Page 1

1-800-547-5740 • Fax: (503) 643-6322

www.ueitest.com • email: info@ueitest.com

DMEG2

INSTRUCTION MANUAL

Page 2

C o n t r ols and Indicators

1. Rotary Selector Knob: Switches measurement function.

2. Ohms: This is the low resistance or “c o n t i n u i ty” position. Used to

i d e n t i fy low resistance circuits such as motor run and start winding

which may differ by only a few ohms.

3. 200MΩ (250, 500V): In this position approximately 500 V DC is

applied to the circuit under test when the TEST switch is pressed. The

0 - 2 0 0 M Ω range is used primarily to test insulation resistances which

have begun to degra d e .

4. 200MΩ (1000V): In this postilion approximately 1000 V DC

is applied to the circuit under test when the TEST switch is

pressed. This is the range which is normally used for preventive

maintenance measurements on electrical equipment. Insulation

resistance values in this application typically exceed 100MΩ.

5. ON/OFF switch: Slide the switch forward to turn the instrument

on, slide it back to turn the instrument off.

6. Test Switch: The TEST switch is normally OFF, spring loaded,

momentary action switch which “turns on” the DMEG2. The

momentary action is a safety feature. The test voltage generated

by the DMEG2 is automatically discharged when the TEST

switch is released.

Introduction

The DMEG2 Insulation Resistance Tester is a completely portable,

self-contained, four range, solid state test instrument.

Power is provided by eight internal, standard 1.5V, size AA (ABI)

batteries. An electronically regulated constant voltage generator

supplies the test voltage for the 2000MΩ range (1000V) and the

2000MΩ range (500V), and the 2000MΩ range (250V). The internal

batteries supply the power directly for the 0-200Ω low resistance range.

This rugged precision instrument can locate intermittent shorts,

defective electrical connections, insulation breakdowns or conductor

failures due to the effects of temperature, moisture, abrasion, corrosion,

or other environmental conditions.

One of the most effective applications, and one of the most overlooked

applications for the DMEG2 is in the field of preventive maintenance.

For example, when the insulation properties of a hermetic compressor

motor begins to fail it usually does so gradually at first. A routine,

periodic monitoring of the insulation resistance of the start and run

winding will usually show evidence of a potential burn out well in

advance of the actual occurrence.

Features include

• Battery operated

• Automatic circuit discharge

• Solid state circuitry

• LCD display

• Automatic zero adjust

• Four ranges

• Automatic low battery indication

• Audible warning signal

• Live circuit indicator

Safety Notes

Before using this instrument, read all safety information carefully. In

this manual the word "WARNING" is used to indicate conditions

or actions that may pose physical hazards to the user. The word

"CAUTION" is used to indicate conditions or actions that may

damage this instrument.

International Symbols

DMEG2-MAN P. 1

1

2

Electrical shock can cause an unstable heart rhythm

that may need medical attention.

3

4

5

6

Page 3

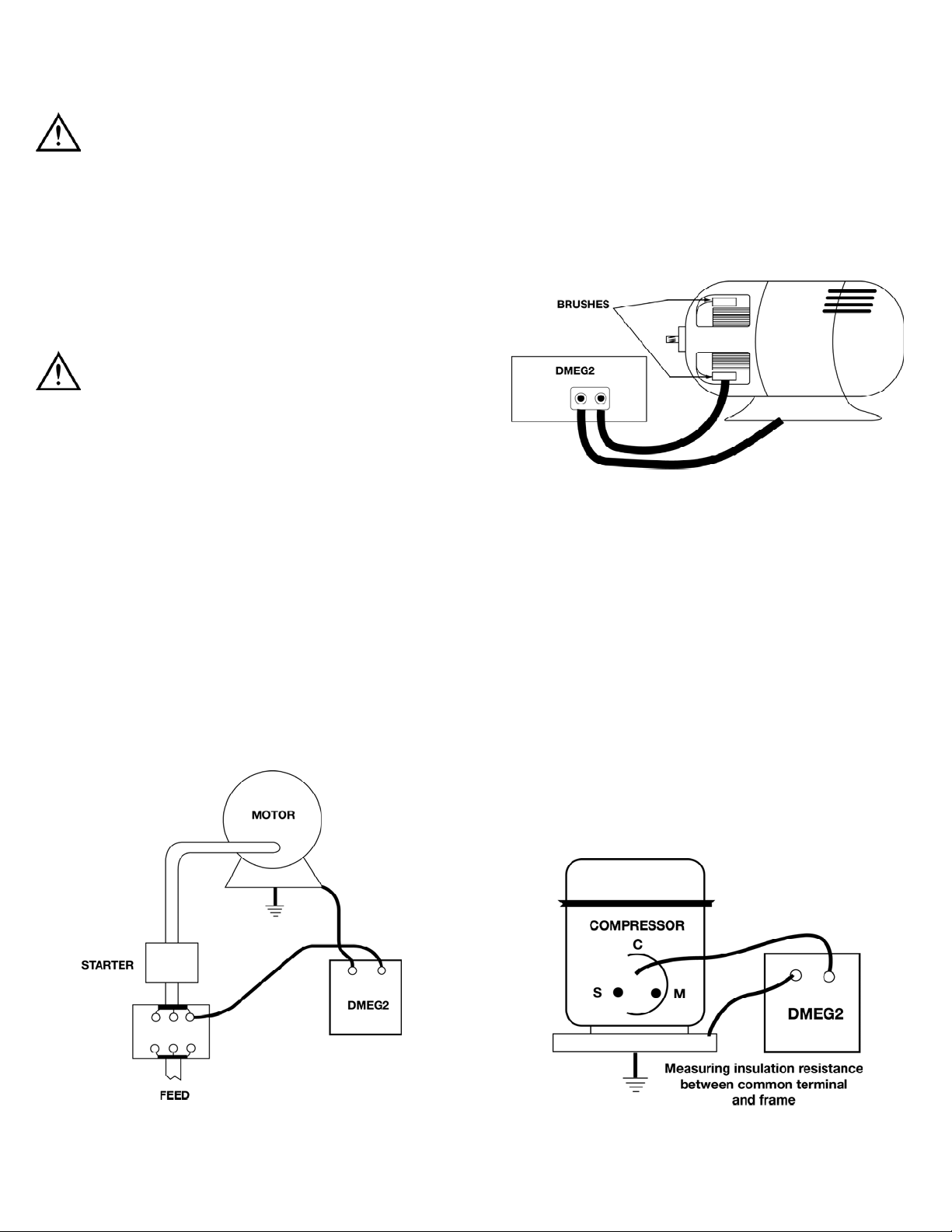

DC Devices

Independent insulation tests may be carried out between the electrical

sections of a DC generator, or motor, and ground. Separate the brushes

from the commutator (Fig. 2) to isolate the brushes and field coil

functions from the rotor. These separated sections may be easily tested

independently of each other. This does not apply, however, when an

overall insulation test is intended. In this case the brushes remain in

contact with the commutator so that the three sections (brushes, coils

and rotor) may be tested integrally.

Hermetic Compressor

Most hermetic compressor utilize a three terminal block for making

electrical connections to the sealed unit (Fig. 3). The connection may be

made by an “umbilical” cord or a screw terminal, but the most common

connection method is usually with a relay that pushes onto the S and M

terminals and an overload protector that pushes onto the C terminal.

(Refer to the manufacturer’s manual)

Shut off power to the unit under test and remove the connections to

the compressor terminal block. Connect the red test lead of the DMEG2

tot he C terminal and the black test lead to the frame, or ground.

Measure the insulation resistance. Low values of insulation resistance

may indicate the presence of contaminated refrigerant. Refer to the

chapter on interpreting test results.

Winding continuity may be checked by setting the SELECTOR switch on

OHMS. Check the start and run winding by measuring the resistance

between the C terminal and the S or M terminal.

Operating Instructions

CAUTION!

Observe all safety precautions when the CONTROL switch is set to

either the 2000MΩ (500V) or the 2000MΩ (1000V) position. Connect

the DMEG2 test leads to the circuit under test before operating the

TEST switch. DO NOT touch the battery clip ends of the test leads when

the TEST switch is in the TEST position. Some electrical equipment,

especially cables, may retain an electrical charge when disconnected

from the line. It is a good practice to discharge such equipment with

grounding straps, or other suitable devices, before touching or making

connections. The DMEG2 automatically discharges the test circuits when

the spring loaded TEST switch is released.

WARNING!

Remove all power to the circuit under test when making resistance

measurements. If any voltage is present in the test circuit an erroneous

reading will result.

Motors and Generators

Disconnect the motor from the line either by opening the main switch

or by disconnecting the wires at the motor terminals. if the main switch

is opened and measurements are made at the switch contacts, then the

insulation resistance of all components between switch and motor will

be measured simultaneously. If a fault is indicated it will be necessary to

test each section separately.

AC Devices

The basic test is to connect the red test lead of the DMEG2 to one of

the motor terminals, or wire, and the black test lead to the frame or

housing (Fig. 1). Start and run winding may be checked for correct

resistance by setting the SELECTOR switch to OHMS and connecting

one test lead to the common winding terminal and the other test lead

to the start or run terminal.

DMEG2-MAN P. 2

(Fig 2)

(Fig 1)

(Fig 3)

Page 4

Circuit Beakers and Switches

Disconnect the circuit breaker or switch from the line. Trip or open the

device and check the insulation resistance between the pole terminals

by connecting one test lead to one pole and the other test lead to the

remaining pole pair. Low values of insulation resistance may be caused

by the presence of contaminates or by carbon arc lines in the insulator

block. If the cause of the low readings is determined to be caused by

carbon arcing, the device should be replaced (Fig. 4).

Cables

Disconnect the cable from the line. As a safety precaution, discharge

the cable by shorting the individual leads to the sheath. This is

especially necessary when testing coaxial cables. Disconnect the cable

from the equipment to which the cable is attached. This will eliminate

any influence of the equipment on the test readings.

Several types of insulation resistance measurements are normally

made: lead to lead(s), lead to sheath, lead to ground, etc. As an

example, when only one of the conductors in a multiconductor cable

is to be insulation tested, the conductor to be tested should be

connected to the test lead of the DMEG2. All of the other conductors

should be connected to the cable shield, which is then connected

to the test lead.

Factors Affecting Actual Insulation Resistance Values

Unlike most basic electrical measurements, such as voltage current,

and resistance, the actual insulation resistance of a device may differ

from the measured value of insulation resistance. This is because the

temperature at which the measurement and the duration of the

measurement may all affect the reading. It may be necessary to correct

the measured insulation resistance value to arrive at a more true value

of insulation resistance. The effects of these factors are discussed below.

Temperature

Most electrical insulation materials have a negative temperature

coefficient. This means that the magnitude of insulation resistance

decreases as the temperature at which the measurement is taken

increases. For example, the insulation resistance of a transformer

measured at 68˚F may be three times the value of the same transformer

measured at a temperature of 100˚F.

If periodic measurements of a device are made at different

temperatures then the temperature must be adjusted to a base value,

usually 68˚F. Otherwise, the insulation resistance of a device may

appear to fluctuate widely (the sign of unstable or deteriorating

insulation) when in reality the actual insulation resistance may be

quite stable. Of course, if the insulation resistance measurements are

always made at, or near, the same temperature then the use of

temperature correction charts may be omitted.

DMEG2-MAN P. 3

Chart 1

Rotating Equipment Temp. (˚F) Class A

Temperature Correction Chart

Corrected to 68˚F Ambient

Rc = K Rm

Rc = Corrected Resistance Value

K = Correction Factor

Rm = Measured Resistance Value

(Fig 4)

Page 5

Chart 1 is a temperature correction chart for Class A rotating

equipment. For example, if a reading of 100 Megohm were obtained

at a temperature of 110˚F then the corrected insulation resistance is

Rc=KRm=6 x 1--=600 Megohms, when Rc is the corrected resistance, K

is the temperature correction factor obtained from the graph, and Rm

is the measured resistance. Chart 2 is a temperature correction chart

for oil filled transformer winding.

Humidity

Measurements made in a humid environment will result in lower

insulation resistance values than measurements taken in a dry

environment. The geometry of the equipment will also have an

influence on the measurements. For example, rotating machinery

has many more leakage paths, especially on the commutators and

armatures, where moisture can be trapped, than would a sealed

transformer or shielded cable. The best practice is to take insulation

resistance measurements when the equipment is safely above the dew

point. In this case, the effects of humidity can largely be ignored.

However, it is always advisable to assure that the equipment be free

of oil, dust, etc., which might affect the test results.

Time Duration of Measurement

The amount of time during which the test voltage is applied will also

affect the reading. Typically, with good insulation, the measured value

of insulation resistance will slowly increase as long as the test voltage

is applied. This is due to the dielectric absorption effect of the applied

DC voltage on the bulk insulation resistance. Refer to Figure 6 for a

representative graph of insulation resistance as a function of the time

during which the test voltage is applied.

A standard test of insulation integrity is to measure the insulation

resistance at 30 seconds and 60 seconds after the test voltage is

applied. The ratio of the reading at 60 seconds to the reading at

30 seconds is called the Dielectric Absorption Ratio.

DMEG2-MAN P. 4

Chart 2

Transformer Winding Temperature (˚F)

Temperature Correction Chart

Corrected to 68˚F Ambient

Rc = K Rm

Rc = Corrected Resistance Value

K = Correction Factor

Rm = Measured Resistance Value

Chart 3

Time (Seconds)

Page 6

DMEG2-MAN P. 5

Typically, a ratio of 1.25 represents the borderline between an insulation

resistance of questionable integrity and of fair integrity. A ratio of 1.6

and above is indicative of insulation of very good integrity. The

Dielectric Absorption Ratio method of testing insulation resistance is

generally not affected by the temperature at which the measurements

are taken. This is one of the advantages of this method. The Dielectric

Absorption Ratio of the example shown in (Fig 6) is 1.5.

Interpretation and Recording of Data

Periodic measurements of insulation resistance of a device, taken

under the same conditions, generally result in much more meaningful

results than measurements taken just once, or at random intervals.

The measurement interval may be weekly, monthly, quarterly or

yearly. This interval chosen will depend in general upon the conditions

under which the device is operated and the cost of suffering an

unexpected breakdown.

The device which operates under conditions of high temperatures,

humidity, load and vibration should be tested more frequently than the

same device which operates under less stressful conditions.

The following “rules” are guidelines which may be used to help

determine whether a piece of equipment is operating normally or

whether it should be pulled out of service and repaired or replaced.

However, the equipment manufacturer’s data on insulation resistance

values and test procedures should be consulted when available.

One Kilovolt/One Megohm Rule

This is an old, generalized rule that states that electrical equipment

rated up to 1000 volts should have minimum insulation resistance

of one-Megohm. Above 1000 volts rating the minimum insulation

resistance should be one Megohm for each 1000 volts of rating.

NOTE: This rule of thumb does not apply to the testing of

hermetic compressors.

Trend Rule

Hermetic Compressor

Dielectric Absorption Ratio Rule

Recording Data

A package of Data Log Cards is supplied with the DMEG2. The use

of these log cards will facilitate the recording and plotting of data

necessary to monitor and evaluate the insulation resistance history and

integrity of an individual piece of equipment. Space is provided on the

front of the card to record the equipment identity and to plot a graph

of insulation resistance values from 0.1 to 1000 Megohms. Space is

provided on the back of the card to record the supporting tabular data.

It is not necessary to make an entry in every column on the back of the

Data Log Card each time a measurement is taken. However, the more

data that is recorded the easier it will be to determine the reason for

changes in the measured insulation resistance.

Determining Moisture Content

The amount of insulation resistance, when drying out or baking

transformers, motors, and generators is an excellent indicator of the

amount of moisture remaining in the device. The insulation resistance

reading will increase as the moisture is driven off. In this way optimum

curing times can be determined.

Insulation Resistance Values Interpretation

High and holding steady Condition good

High but tapering off Breakdown may be starting

Decrease test interval or

repair equipment

Moderately low and holding May be all right. Depends on

steady history of device. Should try to

identify cause of low reading.

Low and declining Failure probable in rear future.

Repair or replace.

Insulation Resistance Values Interpretation

100 Megohms & above Condition good

50 to 100 Megohms Evidence of moisture in

refrigerant. Check drier.

20 to 50 Megohms Excessive moisture in refrigera n t .

Examine system.

Below 20 Megohms Failure of system likely.

Purge system

Ratio Interpretation

Above 1.6 Condition good

1.25 to 1.6 Condition moderately good

1.1 to 1.25 Condition questionable to

unstable

Page 7

DMEG2-MAN P. 6

M a i n t e n a n c e

The DMEG2 is a precision test instrument. DO NOT operate the DMEG2

where it will be subjected to high levels of temperature, humidity, or

mechanical shock.

Cleaning

Use a damp cloth and mild soap to clean the case. DO NOT use harsh

detergents or abrasive as these may harm the finish or weaken the

structure with an adverse chemical reaction.

Battery replacement

The internal batteries supply the operating power for the DMEG2.

Dispose of batteries in accordance with your local solid-waste disposal

regulations. Never expose batteries to high temperature or incineration.

To test for defective or weak batteries:

1. Press TEST switch.

2. If LED does not flash, replace battery.

A. Remove the flat head screws which secure the DMEG2

back panel

B. Carefully remove the back panel to gain access to the battery

compartment located in the case back.

C. Remove the batteries and install eight new 1.5V, size AA

alkaline batteries (stock no ABB). Observe battery polarity as

shown on the label below the battery holders.

D. Before replacing the back panel, repeat steps 1-2 above, to

verify that the LED is flashing.

E. Replace the back panel.

If the DMEG2 is to be stored, or left unused for long periods of time,

remove the batteries. This is a standard precaution

Trouble Shooting

Current leakage paths are difficult, if not impossible, to detect with a

conventional multitester. The resistance of such leakage paths may

be too high to measure with a multitester but still be low enough to

cause inefficient operation, overheating, and other indications of

operating problems.

S p e c i f i c a t i o n s

Ranges

Open Circuit Terminal Voltage

(refer to chart 1)

Short Circuit Terminal Current

Accuracy

Batteries

Standard Accessories

Standard

Batteries, 1.5V, size AA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .AB8

Test leads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ATL15

Insulation Resistance Data Log Cards (pkg) . . . . . . . . . . . . . . .ADC1

0-2000MΩ (1000 DC V test voltage)

0-2000MΩ (500 DC V test voltage)

0-2000MΩ (250 DC V test voltage)

0-200Ω

0-2000MΩ: +950 DC V (approximately)

0-2000MΩ: +480 DC V (approximately)

0-2000MΩ: +250 DC V (approximately)

0-200Ω: +170 DC mA (approximately)

0-2000MΩ: 1.2 DC mA (approximately)

0-2000MΩ: 1.0 DC mA (approximately)

0-2000MΩ: 1.1 DC mA (approximately)

0-200Ω: 24 DC mA (approximately)

O H M 250 V 50 0 V 10 0 0 V

0 - 2 0 0 Ω ± 1.5% ±2 dgt

0 - 10 0 M Ω ± 1.5% ±3 dgt ± 1.5% ±2 dgt

10 0 - 20 0 M Ω ±2% ±5 dgt

20 0 - 170 0 M Ω ±3% ±7 dgt ±3% ±4 dgt ±3% ±3 dgt

170 0 - 2 0 0 0 M Ω ±4% ±8 dgt ±4% ±6 dgt ±4% ±5 dgt

2000 M

Range

200 M

Range

Load Resistance Megohms

Terminal Voltage VS Load Resistance

Page 8

Limited Warranty

The DMEG2 is warranted to be free from defects in materials and workmanship for a period

of three years from the date of purchase. If within the warra n ty period your instrument should

become inoperative from such defects, the unit will be repaired or replaced at UEi’s option.

This warra n ty covers normal use and does not cover damage which occurs in shipment or

failure which results from alteration, tampering, accident, misuse, abuse, neglect or improper

maintenance. Batteries and consequential damage resulting from failed batteries are not

covered by warra n ty.

Any implied warranties, including but not limited to implied warranties of merchantability

and fitness for a particular purpose, are limited to the express warranty. UEi shall not be

liable for loss of use of the instrument or other incidental or consequential damages,

expenses, or economic loss, or for any claim or claims for such damage, expenses or

economic loss. A purchase receipt or other proof of original purchase date will be required

before warra n ty repairs will be rendered. Instruments out of warra n ty will be repaired (when

r e p a i r able) for a service charge. Return the unit postage paid and insured to:

1-800-547-5740 • FAX: (503) 643-6322

www.ueitest.com • Email: info@ueitest.com

This warranty gives you specific legal rights. You may also have other rights which vary from

state to state.

DMEG2

Insulation Resistance Tester

Copyright © 2007 UEi DMEG2-MAN 1/07

PLEASE

RECYCLE

Loading...

Loading...