ZMaster

®

Professional7500-DSeriesRidingMower

With96inTURBOFORCE

ModelNo.72098—SerialNo.400000000andUp

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

®

RearDischargeMower

FormNo.3445-193RevA

SetupInstructions

ProcedureDescription

1

2

3

4

5

6

7

8

9

10

11

Qty.

Nopartsrequired

Nopartsrequired

Nopartsrequired

Nopartsrequired

Nopartsrequired

Nopartsrequired

J-bolt2

Wingnut2

Hold-downclamp1

Nopartsrequired

Hood-IntakeKit1InstalltheHood-IntakeKit.

Nopartsrequired

Operator'sManual

Engineowner'smanual1

Registrationcard1

Operatortrainingmaterial

Key2

–

–

–

–

–

–

–

–

1

1

Addfueltothemachine.

Checktheengine-oillevel.

Checkthetirepressure.

Checkthehydraulic-uidlevel.

Checkthedeckgearbox-uidlevel.

Checkthewheellugnuttorque.

Installthebattery.

Raisetherolloverprotectionsystem

(ROPS).

Checkthemachinebeforedeliveryto

thecustomer(Allmachines).

Deliveringthemachinetothecustomer.

Use

©2021—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3445-193*

1

4

AddingFueltotheMachine

NoPartsRequired

Procedure

Addfueltothemachinebeforestartingit.Refer

toyourOperator’sManualforthecorrectfueland

procedure.

2

CheckingtheEngine-Oil

Level

NoPartsRequired

Procedure

Checkingthe

Hydraulic-FluidLevel

NoPartsRequired

Procedure

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch,andengagetheparking

brake.

2.Movethemotion-controlleverstothe

NEUTRAL-LOCKpositionandstarttheengine.

Note:Runtheengineatthelowestpossible

rpmtopurgeanyairinthesystem.

Important:DonotengagethePTO.

3.Raisethedecktoextendtheliftcylinders,shut

offtheengine,andremovethekey.

4.Raisetheseattoaccessthehydraulic-uidtank.

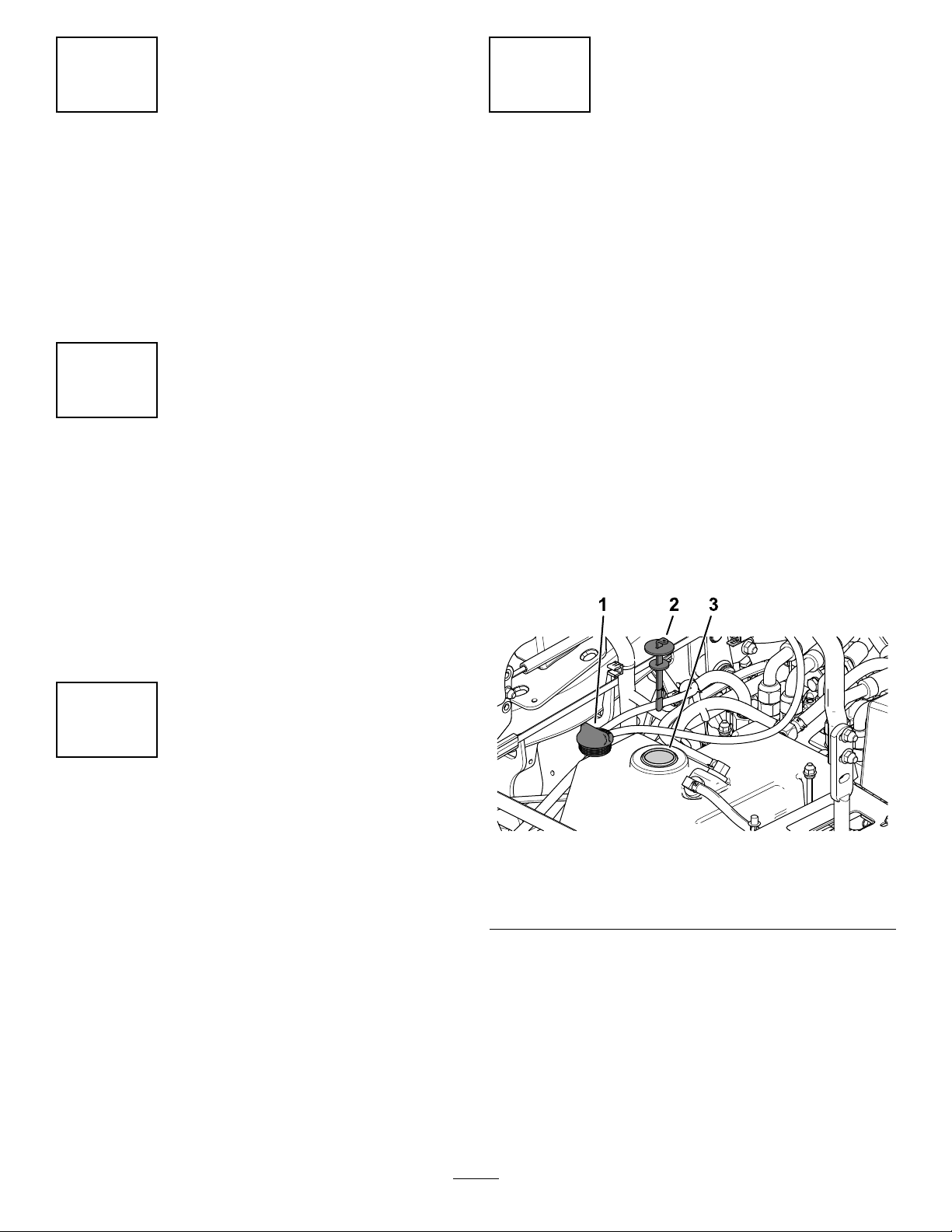

5.Removethehydraulic-tankcap(Figure1).

Beforeyoustarttheengineandusethemachine,

checktheoillevelintheenginecrankcase;referto

theOperator'sManual.

3

CheckingtheTirePressure

NoPartsRequired

Procedure

Frontandreartiresairpressurespecication:124

kPa(18psi).

Note:Checkthetirepressurebeforestartingthe

machine.RefertoyourOperator’sManualforthe

correcttiretype,correctairpressureneeded,and

procedure.

g227849

Figure1

1.Hydraulic-tankcap3.Fillerneck

2.Dipstick

6.Removethedipstickandwipeitwithacleanrag

(Figure1).

7.Placethedipstickintothellerneck,removeit,

andchecktheuidlevel(Figure2).

Note:Ifthelevelisnotwithinthenotchedarea

ofthedipstick,addenoughhigh-qualityhydraulic

uidtoraisetheleveltowithinthenotchedarea.

Important:Donotoverll.

2

Figure2

g228816

1.Fullline2.Addline

8.Replacethedipstickandthreadthellcap

nger-tightontothellerneck.

9.Checkallhosesandttingsforleaks.

5

CheckingtheDeck

Gearbox-FluidLevel

NoPartsRequired

Procedure

1.Parkthemachineonalevelsurface.

2.Lowerthemowerdecktothe25mm(1inch)

heightofcut.

3.Disengagetheblade-controlswitch,movethe

motion-controlleverstotheNEUTRAL-LOCK

position,andengagetheparkingbrake.

4.Shutofftheengineandremovethekey .

g231764

Figure3

1.Dipstick/llplug

7.Iftheuidlevelislow,adduiduntilthelevelis

betweenthemarksonthedipstick.

Important:Donotoverllthegearbox;

overllingthegearboxmaydamageit.

6

CheckingtheWheelLug

NutTorque

NoPartsRequired

Procedure

Beforeyoustarttheengineandusethemachine,

checkthewheellugnuttorque;refertoCheckingthe

WheelLugNutsintheOperator'sManual.

5.Raisethedeck-liftpedaltoexposethetopofthe

mowerdeck.

6.Removethedipstick/llplugfromthetopofthe

gearboxandensurethatthelubricantisbetween

themarksonthedipstick(Figure3).

3

7

InstallingtheBattery

Partsneededforthisprocedure:

2J-bolt

2Wingnut

1Hold-downclamp

Procedure

Important:Thisprocedureonlyappliesto

machinesthatdonotcomewithabattery

installed.

Purchasea12Vbatteryandinstallitintothemachine.

Theenginerequiresaminimumof540A(cold

cranking).

Usethehardwareincludedtoinstallthenewbattery.

RefertoInstallingtheBatteryintheOperator's

Manual.

Figure4

1.Upperpartoftherollbar4.Rotatetheknobout90°

2.Knobinthelatched

position

3.Pulltheknobtounlatch.

4.Pushontherollbarandensurethatbothpins

areengaged(Figure5).

toholditintheunlatched

position.

5.Knobintheunlatched

position

g243267

8

RaisingtheRollover

ProtectionSystem(ROPS)

NoPartsRequired

Procedure

1.Pulltheknobandrotate90°totheunlatched

position(Figure4).

2.Raisetherollbartotheoperateposition,and

rotatetheknobssothattheymovepartiallyinto

thegrooves(Figure4).

3.Raisetherollbartothefulluprightpositionwhile

pushingontheupperrollbarandthepinssnap

intopositionwhentheholesalignwiththepins

(Figure4).

Important:Alwaysusetheseatbeltwiththe

rollbarintheraisedposition.

g008619

Figure5

1.Engagedposition2.Partiallyengaged—do

notoperatethemachine

withtherollbackinthis

position.

4

9

InstallingtheHood-Intake

Kit

Partsneededforthisprocedure:

1Hood-IntakeKit

Procedure

InstalltheHood-IntakeKit;refertotheInstallation

Instructions.

5

10

CheckingtheMachineBeforeDeliverytotheCustomer

(AllMachines)

NoPartsRequired

Procedure

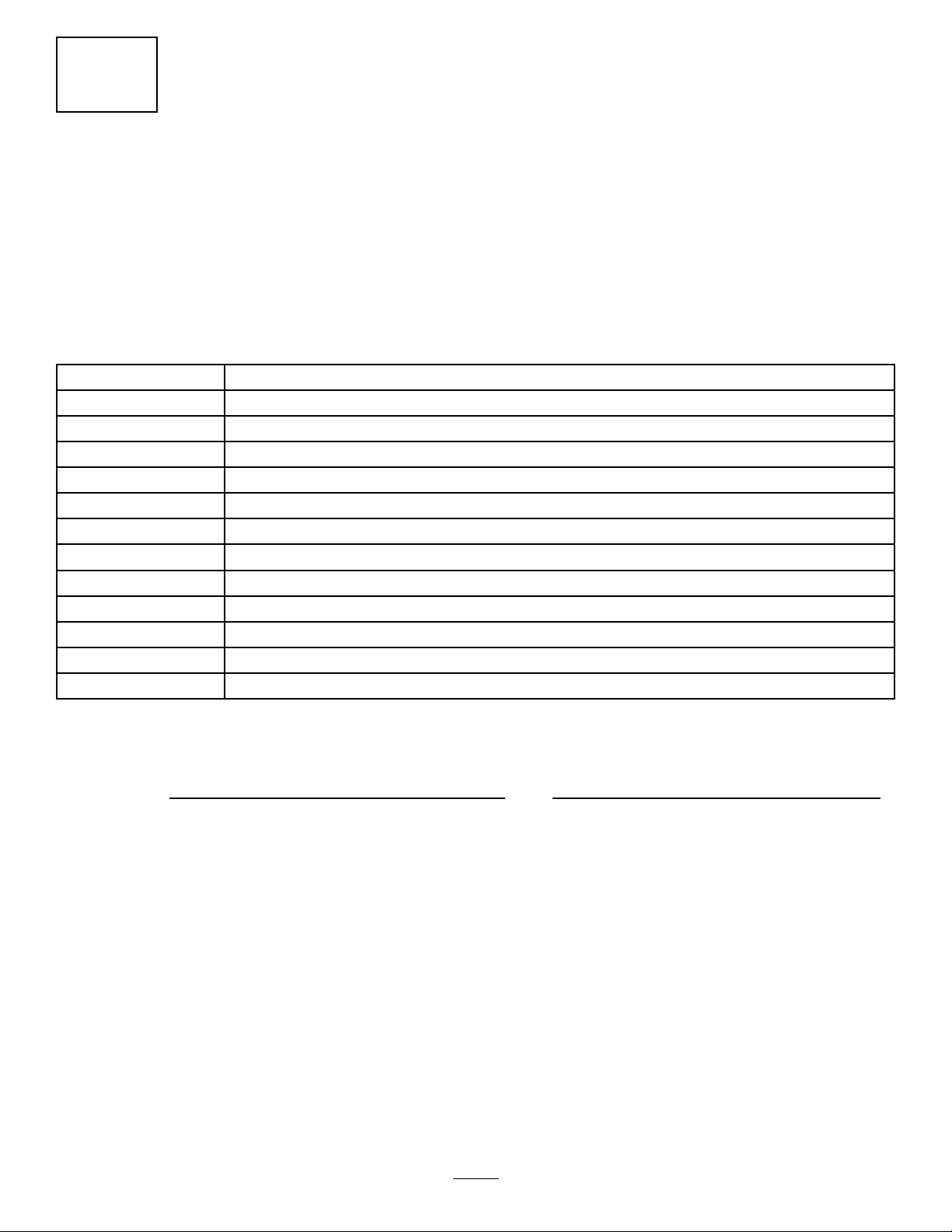

Beforedeliveringthemachinetothecustomer,ensurethatyouperformorhaveperformedtheprocedures

listedinthefollowingtableandinitialeachwhennished.RefertotheOperator'sManualforinstructionson

performingtheseprocedures.

Initial

Checkthetirepressure.

Checkthelevelofthemachine.

Checkthatallspindlesaregreased.

Checktheengine-oillevel.

Checkthehydraulic-uidlevel.

CheckROPSissecure.

Onliquidcooledmachines,checkthelevelofthecoolantintheradiatorandoverowbottle.

Checktheadjustmentoftheparkingbrake.

Ensurethatthemachinetrackscorrectly;refertotheOperator'sManualfortheadjustmentprocedure.

Checkthesafetyinterlocksystem;refertotheOperator'sManual.

EnsurethatthePTOworks.

Checkallfastenersthatyouinstalledtoensurethattheyaretight.

Whenyounishsettingupthemachine,signanddateinthespaceprovidedbelow:

Signature:

CheckProcedure

Date:

6

11

DeliveringtheMachinetotheCustomer

Partsneededforthisprocedure:

1

Operator'sManual

1Engineowner'smanual

1Registrationcard

1

Operatortrainingmaterial

2Key

Procedure

Atdelivery,llinthemodelandserialnumber,completetheitemslistedinthefollowingtable,andinitial

eachwhennished.

ModelNo.

SerialNo.

7

DealerInitial

CustomerInitialCheckProcedure

Showthecustomerwherethefollowingfeaturesarelocatedandhowtheyfunction:

•

Fueltank

•

Oilllcap/Oildipstick

•

Engine-oillter

•

Engine-oildrain

•

Fuelgauge,valveandhose

•

Airlter

•

Radiatorcoolant(ifapplicable)

•

Hydraulic-uidreservoir

•

Hydrauliclter

•

Battery

•

Keyswitch

•

Throttlelever

•

Choke(ifapplicable)

•

Powertakeoffswitch(PTO)

•

Motion-controllevers

•

Parkingbrake

•

Heightofcut

•

Lift-assistlever(ifapplicable)

•

Adjustableseat

•

Hydraulic-bypassvalves

•

RolloverProtectionSystem(ROPS)

•

Deck-owbafe

RefertotheOperator'sManualtopointoutsafetyprocedures,operation,and

maintenanceprocedures.

ReviewthewarrantystatementasshownintheOperator'sManual.

Describethepostsaleserviceproceduresforyourstore.

Assistthecustomerinllingoutandmailingtheregistrationcardorregisteronlineat

www.T oro.com

EnsurethatthecustomerreceivestheOperator'sManual,engineowner’smanual,

SetupInstructions,andoperatortrainingmaterial.

EnsurethatthecustomerknowsthePartsCatalogisavailableatwww.T oro.com.

Assistthecustomerinloadingthemachineusingafull-widthtrailerramp.

Note:Whenyou,thedealerrepresentative,havenisheddeliveringthemachinetothecustomer,signand

dateinthespaceprovidebelowandkeepacopyofthispagefordealerrecords.Also,thedealermustremind

thecustomertouseafull-widthtrailerramptoloadthemachine.

Signature:Date:

Signature:Date:

8

Loading...

Loading...