Page 1

HMP228

Moisture and Temperature

Transmitter for Oil

USER'S GUIDE

M210282en-A

May 2002

Page 2

PUBLISHED BY

Vaisala Oyj Phone : (+358 9) 894 91

P.O. Box 26 Fax: (+358 9) 8949 2227

FIN-00421 Helsinki

Finland

Visit our Internet pages at http://www.vaisala.com/

© Vaisala 2002

No part of this manual may be reproduced in any form or by any

means, electronic or mechanical (including photocopying), nor may its

contents be communicated to a third party without prior written

permission of the copyright holder.

The contents are subject to change without prior notice.

ii

Page 3

HMP228

M210282en-A Operating Manual

Contents

1. PRODUCT DESCRIPTION...................................................................................................1

1.1 General characteristics........................................................................................... 1

1.2 Typical applications................................................................................................1

1.2.1 About the method used for measuring moisture in oil................................1

1.2.2 Lubrication oil in paper machines..............................................................2

1.2.3 Transformer oil ......................................................................................... 2

2. INSTALLATION ................................................................................................................... 3

2.1 Selecting the place of installation for the probe and the transmitter................... 3

2.2 Mounting..................................................................................................................4

2.2.3 Installing the probe through the ball valve assembly.................................. 6

2.2.4 Mounting the probe directly in the process pipe ......................................... 9

2.3 Signal cabling and grounding .............................................................................. 10

2.3.1 Electrical connections ............................................................................. 10

2.3.2 Connection to an AC supply.................................................................... 11

2.3.3 Grounding...............................................................................................12

3. COMMISSIONING.............................................................................................................. 14

3.1 Changing the parameters ..................................................................................... 14

3.1.1 Security lock jumper................................................................................ 14

3.1.2 Commands and security lock jumper....................................................... 15

3.2 Using the RS 232C serial bus............................................................................... 16

3.3 Using LED commands........................................................................................... 18

3.4 Using display/keypad commands......................................................................... 18

3.4.1 Display mode.......................................................................................... 18

3.4.2 Command mode ..................................................................................... 19

3.4.3 Entering numbers.................................................................................... 19

4. MAINTENANCE ................................................................................................................. 20

4.1 Self-diagnostics ....................................................................................................20

4.2 Reference measurements..................................................................................... 20

4.3 Moisture calibration.............................................................................................. 21

4.3.1 Two point calibration procedure ............................................................... 22

4.3.1.1 Using serial commands............................................................................22

4.3.1.2 Using display/keypad commands ............................................................. 22

4.3.1.3 Using LED commands.............................................................................. 23

4.3.2 One point calibration procedure ............................................................... 23

4.3.2.1 Using serial commands............................................................................23

4.3.2.2 Using display/keypad commands ............................................................. 24

4.3.2.3 Using LED commands.............................................................................. 24

4.4 Changing the moisture sensor.............................................................................24

4.4.1 Calibration procedure after sensor change...............................................25

4.4.1.1 Using serial commands............................................................................25

4.4.1.2 Using display/keypad commands ............................................................. 25

4.4.1.3 Using LED commands.............................................................................. 26

4.4.5 Humidity calibration table......................................................................... 27

4.6 Temperature calibration........................................................................................ 27

4.6.1 One point offset correction.......................................................................27

4.6.1.1 Using serial commands............................................................................27

iii

Page 4

HMP228

Operating Manual M210282en-A

4.6.1.2 Using display/keypad commands..............................................................28

4.6.1.3 Using LED commands.............................................................................. 28

4.6.2 Two point temperature calibration.............................................................28

4.6.2.1 Using serial commands ............................................................................ 28

4.6.2.2 Using display/keypad commands..............................................................29

4.6.2.3 Using LED commands.............................................................................. 29

4.6.3 Temperature channel adjustment with Pt 100 simulators..........................30

4.7 Analogue output channels....................................................................................31

4.7.1 Setting the analogue outputs ....................................................................31

4.7.1.1 Using serial output....................................................................................32

4.7.1.2 Using display/keypad commands..............................................................33

4.7.2 Selecting and scaling the analogue output quantities................................34

4.7.2.1 Using serial output....................................................................................34

4.7.2.2 Using display/keypad commands..............................................................34

4.8 Checking and calibrating the analogue outputs..................................................35

4.8.1 Measurement of output currents using test points .....................................35

4.8.1 Calibration of the analogue outputs ..........................................................36

4.8.1.1 Using serial commands ............................................................................ 37

4.8.1.2 Using display/keypad commands..............................................................37

4.8.1.3 Using LED commands.............................................................................. 38

4.9 Other functions......................................................................................................38

4.9.1 Adjusting the contrast of the display.........................................................38

4.9.2 Reverting to factory settings of the serial port.......................................... 38

5. TECHNICAL DATA.............................................................................................................40

5.1 Water activity.........................................................................................................40

5.2 Temperature...........................................................................................................40

5.4 Analogue outputs..................................................................................................40

5.5 Electronics.............................................................................................................41

5.6 Mechanics..............................................................................................................41

5.7 Electromagnetic compatibility.............................................................................. 43

5.7.1 Emissions................................................................................................43

5.7.2 Immunity .................................................................................................43

6. OPTIONS ...........................................................................................................................44

7. SPARE PARTS ...................................................................................................................44

APPENDIX 1: SERIAL COMMANDS..........................................................................................45

APPENDIX 2: DISPLAY COMMANDS........................................................................................66

APPENDIX 3: POWER SUPPLY MODULE ................................................................................ 73

APPENDIX 4: INSTALLING AND USING THE RS 485/422 SERIAL PORT MODULE ................77

APPENDIX 5: INSTALLING AND USING THE DIGITAL CURRENT LOOP MODULE ................88

APPENDIX 6: ERROR MESSAGES ...........................................................................................98

APPENDIX 8: CONNECTORS..................................................................................................105

APPENDIX 9: WIRING 109

iv

Page 5

HMP228

M210282en-A Operating Manual

This page intentionally left blank.

v

Page 6

Page 7

HMP228

M210282en-A Operating Manual

1. PRODUCT DESCRIPTION

1.1 General characteristics

The HMP228 transmitter is a microprocessor based instrument for the

measurement of moisture in terms of water activity e.g. in the lubrication of

circulation systems or in transformer oil. The transmitter incorporates a

capacitive thin film sensor. The operation of the sensor is based on changes in

its capacitance as the thin polymer film absorbs water molecules.

The HMP228 transmitter has two analogue outputs and can be connected to a

serial bus via the RS 232C interface or through an RS 485/422 serial module

or a current loop module.

The transmitter can be configured in many ways. It can have either a blank

cover or a cover with a local display and keypad with which the user can

operate the transmitter. The power supply voltage can be selected from three

alternatives. Two analogue output signals can be scaled and the measurement

ranges changed within certain limits. The HMP228 transmitter can be supplied

with two, five or ten metre sensor head cable.

The HMP228 also provides for accurate temperature measurement. It is an

easy-to-install on-line transmitter which can be calibrated against traceable

salt solutions.

Options

Power supply 24 VDC (standard); (24 VAC: see Chapter 2.3.2),

Serial interface RS 232C (standard), RS 485/422, current loop

Display cover cover with or without local display & keypad

Alarm output unit not with 115/230 VAC power supply

Cable length 2, 5 or 10 metres

Cable connectors for 24 VDC supply, for analogue outputs, for RS

1.2 Typical applications

1.2.1 About the method used for measuring moisture in oil

The HMP228 transmitter measures water in oil in terms of water activity (aw)

which can be determined as follows: water activity indicates the amount of oil

in the scale of 0 - 1 aw. In this scale, 0 aw is an indication of completely water

free oil and 1 aw an indication of oil fully saturated with water. Water is

present in free form.

115/230 VAC

232C line and for RS 485 single loop line; see

Appendix 8 for details.

The most important feature which distinguishes the measurement of water

activity (aw) from the traditional measurement of absolute water content (in

1

Page 8

HMP228

Operating Manual M210282en-A

ppm) is that the saturation point remains stable regardless of the oil type or the

aging of oil, additives used etc. As water activity exceeds 0.9 aw in any

system, there is a risk for segregation (especially if the temperature decreases).

The water activity is used for alarming at the point of >0.9 aw that the risk for

free water in the system is obvious. The most important advantages of this

system are the fact that water activity is immune to the aging of oil and to

additives, and that the HMP228 transmitter can be used for continuous on-line

measurements. In addition, the HMP228 can be calibrated against salt

solutions and no reference oils are needed.

1.2.2 Lubrication oil in paper machines

Typically, a paper machine contains two or three separate lubrication systems.

Usually, one is located at the wet end and the other at the dry end. There is a

certain amount of free moisture constantly present which means that there is a

risk of this moisture becoming into contact with the machine bearings. The

most common reasons for the entrance of water are an inadequate sealing of

the housing and cleaning with high pressure. However, accidental leakages

from oil coolers and other equipment may also cause damage. In paper

machines, the oil should absorb water while lubricating the bearings and then

release this water when collected into the reservoir. It is to be noted that

bearings should never be exposed to oils that have a high water content; this is

especially important during standstill because the risk for corrosion process

increases as the oil temperature decreases. It is essential to monitor the water

content and keep it on a suitable level.

When measuring the water content of oil in paper machines, it would be useful

to measure the water activity before an oil reservoir and from a pressure line

flow. This way, the performance of dehumidifiers can be kept under control to

ensure that no free water reaches the bearings.

1.2.3 Transformer oil

The determination of moisture in oil is an essential part of a comprehensive

transformer maintenance program. Aging and deterioration increase the

capacity of oil to absorb water. The primary interest in transformers is to

measure the water not in oil but in the cellulosic insulation around the

transformer windings. Heating and cooling have a considerable effect on

moisture levels in oil. While temperature raises, the paper insulation of

transformers tends to loose moisture which is absorbed by the oil surrounding

it. Saturation level is thus a true indicator of moisture present. The HMP228

method provides for a reliable detection of the aging of oil and possible

leakages. Water activity helps to prevent heavy overloadings and to monitor

the transportation of moisture in the transformer.

2

Page 9

HMP228

M210282en-A Operating Manual

2. INSTALLATION

2.1 Selecting the place of installation for the probe and the transmitter

Select a place which gives a true picture of the process. Oil should circulate

freely around the sensor; a rapid oil flow is recommended. Install the sensor

directly into the circulation system and not into the oil reservoir because of

deposition.

It is recommended that the sensor head is installed directly in the process

through the ball valve assembly. When the ball valve assembly is used, the

pipe does not have to be emptied or shut down for installation or removal of

the probe. Install the sensor head transversely against the direction of the

process flow.

NOTE

Avoid mounting the transmitter housing close to steam

sources or directly exposed to rain. To ensure an IP 65

class protection:

1. Always mount the transmitter housing with the cable

bushings pointing downwards.

2. Make sure that the connection cable has the right

thickness (∅ 7...10 mm) and that the cable bushing

is carefully tightened.

3. Pay always special attention to closing the

transmitter cover carefully and remember to tighten

all four screws.

NOTE

Take care not to damage the pipe of the probe. If the

pipe is damaged, the probe head is less tight and will

not go through the clasp nut. Make sure that the filter is

tightly fastened to protect the sensors.

3

Page 10

HMP228

Operating Manual M210282en-A

2.2 Mounting

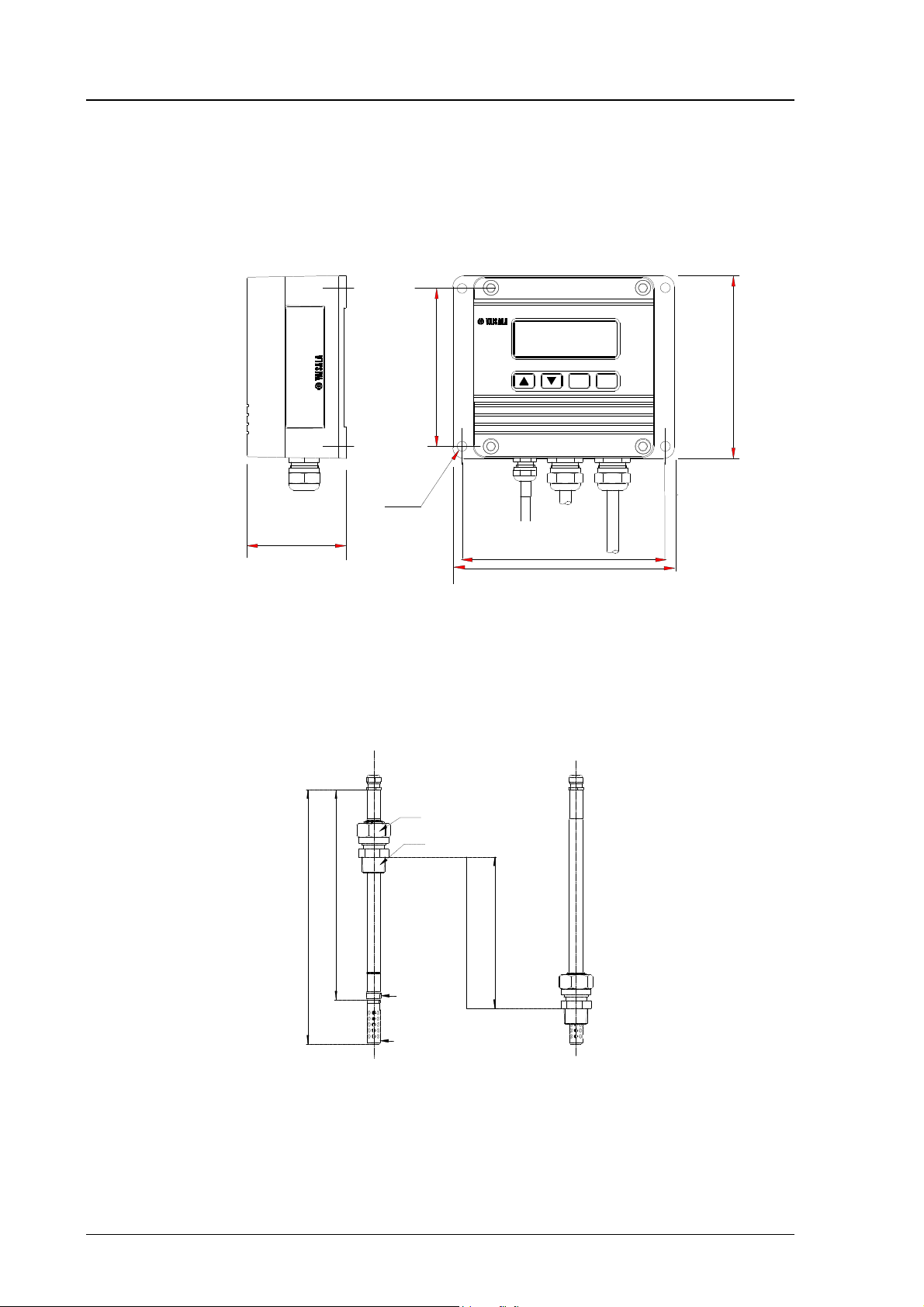

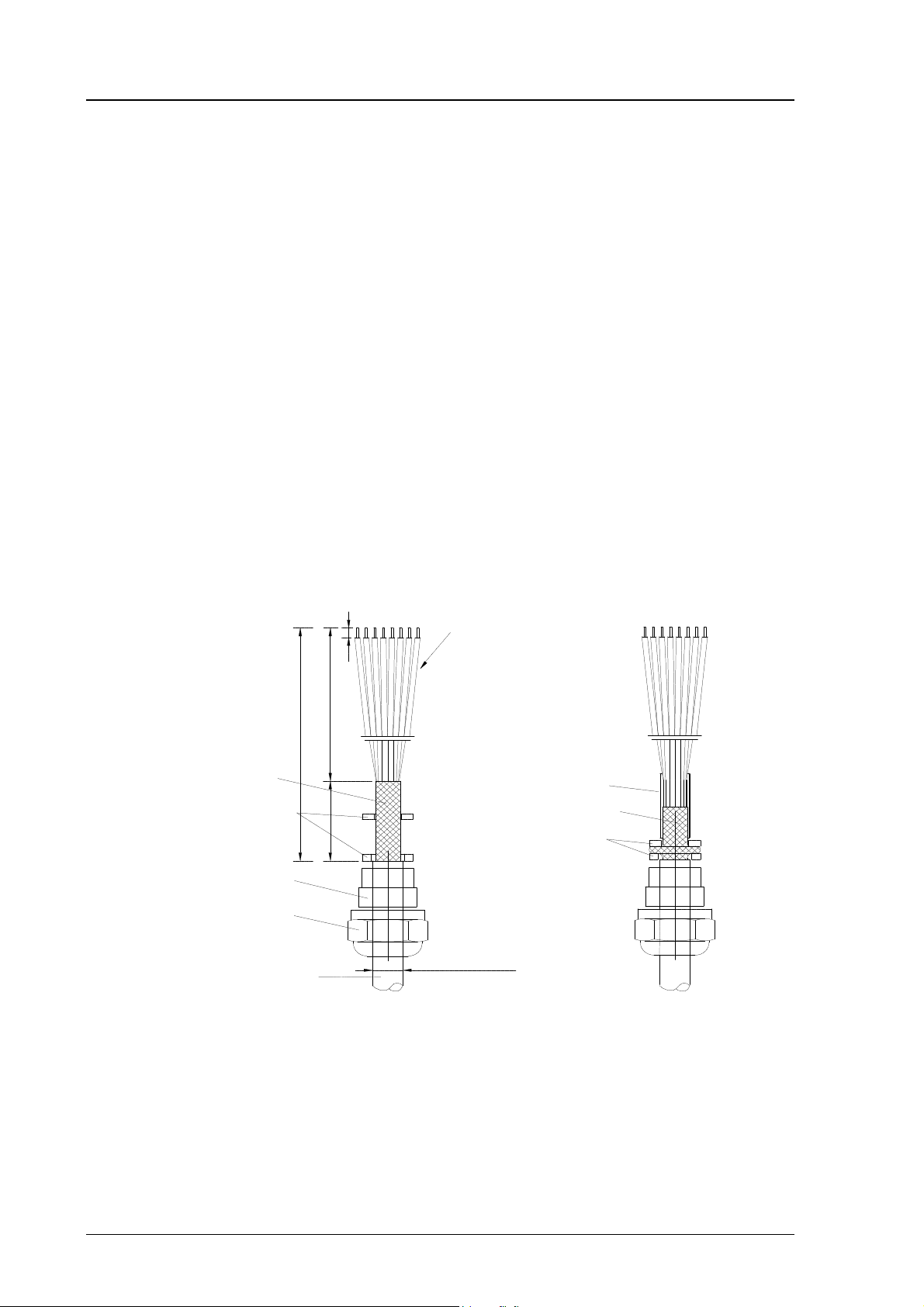

In Figures 2.2.1 and 2.2.2 you can see the dimensions of the HMP228

transmitter and probe:

104

CL

ENT

120

ø6.5

65

133

145

Figure 2.2.1 Dimensions of the HMP228 electronics housing (in mm)

Probe pushed down

Probe up

Parallel thread

Tapered thread

180 / 400

216 / 435

Ø13.5

Ø12

A:Probe 180mm adjustment

range 120mm

Probe 400mm adjustment

range 340mm

A

Figure 2.2.2 Probe dimensions (in mm).

4

Page 11

HMP228

M210282en-A Operating Manual

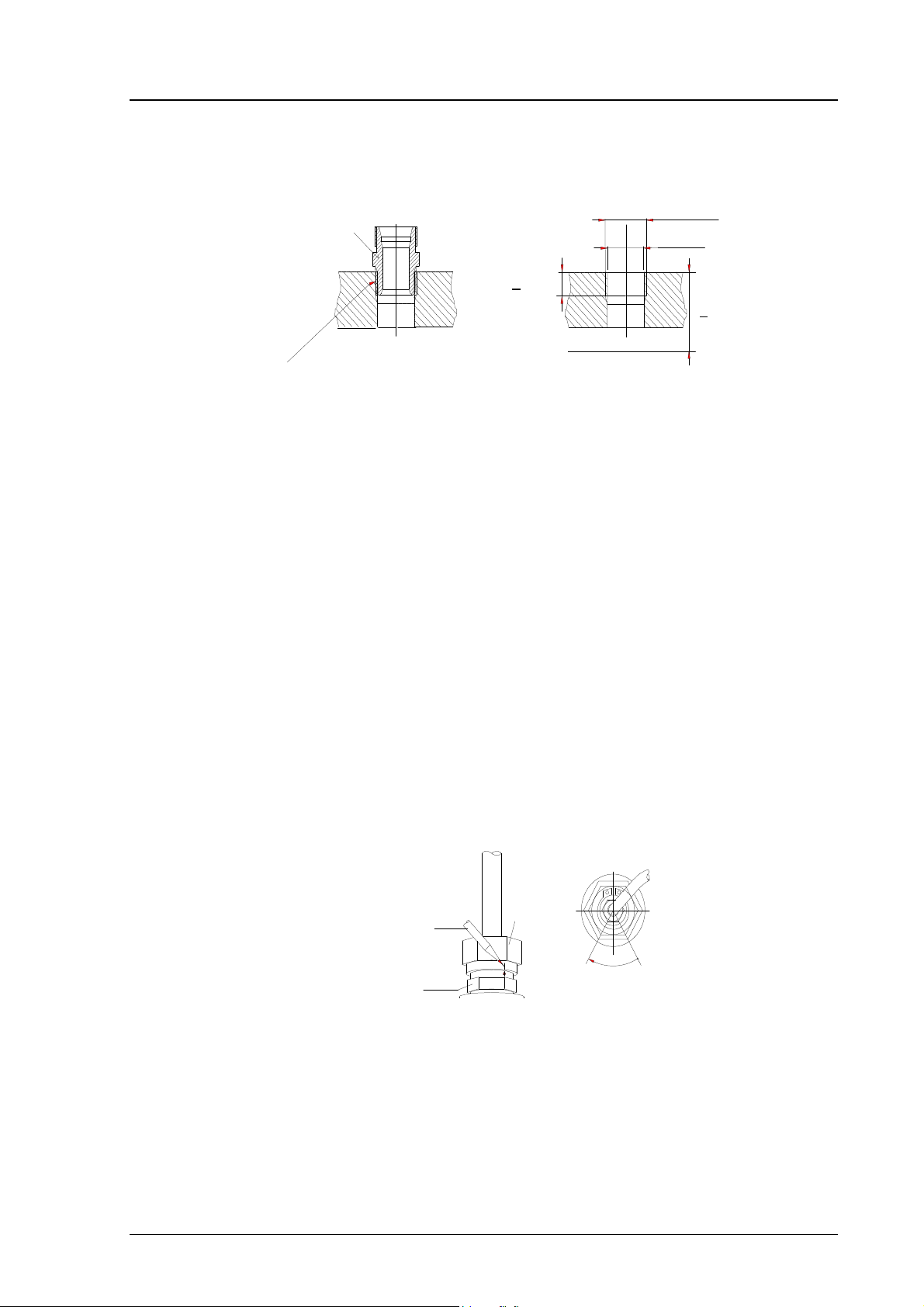

fitting body

hex = 24mm

tapered thread

R1/2 ISO 7/1

>10.5mm

sealing with:

1. LOCTITE® No 542 + activ. No 7649 (t=-55...+150 °C)

2. MEGA-PIPE EXTRA No 7188 (t=-55...+170 °C)

3. PTFE tape (t=-60...+210 °C) NOTE: the tape does not lock

the parts together . Therefore, use two fork spanners (hex 24 and

27 mm) for tightening and opening the clasp nut of the probe

Process or pipe wall

parallel thread

G1/2 ISO 228/1

(BS 2779, JIS B0202)

ø19mm drilling

>40mm

Figure 2.2.3 Sealing and thread cutting for the fitting body

The fitting body can be installed e.g. on standard pipe fittings (G 1/2 ISO

228/1) or on a thread in the process wall. If the wall thickness is less than

10.5 mm, it is recommended to use a welded sleeve (see Figure 2.2.4). Note

that the minimum recommended distance of the fitting body and the probe

head is 40 mm (see Figure 2.2.3).

Adjust the probe to a suitable distance according to the type of installation and

tighten the clasp nut first manually; mark the fitting body and the clasp nut

and tighten the clasp nut a further 50 - 60 ° with a fork spanner (see Figure

2.2.4).

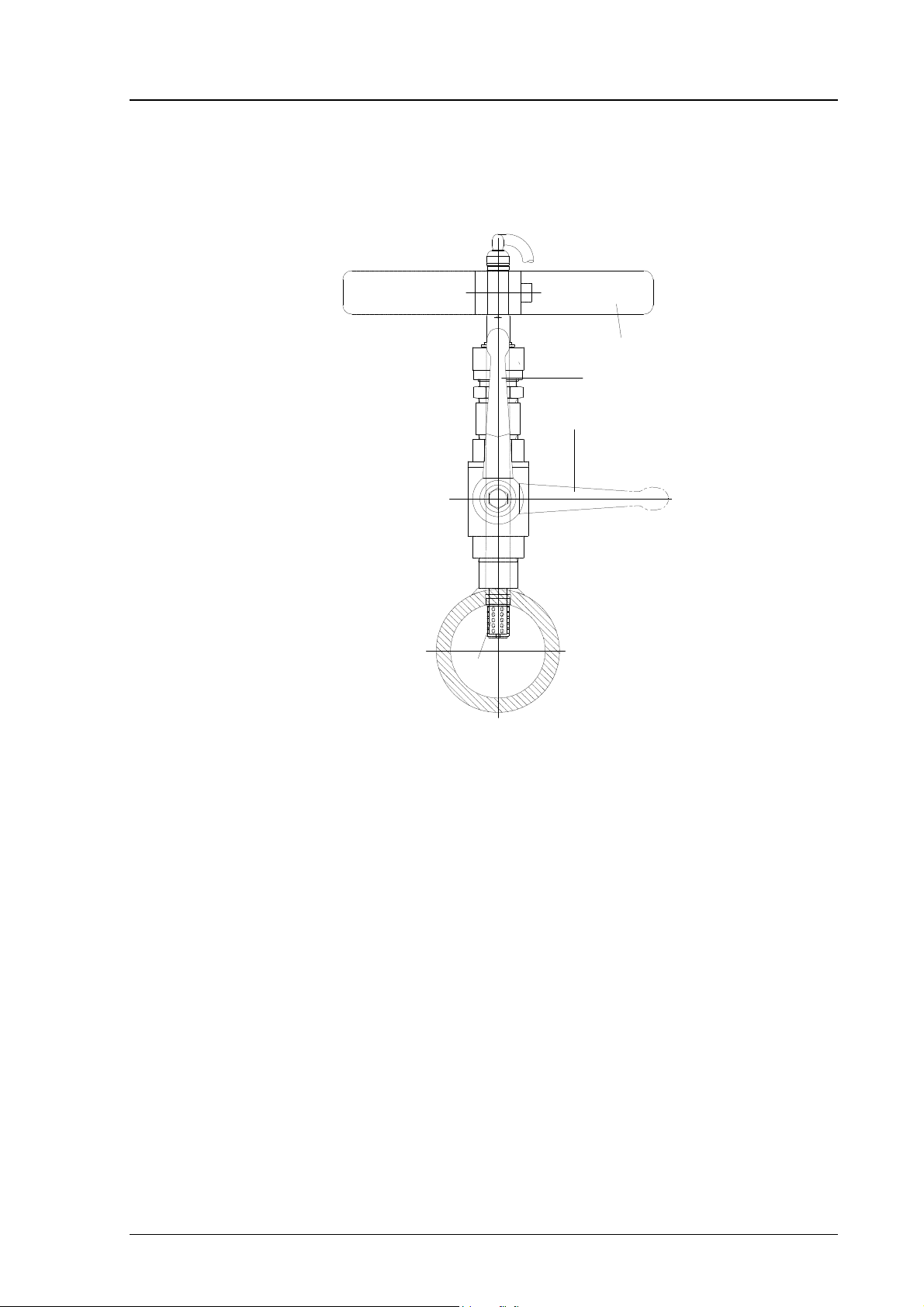

Pushing the probe head through the ball valve assembly. Open and close the

ball valve assembly with the marking groove always in sight. When the probe

has been pressed through, the nut is tightened 50 - 60 ° with a fork spanner

(hexacon 27 mm).

probe

a pen

fitting body

clasp nut

60°

max.

Figure 2.2.4 Tightening the clasp nut

NOTE

Be careful not to tighten the clasp nut more than 60°

as this may result in difficulties when trying to pull

the probe head up.

5

Page 12

HMP228

Operating Manual M210282en-A

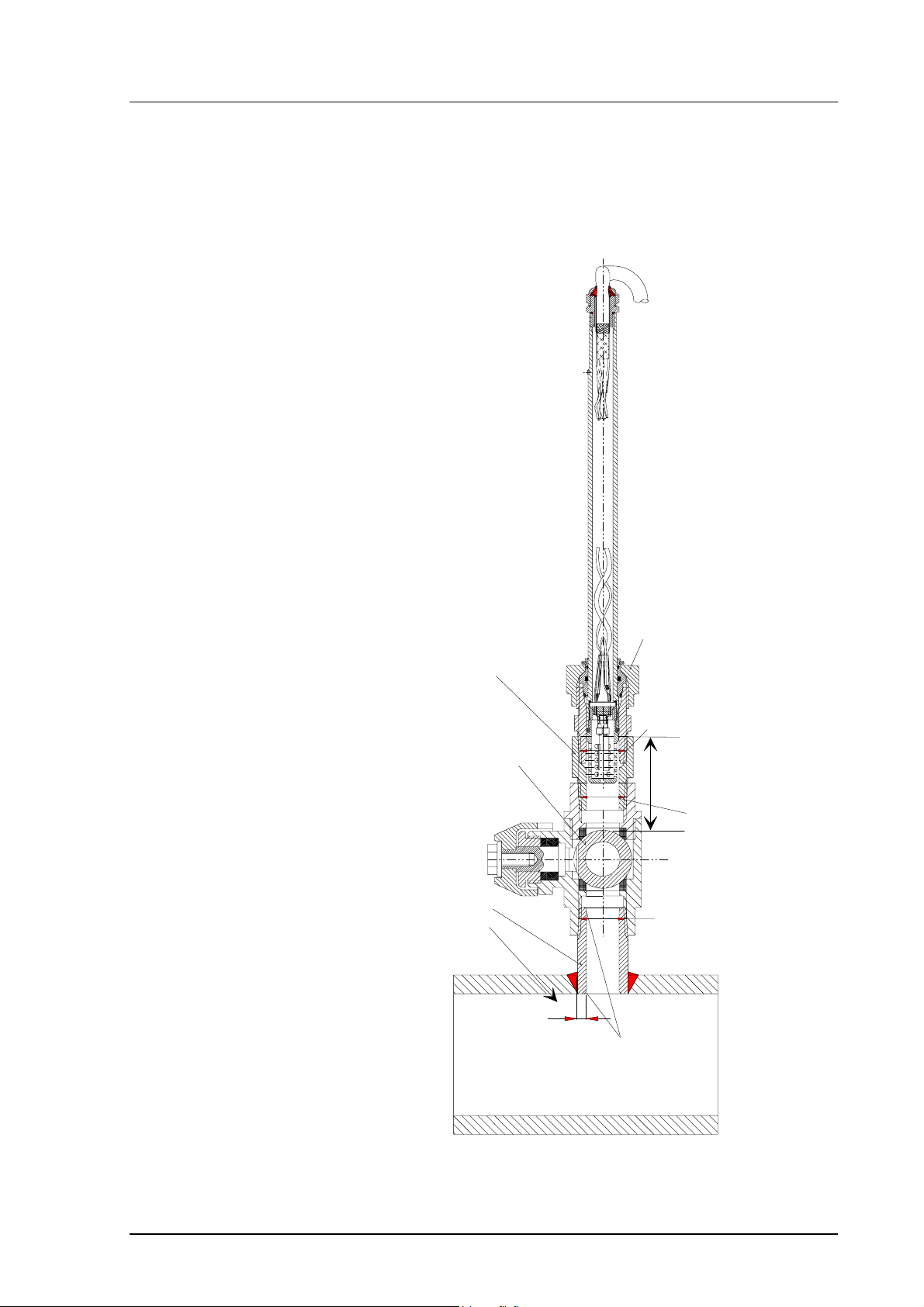

2.2.3 Installing the probe through the ball valve assembly

It is recommended that the sensor head is installed in the process through the

ball valve assembly. Use a 1/2" ball valve assembly with a hole diameter of

14 mm or more. With this installation, it is not necessary to empty or shut

down the process for installing or removing the sensor head. If the sensor head

is installed in a process pipe, please note that the nominal size of the pipe

must be at least 1 inch. See Figure 2.2.3.1. for detailed instructions.

probe

handle

>30 mm

ball of the

ball valve

(hole diameter

> 14 mm)

process pipe / chamber

Figure 2.2.3.1 Installing the sensor head through the ball valve assembly

NOTE

The probe can be installed in the process through the

ball valve assembly provided that the process pressure

is less than 10 bars. This way, the process does not have

to be shut down for installing or removing the probe.

However, if the process is shut down before removing

the probe, the process pressure can be max. 20 bars.

6

Page 13

HMP228

bushing R1/2 cone/ G1/2 (40 bar)

e.g. Camozzi 2520-1/2-1/2

(the bushing serves for

moving the probe (sinter)

so such a distance from the

ball valve that the valve

can be closed)

NOTE

tighten the clasp

nut manually

fitting body

R1/2 cone, sealed

ball valve 1/2" (40 bar)

e.g. Atlas Copco:

BAL-1A 15 (G1/2)

bushing

R1/2 cone,

sealed

nipple

R1/2 cone,

sealed

> 30 mm

welded nipple

diam. 21.3 x S

material: steel

or AISI 304L

the nipple edges have

to be rounded

s

Operating Manual

See Figures 2.2.3.2 - 2.2.3.4 for detailed description of installation through the

ball valve assembly. Note also that if the sensor head is installed in a process

pipe, the nominal size of the pipe must be at least 1 inch.

• STEP I: mount the probe with the ball valve assembly closed

Figure 2.2.3.2 Installing the probe through the ball valve

assembly; step 1

7

Page 14

HMP228

R1/2 ISO 7/1

53.6

ø5.5

adjustment range 120mm

148

ø14

(40)

>ø14

ø12

~8.5

~22.5

sintered

filter

moisture

sensor

O-ring

wedge

ring

nut

(AV=27mm)

screw A

process pipe or chamber

Operating Manual

• STEP 2: open the ball valve assembly

Figure 2.2.3.3 Installing the probe through the ball valve

assembly; step 2 (measures in mm)

The clasp nut is tightened manually prior to opening the ball valve assembly.

8

Page 15

HMP228

M210282en-A Operating Manual

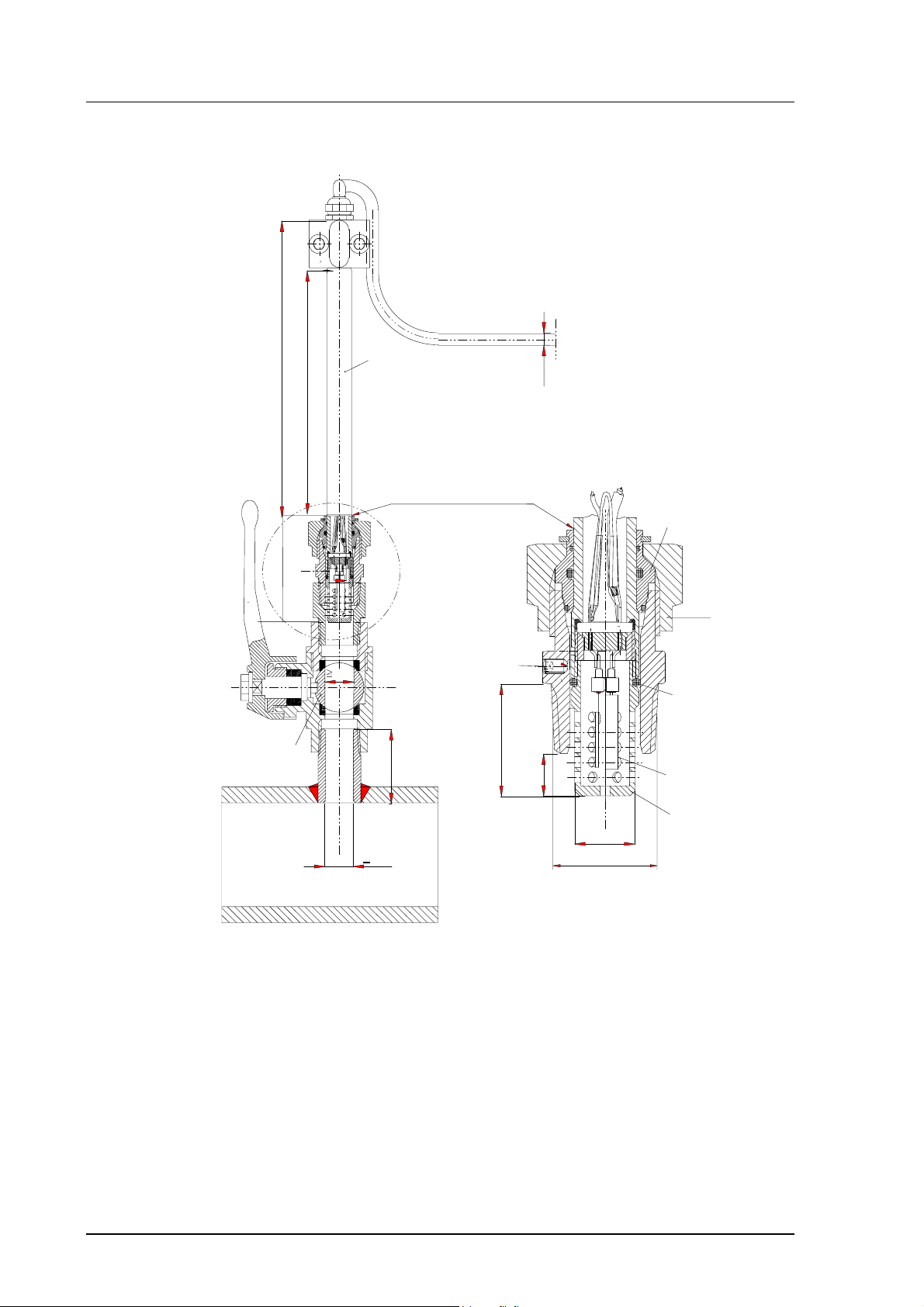

• STEP 3: push the probe head through the ball valve assembly into the

process. Note that the sensor head must be pushed so deep that the filter is

completely inside the process flow.

MANUAL PRESS TOOL

VALVE OPEN

VALVE CLOSED

FILTER

Figure 2.2.3.4 Installing the probe through the ball valve

assembly: step 3

2.2.4 Mounting the probe directly in the process pipe

When the probe is installed directly in a process pipe, note that a closing valve

is needed on both sides of the installed probe so that the sensor head can be

removed from the process for calibration and maintenance.

9

Page 16

HMP228

CH1- and CH2- are connected

DO NOT USE POWER SUPPLY

Power supply

Operating Manual M210282en-A

when the probe is pulled

out for maintenance, cap

the hole with a capped nut;

this way, the process can

be open although the probe

is not in place

welded sleeve

(G1/2) or tube

with thick walls

capped nut

DIN 917-M22x1.5

sealing

probe

closing valve

(ball valve)

Figure 2.2.4 Installing the sensor head directly in a process pipe

2.3 Signal cabling and grounding

2.3.1 Electrical connections

X2

+

Ch1

Rx

Current loop or

RS485 module

Sensor connections

GND

Tx

nc

Figure 2.3.1 Electrical connections

+

Ch2

24V

+

+ Ch1 -

V

mA

--

+ 24V -

+ Ch2 -

V

mA

together internally (X2).

-

X1

GROUND (-) AS OUTPUT

SIGNAL GROUND (X1)!

10

Page 17

HMP228

common

M210282en-A Operating Manual

Power supply 24 VDC

24 VAC (see Chapter 2.3.2)

with power supply module 115/230 VAC

Output signals 0...20 mA

4...20 mA

0...1 V

0...5 V

0...10 V

Power supply ground (-) is connected to the housing with parallel connection

of 15 nF capacitor and 300 kΩ resistor.

See Appendix 3 on how to connect the power supply module to the

transmitter.

2.3.2 Connection to an AC supply

The HMP228 transmitter can also be connected to an AC supply without an

external rectifier. However, when more than one transmitter is connected for

example to one 24 VAC transformer, a common loop is formed and there is an

increased risk of a short-circuit. To avoid this, always use separate floating

supply for each transmitter (see Figure 2.3.2 A). However, if several

transmitters have to share one transformer, the phase (∼) must always be

connected to + connector in each transmitter (see Figure 2.3.2 B).

A) NO COMMON LOOP FORMED - RECOMMENDED

HMP228 transmitter Controller

24 VAC

24 VAC

HMP228 transmitter

B) COMMON LOOP FORMED -

HMP228 transmitter

signal

supply

supply

NOT RECOMMENDED!

o utput

voltage

signal

output

voltage

Controller

24 VAC

HMP228 transmitter

signal

supply

supply

output

voltage

shared

line

voltage

signal

o utp ut

Figure 2.3.2 Connecting the transmitter to an AC supply

11

Page 18

HMP228

Operating Manual M210282en-A

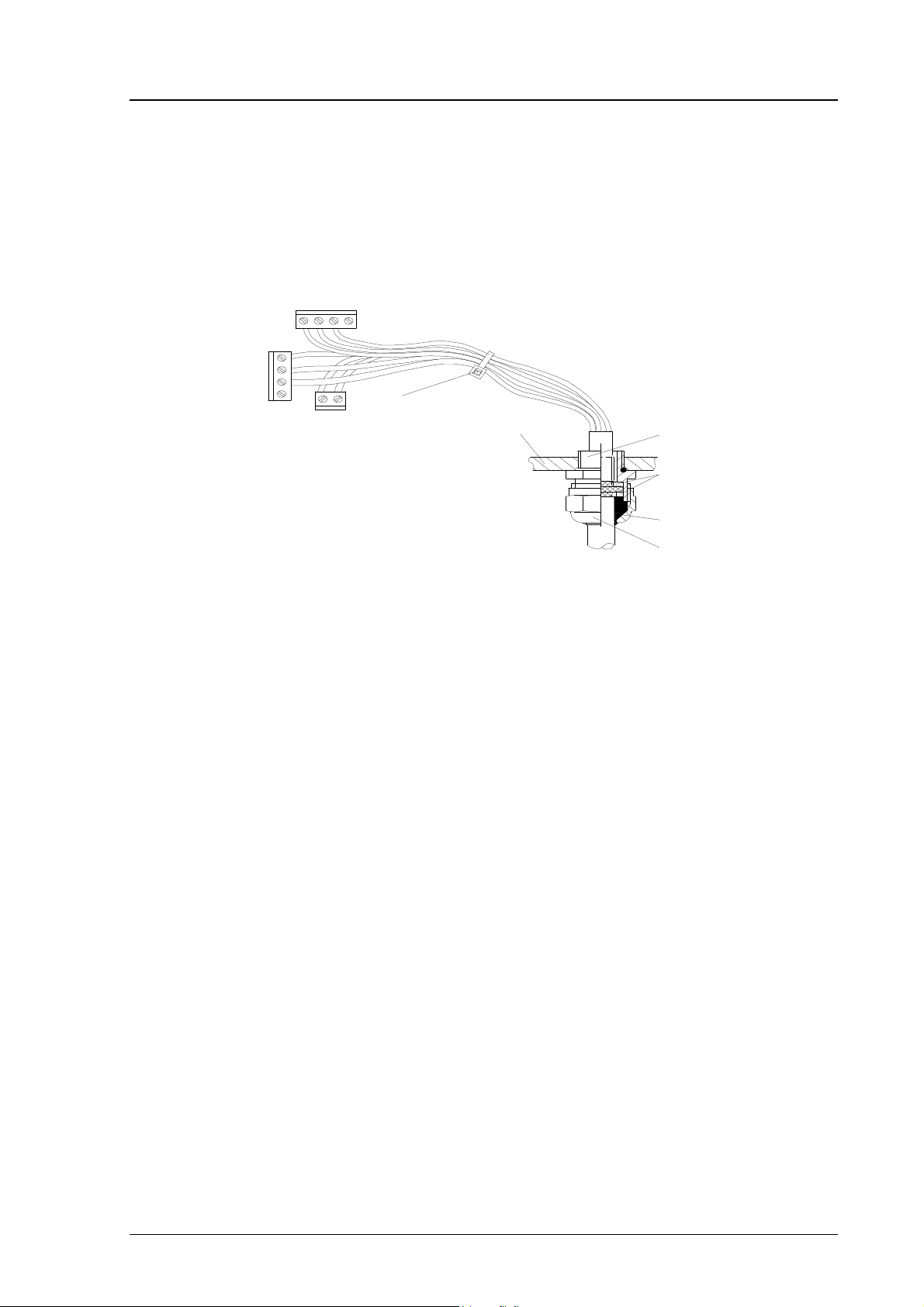

2.3.3 Grounding

A single electrical cable with a screen and three to ten wires is recommended

for power and analogue output/serial bus connections. The cable diameter

should be 7...10 mm.

The screen of the electrical cable must be grounded properly to achieve best

possible EMC performance. Recommended cable shield is done in the cable

gland as shown.

• remove the brass disks, rubber ring and nut from the transmitter

housing

• strip 165 mm of the cable insulation, but leave 25 mm of the braid

visible

• slip the nut and rubber ring over the cable insulation

• slip the brass disk that has the bigger hole in it over the braid so that

it rests against the cable insulation

• slip the other brass disk over the wires to the middle of the braid

flexible wires 0.5 mm²

(AWG 20), stranded wires

recommended

3

140

165

braid

brass

disks

rubber

ring

nut

cable

25

D = Ø 7...10 mm

(If the cable diameter is less

than 7mm, use a shrinking

tube or an adhesive tape)

shielding tube

braid

brass disks

12

• push back the braid and press it between the two brass disks to

achieve a full 360° grounding; the fold between the disks should have

the same diameter as the brass disks

• secure the braid with a shielding tube

• insert the wires into the transmitter housing through the gland

• tighten the nut

Page 19

HMP228

M210282en-A Operating Manual

• connect the wires into the screw terminals and fasten a cable tie

around the wires

Use connectors instead of traditional cabling. See Appendix 8 for connector

types available and for detailed instructions.

cable tie

transmitter housing

gland

brass disks

rubber ring

nut

NOTE

When the cable is grounded as explained, the metallic

parts of the sensor head, the screen of its cable, the

transmitter housing and the screen of the signal cable to

external system are all connected to each other. After

this the whole system can be grounded from one point

only. If the grounding is made via several points (sensor

head, transmitter housing, signal cable), make sure that

the different groundings are made to the same

grounding potential. Otherwise harmful grounding

currents may be generated. If you do the grounding via

the transmitter housing, use one serrated lock washer

between a mounting screw and the housing; the lock

washer breaks the paint on the housing.

When mains power supply is used, ground the housing with a protective

ground wire using a grounding screw on the right side of the power supply

module (see Appendix 3 for details).

13

Page 20

HMP228

Operating Manual M210282en-A

3. COMMISSIONING

When the HMP228 transmitter leaves the factory, its measurement ranges and

output signals have already been scaled according to the order form completed

by the customer. The unit is calibrated at the factory and ready to operate

when the power is turned on. If you take into use active current, voltage or

serial bus outputs, make these connections first; appendix 9 describes them in

detail.

NOTE

Make sure that the power is not turned on until cables

have been connected to screw terminals!

In transmitters with display, the software version appears for a few seconds

when the power is turned on. After this, measurement results appear

automatically. Should an error message appear on the display, consult

Appendix 6.

If your transmitter has a blank cover and the LED indicator inside the housing

lights up, consult Appendix 6 for further information.

Appendix 7 contains information on how to determine the ranges for alarm

outputs and alarm controls when an alarm output unit is used, and Appendix 8

describes the use of connectors.

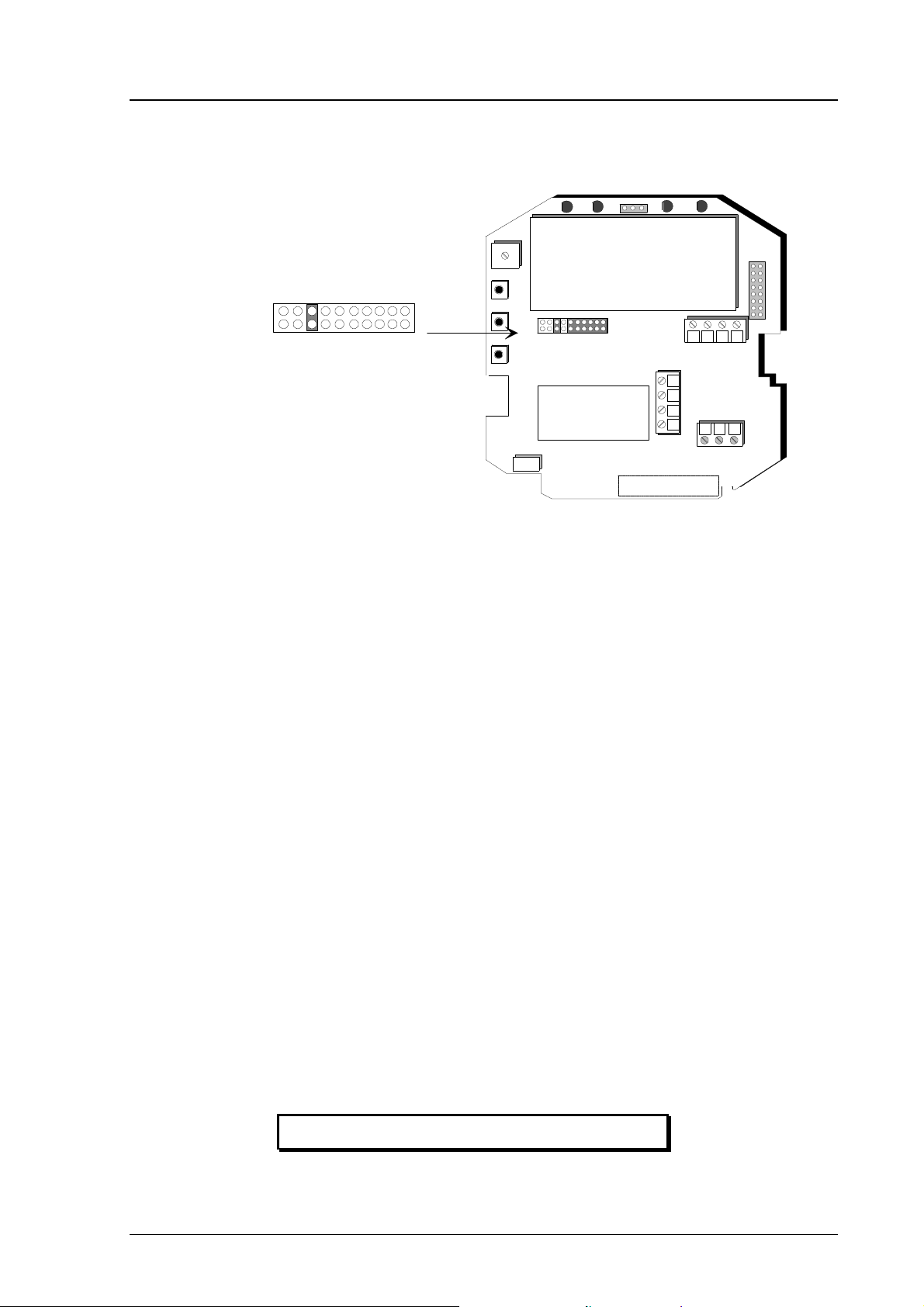

3.1 Changing the parameters

If necessary, the user can subsequently change the measurement units between

metric and non-metric and select and scale the output signals with software

functions. This is done through commands, either utilizing the menus on the

local display or giving commands through the serial interface (see

Appendices). Most often the commands are used to change the settings of the

two analogue channels.

A limited range of commands can be given with the three press switches (up,

down, enter) inside the transmitter housing. There are four LEDs to indicate

the commands given with the up and down switches. All HMP228 units

incorporate these switches and LED indicators. LED commands can be used to

calibrate the transmitters (both humidity and temperature) or to calibrate the

analogue outputs.

14

If you need to change some functions, read the following chapters carefully.

3.1.1 Security lock jumper

Before the settings can be changed, the user must first remove the security

lock jumper in connector X15 (see Figure 3.1.1). The security lock jumper

Page 21

HMP228

M210282en-A Operating Manual

makes it impossible to change the transmitter settings by mistake. The jumper

should be removed only for changing the settings and for calibration.

X15

Change of settings

disabled

Current loop or

RS485 module

Sensor connections

+

Ch1

Rx

GND

Tx

--

+

Ch2

24V

nc

-

+

Figure 3.1.1 Location of the security lock jumper

When the security lock jumper is connected, some commands cannot be used,

see Chapter 4.

If you wish to take into use variables that are not included in the configuration

of your transmitter, contact Vaisala for more information.

3.1.2 Commands and security lock jumper

In order to prevent any tampering with the transmitter settings, the transmitters

cannot be calibrated, the analogue outputs set or the analogue output

quantities selected or scaled unless the security lock jumper has been

disconnected. The commands involved are:

• serial commands: CRH, CT, FCRH, ACAL; AMODE, ASEL, ASCL

• all LED commands

• display/keypad commands:

Cali ð RH T

Analog outputs

Mode ð Analog outputs ð Mode

Scale

In the following, the description of these functions is preceded with a

reminder of the security lock jumper:

Disconnect the security lock jumper!

15

Page 22

HMP228

GND

HMP228

Operating Manual M210282en-A

3.2 Using the RS 232C serial bus

Rx GND Tx

X17

Rx

Tx

Nc

Current loop or

RS485 module

+

Ch1

X6

Rx

GND

Tx

nc

Sensor connections

+

Ch2

24V

+

--

-

Figure 3.2.1 Serial bus connections

To connect a PC to the HMP228 transmitters via the RS 232C serial bus, one

of the following cables is required. The type of cable depends on the terminal

and the connector type.

RXD

RXD

RXD

TXD

TXD

TXD

TX

GND

RX

TX

GND

RX

TX

GND

RX

PC

TERMINAL

D9S

D25S

D25P

2

5

3

4

6

7

8

3

7

2

5

6

8

20

3

7

2

Figure 3.2.2 Connection of cables

When the serial bus has been connected between the PC and the transmitter,

the PC is switched on. When using a PC, a terminal emulation programme

(e.g. Procomm Plus, Datastorm or Windows terminal) is started.

The factory settings for data transfer are:

• 4800 baud

• even parity

• 7 data bits

• 1 stop bit

• full duplex

16

Page 23

HMP228

M210282en-A Operating Manual

NOTE

When the serial bus settings are changed, the transmitter has to be reset before the new settings become effective.

The processor does not allow the following combinations:

• no parity, 7 data bits, 1 stop bit: if this combination is given the

HMP228 programme will change the number of stop bits to 2

• even or odd parity, 8 data bits, 2 stop bits: if this combination is given

the programme changes the number of stop bits to 1

Refer to the manuals of the PC and the terminal emulation programme when

giving serial settings.

The RS 232C screw terminal cannot be used if an RS 485/422 serial module

or a current loop module is used. See Appendices 3 and 4 on how to install

and operate these modules.

In calibrating or changing the settings of the transmitter it can be more convenient to use the connector X17, if connector X6 is already in use. This connector, however, transfers only RS 232C signals. If an RS 485/422 serial port

module or a current loop module has been installed, it has to be removed before communicating through the X17 connector.

NOTE

Some PC computers can generate interferences to the

measured humidity and temperature values if the

transmitter and the PC are connected to different mains

outlets. To minimize the possibility of these interferences, always use the same main outlet (same phase of

the main electricity) for the PC and the power supply of

HMP228. It is always preferable to use the connector

X16 instead of the connector X17 because it is more

immune to interferences.

The serial commands are described in Appendix 1.

17

Page 24

HMP228

Operating Manual M210282en-A

3.3 Using LED commands

NOTE

If the transmitter has a display/keypad cover, the LED

commands cannot be used.

LED commands can be used to operate the transmitters in the field. These

commands can be used in humidity and temperature calibration and calibration

of the analogue outputs.

Open the housing and press any one of the three press switches. The LEDs

will light up for 2...3 seconds.

LEDS

UP

PRESS SWITCHES

DOWN

+

ENT

Current loop or

RS485 module

Sensor connections

Ch1

Rx

GND

Tx

Figure 3.3 Location of press switches and LEDs

Use the up and down switches (marked with arrows on the printed board) to

find the desired command code and acknowledge it with the ENT switch. The

command codes are (l = lit, ¡ = dark):

¡¡¡¡ (0) return to normal state

¡¡¡l (1) relative humidity calibration

¡¡l¡ (2) temperature calibration

¡¡ll (3) calibration of analogue outputs

l¡¡l (9) forced auto-calibration (one auto-calibration; the

security lock jumper must be connected)

--

+

Ch2

24V

nc

-

+

3.4 Using display/keypad commands

3.4.1 Display mode

In the display mode the transmitters output measurements on the display; different quantities can be scrolled with the arrow keys. The first line is scrolled

18

Page 25

HMP228

M210282en-A Operating Manual

with button s and the second line with button t; all selections are stored

with ENTER. The selected quantities appear on the display also after power

failure. After reset the transmitters are always in the display mode.

The display also shows error messages and alarms if they occur.

3.4.2 Command mode

Press the CL key to enter the command mode. The first display is the main

menu:

The commands can be scrolled with the arrow keys. The currently active

command flashes; the desired command is selected with the ENT key. When a

menu is displayed, either the first command or the currently valid setting

flashes. The CL key takes the transmitter back to the display mode.

3.4.3 Entering numbers

When the transmitter needs numbers to be entered into the programme (e.g.

when scaling or setting the analogue outputs, in calibration or when giving the

transmitter an address), the field is either empty or the currently valid figure

is displayed. Any previously given value is deleted with the CL key.

When the field is empty, a cursor blinks on the right side of the display.

Pressing the arrow keys brings either a blank ( ), a comma (,), a dash (-), a full

stop (.) or a number from 0 to 9 on the display. The right character is selected

with ENT; after that the number or numbers move left one step. Entering

numbers is ended with selecting a blank ( ) and pressing ENT. The last character entered can be deleted with CL. If CL or ENT key is pressed when the field

is empty, the programme returns to the previous display.

With some commands (e.g. calibration) figures are changed using the arrow

keys. When an arrow key is pressed continuously for a while, the numbers

start changing at an increasing rate.

The display commands are described in Appendix 2.

19

Page 26

HMP228

Operating Manual M210282en-A

4. MAINTENANCE

4.1 Self-diagnostics

The HMP228 transmitter goes through a self-diagnostics procedure when the

power is switched on. If the procedure does not reveal any errors or faults, the

transmitter starts operating normally. If errors or faults are found, check first if

the moisture and temperature sensors are damaged. If they are intact, send the

transmitter to Vaisala for repairs. The error messages are listed in Appendix 3.

If any errors occur during operation, the error messages are output on the local

display if the transmitter displays measurements; if the menus are used, error

messages are not output. The LEDs indicate errors at all times. During operation, however, the error messages are not output automatically through the serial interface. If there is any reason to doubt that there is something wrong

with the transmitter, use command ERRS:

If there are no error messages, only a prompt is displayed:

>ERRS <cr>

>

When errors have occurred, the transmitter outputs the error code (see Appendix 3 for all error messages):

>ERRS <cr>

E40 f ( all ) out of range

>

4.2 Reference measurements

Reference measurements are needed to verify whether the transmitter readings

are within specifications. This way the user can check if the transmitter needs

calibration or service.

Whatever the technique used, make sure that the reference instrument is at the

same temperature as the checked instrument in order to avoid errors caused by

temperature differences. The reference measurement should be made as close

to the checked sensor as possible and the readings should be read at the same

time, when possible.

ERRS <cr>

20

Page 27

HMP228

M210282en-A Operating Manual

4.3 Moisture calibration

The HMP228 transmitter has been fully calibrated at the factory so there

should be no immediate need for recalibration. The transmitter should be

calibrated only if there is reason to believe that the adjustments have changed.

The optimal interval for moisture calibrations depends on the process and the

recommended interval varies from 3 months to 2 years.

NOTE

The HMP228 transmitter measures water activity in

liquid/oil and the calibration is performed as for relative

humidity transmitters. In calibration mode the

transmitter automatically outputs relative humidity as

the calibration parameter. It is essential to clean the

sensor surface of oil before calibration; use e.g.

instrument air or nitrogen to blow off the oil. Even the

smallest amount of oil may destroy the salt solution.

NOTE

As oil performs a membrane over the sensor surface,

the sensor's capability of absorbing moisture is slowed

down. The stabilization time is thus at least double the

time of a clean sensor; pay special attention to

controlling the stabilization time.

A two-point calibration can be performed with Vaisala’s HMK15 or HMK13B

Calibrator or the instrument can be sent to Vaisala. The instrument has to be

recalibrated each time the moisture sensor is changed.

A Ø 13.5 adapter must be used when calibrating with the HMK13B Calibrator.

The adapters (part no. 16611) can be ordered from Vaisala or Vaisala

representatives.

Calibration can be performed by giving the commands using the press

switches inside the housing, through the serial bus or through the menus on

the local display.

When LED commands are used, relative humidity is output instead of water

activity. When the transmitter is calibrated at two points, the points must be

either 50 %RH or 50 °C apart from each other.

NOTE

If the sensor has been changed, perform a calibration according to Chapter

4.4.1.

21

Page 28

HMP228

Operating Manual M210282en-A

4.3.1 Two point calibration procedure

A two point calibration should be performed in stable conditions using

saturated salt solutions as references.

Disconnect the security lock jumper!

4.3.1.1 Using serial commands

• Leave the calibrator and the transmitter for at least 4 hours in the

same space so that their temperatures have time to equalize. Remove

the filter cap on the transmitter.

• Insert the sensor head into the calibration hole of the LiCl chamber of

the humidity calibrator.

• Wait at least 30 minutes.

• Give command CRH <cr>, enter the first point value and press <cr>.

>CRH <cr>

RH : 11.9 Ref1 ? yy.y <cr>

Press any key when ready...

• If you want to see how the sensor stabilizes to the humidity in the

calibrator, enter c <cr> instead of the first reference:

RH : 11.9 Ref1 ? c <cr>

RH : 11.5 Ref1 ? c <cr>

RH : 11.5 Ref1 ? 11.3 <cr>

Press any key when ready...

• Insert the sensor head into the calibration hole of the NaCl chamber of

the humidity calibrator.

• Wait at least 30 minutes.

• Press any key and enter the second point value; press <cr>.

RH : 75.5 Ref2 ? yy.y <cr>

• The stabilization of the sensor can be monitored by entering c <cr>

instead of the reference value.

4.3.1.2 Using display/keypad commands

22

• Leave the calibrator and the transmitter for at least 4 hours in the

same space so that their temperatures have time to equalize. Remove

the filter cap on the transmitter.

• Select Cali in the main menu and then RH cal; select Not changed

and then two point calibration RH 2 point cal. Change the first point

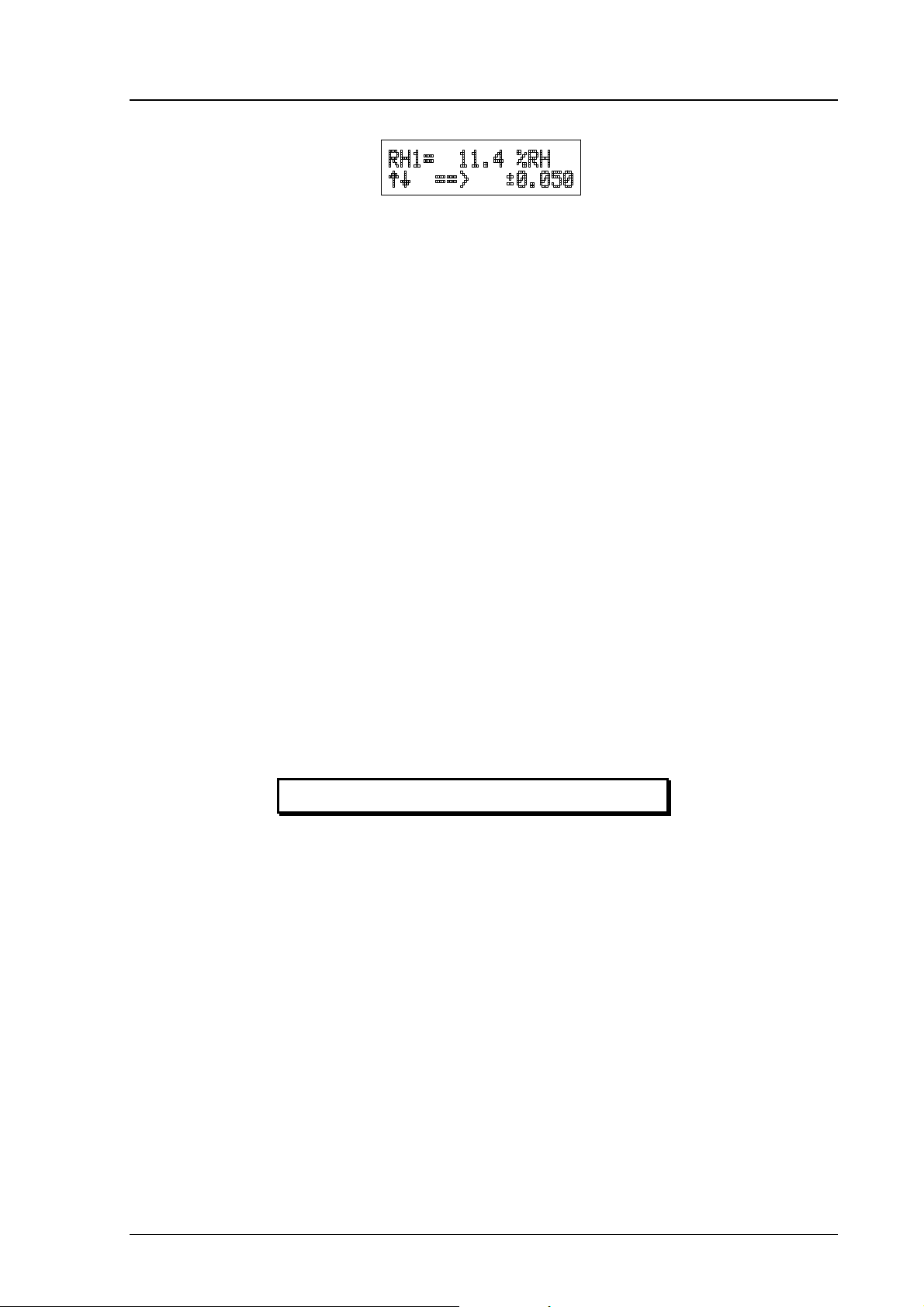

reading with the arrow keys to correspond to the reference humidity

and press ENT; pressing an arrow once changes the reading by

0.05 %RH.

Page 29

HMP228

M210282en-A Operating Manual

4.3.1.3 Using LED commands

• Leave the calibrator and the transmitter for at least 4 hours in the

same space so that their temperatures have time to equalize. Remove

the filter cap on the transmitter.

• Connect an ammeter/voltmeter to the analogue outputs (connector

X2). Give command ¡¡¡l. At the first calibration point the LED

on the left flashes; adjust the first point (offset) with the arrow

switches to the value given in the calibration table (Chapter 4.4.5) and

press ENT switch.

• Insert the sensor head into the calibration hole of the NaCl chamber in

the humidity calibrator.

• Wait at least 30 minutes.

• Check that the reading corresponds within the desired accuracy to the

value given in the calibration table (Chapter 4.4.5). If not, adjust the

second point with the arrow switches to the correct value and press

ENT. At the second calibration point the second LED from the left

flashes.

4.3.2 One point calibration procedure

A one-point correction can be done manually in the field against an accurate

reference but it is always recommended to perform a two point calibration.

Disconnect the security lock jumper!

4.3.2.1 Using serial commands

• Make sure that the sensors of the transmitter and the reference

instrument are close to each other. Allow enough time for the sensors

to stabilize to the measurement conditions.

• Give command CRH <cr>, enter the humidity value and press <cr>.

>CRH <cr>

RH : 11.9 Ref1 ? yy.y <cr>

Press any key when ready...

• If you want to see how the sensor stabilizes to the humidity in the

calibrator, enter c <cr> instead of the first reference:

RH : 11.9 Ref1 ? c <cr>

RH : 11.5 Ref1 ? c <cr>

RH : 11.5 Ref1 ? 11.3 <cr>

Press any key when ready...

23

Page 30

HMP228

Operating Manual M210282en-A

• Press any key and press <cr> when the transmitter requests the second

point value.

RH : 75.5 Ref2 ? yy.y <cr>

4.3.2.2 Using display/keypad commands

• Make sure that the sensors of the transmitter and the reference

instrument are close to each other. Allow enough time for the sensors

to stabilize to the measurement conditions.

• Select Cali in the main menu and then RH cal; select Not changed

and then one point offset calibration RH 1 point cal. Change the

humidity reading with the arrow keys to correspond the reference

humidity and press ENT; pressing an arrow once changes the reading

by 0.05 %RH.

4.3.2.3 Using LED commands

• Make sure that the sensors of the transmitter and the reference

instrument are close to each other. Allow enough time for the sensors

to stabilize to the measurement conditions.

• Connect an ammeter/voltmeter to the analogue outputs (connector

X2). If the outputs are already connected to e.g. a process computer

and you do not want to disconnect them, the current output can be

measured at separate test points located next to connector X15 (see

the mother board).Give command ¡¡¡l. At the first calibration

point the LED on the left flashes; adjust the humidity point (offset)

with the arrow switches to the reference value. One push of a switch

changes the output by 0.05 %RH; the change of the output voltage or

current depends on the output scaling. Press ENT switch. The second

LED from the left starts flashing; press ENT again.

4.4 Changing the moisture sensor

Remove the damaged sensor and insert a new one. Handle the sensor by the

plastic socket. DO NOT TOUCH THE SENSOR PLATE. After sensor change,

the moisture calibration must be performed according to the instructions in

section 4.4.1.

24

Page 31

HMP228

M210282en-A Operating Manual

4.4.1 Calibration procedure after sensor change

Humidity calibration should be performed in stable conditions using saturated

salt solutions as a reference.

Disconnect the security lock jumper!

4.4.1.1 Using serial commands

• Leave the calibrator and the transmitter for at least 4 hours in the

same space so that their temperatures have time to equalize. Remove

the filter cap on the transmitter.

• Insert the sensor head into the calibration hole of the LiCl chamber of

the humidity calibrator.

• Wait for 30 minutes.

• Give command FCRH <cr>, enter the first point value and press <cr>:

>FCRH <cr>

RH: 11.9 Ref1 ? yy.y <cr>

Press any key when ready...

• The stabilization of the sensor to the reference humidity can be

monitored by giving c <cr>:

RH: 11.9 Ref1 ? c <cr>

RH: 11.5 Ref1 ? c <cr>

RH: 11.5 Ref1 ? 11.3 <cr>

Press any key when ready...

• Insert the sensor head into the calibration hole of the NaCl chamber of

the humidity calibrator.

• Wait for 30 minutes.

• Press any key, enter the second point value and press <cr>:

RH: 75.5 Ref2 ? yy.y <cr>

• The stabilization of the sensor can be monitored by entering c <cr>

instead of the reference value.

4.4.1.2 Using display/keypad commands

• Leave the calibrator and the transmitter for at least 4 hours in the

same space so that their temperatures have time to equalize. Remove

the filter cap on the transmitter.

• Insert the sensor head into the calibration hole of the LiCl chamber of

the humidity calibrator.

• Wait for 30 minutes.

25

Page 32

HMP228

Operating Manual M210282en-A

• Select Cali in the main menu and then RH cal; select Sensor

changed. Change the first point reading with the arrow keys and

press ENT.

• Insert the sensor head into the calibration hole of the NaCl chamber of

the humidity calibrator.

• Wait at least 30 minutes.

• If necessary, change the second point reading with the arrow keys and

press ENT.

4.4.1.3 Using LED commands

• Leave the calibrator and the transmitter for at least 4 hours in the

same space so that their temperatures have time to equalize. Remove

the filter cap on the transmitter. '

• Insert the sensor head into the calibration hole of the LiCl chamber of

the humidity calibrator.

• Wait for 30 minutes.

• Connect an ammeter/voltmeter to the analogue outputs (connector

X2). Give command l¡¡¡. At the first calibration point the LED

on the left flashes; adjust the first point (offset) with the arrow

switches to the value given in the calibration table (Chapter 4.4.5) and

press ENT switch.

• Insert the sensor head into the calibration hole of the NaCl chamber in

the humidity calibrator.

• Wait at least 30 minutes.

• Check that the reading corresponds within the desired accuracy to the

value given in the calibration table (Chapter 4.4.5). If not, adjust the

second point with the arrow switches to the correct value and press

ENT. At the second calibration point the second LED from the left

flashes.

The basic capacitance of the new sensor may differ considerably from that of

the previous one. Therefore, the corresponding humidity reading of the

transmitter may be below 0 %RH at the low or above 100 %RH at the high

calibration point. However, the current/voltage reading of the analogue output

shows only the minimum or maximum value of the selected current/voltage

scale and the output value may not change even though the arrow switches are

pressed several times. If this happens, press the up or down arrow switch

continuously to bring the output back into the selected scale; this may take as

long as half a minute.

26

Page 33

HMP228

M210282en-A Operating Manual

4.4.5 Humidity calibration table

Temperature °C 15 20 25 30 35

°F 59 68 77 86 95

LiCl %RH * 11.3 11.3 11.3 11.3

4...20 mA 5.81 5.81 5.81 5.81

0...20 mA 2.26 2.26 2.26 2.26

0...1 V 0.113 0.113 0.113 0.113

0...5 V 0.565 0.565 0.565 0.565

0...10 V 1.13 1.13 1.13 1.13

NaCl %RH 75.6 75.5 75.3 75.1 74.9

4...20 mA 16.10 16.08 16.05 16.02 15.98

0...20 mA 15.12 15.10 15.06 15.02 14.98

0...1 V 0.756 0.755 0.753 0.751 0.749

0...5 V 3.780 3.775 3.765 3.755 3.745

0...10 V 7.56 7.55 7.53 7.51 7.49

Table 1 Greenspan's calibration table

*) If the LiCl solution is used or stored in temperatures below +18 °C (+64 °F), the

equilibrium humidity of the salt solution changes permanently.

4.6 Temperature calibration

The temperature channel has been calibrated at the factory and since it is very

stable, adjustment should be made only when there is strong reason to believe

that the adjustments have changed.

Temperature calibration should be performed against some accurate

temperature reference. It can be done either using the press switches inside the

housing, through the serial bus or the menus on the local display. Either a one

point offset correction or a two point calibration is possible.

Disconnect the security lock jumper!

4.6.1 One point offset correction

4.6.1.1 Using serial commands

• Leave the reference instrument and the transmitter for at least 4 hours

in the same space so that their temperatures have time to equalize.

Remove the filter cap prior to calibration.

• Check the transmitter against the reference.

• Give command CT <cr>, enter the first point value and press <cr>:

>CT <cr>

T : 0.90 Ref1 ? yy.y <cr>

Press any key when ready

• If you want to see how the sensor stabilizes to the reference

temperature, enter c <cr> instead of the first reference:

27

Page 34

HMP228

Operating Manual M210282en-A

T : 0.90 Ref1 ? c <cr>

T : 0.55 Ref1 ? c <cr>

T : 0.55 Ref1 ? 0.0 <cr>

Press any key when ready...

• After giving the correct temperature value (Ref1) and pressing <cr>

press any key and then <cr>.

4.6.1.2 Using display/keypad commands

• Leave the reference instrument and the transmitter for at least 4 hours

in the same space so that their temperatures have time to equalize.

Remove the filter cap prior to calibration.

• Check the transmitter against the reference.

• Select Cali in the main menu and then T cal; select one-point

calibration T 1 point cal.

• Change the reading with the arrow keys to correspond to the reference

and press ENT.

4.6.1.3 Using LED commands

• Leave the reference instrument and the transmitter for at least 4 hours

in the same space so that their temperatures have time to equalize.

Remove the filter cap prior to calibration.

• Check the transmitter against the reference.

• Connect an ammeter/voltmeter to the analogue outputs (connector

X2). Give command ¡¡l¡. At the first calibration point the LED

on the left flashes; adjust the first point (offset) with the arrow

switches to the same reading with the reference and press ENT

switch.

• After adjusting the offset point and pressing ENT the second LED

from left flashes. Press ENT without changing the output value.

4.6.2 Two point temperature calibration

Disconnect the security lock jumper!

4.6.2.1 Using serial commands

28

• Leave the reference instrument and the transmitter for at least 4 hours

in the same space so that their temperatures have time to equalize.

Remove the filter cap prior to calibration.

• Check the transmitter against the reference.

• Give command CT <cr>, enter the first point value and press <cr>:

>CT <cr>

T : 0.90 Ref1 ? yy.y <cr>

Press any key when ready

Page 35

HMP228

M210282en-A Operating Manual

• If you want to see how the sensor stabilizes to the reference

temperature, enter c <cr> instead of the first reference:

T : 0.90 Ref1 ? c <cr>

T : 0.55 Ref1 ? c <cr>

T : 0.55 Ref1 ? 0.0 <cr>

Press any key when ready...

• Change the temperature and again check the transmitter against the

reference.

• Check that the reading corresponds with the reading of the reference

instrument. If not, adjust the second point.

• Press any key, enter the second point value and press <cr>.

T : 20.0 Ref2 ? yy.y <cr>

• The stabilization of the sensor can be monitored well by entering c

<cr> instead of the reference value.

4.6.2.2 Using display/keypad commands

• Leave the reference instrument and the transmitter for at least 4 hours

in the same space so that their temperatures have time to equalize.

Remove the filter cap prior to calibration.

• Check the transmitter against the reference.

• Select Cali in the main menu and then T cal; select two-point

calibration T 2 point cal. Change the first point reading with the

arrow keys and press ENT.

• Change the temperature and again check the transmitter against the

reference.

• Check that the reading corresponds with the reading of the reference

instrument. If not, adjust the second point.

• If necessary, change the second point reading with the arrow keys and

press ENT.

4.6.2.3 Using LED commands

• Leave the reference instrument and the transmitter for at least 4 hours

in the same space so that their temperatures have time to equalize.

Remove the filter cap prior to calibration.

• Check the transmitter against the reference.

• Connect an ammeter/voltmeter to the analogue outputs (connector

X2). Give command ¡¡l¡. At the first calibration point the LED

on the left flashes; adjust the first point (offset) with the arrow

switches to the same reading with the reference and press ENT

switch.

• Change the temperature and again check the transmitter against the

reference.

29

Page 36

HMP228

Operating Manual M210282en-A

• Check that the reading corresponds with the reading of the reference

instrument. If not, adjust the second point.

• If necessary, adjust with the arrow switches to the correct value and

press ENT. At the second calibration point the second LED from the

left flashes.

4.6.3 Temperature channel adjustment with Pt 100 simulators

Switch the power off and disconnect the wires to the Pt 100 sensor from solder

lugs TP5, TP6 and TP7.

TP6

X88

TP7

TP5

Figure 4.6.3.1 Location of solder lugs TP5, TP6 and TP7 and

connector X88

Connect a Pt 100 simulator to connector X88 and set it at the lowest temperature to be calibrated.

Pt 100

X88

Figure 4.6.3.2 Connecting the Pt 100 simulator to connector X88

Switch the power on. Follow the one or two point calibration instructions in

Chapters 4.6.1 - 4.6.2.

30

Switch the power off. Disconnect the Pt 100 simulator and reconnect the Pt

100 wires to solder lugs TP5, TP6 and TP7.

The correct connections according to the wire colours are:

TP5 TP6 TP7 TP8

blue green yellow black

If there is not a Pt 100 simulator available, the adjustment can be made with

two resistors of 84 Ω and 154 Ω whose resistance is known precisely. Measure

the resistor with a resistance meter. Look up the corresponding temperature

value from a Pt 100 conversion table or calculate it using the following

equation:

Page 37

HMP228

jumpers

M210282en-A Operating Manual

T = D0 +R x {D1 + R x [D2 + R x (D3 + R x D4)]}

where

D0 = -243.5673014

D1 = 2.278542701

D2 = 0.002050681

D3 = -6.15025E-06

D4 = 1.34949E-08

4.7 Analogue output channels

4.7.1 Setting the analogue outputs

The HMP228 transmitters can be ordered with the required current or voltage

outputs already selected. If the outputs need to be changed, move the jumpers

in connector X15 into positions as shown in Figure 4.7.1.2.

Spare

+

X55

Current loop or

RS485 module

Sensor connections

Ch1

Rx

GND

Tx

Figure 4.7.1.1 Spare jumpers

--

+

Ch2

24V

nc

-

+

31

Page 38

HMP228

Operating Manual M210282en-A

Ch2

Ch1

Ch2

Ch1

Current outputs

0... 20/4... 20 mA

Ch2

Ch1

Ch2

Ch1

Voltage outputs

0... 5/0... 10 V

X15

+

Ch1

+

Ch2

--

Ch2

Ch1

Ch2

Ch1

Ch1

Ch1

Ch2

Voltage outputs

0... 1 V

Ch2

Ch1 0... 1 voltage ouput

Current loop or

RS485 module

Sensor connections

Rx

GND

Tx

24V

nc

-

+

Ch 2 current output

Figure 4.7.1.2 Selecting the analogue outputs with jumpers

All jumpers are used only with the 0...1 V outputs. When other outputs are in

use, the spare jumpers are kept in connector X55.

4.7.1.1 Using serial output

Disconnect the security lock jumper!

AMODE a bb.bbb cc.ccc d ee.eee ff.fff <cr>

a = channel 1: U = voltage output I = current output

bb.bbb = lower limit of channel 1

cc.ccc = upper limit of channel 1

d = channel 2: U = voltage output I = current output

ee.eee = lower limit of channel 2

ff.fff = upper limit of channel 2

32

The bb.bbb, cc.ccc, ee.eee and ff.fff parameters are entered in volts or

milliamperes.

Example: lower limit of channel 1 is 0 V and upper limit 1 V (U 0 1)

lower limit of channel 2 is 2 V and upper limit 10 V (U 2 10)

>AMODE U 0 1 U 2 10 <cr>

Ch1 : 0.000 ... 1.000 V

Ch2 : 2.000 ... 10.000 V

Page 39

HMP228

M210282en-A Operating Manual

4.7.1.2 Using display/keypad commands

Disconnect the security lock jumper!

• Select Mode in the main menu and Analog outputs in the Mode

menu:

• Select Mode (ma/V). The current settings for channel 1 are displayed:

• If the settings are correct, press ENT.

• If the settings need to be changed, press CL:

- the quantity (mA/V) starts flashing; it can be changed with the arrow

key and acknowledged with ENT

- the lower limit starts flashing

- acknowledge the lower limit with ENT or start changing it by pressing

CL; a new lower limit is given one character at a time with the arrow

keys

- the upper limit starts flashing

- acknowledge the upper limit with ENT or start changing it by pressing

CL; a new upper limit is given one character at a time with the arrow

keys

When channel 1 has been set, the programme goes on to channel 2; the

procedure is the same as with channel 1.

33

Page 40

HMP228

Operating Manual M210282en-A

4.7.2 Selecting and scaling the analogue output quantities

Disconnect the security lock jumper!

4.7.2.1 Using serial output

ASEL xxx yyy <cr>

xxx = channel 1's quantity

yyy = channel 2's quantity (Aw, T)

Example: water activity is selected on channel 1 and temperature on

channel 2

>ASEL aw T <cr>

Ch1 (aw) lo 0.000 aw ? <cr>

Ch1 (aw) hi 1.000 aw ? <cr>

Ch2 (T ) lo -40.000 'C ? <cr>

Ch2 (T ) hi +160.000 'C ? <cr>

ASCL <cr>

Example: water activity is scaled on the range of 0...1 Aw and temperature

0...+100 °C

>ASCL <cr>

Ch1 (Aw) lo 0.000 Aw ? <cr>

Ch1 (Aw) hi 1.000 Aw ? <cr>

Ch2 (T ) lo -40.000 'C ? 0 <cr>

Ch2 (T ) hi 160.000 'C ? 100 <cr>

4.7.2.2 Using display/keypad commands

Disconnect the security lock jumper!

• Select Mode in the main menu and Analog outputs in the Mode

menu:

34

• Select Scale. The quantity and scaling for channel 1 are displayed:

• If the settings are correct, press ENT.

Page 41

HMP228

M210282en-A Operating Manual

• If the settings need to be changed, press CL:

− the quantity (aw, T) starts flashing; it can be changed with the

arrow keys and acknowledged with the ENT key

− the lower limit starts flashing

− acknowledge the lower limit with ENT or start changing it by

pressing CL; a new lower limit is given with the arrow keys

− the upper limit starts flashing

− acknowledge the upper limit with ENT or start changing it by

pressing CL; a new upper limit is given with the arrow keys

• When channel 1 has been set, the programme goes on to channel 2;

the procedure is the same as with channel 1.

4.8 Checking and calibrating the analogue outputs

The operation of analoque outputs can be tested by forcing the outputs to

given values. See on appendix n. ITEST command.

4.8.1 Measurement of output currents using test points

If a current output has been connected e.g. to a process computer, the output

current cannot be measured at the output connector X2 without disconnecting

the external load. The output current can, however, be measured at test points

CH1+/CH1- and CH2+/CH2- without disconnecting the output wires. These

test points can therefore be used in one point offset correction against an accurate reference or in checking the current output without disconnecting the

analogue output from the process.

35

Page 42

HMP228

Operating Manual M210282en-A

+

-

+

Current loop or

RS485 module

Ch1

-

Ch2

X15

X2

+

Ch1

Rx

GND

Tx

nc

Sensor connections

+

Ch2

24V

+

--

-

Figure 4.8.1.1 Location of the CH1 and CH2 test points

mA

X2

CH1+

CH1+

TEST POINTS

CH1-

CH1-

R

L

Figure 4.8.1.2 Circuit diagram of the analogue output current test

points.

4.8.1 Calibration of the analogue outputs

The analogue outputs have been calibrated at the factory and since they are

very stable, calibration of the outputs should be performed only when there is

reason to believe that their adjustments have changed.

Disconnect the security lock jumper!

36

Page 43

HMP228

M210282en-A Operating Manual

4.8.1.1 Using serial commands

ACAL <cr>

The outputs on channels 1 and 2 are measured and the measured values (mA

or V) entered as calibration coefficients.

Example: both channels have 0...10 V outputs (set with AMODE command);

enter the voltages measured at the analogue outputs:

>ACAL <cr>

Ch1 U1 ( V ) ? 0.123 <cr>

Ch1 U2 ( V ) ? 9.980 <cr>

Ch2 U1 ( V ) ? 0.120 <cr>

Ch2 U2 ( V ) ? 9.980 <cr>

4.8.1.2 Using display/keypad commands

• Connect an ammeter/voltmeter to the output of channel 1, select Cali

in the main menu and Analog outputs in the Cali menu. The following is displayed (the quantity can be either mA or V):

• Enter the measured lower end current/voltage on channel 1.

• Enter the measured upper end current/voltage on channel 1.

• Connect the meter to the output of channel 2 and enter the measured

lower end current/voltage on channel 2.

• Enter the measured upper end current/voltage on channel 2.

37

Page 44

HMP228

Operating Manual M210282en-A

4.8.1.3 Using LED commands

If both the analogue outputs and humidity/temperature channels are calibrated,

the analogue outputs should be calibrated first. This applies only when the

calibrations are made using the LED commands!

• connect an ammeter/voltmeter to the analogue outputs (connector X2)

• Give command ¡¡ll.

• the LED on the left flashes; set the low end of channel 1 with the ar-

row keys and press ENT

• the second LED from the left flashes; set the high end of channel 1

with the arrow keys and press ENT

• the LED on the left flashes; set the low end of channel 2 with the ar-

row keys and press ENT

• the second LED from the left flashes; set the high end of channel 2

with the arrow keys and press ENT

The analogue outputs are calibrated to ensure that outputs are correctly scaled:

for example, when the output is scaled to 4...20 mA, the low end of the scale

is 4 mA and high end 20 mA exactly. However, when 0... 20 mA output is

used, the output cannot be adjusted to exactly 0 mA, but to 50 µA. When 0...1

V, 0...5 V or 0...10 V output is in use, the output is adjusted to 50 mV. The

following table summarizes the correct output values.

low end: 50 µA 4 mA 50 mV 50 mV 50 mV

high end: 20 mA 20 mA 1 V 5 V 10 V

4.9 Other functions

4.9.1 Adjusting the contrast of the display

The contrast of the display can be adjusted using the trimmer "LCD display

contrast" located next to the press switches.

Summary of the correct output values:

Output scale:

0...20 mA 4...20 mA 0...1 V 0...5 V 0...10 V

38

4.9.2 Reverting to factory settings of the serial port

If the serial port settings are not known, no commands can be given via the

serial interface. The settings can be reverted to the factory settings by inserting

a jumper in connector X16. The jumper must be inserted when the power is

on!

Page 45

HMP228

M210282en-A Operating Manual

X16

Current loop or

RS485 module

+

Ch1

Rx

GND

Tx

Sensor connections

--

+

Ch2

24V

nc

-

+

Figure 4.9.2 Forcing the serial port settings back to factory settings

When the jumper is inserted the serial line factory settings become valid, but

only temporarily. The transmitter must be given new settings; otherwise

the transmitter uses the old, unknown settings after power-up. When the

new settings have been given, the transmitter must be reset. The jumper must

be removed before the transmitter is reset; if the jumper is in place when

power is turned on, the transmitter does not work.

After jumper insertion the transmitter is in STOP mode, ready to receive

commands.

The same method is used when the transmitter is in POLL mode and the user

has forgotten its address.

CAUTION

Inserting a jumper in any other place in connector X16

voids the guarantee of the transmitter.

39

Page 46

HMP228

Operating Manual M210282en-A

5. TECHNICAL DATA

5.1 Water activity

Measuring range of water activity 0...1

Accuracy (including nonlinearity and repeatability)

maximum achievable accuracy when calibrated against high quality,

when calibrated against salt solutions (ASTM E104-85):

±0.02 (0...0.9)

±0.03 (0.9...1.0)

maximum achievable accuracy when calibrated against high-quality,

certified humidity standards:

±0.01 (0...0.9)

±0.02 (0.9...1.0)

Response time (90 %) at +20 °C in

still oil (stainless steel filter) 10 min

Sensor HUMICAP

5.2 Temperature

Measuring range -40...+180 °C

Typical accuracy of electronics at ± 0.1 °C

+20 °C (+68 °F)

Typical temperature dependence of ± 0.005 °C/°C

electronics

Temperature sensor Pt 100 IEC 751 1/3 class B

5.4 Outputs

thin film polymer sensor

(part no. 19525HM)

(part no. 10429)

40

Two analogue outputs selectable 0...20 mA 4...20 mA

0...1 V 0...5 V

0...10 V

Typical accuracy of analogue output ± 0.05 % full scale

at +20 °C

Typical temperature dependence of 0.005 %/°C full scale

analogue output

Serial output RS232C

Page 47

HMP228

M210282en-A Operating Manual

5.5 Electronics

User interface 3 keys and 4 LEDs inside the

housing or local display keypad

Display 2 x 16 character alphanumeric

high-contrast, wide view angle

LCD

character height 3.85 mm (0.15")

Keyboard 1 x 4 keypad

Connections screw terminals, 0.5 mm2 wires

(AWG 20), stranded wires

recommended

Operating voltage 24 VDC / isolated 24 VAC

(20...28 V)

option 115/230 VAC with power supply

module

Power consumption 100 mA maximum (24 VDC)

of the alarm relays 55 mA max (24 VDC)

Recommended external load for

current outputs <500 Ω

0...1 V voltage output >2 kΩ (to ground)

0...5 and 0...10 V voltage outputs >10 kΩ (to ground)

Operating temperature (electronics) -40...+60 °C

with display cover 0...+50 °C

with power supply module -40...+45 °C

with alarm outputs up to 8A -40...+45 °C

with alarm outputs up to 6A -40...+60 °C

Storage temperature -40...+70 °C

Pressure range of the HMP228 0...40 bar

sensor head

5.6 Mechanics

Housing material G-AlSi12 (DIN 1725)

Housing classification IP 65 (NEMA 4)

41

Page 48

HMP228

Operating Manual M210282en-A

Bushing for 7...10 mm diameter cable

(8 x 0.5 mm2 shielded cable)

Sensor protection Stainless steel filter

(part no. HM46999)

Housing dimensions 145 x 120 x 65 mm

Sensor head dimensions (see Figure) length 170 mm, Ø 13.5 mm:

Probe pushed down

180 / 400

216 / 435

Parallel thread

Tapered thread

Ø13.5

A:Probe 180mm adjustment

Ø12

range 120mm

Probe 400mm adjustment

range 340mm

A

Probe up

Cable diameter 5.5 mm

Weight (without display cover and power supply module):

With 2 m cable 1300 g

With 5 m cable 1600 g

With 10 m cable 2100 g

42

Weight of display cover 420 g

Weight of power supply module 240 g

Page 49

HMP228

M210282en-A Operating Manual

5.7 Electromagnetic compatibility

The emission and immunity tests have been performed according to

thestandard EN61326-1:1997+Am1:1998; Industrial environment.

5.7.1 Emissions

Test: Setup according to:

Radiated emissions EN 55022/CISPR 22 (class B)

With power supply unit (HMP230PW):

Conducted emissions EN 55022/CISPR 22 (class B)

Harmonic currents EN/ IEC 61000-3-2

Voltage fluctuations EN/ IEC 61000-3-3

5.7.2 Immunity

Test: Setup according to:

Electrostatic discharge EN/ IEC 61000-4-2

Electrical fast transients EN/ IEC 61000-4-4

Radiated immunity EN/ IEC 61000-4-3

Conducted immunity EN/ IEC 61000-4-6

Voltage proof, AC: DC supply (+ or -) to housing 250 VAC, 1 minute (300 kΩ

and 15 nF parallel)

43

Page 50

HMP228

Operating Manual M210282en-A

6. OPTIONS

Power supply module

Operating voltage 115 VAC (93...127 V)

230 VAC (187...253 V)

Serial interface RS485/422 module HMP230RS

current loop module HMP230CL

Cable length 2, 5 or 10 metres

Display cover cover with or without local

display & keypad

Connectors for supply, signal, RS232C

and RS485 lines see Appendix 8 for details

Ball valve set DMP248BVS

Alarm output unit DMP240ALSP;2 pcs 8A/230 V

CPCO (single pole change over)

7. SPARE PARTS

Order code Description

19525HM Moisture sensor

HM46999 Stainless steel filter, outer thread

HM47453 Stainless steel filter, inner thread

5237 Fuse 160 mA T 5x20 mm for power supply module

17143 Fuse 8A for alarm output unit

16611 Calibration adapter for the HMK15 Calibrator

for adjustable low and high alarm

44

Page 51

HMP228 Transmitters

M210282en-A Appendix 1: Serial commands

APPENDIX 1: SERIAL COMMANDS