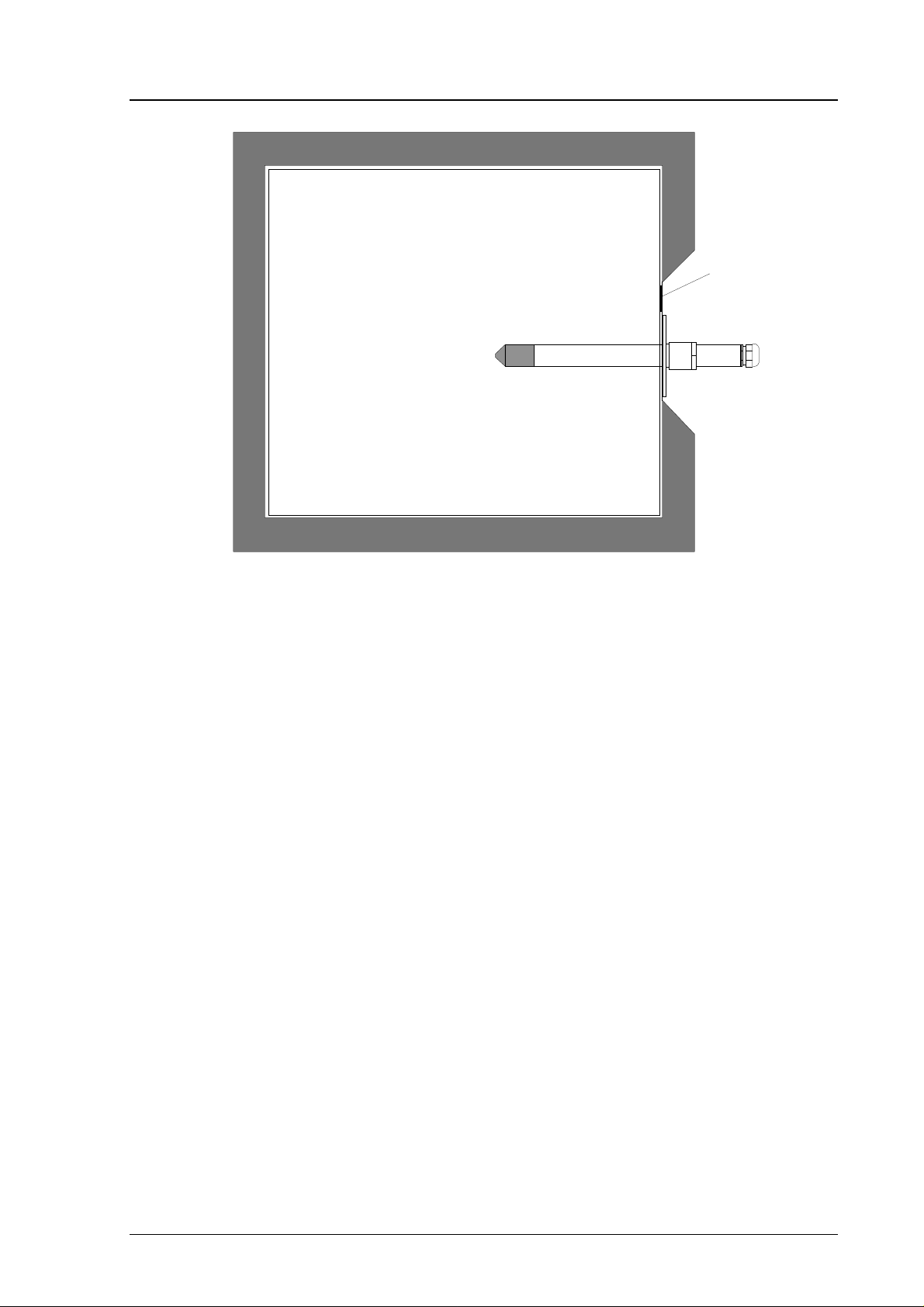

When mounted on the side of a duct or channel, the sensor head must be inserted from the side (see Figure 3.7). If this is not possible and the sensor head

must be inserted from the top, the point of entry must be carefully insulated.

NOTE

During installation the protective cover of the

protective unit must not be opened and the sensor head

must not be unsoldered from and then resoldered to the

protective unit of the transmitter. This procedure is not

allowed for the user. Vaisala is not responsible for any

damages caused by incorrect use.

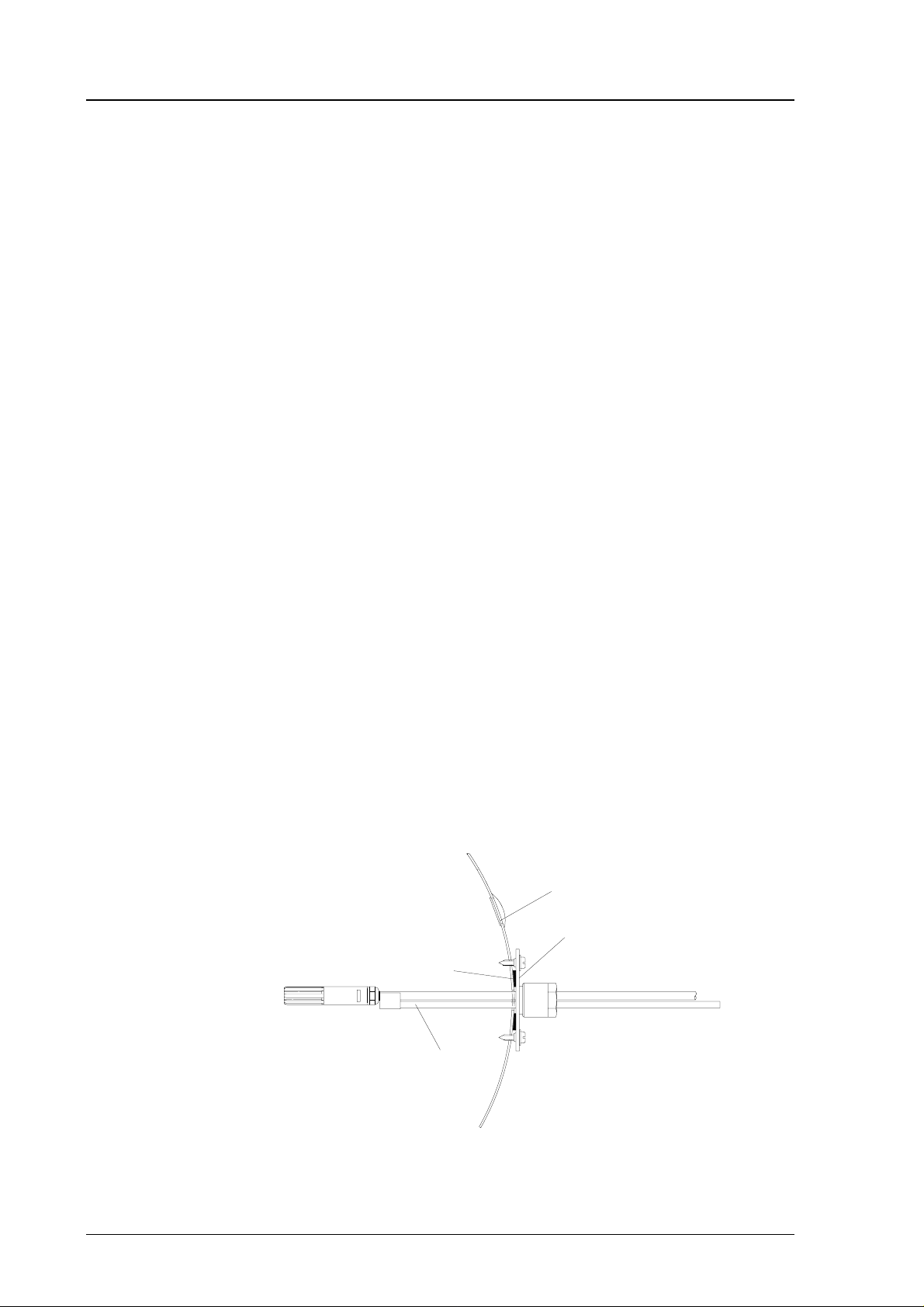

3.2.1. HMP263 transmitter

The HMP263 can be installed in ducts and channels with the help of the installation kit available; the kit consists of a flange, a supporting bar for the

sensor head cable and screws for attaching the flange to the wall of a duct.

With the help of the installation kit the distance between the sensor head and

the channel wall can be easily adjusted. The range of adjustment is 100...320

mm; the distance is measured from the tip of the sensor head to the flange.

duct wall

a plugged hole for reference

measurements

flange

sealing

supporting bar

HAZARDOUS

AREA

SAFE AREA

Fig. 3.2 Installing the sensor head of the HMP263 in a channel with the

help of flange and supporting bar

6 1997-11-25

Page 13

HMP260 SERIES

when a bushing is used, its size is

selected according to the diameter

of the sensor head; the diameter

of the cable increased by using

e.g. tape at the bushing

to be sealed

(loop type)

clamp

mounting the

sensor head

on a support

HAZARDOUS

AREA

SAFE AREA

HMP260-U017en-1.5 Operating Manual

NOTE

When using the support bar the lead-through piece and

the space between the duct wall and the flange must be

sealed e.g. with silicon. The sealings must fulfil EEx

requirements.

The sensor head can also be installed vertically.

Fig. 3.3 Vertical installation of the HMP263 sensor head

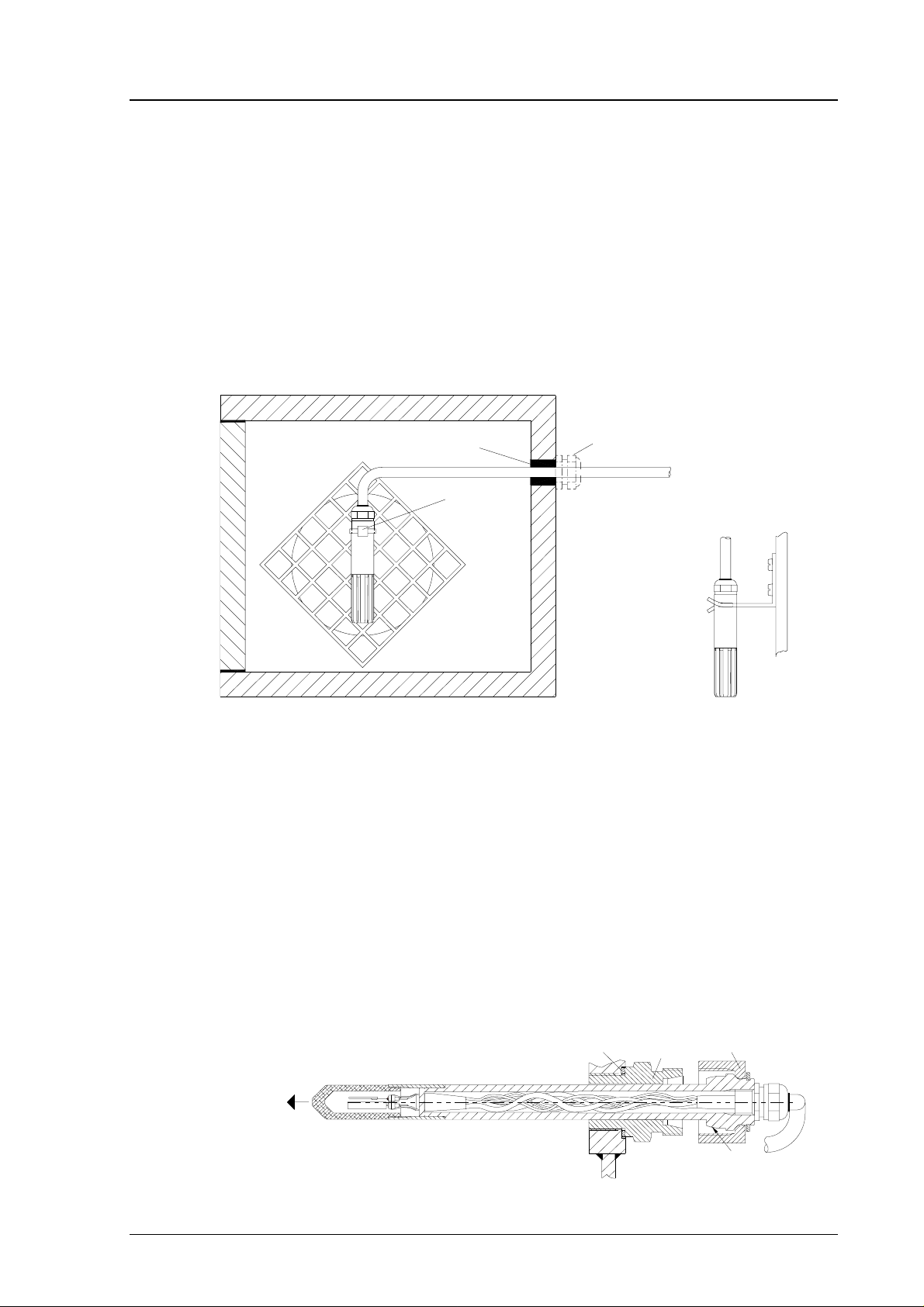

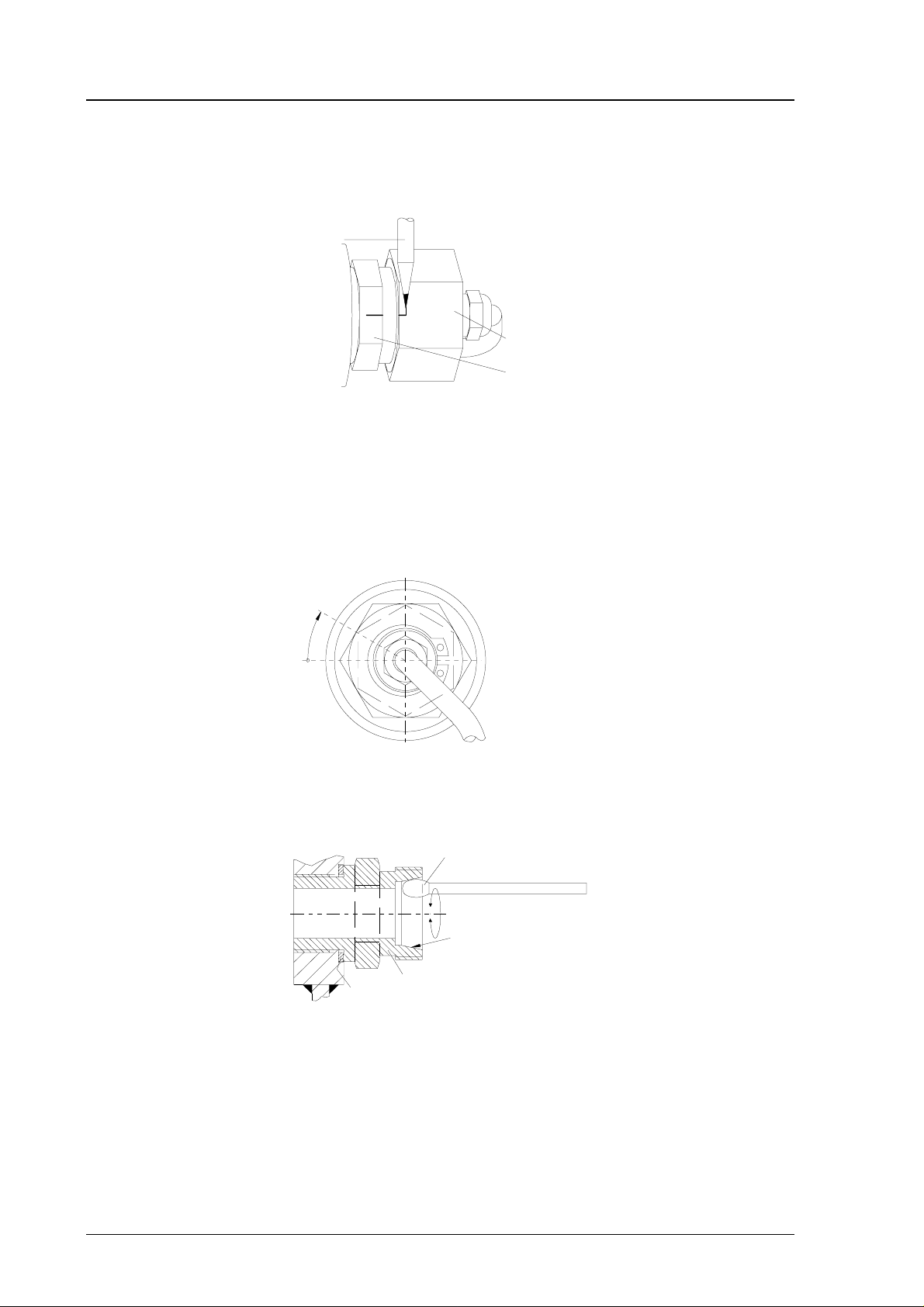

3.2.2. HMP264 transmitter

The HMP264 is supplied with a nut, a fitting body and a sealing washer.

During handling the fitting body and the nut should remain in place on the

body of the sensor head to prevent damage to the highly polished surface.

To achieve a leak-tight assembly:

1. Remove the fitting body from the nut and the sensor head.

2. Fasten the fitting body to the chamber wall. Tighten the fitting body

into the threaded sleeve with a torque spanner. The tightening torque

is 150 ±10 Nm.

HAZARDOUS AREA

sealing washer

fitting body

nut

tightening cone

SAFE AREA

1997-11-25 7

Page 14

HMP260 SERIES

Operating Manual HMP260-U017en-1.5

3. Insert the body of the sensor head into the fitting body and screw the

nut manually to the fitting body until the connection feels tight.

4. Mark both the fitting body and the nut hex.

A pen

nut

fitting body

5. Tighten the nut a further 30° (1/12 turn) or if you have a torque spanner tighten it with a torque of 80 ±10 Nm.

NOTE

After detachment the nut must be tightened without

increased effort.

30°

6. The tightening cone of the fitting body has to be cleaned and greased

after each tenth detachment. Use high-vacuum grease (Down Corning,

Europe) or a similar grease.

clean cotton stick

tightening cone

sealing

washer

fitting body

The sealing washer has to be changed every time the fitting body is

detached.

8 1997-11-25

Page 15

HMP260 SERIES

HMP260-U017en-1.5 Operating Manual

Fasten by threaded sleeve

Sealing by Metal sealing washer DIN 7603

M22x1.5

threaded sleeve M22x1.5/Ø40 x15

sheet metal

Fasten by Nut DIN 80705

Check the thickness of the sheet metal

according to the pressure of the chamber

nut DIN 80705-M22x1.5 (AISI 316)

tightening torque=150 Nm ±10 Nm

NPT Conical pipe threaded connection

ANSI/ASME B1.20.1-1983

sealing by anaerobic pipe thread seal

(SWAK, Cajon Company) or PTFE

(teflon) tape

1/2-14 NPT

(boring)

Ø22+0.3

s=3...6mm

sealing by Metal sealing washer

DIN 7603

fitting body. VAISALA code 17225

(AISI 316Ti). Body hex = 27 mm

tightening torque=150 Nm ±10 Nm

Fig. 3.4 Some examples on the installation of the HMP264 sensor head

1997-11-25 9

Page 16

HMP260 SERIES

Operating Manual HMP260-U017en-1.5

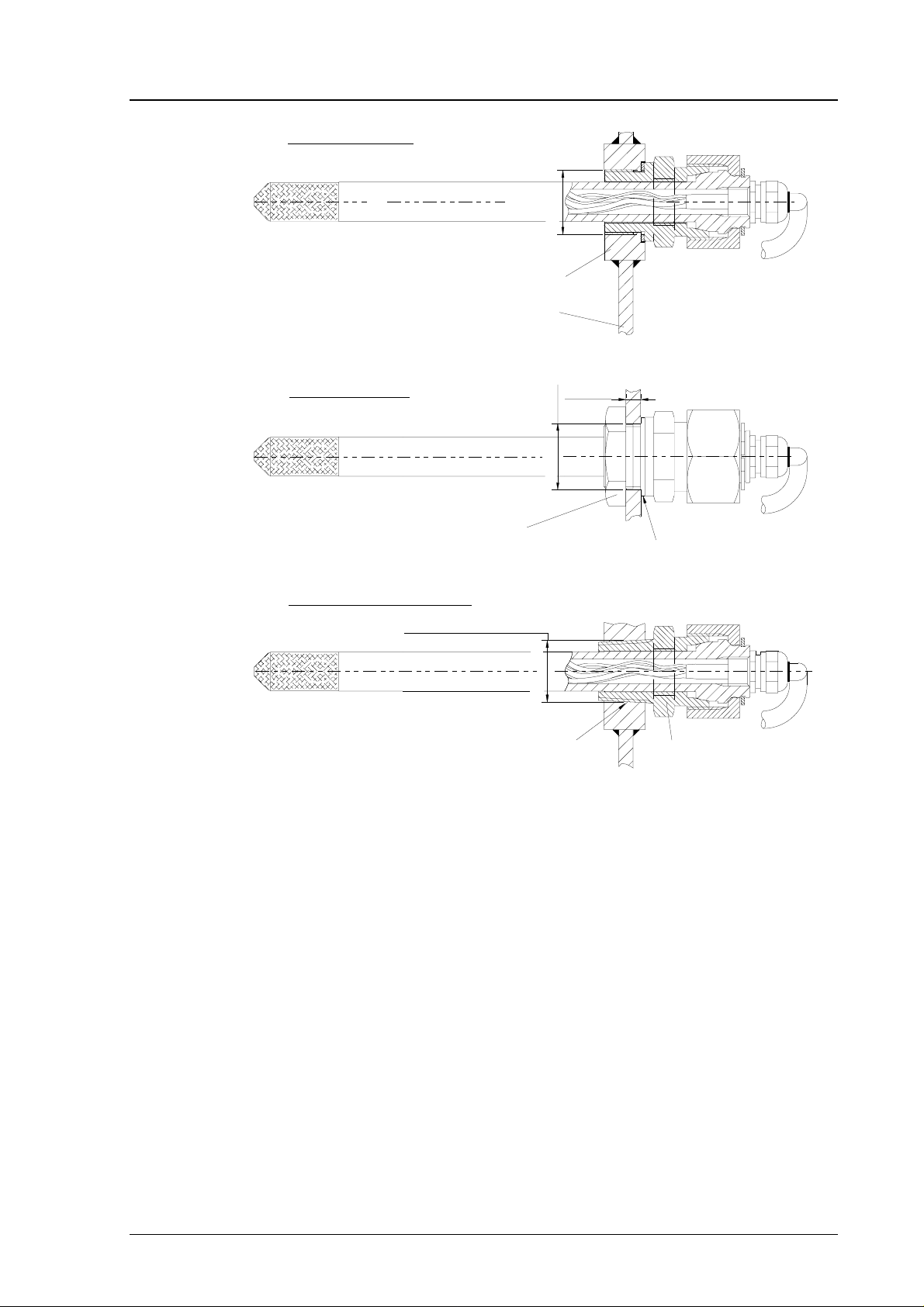

3.2.3. HMP265 transmitter

SAFE AREA

to be sealed

to be insulated

HAZARDOUS AREA

Fig. 3.5 Installing a transmitter in a process with the sensor head hori-

zontally

SAFE AREA

to be sealed

to be insulated

HAZARDOUS AREA

Fig. 3.6 Installing a transmitter in a process with the sensor head down-

wards (not recommended)

10 1997-11-25

Page 17

HMP260 SERIES

HMP260-U017en-1.5 Operating Manual

a plugged hole

HAZARDOUS AREA

for an Exi-approve d

reference meter

SAFE AREA

Fig. 3.7 Mounting the sensor head on a duct or channel

When the sensor head is installed in a duct or a channel, the temperature

difference of the air inside and outside the duct must be small as the sensor

head conducts heat.

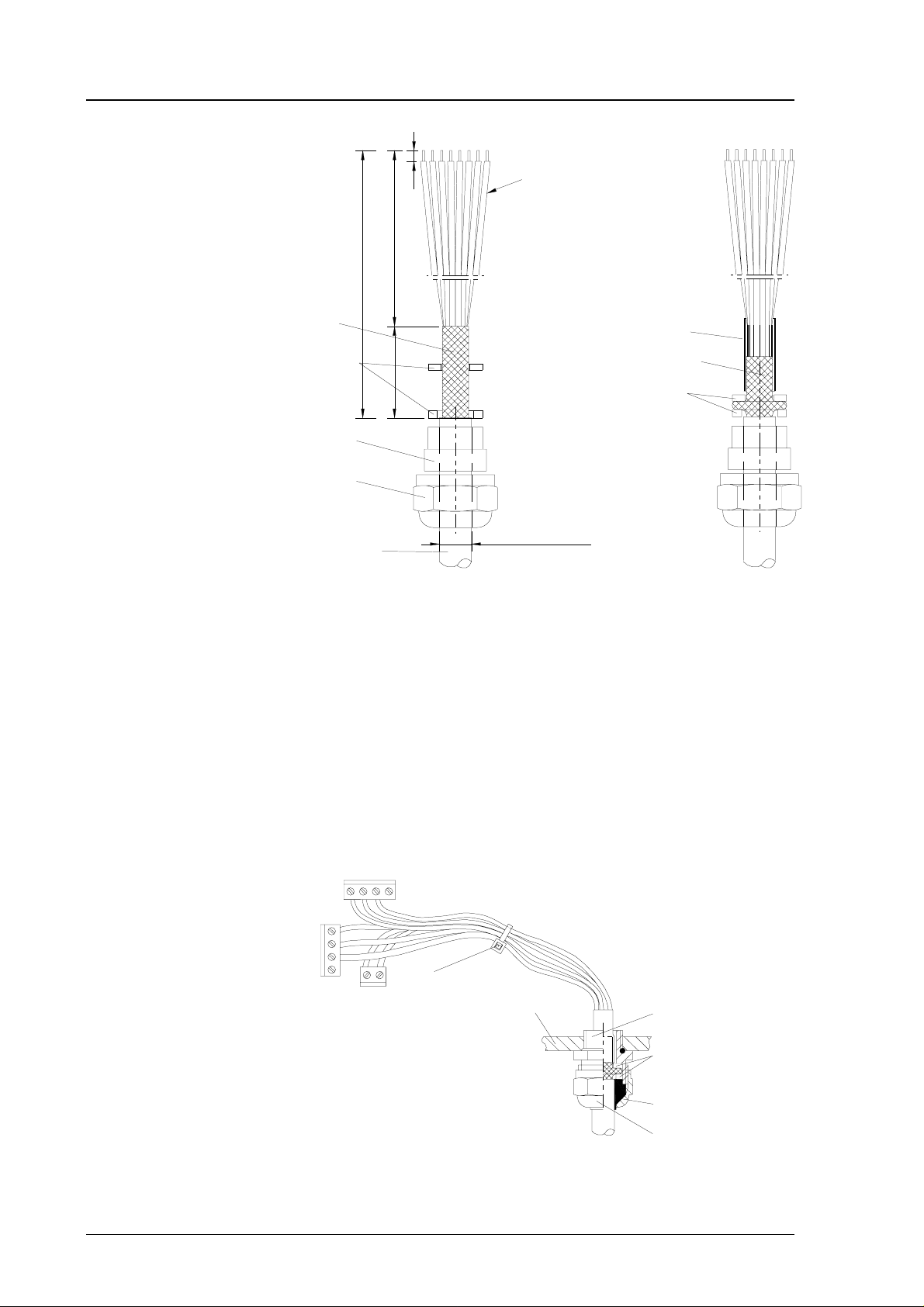

3.3. Grounding

A single electrical cable with a screen and three to ten wires is recommended

for power and analogue output/serial bus connections. The cable diameter

should be 7...10 mm.

The screen of the electrical cable must be grounded properly to achieve best

possible EMC performance. Recommended cable shield is done in the cable

gland as shown below.

• remove the brass disks, rubber ring and nut from the transmitter

housing

• strip 165 mm of the cable insulation, but leave 25 mm of the braid

visible

• slip the nut and rubber ring over the cable insulation

• slip the brass disk that has the bigger hole in it over the braid so that

it rests against the cable insulation

• slip the other brass disk over the wires to the middle of the braid

1997-11-25 11

Page 18

HMP260 SERIES

Operating Manual HMP260-U017en-1.5

braid

rubber

ring

165

brass

disks

nut

cable

140

25

3

flexible wires 0.5 mm

(AWG 20), stranded wires

recommended

D = Ø 7...10

(If the cable diameter is less

than 7mm, use a shrinking

tube or an adhesive tape)

2

shielding tube

braid

brass disks

• push back the braid and press it between the two brass disks to

achieve a full 360° grounding; the fold between the disks should have

the same diameter as the brass disks

• secure the braid with a shielding tube

• insert the wires into the transmitter housing through the gland.

• tighten the nut

• connect the wires into the screw terminals and fasten a cable tie

around the wires

cable tie

transmitter housing

gland

brass disks

rubber ring

nut

12 1997-11-25

Page 19

HMP260 SERIES

HMP260-U017en-1.5 Operating Manual

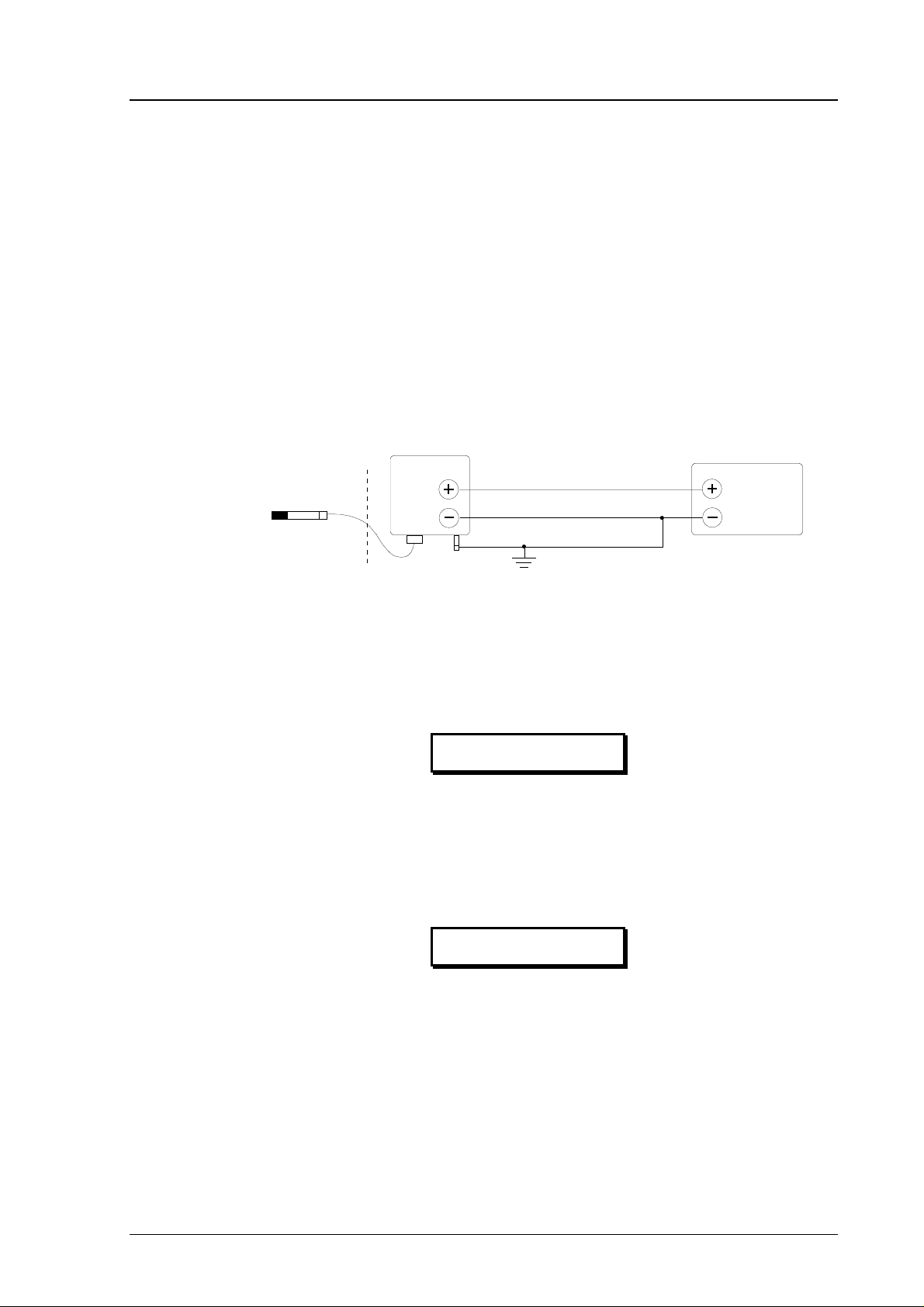

NOTE

When the cable is grounded as above, the metallic parts

of the sensor head, the shield of its cable, the

transmitter housing and the shield of the signal cable to

external system are all connected to each other. The

transmitter housing must be grounded via the

grounding terminal located at the lower right hand

corner of the housing. In addition to this the

negative terminal of the power supply must be

grounded. If these groundings have not been made

correctly, the transmitter does not work.

HMP26x

Hazardous

area

Power

supply

The electrical safety of the grounding must comply with the EN 50014/13

standard. When compliance with Factory Mutual Standards is required, the

grounding must comply with ANSI/ISA RP 12.6 and ANSI/NFPA 70.

Always use the grounding terminal to connect the

transmitter to safety ground.

3.4. Electrical connections

All the component boards are grounded via the housing

frame. Make sure that the fixing screws of the boards

are firmly tightened before connecting the cables.

WARNING

CAUTION

1997-11-25 13

Page 20

HMP260 SERIES

P

Operating Manual HMP260-U017en-1.5

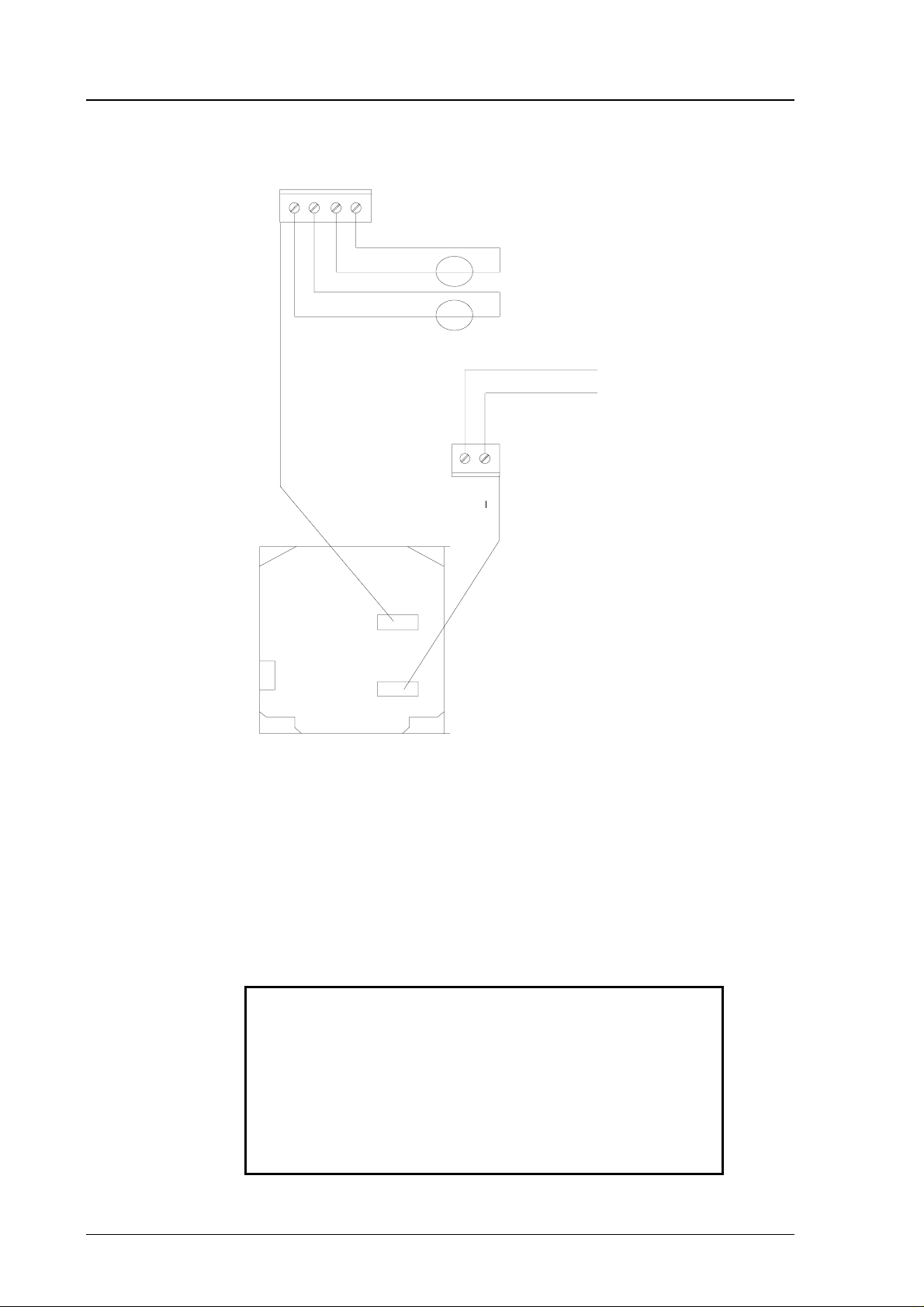

CH1- and CH2- are connected

CH1+

CH1-

CH2+

together internally

CH2-

X2

X1

+-

V

mA

+-

V

mA

24 V +

CURRENT/VOLTAGE

OUTPUTS

EXTERNAL

POWER SUP

Do not use power supply

ground (-) as output signal

ground

OPENED COVER OF THE HMP260

Fig. 3.8 Electrical connections

Power supply 24 VDC

Output signals 0...20 mA

4...20 mA

0...1 V

0...5 V

0...10 V

IF THE CONNECTION INSTRUCTIONS ARE NOT

CAREFULLY FOLLOWED OR THE COMPONENTS

IN THE PROTECTION UNIT ARE MODIFIED OR

TAMPERED WITH, THE DEVICE DOES NOT MEET

THE REQUIREMENTS OF EXi CLASSIFICATION.

VAISALA IS NOT RESPONSIBLE FOR ANY DAMAGES CAUSED BY INCORRECT USE.

14 1997-11-25

Page 21

HMP260 SERIES

HMP260-U017en-1.5 Operating Manual

4. COMMISSIONING

When the HMP260 transmitters leave the factory, their measurement ranges

and output signals have already been selected. The user can subsequently

change the measurement units between metric and non-metric and select and

scale the output signals with software functions, see Chapter 5 Commands and

Appendix 1.

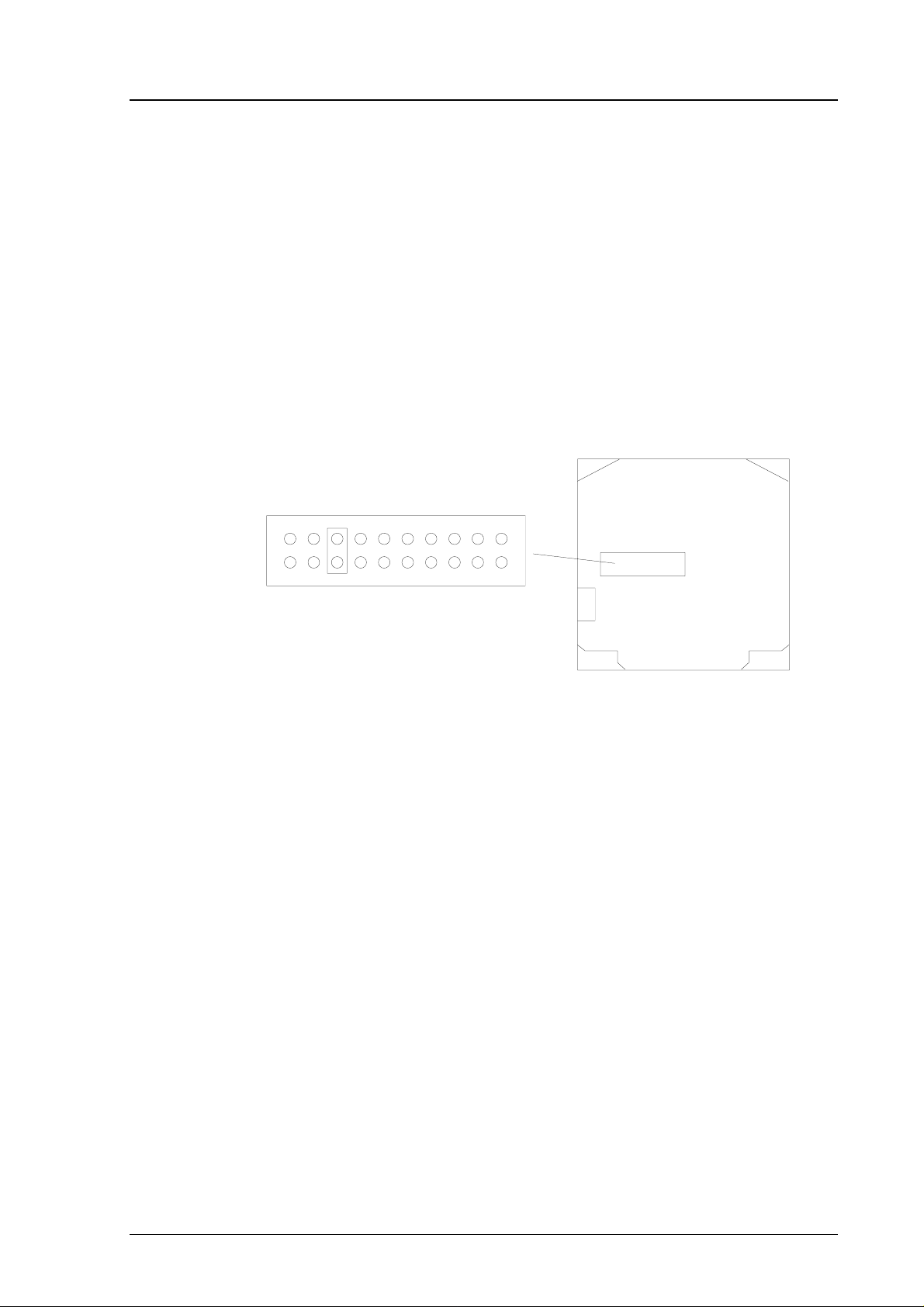

4.1. Security lock jumper

Before the settings can be changed, the security lock jumper in connector X15

must be removed (see Fig. 4.1). The security lock jumper makes it impossible

to change the transmitter settings by mistake.

CHANGE OF SETTINGS

DISABLED

Fig. 4.1 Location of the security lock jumper

When the security lock jumper is connected, some commands are not avail able

(see Chapter 5 Commands).

Should the application require variables that are not included in the

configuration of the transmitter, the user is invited to contact Vaisala or a

Vaisala representative.

4.2 Selecting the analogue outputs

The HMP260 transmitters can be ordered ready with the current or voltage

outputs required. If the outputs need to be changed, move the jumpers in connector X15 into positions as shown in the Figure 4.2.

X15

1997-11-25 15

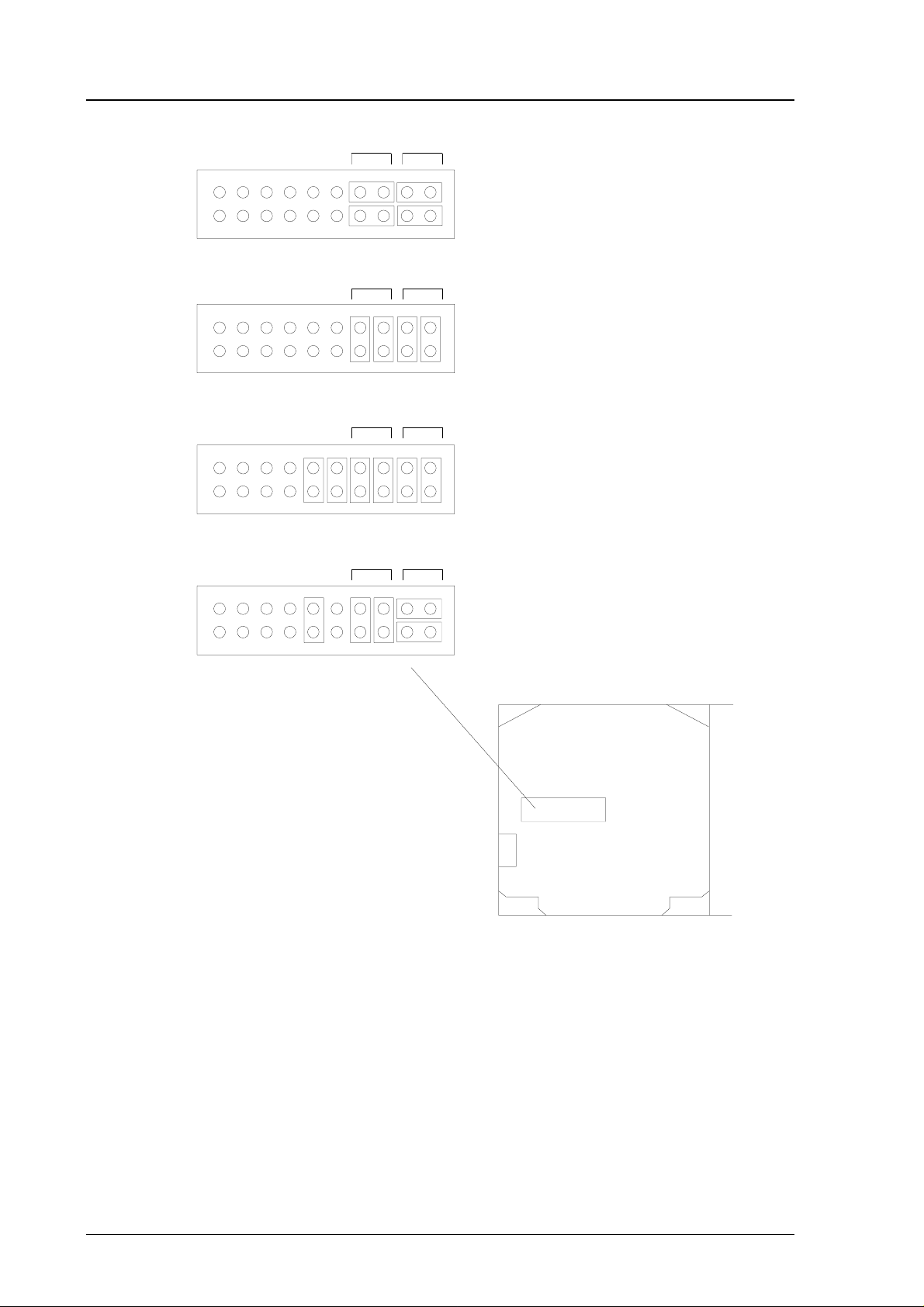

Page 22

HMP260 SERIES

Operating Manual HMP260-U017en-1.5

CH1

CH1

CH1

CH1

CH1

CH2

CH1

CH2

CH1

CH2

CH1

CH2

CH2

CURRENT OUTPUTS

0 ... 20 / 4 ... 20 mA

CH2

VOLTAGE OUTPUTS

0 ... 5 V / 0 ... 10 V

CH2

VOLTAGE OUTPUTS

0 ... 1 V

CH2

CH1 0 ... 1 VOLTAGE OUTPUT

CH2 CURRENT OUTPUT

X15

OPENED COVER OF THE HMP260

Fig. 4.2 Selecting the analogue outputs with jumpers

The software has to be informed which outputs are in use. This is done either

through the serial interface or the menus on local display when one is in use.

The serial command is AMODE and the display/keypad command "Mode

Analog outputs Mode" (see Chapter 5 Commands). If the outputs need to

be scaled, see serial command ASCL and the display command "Mode

Analog outputs Scale".

All the jumpers are used only with the 0...1 V outputs. When other outputs are

in use, the spare jumpers are kept in connector X55.

16 1997-11-25

Page 23

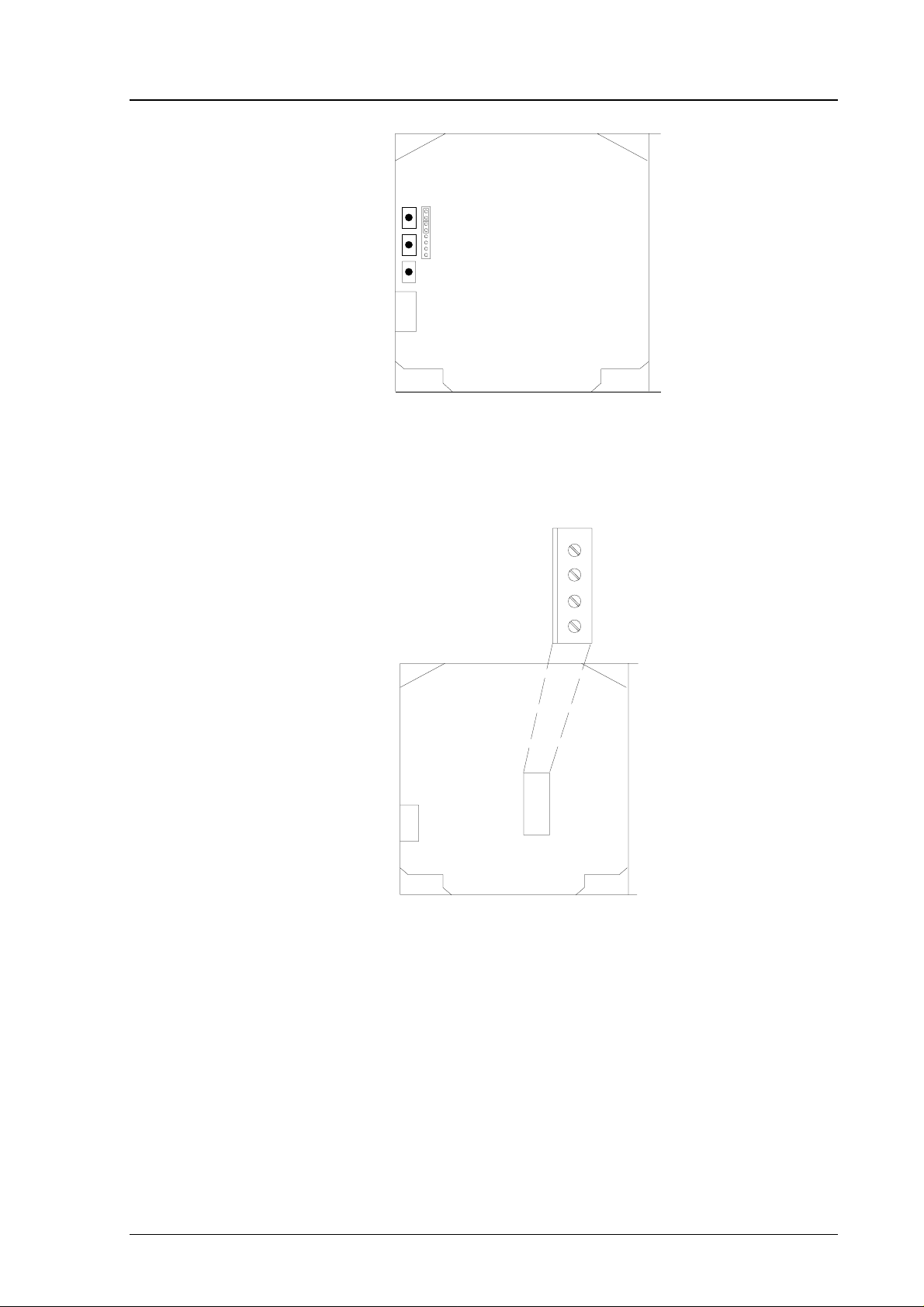

HMP260 SERIES

HMP260-U017en-1.5 Operating Manual

X55

spare jumpers

Fig. 4.3 Spare j umpers

4.3 Connecting the RS 232C serial bus

RX

GND

TX

NC

X6

Fig. 4.4 Serial bus connections

To connect a PC to the HMP260 transmitters via the RS 232C serial bus, one

of the following cables is required. The type of cable depends on the terminal

and the connector type.

1997-11-25 17

Page 24

HMP260 SERIES

3

Operating Manual HMP260-U017en-1.5

RXD

RXD

RXD

TXD

TXD

TXD

TX

GND

RX

TX

GND

RX

TX

GND

RX

HMP 2

PC

TERMINAL

D9S

D25S

D25P

2

5

3

4

6

7

8

3

7

2

5

6

8

20

3

7

2

Fig. 4.5 Connection of cables

When the serial bus has been connected between the PC and the transmitter,

the PC is switched on. When using a PC, a terminal emulation programme

(e.g. Procomm Plus, Datastorm or Windows terminal) is started.

The factory settings for data transfer are:

• 4800 baud

• even parity

• 7 data bits

• 1 stop bit

• full duplex

NOTE

When the serial bus settings are changed, the transmitter has to be reset before the new settings become effective.

The processor does not allow the following combinations:

• no parity, 7 data bits, 1 stop bit: if this combination is given the

HMP260 programme will change the number of stop bits to 2

• even or odd parity, 8 data bits, 2 stop bits: if this combination is given

the programme changes the number of stop bits to 1

Refer to the manuals of the PC and the terminal emulation programme when

giving serial settings.

18 1997-11-25

Page 25

HMP260 SERIES

X

HMP260-U017en-1.5 Operating Manual

The RS 232C screw terminal cannot be used if an RS 485/422 serial module

or a digital current loop module is used. See appendices 3 and 4 on how to

install and operate these modules.

In calibrating or changing the settings of the transmitter it can be more convenient to use the connector X17, if connector X6 is already in use. This connector, however, transfers only RS 232 signals. If an RS 485/422 serial port

module or a digital current loop module has been installed, it has to be

removed before communicating through the X17 connector.

RX GND T

X17

Fig. 4.6 Location and connections of connector X17

4.3.1 Reverting to factory settings of the serial port

If the serial port settings are not known, no commands can be given via the

serial interface. The settings can be reverted to the factory settings by inserting

a jumper in connector X16. The jumper must be i nserted wh en the pow er is

on!

cover of the protection unit

X16

Fig. 4.7 Forcing the serial port settings back to factory settings

When the jumper is inserted the serial line factory settings become valid, but

only temporarily. The transmitter must be given new settings; otherwise

the transmitter uses the old, unknown settings after power-up. When the

new settings have been given, the transmitter must be reset. Note that the

1997-11-25 19

Page 26

HMP260 SERIES

Operating Manual HMP260-U017en-1.5

jumper must be removed before the transmitter is reset. If the jumper is in

place when power i s turned on, the tran smitter does not w ork.

After jumper insertion the transmitter is in STOP mode, ready to receive

commands.

The same method is used when the transmitter is in POLL mode and the user

has forgotten its address.

NOTE

Inserting a jumper in any other place in connector X16

voids the guarantee of the transmitter.

20 1997-11-25

Page 27

HMP260 SERIES

HMP260-U017en-1.5 Operating Manual

5. COMMANDS

As the HMP260 transmitters are microprocessor based devices, their

configuration can be set to correspond to the specific needs of the user. This is

done through commands, either utilizing the menus on the local display or by

giving commands through the serial interface (see Appendix 1). Most often

the commands are used to change the settings of the two analogue channels.

A limited range of commands can be given by using the three press switches up, down and enter - inside the transmitter housing. Four LEDs indicate the

command given with the up and down switches. The switches and LEDs are in

all HMP260 transmitters. LED commands can be used to calibrate the transmitters (both humidity and temperature) or to calibrate the analogue outputs.

A full range of commands can be given through the display/keypad or through

the RS 232C serial bus. The commands can be used e.g. to select and scale the

outputs, to calibrate the humidity and temperature channels as well as the

analogue outputs and to set the serial interface.

5.1 Commands and security lock jumper

In order to prevent any tampering with the transmitter settings, the transmitters

can not be calibrated, the analogue outputs set or the analogue output quantities selected or scaled unless the security lock jumper has been disconnected.

The commands involved are:

• all LED commands

• display/keypad commands:

Cali RH cal T cal

Analog outputs

Mode Analog outputs Mode

• serial commands:

CRH, CT, FCRH, ACAL; AMODE, ASEL, ASCL

In the following, the description of these functions is preceded with a reminder of the security lock jumper:

Disconnect the security lock jumper!

Scale

1997-11-25 21

Page 28

HMP260 SERIES

Operating Manual HMP260-U017en-1.5

5.2 LED commands

NOTE

If the transmitter has a display/keypad cover, the LED

commands cannot be used.

LED commands can be used to operate the transmitters in the field. These

commands can be used in humidity and temperature calibration and calibration

of the analogue outputs.

Open the housing and press any one of the three press switches. The LEDs

will light up for 2...3 seconds.

UP

DOWN

ENT

press switches

LEDs

Fig. 5.1 Location of press switches and LEDs

Use the up and down switches (marked with arrows on the printed board) to

find the desired command code and acknowledge it with the ENT switch. The

command codes are (l = lit, ¡ = dark):

¡¡¡¡ (0) return to normal state

¡¡¡l (1) relative humidity calibration

¡¡l¡ (2) tem perature cali bration

¡¡ll (3) calibration of analogue outputs

l¡¡¡ (8) relative humidity calibration after sensor change

22 1997-11-25

Page 29

HMP260 SERIES

HMP260-U017en-1.5 Operating Manual

5.3 Display/keypad commands

5.3.1 Display mode

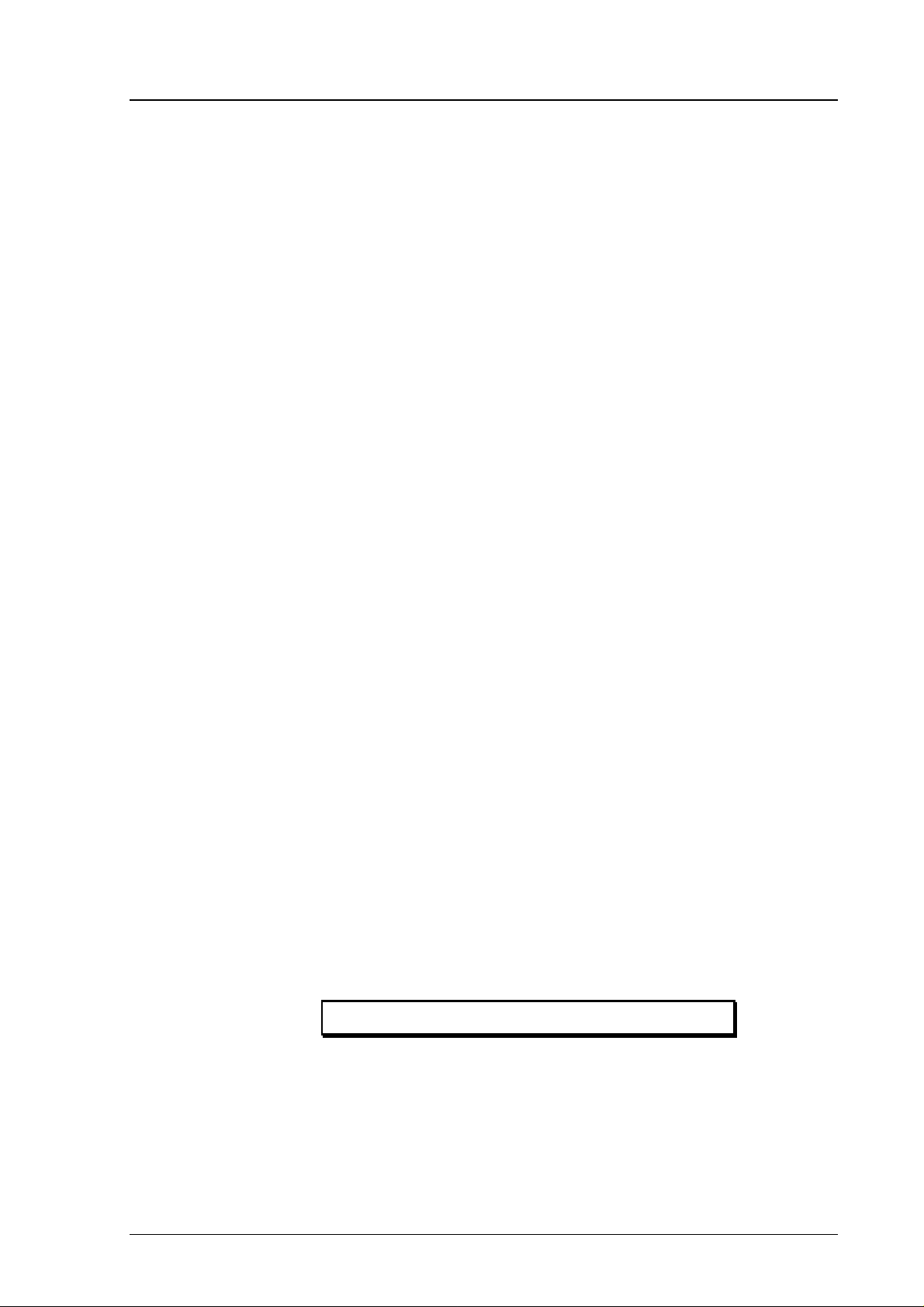

In the display mode the transmitters output measurements on the display; different quantities can be scrolled with the arrow keys according to the variables

selected when ordering the transmitter. After reset the transmitters are always

in the display mode.

The display also shows error messages and alarms if they occur.

5.3.2 Command mode

Press the CL key to enter the command mode. The first display is the main

menu:

The commands can be scrolled with the arrow keys. The currently active

commands flashes; a command is selected with the ENT key. When a menu is

displayed, either the first command or the currently valid setting flashes. The

CL key takes the transmitter back to the display mode.

5.3.3 Entering numbers

When the transmitter needs numbers to be entered into the programme (e.g.

when scaling or setting the analogue outputs, in calibration or when giving the

transmitter an address), the field is either empty or the currently valid figure is

displayed. Any previously given value is deleted with the CL key.

When the field is empty, a cursor blinks at the right side of the display.

Pressing the arrow keys brings either a blank ' ', a comma ',', a dash '-', a full

stop '.' or a number from '0' to '9' on the display. The right character is selected

with ENT; after that the number or numbers move left one step. Entering

1997-11-25 23

Page 30

HMP260 SERIES

Operating Manual HMP260-U017en-1.5

numbers is ended with selecting a blank ' ' and pressing ENT. The last character entered can be deleted with CL. If CL or ENT key is pressed when the field

is empty, the programme returns to the previous display.

With some commands (e.g. calibration) the figures are changed using the arrow keys. When an arrow key is pressed continuously for a while, the numbers

start changing at an increasing rate.

5.3.4 Analogue output commands

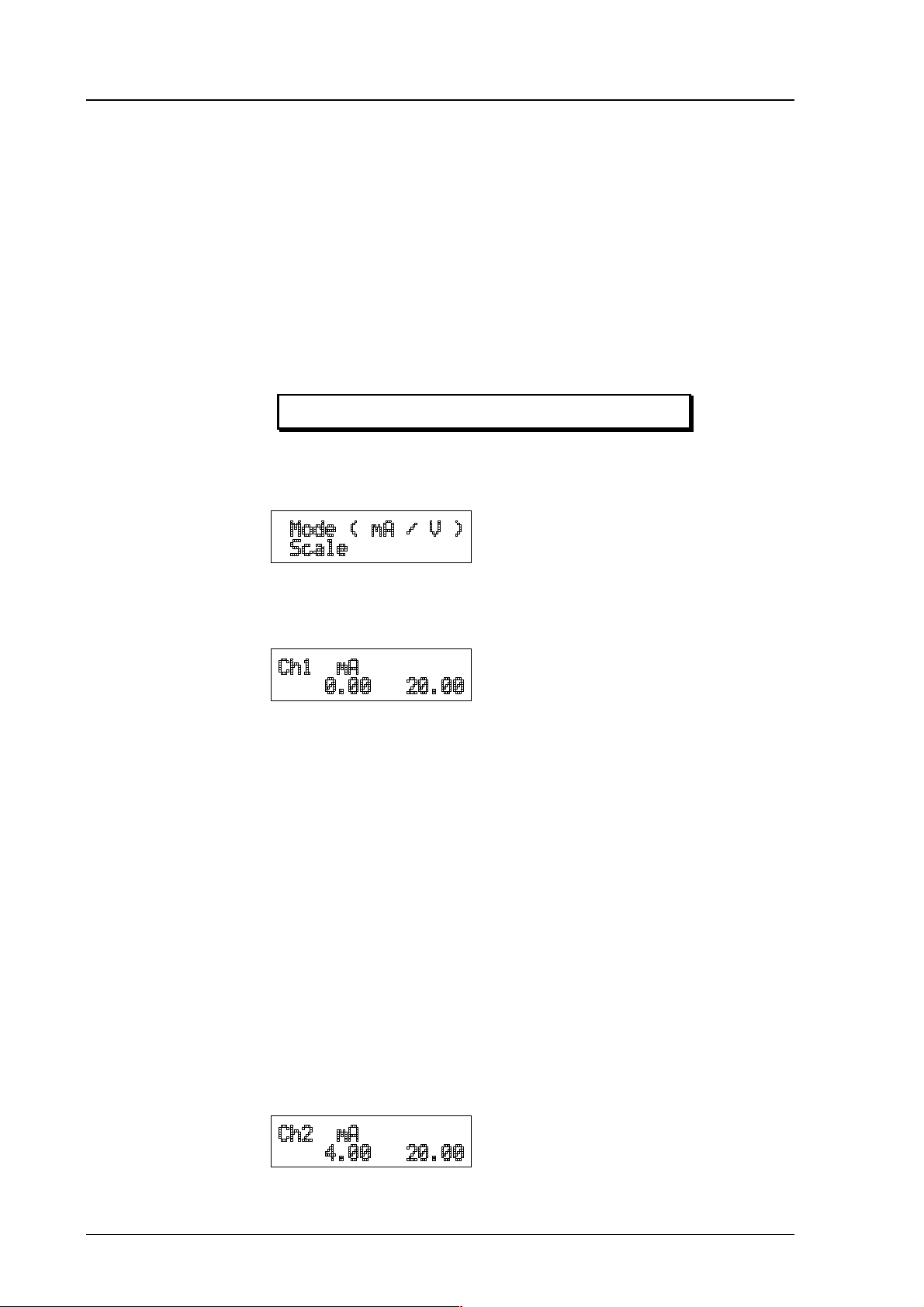

5.3.4.1 Selecting the output (mA/V)

Disconnect the security lock jumper!

• Select Mode in the main menu and Analog outputs in the Mode

menu:

• Select Mode ( mA / V ). The current settings for channel 1 are dis-

played:

• If the settings are correct, press ENT.

• If the settings need to be changed, press CL:

− the quantity (mA/V) starts flashing; it can be changed with the ar-

row keys and acknowledged with the ENT key

− the lower limit starts flashing

− acknowledge the lower limit with ENT or start changing it by

pressing CL; a new lower limit is given one character at a time

with the arrow keys

− the upper limit starts flashing

− acknowledge the upper limit with ENT or start changing it by

pressing CL; a new upper limit is given one character at a time

with the arrow keys

When channel 1 has been set, the programme goes on to channel 2;

the procedure is the same as with channel 1.

24 1997-11-25

Page 31

HMP260 SERIES

HMP260-U017en-1.5 Operating Manual

NOTE

The analogue output jumpers must be set to right places

(see Fig. 4.2).

5.3.4.2 Selecting and scaling the analogue output quantities

Disconnect the security lock jumper!

• Select Mode in the main menu and Analog outputs in the Mode

menu:

• Select Scale. The quantity and scaling for channel 1 are displayed:

• If the settings are correct, press ENT.

• If the settings need to be changed, press CL:

− the quantity (RH, T, Td, x, a Tw) starts flashing; it can be changed

with the arrow keys and acknowledged with the ENT key

− the lower limit starts flashing

− acknowledge the lower limit with ENT or start changing it by

pressing CL; a new lower limit is given with the arrow keys

− the upper limit starts flashing

− acknowledge the upper limit with ENT or start changing it by

pressing CL; a new upper limit is given with the arrow keys

• When channel 1 has been set, the programme goes on to channel 2;

the procedure is the same as with channel 1.

Please note that the selections that are possible are affected by the choice of

output parameters. Also make sure that the temperature measuring ranges are

not exceeded, e.g. the HMP263 can not be used in temperatures above

+120 °C.

1997-11-25 25

Page 32

HMP260 SERIES

Operating Manual HMP260-U017en-1.5

5.3.5 Output via the serial bus

5.3.5.1 Turning the serial interface echo ON/OFF

• Select More in the main menu, select More in the More menu and

select Echo in the second More menu.

• Use the arrow keys to select the right alternative and press ENT.

5.3.5.2 Serial bus settings

• Select Seri in the main menu; the currently valid serial interface set-

tings are displayed:

• If the settings are correct, press ENT; the programme returns to the

display mode.

• If the settings need to be changed, press CL:

• Select the parameter to be changed with the arrow keys and ENT key.

Selecting baud rate:

Selecting parity:

Selecting data bits:

26 1997-11-25

Page 33

HMP260 SERIES

HMP260-U017en-1.5 Operating Manual

Selecting stop bits:

Full duplex/half duplex:

The processor does not allow the following combinations:

• no parity, 7 data bits, 1 stop bit: if this combination is given the

HMP260 programme will change the number of stop bits to 2

• even or odd parity, 8 data bits, 2 stop bits: if this combination is given

the programme changes the number of stop bits to 1

NOTE

The serial bus settings become effective only after reset.

5.3.5.3 Setting the transmitter address

Address is used when more than one transmitters are connected to one serial

bus; this way, it is possible to communicate with one transmitter at a time.

• Select Addr in the main menu; the following is displayed:

• Pressing ENT returns the programme to the main menu.

• Pressing CL deletes the old address; enter the new address with the

arrow keys.

1997-11-25 27

Page 34

HMP260 SERIES

Operating Manual HMP260-U017en-1.5

5.3.5.4 Selecting the output units

• Select Unit in the main menu:

• Use the arrow keys to select the right alternative and press ENT.

metric non-metric

RH %RH %RH

T°C °F

Td °C °F

ag/m3gr/ft

3

x g/kg gr/lb

Tw °C °F

5.3.6 Output modes

The output modes only affect output through the serial interface: the transmitter accepts all display and LED commands irrespective of which serial output

mode it is in. The HMP260 transmitters have three serial output modes: RUN,

STOP and POLL.

In the RUN mode the transmitter outputs measurements automatically through

the serial interface to a PC or a peripheral. The only command that can be

given through the serial interface is S (stop), which ends the RUN mode.

In the STOP mode serial commands are given to the transmitters. Measurements are then output only by entering command SEND.

The POLL mode is used when more than one transmitter is connected to the

same serial bus; a single transmitter can be addressed and communicated with.

When the connection to a given transmitter is opened in the POLL mode, the

transmitter goes into STOP mode and can then receive commands normally.

Closing the connection returns the transmitter to POLL mode. In POLL mode

the transmitter outputs measurement only when requested (command SEND

aa). If the user has forgotten the address of the transmitter and the transmitter

does not have a display, the transmitter has to be reverted to the factory settings (see Chapter 4.3.1). If the transmitter has a display, the settings can be

checked through it.

28 1997-11-25

Page 35

HMP260 SERIES

HMP260-U017en-1.5 Operating Manual

5.3.6.1 Setting the serial interface operation mode

• Select Mode in the main menu; the following is displayed:

• Select Serial output:

• The currently valid setting flashes. Select the desired mode with the

arrow keys and press ENT. After this the programme returns to the

Mode Menu.

• When Run mode is selected, the currently valid output interval is dis-

played:

The output interval setting can be changed as follows:

• press CL

• the number starts flashing

• if the interval needs to be changed, press CL again and enter the new

interval; otherwise press ENT

• the unit (seconds or hours) starts flashing

• the unit can be changed with the arrow keys and acknowledged with

ENT

• after this the programme returns to Mode menu

5.3.7 Others

5.3.7.1 Setting the measurement integration time

By lengthening the measurement integration time any stray changes in the output can be filtered out: the transmitter calculates the average of a number of

measurement cycles defined by the user.

1997-11-25 29

Page 36

HMP260 SERIES

Operating Manual HMP260-U017en-1.5

• Select More in the main menu, select More in the More menu and

select Mtim in the second More menu:

• Pressing ENT returns the programme to the main menu without

changing the integration time.

• If the integration time needs to be changed, press CL; enter the new

integration time with the arrow keys (4...255)

5.3.7.2 Setting the pressure for mixing ratio and wet bulb calculations

The atmospheric pressure has an effect on mixing ratio and wet bulb. Accurate

calculations can be achieved only when the ambient pressure is taken into

consideration.

• Select More in the main menu:

• Select Pressure:

• Pressing ENT returns the programme to the main menu without

changing the pressure reading.

• If the pressure needs to be changed, press CL; enter the new pressure

with the arrow keys

30 1997-11-25

Page 37

HMP260 SERIES

HMP260-U017en-1.5 Operating Manual

5.3.7.3 Setting the date

• Select More in the main menu; select Date in the More menu:

• If the date is correct, acknowledge it by pressing ENT; this takes the

programme back to the More menu.

• If the date needs to be changed, press CL.

− first the centuries (19) start flashing; use the arrow keys to change

them and press ENT

− the years (92) start flashing; use the arrow keys to change them and

press ENT

− the months (06) start flashing; use the arrow keys to change them

and press ENT

− the days (17) start flashing; use the arrow keys to change them and

press ENT

5.3.7.4 Setting the time

• Select More in the main menu; select Time in the More menu:

• If the time is correct, acknowledge it by pressing ENT; this takes the

programme back to the More menu.

• If the time needs to be changed, press CL.

− first the hours (14) start flashing; use the arrow keys to change

them and press ENT

− the minutes (25) start flashing; use the arrow keys to change them

and press ENT

− the seconds (32) start flashing; use the arrow keys to change them

and press ENT

Please note that the transmitter does not have a real-time clock with backup

battery. This means that the date and time settings are not permanent.

1997-11-25 31

Page 38

HMP260 SERIES

Operating Manual HMP260-U017en-1.5

5.4 Serial commands

More detailed descriptions of the serial commands can be found in Appendix

1. Here only the most commonly used command sequences are described. The

instructions on how to connect the HMP260 transmitters to serial bus are

given in Chapter 4.3.

Pressing ESC always interrupts any serial command being given. In the commands <cr> stands for carriage return.

5.4.1 Analogue output commands

5.4.1.1 Setting the analogue outputs

Disconnect the security lock jumper!

AMODE a bb.bbb cc.ccc d ee.eee ff.fff <cr>

a = channel 1: U = voltage output

I = current output

bb.bbb = lower limit of channel 1

cc.ccc = upper limit of channel 1

d = channel 2: U = voltage output

I = current output

ee.eee = lower limit of channel 2

ff.fff = upper limit of channel 2

The bb.bbb, cc.ccc, ee.eee and ff.fff parameters are entered in volts or

milliamperes.

Example:

lower limit of channel 1 is 0 V and upper limit 1 V (U 0 1)

lower limit of channel 2 is 2 V and upper limit 10 V (U 2 10)

AMODE U 0 1 U 2 10 <cr>

Ch1 : 0.000 ... 1.000 V

Ch2 : 2.000 ... 10.000 V

32 1997-11-25

Page 39

HMP260 SERIES

HMP260-U017en-1.5 Operating Manual

5.4.1.2 Selecting and scaling the analogue output quantities

Disconnect the security lock jumper!

ASEL xxx yyy <cr>

xxx = channel 1's quantity

yyy = channel 2's quantity (RH, T, Td, Abs, Mix or Tw)

Example:

relative humidity selected on channel 1 and temperature on channel 2

ASEL RH T <cr>

Ch1 (RH) lo 0.000 %RH ? <cr>

Ch1 (RH) hi 100.000 %RH ? <cr>

Ch2 (T ) lo -40.000 'C ? <cr>

Ch2 (T ) hi +160.000 'C ? <cr>

5.4.1.3 Scaling the analogue outputs

Disconnect the security lock jumper!

ASC L <cr>

Example:

relative humidity is scaled on the range of 0...100 %RH and temperature -

40...+160 °C

ASCL <cr>

Ch1 (RH) lo 0.000 %RH ? <cr>

Ch1 (RH) hi 100.000 %RH ? <cr>

Ch2 (T ) lo 0.000 'C ? -40 <cr>

Ch2 (T ) hi 100.000 'C ? 160 <cr>

1997-11-25 33

Page 40

HMP260 SERIES

Operating Manual HMP260-U017en-1.5

5.4.2 Output via the serial bus

5.4.2.1 Starting the measurement output

R <cr>

Starts output of measurements to the peripheral devices (RUN mode); the only

available command is S (stop).

The output mode can be changed with command FORM (see Appendix 1).

5.4.2.2 Stopping the measurement output

S<cr>

Ends the RUN mode; after this command all other commands are available.

5.4.2.3 Outputting the reading once

SEND <cr> in STOP mode

or

SEND aa <cr> in POLL mode

aa = address of the transmitter when more than one transmitter is

connected to a serial bus (0...99)

The output format depends on which parameters the transmitter can output.

Output types:

"RH=999.9 %RH T=999.9 *C",<cr><lf >

"RH=999.9 %RH T=999.9 *C Td=9999.9 *C",<c r><lf>

"RH=999.9 %RH T=999.9 *C a=9999.9 g/m 3 x=9999.9 g/kg Tw=999.9*C",<c r><lf>

"RH=999.9 %RH T=999.9 *C Td=9999.9 *C a=9999.9 g/m 3 x=9999.9 g/kg Tw=999.9 *C", <cr><lf>

The output mode can be changed with command FORM (see Appendix 1).

34 1997-11-25

Page 41

HMP260 SERIES

HMP260-U017en-1.5 Operating Manual

5.4.2.4 Setting the output interval for the RUN mode

INTV xxx yyy <cr >

xxx = output interval (0...255)

0: no pause between outputs

yyy = unit (s, min or h)

Example:

output interval is changed into 10 minutes

INTV 10 min <cr>

Output intrv. : 10 min

5.4.2.5 Serial bus settings

SERI b p d s x <cr>

b = bauds (300, 600, 1200, 2400, 4800, 9600)

p = parity (n = none, e = even, o = odd)

d = data bits (7 or 8)

s = stop bits (1 or 2)

x = duplex (H = half, F = full)

The processor does not allow the following combinations:

• no parity, 7 data bits, 1 stop bit: if this combination is given the

HMP260 programme will change the number of stop bits to 2

• even or odd parity, 8 data bits, 2 stop bits: if this combination is given

the programme changes the number of stop bits to 1

NOTE

The serial bus settings become effective only after reset.

The settings can be changed one parameter at a time or all parameters at once:

SERI O <cr> changing parity only

4800 O 7 1 HDX

SERI 600 N 8 1 F <cr>

600 N 8 1 FDX

changing all parameters

When the half-duplex mode is set, it will automatically turn the echo off. Even

then the ECHO command can indicate that echo is on.

1997-11-25 35

Page 42

HMP260 SERIES

Operating Manual HMP260-U017en-1.5

5.4.2.6 Selecting the output units

UNIT x <cr>

x = m(etric units)

n(on-metric units)

metric non-metric

RH %RH %RH

T°C °F

Td °C °F

ag/m3gr/ft

3

x g/kg gr/lb

Tw °C °F

5.4.2.7 Setting the transmitter address

ADDR aa <cr>

aa = address (0...99)

Example:

transmitter is given address 99

ADDR <cr>

Address : 2 ? 99 <cr>

5.4.2.8 Resetting the transmitter

RESET <cr>

5.4.3 Operating the transmitter via the serial bus

5.4.3.1 Setting the serial interface

SMODE xxxx<cr>

xxxx = STOP, RUN or POLL

In STOP mode: measurements output only by command, all commands can be

used

In RUN mode: outputting automatically, only command S can be used

36 1997-11-25

Page 43

HMP260 SERIES

HMP260-U017en-1.5 Operating Manual

In POLL mode: measurements output only with command SEND. When in

POLL mode, the output state is changed as follows:

OPEN aa <cr>

SMODE xxxx<cr>

aa = address of the transmitter

xxxx = STOP, RUN or POLL

The OPEN command sets the bus temporarily in STOP mode so that the

SMODE command can be given.

Example:

>SMODE STOP <cr> setting STOP mode

Serial mode : STOP

5.4.3.2 OPEN & CLOSE

OPEN nn <cr>

nn = address of the transmitter (0...99)

CLOSE <cr>

In STOP mode: command OPEN has no effect, CLOSE sets the transmitter in

POLL m o d e

In POLL mode: command OPEN sets the transmitter temporarily in STOP

mode, command CLOSE returns the instrument to POLL

mode

Example:

relative humidity calibration is performed at transmitter 2 which is in POLL

mode

OPEN 2 <cr> opens the line to transmitter 2

CRH <cr> calibration started

...

CLOSE <cr>

1997-11-25 37

line closed

Page 44

HMP260 SERIES

Operating Manual HMP260-U017en-1.5

6. CALIBRATION

The HMP260 transmitters have been fully calibrated at the factory and there

should be no immediate need for recalibration. The transmitters should be

calibrated only if there is reason to believe that the adjustments of the

transmitters have changed. The adjustments of the temperature measurement

channel and the analogue outputs are particularly stable and in normal

circumstances there is no need to recalibrate them. Humidity calibration

should be performed at least once a year.

6.1 Humidity calibration

A two-point calibration can be done with the HMK11 or the HMK13B

Calibrator, or the instrument can be sent to Vaisala. We recommend

recalibration at least once a year. The instruments must be recalibrated every

time the HUMICAP humidity sensor is changed.

The covers of the calibration jars of the HMK11 and HMK13B Calibrator do

not have a hole for the Ø 13.5 mm sensor heads of the HMP260 transmitters;

therefore an adapter must be used when calibrating with the HMK11 or

HMK13B Calibrator. The adapters (part no. 16612 or 16611 respectively) can

be ordered from Vaisala or Vaisala representatives.

Calibration can be performed by giving the commands using the press

switches inside the housing (see Chapter 5.2 LED commands), through the

serial bus (Chapter 5.4 serial commands) or through the menus on the local

display (Chapter 5.3 display/keypad commands).

When LED commands are used and when the two analogue channels do not

output either relative humidity and/or temperature, relative humidity is calibrated on channel 1 and temperature is calibrated on channel 2. The calibration ranges are 0...100 %RH and -20...+80 °C. When the transmitters are

calibrated at two points, the points must be either 50 %RH or 50 °C apart from

each other.

38 1997-11-25

Page 45

HMP260 SERIES

HMP260-U017en-1.5 Operating Manual

NOTE

If the sensor has been changed, the calibration has to be

done according to the instructions in Chapter 6.1.3.

6.1.1. One point calibration procedure

6.1.1.1 Using serial commands

Disconnect the security lock jumper!

• Make sure that the sensors of the transmitter and the reference in-

strument are close to each other. Allow enough time for the sensor

heads to stabilize to the measurement conditions

• Give command CRH <cr> and enter the humidity value and press

<cr>.

>CRH <cr>

RH : xx.x Ref1 ? yy.y <cr>

Press any key when ready...

•

If you want to see how the sensor stabilizes to the reference humidity

enter c <cr> instead of the first reference:

RH : 11.9 Ref1 ? c <cr>

RH : 11.5 Ref1 ? c <cr>

RH : 11.5 Ref1 ? 11.3 <cr>

Press any key when ready...

•

Press any key and press <cr> when the transmitter requests the second

point value.

RH : yy.y Ref2 ? <cr>

6.1.1.2 Using display/keypad commands

Disconnect the security lock jumper!

• Make sure that the sensors of the transmitter and the reference in-

strument are close to each other. Allow enough time for the sensor

heads to stabilize to the measurement conditions

• Select Cali in the main menu and then RH cal; select Not changed

and then one-point offset correction RH 1 point cal. Change the

humidity reading with the arrow keys to correspond to the reference

value and acknowledge it with ENT; pressing an arrow once changes

the reading by 0.05 %RH.

1997-11-25 39

Page 46

HMP260 SERIES

Operating Manual HMP260-U017en-1.5

6.1.1.3 Using LED commands

Disconnect the security lock jumper!

• Make sure that the sensors of the transmitter and the reference in-

strument are close to each other. Allow enough time for the sensor

heads to stabilize to the measurement conditions

• Connect an ammeter/voltmeter to the analogue outputs (connector

X2); if the outputs are already connected e.g. to a process computer

and you do not want to disconnect them, the current output can be

measured at separate test points located next to connector X15 (see

Chapter 7.5). Give command ¡¡¡l (see Chapter 5.2). At the first

calibration point the LED on the left flashes; adjust the humidity point

(offset) with the arrow switches to the reference value. One push of a

switch changes the output by 0.05 %RH; the change of the output

voltage or current depends on the output scaling. Press ENT switch.

The second LED from left starts flashing; press ENT again.

6.1.2 Two point calibration procedure

A two-point humidity calibration should be performed in stable conditions

using saturated salt solutions a reference.

NOTE.

If the humidity sensor has been changed, the calibration

has to be done according to the instructions in Chapter

6.1.3.

6.1.2.1 Using serial commands

Disconnect the security lock jumper!

• Leave the calibrator and the transmitter for at least 4 hours in the

same space so that their temperatures have time to equalize. Remove

the filter cap on the transmitter.

• Place the sensor head into the calibration hole of the LiCl bottle in the

humidity calibrator.

• Wait for 10 minutes.

• Give command CRH <cr> and enter the first point value and press

<cr>.

CRH <cr>

RH : xx.x Ref1 ? yy.y <cr>

Press any key when ready...

40 1997-11-25

Page 47

HMP260 SERIES

HMP260-U017en-1.5 Operating Manual

• If you want to see how the sensor stabilizes to the humidity in the

calibrator, enter c <cr> instead of the first reference:

RH : 11.9 Ref1 ? c <cr>

RH : 11.5 Ref1 ? c <cr>

RH : 11.5 Ref1 ? 11.3 <cr>

Press any key when ready...

Place the sensor head into the calibration hole of the NaCl bottle in

•

the humidity calibrator.

• Wait for 10 minutes.

• Press any key and enter the second point value and press <cr>.

RH : xx.x Ref2 ? yy.y <cr>

The stabilization of the sensor can be monitored by entering c <cr>

•

instead of the reference value.

6.1.2.2 Using display/keypad commands

Disconnect the security lock jumper!

• Leave the calibrator and the transmitter for at least 4 hours in the

same space so that their temperatures have time to equalize. Remove

the filter cap on the transmitter.

• Place the sensor head into the calibration hole of the LiCl bottle in the

humidity calibrator.

• Wait for 10 minutes.

• Select Cali in the main menu and then RH cal; select Not changed

and then two-point calibration RH 2 point cal. Change the first point

reading with the arrow keys and press ENT.

• Place the sensor head into the calibration hole of the NaCl bottle in

the humidity calibrator.

• Wait for 10 minutes.

• If necessary, change the second point reading with the arrow keys and

press ENT.

6.1.2.3 Using LED commands

Disconnect the security lock jumper!

• Leave the calibrator and the transmitter for at least 4 hours in the

same space so that their temperatures have time to equalize. Remove

the filter cap on the transmitter.

• Place the sensor head into the calibration hole of the LiCl bottle in the

humidity calibrator.

1997-11-25 41

Page 48

HMP260 SERIES

Operating Manual HMP260-U017en-1.5

• Wait for 10 minutes.

• Connect an ammeter/voltmeter to the analogue outputs (connector

X2). Give command ¡¡¡l. At the first calibration point the LED

on the left flashes; adjust the first point (offset) with the arrow

switches to the value given in the calibration table (Chapter 6.1.4) and

press ENT switch.

• Place the sensor head into the calibration hole of the NaCl bottle in

the humidity calibrator.

• Wait for 10 minutes.

• Check that the reading corresponds within the desired accuracy to the

reading given in the calibration table (Chapter 6.1.4). If not, adjust the

second point with the arrow switches to the correct value and press

ENT. At the second calibration point the second LED from the left

flashes.

6.1.3 Calibration procedure after sensor change

Humidity calibration should be performed in stable conditions using saturated

salt solutions as a reference.

6.1.3.1 Using serial commands

Disconnect the security lock jumper!

• Leave the calibrator and the transmitter for at least 4 hours in the

same space so that their temperatures have time to equalize. Remove

the filter cap on the transmitter.

• Place the sensor head into the calibration hole of the LiCl bottle in the

humidity calibrator.

• Wait for 10 minutes.

• Give command FCRH <cr> and enter the first point value and press

<cr>:

FCRH <cr>

RH : xx.x Ref1 ? yy.y <cr>

Press any key when ready...

The stabilization of the sensor to the reference humidity can be

•

monitored by giving c <cr>:

RH : 11.9 Ref1 ? c <cr>

RH : 11.5 Ref1 ? c <cr>

RH : 11.5 Ref1 ? 11.3 <cr>

Press any key when ready...

Place the sensor head into the calibration hole of the NaCl bottle in

•

the humidity calibrator.

• Wait for 10 minutes.

42 1997-11-25

Page 49

HMP260 SERIES

HMP260-U017en-1.5 Operating Manual

• Press any key and enter the second point value and press <cr>.

RH : xx.x Ref2 ? yy.y <cr>

The stabilization of the sensor can be monitored by entering c <cr>

•

instead of the reference value.

6.1.3.2 Using display commands

Disconnect the security lock jumper!

• Leave the calibrator and the transmitter for at least 4 hours in the

same space so that their temperatures have time to equalize. Remove

the filter cap on the transmitter.

• Place the sensor head into the calibration hole of the LiCl bottle in the

humidity calibrator.

• Wait for 10 minutes.

• Select Cali in the main menu and then RH cal; select Sensor

changed. Change the first point reading with the arrow keys and

press ENT.

• Place the sensor head into the calibration hole of the NaCl bottle in

the humidity calibrator.

• Wait for 10 minutes.

• If necessary, change the second point reading with the arrow keys and

press ENT.

6.1.3.3 Using LED commands

Disconnect the security lock jumper!

• Leave the calibrator and the transmitter for at least 4 hours in the

same space so that their temperatures have time to equalize. Remove

the filter cap on the transmitter.

• Place the sensor head into the calibration hole of the LiCl bottle in the

humidity calibrator.

• Wait for 10 minutes.

• Connect an ammeter/voltmeter to the analogue outputs (connector

X2). Give command l¡¡¡. At the first calibration point the LED

on the left flashes; adjust the first point with the arrow switches to the

value given in the calibration table (Chapter 6.1.4) and press ENT

switch.

• Place the sensor head into the calibration hole of the NaCl bottle in

the humidity calibrator.

• Wait for 10 minutes.

1997-11-25 43

Page 50

HMP260 SERIES

Operating Manual HMP260-U017en-1.5

• Check that the reading corresponds within the desired accuracy to the

reading in the calibration table. If not, adjust the second point with the

arrow switches to the correct value and press ENT. At the second

calibration point the second LED from the left flashes.

The basic capacitance of the new sensor may differ considerably from that of

the previous one. Therefore the corresponding humidity reading of the

transmitter may be below 0 %RH at the low or above 100 %RH at the high

calibration point. However, the current/voltage reading of the analogue output

shows only the minimum or maximum value of the selected current/voltage

scale and the output value may not change even though the arrow switches are

pressed several times. If this happens, press the up or down arrow switch

continuously to bring the output back into the selected scale; this may take as

long as half a minute.

6.1.4 Humidity calibration table

Temperature °C 15 20 25 30 35

°F 59 68 77 86 95

LiCl %RH *) 11.3 11.3 11.3 11.3

4...20 mA 5.81 5.81 5.81 5.81

0...20 mA 2.26 2.26 2.26 2.26

0...1 V 0.113 0.113 0.113 0.113

0...5 V 0.565 0.565 0.565 0.565

0...10 V 1.13 1.13 1.13 1.13

NaCl %RH 75.6 75.5 75.3 75.1 74.9

4...20 mA 16.10 16.08 16.05 16.02 15.98

0...20 mA 15.12 15.10 15.06 15.02 14.98

0...1 V 0.756 0.755 0.753 0.751 0.749

0...5 V 3.780 3.775 3.765 3.755 3.745

0...10 V 7.56 7.55 7.53 7.51 7.49

Table 1 Greenspan's calibration table

*) LiCl solution must not be used or stored in temperature below +18 °C,

otherwise the equilibrium humidity of the salt solution changes permanently.

6.2 Temperature calibration

The temperature channel has been calibrated at the factory and since it is very

stable, calibration should be performed only when there is strong reason to

believe that the adjustments have changed.

Temperature calibration should be made against some accurate temperature

reference. It can be done either using the press switches inside the housing,

through the serial bus or the menus on the local display. Either a one point or a

two point calibration can be done.

44 1997-11-25

Page 51

HMP260 SERIES

HMP260-U017en-1.5 Operating Manual

6.2.1 One point offset correction

6.2.1.1 Using serial commands

Disconnect the security lock jumper!

• Leave the reference instrument and the transmitter for at least 4 hours

in the same space so that their temperatures have time to equalize.

Remove the filter cap prior to calibration.

• Check the transmitter against the reference.

• Give command CT <cr> and enter the first point value and press

<cr>:

CT <cr>

'T : xx.x Ref1 ? yy.y <cr>

Press any key when ready

If you want to see how the sensor stabilizes to the reference

•

temperature, enter c <cr> instead of the first reference:

T : 0.90 Ref1 ? c <cr>

T : 0.55 Ref1 ? c <cr>

T : 0.55 Ref1 ? 0.0 <cr>

Press any key when ready...

After giving the correct temperature value (Ref1) and pressing <cr>

•

press any key and press <cr>.

6.2.1.2 Using display/keypad commands

Disconnect the security lock jumper!

• Leave the reference instrument and the transmitter for at least 4 hours

in the same space so that their temperatures have time to equalize.

Remove the filter cap prior to calibration.

• Check the transmitter against the reference.

• Select Cali in the main menu and then T cal; select two-point

calibration T 2 point cal. Change the first point reading with the

arrow keys and press ENT.

• Select T 1 point cal, change the reading to correspond to the

reference and press ENT.

1997-11-25 45

Page 52

HMP260 SERIES

Operating Manual HMP260-U017en-1.5

6.2.1.3 Using LED commands

Disconnect the security lock jumper!

• Leave the reference instrument and the transmitter for at least 4 hours

in the same space so that their temperatures have time to equalize.

Remove the filter cap prior to calibration.

• Check the transmitter against the reference.

• Connect an ammeter/voltmeter to the analogue outputs (connector

X2). Give command ¡¡l¡. At the first calibration point the LED

on the left flashes; adjust the first point (offset) with the arrow

switches to the same reading with the reference and press ENT

switch.

• After adjusting the offset point and pressing ENT the second LED

from left flashes. Press ENT without changing the output value.

6.2.2 Two point temperature calibration

6.2.2.1 Using serial commands

Disconnect the security lock jumper!

• Leave the reference instrument and the transmitter for at least 4 hours

in the same space so that their temperatures have time to equalize.

Remove the filter cap prior to calibration.

• Check the transmitter against the reference.

• Give command CT <cr> and enter the first point value and press

<cr>:

CT <cr>

'T : xx.x Ref1 ? yy.y <cr>

Press any key when ready

If you want to see how the sensor stabilizes to the reference

•

temperature, enter c <cr> instead of the first reference:

T : 0.90 Ref1 ? c <cr>

T : 0.55 Ref1 ? c <cr>

T : 0.55 Ref1 ? 0.0 <cr>

Press any key when ready...

Change the temperature and check the transmitter again against the

•

reference.

• Check that the reading corresponds to the reading of the reference

instrument. If not, adjust the second point

• Press any key, enter the second point value and press <cr>.

'T : xx.x Ref2 ? yy.y <cr>

46 1997-11-25

Page 53

HMP260 SERIES

HMP260-U017en-1.5 Operating Manual

• The stabilization of the sensor can be monitored by entering c <cr>

instead of the reference value.

6.2.2.2 Using display/keypad commands

Disconnect the security lock jumper!

• Leave the reference instrument and the transmitter for at least 4 hours

in the same space so that their temperatures have time to equalize.

Remove the filter cap prior to calibration.

• Check the transmitter against the reference.

• Select Cali in the main menu and then T cal; select two-point

calibration T 2 point cal. Change the first point reading with the

arrow keys and press ENT.

• Change the temperature and check the transmitter again against the

reference.

• Check that the reading corresponds to the reading of the reference

instrument. If not, adjust the second point

• If necessary, change the second point reading with the arrow keys and

press ENT.

6.2.2.3 Using LED commands

Disconnect the security lock jumper!

• Leave the reference instrument and the transmitter for at least 4 hours

in the same space so that their temperatures have time to equalize.

Remove the filter cap prior to calibration.

• Check the transmitter against the reference.

• Connect an ammeter/voltmeter to the analogue outputs (connector

X2). Give command ¡¡l¡. At the first calibration point the LED

on the left flashes; adjust the first point (offset) with the arrow

switches to the same reading with the reference and press ENT

switch.

• Change the temperature and check the transmitter again against the

reference.

• Check that the reading corresponds to the reading of the reference

instrument. If not, adjust the second point.

• If necessary, adjust with the arrow switches to the correct value and

press ENT. At the second calibration point the second LED from the

left flashes.

1997-11-25 47

Page 54

HMP260 SERIES

Operating Manual HMP260-U017en-1.5

6.3 Calibration of analogue outputs

The analogue outputs have been calibrated at the factory and since they are

very stable, calibration of the outputs should be performed only when there is

reason to believe that their adjustments have changed.

6.3.1 Using serial commands

Disconnect the security lock jumper!

ACAL < cr>

The outputs on channels 1 and 2 are measured and the measured values (mA

or V) entered as calibration coefficients.

Example: both channels have 0...10 V outputs (set with AMODE command);

enter the voltages measured at the analogue outputs:

>ACAL <cr>

Ch1 U1 ( V ) ? 0.123 <cr>

Ch1 U2 ( V ) ? 9.98 <cr>

Ch2 U1 ( V ) ? 0.120 <cr>

Ch2 U2 ( V ) ? 9.98 <cr>

6.3.2 Using display/keypad commands

Disconnect the security lock jumper!

• Connect an ammeter/voltmeter to the output of channel 1, select Cali