Page 1

HIGH

FOG

12.00

01

VD

-1.2525

-0.5050

7.8 0

7.7 5

180

180

PR2

0000100001000

00001000010 00

00001000010 00

mm

R

S

C

A

K

R1

R2

A

PR1

1

MANUAL

7.80

0

1 0

R

S

C

A

K

R1

R2

A

PR1

PR2

PA1

PA1

ID

R L

-1.

-0.

180

R1

7.80

R2

7.75

180

PR1

7.80

01

R/K

0000100001000

MANUAL

R1

R2

PR2

PA1

mm

FOG

HIGH

PR1

PR2

PA1

VD

12.00

M

USER MANUAL

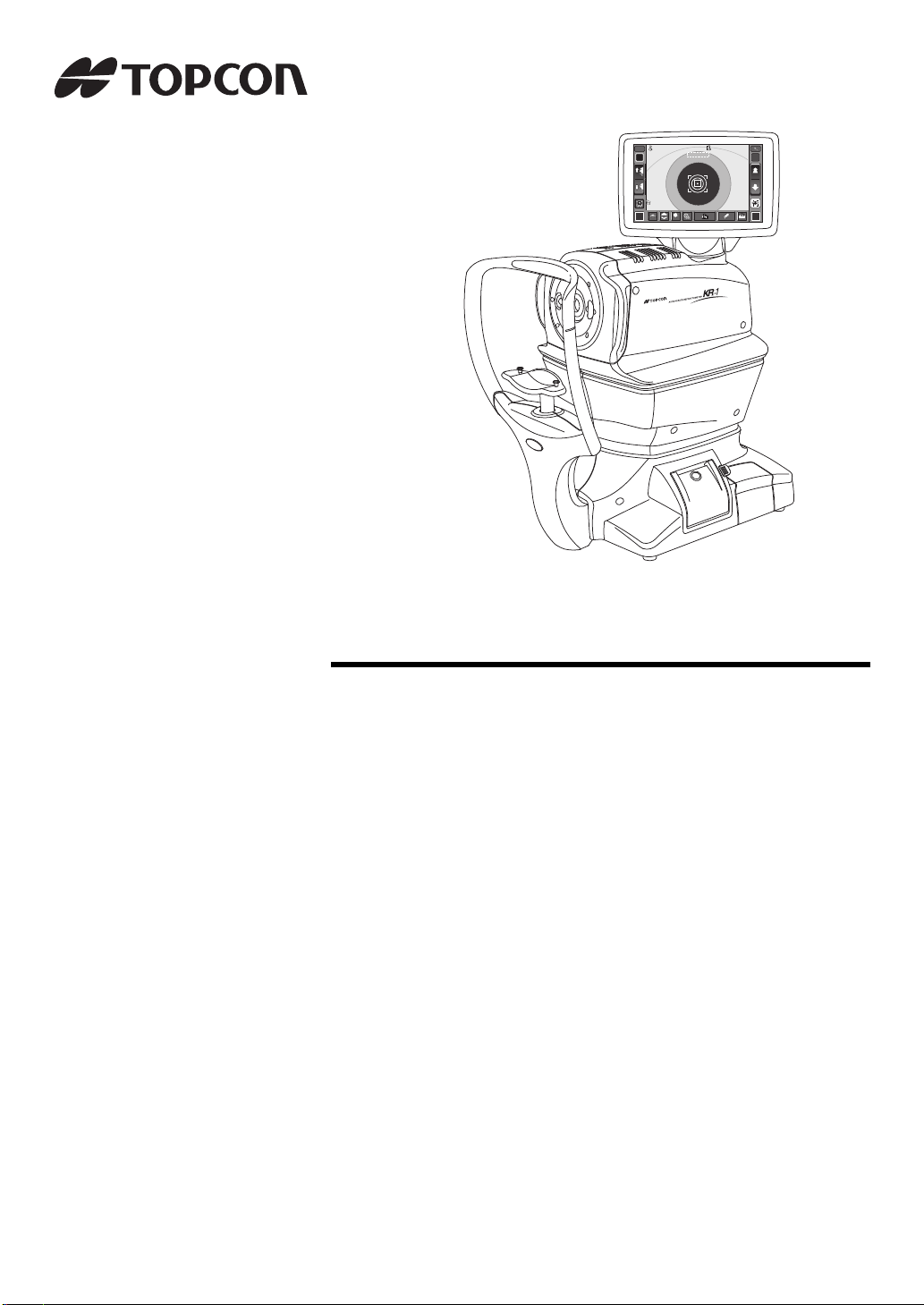

AUTO KERATO-REFRACTOMETER

KR-1

Page 2

Page 3

INTRODUCTION

Thank you for purchasing the TOPCON Auto Kerato-Refractometer KR-1.

INTENDED USE / INDICATIONS FOR USE

This instrument is used to measure the spherical refractive-power, cylindrical refractive power, the

direction of astig mat ic ax i s, the ra diu s of c urv atu re , th e c orneal astigmatic ax is an gle and the corneal refractory power.

FEATURES

This instrument features the following:

• The KR-1 is simple to operate and measures the refraction and corneal curvature of the eye.

• The position of the touch panel can be adjusted to accommodate the user's preferred position.

• The auto start function facilitates quick measurements under the optimal condition.

PURPOSE OF THIS MANUAL

This User Manual provides an overview of the basic operation, troubleshooting, checking, maintenance and

cleaning of the TOPCON Auto Kerato-Ref ractometer KR-1.

To get the best use of the instrument, read Safety Displays and Safety Cautions.

Keep this Manual at hand for future reference.

INTENDED PATIENT POPULATION

• The patient who undergoes an examination by this instrument must maintain concentration for a few minutes and keep to the following instructions:

To fix the face to the chinrest, forehead rest.

To keep the eye open.

To understand and follow instructions when undergoing an examination.

• Since this product is a precision instrument, always use and keep it in a normally controlled living environment, within a temperature range of 10-40°C, humidity levels between 30-90% and an atmospheric pressure range of 700hPa-1,060hPa.

The instrument should also be placed away from direct sunlight.

• To ensure smooth operation, install the instrument on a level floor free of vibrations. Also, do not place

anything on the instrument.

• Connect all cables properly before using.

• Use the power at a rated voltage.

• When not in use, switch off the power source and apply the rubber cap and dust cover.

• For accurate measureme nt res ul t s, take care to keep the measuring window cl ean and free of fingerpr int s ,

spots and dust.

[CAUTION] Federal law restricts this device to sale by or in the order of a Physician or Practitioner.

Since this product partly uses a program derived from IPA Font, using the product is regarded as consent to the IPA Font License

Agreement v1.0.

For the IPA Font License Agreement v1.0, see page 71 or the following URL.

http://ipafont.ipa.go.jp/ipa_font_license_v1.html

1

Page 4

DISPOSAL

When disposing of the i nstrume nt and/or parts, fo llow loca l regulation s for dis posal and re cycling.

This product contains a CRL Lithium Battery which contains Perchlorate Material-special handling may apply.

See http://www.dtsc.ca.gov/hazardouswaste/perchlorate/

Note; This is applicable to California, U.S.A. only

STORAGE AND USAGE PERIOD

1. WHEN STORING THE INSTRUMENT, ENSURE THAT THE FOLLOWING CONDITIONS ARE MET:

(1) The instrument should not be splashed with water.

(2) Store the instrument away from envir onments where air pressure , temperature , humidity,

ventilation, sunlight, dust, salty/sulfurous air, etc. could cause damage.

(3) Do not store or trans port the instrument on a slanted or uneven su rface or in an area

where it is subject to vibrations or instability.

(4) Do not store the instrument where chemicals are stored or gas is generated.

2. NORMAL LIFE SPAN OF THE INSTRUMENT:

8 years from delivery providing regular maintenance is performed (according to the self-certification [Topcon data])

USER MAINTENANCE

1. Regularly measure the attached model eye and check the accuracy.

2. Clean the measuring window when it is soiled.

3. Clean the forehead rest and chinrest when these are soiled.

4. Put on the dust cover when not in use.

2

Page 5

HOW TO READ THIS MANUAL

• Read the instructions on pages 1 to 8 before using the machine.

• Regarding connection to various devices, see "CONNECTING EXTERNAL I/O TERMINALS" on page 20.

• If you would like an overview of the system, begin by reading "BASIC OPERATIONS"(page

24).

• For setting various functions, see "SETTING FUNCTIONS ON SETUP SCREEN" on page

44.

SYMBOLS IN TEXT

MEMO: Useful functions to know and attentions to prevent troubles are noted.

3

Page 6

DISPLAYS FOR SAFE USE

WARNING

CAUTION

In order to encourag e th e s afe us e of t he ins trum ent and to avoid dange r to t he opera t or an d o thers as well as dam age to prop erties, warnings are descr ibed in the User Manual and marked on

the instrument body.

We suggest you thor oughly understand the meaning of the following displays/icons and Safety

Cautions, as well as read the Manual, and strictly observe the instructions.

DISPLAYS

DISPLAY MEANING

Improper handling or ignori ng this display may lead to

the danger of death or serious injury.

Improper handling or ignoring this display may ca use

personal injury or physical damage.

• Injury means hurt, burn, electric shock, etc.

• Ph ysical d amage mea ns exten sive dama ge that ma y invol ve buil ding, pe ripheral equipment and furniture.

4

Page 7

GENERAL SAFETY INFORMATION

WARNINGS

Ensuring the Safety of Patients and Operators

When operating the instrument, do not touch the patient's eye or nose.

Handling the cord o n this produ ct or cords ass ociated with a cces sories s old with th is pro duct,

will expose you to lead, a chemical kn own to the State of California to cause birth detects or

other reproductive harm. Wash hands after handling.

Preventing Electric Shocks and Fires

To avoid fire and electric shock, install the instrument in a dry place free of water and other liquids.

To avoid fire and electric shock, do not put cups or other containers with liquids near the instrument.

To avoid electr ic shoc ks, do not i nsert metal objects into the inst rumen t body thro ugh th e vent

holes or gaps.

To avoid fire in the event of an instrument malfunction, immediately turn OFF the power switch

" " and disconnect the p ower plug from the outlet i f you see smoke comi ng from the instrument, etc. Don't install the instrument where it is difficult to disconnect the power plug from the

outlet. Ask your dealer for service.

5

Page 8

Ensuring the Safety of Patients and Operators

CAUTIONS

To avoid injury when operating the chinrest up/down button, be careful not to catch the

patient's fingers.

Preventing Electric Shocks and Fires

To avoid injury by electric shock, do not open the cover. For repair, call your service engineer.

To avoid inj ury by electric shock wh en changing the fuse, turn off the power and pull off the

power cable. Use the rated fuse.

Electromagnetic Compatibility (EMC)

This instrument has been test ed (with 100/120/230V) and found to comply with IEC60601-12:Ed.3.0:2007. This instrument radiates radio frequency energy within standard and may affect

other devices in the vicinity. If you have discovered that turning on/off the i nstrument affects

other devices, we recommend you change its position, keep a proper distance from other

devices, or plug it into a different out let. Please consult your au tho rize d dea le r if you hav e any

additional questions.

6

Page 9

USAGE AND MAINTENANCE

Usage:

• Since the Auto Kerato-Refractometer KR-1 is medical device, the operation should be

supervised by a physician.

USER MAINTENANCE

To maintain the safety and performance of the equipment, never attempt to do maintena nce

except for the items specified below. For details, follow the instructions.

FUSE CHANGE

For details, See “FUSE CHANGE” on page 68.

CLEANING OF MEASURING WINDOW

For details, See “CLEANING THE INSTRUMENT” on page 65.

DISCLAIMERS

• TOPCON is not responsible for damage due to fire, earthquakes, actions or inactions of third

persons or other accid ents, or damage due to negligen ce and misuse by the us er and any

use under unusual condit io ns.

• TOPCON is not responsible for damage derived from in ability to properly use this equipment, such as loss of business profits and suspension of business.

• TOPCON is not responsible for damage caused by operations other than those described in

this User Manual.

• The devi ce doe s not p rovide a diagn osis of any c onditi on or la ck the reof o r any r ecomm endations for appropriate treatment. The relevant healthcare provider is fully responsible for all

diagnosis and treatment decisions and recommendations.

7

Page 10

POSITIONS OF WARNING AND CAUTION

3 14 2 5

INDICATIONS

To secure safety, this equipment provides warnings.

Correctly use the equipment following these warning instructions. If any of the following marking labels are missi ng, please contact your dealer or TOPCON at the addres s stated on the

back cover.

No. Label Meaning

WARNING

1

2

3

4

5

To avoid injury caused by electric shock, do not open the cover.

Ask your dealer for service.

WARNING

Electric shock may cause burns or a possible fire.

Turn the power switch OFF and unplug the power cord before

replacing the fuses.

Replace only with fuses of the correct rating.

CAUTION

Be careful not to hit the patie nt's eyes or nose wit h the instr ument

during operation.

CAUTION

When operating the chinrest up/down switch, be careful not to

pinch the patient's hand.

The patient may be injured.

Degree of protection against electric shock:

TYPE B APPLIED PART

8

Page 11

CONTENTS

INTRODUCTION ....................................................................................................1

HOW TO READ THIS MANUAL.............................................................................3

SYMBOLS IN TEXT ........................................... ...... ...... ..............................3

DISPLAYS FOR SAFE USE...................................................................................4

DISPLAYS....................................................................................................4

GENERAL SAFETY INFORMATION .....................................................................5

USAGE AND MAINTENANCE ...............................................................................7

USER MAINTENANCE...........................................................................................7

FUSE CHANGE............................................................................................7

CLEANING OF MEASURING WINDOW ............................................ ...... ....7

DISCLAIMERS .......................................................................................................7

POSITIONS OF WARNING AND CAUTION INDICATIONS..................................8

COMPONENTS

COMPONENT NAMES.........................................................................................11

COMPOSITION OF PARTS WHICH CONTACT THE HUMAN BODY................11

OPERATION METHOD OF CONTROL PANEL...................................................12

CONTROL PANEL COMPONENTS.....................................................................12

FUNCTION BUTTON .................................................................................13

MONITOR SCREEN.............................................................................................14

MEASUREMENT SCREEN........................................................................14

SETTINGS SCREEN..................................................................................14

CORNEA DIAMETER MEASUREMENT SCREEN....................................14

PRINTER OUTPUT ..............................................................................................15

PRINTOUT FORMAT SETTING ........................................... ...... ....... ...... ..17

STANDARD ACCESSORIES ...............................................................................18

PREPARATIONS

INSTALLATION ....................................................................................................19

CONNECTING POWER CABLE ..................... ...... ....... ...... ..................................19

CONNECTING EXTERNAL I/O TERMINALS ......................................................20

DATA OUTPUT ..........................................................................................20

DATA INPUT ..............................................................................................21

PRINTER PAPER SETTING ................................................................................21

RECOVERY FROM POWER SAVE STATUS......................................................23

ADJUSTING THE CONTROL PANEL POSITION................................................23

BASIC OPERATIONS

PREPARATION BEFORE MEASUREMENT .......................................................24

TURNING ON THE INSTRUMENT............................................................24

SELECTING THE MEASUREMENT MODE..............................................24

PATIENT POSITIONING............................................................................25

AUTO MODE MEASUREMENT...........................................................................27

SETTING THE AUTO MODE.....................................................................27

ALIGNMENT AND MEASUREMENT.........................................................28

DISPLAYING MEASUREMENT VALUES..................................................29

MANUAL MODE MEASUREMENT......................................................................30

SETTING THE MANUAL MODE................................................................30

ALIGNMENT AND MEASUREMENT.........................................................30

DISPLAYING MEASUREMENT VALUES..................................................33

PRINT-OUT OF MEASUREMENT VALUES........................................................34

CLEARING MEASUREMENT VALUES...............................................................35

DISPLAYING ALL MEASUREMENT DATA .........................................................36

OPERATION OF AFTER USE .............................................................................37

9

Page 12

OPTIONAL OPERATIONS

DISPLAYING THE PATIENT ID (PATIENT No.) OR EXAMINER ID ...................38

MEASURING ONE EYE ONLY............................................................................38

MEASURING THE RIGHT EYE ONLY ......................................................38

MEASURING THE LEFT EYE ONLY.........................................................38

MEASUREMENT OF CORNEA DIAMETER........................................................39

MEASUREMENT ON THE ACTUAL IMAGE .............................................39

MEASUREMENT ON THE STILL IMAGE..................................................41

OUTPUT USING RS232C....................................................................................43

INPUT USING USB ............................ ...... ....... ...... ....... ...... ...... ....... .....................43

OUTPUT USING LAN...........................................................................................43

SETTING FUNCTIONS ON SETUP SCREEN

OPERATING THE SETUP SCREEN ...................................................................44

PREPARATONS FOR SETTING...............................................................44

OUTLINE OF SETUP SCREEN OPERATIONS ........................................45

RETURNING TO THE MEASUREMENT SCREEN...................................47

LIST OF SETUP ITEMS .......................................................................................48

INITIAL (INITIAL SETTING) .......................................................................48

SETTING OF INTERNAL PRINTER (PRINT) ............................................50

DATA COMMUNICATION (COMM) ...........................................................52

LAN CONNECTION (LAN).........................................................................53

OPERATOR ID...........................................................................................53

SPECIAL ....................................................................................................53

TROUBLESHOOTING

MESSAGE LIST .........................................................................................54

TROUBLE-SHOOTING OPERATIONS......................................................55

SPECIFICATIONS AND PERFORMANCE

SPECIFICATIONS AND PERFORMANCE ..........................................................56

ENVIRONMENTAL CONDITIONS OF USE...............................................57

ENVIRONMENTAL CONDITIONS OF STORAGE ....................................57

ENVIRONMENTAL CONDITIONS OF TRANSPORT................................57

ELECTROMAGNETIC COMPATIBILITY .............................................................58

ELECTRIC RATING . ...... ....... ...... ............................................. ............................62

SAFETY DESIGNATIONS PER IEC 60601-1 STANDARD .................................62

DIMENSIONS AND WEIGHT...............................................................................62

OPERATION AND PRINCIPLE OF OPERATION................................................63

REFERENCE

OPTIONAL ACCESSORIES.................................................................................64

SHAPE OF PLUG.................................................................................................64

SYMBOL...............................................................................................................64

MAINTENANCE

DAILY CHECKUPS ..............................................................................................65

CHECKING THE MEASURING ACCURACY ............................................65

CLEANING THE INSTRUMENT ................................................................65

CLEANING THE FOREHEAD REST AND CHIN REST ............................65

DAILY MAINTENANCE.................. ....... ...... ....... ...... ...... ....... ...... ....... ...... ..66

ORDERING CONSUMABLE ITEMS..........................................................66

USER MAINTENANCE ITEM.....................................................................66

BRIGHTNESS ADJUSTMENT OF CONTROL PANEL..............................67

PRINTER PAPER JAM ............................................ ...... ....... ...... ....... ........67

FUSE CHANGE..........................................................................................68

SUPPLYING THE CHINREST TISSUE .....................................................69

MAINTENANCE....................................................................................................70

CLEANING THE COVER ...........................................................................70

CLEANING THE CONTROL PANEL..........................................................70

10

Page 13

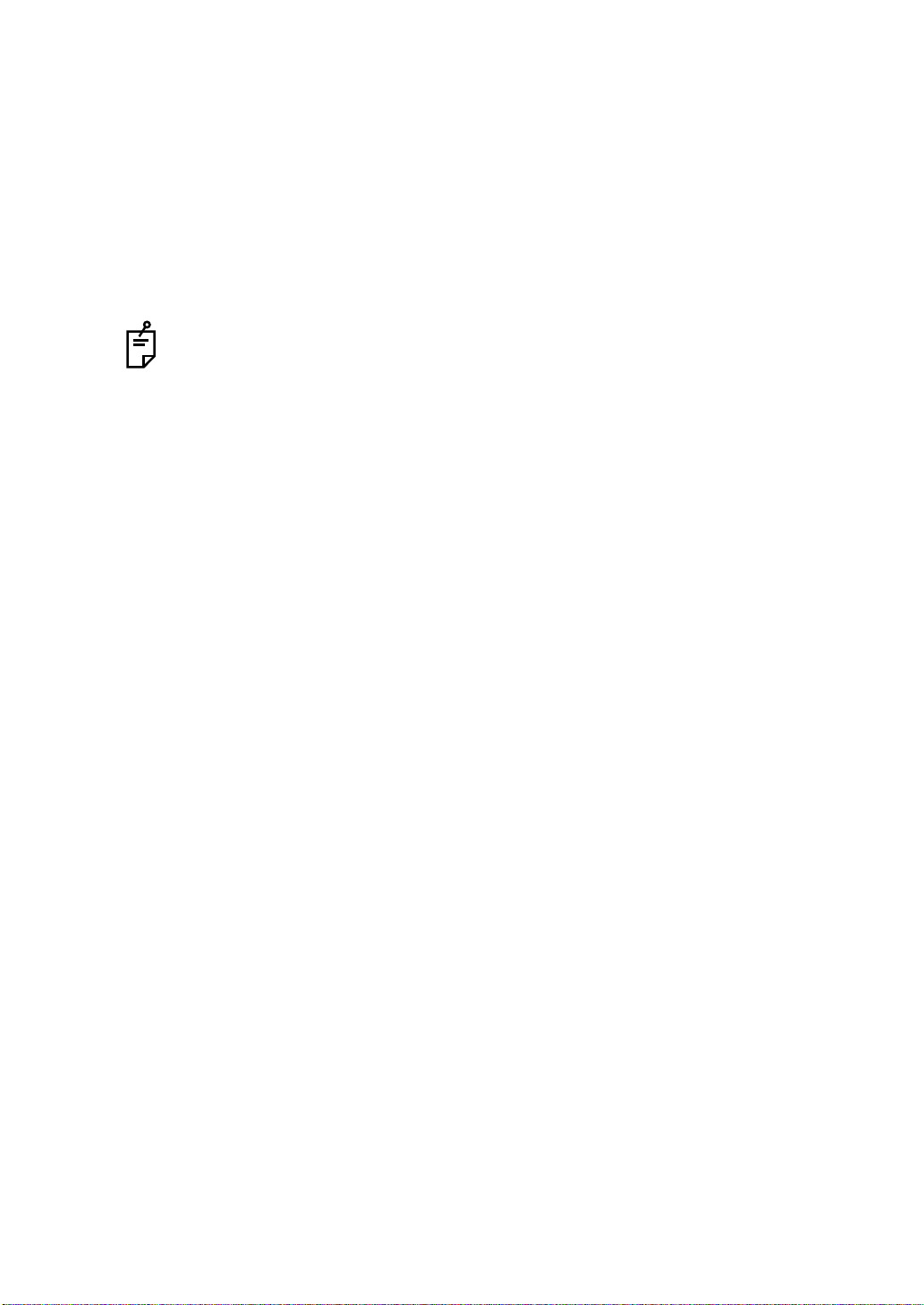

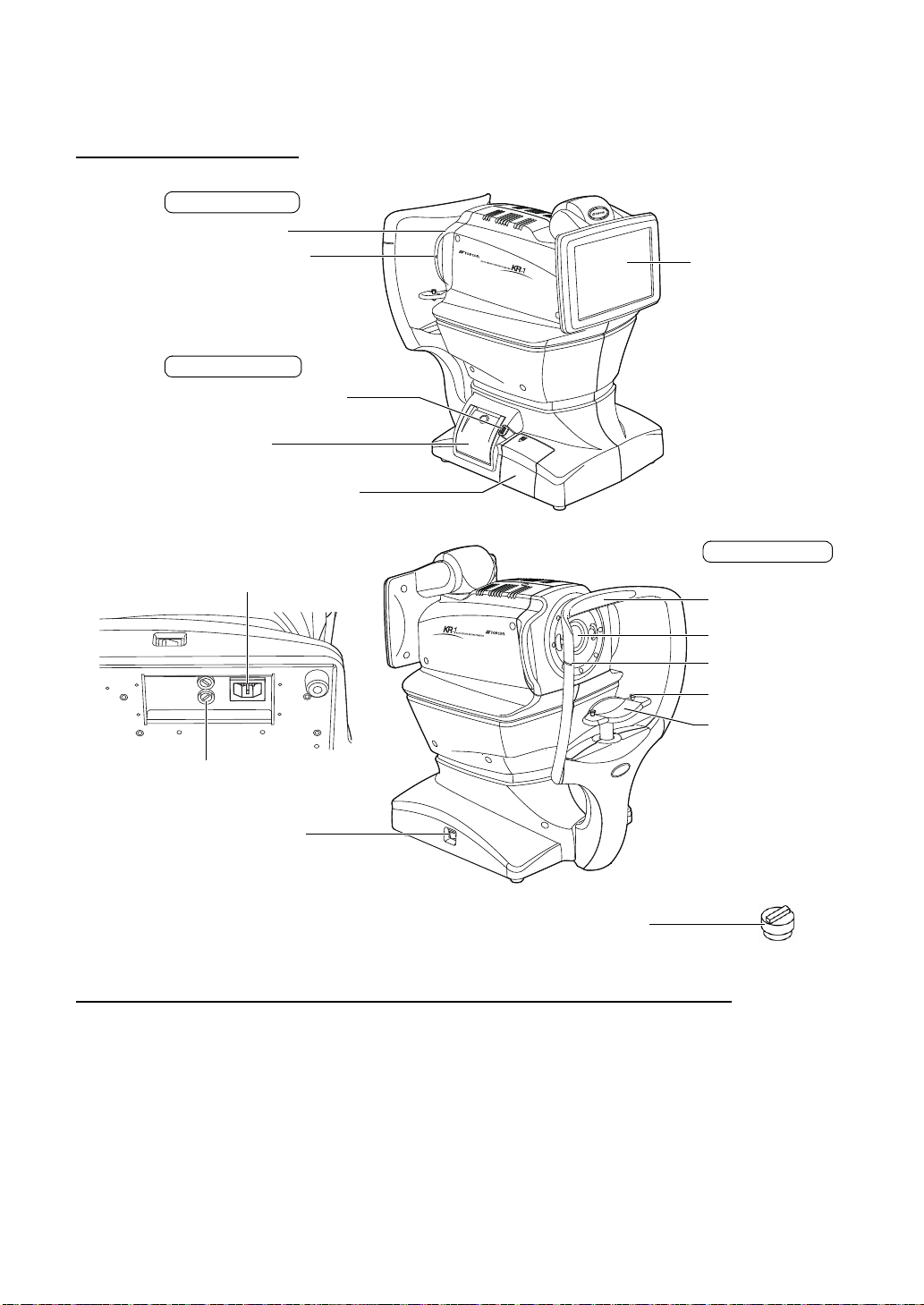

COMPONENTS

Control panel

Eye height mark of

measuring window

POWER switch

Forehead rest

Measuring window

Eye height mark

Chinrest tissue pin

Chinrest

Main body Section

Chinrest Section

Power unit Section

Printer cover open switch

Printer cover

External I/O terminal cover

Rubber cap

Measuring head

Power inlet

Fuse folder

*1

*1: Contacting part (class B)

*1

COMPONENT NAMES

COMPOSITION OF PARTS WHICH CONTACT THE HUMAN BODY

Forehead rest : Silicone rubber

Chinrest : Acrylonitrile butadiene styrene resin

11

COMPONENTS

Page 14

OPERATION METHOD OF CONTROL PANEL

R L

R/K

ID

A

13.7513.75

-1.-1 .2525

-0.-0 .5050

7.807. 80

7.807. 80

7.757. 75

18018 0

18018 0

010 1

VDVD

PR2PR2

0000100001000000010 0001000 00001000010000 000100001000

mmmm

R

S

C

A

K

R1

R1

R2R2

A1A1

PR1PR1

3/33/3

3/33/3

AUTOAUTO 0/30/3

0/30/3

R

S

C

A

K

R1

R1

R2R2

A1A1

PR1PR1

PR2PR2

PA1PA1

PA1PA1

LOWLOW

FOGFOG

R L

R/K

00001000010000100001000010 00010000100 001 0000100001000010 0001

13.7513.75

diodio

AUTOAUTO

010 1

VDVD

S

ID

A

mmmm

R

S

C

A

K

R1R1

R2R2

A1A1

PR1PR1

PR2PR2

PA1PA1

PR2PR2

PA1PA1

R

S

C

A

K

R1R1

R2R2

A1A1

PR1PR1

HIGHHIGH

FOGFOG

0/30/3

0/30/3

0/30/3

0/30/3

Settings button

Display

L button

Measuring head forward

button

Measuring head backward button

Start button

Auto/Manual button

Function button

ID button

R button

Up/down button for

chinrest

Reset button

Measurement mode button

NOTE:

The control panel is a touch panel. Do not use a ny sharp too ls; e.g. ba ll

point pen.

Tap To select any relevant item. Continue to press Used for continuous moving.

(Moving of chinrest and

measuring head)

Touch the screen softly with a finger. Continue to touch the screen softly with a finger.

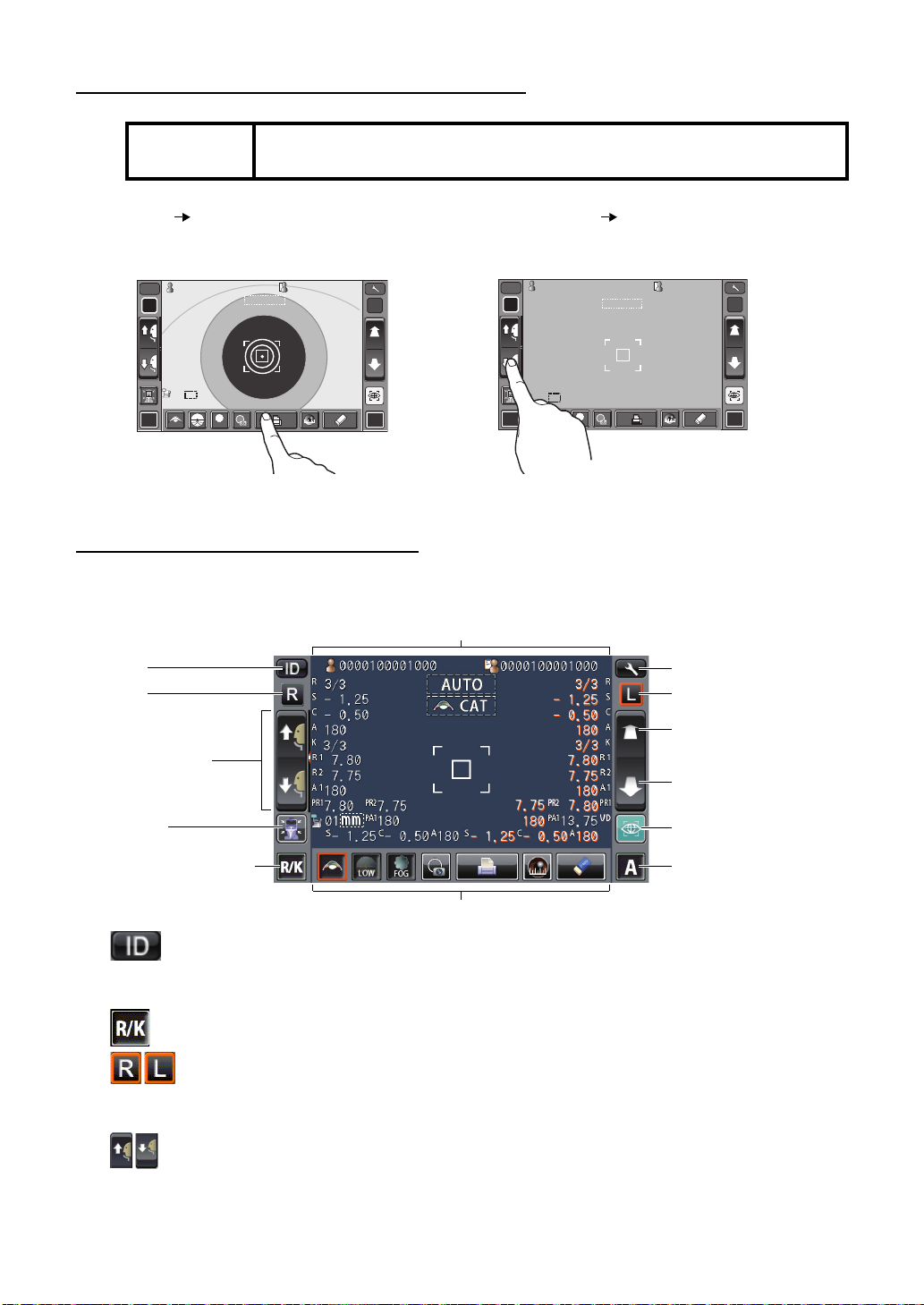

CONTROL PANEL COMPONENTS

The control panel is designed as a touch panel for performing various operations and settings.

It displays images and shows information, including set conditions and measurement results.

ID button ........................... .....Input the patient ID (up to 13 characters) and operator

Measurement mode button...... Selects a measurement mode from REF, KRT and R/K.

12

COMPONENTS

R button/L button................. Selects the right/left eye. By tapping the button, the

Up/down button for chinrest ... Moves the chinrest up/down.

ID (up to 21 characters). However, if no patient ID is

input, the patient No. is allocated automatically.

main body moves to the selected direction.

The selected button is framed in orange.

Page 15

Reset button ............................ Returns the chinrest and measu ring head to the initial

Cataract button

ALL CLEAR button

Cornea diameter buttonFixation target button

Print out button

Target image button

FOG button

position.

Forward/backward button for measu ring head

.............Moves the measuring head closer to/away from the

patient's eye.

Start button...............................Starts measurement .

Auto/Manual button..................Selects Au to/Manual mode (A: Auto mode, M: Man ual

mode). The name of selected (Auto/Manual) is displayed on the control panel.

Settings button....................... Displays the Settings screen.

FUNCTION BUTTON

Cataract button............... If error messages occur in patient's with cataracts, push the

Cataract button may improve measurements. When the button

is selected, "CAT" is displayed on the monitor and the selected

button is framed in orange.

Fixation target button .....Brightness of the fixation target can be changed.

FOG button ....................Changes setting temporarily to perform fogging only in the first

measurement or each time in the continuous measurement.

Target image button .......The captured measurement target can be observed on the

control panel.

Print out button ..............Prints measurement results. Tap the button when no measure-

ment data is present to feed the paper.

By setting the print er mode to G raphic Print er on the Se ttings

screen, figures showing refractive conditions can be printed. In

this case, the printer button changes to .

Cornea diameter button

..Changes to cornea diameter measurement mode.

ALL CLEAR button.........Clears all measurement data.

13

COMPONENTS

Page 16

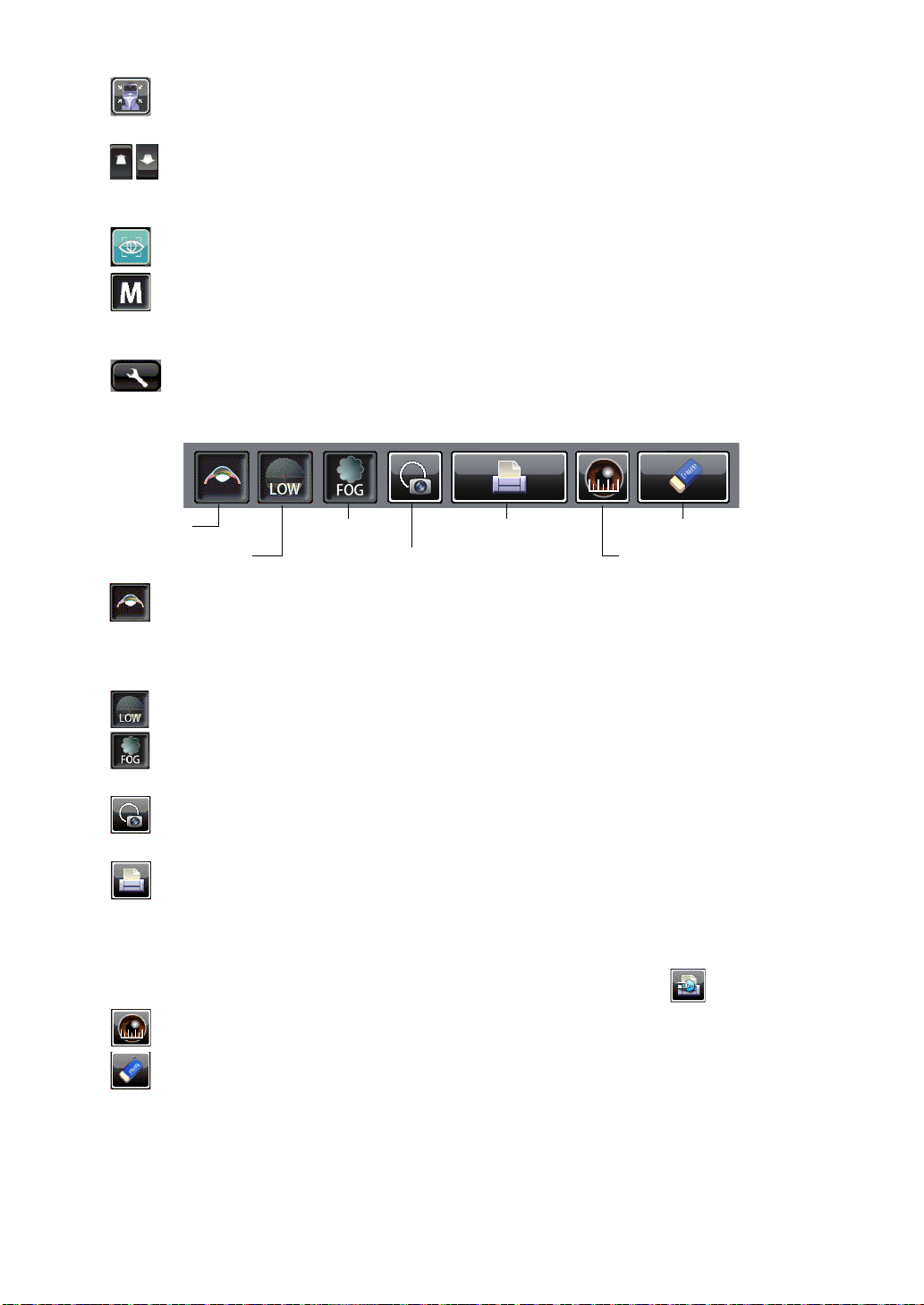

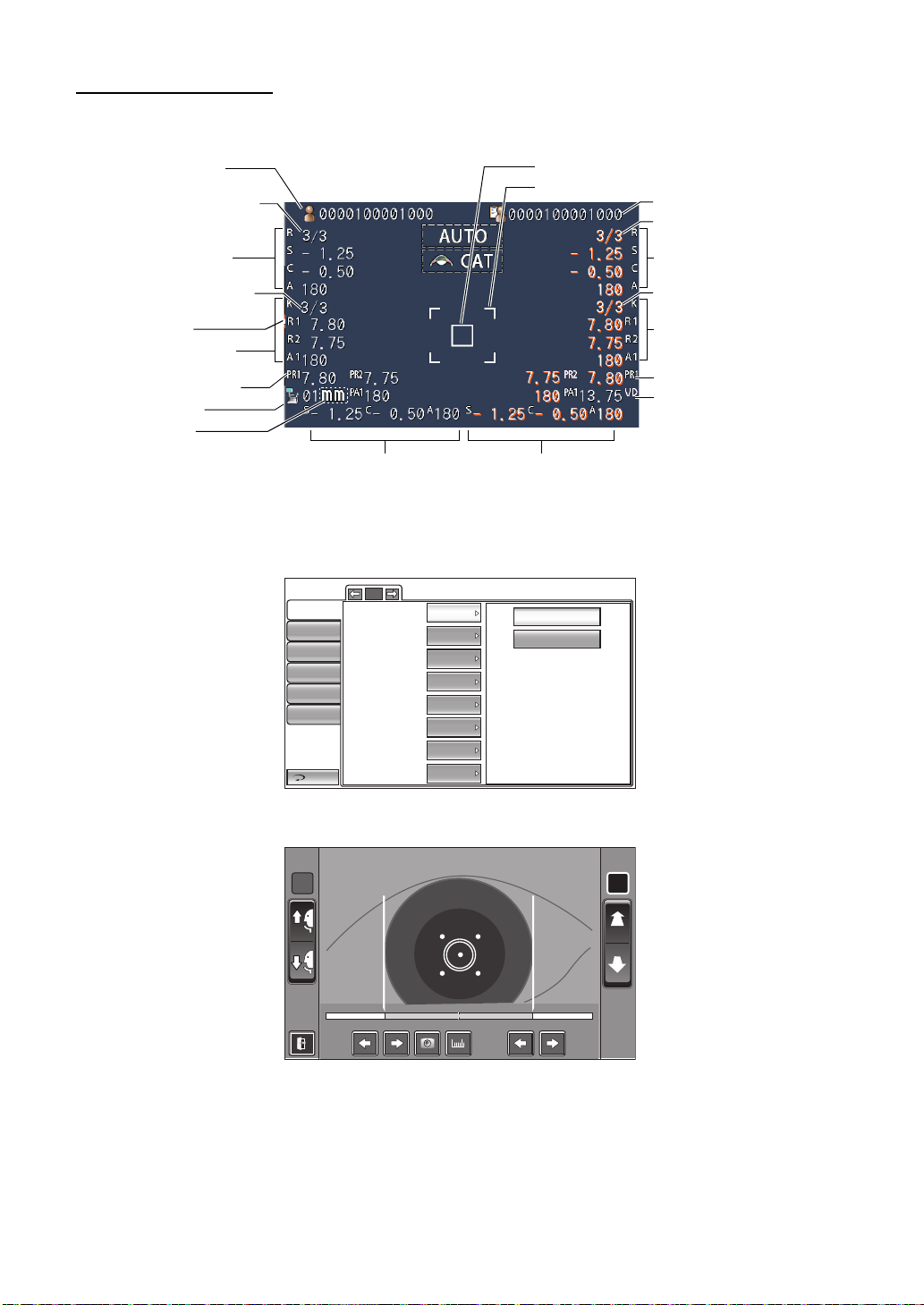

MONITOR SCREEN

Operator ID

Refractive power

measurement result (L)

Corneal curvature radius

measurement result (L)

Number of reading/setting

(L, REF)

Number of reading/setting

(L, KRT)

VD (Vertex distance)

Typical value of L measurementTypical value of R measurement

Patient No. (Patient ID

when patient ID is input)

Outer alignment mark

Alignment mark

Refractive power

measurement result (R)

Corneal curvature radius

measurement result (R)

Number of reading/setting

(R, REF)

Number of reading/setting

(R, KRT)

Device ID number

D/mm unit display

Peripheral KRT value (L)

Peripheral KRT value (R)

*Eye Height mark: Shows the position of the eye height mark on the chinrest.

*Eye Height mark

R L

R:0.00R: 0.0 0 L:9.50L :9. 50

MEASUREMENT SCREEN

SETTINGS SCREEN

Initial

Print

Comm

Operator ID

Special

CORNEA DIAMETER MEASUREMENT SCREEN

14

COMPONENTS

LAN

Return

1/5

Buzzer

Start mode

Auto Print

Printer

Patient No. reset

Show patient ID

Required patient ID

Device ID number

ON

AUTO

ON

ON

OFF

ON

OFF

1

OFF

ON

Page 17

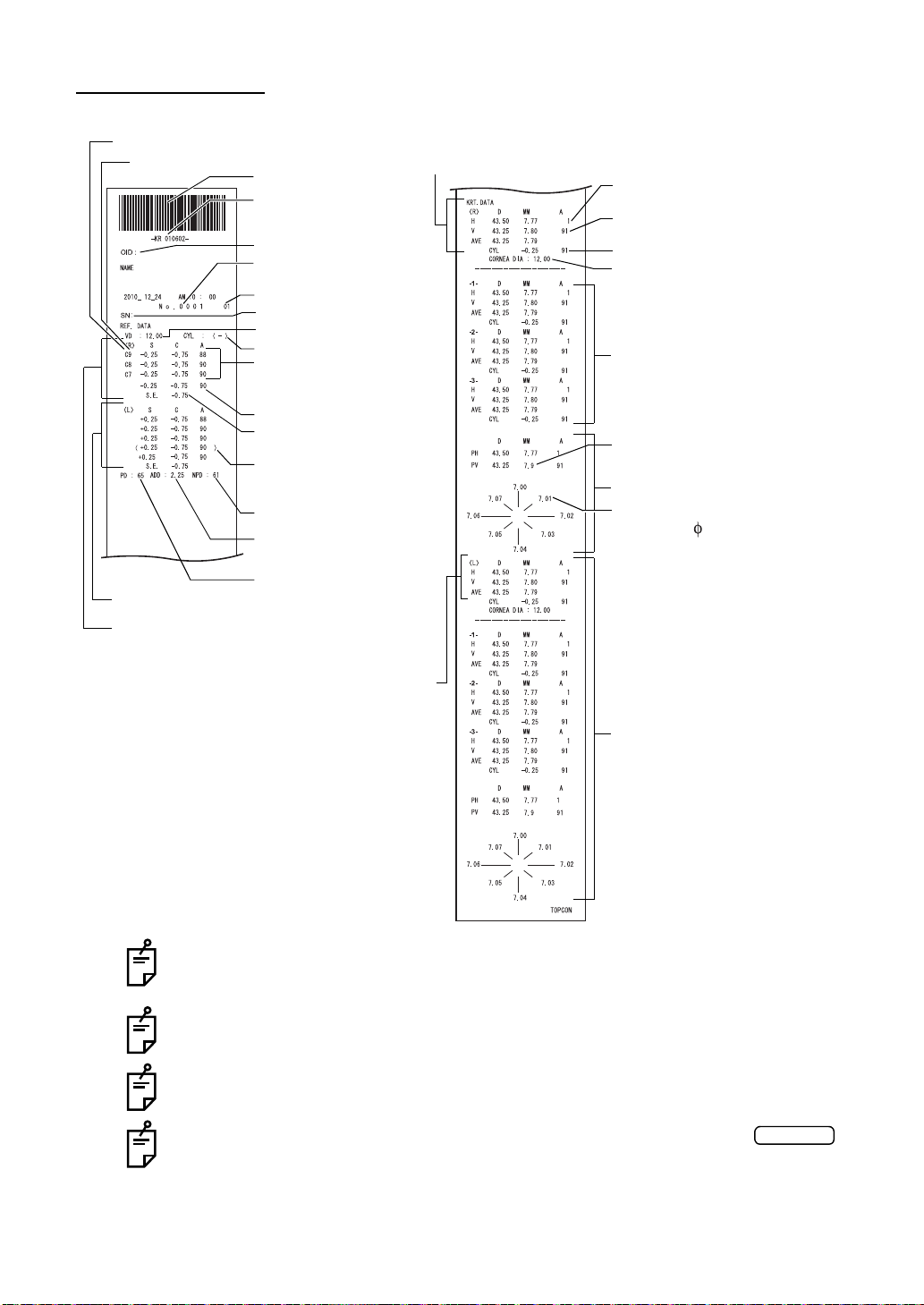

PRINTER OUTPUT

Operator ID

Device ID number

3 readings of REF right

measurement (recordable

up to 10 measurements)

Pupil distance (PD value)

VD (vertex distance)

Work ID No.

Bar code

Patient No.(Patient ID

when patient ID is input)

Serial number

Cylinder sign

Typical value of right eye

SPHERICAL EQUIVA LENT

of right eye

The ( ) mark is added when

measurement values are not

fully reliable.

ADD

(standard additional power)

Near vision PD value

Refractive power measurement result (L)

Refractive power measurement result (R)

Typical measured value of right eye corneal curvature

Typical measured value of

Left eye corneal curvature

Measured value of horizontal

corneal curvature

Measured value of vertical corneal

curvature

3 readings of kerato-cylinder value,

average value and kerato-cylinder

value (recordable up to 10 measurements each for right/left eye)

Left eye

corneal curvature measurement

Measured value of right eye cornea

Corneal astigmatic axis angle

Peripheral KRT measurement

values near 6mm

Peripheral KRT value

Typical measured value of

Peripheral KRT value (R)

C(Cataract mode) mark

Reliability factor

Cataract

KRT typical value style and KRT print format are HV

The reliability factor is defined with integers 1 to 9 in increasing order of reliability.

Additionally, if the reliability is high enough, the reliability factor is not shown on the

printout.

The Near PD value is calculated based on the ADD.

( ) appears when normal measurement is not expected du e to eyelid, eyela sh, or

blinking.

*-mark appears w hen normal measurement is not expected with the

button selected.

15

COMPONENTS

Page 18

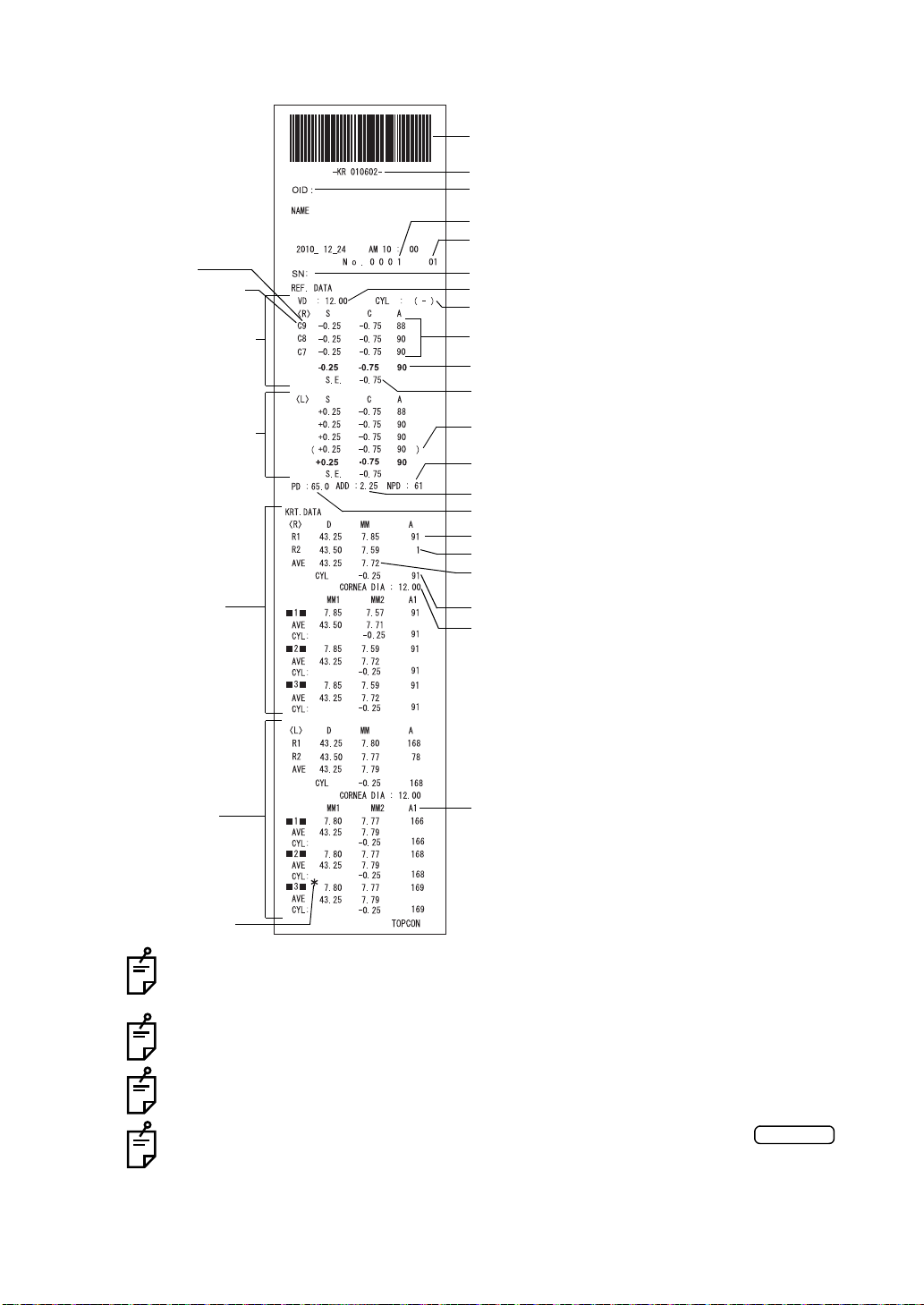

KRT typical value style and KRT print format are R1R2

Patient No. (Patient ID when patient ID is input)

Work ID No.

Cylinder sign

3 readings of REF right measurement

(recordable up to 10 measurements)

Typical value of right eye

Spherical equivalent of right eye

Pupil distance (PD value)

(mm)

Corneal astigmatic axial angle

VD (vertex distance)

Barcode

MM1: Corneal refractive power at flat meridian

MM2: Corneal refractive power at steep meridian

A1: Angle of steep meridian

Measured value of horizontal corneal curvature

Measured value of vertical corneal curvature

Operator ID

Device ID number

Serial number

The ( ) mark is added when measurement values are

not fully reliable.

ADD (ordinary additional power)

Near vision PD value

D: Average value of corneal refractive power

MM: Average value of cornea curvature radius

Measured value of right eye cornea diameter (mm)

Result of refractory power

measurement (Right eye)

Result of refractory power

measurement (Left eye)

KRT data (Right eye)

KRT data (Left eye)

C(Cataract mode) mark

Reliability factor

*-mark appears when

reliability of the measurement is too low.

Cataract

16

COMPONENTS

The reliability factor is defined with integers 1 to 9 in increasing order of reliability.

Additionally, if the reliability is high enough, the reliability factor is not shown on the

printout.

The Near PD value is calculated based on the ADD.

( ) appears when normal measurement is not expected du e to eyelid, eyela sh, or

blinking.

*-mark appears w hen normal measurement is not expected with the

button selected.

Page 19

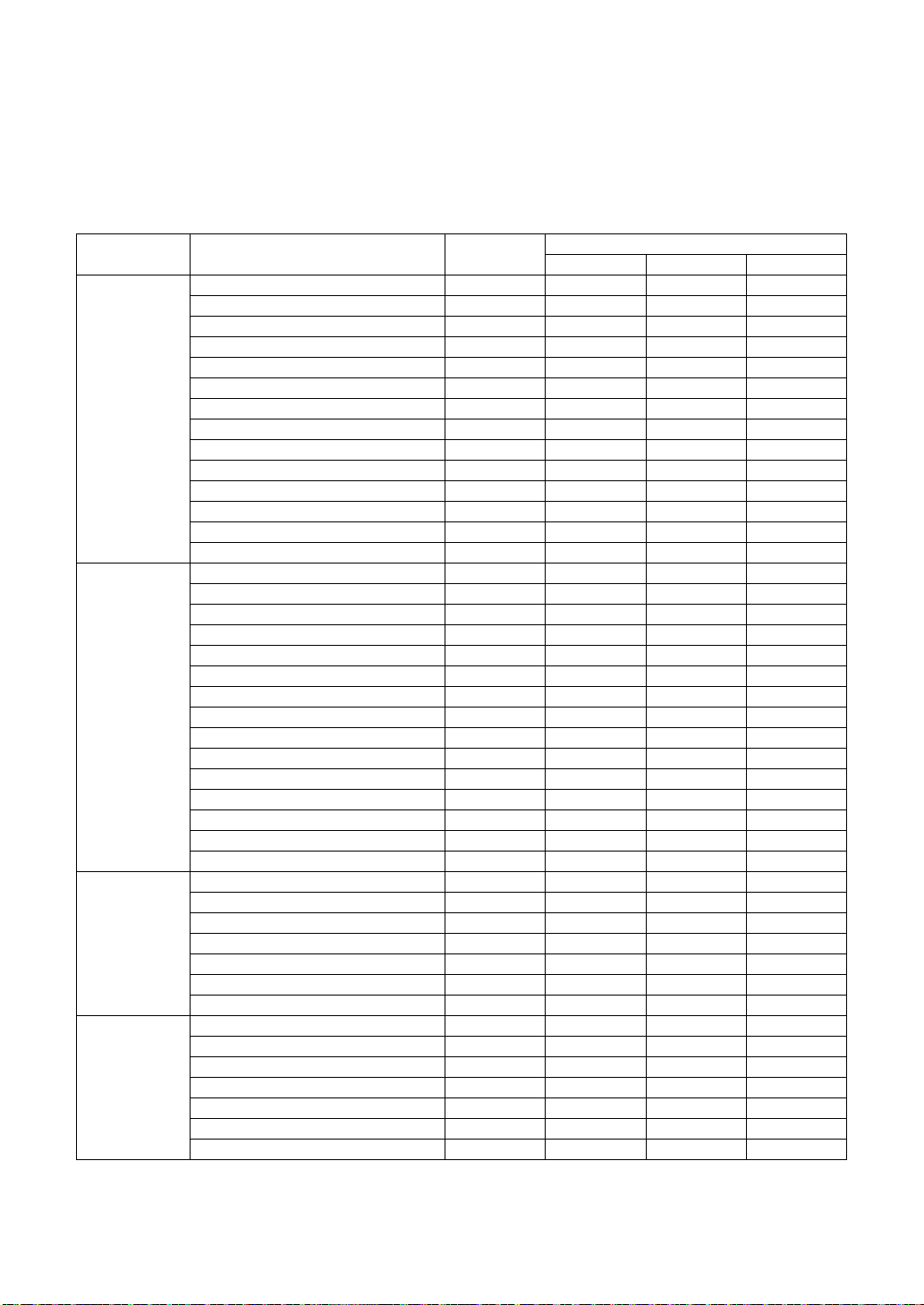

PRINTOUT FORMAT SETTING

Printout format can be cha nged by pushing "Print" in the S ettings screen. For Print se ttings,

see "SETTING FUNCTIONS ON SETUP SCREEN" on page 44.

PRESET

All: Initial setting (all measurement values are printed.)

Ave: Only typical value are printed.

Classic: Equivalent with RM/KR-8900 Classic 2

Common

REF/KRT

REF

KRT

ITEM INITIAL

Barcode OFF OFF OFF OFF

Operator ID OFF OFF OFF OFF

Name ON ON ON ON

Date ON ON ON ON

Date style YMD YMD YMD YMD

Patient ID ON ON ON ON

Device ID number OFF OFF OFF OFF

Serial number ON ON ON ON

Include error data OFF OFF OFF OFF

TOPCON logo ON ON ON ON

Message OFF OFF OFF OFF

Message data NULL NULL NULL NULL

Between the lines 0 0 0 0

Auto Cut ON ON ON ON

Print order DATA DATA DATA DATA

VD ON ON ON ON

Cylinder sign ON ON ON ON

REF format ALL ALL AVE ALL

Credibility OFF OFF OFF OFF

S.E. ON ON ON ON

PD ON ON ON ON

ADD OFF OFF OFF OFF

KRT print order D/mm D/mm D/mm D/mm

KRT format ALL ALL AVE AVE

KRT style R1R2 R1R2 R1R2 HV

KRT print format R1R2 R1R2 R1R2 HV

KRT average ON ON ON ON

KRT cylinder ON ON ON ON

Cornea diameter ON ON ON ON

VD ON ON ON ON

Cylinder sign ALL ALL AVE ALL

REF format OFF OFF OFF OFF

Credibility ON ON ON ON

S.E. ON ON ON ON

PD OFF OFF OFF OFF

ADD OFF OFF OFF OFF

KRT print order D/mm D/mm D/mm D/mm

KRT format ALL ALL AVE ALL

KRT style R1R2 R1R2 R1R2 HV

KRT print format R1R2 R1R2 R1R2 HV

KRT average ON ON ON ON

KRT cylinder ON ON ON ON

Cornea diameter ON ON ON ON

All Ave Classic

PRESET

17

COMPONENTS

Page 20

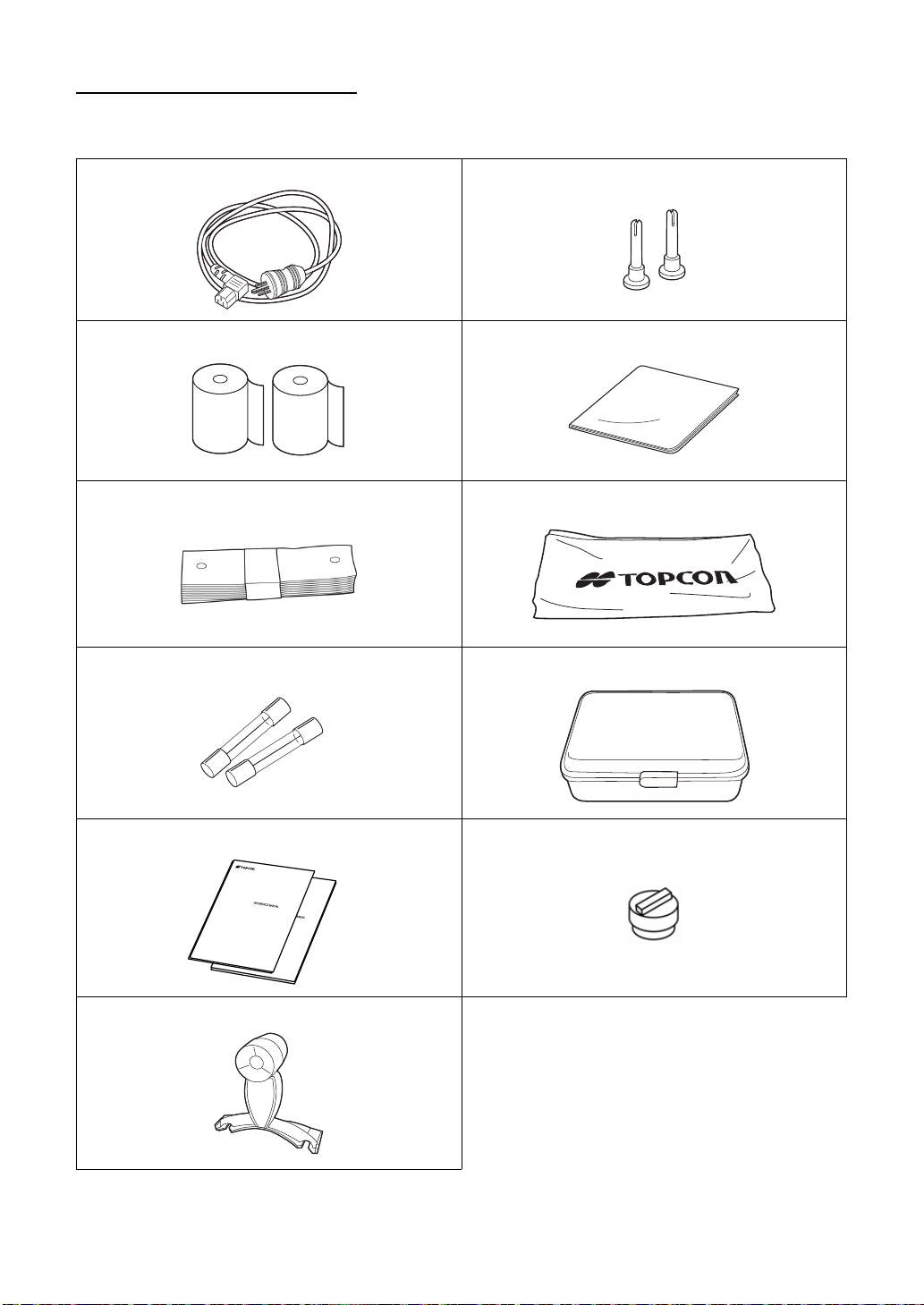

STANDARD ACCESSORIES

The following are standard accessories. Make sure that all these items are included (quantity).

Power cable (1) Chinrest tissue pin (2)

Printer paper (2) Monitor cleaner (1)

Chinrest tissue (1) Dust cover (1)

Fuse (2) Accessory case (1)

User manual, Unpacking and Assembing

(1 each)

Model eye (1)

Rubber cap (1)

18

COMPONENTS

Page 21

PREPARATIONS

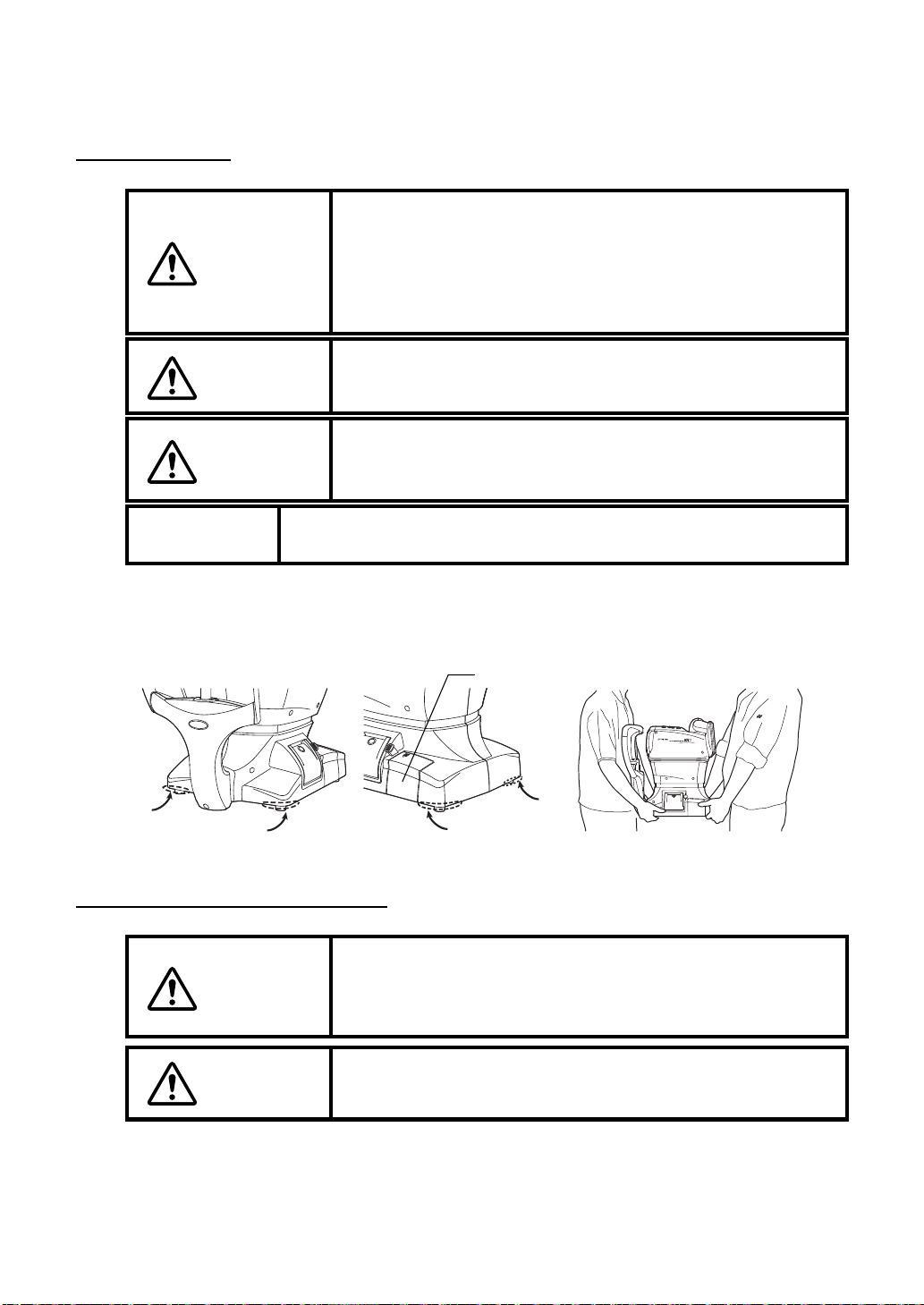

Holding positions Holding the instrument

External I/O terminal cover

INSTALLATION

CAUTION

CAUTION

CAUTION

When moving the instrumen t, two people should lift from the

bottom of the device.

One person lifting the device may ca use harm to his back or

injury by falling parts. Also, holding areas other than the bottom

and holding the Exte rnal I/O terminal cove r may cause injury,

as well as damage to the instrument.

To prevent dama ge and injuries, do not install the in strument

on an uneven, unsteady or sloped surface.

When setting an instrument on an instrument table, pay attention not to injury the patient's fi ngers between the instrument

and the table.

NOTE:

The instrument should also be placed away from strong light like

direct sunlight. Auto alignment may not function properly.

1 Firmly hold the instrument at the position shown below and place it on the automatic

instrument table.

For the adjustable instrument table, see “OPTIONAL ACCESSORIES” on page 64.

CONNECTING POWER CABLE

Be sure to connec t the power plug to an AC 3-pin receptacle

WARNING

equipped with groundin g. Connection with receptacle without

grounding may cause fire and electric shock in case of s hortcircuiting.

CAUTION

To avoid electric shocks, do not handle the power plug with wet

fingers.

1 Make sure the POWER switch of the instrument is OFF.

19

PREPARATIONS

Page 22

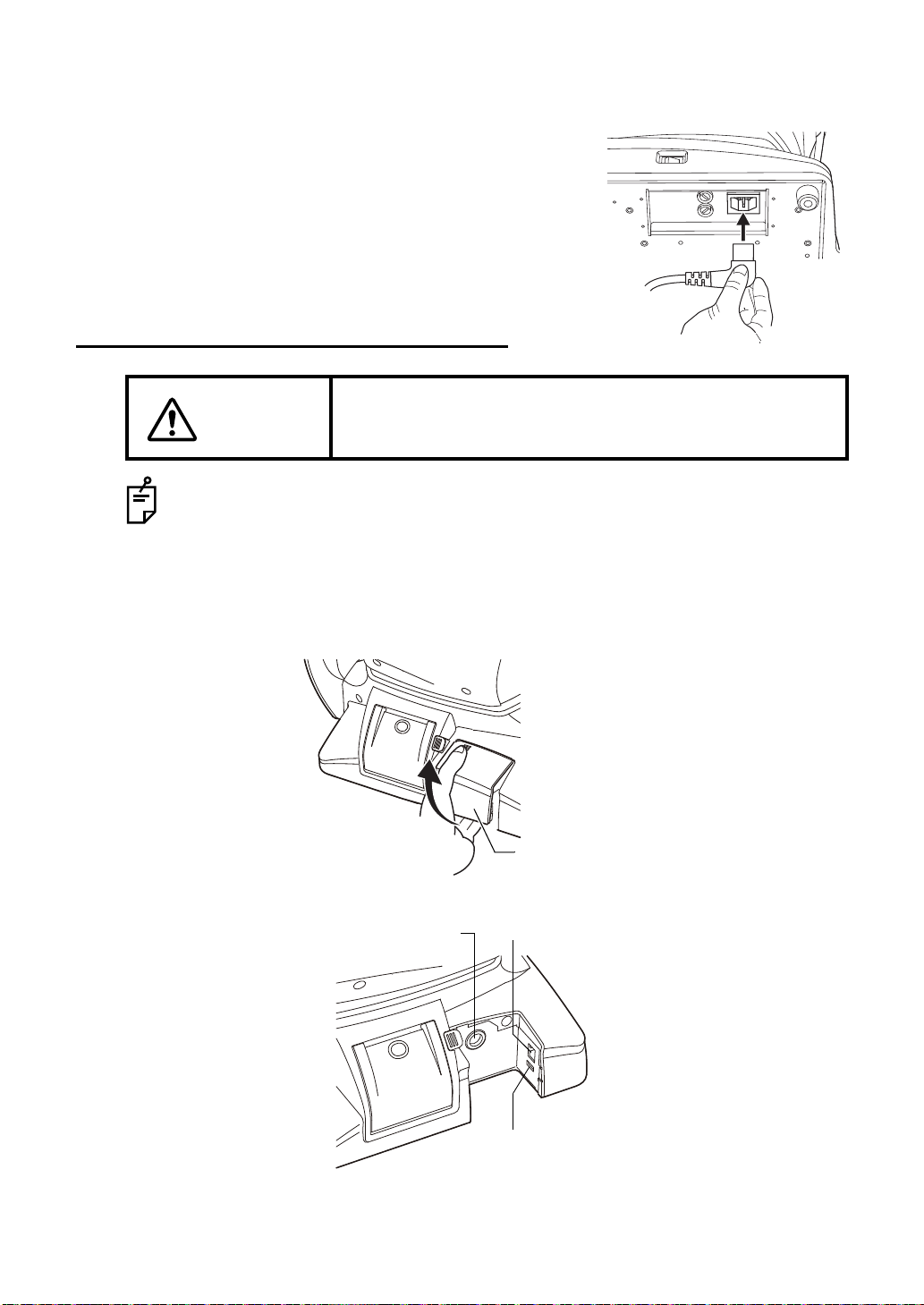

2 Tilt the body slowly so that the POWE R switch is on top and the power in let at the bo ttom

External I/O terminal cover

USB input terminal

LAN output terminalRS232C output terminal

can be seen.

3 Connect the power cable to the Power inlet.

4 Insert the power cable plug into the 3-pin AC grounding

receptacle.

CONNECTING EXTERNAL I/O TERMINALS

CAUTION

Use the external device complying with IEC60950/IEC60950-1.

DATA OUTPUT

This product can be connected to a pers onal computer (PC) and other external dev ices via

the RS232C or LAN.

To avoid electri c shock, do not touch the external connec tion

terminal and the patient at the same time.

1 Remove the External I/O terminal cover by pulling up as follows.

2 Connect the connection cable to the output terminal of the instrument.

20

PREPARATIONS

Page 23

3 Connect the other end of the connection cable to the PC, etc.

Printer cover

Printer cover open switch

4 Replace the External I/O terminal cover.

DATA INPUT

This product can be connected to a bar-code reader and other external devices via USB.

1 Connect the connection cable to the input terminal of the instrument.

2 Connect the other end of the connection cable to the external device.

For questions about connections, contact your TOPCON dealer.

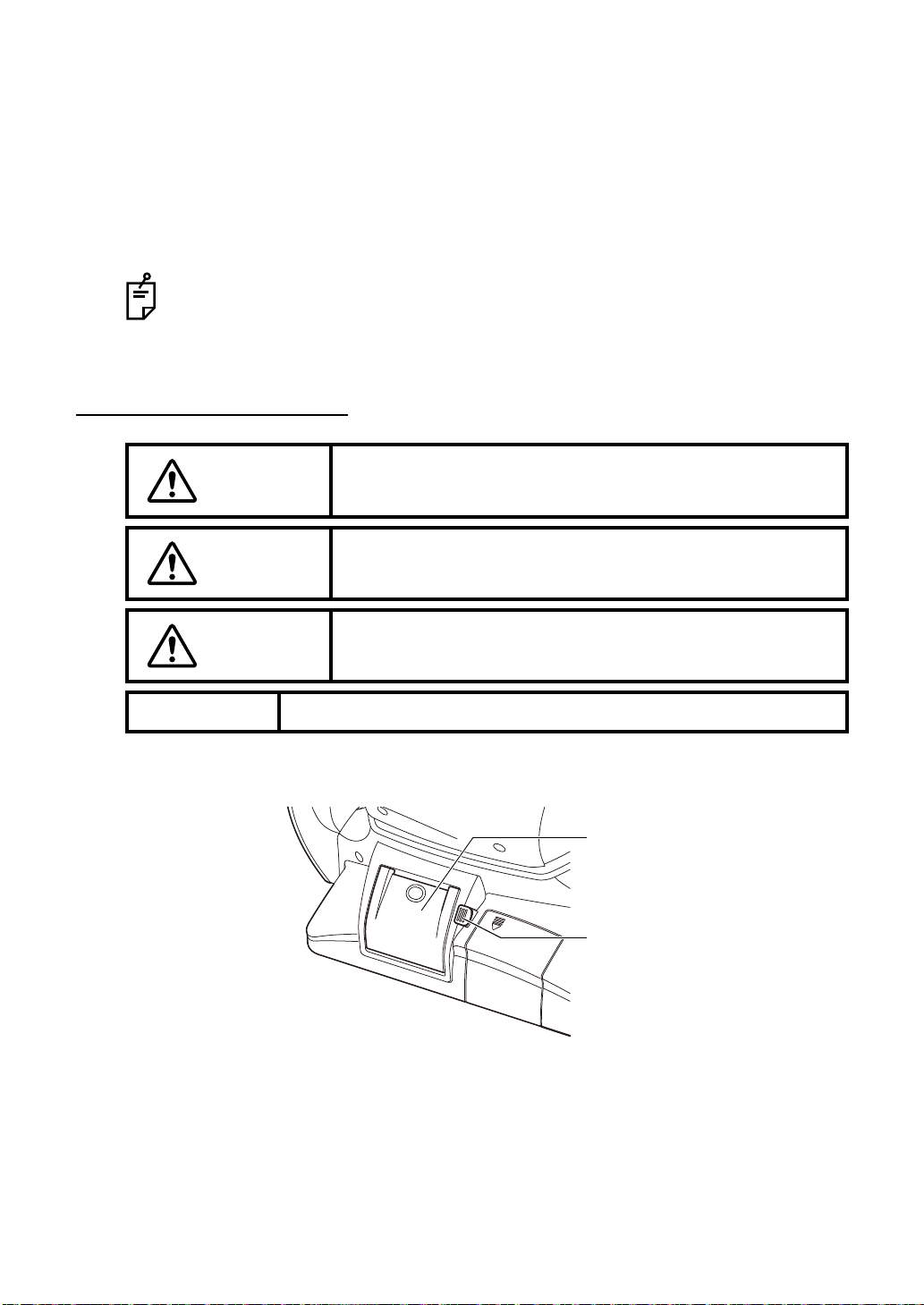

PRINTER PAPER SETTING

CAUTION

CAUTION

CAUTION

NOTE:

To avoid failure or potential injury , do not open the printer cover

while the printer is in operation.

To avoid potential injury in case of malfunction, including a

paper jam, be sure to shut off the power be fore attempting to

repair it.

To avoid potential injury, do not touch the printer body including

metal parts or the paper cutter, while the printer i s in opera tion

or when replacing the printer paper.

• If you insert the printer paper backwards, printing will not start.

1 Press the printer cover open switch to open the printer cover.

21

PREPARATIONS

Page 24

2 Open the printer cover to the limit.

Roll direction

3 Insert the printer paper in the dire ction shown below and p ull out the paper end to yo ur

side by 7 to 8cm.

4 Bring the paper into the center, then close the printer cover.

.

In case the printer cover is not firmly closed, p rinting will not start, and "CLO SE

PRT COVER" wil be displayed on the monitor screen.

A 58mm wide paper roll (example: TP-50KJ-R [Nippon Paper Co.]) is recommended.

Other paper rolls may cause abnormal printing noise or unclear print.

22

PREPARATIONS

Page 25

RECOVERY FROM POWER SAVE STATUS

R

ID

L

R/K

00001000010000000100 001000 00001000010000000100 001000

13.7513.75

mmmm

0101

R

S

C

A

K

R1

R1

R2R2

A1A1

PR1PR1

PR2PR2

0/30/3 0/30/3

0/30/3 0/30/3

R

S

C

A

K

R1

R1

R2R2

A1A1

PR1PR1

PR2PR2

VDVD

A

AUTOAUTO

PA1PA1 PA1PA1

LOWLOW

FOGFOG

R

ID

L

R/K

00001000010000000100 001000 00001000010000000100 001000

13.7513.75

mmmm

0101

R

S

C

A

K

R1

R1

R2R2

A1A1

PR1PR1

PR2PR2

0/30/3 0/30/3

0/30/3 0/30/3

R

S

C

A

K

R1

R1

R2R2

A1A1

PR1PR1

PR2PR2

VDVD

A

AUTOAUTO

PA1PA1 PA1PA1

LOWLOW

FOGFOG

This instrument adopts the power save system for saving electric power. When the machine is

not operated for a set time, the control panel becomes a screensaver.

1 Tap the con tr ol panel.

In a few seconds, the measurement screen is displayed and measurement is enabled.

The time to start th e power sa ve s tatus can be c hange d in the in itial setting "Auto

power save" (see page 48).

ADJUSTING THE CONTROL PANEL POSITION

The control panel may be positioned by swinging and tilting the monitor to your desired

position. Touching the control panel controls operations including chinrest movements,

alignment and measurement.

The layout of R button /L bu tton is reve rs ed ac co rding to the position of the contr ol

panel.

The moving direction by tapping is changed according to the position of the control

panel.

The moving direc tion by continuing to p ress on control panel is changed for the

setting of Initial setting "XZ MOTOR direction". (see page 50).

PREPARATIONS

23

Page 26

BASIC OPERATIONS

POWER

MEASUREMENT MODE

MEASUREMENT MODE

R

ID

L

R/K

0000100001000000010 00010 00 0000100001000000010 00010 00

13.7513.75

mmmm

010 1

R

S

C

A

K

R1

R1

R2R2

A1A1

PR1PR1

PR2PR2

0/30/3 0/30/3

0/30/3 0/30/3

R

S

C

A

K

R1

R1

R2R2

A1A1

PR1PR1

PR2PR2

VDVD

A

AUTOAUTO

PA1PA1 PA1PA1

LOWLOW

FOGFOG

PREPARATION BEFORE MEASUREMENT

TURNING ON THE INSTRUMENT

1 Make sure the power cable is connected properly.

For the details of connection, refer to “CONNECTING POWER CABLE” on page 19.

2 Press on the SWITCH.

3 Make sur e that the title s creen is displa yed and then the M EASUR EMENT sc reen is dis-

played in a few seconds.

SELECTING THE MEASUREMENT MODE

This product has thr ee meas urement m ode s: R/K (R EF/KRT conti nuous measu rement) , KRT

(KRT single measur ement) and REF (REF single measurement).

1 Check that the MEASUREMENT screen is on.

2 Tap the button on the control panel and sel ect the measurement

mode. Indication of the button is changed.

REF: Only REF me asurement

KRT: Only KRT measurement

R/K: REF/KRT continuous measurement

24

BASIC OPERATIONS

Page 27

PATIENT POSITIONING

R

S

C

A

R1

R2

A

PR1

000010 00010 000100 001

000010 0001

13.75

di o

AUTO

01

R

S

C

A

K

R1

R2

A1

PR1

PR2

PA1

PR2

PA1

R

S

C

A

K

R1

R2

A1

PR1

VD

S

mm

LOW

FOG

0/3

0/3

0/3

0/3

Center position

Eye height mark

on the center position

Eye height mark

CAUTION

terminal and the patient at the same time.

To avoid inj ury when moving the chin rest up/down button, be

To avoid electri c shock, do not touch the external connec tion

CAUTION

careful not to catch the patient's fingers.

To avoid injury wh en operating the machine, be ca reful about

CAUTION

the cover not to catch fingers of the patient.

Tell this to the patient, too.

Adjust the height of the adjustable instrument table so that the patient

NOTE:

can sit on the chair comfortably. Otherwise, correct measurement values may not be obtained.

When operating the inst rument, be careful that the instrument d oes

NOTE:

not touch the patient's lip or nose. If touched, clean the instrument following "CLEANING THE INSTRUMENT" on page 65.

1 Check the measurement screen.

2 Make sure that the eye height mark is at the center position as explained below.

If the eye height m ark is above the center position , press the lower side of the co ntrol

panel display, or if it is below the center position, press the upper side of the control panel

display, so as to move the eye height mark to the center position.

00001000010000100001

ID

R L

0/3

0/3

R1

R2

PR2

A1

PR1

PA1

mm

01

R/K

LOW

AUTO

FOG

0000100001

PR2

PA1

13.75

R

0/3

0/3

R1

R2

A1

PR1

VD

dio

A

R1

R2

PR1

3 Have the patient sit in front of the instrument.

4 Adjust the adjustable instrument table or the chair height for the patient to put his/her chin

on the chinrest comfortably.

BASIC OPERATIONS

25

Page 28

5 Place the patien t's chin on t he chin rest and che ck that his /her fo rehead is touch ing to the

UP/DOWN

Eye height mark

R L

R/K

000010000100001000010000100 00100001000 01 0000100001000010 0001

12.0012.00

diodio

AUTOAUTO

010 1

VDVD

ID

A

mmmm

PR2PR2

PA1PA1

PR2PR2

PA1PA1

HIGHHIGH

FOGFOG

R

S

C

A

K

R1

R1

R2R2

A1A1

PR1PR1

0/30/3 0/30/3

0/30/3 0/30/3

R

S

C

A

K

R1

R1

R2R2

A1A1

PR1PR1

Chinrest up/down

button

Eye height mark of

measuring window

forehead rest.

6 Press the button to adjust the chin rest hei ght until th e eye hei ght mark o f the

chinrest reaches the same he ight as the patient's eye. At this moment, confi rm that the

height mark of the measuring window is at the height of the patient's visual line.

26

BASIC OPERATIONS

Page 29

AUTO MODE MEASUREMENT

AUTO/MANUAL

R

ID

L

R/K

000010000100000001 000010 00 00001000010000000100 00100 0

13.7513.75

mmmm

0101

R

S

C

A

K

R1

R1

R2R2

A1A1

PR1PR1

PR2PR2

0/30/3

0/30/3

0/30/3

0/30/3

R

S

C

A

K

R1

R1

R2R2

A1A1

PR1PR1

PR2PR2

VDVD

A

AUTOAUTO

PA1PA1 PA1PA1

LOWLOW

FOGFOG

Auto measurement mode may not be possible, in case the eyelid and

NOTE:

the eyelashes cover the pupil.

If this occurs, the operator should tell the patient to open their eyes as

wide as possible, or lift the eyelid to allow for measurement.

Auto measurement mode may not be possible due to frequent bl inks

NOTE:

or existing abnor malities in the corneal surfac e caused corneal disease etc.

In this case, select manual mode.

When operating the instrument, be careful that the instrument d oes

NOTE:

not touch the patient's face or no se. If touched, cle an the instrumen t

as specified in "CLEANING THE INSTRUMENT" on page 65.

If the patient is wearing mak e up on the eyelid or around t he eyelid

NOTE:

using glitter, the auto alignment may not function properly.

In this case, select manual mode.

SETTING THE AUTO MODE

1 Make sure the button is on A on the measurement scr een. "A" is Auto

mode.

2 If "M" (Manual mode) is displayed, tap it and change to the Auto mode.

27

BASIC OPERATIONS

Page 30

ALIGNMENT AND MEASUREMENT

R L

R/K

13.7513.75

010 1

VDV D

S C A

R L

R/K

13.7513.75

010 1

VDV D

ID

A

ID

A

0000100001000000010 0001000 0000100001000000010 0001000

mmmm

R

S

C

A

K

R1

R1

R2R2

A1A1

PR1PR1

PR2PR2

AUTOAUTO

R

S

C

A

K

R1

R1

R2R2

A1A1

PR1PR1

PR2PR2

PA1PA1

PA1PA1PA1PA1

0000100001000000010 0001000 0000100001000000010 0001000

mmmm

R

S

C

A

K

R1

R1

R2R2

A1A1

PR1PR1

PR2PR2

0/30/3

0/30/3

AUTOAUTO 0/30/3

0/30/3

0/30/3

0/30/3

0/30/3

0/30/3

R

S

C

A

K

R1

R1

R2R2

A1A1

PR1PR1

PR2PR2

LOWLOW

FOGFOG

LOWLOW

FOGFOG

13.75

0 1

R

K

VD

000010 00010 00

000010 00010 00

mm

R

S

C

A

K

R1

R2

A1

PR1

PR2

PA1

PA1

0/3

AUTO

0/3

0/3

0/3

R

S

C

A

K

R1

R2

A1

PR1

PR2

LOW

FOG

Limit mark

R L

R/K

13.7513.75

010 1

VDV D

ID

A

00001000010000000100 001000 000010000100000 001000 01000

mmmm

TOO CLOSETOO CLOSE

R

S

C

A

K

R1

R1

R2R2

A1A1

PR1PR1

PR2PR2

0/30/3 AUTOAUTO 0/30/3

0/30/3 0/30/3

R

S

C

A

K

R1

R1

R2R2

A1A1

PR1PR1

PR2PR2

PA1PA1 PA1PA1

LOWLOW

FOGFOG

Limit of movement in the

forward direction

Limit of movement in the

backward direction

Measuring Head

Forward button/

Measuring Head

Backward button

R L

R/K

13.7513.75

010 1

VDV D

ID

A

00001000010000000100 001000 000010000100000 001000 01000

mmmm

TOO FARTOO FAR

R

S

C

A

K

R1

R1

R2R2

A1A1

PR1PR1

PR2PR2

0/30/3 AUTOAUTO 0/30/3

0/30/3 0/30/3

R

S

C

A

K

R1

R1

R2R2

A1A1

PR1PR1

PR2PR2

PA1PA1

PA1PA1

LOWLOW

FOGFOG

Alignment can be operated from the control panel.

1 When the pupil is displayed, tap the display around the pupil. The measuring head moves

to display the pupil image and alignment dot on the center of the screen . Then tell the

patient to look at red-roof house.

If the pupil is not displayed on the control panel, move the measuring head by

press the control panel, checking the eye height mark on the measurement window as a guide (see page 26).

When the measuring head has reached the limit of movement (vertical/lateral

directions), a yellow-colored limit mark appears, showing it is the movement limit

in that direction. Tap the display, move the measuring head to a position until pupil

image comes to the center.

0000100001000

ID

0/3

R L

0/3

R1

R2

A1

PR1

PR2

PA1

mm

01

R/K

LOW

FOG

AUTO

0000100001000

0/3

0/3

PR2

PA1

13.75

R1

R2

A1

PR1

VD

A

When the measuring head is at the limit of movement in the forward direction,

"TOO CLOSE" is displayed and the buzzer sounds, and when it is at the limit of

movement in the backward direction, "TOO FAR" is displayed. Using the Measuring Head Forward button and Measuring Head Backward button, move the measuring head to a position until pupil image comes to the center.

28

BASIC OPERATIONS

Page 31

2 Alignment starts automatic ally, and measurement is performed. The measurement r esult

R L

R/K

ID

A

13.7513.75

-1.-1 .2525

-0.-0 .5050

7.807 .8 0

7.757 .7 5

18018 0

18018 0

010 1

VDV D

PR2PR2

000010000100000001 00001 000 00001000010000000 10000 1000

mmmm

R

S

C

A

K

R1

R1

R2R2

A1A1

PR1PR1

3/33/3 AUTOAUTO

7.807.80

0/30/3

3/33/3 0/30/3

R

S

C

A

K

R1

R1

R2R2

A1A1

PR1PR1

PR2PR2

PA1PA1 PA1PA1

LOWLOW

FOGFOG

is displayed.

3 When Right/Left eye continuous measurement is selected, the instrument measuring

head moves automatically from the right to the left eye.

If auto mode measurement does not work, select manual mode.

NOTE:

Auto mode measurement may not work depending on the cornea

condition.

NOTE:

If the machine is moved before measurement values are displayed, it

might cause an incorrect measurement.

Auto print (available only under Auto mode)

When auto print setting is " ON" in the i nitia l se tting, the buz zer s ounds twice a fter

measuring the ri ght and left eyes, and measureme nt results are printed out automatically.

DISPLAYING MEASUREMENT VALUES

Data of the latest measurement are displayed on the control panel screen.

Figures only: Measurement was done correctly.

ERROR: Measurement was not done correctly.

For explanation of the mes sa ges on th e co ntrol panel s cree n, r efer to “M E SS AGE

LIST” on page 54.

When auto print setting is "OFF" in the initial setting, print out measurement results by tapping

the Print button, as necessary.

29

BASIC OPERATIONS

Page 32

MANUAL MODE MEASUREMENT

AUTO/MANUAL

R L

R/K

13.7513.75

010 1

VDV D

ID

M

0000100001000000010 0 00100 0 0000100001000000010 00010 00

mmmm

R

S

C

A

K

R1

R1

R2R2

A1A1

PR1PR1

PR2PR2

0/30/3 MANUALMANUAL 0/30/3

0/30/3 0/30/3

R

S

C

A

K

R1

R1

R2R2

A1A1

PR1PR1

PR2PR2

PA1PA1 PA1PA1

LOWLOW

FOGFOG

R

L

13.75

0 1

VD

00001 00001 000

00001 00001 000

mm

R

S

C

A

K

R1

R2

A1

PR1

PR2

0/3

MANUAL

0/3

0/3

0/3

R

S

C

A

K

R1

R2

A1

PR1

PR2

PA1

PA1

LOW

FOG

13.75

dio

01

VD

13.75

01

VD

000010 0001000

000010 0001000

mm

R

S

C

A

K

R1

R2

A1

PR1

PR2

0/3

0/3

0/3

0/3

R

S

C

A

K

R1

R2

A1

PR1

PR2

PA1

PA1

000010 0001000

000010 0001000

mm

R

S

C

A

K

R1

R2

A1

PR1

PR2

PA1

0/3

MANUAL

MANUAL

0/3

0/3

0/3

R

S

C

A

K

R1

R2

A1

PR1

PR2

LOW

FOG

LOW

FOG

SETTING THE MANUAL MODE

1 Check the MEASUREMENT screen is on. If the button is "M," the mode is

Manual mode.

2 If "A" (Auto mode) is displayed, tap it and change to "M".

ALIGNMENT AND MEASUREMENT

Alignment is operated on the control panel.

1 Select the right/left eye by tapping the button/ button.

2 When the pupil is displayed, tap the display around the pupil. The measuring head moves

to display the pupil image and alignment dot on the center of the screen . Then tell the

patient to look at red-roof house.

ID

30

BASIC OPERATIONS

0000100001000

0/3

R L

R1

R2

A1

PR1

R/K

0/3

PR2

PA1

01

mm

FOG

LOW

0000100001000

ID

0/3

R L

0/3

R1

R2

A1

PR1

PR2

PA1

01

mm

R/K

MANUAL

LOW

0000100001000

PR2

13.75

MANUAL

FOG

0/3

0/3

R1

R2

A1

PR1

VD

dio

0000100001000

ID

R L

R1

R2

A1

PR1

R/K

0/3

0/3

PR2

PA1

13.75

0000100001000

0/3

0/3

PR2

PA1

01

mm

FOG

LOW

R1

R2

A1

PR1

VD

M

0000100001000

MANUAL

0/3

0/3

R1

R2

A1

PR1

PR2

PA1

VD

13.75

MM

Page 33

If the pupil is not displayed on the control panel, move the measuring head by

13.75

0 1

R

K

VD

000010 00010 00

000010 00010 00

mm

R

S

C

A

K

R1

R2

A1

PR1

PR2

0/3

MANUAL

0/3

0/3

0/3

R

S

C

A

K

R1

R2

A1

PR1

PR2

PA1

PA1

LOW

FOG

Limit mark

13.75

01

VD

000010 0001000

000010 0001000

mm

TOO CLOSE

R

S

C

A

K

R1

R2

A1

PR1

PR2

0/3

MANUAL

0/3

0/3

0/3

R

S

C

A

K

R1

R2

A1

PR1

PR2

PA1

PA1

LOW

FOG

Limit of movement in the

forward direction

Limit of movement in the

backward direction

Measuring Head

Forward button/

Measuring Head

Backward button

R L

R/K

13.7513.75

010 1

VDV D

ID

00001000010000000100 001000 000010000100000 001000 01000

mmmm

TOO FARTOO FAR

R

S

C

A

K

R1

R1

R2R2

A1A1

PR1PR1

PR2PR2

0/30/3 MANUALMANUAL 0/30/3

0/30/3 0/30/3

R

S

C

A

K

R1

R1

R2R2

A1A1

PR1PR1

PR2PR2

PA1PA1 PA1PA1

M

LOWLOW

FOGFOG

MEASURING HEAD FORWARD

MEASURING HEAD BACKWARD

R L

R/K

13.7513.75

010 1

VDVD

ID

M

00001000010000 00010 00010 00 00001000010000000 10000 1000

mmmm

R

S

C

A

K

R1

R1

R2R2

A1A1

PR1PR1

PR2PR2

0/30/3 MANUALMANUAL 0/30/3

0/30/3 0/30/3

R

S

C

A

K

R1

R1

R2R2

A1A1

PR1PR1

PR2PR2

PA1PA1 PA1PA1

LOWLOW

FOGFOG

Outer alignment mark

Measuring head forward

button/Measuring head

backward button

Alignment dot

Alignment mark

press the control panel, checking the eye height mark on the measurement window as a guide (see page 26).

When the measuring head has reached the limit of movement (vertical/lateral

directions), a yellow-colored limit mark appears, showing it is the movement limit

in that direction. Tap the display, move the measuring head to a position until pupil

image comes to the center.

ID

0000100001000

0/3

R L

MANUAL

0000100001000

0/3

R/K

0/3

R1

R2

A1

PR1

PR2

PA1

mm

01

FOG

LOW

0/3

R1

R2

A1

PR1

PR2

PA1

VD

13.75

M

When the measuring head is at the limit of movement in the forward direction,

"TOO CLOSE" is displayed and the buzzer sounds, and when it is at the limit of

movement in the backward direction, "TOO FAR" is displayed. Using the Measuring Head Forward button and Measuring Head Backward button, move the measuring head to a position until pupil image comes to the center.

0000100001000

ID

0/3

R L

0/3

R1

R2

A1

PR1

PR2

PA1

mm

01

R/K

LOW

FOG

MANUAL

TOO CLOSE

0000100001000

0/3

0/3

PR2

PA1

13.75

R1

R2

A1

PR1

VD

M

3 Tap the button/ button and

focus on the patient's eye. Alignment dot is reflected off-focus on the cornea.

31

BASIC OPERATIONS

Page 34

4 When the mai n body is brought closer to the patie nt's eye, alignment arrows ap pear on

R L

R/K

13.7513.75

010 1

VDVD

ID

M

FORWARDFORWARD

00001000010000 00010 00010 00 00001000010000000 10000 1000

mmmm

R

S

C

A

K

R1

R1

R2R2

A1A1

PR1PR1

PR2PR2

0/30/3 MANUALMANUAL 0/30/3

0/30/3 0/30/3

R

S

C

A

K

R1

R1

R2R2

A1A1

PR1PR1

PR2PR2

PA1PA1 PA1PA1

LOWLOW

FOGFOG

Outer alignment mark

Alignment arrows

R L

R/K

13.7513.75

010 1

VDVD

ID

M

00001000010000 000100 001000 00001000010000000 100001 000

mmmm

R

S

C

A

K

R1

R1

R2R2

A1A1

PR1PR1

PR2PR2

0/30/3 MANUALMANUAL 0/30/3

0/30/3 0/30/3

R

S

C

A

K

R1

R1

R2R2

A1A1

PR1PR1

PR2PR2

PA1PA1 PA1PA1

LOWLOW

FOGFOG

Too close

13.75

01

VD

BACKWARD

000010 000100 0

000010 000100 0

mm

R

S

C

A

K

R1

R2

A1

PR1

PR2

0/3

MANUAL

0/3

0/3

0/3

R

S

C

A

K

R1

R2

A1

PR1

PR2

PA1

PA1

LOW

FOG

Too far

13.75

01

VD

FORWARD

000010 000100 0

000010 000100 0

mm

R

S

C

A

K

R1

R2

A1

PR1

PR2

0/3

MANUAL

0/3

0/3

0/3

R

S

C

A

K

R1

R2

A1

PR1

PR2

PA1

PA1

LOW

FOG

Off the alignment range

the control panel screen.

Do not allow the ey elash and eyeli d to cover the out er alignment m ark to ensure

stable measurement.

If the machine is too near to the patien t in comparison with the opti mal alignmen t

position, the alignment ar rows are displayed outward with the message "BACKWARD," or if it is too far from the patient, the alignment arrows are displayed

inward with the message "FORWARD." The number of arrow are reduced accordingly as the optimal alignment ref erenc e pos ition com es closer.

ID

0000100001000

0/3

R L

MANUAL

0000100001000

0/3

32

BASIC OPERATIONS

0/3

R1

R2

A1

PR1

PR2

BACKWARD

PA1

mm

01

R/K

ID

R L

R/K

LOW

0000100001000

0/3

0/3

R1

R2

A1

PR1

PR2

PA1

mm

01

LOW

FOG

MANUAL

FORWARD

FOG

PR2

PA1

13.75

0000100001000

PR2

PA1

13.75

0/3

R1

R2

A1

PR1

VD

M

0/3

0/3

R1

R2

A1

PR1

VD

M

Page 35

5 When the alignment dot becomes smaller in size and "Alignment OK" is displayed, tap the

START

START

START

R L

R/K

ID

M

LOWLOW

FOGFOG

13.7513.75

010 1

VDV D

-1.-1 .2525

-0.-0 .5050

7.807 .8 0

7.757 .7 5

18018 0

18018 0

PR2PR2

0000100001000000010 00010 00 000010000100000001 00001 000

mmmm

R

S

C

A

K

R1

R1

R2R2

A1A1

PR1PR1

3/33/3 MANUALMANUAL

7.807.80

0/30/3

3/33/3 0/30/3

R

S

C

A

K

R1

R1

R2R2

A1A1

PR1PR1

PR2PR2

PA1PA1 PA1PA1

button.

Even if fine alignment has not been achieved, measurement can be performed by

tapping the button. To ensure correct measurement, try to get fine align-

ment.

Measurements can be performed off center if necessary by tapping the

button after placing the measuring head in the desired off center position.

6 Measurement is performed and measurement values are displayed on the control panel.

After finishing the measurem ent, auto alignment is performe d if the patient's eye

position is moved right/left and up/down.

NOTE:

DISPLAYING MEASUREMENT VALUES

Data of the latest measurement are displayed on the control panel screen.

Figures only: Measurement was done correctly.

ERROR: Measurement was not done correctly.

For explanation of messages on the control panel screen, refer to “MESSAGE

LIST” on page 54.

If the machine is moved before measurement values are displayed, it

may cause incorrect measurement result.

33

BASIC OPERATIONS

Page 36

PRINT-OUT OF MEASUREMENT VALUES

PRINT OUT

ALL CLEAR

PRINT OUT

• To avoid a paper jam in the printer, do not feed the paper i f it is

partly cut or wrinkled.

• To avoid discoloring of the printer paper (particul arly the reco rding

area) during storage, use a polyp ropylene bag and not one containing plasticizer (PVC, etc.).

NOTE:

This instrument can print out measurement values by a printer.

• To avoid discoloring of the printer paper (particul arly the reco rding

area) after pasting, use water -soluble glue and not one containing

solvent.

• Since the printer paper is thermosensitive, it is not suitable for

keeping records for a long period. If necessary, prepare copies

separately.

1 Check the Measurement screen is on.

2 Tap the button on the control panel.

Measurement values on the monitor are printed out.

After being printed out, the measurement values on the screen are deleted automatically.

When the cylindri cal refractive power is "0," the d irection of astigmatic axis and

measurement values are not displayed/printed.

When a red line is printed at the end of the printer paper, replace it with a new one.

For details about the rep lacement of printer paper, see “PRINTER PAPER SETTING” on page 21. 58mm wide printer paper (example: TP-50KJ-R, Nippon

Paper) is recommended.

"CLOSE PRT COVER" is in dicating that the printer cover is le ft opened, ensure

that the printer cover is completely closed.

When auto print is set ting is "O N" in the i nitial se tting, meas urement is p erformed

under Auto mode, and me asurement results are printed out automatically. (See

page 48.)

After printing out measurement va lues, the measuring head moves to the "f inish

mode" position of the initial setting.

When the Auto cut setting is off and you n eed t o cu t a prin ter form, the way is that

erase the measurement value by tapping the button, and tap the

button. (See page 50.)

34

BASIC OPERATIONS

Page 37

CLEARING MEASUREMENT VALUES

ALL CLEAR

13.75

di o

- 1 .2525

- 0 .5050

- 0 .2525

- 0 .5050

1 8 0

1 8 0

0 1

S C

VD

A S C A

- 1 .2525

- 0 .5050

7 . 8 0

7 . 7 5

1 8 0

1 8 0

- 0 .2525

- 0 .5050

7 . 8 0

7 . 7 5

1 8 0

1 8 0

PR2

00001 00001 000

00001 00001 000

mm

R

S

C

A

K

R1

R2

A1

PR1

3/3

AUTO

7.80

3/3

3/3

3/3

R

S

C

A

K

R1

R2

A1

PR1

PR2

PA1

PA1

LOW

FOG

1 Tap the button on the control panel.

All measurement values of both eyes are cleared.

0000100001000

ID

3/3

R L

-1.

-0.

180

3/3

R1

7.80

R2

7.75

A1

180

PR1

PR2

7.80

PA1

mm

01

-1.

R/K

LOW

-0.

FOG

AUTO

180

0000100001000

-0.

-0.

3/3

-0.

-0.

180

3/3

R1

7.80

R2

7.75

A1

180

PR1

PR2

PA1

VD

13.75

dio

180

A

35

BASIC OPERATIONS

Page 38

DISPLAYING ALL MEASUREMENT DATA

TARGET IMAGE

R L

R/K

ID

A

LOWLOW

FOGFOG

13.7513.75

-1.-1 .2525

-1.- 1. 2525 -0.-0 .5050 -0.- 0 . 2525 -0.- 0. 5050

-0.-0 .5050

7.807 .8 0

7.757 .7 5

18018 0

18018 0

-0.-0 .2525

-0.-0 .5050

7.807 .8 0

7.757 .7 5

18018 0

18018 0

1801 8 0 1801 8 0

010 1

S C

VDV D

A S C A

PR2PR2

0000100001000000010 00010 00 000010000100000001 00001 000

mmmm

R

S

C

A

K

R1

R1

R2R2

A1A1

PR1PR1

3/33/3 AUTOAUTO

7.807.80

3/33/3

3/33/3 3/33/3

R

S

C

A

K

R1

R1

R2R2

A1A1

PR1PR1

PR2PR2

PA1PA1 PA1PA1

ALL DATA DISPLAY

REF

S

C1

2

( 3 )

4

5

6

7

8

9

10

AVE

CA

RIGHT

S

1

2

3

4

5

6

7

8

9

10

AVE

CA

-1.25 -0.50 180 -0.25 -0.50 180

-1.25 -0.50 180 -0.25 -0.50 180

-1.25 -0.50 180 -0.25 -0.50 180

-1.25 -0.50 180 -0.25 -0.50 180

LEFT

S

C1

2

( 3 )

4

CA

RIGHT

S

1

2

3

4

CA

-1.25 -0.50 180 -0.25 -0.50 180

-1.25 -0.50 180 -0.25 -0.50 180

-1.25 -0.50 180 -0.25 -0.50 180

LEFT

When measurement is performed

with the Cataract button ON, "C"

comes at the head of figures.

When Cataract mode starts automatically during the measurement, figures will be put in ( ).

Normally the latest measurement is displayed, but it is possible to display and confirm all measurement dat a.

1 Tap the button of the control panel.

2 Tap the button.

R L

3 The Data Display screen is displayed.

36

BASIC OPERATIONS

REF

Page 39

When no data is memorized, the data table shows blank.

R1

1

2

*

3

*

4

R2 A1

RIGHT

R1

1

2

3

4

R2 A1

7.80 7.75 180 7.80 7.75 180

7.80 7.75 180 7.80 7.75 180

7.80 7.75 180 7.80 7.75 180

LEFT

KRT

R1

1

2

*

3*

4

5

6

7

8

9

10

AVE

R2 A1

RIGHT

R1

1

2

3

4

5

6

7

8

9

10

AVE

R2 A1

7.80 7.75 180 7.80 7.75 180

7.80 7.75 180 7.80 7.75 180

7.80 7.75 180 7.80 7.75 180

7.80 7.75 180 7.80 7.75 180

LEFT

When the reliability of KRT data is

low, "*" is attached after the figures.

EXIT

KRT

R1

1

2

*

3*

4

5

6

7

8

9

10

AVE

R2 A1

RIGHT

R1

1

2

3

4

5

6

7

8

9

10

AVE

R2 A1

7.80 7.75 180 7.80 7.75 180

7.80 7.75 180 7.80 7.75 180

7.80 7.75 180 7.80 7.75 180

7.80 7.75 180 7.80 7.75 180

LEFT

4 To change "REF data" and "KRT data," tap the REF/KRT button.

5 To exit the data display and return to the Measurement screen, tap the button.

OPERATION OF AFTER USE

1 Turn the POWER switch to off.

When external devi ces a re connec ted to e xtern al I/O ter minals, turn off the po wer

of these devices too.

2 Unplug the power cable from a 3-pin AC inlet with grounding.

When the instrument is not used for a long period, unplug the power supply cable,

and detach the cable connected to the external I/O terminal.

37

BASIC OPERATIONS

Page 40

OPTIONAL OPERATIONS

IDOKALL CLEAR

00001 00001 00001 00001

00001 00001

13.75

di o

0 1

VD

mm

AUTO

R

S

C

A

K

R1

R2

A1

PR1

R

S

C

A

K

R1

R2

A1

PR1

LOW

FOG

0/3

0/3

0/3

0/3

PR2

PA1

PR2

PA1

DISPLAYING THE PATIENT ID (PATIENT No.) OR OPERATOR ID

A patient ID or operator ID of up to 13 charac ters can be input and displ ayed on the control

panel and printout.

However, if no patient ID is input, the patient No. is allocated automatically by the device.

1 Tap button.

2 T ap keyboard on the screen and enter characters. T ap button and fix the input value.

Patient ID is reset when measurement values are printed or if the button is tapped.

Patient No. reset condition can be selec ted such tha t the patien t No. is rese t upon

power on or not, in the initial setting of setup screen.

"Refer to "Patient No.reset" on page 48.

MEASURING ONE EYE ONLY

In Auto mode, it is possible to measure one eye only.

The current measurem ent po si tio n is disti ngu is hed by the color of the / button; orange

indicates active measurement position.

00001000010000100001

ID

R L

0/3

AUTO

0000100001

0/3

R/K

0/3

R1

R2

A1

PR2

PR1

PA1

mm

01

FOG

LOW

0/3

R1

R2

A1

PR2

PR1

13.75

PA1

VD

dio

A

MEASURING THE RIGHT EYE ONLY

1 Tap the button to move the measuring head to the right.

2 When the measu ring head stops moving tap the button once again: the lock icon is

displayed .

• When the lock icon is dis played, the mea suring head does n ot mov e to th e othe r eye e ven

when the measurement of one eye is finished.

3 To release the lock, tap the icon: The lock icon disappears.

MEASURING THE LEFT EYE ONLY

Operation is the same as measuring the right eye.

In order to measure the ot her eye when the lock icon is dis played, tap the other

side button or button.

38

OPTIONAL OPERATIONS

Page 41

MEASUREMENT OF CORNEA DIAMETER

R

L

R L

R/K

13.7513.75

010 1

VDV D

ID

M

00001000010000000100 001000 000010000100000 001000 01000

mmmm

R

S

C

A

K

R1

R1

R2R2

A1A1

PR1PR1

PR2PR2

0/30/3 MANUALMANUAL 0/30/3

0/30/3 0/30/3

R

S

C

A

K

R1

R1

R2R2

A1A1

PR1PR1

PR2PR2

PA1PA1 PA1PA1

LOWLOW

FOGFOG

CORNEA DIAMETER

R L

R/K

13.7513.75

010 1

VDVD

ID

M

PR2PR2

000010000100000001000 01000 000010000100000001000 01000

mmmm

R

S

C

A

K

R1

R1

R2R2

A1A1

PR1PR1

0/30/3 MANUALMANUAL 0/30/3

0/30/3 0/30/3

R

S

C

A

K

R1

R1

R2R2

A1A1

PR1PR1

PR2PR2

PA1PA1 PA1PA1

LOWLOW

FOGFOG

R L

R:0.00R: 0.0 0 L:0.00L :0. 00

Positioning bar R/L balance display

Positioning bar

Exit button

Positioning bar control button (L)

Positioning bar control button (R)

Capture button Measurement button

MEASUREMENT ON THE ACTUAL IMAGE

1 Tap the button/ button to select the right/left eye.

2 Tap the button.

3 The Cornea Diam eter Measurement sc reen is displayed, and T he positioning bar is dis -

played.

OPTIONAL OPERATIONS

39

Page 42

4 When the pup il is di splaye d, tap around t he pupil. Th e measurin g head moves to dis play

R L R L

R:0.00R :0. 00 L:0.00L:0. 00 R:0.00R :0. 00 L:0.00L:0. 00

POSITIONING BAR CONTROL

R L

R:0.00R: 0. 00 L:0.00L :0. 00

POSITIONING BAR CONTROL

R L

R:0.00R :0 .00 L:0.00L :0. 00

MEASUREMENT

R L

R:0.00R :0. 00 L:9.50L:9 .5 0

the pupil image and alignment dot at the center of the screen.

5 Using the button (L), move the left po si tio ning bar to the left

end of the iris from the operator side.

6 Using the button (R), move the right positioning bar to the

right end of the iris from the operator's side.

7 Tap the button.

8 The cornea diameter is displayed.

40

OPTIONAL OPERATIONS

Page 43

9 Tap the button and move to the other eye.

RLEXIT

CAPTURE

R L

R:0.00R :0. 00 L:0.00L: 0. 00

EXIT

MEMORY

R: 0.0 0

L: 0.0 0

Memory button

MEMORY

In like manner, measure the other eye.

10 Tap the button and measure the other eye.

MEASUREMENT ON THE STILL IMAGE

When KRT measurement values are available, the still image of the measurement is displayed.

1 Follow steps 1 to 5 of "MEASUREMENT ON THE ACTUAL I MAGE" and display the cor-

nea image at the screen center.

2 T ap the button. The eye image is displayed full-screen, and the cornea image

is saved.

3 Tap button to exit the full-screen display.

The button appears indicating that the image is saved.

4 Tap the button to display the saved image.

R:0.00

R L

L:0.00

41

OPTIONAL OPERATIONS

Page 44

5 Tap either of the (R)/(L) buttons and move the posit ioning

POSITIONING BA R C ONTROL

R L

R:0.00R: 0.0 0 L:0.00L: 0.0 0

R L

R:0.00R: 0.0 0 L:9.50L :9. 50

bar.

6 Follow steps 6 to 8 of "MEASUREMENT ON THE ACTUAL IMAGE."

7 The cornea diameter is displayed.

42

OPTIONAL OPERATIONS

Page 45

OUTPUT USING RS232C

PRINT OUT

PRINT OUT

This instrument can output data to a PC, etc via the RS232C interface.