Vaisala HMP243 Operating Manual

4F:

HMP243

TRANSMITTER

Operating

Manual

U145en°2.1

May

1998

t

Vaisala

1998

-Clio

A

VIA,

U$.4

VAISALA

©Vaisala

Oyj

1998

No

part

of

this

document

may

be

reprodu'ced

in

any

form

or

by

any

means.

electronic

or

mechanical

(including

photocopying).

nor

may

its

contents

.be

commnunicated to a third

party

without a prior

written notice

of

the

copyright

holder.

T'he

instruction

manuals may

be

changed

without prior

notice.

YkisjciIjcnnds

05/1998

U)

H&1F243

Contents

1.PRODUJCT

DESCRIPTION.....................................................................

1

2.

ADVANTAGES

OF

AWARMED

SENSOR

HEAD...........................................

3

3.

INSTALLATION

...................................

...........................

I.. ....4

3.1

Selecting

the

place

of

Installation

..................................................

4

3.2

Grounding....................................

.

.............................-......

7

3.3

Electrical

connections.....................................................

3.3.1

Connection

to a 24

VAC

supply

..........................................

10

4.

COMMISSIONING.............................................................................1.I1

4.1

Changing

the

parameters

....................................

1............1....

4.2

Security

lock

jumper...........................................................

12

.4.3

Selecting

the

analogue

outputs...................................................1

4.4

Connecting

the

RS

232C

serial

bus

.....

.....................-..........

1

4.4.1

Reverting

to

factory settings of

the

serial

port...........................

16

5.

COMMANDS.................

....................................................

18

5.1

Commands and

security

lock

Jumper

.....................

. .. .

.~...

........

1

5.2

LED

commands

....................................................................

1

5.3

Display/keypad

commands

...............................................

2

5.3.1

Display

mode

..............................................................

20

5.3.2

Command

mode...........................................................

20

5.3.3

Entering

numbers..........................................................

20

5.3.4

Analogue

output

commands..............................................

21

5.3.4.1

Selecting the

output

(mAN)...............................................

21

5.3.4.2 Selecting

and

scaling

the

analogue

output

quantities..................

22!

5.3.5

Output

via

the

serial

bus

..................................................

23

5.3.5.1

Turning

the

serial

interf

ace

echo

ON/OFF...............................

23

5.3.5.2

Serial

bus

settings

.........................................................

23

5.3.5.3

Setting

the transmitter

address...........................................

24

5.3.5.4

Selecting

the

output

units.................................................

25

5.3.5.5

Selecting

the

calculation

mode

...........................................

25

5.3.6 Output

modes..............................................................

25

5.3.6.1

Setting the

serial

Interface

operation

mode..............................

26

5.3.7

Others

......................................................................

27

5.3.7.1

Setting

the

averaging

time

................................................

27

5.3.7.2

Setting

the

pressure

for

mixing

ratio

and

wet bulb

calculations..............................................................

27

5.3.7.3

Setting

the.

date

............................................................

28

5.3.7.4

Setting

the

time

............................................................

28

5.3.7.5

Heal

on I heat

off

command...............................................

29

5.4

Serial

commands

..

....................................................

2

5.4.1

Analogue

output

commands..............................................

29

5.4.1.1

Setting

the

analogue outputs

.............................................

29

5.4.1.2

Selecting

and

scaling

the

analogue

output

quantities..................

30

5.4.1.3 Scaling

the

analogue

outputs.............................................

30

5.4.2

Output

via

the

serial

bus

..................................................

30

5.4.2.1

Starting

the

measurement

output.........................................

30

HMP243

Oparaii,-g

Manuai

U145en-2.1

.

5.4.2.2

Stopping

Mhe

measurement

output

......................................................

31

5.4.2.3

Outputting

the

reading

once

.........................................................

31

5.4.2.4

Setting

the

output

Interval for

the

RUN

mode

................................

31

5.4.2.5

Serial

bus

settings

..............................................................................

31

5.4.2.6

Selecting

the

output units

.............................................................

32

5.4.2.7

Setting

the

averaging

time

..............................................................

33

5.4.2.8

Setting

the

transmitter

address

.....................................................

33

5.4.2.9

Setting

the

calculation

mode

.........................................................

33

5.42.10

Resetting

the

transmitter

...............................................................

34

5.4.3

Operating

the

transmitter

via

the

serial

bus

...................................

35

5.4.3.1

Setting

the

serial

interface

.............................................................

35

-5.4.3.2

OPEN

&

CLOSE

...........................................................................

36

6.

CALIBRATION

........................................................................................................

37

6.1

Humidity

calibration

......................

37

6.1.1

One

point

humidity

calibration ......................................................

38

6.1.1.1

With

serial

commands

..................................................................

39

6.1.1.2

With

display/

keypad

commands

..........

............................................

39

6.1.1.3

With

LED

commands

......

..

..............................................

40

6.1.2

Two

point

humidity

calibration ......................................................

40

6.1.2.1

With

serial

commands

..................................................................

41

6.1.22

With

display I keypad

commands

..................................................

41

6.1.2.3

With LED

commands

....................................................................

42

6.1.3

Humidity

calibration

procedure

alter

sensor

change

.....................

44

6.1.3.1

With

serial

commands

..................................................................

44

6.1.3.2

With

display

I keypad

commands

..................................................

44

6.1.3.3

With LED

com mands

....................................................................

45

6.1.4

Humidity

calibration table

.............................................................

46

6.2

Temperature

calibration

.................................................................................

46

6.2.1

One

point

offset

calibration

...........................................................

47

6.2.1.1

With

serial

commands

.

.............................................................

47

6.2.1.2

With

display I keypad

commands

..................................................

47

6.2.1.3

With

LED

commands

....................................................................

47

6.22

Two

point

temperature

calibration ................................................

48

6.2.2.1

With

serial

commands

..................................................................

48

6.2.2.2

With

display I keypad

commands

..................................................

49

6.2.2.3

With

LED

commands

....................................................................

49

6.3

Calibration

of

analogue

outputs

.........

.

.

................

50

6.3.1

With

serial

commands

..................................................................

50

6.3-2

With

display

I

keypad

commands

..................................................

50

6.3.3

With

LED

commands

....................................................................

51

7.

MAINTENANCE

...................................................................................................

53

7.1

Reference

measurements

.

..................

.................................................

53

7.2

Self-diagnostics

.....

....... ..........................................

..................

5........

53

7.3

Replacing

the

composite

sensor

...............................................

.

54

7.4

Temperature

channel

(additional)

adjustment

with

Pt

100

simulators

.....

54

7.4.1

With

serial

commands

..................................................................

55

7.4.2

With

display

commands

................................................................

55

7.4.3

With

LED

commands

....................................................................

55

Ii

r:-2,

,-,-

4-

HiMP2-4.3

Operating

bMarua!

U i 43•r,-•.I

7.5

Temperature

channel

adjustment

with

PI

100

slmulatrs

(composite

sensor)

.,.................

...

o..................,.....................

..........................................

........, .......

°.....56

7.5.1.1

With

serial

commands

..................................................................

57

7.5.1.2

With

display

commands

................................................................

57

7.5.2

With LED

commands

.....................................................................

57

7.6

Measurement

of

output

currents

using

test

points

.................................

58

7.7

Adjusting

the

contrast

of

the

display

.........................................................

59

8.

TECHNICAL

DATA

........................................................................................................

60

8.1

Dewpoint

temperature

.....................................................................................

60

8.2

Temperature

(with

additional

T

sensor

head)

.

...............

61

8.3

Calculated

variables

.................

.

...........

61

8.3.1

Relative

humidity

(with

additional

T

sensor

head)

..........................

61

8.3.2

Accuracy

of

other

calculated

variables

.........................................

62

8.4

Outputs

..................................................................................................

64

K

4

8.5

Electronics

8.6

Mechanics.

8.7

Electromagi

.................

.

..................................

..............................................

65

netIc

compatibility

.......................................

66

8.7.1

Emissions

8.7.2

Immunity.

............................................................................................

M

9.

bFAKE

VAH

I b

ANU

....... . ... . ....................................... . ................ . 00

APPENDIX 1:

SERIAL

COMMANDS

...........................................

63

APPENDIX

2:

INSTALLING

AND

USING

THE

RS

485/422

SERIAL

PORT

MODULE

......

85

APPENDIX

3:

INSTALLIND

AND

USING

THE

DIGITAL

CURRENT

LOOP

MODULE

.......

97

APPENDIX

4:

ERROR

MESSAGES ................................................................................

107

APPENDIX

5:

CALCULATION

FORMULAS

......

. .......

.........

._.....................................

..

113

APPENDIX

6:

WIRING DIAGRAM

MK4456

..........................

115

APPENDIX

7:

RE-GAINING

.........................................

117

III

HMP243

Operating

Manuai

U145en-2.1

This

page

intentionally

left

blank.

IV

IHMP243

U145an-2.1

Operating

Manual

~

1.

PRODUCT DESCRIPTION

The

HMP243

transmitter

is a microprocessor

based

instrument

for

the

measurement

of

dewpoint

temperature

especially

in

high

humidities and/or

fast

changing

temperatures.

The

dewpoint

temperature

is

measured

through

relative

humidity and

temperature.

The

dewpoint temperature,

although a calculated

variable.

is

the

primary

reading

obtained

with

the HMP243.

As

the probe

is

equipped

with

the

warming

function, the

relative

humidity

reading

obtained

is

,

not

correct

as

such

whereas

the

dewpoint

temperature

is.

If

the

temperature

is

below 0

*C.

the

user

can

select

whether

the

transmitter

calculates

dewpoint

or

'rostpoint

reading:

as

deranlt.

the

transmitter

calculates

frostpoint.

The

transmitter

can

be

ordered

with

one

or

two

sensor

heads.

If

the transmitter

has

only a humidity

sensor

head,

it

can

output the

dewpoint temperature

or the

mixing

ratio.

If

the

transmitter

is

ordered

with an

additional

temperature

head,

the

user

can

choose the

output

from

the

following

readings:

dewpoint, relative

humidity, ambient

temperature, dewpoint

difference

(=

ambient temperature

-

dewpoint),

mixing

ratio,

absolute

humidity,

and

wet

bulb temperature.

The

configuration that

the

user

completes

in

the

order

form

determines

the

available

readings.

The

transmitter

has two

analogue

outputs

and

can

be

connected

to a serial

bus

via the

RS

232C

interface

or through

an

RS

485/422

serial

module

or

a

digital

current

loop

module.

There

are

various

possibilities

for

the

configuration

of

the

transmitter.

It can

have

either a blank

cover,

or a cover

with

a

local

display

and

keypad

with

which

to

operate

the

transmitter.

Two

analogue

output signals

are

selected

from

the

measured

and

calculated

quantities;

the

signals

can

be

scaled

and

the

measurement

ranges

changed.

The

HMP243

can

be

supplied

with

two, five

or

ten

meter

sensor

head

cables.

The

dewpoint

measurement

range

is

-40...+100

*C. The

range

depends

on

the

desired

accuracy

because

the

dewpoint

is calculated

through

the

RH

and

the

T

readings

(see

Chapter

8).

The

analogue

temperature

output

can

be

scaled

quite

freely, for

example

-20...+60

°C

can

be

set to correspond

to

0...

tO

V.

The

relativt

humidity, absolute

humidity,

dewpoint

difference,

mixing

ratio

and

wet

bulb temperature

ranges

are also

scalable.

In

some

specific applications,

the

sensor

gain

may

gradually

decrease

because

of

an

interference

caused

by

some

particular chemicals

present

in

the

ambient.

These

changes

can

be

recovered

with

an

optional

re-gaining

function.

The

transmitter

is

equipped

with a composite

humidity

and

temperature sensor;

the

operation

of

the

HUMICAPOKC

humidity

sensor

is

based

on

changes

in

the

capacitance

of

the

sensor

as

its

thin

polymer

film

absorbs water molecules.

I

HNIP243

Operating

Manual

U145an-2.

I

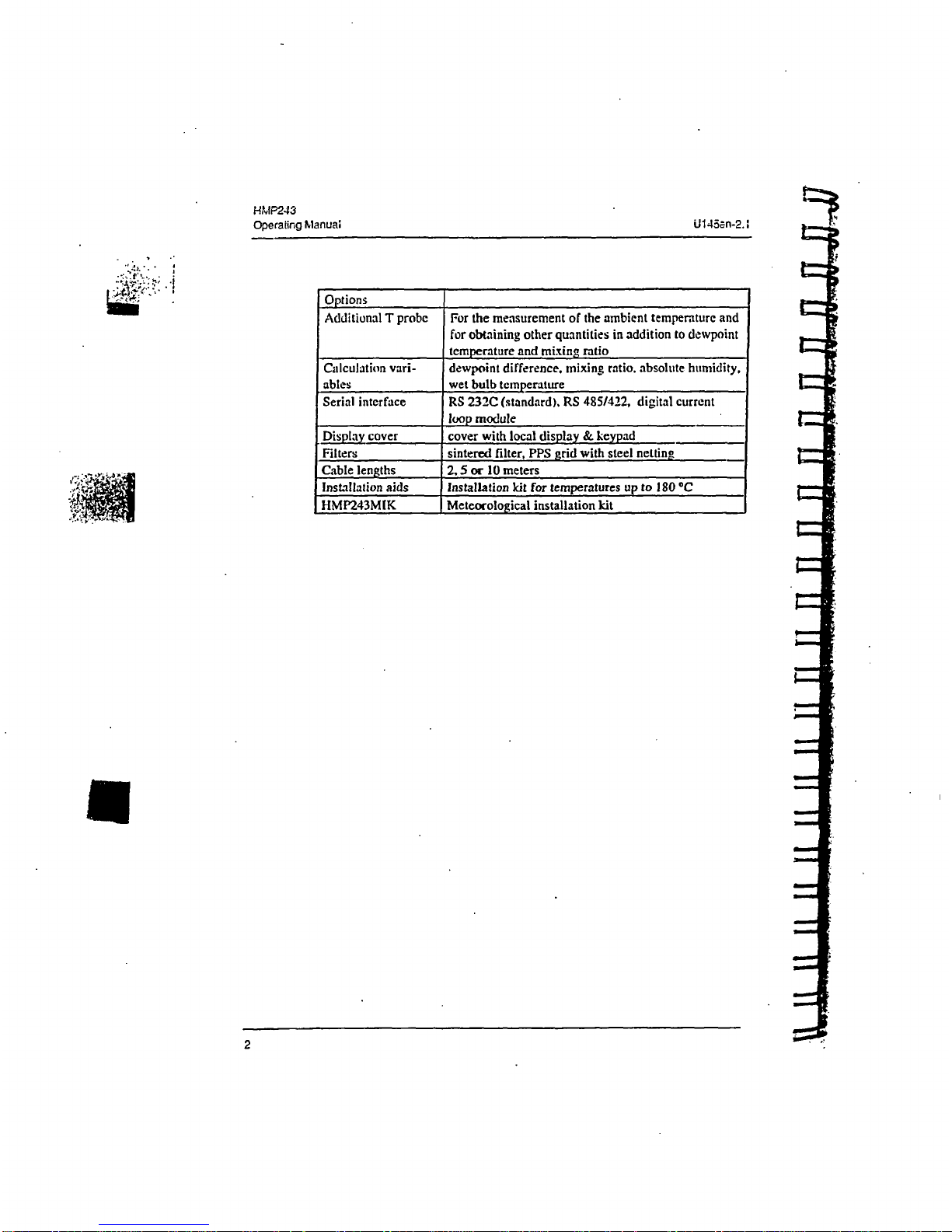

Options

Additional T probe

For

the

measurement

of

the

ambient temperature

and

for

obtaining

other

quantities

in

addition

to

dewpoint

temperature and

mixing

ratio

Calculation

vari-

dewpoint

difference,

mixing ratio, absolute humidity,

ables

wet

bulb

temperature

Serial

interface

RS

232C (standard),

RS

485/422,

digital

current

loop module

Display

cover

cover with

local

display

&

keypad

Filters

sintered

filter,

PPS

grid

with steel

netting

Cable

lengths

2,5

or

10

meters

Installation

aids

Installation

kit

for

temperatures

up

to

180

*C

HMP243MIK

Meteorological

installation

kit

t::ý'

1=

2

EHMP243

U145en-2.1

Operating

Manual

~z:

2.

ADVANTAGES

OF A WARMED SENSOR

HEAD

In

some

measurement

applications,

unwanted

dew

formation

makes

humidity

measurement

difficult

or

even

impossible.

At a weather

station,

for example.

high

humidity

combined

with rapidly

changing

outdoor

temperature

can

condense

the

water

vapour

in

the

air

onto

the

sensor

head.

Until

this

dew

evaporates

or

dries,

it

is

impossible

to

obtain a true reading.

Dew

formation

is

also a problem

in

environmental chambers

and

in

processes

involving

high

humidity,

such

as

meat

processing.

Itn

some

applications,

rapid

temperature

changes are

the

source

of

difficulty.

Normally.

relative humidity

sensors must

be

at

the

saute

temperature

as

tile

ambient

air or

the

measurement

is

incorrect.

At

+20

*C

and

90

%RH a dif-

ference

of

±1 0C causes

an

error

of

±6

%RH.

This

makes reliable

humidity

measurements

difficult

in

rapidly

changing temperatures.

In

other applications,

the problem

is a combination

of

both

the

dew

formation

and

rapid

changes

of

temperature; a rapid rise

in

temperature

can

cause

a

corresponding increase

of

water

vapour

in

the

ambient.

In

these

conditions,

the

temperature

of

the

sensor

head rises

more

slowly,

and

can remain

below

the

dewpoint

of

the

ambient

for a

while.

Dew then forms

on

the

sensor

head.

and

it

may

take

several

hours

or

in

the

worst

case,

several

days

for

the

sensor

to

recover

from

the

condensation.

Vaisala's

HMP243

dewpoint

transmitter offers

a

reliable

solution

for

humidity

measurement

in

all

these

demanding conditions.

The

humidity sensor

head

is

kept

dry

by

warming it.

As

the measurement

is

fully temperature

compensated,

changes

in

the process

temperature

do

not

delay

the measurement.

This

means

that

the

response time

of

dewpoint

measurement

is

proportional

only

to the

diffusion

time

of

water

molecules inside

the

sensor

head.

The

HMP243

has

an

excellent performance also

at

normal humidities

and

in

stable

environments,

but

it

will

mostly

be

used

in

applications

where

very high

humidity

can take

place.

In

these

kinds

of

applications,

the use

of

traditional

transmitters has

been

restricted.

HMP243

Operating

Manual

U145en-2.1

3.

INSTALLATION

3.1

Selecting

the

place

of

Installation

The

transmitter

should

be

installed

in

a place

that

gives

a

true picture

of

the

environment

or

process

and

is

as

clean

as

possible.

Air

should

'circulate

freely

around

the

sensor.

If

necessary,

the

transmitter

can

be

installed

in a place

where a hot

spot

may

develop.

However,

cold

spots

should

be

avoided.

When

the

sensor

head

is

installed

in

a

duct

or a process channel

where

the

temperature

is

different

from

the

ambient

temperature,

insulate

the

point

of

entry;

this

is

particularly

important

if

the

transmitter

is

installed with

the

sensor

head

pointing downwards.

Installing

the

sensor

head

of

the

HMP243

vertically

is

not

recommended

because

in

high

humidities,

the

humidity

may

condence

on

the

sensor

head

cable

and

then

flow

on

to the

sensor

head.

When

there

is

no

alternative

but

to

install

the

sensor

head

in

the

process

vertically,

the

point

of

entry

must

be

carefully

insulated.

The cable

must

also

be

allowed

to

hang

loosely

in order

to prevent

any

water

that

possibly

condenses

on

the

cable

from

running

onto

the

sensor

head.

Install

the

humidity

sensor

head

in

the

process

wherever

possible.

Avoid

sample

flows

where the

gas

temperature

can

drop

below

dewpoint

temperature;

this

might

result

in

erroneous

measurement readings.

Install

the

sensor

head

transversely

against

the

direction

of

the

process

flow.

If

the

process

temperature

is

much

higher

than

that

of

the environment,

the

whole

sensor

head

and

preferably

part

of

the

cable

must

be

inside

the

process.

In

duct

or

channel

installations

drill a hole

ready

for a reference meter.

Plug

the

reference

hole

tightly

(see

Figure

3.2).

Install

the

electronics

housing

away

from

possible

steams

escaping

from

the

process.

4

Vl:

4-

:4--:

4-

.HMP243

O~parating

&Manual

U145÷-n-2.1

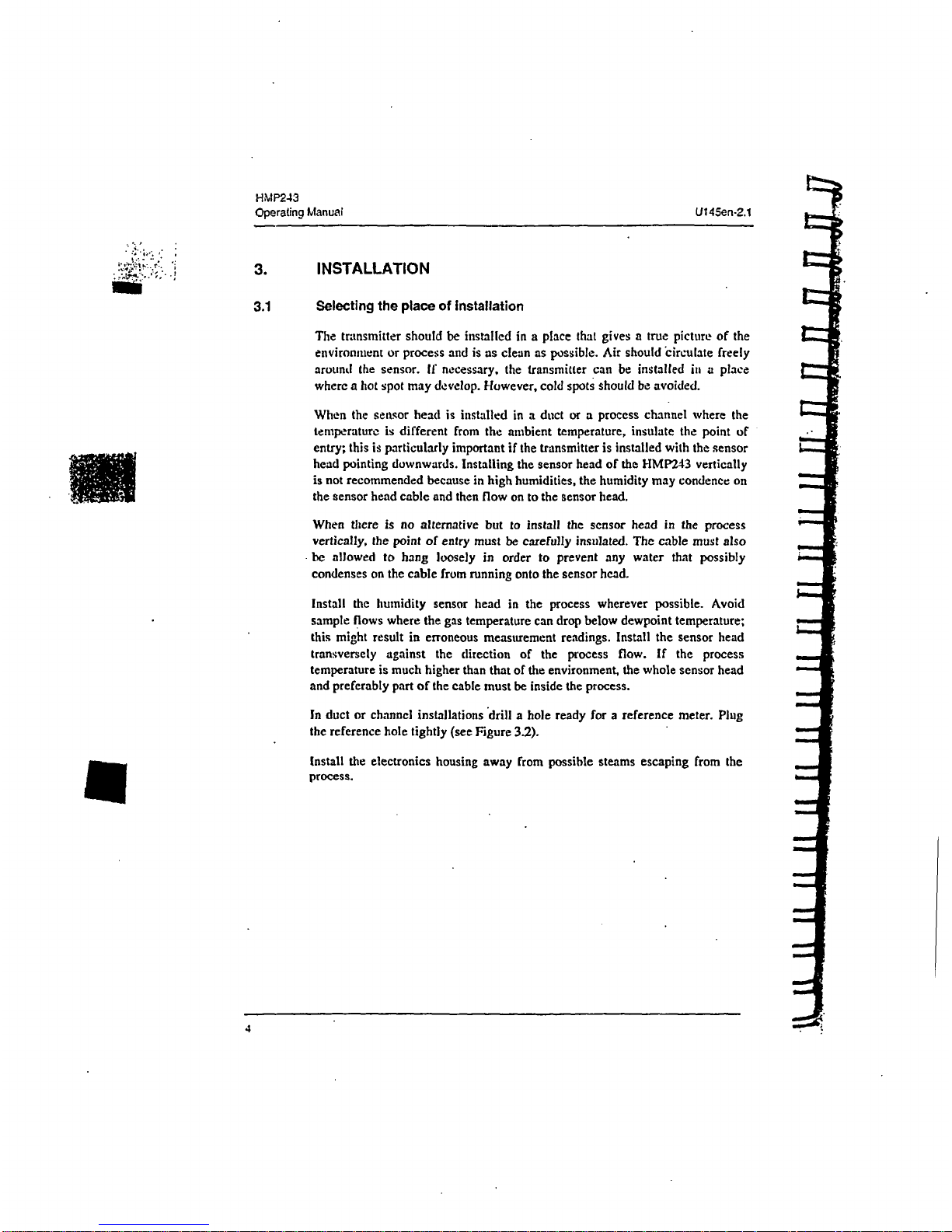

humidity

sensor

head

Tsensor

head

toptional)

II

Cable

length

2000,

5000

or

10000

mm

.1

bo~

* I

it

II

II,*i

;6.5

Sliding

PTFE-sleeve

for

flange

Installation

and

cable-gland

Installation

Figure

3.1

HMP243

transmitter

with a humidity

sensor

head

and

an

additional

T

sensor

head

When

mounted

on

the

side

of a duct

or

channel,

the

sensor

head

must

be

in-

serted from

the

side

(see

Figure

3.2).

If

this

is

not

possible

and the

sensor

head

must

be

inserted

from

the

top,

the

point

of

entry

must

be

carefully

insulated.

NOTE

The

two

sensor

heads

should

be

installed

so

that

the

humidity

sensor

head does

not warm

the

T

sensor

head.

i.e.

the T sensor

head

is

installed

closer

to

the

process

flow.

When

the

RH

reading

is

required,

always install

the

T

sensor

head

in

the

place

where

you

need

the

reading

from.

The

HMP243

can be

installed

in

ducts

and

channels

with

the

help

of

the

instal-

lation

kit;

the kit consists

of a flange,.a

supporting

bar

for

the

sensor

head

cable

and screws

for

attaching

the

flange

to the

wall

of a duct.

With

the

help

of

the

installation

kit

the

distance

between

the

sensor

head

and

the

channel

wall

can

be

easily

adjusted.

The

range

of

adjustment is

100...320 mm;

the

distance

is

measured

from

the

tip

of

the

sensor

head

to

the

flange.

5

HMP243

Operawing

Manual

U145an-2.1

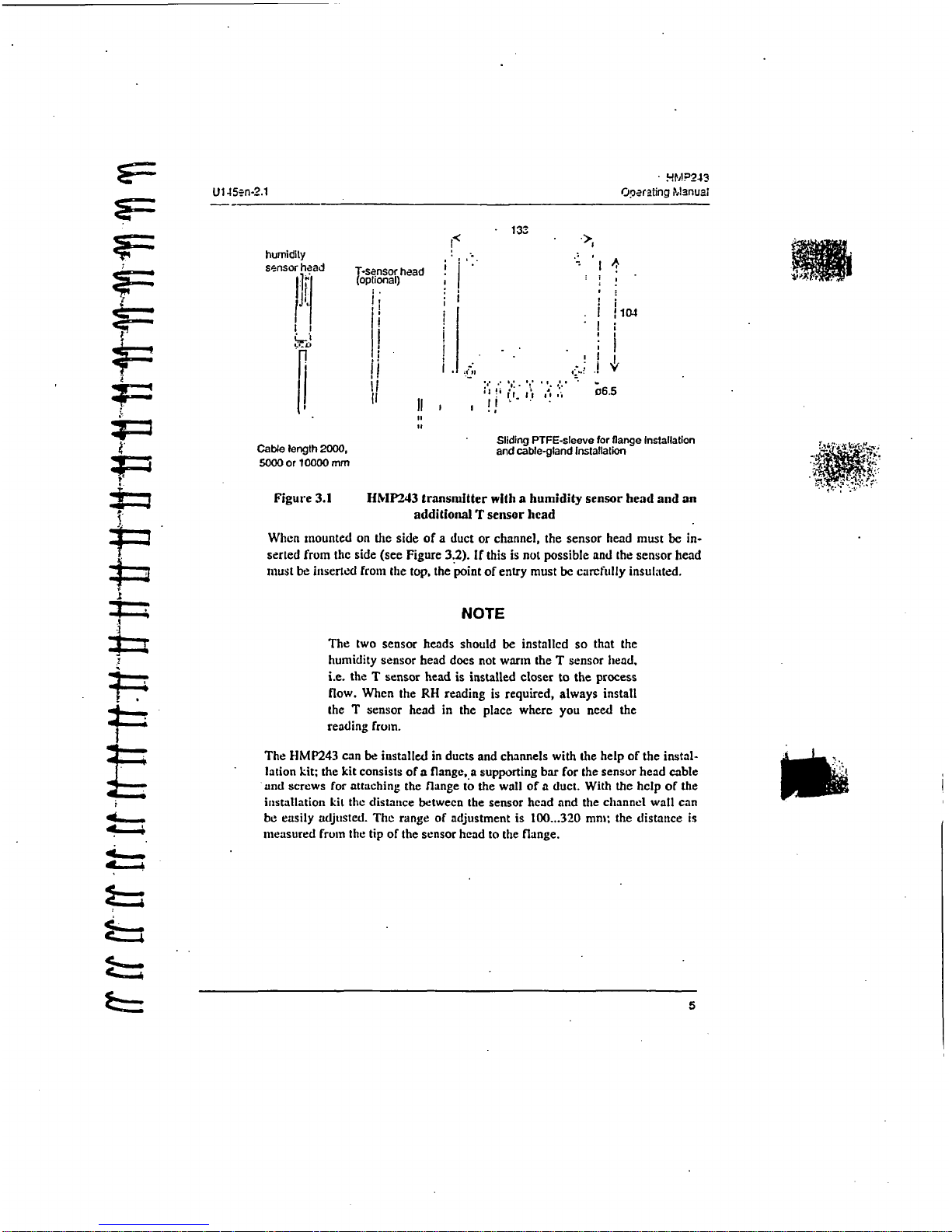

"'(1 " < ""

duct

wall

sealing

(silicone).-

....

lange

humidity

sensor

head

/

supporting

bar

a

plugged

hole

for

reference

measurements

T-sensor

head

(optional)

PTFE

sleeve

Figure

3.2

Installing

the

sensor

heads

or

the

HMP243

li a channel

with

the

help

of

flanges

and

supporting

bars

The

sensor

head can

also

be

installed

vertically.

7--

PTFE-sleve

when a bushing

is

used,

its

size

is

selected according

to

the

diameter

of

the sensor

head;

the

diameter

of

the cable

is

increased

by

using

e.g.

.

silicon tape

at

the

bushing

stainless

steel

cable tic

or

a

[

imilnr

filo.""

I~

T.sensof

head

(optonal)

Figure

3.3

Vertical Installation

of

the

HMP243

sensor

heads

6

S7-

*7'

HNIPi243

NOTE

During

installation

the

sensor

head

must

not

be

unsol-

dered

fronm

and

then

resoldered

to

the

main

printed

board

of

the

transmitter.

This

procedure

may

interfere

with

the

humidity

calibration

of

the

transmitter.

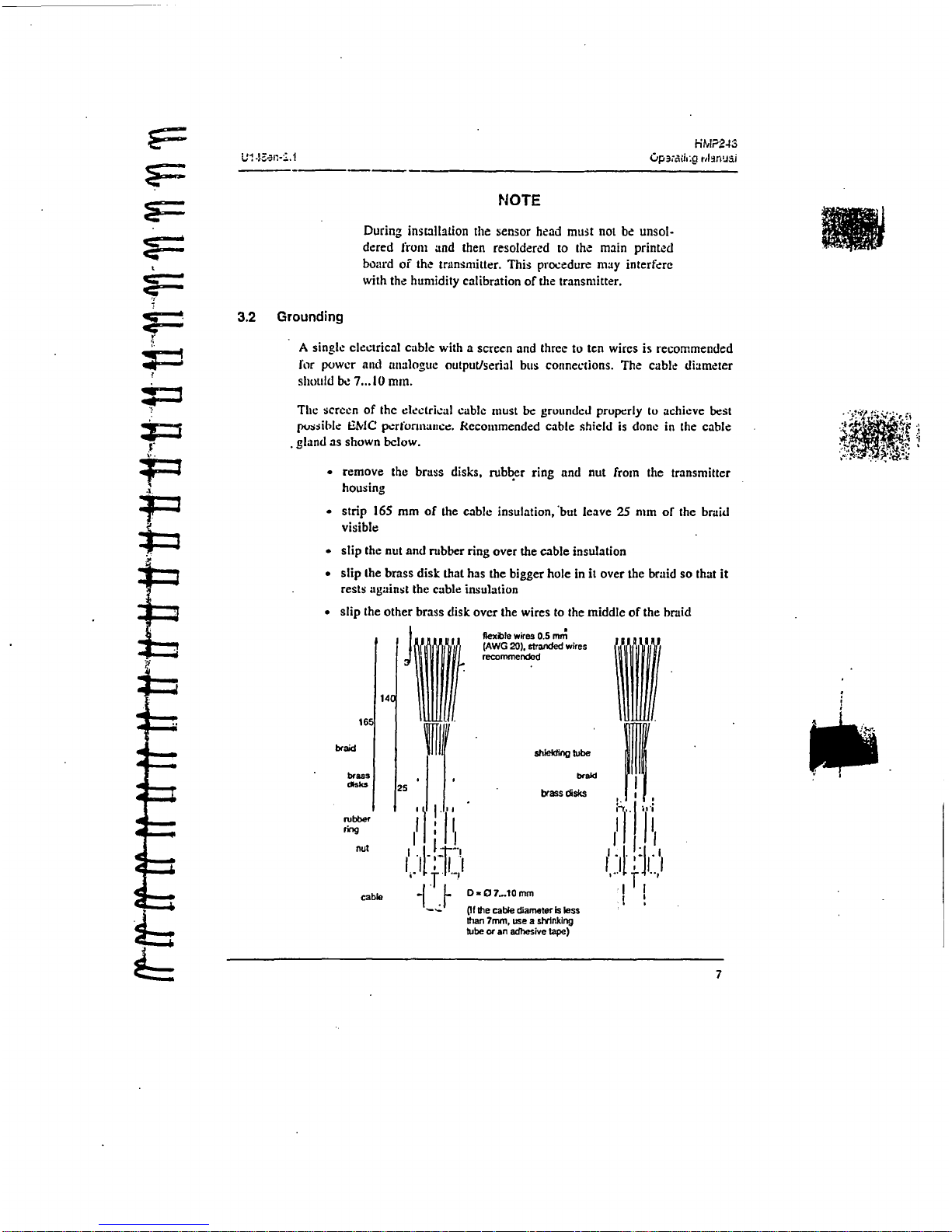

3.2

Grounding

A

single

electrical

cable

with

a

screen

and

three

to

ten wires

is

recommended

for

power

and

analogue

output/serial

bus

connections.

The

cable

diameter

should

be 7...

10

man.

The

screen

of

the

electrical

cable

must

be

grounded

properly

to

achieve

best

possible

W2MC

performance.

Recommended

cable

shield

is

done

in

the

cable

gland

as

shown

below.

"

remove

the

brass

disks,

rubber

ring

and

nut

from

the

transmitter

housing

*

strip

165

mm

of

the

cable

insulation,

but leave

25

mm

of

the

braid

visible

•

slip

the

nut

and

rubber

ring

over

the

cable

insulation

•

slip

the

brass

disk

that

has

the bigger

hole

in

it

over

the

braid so

that

it

rests

against

the

cable

insulation

"

slip

the

other

brass

disk

over

the

wires

to

the

middle

of

the

braid

.... i?

4~

~.

a

a

a

a

a

H

braid

flexible

wires

0.5 mm

(AWG

20),

stranded

wires

recommended

shiedn

tube

braid

brass

disks

DO7...10

mm

Of

the

cable

diameter

is

less

0thn

7mm,

use

a

shrinking

tube

or

an

adhesive

tape)

7

7

HMP243

Op-.rating

PlAnual

U145en-2..

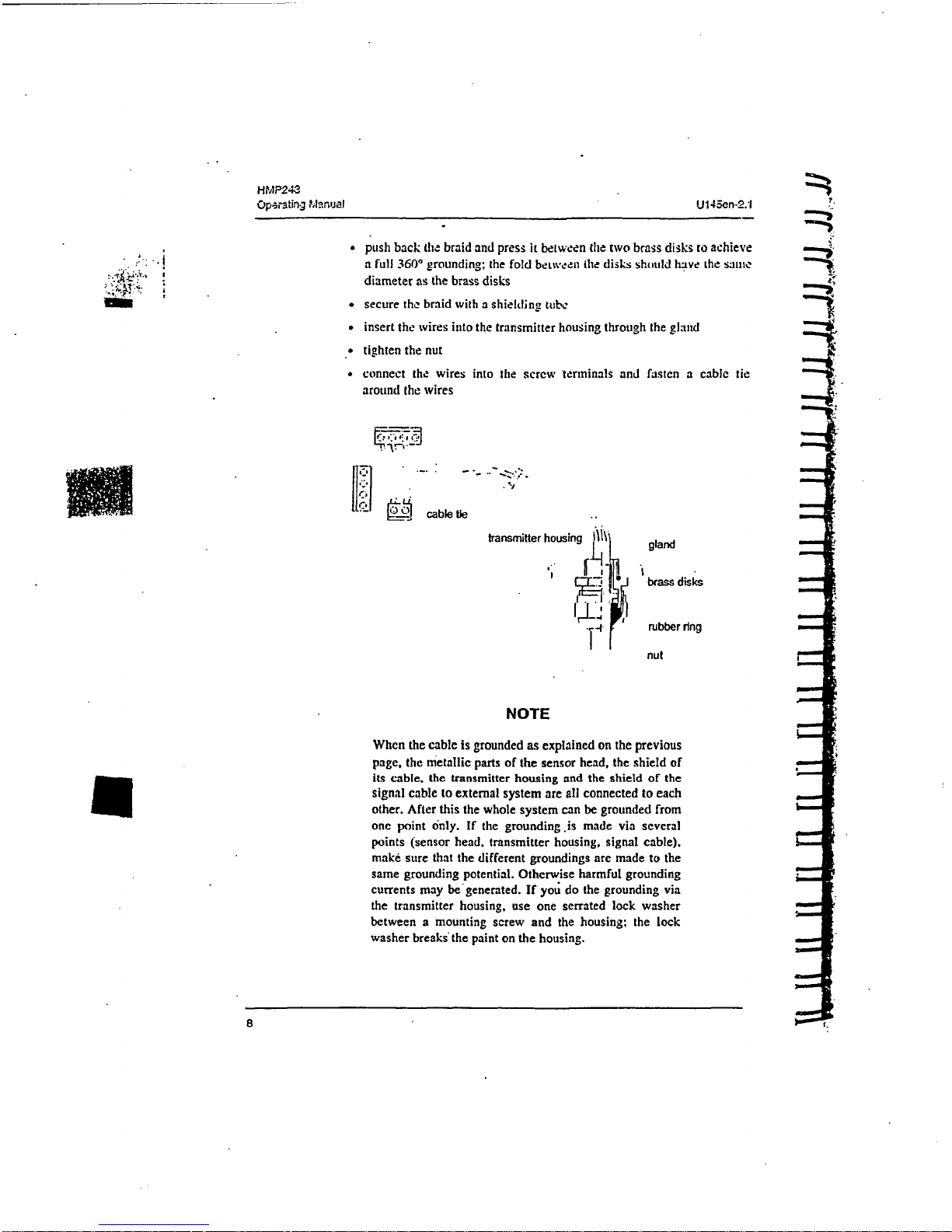

"

push

back

the

braid

and

press

it

between

the

two

brass

disks

to

achieve

a

full

360*

grounding;

the

fold

betweea

the

disks

should

have

the

saute

diameter

as

the

brass

disks

"

secure

the

braid

with

a

shielding,

tube

insert

the

wires into

the

transmitter

housing

through

the

gland

"

tighten

the

nut

*

connect

the

wires

into

the

screw

terminals and

fasten

a

cable

tie

around

the wires

lI17

cable tie

transmitter

housing

gland

--

brass

disks

-L

rubber

ring

nut

NOTE

When

the

cable

is

grounded

as

explained

on

the

previous

page,

the

metallic

parts

of

the

sensor

head, the

shield

of

its

cable,

the

transmitter

housing

and the

shield

of

the

signal cable

to

external

system

are

all

connected

to

each

other.

After

this

the whole

system

can

be

grounded

from

one

point

only.

If

the

grounding

is

made

via

several

points

(sensor

head,

transmitter

housing,

signal

cable).

make

sure

that

the

different

groundings

are

made

to

the

same grounding

potential.

Otherwise

harmful

grounding

currents

may

begenerated.

If

you

do

the

grounding

via

the

transmitter

housing,

use

one

serrated

lock

washer

between

a mounting screw

and

the

housing.

the

lock

washer

breaks

the

paint

on

the

housing.

8iI

HMP243

U

145en-2.1

Operaling

Manual

a

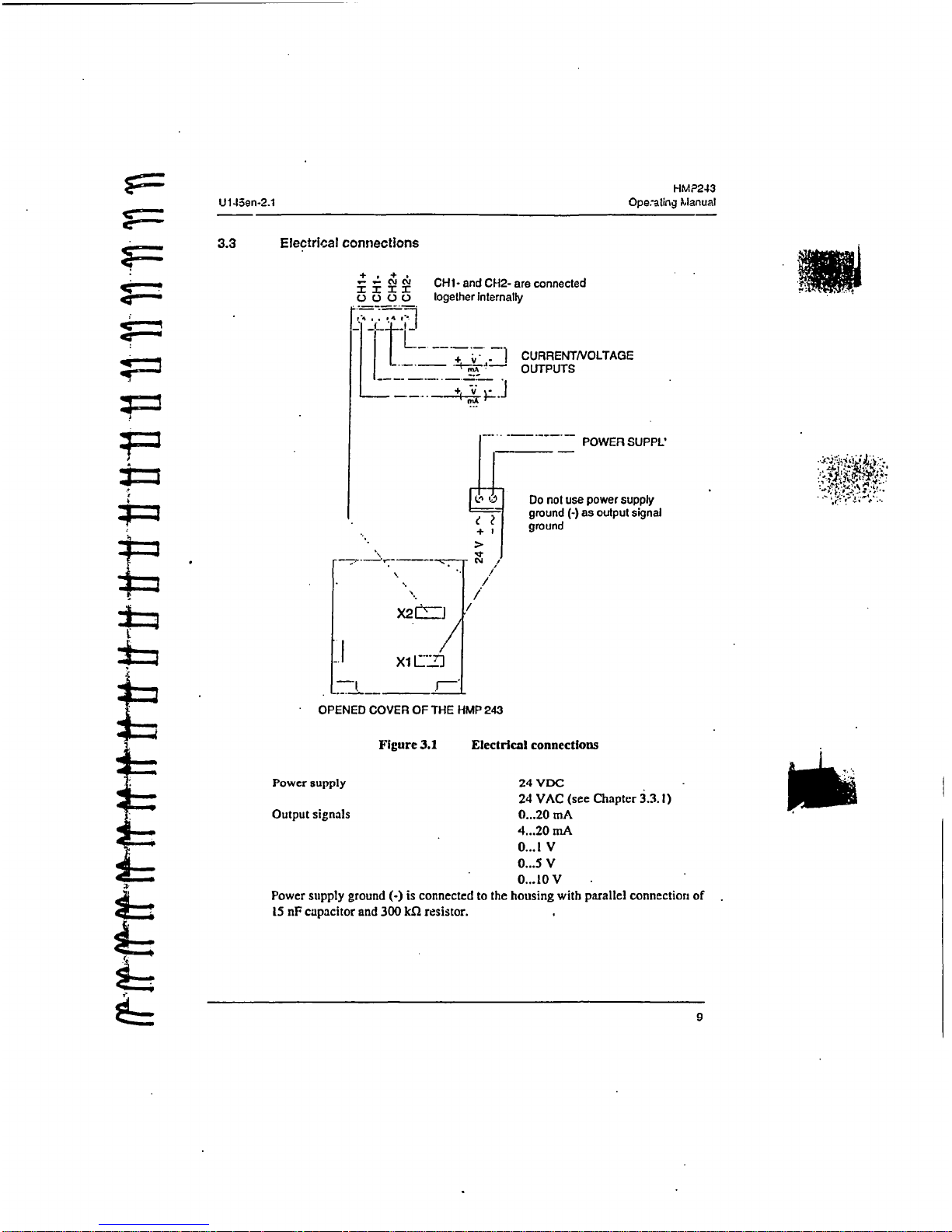

3.3

Electrical

connections

c+

J

CHI-

and

CH2-

are

connected

.)

O

t

Iogether

Internally

Lt

"1

CURRENTNVOLTAGE

*--~*--~

OUTPUTS

POWER

SUPPL'

L

Do

not

use

power supply

e

ground

(-)

as

output

signal

+

ground

C>

°/:

i/

'/

*1~

X2t~

XI

CL7]

--

t

_

r--1

OPENED

COVER

OF

THE

HMP

243

Figure

3.1

Electrical

connections

Power

supply

Output

signals

24

VDC

24

VAC

(see

Chapter

3.3.

1)

0...20

mA

4...20

mA

0...

1 V

0...5

V

0...

10V

Power

supply

ground

(-)

is

connected

to

the

housing

with

parallel

connection

of

15

nF

capacitor

and

300

kfl

resistor.

9

j;P,•,.,.!

,g

Minual

U145sn-2.1

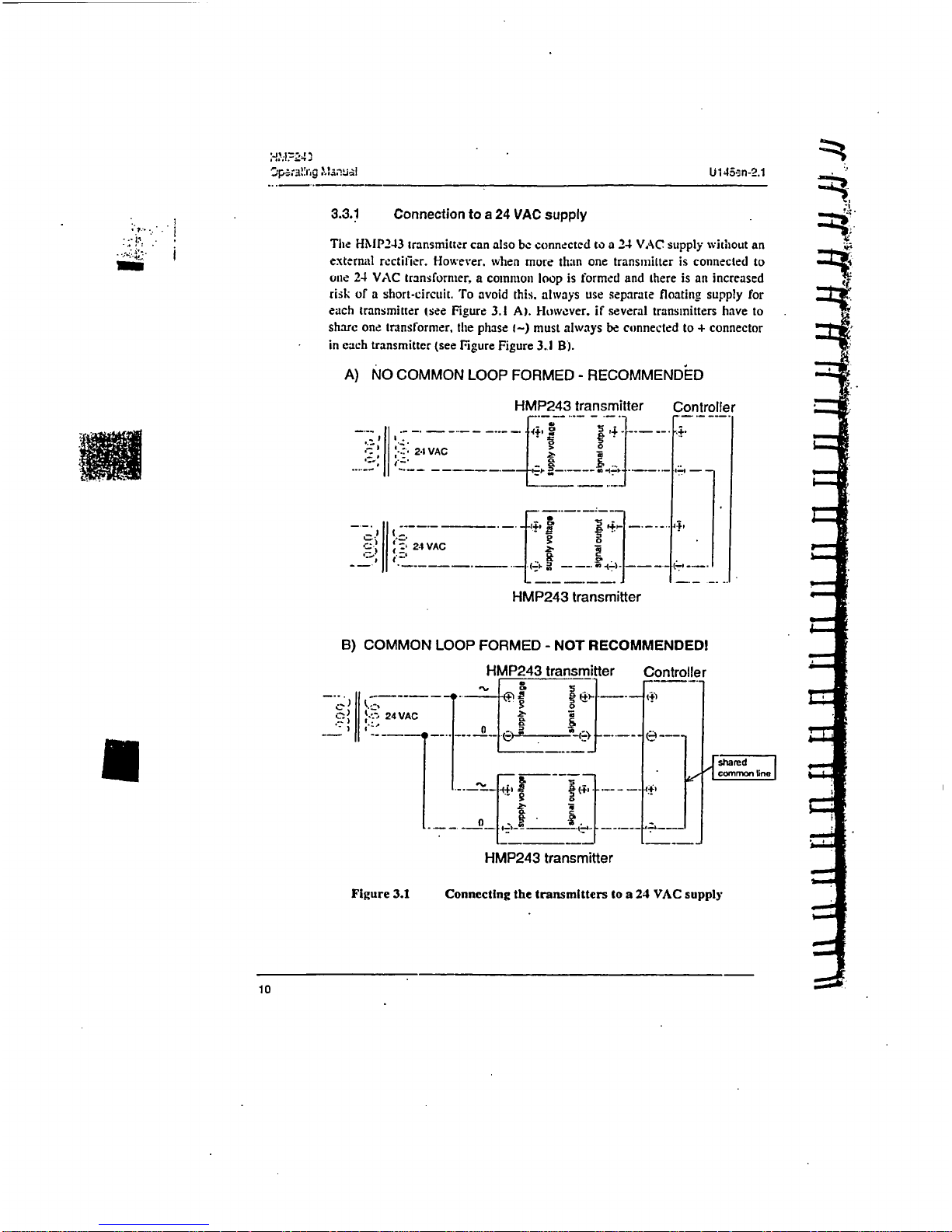

3.3.1

Connection

to a 24

VAC

supply

The

HIMP243

transmitter

can

also

be

connected

to a 24

VAC

supply

without

an

external

rectifier.

However.

when

more

than

one

transmitter

is

connected

to

one

24

VAC

transformer,

a

common

loop

is

formed

and

there is

an increased

risk

of

a

short-circuit.

To

avoid

this, always

use

separate

floating supply

for

each

transmitter

(see

Figure

3.1

A).

However,

if

several

transmitters

have

to

share

one

transformer,

the phase

t-)

must

always

be

connected

to

+

connector

in

each

transmitter

(see

Figure

Figure

3.A

B).

A)

NO COMMON

LOOP

FORMED

-

RECOMMENDED

HMP243

transmitter

Controller

-", -

*-

...

24

VAC

I

I

.....

-.

-LI-..

,

HMP243

transmitter

B)

COMMON

LOOP

FORMED

-

NOT

RECOMMENDED!

HMP243

transmitter

Controller

24VAC

"

--- -

--

e

~m•

sh~ared

_____

~common

ln

HMP243

transmitter

Figure

3.1

Connecting

the

transmitters

to a 24

VAC

supply

10

~H,'.lP24S

U145an-2..

Operating

Mlanual

4.

COMMISSIONING

_ _When

the

HMP243

transmitter

leaves

the

factory,

its

measurement

ranges

and

output

signals

have

already

been

scaled

according

to

the

order

form

completed

•-by

the

customer.

The

unit

is

calibrated

at

the

factory

and

ready

to operate

when

the

power

is

turned

on.

If

you take

into

use

active

current, voltage

or

serial bus

outputs,

make

these

connections

first:

appendix

9

describes

them

in

detail.

NOTE

Make sure

that

(lie

power

is

itot

turned

uu

unttil

cables

have been

connected

to

screw terminals!

In

transmitters

with

display,

the

software

version appears

for a few

seconds

Swhen

the

power

is

turned

on.

After

this,

measurement

results

appear

automatically.

Should

an

error

message

appear

on

the

display,

consult

Appendix

6.

-'If

your transmitter

has

a

blank

cover

and

the

LED

indicator

inside

the

housing

lights

up,

consult

Appendix

6

for further

information.

• "

Appendix

7

contains

information

on

how

to

determine

the

ranges

for alarm

outputs

and

alarm

controls

when an

alarm output

unit

is

used.

4.1

Changing

the

parameters

If

necessary,

the

user

can

subsequently change

the

measurement

units

between

metric

and

non-metric

and

select

and

scale

the

output

signals

with

software

functions.

This

is

done

through

commands,

either

utilizing

the

menus

on

the

local

display

or

giving commands

through

the serial

interface

(see

Appendices).

Most

often

the

commands

are

used

to

change

the

settings

of

the

two

analogue channels.

A'limited

range

of

commands can

be

given

with

the

three

press

switches

(up.

down,

enter)

inside

the

transmitter housing.

There

are

four

LEDs

to indicate

the

commands given

with

the

up

*and

down

switches.

All

HMP243 units

incorporate

these

switches

and

LED

indicators.

LED

commands

can be

used

to

calibrate

the

transmitters

(both

humidity

and temperature)

or

to

calibrate

the

analogue

outputs.

If

you

need

to

change

some

functions,

read

the

following

chapters carefully.

HMP243

Operating

Manual

U145-en-2.1

* I

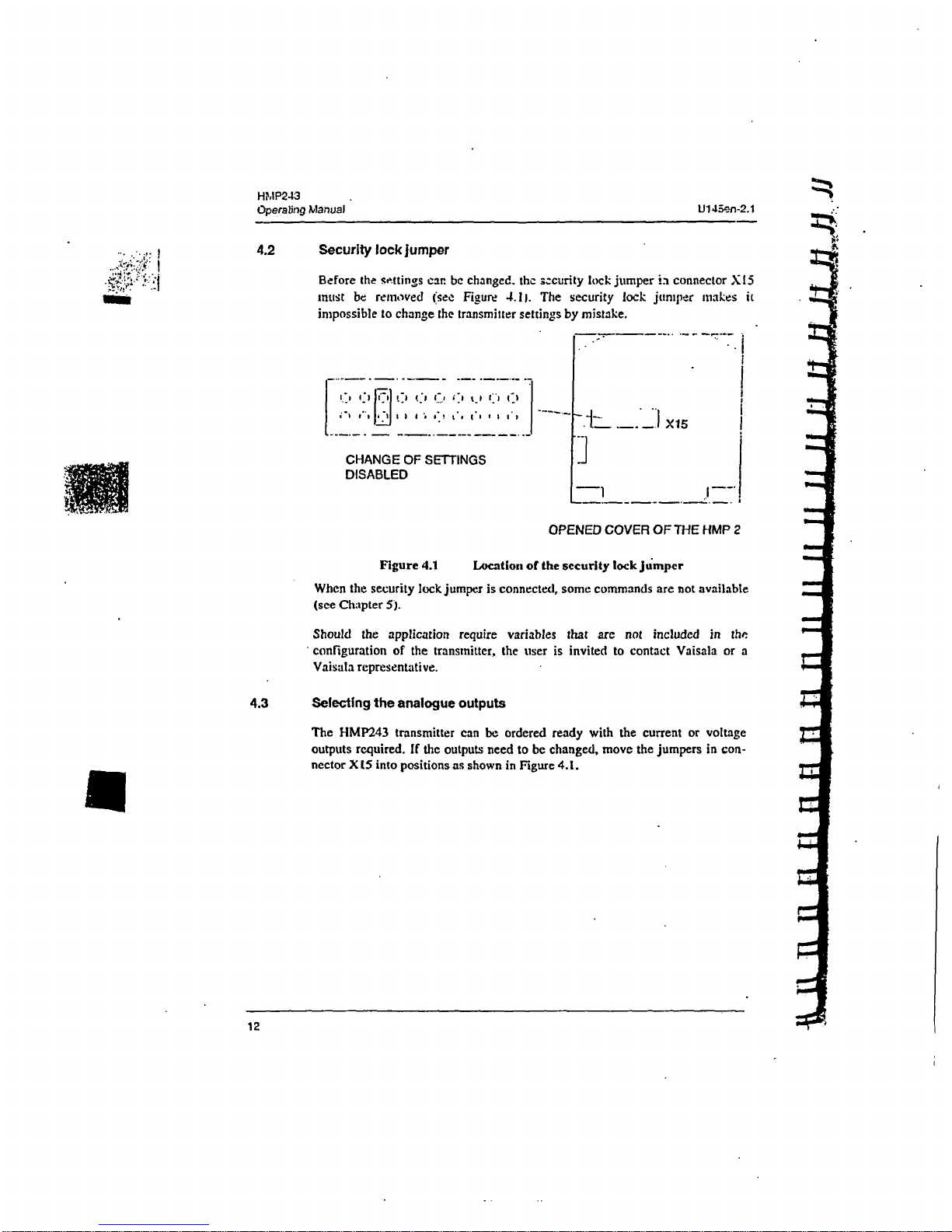

4.2

Security

lock

jumper

Before

the

s,.ttings

can

bc

changed.

thc

szcurity

lock

jumper

ia

connector

X15

must

be

removed

(see Figure

4.11.

The

security

lock

jumnper

makes

it

impossible

to

change

the

transmitter

settings

by mistake.

Ii' I°' - - - i "

*

'tI

~I

|

9'

CHANGE

OF

SETTINGS

DISABLED

]1

OPENED

COVER

OF

THE

HMP

2

Figure

4.1

Location

of

the

security

lock

Jumper

When

the

security

lock

jumper is

connected,

some

commands

are

not

available

(see

Chapter

5).

Should

the

application

require variables

that

are

not

included

in

thne

configuration

of

the

transmitter,

the

user

is

invited

to

contact

Vaisala

or

a

Vaisala

representative.

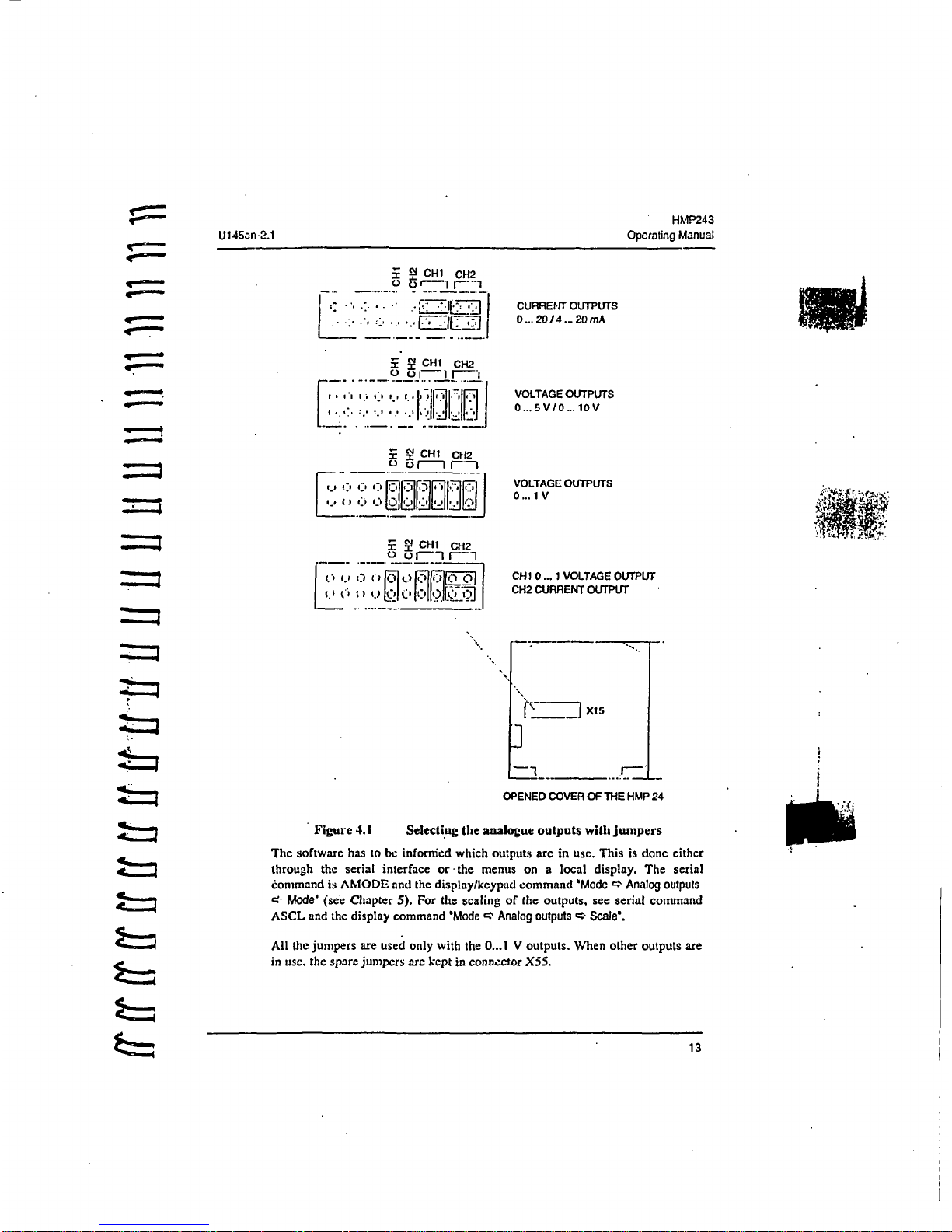

4.3

Selecting

the

analogue

outputs

The

HMP243

transmitter

can

be

ordered

ready with

the current or

voltage

outputs required.

If

the outputs

need to

be

changed,

move the

jumpers

in

con-

nector

XI5

into

positions

as

shown in

Figure

4.1.

I'mo

12

HMP243

U145an-2.1

Operating

Manual

-

CHI

CH2

N

CHI

CH2

SCHI

CH-2

oC.)

r__1_l----

13

WiF1FiFIF11

SCHI

CH2

o

C__1

o.'

C

o

1'

W

i

L

I

`,*

2

.

J

I

CURREtNT

OUTPUTS

0...

201/4...20

mA

VOLTAGE

OUTPUTS

0...5VI0...

1OV

VOLTAGE

OUTPUTS

0...

1V

CHI

0... 1 VOLTAGE

OUTPUT

CH2

CURRENT OUTPUT

X115

OPENED

COVER

OF

THE

HMP

24

Figure

4.1

Selecting the

analogue

outputs

with

jumpers

The

software

has

to

bc

inforried

which

outputs

are

in use. This

is

done

either

through

the

serial interface

or

'the menus

on a local

display.

The serial

,ommand

is

AMODE

and

the

display/keypad command

'Mode

c"

Analog

outputs

-L

Mode'

(see

Chapter 5).

For

the

scaling

of

the

outputs,

see

serial command

ASCL

and

the

display

command

'Mode

c' Analog

outputs * Scale%.

All

the

jumpers

are

used

only

with

the

0... t V

outputs.

When

other

outputs

are

in

use,

the

spare

jumpers

are

kept

in

connector

X55.

t

13

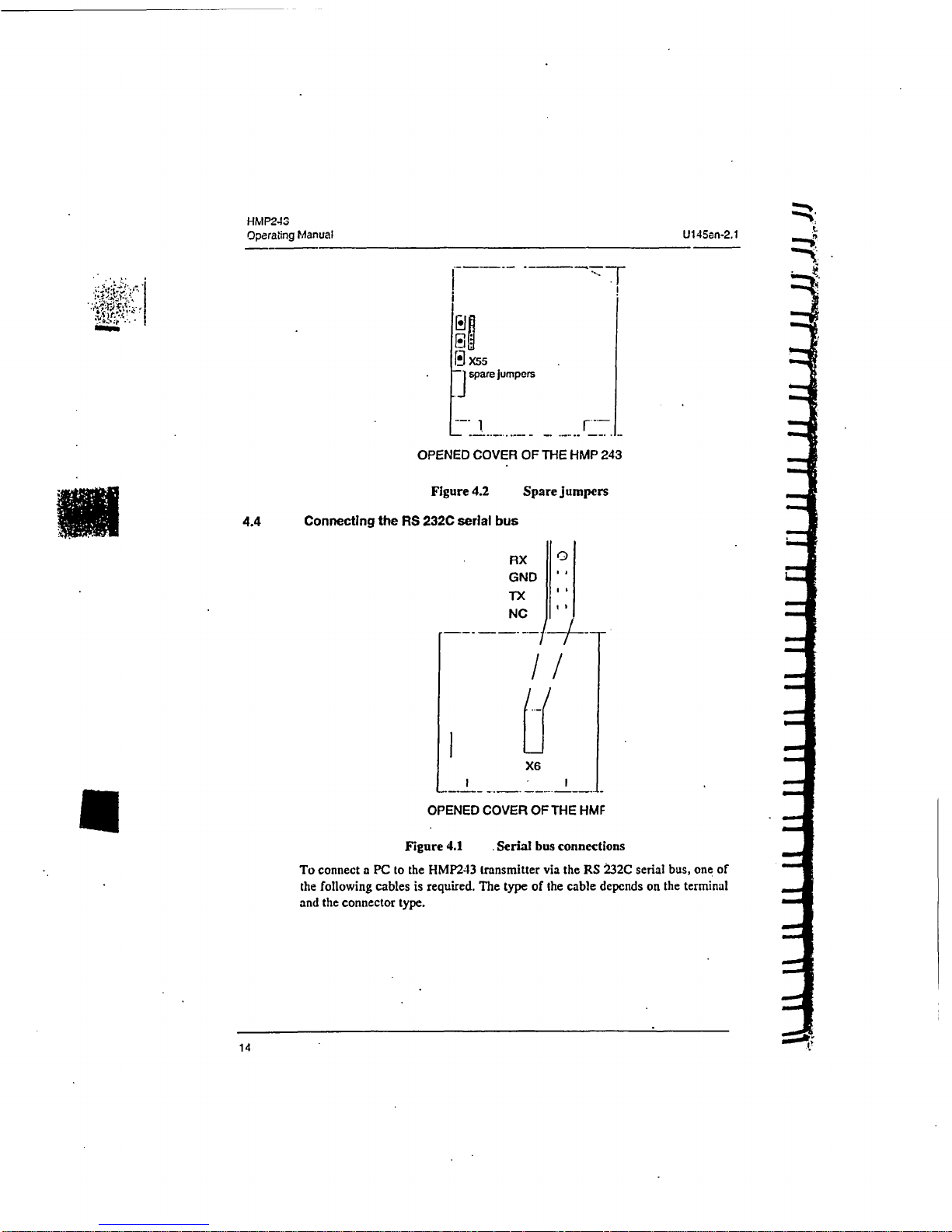

HMP243

Operating

Manual

U145on-2.1

MOWN

[~X55

J

spare

jumpers

"-'1

r-..

F-

OPENED

COVER

OF

THE

HMP

243

Figure

4.2

Spare

jumpers

4.4

Connecting

the

RS

232C

serial

bus

OPENED

COVER

OF

THE

HMF

Figure

4.1

Serial

bus

connections

To

connect

a

PC

to

the

HMP243

transmitter

via

the

RS

232C

serial

bus,

one

of

the

following

cables

is

required.

The

type

of

the

cable

depends

on

the

terminal

and the

connector

type.

14

i-H%,1243

U t

45er-2.1

Oparating

Manual

3

.TXD

b

TX

75 "--

GND

61

PC

TEMHL

~P7

=- -

Gtl

DIS

2

-

XDI

RX

HMP243

5.5

TERMINAL

D25P

7

-

GHD

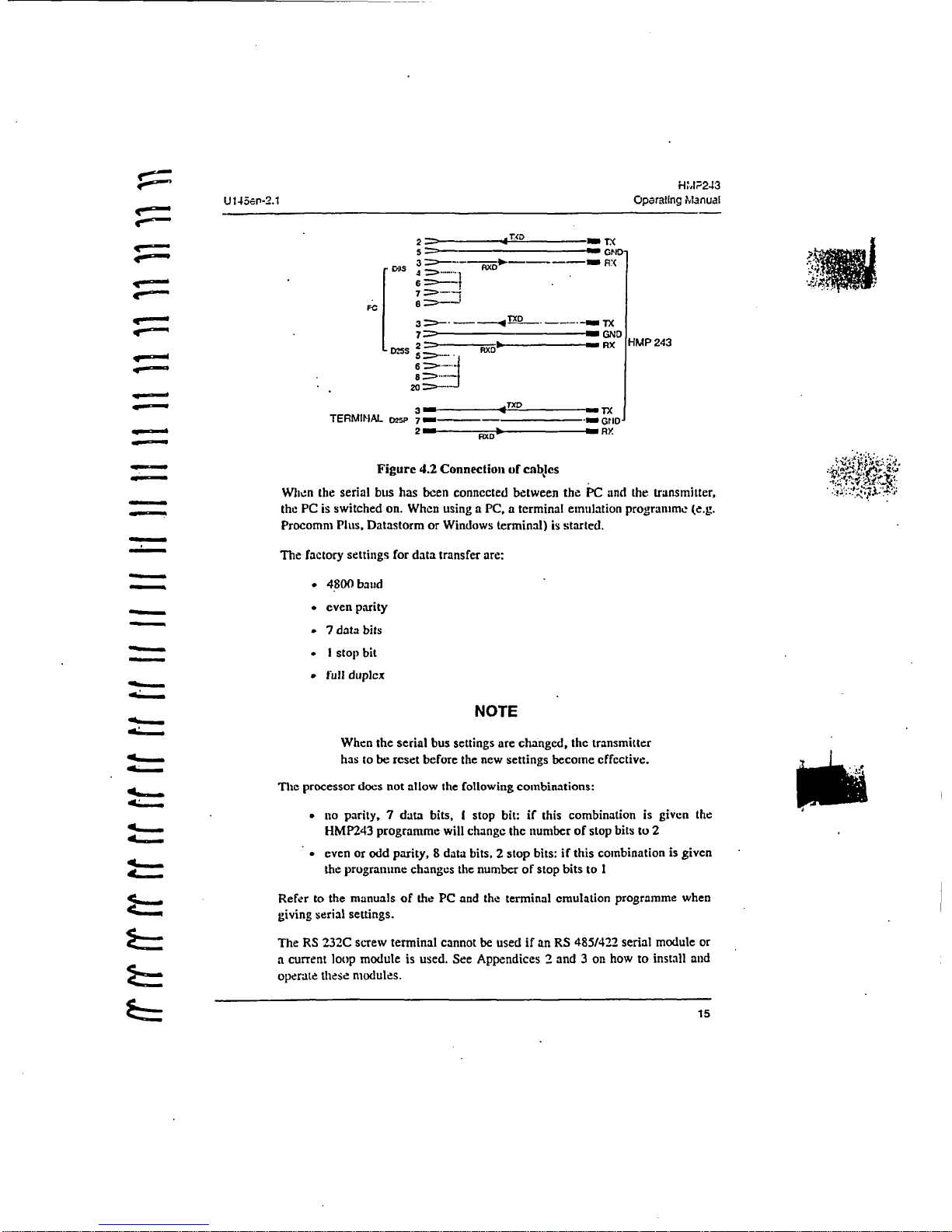

Figure

4.2

Connection

of cables

When

the

serial

bus

has

been connected

between the

PC

and

the

transmitter,

the

PC

is

switched

on.

When

using a PC, a terminal emulation programme

(e.g.

Procomm Plus,

Datastorm

or

Windows

terminal)

is

started.

-

The factory

settings

for

data

transfer

are:

•#

4800

baud

*

even

parity

-7 data

bits

- I

stop

bit

-

full

duplex

NOTE

When

the

serial

bus

settings

are

changed,

the transmitter

4-

has

to

be

reset

before

the

new

settings

become cffcctive.

_Thc

processor

does

not

allow

the

following

combinations:

-

no

parity,

7

data

bits, I stop

bit:

if

this

combination

is given the

~HMP243

programme

will

change

the number

of

stop bits

to

2

-

even

or odd

parity, 8 data

bits, 2 stop

bits:

if

this

combination

is

given

the

programme

changes

the

number

of

stop

bits to

I

*-

Refer

to

the

manuals

of

the

PC

and

the

terminal

emulation

programme

when

giving

serial settings.

The

RS

232C

screw

terminal

cannot

be

used

if

an

RS

485/422

serial

module

or

a current

loop module

is

used.

See

Appendices 2 and 3 on how

to

install

and

operate

these

modules.

15

-7

i•:;.:J

t'-.i::U145.a-.-2.'!

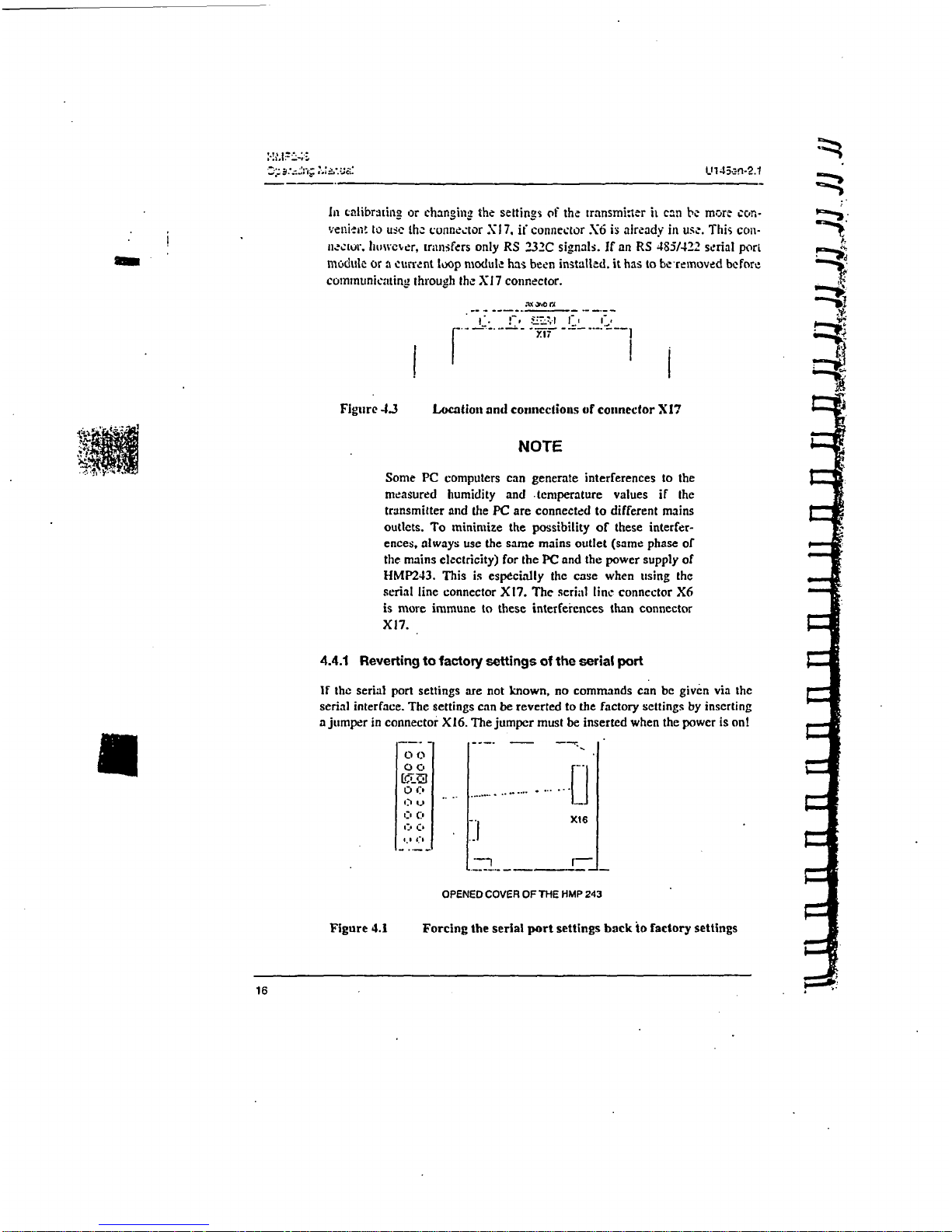

In

calibrafin2

or

changing

the

settings

of

the

transminter

it

can

be

more con-

venient

to

use

the

connector

XN

7.

if

connector

X6

is

already

in

use.

This

coil-

hector.

huwcrer,

transfers

only

RS

232C

signals.

If

an

RS

485/422

serial

port

module

or a current

loop module

has

been

installed,

it

has

to

be

removed before

communicating

through

the

XI 7 connector.

Figure

4.3

Location

and connections

of

connector

XI7

NOTE

Some

PC

computers

can

generate

interferences

to

the

measured

humidity

and

temperature

values

if

the

transmitter

and

the

PC

are

connected

to

different

mains

outlets.

To

minimize

the

possibility

of

these

interfer-

ences,

always

use

the

same

mains

outlet

(same

phase

of

the

mains

electricity)

for

the

PC

and

the

power

supply

of

HMP243.

This

is

especially

the

case

when

using

the

serial

line

connector

X17.

The serial

line

connector

X6

is

more

immune

to these

interferences

than

connector

Xl7.

4.4.1

Reverting

to

factory

settings

of

the serial

port

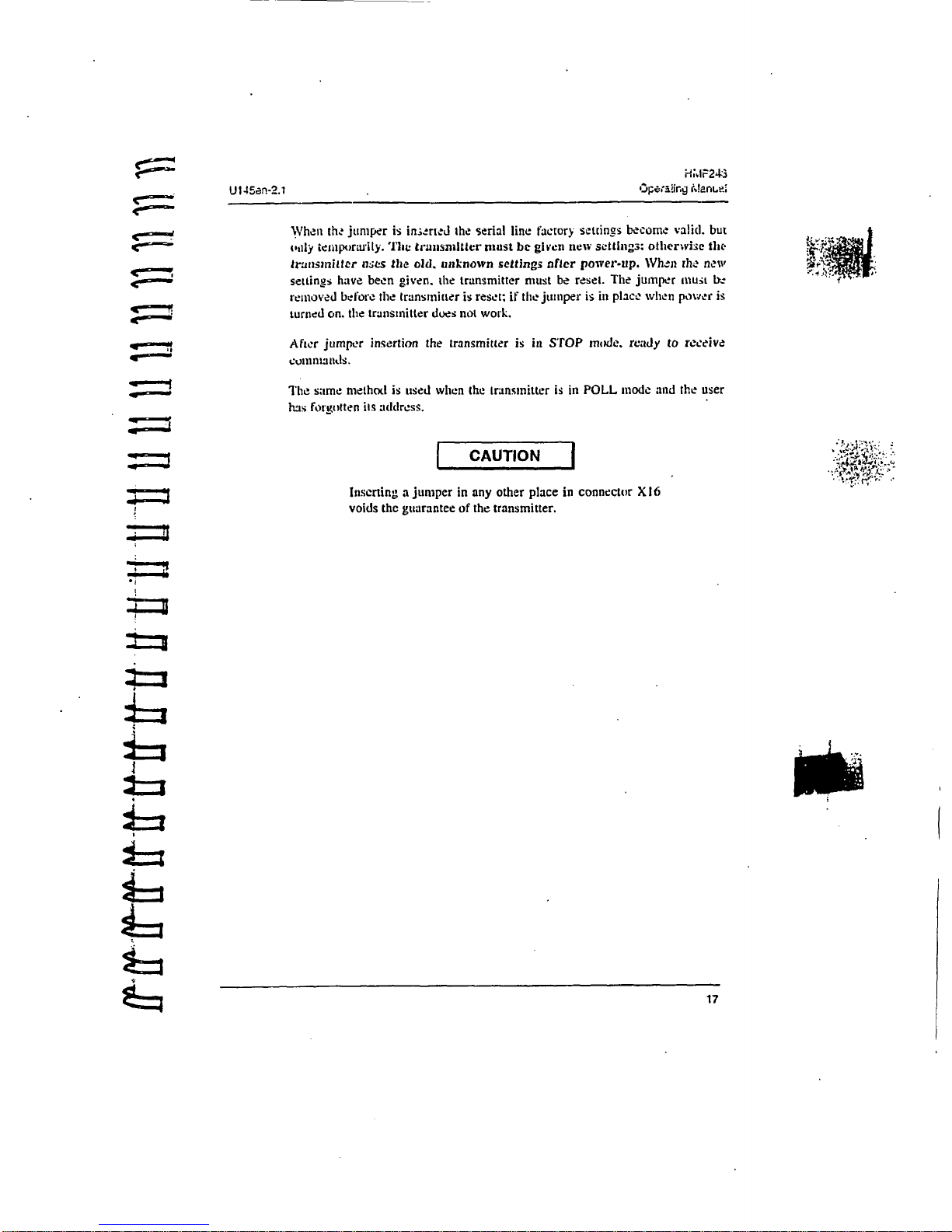

If

the

serial port

settings

are

not

known,

no

commands

can be

given

via

the

serial

interface.

The

settings

can be

reverted

to

the

factory

settings

by

inserting

a

jumper

in

connector

X16.

The

jumper

must

be

inserted

when

the power

is

on!

O00

NG

0

C, .

.

____I

.f

OPENED

COVER

OF

THE

HMP

243

Figure

4.1

Forcing

the

serial

port

settings

back

to

factory

settings

16

~HMdF24•3

U

145en-2.1

,O1eirg

ManLe,

When

the

juniper

is

in;.±rted the

serial

line factory

settings

become valid,

but

itily

iemp.'ura'ily.

'1rhe

tr-ansmltter

muast

be

given

new

setting3:

otherwise

the."

transmitter

aues

the

old.

unknown

settings

after

power-up.

WVhe.n

the

new

-settings

have

been

given,

the

transmitter

must

be

reset.

The

jumper

must

by

removed

before

the

transmitter

is

reset;

if

the

jumper

is

in

place

when

power

is

_turned

on.

the

transmitter

does

not

work.

After

jumper

insertion

the

transmitter

is

in

STOP

mtde.

ready

to

receive

S¢colnniands.

The

same

method

is

used

when the

transmitter

is

in

POLL

mode

and

the

user

has

forgaotten

its

address.

-

CAUTIONý

Inserting

a

jumper

in

any

other place

in

connector

X16

voids

the

guarantee

of

the

transmitter.

17

HMP243

Operating

Manual

U!45en-2.1

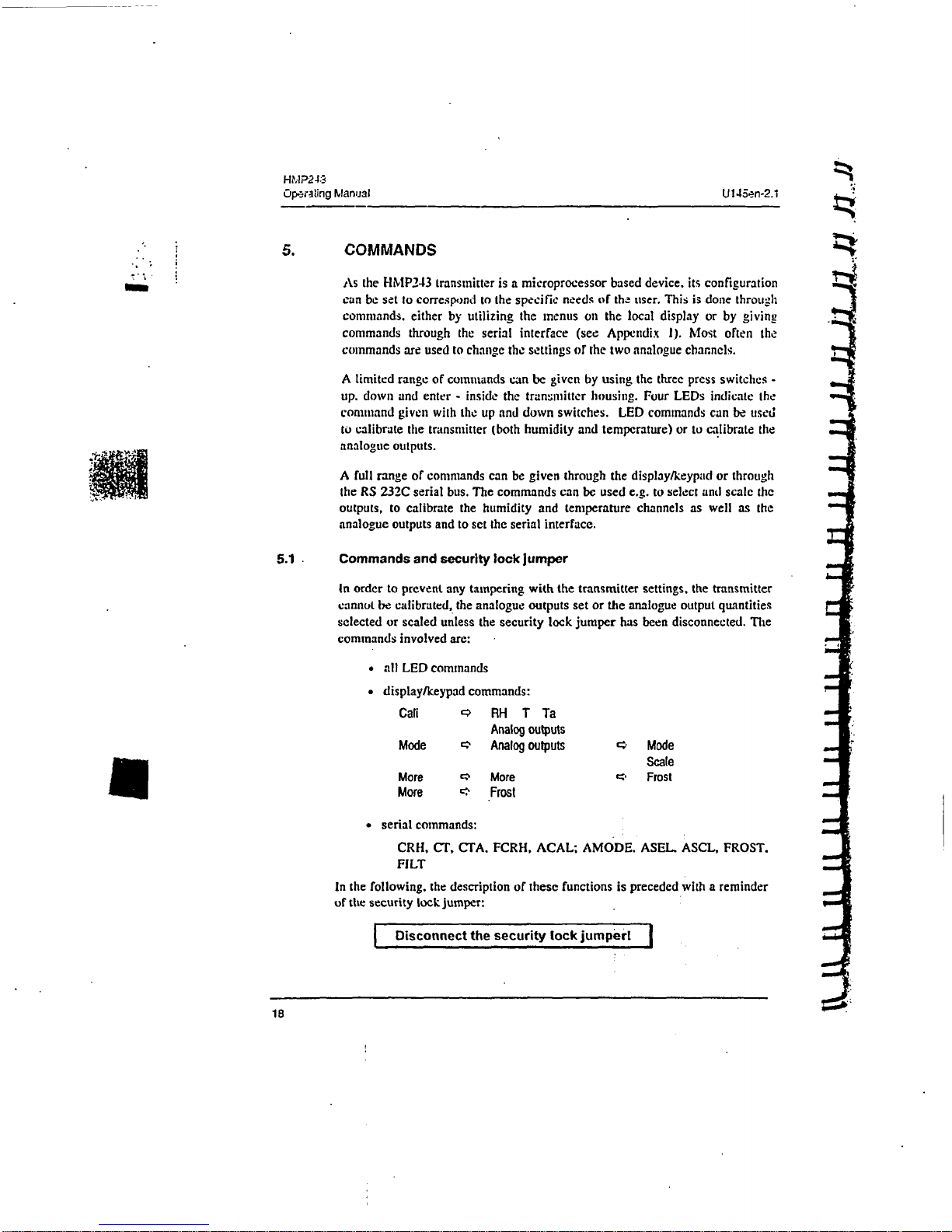

5.

COMMANDS

_

As

the

HIMP243

transmitter

is a microprocessor

based

device,

its

configuration

can

be

set

to

correspond

to

the

specific

needs

of

thc

user.

This

is

done through

commands,

either

by

utilizing

the

menus

on

the

local

display

or

by

giving

commands

through

the

serial interface

(see

Appendix

1).

Most

often

the

commands

are

used

to

change the

settings

of

the two analogue

channels.

A

limited

range

of

commands

can be

given

by

using

the

three

press

switches

-

up.

down

and

enter

-

inside

the

transmitter

housing.

Four

LEDs

indicate

the

command

given

with

the

up

and

down switches.

LED

commands

can

be

used

to

calibrate

the

transmitter

(both

humidity

and

temperature)

or

to

calibrate

the

analogue

outputs.

A

full

range

of

commands

can

be

given

through

the

display/keypad

or

through

the

RS

232C

serial

bus.

The

commands

can

be

used

e.g. to

select

anti

scale

the

outputs,

to

calibrate

the

humidity

and

temperature

channels

as

well

as

the

analogue

outputs

and

to

set the

serial

interface.

5.1

Commands and security

lock

jumper

In

order

to

prevent

any

tampering

with

the

transmitter

settings,

the

transmitter

cannot

be

calibrated,

the

analogue

outputs set or

the

analogue

output

quantities

selected

or

scaled

unless

the

security

lock

jumper

has

been

disconnected.

The

commands

involved

are:

•

all

LED commands

"

display/keypad

commands:

Cali

•

RH

T Ta

Analog

outputs

Mode

c:

Analog

outputs

•

Mode

Scale

More

cc

More

C:,

Frost

More

,

Frost

*

serial

commands:

CRH,

CT,

CTA.

FCRH,

ACAL; AMODE.

ASEL.

ASCL,

FROST.

FILT

In

the

following,

the

description

of

these

functions

is

preceded

with

a reminder

of

the

security

lock

jumper:

Disconnect

the

security

lock

jumpert

IV

FHNI24S

U145.en-2.1

Operating

',Aanuai

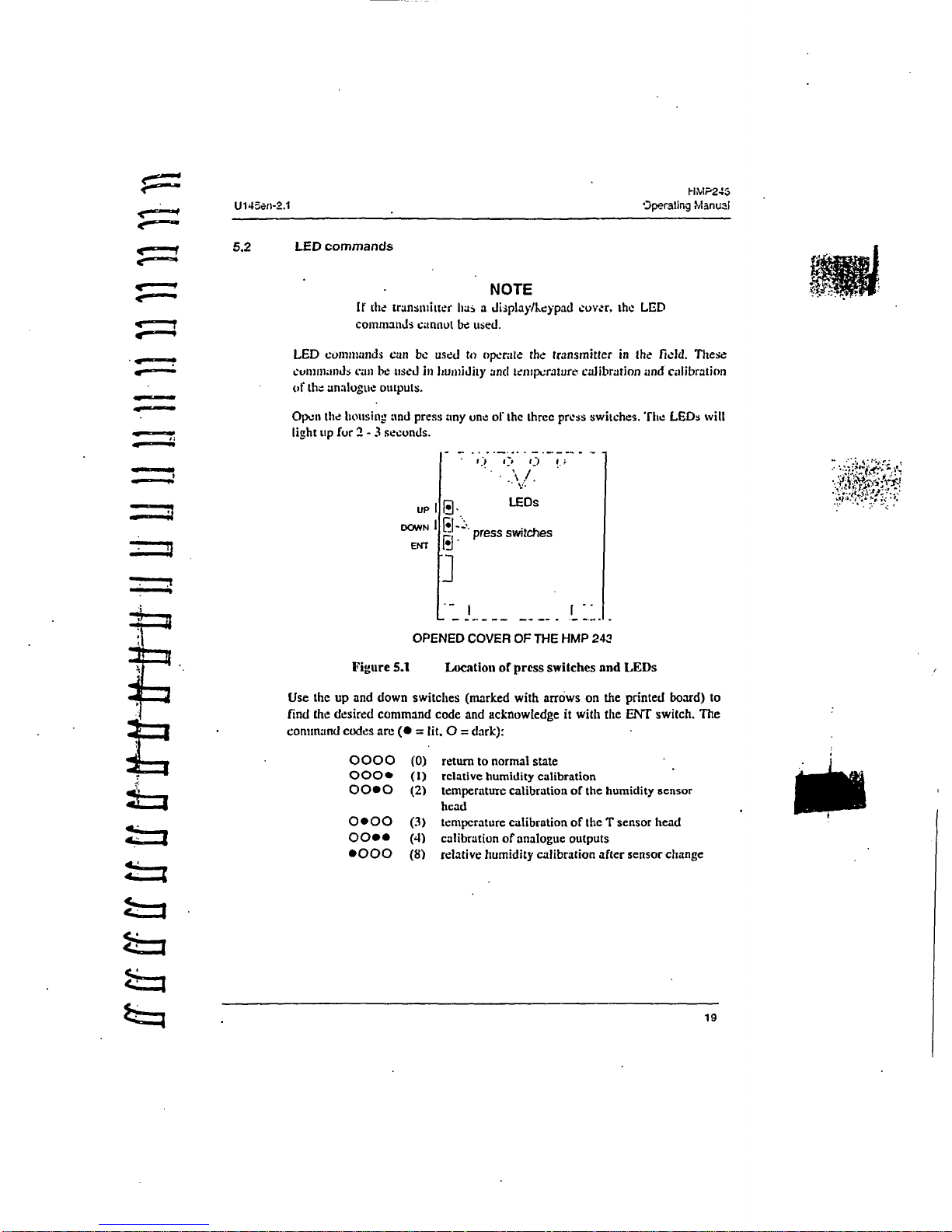

5.2

LED

commands

Jar

NOTE

If

the

transmitter

has a di3play/keypad

cover.

the

LED

commands cannot

be

used.

.

=.-.

LED

commands

can be used

to

operate

the

transmitter

in the

field.

These

cuminands

can

be

used

in

humidity

and

tenipcrature

calibration

and

calibration

of

tha

analogue

outputs.

Open

the

housing and

press

any

one

of

the

three

press

switches.

hie

LEDs

will

light

up

fur

2 -3 seconds.

up

DOWN

ENT

LEDs

]"

press

switches

.-A

OPENED

COVER

OF

THE

HMP

242

Figure

5.1

Location

of

press

switches

and

LEDs

Use

the

up

and

down switches

(marked

with

arrows

on

the

printed

board)

to

find

the

desired

command

code

and acknowledge

it

with

the

ENT

switch.

The

command codes

are

(*

=

lit. 0 =

dark):

0000

0000

0000

(0)

return

to

normal

state

(1)

relative humidity

calibration

(2)

temperature

calibration

of

the

humidity

sensor

head

0000

(3)

temperature

calibration

of

the T sensor

head

0000

(4)

calibration

of

analogue

outputs

0000

(8)

relative humidity

calibration

after

sensor

change

19

HWP'24:3

Operatt.g1

Mm•'.;

U145e-r-2.1

5.3

Displaylkeypad

commands

loin

5.3.1

Display

mode

In

the

display

mode

the

transmitter

outputs

measurements

on

the

display:

dif-

.

ferent

quantities

can

be

scrolled with arrow

keys.

The first

line

is

scrolled

with

button o and

the second

line with

button

r; all selections

are

stored

with

ENTER.

The selected

quantities

appear

on

the

display also

after

power failure.

Afwtr

reset

the

transmitter

is

always

in

the

display

mode.

The

display

also

shows

error messages

and

alarms

if

they

occur.

5.3.2

Command

mode

Press

the

CL

key

to

enter

the command

mode.

The

first display

is

the

main

menu:

Cali i MrV.

ttre

The

commands

can

be

scrolled

with

the arrow keys.

The

currently

active

command

flashes; a command

is

selected

with

the

ENT

key.

When a menu

is

displayed,

either

the first command

or

the

currently

valid

$etting flashes.

The

CL

key

takes

the

transmitter

back

to

the display

mode.

5.3.3

Entering

numbers

When

numbers

need

to

be

entered

into

the

transmitter

programme

(e.g.

when

scaling

or

setting

the

analogue outputs, in

calibration or

when

giving

the

transmitter

an

address),

the

field

is

either

empty

or

the

currently valid

figure

is

displayed.

Any

previously

given value

is

deleted with

the

CL

key.

When

the

field

is empty,

a

cursor

blinks

on

the right side

of

the

display.

Pressing

the arrow

keys

makes

either

a blank

' .a comma

'. a dash

'-.

a full

stop

'.'

or a number

from 0 to

'9'

appear

on

the

display.

The

right character

is

selected

with ENT; after

that the number or

numbers

move

left one

step.

Entering

numbers

is

ended

with

selecting a blank

''and

pressing

ENT.

The

last

character

entered

can

be

deleted

with

CI.,.

If

CL

or

ENT

key

is

pressed

when

the

field

is

empty,

the

programme

returns

to

the

previous

display.

With some commands

(e.g.

calibration)

the

figures are changed

using

the

arrow

keys.

When

an

arrow

key

is

pressed

continuously

for a

while,

the

numbers

start

changing

at

an

increasing

rate.

20

U',45er,.2.I

Operating

;.,t&-.'ual

e.==-=43

5.3.4

Analogue

output

commands

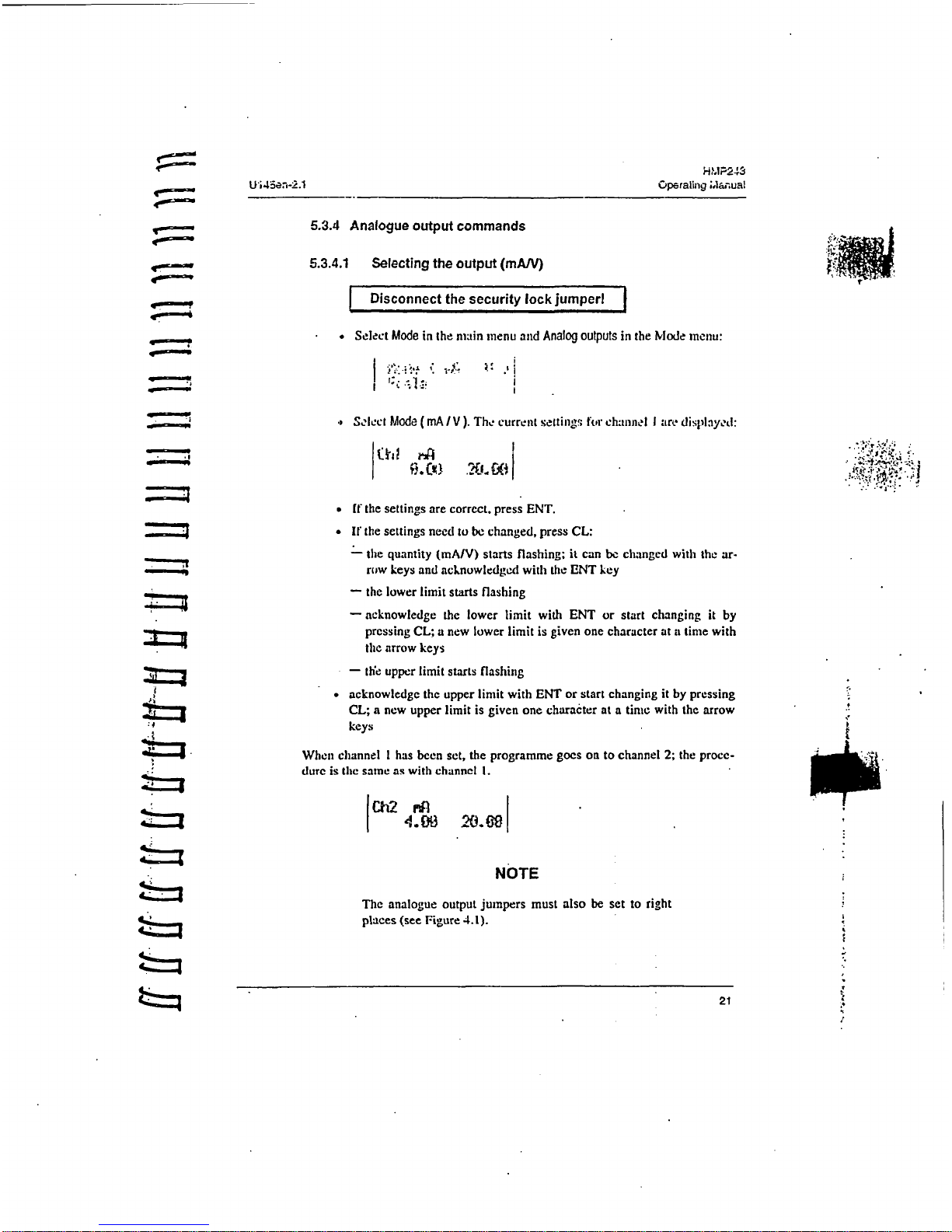

5.3.4.1

Selecting

the

output

(mAN)

Disconnect

the

security

lock

jumper!

•

Select

Mode

in

the

main

menu

and

Analog

outputs

in

the

Mode menu:

Select

Mode

(mA/V

).

The

current settings

ftr

chaimnl I are

displayed:

*

If

the

settings

are

correct,

press

ENT.

.

If

the

settings

need

to

be

changed,

press

CL:

-

the

quantity

(mA/V)

starts

flashing;

it

can

be

changed

with

the

ar-

row

keys

and

acknowledged

with

the ENT

key

-

the

lower

limit starts flashing

-

acknowledge

the

lower

limit

with

ENT

or

start

changing

it

by

_ _pressing

CL;

a

new

lower

limit

is

given one

character

at a time

with

the arrow keys

--

the

upper

limit starts

flashing

*

acknowledge

the

upper

limit with

ENT

or

start

changing

it

by

pressing

CL; a

new

upper

limit

is

given

one

character

at a

time

with

the

arrow

keys

When

channel

I

has

been set, the

programme goes

on

to

channel

2;

the

procc-

dure

is

the

same

as

with channel

I.

Ch2

MA

NOTE

The analogue

output

jumpers

must

also

be

set

to

right

places

(see

Figure

4.

1).

21

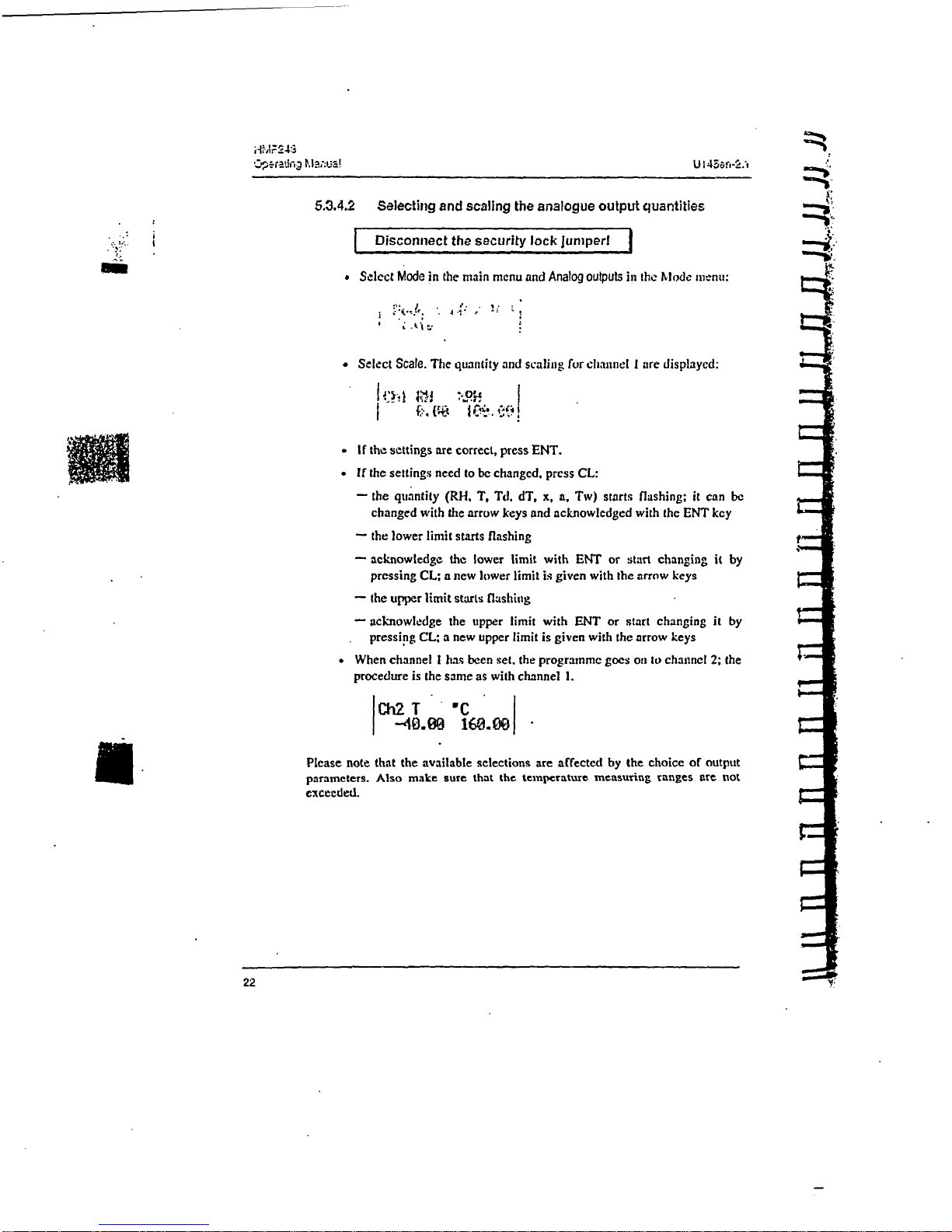

5.3.4.2

Selecting

and scaling

the

analogue

output

quantities.

Disconnect

the

security

lock

juniper.

a

Select

Mode

in

the

main menu

and

Analog

outputs

in

the

Mode

menu:

Select

Scale.

The

quantity

and

scaling for

channel I are

displayed:

"

If

the

settings

are

correct,

press ENT.

-

If

the

settings

need

to

be

changed,

press

CL:

-

the quantity

(RH,

T, Td,

dT,

x,

a,

Tw)

starts

flashing:

it

can

be

changed

with

the

arrow

keys

and

acknowledged

with

the ENT

key

-

the

lower

limit

starts

flashing

-

--

acknowledge

the

lower

limit

with

ENT

or start

changing

it

by

pressing

CL;

a

new

lower

limit

is

given

with

the

arrow

keys

-

the

upper

limit

starts

flashing

-

acknowledge

the upper

limit

with

ENT

or

start changing

it

by

pressing

CL; a new

upper

limit

is given

with

the

arrow

keys

*

When

channel

I

has

been

set.

the

programme

goes

on

to

channel

2;

the

procedure

is

the

same

as

with

channel

1.

--

40.N

16•.

O0

U

.

Please

note that the available

selections

are

affected

by

the choice

of

output

parameters.

Also

make

sure

that the

temperature

measuring

ranges

are

not

exceeded.

22

Hr.-!I P2an

La

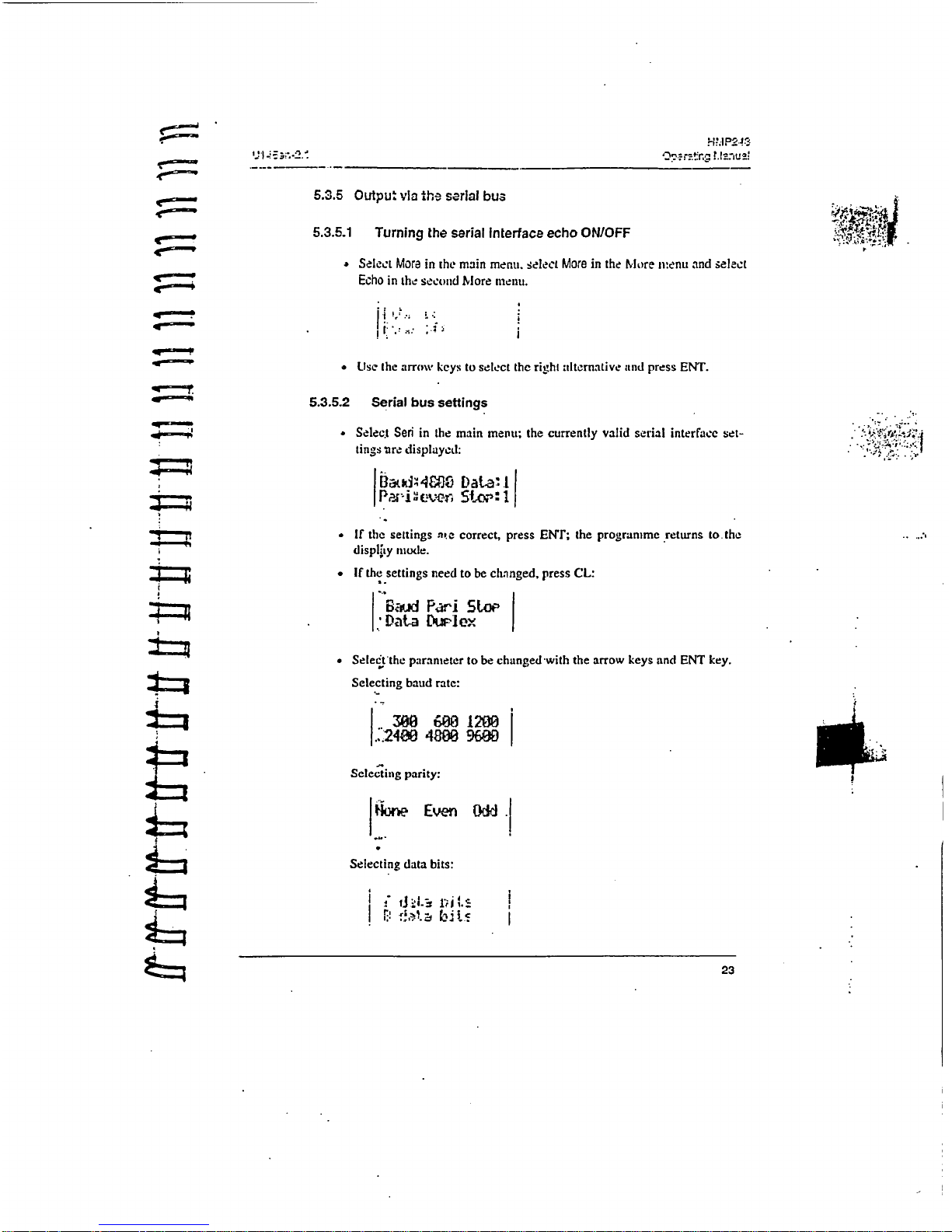

5.3.5

Output

via

the

serial

bu.

5.3.5.1

Turning

the

serial

Interface

echo

ON/OFF

Select

More

in

the

main

menu.

select

More

in

the

More

ne:nu

and

•elect

-.

Echo

in

the

second

More

menu.

*

Use

the

arrow

keys

to

select

the

righi

alternative

and

press

ENT.

5.3.5.2

Serial

bus

settings

'

-

-Selec.t

Seri

in

the

main

menu;

the

currently

valid

serial

interface

set-

.

lings

ure

displayed:

ZP

.="4:-.•r

ZLOP

1

,:

__

i

I

___

If

the

settings

ate

correct,

press

ENT;

the

programme

.returns

to.the

display

mode.

.

If

the

settings

need

to

be

changed,

press

CL:

"B6-

Pari

RLoe

..

'

Data

I

I

lex

Seleiitthe

parameter

to

be

changed

with

the

arrow

keys

and

ENT

key.

Selecting

baud

rate:

4800

9600

Seleýting

parity:

hoe

Even,

OMd

Selecting

data

bits:

23

Selecting

stop

biti:

Full

duplex/half

duplex:

The

processor

does

not

allow

the

following combinations:

-

no

parity, 7 data

bits, I

stop

bit:'if

this

combination

is

given

the

HMP243

programme

will

change

the

number

of

stop

bits

to

2

#

even

or

odd

parity,

8

data

bits.

2

stop

bits:

if

this

combination

is

given

the

programme

changes

the

number

of

stop

bits

to

I

NOTE

The

serial

bus

settings

become

effective

only

after reset.

5.3.5.3

Setting

the

transmitter

address

Address

is

used

when more

than

one

transmitter

is

connected

to

one

serial

bus;

this

way,

it

is

possible

to communicate

with

one'transmitter

at

a

time.

.

Select

Addr

in

the main

menu:

the

following

is

displayed:

99

Pressing

ENT

returns

the

programme

to

the

main

menu.

o

Pressing

CL deletes

the old

address;

enter

the

new

address

with

the

arrow

keys.

Loading...

Loading...