Page 1

]

WARBIRD DROP TANK

INSTRUCTIONS

Thank you for purchasing the Top Flite 108 Gallon Drop Tank

kit. This tank will add a great deal of realism and presence to

many 1/8th scale warbirds. The tank is lightweight and easy to

assemble and finish. It is easy to make droppable on a warbird

under construction. If you are going to add it to a model that is

already built, it would be easier to make it removable manually,

without servo control.

TANK ASSEMBLY

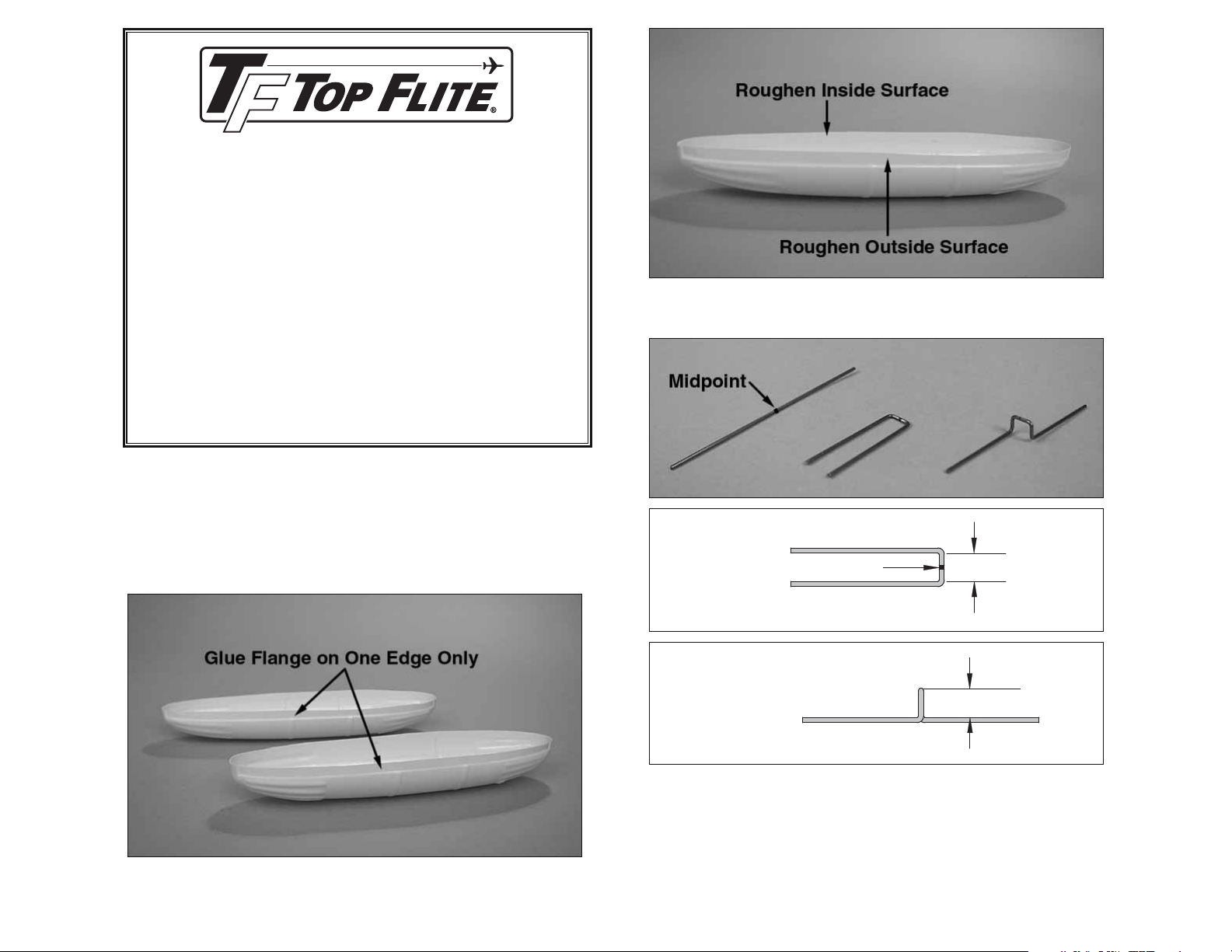

3. Use 220 or 150-grit sandpaper to roughen the edges of the

❑

flanges where the two halves will be glued together.

1. Lightly sand the outside of the drop tank halves with 400-grit

❑

sandpaper. This will help the primer and paint adhere to the surface.

2. Trim off the excess plastic to the cut lines on the inside of the

❑

tank with scissors or a hobby knife. Use 220-grit sandpaper to even

up the edges of the glue flange.

Sketch #1

MIDPOINT

Sketch #2

4. The supplied 0.046" dia x 3" steel wire needs to be bent by

❑

following these steps.

A. Mark the midpoint on the wire.

❑

B. Using Sketch #1 as a template, bend the wire to create a “U”

❑

shape as shown in the above image. The center section is 1/4" wide.

C. Using Sketch #2 as a template, bend the legs in opposite

❑

directions as shown in the above image. The center section has a

height of 1/4".

1/4" [6.35mm

1/4" [6.35mm]

Page 2

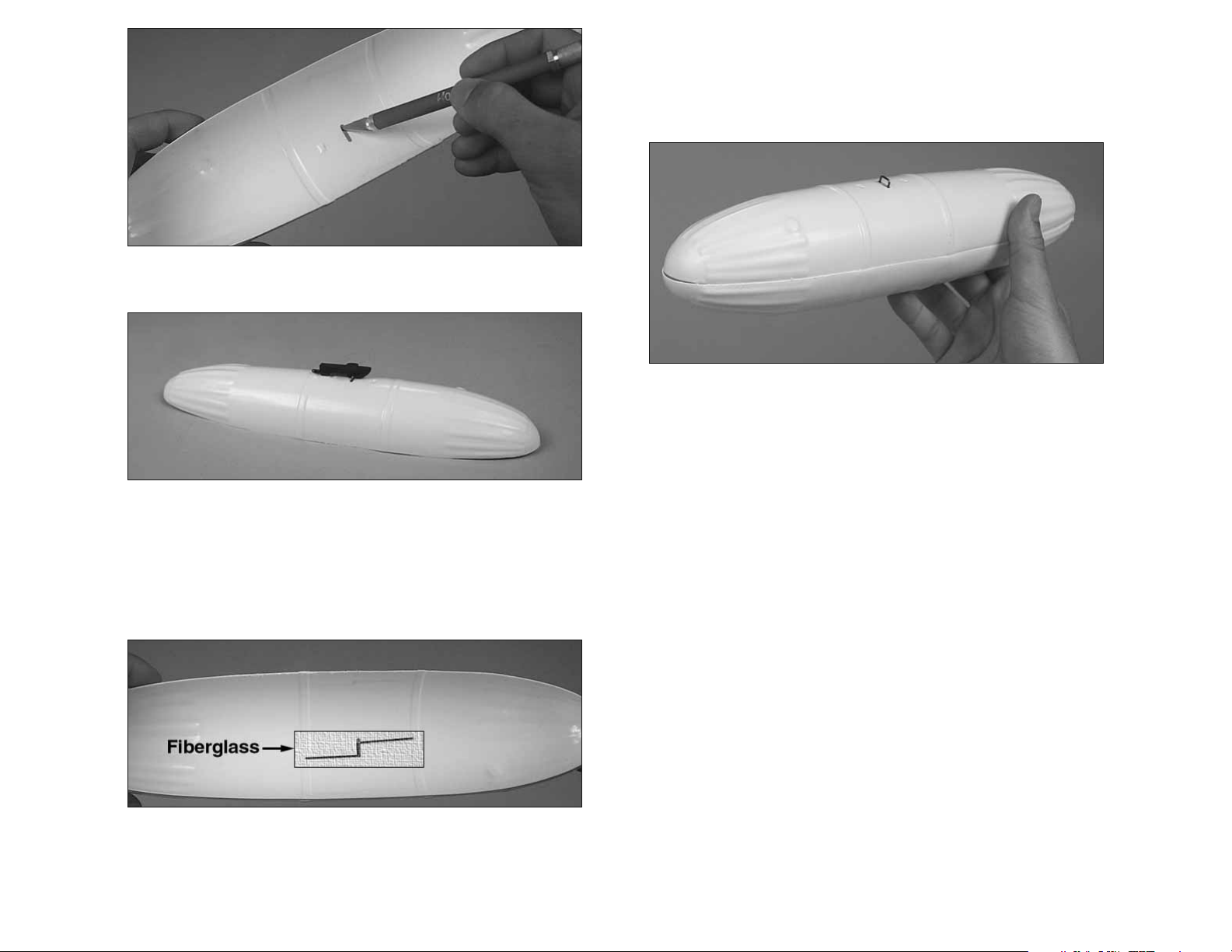

5. Cut out the slot in the top half of the tank to allow the Release

❑

Loop to exit through the top of the tank from the inside.

10. You may wish to add about 1/4 oz of nose weight (not included)

❑

to the inside nose of the tank. This will make the tank more neutrally

balanced when it falls. If you choose to add nose weight, roughen the

inside surface thoroughly and use epoxy to glue the weight securely

in place. A couple of old washers work well for this.

11. Tape the two halves of the tank together in several places with

❑

masking tape. Glue the two halves together by wicking thin CA into the

seam. Do not use accelerator as it will weaken the plastic.

12. Prime and paint the tank as desired.

❑

6. Use 150-grit sandpaper to thoroughly roughen the inside of the

❑

tank where the release hook is secured. With the Release Loop

inserted through the top half of the tank, test fit the Release Loop to

the Release Mechanism to make sure there is no interference.

7. Roughen the portion of the Release Loop that will be glued to the

❑

tank with 150-grit sandpaper.

8. Glue the Release Loop to the inside of the top half of the tank

❑

with 30-minute epoxy and the supplied 1" x 3" fiberglass tape. Allow

the epoxy to cure.

9. Check the fit of the top and bottom halves of the tank carefully.

❑

Sand away any obstructions so you have a good fit.

TYPICAL INSTALLATION OF THE

RELEASE MECHANISM

Note: These are the latest instructions for the installation of this

drop tank. Please disregard any earlier instructions from any of

our plans or manuals.

Note: These are generic instructions explaining how to install the

Release Mechanism on a Warbird’s wing. Depending on the airplane or location on the airplane that you are installing your

release mechanism on, the procedure may vary slightly.

1. Reinforce the area that you are going to install the Release

❑

Mechanism on with hardwood blocks, or stringers. You can also use

fiberglass if you wish.

2. Position the Release Mechanism in the location where you

❑

want to install it. Route a thin flexible cable (Sullivan #507) from the

release servo to the release tab. Tin the cable with silver solder at

the release tab end and put a Z-bend in it. If you wish, you could also

use a string tied to the release tab and to the servo arm.

Page 3

PARTS LIST

#4 x 5/8"

Screws

Release

Tab

3. Drill two 1/16" holes for the Release Mechanism's mounting

❑

#2 x 3/8"

Screws

Release

Mechanism

screws. Using the sketch above as a sample, drill four holes for the

drop tank positioning screws. The location of these screws will vary

from airplane to airplane. Use thin CA to harden all the holes. Install

the mechanism with two #2 x 3/8" screws included. Install the four

#4 x 5/8" sheet metal screws included at the outer holes. These

screws will be used to position the tank in the correct attitude.

Part # Qty. Description

FORQ2219 .................. 1 .................................. Release Mechanism

P4076DT01 ................. 1 ...............................................Tank Bottom

P4076DT01 ................. 1 .....................................................Tank Top

SCRW024 .................... 2 ................... #2 x 3/8" Sheet Metal Screws

SCRW010 .................... 4 ................... #4 x 5/8" Sheet Metal Screws

GLTP018...................... 1 ..............................1" x 3" Fiberglass Tape

WIRES114 ................... 1 .............................. 0.046" x 3" Music Wire

If you need to order replacement parts, send a check or money order

for the total amount (IL residents add 8.75% tax) plus $9.99 shipping. Add $9.99 for C.O.D. orders to:

Top Flite Models

3002 N Apollo Drive, Suite 1

Champaign, IL 61822

Ph: (217) 398-8970, Fax: (217) 398-7721

E-mail: productsupport@top-fl ite.com

4. Install the tank on the Release Mechanism and tighten or

❑

loosen the #4 x 5/8" screws until you get the desired tank position.

Ideally, the tank should have a slightly negative attitude so that it falls

away from the airplane as soon as it is released. Wick thin CA on the

screws to keep them from moving.

You can add even more realism to your warbird by installing an

authentic multiple blade static propeller, a replica radial engine, a

pilot and a cockpit kit to your airplane. These are available for most

of our Top Flite airplanes. Visit Top Flite’s web site at www.top-flite.

com for more information.

Printed in USA © 2010 Hobbico®, Inc. V1.1 DT18P01

Loading...

Loading...