Page 1

USER'S GUIDE

Vaisala HUMICAP® Set for Measuring

Humidity in Concrete

HM44

M010068EN-A

Page 2

PUBLISHED BY

Vaisala Oyj Phone (int.): +358 9 8949 1

P.O. Box 26 Fax: +358 9 8949 2227

FIN-00421 Helsinki

Finland

Visit our Internet pages at http://www.vaisala.com/

© Vaisala 2006

No part of this manual may be reproduced in any form or by any means, electronic or

mechanical (including photocopying), nor may its contents be communicated to a third

party without prior written permission of the copyright holder.

The contents are subject to change without prior notice.

Please observe that this manual does not create any legally binding obligations for

Vaisala towards the customer or end user. All legally binding commitments and

agreements are included exclusively in the applicable supply contract or Conditions of

Sale.

Page 3

_________________________________________________________________________________

Table of Contents

CHAPTER 1

GENERAL INFORMATION ............................................................................3

Safety.........................................................................................3

Version Information..................................................................3

Warranty ....................................................................................4

CHAPTER 2

PRODUCT DESCRIPTION.............................................................................5

CHAPTER 3

TO BE NOTED WHEN MEASURING HUMIDITY..........................................6

CHAPTER 4

TAKEN INTO USE..........................................................................................7

Feeding the individual adjustment coefficients ....................7

Numbering the probes......................................................8

Feeding the offset correction............................................8

Feeding the gain correction..............................................8

Changing the settings..............................................................9

Enter the setup menu.......................................................9

Display units...................................................................10

Setting the automatic power-off function........................10

Selecting the display quantities......................................11

Setting the pressure for mixing ratio and wet bulb

temperature calculations ................................................11

Setting the probe type....................................................12

Select the function..........................................................12

CHAPTER 5

HUMIDITY MEASUREMENTS IN CONCRETE ...........................................13

General about humidity measurements in a drilled hole ...13

Measurement depth................................................................13

Maximum humidity levels for coating ..................................15

Preparations for the measurements.....................................16

Starting the measurements ...................................................18

Measurement readings on display........................................19

HOLD-mode ........................................................................19

MIN and MAX modes ..........................................................19

VAISALA ___________________________________________________________________

1

Page 4

User's Guide _______________________________________________________________________

CHAPTER 6

COLLECTING DATA ................................................................................... 21

Data collecting modes........................................................... 21

Entering the data collecting modes..................................... 21

Automatic data collecting mode

REC AUTO .......................... 22

Setting the measurement duration...................................... 22

Setting the measurement interval....................................... 23

Manual data collecting

Reading the measurement results

MIN and MAX in data collecting

CHAPTER 7

REC CATCH ........................................ 24

REC READ....................... 25

REC READ mode................ 26

TRANSFERRING DATA TO A PC .............................................................. 28

Giving the communication parameters ............................... 29

Transferring the data............................................................. 31

Commands.......................................................................... 32

PLAY Transferring the data ............................................... 32

CPLAY Setting characters between decimals and fields... 33

HELP Outputting available commands and their contents 33

? Outputting the HMI41 settings........................................ 34

CHAPTER 8

CALIBRATION............................................................................................. 35

Two-point humidity calibration............................................. 37

CHAPTER 9

MAINTENANCE........................................................................................... 39

Replacing the HUMICAP

180 sensor ................................. 39

Replacing the filter................................................................. 39

CHAPTER 10

TROUBLESHOOTING................................................................................. 40

Erroneous readings............................................................. 40

Trouble shooting ................................................................. 40

CHAPTER 11

SPARE PARTS AND ACCESSORIES........................................................ 42

Optional probes...................................................................... 43

CHAPTER 12

TECHNICAL DATA...................................................................................... 44

HMP44 probe.......................................................................... 44

HMI41 indicator ...................................................................... 45

______________________________________________________________________________

2

Page 5

Chapter 1 _________________________________________________________ General Information

CHAPTER 1

GENERAL INFORMATION

Safety

Throughout the manual, important safety considerations are

highlighted as follows:

WARNING

CAUTION

NOTE

Warning alerts you to a serious hazard. If you do not read and follow

instructions very carefully at this point, there is a risk of injury or

even death.

Caution warns you of a potential hazard. If you do not read and

follow instructions carefully at this point, the product could be

damaged or important data could be lost.

Note highlights important information on using the product.

Version Information

Table 1 Manual Revisions

Manual Code Description

U254en-1.3 March 1998

M010068en-A

VAISALA ___________________________________________________________________

3

Page 6

User's Guide _______________________________________________________________________

Warranty

Vaisala hereby represents and warrants all Products

manufactured by Vaisala and sold hereunder to be

free from defects in workmanship or material during

a period of twelve (12) months from the date of

delivery save for products for which a special

warranty is gi ven. If any P roduct p roves ho wever to

be defective in workmanship or material within the

period herein provided Vaisala undertakes to the

exclusion of any other remedy to repair or at its own

option replace the defective Product or part thereof

free of charge and otherwise on the same conditions

as for the original Product or part without extension

to original warranty time. Defective parts replaced in

accordance with this clause shall be placed at the

disposal of Vaisala.

Vaisala also warrants the quality of all repair and

service works performed by its employees to

products sold by it. In case the repair or service

works should appear inadequate or faulty and should

this cause malfunction or nonfunction of the product

to which the service was performed Vaisala shall at

its free option either repair or have repaired or

replace the product in question. The working hours

used by employees of Vaisala for such repair or

replacement shall be free of charge to the client.

This service warranty shall be valid for a period of

six (6) months from the date the service measures

were completed.

This warranty is however subject to following

conditions:

a) A substantiated written claim as to any alleged

defects shall have been received by Vaisala

within thirty (30) days after the defect or fault

became known or occurred, and

b) The allegedly defective Product or part shall,

should Vaisala so require, be sent to the works of

Vaisala or to such other place as Vaisala may

indicate in writing, freight and insurance prepaid

and properly packed and labelled, unless Vaisala

agrees to inspect and repair the Product or

replace it on site.

a) normal wear and tear or accident;

b) misuse or other unsuitable or unauthorized use of

the Product or negligence or error in storing,

maintaining or in handling the Product or any

equipment thereof;

c) wrong installation or assembly or failure to

service the Product or otherwise follow Vaisala

service instructions including any repairs or

installation or assembly or service made by

unauthoriz ed personnel not a pproved by V aisala

or replacements with parts not manufactured or

supplied by Vaisala;

d) modifications or changes of the Product as well

as any adding to it without Vaisala's prior

authorization;

e) other factors depending on the Customer or a

third party.

Notwithstanding the aforesaid Vaisala's liability

under this clause shall not apply to any defects

arising out of materials, designs or instructions

provided by the Customer.

This warranty is expressly in lieu of and excludes all

other conditions, warranties and liabilities, express

or implied, whether under law, statute or otherwise,

including without limitation ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR OF

FITNESS FOR A PARTICULAR PURP OSE and all

other obligations and liabilities of Vaisala or its

representatives with respect to any defect or

deficiency applicable to or resulting directly or

indirectly from the Products supplied hereunder,

which obligations and liabilities are hereby

expressly cancelled and waived. Vaisala's liability

shall under no circumstances exceed the invoice

price of any Product for which a warranty claim is

made, nor shall Vaisala in any circumstances be

liable for lost profits or other consequential loss

whether direct or indirect or for special damages.

This warranty does not however apply when the

defect has been caused through

______________________________________________________________________________

4

Page 7

Chapter 2 _________________________________________________________ Product description

CHAPTER 2

PRODUCT DESCRIPTION

The HM44 set is a practical tool for humidity measurements of concrete or other structures.

The accuracy and reliability performance of the HMP44 probe comes from advanced Vaisala

HUMICAP© 180 sensor.

The HM44 package includes:

• HMP44 humidity and temperature probe

• HMI41 indicator with batteries

• installation cover and lid, 3 pcs

• rubber plugs, 12 pcs

• plastic sleeves, 12 pcs

• carrying case

• user 's guide

Figure 2.1HM44 set for measuring humidity in concrete.

VAISALA__________________________________________________________________________

5

Page 8

User's Guide _______________________________________________________________________

CHAPTER 3

TO BE NOTED WHEN MEASURING HUMIDITY

Temperature of the probe and the concrete shall be the same!

In humidity measurement and especially in calibration it is essential that temperature of the

probe and measured object is the same. Even a small difference in temperature between the

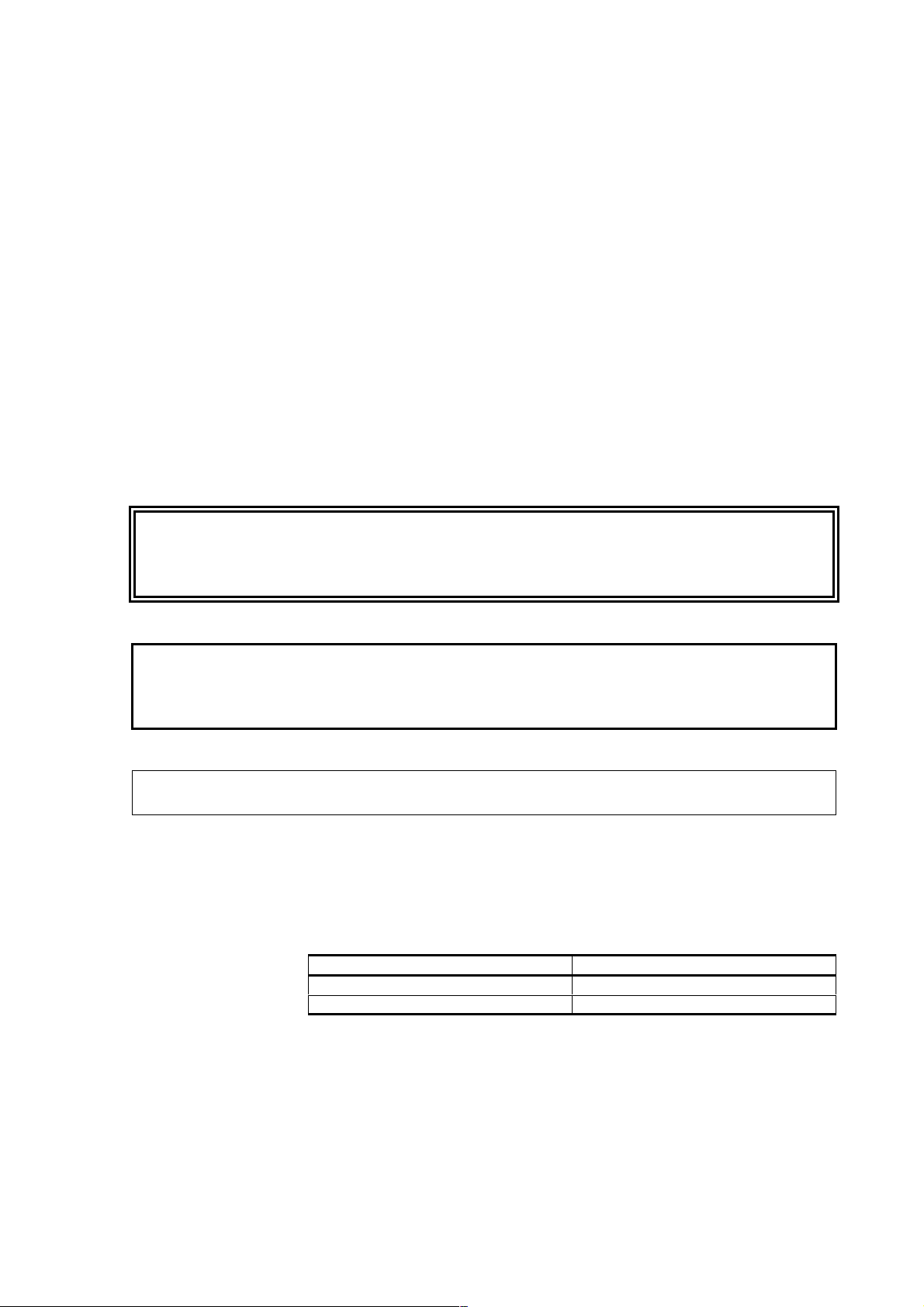

measured object and the probe causes an error. As the curve below shows, if the temperature

is +20 °C and the relative humidity 100 %RH, a difference of ±1 °C between the measured

object and the probe causes an error of ±6 %RH. When the humidity is 90 %RH, the

corresponding error is ±5.4 %RH.

A temperature difference of a few degrees can also cause water to condense on the sensor

surface. HUMICAP sensor starts to function normally as soon as the water has evaporated. If

the condensed water is contaminated, the life span of the probe may shorten and calibration

may change.

10

9

8

7

6

5

4

dRH (%RH)

3

2

1

0

-40-200 20406080100

Temperature (°C)

Figure 3.1 Measurement error at 1 00 %RH w hen the dif feren ce

between the ambien t and sens or te mpera ture is 1 °C

_________________________________________________________________________________

6

Page 9

Chapter 4 _____________________________________________________________ Taken into use

CHAPTER 4

TAKEN INTO USE

Before taking into use the HM44 do the following:

- place the batteries into HMI indicator

- connect the probe

- feed the individual probe adjustment coefficients

- if needed, check and change the settings

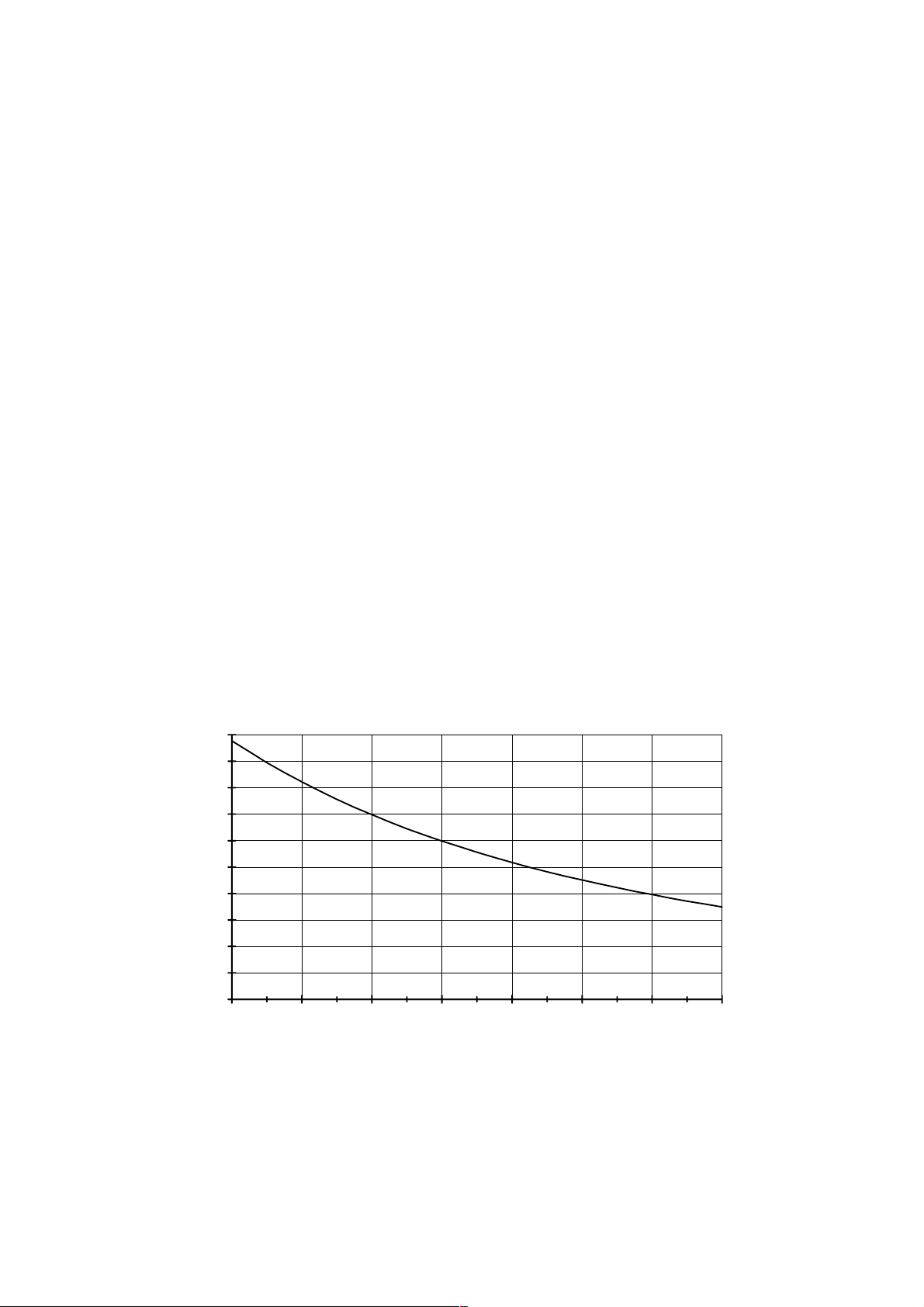

The basic display appears when turning the device on:

RH

T

Currently selected probe

%

°C

Relative

humidity

Temperature

Feeding the individual adjustment coefficients

Each probe has an individual adjustment coefficients which are written in the calibration

certificate (see Appendix 1). These coefficients should be fed to the HMI41 memory to reach

the measurement accuracy of ±2 %RH.

- When using one probe, numbering of the probe is not needed.

- When using more than one probe, firstly select a number for the probe and then feed the

probe individual coefficients to the HMI41 memory. Remember to write the probe number

(1-10) in the product label to be able to identify the probes afterwards.

VAISALA__________________________________________________________________________

7

Page 10

User's Guide _______________________________________________________________________

Numbering the probes

The first number of the second line of display indicates the currently selected probe (1-10).

Connect a probe and change the number on the display by pressing ENTER and

simultaneously buttons ▲ or ▼. Remember to write the probe number (1-10) in the product

label to be able to identify the probes.

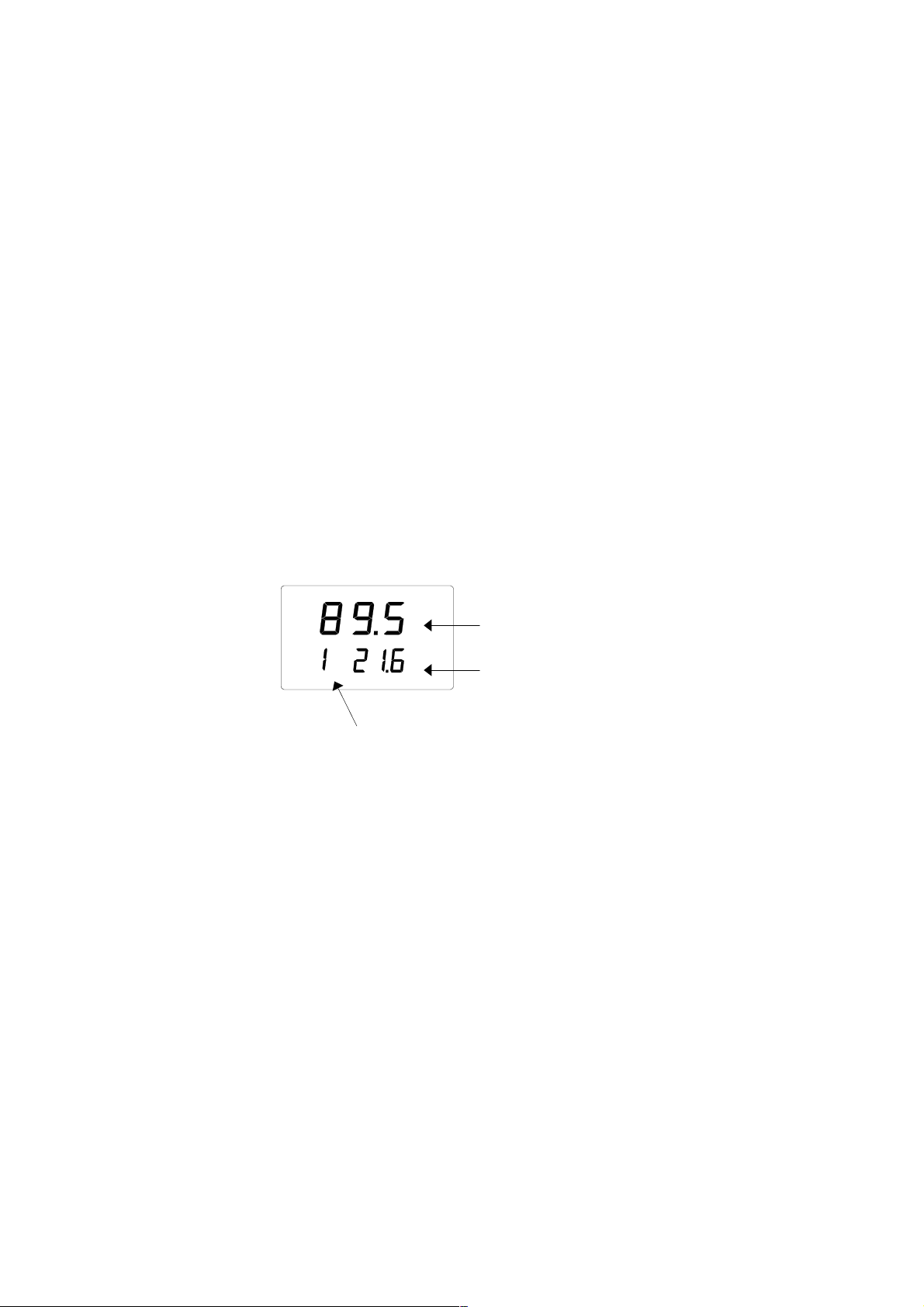

Feeding the offset correction

1. Press the button ENTER continuously for about 5 seconds until a text similar

to the following appears on the display (numbers on the second line are

blinking):

RH

set

2. Feed the individual offset correction (see the calibration certificate) in the

HMI41 memory with buttons ▲ and ▼. Each time the button is pressed, the

numbers change 0.1 %RH. If the button is pressed continuously, the numbers

change in a faster rate.

3. When the reading is correct, press ENTER and the display changes to show

the gain correction.

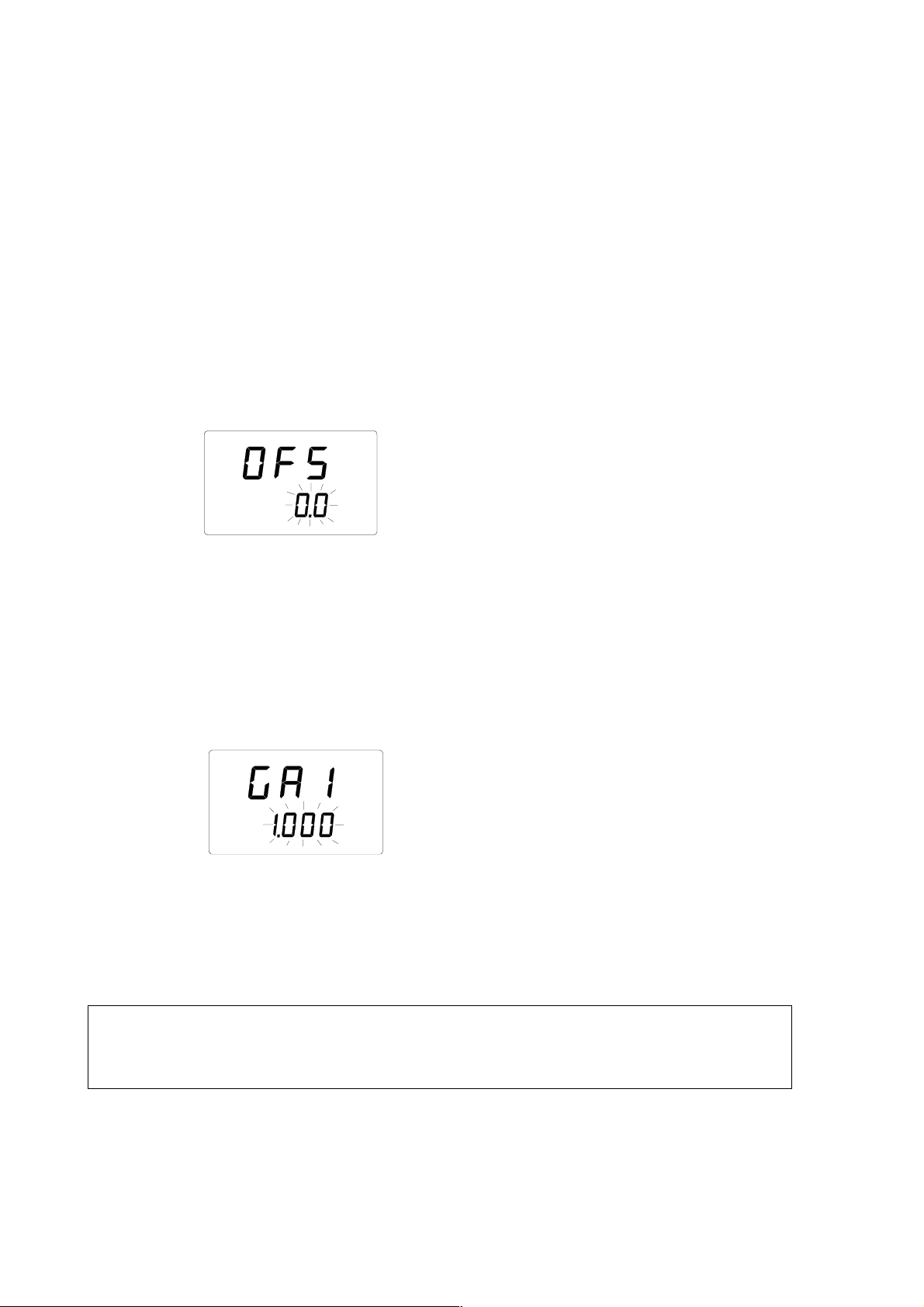

Feeding the gain correction

RH

set

4. Numbers on the second line are blinking; you can now enter the individual

gain correction in the HMI41 memory. The numbers are changed with

buttons ▲and ▼. Each time the button is pressed, numbers change 0.001. If

the button is pressed continuously, the numbers change in a faster rate.

NOTE

If the correction given in the calibration certificate has only two

decimals (e.g. 1.03), enter a zero in place of the third decimal (e.g.

1.030).

_________________________________________________________________________________

8

Page 11

Chapter 4 _____________________________________________________________ Taken into use

5. When the reading is correct, press ENTER and the display changes to show

the humidity and temperature readings. However, an arrow is now displayed

as an indication of the individual corrections in the HMI41 memory:

RH

T

%

°C

Changing the settings

Change the settings ONLY if there is a need to change the following factory settings:

Factory settings

• display units: 0 (metric)

• automatic power-off: 5 (minutes)

• display quantities: 0 (RH, T and Td)

• pressure: 1013.25 hPa (1 hPa = 1 mbar)

• probe t ype AUT

• start 5

To change the settings, enter the setup menu.

Enter the setup menu

Turn the device ON (by using ON/OFF button) and immediately (within 1..2 seconds) after

turning on, press together both the buttons ENTER and MODE for about 3 seconds, until the

following appears:

In a few seconds, the text changes automatically to the following:

°C

set

VAISALA__________________________________________________________________________

9

Page 12

User's Guide _______________________________________________________________________

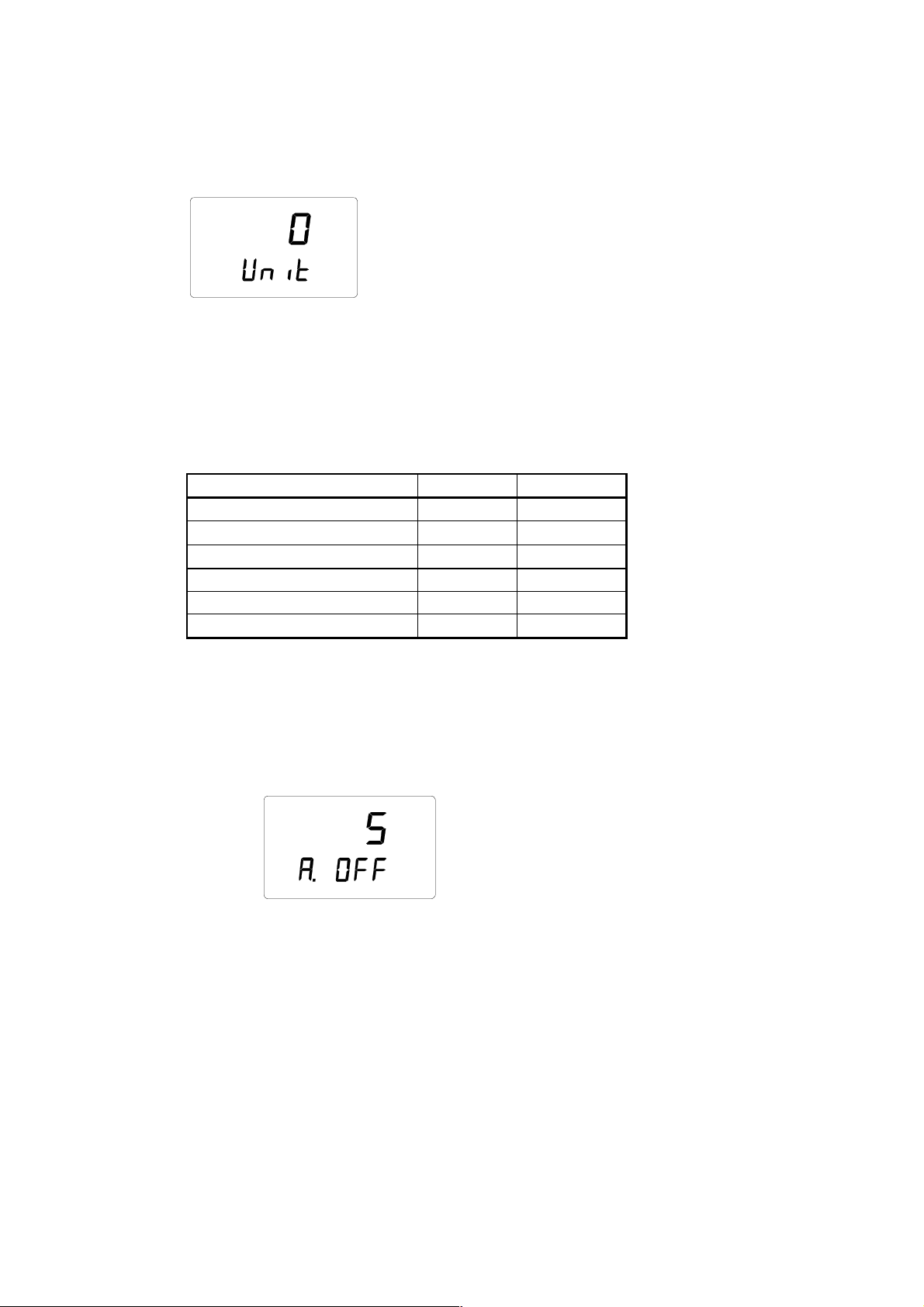

Display units

°C

set

• Select the display units with buttons ▲ or ▼. Choose 0 for metric units or 1 for non-

metric units (see Table 1).

• Press ENTER and the display changes to show the setting of the automatic power-off

function.

Table 1. Metric and non-metric units

quantity metric non-metric

relative humidity (RH) %RH %RH

temperature (T)

dewpoint temperature (Td)

absolute humidity (a) g/m

mixing ratio (x) g/kg gr/lb

wet bulb temperature (Tw)

°C °F

°C °F

3

gr/ft

°C °F

3

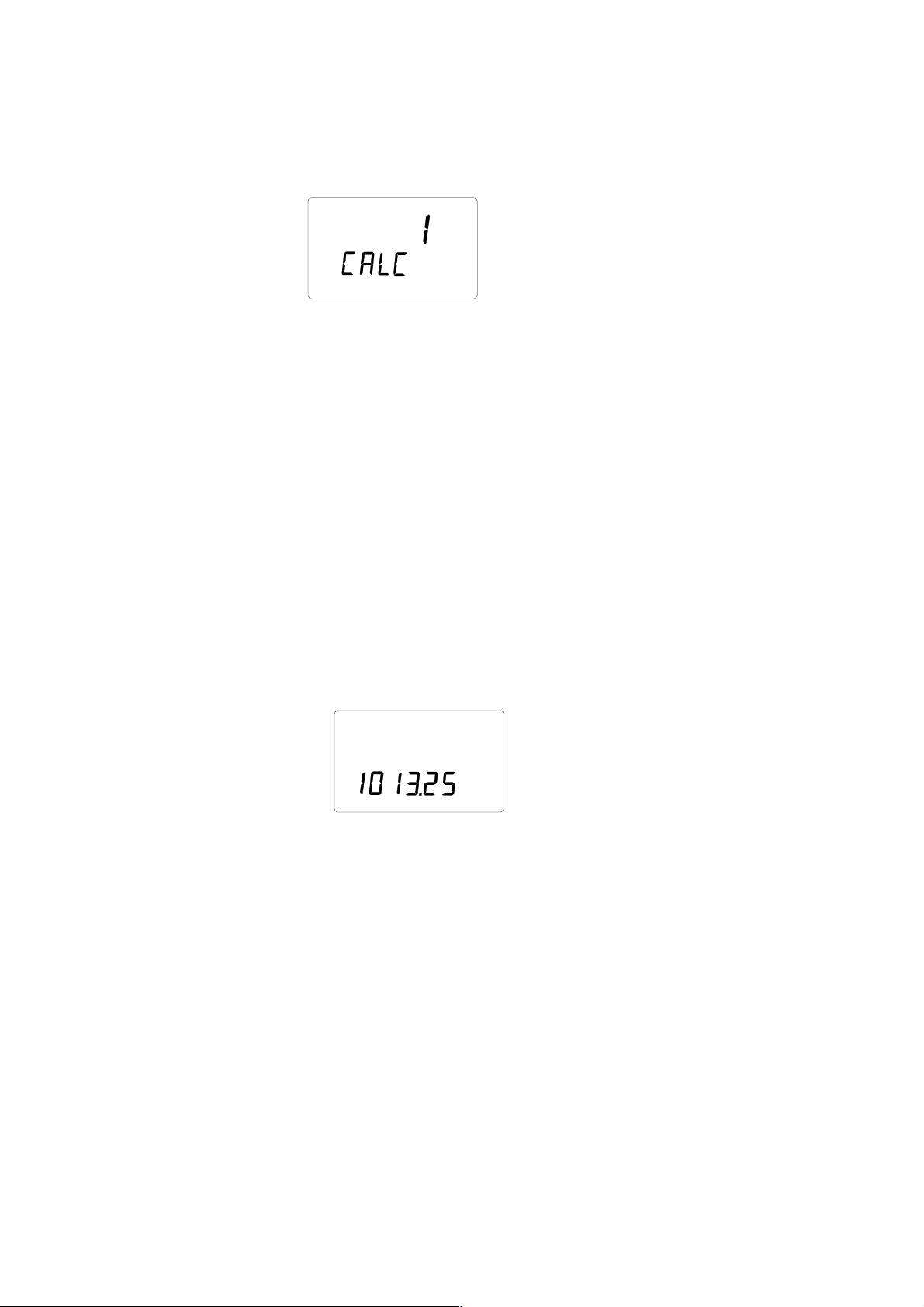

Setting the automatic power-off function

set

The number (or text NO) on the first line of the display indicates in minutes (1...60) the time

that the HMI41 stays on before an automatic power-off if no buttons are pressed.

• changed with buttons ▲ and ▼. If NO is chosen, the automatic power-off

function is not activated.

• Press ENTER and the display changes to show the selection of the display

quantities. NOTE: during data collecting this setting is not valid.

_________________________________________________________________________________

10

Page 13

Chapter 4 _____________________________________________________________ Taken into use

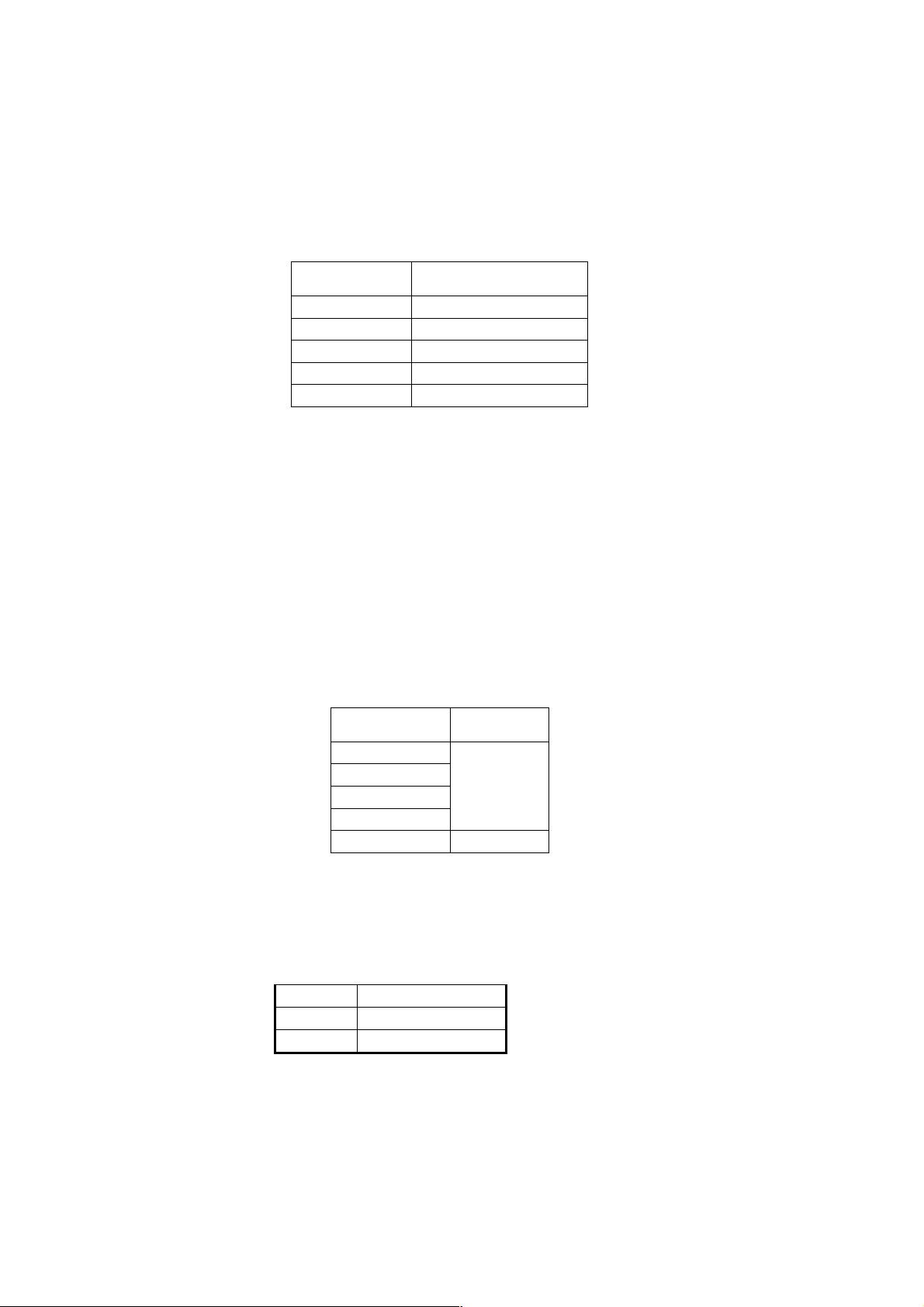

Selecting the display quantities

set

The HMI41 displays relative humidity (RH), temperature (T) and dewpoint temperature (Td)

readings. Additionally, one of the following quantities can be chosen: absolute humidity (a),

wet bulb temperature (Tw) and mixing ratio (x). The number on the display indicates the

following quantities:

0 = RH, T, Td

1 = RH, T, Td, abs

2 = RH, T, Td, Tw

3 = RH, T, Td, x

• select the number with buttons ▲ and ▼

• press ENTER and the display changes to show the setting of the pressure for

mixing ratio and wet bulb temperature calculations.

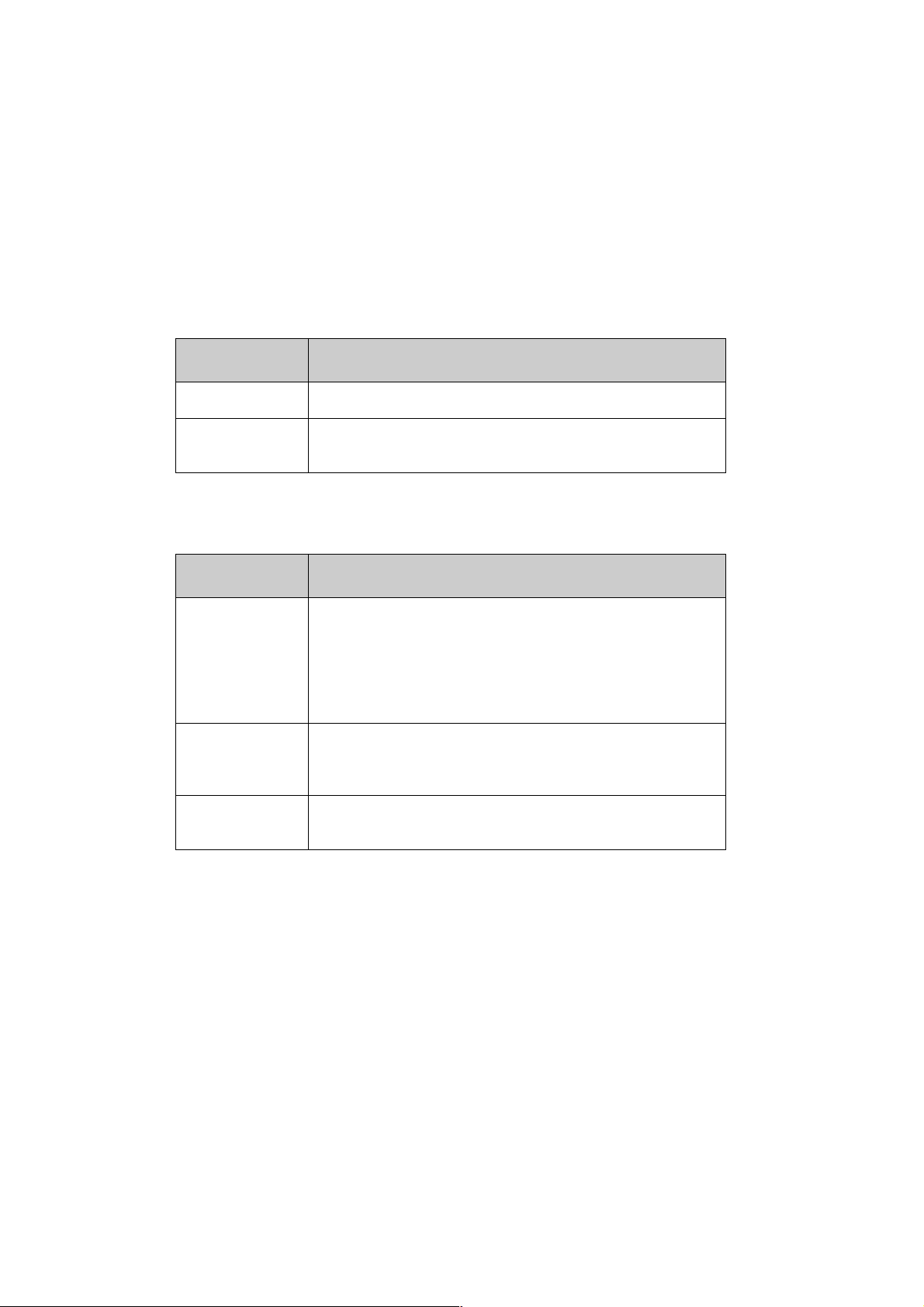

Setting the pressure for mixing ratio and wet bulb temperature calculations

PPah

set

• change the pressure (in steps of 0.25 hPa) with buttons ▲ and ▼

• press ENTER; the display now changes to show the text PROBE n (n=probe

number). Change this setting only if there is no ID-marking on the indicator

label. Otherwise do not change this setting.

VAISALA__________________________________________________________________________

11

Page 14

User's Guide _______________________________________________________________________

Setting the probe type

In cases where an indicator (or a probe) is without an ID-marking, the following probe

numbers have to be selected:

Probe Probe setting

HMP41 1

HMP42 2

HMP44 1...10

HMP45 1

HMP46 2

• change the setting with buttons ▲ and ▼

With the probe HMP44 there is no need to change the setting.

• press ENTER; the display now changes to show the text START. Change this

setting only if there is no ID-marking on the indicator label. Otherwise do not

change this setting.

Select the function

In cases where an indicator (or a probe) is without an ID-marking on the label the following

function selection is made:

Probe Setting

HMP41

HMP42

HMP45

HMP46

HMP44 Start 5

• change the setting with buttons ▲ and ▼

• press ENTER three times; the display now changes to show the following

settings (do not change them):

baud 4.8

seri E.7.1

calib def (*

(* when entering the setting calib, the value is always ‘no’; the factory settings are

restored by selecting ‘def’. After this, the previously entered adjustment coefficients

are no longer valid.

Start 1

_________________________________________________________________________________

12

Page 15

Chapter 5 ____________________________________________ Humidity measurements in concrete

CHAPTER 5

HUMIDITY MEASUREMENTS IN CONCRETE

General about humidity measurements in a drilled hole

The HMP44 probe measures humidity of concrete in a drilled hole. In equilibrium stage, the

humidity of a concrete and air humidity in a drilled hole become same.

Drilling changes the stage of the concrete. This is due to the fact that heat is formed during

drilling.(Meantime the humidity of the concrete changes, because of the temperature

changes). To reach the equilibrium stage after drilling takes about three days. When the

equilibrium stage has been reached, the air humidity in a drilled hole and the concrete

humidity become equal. Then it is possible to make the humidity measurement.

For getting more reliable results, it is recommended to have several measurement points.

Measurement depth

Depth of a drilled hole

When drying of a concrete slab takes place from both sides, the minimum depth of

measurement (d) is made 20 % of the depth of the slab. When drying occurs from one side

only, the measurement depth (d ) is 40 % of the depth of a slab. See Figure 5.1.

Humidity profile (Figure 5.1)

The humidity profile of the slab depends on the drying of the concrete, i.e. whether the

concrete dries in one or in two directions. In concrete slabs drying in two directions, the

humidity is highest in the middle. After coating, the humidity spreads evenly throughout the

VAISALA__________________________________________________________________________

13

Page 16

User's Guide _______________________________________________________________________

slab until it corresponds to readings measured at the depth of approximately 20% of the slab.

In concrete slabs drying in one direction only, the humidity is highest at the bottom. After

coating, the humidity spreads evenly throughout the slab until it corresponds to readings

measured at the depth of approximately 40% of the slab.

DRYING IN TWO DIRECTIONS

coating

hole for the

plastic tube

humidity profile

hole for the

plastic tube

humidity profile

concrete slab

BEFORE COATING

hole for the

plastic tube

concrete slab

0.2xd

d

concrete slab

0.2xd

AFTER COATING

DRYING IN ONE DIRECTION

coating

humidity profile

0.4xd

BEFORE COATING

concrete slab

d

hole for the

plastic tube

AFTER COATING

humidity profile

0.4xd

Figure 5.1 Humidity profile before and after the coating

d

d

_________________________________________________________________________________

14

Page 17

Chapter 5 ____________________________________________ Humidity measurements in concrete

Maximum humidity levels for coating

SisäRYL 2000 Code of Building Practice (RT 14-10668, 2000, ISBN 951-682-506-0)

recommends the following maximum humidity levels (at +20°C) for coating of various

materials :

Wooden floor coverings

Maximum

RH (%)

60

80

1

SisäRYL 2000 Code of Building practice, RT 14-10668, 2000, ISBN 951-682-506-0, page 332.

Other materials

Maximum

RH (%)

85

90

97

1

SisäRYL 2000 Code of Building practice, RT 14-10668, 2000, ISBN 951-682-506-0, page 318.

Coating

1

1

Wooden parquet boards without moisture barrier (plastic film)

between wood and concrete.

Enlaid wooden floor coverings.

Floating wooden floor coverings with moisture barrier (plastic

film) between wood and concrete.

Coating

1

1

Plastic floor coverings with fibre felt base or cellular plastic

base

Rubber floor coverings

Cork tiles with moisture barrier (plastic film)

Textile floor coverings with rubber, PVC or latex base

Natural fibre textile floor coverings without base

Plastic tiles

Plastic floor coverings without felt or cellular plastic base

Linoleum (Cork)

Man-made fibre textile floor coverings without base structure

Epoxy mass

Acrylic mass

Polyester plastic mass

VAISALA__________________________________________________________________________

15

Page 18

User's Guide _______________________________________________________________________

Preparations for the measurements

The holes shall be drilled 3 days before the measurements. A plastic sleeve and an installation

cover are placed to the hole immediately after drilling. A probe can be placed to the plastic

sleeve immediately after drilling or before measurements. Follow the instructions below.

1. Bore 3 days before the measurements at least two holes with diameter of ∅ 16 mm and

sufficient depth, see page 13. Clean the hole thoroughly e.g. by blowing air or with a

vacuum cleaner.

2. Press a plastic sleeve into the hole. If you need something to press it with, use e.g. the

lid of the installation cover.

Figure 5.1 Pressi ng the sleeve i nto th e hole

NOTE

3. Close the hole by using an installation cover as described in the following or Press an

installation cover on the plastic sleeve and make it slide down freely. Press the installation

cover against the base so that the sealing presses down slightly. Turn the cover 90° to lock

it in place.

Figure 5.2.Locking the

cover in place

Make sure that the sleeve and the probe are not colder than the

concrete during installation: this might cause condensation on the

probe and the readings can be incorrect.

_________________________________________________________________________________

16

Page 19

Chapter 5 ____________________________________________ Humidity measurements in concrete

p

s

4. Insert the probe into the sleeve by feeding it in with the cable until it touches the

bottom. Close a rubber plug around the cable and seal the sleeve with it:

Figure 5.3Sealing the sleeve w ith a plastic plug

5. Fold the cable in the installation cover and close the lid. Leave the probe to stabilize

before starting the measurements.

rubber

plug

probe

lastic

leeve

lid

probe

cable

installation

cover

sealing

§

Figure 5.4Cable folded in the installation cover

Alternatively, you can insert the probe into the sleeve about 30 minutes before starting the

measurements. In this case, close the cable lead-through of a rubber plug with its cap as

shown in the photo, and seal the sleeve with the plug:

VAISALA__________________________________________________________________________

17

Page 20

User's Guide _______________________________________________________________________

Figure 5.5Close the cable lead-through of the rubber plug

However, we recommend that you leave the probe into the sleeve as this ensures the best

possible reliability of the readings. When the concrete is dry enough and measurements are no

longer necessary, pull the probe out with the installation cover and the sleeve.

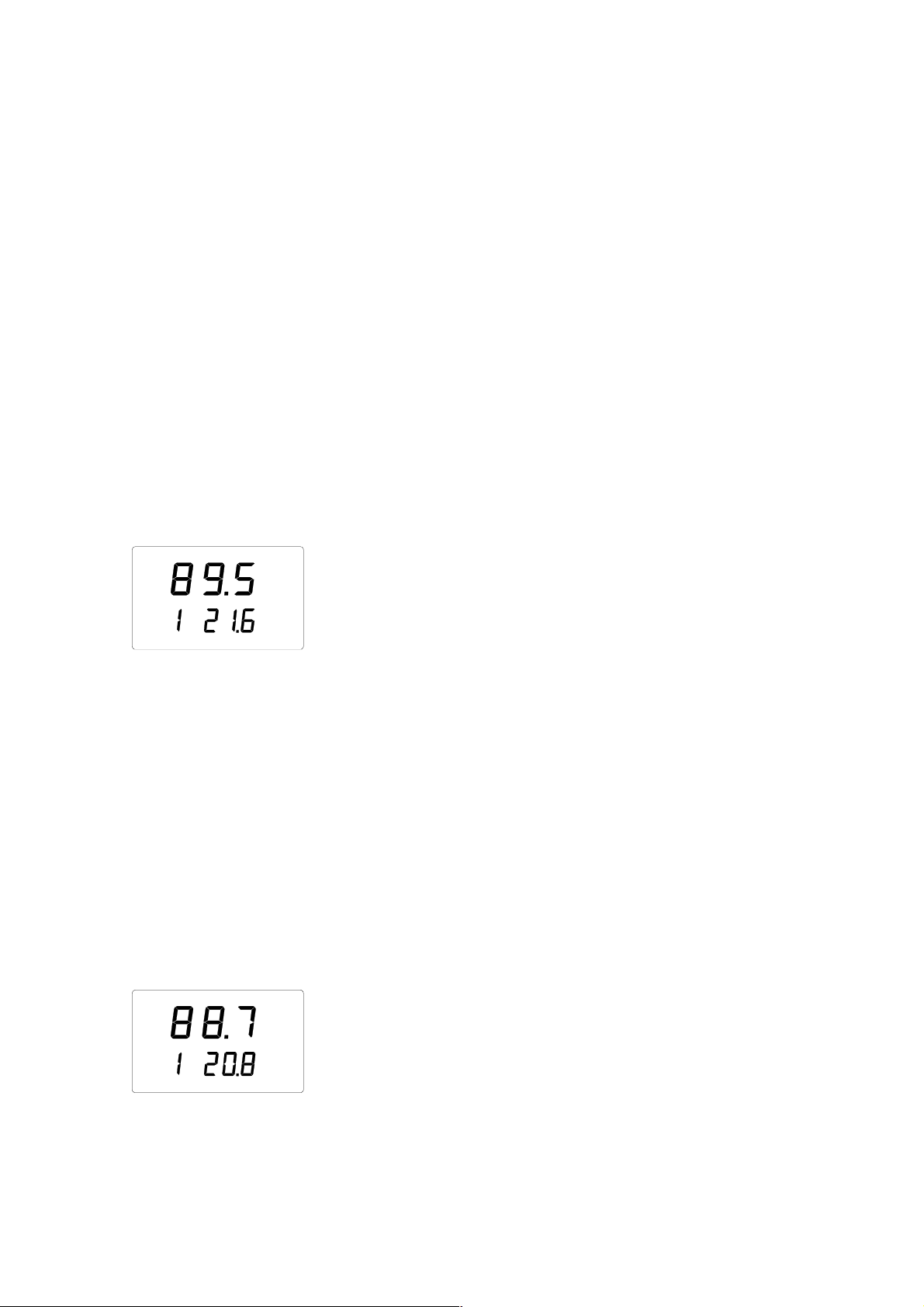

Starting the measurements

The humidity of the hole reaches an equilibrium with the humidity of the concrete

approximately in three days. Before this, the measurements cannot be taken. If the probe has

not been left in the sleeve, insert it at least 30 minutes before starting the measurements. Do

not start measurements before readings have stabilized. Connect the cable in the connector

(PROBE) at the bottom of the HMI41. Then follow the instructions of this manual. Turn the

indicator on with the button ON/OFF:

RH

T°C

%

Numbers on the first line indicate the humidity reading and numbers on the second line

indicate the temperature reading. The first number on the second line (here 1) indicates the

currently selected probe (1-10). If the individual adjustment coefficients have been entered in

the HMI41 memory, make sure that this number corresponds to that marked on the product

label. If necessary, change the number on the display: press ENTER and simultaneously the

button ▲ (number up) or the button ▼ (number down). When the probe number is correct,

release the buttons.

The readings measured by the probe appear on the display. When the measurements have

been taken, turn the HMI41 off and disconnect the cable. Fold the probe cable in the

installation cover and close the lid carefully. If you do not wish to leave the probe into the

sleeve, close the sleeve with the rubber plug.

_________________________________________________________________________________

18

Page 21

Chapter 5 ____________________________________________ Humidity measurements in concrete

Measurement readings on display

Relative humidity and temperature readings appear automatically after the battery charge

indication.

Other readings (dewpoint temperature, absolute humidity, wet bulb temperature, mixing ratio)

appear on the display by pressing the button MODE. If it is pressed once, dewpoint

temperature (Td) reading is displayed, and further pressings bring one of the other quantities

on the display.

HOLD-mode

Press the HOLD button to freeze the display to show the current readings:

RH

T°C

The normal display mode returns with buttons MODE or ENTER.

If the indicator turns itself off with the automatic power-off function during the HOLD mode,

it wakes up in the same mode when turned on again. The text ‘hold’ is blinking and the

indicator can be returned to the normal display mode with any button except ON/OFF.

%

hold

MIN and MAX modes

Press the button HOLD again when the indicator is in the HOLD mode, the minimum

readings measured after power-up appear (if the text ‘hold’ is blinking, the HMI41 must first

be returned to the normal display mode, see previous section):

RH

%

T°C

min

The indicator returns to the normal display mode with buttons MODE or ENTER.

VAISALA__________________________________________________________________________

19

Page 22

User's Guide _______________________________________________________________________

If you press the button HOLD when the indicator is in the MIN mode, the maximum readings

measured after power-up appear:

RH

T°C

max

%

The indicator returns to the normal display mode with any button except ON/OFF.

_________________________________________________________________________________

20

Page 23

Chapter 6 _____________________________________________________________ Collecting data

CHAPTER 6

COLLECTING DATA

The HMI41 indicator can be used for collecting the measurement data. The data is

stored in the indicator's non-volatile memory; it is not lost when the indicator is

turned off. Please, note also that the automatic power-off function is not active

during data collecting even if previously selected. When data collecting has

ended, the automatic power-off function becomes active again.

Data collecting modes

The following three modes are used when collecting data:

- REC AUTO: automatic data collecting

- REC CATCH: manual data collecting

- REC READ: reading the measurement results

Entering the data collecting modes

Turn the device ON (by using ON/OFF button) and immediately (within 1..2 seconds) after

turning on press immediately the button HOLD for at least 5 seconds. The software version

and the probe type indication appear for a second, after which the text REC AUTO appears on

the display; then release the HOLD button.

REC AUTO is the main display of the data collecting mode. With the button MODE you can

enter the REC CATCH mode (manual data collecting, see page 24) and by pressing MODE

again, the REC READ mode (reading the measurement results, see page 25).

VAISALA__________________________________________________________________________

21

Page 24

User's Guide _______________________________________________________________________

Automatic data collecting mode REC AUTO

Enter the REC AUTO mode as instructed on page 21.

Setting the measurement duration

Press ENTER and a text similar to the following appears on the display:

In this mode, you can set the time between the first and the last measurement

bat

(previously set duration)

stored, e.g. 30 minutes or 3 days. When entering this mode, previously set

duration time appears on the display. If the previously set duration time is too

long for the current battery charge, the longest calculated duration time possible

appears instead. This is also indicated with the text 'MAX'. The duration of the

measurement can be set from 15 minutes to 7 days. The batteries last for 7 days

during data collecting provided that they are of the same type as those delivered

with the indicator.

Set the duration with buttons ▲ and▼. The duration time can be selected in steps

according to the following:

• 15 min; 30 min

• 1 - 6 h: each pressing = 1 h

• 12 h

• 1 - 7 d: each pressing = 1 d

If the duration selected is too long for the current battery charge, the text 'BAT'

appears. Select a shorter duration time. Press ENTER to set the measurement

interval.

_________________________________________________________________________________

22

Page 25

Chapter 6 _____________________________________________________________ Collecting data

Setting the measurement interval

min

In this mode, you can set the time between two measurements stored, e.g. 5

minutes or 2 hours. When entering this mode, previously set interval appears on

the display. If the previously set measurement interval is too short for the current

memory capacity of the indicator, the shortest calculated measurement interval

appears instead. This is also indicated with the text 'MIN'.

Select the interval with buttons ▲ and▼. The measurement interval can be

selected in steps according to the following:

• 1 - 5 min: each pressing = 1 minute

• 10 min; 15 min; 30 min

• 1 - 6 h: each pressing = 1 hour

• 12 h

(Note: Interval can not be set lon ger than the measu rement dur ation).

The text 'LO' on the display indicates that there is not enough memory for the

chosen interval; select a longer interval. Press ENTER and a text similar to the

following appears:

(previously set interval)

RH

T°C

set

This is the measurement mode with the data collecting feature activated. It can be

%

distinguished from the normal measurement mode by the text 'SET' on the lower

left-hand corner of the display. The readings on the display are updated once a

minute, and the display is dim except during this updating in order to minimize

the consumption. If the indicator is turned off, the measurements stored so far

remain in the memory and they can be read by turning the indicator on in the REC

mode (see page 25). You can end data collecting by pressing ON/OFF.

READ

VAISALA__________________________________________________________________________

23

Page 26

User's Guide _______________________________________________________________________

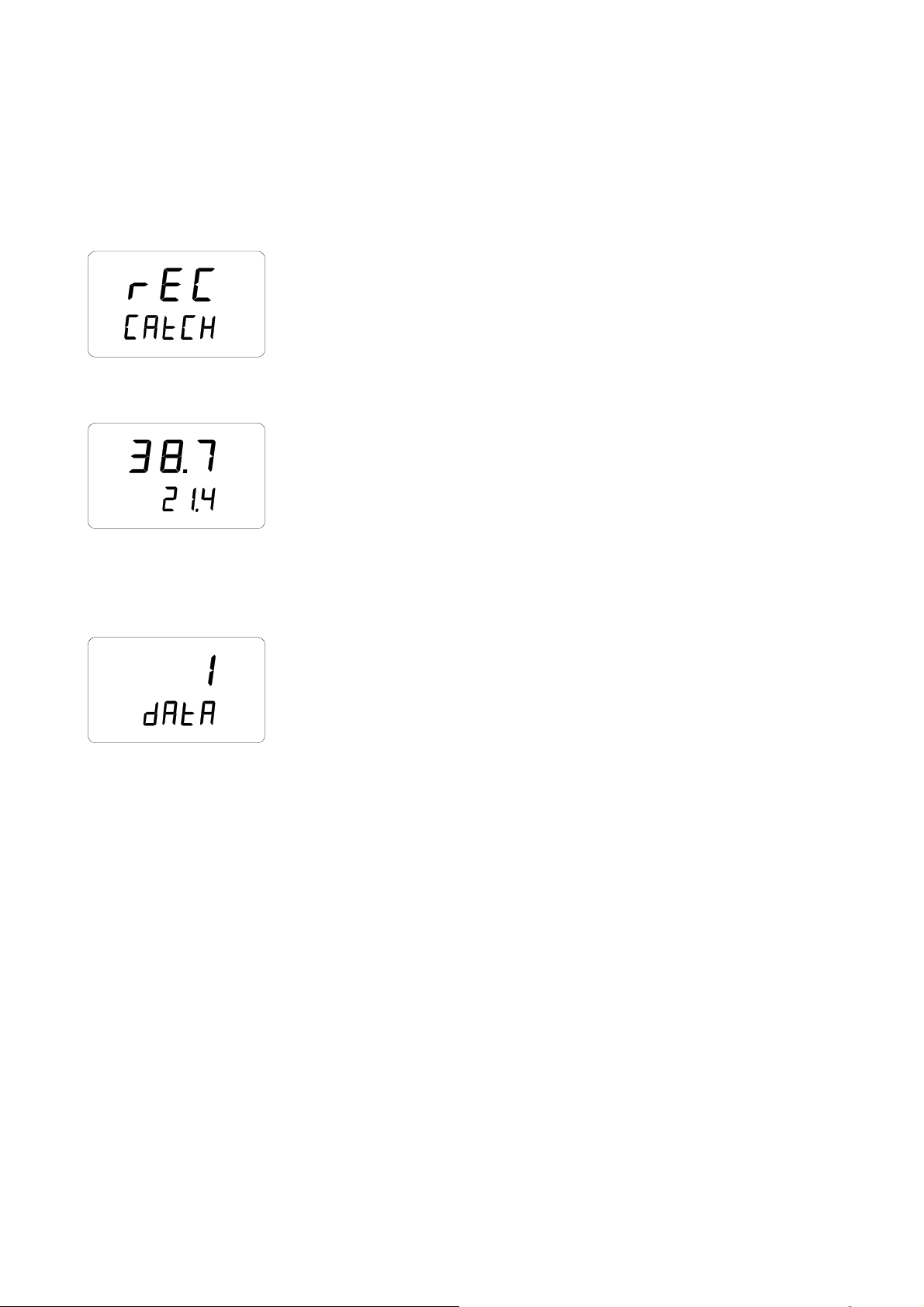

Manual data collecting REC CATCH

Enter the REC CATCH mode, see page 21.

Press ENTER and a text similar to the following appears:

RH

T°C

set

%

The probe is now taking measurements and you can store the readings at appropriate intervals

by pressing the button HOLD. Each time you store a reading, its sequence number in the

indicator memory appears for a couple of seconds:

The indicator returns automatically to show the readings. You can store 199 measurement

readings in the indicator memory (numbers 1 - 199). In automatic data collecting, you can

store 200 readings (0 - 199). End data collecting by turning the indicator off. You can read the

readings in the REC READ mode (see page 25). The readings will disappear from the memory

when starting a new collecting.

When having several probes, firstly give a number to the probe and then feed the probe

individual coefficients to the HMI41 memory (see page 7). Before data reading select the

correct probe number and store the reading of the different probes under different data

sequence numbers. Write down the corresponding probe and sequence numbers.

Note, do not turn the indicator off between the measurements, all the stored data will

disappear when starting the REC CATCH mode again.

_________________________________________________________________________________

24

Page 27

Chapter 6 _____________________________________________________________ Collecting data

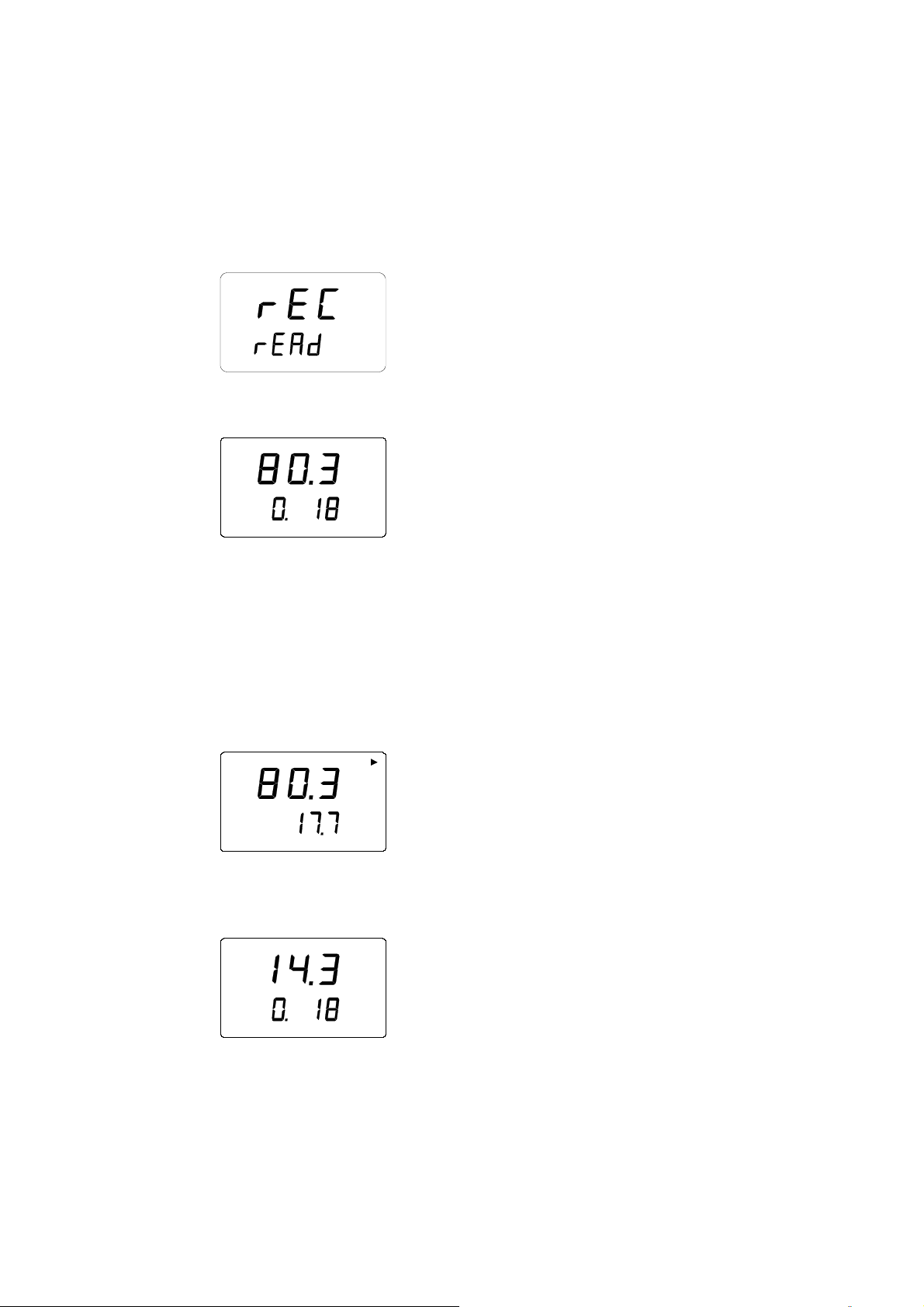

Reading the measurement results REC READ

Enter the REC READ mode as instructed on page 21.

Press ENTER, and a text similar to the following appears on the display:

RH

T°C

Numbers on the first line indicate the reading of the quantity in question (in this

%

example, RH). The number on the left on the second line (in this example number

0.) is the sequence number of the measurement. This number helps to estimate the

time of the measurement during automatic data collecting provided that the

starting time and the measurement interval are known. Numbers on the right on

the second line indicate the temperature reading measured simultaneously with the

reading on the first line; if you wish to see the decimals, press ENTER. The

reading appears on the display with one decimal:

RH

T°C

In a couple of seconds the indicator returns to the previous display.

Press MODE to change the quantity on the first line:

%

d

T

T

When you press ENTER (with any quantity on the first line), an arrow appears on

°C

°C

the higher right hand corner of the display:

VAISALA__________________________________________________________________________

25

Page 28

User's Guide _______________________________________________________________________

RH

T°C

Press HOLD while the arrow is displayed to scroll the measurement results (note

%

that the sequence number changes):

RH

T°C

HOLD:

RH

T°C

If the button HOLD is pressed continuously, numbers change in a faster rate.

%

%

etc.

MIN and MAX in data collecting REC READ mode

When the data collecting REC READ mode has been activated, the HOLD button

brings four different modes on the display: MIN HI, MAX HI, MIN LO and MAX LO.

These modes indicate the maximum and minimum readings measured for the

quantities on the display.

one on the first line (

whether the reading on the display is the minimum or the maximum value. In

other words, if the text is MIN HI it means that you are now observing the

minimum reading of the quantity on the first line.

By pressing HOLD repeatedly you can change from one display mode to another,

and by pressing MODE you can change the quantity on the first line. In all these

modes, the decimals of the second line reading are shown by pressing the button

ENTER.

HI and LO tell you whether the reading observed is the

HI) or the one on the second line (LO). MIN and MAX indicate

_________________________________________________________________________________

26

Page 29

Chapter 6 _____________________________________________________________ Collecting data

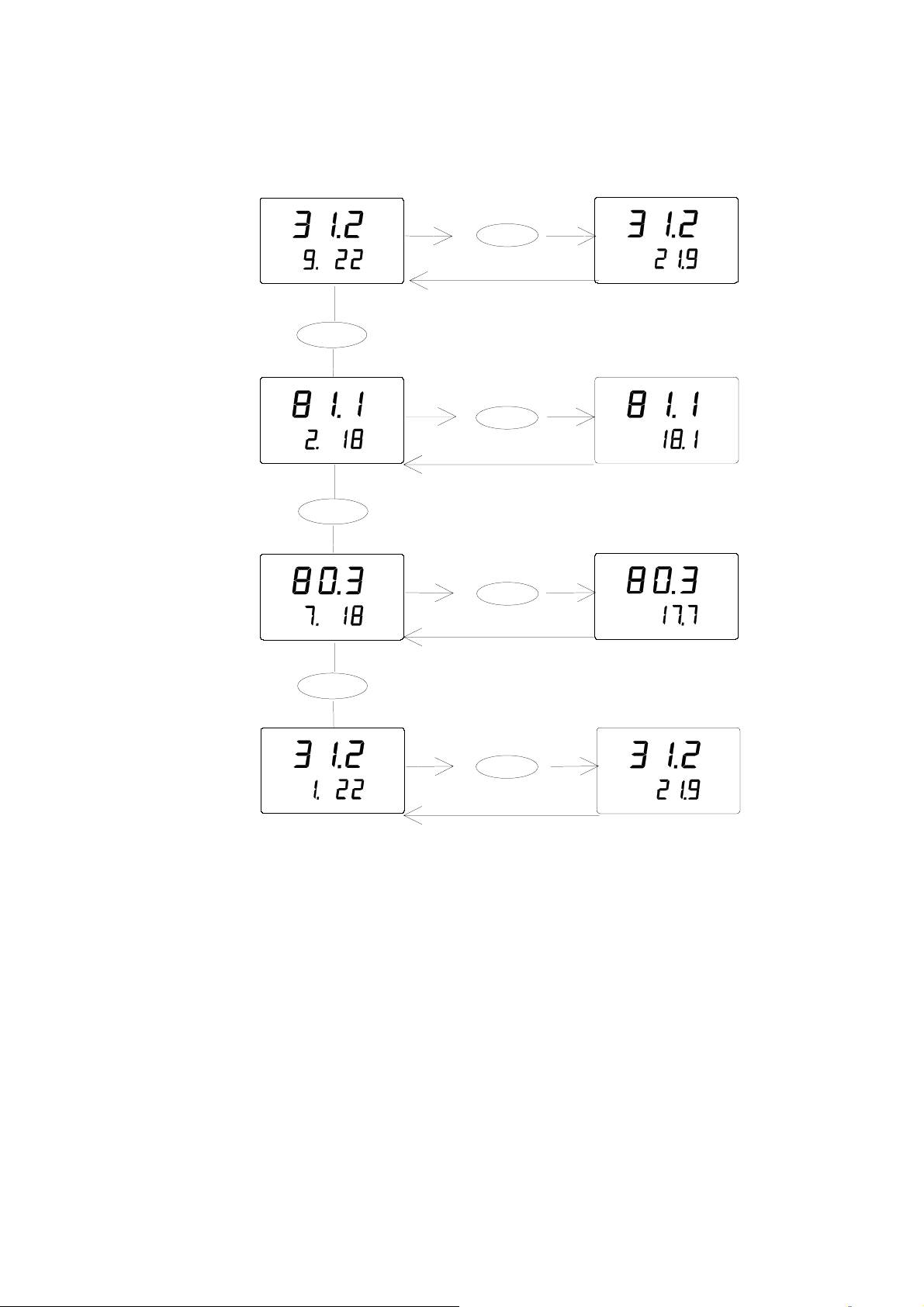

Examples:

RH

%

RH

%

ENTER

T°C

min

Hi

returns automatically

T°C

min

Hi

(minimum reading of the 1st line quantity) (decimals of the 2nd line)

HOLD

RH

%

RH

%

ENTER

T°C

max Hi

returns automatically

(maximum reading of the 1st line quantity)

T°C

max

Hi

(decimals of the 2nd line)

HOLD

RH

%

RH

%

ENTER

T°C

min

Lo

Returns automatically

(minimum reading of the 2nd line quantity)

T°C

min

Lo

(decimals of the 2nd line)

HOLD

RH

%

ENTER

T°C

max

(maximum reading of the 2nd line reading)

Lo

Returns automatically

RH

T°C

max

%

Lo

(decimals of the 2nd line)

VAISALA__________________________________________________________________________

27

Page 30

User's Guide _______________________________________________________________________

CHAPTER 7

TRANSFERRING DATA TO A PC

The readings that have been stored in the HMI41 memory manually or automatically in the

data collecting mode, can be transferred to a computer and then printed if desired. In order to

do this, connect a serial connection cable (order code 19446ZZ) to the appropriate connectors

on your PC and in the HMI41:

connect the

serial cable

to the EXT

connector

Figure 7.1Connecting the cable

_________________________________________________________________________________

28

Page 31

Chapter 7 _____________________________________________________ Transferring data to a pc

Giving the communication parameters

Give the communication parameters when using this terminal session for the first time; save

them for future use. See instructions in the following tables.

Table 7.1 Giving parameters in Windows 3.1

MENU DESCRIPTION

PROGRAM MANA GER

ò

ACCESSORIES

double click

ò

TERMINAL

double click

ò

Settings

click

ò

click and select param eters

Communications

ò

File

(see figure 7.2); click OK

move the cursor to:

click

ò

Save as

click and save settings: type

the name of the file (e.g.

HMI41) and click OK

Turn the HMI41 on, and follow the instructions on page

32.

NOTE: select the

connector according to your

computer. Select

the connector first

and give then

other parameters

Figure 7.2Giving the communication para meters in Windows 3.1

VAISALA__________________________________________________________________________

29

Page 32

User's Guide _______________________________________________________________________

Table 7.2 Giving para meters in Windows 95/98 and Windows NT

WINDOWS 95 WINDOWS NT

MENU WHAT TO DO MENU WHAT TO DO

Start Start

ò

move the cursor to:

ò

move the cursor to:

Programs Programs

ò

move the cursor to:

ò

move the cursor to:

Accessories Accessories

ò

move the cursor to:

ò

move the cursor to:

HyperTerminal

ò

Hyperterminal

òò

Connection

Description

ò

Phone Number

òò

COM x properties

click

move the cursor to:

double click

type the name of the

connection (e.g.

HMI41) in the

appropriate field

and select an icon if

available; click OK.

move the cursor to

the field CONNECT

and select

USING

'direct to COM x'

(x = serial port

available); click OK

select parameters

according to the

screen in figure 7.3;

click OK

HyperTerminal

ò

Hyperterminal

Connection

Description

Connect to

COM x properties

move the cursor to:

click

type the name of the

connection (e.g.

HMI41) in the

appropriate field and

select an icon if

available; click OK.

move the cursor to

the field CONNECT

and select

USING

'COM x' (x = serial

port available); click

OK

select parameters

according to the

screen in figure 7.3;

click OK

Turn the HMI41 on and follow the instructions on page 32.

_________________________________________________________________________________

30

Page 33

Chapter 7 _____________________________________________________ Transferring data to a pc

Figure 7.3. Communication parameter

selection window.

VAISALA__________________________________________________________________________

31

Page 34

User's Guide _______________________________________________________________________

Transferring the data

When you have given the communication parameters, you can start transferring the data from

the HMI41. Note that communication parameters can be stored in the computer for future use.

To start transferring the data, make sure that the HMI41 is connected to a serial port of your

computer and that the terminal session is open. Turn the HMI41 on with the ON/OFF button.

A text similar to the following should now appear on your computer display:

HMI41 / 2.02

>

Commands

PLAY Transferring the data

To transfer the data on your PC, type PLAY and press ENTER. An example of outputting

automatically stored data:

>play

Reading Log... OK

data hh:mm:ss RH T Td

0 00:00:00 12.54 21.53 -8.48

1 00:01:00 12.10 21.23 -9.16

2 00:02:00 12.18 21.18 -9.12

3 00:03:00 12.12 21.15 -9.21

4 00:04:00 12.16 21.14 -9.18

5 00:05:00 12.09 21.12 -9.27

6 00:06:00 12.09 21.09 -9.28

>

An example of outputting manually stored data:

>play

Reading Log... OK

data RH T Td

1 12.10 21.23 -9.16

2 12.18 21.18 -9.12

3 12.12 21.15 -9.21

4 12.16 21.14 -9.18

5 12.09 21.12 -9.27

6 12.09 21.09 -9.28

>

_________________________________________________________________________________

32

Page 35

Chapter 7 _____________________________________________________ Transferring data to a pc

If you know the starting time of the automatic data collecting, you can enter it with the

command and get an output showing the actual time of measurement. For example:

>play 15:05

Reading Log... OK

data hh:mm:ss RH T Td

0 15:05:00 8.52 23.69 -11.70

1 15:06:00 9.58 23.66 -10.26

2 15:07:00 9.60 23.50 -10.35

3 15:08:00 9.61 23.30 -10.48

4 15:09:00 9.65 23.25 -10.47

5 15:10:00 11.22 23.41 -8.44

6 15:11:00 9.93 23.30 -10.08

7 15:12:00 9.92 23.22 -10.15

>

CPLAY Setting characters between decimals and fields

With the CPLAY command, you can select what you want to appear between decimals and

various fields. An example:

>cplay

Desimal separat or : .

Field separator : TAB

example:

1 01:00:00 38.72 21.61 7.01

>

To change the output, type CPLAY, then the character you wish to appear between decimals,

then the character you wish to use between fields and then <cr>. An example:

>cplay , <cr>

Desimal separat or : ,

Field separator : TAB

example:

1 01:00:00 38,72 21,61 7,01

>

HELP Outputting available commands and their contents

If you wish to see which commands are available, type HELP and press ENTER. The

following list appears:

>help

Available comma nds :

HELP ? PLAY CPLAY

Type HELP <command_name> for more help

>

To see the contents of each command, type HELP, command name (e.g. PLAY) and press

ENTER; this brings an explanation of the command and its usage on the display:

VAISALA__________________________________________________________________________

33

Page 36

User's Guide _______________________________________________________________________

>help play

Command : PLAY

Purpose : Send recordings from memory to serial port

Usage : PLAY hh:mm <cr>, hh:mm = rec starting time (optional)

if command is used without parameters it uses default setting

>

? Outputting the HMI41 settings

If you need to know which parameters and settings are currently stored in your HMI41

indicator, type ? and press ENTER:

>?

HMI41 / 2.01

Serial number : A0000000

Output units : metric

BaudPDS : 4800E71FDX

Pressure : 1013.25

Auto Off : 5

Probe : 2

Start-up mode : 1

4.th variable : none

>

To exit the terminal session, go to FILE menu and select EXIT. Confirm

that you wish to quit and then select whether you wish to store the

parameters of this session for future use or not (SAVE - YES/NO)

_________________________________________________________________________________

34

Page 37

Chapter 8 ________________________________________________________________ Calibration

CHAPTER 8

CALIBRATION

Calibration interval

The HMP44 probes are calibrated at the factory. A new probe should be calibrated first time 6

months from implementation, after that annually. In case the adjustment is needed, contact

Vaisala SSD Service or local Vaisala representative (see Chapter 9, Maintenance).

Calibration coefficients

During calibration, the HMI41 calculates new adjustment coefficients for the probe and the

previously set coefficients are no longer valid. It is recommended to check the new

coefficients and write them down. The coefficients can be checked by pressing ENTER for

about 5 seconds continuously and the offset correction is displayed; press ENTER once more

and the gain correction is displayed.

Calibration mode

The calibration can be performed with Vaisala HMK15 calibrator and saturated salt solutions.

Check the reference values from the calibration table below:

Temperature °C 15 20 25 30 35

LiCl %RH *) 11.3 11.3 11.3 11.3

NaCl %RH 75.6 75.5 75.3 75.1 74.9

K2SO

4

*) Do not use or store the LiCl solution in temperatures below +18°C as its humidity

equilibrium may change permanently

Calibration procedure is included in the HMI41 setup mode. Note that the calibration is done

for currently selected probe.

%RH 97.9 97.6 97.3 97.0 96.7

Greenspan’s calibration table

Enter the setup mode, refer to Enter the setup menu on page 9.

VAISALA__________________________________________________________________________

35

Page 38

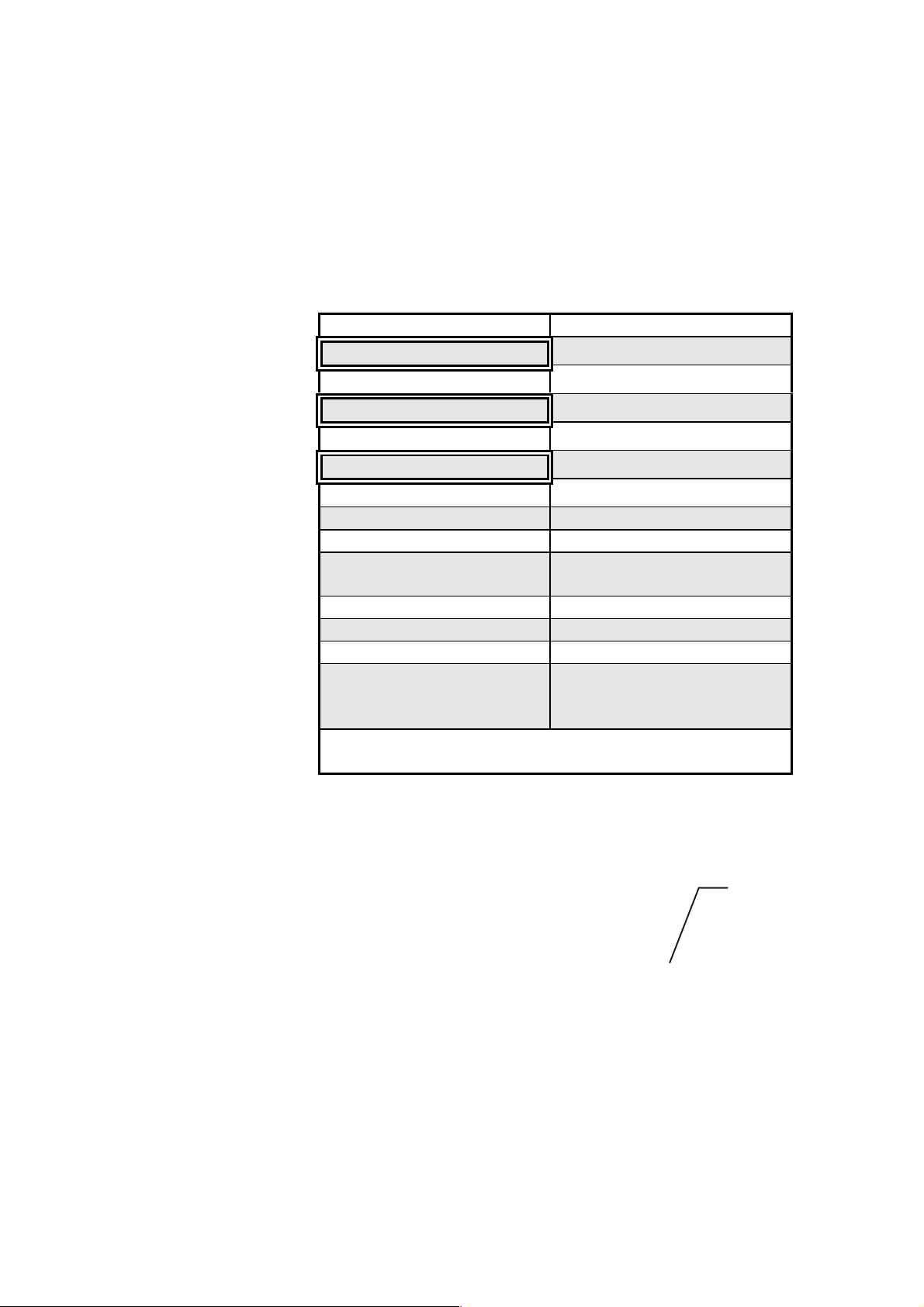

User's Guide _______________________________________________________________________

After a few seconds, the text changes automatically to show the following:

°C

set

Press ENTER repeatedly until the following appears:

set

This indicates that no calibration has been selected. In addition to this, there are five

calibration types available. Select the desired type with buttons ▲ or ▼. All selections are

acknowledged with ENTER. In the table below, you can find a summary of all the calibration

options.

RH

T

set

RH

set

RH

set

RH

set

Default calibration restores the facto ry settings o f the

humidity and temperature calibrations.

One point humidity calibration; select this for performing

a humidity calibration at one point (not instructed).

Two point humidity calibration; select this for performing

a humidity calibration at one point (see sectio n

Two-

point humidity calibration on page 37).

Entering the offset correction manually; corresponds to

the mode explained in

Section

Feeding the offset cor rectio n on page 8.

RH

Entering the gain correction manually; corresponds to the

mode explained in

set

Section

_________________________________________________________________________________

Feeding the gain correction on page 8.

36

Page 39

Chapter 8 ________________________________________________________________ Calibration

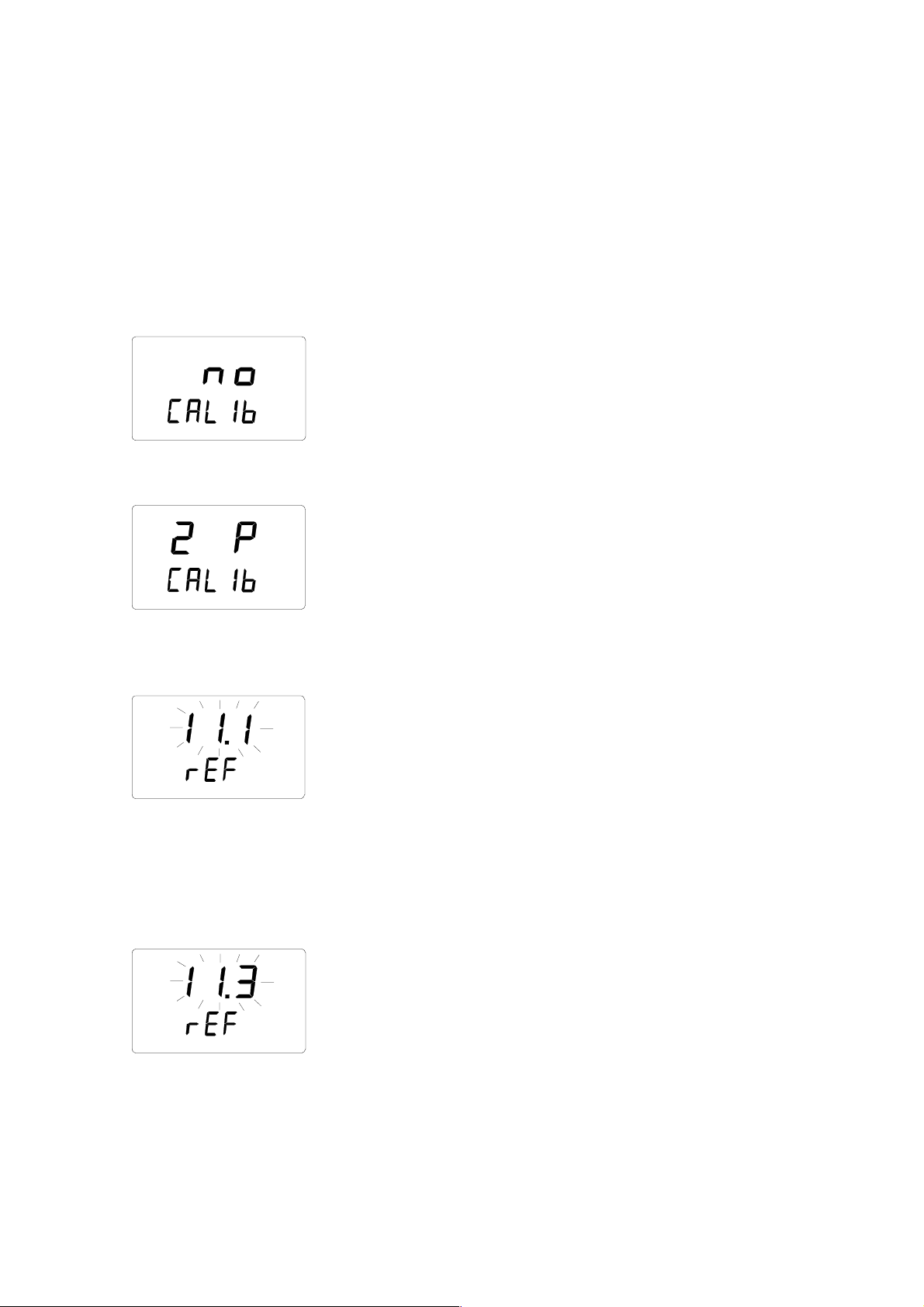

Two-point humidity calibration

In two-point humidity calibration, two accurate references (e.g. the HMK15 Calibrator) are

needed. Leave the reference instrument and the probe at the calibration site for at least 1 hour

so that the probe temperature stabilizes to the room temperature. Start the calibration by

inserting the probe to the lower reference humidity. In setup mode press ENTER repeatedly

until the following is displayed:

set

Then press MODE three times, and the following appears:

RH

set

Press ENTER to activate the two-point humidity calibration mode. A message similar to the

following appears with the first line blinking:

RH

set

%

Lo

The blinking number indicates the value of the lower humidity reference stored in the HMI41

memory. Check the salt chamber temperature, read the closest humidity value in the

calibration table and adjust the display with buttons ▲ and ▼ to correspond to the value given

in the table. For example, if the temperature of the LiCl salt chamber is 22 °C, adjust the

value to 11.3 %RH:

RH

set

%

Lo

Press ENTER, and the HMI41 shows the value that the probe is currently measuring.

Wait for the reading to stabilize (about 30 minutes) and then press ENTER. Now the lower

humidity value is corrected to the given low reference. Press ENTER again to conclude the

VAISALA__________________________________________________________________________

37

Page 40

User's Guide _______________________________________________________________________

lower point calibration. A message similar to the following appears with the first line

blinking:

RH

set

%

The blinking number indicates the value of the higher humidity reference stored in the HMI41

memory. Insert the probe to the higher reference humidity. Check the salt chamber

temperature, read the closest humidity value in the calibration table and adjust the display

with buttons ▲ and ▼ to correspond to the value given in the table. For example, if the

temperature in the calibrator's NaCl salt chamber is 20.5 °C, adjust the value to 97.6 %RH:

RH

set

%

Press ENTER and the HMI41 indicator shows the value that the probe is currently measuring.

Wait for the reading to stabilize (about 30 minutes) and press ENTER. Now the higher

humidity value is corrected to the given high reference. Press ENTER again to conclude the

calibration. If the calibration has been successful, the following message appears:

The correction data has now been calculated and stored in the HMI41 memory. The HMI41

returns automatically to the basic display and it can be turned off. If the correction data differs

from the factory settings, an arrow in the upper right-hand corner is displayed showing that

the correction has taken place.

If the message “cal pass” does not appear (instead, some other text may appear, e.g. “too

close”, “err offset” or “err gain”), the correction has not been stored in the memory. The error

may be due to an incorrect reference value or to measured values that are out of the range.

_________________________________________________________________________________

38

Page 41

Chapter 9 _______________________________________________________________Maintenance

CHAPTER 9

MAINTENANCE

Replacing the HUMICAP

Remove damaged sensor and insert a new one. Handle the sensor from the plastic frame; do

not touch the sensor plate. Calibrate the probe (with a new sensor) with the calibrator

HMK15. The probe can be sent to Vaisala service for sensor change.

180 sensor

Replacing the filter

The combination of a grid (of the probe head) and the membrane filter can be changed if

needed (order code 17039HM).

Vaisala SSD Service Centres

Vaisala SSD Service, Vanha Nurmijärventie 21, FIN-01670 Vantaa, FINLAND,

Phone: +358 9 8949 2658, Fax +358 9 8949 2295

Vaisala KK, 42 Kagurazaka 6-Chome, Shinjuku-Ku, Tokyo 162-0825, JAPAN,

Phone: +81 3 3266 9611, Fax +81 3 3266 9610

Vaisala Inc., 100 Commerce Way, Woburn, MA 01801-1068, USA

Phone: +1 781 933 4500, Fax +1 781 933 8029

Internet: http://www.vaisala.com

Technical support: ssdservice@vaisala.com

VAISALA__________________________________________________________________________

39

Page 42

User's Guide _______________________________________________________________________

CHAPTER 10

TROUBLESHOOTING

Erroneous readings

If any of the following points is neglected, the readings may result erroneous. Therefore,

follow these instructions carefully:

• clean the hole carefully (by blowing air or wit h a vacu um cle aner)

• follow the indications of the recommended hole d epths (see pa ge 13)

• make sure that the probe is not colder than the concrete: this causes

condensation on the probe and ev aporation ma y take ver y long (see

page 6)

• replace worn plastic sleev es

• make sure that the lid of the installation cover and the rubb er plug ar e

carefully closed

• calibrate the HMP44 at regular intervals (se e page 35)

• let the probe stabilize (see page 18)

• wait three days after drilling to achieve air humidity equilibrium

Trouble shooting

If there seems to be something wrong with the HM44 or error messages appear on the HMI41

display, please consult the short list next page for trouble-shooting. The HMI41 goes through

a continuous self-diagnostic procedure. If any problems occur, it displays the corresponding

error message:

where nn = the number indicating the error (the first number, here 1, indicates the probe)

_________________________________________________________________________________

40

Page 43

Chapter 10 ___________________________________________________________ Troubleshooting

In the following, a short list for trouble shooting:

PROBLEM: WHAT TO DO:

the display is blank

• check the batteries

• if the bat teri es ar e in o rder, cont act V aisal a or a

Vaisala representat ive

the display is dim

• during automatic data collecting, the display is

dim except when the rea din gs are updat ed (once

a minute)

readings seem to be

wrong

• let the probe stabilize (see page 18)

• make sure that the probe cable is co rr ectl y

connected to the HMI41

• check that the grid and the filter are clean

• if the individual adjustment coeffici ents have

been entered (there is an arrow o n the displa y),

make sure that the probe number on the displa y

and in the product label correspond (s ee page

8).

• make sure that the HMI41 function is Start 5

with probe HMP44 (see page 12)

• make sure that the adjustm ent coef ficie nts ar e

correct (see page 7)

• check that there is marking [ID] in the HMI41

indicator label (and in the probe). If not, please

change the settings (see page 12)

you have accidentally

changed some settings

• enter the setup mode (see page 9 ) select the

setting with buttons ▲or ▼.

VAISALA__________________________________________________________________________

41

Page 44

User's Guide _______________________________________________________________________

CHAPTER 11

SPARE PARTS AND ACCESSORIES

Order code Description

HMP41 RH & T probe; for fixed mounting

HMP42 RH & T probe; for tight spaces

HMP44 RH & T probe with 0.3 m cable

HMP44L RH & T probe with 2.7 m cable

HMP45 RH & T probe; cable model

HMP46 RH & T probe; cable model for dirt y or hot process es

HMI41 Humidity and temperature indicator

HUMICAP180

17039HM Membrane filt er

19266HM Plastic sleeve, 12 p cs

19267HM Rubber plug, 12 pcs

19268HM Installation cover and lid, 3 pcs

HM26849 Carrying cas e (HM44/ L and a ccessories; HMI41 and

HM36736 Carrying cas e (HM I41, HMP41 and HMP45)

HM27104 Carrying case (HM I41 and HMP42)

19446ZZ Serial interface cable for HM I41

19116ZZ Calibration cable (fo r HMD/W60/70, HMP140 series)

19164ZZ Calibration cable (fo r HMP230 series )

19165ZZ Calibration cable (fo r HMD/W20/30, HMP130 series)

HMK15 Humidity calibrator

Humidity sensor

HMP46)

_________________________________________________________________________________

42

Page 45

Chapter 11 _________________________________________________ spare parts and accessories

Optional probes

• HMP41 probe for me asuring humidit y and temperature in va rious

applications, for example in spot checks.

• HMP42 probe head h as a diamet er o f onl y 4 mm and is 23.5 cm long.

This probe structure is speci all y for measu rem ents in ve ry tight

places, e.g. in joint spaces between tiles or in air conditionin g

channels as well as for measuring the equilibrium humidity of e.g.

timber

• HMP44L for measuring humidit y in concrete and oth er structur es .

• HMP45 probe for measurements in channels a nd other places th at are

difficult to reach and therefore require a p robe head with cable.

• HMP46 consists of a 32 cm long probe he ad of stainless st eel; the

HMP46 is optimized for measurements in relatively high

temperatures (up to +100°C, temporaril y even +180 °C), in di rt y

processes and in general in applications that require a robust probe

structure.

VAISALA__________________________________________________________________________

43

Page 46

User's Guide _______________________________________________________________________

CHAPTER 12

TECHNICAL DATA

HMP44 probe

Humidity

Measurement range 0...100 %RH non-condensing

Accuracy at +20°C: ±2 %RH (0...90%RH)

±3 %RH (90...100%RH)

Temperature dependence:

%RH

1.5

1.0

0.5

0

-0.5

-1.0

-1.5

Typical long-term stability in air 1 %RH/year

Response time (90%) at +20°C

in still air 15 seconds

Humidity sensor HUMICAP

Temperature

Operating temperature -40...+60 °C

Measurement range -20...+60 °C

Accuracy at +20 °C ±0.4 °C

-20

-10 0 10 20 30 40 50 60

°C

®

180

Accuracy over the enti re ran ge:

_________________________________________________________________________________

44

Page 47

Chapter 12 ____________________________________________________________ Technical data

°C

0.6

0.4

0.2

0

-0.2

-0.4

-0.6

-20 -10 0 10 20 30 40 50 60 °C

Temperature sensor Pt1000 IEC 751 Class B

General

Cable length:

HMP44 0.3 m

HMP44L 2.7 m

Probe diameter 12 mm

Probe length 69 mm

Operating temperatu re range of

electronics -40...+60 °C

Housing material ABS plastic

Housing classification IP65 (NEMA 4)

Sensor protection membrane filter 17039HM

Weight:

HMP44 50 g

HMP44L 120 g

HMI41 indicator

Maximum measurement

error caused by the indicator at 20 °C:

humidity +0.1 %RH

temperature +0.1 °C

Calculated variables dewpoint temperature, absolute humidit y,

Resolution 0.1 %RH; 0.1 °C

wet bulb temperature, mixing ratio

Power supply 4 batteries, type AA (IEC LR6)

VAISALA__________________________________________________________________________

45

Page 48

User's Guide _______________________________________________________________________

Battery operation time 72 h continuous use

Operating humidity range 0...100 %RH non-condensing

Operating temperature -20...+60 °C

Storage temperature -40...+70 °C

Display two line LCD

Housing material ABS plastic

Housing classification IP 53 (with conne ctors blocked )

Connector type modular connector

Weight (incl. batteries) 300 g

The guarantee does not incl ude the norm al w ear of th e plastic sl eev es,

installation covers and rubber plugs.

_________________________________________________________________________________

46

Page 49

Chapter 12 ____________________________________________________________ Technical data

APPENDIX 1: Example of a calibration certificate.

Adjustment

coefficients

VAISALA__________________________________________________________________________

47

Page 50

Page 51

Page 52

*M010068

EN

*

www.vaisala.com

Loading...

Loading...