Page 1

DUMMY RADIAL

ENGINE

ASSEMBLY AND FINISHING

INSTRUCTIONS

The Top Flite

®

Dummy Radial Engine (hereafter

referred to as

Radial

) is patterned after the Pratt &

Whitney radial engines that powered numerous air-

craft from the

Golden Age

of aviation. Modeled to

fit the Top Flite F4U Corsair and AT-6 Texan, this

1/7th scale Radial will fit any cowls with a frontal

opening of 6-1/2" to 7". Not only does the Radial

enhance scale appearance, but it also serves as

an air-flow baffle for more efficient engine cooling.

WARNING

Do not attempt to start your engine unless the

Radial has been modified to permit cooling airflow

to the engine! See text for more information.

TOOLS AND SUPPLIES NEEDED (Not Included)

Hobby Knife with # 11 Blade

Hand Drill or Dremel

®

Moto-Tool

®

1/16" and 1/8" Drill Bits

CA - Medium (Great Planes

®

Pro

™

recommended)

1/8" x 8" x 8" Lite-ply

Round File or 1/2" Drum Sander

Small Paint Brushes

Paint (see painting instructions)

Scroll or Coping Saw

Rubber Cement or Spray Adhesive

100 & 240 Grit Sandpaper

ASSEMBLY

The following procedure covers the assembly and modifi-

cations required for a flying model. Static display models

require no modification.

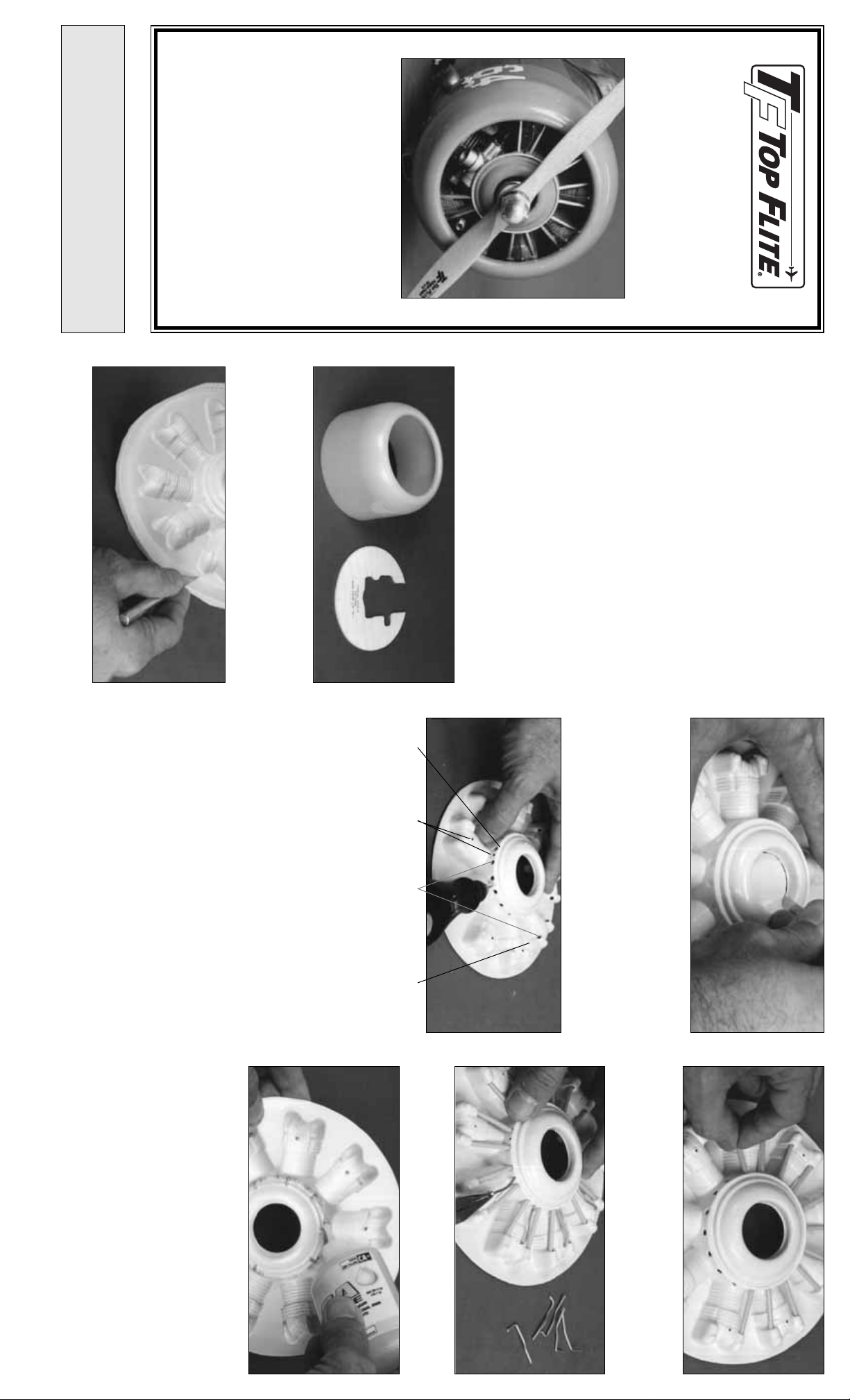

❑ 1.

Measure the inside diameter of your cowl about

1-1/2" from the frontal opening and match this size to the

concentric circles on the Baffle Template.

The correct size

for the Top Flite Corsair and AT-6 is the innermost circle.

❑ 3.

Score around the inside corner of the Radial with a

hobby knife. Flex the plastic around the rim until it breaks off.

❑ 4. Cut away the prop shaft opening from the center of

the Radial. Smooth the edges with a round file or

drum sander.

❑ 5. Tape the Radial to the ply baffle, then test fit the

assembly inside the cowl. If necessary, sand the ply baffle

for a better fit. The forward edge of the Crankcase should

be flush with the outside forward edge of the cowl.

❑ 6. Drill a 1/8" hole through each of the

indented marks

around the perimeter of the Crankcase and also through

the

bottom

of each Rocker Arm Cover. Drill a 1/16" hole

through the

dimple

near the top of each Cylinder and also

into the Ignition Harness Ring between the Push

Rod holes.

❑ 7. Use 240 grit sandpaper to lightly sand the full length

of the 3 plastic tubes for better glue and paint adhesion.

Cut 18 pieces 1-1/4" long to use for the Push Rod Tubes.

❑ 8. Sand the 16" wire, then cut 9 pieces 1-1/2" long to

use for the Ignition Leads. Make a 90 degree bend 3/8"

from one end. Randomly bend the

long

section to

simulate flexible wires.

Note:

As you will probably be removing at least one

Cylinder when you use the Radial as an air baffle, you

need not install Push Rod Tubes and an Ignition Lead in

one Cylinder. Complete all 9 cylinders if you will only be

using the Radial for static display.

Painting Hint:

Most modelers find that it’s easier to paint

this type of structure before final assembly. If this is your

preference, skip down to the section on Painting then

return to step 9 when you are ready to proceed.

❑ 9. Insert the Push Rod Tubes into the Rocker Arm

Covers and the crankcase as shown in the photo. They

should protrude inside the Radial about 3/32" at each

end of each piece. Don’t worry about gluing them yet.

❑ 10. Insert the Ignition Leads into the Crankcase and

the Cylinders.

❑ 11. Turn the Radial over and apply a drop of CA to

both ends of all Push Rod Tubes and Ignition Leads.

(From the inside)

❑ 12. (Flight Modification) Trim away one of the

Cylinders but leave excess backing material in place.

This material will be trimmed off during final fitting to

the engine.

❑ 13. Glue the Radial to the ply baffle with CA. Be sure

to align the “removed Cylinder” with the opening in the

baffle. Hint:

Roughen the back surface of the Radial with

coarse sandpaper for a better glue bond.

1/16" HolesCrankcase Rocker Arm Cover1/8" Holes

Top Flite Models

3002 N. Apollo, Suite 1

Champaign, IL 61822

(217) 398-8970

productsupport@top-flite.com

© Copyright 2004 RADIALP1

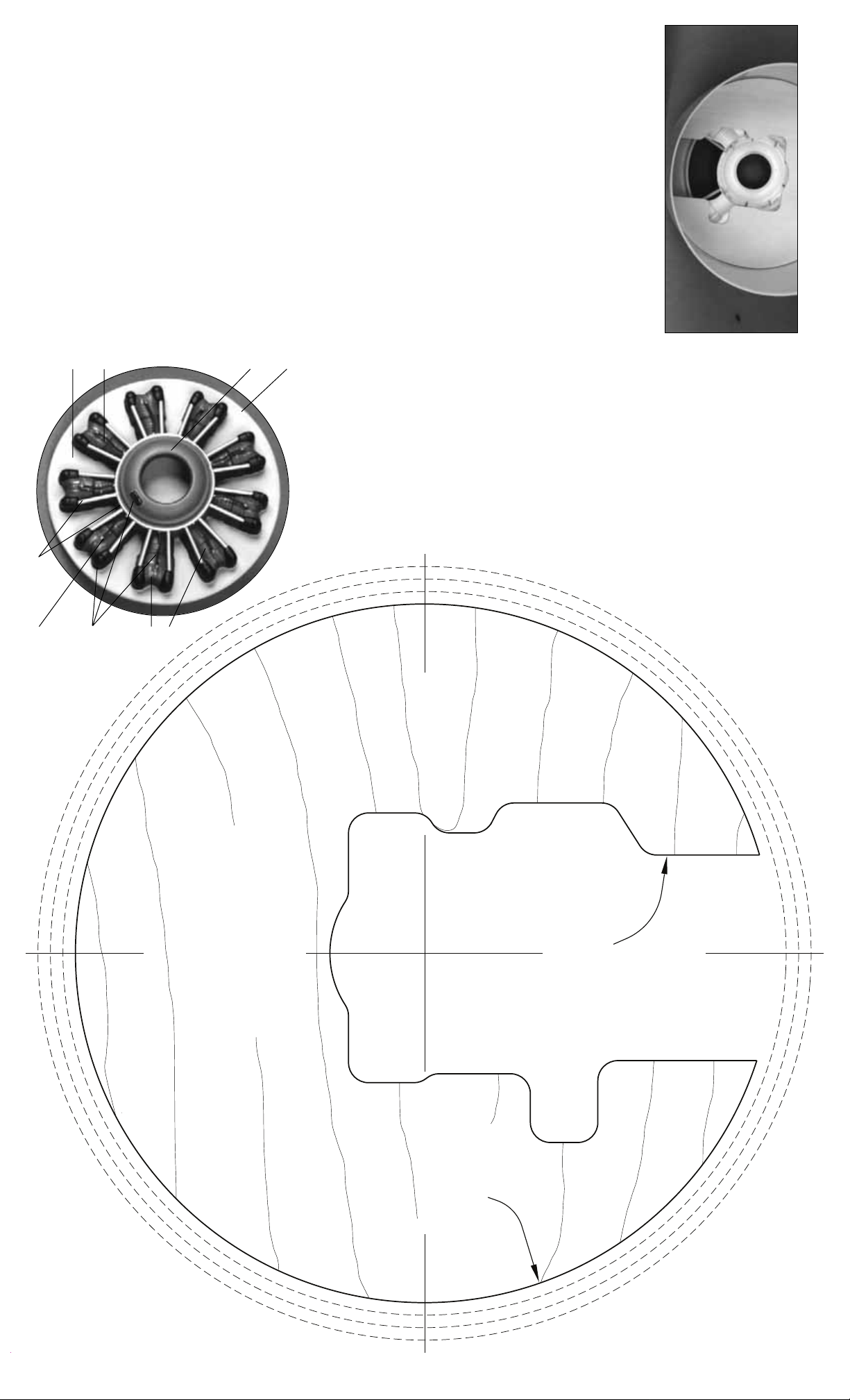

❑ 2. Trace or photocopy the Baffle Template, then glue

the copy to a sheet of 1/8" lite-ply (not included). Cut

around the circumference and the engine opening with a

scroll or coping saw.

Page 2

❑ 14. Tape the Radial assembly inside the cowl. Make

final adjustments to the fit between the cutouts and the

engine. By working from the

inside

it’s possible to

remove material from the Radial without affecting the

Push Rods Tubes and Ignition Leads. Pay special atten-

tion to provide unrestricted throttle and needle

valve movement.

❑ 15. When satisfied with the fit, smooth all rough

edges with fine sandpaper then paint the Radial. After

painting, epoxy the baffle to the inside of the cowl.

Baffle Template

The cutout in this baffle is sized

to fit an O.S.

®

.61SF Engine

and should provide a starting

point for other 2 Stroke engines

in the .60 - .90 range.

PAINTING SUGGESTIONS

We painted our prototype Radials with Enamel paint (not

fuel proof) then sprayed two light top-coats of K&B

®

Super Poxy Satin over the completed job to fuel proof

the finish. This finish withstands fuel and normal wear

and tear quite well.

If you are building a scale replica of a particular aircraft,

paint the Radial in similar colors to the full scale version.

The colors we chose represent typical P&W colors with

chrome plated

Push Rod Tubes and Ignition Harness Ring.

PAINTING SEQUENCE AND COLORS USED

Top Flite

®

LustreKote

™

(Aerosol)

1. Entire Exterior – Gray Primer

Testors Model Master Enamel (Brushed on)

2. Crankcase – Gunship Gray

3. Cylinders – Euro Gray

4. Background – Light Gray

5. Push Rod Tubes & Ignition Harness Ring – Silver

6. Ignition Leads & Rocker Arm Covers – Black

7. Spark Plug Connectors – Gold or Copper

8. Cylinder Fins and weathering – Silver & black

Random Fine Lines On The Fins.

9. Engine I.D. Plate – Black with Silver details

K&B

®

Super Poxy (Sprayed with Air Brush)

10. Satin Finish Clear Coat - Fuel Proofing

2

9

8

7

6

5

4

3

PARTS LIST

Qty. Description Part No.

1 ABS Plastic Radial RADIAL01

3 8" Plastic Push Rod Tubes PLTB025

1 16" Wire for Ignition Leads WIRES58

1 Instruction Sheet RADIALP1

1

O.S. .61SF

ENGINE CUTOUT

MAKE FROM 1/8" PLY

TYPICAL BAFFLE

ENGINE CUTOUT

TEMPLATE

(NOT INCLUDED)

AT-6 / F-4U

OUTLINE

TOP FLITE

OS .61SF

Loading...

Loading...