Troy Bilt 34061, 34062, 34337, 34063, 34064 Owners Manual

OWNER’S MANUAL

Sickle Bar Mowers

• Safety

• Assembly

• Controls and Features

• Operation

• Maintenance

• Parts List

GARDEN WAY INCORPORATED

Models

34061 – 34", 3-1/2 HP Recoil Start

34062 – 38", 4HP Recoil Start

34337 – 34", 4HP Recoil Start

34063 – 42", 5HP Recoil Start

34064 – 42", 5HP Electric Start

SAFETY FIRST!

Before operating this equipment, read this

Owner's Manual and the separate manual

supplied by the engine manufacturer.

2

Dear Owner:

Thank you for purchasing our product. We feel you now own

one of the finest pieces of outdoor power equipment available.

Our equipment is carefully designed, engineered and manufactured for excellent performance if properly operated and maintained.

Read this manual carefully to familiarize yourself with the unit,

its features, and its safe operation. Be sure that you and any

other operators carefully follow the recommended safety practices at all times. Failure to do so could result in personal injury

or property damage.

This is a safety, operation and general maintenance manual

which does not attempt to cover major repairs. All information

in this manual is based on the latest product information available at the time of printing. This manual is considered a permanent part of the unit and it must stay with the unit if resold. A

replacement manual can be obtained from the factory or an

authorized dealer.

Please fill out and return the postpaid owner registration card

included with this manual. The purpose of the card is to register

each unit and owner at the factory to provide product updates

and warranty service.

If you have any problems or questions concerning the unit,

please contact your local authorized dealer or the factory (see

back cover of this manual). We want to be sure that you are

completely satisfied at all times.

INTRODUCTION ................................................. 2

Service Information ...................................................... 3

Identification Numbers ................................................. 3

California Operators Warning ....................................... 3

SAFETY .......................................................... 3

Safety Decals ................................................................ 5

ASSEMBLY ...................................................... 6

FEATURES AND CONTROLS ................................... 14

Throttle/Choke Control Lever ........................................ 14

Operator Presence Controls (OPC) ............................... 14

Wheel Drive Levers ....................................................... 14

Engine Oil Dipstick/Fill Hole .......................................... 14

Shoes ........................................................................... 14

Cutter Bar (with guard) ................................................. 15

Fuel Tank Cap ............................................................... 15

Starter Rope Handle ..................................................... 15

Engine Keyswitch (electric-start units).......................... 15

Cutter Bar Lever ........................................................... 15

Weed Diverter ............................................................... 15

Engine Primer Bulb ....................................................... 15

OPERATION ..................................................... 16

Pre-start Checklist ........................................................ 16

Starting the Engine ....................................................... 16

Stopping the Engine...................................................... 17

Operator Presence Controls (OPC) System Test .......... 17

Operation....................................................................... 18

Operating on Slopes...................................................... 19

Stopping ....................................................................... 19

MAINTENANCE ................................................. 20

Maintenance Schedule................................................... 20

Tire Pressure................................................................. 20

Clearing Wheel Wrap .................................................... 20

Wheel Drive Control Rod Adjustment ........................... 20

Cutter Bar Drive Belt Removal/Replacement ................ 21

Cutter Bar Belt Guide Adjustment ................................ 21

Wheel Drive Belt Adjustment ........................................ 21

Wheel Drive Belt Removal/Replacement ....................... 21

Wheel Drive Belt Guide Adjustment .............................. 21

Drive Chain Adjustment and Lubrication ...................... 22

Cutter Bar Maintenance ............................................ 22-24

High-Wear Parts ........................................................... 24

Housing Assembly Tightening Sequence....................... 26

Front Housing Removal................................................. 26

Eccentric Shaft Removal/Replacement.......................... 26

Engine Maintenance.................................................. 26-27

Battery Maintenance...................................................... 27

Check and Tighten Hardware......................................... 27

Lubrication.................................................................... 27

Storage ......................................................................... 28

Troubleshooting ....................................................... 28-29

PARTS LIST...................................................... 30

CUSTOMER SERVICE INFORMATION ............. BACK COVER

T able of Contents

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm.

WARNING

Safety Alert Symbol

This is a safety alert symbol. It is used in this

manual and on the unit to alert you to potential hazards. When you see this symbol, read and obey the

message that follows it. Failure to obey safety messages could result in personal injury or property

damage.

See Back Cover for

Customer Service Information

Left and Right Sides

Left and right sides of the unit are determined by standing in

the operator position and facing the direction of forward

travel.

PREPARATION

1. Unit is capable of amputating hands

and feet and

throwing

objects.

Failure to

observe the

following safety instructions could result

in serious injury or property damage.

2. Serious accidents which may cause

injury or property damage can occur if the

following safety guidelines are not followed. The operator is solely responsible

for accidents or hazards that occur when

using the unit. Preventing accidents is the

responsibility of every equipment operator. Accidents can be prevented. Be

careful before, during and immediately

after use of any powered equipment. The

following general safety precautions must

be fully understood and followed during

operation. Review these instructions frequently and never take chances. If you do

not understand any part of this manual or

need assistance, contact your dealer or

our service department.

TRAINING

1. Read, understand, and follow this

Owner’s Manual, the separate engine

owner’s manual, and all other literature

received before you use the unit.

Be thoroughly familiar with the controls

and proper use of the unit. Know how to

stop the unit and disengage controls

quickly in case of emergency.

Read and follow all safety information in

this manual. Failure to comply could result

in serious personal injury or property

damage.

Make sure all operators of the equipment

read, understand, and follow these safety

instructions.

2. Never allow children to operate the unit.

Do not allow adults to operate the unit

without proper instruction. Do not allow

irresponsible adults to operate the unit.

3. Keep the operating area (within 25 feet

of unit) clear of all people (especially children) and pets.

PREPARATION

1. Wear proper clothing when operating

unit. Always wear sturdy footwear (preferably steel-toed shoes) and hearing protection during operation.

a. Wear heavy leather gloves whenever

working near or servicing any cutting

edges on the unit.

b. Do not wear loose-fitting clothing,

jewelry, scarves, ties, etc., which may

get caught in moving parts. Tie up or

restrain hair.

c. Do not operate the unit while bare-

foot. Do not wear sandals.

d. Wear long trousers.

e. Wear hearing protection.

2. Do not operate the unit when tired, ill

or under the influence of alcohol and/or

other drugs.

3. Be prepared for an emergency. Keep a

first aid kit and fire extinguisher handy.

Keep emergency telephone numbers for

ambulance, fire, hospital, doctor and

rescue near your telephone.

4. When charging the battery on electricstart units, use only the battery charger

provided with the unit.

5. Do not operate the unit if the cutter bar

assembly is not securely installed and

operating properly.

6. Mow only during daylight or in good

artificial light.

7. Never operate the unit in wet grass.

Always be sure of your footing. Always hold

handlebar grips firmly, and walk––never

run.

25 Ft.

25 Ft.

25 Ft.

25 Ft.

Safety

1

Section

3

SPARK ARRESTER WARNING TO RESIDENTS

OF CALIFORNIA AND SEVERAL OTHER STATES

Under California law, and under the laws of several

other states, you are not permitted to operate an

internal combustion engine using hydrocarbon fuels on

any forest, brush, hay, grain, or grass covered land; or

land covered by any flammable agricultural crop

without an engine spark arrester in continuous effective

working order.

The engine on the unit is an internal combustion engine

which burns gasoline, a hydrocarbon fuel, and must be

equipped with a spark arrester muffler in continuous

effective working order. The spark arrester must be

attached to the engine exhaust system in such a

manner that flames or heat from the system will not

ignite flammable material. Failure of the owner/operator of the unit to comply with this regulation is a misdemeanor under California law (and other states) and

may also be a violation of other state and/or federal

regulations, laws, ordinances or codes. Contact your

local fire marshal or forest service for specific information about which regulations apply in your area.

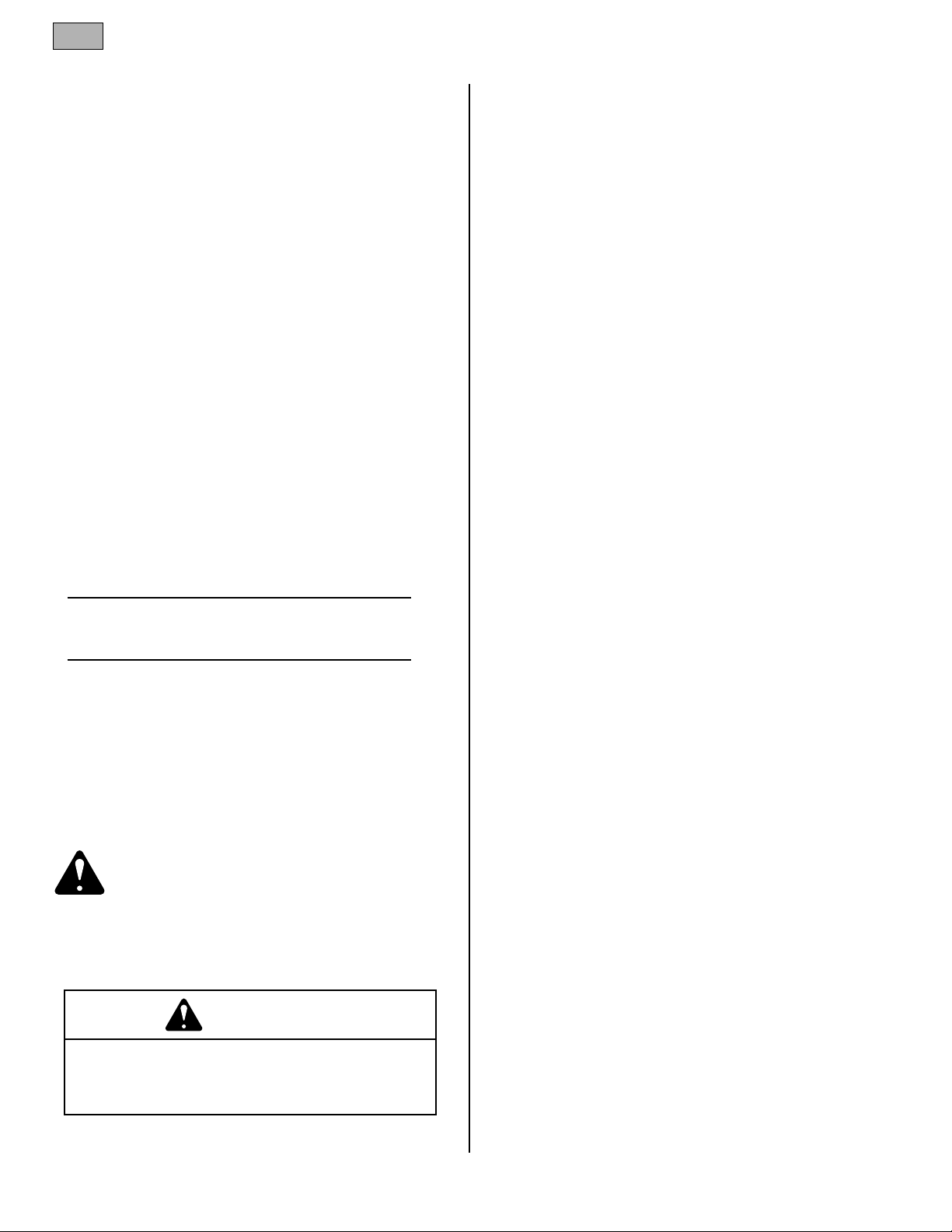

Throttle/Choke Control Lever

Wheel Drive

Levers

Cutter Bar and Guard

Cutter Bar Lever

(on rear of unit)

Operator Presence Controls

Figure 1-1

4 Section 1: Safety

BEFORE OPERATION

1. Before each use, thoroughly inspect the

mowing area. Remove all

metal, debris, and other

hazards. Inspect for holes,

ruts or bumps. Uneven terrain could overturn the unit.

Tall vegetation can hide

hazards.

2. Never operate the unit without all

guards in place and working properly

(except for the plastic blade protector,

which should be removed before starting

the engine).

3. Before removing or installing the

plastic blade protector, shut the engine

off, disconnect the spark plug wire, and

prevent it from touching the spark plug.

On electric start models, also remove the

ignition key from the keyswitch.

4. Check the operation of the control

levers under each handlebar grip. See the

"Operation" Section in this manual for specific instructions. Do not use the unit if

control levers are not functioning properly.

CORRECT ANY MALFUNCTION BEFORE

USING THE UNIT!

HANDLING GASOLINE

1. Use extreme care in handling gasoline and other fuels.

Gasoline is highly

flammable and its vapors

are volatile, explosive,

and dangerous. Keep gasoline and gasoline containers away from hot engine

exhaust. Never allow flame, sparks,

smoking materials or other hot objects

near gasoline, gasoline fumes, the fuel

container or fuel tank.

2. Use an approved fuel container only.

Wipe up any spilled gasoline immediately.

3. Leave one inch of air space at top of

fuel tank to allow room for expansion.

4. Store gasoline in a cool, well-ventilated

area. Never store unit or fuel container

inside where there is an open flame or

spark, such as a hot water heater, furnace,

etc.

5. Never remove fuel fill cap, or add fuel

to fuel tank, if engine is running or hot.

Allow the engine to cool for several minutes before filling the fuel tank. Always

replace fuel fill cap before starting engine.

6. Never refuel unit indoors. Refuel outdoors in a well-ventilated area only.

7. Check the gasoline level in the fuel tank

outdoors, before starting the engine.

Reinstall the fuel tank cap securely and

clean up any spilled gasoline before

starting the engine.

8. Do not smoke while mowing.

9. Move the unit away from gasoline

fumes before starting the engine.

OPERATION

1. Keep the plastic blade protector on the

cutter bar blade until you are ready to start

the engine.

2. Do not put hands or feet near or under

any moving parts. Keep clear of the cutter

bar at all times while the engine is

running.

3. Never leave the operator position while

the engine is running. Stop

the engine, disconnect the

spark plug wire and move it

away from the spark plug to

help prevent accidental

starting whenever leaving the unit unattended. On electric start models, remove

the ignition key to help prevent accidental

starting or unauthorized use.

4. Before removing or installing the

plastic blade protector, shut the engine

off, disconnect the spark plug wire, and

prevent it from touching the spark plug.

On electric start models, also remove the

ignition key from the keyswitch.

5. Do not change the engine governor setting. Over-speeding may damage the

engine and unit and will void the warranty.

See an authorized engine service dealer if

an engine problem exists.

6. Disengage the cutter bar when

crossing gravel drives, walkways or roads.

7. Watch for, and avoid, traffic when

operating near roadways.

8. Disengage the cutter bar

drive and the wheel drive if

you are approached by a child,

inattentive person or a pet.

9. Before inspecting, adjusting or

repairing the unit or cutter

bar, stop the engine, let all

moving parts come to a

complete stop, disconnect

the spark plug wire, and

install the plastic blade guard. On electric

start models, remove the ignition key from

the keyswitch.

10. If the unit should start to vibrate

abnormally, stop the engine, wait for all

moving parts to stop completely, disconnect the spark plug wire and prevent it

from touching the spark plug. Remove the

engine ignition key on electric start

models. Inspect the unit for damage.

Repair any damage before continuing.

11. If the unit should strike a foreign

object, stop the engine, wait for all moving

parts to stop completely, disconnect the

spark plug wire and prevent it from

touching the spark plug. Remove the

engine ignition key on electric start

models. Inspect the unit for damage.

Repair any damage before continuing.

12. Do not run the engine in an enclosed

area. Engine exhaust contains carbon

monoxide, a deadly, poisonous gas that is

odorless, colorless and tasteless. Always

run the engine outdoors with adequate

ventilation.

13. Always mow across the face of slopes.

Do not operate unit on slopes steeper than

15°.

14. Keep all movements on a slope slow

and gradual. Do not make sudden changes

in speed or direction.

15. Do not touch engine parts which may

be hot from operation. Let parts cool for

several minutes before going near them.

16. Keep children out of the mowing area

and under the supervision of a responsible

adult other than the unit operator.

17. Before and when backing, check for

and avoid obstacles and hazards.

18. Disengage the cutter bar drive when

not mowing.

19. Do not mow near drop-offs, ditches or

embankments. If a wheel drops off an

edge, the unit could suddenly overturn.

20. To help reduce fire hazard, keep the

engine free of grass, leaves, grease and

other debris.

CHILDREN

1. Tragic accidents can occur if the operator is not alert to the presence of children. Children are often attracted to the

unit and the mowing activity. Never

assume that children will remain where

you last saw them.

2. Never allow children to operate the

unit, even under adult supervision. Local

regulations may restrict operator age. Only

allow responsible adults, who are familiar

with these instructions, to operate the

unit.

Section 1: Safety 5

3. Never carry children as passengers.

Do not carry ANY passengers. They may

fall off, become seriously injured, or interfere with safe unit operation.

4. Keep children out of the work area and

under the watchful care of a responsible

adult other than the unit operator.

5. Be alert and turn unit off if children

enter the area.

6. Before and when backing, look behind

and down for children.

7. Use extra care when approaching blind

corners, shrubs, trees, or other objects

that may obscure vision.

8. Keep children away while performing

maintenance or adjustments.

MAINTENANCE AND STORAGE

1. Before inspecting, cleaning, adjusting

or repairing the unit, stop the engine, let

all moving parts come to a

complete stop, disconnect

the spark plug wire, and

install the plastic blade

guard on the cutter bar. On

electric start models, remove the ignition

key from the keyswitch.

2. Always wear sturdy footwear (preferably steel-toed shoes), long trousers,

hearing and eye protection while doing

any maintenance on the unit. Do not wear

loose-fitting clothing, jewelry, scarves,

ties, etc., which could get caught in

moving parts. Tie up or restrain hair.

3. Install the plastic blade guard before

removing the cutter bar assembly and

wear sturdy leather gloves to help protect

your fingers and hands.

4. Keep children away while performing

maintenance or adjustments.

5. Remove any metal jewelry when

working on or near electrical system components.

6. Use only original equipment replacement parts. Parts manufactured by others

could create a hazard even though they

may fit on the unit.

7. Keep the equipment in safe working

condition. Keep all nuts, bolts and screws

tight. Frequently check the engine

mounting bolts and cutter bar mounting

bolts for tightness.

8. Provide safe, adequate light in your

work area. NEVER USE AN OPEN FLAME

FOR ILLUMINATION! Use only a portable

safety light enclosed in a wire cage for

working on unit. NOTE:

Hot filaments from a

broken light bulb can

ignite spilled fuel or oil.

9. If the unit has gasoline in its fuel tank,

do not store it inside a building where

fumes from the gasoline could reach an

open flame or spark. Let the engine cool

before storing the unit.

10. Store gasoline in a cool, well-ventilated area, away from spark- or flame-producing equipment. Store gasoline in an

approved container, away from children.

11. Keep unit free of grass, leaves or

build-up of other debris. Clean up oil or

fuel spillage. Allow unit to cool before

storing.

12. Replace muffler if worn or defective.

13. Use extra care when loading or

unloading unit into a trailer or truck.

14. Do not use food or beverage containers to store waste materials. Using

such containers could result in accidental

poisoning.

ENGINE

1. Before starting the engine or operating

the unit, read the separate engine manual

completely. Read and follow all safety

instructions provided in that manual.

2. BEFORE SERVICING THE ENGINE:

Disconnect the spark plug wire and keep it

from touching the spark plug.

3. Keep the engine free of grass, leaves,

oil, and grease.

4. Engine exhaust is extremely hot. Keep

grass, oil, fuel, and other combustible

materials far away from engine exhaust.

5. Do not change the engine governor setting. Over-speeding may damage the

engine and unit and will void the warranty.

See an authorized engine service dealer if

a problem exists.

6. Never run an internal combustion

engine inside a closed area. Engine

exhaust contains carbon monoxide gas, a

deadly poison. Carbon monoxide is odorless, colorless and tasteless. Do not

operate the unit near buildings, windows,

or air conditioners. If the engine is run in a

garage, open all doors and allow for adequate ventilation.

Place Hand Here When

Pulling Starter Rope

Hot Surfaces

Warning

Sharp Cutter Bar

Blades Danger

Danger - Keep Hands

and Feet Away

On Rear Panel

Warning - Operating

Engine - Electric

Start Only

Cover “Top” Decal

Engine Throttle Settings

SAFETY DECAL LOCATION

Operator Presence

Controls

SAFETY DECALS

Keep all safety decals clean and in

good condition. The location of each

decal is shown in Figure 1-2.

Refer to the Parts List for ordering

replacement decals.

Figure 1-2

Assembly

2

Section

6

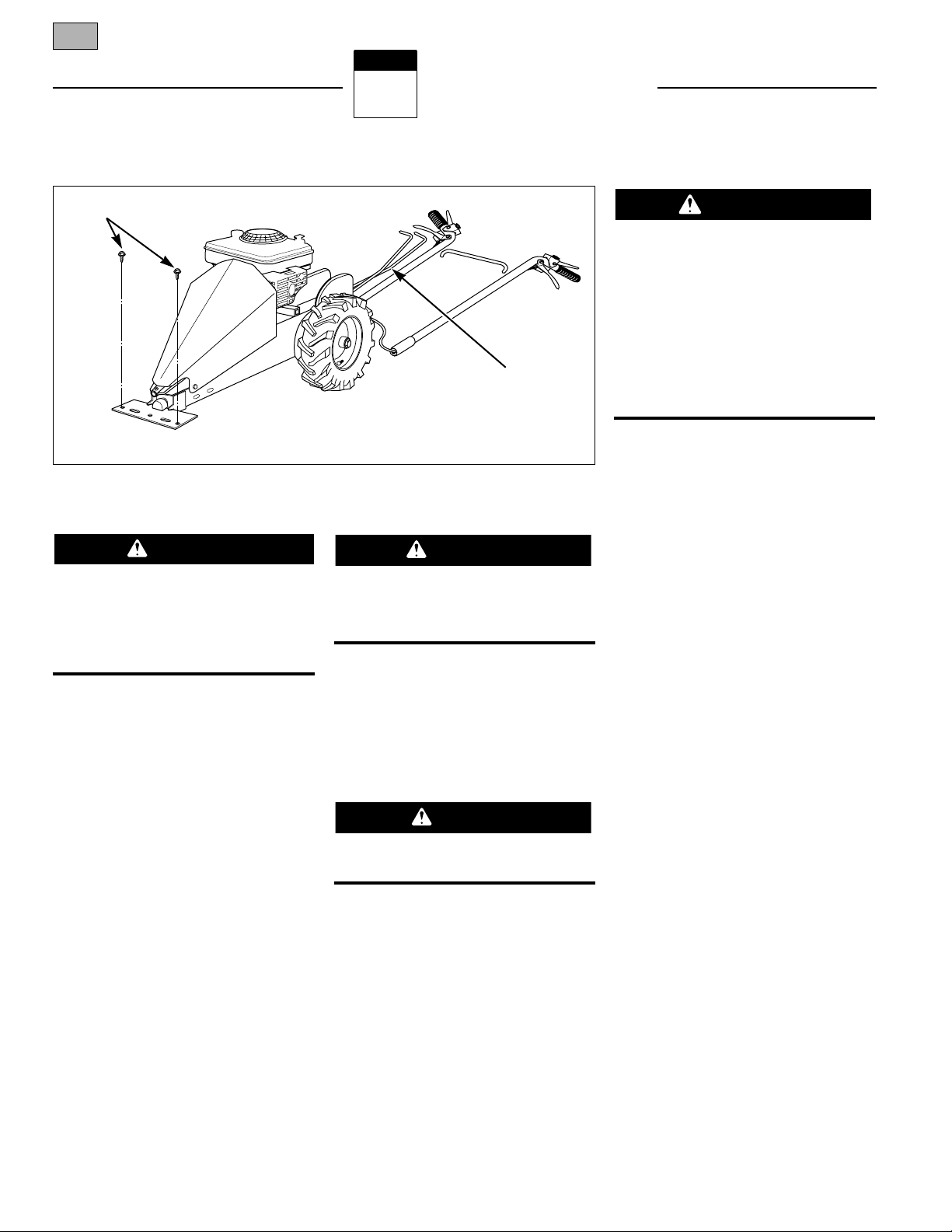

BEFORE ASSEMBLY

Carefully follow all steps in this section to

assemble the unit.

CARTON INSPECTION

Inspect the unit immediately after delivery.

Check the carton and contents for any

damage.

Contact the carrier (trucking company)

immediately if the unit is damaged. Inform

the carrier that you wish to file a claim.

The carrier will let you know how to proceed with the claim. To protect your

rights, file a written claim with the carrier

within 15 days of receiving the unit. Contact our service department if you need

assistance.

Do not start the engine until oil is added!

The engine is shipped without oil.

Engine damage will occur if engine is

started before oil is added.

IMPORTANT: Oil must be added before

starting the engine. Starting or operating

the engine without oil will damage the

engine and void the warranty. See the

engine manual.

Do not overfill engine with oil. Engine

damage will occur.

Cutter bar blades are extremely sharp.

To help avoid serious injury:

• Keep the plastic guard on the CUTTER

BAR ASSEMBLY when the unit is not

running.

• Wear heavy leather gloves when han-

dling the cutter bar.

• Do not place fingers between blades.

Amputation could result.

UNPACKING THE UNIT

The cutter bar blade and attached plastic

blade guard are packaged separately

within the main shipping crate. Leave the

cutter bar blade attached to the shipping

pallet until instructed to remove it.

The handlebars are packed on each side of

the unit, connected with wiring to the

underside of the unit. IMPORTANT: Do

not damage the wiring when removing the

handlebars from the carton.

The included parts and hardware required

for assembly are listed on the following

pages.

Remove and discard the two screws that

secure the front of the unit to the wooden

pallet (see Fig. 2-1). However, leave the

unit on the pallet until instructed to

remove it. Fig. 2-1 shows the position of

the unit for assembly.

TOOLS/MATERIALS NEEDED

(2 ea.) Wrenches: 7/16", 1/2", 9/16" (or

adjustable wrenches)

(1) Adjustable Wrench

(1) 13mm Socket

(1) Phillips (or thin straight blade)

Screwdriver

(1) All-purpose Oil

(1) Tire Pressure Gauge

(1) Measuring Tape or Ruler

DANGER

CAUTION

WARNING

Fig. 2-1

Remove shipping

screws

Remove control rods

from handlebar

To prevent personal injury or property

damage, do not start the engine until all

assembly steps are complete and you

have read and understand the safety and

operating instructions in this Manual

and the engine manual.

WARNING

Section 2: Assembly 7

2

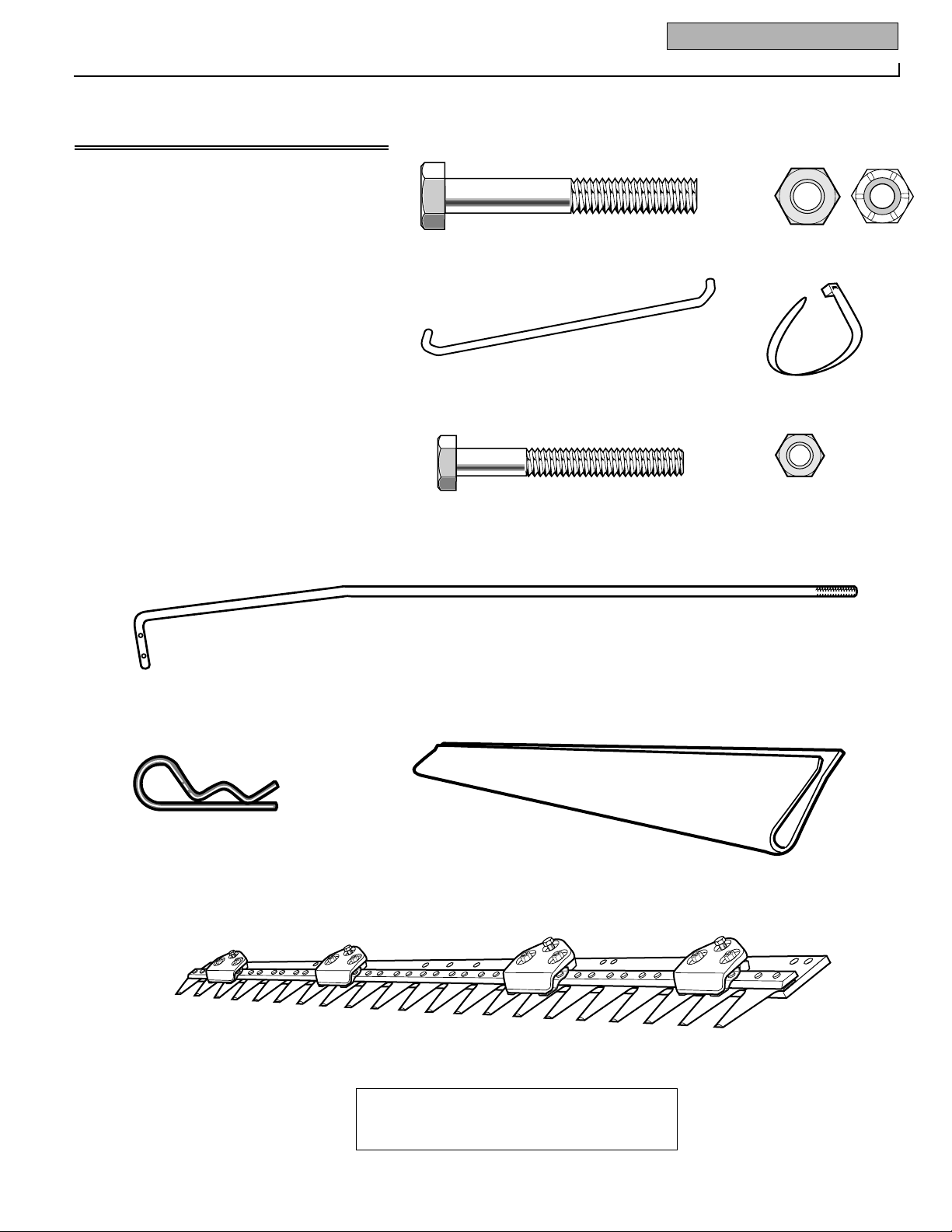

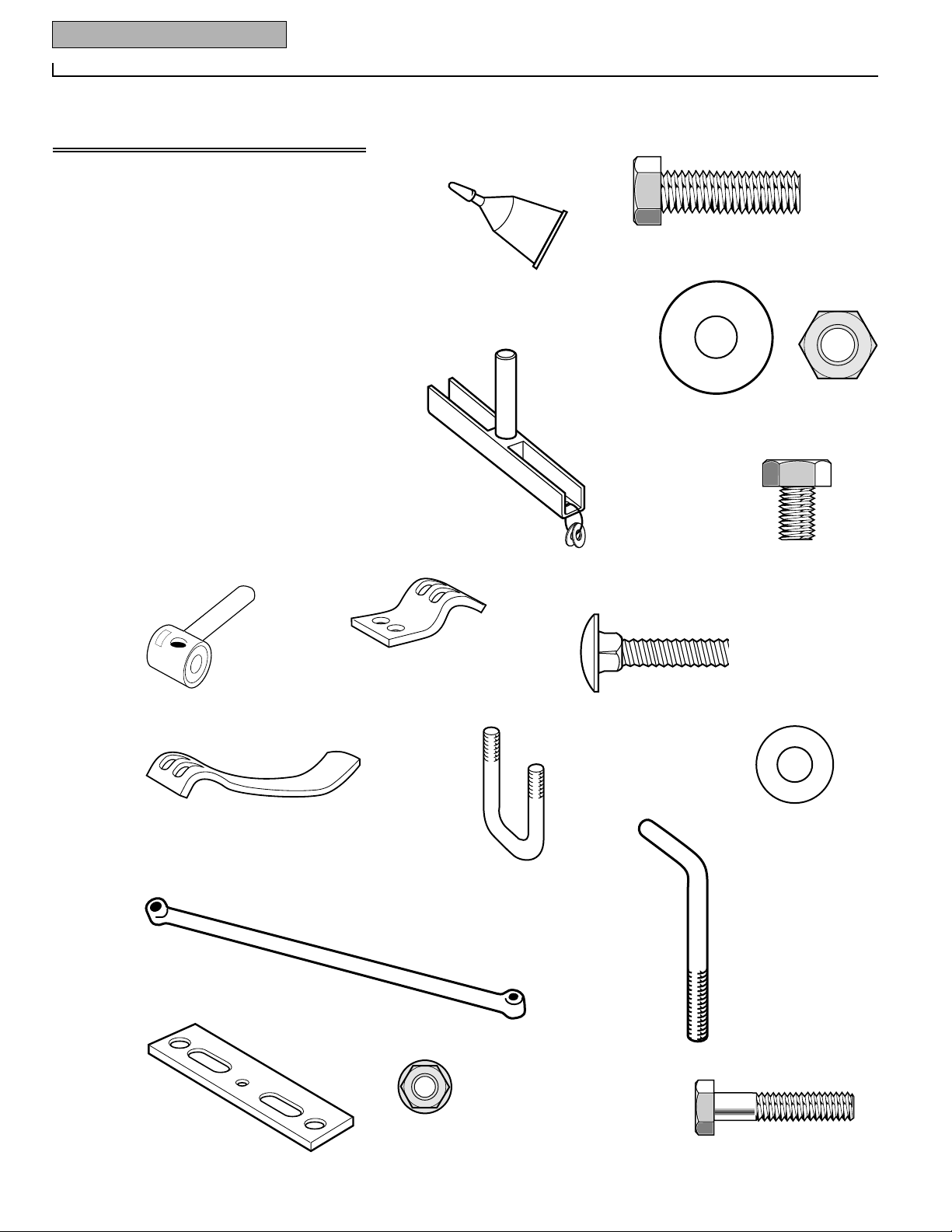

Ref. Description Qty.

Right Handlebar (shipped connected to

unit by wiring)...............................................1

Left Handlebar (shipped connected to

unit by wiring)...............................................1

1 Hex Head Capscrew, 5/16"–18 x 2-1/4" ........2

2 Locknut, 5/16"–18.......................................10

3 Handlebar Bridge..........................................1

4 Cable Ties (total of six - two already

installed on unit)...........................................4

5 Hex Head Capscrew, 1/4"–20 x 2".................1

6 Locknut, 1/4".................................................1

7 Control Rod..................................................2

8 Hair Pin ..................................................2

9 Plastic Blade Guard (on blade)......................1

10 Cutter Bar......................................................1

HARDWARE IS APPROXIMATE SIZE SHOWN

Large parts (with

*) shown reduced

1

4*

8

7*

9*

10*

5

6

3*

Ref. Description Qty.

-- Right Handlebar (shipped connected to

unit by wiring)..............................................1

-- Left Handlebar (shipped connected to

unit by wiring)..............................................1

1 Hex Head Capscrew, 5/16"–18 x 2-1/4" ...........2

2 Toplock Nuts, 5/16"–18 (to mount

handlebars)..................................................2

2a Nylock Nuts, 5/16"–18 .....................................8

3 Handlebar Bridge .............................................1

4 Cable Ties (total of six - two already

installed on unit)..........................................4

5 Hex Head Capscrew, 1/4"–20 x 2" ....................1

6 Locknut, 1/4"....................................................1

7 Control Rod (attached to handlebars)..............2

8 Hair Pin Clip.....................................................2

9 Plastic Blade Guard (on Cutter Bar Assembly) .1

10 Cutter Bar.........................................................1

5

8

1

6

2

2a

3*

7*

NOTE: Control rods are attached to one handlebar with a wire tie (see Fig. 2-1). Cut

wire tie and remove rods before starting assembly steps.

9*

10*

4*

HARDWARE IS SHOWN APPROXIMATE SIZE

(Large parts [with *] shown reduced size)

8 Section 2: Assembly

11*

15*

13

16

17

14

Ref. Description Qty.

11 Mounting Bracket (already installed).............1

12 Hex Flange Screw, 3/8"–16 x 1-1/4" long......3

13 Flat Washer, 3/8"...........................................3

14 Centerlock Nut, 3/8"–16................................3

15 Knife Head.....................................................1

16 Metric Hex Head Screw, M8 x M25...............2

17 Metric Internal Tooth Lockwasher, M8 .........2

18 Pitman Arm Assembly ..................................1

19 Shoe Holder..................................................2

20 Carriage Bolt, 5/16"–18 x 1"..........................4

21 Shoe..............................................................2

22 U-Bolt, 5/16" x 18..........................................2

23 Flat Washer, 5/16".........................................4

24 Weed Diverter...............................................1

25 Upper Hook ..................................................1

26 Doubler Plate................................................1

27 Flange Nut 1/4"– 20.......................................2

28 Flat Washer, 1/4"...........................................1

29 Hex Head Screw, 1/4"–20 x 1-1/4" long.........1

30 Battery Charger (optional - not shown).........1

31 Key (In Keyswitch) (optional - not shown)....1

18*

19*

21*

20

25

27

24*

22

23

26*

12

Ref. Description Qty.

11 Loctite®Thread Fastener, (bottle or tube)....1

12 Hex Cap Screw, 3/8"–16 x 1-1/4" (Grade 8) ..3

13 Flat Washer, hardened, 3/8"..........................3

14 Centerlock Nut, 3/8"–16................................3

15 Knife Head.....................................................1

16 Metric Hex Head Screw, M8 x M12...............2

-- Flat Washer, hardened, 5/16" (wire-tied to

knife head (Ref. 15) -- do not remove

until instructed to do so) ..........................2

18 Pitman Arm Assembly ..................................1

19 Shoe Holder..................................................2

20 Carriage Bolt, 5/16"–18 x 1"..........................4

21 Shoe..............................................................2

22 U-Bolt, 5/16" x 18..........................................2

23 Flat Washer, 5/16".........................................5

24 Weed Diverter...............................................1

25 Upper Hook ..................................................1

26 Doubler Plate................................................1

27 Flange Nut 1/4"– 20.......................................2

28 Hex Head Screw, 1/4"–20 x 1-1/4" ...............1

29 Battery Charger (optional - not shown).........1

30 Key (optional - not shown)...........................1

11

12

13

14

16

18*

19*

20

22

23

25

27

28

24*

26*

21*

15*

Section 2: Assembly 9

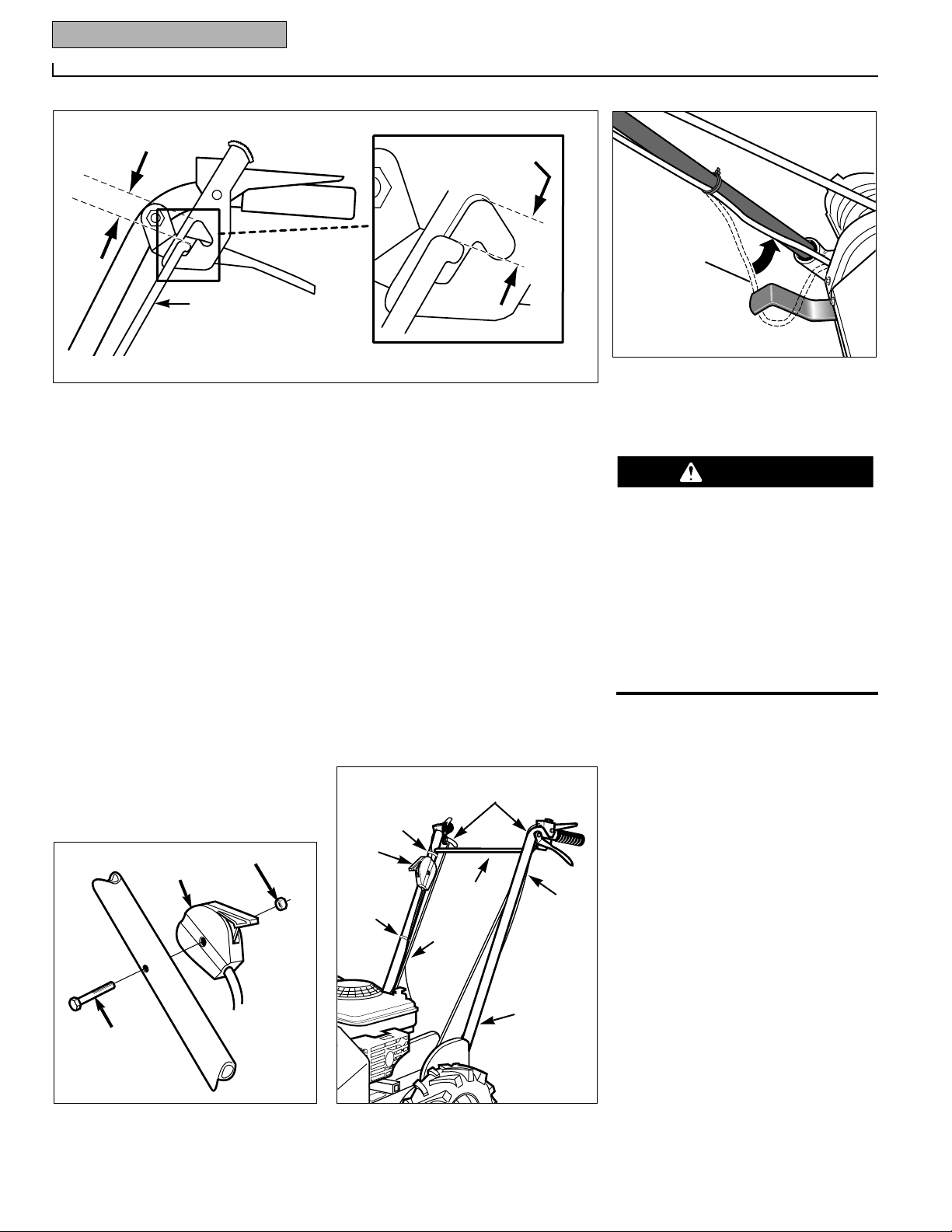

HANDLEBAR INSTALLATION

NOTE: Handlebar wiring from the operator presence controls (OPC) is connected

to a switch under the unit. DO NOT disconnect this wiring!

1. Before beginning assembly, disconnect

the spark plug wire from the spark plug.

2. Place the handlebars on the ground

behind the unit.

3. With the ends of the bridge (C,

Fig. 2-2) positioned as shown, insert the

bridge in between the handlebars into the

upper set of handlebar holes.

4. Align the holes in the plastic sleeves

(on the bottom ends of the handlebars)

with the corresponding handlebar holes in

the deck. For easier installation, apply a

small amount of oil to the sleeve ends.

5. Insert the bottom ends of the handlebars into their mounting brackets in the

deck (Fig. 2-3). Do not pinch or damage

the attached wiring. Align the screw holes

(it may be helpful to align the holes with a

punch or drift pin prior to installing the

screws in the next step).

NOTE: Position the handlebars with

thumb latches (F, Fig. 2-5) on the inner

sides of handlebars.

6. Secure each handlebar with a 5/16-18

x 2-1/4 hex head capscrew (A, Fig. 2-3)

and 5/16"-18 toplock nut (B).

NOTE: When correctly installed, the handlebars feel loose. The looseness or “play”

is intentionally designed to reduce vibration which occurs during operation. The

rubber sleeves on the handlebar ends act

as “shock absorbers” and also help reduce

vibration.

WHEEL DRIVE CONTROL ROD

INSTALLATION

1. Place the control rods (D, Fig. 2-4)

BETWEEN the handlebars and UNDER the

bridge, with the threaded ends down. For

easier installation, apply oil or grease to

the threads. Thread the rods into the

pivots (E) twelve turns each. If necessary,

use a screwdriver or a punch to move the

pivots into position. Be sure that the wire

harness on each handlebar is located to

the outside of each control rod.

2. Insert the upper end of each control

rod (G, Fig. 2-5) into the plastic thumb

latch (F) slots, then outward through the

holes in the wheel drive levers (H).

3. Insert hair pin clips (J, Fig. 2-5)

through the hole in each control rod. Position hair pin clips with loops up, as

shown.

CONTROL ROD ADJUSTMENT

1. With the controls positioned as shown

(Fig. 2-6), measure the gap between the

top of the slot in the thumb latch bracket

and the control rod. Do not put any pressure on the handlebars when measuring.

The gap must measure 1-1/4" (32mm).

If adjustment is required, remove the hair

pin clip (J, Fig. 2-5) from the control rod.

Remove the control rod from the wheel

drive lever (H) and thumb latch (F). Turn

the control rod as needed to achieve the

1-1/4" (32mm) gap.

NOTE: Adjust the wheel drive control rods

properly. Improper adjustment will result

in broken thumb latches.

C

A

B

D

D

C

B

Install hair pins (D) OUTSIDE levers (C)

D

A

J on outside with loop up

Fig. 2-2

Fig. 2-3

Fig. 2-4

Fig. 2-5 Outer view of left handlebar

F

J

G

H

J

E

10 Section 2: Assembly

THROTTLE CONTROL LEVER

INSTALLATION

1. Unwind the throttle cable from around

the left side of the engine, then position

the throttle control lever (Z, Fig. 2-7) on

the inside of the right handlebar as shown

(Figs. 2-7 and 2-8). THE CABLE MUST BE

ROUTED UNDERNEATH THE CONTROL

ROD (see AA, Fig. 2-8).

2. Secure the throttle control lever to the

handlebar with a 1/4–20 x 2" hex-head

capscrew (A, Fig. 2-7) and 1/4"-20 locknut

(B). TO AVOID DAMAGING PLASTIC

ASSEMBLY, DO NOT OVER-TIGHTEN

SCREW AND LOCKNUT.

CABLE TIE INSTALLATION

Secure the throttle cable and OPC wiring

to the handlebars with cable ties (C, Fig.

2-8) to help prevent them from being

damaged during operation. Two of the

cable ties are already installed at the upper

end of the handlebars. Remove any slack

from the bottom of the OPC wires (see Fig.

2-8A) to avoid catching the cutter bar lever

on the wires. Twist the OPC wires (but not

the throttle cable) in a corkscrew pattern

along the length of the handlebars and

install the four cable ties (two on each

side). Cut off excess cable tie with scissors.

UNIT REMOVAL

Squeeze the four control levers on the

handlebars and carefully roll the unit from

off the shipping crate. Park the unit on a

flat, clean surface where you can complete

the remaining assembly steps.

CUTTER BAR ASSEMBLY

AND INSTALLATION

Cutter bar blades are extremely sharp!

To help avoid serious injury:

• When handling cutter bar, wear heavy

leather gloves and wrap cutter bar

with rags.

• Keep plastic guard on blade assembly

until you are ready to start engine.

• Contact with the blades will cause

serious personal injury.

Avoid contact with the cutter bar blades.

1. Remove the screws securing the cutter

bar to the crate. Wear heavy leather

gloves and wrap cutter bar with rags to

avoid cutting yourself on the blades.

2. Carefully remove the cutter bar from

the shipping crate. Keep the plastic blade

guard on the cutter bar to protect yourself

from injury.

IMPORTANT: To help prevent the unit

from tipping, have an assistant stand in

the operator position and firmly hold the

handlebars during installation of the cutter

bar.

3. REMOVE SPARK PLUG WIRE FROM

SPARK PLUG (IF ATTACHED).

4. Have an assistant available to hold the

unit firmly by the handlebars.

DANGER

B

A

(C) Already installed

1

1

/

4

" (32mm)

Gap here

(right side shown)

1

1

/

4

" (32mm)

A

C

C

C

Bridge

Fig. 2-6

Fig. 2-7

Fig. 2-8

Z

B

A

Z

C

AA

Fig. 2-8A

Remove

slack in wire

(on both

handlebars).

Section 2: Assembly 11

Disconnect the spark plug wire from the

spark plug before attempting to install

the cutter bar. Move the spark plug wire

away from the spark plug and prevent the

wire from contacting the plug.

5. Center eccentric arm (A, Fig. 2-14), if

necessary, by moving cutter bar lever to

ON (Fig. 2-15) and pulling starter rope.

6. Position the cutter bar (B, Fig. 2-9) at

the front of the cutter bar mounting

bracket (C) as shown. Place the doubler

bracket (D) on the cutter bar and align the

three mounting holes as shown.

7. Apply a small amount of Loctite®

Thread Fastener (use only a small amount,

as a total of five screws need to be coated

during the assembly procedure) to the

threads of the three 3/8-16 x 1-1/4 hex

cap screws (E, Fig. 2-9). Have an assistant

hold the unit firmly by the handlebars and

raise the front of the unit a few inches off

the ground. Securely attach the cutter bar

and doubler bracket to the cutter bar

mounting bracket with the three hex cap

screws (E), 3/8 flat washers (F) and 3/816 center locknuts (G). Torque to 35 ftlbs. if you have a torque wrench. Lower

the unit to the ground.

IMPORTANT: Allow the Loctite® to cure

for at least one hour (preferably 24 hours

at 72oF.) before operating unit.

8. Align the middle hole (B, Fig. 2-10) in

the cutter bar with the middle locknut (CC,

Fig. 2-10) on the cutter mounting bracket.

If needed, tap the ends of the cutting blade

back and forth (see inset, Fig. 2-10) to

align the middle hole (use a wood block to

avoid damaging the blade).

9. Slide the pitman assembly (H, Fig. 210A-1) onto the post of the knife head (I).

The “Top” decal on the pitman assembly

must be facing up. Remove the two 5/16

hardened flat washers that are wire-tied to

the knife head for shipping purposes.

CAUTION

Fig. 2-9

B

E

G

F

C

D

J

Fig. 2-10

Fig. 2-10A

B

CC

Tap top section of

cutting blade from

side-to-side to

align middle hole

(B) with middle

locknut (CC).

H

I

1

2

3

4

L

K

Loading...

Loading...