Toyota Camry 1994 User Manual

FOREWORD

This wiring diagram manual has been prepared to provide

information on the electrical system of the 1994 TOYOTA

CAMRY.

Applicable models: SXV10 Series

MCV10 Series

For service specifications and repair procedures of the above

models other than those listed in this manual, refer to the

following manuals;

Manual Name Pub. No.

1994 CAMRY Repair Manual

Volume 1

Volume 2

1994 Model New Car Features

RM361U1

RM361U2

NCF099U

All information in this manual is based on the latest product

information at the time of publication. However, specifications

and procedures are subject to change without notice.

TOYOTA MO TOR CORPORATION

NOTICE

When handling supplemental restraint system components (removal,

installation or inspection, etc.), always follow the direction given in the repair

manuals listed above to prevent accidents and supplemental restraint

system malfunction.

1

INTRODUCTION

A

This manual consists of the following 11 sections:

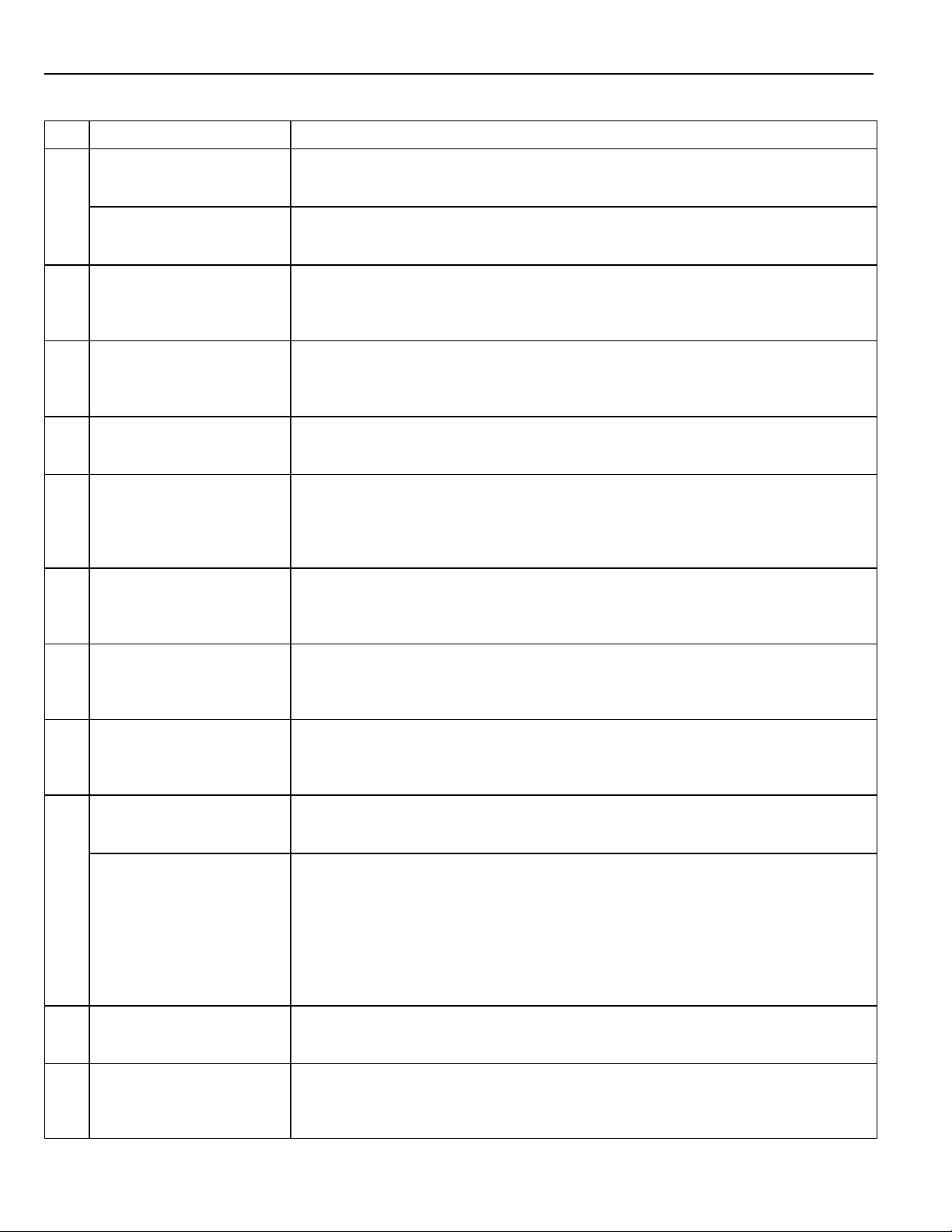

No.

INDEX Index of the contents of this manual.

INTRODUCTION Brief explanation of each section.

B

C

D ABBREVIATIONS Defines the abbreviations used in this manual.

E

HOW TO USE

THIS MANUAL

TROUBLE–

SHOOTING

GLOSSARY OF

TERMS AND

SYMBOLS

Section Description

Instructions on how to use this manual.

Describes the basic inspection procedures for electrical circuits.

Defines the symbols and functions of major parts.

F RELAY LOCATIONS

G

H

I

J GROUND POINTS Shows ground positions of all parts described in this manual.

ELECTRICAL

WIRING ROUTING

POWER SOURCE

(Current Flow Chart)

INDEX Index of the system circuits.

SYSTEM CIRCUITS

Shows position of the Electronic Control Unit, Relays, Relay Block, etc.

This section is closely related to the system circuit.

Describes position of Parts Connectors, Splice points, Ground points, etc.

This section is closely related to the system circuit.

Describes power distribution from the power supply to various electrical

loads.

Electrical circuits of each system are shown from the power supply through

ground points. Wiring connections and their positions are shown and

classified by code according to the connection method. (Refer to the

section, “How to use this manual”).

The “System Outline” and “Service Hints” useful for troubleshooting are

also contained in this section.

K

2

OVERALL

WIRING DIAGRAM

Provides circuit diagrams showing the circuit connections.

HOW TO USE THIS MANUAL

This manual provides information on the electrical circuits installed on vehicles by

dividing them into a circuit for each system.

The actual wiring of each system circuit is shown from the point where the power source

is received from the battery as far as each ground point. (All circuit diagrams are shown

with the switches in the OFF position.)

When troubleshooting any problem, first understand the operation of the circuit where

the problem was detected (see System Circuit section), the power source supplying

power to that circuit (see Power Source section), and the ground points (see Ground

Points section). See the System Outline to understand the circuit operation.

When the circuit operation is understood, begin troubleshooting of the problem circuit

to isolate the cause. Use Relay Location and Electrical Wire Routing sections to find

each part, junction block and wiring harness connectors, wiring harness and wiring

harness connectors, splice points, and ground points of each system circuit. Internal

wiring for each junction block is also provided for better understanding of connection

within a junction block.

Wiring related to each system is indicated in each system circuit by arrows (from

, to ). When o verall connections a re required, see the O verall Wiring Diagram

at the end of this manual.

3

HOW TO USE THIS MANUAL

* The system shown here is an EXAMPLE ONLY. I t i s different to the

actual circuit shown in the SYSTEM CIRCUITS SECTION.

4

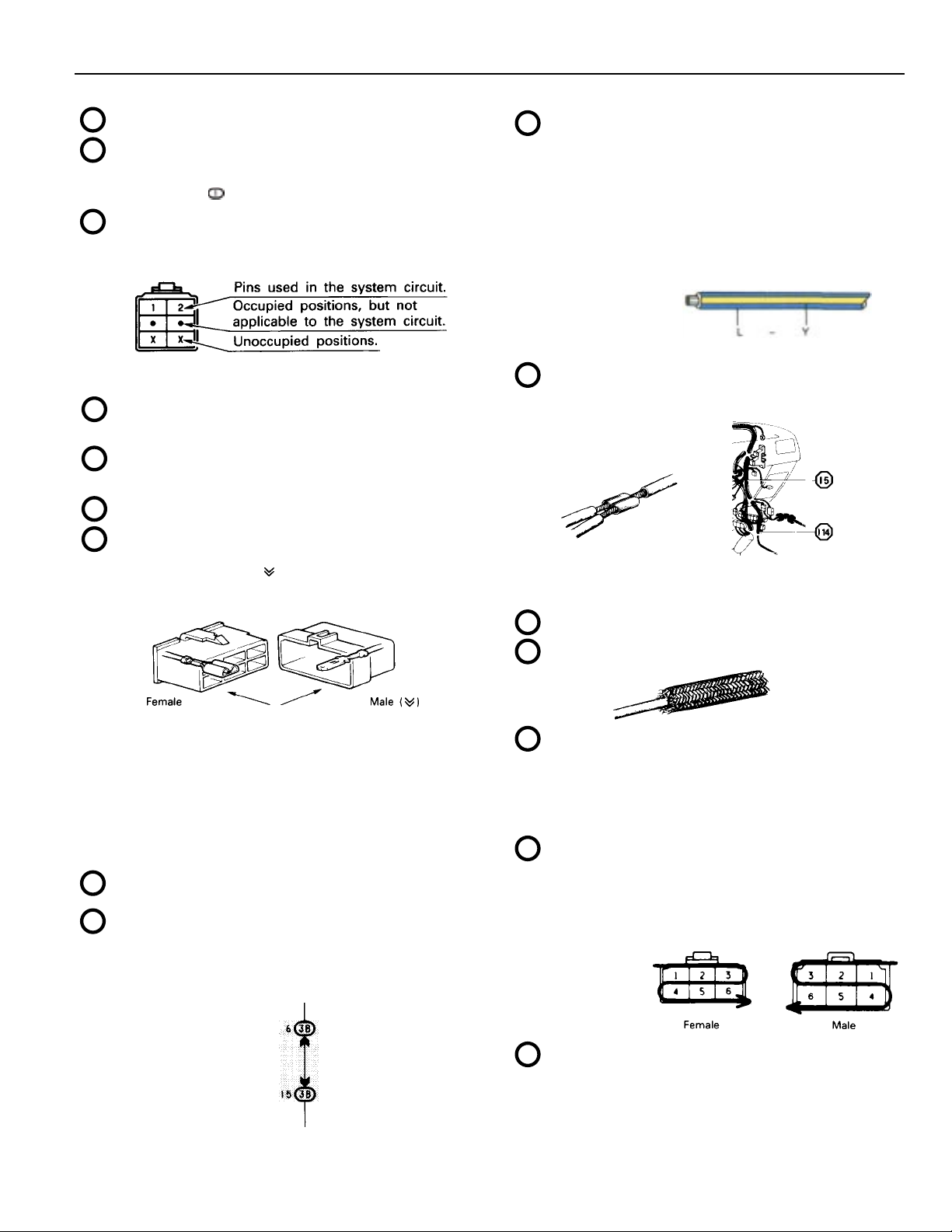

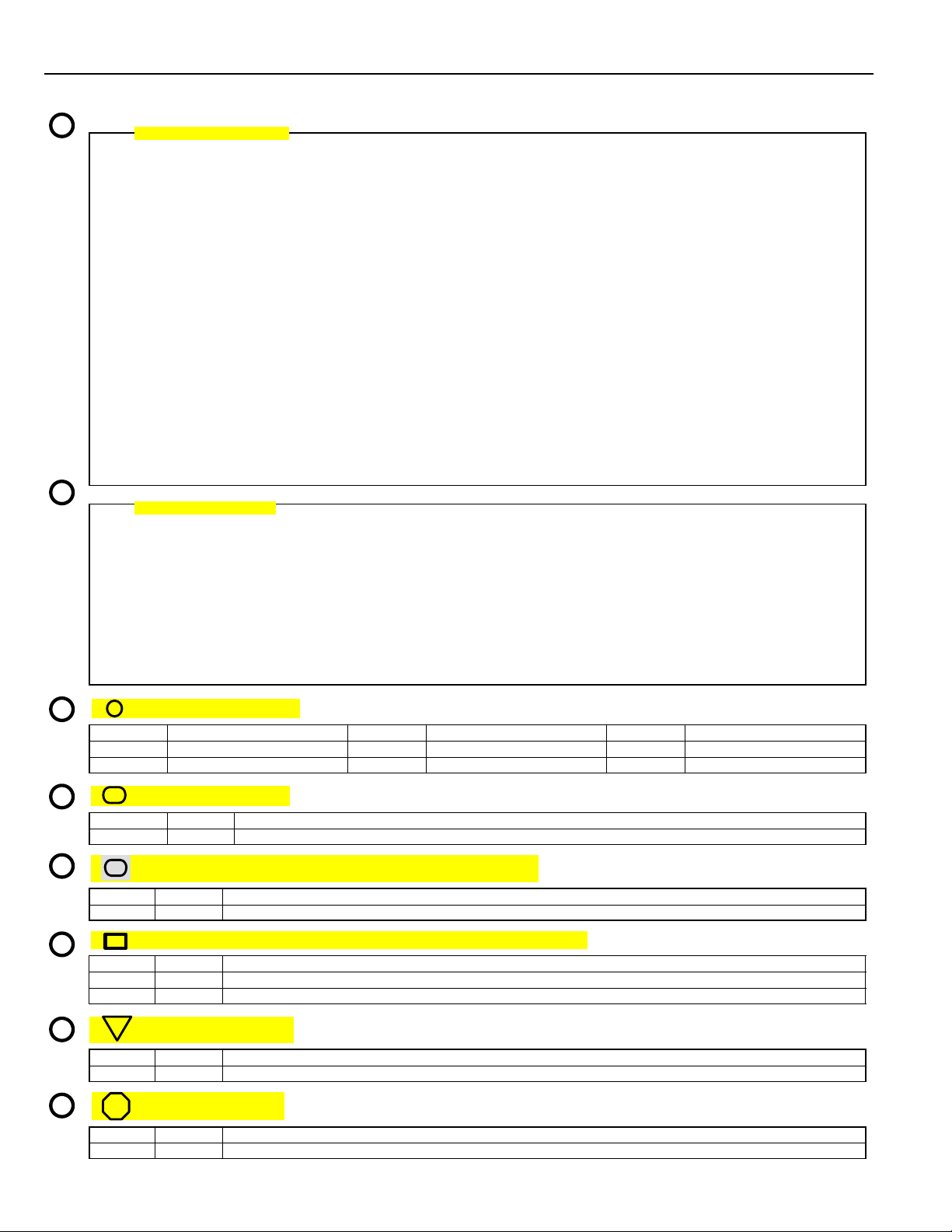

: System Title

A

: Indicates a Relay Block. No shading is used and only

B

C

G

the Relay Block No. is shown to distinguish it from the

J/B.

Example: Indicates Relay Block No. 1.

: Indicates the connector to be connected to a part (the

numeral indicates the pin No.)

Explanation of pin use.

The pins shown are only for the highest grade, or only

include those in the specification.

D

: Connector Color

Connectors not indicated are milky white in color.

E

: ( ) is used to indicate different wiring and connector,

etc. when the vehicle model, engine type, or

specification is different.

F

: Indicates related system.

: Indicates the wiring harness and wiring harness

connector. The wiring harness with male terminal is

shown with arrows ( ).

Outside numerals are pin numbers.

: Indicates the wiring color.

J

Wire colors are indicated by an alphabetical code.

B = Black L = Blue R = Red

BR = Brown LG = Light Green V = Violet

G = Green O = Orange W = White

GR = Gray P = Pink Y = Yellow

The first letter indicates the basic wire color and the

second letter indicates the color of the stripe.

Example: L – Y

(Blue) (Yellow)

: Indicates a wiring Splice Point (Codes are “E” for the

K

L

M

Engine Room, “I” for the Instrument Panel, and “B” for

the Body).

Example:

The Location of Splice Point I 5 is indicated by the

shaded section.

: Page No.

: Indicates a shielded cable.

The first letter of the code for each wiring harness and

wiring harness connector(s) indicates the component’s

location, e. g . , “ E ” f o r t h e Engine Compartment, “I” for the

Instrument Panel and Surrounding area, and “B” for the

Body and Surrounding area.

When more than one code has the first and second

letters in c o m m on, followed by numbers (e.g., IH1, IH2),

this indicates the same type of wiring harness and

wiring harness connector.

: Represents a part (all parts are shown in sky blue). The

H

code is the same as the code used in parts position.

I

: Junction Block (The number in the circle is the J/B No.

and the connector code is shown beside it). Junction

Blocks are shaded to clearly separate them from other

parts (different junction blocks are shaded differently for

further clarification).

Example:

3B indicates

that it is inside

Junction Block

No. 3.

: Indicates a ground point.

N

The first letter of the code for each ground point(s)

indicates the component’s location, e.g., “E” for the

Engine Compartment, “I” for the Instrument Panel and

Surrounding area, and “B” for the Body and

Surrounding area.

: Indicates the pin number of the connector.

O

The numbering system is different for female and male

connectors.

Example: Numbered in order

: When 2 parts both use one connector in common, the

P

parts connector name used in the wire routing section

is shown in square brackets [ ].

from upper left to

lower right

Numbered in order

from upper right to

lower left

5

HOW TO USE THIS MANUAL

Q

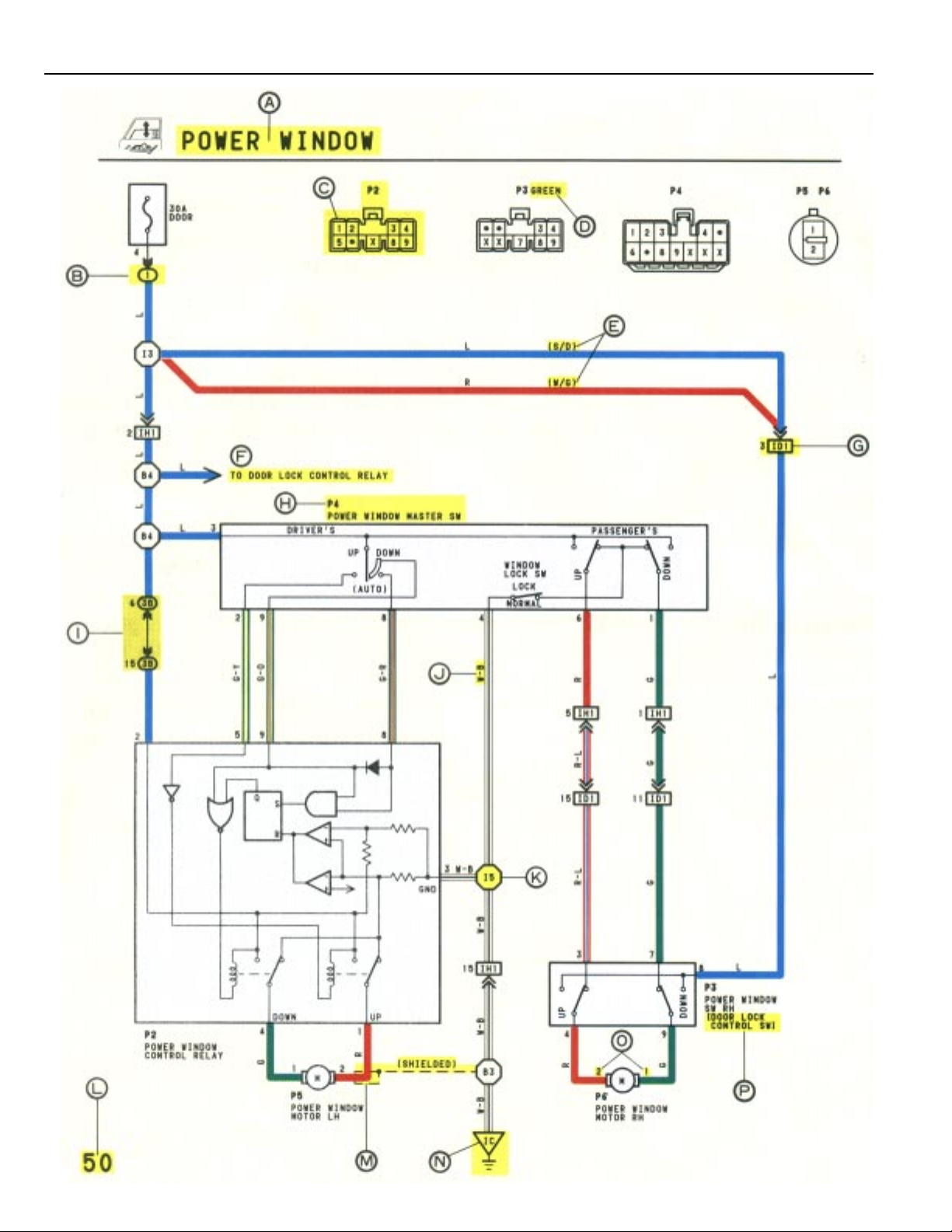

WITH THE IGNITION SW TURNED ON, THE CURRENT FLOWS TO TERMINAL 3 OF THE POWER WINDOW MASTER SW, TERMINAL 2 OF THE POWER WINDOW CONTROL RELAY

AND TERMINAL 8 OF THE POWER WINDOW SW THROUGH THE DOOR FUSE.

1. DRIVER’S WINDOW “MANUAL UP” OPERATION BY MASTER SW

HOLDING MANUAL SW (DRIVER’S) ON “UP” POSITION LOCATED IN POWER WINDOW MASTER SW, THE CURRENT FLOWS TO TERMINAL 5 OF THE POWER WINDOW

CONTROL RELAY THROUGH TERMINAL 3 OF THE MASTER SW TERMINAL 2 TO OPERATE A POWER WINDOW CONTROL RELAY . THUS THE CURRENT INSIDE THE RELAY

FLOWS FROM TERMINAL 2 OF THE RELAY TERMINAL 1 TERMINAL 2 OF THE POWER WINDOW MOTOR TERMINAL 1 TERMINAL 4 OF THE RELAY TERMINAL

3 TO GROUND. THE MOTOR TURNS TO ASCENT THE WINDOW. RELEASING THIS SW, THE ROTATION OF MOTOR IS STOPPED AND THE WINDOWS CAN STOP AT WILL

POINT.

(FOR THE “MANUAL DOWN” OPERATION, CURRENT FLOWS IN THE REVERSE DIRECTION BECAUSE THE TERMINALS WHERE IT FLOWS ARE CHANGED).

2. DRIVER’S WINDOW “AUTO DOWN” OPERATION BY MASTER SW

ONCE THE “AUTO DOWN” BUTTON OF THE MASTER SW IS PUSHED, THE CURRENT FLOWS TERMINAL 9 OF THE POWER WINDOW CONTROL RELA Y THROUGH TERMINAL

3 OF THE MASTER SW TERMINALS 8 AND 9 TO OPERATE THE RELAY. THUS THE CURRENT INSIDE THE POWER WINDOW CONTROL RELAY FLOWS FROM TERMINAL

2 OF THE RELAY TERMINAL 4 TERMINAL 1 OF THE POWER WINDOW MOTOR TERMINAL 2 TERMINAL 1 OF THE RELAY TERMINAL 3 TO GROUND.

THE MOTOR CONTINUES THE ROTATION ENABLING TO DESCENT THE WINDOW.

THE WINDOW DESCENDS TO THE END POSITION. THE CURRENT WILL BE CUT OFF TO RELEASE THE AUTO DOWN FUNCTION BASED ON THE INCREASING CURRENT

BETWEEN TERMINAL 2 OF THE RELAY AND TERMINAL 1 IN RELAY.

3. DRIVER’S WINDOW AUTO DOWN RELEASE OPERATION BY MASTER SW

HOLDING THE MANUAL SW (DRIVER’S) ON “UP” POSITION IN OPERATING AUTO DOWN. THE CURRENT FROM TERMINAL 3 OF THE MASTER SW PASSING TERMINAL 2

FLOWS TERMINAL 5 OF THE RELAY AND RELEASES THE AUTO DOWN FUNCTION IN THE POWER WINDOW CONTROL RELAY. RELEASING THE HAND FROM SW , WINDOW

STOPS AND CONTINUING ON TOUCHING SW, THE FUNCTION SWITCHES TO MANUAL UP OPERATION.

4. PASSENGER’S WINDOW UP OPERATION (MASTER SW) AND WINDOW LOCK SW OPERATION

HOLDING PASSENGER’S WINDOW SW (MASTER SW) ON “UP”, THE CURRENT FLOWS FROM TERMINAL 3 OF THE MASTER SW PASSING TERMINAL 6 TO TERMINAL 3 OF

THE POWER WINDOW SW (PASSENGER’S) TERMINAL 4 TERMINAL 2 OF THE MOTOR TERMINAL 1 TERMINAL 9 OF THE POWER WINDOW SW TERMINAL

7 TERMINAL 1 OF THE MASTER SW TERMINAL 4 TO GROUND. THE MOTOR RUNS TO ASCENT THE WINDOW. RELEASING THIS SW, THE ROTATION OF MOTOR IS

STOPPED AND WINDOW CAN STOP AT WILL PLACE.

SWITCHING THE WINDOW LOCK SW IN “LOCK” POSITION, THE CIRCUIT IS OPENED AND STOPPED THE MOTOR ROTATION.

(FOR THE DOWN OPERATION, CURRENT FLOWS IN THE REVERSE DIRECTION BECAUSE THE TERMINALS WHERE IT FLOWS ARE CHANGED).

SYSTEM OUTLINE

R

P2 POWER WINDOW CONTROL RELAY

3–GROUND: ALWAYS CONTINUITY

2–GROUND: APPROX. 12 VOLTS WITH IGNITION SW AT ON POSITION

5–GROUND: APPROX. 12 VOLTS WITH IGNITION SW AT ON POSITION AND MASTER SW AT UP POSITION

8–GROUND: APPROX. 12 VOLTS WITH IGNITION SW AT ON POSITION AND MASTER SW AT AUTO DOWN POSITION

9–GROUND: APPROX. 12 VOLTS WITH IGNITION SW AT ON POSITION AND MASTER SW AT DOWN OR AUTO DOWN POSITION

P 4 POWER WINDOW MASTER SW

4–GROUND: ALWAYS CONTINUITY

3–GROUND: APPROX. 12 VOLTS WITH IGNITION SW AT ON POSITION

WINDOW LOCK SW

OPEN WITH WINDOW LOCK SW AT LOCK POSITION

SERVICE HINTS

S

T

U

V

W

X

: PARTS LOCATION

CODE SEE PAGE CODE SEE PAGE CODE SEE PAGE

P2 21 P4 21 P6 21

P3 21 P5 21

: RELAY BLOCKS

CODE SEE PAGE RELAY BLOCK (RELAY BLOCK LOCATION)

1 16 R/B NO. 1 (INSTRUMENT PANEL LEFT SIDE)

: JUNCTION BLOCK AND WIRE HARNESS CONNECTOR

CODE SEE PAGE JUNCTION BLOCK AND WIRE HARNESS (CONNECTOR LOCATION)

3B 14 J/B NO. 3 AND COWL WIRE (INSTRUMENT PANEL LEFT SIDE)

: CONNECTOR JOINING WIRE HARNESS AND WIRE HARNESS

CODE SEE PAGE JOINING WIRE HARNESS AND WIRE HARNESS (CONNECTOR LOCATION)

ID1 26 FRONT DOOR RH WIRE AND COWL WIRE (RIGHT KICK PANEL)

IH1 26 FRONT DOOR LH WIRE AND COWL WIRE (LEFT KICK PANEL)

: GROUND POINTS

CODE SEE PAGE GROUND POINT LOCATION

IC 24 COWL LEFT

: SPLICE POINTS

CODE SEE PAGE WIRE HARNESSES WITH SPLICE POINTS

I5 24 COWL WIRE

6

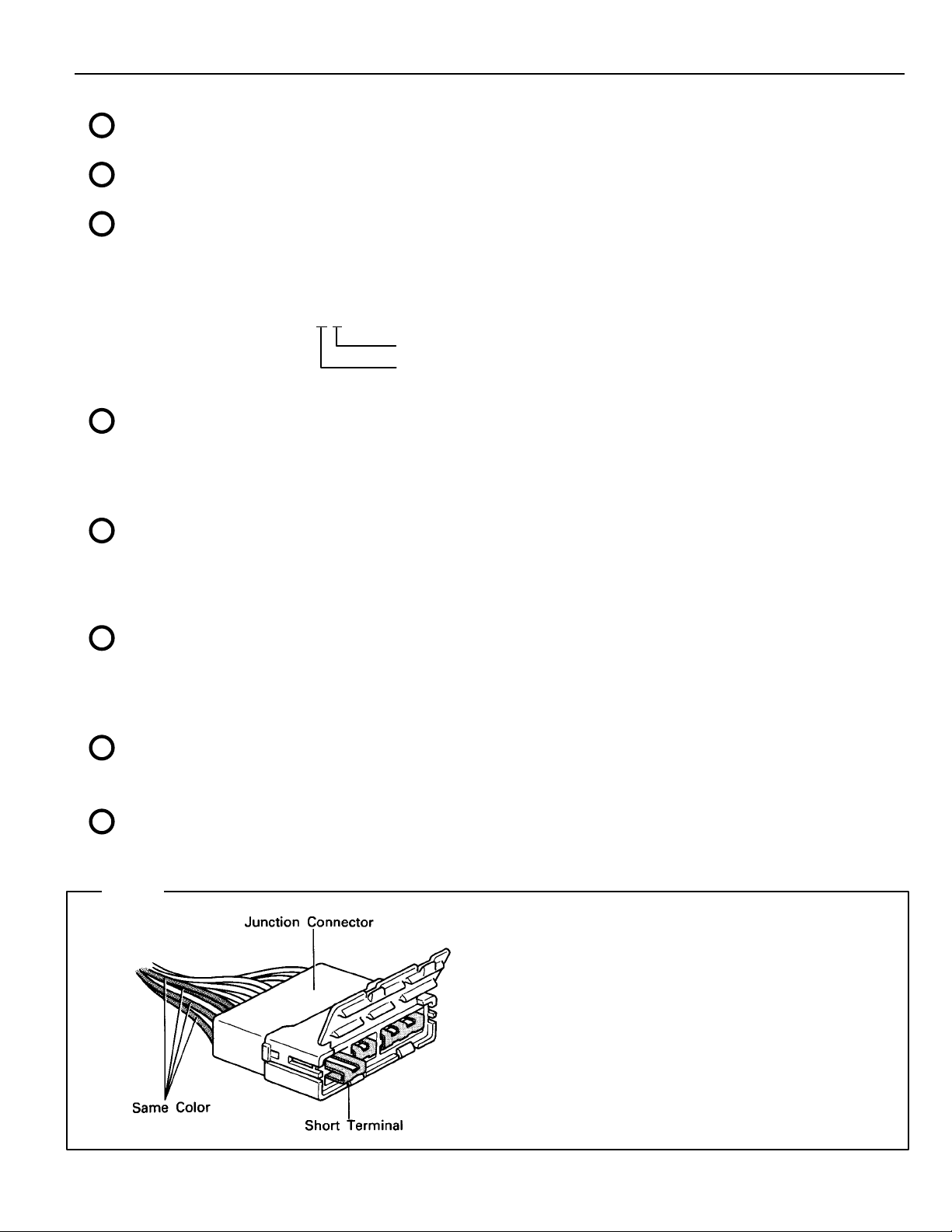

Q

: Explains the system outline.

R

: Indicates values or explains the function for reference during troubleshooting.

: Indicates the reference page showing the position on the vehicle of the parts in the system circuit.

S

Example: Part “P4” (Power Window Master SW) is on page 21 of the manual.

* The letter in the code is from the first letter of the part, and the number indicates its order

in parts starting with that letter.

Example: P

: Indicates the reference page showing the position on the vehicle of Relay Block Connectors in the

T

system circuit.

Example: Connector “1” is described on page 16 of this manual and is installed on the left side of the

instrument panel.

: Indicates the reference page showing the position on the vehicle of J/B and Wire Harness in the system

U

circuit.

Example: Connector “3B” connects the Cowl Wire and J/B No. 3. It is described on page 14 of this

manual, and is installed on the instrument panel left side.

V

: Indicates the reference page describing the wiring harness and wiring harness connector (the female

wiring harness is shown first, followed by the male wiring harness).

Example: Connector “ID1” connects the front door RH wire (female) and cowl wire (male). It is

described on page 26 of this manual, and is installed on the right side kick panel.

: Indicates the reference page showing the position of the ground points on the vehicle.

W

4

Part is 4th in order

Power Window Master SW

Example: Ground point “IC” is described on page 24 of this manual and is installed on the cowl left side.

: Indicates the reference page showing the position of the splice points on the vehicle.

X

Example: Splice point “I 5” is on the Cowl Wire Harness and is described on page 24 of this manual.

HINT:

Junction connector (code: J1, J2, J3, J4, J5,

J6, J7) in this manual include a short terminal

which is connected to a number of wire

harnesses. Always perform inspection with

the short terminal installed. (When installing

the wire harnesses, the harnesses can be

connected to any position within the short

terminal grouping.

Accordingly, in other vehicles, the same wire

harness from a different part.)

Wire harness sharing the same short terminal

grouping have the same color.

7

HOW TO USE THIS MANUAL

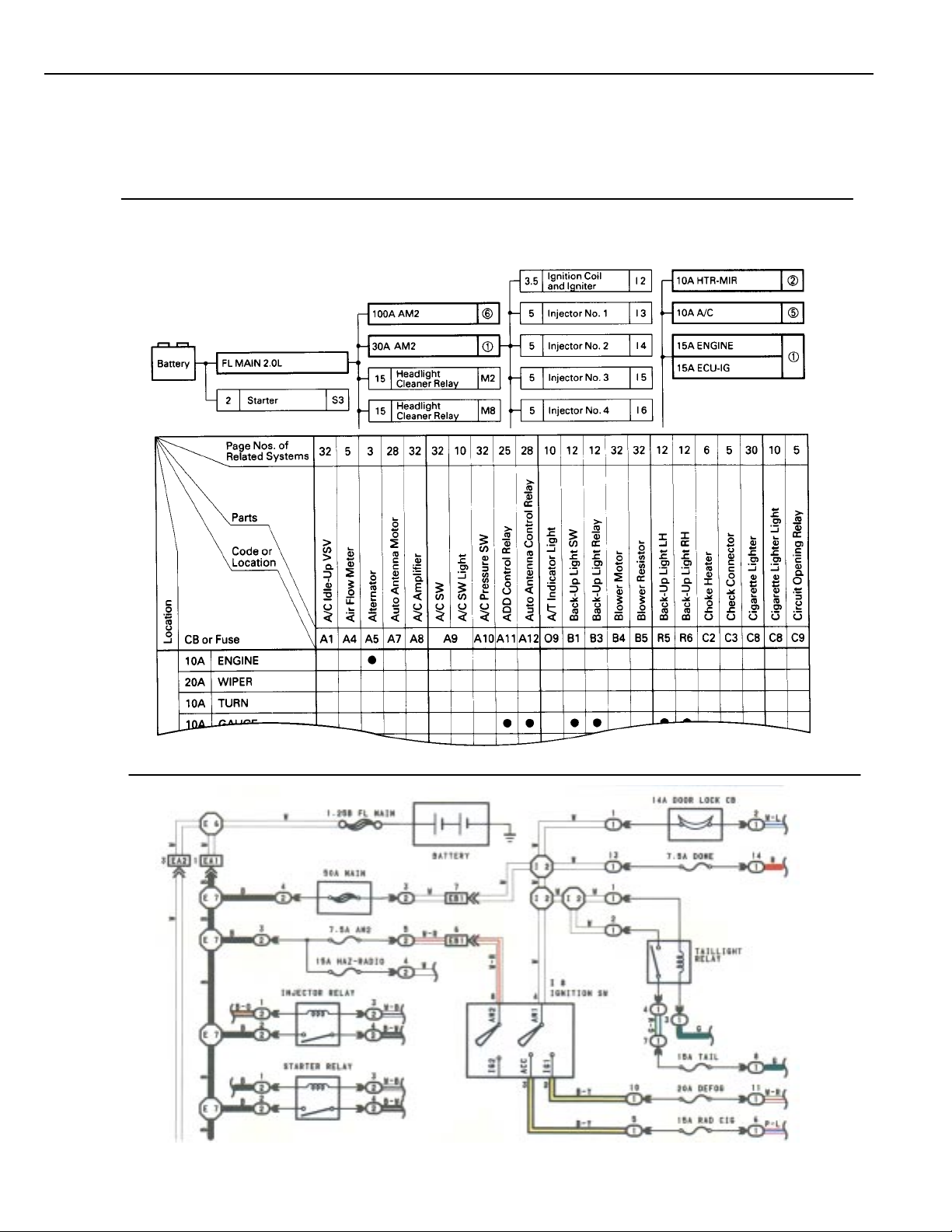

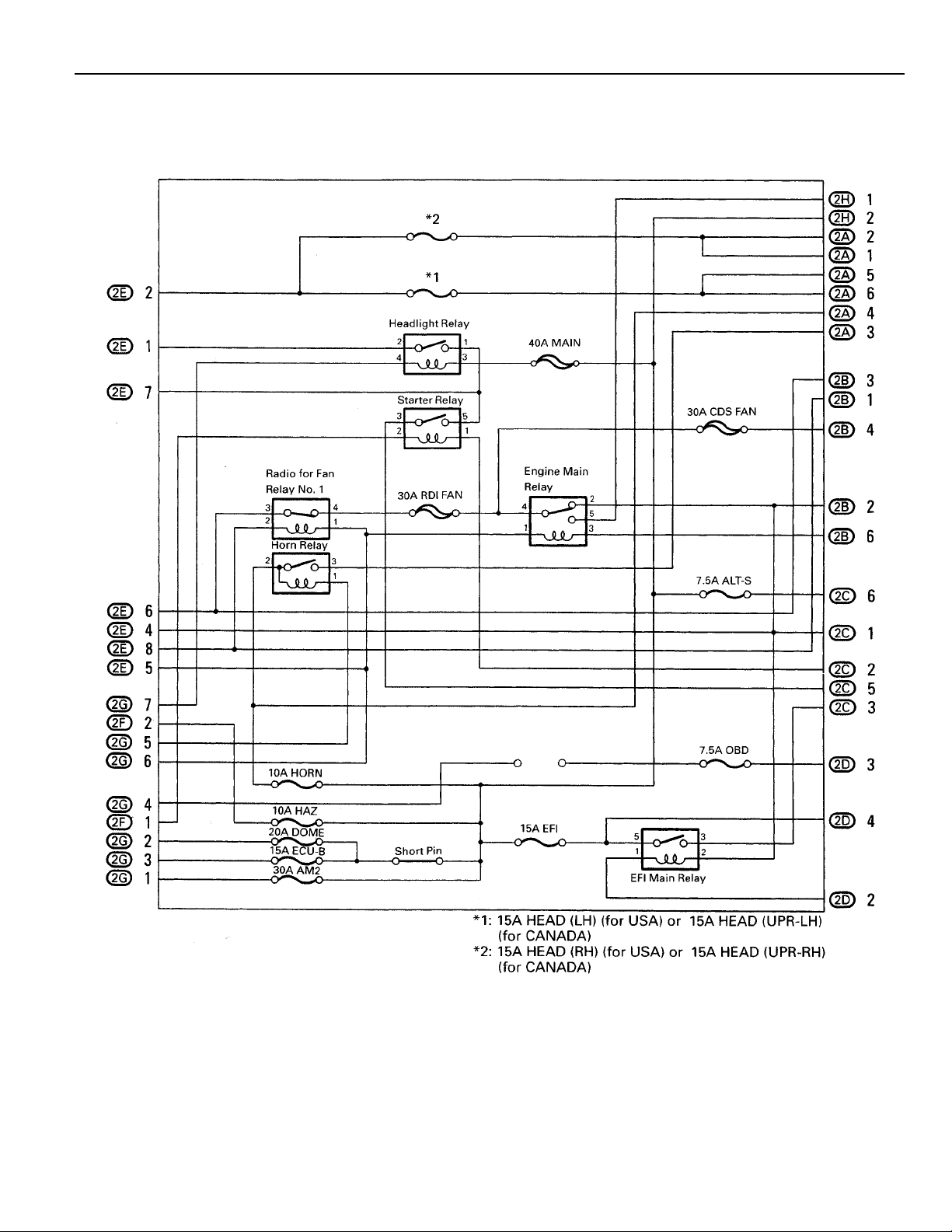

The “Current Flow Chart” section, describes which parts each power source (fuses, fusible links, and circuit breakers)

transmits current to. In the Power Source circuit diagram, the conditions when battery power is supplied to each system are

explained. Since all System Circuit diagrams start from the power source, the power source system must be fully understood.

POWER SOURCE (Current Flow Chart)

The chart below shows the route by which current flows from the battery to each electrical source (Fusible Link, Circuit

Breaker, Fuse, etc.) and other parts.

The next page and following pages show the parts to which each electrical source outputs current.

8

POWER SOURCE

* The system shown here is an EXAMPLE ONLY. It is different to the actual circuit shown in the SYSTEM CIRCUITS SECTION.

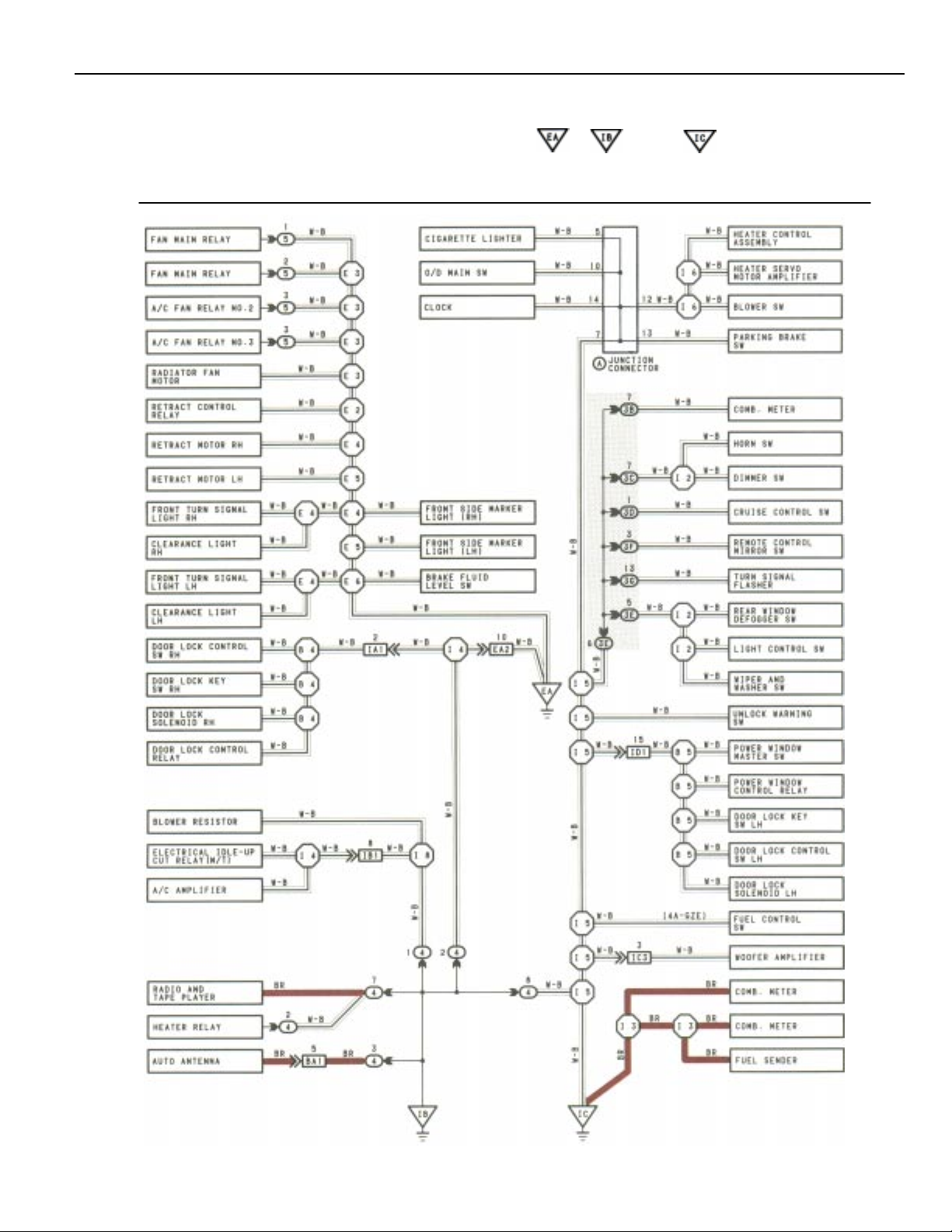

The ground points circuit diagram shows the connections from all major parts to the respective ground points. When

troubleshooting a faulty ground point, checking the system circuits which use a common ground may help you identify the

problem ground quickly. The relationship between ground points ( , , and shown below) can also be

checked this way.

GROUND POINT

* The system shown here is an EXAMPLE ONLY. It is different to the actual circuit shown in the SYSTEM CIRCUITS SECTION.

9

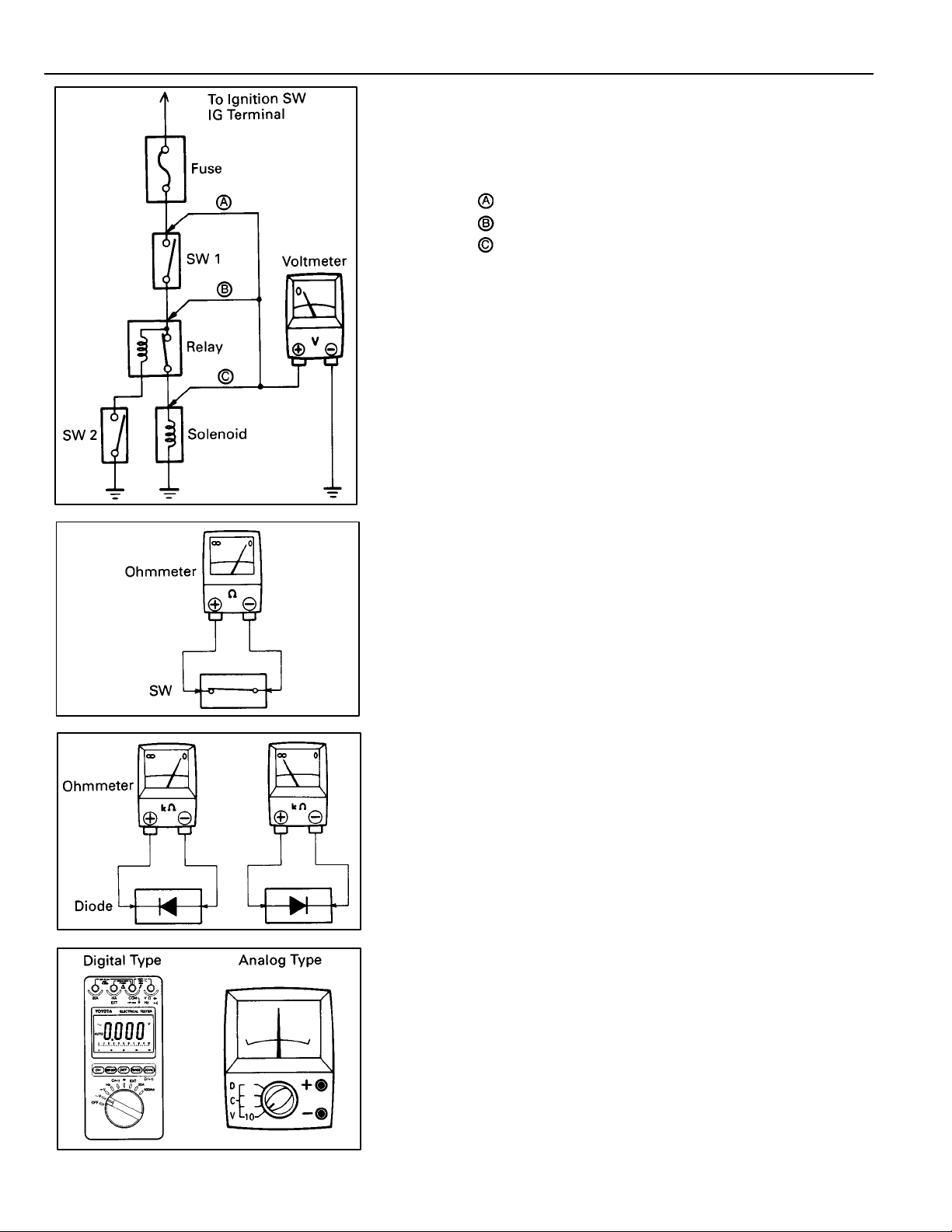

TROUBLESHOOTING

VOLTAGE CHECK

(a) Establish conditions in which voltage is present at the

check point.

Example:

– Ignition SW on

– Ignition SW and SW 1 on

– Ignition SW, SW 1 and Relay on (SW 2 off)

(b) Using a voltmeter, connect the negative lead to a good

ground point or negative battery terminal, and the

positive lead to the connector or component terminal.

This check can be done with a test light instead of a

voltmeter.

CONTINUITY AND RESISTANCE CHECK

(a) Disconnect the battery terminal or wire so there is no

voltage between the check points.

(b) Contact the two leads of an ohmmeter to each of the

check points.

If the circuit has diodes, reverse the two leads and check

again.

When contacting the negative lead to the diode positive side

and the positive lead to the negative side, there should be

continuity.

When contacting the two leads in reverse, there should be no

continuity.

(c) Use a volt/ohmmeter with high impedance (10 kΩ/V

minimum) for troubleshooting of the electrical circuit.

10

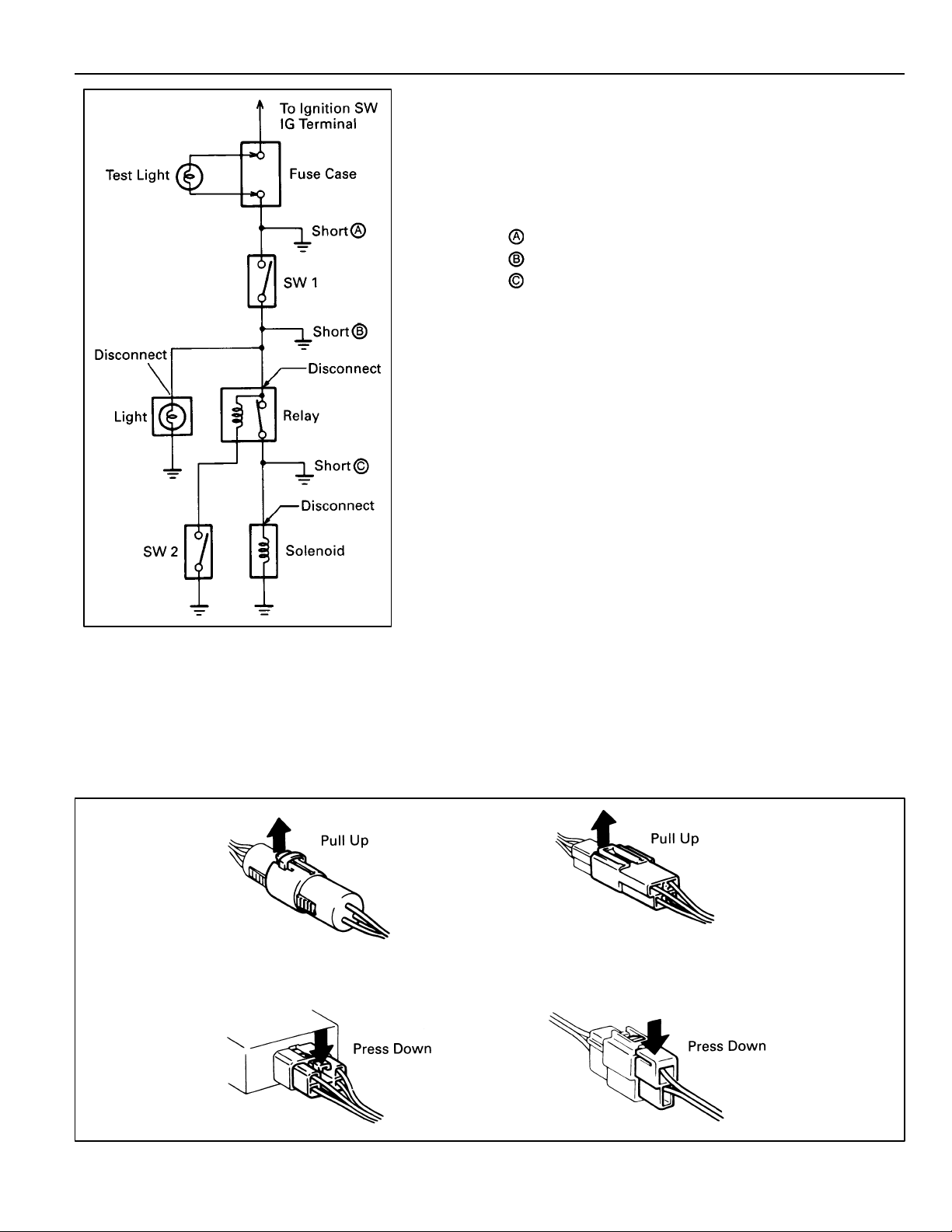

FINDING A SHORT CIRCUIT

(a) Remove the blown fuse and disconnect all loads of the

fuse.

(b) Connect a test light in place of the fuse.

(c) Establish conditions in which the test light comes on.

Example:

– Ignition SW on

– Ignition SW and SW 1 on

– Ignition SW, SW 1 and Relay on (Connect the

Relay) and SW 2 off (or Disconnect SW 2)

(d) Disconnect and reconnect the connectors while

watching the test light.

The short lies between the connector where the test

light stays lit and the connector where the light goes

out.

(e) Find the exact location of the short by lightly shaking

the problem wire along the body.

CAUTION

(a) Do not open the cover or the case of the ECU unless

absolutely necessary . (If the IC terminals are touched,

the IC may be destroyed by static electricity.)

(b) When replacing the internet mechanism (ECU part) of

the digital meter , be careful that no part of your body or

clothing comes in contact with the terminals of leads

from the IC, etc. of the replacement part (spare part).

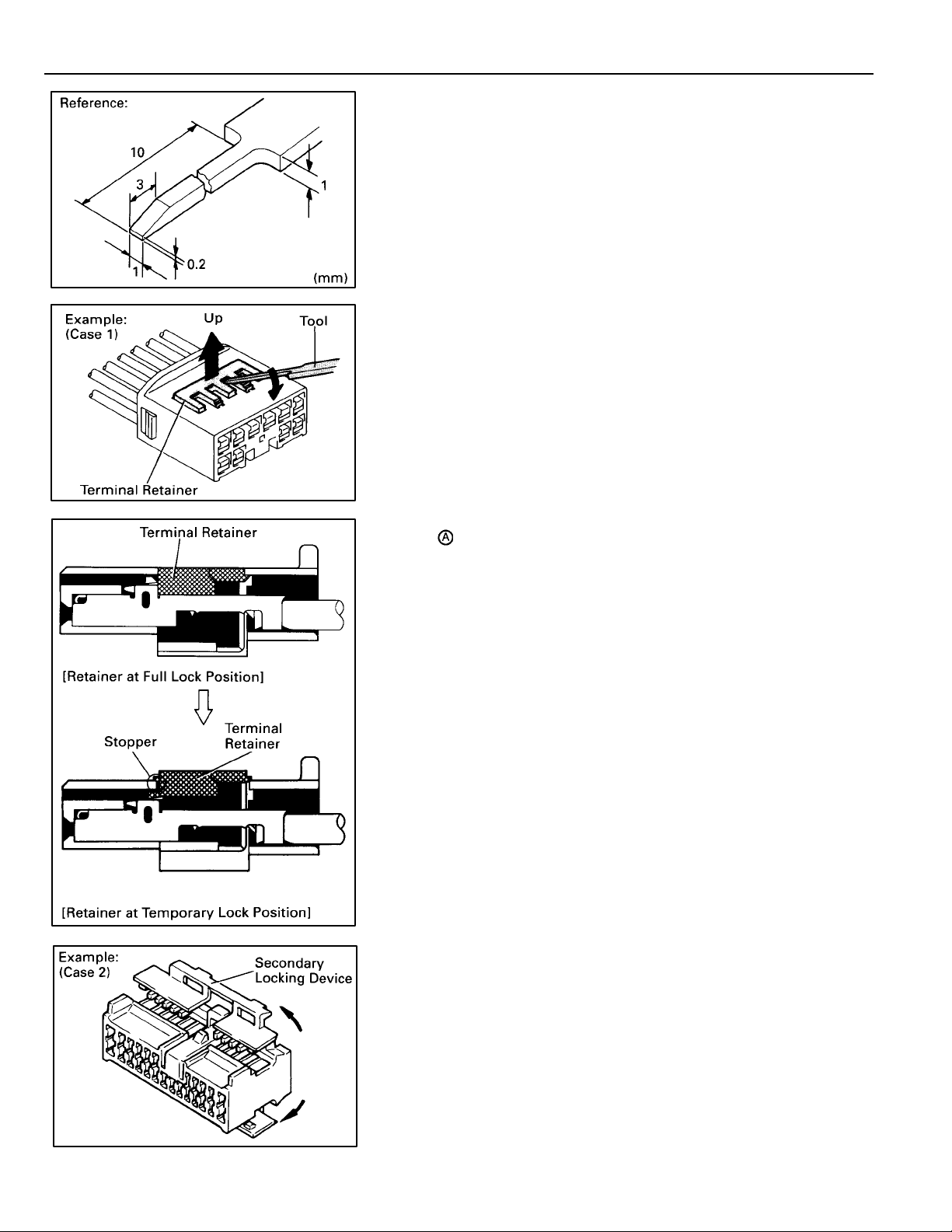

DISCONNECTION OF MALE AND FEMALE

CONNECTORS

To pull apart the connectors, pull on the connector itself, not the

wire harness.

HINT: Check to see what kind of connector you are disconnecting

before pulling apart.

11

TROUBLESHOOTING

HOW TO REPLACE TERMINAL

(with terminal retainer or secondary locking

device)

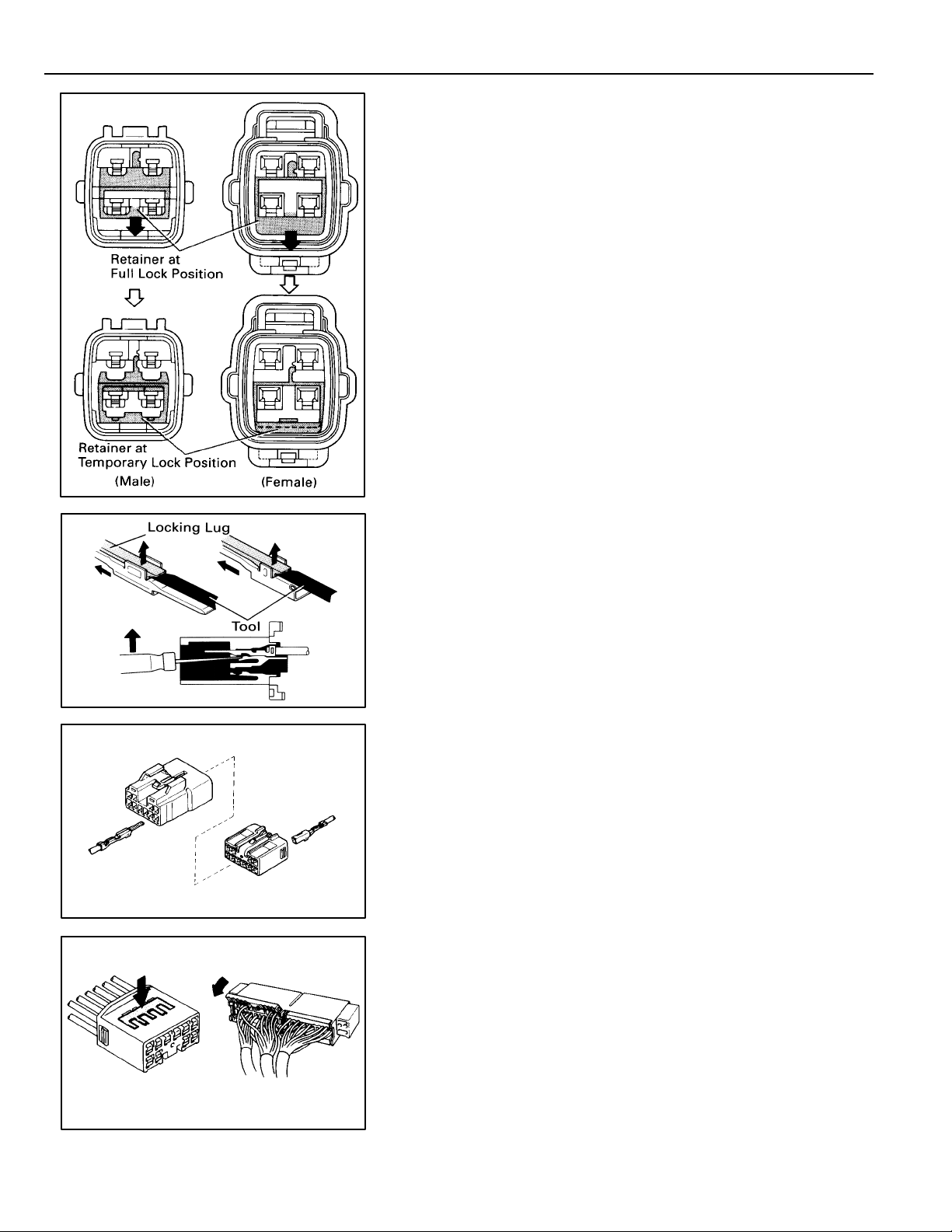

1. PREPARE THE SPECIAL TOOL

HINT: To remove the terminal from the connector, please

construct and use the special tool or like object shown

on the left.

2. DISCONNECT CONNECTOR

3. DISENGAGE THE SECONDARY LOCKING DEVICE OR

TERMINAL RETAINER.

(a) Locking device must be disengaged before the

terminal locking clip can be released and the terminal

removed from the connector.

(b) Use a special tool or the terminal pick to unlock the

secondary locking device or terminal retainer.

NOTICE:

Do not remove the terminal retainer from connector body.

For Non–Waterproof Type Connector

HINT: The needle insertion position varies according

to the connector ’s shape (number of terminals

etc.), so check the position before inserting it.

“Case 1”

Raise the terminal retainer up to the temporary

lock position.

“Case 2”

Open the secondary locking device.

12

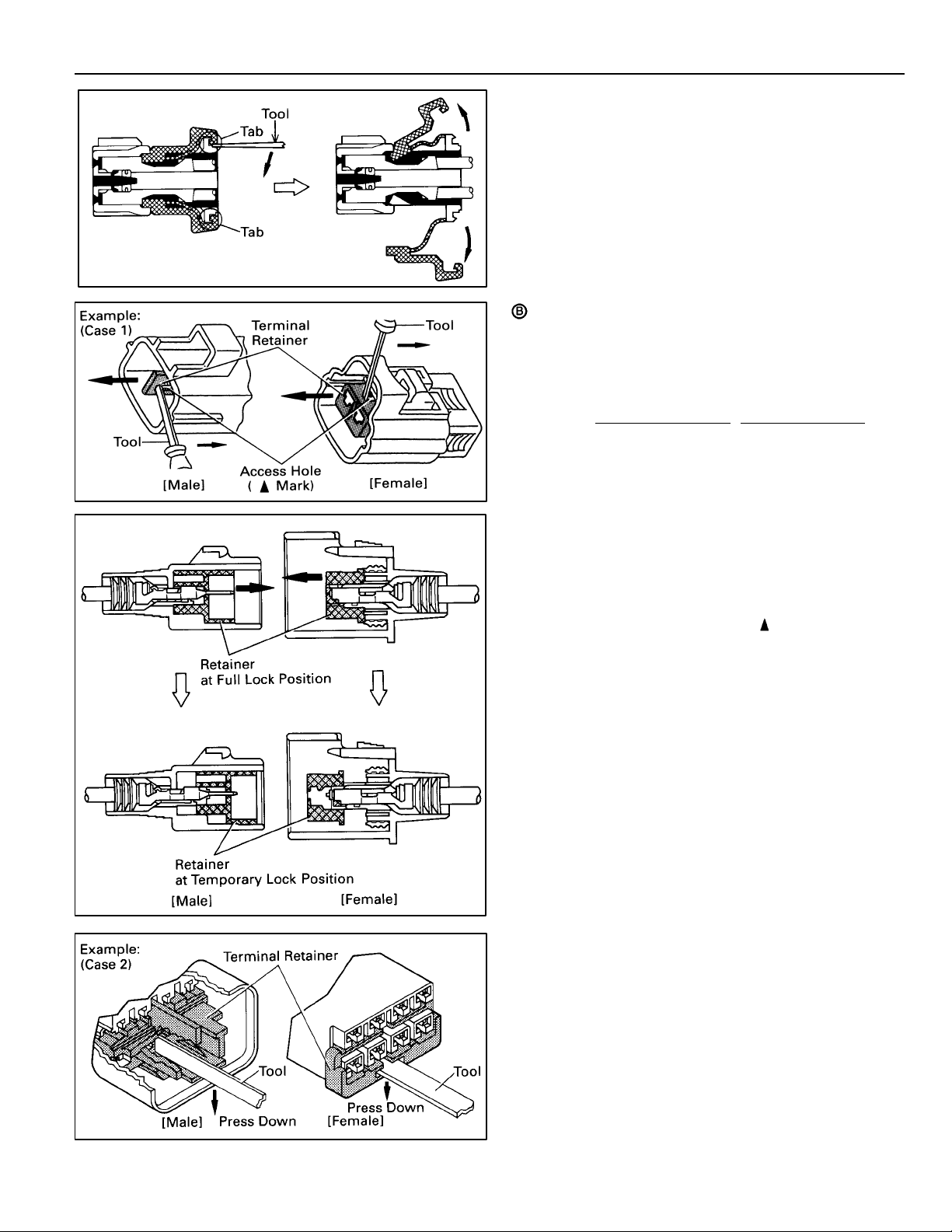

For Waterproof Type Connector

HINT: Terminal retainer color is different

according to connector body.

Example:

Terminal Retainer

Black or White : Gray

Black or White : Dark Gray

Gray or White : Black

“Case 1”

Type where terminal retainer is pulled up

to the temporary lock position (Pull Type).

Insert the special tool into the terminal

retainer access hole ( Mark) and pull the

terminal retainer up to the temporary lock

position.

HINT: The needle insertion position varies

according to the connector’s shape

(Number of terminals, etc.), so check the

position before inserting it.

: Connector Body

“Case 2”

Type which cannot be pulled as far as

Power Lock insert the tool straight into the

access hole of terminal retainer as shown.

13

TROUBLESHOOTING

Push the terminal retainer down to the temporary lock

position.

(c) Release the locking lug from terminal and pull the

terminal out from rear.

4. INSTALL TERMINAL TO CONNECTOR

(a) Insert the terminal.

HINT:

1. Make sure the terminal is positioned correctly.

2. Insert the terminal until the locking lug locks firmly.

3. Insert the terminal with terminal retainer in the

temporary lock position.

(b) Push the secondary locking device or terminal retainer

in to the full lock position.

14

5. CONNECT CONNECTOR

ABBREVIATIONS

The following abbreviations are used in this manual.

ABS = Anti–Lock Brake System

ACIS = Acoustic Control Induction System

A/C = Air Conditioning

A/T = Automatic Transmission

COMB. = Combination

C/P = Coupe

ECU = Electronic Control Unit

EFI = Electronic Fuel Injection

EGR = Exhaust Gas Recirculation

ESA = Electronic Spark Advance

Ex. = Except

FL = Fusible Link

IAC = Idle Air Control

ISC = Idle Speed Control

J/B = Junction Block

LH = Left-Hand

MFI = Multiport Fuel Injection

M/T = Manual Transmission

O/D = Overdrive

R/B = Relay Block

RH = Right–Hand

RPM = Engine Speed

S/D = Sedan

SFI = Sequential Multiport Fuel Injection

SRS = Supplemental Restraint System

SW = Switch

TEMP. = Temperature

VSV = Vacuum Switching Valve

W/G = Wagon

w/ = With

w/o = Without

ABBREVIATIONS

* The titles given inside the components are the names of the terminals (terminal codes) and

are not treated as being abbreviations.

15

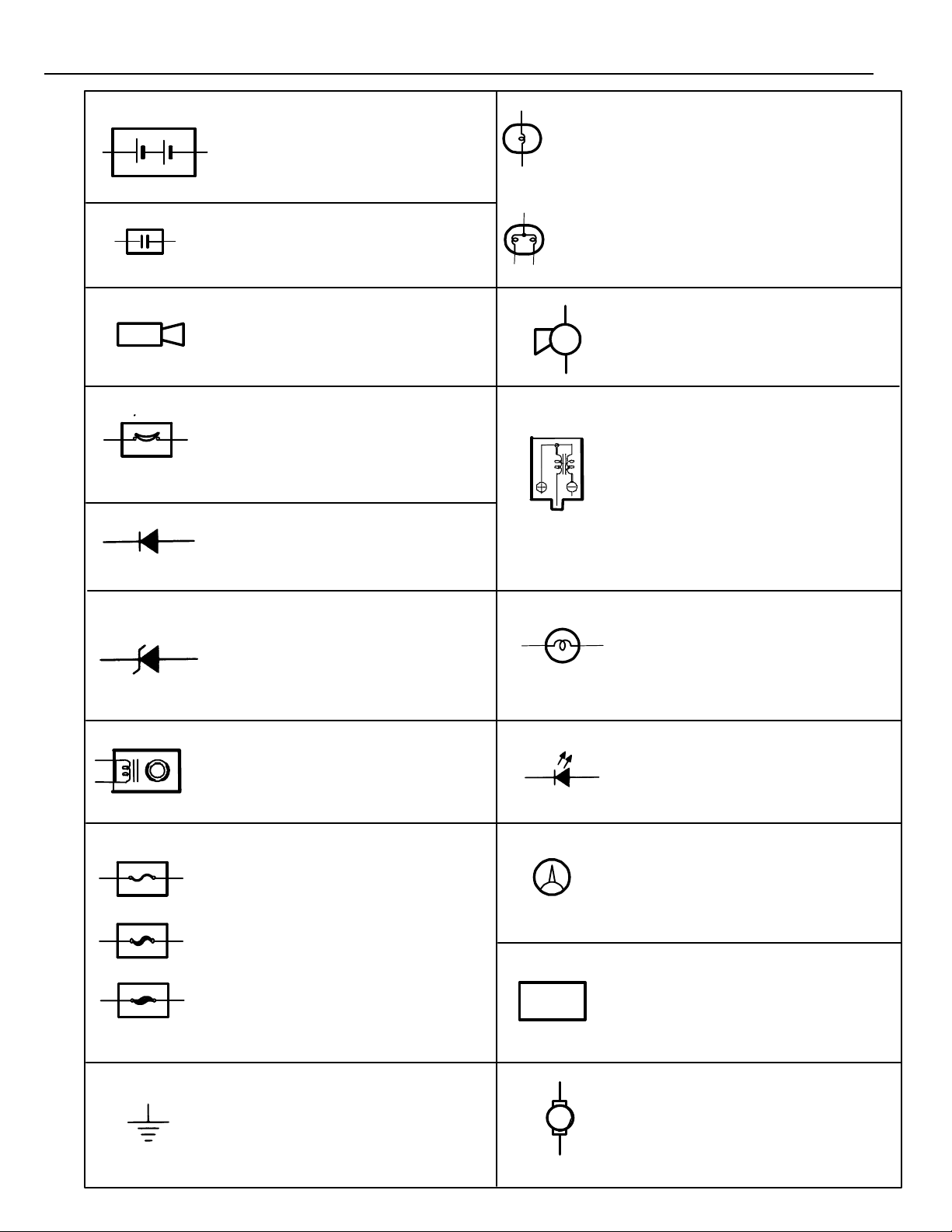

GLOSSARY OF TERMS AND SYMBOLS

BATTERY

Stores chemical energy and

converts it into electrical energy.

Provides DC current for the auto’s

various electrical circuits.

CAPACITOR (Condenser)

A small holding unit for temporary

storage of electrical voltage.

CIGARETTE LIGHTER

An electric resistance heating

element.

CIRCUIT BREAKER

Basically a reusable fuse, a circuit

breaker will heat and open if too

much current flows through it. Some

units automatically reset when cool,

others must be manually reset.

DIODE

A semiconductor which allows

current flow in only one direction.

HEADLIGHTS

1. SINGLE

FILAMENT

2. DOUBLE

FILAMENT

Current flow causes a headlight

filament to heat up and emit light.

A headlight may have either a

single (1) filament or a double (2)

filament.

HORN

An electric device which sounds a

loud audible signal.

IGNITION COIL

Converts low–voltage DC current

into high–voltage ignition current

for firing the spark plugs.

(for Medium Current Fuse)

(for High Current Fuse or

Fusible Link.)

16

DIODE, ZENER

A diode which allows current flow

in one direction but blocks reverse

flow only up to a specific voltage.

Above that potential, it passes the

excess voltage. This acts as a

simple voltage regulator.

DISTRIBUTOR, IIA

Channels high–voltage current

from the ignition coil to the

individual spark plugs.

FUSE

A thin metal strip which burns

through when too much current

flows through it, thereby stopping

current flow and protecting a

circuit from damage.

FUSIBLE LINK

A heavy–gauge wire placed in

high amperage circuits which

burns through on overloads,

thereby protecting the circuit.

The numbers indicate the cross–

section surface area of the wires.

GROUND

The point at which wiring attaches

to the Body, thereby providing a

return path for an electrical circuit;

without a ground, current cannot

flow.

FUEL

M

LIGHT

Current flow through a filament

causes the filament to heat up

and emit light.

LED (LIGHT EMITTING DIODE)

Upon current flow, these diodes

emit light without producing the

heat of a comparable light.

METER, ANALOG

Current flow activates a magnetic

coil which causes a needle to

move, thereby providing a relative

display against a background

calibration.

METER, DIGITAL

Current flow activates one or

many LED’s, LCD’s, or fluorescent

displays, which provide a relative

or digital display.

MOTOR

A power unit which converts

electrical energy into mechanical

energy, especially rotary motion.

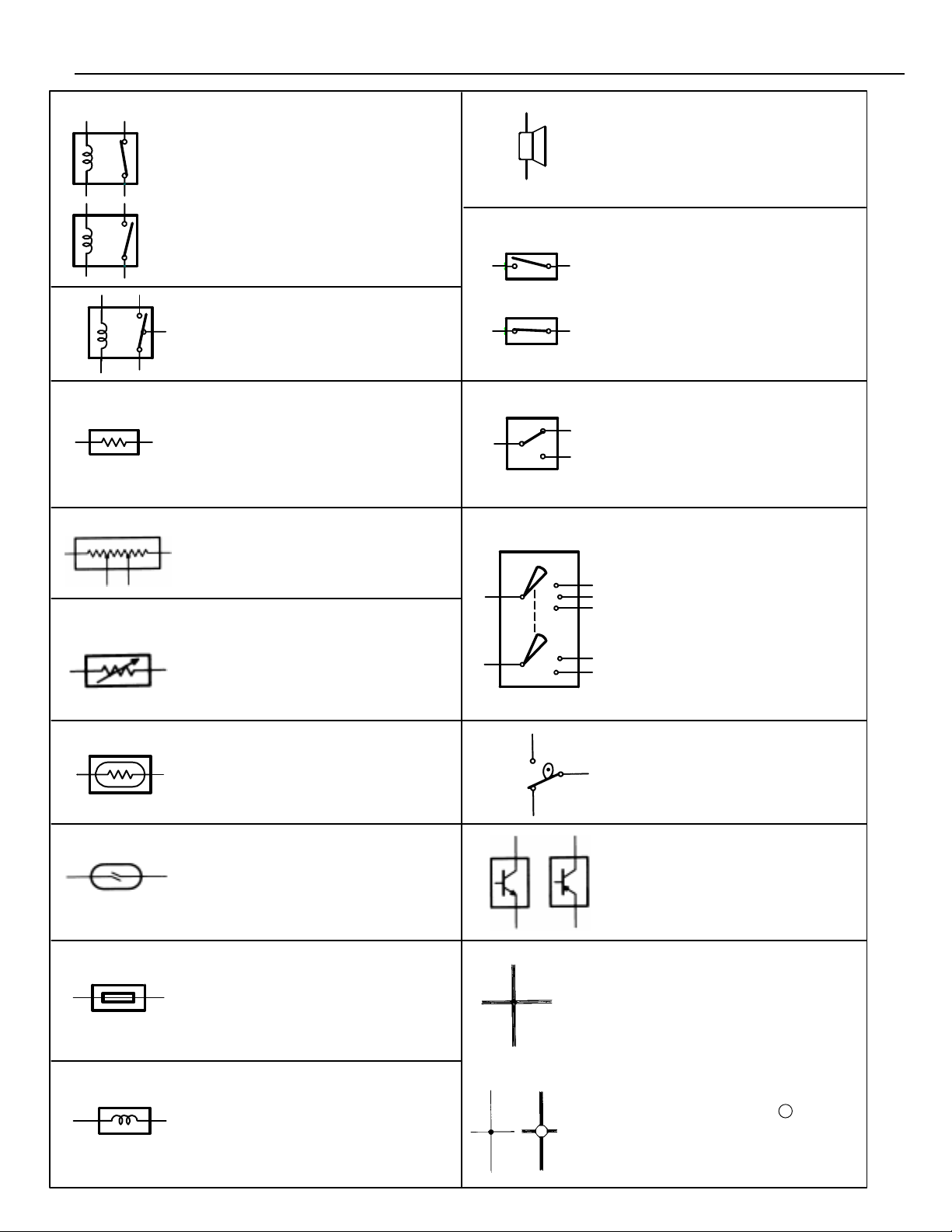

RELAY

1. NORMALLY

CLOSED

2. NORMALLY

OPEN

RELAY, DOUBLE THROW

A relay which passes current

through one set of contacts or the

other.

Basically, an electrically

operated switch which may

be normally closed (1) or

open (2).

Current flow through a

small coil creates a

magnetic field which either

opens or closes an

attached switch.

SPEAKER

An electromechanical device

which creates sound waves from

current flow.

SWITCH, MANUAL

1. NORMALLY

OPEN

2. NORMALLY

CLOSED

Opens and

closes circuits,

thereby

stopping (1) or

allowing (2)

current flow.

RESISTOR

An electrical component with a

fixed resistance, placed in a circuit

to reduce voltage to a specific

value.

RESISTOR, TAPPED

A resistor which supplies two or

more different non adjustable

resistance values.

RESISTOR, VARIABLE or

RHEOSTAT

A controllable resistor with a

variable rate of resistance.

Also called a potentiometer or

rheostat.

SENSOR (Thermistor)

A resistor which varies its

resistance with temperature.

SENSOR, ANALOG SPEED

Uses magnetic impulses to open

and close a switch to create a

signal for activation of other

components.

SWITCH, DOUBLE THROW

A switch which continuously

passes current through one set

of contacts or the other.

SWITCH,

IGNITION

A key operated switch with

several positions which allows

various circuits, particularly the

primary ignition circuit, to

become operational.

SWITCH, WIPER PARK

Automatically returns wipers to

the stop position when the wiper

switch is turned off.

TRANSISTOR

A solidstate device typically used

as an electronic relay; stops or

passes current depending on the

voltage applied at “base.”

SHORT PIN

Used to provide an unbroken

connection within a junction block.

SOLENOID

An electromagnetic coil which

forms a magnetic field when

current flows, to move a plunger,

etc.

WIRES

(1) NOT

CONNECTED

(2) SPLICED

Wires are always

drawn as straight lines

on wiring diagrams.

Crossed wires (1)

without a black dot at

the junction are not

joined; crossed wires

(2) with a black dot or

octagonal ( ) mark at

the junction are spliced

(joined) connections.

17

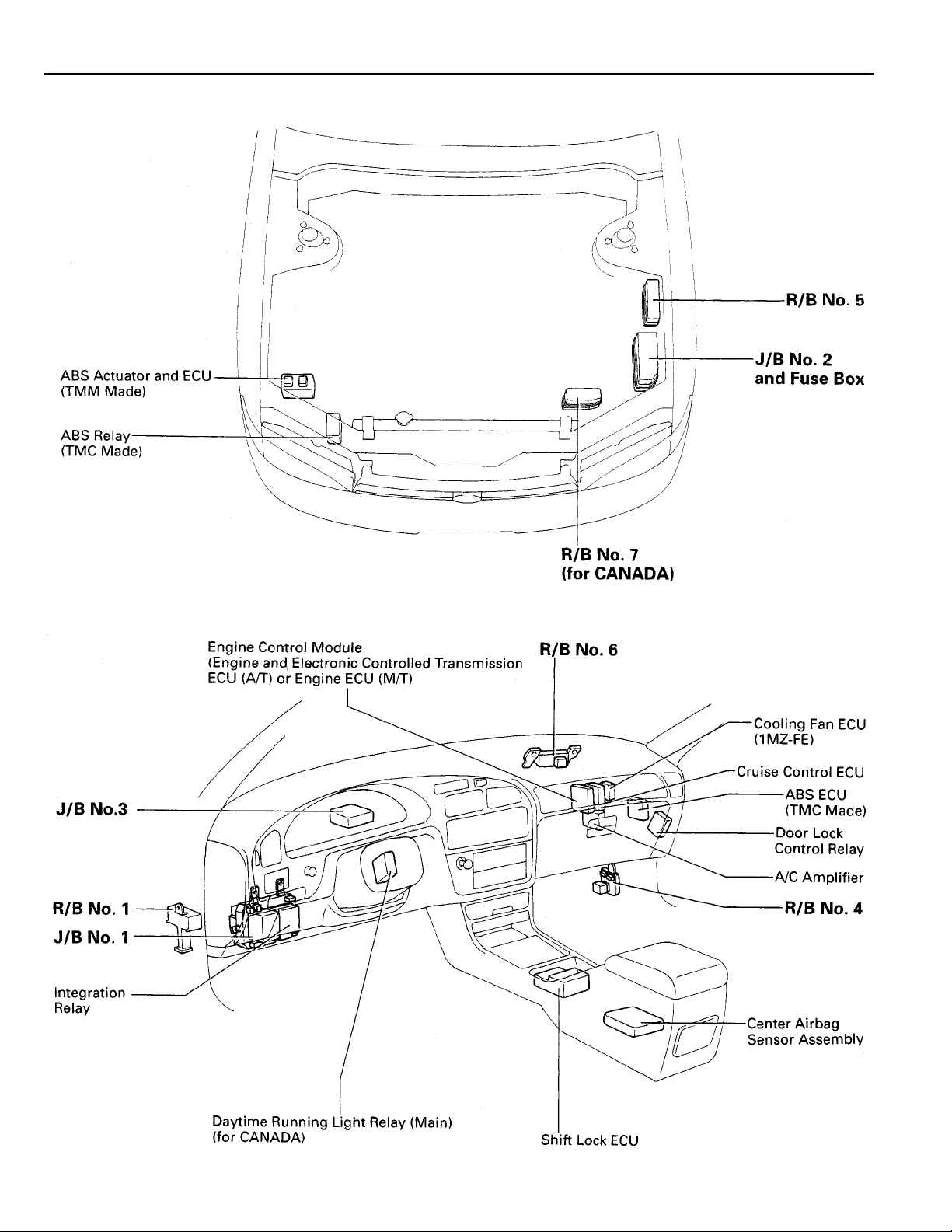

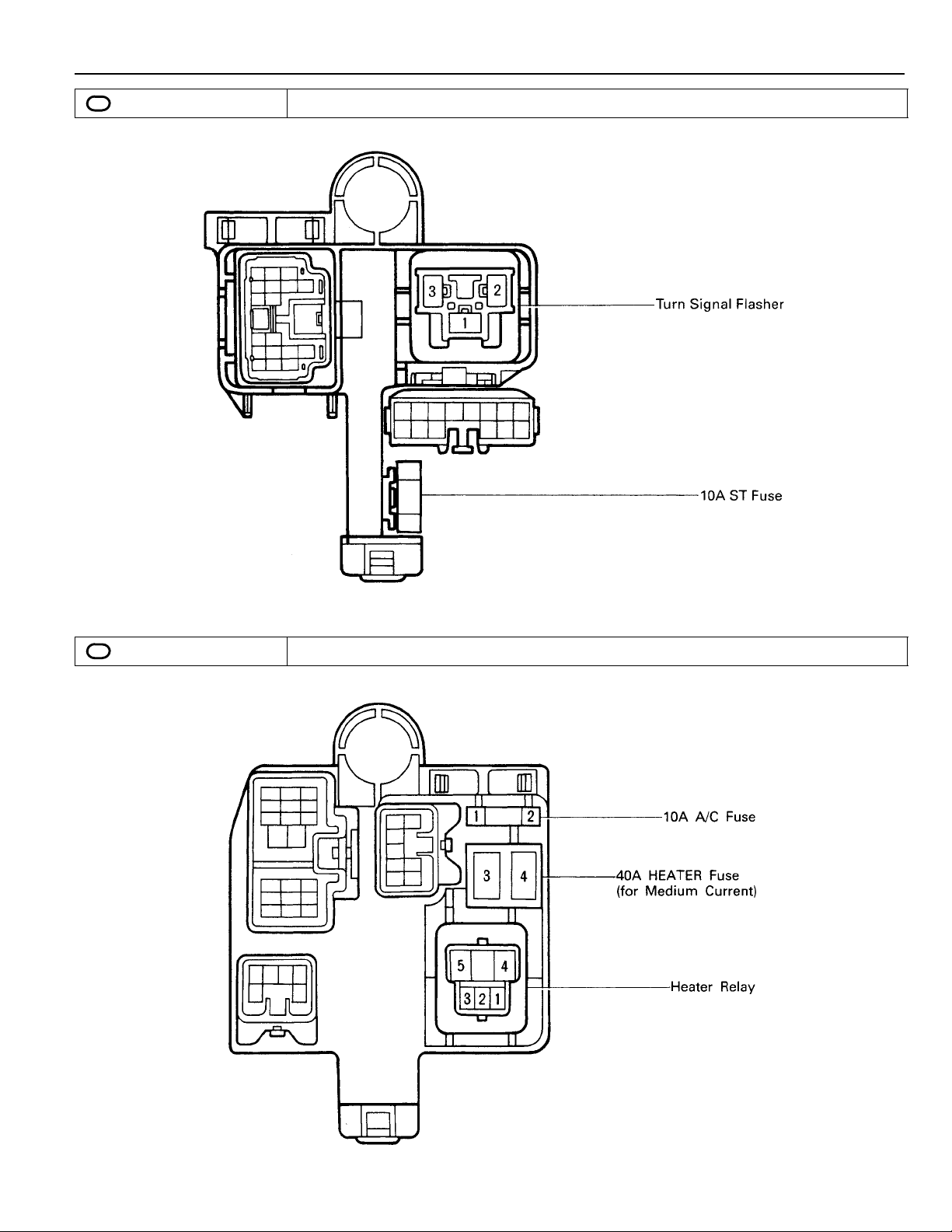

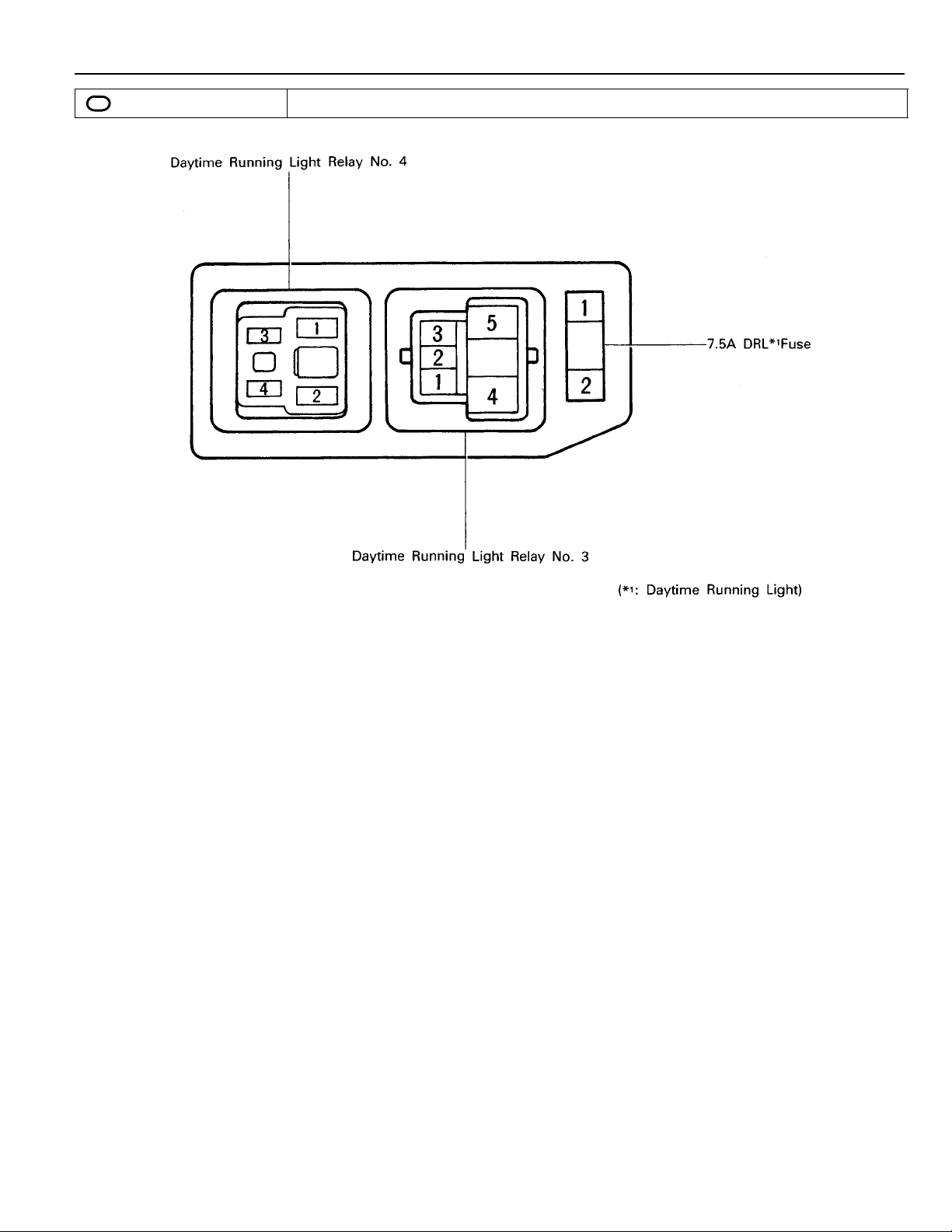

RELAY LOCATIONS

[Engine Compartment]

[Instrument Panel]

18

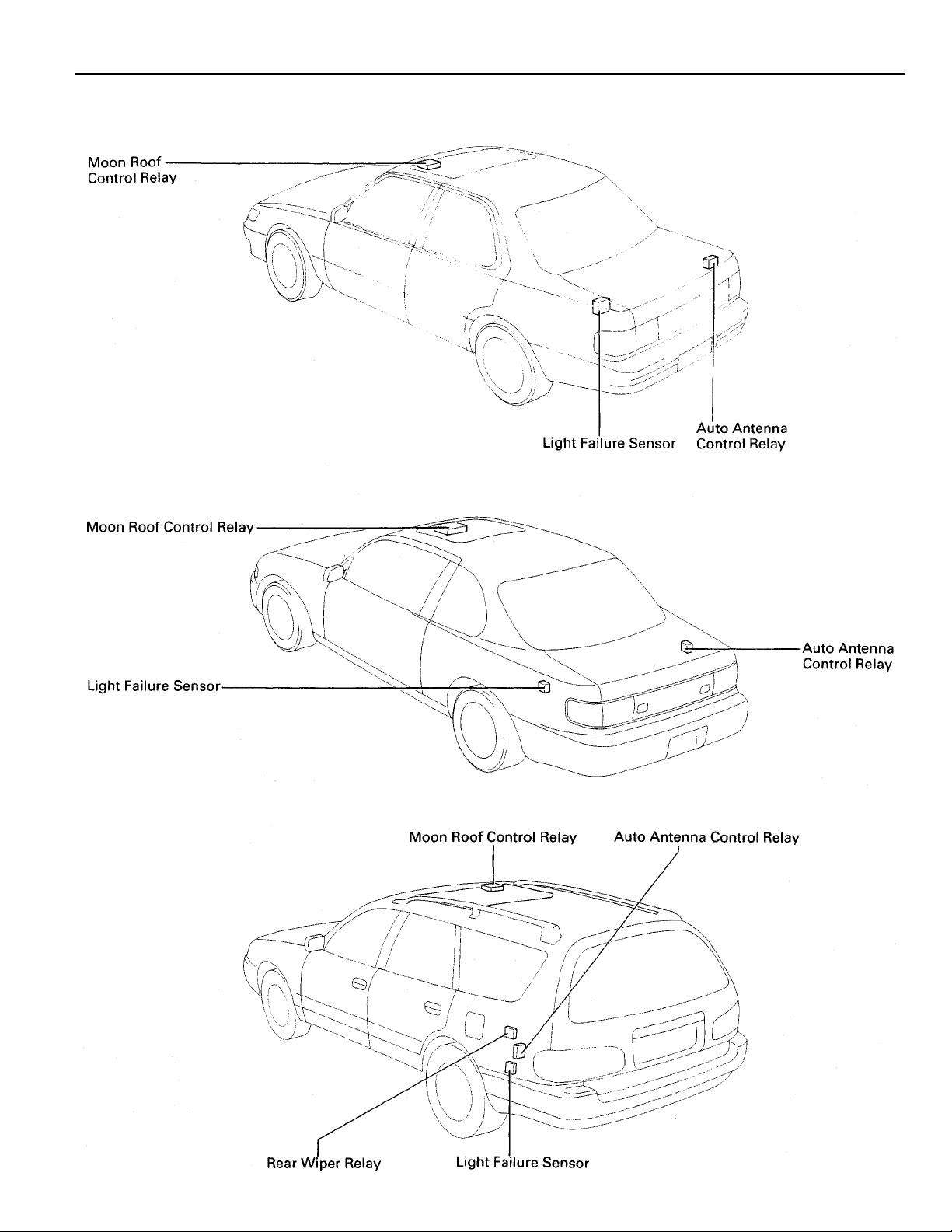

[Body]

[Sedan]

[Coupe]

[Wagon]

19

RELAY LOCATIONS

,

,,,

,,

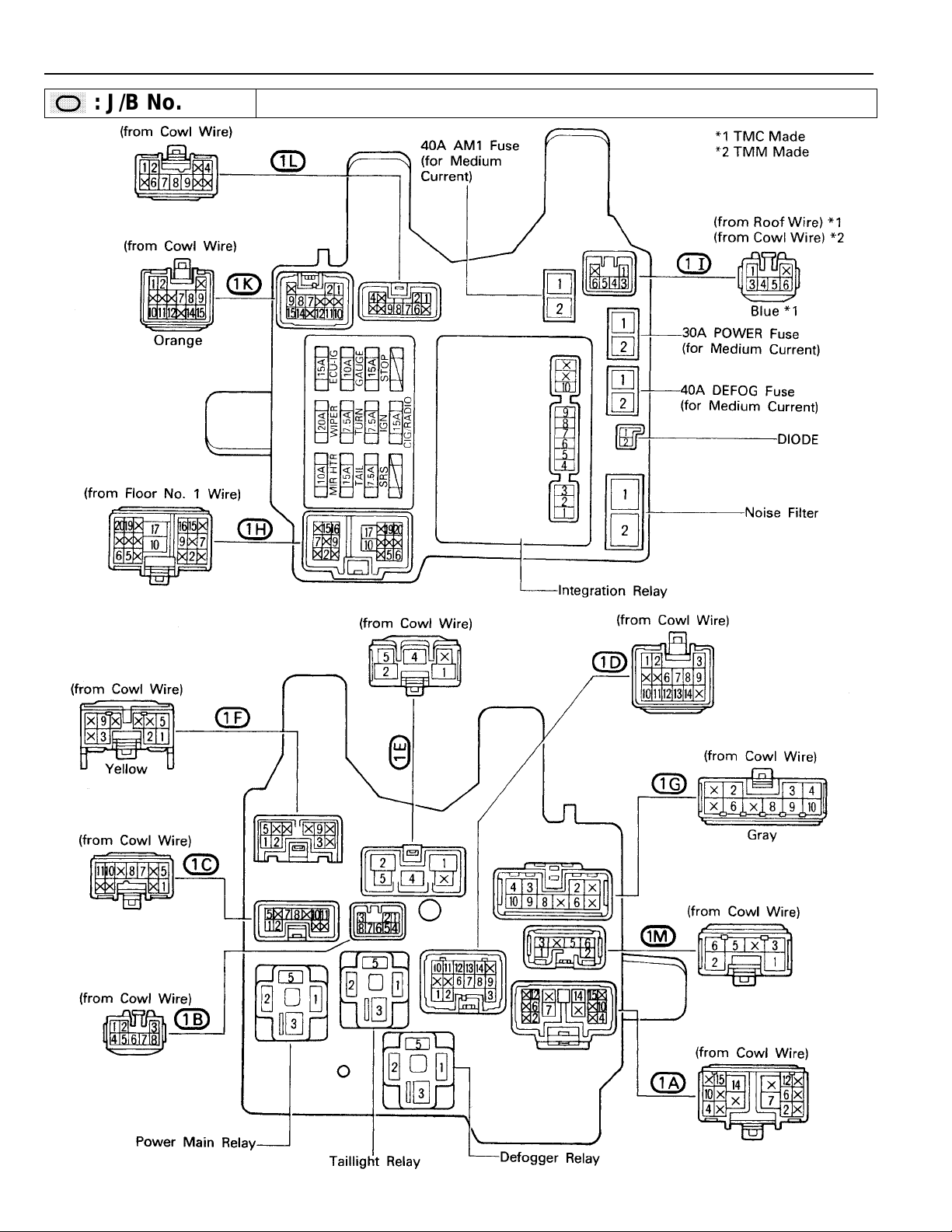

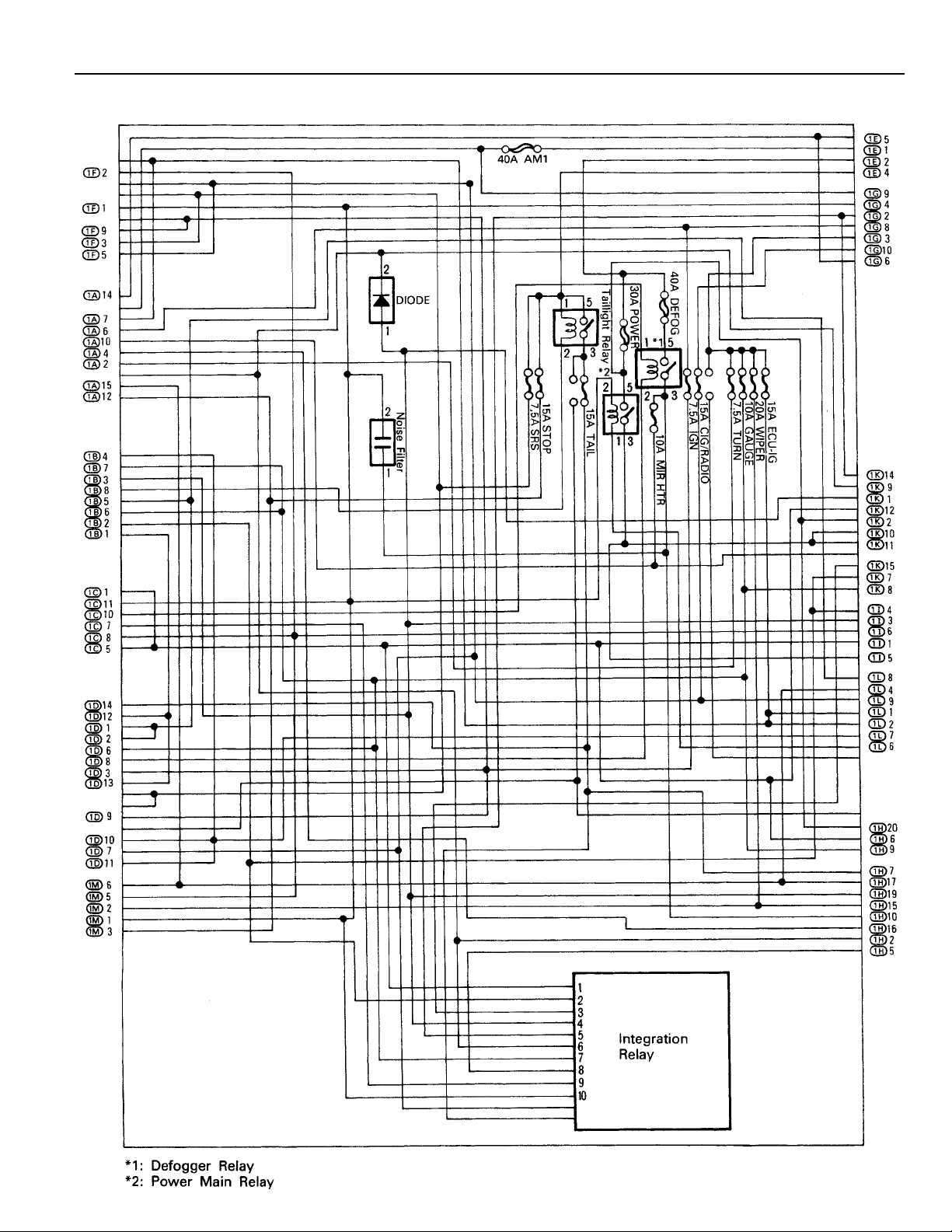

: J/B No. 1 Instrument Panel Left

(See Page 18)

20

[J/B No. 1 Inner Circuit]

21

RELAY LOCATIONS

,

,,,

,,

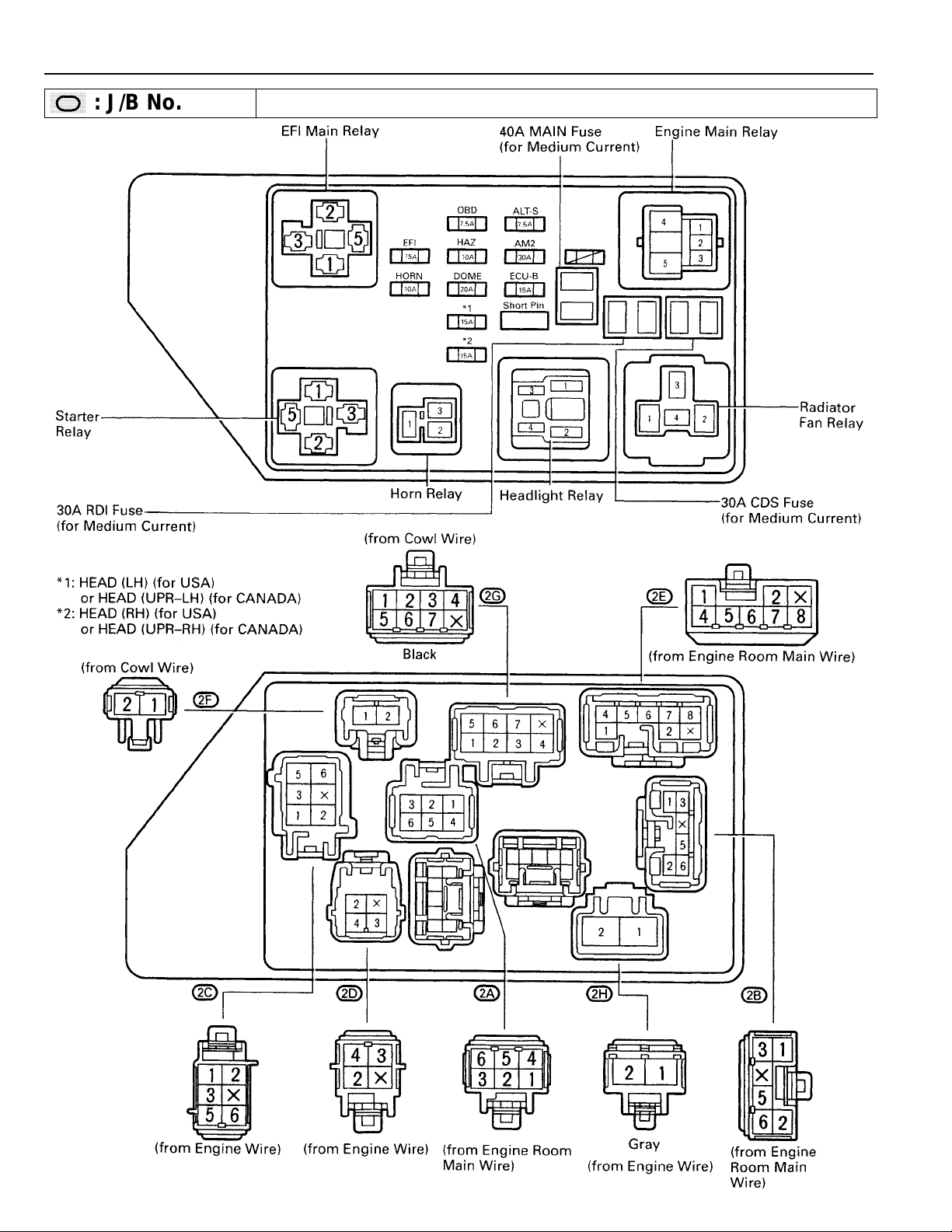

: J/B No. 2 Engine Compartment Left

(See Page 18)

22

[J/B No. 2 Inner Circuit]

23

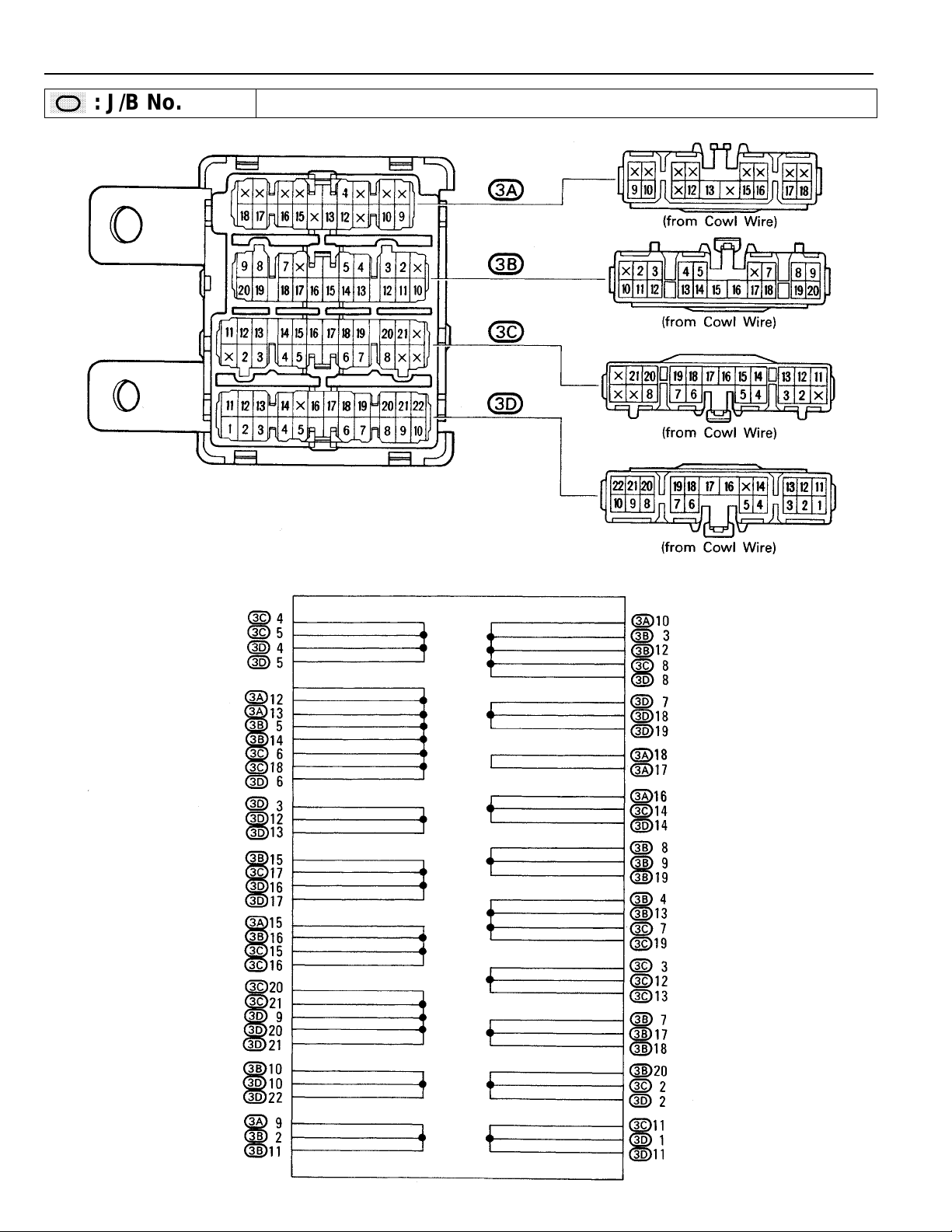

RELAY LOCATIONS

,

,,,

,,

: J/B No. 3 Behind Combination Meter

(See Page 18)

[J/B No. 3 Inner Circuit]

24

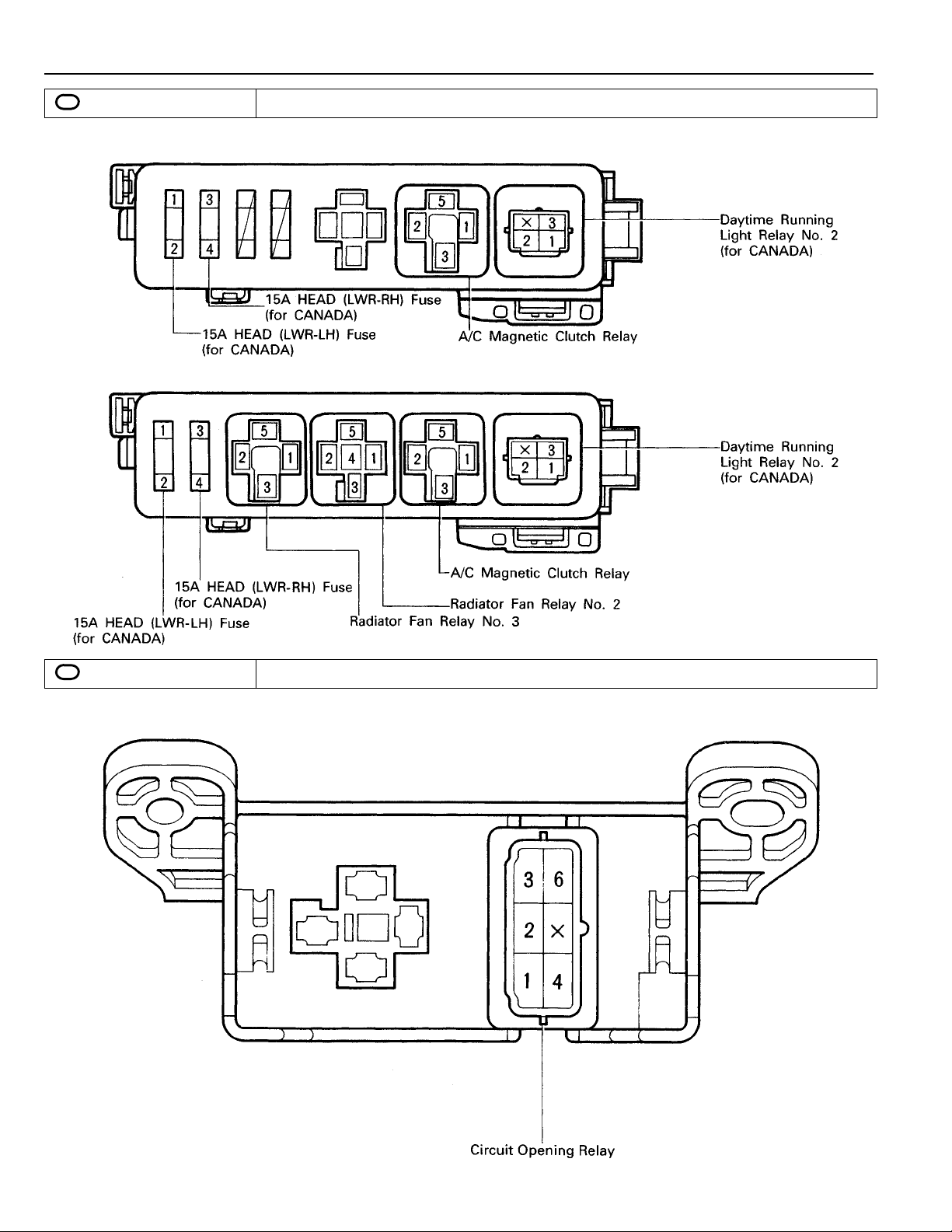

1

: R/B No. 1 Left Kick Panel

(See Page 18)

4

: R/B No. 4 Right Kick Panel

(See Page 18)

25

RELAY LOCATIONS

5

: R/B No. 5 Engine Compartment Left

(for 1MZ–FE)

(See Page 18)

6

: J/B No. 6 Behind Glove Box

(for 5S–FE)

(See Page 18)

26

7

: R/B No. 7 Near The Battery

(See Page 18)

27

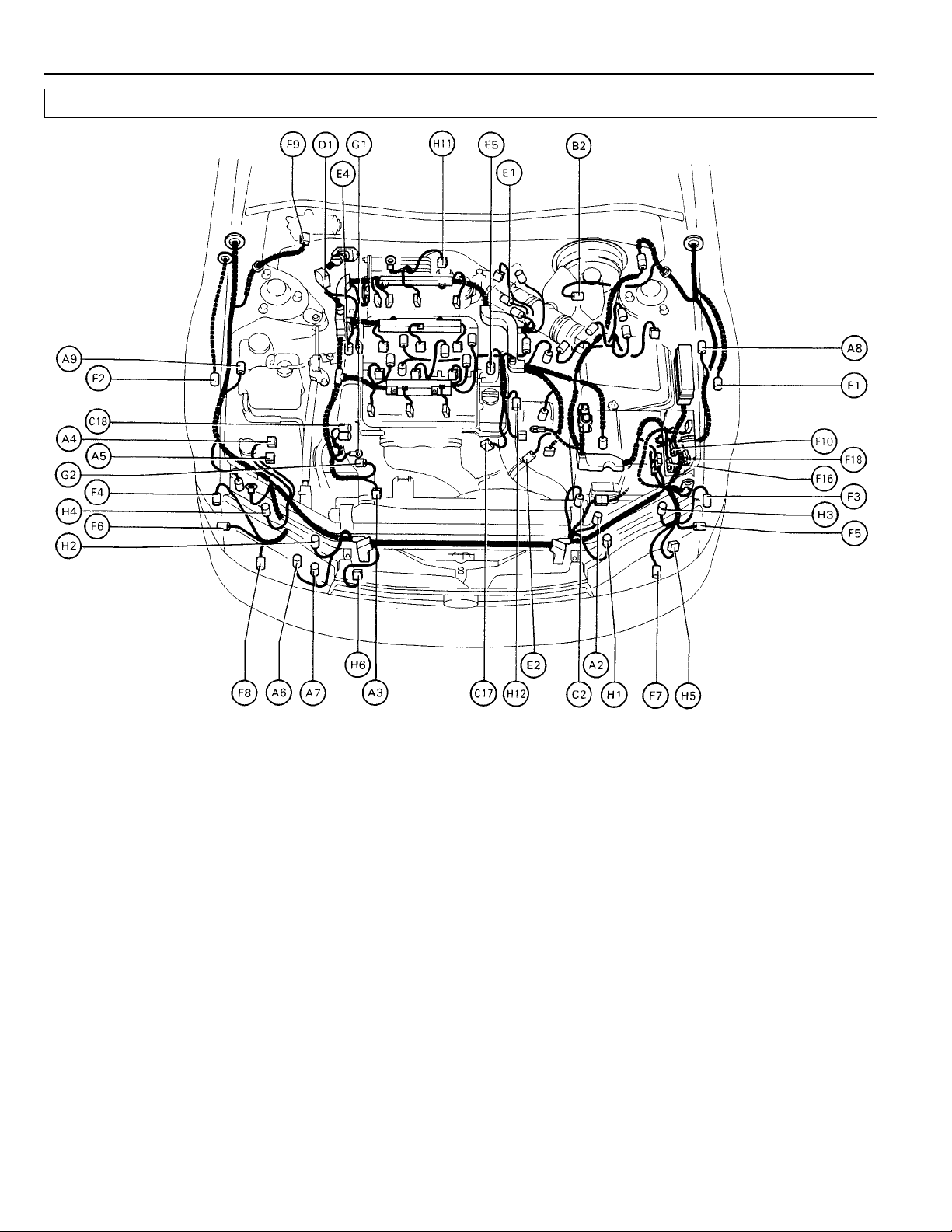

ELECTRICAL WIRING ROUTING

Position of Parts in Engine Compartment

[1MZ–FE]

A 2 A/C Triple Pressure SW (A/C Dual and Single Pressure F 1 Front Airbag Sensor LH

A 3 A/C Magnetic Clutch and Lock Sensor F 3 Front Clearance Light LH

A 4 ABS Actuator F 4 Front Clearance Light RH

A 5 ABS Actuator F 5 Front Side Marker LH

A 6 ABS Relay F 6 Front Side Marker RH

A 7 ABS Relay F 7 Front Turn Signal Light LH

A 8 ABS Speed Sensor Front LH F 8 Front Turn Signal Light RH

A 9 ABS Speed Sensor Front RH F 9 Front Wiper Motor

B 2 Brake Fluid Level SW F 16 Fuse Box

C 2 Cruise Control Actuator

C 17 Camshaft Position Sensor G 1 Generator (Alternator)

C 18 Crankshaft Position Sensor G 2 Generator (Alternator)

D 1 Data Link Connector 1 (Check Connector) H 1 Headlight Hi LH

D 2 Distributor H 2 Headlight Hi RH

E 1 EGR Gas Temp. Sensor H 4 Headlight Lo RH

E 2 Electronic Controlled Transmission Solenoid H 5 Horn LH

E 4 Engine Coolant Temp. Sensor (EFI Water Temp. H 6 Horn RH

E 5 Engine Coolant Temp. Sensor (Water Temp. Sensor) H 12 Heated Oxygen Sensor (Bank 2 Sensor 1)

SW) F 2 Front Airbag Sensor RH

F 10 Fuse Box

F 18 Fuse Box

H 3 Headlight Lo LH

Sensor) H 11 Heated Oxygen Sensor (Bank 1 Sensor 1)

(for Cooling Fan)

28

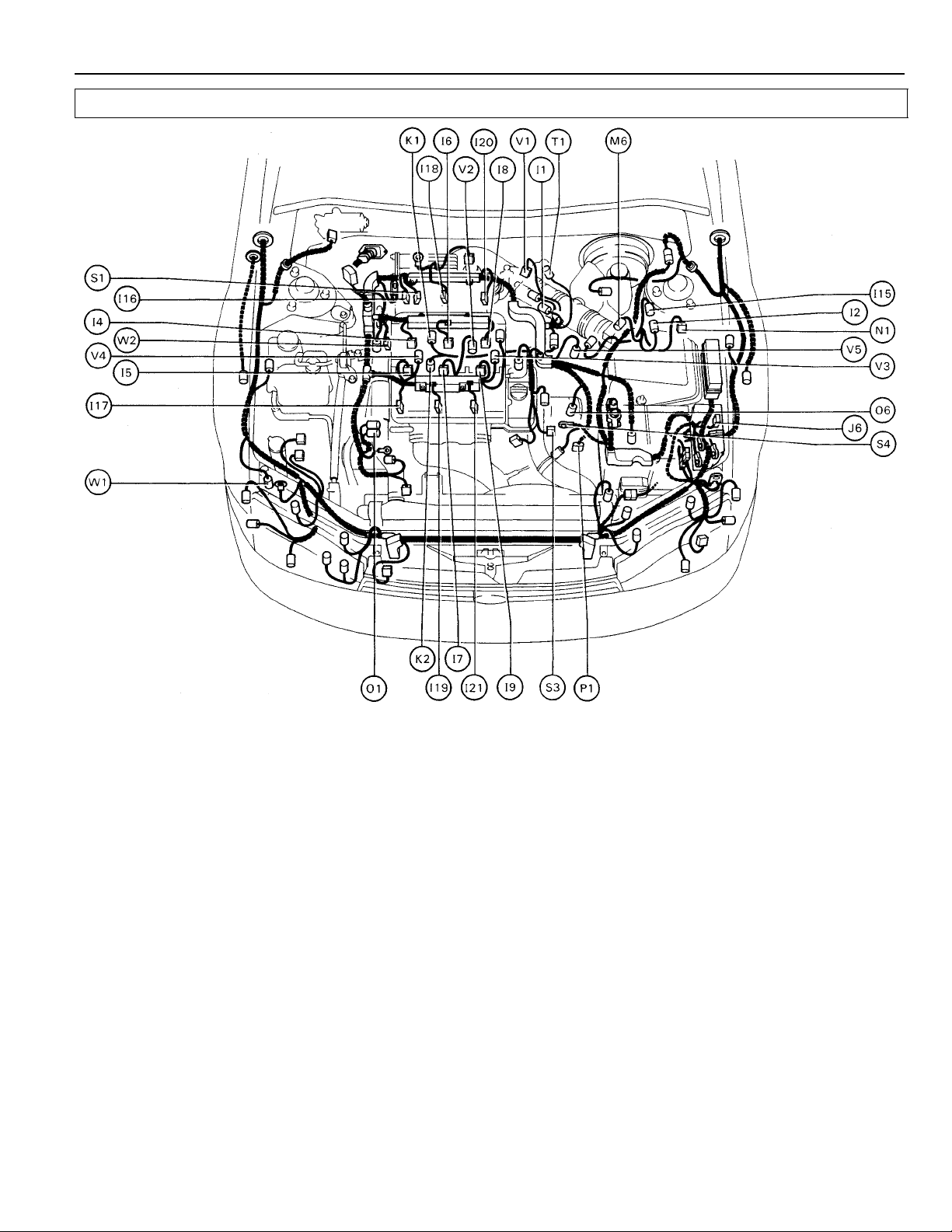

[1MZ–FE]

Position of Parts in Engine Compartment

I 1 Idle Air Control Valve (ISC Valve) N 1 Noise Filter (for Ignition System)

I 2 Igniter

I 4 Injector No. 1 O 1 Oil Pressure SW

I 5 Injector No. 2 O 6 O/D Direct Clutch Speed Sensor

I 6 Injector No. 3

I 7 Injector No. 4 P 1 Park/Neutral Position SW (Neutral Start SW) (A/T)

I 8 Injector No. 5

I 9 Injector No. 6 S 1 Solenoid Valve (for Hydrauric Motor)

I 15 Igniter S 3 Starter

I 16 Ignition Coil No. 1 S 4 Starter

I 17 Ignition Coil No. 2

I 18 Ignition Coil No. 3 T 1 Throttle Position Sensor

I 19 Ignition Coil No. 4

I 20 Ignition Coil No. 5 V 1 VSV (for A/C Idle–Up)

I 21 Ignition Coil No. 6 V 2 VSV (for EGR System)

J 6 Junction Connector V 4 VSV (for Intake Air Control)

K 1 Knock Sensor 1

K 2 Knock Sensor 2 W 1 Washer Motor

M 6 Mass Air Flow (Air Flow Meter)

V 3 VSV (for Fuel Pressure Up)

V 5 V ehicle Speed Sensor (Speed Sensor)

W 2 Water Temp. Sender

29

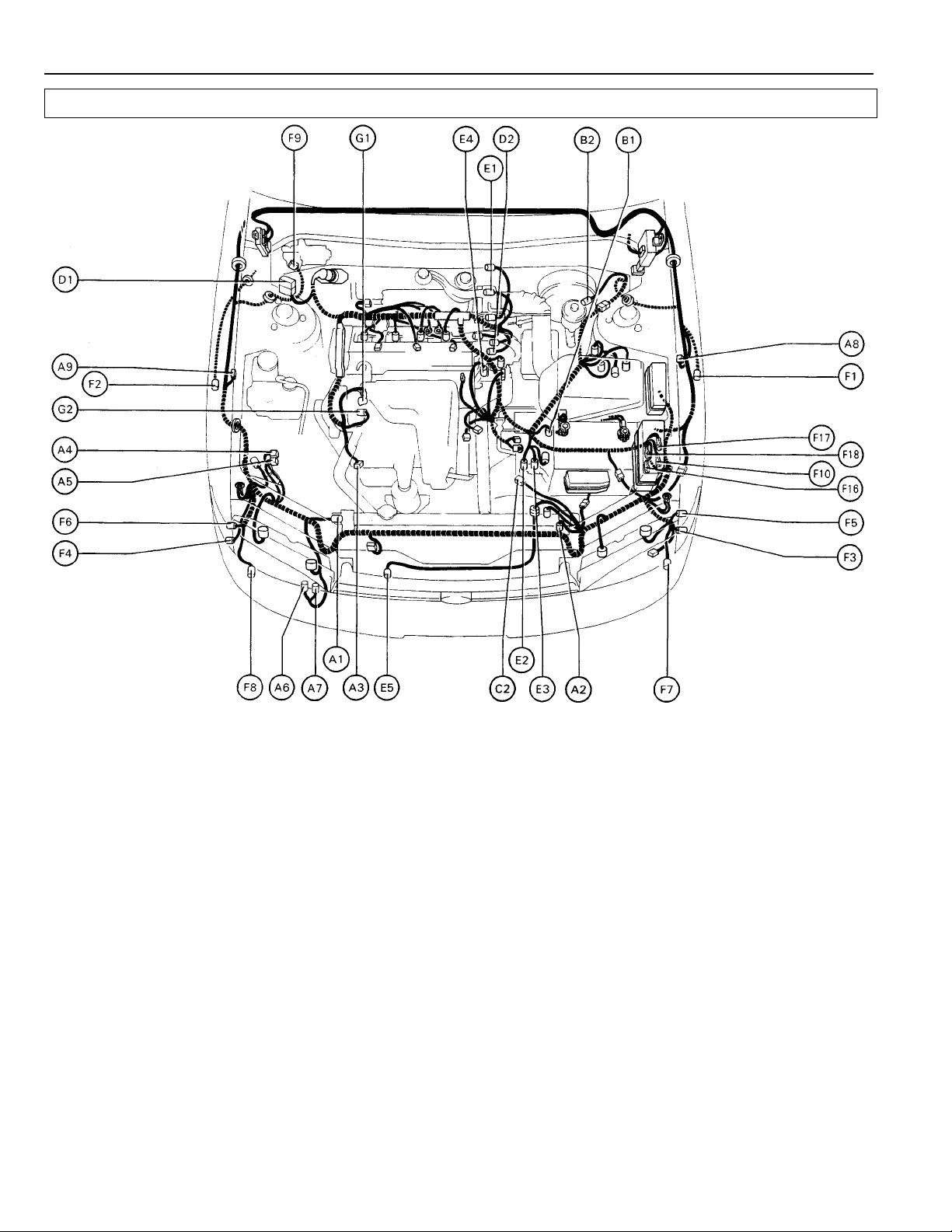

ELECTRICAL WIRING ROUTING

Position of Parts in Engine Compartment

[5S–FE]

A 1 A/C Condenser Fan Motor E 1 EGR Gas Temp. Sensor

A 2 A/C Triple Pressure SW (A/C Dual and Single Pressure E 2 Electronic Controlled Transmission Solenoid

A 3 A/C Magnetic Clutch and Lock Sensor E 4 Engine Coolant Temp. Sensor (EFI Water T emp.

A 4 ABS Actuator Sensor)

A 5 ABS Actuator E 5 Water Temp. SW (for Cooling Fan)

A 6 ABS Relay

A 7 ABS Relay F 1 Front Airbag Sensor LH

A 8 ABS Speed Sensor Front LH F 2 Front Airbag Sensor RH

A 9 ABS Speed Sensor Front RH F 3 Front Clearance Light LH

B 1 Back–Up Light SW (M/T) F 5 Front Side Marker LH

B 2 Brake Fluid Level SW F 6 Front Side Marker RH

C 2 Cruise Control Actuator F 8 Front Turn Signal Light RH

D 1 Data Link Connector 1 (Check Connector) F 10 Fuse Box

D 2 Distributor F 16 Fuse B o x

SW) E 3 Electronic Controlled Transmission Solenoid

F 4 Front Clearance Light RH

F 7 Front Turn Signal Light LH

F 9 Front Wiper Motor

F 17 Fuse Box

F 18 Fuse Box

G 1 Generator (Alternator)

G 2 Generator (Alternator)

30

Loading...

Loading...