Page 1

Building th e

P-47 THUNDERBOLT

© 1976 - TOP FLITE MODELS, INC.

Page 2

Congratulations!

You now own the most accurate R/C Stand-Off Scale kit ever produced.

We at Top Flite hope that you will find this model the most pleasant to build,

inspiring to look at an d exciting to fly that you have constructed.

It is honest to point out, however, that while this model is no more difficult - in

fact is simpler than most comparable kits to make, R/C Scale models generally are not

for the newcomer to this hobby. Previous modeling experience and careful attention to

craftsmanship are necessary. Even the "old hand" will do well to study and follow the

instructions and guidance given in this booklet.

It is our aim to have you say: "This is the finest model I have ever built."

TOP FLITE MODELS, INC.

ACKNOWLEDGEMENTS

The staff of Top Flite wishes to acknowledge the assistance of the following

individuals who contributed their time and talent to the successful creation of this kit:

Col. JIM G1LHULY (USAF RET.)

ART SCHROEDER

ART SAB1N

CLARK MACOMBER

Top Flite Models, Inc.

WARNING

A RADIO CONTROLLED MODEL IS NOT A "TOY". CARE AND CAUTION

MUST BE TAKEN IN PROPERLY BUILDING THE MODEL AS WELL AS IN THE

INSTALLATION AND USE OF THE RADIO CONTROL DEVICE. IT IS IMPORTANT

TO FOLLOW ALL DIRECTIONS AS TO CONSTRUCTION OF THIS KIT AS WELL AS

INSTALLATION A ND USE OF THE ENGINE AND RADIO GEAR. THE ADVICE AND

ASSISTANCE OF A WELL-EXPERIENCED BUILDER A ND PILOT ARE ESSENTIAL.

DON'T TAKE CHANCES. IMPROPER BUILDING, OPERATION OR FLYING OF THIS

MODEL MAY RESULT IN SERIOUS BODILY INJURY TO OTHERS, TO YOURSELF

OR PROPERTY DAMAGE.

Page 3

THE P-47 STORY

The P47 was produced in larger numbers than any other U.S. Fighter of WWII.

15,683 production versions ranged from the P47-B, C, D, E, F, G, H, J, M, and N. Somewhat overshadowed by the publicity accorded the "Mustang" and the "Spitfire", the

"Thunderbolt" was, nonetheless a most distinguished and respected aircraft by friend and

foe alike.

The first P47 was test flown in May, 1941 and was known as the XP-47B. This aircraft was designed to fill th e need for a fighter aircraft able to exceed the anticipated ceilings

of enemy bombers, out gun them offensively; to escort and provide cover for American

bombers flying in the Substratosphere, and to out-gun enemy interceptors.

The first production models were assigned to fighter units in England where it be-

came extremely popular with AAF Pilots because of its ability to absorb extensive battle

damage and still remain flying.

Perhaps the most outstanding tribute to this aircraft is the fact that all ten of the

leading Thunderbolt "Aces" survived the war. Colonel Glenn T. Eagleston was one of these.

This kit is the P47D-25-RE version flown by Colonel Eagleston while a member of the

35rd Sq, 354th Gp, 19th Tactical Air Force commanded by General O.P. Weyland.

Col. Eagleston was the top "Ace" of the ninth Air Force, credited with 23'/2 destroyed, 2

probables and 7 damaged enemy aircrafts. It is to Colonel Eagleston that this kit is re-

spectfully dedicated.

References: Aero Publishers, Inc. Camouflage & Markings

329 Aviation Road Ducemus Books, Ltd.

Fallbrook, California London, England

Thunderbolt in Action U.S. A rm y & Air Force Markings, 1916-1961

3461 E. Ten Mile R oa d Library of Congress Card No. 61-16739

Warren, Michigan 48091

CONSTRUCTION OF P-47

BEFORE YOU START, READ THIS:

The assembly sequence of your Top Flite P47 has been carefully developed to help

assure the correct alignment of your model. Utilize the check-off blocks as you build;

this will allow assembly of your model in minimum time.

Before beginning an assembly step, read the instructions to familiarize yourself with

the parts to be used. Find the parts mentioned and double check them for proper identification and size with the plans. Do nut separate parts from the die cut sheets until you need

them. There are machined parts in your kit which are not identified, such as the fuselage

siders, stab, ailerons, etc. These parts can be easily identified by checking the parts against

the plans.

We are sometimes asked which glues are best for model construction. The answer to

this depends upon the particular job. This is our normal recommendation: For all

hardwood-to-hardwoud or hardwood-to-balsa joints, use white wood glue. "Titebond" is

especially good, as it dries faster than other white glues and is very strong. For balsa-tobalsa joints, regular balsa-wood cements are ample for the job, although white glue can be

used here too. Whichever type you use, remember that excess glue is no substitute for a

well-fitting joint. Use a m i ni m u m of glue at a ll times, and wipe off excess glue that squeezes

out of joints before it sets hard; when set it is difficult to remove, but if not removed it

could spoil th e cov eri ng job.

1

Page 4

CONSTRUCTION

SEQUENCE

Follow each step in order and put

check marks in the blocks as you

complete each phase described.

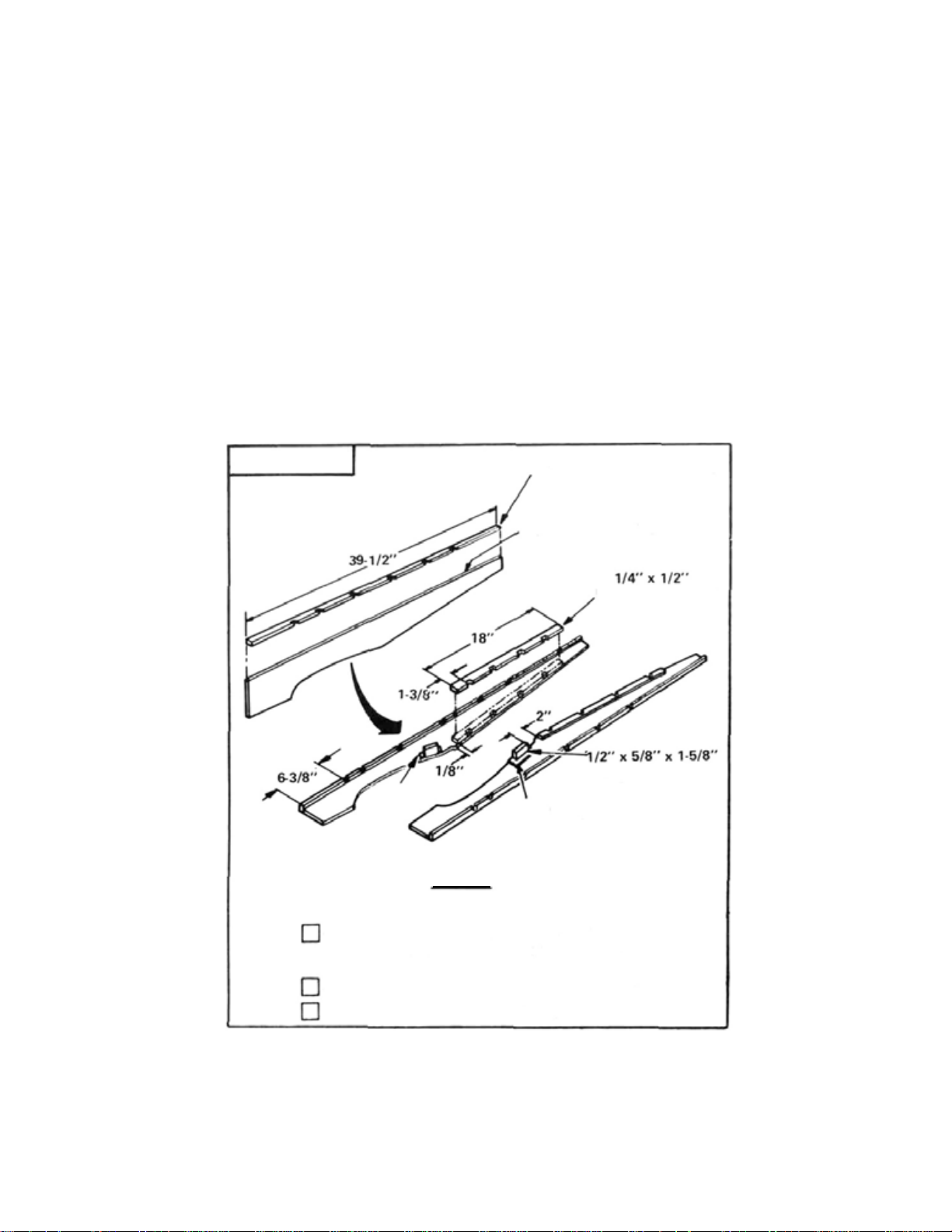

FUSELAGE

RIGHT

FUSELAGE SIDE

F-31

(PLY)

FIG.

1/4" x 1/2" NOTCHED STRIPS

NOTE CURVED TOP EDGE

NOTCHED STRIPS

WING SCREW BLOCK

F-31

(PLY)

LEFT FUSELAGE SIDE

1

HARDWOOD

STEP

1

Glue 1/4 x 1/2 notched balsa strips to fuselage sides. Make a

right and left side. Note: Curve on top edge of fuselage sides is

intentional.

Glue ply braces F-31 to fuselage sides. (See plans for position)

Glue hardwood wing screw blocks in place.

2

Page 5

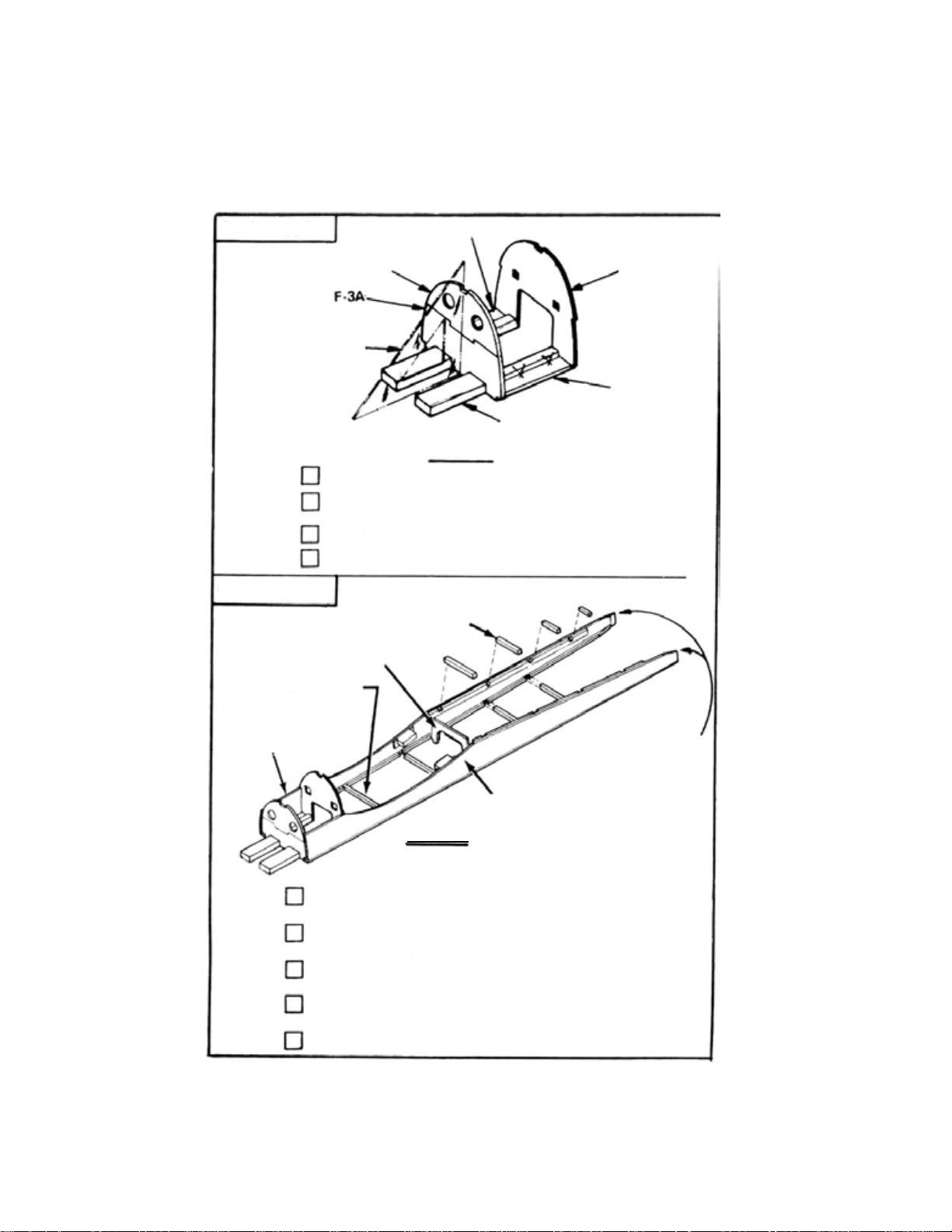

FUSELAGE

F-5

USE TRIANGLE O R

SQUARE TO CHECK

ALIGNMENT.

STEP

2

Glue F-3A and F-3B together.

Pin F-5 spacers over bottom view of plans BETWEEN F-3AB

and F-7.

Glue motor mounts to the two F-5's.

Glue F-3AB assembly and F-7 (ply) vertical in position.

FUSELAGE

F-17

(PLY)

BULKHEAD SPACER

FOR

F-8

F-3B

FIG.

1/4" SQ. SPACERS

F-7

F-5SPACERS

HARDWOOD MOTOR MOUNTS

2

(PLY)

MOTOR MOUNT

ASSEMBLY

STEP

3

Using bottom view of plans, cut 1/4 SQ. bulkhead spacers from

1/4 x 1/4 x 36 balsa strips.

Glue MOTOR MOUNT ASSEMBLY to fuselage sides over

bottom view of plans.

Starting with bulkhead spacer for F-8, glue and pin spacers in

place, working toward rear.

Glue F-17 (ply) in place. (Check plans for position). Hold

fuselage sides together with tape if necessary.

Trim rear, glue, and clamp together.

FIG.

TRIM TO 1/8" EACH

SIDE, GLUE, AND

CLAMP TOGETHER

FUSELAGE SIDE

3

3

Page 6

FUSELAGE

1/4" x 15" SO . S T RI P S

CARDBOARD

COOLING TUBES

FIG.

15"

4

STEP

4

Cut two 1/4 SQ. strips to 15" and glue on top of notched strips

flush with the inside edge. Refer to fuselage cross SECTION B-B.

Using pattern on plans, cut 2 cardboard cooling tubes to size

and glue in place.

FUSELAGE

1/4" x 1/2"

BACKBONE

STEP

5

1/4" x 1/2" BACKBONE.

F

F-19

F-24

F-22

F20

FIG.

5

Glue bulkheads F-19, F-20, F-22, F-24, and F-26 in place.

Note angle of F-19 on plans.

Fit and cut 1/4 x 1/2 backbones to length and glue in place.

4

26

Page 7

GENERAL INSTRUCTIONS

FITTING SHELLS

TOP SHELL

BOTTOM SHELL

TRIM OFF HERE

CENTER EDGE

BOTTOM EDGE

FIG.

6

CENTER EDGE

BOTTOM EDGE

TRIM OFF HERE

CUT ALONG CENTER

BOTTOM EDGE

FIG.

7

HOLD IN PLACE WITH TAPE

Extensive effort has gone into the development of the shells

provided in this kit. Occasionally one shell may split or crack due

to rough treatment during shipment. If this occurs it can easily

be repaired with glue. Each shell is purposely oversize. This is to

allow you enough wood to work with and attain a perfect fit.

When fitting, cut small portions at a time. Trim the shells as in

FIG.

6.

When fitting a shell, lay it lengthwise on it's BOTTOM EDGE.

If it is not flush, sand it until it is. Tape or pin it in place and

cut along the top center. Do the same with the opposite side.

When both shells fit properly, glue them in place. Masking tape

works well in holding them while drying.

5

Page 8

FUSELAGE

F-7

p-19

HARDWOOD

TAIL

BLOCK

BALSA

TAIL

BLOCK

F-26

F-3AB

FORWARD SHELL SECTION

STEP

6

Cut and fit the REAR SECTIONS and glue in place.

Glue the tail blocks in place.

Trim and fit forward shell sections. DON'T GLUE IN PLACE

YET.

FUSELAGE

COCKPIT

ASSEMBLY

P-9

P-12

F-13R

F-10

REAR SECTION

SET CENTER SECTION ASIDE

FIG.

8

F-14

F-13L

F-15

2"

STEP

7

FIG.

F-11

Glue F-13R and F-13L together.

Glue F-11 to bottom part of F-9.

Glue F-15 to bottom part of F-16.

Glue F-13R L assembly on top edges of F-11 and F-15.

Glue F-10 and F-14 on top of F-13 RL.

Glue F-12 2" behind F-10.

6

9

Page 9

FUSELAGE

F-4

1/4" x 1/2" BACKBONES.

COCKPIT ASSEMBLY

F25

F-23

1/4" x 1/4"

x 33-1/2"

STRIPS

F-2

STEP

8

FUSELAGE

TOP RIGHT

FUSELAGE SHELL

F27

F-8

F6

F-18

NOTCH STRIP

FIG.

10

Glue F-27'S to rear of fuselage.

Cut and glue 1/4 x 1/4 x 33-1/2 strips to inside half of

NOTCHED STRIPS. See fus cross section A-A.

Glue COCKPIT ASSEMBLY in place.

Glue bulkheads F - 2 thru F-25 in place.

Cut and glue 1/4x1/2 backbones in place.

F21

TRIM REAR

OF F-27'S

TO

1/4"

THICKNESS

STEP

9

TOP LEFT

FUSELAGE SHELL

FIG.

11

Trim, fit, and glue top fuselage shells in place.

7

Page 10

WING

3/32" x 4" x 30" BALSA SHEETS

FIG.12

STEP

1

WING

Join three 3/32 x 4 x 30 balsa sheets using masking tape as

shown.

Turn over and glue joints as shown.

Pin to a flat surface and allow to dry.

Remove tape.

Make 4 SETS of panels.

PLY

W-13

W-5

W-3

W-2

W-2A

FIG.

13

STEP

2

Glue balsa half rib W -2A to R IB W-2.

Glue landing gear brace W -13 (PLY) to ribs W-3 and W-5

Make sets for RIGHT WING half and LEFT WING half.

8

Page 11

WING

1/2" x 5/8" x 3" BALSA BLOCK

CUTTING LINE

STEP

3

WING

WING TIP END

TOP VIEW

MACHINED BALSA

TRAILING EDGE

FIG.14

Glue 1/2 x 5/8 x 3 balsa blocks to trailing edges as shown.

Place above assembly over wing plan and cut ANGLE in center

so the two will be flush when joined later. Make sure both

trailing edges are equal length after trimming.

TRAILING EDGE ASSEMBLY

WIDE END

WING ALIGNMENT WEDGE

NARROW END

OF WEDGE AT TIP

STEP

4

FIG.15

Pin wing ALIGNMENT WEDGE to plans over location o f

machined trailing edge.

Pin trailing edge assembly over wing alignment wedge. (Do

not glue)

9

Page 12

WING

W-11

W-10

W-14

1/4" x 1/2" TOP SPAR

(PLY)

MARK

W-15

(PLY)

,W.2

W-1

STEP

5

WING

1/4" x 1/2"

BOTTOM SPAR

Pin 1/4 x 1/2 BOTTOM SPAR over plans.

Glue brace W-15 (ply) to front of bottom spar.

Glue AL L RIBS in place over bottom spar.

Glue W-14 (ply) to top spar.

Glue TOP SPAR in place.

Glue LEADING EDGE in place.

Mark leading edge at W -2 for location of wing dowel

FIG.

17

W-6

FIG.

16

NARROW END

WING ALIGNMENT WEDGE

STEP

6

Switch wing alignment wedge to right side.

Block left wing up 4-1/2 under tip.

Construct right half in the same manner as the left.

Glue the two wing halfs together.

10

Page 13

WING

STEP

7

ALIGNMENT WEDGE

FIG.

18

Remove pins from spar and cover the top of right wing with

sheets prepared in Step 1. Allow to dry.

Switch wing alignment wedge back to left side, block right half

up 4-1/2, and sheet the top of the left side.

Allow to dry completely.

WING

LANDING GEAR

KEY BLOCK

LANDING GEAR

BLOCKS

WING TIP

AILERON BELLCRANK

ASSEMBLY

NOTE: IF RETRACTABLE LANDING GEAR IS TO BE USED,

FOLLOW INSTALLATION INSTRUCTIONS PROVIDED BY

GEAR MFG.

STEP

8

HARDWOOD WING

DOWELS

Install

LANDING

holes for gear strut.

Drill

1/4

holes

in

Install aileron bellcrank assembly and aileron pushrod wires.

(See wing cross SECTION CC)

Sheet both bottom halfs marking location for landing gear.

Glue wing TIPS and FLAPS in place.

Glue fabric reinforcing TAPE to center section.

Sand ailerons to final shape. Glue W-16 (ply) insert in place in

each aileron.

REINFORCE CENTER WITH FABRIC

TAPE AFTER SHEETING

FLAPS

W-16 (PLY)

INSERT

GEAR BLOCKS and key

leading

edges and

install

FIG.

hardwood

19

blocks.

AILERON

Drill

5/32

dowels.

11

Page 14

WING

WING SHELL

1/4" x 1/2" BACKBONE

F-32

(PLY)

F-7

(PLY)

W-17

HOLD WIN G IN PLACE WITH

NAIL WHILE DRILLING OPPOSITE

SIDE

W-20

F-29

F-28 FILLET

F-30

(PLY)

MAKE CUTS WITH

RAZOR SAW

STEP

9

FIG.

20

Place wing on fuselage. Put braces F-32 (ply) over wing dowel:

and glue to bulkhead F-7 (ply). DON'T GLUE DOWELS.

Drill

1/8

holes in wing and

Remove wing and tap threads in hold down block with NO. 8

SELF TAPPING SCREW SUPPLIED.

Glue fillet base F-30 (ply) to fuselage and replace wing,

holding with nylon screws. (Protect with monokote backing)

Glue fillets F 28 and fillet ends F-29 in place.

Glue formers W-17, W-18. W-19. and W-20 to wing bottom.

Glue 1/4 x 1/2 backbone in place.

Fit and glue SHE LLS to wing bottom.

Cut notch in shells for access to wing screws.

Fit and glue shells to bottom front of fuselage.

12

hold

down block

for

wing

screws.

Page 15

COWL ASSEMBLY

SAND EDGES

WOOD SCREWS

COWL RING

Sand edges of F-1 (ply) to fit losely inside plastic rear COWL

RING.

Glue F-1 (ply) to fuselage and sand entire fuselage to final shape.

Mount cowl ring to fuselage with wood screws.

Align and glue cowl sections together as shown with model

cement (ambroid, sigment, etc.)

Remove assembled cowl and sand lightly with 400 grit paper.

Mak e CUT-OUTS for exhaust and glow pl u g access.

Cowl will accept most common model paints available in your

local hobby shop. Paint as desired.

FIG.

21

COWL RING

r-1

(Ply)

FIG.22

EXHAUST CUT OUT

TO SUIT ENGINE

TAIL

ASSEMBLY

TOOTHPICK

Join elevators with 1/ 4 x

1/2x4 hardwood strip.

Glue HORIZONTAL

STABILIZER to fuselage body.

Glue FIN on top of horizontal

stabilizer.

Shape and glue balsa STAB

FILLETS in place.

Attach landing gear cover W-21 (ply) to landing gear strut.

Trim excess from canopy. Attach after covering fuselage.

Attach plastic scoop t o bottom rear of fuselage. (See plans for

location)

NYLON

HINGE

ELEVATOR

WOOD SCREWS

13

FIN

STAB FILLETS

HORIZONTAL STABILIZER

1/4"x 1/2" HARDWOOD

ELEVATOR JOINER

FIG.

23

RUDDER

Page 16

COVERING

Sand the entire airplane with 200 grit paper. Then final sand with 400 or 500 grit

paper. Remove all sanding dust with a clean cloth and cover model. A very realistic finish for this model can be obtained with MONOKOTE. This material can be

scratched and textured to look like the skin on the actual P-47. Try to have the

seams along rivet lines, panels, etc. and they will be unnoticeable.

FINAL STEPS

Install the R/C equipment, hinge control surfaces, install engine, fuel tank, wheels,

and push rods using the plans for location. Make sure PLANE BALANCES at or

slightly forward of the CENTER 01 GRAVITY shown on plans, NOTE: THE

FAILURE TO BALANCE THE COMPLETED MODEL AS SHOWN WITH ALL

RADIO GEAR INSTALLED MAY MAKE THE MODEL UNCONTROLLABLE

IN FLIGHT RESULTING IN POSSIBLE INJURY TO OTHERS, TO YOURSELF

OR TO PROPERTY DAMAGE. Make sure all controls work freely, with no binding

and in the proper direction. Carefully follow all installation and operation instructions given by th e radio c ontrol unit manufacturer.

FIRST FLIGHT

It is CRUCIAL that a well-experienced R/C Modeler-Pilot go over the plane carefully

before attempting the first flight. If you are not well-experienced in checking out all

construction and operating details and in flying, GET HELP. R/C modelers are a fine

group of people that will gladly offer help when asked. Your hobby dealer may also

be able to assist you. Write (and join!) the Academy of Model Aeronautics, 806

Fifteenth

Clubs in your state and you can contact one of them. They will be happy to help.

The well-experienced R/C modeler-pilot will thoroughly go over all aspects of your

construction and gear installation. He will then re-check everything at the flying

field and then, if-but only if-all is right, he will perform the all important first

flight of your aircraft and "trim it out", that is, make in-flight adjustments of the

moving surfaces and make further changes on the ground, as necessary. Remember

that even experienced R/C pilots tu rn to really well-experienced modeler-pilots

for this crucial final check-out and trim-flight.

What is at stake is not just your model, but the SAFETY of others, yourself and

property. Do Not fly until you are certain you are flying a checked-out model that

you can SAFELY control under all circumstances!

St.,

N.W.,

Washington,

D.C.

20005.

They

will

supply

you

with a

list

of

R/C

We believe that we have passed on to you some helpful ideas gathered from our own

experience and sincerely hope that building and flying your P-47 will be a rewarding

experience.

Best of Luck!

TOP FLITE MODELS

FLIGHT LOG

14

Loading...

Loading...