Page 1

TOSHIBA

2E MOTOR PROTECTION RELAYS

MODEL

■ OVERLOAD & SINGLE-PHASE

PROTECTION

■ SOLID-STATE

■ lUIANUAL TEST FEATURE

■ MANUAL/REMOTE/AUTO RESET

■ SURFACE/FLUSH MOUNTING

RC8SO

Page 2

2E MOTOR PROTECTION R^AYS

MODEL

Toshiba’s 2E relay eliminates many motor

failures. Thissolid state relay features precise

motor protection for any horsepower/voltage

combination in just three ratings. The 2E

provides overload and single phase protection

and has an adjustable setting for very wide

FEATURES

■ OVERLOAD & SINGLE-PHASE PROTECTION

Two protective functions are incorporated.

■ SOLID-STATE

Fully solid-state circuit provides high reliability and

precise operation.

■ MANUAL TEST FEATURE

Manual test switch offers convenience for sequence

testing.

■ MANUAL/REMOTE/AUTO RESET

Wide selection of reset mode gives application

flexibility.

range from 3 to 40 sec. (starting characteristic,

at 600% current) to accomodate reduced voltage

start-ups and high inertia loads.

The 2E relay complies with international

standards as well as UL (USA) listed and CSA

(Canada) certified.

ISURFACE/FLUSH MOUNTING

Selectable surface or flush mounting,

I FLEXIBILITY

The relay allows for a high degree of flexibility for

coordinating with wide range of current and trip time

settings.

I VISIBLE TRIP INDICATOR

LED indicator shows relay trip status dearly until reset.

I INTERNATIONALLY RECOGNIZED

The relay complies with international standards as well

as UL (USA) listed and CSA (Canada) certified.

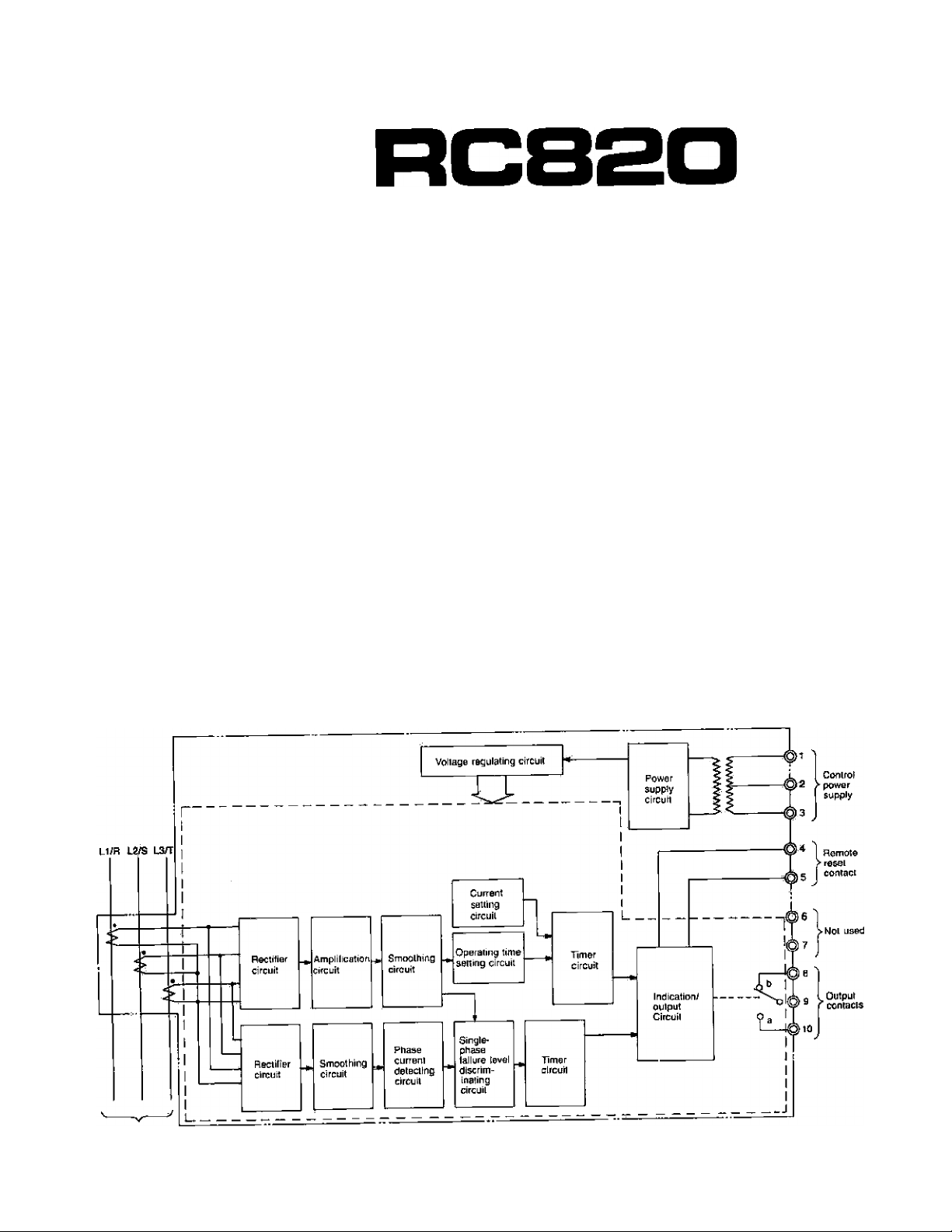

Load circuit

Page 3

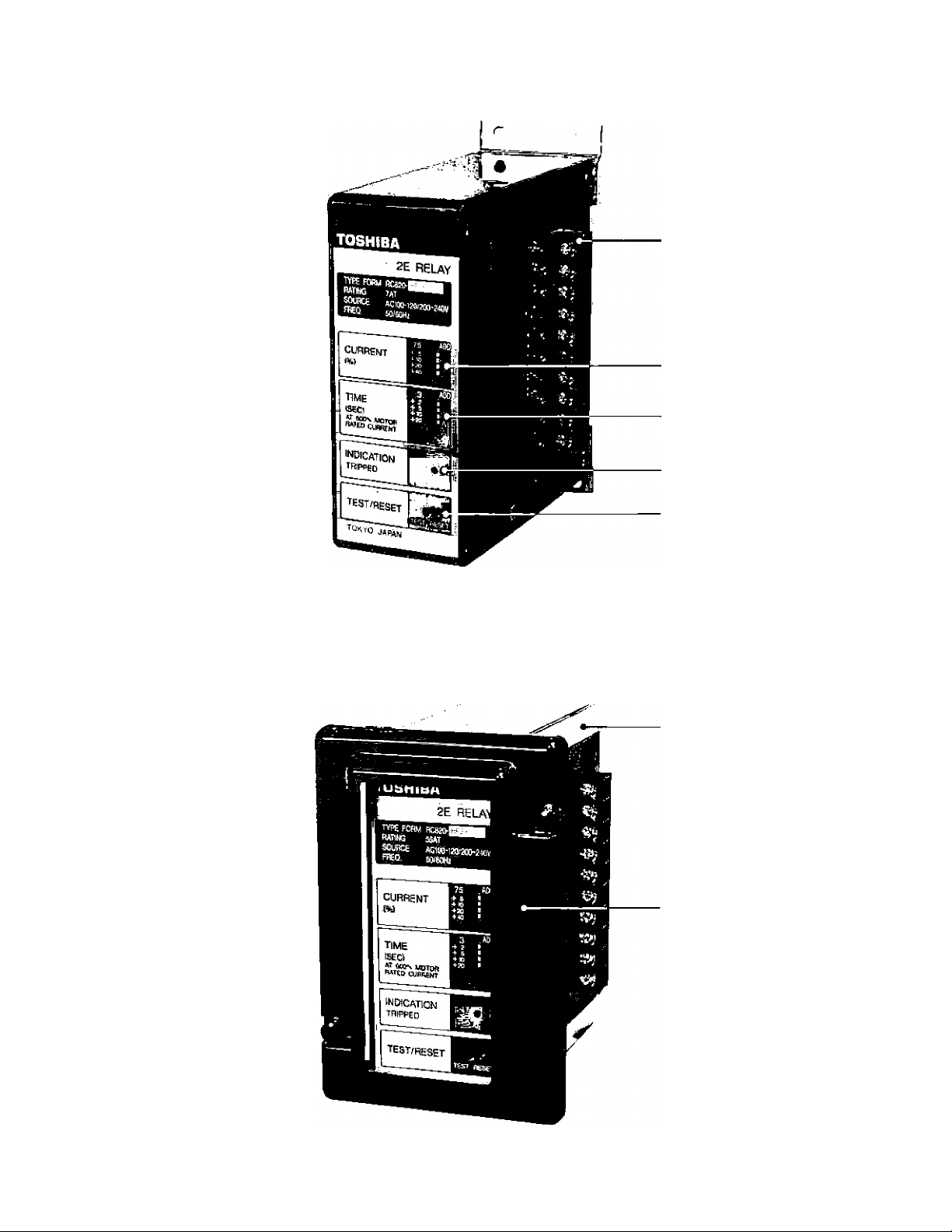

CONTROL TERMINALS

CURRENT SETTING

TRIP TIME SETTING

LED TRIP INDICATOR

TEST/RESET SWITCH

(SPRING RETURN)

FLUSH MOUNTING FEET

FLUSH COVER

Page 4

NOMENCLATURE RC820—HP 1 Y 12

(1) {2) (3) {4) (5)

(1) Model (Series) No. RC820

(2) Reset Mode HP ... Manual Reset

AP,,.. Auto Reset

(3) Current Rating 1

(4) Control Volt. Y

..................

2

......

3

......

.......

7 AT

55 AT

110 AT

100-120/200-240 V AC

(5) Variation — Standard Surface Mounting

2

.......

Rush Mounting

12 .... Remote Reset (Standard)

72.... Remote Reset

(UL Listed/CSA Certified)

RATINGS & SPECIFICATIONS

SELECTION

RESET

MANUAL

AUTO

REMOTE SURFACE

MOUNTING UL & CSA

SURFACE YES

FLUSH

SURFACE YES RC820-APL'

MODEL NO.

RC820-HPL';:;jY

NO RC820-HPL

NO

YES

RC820-HPÌ':;;iYi2

RC820-HPL::ìy72

;:]Y2

:;:iY

Applicable Circuit

Rated Current

Overload Protection

Single-Phase Protection

Control Power

Rated Ampere-turns (AT)

Setting Range

Ultimate Operating

Current

Trip Time Setting Range

Operating Time

Accuracy

Minimum Operating

Current

Operating Time

Rating

RC820-

HP1Y

AP1Y

RC820-

HP2Y

AP2Y

RC820-

HP3Y

AP3Y

Three-phase circuit rated up to 600V AC, 50/60 Hz—Direct

(Also, applicable to high-voltage circuit by combining with highvoltage CT)

7AT

55AT

11 OAT

75—150% of rated AT

105—125% of setting current

3—40 sec. for starting characteristics at 600% of setting current

±20% of setting time

85% of setting current under one-phase completely loss (When

measured on either remaining phase).

Less than 4 sec.

100—120V/200—240 V AC, ^<l>, 50/60 Hz

Power Consumption

Output Contact Capacity

Weight

Allowable Volt.

Fluctuation

Control Power Circuit

Detecting (CT) Circuit

1 ICo^ctTArrangement

Contact Capacity

85%—110%

2 VA

0.3 VA/phase at rated current

1 NO—NC (SPDT/Form C)

120V AC-5.0A (Resistive load)

120 V AC-3.0A (Inductive load, pf = 0.40)

125V DO0.2A (L/R = 7ms)

250V DC-0.1A (UR = 7ms)

NEMA B300

Approx. 1 kg (2.2 lbs.)

Page 5

OPERATING CHARACTERISTIC CURVE

MULTIPLES OF LOAD CURRENT

STARTING CHARACTERISTIC

(Notes) (1) Overload operating ctiaracteristics

Ultimate operating current—105—125% of setting current

(2) Single-phase operating characteristics

Min. operating current—85% of setting current

MULTIPLES OF LOAD CURRENT

► RUNNING CHARACTERISTIC

Page 6

INSTALLATION

40(1.58)

-----

60(2.36),

76 (3.66)

16

(0.63)

5 (0.20)

Dta-4

Mounting

Hoies

-----

—C

(1.58)

Unit; mm {in)

^

----

40

SURFACE MOUNTING

Mounting Pane!

(0.06 Min—0.125 Max.)

FLUSH MOUNTING

6

Page 7

WIRING

Low-vo(tage power supply

600 V AC or less

I WOTOn

-Sh

Low-voltage

Contractor

2E Relay

(Notes)

^Stop

Start

iJ\Operatìng

Xoil

I Ì I a I 3 I 4 15 [ 5 I 7 f

L/

"Connections of control power source

AC 100-120V—Terminals 1-2

AC 200-240V—Terminals 1-3

For other voit., use CPT.

"‘Connections of output contacts

NC“Oontact {opened when the 2E

Relay operated)—Terminals 8-9

NO-contact (closed when the 2E

Relay operated)—Terminals 9-10

“‘Connections of Remote reset switch

LOW-VOLTAGE

Control

Tsrminal

Numbers

Higti-voltaga power supply PT w control transformer

2.AKV—13.8K\/ AC /[100~t20V Sacondaiy)

High

voltage

CT

|_High-vortag©

^ contactor

__

i|i

l|2[3Ì4|5Ì6|7|a|9|To

I 2£ Relay

P\

o

Hlgh“V0ita9& CT sscondar/ circuit

wires pass through the windows of

the built-in CT's,

HIGH-VOLTAGE

^ stop

^ Start

15 Operating

' Coll

b a

HOW TO SET

Selection of the suitable model may require some preli

minary calculations. See “Current Setting” to determine

if the calculated “Current Setting %” can be obtained

with the selected model given the motor full load current

(FLA). Model Selection can also be influenced by wire

size which limits the number of turns that can be passed

through the CT windows.

(1) Current Setting

N{g-i

N(T) = Number of wire turns through 2E built-in CTs,

/m .0 4*- FLAxNxIOO

Notes: * Select the external CT ratio so that the current

(2E AT Rating)X(External CT Ratio)

-------------------------

----------------------------

round off to nearest integer.

® "^9 0) ^2^ yjj p3(jpg| ^ (External CT Ratio)

setting % is as close to 100% as possible.

If no external CT are used, substitute with

“1.0”.

**For 1.15 Service Factor Motors. If the motor

has a 1.0 S.F. multiply the calculated “Current

Setting %” by 0,93, (Practice in USA)

Example: 200HP, 460V, 240A Full Load. 1.15 S.F.

Across-the-line start.

240 Amps exceeds the highest rated 2E

Relay, therefore, external CT’s must be

used, and the HPIY, 7 AT rated 2E, will be

chosen as the standard model when the

current exceeds the HP3Y’s rating. If 300/5

CT’s are used,

41, m 4 0,4- n/ 240xNfT)x100%

the Current Setting % =

------------7x(M0)

--------------

= N01x57.14%.

And if 2 turns through the 2E Relay’s CT

windows (from the external CT’s) are used,

the % Dial

Setting = 2x57.14=114% = 110% or 115%

(2) Time setting

Determine the protection curve from 2E Relay

operating curves, and read the operating time at 600%

of setting current. Adjust the time setting dip switch

to the nearest setting above the operating time.

5"'

Page 8

ORDERING INFORMATION

When ordering specify;

■ Model No. & Quantity

■ Any Special Requirement

Tostliba International Corporation:

Houston, Vancouver

TOSHIBA

TOSHIBA CORPORATIOISJ

Industrial Equiprirent Department

1 - 1 . SHIBAURA 1 -CHOME, MINATO-KU, TOKYO. 1 D5. JAPAN

phone: 3457-.daoO. FAX: SA aa -a BB B

• For further information, please contact your nearest Toshiba Liaison Representative pr internatipnai Operations—Producer Goods.

• The data given in this catalog are subject to change without notice.

Toshiba International Corporation

Pty. Ltd,: Sydney, Melbourne

Toshiba Intematlonal {Europe) Ltd.

'as-ia(NA)7oa*3

Printed in Japan

Loading...

Loading...