Page 1

USER'S GUIDE

Vaisala HUMICAP® Humidity

Transmitter Series

HMP140A

U175EN15

Page 2

PUBLISHED BY

Vaisala Oyj Phone (int.): +358 9 8949 1

P.O. Box 26 Fax: +358 9 8949 2227

FIN-00421 Helsinki

Finland

Visit our Internet pages at http://www.vaisala.com/

© Vaisala 2006

No part of this manual may be reproduced in any form or by any means, electronic or

mechanical (including photocopying), nor may its contents be communicated to a third

party without prior written permission of the copyright holder.

The contents are subject to change without prior notice.

Please observe that this manual does not create any legally binding obligations for

Vaisala towards the customer or end user. All legally binding commitments and

agreements are included exclusively in the applicable supply contract or Conditions of

Sale.

Page 3

HMP140A SERIES

U175en-1.5 Operating Manual

Contents

1. PRODUCT DESCRIPTION ...................................................................................................1

2. TO BE NOTED WHEN M EASURING HUMIDITY ..................................................................2

3. INSTALLATION....................................................................................................................3

3.1 Selecting the place of installation ..........................................................................3

3.2 Mounting..................................................................................................................3

3.2.1 Mounting the HMP141A .............................................................................4

3.2.2 Mounting the HMP142A .............................................................................4

3.2.3 Mounting the HMP143A .............................................................................5

3.3 Electrical connections.............................................................................................6

3.4 Connectors and potentiometers on the main PCB................................................7

3.5 Selecting the outputs..............................................................................................7

3.6 Connection to an AC supply..................................................................................8

4. CALIBRATION .....................................................................................................................9

4.1 One-point humidity calibration...............................................................................9

4.2 Two-point humidity calibration...............................................................................9

4.2.1 Two-point humidity calibration procedure ...................................................9

4.3 Temperature calibration........................................................................................10

4.4 Calibration table.................................................................................................... 11

5. MAINTENANCE..................................................................................................................11

5.1 Replacing the HUMICAP

6. TECHNICAL DATA.............................................................................................................12

6.1 Relative humidity...................................................................................................12

6.2 Temperature...........................................................................................................12

6.3 General...................................................................................................................13

6.4 Electromagnetic compatibility..............................................................................14

6.4.1 Emissions................................................................................................14

6.4.2 Interference.............................................................................................14

7. SPARE PARTS AND ACCESSORIES ................................................................................14

180 sensor and the filter ............................................11

APPENDIX 1: CURRENT OUTPUT MODULE

APPENDIX 2: SETTINGS OF THE LOCAL DISPLAY

APPENDIX 3: HMP143A PROBE CABLE EXTENSION

TECHNICAL DATA

1999-12-08 i

Page 4

HMP140A SERIES

Operating Manual U175en-1.5

This page intentionally left blank.

ii 1999-12-08

Page 5

HMP140A SERIES

U175en-1.5 Operating Manual

1. PRODUCT DESCRIPTION

The HMP140A series transmitters are reliable and easy to use instruments for

the measurement of relative humidity and temperature. The series consists of

three different types of transmitters to be chosen according to the requirements

of the application:

• HMP141A for wall installations

• HMP142A for duct installations

• HMP143A for installation in tight places

The configuration can be chosen from various possibilities to meet the specific

requirements of the customer. The transmitters can be ordered with a blank

cover or a cover with a local display which outputs relative humidity and

temperature readings. The reading to be displayed is chosen with a pushbutton

on the cover and the desired temperature unit (Celsius or Fahrenheit) can be

chosen with a jumper (see Appendix 2).

All HMP140A transmitters measure relative humidity in the range of

0...100 %RH and temperature from -40 to +60 °C; the measurement is

temperature compensated. The HMP140A transmitters have four different

analogue outputs: 0...20 mA (4...20 mA), 0...1 V, 0...5 V and 0...10 V. The

outputs are also scalable if necessary, e.g. 4...20 mA from 0...20 mA.

The durable plastic cover provides IP65 protection from dust and sprayed

water. The HMP140A transmitters are therefore suitable for most indoor and

outdoor applications, including those with high humidities like indoor

swimming pools etc. These versatile transmitters are also easy to install and to

use. When necessary, they can be recalibrated on site with Vaisala’s HMI41

indicator equipped with an appropriate probe and optional calibration cable

(19116ZZ).

The HMP140A series transmitters incorporate the HUMICAP180 sensor, the

operation of which is based on the changes in its capacitance as the thin

polymer film absorbs water molecules. The sensor is immune to most

chemicals and has an excellent long-term stability. The temperature is

measured with a Pt 1000 sensor.

1999-12-08 1

Page 6

HMP140A SERIES

Operating Manual U175en-1.5

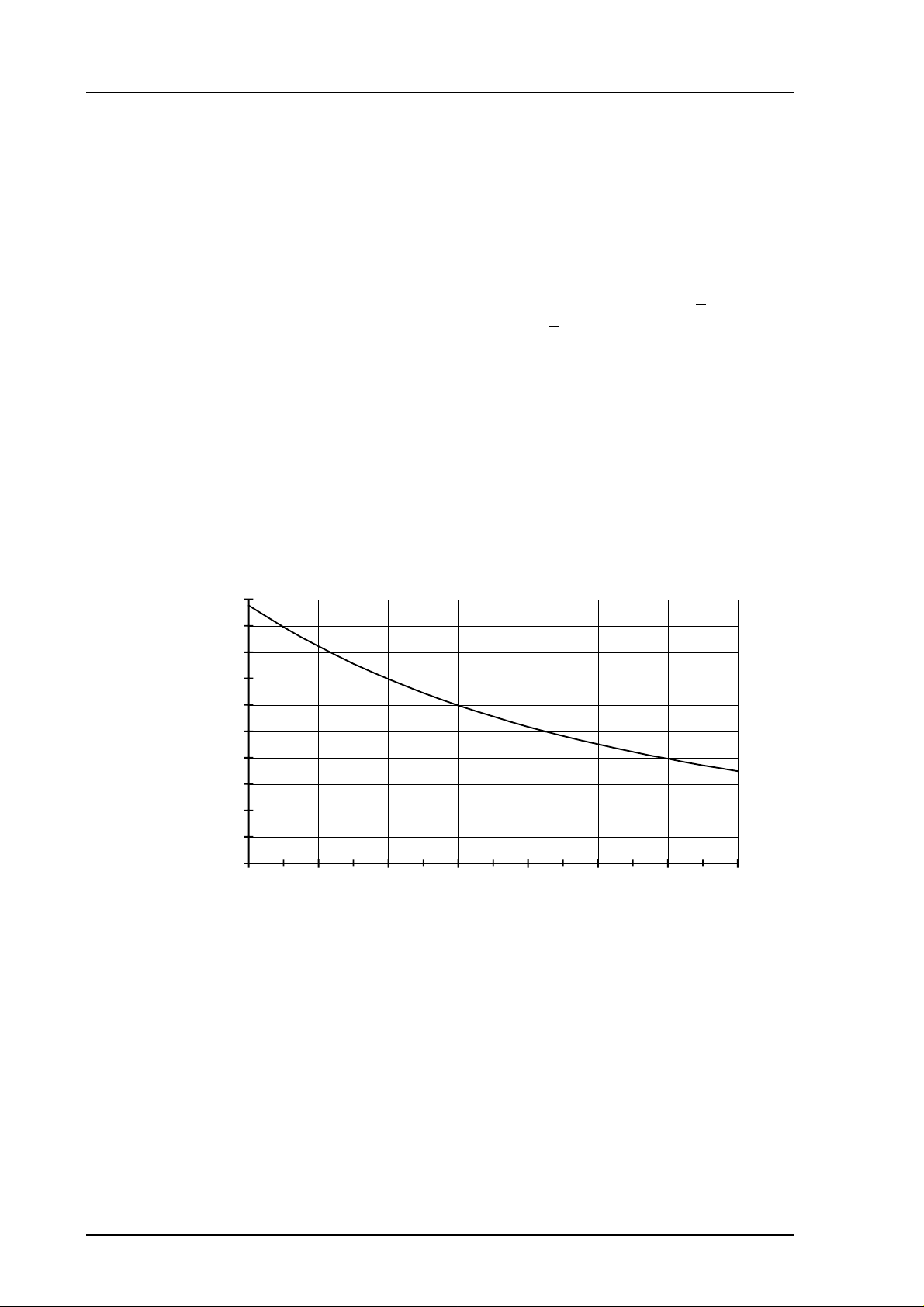

2. TO BE NOTED WHEN MEASURING HUMIDITY

In the measurement of humidity and especially in calibration, it is essential

that the temperature equilibrium is reached. Even a slight difference in the

temperature between the measured object and the sensor causes an error. For

example, at +20 °C (+ 68 °F) and 50 %RH, a temperature difference of +1 °C

between the measured object and the sensor causes an error of +3 %RH. If

relative humidity is 90 %RH, the error is about +5.4 %RH.

The error is at its greatest when the temperature of the sensor differs from that

of the surroundings and the humidity is high. A few degrees’ difference in

temperature may cause water to condense on sensor surface. Efficient

ventilation accelerates evaporation whereas in an unventilated space, it may

take hours. The HUMICAP180 sensor returns to its normal functioning as

soon as water has evaporated. Any contaminated water condensing on the

sensor may shorten its life span and change the calibration.

10

9

8

7

6

5

4

dRH (%RH)

3

2

1

0

-40-200 20406080100

Temperature (°C)

Figure 2.1 Measurement error at 100 %RH when the temperature

difference between th e ambient and the sensor i s 1 °C

2 1999-12-08

Page 7

HMP140A SERIES

U175en-1.5 Operating Manual

3. INSTALLATION

3.1 Selecting the place of installation

Select a place that gives a true picture of the environment or process and is as

clean as possible. Air should circulate freely around the sensor. A rapid air

flow is recommended as it ensures the same temperature for the ambient air

and the sensor head.

Install the transmitter in a place where no cold or hot spot can develop. If the

sensor head is installed in a duct or channel where the temperature is different

from the ambient temperature, insulate the point of entry; this is particularly

important if the transmitter is installed with the sensor head pointing

downwards. Vertical installation of the HMP142A and HMP143A is not

recommended; they should be mounted with the sensor head horizontally

whenever possible. An uninsulated installation might lead to condensation on

the sensor head and even if no condensation occurs, the resultant air flow may

change the temperature near the sensor head and distort the readings.

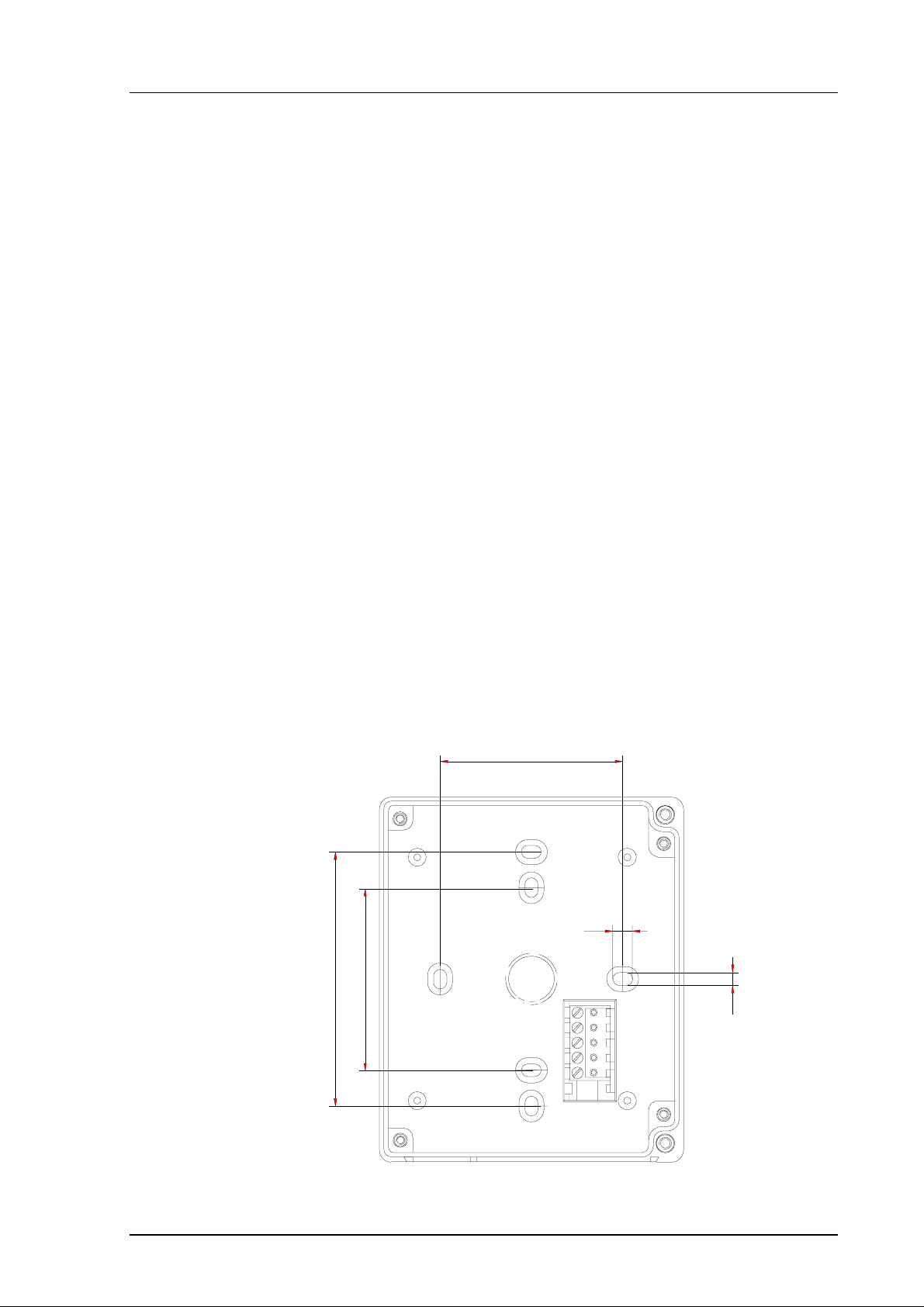

3.2 Mounting

The electronics of the HMP140A series can be disconnected for ease of

installation and service. The housing can be conveniently installed and the

electronics then consequently mounted. For service and maintenance purposes

the electronics can be disconnected without disconnecting the cabling, and

taken to an appropriate environment for necessary adjustments.

60

6.5

60

83.5

4.2

Figure 3 Drilling dimensions (in mm)

1999-12-08 3

Page 8

HMP140A SERIES

Operating Manual U175en-1.5

3.2.1 Mounting the HMP141A

The optimal installation of the HMP141A is with the sensor head pointing

downwards. Upward mounting should be avoided due to internal heat transfer.

1. Mounting and wiring:

cable feedthrough

on the surface or

in the connection box.

2. Mount the protection

lid to the conn ection

box.

3. Push the s e nsor h ea d

through the protection

lid a s in fig ure a n d

connect the electronics

housing to the connection

box. Make sure that the

pins at the bottom of

the electronics housing

are in co nt ac t with the

sc r ew termin a l .

4. Fasten the four

conn ec ting s cre w s of

the electronics housing.

5. Place the sensor head

into the p ro t e ct io n lid .

6. Close the cover and fasten

the two co n ne c tion s c rews.

1

3

4

4

6

4

4

5

2

Figure 3.2.1 Mounting of the HMP141A

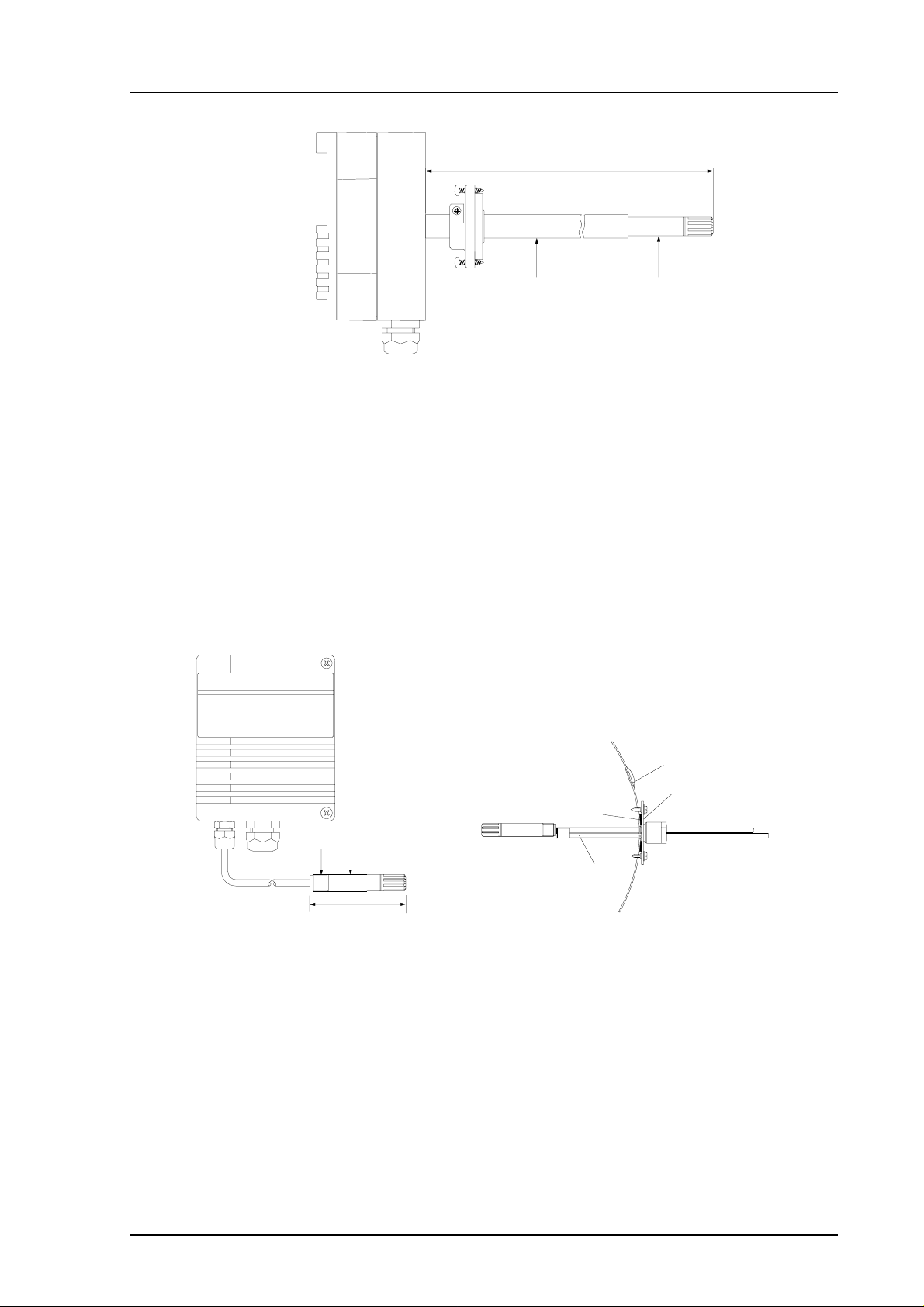

3.2.2 Mounting the HMP142A

The HMP142A transmitter should be mounted with the sensor head

horizontally whenever possible. This way, any water that might condense on

the tube cannot flow on to the sensors. When there is no alternative but to

install the sensor head in the process vertically, the point of entry must be

carefully insulated.

4 1999-12-08

Page 9

HMP140A SERIES

U175en-1.5 Operating Manual

225

Ø 15

Ø 12

Figure 3.2.2 Dimensions of the HMP142A (in mm)

3.2.3 Mounting the HMP143A

The cable model HMP143A should also be mounted with the sensor head

horizontally whenever possible. This model is provided with two plastic nuts

and a gasket. Mount the nuts on the sensor head: disconnect the cable from the

transmitter, insert the nuts and fasten them on the sensor head. Then reconnect

the cable. A mounting flange is also available (see Fig. 3.2.3). The cable can

also be extended up to 100 metres; see Appendix 3 for details.

M12x1

Ø 12

69

duct wall

sealing

supporting bar

a plugged hole for

reference measurements

flange

Figure 3.2.3 Dimensions of the HMP143A probe (in mm) and

installation in a channel with the help of flange

(part no. HMP233FA) and supporting bar

1999-12-08 5

Page 10

HMP140A SERIES

Operating Manual U175en-1.5

3.3 Electrical connections

The wiring can be done in either of the two ways shown in Figure 3.3.

mounting on a juction box surface mount

GND

Tout

SHIELD

RHout

Vs

(OHFWULFDOFRQQHFWLRQVP$RXWSXW

9V

*1'

$

$

7

RXW

6+,(/'

5+

RXW

9V

(OHFWULFDOFRQQHFWLRQV9RXWSXW

9V

9

9

Figure 3.3 Electrical connections

Outputs

0...20 mA (4...20 mA) 20...35 VDC 17...24 VAC

min.

L

+ VDC

)(12ohmR

50

0...1 V 9...35 VDC 9...24 VAC

0...5 V 15...35 VDC 12...24 VAC

0...10 V 20...35 VDC 16...24 VAC

Current consumption 6...10 mA + output currents

*1'

7

RXW

6+,(/'

5+

RXW

9V

Electrical connections screw terminals for 0.5 - 1.5 mm2 wires (AWG

15...20), stranded wires recommended

6 1999-12-08

Page 11

HMP140A SERIES

U175en-1.5 Operating Manual

3.4 Connectors and potentiometers on the main PCB

DISPLAY CONNECTOR

PROBE CONNECTOR

VIO

X15

X16

SHIELD

GRN

YEL

BRN

Toffset

RHoffset

RHoutput

selection

RHgain

Tgain

Spare

jumpers

Toutput

selection

Test connector

for factory use;

leave the jumper

as indicated here

Test connector for

one point calibration

Connectors

for the

current module

Figure 3.4 Connectors and potentiometers on the main PCB

3.5 Selecting the outputs

The HMP140A series transmitters can be ordered with the desired output

signals already selected. If the outputs are changed, the jumpers have to be

moved to corresponding places (see Figure 3.5). For current outputs, see

Appendix 1. Jumper changes may change the output < ±0.15 %FS within the

chosen range; this usually does not give cause to recalibration.

DISPLAY CONNECTOR

Test connector for

one point calibration

PROBE CONNECTOR

VIO

SHIELD

GRN

YEL

BRN

RHoutput

selection

Toutput

selection

Voltage

Toutput selection

0-1V

0-5V

0-10V

Voltage

RHoutput selection

0-1V

0-10V

0-5V

Figure 3.5 Jumper positions for voltage outputs

1999-12-08 7

Page 12

HMP140A SERIES

Operating Manual U175en-1.5

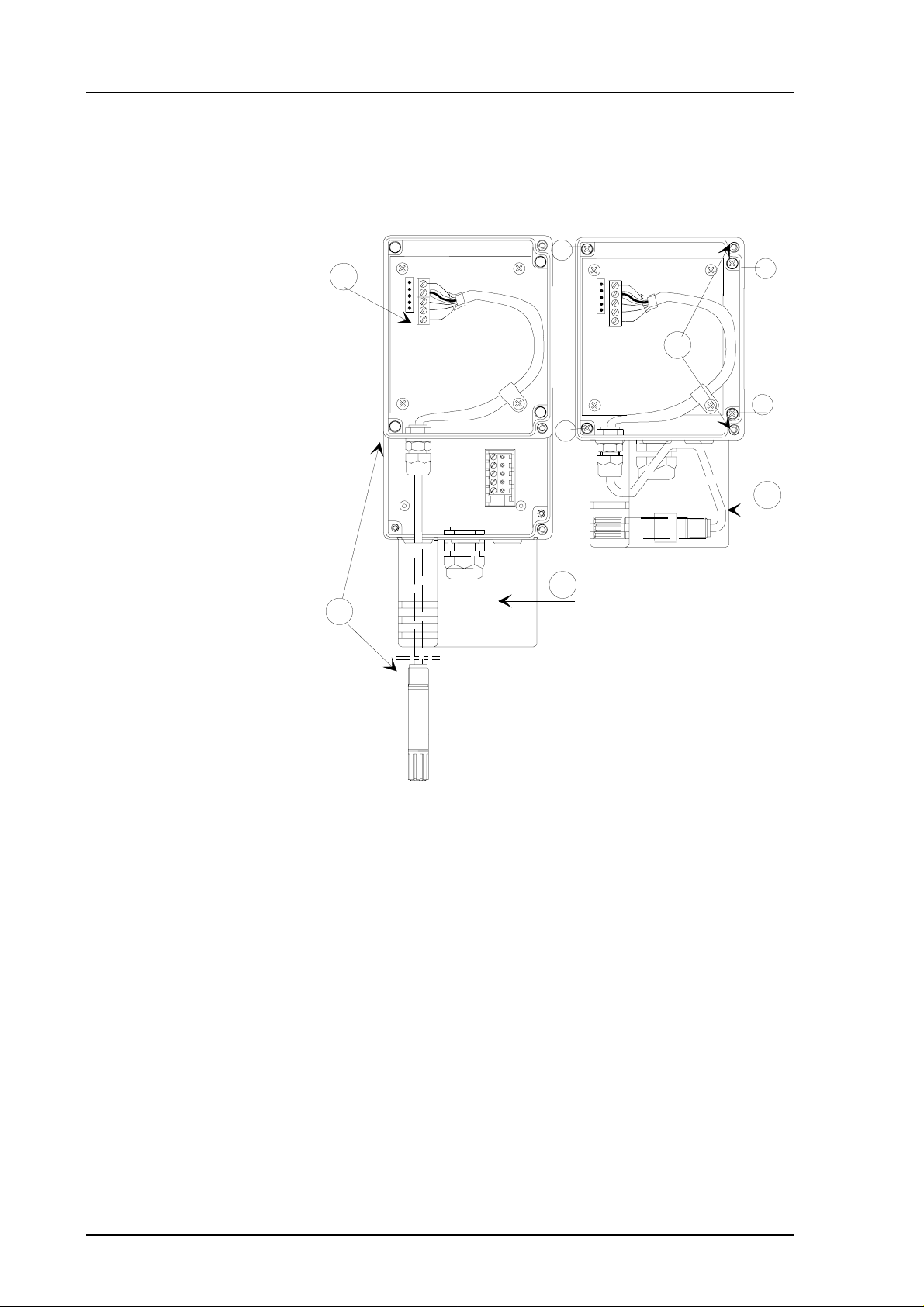

3.6 Connection to an AC supply

The HMP140A transmitters can also be connected to an AC supply without an

external rectifier. However, when two or more transmitters are connected to

one 24 VAC transformer, a common loop is formed and there is an increased

risk of a short-circuit. To avoid this, always use separate floating supply for

each transmitter (see Figure 3.6 A). However, if several transmitters have to

share one transformer, always connect the phase (∼) to + connector in each

transmitter (see Figure 3.6 B).

A) NO COMMON LOOP FORMED - RECOMMENDED

HMP140 transmitter

HMP140 transmitter

B) COMMON LOOP FORMED -

HMP140 transmitter

supply voltage

Controller

supply volt a g e

supply voltage

signal output

signal output

NOT RECOMMENDED!

Controller

signal output

shared

common line

supply voltage

signal output

HMP140 transmitter

Figure 3.6 Connecting the transmitters to a 24 VAC supply

8 1999-12-08

Page 13

HMP140A SERIES

U175en-1.5 Operating Manual

4. CALIBRATION

4.1 One-point humidity calibration

The HMP140A series transmitters should be recalibrated approximately once a

year. The interval depends on the operating conditions and the required

accuracy. One-point calibration can be done with Vaisala’s portable HMI41

indicator equipped with an appropriate probe and optional calibration cable

(19116ZZ). The cable is connected to a test connector either on the main

component board of the HMP140A or, if a current output module is installed,

on the module (see Figure 4.1). For more detailed instructions, see the

operating manual of the calibration cable (U218en).

DISPLAY CONNECTOR

PROBE CONNECTOR

VIO

SHIELD

GRN

YEL

BRN

Test connector for

one point calibration

on the main PCB

X15

X16

Test connector for

one point calibration

on the current

module

Current Module

Figure 4.1 Location of the test connectors

4.2 Two-point humidity calibration

The calibration can also be done with the HMK11 or the HMK13B Calibrator,

or the instrument can be sent to Vaisala or a Vaisala represent ative.

4.2.1 Two-point humidity calibration procedure

• Leave the calibrator and the transmitter for at least 30 minutes in the

same space so that their temperatures have time to equalize.

• Place the probe into the calibration hole of the LiCl bottle in the

humidity calibrator.

• Wait for 10 minutes.

1999-12-08 9

Page 14

HMP140A SERIES

Operating Manual U175en-1.5

• Use the RH offset potentiometer (see Figure 4.2) to adjust the output

signal to the value given in the calibration table (Chapter 4.4).

• Place the probe into the calibration hole of the NaCl bottle in the

calibrator.

• Wait for 10 minutes.

• Check that the reading corresponds within the desired accuracy to the

reading given in the calibration table. If not, adjust the reading with

the RH gain potentiometer (see Figure 4.2).

• Check again the reading at the first point and adjust if necessary.

DISPLAY CONNECTOR

PROBE CONNECTOR

Figure 4.2 Calibration potentiometers

4.3 Temperature calibration

One point temperature calibration can be performed with the HMI41 equipped

with an appropriate probe and optional calibration cable if the accuracy of

+0.5 °C is sufficient. For further details, see the operating manual of the

HMI41 and calibration option.

Toffset

RHoffset

RHgain

Tgain

10 1999-12-08

Page 15

HMP140A SERIES

U175en-1.5 Operating Manual

4.4 Calibration table

Temperature °C 15 20 25 30 35

°F 59 68 77 86 95

LiCl %RH *) 11.3 11.3 11.3 11.3

4...20 mA mA 5.81 5.81 5.81 5.81

0...20 mA mA 2.26 2.26 2.26 2.26

0...1 V V 0.113 0.113 0.113 0.113

0...5 V V 0.565 0.565 0.565 0.565

0...10 V V 1.13 1.13 1.13 1.13

NaCl %RH 75.6 75.5 75.3 75.1 74.9

4...20 mA mA 16.10 16.08 16.05 16.02 15.98

0...20 mA mA 15.12 15.10 15.06 15.02 14.98

0...1 V V 0.756 0.755 0.753 0.751 0.749

0...5 V V 3.780 3.775 3.765 3.755 3.745

0...10 V V 7.56 7.55 7.53 7.51 7.49

*) LiCl solution must not be used or stored in temperatures below +18 °C (+64 °F) ;

otherwise the equilibrium humidity of the salt solution changes permanently

Table 1 Greenspan’s calibration table with output values accordin g to

the chosen scale

5. MAINTENANCE

5.1 Replacing the HUMICAP180 sensor and the filter

Remove the damaged sensor and insert a new one. Handle the sensor by the

plastic socket. DO NOT TOUCH THE SENSOR PLATE. Check the output

after sensor change. If it deviates too much from the reference value,

recalibrate the transmitter. Note that even after sensor change, the accuracy is

still +7 %RH.

Replace a dirty filter to ensure a maximum lifetime for the sensor. Do not try

to clean the filter. The sensor can be cleaned with distilled water; if this does

not help, replace the sensor. Do not use any mechanical methods.

1999-12-08 11

Page 16

HMP140A SERIES

0

Operating Manual U175en-1.5

6. TECHNICAL DATA

6.1 Relative humidity

Measurement range 0...100 %RH

Accuracy (including non-linearity and repeatibility)

when calibrated against salt solutions (ASTM E104-85):

0...90 %RH +2 %RH

90...100 %RH +3 %RH

Temperature dependence:

dRH (%RH)

2

1.5

1

0.5

0

-0.5

-1

-1.5

-2

-20

-10

0102030

40

50

6

T (°C)

Response time (90%) 15 s at +20 °C in still air (with sintered filter)

Maximum error between

the display and the outputs 0.2 %RH

Humidity sensor HUMICAP180

6.2 Temperature

Measurement range -20...+60 °C

Typical accuracy at:

+20 °C +0.2 °C

-10...+40 °C +0.3 °C

-20...+60 °C +0.4 °C

Temperature sensor Pt 1000 IEC 751 Class B

12 1999-12-08

Page 17

HMP140A SERIES

U175en-1.5 Operating Manual

6.3 General

Power supply

current outputs: 20...35 VDC 17...24 VAC

min. 12 +

RL(ohm)

50

0...1 V 9...35 VDC 9...24 VAC

0...5 V 15...35 VDC 12...24 VAC

0...10 V 20...35 VDC 16...24 VAC

Current consumption 6...10 mA + output currents

Electrical connections screw terminals for 0.5 - 1.5 mm2 wires (AWG

15...20), stranded wires recommended

Alternative analogue

output signals (scalable) 0...20 mA (4...20 mA)

0...1 V, 0...5 V, 0...10 V

NOTE! Output scales correspond to 0…100 %RH and -40…+60°C.

External loads for

current outputs < 500 Ω

0...1 V > 1 kΩ (to ground)

0...5 V > 5 kΩ (to ground)

0...10 V >10 kΩ (to ground)

Operating temperature range

for electronics -20...+60 °C

with display option 0...+50 °C

Storage temperature range -40...+80 °C

Operating humidity range 0...100 %RH

Bushing for ∅ 7...10 mm cables

Sensor protection

standard membrane filter, part no. 17039HM

option plastic grid, part no. 17038

Cable length of HMP143A

standard 2.5 m

maximum 100 m (user extendable, see Appendix 3)

Housing material ABS plastic

Housing classification IP65 (NEMA 4)

1999-12-08 13

Page 18

HMP140A SERIES

Operating Manual U175en-1.5

6.4 Electromagnetic compatibility

6.4.1 Emissions

Test: Setup according to:

Radiated interference EN55022 (class B)

6.4.2 Interference

Test: Setup according to: Performance:

Electrostatic discharge IEC 801-2 criteria B

RF-radiated fields IEC 801-3 criteria A

(allowed temporary effect

±1 °C in temperature)

Electrical fast transients IEC 801-4 criteria B

7. SPARE PARTS AND ACCESSORIES

Order code Description

HMP233FA mounting flange for the HMP143A

19326 junction box for the HMP143A cable ex tension

(seeApp.3)

1535 extension cable for the HMP143A (see Appendix 3)

17039HM membrane filter

17038 plastic grid

HUMICAP®180 humidity sensor

GUARANTEE

Vaisala issues a guarantee for the material and workmanship of this product

under normal operating conditions for one (1) year from the date of delivery.

14 1999-12-08

Page 19

HMP140A SERIES

U175en-1.5 Operating Manual

Exceptional operating conditions, damage due to careless handling and misapplication will void the guarantee.

1999-12-08 15

Page 20

Page 21

HMP140A SERIES

U175en-1.5 Appendix 1

APPENDIX 1: CURRENT OUTPUT MODULE

Spare jumpersCurrent module

X15

T output

selection

X16

RH output

selection

Figure 1

The current module is available only for HMP142A and HMP143A

transmitters. To install the current module to connectors X15 and X16, first

disconnect the jumpers (4 pcs). Insert them to the connector for spare jumpers

(see Figure 1) and install the current module. Note that the module must be

installed exactly as indicated in Figure 1. The jumpers for RH and T output

selections must be connected in two middle pins of the connectors (Figure 1).

Recalibrate the transmitter after having installed the current module. The

maximum error in output without recalibration is ± 0.5 %FS.

1999-12-08 1

Page 22

Page 23

HMP140A SERIES

U175en-1.5 Appendix 2

APPENDIX 2: SETTINGS OF THE LOCAL DISPLAY

°F

RH/T

°C

Figure 1 Location of the RH/T button and the °C/°F jumpers

The reading on the local display (relative humidity or temperature) can be

chosen by pressing the RH/T button beside the display. At power-up, the

display always shows the relative humidity reading. This can be changed to

temperature reading by pressing the RH/T button once. Further pressings will

change the reading between RH and T.

The temperature unit (°Celsius or °Fahrenheit) is chosen with the jumper on

back of the local display unit. For °C, the jumper is connected to the lower

position and for °F, it is connected to the upper position (see Figure 1).

NOTE!

The HMP140A series transmitters with the local

display and current output cannot be re-scaled.

1999-12-08 1

Page 24

HMI41

Appendix 2 HMI41-Uxxxen-1.1

2 1999-12-08

Page 25

HMP140A SERIES

S

U175en-1.5 Appendix 3

APPENDIX 3: HMP143A PROBE CABLE EXTENSION

The cable of the HMP143A probe can be extended up to 100 metres with the

help of the extension set including a junction box (part no. 19326) and a

shielded six wire extension cable (part no. 1535).

The junction box has a 5-pole terminal block and two PG9 lead-throughs. The

extension cable is a shielded 6 x 0.22 mm2 copper wire cable. This cable

enables the extension without the need for transmitter adjustments. The user

can also use some other cable for this purpose provided that it is a shielded

copper wire cable. A shielded cable is recommended as it ensures the best

possible EMC protection. The diameter of the cable should not exceed 7 mm

as larger cables do not fit to the lead-through of the transmitter.

The HMP143A probe head uses a combined signal ground and supply voltage

ground. Ground wire resistance Rc causes an offset type error to the

transmitter output. The error is -0.11 x Rc both in %RH and in °C. This means

that if maximum error allowed is e.g. -0.3 %RH or -0.3 °C, the ground wire

resistance should not exceed 2.7Ω. The resistance of the cable 1535 is

minimized by connecting three wires as a ground conductor (see Figure 1).

Possible error can also be leveled out by readjusting the transmitter offset

(RH offset and T offset).

PROBE CONNECTOR ON THE

HMP143 PCB; THE COLOURS

SHOW THE DIRECT CONNECTION

OF THE HMP143 PROBE HEAD

PROBE CONNECTOR

VIO

SHIELD

GRN

YEL

BRN

Figure 1 Schematic of the extension set connections

HMP143 PROBE

CONNECTOR

THREE WIRES CONNECTED

TOGETHER (WHT, GRN, RED)

EXTENSION

CABLE

CABLE SHIELD

BLU

GREY

YEL

BLK

JUNCTION

BOX

HMP143 CABLE

VIO

SHIELD

GRN (ground)

YEL

BRN

1999-12-08 1

Page 26

HMP140A

Appendix 3 U175en-1.5

TECHNICAL DATA

Junction box (part no. 19326)

Housing:

material ABS plastic

dimensions 65 x 50 x 35 mm (l x w x h)

classification IP 65

temperature range -40...+80 °C

Lead-throughs:

size PG 9

cable diameter 4...7 mm

housing classification IP 68

Terminal block:

max. wire area 1.5 mm

Extension cable (part no. 1535)

Type PFSK 6 x 0.22 mm

Wire resistance 80 Ω / km

Covering braided, tinned copper wire

Cross-sectional area

of the wires 0.22 mm

Cover PVC, light grey

Temperature range -30...+70 °C

Wire colours red, blue, green, yellow, white, black

2

2

2

(DEF-STAN 61-12)

2 1999-12-08

Page 27

Page 28

www.vaisala.com

Loading...

Loading...