Page 1

INSTRUCTIONS

Thank you for purchasing the Top Flite

PRECISION MAGNETIC BALANCER. We think

you’ll agree that this ingenious design, which

uses powerful magnets to support the balancer

shaft, is the simplest, easiest-to-use and most

friction-free balancer available. The compact,

rugged case halves press together to provide a

convenient carrying case for the balancer parts.

Originally designed by Mark McCormack

IMPORTANT: Please read through this

booklet in its entirety before attempting

to assemble or use the balancer.

Use the Top Flite PRECISION MAGNETIC BALANCER to balance all spinning

•

components of your models (propellers, spinners, rotors, and even wheels!).

Accurately balancing these components will provide noticeably smoother, quieter

operation and will help extend the life of your models, radio gear and engines.

This balancer is capable of suspending objects up to a maximum weight of

•

approximately 5.5 ounces (156 grams). For example, this permits balancing up

to a 24x16 wood propeller. Your balancer may have slightly greater or less

capacity, depending on the strength of the magnets which varies slightly.

This booklet also explains how you can use your Top Flite PRECISION

•

MAGNETIC BALANCER as a wind speed indicator!

CAUTION - STRONG MAGNETS:

1. When removing the magnets from the carton and when handling the magnets,

use care to prevent them from snapping against each other. The ceramic magnet

material is brittle and a hard impact can result in chipping or breaking.

2. If not handled properly, the powerful magnets in this balancer may cause

temporary or permanent damage to TV SCREENS, COMPUTER MONITORS, VIDEO

TAPES, AUDIO TAPES, FLOPPY DISKS, TAPE STORAGE MEDIA, etc. To avoid

damage, keep the magnets at least 24 inches (600mm) away from components that

are sensitive to magnetic fields.

Page 2

ASSEMBLY

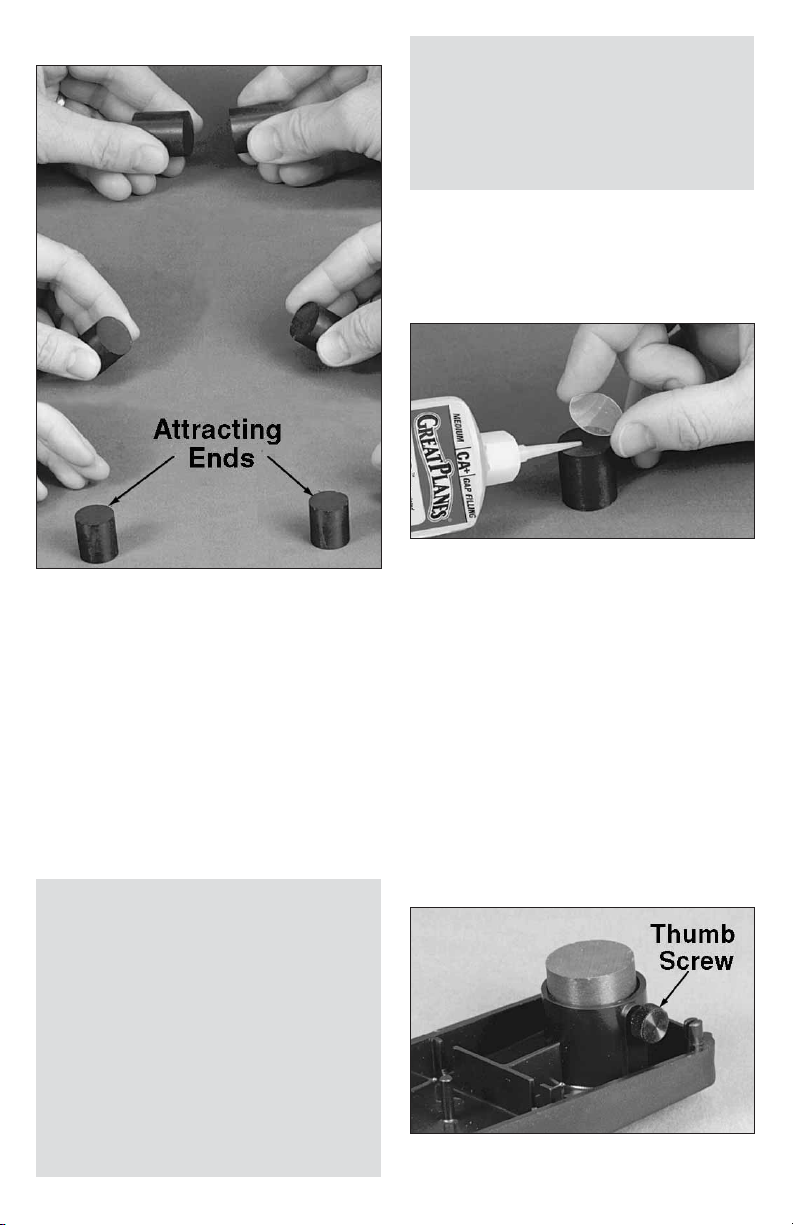

❑ 1.

Carefully remove the magnets from

the carton (see CAUTIONS on page 1).

Note how the magnets have a strong

attraction for one another. Note also how

they repel one another if one of the magnets

is turned end-for-end. When installed in the

magnet tubes, the magnets must be

positioned so they attract, not repel. Place

the magnets on your workbench with the

attracting ends pointing up. Separate the

magnets at least 12", so they won’t

accidentally snap together.

NOTE: To make the balancer as

friction-free as possible, it is very

important to provide smooth magnet

faces on which the balancer shaft

ends will spin. There are two ways of

doing this: 1) Glue the supplied clear

plastic disks to the magnet faces; or,

2) Polish the magnet faces to a

smooth and high gloss finish using

#400 and #600-grit wet-or-dry

sandpaper, followed by a rubbing/

polishing compound. Method #1 is

quick and easy and is described in

the following steps. Method #2 results

in a more scratch-resistant and

friction-free surface, but it requires

more work. The choice is yours which

method to use.

❑ 2. Remove all oil and foreign

particles from the exposed magnet

ends by wiping with a tissue dampened

with rubbing alcohol.

❑ 3. Glue one of the clear plastic

disks to each of the exposed magnet

ends by applying one drop of thick or

medium CA glue to the magnet. Center

the clear disk over the magnet and

press the disk down firmly until the CA

has spread evenly between the magnet

and the disk. Epoxy may be used

instead of CA, if you prefer. Wipe off all

excess glue before it cures, wiping

downward to avoid getting any glue on

the face of the disk. The disk will protect

the magnets and provide a smoother

bearing surface for the balancer shaft.

❑ 4. After the adhesive cures, place

the magnets into the magnet holder

Page 3

tubes in the plastic balancer cases.

When installed in the magnet tubes,

the magnets must be positioned so

they attract, not repel. Secure each of

the magnets in the magnet tubes with

a thumb screw. Do not over-tighten

the screws, as this can deform the

plastic and put the magnets out of

alignment. Slight screw pressure is all

that is required. NOTE: The 6-32

threads will self-tap into the plastic, but

you may cut threads with a 6-32 tap,

making the thumb screw easier to

adjust with your fingertips.

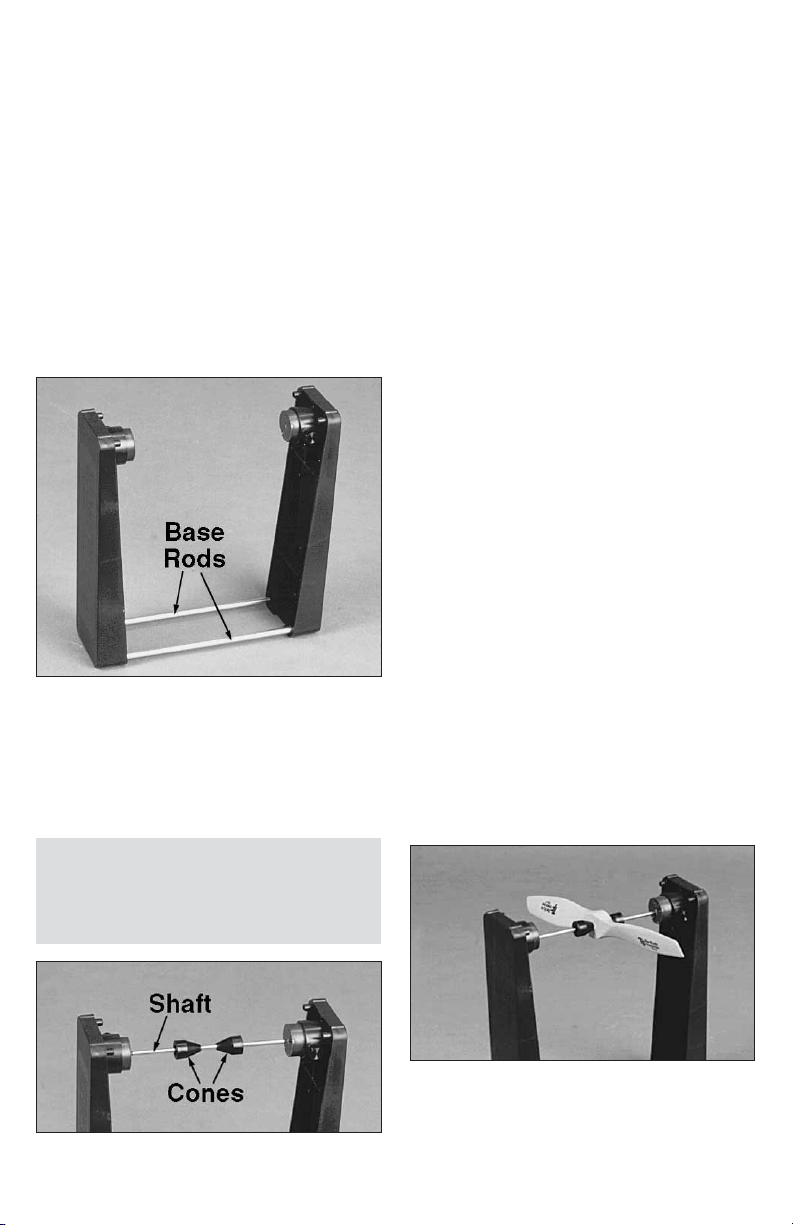

❑ 5. Push and twist the two long base

rods into the sockets in one of the case

halves. Assemble the second case

half to the other ends of the base rods.

Press firmly to seat the rods. Stand the

assembly up as shown.

shaft between the two magnets. The

balancer shaft will touch one magnet

and the other end will be suspended in

the magnetic field. For the lowest

possible friction, adjust the magnets

by loosening the thumb screws and

sliding the magnets in or out until the

gap is very small (approximately 1/32"

[0.8mm]) at the shaft end. Secure the

magnets in this position with the thumb

screws. NOTE: The smaller gap

provides lower friction and greater loadcarrying capability.

HOW TO USE YOUR TOP FLITE

PRECISION MAGNETIC BALANCER

The general principle of balancing is

to determine the “heavy side” of an

object and then to either remove

material from the heavy side, or add

weight to the light side (see safety

precautions below). Because the

Top Flite PRECISION MAGNETIC

BALANCER is so nearly frictionless,

you’ll wait a long time for a propeller

to stop swinging; therefore, you

should help the object to nearly stop

by applying light friction to the

balancer shaft with your finger. An

object is perfectly balanced if it can

be stopped and will remain stationary

in any position.

CAUTION: Do not allow the balancer

rod ends to snap hard against the

magnets, as this will damage the rod

ends or the plastic discs.

❑ 6. Slide the balancing cones onto

the balancer shaft. Place the balancer

How to balance SMALL AND MEDIUM

SIZE PROPELLERS: Slide the cones

onto the balancer shaft with the tapered

ends facing each other, trapping the

propeller between the cones. The object

Page 4

is to hold the item to be balanced

perpendicular and concentric to the

center line of the balancing shaft. Always

position the item to be balanced near

the midpoint of the balancing shaft for

best results. Determine which are the

heavy and light blades of the propeller.

BALANCING

Below are several commonly accepted

methods for balancing.

Method 1: Lightly sand the back side of

the heavier blade with fine sandpaper.

Recheck often to avoid removing too

much material.

Method 2: Apply a drop of medium CA to

the back side of the light blade and use a

piece of waxed paper or a plastic bag

over your finger to smooth the CA into a

thin film. Cure the CA with a light spray of

accelerator. Re-check the balance. Apply

more CA in thin layers until the propeller

is balanced. NOTE: Before adding glue

to a prop, make sure it is absolutely clean

and free of any oil residue.

CAUTION: Never remove material

in a way that will cause weak spots

or structural failure in the propeller.

How to balance HEAVY OBJECTS:

The capacity of the balancer can be

significantly increased by loosening the

thumb screw of one magnet. This will

allow both magnets to remain in contact

with the shaft. Allow one magnet to

“float” by leaving the thumb screw

loose. The friction between the shaft

and the magnets increases in this

mode, but balancing accuracy will not

be significantly affected with heavy

objects. Also, keep in mind that large

propellers do not have to make a full

revolution to enable balancing.

Method 3: Balance by sanding material

from the very end of the heavy blade.

This will avoid changing the airfoil shape

and avoid the possibility of weakening

the blade. NOTE: Do not attempt to

remove material by carving with a knife,

as this can leave cuts where cracks can

begin to form.

A prop is truly balanced if it can be

stopped and will remain stationary in

any position. If the prop comes to rest in

a level position, but is still obviously out

of balance (hole slightly off-center), you

may need to add weight to the lighter

side of the hub (see method 2). Do not

remove material from the hub. This

could weaken the prop, making it unsafe.

How to balance THIN OBJECTS (such

as spinner backplates), or a propeller

with a LARGE HOLE: For this

application, the tapered ends of the

cones would probably touch each other

before centering the object on the shaft,

so you’ll have to turn one of the cones

around (both cones facing the same

direction). This configuration does not

Page 5

hold the object as securely, so check the

cones frequently to make sure they are

tight against the object while balancing.

BALANCING SUGGESTIONS: To

balance a spinner, balance the backplate

first. Mark the light side (up), then

remove material from the heavy side by

drilling several shallow holes in the

backplate. Don’t drill through the

backplate and don’t drill where it will

weaken the structure. Repeat by trial

and error, until the backplate balances

perfectly. If the spinner cone has a front

hole, you can now join the backplate and

the cone on the balancer, to determine

the balance of the cone. To balance the

cone, carefully remove material from the

inside of the cone with a piece of

medium-grit sandpaper, being careful

not to remove so much material in one

place that it would weaken the cone.

NOTE: Spinners that do not have a hole

in the front of the cone do not lend

themselves to balancing, so in this case

just balance the backplate.

balancer using the method described

above and doing so will make a big

difference in the smoothness and

handling of your car. Certain car wheels

which have large diameter holes (such

as 1/10 scale on-road rear wheels) will

also require the use of an inexpensive

adapter, such as the DuraTrax®

#DTXC9581 BBS Wheel Adapter

(available from your hobby dealer),

which reduces the center hole to a size

that this balancer can accommodate.

Another way to balance rear on-road

wheels is to mount them to an extra left

diff side from your model.

When balancing car wheels,

safety is of utmost importance.

Do not attempt to balance car

wheels by sticking pins into the

rubber, as these can come loose.

Also, a spinning wheel with any

protruding metal can be very

hazardous to a person holding the

car. Self-adhesive lead tape works

great for balancing wheels. Check

with your hobby dealer or a golf

supply store for this type of tape.

Consult with your local hobby dealer

and track owner for methods that

are acceptable in your area.

TIPS FOR ULTRA-PRECISION

BALANCING:

If you need to balance small objects

with high precision, such as boat

propellers, you can follow this

procedure to increase the precision of

your balancer:

How to balance CAR WHEELS: Most

car wheels can be balanced with this

1. Examine the balancer shaft ends

with a magnifying glass. The shaft ends

should be concentric with the shaft

centerline and should not be blunt or

scratched. If a careful inspection of the

shaft ends reveals any imperfections,

you may carefully true up the points

Page 6

with a knife-sharpening stone, then

polish the points with 600-grit

sandpaper followed by rubbing

compound. The smoother the points,

the less friction. However, don’t

sharpen the points too much. Leave a

very small polished radius at the tip.

2. Before using the balancer, spread a

very thin film of oil on the magnet ends.

3. Check the balancer shaft for

straightness by rolling it slowly on a

piece of clean, dust-free plate glass. If

the shaft it bent, you’ll be able to see

light under the shaft as you roll it on the

glass. If the shaft has any significant

bend, it will not balance accurately.

Straighten the shaft by carefully

bending it. You can check the trueness

of the shaft by placing it on the balancer

without the cones.

4. Balance each individual balancer

cone, one at a time.

5. Your balancer is now ready to be

used for high precision work.

PROPER CARE OF

YOUR BALANCER

Place all components into the case

•

halves in the positions shown in the

photo. Press on the ends of the rods

(not in the middle) when storing, to

prevent bending. We recommend

storing one base rod in each case

half, for minimum case distortion.

If the balancer parts become exposed

•

to water, dry them thoroughly. Do not

close the balancer case halves

together with metal parts inside if there

is moisture in the case, as this can

result in corrosion of the metal parts.

Do not drop the magnets, or allow the

•

magnets to snap together. NOTE: If

you should happen to break a magnet,

you may glue the magnet pieces back

together with epoxy or CA glue, with

very little reduction in magnet strength.

Handle the balancer shaft with care.

•

It is made of soft steel (for high

magnetic attraction) which will bend

easily if handled roughly. When

pushing the shaft into the storage

slots in the case, push down near

both ends of the shaft, rather than at

the middle. Also, when removing the

shaft from the case, pull up near the

ends. Don’t let the shaft snap hard

against the magnets, as this will blunt

and deform the shaft ends.

When disassembling the balancer,

•

gently twist the base rods as you pull

them out.

Always open the case halves by

•

popping both ends open with a coin.

Don’t try to force the halves open

from one end only.

Do not subject the balancer to high

•

temperatures, above 120°F (49°C),

such as on the dashboard of a closed

automobile on a hot, sunny day, as

high temperatures may deform the

plastic and permanently reduce the

strength of the magnets.

If you need more friction or “holding

•

power” between the shaft and the cones

(for balancing heavy objects), try

cleaning the shaft with rubbing alcohol

or solvent. If you still need additional

friction, try roughening the plated surface

of the shaft with 320-grit sandpaper.

Page 7

MODIFICATION

In the years since its introduction, users

have informed us of various useful

modifications they have discovered. One

particularly useful one is to drill out the

Base Rod holes in one of the balancer

cases with a 3/16" drill bit, allowing the

two halves of the case to be positioned

closer together. Doing this makes it

possible to suspend a Great Planes

Fingertip Prop Balancer (GPMQ5000),

which has a threaded shaft that will hold

some items more securely.

HOW TO USE YOUR BALANCER AS

A WIND SPEED INDICATOR

(ANEMOMETER)

A unique feature of the Precision

Magnetic Balancer is its ability to read

the wind speed. Because of its nearly

friction-free design, it can determine

the wind speed to within 2 mph. All you

need is a photocell tachometer and a

balanced Top Flite 11 x 8 Power Point

prop. Any tachometer will work to read

the wind speed, but the Hobbico

Digital Mini Tach (HCAP0401) is ideal.

You can temporarily mount it on the

balancer which will allow you to set the

unit down and read the wind speed

without having to hold any of the

components.

PROCEDURE

Mount the 11 x 8 Power Point prop on

the balancer shaft and place the shaft

between the magnets. Adjust the

magnets if necessary until the shaft is

touching only one magnet. For stronger

winds, adjust the Magnets so they

touch both ends of the shaft.

Place the balancer unit on a flat surface

(or hold it) in free flowing air so the

back of the prop is facing the direction

the wind is coming from. Turn on the

tach and read the wind speed. The

wind speed with the 11 x 8 Power Point

prop will be the RPM divided by 100.

The Hobbico Digital Mini Tach reads

RPM in thousands so the wind speed

will be in tens. For example, a reading

of 0.5 on the tach is 5 mph. A reading

of 18.8 on the tach is 188 mph (in which

case you should not fly) and so on.

To temporarily mount the Hobbico Digital

Mini Tach on the balancer, use a piece of

Page 8

2" length of self-adhesive Velcro® near

the middle of one balancer case half.

Position another piece of Velcro® on the

Hobbico Digital mini-tach so that the

sensor faces the propeller blade.

NOTE: The Top Flite 11 x 8 Power

Point prop is the best prop we have

found that will give an accurate wind

speed reading without having to use

a calculator. Other props will work but

you will have to use the following

formula to determine the wind speed.

The accuracy may also be affected

due to the different efficiencies of

prop designs and pitches, but the

results will be reasonably close for

approximating the wind speed.

Wind Speed (in MPH) = RPM x Pitch

of the prop(in inches) x .00114

PARTS LIST

PART # UNITS DESC.

NYLON92 ...........2 ...............Case Half

WIRES80 ............1 .......Balancer Shaft

METAL058 .......... 2 .................. Magnet

WIRES81 ............2 ...............Base Rod

SCRW102 ...........2 ........ Thumb Screw

NYLON97 ...........2 ......................Cone

PSDC001 ............2 ..............Clear Disk

Visit our website for prices and

ordering information:

www.top-flite.com/manuals/index.html

We accept Visa and MasterCard. Note:

Parts and prices subject to change

without notice.

Top Flite Model Mfg.

3002 N Apollo Drive, Suite 1

Champaign, IL 61822

Ph: (217) 398-8970

Fx: (217) 398-7721

E-mail: partssupport@top-flite.com

© 2011 Hobbico®, Inc. All rights reserved. TOPZP01 V2.1

Loading...

Loading...