Page 1

INSTRUCTION MANUAL

DL99B

True RMS Clamp-On Meter

1-800-547-5740 • Fax: (503) 643-6322

www.ueitest.com • email: info@ueitest.com

Page 2

Introduction

The D99B Digital Clamp-On Meter is designed for professional electrician's,

lant maintenance specialists and service technicians. Now technicians can

p

ork with added confidence, knowing they’re measuring with the superior

w

accuracy of True RMS, increasing safety by illuminating dark work areas

with a bright LCD Work Light, back light display and extending their

measurement capabilities to 1000V AC/DC.

Features include

• True RMS

• Work light and backlit display

• 1000 Amps AC and DC

• 1000 Volts AC and DC

• Resistance to 40 kilohms

• Continuity

• Push-button ranging

• Peak hold

• Data hold

• 0.1 mV DC resolution allows use of DMM adapters

• 1-3/8” jaw capacity

• CE and UL listed CAT III

If any of the following indications occur during testing, turn

•

off the power source to the circuit under test:

• Arcing

• Flame

• Smoke

• Extreme Heat

• Smell of Burning Materials

Discoloration or Melting of Components

•

Read the safety precautions associated with the equipment being

•

tested and seek assistance or advice when performing

unfamiliar tasks.

• Keep your fingers away from the test lead metal probe contacts

and bus-bars when making measurements. Always grip the

instrument and test-leads behind the hand guards (molded into

the probes).

• In the event of electrical shock, ALWAYS bring the victim to

the emergency room for evaluation, regardless of the victim’s

apparent recovery. Electrical shock can cause an unstable heart

rhythm that may need medical attention.

International Symbols

Safety Notes

Before using this meter, read all safety information carefully. In

this manual the word "WARNING" is used to indicate conditions

or actions that may pose physical hazards to the user. The word

"CAUTION" is used to indicate conditions or actions that may

damage this instrument.

WARNING!

Exceeding the specified limits of this meter is dangerous and can

expose the user to serious or possibly fatal injury.

T

O

O N

• D

DC or AC-RMS with this meter - UEi offers numerous alternatives

for measuring high voltage and current

Voltages above 60 volts DC or 25 volts AC may constitute a

•

serious shock hazard

•

DO NOT attempt to use this meter if either the meter or the test

leads have been damaged. Send unit in for repair by a qualified

repair facility

• Test leads must be fully inserted prior to taking measurements

• Always turn off power to a circuit (or assembly) under test before

cutting, unsoldering or breaking the current path. Even small

amounts of current can be dangerous

Always disconnect the live test lead before disconnecting the

•

common test lead from a circuit

• When measuring high voltage, disconnect the power source before

making test lead connections. Connect the test leads to the meter

first then to the circuit under test. Reapply po

attempt to measure any voltage that exceeds 1

wer

000 volts

Listings

This instrument is designed and tested in accordance with:

I

EC Publication 1010-1 (Overvoltage category III), the safety requirements

for hand-held current clamps for electrical measurements and tests, the

MC directive, and other safet

E

y standards.

DL99B-MAN

. 1

P

Page 3

eak Hold Push-Button:Used to capture the highest AC or DC

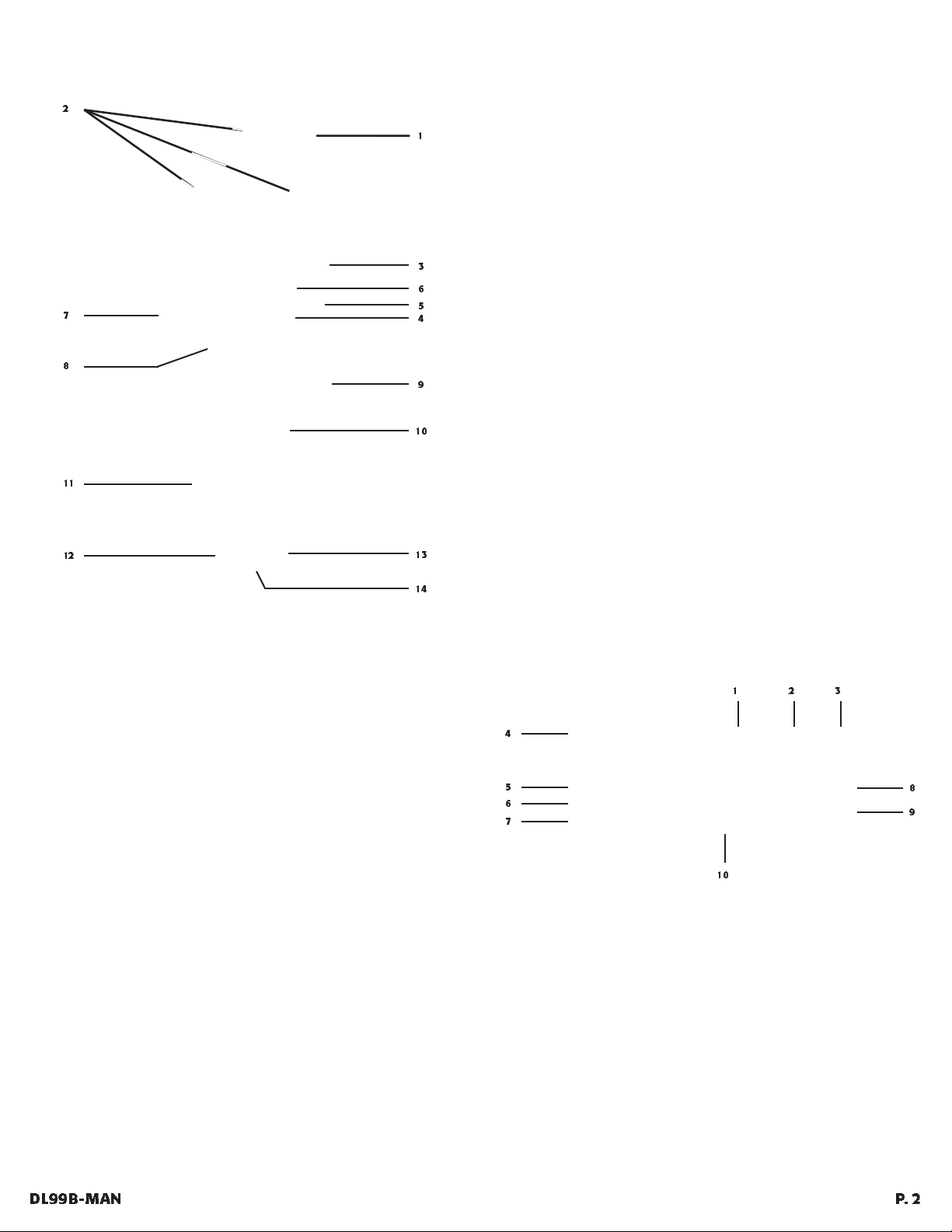

Controls and Indicators

6.P

inductive amp reading.

2

1

7. Clamp Lever: Opens and closes current clamp jaw.

8.

DC A Zero: Used to establish the “zero reference” when preparing

to make DC amperage measurements. Magnetic fields in the iron

core of the jaws will be interpreted as a current reading if not

lectronically compensated when measuring DC amps.

e

9. Rotary Function Switch: Used to power the meter on and off, or

to select on of these available measurement functions:

3

6

7

5

4

• Inductive AC or DC current using the clamp

• Volts AC or DC at the test lead inputs

• Resistance or continuity at the test lead inputs

10. Off Position: Turns the meter off. Always store your meter in the

off position. If the meter will not be used for a month or more,

8

9

remove the batteries.

Display: Communicates function, range, and value information to

11.

the user.

10

Common Terminal: The black test lead is plugged into this

12.

terminal to supply the ground or “low” reference for voltage and

11

resistance measurements.

13. Volt / Ohm (Ω) Terminal: The red lead is plugged into this

terminal for AC/DC volts, ohms, and continuity measurements.

12

13

14

Maximum Input Statements: MAX 600V indicates that a

14.

maximum of 600 Volts can be applied between the two terminals or

between earth ground and any terminal for CAT III, 1000 V CAT II.

1. Clamp: Wrapped around a single conductor when measuring

inductive AC or DC current. Opens to 1-1/4” (32 mm).

CAUTION!

The clamp uses a high-tension spring to close the jaw. DO NOT allow

fingers or objects to become pinched in the base as jaw closes.

2. Conductor Alignment Marks: Used to aid in the visual

alignment of a conductor when measuring inductive amperage.

y is achieved when the conductor inside the clamp

Greatest accur

ac

is centered at the intersection of these marks.

3.

Hand Guard: Used as a point of reference for the operator’s safety.

WARNING!

Always k

measuring current on e

in serious safety

eep your hands and fing

xposed conductors. Contact may r

ground or “low” reference for all measurements.

Data Hold Push-Button: Freezes the value displayed on the

4.

ers behind the hand guards when

esult

digital read-out.

Range / Worklight - Backlit display Push-Button: Used to

5.

switch from low to high range in the function selected. Note that AC

and DC voltage auto-range from 400 to 1000 volts when more than

400 volts are applied. Push and hold for 5 seconds to activate the

worklight and back light of the display.

LCD Display Functional Description

1

4

5

6

7

0

1

2 3

1. Peak Hold: Indicates the meter is displaying the maximum inductive

C or DC current value recorded.

A

2. Continuity: Indicates the meter is in the continuity measurement

mode and will sound a tone when measuring resistance below

approximately 40 ohms.

Hold: Indic

3.

O

H

4.

BAT (Low Battery Indicator): This symbol appears when the

ates the value displayed is frozen on screen (the “DA

LD

” push-button is pressed).

battery needs replacement.

y

Note: A low battery will adversely affect accur

ac

8

9

A

T

DL99B-MAN

. 2

P

Page 4

5. AC: Indicates that alternating current (AC) amperage or voltage is

being measured.

6.

Minus: Indicates the value measured has a negative polarity. This

will appear only while measuring DC amperage or voltage.

an be switched between one of the two available ranges by pressing the

c

RANGE” push-button on the side of the meter. The button is located

“

where it can be accessed using your thumb, allowing you to use just one

hand to control the instrument.

7. DC: Indicates that direct-current (DC) amperage or voltage is

being measured.

mVA: Indicates that millivolts (mV), volts (V), or amps (A) is

8.

being displayed.

9. KΩ: Indicates that Kilohms, or ohms are being displayed.

10. Numerical Value: Displays the total value of the measured input.

Operating Instructions

Auto Power Off

This instrument automatically shuts off after 30 minutes of inactivity. The

meter is considered active when there is a change of at least 10 digits

during this period (i.e., the meter senses a change from 24.04 volts to

24.14 volts).

Rotary Function Select Switch

The rotary function select switch is used to select the measurement

mode and to turn the meter on and off. A long audible tone is heard

when the meter is turned on.

WARNING!

Set the rotary function select switch to the appropriate setting before

connecting the test leads to circuits under test. Observe the safety

practices outlined in the beginning of this manual.

Peak Hold

When measuring AC or DC amps you can use the “PEAK HOLD”

push-button at the top of the instrument to capture the highest

measured value. The word “PEAK” will appear along the top of the

display and the only the highest measured value will be displayed on

the LCD. Press the “PEAK HOLD” push-button a second time or

changing functions with the rotar

the instrument to the real-time measurement mode. An audible tone

is heard when this function is engaged or disengaged.

Data Hold

The “DATA HOLD” push-button freezes the reading displayed on the

LCD at the moment it is pressed. To engage data hold, press the “DATA

LD

O

H

” push-button, loc

function is active, the symbol “

cancel data hold, press the “DATA HOLD” push-button again, or select

any other measurement function using the rotary function select switch.

An audible tone is heard when this function is engaged or disengaged.

Selecting the Range and Resolution

Select the range and resolution you intend to use prior to preparing

equipment for measurement or touching test leads to measurement

points. All measurement functions offered on the DL99, except

continuity, have two ranges. An autorange feature has been built in to

the AC and DC volts functions to allow quick measurements of various

line voltages with the best possible resolution. All other functions.

ated on the face of the instrument. When this

y function select switch will return

D.H” appears on the digital display. To

Measuring Inductive Current

The inductive current measurement mode relies on the induced

electromagnetic field that occurs when electricity flows through a

conductor. Prepare your unit under test for measurement by separating

a single live conductor from any other phase, neutral or ground

conductor. Squeeze the clamp lever, place the conductor in the open

jaws then close the jaws around the conductor. To get the most accurate

reading, ensure the conductor is centered in the alignment marks and

the jaws are closed tight. The conductor must be able to fit inside the

1.25” (32 mm) fully open jaw.

To measure inductive AC current:

1. Place the function select switch in the 400/1000 Amp AC position.

2. Select the appropriate range using the button on the side - The

400 Amp range will display a decimal place while the 1000 Amp

range will not.

3. Place the clamp jaw around a single, live conductor.

4. Allow meter to stabilize - Observe reading.

NOTE: The maximum limit for this function is 1000 amps AC. Too

much current will saturate the ferrous material in the clamp and

adversely affect accuracy.

To measure inductive DC current:

1. Place the function select switch in the 400/1000 Amp DC position.

2. Select the appropriate range using the button on the side - The

400 Amp range will display a decimal place while the 1000 Amp

range will not.

3. Place the clamp jaw around a single, live conductor - An arrow points

from the front of the meter toward the back to indicate the direction

of the positive terminal of the DC source.

4. Allow meter to stabilize - Observe reading.

NOTE: The maximum limit for this function is 1000 amps DC. Too

ate the ferrous material in the clamp and

y unknown voltag

e an

xceed 1

V/Ω/ “ por

e or curr

e, open cir

000 volts A

t and the black lead into the

ent measur

cuit voltage for the

C or DC (R

ements

MS).

W

AR

t.

ent will satur

NG!

I

N

much curr

adversely affect accuracy. If DC current is measured over an

extended period of time the clamp may become difficult to zero.

oper operation can sometimes be restored by rapidly opening

Pr

and closing the jaws or be temporarily reversing the meter’s

direction on the conductor (effectively reversing current flow).

Do not attempt to tak

that may be in excess of this meter’s maximum limits. To avoid the risk

of electrical shock and instrument damag

cuit under test must not e

cir

NOTE: For all measurement requiring the use of the meter leads, insert

ed lead into the “

the r

M

“CO

” por

DL99B-MAN

. 3

P

Page 5

easuring Voltage

M

When taking voltage measurements your meter must be connected

in parallel to the circuit, or circuit element, under test. When the 1000 V

AC or DC function is selected the meter will automatically increase

its range form 400 volts with (0.1 - volt resolution) to 1000 volts (with

-volt resolution) when the voltage measured exceeds 400. The

1

400-millivolt DC range allows you to use various adapters while the

1000-volt DC range allows you to measure most of the DC voltage

sources found in industrial applications.

WARNING!

Working with high voltage requires a greater awareness of physical

safety hazards. Before making live circuit tests, set the meter to the

desired function and range; connect the test leads to the meter first,

then to the circuit under test. Whenever possible, make test lead

connections when power is off then apply power to read the

measurement. If an erroneous reading is observed, disconnect power

immediately and recheck all settings and connections.

o measure AC or DC volts:

T

1. Set the rotary function select switch to the desired AC or DC

voltage position (Fig 1).

2. If measuring DC voltage, select the desired range.

3. Insert the test leads - Be sure your meter leads are firmly seated in

the meter’s jacks - Loose leads (or accessories) can cause readings to

fluctuate or allow less than the full signal into the meter.

4. Touch the test leads to the test points of the unit under test - The

black lead will typically be connected to the ground (or return)

terminal and red to the hot (or positive) terminal.

5. When measuring AC voltage, polarity is not critical - The accepted

practice (as a safety discipline) is to connect the black (common) lead

to ground or neutral and the red to the hot terminal.

6. The measured voltage will be displayed.

. If the input on the red “

7

V/Ω/ “ test lead is lo

wer (more negative)

will appear on the left of the display.

If the test leads were attached to the circuit with po

8.

wer off,

disconnect power before removing them.

easuring Resistance

M

WARNING!

Turn off power and discharge all capacitors on the circuit to be tested

efore attempting “in circuit” resistance measurements. Failure to do so

b

may result in equipment or instrument damage. It is critical to both the

welfare of the meter, and the accuracy of the measurement, that you

remove all power to the circuit under test when making resistance

measurements. If any voltage is present in the test circuit, whether from

a conventional power supply, or energy stored in a capacitor, an erroneous reading will result. This meter may be damaged if more than

1000 volts are present.

NOTE:

• When measuring continuity or resistance, polarity does

not matter

• When measuring critically low ohm values, touch the tips of the

test leads together and record the test lead resistance value.

act this value from the measured circuit’s resistance to

Subtr

obtain the most accurate reading

To measure Resistance:

1. Set the rotary switch to the resistance function.

2. Select the desired range using the button on the side of the meter.

3. Insert the test leads - Be sure your meter leads are firmly seated in

the meter’s jacks - Loose leads can cause erroneous or

fluctuating readings.

4. Turn off power to the circuit under test and ensure there is no

residual voltage present from any source - Charged capacitors and

batteries used for data back-up will adversely affect accuracy.

5. Touch the probes to the test points and read the display - Be sure you

have good contact between the test leads and the circuit - Dirt, oil,

solder-flux or other foreign matter alters the reading value.

Measuring Continuity

Use the continuity mode “ “ to make quick checks for continuity in

circuits, such as electric

ables. in the continuity mode, an audible tone sounds when the value

c

al wiring, switch contacts, relays and audio

measured is approximately 40Ω or less.

DL99B-MAN

(Fig 1)

To test for continuity:

Set the rotar

.

1

y switch to the continuit

y function.

2. Place one probe to each side of the circuit to be tested - If

approximately 40

Ω or less resistance is in the circuit, the meter

sounds a continuous tone - The resistance value (up to 400Ω) will

be displayed regardless of the continuity tone.

. 4

P

Page 6

Maintenance

eriodic service

P

WARNING!

Repair and service of this instrument is to be performed by qualified

ersonnel only. Improper repair or service could result in physical

p

egradation of the meter. This could alter the protection from

d

electrical shock and personal injury this meter provides to the

operator. Perform only those maintenance tasks that you are

qualified to do.

These guidelines will help you attain long and reliable service from

your meter:

1. Calibrate your meter annually to ensure it meets original

performance specifications.

2. Keep your meter dry. If it gets wet, wipe it dry immediately. Liquids

damage electronic circuits.

3. Whenever practical, keep the meter away from dust and dirt, which

can cause premature wear.

4. Although your meter is built to withstand the rigors of daily use, it

can be damaged by severe impacts. Use reasonable caution when

using and storing the meter.

ARNING!

W

Under NO circumstance should you expose batteries to extreme heat or

fire as they may explode and cause injury.

3. Place a fresh 9V battery in the compartment.

NOTE: If you do not plan to use the meter for a month or more,

remove the battery and store it in an area that won’t be damaged by a

leaking battery.

4. Reattach the battery compartment cover to the meter and

reinstall the screw.

Remove cover

NOTE: When servicing the meter, use only the replacement parts specified.

Battery: 9V, NEDA 1604 or IEC 6LR 61

Test lead set: ATL55

Cleaning and Decontamination

Periodically clean your meter’s case using a damp cloth. DO NOT use

abrasives, cleaning solvents or strong detergents, as they may damage

the finish or affect the reliability of the structural components.

Battery Replacement

Always use a fresh replacement battery of the specified size and type.

Immediately remove the old or weak batter

dispose of it in accordance with your local disposal regulations. Old or

defective batteries can leak chemicals that corrode electronic circuits.

WARNING!

o avoid electric shock, be sure to turn off the meter’s power and

T

disconnect both test leads fr

or install batteries.

To install a new battery, follow these procedures:

Remove the screw from the battery compartment cover on the

.

1

back (lower half) of the meter and lift the cover (Fig 2).

om any equipment before you remove

y from the meter and

(Fig 2)

2. Remove and discard the old battery. Always dispose of old batteries

promptly in a manner consistent with local disposal regulations.

DL99B-MAN

. 5

P

Page 7

Troubleshooting

Specifications

If I see this I should check for Then take this

malfunction corrective action

Debris on switch controls Move switch through all

functions 3 to 4 times

Instrument does not Battery voltage Replace low battery

t

urn on Rotary switch position Ensure switch moves freely

and is set to a

measurement position

Instrument turns on but Peak Hold button pressed Look for PEAK or HOLD

LCD indicates some icons displayed on the LCD

unreasonable or HOLD button pressed Turn off one or both buttons

unchanging value

S

hort test leads together -

A value appears Stray voltage or EMF fields If a value near 000 appears,

on screen with no instrument is OK

input applied Move meter and leads

away from devices that

create electrical fields

Defective test leads Short test leads together

in the 400 ohm scale -

for 2 seconds

ERO

y mode -

Ω

Expect less than .5

A known value is not PEAK or HOLD buttons pressed Turn off one or both

displayed on the LCD buttons (check for icons

when measured on LCD)

Bad test lead connections Ensure test leads are fully

inserted and free of

corrosion or dirt

DC Amps not zeroed Move meter away from

power source and press

DC or Z

Battery voltage Replace low battery

Jaws are not closed tight Clean top and bottom

mating surfaces of

clamp jaws

Meter reading is Rotary selector knob is offset Ensure knob is firmly

unstable

Bad test lead connection Ensure there is no

No audible tone with Improper selector position Tone sounds only in

near zero resistance

value Place selector in

Amps reading does Proper switch position Ensure switch is in proper

not work AC or DC amps position

placed in switch position

insulating material, dirt

or debris at contact points

continuit

position

C or A DC)

(A A

Measurement limits

AC Amperage 1000 Amps

DC Amperage 1000 Amps

AC Voltage 1000 Volts

DC Voltage 1000 Volts

O

hms 400 Kilohms

Continuity < 40 ohms

General Specifications

Size H x W x L, in (mm) 9.20” x 3.42” x 1.77”

(234 x 87 x 45)

Maximum Jaw Opening 1.25” (32 mm)

S

torage Temperature -4˚ to 140˚F

(-20˚ to 60˚C)

Operating Temperature 32˚ to 113˚F

(0˚ to 45˚C)

Relative Humidity 0% to 80% RH

(Storage and Use)

Weight (approximate) 14.8 oz (420 g)

Electrical Certification Standards:

IEC 1010-1 CAT III 600 Volts

1000 Amps AC/DC

CSA C22.2 No. 1010.1

ISA S 82,01

Battery Type 9V, NEDA 1604, 6F22 or 006P

Electrical Specifications

Function Range Resolution Accuracy

AC Amps @ 400 A 0.1 A ±(2% + 5 digits)

(50 Hz to 450 Hz) 1000 A 1 A

DC Amps

400 A 0.1 A

1000 A 1 A ±(1.5% + 3 digits)

AC Volts* 400 V 0.1 V ±(1.9% + 3 digits)

(50 Hz to 400 Hz) 1000 V 1 V

DC Volts* 400 mV 0.1 mV ±(1.0% + 2 digits)

400 V 0.1 V

1000 V 1 V

Ω 400

Ohms

Ω 0.1 Ω ±

40 K

Ω 0.01 KΩ

(1.0% + 2 digits)

Continuity 400 Ω 600 VΩ Tone sounds @ < 40 Ω

*1000 V AC and Dc scales autorange from 400 to 1000 when greater than

400 volts are applied.

NOTE: This unit contains no user serviceable parts beyond those listed in

table above. In the event your instrument is ph

ysically damaged or does not

function properly after taking the listed action, please return the instrument

to UEi following the warranty and service instructions.

DL99B-MAN P. 6

Page 8

Standard & Optional Accessories

Standard

Soft carrying case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .AC259

Test leads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ATL55

ptional

O

lug-in line splitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ASL1

P

Temperature measurement adapter . . . . . . . . . . . . . . . . . . . . . .TA2K

Soft Carrying Case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .AC319

DL99B-MAN P. 7

Page 9

DL99B

True RMS Clamp-On Meter

Limited Warranty

The DL99B is warranted to be free from defects in materials and workmanship for a period of

three years from the date of purchase. If within the warranty period your instrument should

become inoperative from such defects, the unit will be repaired or replaced at UEi’s option.

This warranty covers normal use and does not cover damage which occurs in shipment or

failure which results from alteration, tampering, accident, misuse, abuse, neglect or improper

maintenance. Batteries and consequential damage resulting from failed batteries are not

covered by warranty.

Any implied warranties, including but not limited to implied warranties of merchantability

and fitness for a particular purpose, are limited to the express warranty. UEi shall not be

liable for loss of use of the instrument or other incidental or consequential damages,

expenses, or economic loss, or for any claim or claims for such damage, expenses or

economic loss. A purchase receipt or other proof of original purchase date will be required

before warranty repairs will be rendered. Instruments out of warranty will be repaired (when

repairable) for a service charge. Return the unit postage paid and insured to:

1-800-547-5740 • FAX: (503) 643-6322

www.ueitest.com • Email: info@ueitest.com

This warranty gives you specific legal rights. You may also have other rights which vary from

state to state.

E

PLEAS

RECYCLE

Copyright © 200

7 U

Ei

DL99B-MAN 1/07

Loading...

Loading...