Traulsen G12000 Operator’s Manual

Quality Refrigeration

OWNER’S MANUAL

G-Series Reach-In & Pass Thru

Refrigertor, Freezer & Hot Holding

*For equipment produced after 09-15-2017 only.

4401 Blue Mound Road Fort Worth, Texas 76106 (USA) |

|

Phone: 800.825.8220 | Service Fax: 817.740.6757 |

| E-mail: service@traulsen.com | Website: traulsen.com |

Hours Of Operation: Monday |

- Friday 7:30 a.m. - 4:30 p.m. (CST) |

|

|

TABLE OF CONTENTS

1. THE SERIAL TAG |

Page 1 |

6. OTHER |

|

|

|

A-Service Information |

Page 6 |

2. RECEIPT INSPECTION |

Page 2 |

B-Spare Parts |

Page 6 |

|

|

C-Warranty Registration |

Page 6 |

3. INSTALLATION |

|

|

|

A-Location |

Page 2 |

7. MICROPROCESSOR CONTROL |

|

B-Packaging |

Page 2 |

A-Control Features |

Page 6 |

C-Installing Legs or Casters |

Page 2 |

B-Control Panel |

Page 7 |

D-Shelf Pins |

Page 3 |

C-Parts Assembly |

Page 7 |

E-Removing The Doors & Hardware |

Page 3 |

D-Notes To The User |

Page 8 |

F-Cord & Plug |

Page 3 |

E-Enter The Customer Password |

Page 8 |

G-Power Supply |

Page 3 |

F-Enter The Technician Password |

Page 9 |

H-Wiring Diagram |

Page 3 |

G-Service Parameters |

Page10 |

I-Clearance |

Page 4 |

H-Adjust The Set Point |

Page 11 |

J-Installing Optional Interior Kits |

Page 4 |

I-Adjust The Set Point Differential |

Page 11 |

K-ON/OFF Switch |

Page 4 |

J-Change The Temperature Scale |

Page 11 |

|

|

K-Set Date & Time |

Page 12 |

4. OPERATION |

|

L-Set Daylight Savings |

Page 12 |

A-Refrigerators |

Page 4 |

M-Start A Defrost |

Page 13 |

B-Freezers |

Page 4 |

N-Set Defrost Mode |

Page 13 |

C-Light Switches |

Page 5 |

O-Set Defrost Schedule |

Page 13 |

D-Turn Off Temperature Display-Main Display |

|

P-View The Sensor Temperatures |

Page 14 |

Short Cut |

Page 5 |

Q-Hot Food-Unlocking The Keypad |

Page 15 |

|

|

R-Hot Food-Adjust The Set Point |

Page 15 |

5. CARE & MAINTENANCE |

|

S-Hot Food-Change The Temperature Set Point |

|

A-Cleaning The Condenser |

Page 5 |

(Short Cut) |

Page 15 |

B-Hinge Replacement |

Page 5 |

T-Hot Food-Turn The Unit Off |

Page 15 |

C-Replacing The Gaskets |

Page 5 |

|

|

D-Cleaning The Exterior |

Page 6 |

8. SPARE & REPLACEMENT PARTS LISTING |

Page 16 |

E-Cleaning The Interior |

Page 6 |

9. TROUBLESHOOTING GUIDE |

Page 17 |

F-Adjusting The Shelves |

Page 6 |

10. WARRANTY INFORMATION |

Page 18 |

FORT WORTH, TX. USA

SERIAL |

MODEL |

|

VOLTS |

Hz |

PH |

TOTAL CURRENT |

AMPS |

|

MINIMUM CIRCUIT |

AMPS |

|

MAXIMUM OVERCURRENT PROTECTION |

AMPS |

|

LIGHTS |

WATTS |

|

HEATERS |

AMPS |

|

REFRIGERANT |

TYPE |

OZ |

DESIGN PRESSURE |

HIGH |

LOW |

REFRIGERANT |

TYPE |

OZ |

DESIGN PRESSURE |

HIGH |

LOW |

370-60294-00 REV (A)

1. THE SERIAL TAG

The serial tag is a permanently affixed label upon which is recorded vital electrical and refrigeration data about your Traulsen product, as well as the model and serial number. This tag is located in the upper right interior compartment on all Traulsen G-Series refrigerator and freezer models.

READING THE SERIAL TAG

•Serial = The permanent ID# of your Traulsen

•Model = The model # of your Traulsen

•Volts = Voltage

•Hz = Cycle

•PH = Phase

•Total Current = Maximum amp draw

•Minimum Circuit = Minimum circuit ampacity

•Lights = Light wattage

•Heaters = Heater amperage (Hot Food units only)

•Refrigerant = Refrigerant type used

•Design Pressure = High & low side operating pressures and refrigerant charge

•Agency Labels = Designates agency listings

G SERIES

Page 1

2. RECEIPT INSPECTION |

3. INSTALLATION (cont’d) |

All Traulsen products are factory tested for performance and are free from defects when shipped. The utmost care has been taken in crating this product to protect against damage in transit. All interior fittings have been carefully secured and the casters/legs are boxed and strapped inside to prevent damage. Door keys will be attached to the handle with a nylon strip. The handle is protected by an easily removable nylon netting.

You should carefully inspect your Traulsen unit for damage during delivery. If damage is detected, you should save all the crating materials and make note on the carrier’s Bill Of Lading describing this. A freight claim should be filed within 5 days. If damage is subsequently noted during or immediately after installation, contact the respective carrier and file a freight claim. Under no condition may a damaged unit be returned to Traulsen without first obtaining written permission (return authorization). You may contact Traulsen customer care at (800) 333-7447 to request a return.

3. INSTALLATION

3A - LOCATION:

Select a proper location for your Traulsen unit, away from extreme heat and allow proper clearance for air circulation (see page 4). Allow enough clearance between the unit and the side wall in order to make use of the door stay open feature at 120° (selfclosing feature operates up to 90°). The door(s) must be able to open a minimum of 90° in order to make use of the maximum clear door width available.

3B - PACKAGING:

All Traulsen units are shipped from the factory bolted to a sturdy wooden pallet and packaged in a durable Styrofoam backed cardboard wrap.

Most exterior stainless steel and aluminum surfaces have a protective vinyl covering to prevent scratching during manufacturing, shipping and installation. After the unit is installed in place of service, remove and discard the covering from all surfaces.

If at all possible we suggest that the cabinet remain bolted to the pallet during all transportation to the point of final installation. To remove the wooden pallet, the bolts can then be removed with a 3/4” socket wrench. Avoid laying the unit on its front, side or back for removal of the pallet.

NOTE: DO NOT LAY THE UNIT ON ITS SIDE DURING TRANSPORTATION OR INSTALLATION.

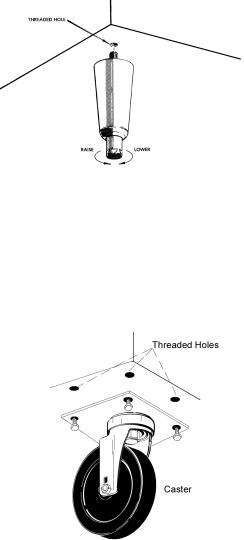

3C - INSTALLING CASTERS OR LEGS:

A set of four (4) 6” high casters and sixteen (16) bolts are supplied standard for all Traulsen G-Series units. These are shipped from the factory packed inside a cardboard box which is strapped inside the cabinet to the lower shelf.

Legs in lieu of casters are available as an optional accessory kit for the same models. These are shipped inside a separate cardboard box. Inside it should contain four (4) legs and sixteen (16) bolts.

WARNING: THE CABINET MUST BE BLOCKED AND STABLE BEFORE INSTALLING LEGS OR CASTERS.

To install the legs or casters, first raise and block the reach-in a minimum of 7” from the floor. For installing legs, thread the legs into the threaded holes on the bottom of the cabinet (see figure

1). Be certain that all legs are tightly secured. When the unit is set in its final position, it is important for proper operation that the unit be level. The legs are adjustable for this purpose, turn the bottom of the leg counterclockwise to raise it, clockwise to lower it. Level the unit from front to back as well as side to side in this manner.

Fig. 1

Please note that Traulsen units are not designed to be moved while on legs. If the unit requires moving, a pallet jack or forklift should be used to prevent damage. For installing casters, the casters are a “plate” type, and require the use of four (4) bolts each to secure them firmly to the cabinet bottom at each corner (see figure 2). The caster bolts are tightened using a 1/2”socket wrench.

Fig. 2

GSERIES Page 2

3. INSTALLATION (cont’d)

3D - SHELF PINS:

The unit is supplied with shelves and shelf pins installed. Check all shelf pins to assure they are tightened down as they may have come loose during shipping. Rotate the pins clockwise until they are secured against the side of the cabinet.

3E - REMOVING THE DOORS & HARDWARE:

In order to fit through narrow (less than 35”) doorways, it may be necessary to remove the door(s), and/or hinges. To remove any solid door, begin by removing the plug at the bottom of the top hinge. Inside the hinge there is a small screw which secures the door in place. Remove this with a flat head screwdriver and the door can then be lifted off the hinges (see figure 3).

Fig. 3

After removing the door, it maybe necessary to remove the hinge assembly and hardware from the door itself.

Fig. 4

3E - REMOVING THE DOORS & HARDWARE (cont’d):

If it is necessary to remove the hinge hardware from the cabinet, begin by removing the three Phillips head screws which hold it in place. Set these components aside for later reassembly. Pay special attention not to loose the door switch actuator button controls evaporator fan and interior light operation (see figure 4).

NOTE: All solid door units include a microswitch for controlling the interior lighting in the top hinge(s). Special care should be taken to not damage the wiring for this during the hinge removal process.

The lock keeper may also require removal in order to reduce the overall cabinet depth to 32”.

Next remove the lock keeper bracket by removing the two

(2) flat head screws which secure it in place. Set these components aside for later reassembly.

To re-install the door and/or hinges, please reverse the appropriate sections of the preceding procedure.

3F - CORD & PLUG:

All G-Series models are supplied with a cord & plug attached. It is shipped coiled at the top of the cabinet, secured by a nylon strip. For your safety and protection, all units supplied with a cord and plug include a special three-prong grounding plug on the service cord. Select only a dedicated electrical outlet with grounding plug for power source.

NOTE: Do not under any circumstances, cut or remove the round grounding prong from the plug, or use an extension cord.

3G - POWER SUPPLY:

The supply voltage should be checked prior to connection to be certain that proper voltage for the cabinet wiring is available (refer to the serial tag to determine correct unit voltage). Make connections in accordance with local electrical codes. Use qualified electricians.

Use of a separate, dedicated circuit is required. Size wiring to handle indicated load and provide necessary over current protector in circuit (see amperage requirements on the unit’s serial tag).

3H - WIRING DIAGRAM:

Refer to the wiring diagram located on the exterior back of the cabinet for any service work performed on the unit. Should you require one, please contact Traulsen Service at (800) 825-8220, and provide the model and serial number of the unit involved.

G SERIES

Page 3

3. INSTALLATION (cont’d)

3I - CLEARANCE:

In order to assure optimum performance, the condensing unit of your Traulsen unit MUST have an adequate supply of air for cooling purposes. Therefore, the operating location must either have a minimum of 12” clearance overhead of the condensing unit or allow for unrestricted air flow at the back of the unit. Clearance of at least 12” above is required in order to perform certain maintenance tasks.

3J - INSTALLING OPTIONAL INTERIOR KITS:

In addition to their standard interiors, G-Series models also offer the option for additional shelves or tray slides. If ordered, these are shipped as kits along with the unit, packaged in a separate cardboard box which contains all the necessary parts and hardware for on-site installation.

To install additional shelves, first remove the white plastic covers from inside the cabinet. These are located along the same vertical line as the pins already in place on the interior side walls, back and center mullion (two and threesection models). This exposes threaded holes in which you may position the new shelves. Next insert the gray plastic shelf pins into these holes and tighten by turning clockwise with your fingers. After all four pins are in place, the new shelf should be placed to rest on top of them. The unused plastic covers may be discarded or saved for future changes to the cabinet interior.

Installation of optional tray slides varies with each cabinet, and with each type of tray slide ordered. To install optional tray slides, follow the directions packaged inside the kit carton.

3K - ON/OFF SWITCH:

An ON/OFF toggle switch for the power supply is provided. It is located on top of the unit, mounted to the side of the evaporator housing. This is shipped from the factory in the ON position.

4. OPERATION

4A - REFRIGERATORS:

Both refrigerators and freezers do not require manual defrosting. During normal operation, a refrigerator continuously circulates above freezing cabinet air through the evaporator coil. An electric defrost occurs every 8 hours for a maximum length of 25 minutes to melt any frost which may accumulate on the coil during the compressor “ON” cycle. With standard holding refrigerators, high relative humidity is also maintained to prevent dehydration of stored product.

4. OPERATION (cont’d)

4B - FREEZERS:

During normal operation, a freezer continuously circulates below freezing cabinet air through the evaporator coil. The coil requires a periodic defrosting for proper operation. This is accomplished by an automatic, time activated, temperature/time terminated, defrost program. The controller is preset at the factory for six equally spaced defrost cycles within each 24-hour period.

The evaporator fan(s) cycle off with each door opening. The evaporator fan(s) will cycle on (15 seconds) and off (45 seconds) during the compressor off cycle. During the compressor on cycle the evaporator fan(s) will run continuously.

At the start of a refrigerator or freezer defrost cycle, both the compressor and evaporator fans are off. The microprocessor control will read “dEF” (see figure 5).

Fig. 5

The electric heater (attached to the coil) is energized. When the temperature sensor affixed to the coil senses 45°F, the coil is fully defrosted and the compressor operation is resumed, defrost heaters are automatically turned off. The evaporator coil fans are delayed from starting at the termination of a defrost cycle. Fan operation is automatically resumed, after a short time or temp delay (whichever comes first).After completion, the total refrigeration system operation is then resumed. During defrost operation, heat is confined to the coil enclosure to prevent any significant rise in temperature within the food zone. The fan delay control function upon termination of a defrost cycle is two-fold. First, to prevent blowing warm air into the food storage area. Second, to prevent any condensation on the defrost coil from being blown into the food storage area.

The microprocessor control is set from the factory to terminate defrost at 25 minutes for refrigerators and 30 minutes for freezers in the event of a sensor failure. This setting should never be tampered with, without first consulting the factory.

GSERIES Page 4

4. OPERATION (cont’d) |

5. CARE & MAINTENANCE (cont’d) |

4C - LIGHT SWITCHES:

All G-Series models include a concealed door switch mounted in the top door hinge(s), which automatically activates the interior light when the door is opened. When the door is closed, the lights are not operating.

In addition, on hinged glass door models, an exterior mounted, illuminated red switch is included for manual light control. In the ON position, the lights are illuminated whether the doors are open or not. In the OFF position, the lights are controlled by the hinge switch as described in the first paragraph.’

4D - TURN OFF TEMPERATURE DISPLAY-MAIN DISPLAY SHORT CUT: There is a short cut to disable the external temperature display. Note that before doing so you must install an interior mounted thermometer in order to conform with local health codes.

DISPLAY DISPLAY SYMBOL DESCRIPTION

Unlock Key

Keypad Unlock

LED

•Press the Unlock Key twice within a second in order to unlock the keypad (think “tap-tap”).

•The Keypad Unlock LED will turn on to indicate the keypad is now live.

•Press and hold the Unlock Key for 3 seconds until the temperature display goes blank.

To restore the temperature display, press any key except the

Unlock Key:

•Press the Unlock Key twice within a second in order to unlock the keypad (think “tap-tap”).

•The Keypad Unlock LED will turn on to indicate the keypad is now live.

•Press any key except the Unlock Key to restore the temperature display.

5. CARE & MAINTENANCE

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY BEFORE CLEANING ANY PARTS OF THE UNIT.

5A - CLEANING THE CONDENSER:

The most important thing you can do to insure a long, reliable service life for your Traulsen is to regularly clean the condenser coil.

The condensing unit requires regularly scheduled cleaning to keep the finned condenser clean of lint and dust accumulation.

Keeping the condenser clean allows the cabinet to operate more efficiently and use less energy. To clean the condenser, first disconnect electrical power to the cabinet and lift up the front louver assembly. To lift this, remove the two screws located on both sides at the bottom of the louver assembly (see figure 5).

Once the screws are removed, the panel can be pivoted upwards allowing full access to the front facing condenser (see figure 6).

5A - CLEANING THE CONDENSER (cont’d):

Fig. 5

Remove

Screws

Fig. 6

Lift-Up Louver

Assembly

Vacuum or brush any dirt, lint or dust from the finned condenser coil, the compressor and other cooling system parts. If significant dirt is clogging the condenser fins, use compressed air to blow this clear. Care should be taken not to bend any of the condenser fins, as this will reduce performance and compressor life. Lower louver assembly and replace screws to hold it in place.

5B - HINGE REPLACEMENT:

To remove the door, remove the plug at the bottom of the top hinge. Behind this is a screw which secures the door in place. Remove this with a flat head screwdriver and then lift the door off the hinge. To remove the door portion of the hinge, lift off the hinge cover and then remove the 3 Phillips head screws which secure the hinge in place. To remove the cabinet portion of the hinge, remove the 3 Phillips head screws which hold it in place. On solid door units, the top hinge(s) contains a switch for controlling the lights.To reassemble the hinge reverse the procedure.

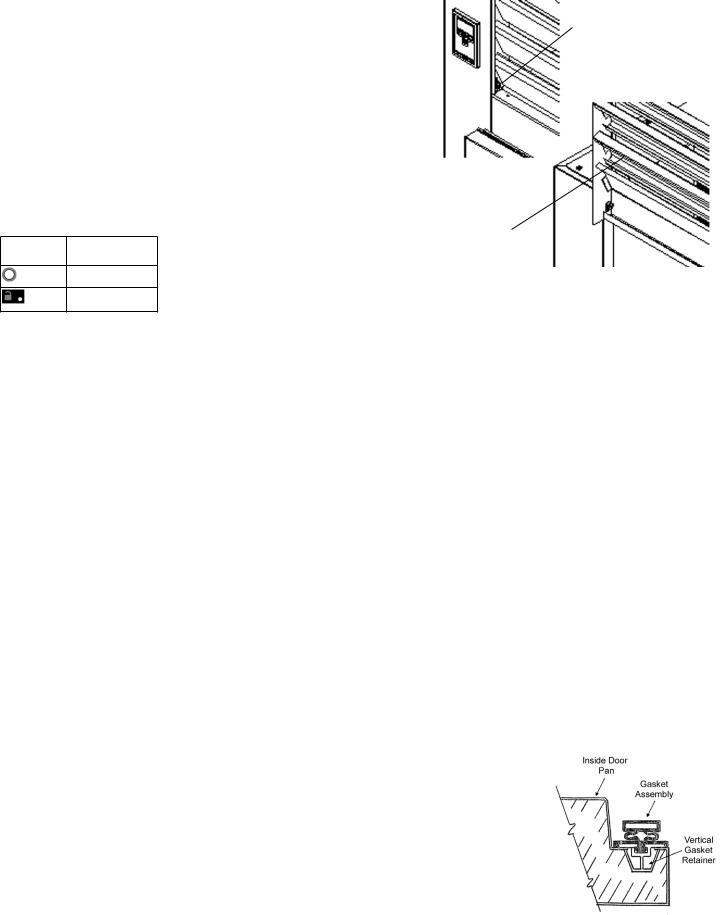

5C - REPLACING THE GASKETS:

To remove the gasket to be replaced, grasp it firmly by one corner and pull it out. Before attempting to install a new gasket, both the unit and gasket must be at room temperature. Insert the four corners first by using a rubber mallet (or hammer with a block of wood). After the corners are properly inserted, work your way towards the center from both ends by gently hitting with a mallet until the gasket is completely seated in place (see figure 7 for proper gasket placement).

NOTE: The gasket may appear too large, but if it is installed as indicated above it will slip into place.

Fig. 7

G SERIES

Page 5

Loading...

Loading...